Page 1

VACON NX QUICK HELP

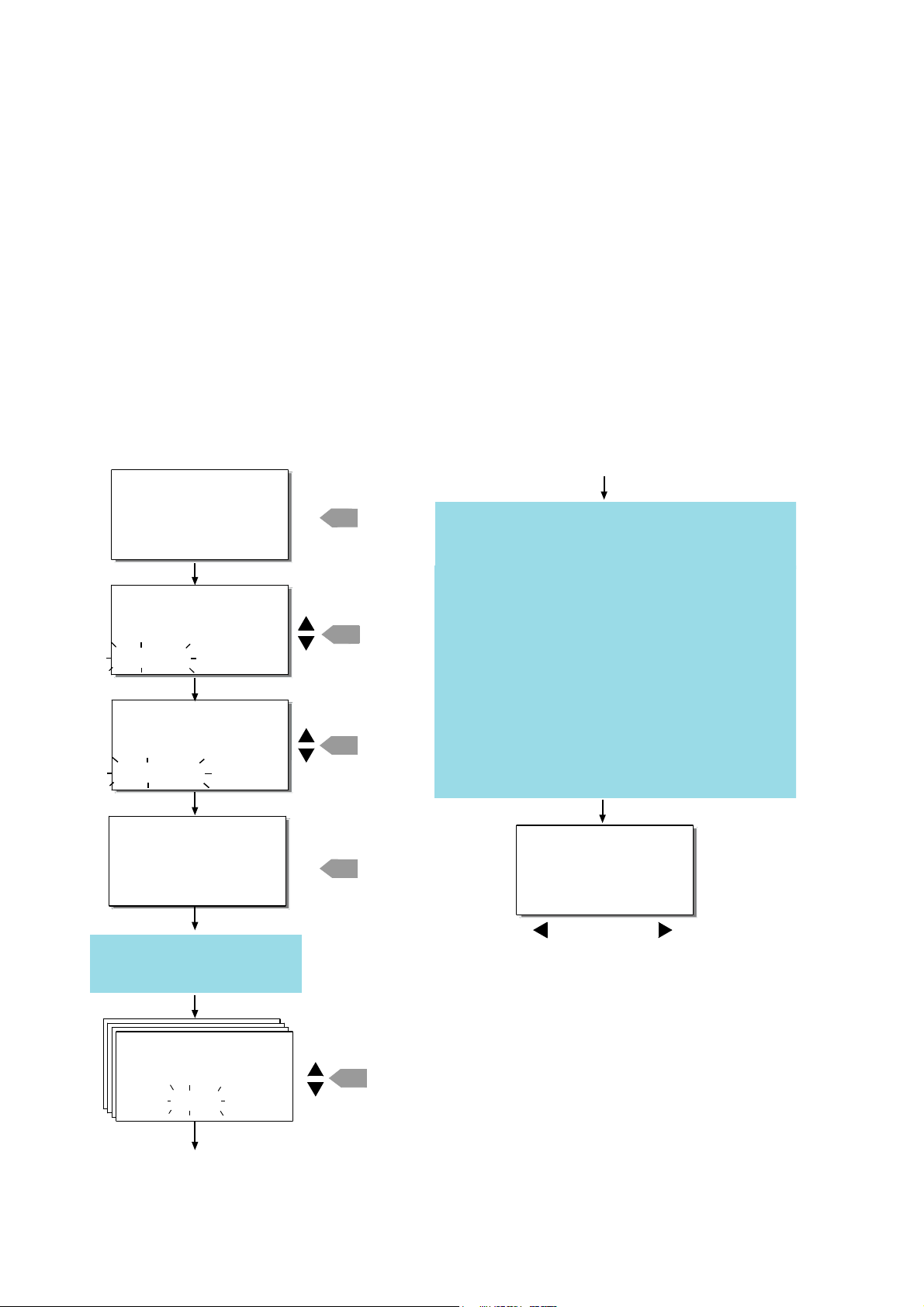

Start-up wizard

The Start Up Wizard is activated when the power to the drive is turned on for the first time, or if the

Start Up Wizard is activated from the System menu (P6.5.3) AND the power is turned OFF and back

ON.

