Page 1

vacon nx

ac drives

design guide

hybridization

®

Page 2

Page 3

vacon • 1

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

TABLE OF CONTENTS

Document ID:DPD01887

Revision release date: 24.10.2016

1. BASICS ........................................................................................................................2

1.1 Power or energy storage....................................................................................................... 3

1.2 Battery current dimensioning............................................................................................... 5

2. BASIC TOPOLOGIES FOR CONNECTION....................................................................... 6

3. SPECIAL CHARACTERISTICS AFFECTING THE SELECTION ......................................... 8

3.1 Voltage window...................................................................................................................... 8

3.2 Galvanic isolation requirement........................................................................................... 11

3.3 Balance or maintenance charge......................................................................................... 14

3.4 System control principles ................................................................................................... 15

4. CHOOSING A CORRECT TOPOLOGY............................................................................ 17

4.1 Allowed topology configurations......................................................................................... 18

5. BASIC VARIANTS....................................................................................................... 19

5.1 Direct to DC ......................................................................................................................... 19

5.1.1 Control structure .................................................................................................. 20

5.2 DC to DC .............................................................................................................................. 22

5.2.1 Filter...................................................................................................................... 22

5.2.2 Control Structure.................................................................................................. 34

6. PRODUCT CONFIGURATION EXAMPLES.................................................................... 36

6.1 Scope of delivery ................................................................................................................. 36

6.1.1 Direct to DC........................................................................................................... 36

6.1.2 DC to DC ................................................................................................................ 37

6.2 Example configurations ...................................................................................................... 39

6.2.1 DC/DC for supply interruptions ............................................................................ 39

6.2.2 Direct DC for Grid Support.................................................................................... 40

7. SIZING OF THE SYSTEM AND PRODUCT .................................................................... 41

7.1 Direct to DC ......................................................................................................................... 41

7.2 DC/DC .................................................................................................................................. 42

8. INFORMATION TO ACQUIRE FROM CUSTOMERS ....................................................... 47

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Page 4

1

vacon • 2 BASICS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

1. BASICS

The basic idea is always to achieve energy and/or power management of Common Point of Coupling.

Typical use cases are

• time shift for production

• peak load shaving for distribution

• smoothen load for average energy

• backup power or black out start

• grid support

Figure 1. Power balancing

Energy Production

kW

Average Power

t

Charging

Discharging

Process Power

Grid Power

kW

Average Power

t

Charging

Discharging

Page 5

BASICS vacon • 3

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

1

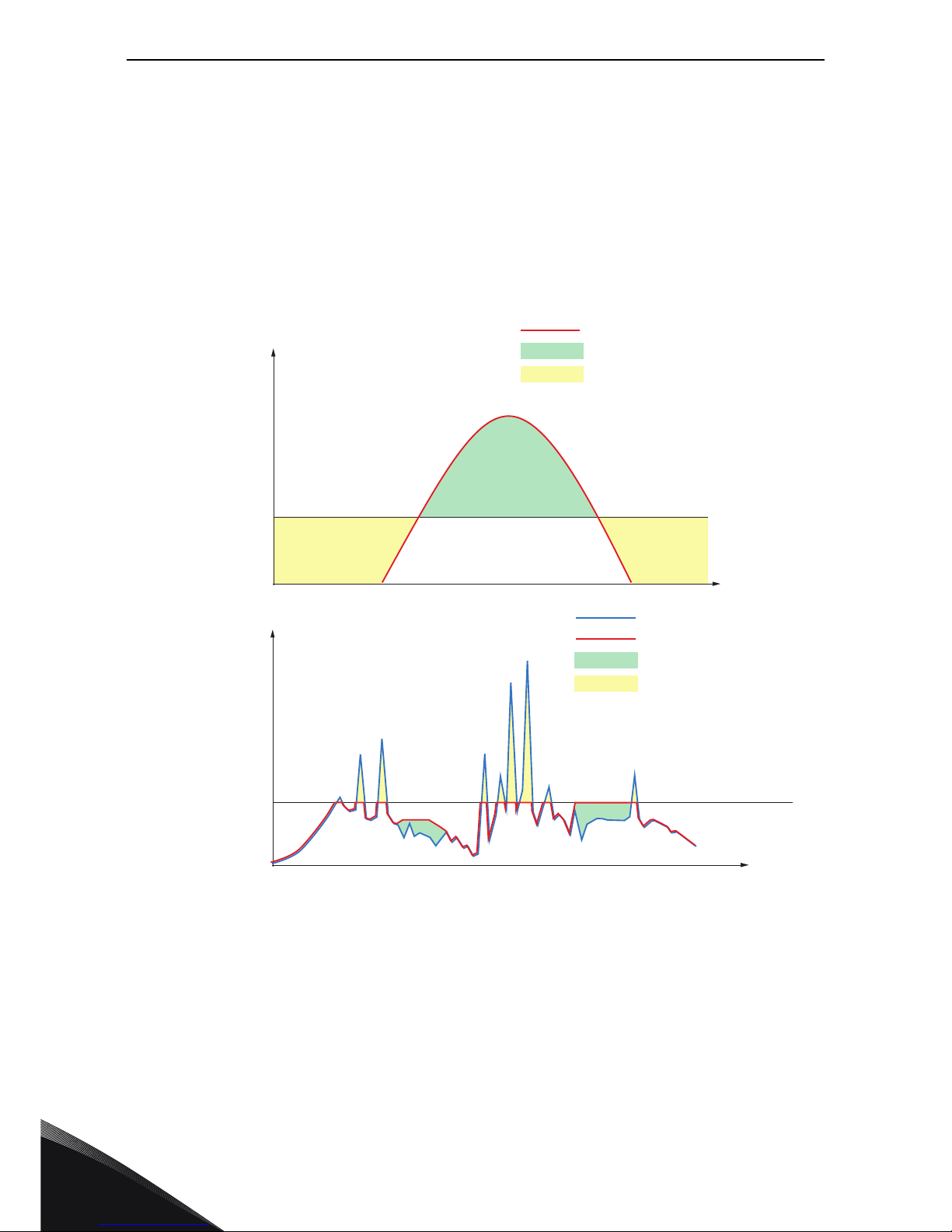

1.1 Power or energy storage

It is important to distinguish the system’s "nature", that is, whether it is a power application or an

energy application. Another relevant thing to note is the dynamic requirements of the application.

Determining the application:

• Energy vs. power (kW/kWh ratio)

• Dynamic requirements:

o Grid support functions (Harmonics, FRT)

o Bulk energy time shift

Figure 2. Power vs. energy

Time [h]

Power: Energy

MW: MWh

4:1 3:1 2:1 1:1

1:1 1:4

1:2 1:3 1:4

Time [h] Time [h]

Power [MW]

Power [MW]

Power [MW]

Power Applications Energy Applications

4:1

Page 6

1

vacon • 4 BASICS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

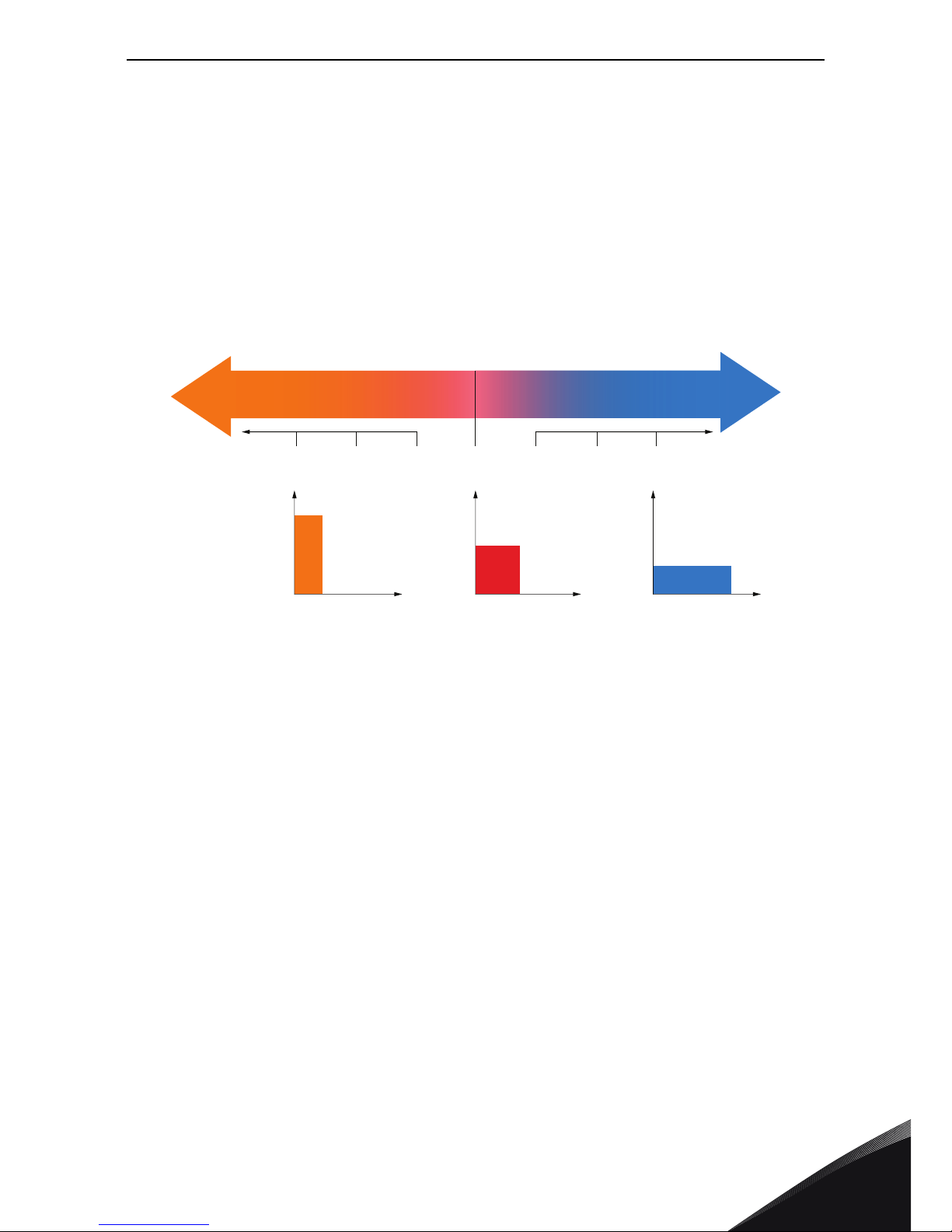

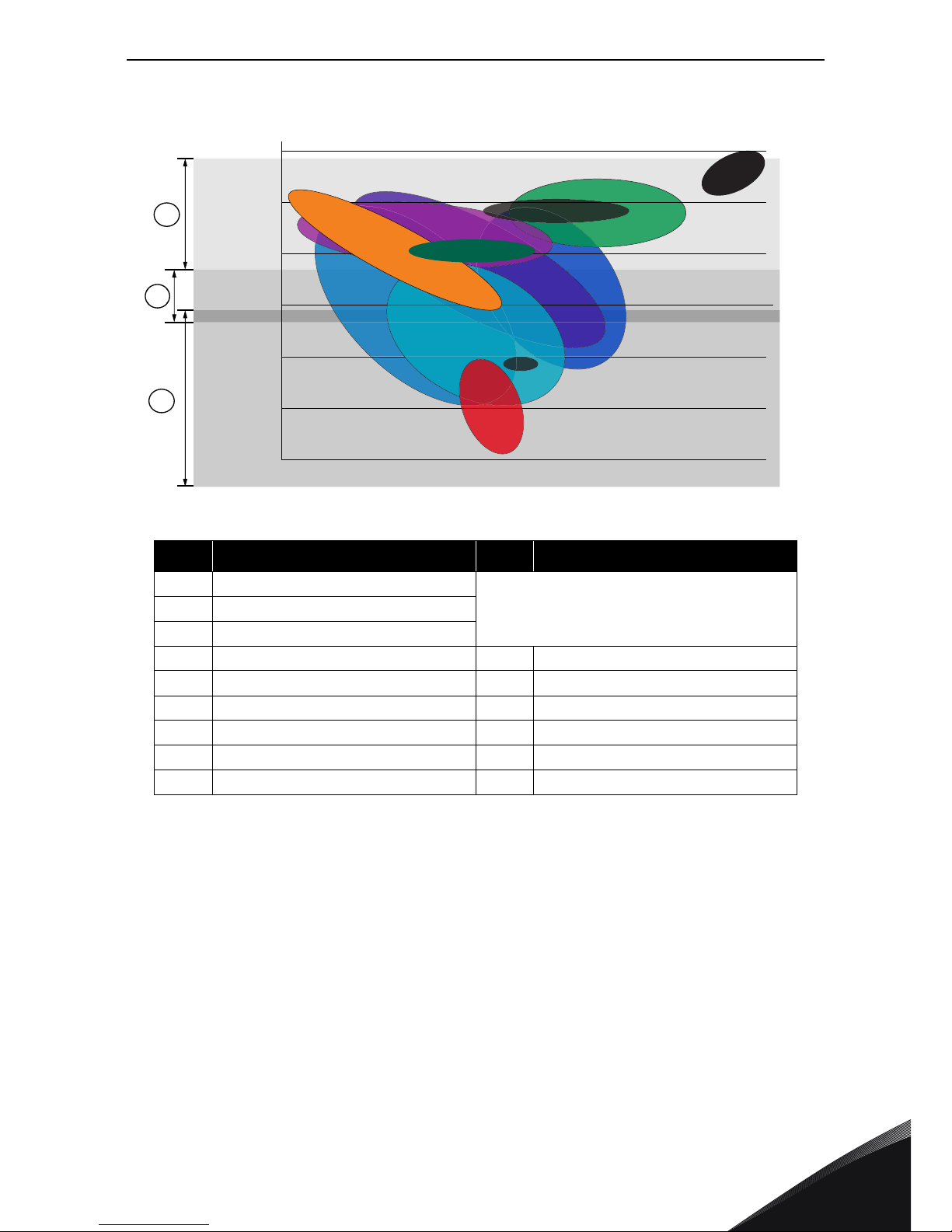

Figure 3. Comparision of battery systems

Table 1. Comparision of battery systems

# Reference # Reference

A Batteries E Li-ion

B Pb F Double layer capacitors

C NiCd G Electrolytic capacitors

DNiMH

Battery type

Energy density

Wh/kg

Power density W/kg

Service life in

cycles/years

Lead acid battery 30-50 150-300 300-1,000/3-5

Nickel-metal hybride

battery

60-80 200-300 >1,000/>5

Lithium-ion battery 90-150 500 -> 2,000 >2,000/5-10

Spercaps (double

layer capac.)

3-5 2,000-10,000 1,000,000/unlimited

BA C D E

F

G

100s

1,000s

1,000

100

10

1

0.1

0.01

10 100 1,000 10.000

10,000s

10s

1s

0.1s

Energy density in Wh/kg

Power density in W/kg

Page 7

BASICS vacon • 5

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

1

© Electricity storage association

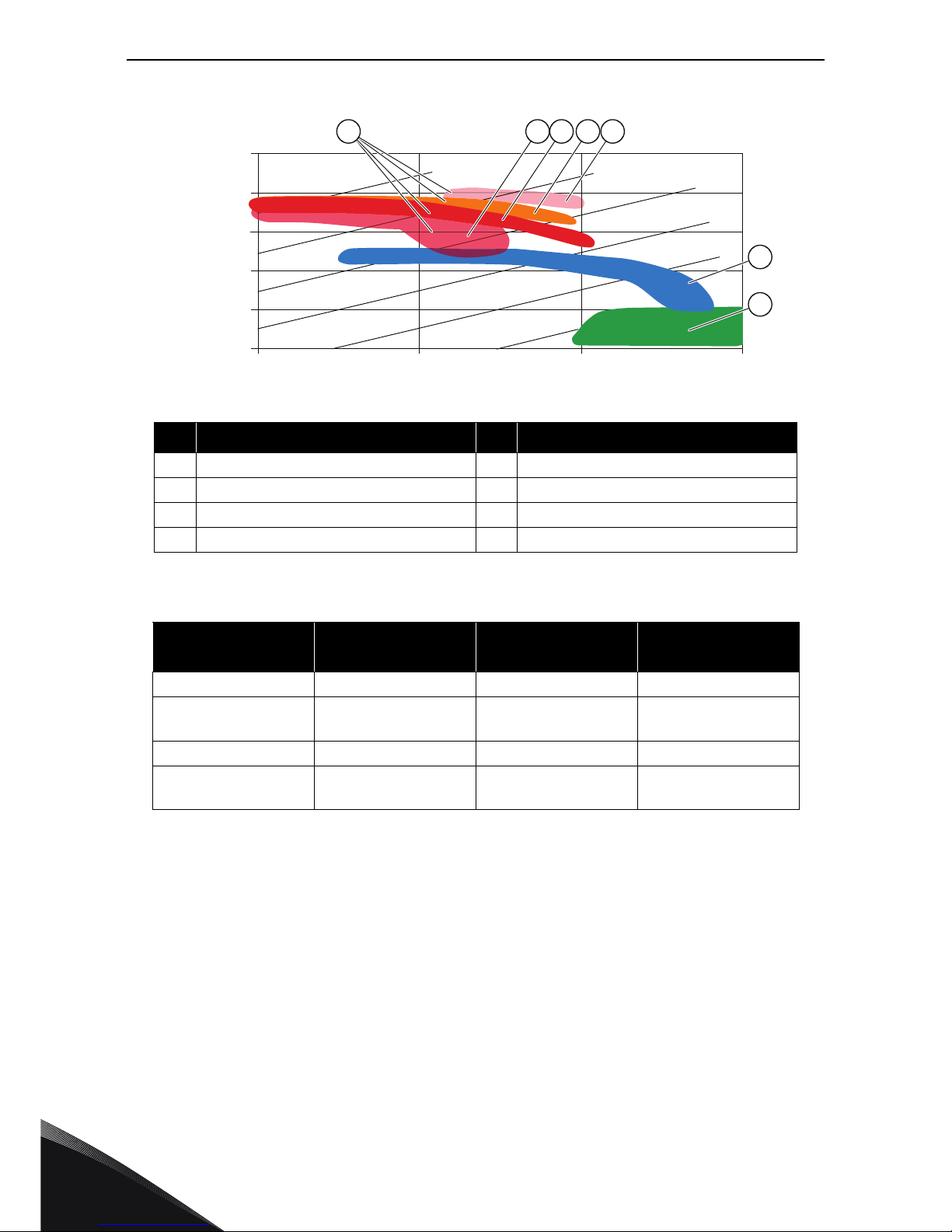

Figure 4. System ratings

1.2 Battery current dimensioning

In a battery, the nominal current is denoted with C. For example, a 10Ah 1C current would be 10A.

In some cases, the below rated currents are marked as 0.5C = C5. In that case, for example a 10Ah

rated current used with a 1A current would mean 0.1C or C1. In the same example, 2C would mean

20A.

# Reference # Reference

A Energy management

Dicharge timeBBridging power

CPower quality

CAES Compressed air Ni-Cd Nickel-cadmium

EDLC Dbl-layer capacitors Ni-MH Nickel-metal hybride

FW Flywheels PSH Pumped hydro

L/A Lead-acid VR Vanadium redox

Li-ion Lithium-ion Zn-Br Zinc-bromine

Na-S Sodium-sulfur

A

C

B

100

10

1

0.1

0.01

0.001

0.0001

0.001 0.01 0.1 1 10 100 1000 10,000

Ni-MH

VR

FW

Ni-CD

L/A

EDLC

Na-S

CAES

PHS

Discharge Time [hr]

Rated Power [MW]

Na-S

Li-ion

Zn-Br

Page 8

2

vacon • 6 BASIC TOPOLOGIES FOR CONNECTION

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

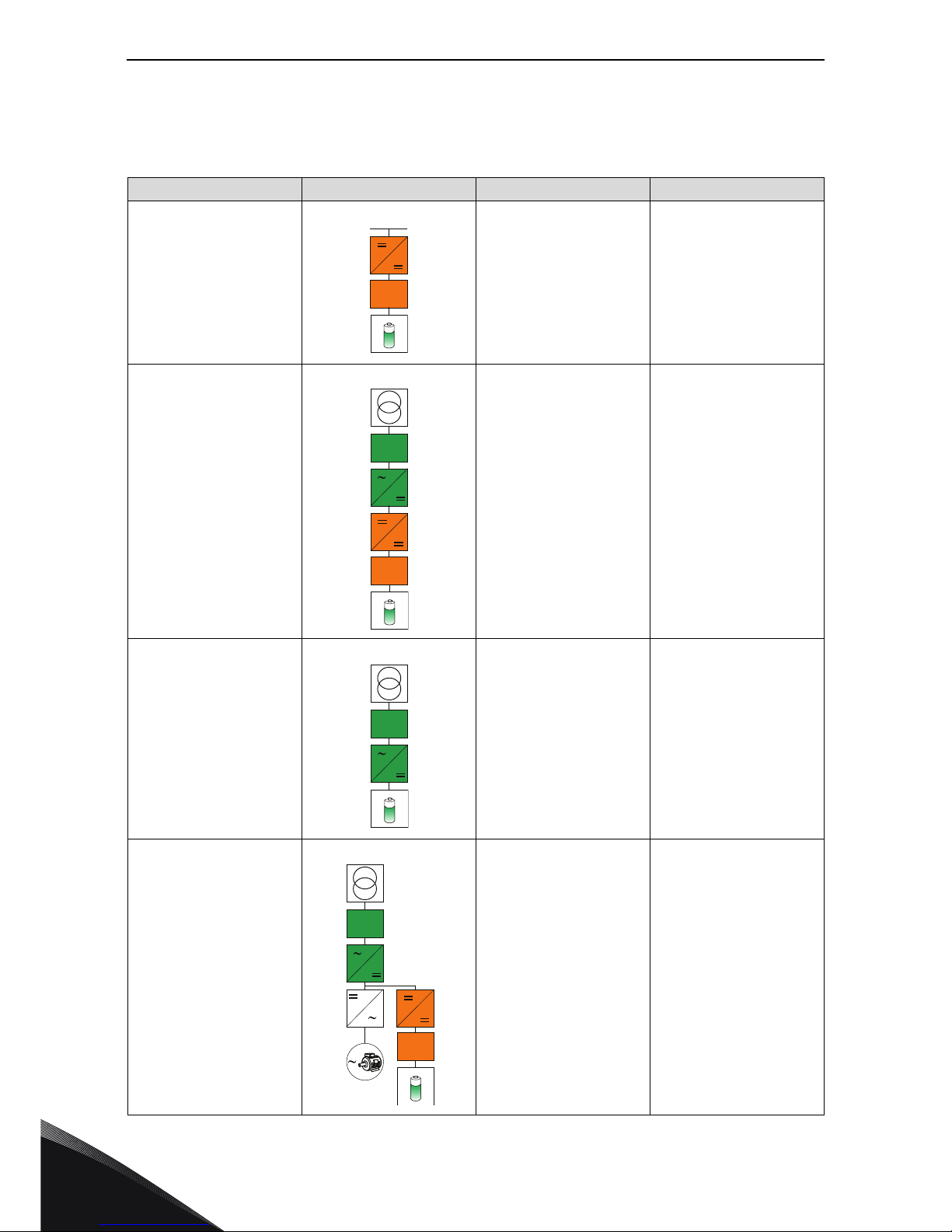

2. BASIC TOPOLOGIES FOR CONNECTION

The basic connections are divided into multible possibilities.