The Start-up Wizard is a feature on the control keypad to facilitate the commissioning of the frequency converter. If selected active (default), the Start-up Wizard prompts the operator for the language and application of his/her choice plus for the values for a set of parameters common to all

applications as well as for a set of application-dependent parameters.

Always accept the value with the

buttons

(up and down arrows). More information on the use of the control panel in Chapter 7 of the

User's Manual.

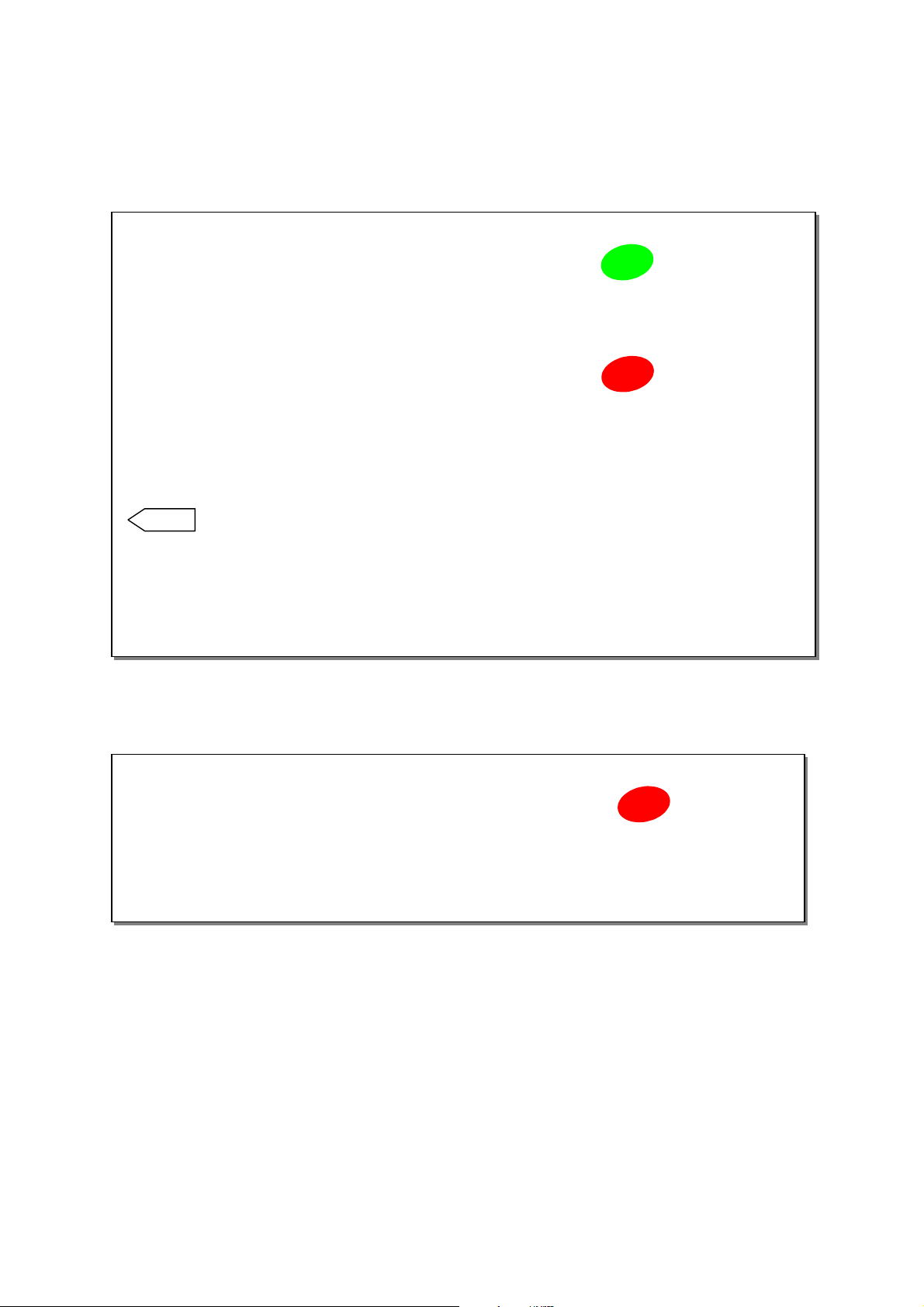

Startup wizard

Press enter

Language

English

Application

Standard

Enter button

enter

enter

enter

, scroll options or change values with the

Browser

Additional parameter settings are prompted

depending on the selected application.