Table 2. Basic connections

Use case Topo logy Pros Cons

Common DC energy

storage connection

• No competitive

"technology" when

DC-grid connection needed

• Different storage

voltage/technology adaptations

Energy storage to ACgrid with combination of

DC/DC converter + grid

converter

• Different storage

voltage/technology adaptations

•Expansion easy

• Battery stack

replacing due to

ageing

•Large number of

components

• Lack of efficiency

•Size

Energy storage directly to

AC-grid with grid

converter

• Small number of

components

• Efficiency

•Size

• Power vs. energy

dimensioning is

independent from

each other

• Expansion difficult

• Battery stack

replacing due to

ageing

Energy storage close to

load and AC-grid with

DC/DC converter connected between DC-link

and storage

•Load power/

energy support

close the consumption

• Different storage

voltage/technology adaptations

•Expansion easy

• Battery stack

replacing due to

ageing

•Large number of

components

•Size

Filter

Filter

Filter

Filter

Filter

Filter

Page 9

BASIC TOPOLOGIES FOR CONNECTION vacon • 7

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

2

Energy storage close to

load and AC-grid with

direct DC-link connection

•Load power/

energy support

close the

consumption

• Large number of

components

• Efficiency

•Size

• Power vs. energy

dimensioning is

independent from

each other

•Voltage window

limiting the scope

only in range of

400 Vac using DC

range 600-1100

Vdc

• System expansion

later with

additional

batteries difficult

Filter

Page 10

3

vacon • 8 SPECIAL CHARACTERISTICS AFFECTING THE

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

3. SPECIAL CHARACTERISTICS AFFECTING THE

SELECTION

Different chemistry causes different behavior in cell voltage as a function of charge/discharge and

SOC (State of Charge). This creates "voltage window" requirement similar to the solar inverter.

Galvanic isolation requirement is different from many industrial drive application. This is due to the

fact that the battery system should not be predisposed for common mode voltage.

For the Battery Management System (BMS) to be able to reset the SOC calculation, it is necessary

to charge the battery to 100% SOC. This ensures that BMS is able to calculate SOC accurately and

maintain the battery in safe operating area. For this, a balance charger or a maintenance charger is

needed in some cases.

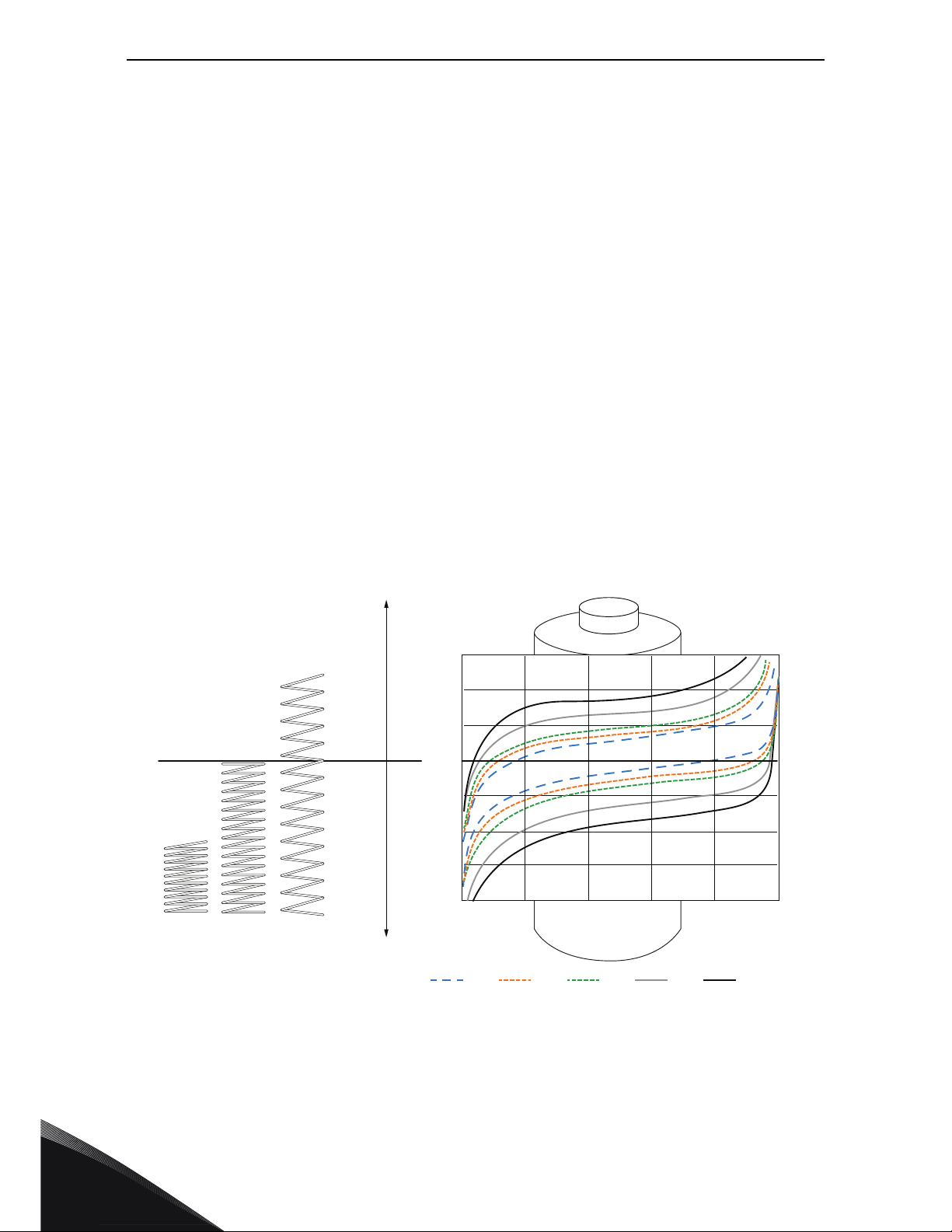

3.1 Voltage window

For both the DC/DC converter and the GTC (Grid Tie Converter) the first dimensioning question

comes from energy storage (battery) voltage dimensioning. It is important to define the “voltage

window" for empty and full battery cell voltage. Depending on battery chemistry the ratio can be full/

empty = 1,2… 2… (meaning, for example, full being 1000 Vdc, and empty being from 800 Vdc to 500

Vdc) and for super capacitors even bigger. Especially for GTC this is a limiting factor. The limitations

come from minimum tolerable DC-link voltage to maintain controllable grid voltage and from

maximum allowed voltage to maintain within design criterion of the hardware.

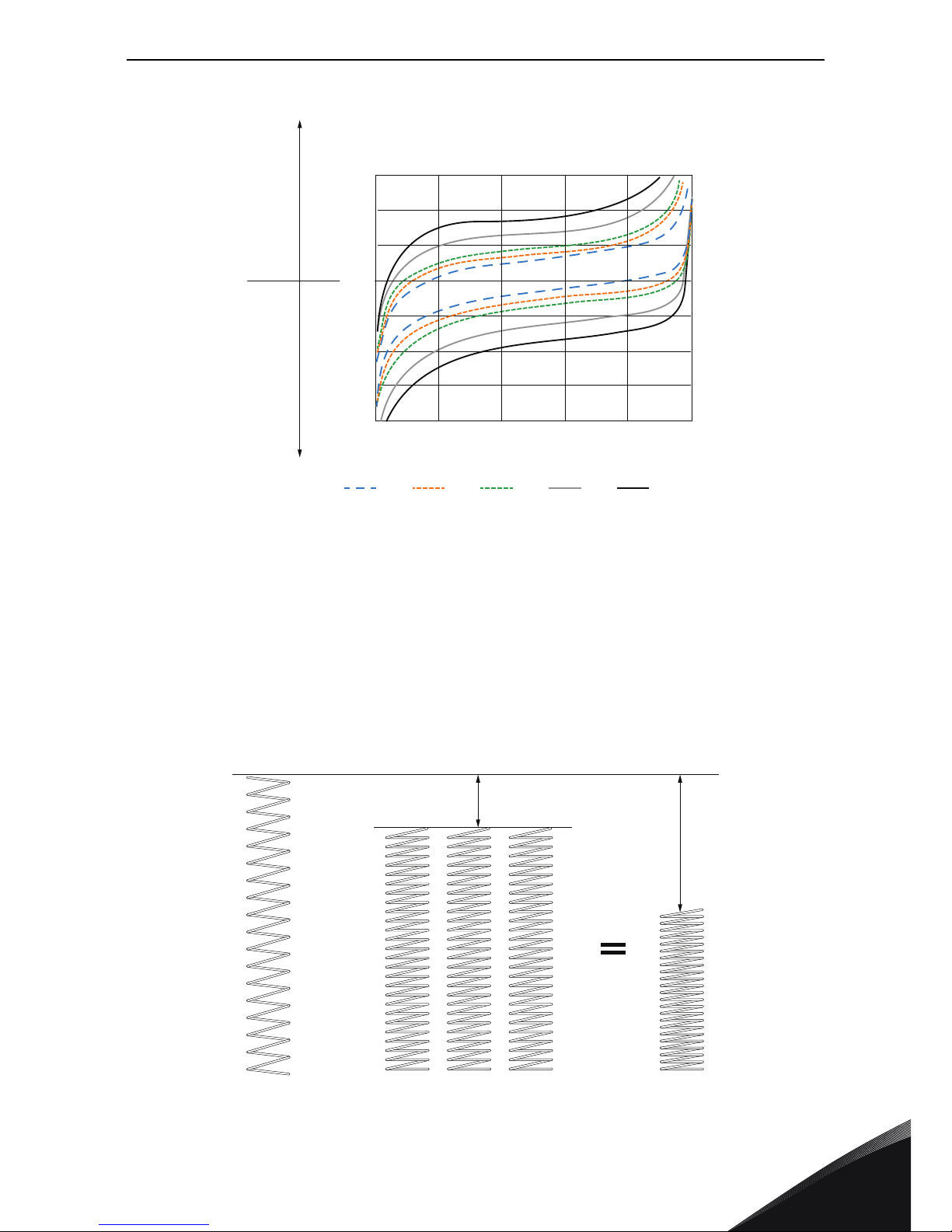

The behavior of voltage stretch in a battery can be illustrated with a spring being pulled or pushed.

Figure 5. Spring analogy of the battery voltage change

120

100

80

0

20 40 60 80 100

U

DC

[%]

SOC [%]

Charging of batteryDischarging of battery

1C 2C 3C 6C 9C

Page 11

SPECIAL CHARACTERISTICS AFFECTING THE SELECTION vacon • 9

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

3

Figure 6. Battery voltage change as a function of State Of Charge (SOC)

The voltage window is important also from the process dynamics point of view. If we expect the

battery system to take energy (either discharge or charge), we create change in voltage of the

battery. The voltage controller needs to be capable to change the actual voltage of the battery in a

controlled way from full to empty value or from empty to full value. For example, if the battery is

wanted to be discharged in 30 s - 300V voltage window from 1000 Vdc - 700 Vdc it means roughly 10

V/s voltage change of rate. This is huge difference in comparison to for example case where

discharge time is longer, say 30 min resulting in 0,2 V/s. This way the SOC (State of Charge) behavior

is observed.

Below is a case where same sized of DC-power units are charged/discharged from the battery.

Figure 7. Battery string number effect on voltage change using the spring analogy

120

100

80

0

20 40 60 80 100

U

DC

[%]

SOC [%]

Charging of batteryDischarging of battery

1C 2C 3C 6C 9C

Page 12

3

vacon • 10 SPECIAL CHARACTERISTICS AFFECTING THE

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

The difference in the cases is that the battery size in energy is changed from 6 strings in parallel to

one string in parallel. This will lead in higher C-rates in the battery having smaller amount of strings

when the same amount of power is taken out of each battery setup (current going from 1C --> 6C).

The effect is visible in higher stretch of voltage levels needed in controlling the battery.

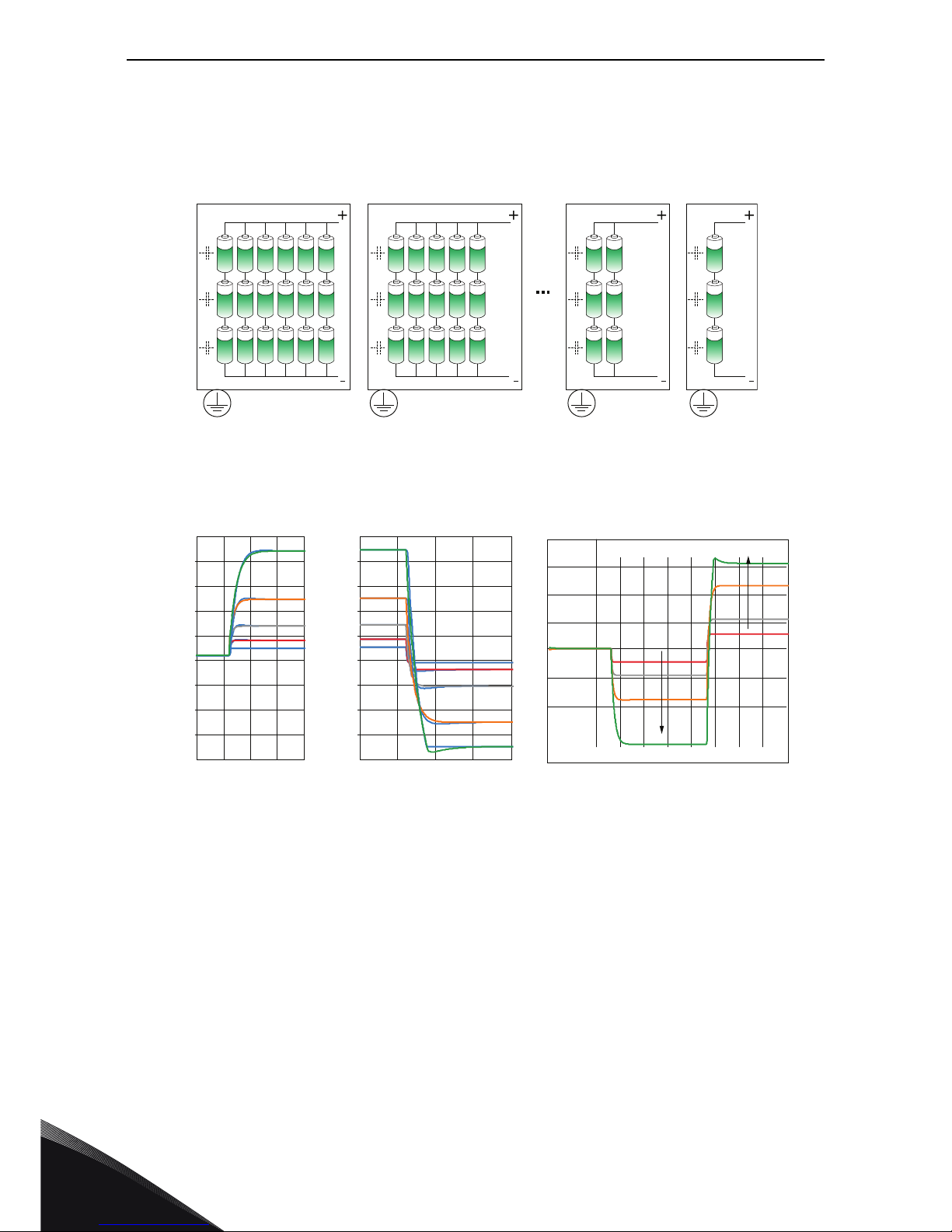

Figure 8. Number of batteries

Figure 9. Battery sizing effect on voltage change during equal power changes

The spring analogy works also when thinking of parallelizing of batteries (springs). The more you

have batteries (springs) in parallel, the less you need to use voltage stretch to gain the same

response.

123456 12345 12 1

120

100

80

120

100

80

8

6

4

2

0

-2

-4

-6

-8

0.2

0.25

0.2

0.35

0.4

0.6

0.65

0.7

0.75

0.8

0

0.1

0.2

0.7

0.5

0.4

0.3

0.8

0.9

1

0.6

tt t

increasing charge current

increasing load current

I [C-rating]U

DC

[%] U

DC

[%]

Page 13

SPECIAL CHARACTERISTICS AFFECTING THE SELECTION vacon • 11

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

3

3.2 Galvanic isolation requirement

The pulse width modulation (PWM) produces common mode voltage. Because every phase (a, b and

c) can be connected only either to positive DC-bus (+U

dc

/2) or to negative DC-bus (-Udc/2), sum of

output voltages is always unequal to zero. The common mode voltage (CM-voltage) U

cm

can be

calculated as average of output voltages:

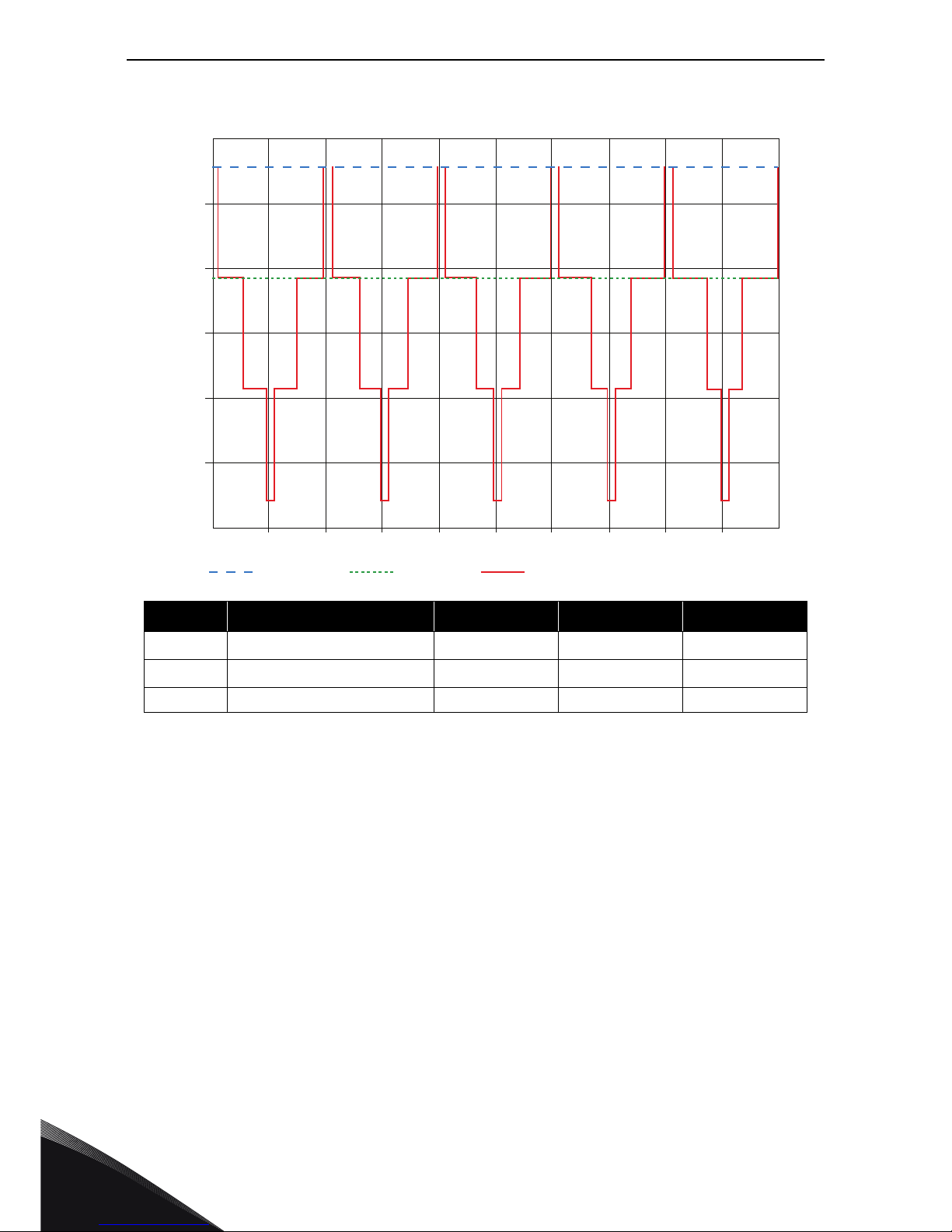

Table 3 presents all possible common mode voltages produced by different switching states. Used

reference point is in the middle of the DC-link.

Table 3. Common mode voltage as function of modulation sequence

Switching vector a b c

U

cm

U

1

+--

-U

dc

/6

U

2

++-

U

dc

/6

U

3

-+-

-U

dc

/6

U

4

-++

U

dc

/6

U

5

--+

-U

dc

/6

U

6

+-+

U

dc

/6

U

7

+++

U

dc

/2

U

8

---

-U

dc

/2

Page 14

3

vacon • 12 SPECIAL CHARACTERISTICS AFFECTING THE

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Figure 10. Simulated CM-voltage, Udc=1025V, fsw=5kHz.

Because of the common mode DC-link starts to jump compared to ground. Main frequency for this

jumping is switching frequency but also higher frequencies will be present. As an example, a typical

measured DC+ to ground voltage can be seen in Figure 11. A rule of thumb is that with a typical DClink voltage 1025V, the voltage spikes will be about 1.5kV.

# Curve info max min rms

......

U

DC

/2

171 171 171

----

U

DC

/6

512 512 512

___ CM voltage 512 -512 264

600

400

40 40.10 40.20 40.30 40.40 40.50

Time [ms]

40.60 40.70 40.80 40.90 41

200

0

-200

-400

-600

UDC/6 UDC/2 CM voltage

CM voltageU [V] Common mode

Page 15

SPECIAL CHARACTERISTICS AFFECTING THE SELECTION vacon • 13

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

3

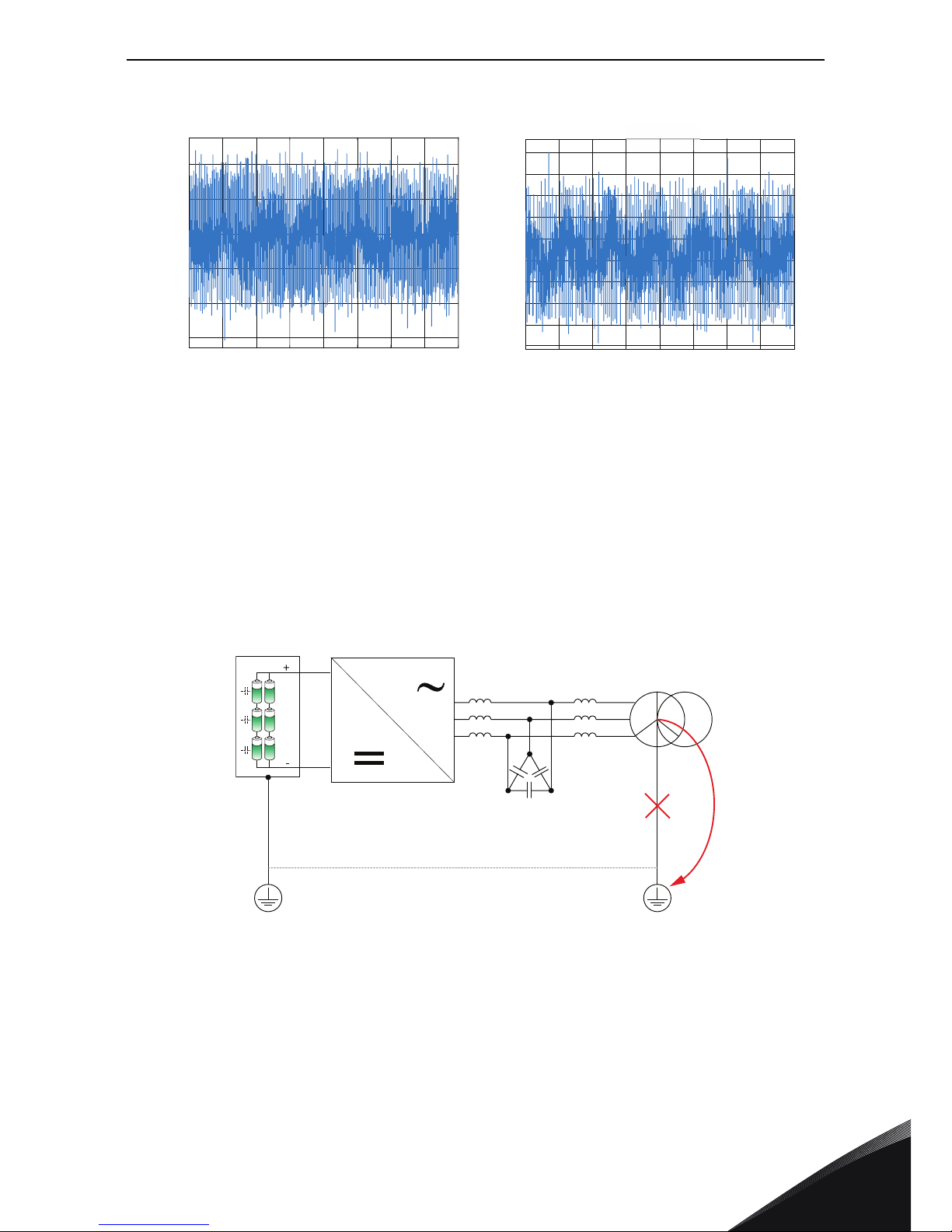

Figure 11. DC+ to ground voltage. On the left U

dc

= 1200 V, on the right 800 V.