Basic application:

I/O reference (P2.14)

Standard application:

I/O reference (P2.1.11)

Local/Remote control

application:

I/O reference A (P2.1.11)

I/O reference B (P2.1.12)

Multi-step speed

application:

I/O reference (P2.1.11)

PID control application:

Act value 1 selection (P2.2.9)

PID controller ref (P2.1.11)

Multi-purpose control

application:

I/O reference (P2.1.11)

Pump and fan control

application:

Act value 1 select (P2.2.1.9)

PID controller ref (P2.1.11)

No. of aux pumps (P2.9.1)

Setup starts

Press enter

Nine parameter settings

are prompted for each

application:

Min Frequency

0.00 Hz

enter

enter

Repeat setup?

<No Yes>

Page 2

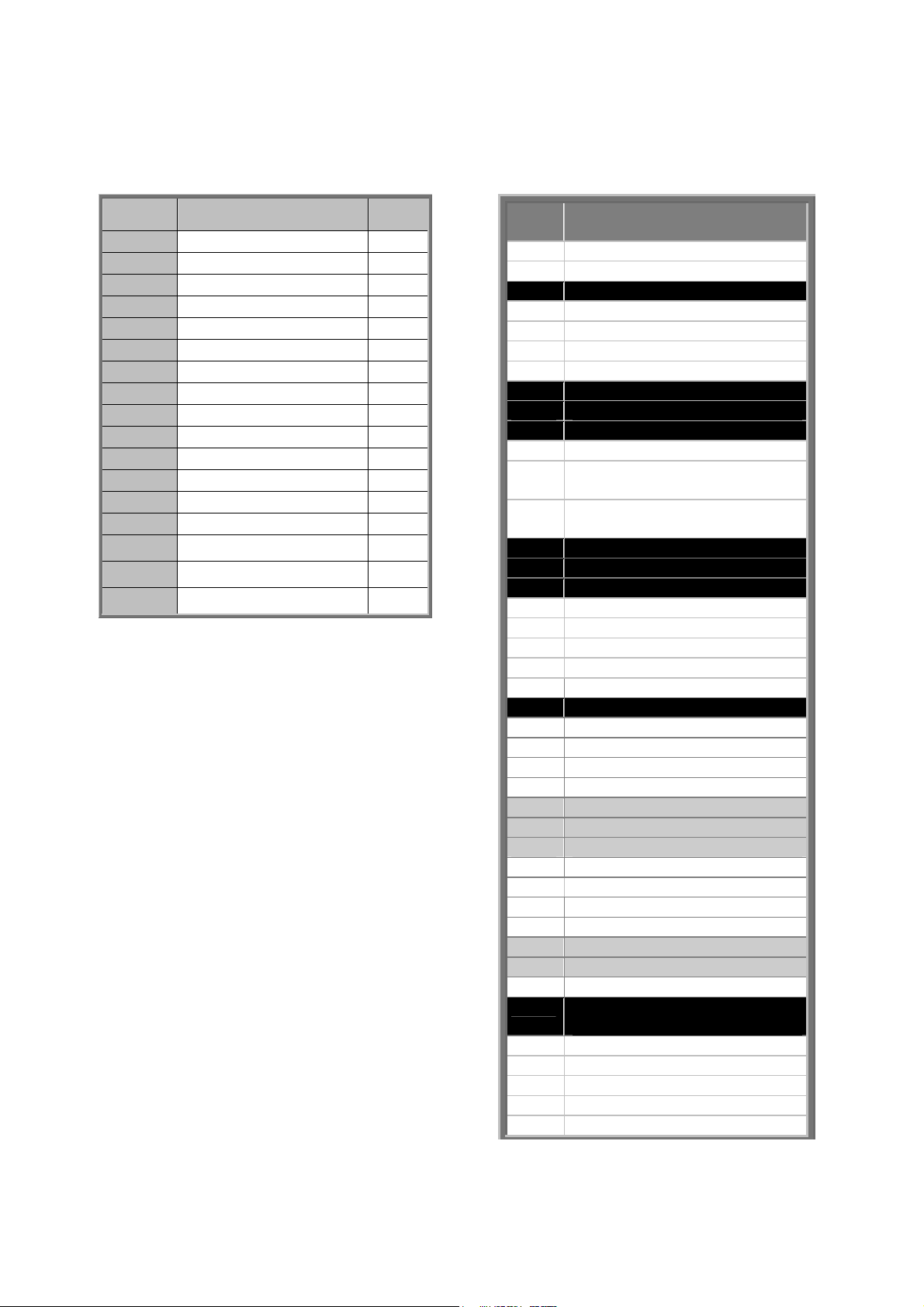

Monitoring values Faults and fault codes

Code Signal name Unit

V1.1

V1.2

V1.3

V1.4

V1.5

V1.6

V1.7

V1.8

V1.9

V1.10

V1.11

V1.12

V1.13

V1.14

V1.15

V1.16

M1.17

Output frequency Hz

Frequency reference Hz

Motor speed rpm

Motor current A

Motor torque %

Motor power %

Motor voltage V

DC-link voltage V

Unit temperature ºC

Motor temperature %

Voltage input V

Current input mA

DIN1, DIN2, DIN3

DIN4, DIN5, DIN6

DO1, RO1, RO2

Analogue output current mA

Multimonitoring items

NOTE! Different All in One applications

embody more monitoring values.

Fault

code

1 Overcurrent

2 Overvoltage

3 Earth fault

5 Charging switch

6 Emergency stop

7 Saturation trip

8 System fault

9 Undervoltage

10 Input line supervision

11 Output phase supervision

12 Brake chopper supervision

13 Frequency converter under-

temperature

14 Frequency converter

overtemperature

15 Motor stalled

16 Motor overtemperature

17 Motor underload

18 Unbalance fault