The battery system does not withstand unfiltered common mode voltage. Because PWM modulation

is a CM voltage source, the DC side of the energy storage system must be stabilized. This means

that there must be a flexible element in electrical system that is able to take this common mode

voltage fluctuation. This element is now a transformer star point (instead of a motor stator star

point) that shall not be grounded.

Figure 12. Transformer must be isolated from ground.

In the grid side filter, if LCL is used, the grounded capacitors cannot be kept connected to ground. If

transformer inductance is bigger or at least the same as proposed grid side inductance, it is

possible to use only an LC filter (sine) to avoid additional voltage drop in the grid side choke.

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

-1000

-500

0

500

1000

1500

Sampled waveform

time [s]

voltage [V] voltage [V]

time [s]

-600

-400

-200

0

200

400

600

800

1000

1200

Sampled waveform

CM

Transformer

LCL-filter

AFE

(Active Front End)

DC-link

Page 16

3

vacon • 14 SPECIAL CHARACTERISTICS AFFECTING THE

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Figure 13. LCL ground capacitor must be disconnected

3.3 Balance or maintenance charge

The maximum voltage of the battery is needed only when charging the battery at the fullest level.

Current in that voltage is small. However, the time during which this voltage prevails can be

theoretically infinite if the battery is continuously kept 100% full (which is not advisable because of

the aging of the battery). When the charging is finished and even only little load is given to the

battery, the voltage decreases rapidly.

It is necessary (after a certain time or a number of battery charge/discharge cycles) to "reset the

trip meter" of the Battery Management System. Otherwise the state of charge calculations can

become misleading and result in poor behavior or even in exceeding the safe operation limits. The

only good way to "reset the trip meter" is to charge the battery to the full state where the Battery

Management System can safely tune its SOC value back to 100%.

Every cell must be charged extremely slowly so that the current of each cell goes as low as possible

(the cell reaches its full voltage). For a big battery system that has many cells in parallel and in

serial this is done from the same DC+ and DC- connections with the same Udc control. Do not start

to dismantle batteries to charge them individually. Because of the differences in cell level (for

example SOC, impedance) this means that some of the cells fill up sooner than others.

To avoid overcharging, the natural passive balancing of the battery system is needed. However, this

is a slow process and that is why the balancing charge needs to be slow with an accurately

controlled small current. It is difficult to say how accurate and small the current needs to be, but

the rule of thumb is that 0.01C is needed. If the device is not able to provide accurately such a

current, it is necessary to add a balance charger to the system. The battery manufacturer can also

be consulted about balance chargers.

-L1

-L2.1

-L2.2

-L2.3

-C1

-C2

HF

HF

-C3

U2 U1

V2

W2

V1

W1

-R1

-C1.1 -C1.2 -C4.1-C4.2

-C5.2

-R4

-R2

-C2.1 -C2.2 -C5.1

-R5

-C6.2

-R3

-C3.1 -C3.2 -C6.1

-R6

no HF

Page 17

SPECIAL CHARACTERISTICS AFFECTING THE SELECTION vacon • 15

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

3

Figure 14. The need of a balance charger

A balance charger is basically the same as a bulk power device (grid converter or DC/DC converter)

but with a smaller rating to be able to reach a control accuracy of storage current of 0.01C.

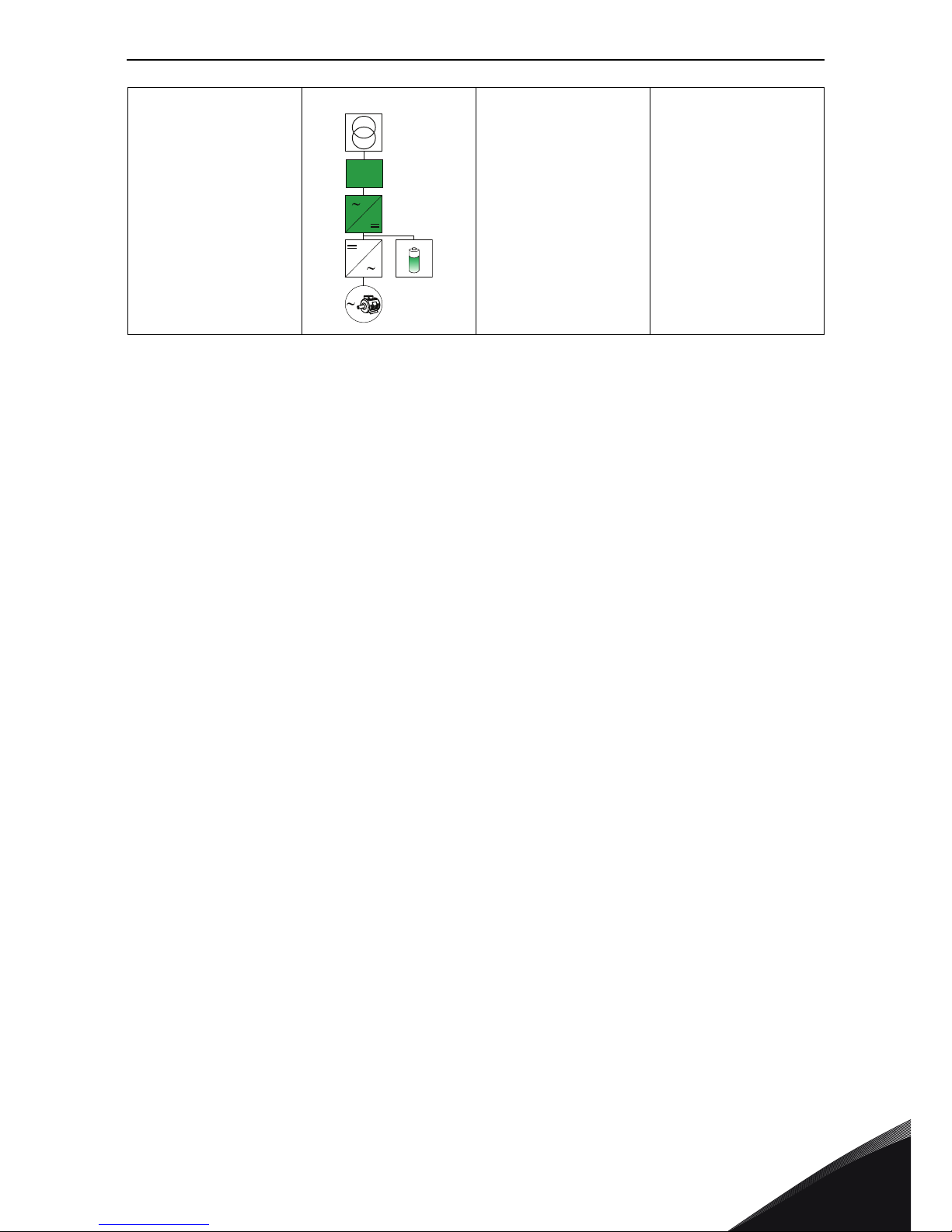

3.4 System control principles

The energy storage systems are often incorporated with different layers of controls having different

responsibilities.

The Energy Management System optimizes the energy efficiency of the system. This can include

choosing and prioritization the usage of different energy sources. Normal time scales are from tens

of seconds to hours.

The Power Management System includes controlling of power balance in a system that has multiple

energy/power sources. Normal time scales are from grid cycle (20ms - 50Hz) to seconds.

The Power Conversion System of this list is the system relevant to the product. The PCS includes

Power Conversion Control and Power Conversion Hardware, which is the VACON® hardware. It is

to control power conversion between the energy storage and the system. Normal time scales are

from micro seconds to grid cycles.

The Storage System includes Battery Management System and the battery. Battery Management

System monitors the storage system as well as the storage cell level phenomena.

# Reference # Reference

A

Not possible to reach 100%

SOC with big current =

Balance charger?

B

Not safe to go empty SOC

with big current. BMS to tell

when stop discharging.

A

B

120

100

80

0

20 40 60 80 100

U

DC

[%]

SOC [%]

Charging of batteryDischarging of battery

1C 2C 3C 6C 9C

Page 18

3

vacon • 16 SPECIAL CHARACTERISTICS AFFECTING THE

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Figure 15. Typical system layers

Energy Management System (EMS)

Power Management System (PMS)

Power Conversion System

Power Conversion

Hardware

Power Conversion Control

(PCC)

Battery Management

System

Battery

Storage System

Page 19

CHOOSING A CORRECT TOPOLOGY vacon • 17

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

4

4. CHOOSING A CORRECT TOPOLOGY

Figure 16. Selection diagram

DC/DC

converter

DC/DC

converter

Connection to

AC or DC

Direct to

DC

Application

Control ref

P / Udc /Idc

Customer

primary

reference

Customer

system

tailoring

Control

modes

Island

AFE

uGrid

Voltage

window

AC

small large

Grid

Converter

needed in

all cases

Grid

Converter

needed in

all cases

DC

Filter

Filter

Filter

Filter

Filter

FilterFilter

For example

VACON®

Common

DC-buss

Page 20

4

vacon • 18 CHOOSING A CORRECT TOPOLOGY

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

4.1 Allowed topology configurations

In the following table, example of allowed and not allowed configurations are given.

These configurations are valid for both with DC/DC converter or with a direct battery connection into

the DC-link. Options shown below are DC/DC configurations A), B) and C) and Direct to DC

connection D). Note that the storage topology does not affect the allowed or not allowed topology of

the connection to the system. There might however be other limitations, for example voltage or

current ratings.

Figure 17. Options A, B, C, D

Table 4.