22 EEPROM checksum fault

24 Counter fault

25 Microprocessor watchdog fault

26 Start-up prevented

29 Thermistor fault

31 IGBT temperature (hardware)

32 Fan cooling

34 CAN bus communication

35 Application fault

37 Device change

38 Device added

39 Device removed

40 Device unknown

41 IGB T temperature

42 Brake resistor overtemperature

43 Encoder fault

44 Device change (default param.)

45 Device added (default param.)

49 Division by zero (application)

50 Analogue input Iin < 4mA

(selected signal range 4-20 mA)

51 External fault

52 Keypad communication fault

53 Fieldbus fault

54 Slot fault

56 PT100 temperature fault

Fault

Page 3

Actual value special display

The

Actual value special display

in a form more informative to the user.

The Actual value special display parameters are available in

Fan Control Application:

Par ID Parameter name Parameter code in

ID1033

ID1034

ID1035

ID1036

Actual value special display minimum

Actual value special display maximum

Actual value special display decimals

Actual value special display unit

Example:

The actual value signal sent from a sensor (in mA) represents the amount of waste water pumped

from a tank per second. The signal range is 0(4)…20mA. Instead of receiving the level of the actual

value signal (in mA) on the display, you wish to receive the amount of water pumped in m

then set a value for par. ID1033 to correspond to the minimum signal level (0/4 mA) and another

value for par. ID1034 to correspond to the maximum signal level (20 mA). The number of decimals

needed can be set with par. ID1035 and the unit (m

signal is then scaled between the set min and max values and displayed in the selected unit.