OK? Configuration Notes

No grounding

allowed in

transformer

No HF/EMC

capacitors in LCL

OK

OK, transformer has

enough inductance

to satisfy filtering

demand of grid

converter:

L

transformer

~

L

grid side choke

HF

HF

HF

HF

HF

HF

HF

HF

AB

CD

33

Options

A, B, C, D

33

HF

Options

A, B, C, D

33

Options

A, B, C, D

33

Options

A, B, C, D

Page 21

CHOOSING A CORRECT TOPOLOGY vacon • 19

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

4

NOT OK

Separate DC

sources create

different output

voltage pattern

which creates

circulating current

Not OK if grid

selectivity is

needed, specially for

uGrid

Not OK if grid

selectivity is

needed, specially for

uGrid

33

33

Options

A, B, C, D

Options

A, B, C, D

33

33

Options

A, B, C, D

Options

A, B, C, D

33

Options

A, B, C, D

Options

A, B, C, D

3

3

3

3

Options

A, B, C, D

Options

A, B, C, D

Options

A, B, C, D

Options

A, B, C, D

3

3

3

3

Page 22

5

vacon • 19 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

5. BASIC VARIANTS

5.1 Direct to DC

Figure 18. Direct to DC

230 V Unit 500 V Unit 690 V Unit Vac

Supply voltage max 240 500 690 Vac

Supply voltage min 208 380 Vac

Over voltage instantly 437 911 1200 Vdc

Over voltage U2t trip - - 1100 Vdc

DC high ready (Stop) 382 797 1099 Vdc

Normal Max 324 675 931 Vdc

Normal Min 280 513 708 Vdc

DC low run (Def.estim.) 242 475 656 Vdc

DC low ready (Stop) 239 436 602 Vdc

DC low running min 225 410 567 Vdc

Under voltage instantly 183 333 461 Vdc

# Reference # Reference

A

Maximum tolerable U

DC

voltage for AFE

operation

B

Minimum tolerable U

DC

voltage for AFE to

stay in grid with cos

ᵩ=1

A

B

Filter

Filter

voltage

drop

Transformer

voltage ratio

and drop

0

20 40 60 80 100

1C

2C

3C

6C

9C

u

INU

u

AFE

AFE DC

Grid converter

INU AC

AFE AC

SOC/%

Rectifying

DC/AC and

AFE control

marginal

u

GRID

Grid AC

+ Tolerance

1 pu

- Tolerance

Grid nominal

value and

voltage

tolerances

Page 23

BASIC VARIANTS vacon • 20

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

5.1.1 Control structure

The power control is as presented below when the battery is directly on DC-link.

Figure 19. DC-link power control

Direct to DC can be used on a system where peak power shaving is desired and grid power sources’

power sharing is done mainly through active power drooping. In such system, the power and grid

frequency behave as shown in the picture below.

Figure 20. Behavior of system power and grid frequency

Grid Converter operation:

• uGrid-operation mode

o Power control possible when operating parallel with other power sources.

•Reference is base current reference (+/-).

•If the device is operating in island mode, the power reference changes the

frequency.

o Grid frequency variations will affect what will be actual power to the grid.

•Operates like a normal generator.

•Power reference is several times faster than a normal diesel generator.

•Frequency drop in a grid will increase Grid Converter power output without power

reference.

- Useful in situations where PMS is not fast enough or is unable to control.

o Upper system needs to give charging and discharging limit to the drive

o Upper system needs to give minimum and maximum voltage limits to the drive (DC-Link

voltage).

U4U3

D7

C

T2

T1

Q1U5Q3

Filter

Source

DC

Grid

Discharge

Power Frequency

Generator Motoring

Average

Charge

Page 24

5

vacon • 21 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

•AFE-operation mode

o Power control possible trough DC voltage reference. Needs controller if customer input

is power reference (instead of DC voltage reference).

o Cannot make or maintain grid by itself, needs existing grid

• Island-operation mode

o Power control not possible, drive will give to the grid what the grid needs.

o Cannot operate parallel with other power sources.

o Makes a grid but cannot synchronize to the existing one.

When doing maintenance charging with the aim of a 100% full battery, charging must be done with

DC reference (possibly with a charging current limit).

Page 25

BASIC VARIANTS vacon • 22

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

5.2 DC to DC

Figure 21. DC to DC

5.2.1 Filter

The filter topologies in focus are:

1. Interleaved

Figure 22. Interleaved filter topology

# Reference # Reference

A

Maximum full battery U

Battery

voltage for

fixed AFE reference voltage operation

B

Minimum tolerable U

Battery

voltage for

DC/DC & filter current ripple

B

A

Filter

Filter

voltage

drop

0

20 40 60

80 100

1C

2C

3C

6C

9C

u

INU

u

AFE

AFE DC

Grid converter

INU AC AFE AC

SOC/%

Rectifying

DC/AC and

AFE control

marginal

Battery DC

L

L

L

HF

HF

Page 26

5

vacon • 23 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

2. Independent output control (not yet supported)

Figure 23. Independent output control

Interleaving is a method to cancel partially or completely certain harmonics from the spectrum.

With a standard 3-phase inverter unit, a natural way is to have a 120 degree phase shift with each

triangle carrier. The result is that the maximum peak to peak ripple is reduced to one third of the

individual phase current ripple. Thus, while the sum current is multiplied by factor of three, the

maximum relative output current ripple is reduced to 1/9. The equivalent switching frequency in the

output is three times the switching frequency.

Figure 24. Example simulation with interleaved control and d = 1/2: leg currents and sum current.

I = 100 A/leg, L = 2050 uH, Udc = 1025V

Curve info rms max min peak to peak

I 1 100.3 113.0 87.0 25.9

I 2 100.3 113.0 87.0 25.9

I 3 100.3 113.0 87.0 25.9

I Battery 300.0 304.6 295.4 9.1

HF

HF

350

I [A]

Time [ms]

I

1

I

3

I

2

I Battery

Currents Interleaved

300

250

200

150

100

50

40 40.10 40.20 40.30 40.40 40.50 40.60 40.70 40.80 40.90 41

Page 27

BASIC VARIANTS vacon • 24

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

Figure 25. Example simulation with traditional control and d=1/2: leg currents and sum current.

I = 100A/leg, L= 2050 uH, Udc = 1025V

The ripple current for the filter choke can be calculated as follows:

It is important to note that the ripple depends on duty cycle which is defined as follows:

Curve info rms max min pk2pk

I 1 100.2 112.6 87.4 25.2

I 2 100.2 112.6 87.4 25.2

I 3 100.2 112.6 87.4 25.2

I Battery 300.7 337.9 262.1 75.7

350

I [A]

Time [ms]

Currents Interleaved

300

250

200

150

100

50

40 40.10 40.20 40.30 40.40 40.50 40.60 40.70 40.80 40.90 41

I1=I2=I3 TraditionalI Battery

Page 28

5

vacon • 25 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

The maximum value for the ripple of the choke is obtained when d = 1/2

For the output current ripple there are three segments. When d < 1/3, two switches are always at

low state and one switch is either low or high. When 1/3 < d < 2/3, one switch is low, one high and

one is either low or high. And when d > 2/3, two switches are always high and one either low or high.

With d = 1/3 and d = 2/3, output ripple is in theory cancelled. In practice simultaneous switching

prohibit causes some ripple. Disabling simultaneous switching prohibit logic will reduce fluctuation

near d = 2/3 and d = 1/3 considerably.

The maximum value is obtained with three different duty cycles:

Page 29

BASIC VARIANTS vacon • 26

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

Figure 26. Peak-to-peak ripple current as function of duty cycle. Scaled values can be converted to real

values by multiplying Udc/(fsw*L)

Interleaved switching helps to reduce the output ripple, but does not affect the single choke ripple.

The choke losses are thus relatively big, when compared to e.g. active front end (AFE). To keep the

losses reasonable, it is recommended to have peak-to-peak ripple one fourth of the nominal choke

current. Thus the proposed formula to calculate the required inductance is:

Using the above filter dimensioning, the relative output ripple is:

Example with a ~ 3% peak-to-peak: The ripple current is a triangle wave and the RMS value is peakto-peak divided by 2 , i.e. 0,8% RMS.

A more general formula for inductance calculation is:

This can be used for example with powder core chokes which tolerate more ripple. With liquid

cooling peak-to-peak ripple can be approximately 35-45% of the nominal current. A bigger ripple in

the choke also directly increases the output side ripple which in this case would be approximately

4-5% peak-to-peak.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.05

0.1

0.15

0.2

0.25

Ripple current: Choke I

L,pp

(blue) / Output I

Out,pp

(black)

Duty cycle

3

Page 30

5

vacon • 27 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

In most cases, a duty cycle d = 0,5 should be used in calculations. This will guarantee that worst case

ripple is taken into consideration. For example, if the application operates with duty cycles 0.7-0.9,

it could be possible to decrease the inductance, and in that way increase the choke ripple (see

Figure 27 below). However, this would also increase the output ripple, and it might not be

acceptable. On the other hand, if output ripple is not important, duty cycle optimization can lead to

significant savings.

Figure 27. Always consider possible duty cycle window

A big DC-link voltage requires more inductance. If the DC/DC converter is sometimes used to boost

DC-link higher than nominal, it must be noted that ripple increases.

In order to minimize size (inductance) of the filter choke switching frequency and current, ripple

should be as high as possible. An optimal design is a compromise between these and power losses.

When the design is ready, switching frequency decrease is not allowed, otherwise ripple will

increase and this can cause temperature problems. In an LCL-filter structure, a smaller switching

frequency can also cause resonances.

The inductance of a traditional laminated iron core choke usually remains constant (L

NOM

) up to

saturation point (I

NOM, PEAK

in Figure 28 below). After saturation point, the inductance starts to

decrease. If overload ability is needed, ripple increases in saturation region and must be considered

in the design. The inductance of a powder core choke behaves differently. Usually inductance as a

function of current decreases continuously which means that with small currents the inductance is

bigger. This is an advantage because ripple with partial loads will be smaller. On the other hand, it

must be verified that the core is not going to saturation too fast, if overload ability is needed. How

big the initial inductance is depends on choke design but typical values range approximately from

20% to 50% over nominal.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.05

0.1

0.15

0.2

0.25

Ripple current: Choke I

L,pp

(blue) / Output I

Out,pp

(black)

Duty cycle

Page 31

BASIC VARIANTS vacon • 28

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

Figure 28. Inductance as function of current (relative values).

The typical tolerance for inductance is ±10%. Also smaller tolerance can be achieved, if needed. In

the DC/DC converter, inductance tolerance does not affect the current balance between legs like in

standard AC applications. Because of tolerance, switching frequency is not totally eliminated from

the output current. This will increase the ripple and can cause some resonance issues with optional

filtering capacitors. Tolerances also increase/decrease individual peak-to-peak ripple currents of

chokes (Figure 29 and Figure 30). Temperature tolerances are not typically a concern with the above

mentioned choke types if all chokes are of the same temperature.

L [H]

I [A]

Powder 1

Powder 2

Laminated iron

L

NOM

L

SAT

I

NOM, RMSINOM, PEAK

L

MAX, PEAK

Page 32

5

vacon • 29 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Figure 29. Example simulation with interleaved control and d = 1/2: leg currents and sum current.

I = 100 A/leg, L = 2050 uH, Udc = 1025V. Leg U has 20% less inductance.

Curve info rms max min peak to peak

I 1 100.4 116.0 83.9 32.1

I 2 100.3 113.0 87.0 26.0

I 3 100.3 113.0 87.0 26.0

I Batteri 300.0 307.6 292.4 15.2

350

I [A]

Time [ms]

I

1

I

3

I

2

I Battery

Currents Interleaved

300

250

200

150

100

50

40 40.10 40.20 40.30 40.40 40.50 40.60 40.70 40.80 40.90 41

Page 33

BASIC VARIANTS vacon • 30

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

Figure 30. Example simulation with interleaved control and d = 1/2: leg currents and sum current.

I = 100 A/leg, L = 2050 uH, Udc = 1025V. Leg U has 20% less and leg W 20% more inductance.

Curve info rms max min peak to peak

I 1 100.4 116.0 84.0 32.0

I 2 100.3 113.0 87.0 25.9

I 3 100.2 110.9 89.1 21.8

I Battery 300.0 308.4 291.6 16.9

350

I [A]

Time [ms]

I

1

I

3

I

2

I Battery

Currents Interleaved

300

250

200

150

100

50

40 40.10 40.20 40.30 40.40 40.50 40.60 40.70 40.80 40.90 41

Page 34

5

vacon • 31 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

The filter consists of three separate chokes, one for each leg (Figure 31). It is not possible to use a

traditional 3-phase choke because the current is DC (common mode) and the magnetic flux does

not have a natural return path in the core structure. There would be only a very small inductance

generated by stray flux and this kind of situation can lead to a burnt filter. That is why a 3 x 1-phase

structure is necessary. In addition, the stray capacitance should be small. Foil winding with many

overlapping turns is not recommended. One way to minimize the stray capacitance is to use wire

winding in one layer.

Figure 31. Simple filter consist of three separate chokes.

The target is that the filtering could be done with chokes only. That is a simple solution, and one

benefit of not having capacitors is that switching the battery/supercapacitor is possible without any

current spikes. When IGBTs are disabled, the connection requires only that the DC-link is higher or

equal. If the output current ripple requirement is low and the required inductance would lead to an

impractical design, one possibility is to use an optional filtering capacitor (Figure 32). The best case

would be to add one more choke to form an LCL-filter structure (Figure 33). Without interleaving,

an LCL-filter is recommended, otherwise ripple will be big (nine times bigger).

Figure 32. Optional capacitor (C) connected to filter output.

DC+

DC-

Battery

C

DC

L

1

DC+

DC-

Battery

C

DC

L

1

Page 35

BASIC VARIANTS vacon • 32

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

Figure 33. LCL-filter structure is best possible solution if output ripple is critical.

The optional capacitor forms an LCL-circuit with the cables and the battery. It is important to know

the cable/battery impedance/inductance in order to evaluate possible resonances and calculate a

safe capacitance value. The impedance of the battery seems to depend on many things so this is not

an easy task. The resonance frequency for the LCL-circuit can be calculated as:

Note that the inductance of the converter side choke is one third because of the parallel connection.

In addition, there can be resonance can happen between L1 and C or L2 and C:

All these resonance frequencies must be well below the switching frequency. In standard inverter

applications, the LCL-circuit resonance frequency is usually one third of the switching frequency.

Because equivalent switching frequency at output is three times bigger, in theory it would be

possible to use higher resonance frequencies. But as explained earlier, the switching frequency is

not totally eliminated at output because of non-idealities in the control and chokes.

Because battery properties are usually not well known, it is recommended to dimension the

optional capacitor as follows:

DC+

DC-

BatteryC

C

DC

L

1

L

2

Page 36

5

vacon • 33 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

This will give some idea what could be expected to work, but because the battery properties are not

taken into account in the design, it is not possible to guarantee a safe operation. If the filter does

not operate as expected, the capacitance value can be increased for example by adding another

capacitor in parallel. Without interleaving, the capacitor must be a lot bigger (for example ten times

bigger) if the target is to be in the same level as with the interleaving control and chokes only. Note,

however, that this especially depends a lot on the battery.

With a real LCL-filter structure, dependence of the battery properties is minimized and the design

is more robust against resonances. The requirements for an additional battery side choke are quite

simple because the ripple is very small. The voltage rating of the filter capacitor should be similar

to the DC/DC converter DC-link capacitors.

The proposed rule to dimension an LCL filter is based on a safe resonance frequency. In this case

it is estimated that half of the switching frequency would be small enough with interleaving. In

addition, the battery side choke L2 is determined as 1/6 of L1 which corresponds to the typical

inductance ratio of chokes in standard inverter applications. With these assumptions, the required

capacitance (minimum value) can be calculated as:

Without testing, the interleaving capacitor must be bigger. At least double the size is recommended.

Crucial tests to verify filter applicability are:

1. Thermal tests: The worst case scenario for the filter in a thermal point of view is an

operation point where continuous current is maximum, DC-link voltage as high as

possible and duty cycle d = 1/2. At this point current ripple is the biggest.

2. Current tests: The worst operation point for current (both choke and output) is same as

in the thermal tests. With interleaving, the output performance can be verified also with

other peak and valley points of the duty cycle curve. If a capacitor is used, also the

capacitor current should be measured.

3. Voltage tests: The voltage at the battery terminals should be measured. If the cable to

the battery is long, the voltage at the filter output can also be measured. The voltage

against ground is also interesting.

Page 37

BASIC VARIANTS vacon • 34

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

5

5.2.2 Control Structure

The figure below presents power control when the DC/DC converter is between DC-Link and the

battery.

Figure 34. Power control example

DC to DC can be used on a system where peak power shaving is desired, and grid power sources’

power sharing is done mainly through active power drooping. In such system, the power and grid

frequency behave as shown in the picture below (Figure 35).

Figure 35. Behavior of system power and grid frequency

Grid Converter operation.

• Power control possible when operating parallel with other power sources.

o Reference is base current reference (+/-).

o If the device is operating in island mode, the power reference changes the

frequency.

• Grid frequency variations will affect what will be actual power to the grid.

o Operates like a normal generator.

o Power reference is several times faster than a normal diesel generator.

o Frequency drop in a grid will increase grid converter power output without power refer-

ence.

•Useful in situations here PMS is not fast enough or is unable to control.

•Upper system needs to give charging and discharging limit to the DC/DC converter.

• Upper system needs to give minimum and maximum voltage limits to the DC/DC converter.

o Grid Converter needs also under voltage limit because battery voltage can come directly

to DC-Link trough DC/DC converter, if DC-Link voltage goes below battery voltage.

U2U3

C

DC-Link

DC/DC

Converter

T2

Q1

U1

L

L

L

Filter

Source

DC

Grid

Discharge

Power

Frequency

Generator Motoring

Average

Charge

Page 38

5

vacon • 35 BASIC VARIANTS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

• Charging can be achieved by upper system control or simply by Value ID Control functions.

Charging will start automatically when the DC/DC converter overvoltage limit is reached

even without charging reference.

• When the grid converter power flow is parallel to the grid, the DC-Link voltage will go down

until it reaches the DC/DC converter undervoltage level, where the voltage remains until the

DC/DC converter discharging current limit is reached.

Figure 36. Charging and discharging

•AFE-operation mode.

o Not practical. Could be possible when DC/DC operated with under voltage control with a

drooping. But DC reference changes makes steep power changes.

• Island-operation mode

o Power control not possible, drive will give to the grid what the grid needs.

o Cannot operate parallel with other power sources.

o Makes a grid but cannot synchronize to an existing one.

DC OV Level

uG OV Level

uG UV Level

DC UV Level

Discharging

Controlled charg i ng poss ib le

Current limit charging

Page 39

PRODUCT CONFIGURATION EXAMPLES vacon • 36

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

6

6. PRODUCT CONFIGURATION EXAMPLES

6.1 Scope of delivery

VACON delivers energy storage related power conversion equipment. The DC/DC converter

includes power conversion hardware and power conversion control related software.

VACON does not deliver energy management systems, power management systems, or battery

management systems.

Figure 37. Vacon offering considering system level.

6.1.1 Direct to DC

The scope of delivery of VACON includes the typical VACON offering from power modules to system

drive or other suitable switchgear.

The simplest delivery includes power modules, LCL filters, NXP controls with an application and a

license. All the rest is handled by the system integrator.

NOTE! The selection of available power modules can be seen in a separate chart.

Energy Management System (EMS)

Power Management System (PMS)

Battery Management

System

Battery

Storage System

nergy Management System (EMS

)

ower Management System (PMS

)

attery Managemen

t

System

Batter

y

Storage Syste

m

Power Conversion System

Power Conversion

Hardware

Power Conversion Control

(PCC)

Page 40

6

vacon • 37 PRODUCT CONFIGURATION EXAMPLES

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

The line measurement board D7 is instructed to be included in the delivery.

Figure 38. Scope of delivery

In tailored customer projects, the scope of delivery may be a switchgear including power modules,

LCLs, NXP controls with an application and a license, but also breakers, fuses, DC pre-charging

components and other possible control circuit.

Figure 39. Scope of delivery

6.1.2 DC to DC

The scope of delivery of VACON includes the typical VACON offering from power modules to system

drive or other suitable switchgear.

The simplest delivery includes power modules, NXP controls with an application and a license.

Deliveries of single phase chokes are not preferred to be handled by VACON as the dimensioning

varies case by case. Still, delivery of chokes is negotiable. All the rest is handled by the system

integrator.

NOTE! The selection of available power modules can be seen in a separate chart.

-L1

-L2.1

-L2.2

-L2.3

-C1

-C2

HF

-C3

U2 U1

V2

W2

V1

W1

-R1

-C1.1-C1.2 -C4.1-C4.2

-C5.2

-R4

-R2

-C2.1-C2.2 -C5.1

-R5

-C6.2

-R3

-C3.1-C3.2 -C6.1

-R6

NXP/NXI HW

Customer/

Danfoss

Danfoss

Application

SW License

LCL or

Sine Filter

no HF

Page 41

PRODUCT CONFIGURATION EXAMPLES vacon • 38

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

6

Figure 40. Scope of delivery

In tailored customer projects, the scope of delivery may be a switchgear including power modules,

chokes, NXP controls with an application and a license but also breakers, fuses, DC pre-charging

components and other possible control circuit.

Figure 41. Scope of delivery

NXP/NXI HW

Customer/

Danfoss

Danfoss

Filter

Application

SW License

Single Phase Choke

Page 42

6

vacon • 39 PRODUCT CONFIGURATION EXAMPLES

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

6.2 Example configurations

6.2.1 DC/DC for supply interruptions

The DC/DC converter can be used to prevent grid voltage drops to interrupt essential drives to stop

for undervoltage. The DC/DC converter is connected to the AC drive's DC-terminals and used to feed

power during the grid voltage drops. Essential motors can run and ride through the voltage drops

without interruption.

Figure 42. Failure ride through with undervoltage control

The DC/DC converter can be used to support the grid by equalizing the power peaks and producing

the power if the main grid voltage drops. The DC/DC converter is connected to the grid converter

and power can run in both directions by charging and discharging the batteries.

Figure 43. Peak shaving of AC-grid

SUPPLY

3

L

L

-L2

-F2

-F1

-L1

-U1

NXP

-M1

-U2

DC/DC

-B1

SUPPLY

LCL

L

-L2

-F2

M

-F1

Q0

-L1

-U1

NXA

-U2

DC/DC

-B1

Page 43

PRODUCT CONFIGURATION EXAMPLES vacon • 40

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

6

6.2.2 Direct DC for Grid Support

In case the battery voltage window is favorable, the batteries can be connected directly into the DC.

The same usage case of power balancing of the grid also applies here. In below an example of case

where connection to the grid transformer is 440Vac and the battery voltage window is set to be 7501100Vdc.

Figure 44. Peak shaving of higher power and high energy AC grid

INCOMING 3PH, AC SUPPLY INCOMING 3PH, AC SUPPLY

3

2

2

3

QA1

2000A, 3P, LSI, 65kA

MAIN

BREAKER

-FC1.1-FC1.3

-RF4

1030A

LCL FILTER

-TB1

NXA10306

AFE UNIT

-FC2

OEVA

SWITCH

-TB1

NXA10306

AFE UNIT

-RF4

1030A

LCL FILTER

-FC1.1-FC1.3 -FC1.1-FC1.3 -FC1.1-FC1.3

QA1

2000A, 3P, LSI, 65kA

MAIN

BREAKER

3

33

3

33

I>

I>

I>>I>>

3

I>

I>

I>>I>>

3

33

-RF4

1030A

LCL FILTER

-TB1

NXA10306

AFE UNIT

-TB1

NXA10306

AFE UNIT

-RF4

1030A

LCL FILTER

3

3

2

2

-FC2

OEVA

SWITCH

OUTGOING DC SUPPLY

2

2

-FC2

OEVA

SWITCH

2

2

-FC2

OEVA

SWITCH

Page 44

7

vacon • 41 SIZING OF THE SYSTEM AND PRODUCT

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

7. SIZING OF THE SYSTEM AND PRODUCT

The basic principles that have an effect on the power unit selection are described in this chapter.

7.1 Direct to DC

The energy storage voltage window sets up the guideline for the voltage class selection. The

maximum voltage sets the requirement for using either 500 V class or 690 V class units. The value

of DC High Ready (Stop) should be taken into account when choosing the appropriate unit with

adequate maximum voltage. If the storage maximum voltage stays below 800 Vdc, it is possible to

use 500 V class units. If it goes above 800 Vdc but stays below 1100 Vdc, the 690 V unit is applicable.

NX8 voltage class liquid cooled units can be used up to 1200 Vdc link voltage.

The minimum voltage of the energy storage is crucial in current dimensioning of the unit size. An

easy rule of thumb is that output voltage of grid converter is

The gain 1.56 is not accurate and depending for example on voltage drop in filters and grid state.