The following units can be selected (par. ID1036):

Value Unit On keypad Value Unit On keypad

0 Not Used 15 m3 /h m3/h

1 %

2

3 m m 18 gal / s GPS

4 bar bar 19 gal / min GPM

5 mbar mbar 20 gal / h GPH

6 Pa Pa 21 ft3 / s CFS

7 kPa kPa 22 ft3 / min CFM

8 PSI PSI 23 ft3 / h CFH

9 m / s m/s 24 A A

10 l / s l/s 25 V V

11 l / min l/m 26 W W

12 l / h l/h 27 kW kW

13 m3 /s m3/s 28 Hp Hp

14 m3 /min m3/m

NOTE: The maximum number of characters that can be shown on keypad is 4. This means that in

some cases the display of the unit on the keypad does not comply with the standards.

°C °C

parameters are used to convert and display the actual value signal

PID Control Application

and

Pump and

Parameter code in

PID ctrl applic.

Pump&Fan ctrl applic.

2.2.46 2.9.29

2.2.47 2.9.30

2.2.48 2.9.31

2.2.49 2.9.32

3

/s. You

3

/s) with par. ID1036. The level of the actual value

%

16

17 ft ft

°F °F

Page 4

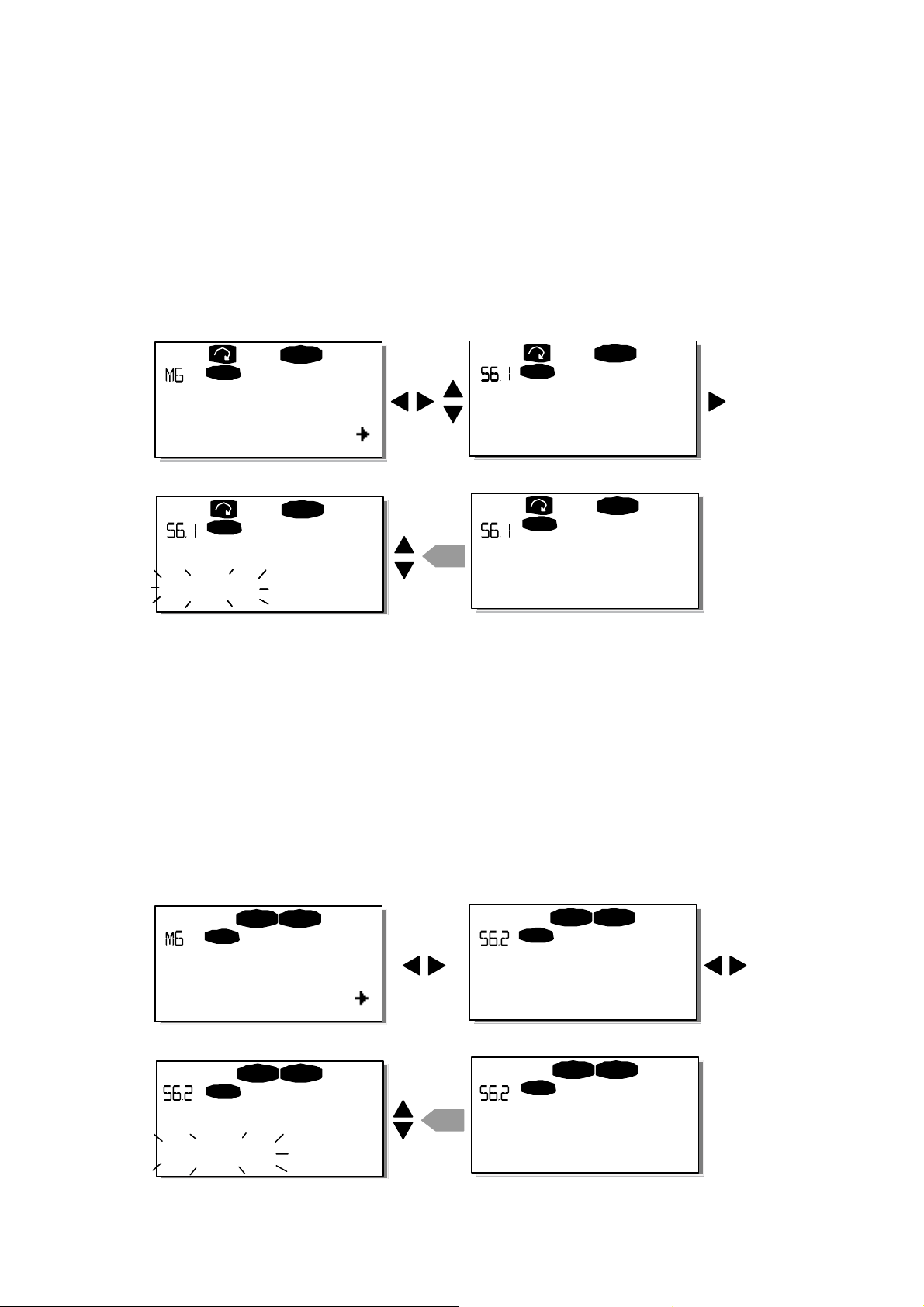

Selection of language

1. Find the System Menu (M6)

2. Enter the

3. Push the

4. Browse through the languages with the Browser buttons and select another language with the

Enter button.

For closer information on language selection, see Chapter 7.3.6.

Language selection page (S6.1)

Menu button right

to make the name of language blink.

.

READY

I/Ot erm

System Menu

S1!S11

READY

I/Ot erm

Language

English

Language

English

enter

Langue

Francais

I/Ot erm

I/Ot erm

READY

READY

Selection of application:

1. Find the System Menu (M6)

2. Enter the

3. Push the

4. Browse through the applications with the Browser buttons and select another application with

the Enter button.

For closer information on application change, see Chapter 7.3.6.

Application selection page (S6.2)

Menu button right

STOP READY

I/O term

to make the name of application blink.

.