Theoretically the gain can vary from 1.41 to 1.89. However 1.56 is a good starting point.

Now if the customer has indicated the needed power P, the corresponding current I

ac

for calculated

voltage U

ac

can be calculated with:

The selection is made by choosing an appropriate current size from the VACON products with the

above defined voltage class based on the maximum storage voltage level. The output voltage is

needed for the transformer dimensioning.

230 V Unit 500 V Unit 690 V Unit Vac/Vdc

Supply voltage max 240 500 690 Vac

Supply voltage min 208 380 525 Vac

Over voltage instantly 437 911 1200 Vdc

Over voltage U2t trip - - 1100 Vdc

DC High Ready (Stop) 382 797 1099 Vdc

Normal Max 324 675 931 Vdc

Normal Min 280 513 708 Vdc

DC Low Run (Def.Estim.) 242 475 656 Vdc

DC Low Ready (Stop) 239 436 602 Vdc

DC Low Running Min 225 410 567 Vdc

Under voltage instantly 183 333 461 Vdc

Page 45

SIZING OF THE SYSTEM AND PRODUCT vacon • 42

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

7

7. 2 DC /D C

The current capability of the DC/DC converter is limited by two constraints. The first constraint is

the current rating defined in the rating plate of the power converter that defines the operating area

in which the CE and UL certification is valid.

Figure 45. Vacon power converter ratings plate and their corresponding values in DC/DC converter

circuit diagram.

The second constraint is the thermal limits of the power converter. There are two parts which are

thermally stressed in the DC/DC application:

• The DC link busbars DC+ and DC- which are dimensioned according to I 1 of the DC/DC

converter.

• The IGBT switches in the DC/DC converter due to high switching frequency.

There is a software current limiter in the DC/DC converter to ensure these constraints are not

violated. The combined effect of the constraints thus becomes dependent on the voltage levels on

the storage side and the converter DC-link according to the figure below. Formulas in the graph

show how to calculate the output current I

3

based on the current I1 which is denoted as I

NOM

in the

ratings tables of the DC/DC converter.

DC+

DC-

I1

I1

I4

I2

I3

Battery

C

DC

L

1

Page 46

7

vacon • 43 SIZING OF THE SYSTEM AND PRODUCT

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Figure 46. Current capability of a DC/DC converter

NOTE! I

NOM

= I1~1.2*I

2

An example curve in above shows the combined current limit line for the DC/DC converter

depending on the ratio of storage voltage and converter DC-link voltage. The nominal current of a

DC/DC converter is defined as I 1 in the DC/DC converter rating plate which is approximately

1.2*I 2 depending on the frame size. The value of I

MAX

and I

1min

vary depending on voltage class and

switching frequency of the DC/DC converter. These values are higher when the switching frequency

is decreased to 4 kHz and higher also for the NX5 voltage class units. In addition, the 1min limit

applies only to frame sizes FI9-FI14.

NOTE! The nominal current of the DC/DC converter is not the same as the inverter current rating.

You may roughly calculate the DC/DC converter current rating by multiplying the inverter current

rating by 1.2. To have an overview, see the following table where the DC/DC converter current

ratings for NX6 are given.

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Iout

Iout 1min

U

BATTERY/UDC

I

OUT

/ I

NOM

Page 47

SIZING OF THE SYSTEM AND PRODUCT vacon • 44

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

7

Table 5. DC/DC converter current ratings for NX6

Air cooled NX6 drives

1025 VDC link voltage 1100 VDC 1025 VDC 931 VDC

I

nom

I

1min

I

max

I

max

I

max

Unit type Frame

IDC nomi-

nal (A)

PDC nom

(KW)

I

1min

5kHz (A)

I

1min

3.6kHz (A)

I

out

5kHz (A)

I

out

3.6kHz (A)

I

out

5kHz (A)

I

out

3.6kHz (A)

I

out

5kHz (A)

I

out

3.6kHz (A)

NXI00106A0TOCSSA FI6/IP21 11.1 11 14.6 18.3 14.6 18.3 14.6 18.3

NXI00136A0TOCSSA FI6/IP21 14.6 15 19 23.7 19 23.7 19 23.7

NXI00186A0TOCSSA FI6/IP21 20.3 21 26.3 32.9 26.3 32.9 26.3 32.9

NXI00226A0TOCSSA FI6/IP21 25 25 32 40 32 40 32 40

NXI00276A0TOCSSA FI6/IP21 31 32 39 49 39 49 39 49

NXI00346A0TOCSSA FI6/IP21 39 40 49 60 49 60 49 60

NXI00416A0TOCSSA FI7/IP21 47 48 60 73 60 73 60 73

NXI00526A0TOCSSA FI7/IP21 60 61 56 75 61 80 69 91

NXI00626A0TOCSSA FI8/IP100 71 73 90 108 90 108 90 108

NXI00806A0TOCSSA FI8/IP100 92 95 91 143 117 143 117 143

NXI01006A0TOCSSA FI8/IP100 117 119 122 167 133 180 146 180

NXI01256AOTOISF FI9/IP100 146 149 188 250 183 228 183 228 183 228

NXI01446AOTOISF FI9/IP100 168 172 216 288 210 263 210 263 210 263

NXI01706AOTOISF FI9/IP100 198 203 255 340 231 309 248 311 248 311

NXI02086AOTOISF FI9/IP100 245 251 312 416 231 309 248 325 264 345

NXI02616AOTOISF FI10/IP100 308 315 392 522 382 477 382 477 382 477

NXI03256AOTOISF FI10/IP100 383 393 488 650 450 594 475 594 475 594

NXI03856AOTOISF FI10/IP100 454 465 578 770 450 600 490 640 530 680

NXI04166AOTOISF FI10/IP100 490 503 624 832 450 600 490 640 530 680

NXI04606AOTOISF FI12/IP100 548 562 690 920 673 841 673 841 673 841

NXI05026AOTOISF FI12/IP100 598 613 753 1004 734 918 734 918 734 918

NXI05906AOTOISF FI12/IP100 703 721 885 1180 863 1079 863 1079 863 1079

NXI06506AOTOISF FI12/IP100 775 794 975 1300 870 1150 951 1189 1030 1189

NXI07506AOTOISF FI12/IP100 894 916 1125 1500 870 1150 977 1200 1030 1300

NXI08206AOTOISF FI12/IP100 977 1002 1230 1640 870 1150 977 1200 1030 1300

Page 48

7

vacon • 45 SIZING OF THE SYSTEM AND PRODUCT

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

Air cooled NX6 drives

1025 VDC link voltage 1100 VDC 1025 VDC 931 VDC

I

nom

I

1min

I

max

I

max

I

max

Unit type Frame

IDC nomi-

nal (A)

PDC nom

(KW)

I

1min

5kHz (A)

I

1min

3.6kHz (A)

I

out

5kHz (A)

I

out

3.6kHz (A)

I

out

5kHz (A)

I

out

3.6kHz (A)

I

out

5kHz (A)

I

out

3.6kHz (A)

NXI09206AOTOISF FI13/IP100 1102 1130 1380 1840 1275 1683 1346 1683 1346 1683

NXI10306AOTOISF FI13/IP100 1234 1265 1545 2060 1275 1645 1414 1780 1448 1884

NXI11806AOTOISF FI13/IP100 1414 1449 1770 2360 1275 1645 1414 1780 1448 1884

NXI15006AOTOISF FI14/IP100 1797 1842 2250 3000 2196 2745 2196 2745 2196 2745

NXI19006AOTOISF FI14/IP100 2276 2333 2850 3800 2568 3477 2696 3477 2781 3477

NXI22506AOTOISF FI14/IP100 2696 2763 3375 4500 2568 3290 2696 3474 2896 3733

Page 49

SIZING OF THE SYSTEM AND PRODUCT vacon • 46

24-hour support +358 (0)201 212 575 • Email: service@vacon.com

7

A dedicated tool is available to help in the selection of a correct power unit based on either power

or current profile. Examples of dimensioning based on storage power and current profiles are

displayed in figures below.

The intermediate steps between I

NOM

and I

MAX

can be calculated with the formulas given in the

previous figure. The shape of the output current curve is due to the limitation of the I

1

in the rating

plate and the relation between input and output current of the DC/DC converter. The plateau part

of the curve is due to thermal performance of the DC/DC converter. Current capability of the DC/DC

converter may seem complicated but it simply yields a constant power capability up to the point I

MAX

where current cannot be increased anymore. The relation between current and power can be

examined in the following graphs. Constant power is available as long as the voltage is sufficiently

high.

Figure 47. Power unit selection tool example based on storage current profile

Figure 48. Power unit selection tool example based on storage current profile

Based on the cases in figures above it is advantageous to limit the power at low battery voltage to

limit the current to a reasonable value. This helps to allow the use of a smaller frame size. Filter

size is also proportional to current. Therefore, high energy storage voltage is preferred from the

DC/DC converter sizing perspective.

Select: Define Storage Power

Storage

g

voltage

g

range

Storage

g

Power

Profile

Storage

g

Current

Profile

[Vdc] [kW] [Adc]

max voltage

700 350 500

g

nom voltage

375 300 800

g

min voltage

150 81 540

DC-link voltage

750 Vdc Class_5

g

DC-link power

343.0 kW

DC-link current

457 Adc dc-link

Storage output current

800 Adc storage

e

r

Energy storage system parameters

7

dcCas

s

_

4

DC/DC Converter design parameters

e

0

0

50

5

0

300

350

350

400

0

0

450

100 200 300 400 500 600 700 800 900

Power [kW]

Voltage [Vdc]

Storage Power Profile

Storage Profile

NXI04605A0T0ISFA1A20000

00

NXI03855A0T0ISFA1A20000

00

00800

smaller device @3.6kHz

0

0

100

0

0

200

0

0

700

0

0

800

800

900

900

1000

100 200 300 400 500 600 700 800 900

Voltage [Vdc]

Storage Current Profile

Storage profile

NXI04605A0T0ISFA1A200000

0

NXI03855A0T0ISFA1A200000

0

7

00800

smaller device @3.6kHz

Power [kW]

Select: Define Storage Current

Storage

voltage

g

range

Storage

Current

Profile

Storage

Power

Profile

[Vdc] [Adc] [kW]

max voltage

700 335 235

g

nom voltage

375 400 150

min voltage

150 400 60

DC-link voltage

750 Vdc Class_5

DC-link power

229.8 kW

DC-link current

306 Adc dc-link

Storage output current

400 Adc storage

Energy storage system parameters

V

_

DC/DC Converter design parameters

0

50

200

250

300

100 200 300 400 500 600 700 800 900

Voltage [Vdc]

Storage Power Profile

Storage Profile

NXI03005A0T0ISFA1A20000

00

NXI02615A0T0ISFA1A20000

00

00800

smaller device @3.6kHz

0

100

200

300

400

500

600

100 200 300 400 500 600 700 800 900

2

0

Voltage [Vdc]

Storage Current Profile

Storage profile

NXI03005A0T0ISFA1A200000

0

NXI02615A0T0ISFA1A200000

0

7

00800

smaller device @3.6kHz

Power [kW]

Power [kW]

Page 50

8

vacon • 47 INFORMATION TO ACQUIRE FROM CUSTOMERS

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 285

8. INFORMATION TO ACQUIRE FROM CUSTOMERS

It is important to find enablers and limiting factors of the customer system. The following list is, in

priority order, the information to be acquired from customer system to continue the discussion of

the offering.

1. Single line diagram

2. Short description of usage case / mission profile / wanted behavior

3. Battery (storage) information

•Voltage window [U

Bat,min

, U

Bat,nom

, U

Bat,max

]

• Power or current requirement at those voltage points [U

Bat,min

, U

Bat,nom

, U

Bat,max

]

• Balance/Maintenance charger?

4. Grid information

• Grid code demands?

5. Preferred topology if any (and why)

6. System control overview

Page 51

Document ID:

DPD01887A

Rev. A

Vacon Ltd

Member of the Danfoss Group

Runsorintie 7

65380 Vaasa

Finland

www.danfoss.com

Loading...

Loading...