STOP READY

I/O term

System Menu

S1!S11

STOP READY

I/O term

Application

Standard

Application

Standard

enter

Application

Multi-step

STOP READY

I/O term

Page 5

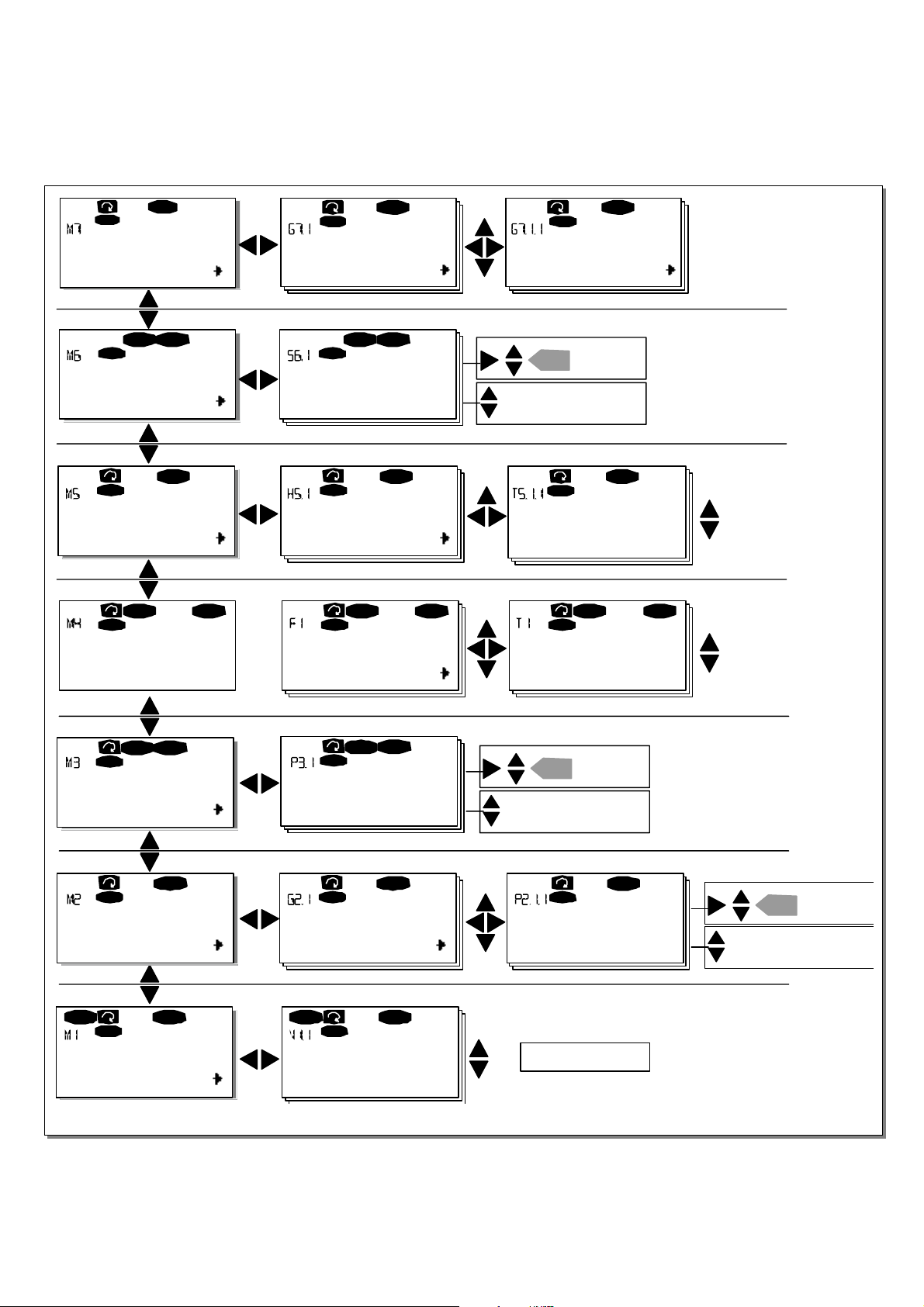

Control panel menus

I/Oterm

Expander boards

RE AD Y

I/Oterm

A:NXOPTA1

G1!G5

STOP READY

I/Oterm

System Menu Language

S1!S9

READY

I/Oterm

I/Oterm

English

I/Oterm

READY

G1!G1

STOP READY

READY

I/ O t er m

Parameters

P1!P3

Change

enter

value

Browse

I/ O t er m

READY

READY

Fault history 11 Output phase Operation days

H1

I/Oterm

H3

!

STOP FAULT

Active faults

F0

or:

11 Output phase Operation days

F T1

T1!T7

STOP FAULT

I/Oterm

!

T7

17

STOP

I/Oterm

17

FAUL T

READY

ST OP

I/Oterm

Keypad control

P1!P3

I/Oterm

READY

I/Oterm

Control Place

I/O Terminal

I/Oterm

ST OP

READY

READY

ent er

Browse

Local

Change

value

READY

Parameters Basic parameters Min Frequency

G1!G9

RU N

I/Oterm

Monitor Output frequency

READY

V1!V15

RUN

I/Oterm

P1

P15

!

READY

13.95 Hz

13.95 Hz

No editing!

enter

Browse

Change

value

Page 6

NOTE! There are some special functions that can be performed when in the M3 menu:

start

Select the keypad as the active control place by keeping the

button pushed

down for 3 seconds when the motor is running. The keypad will become the active

control place and the current frequency reference and direction will be copied to the

keypad.

stop

Select the keypad as the active control place by keeping the

button pushed

down for 3 seconds when the motor is stopped. The keypad will become the active

control place and the current frequency reference and direction will be copied to the

keypad.

Copy the frequency reference set elsewhere (I/O, fieldbus) to the panel by keeping the

enter

button pushed down for 3 seconds.

Note that if you are in any other than M3 menu these functions will not work.

M3

If you are in some other than

when the keypad is not selected as the active control place you will get an error message

Control NOT ACTIVE

.

menu and try to start the motor by pressing the START button

Keypad

NOTE 2:

stop

By default, the motor can be stopped at all times by pushing the

button

regardless of the selected control place. This default setting can be inactivated by giving

parameter

Stop Button Activated

(P3.4 or P3.6) (menu M3) the value 0. With this value

given to the parameter, pushing the STOP button stops the motor only when the keypad

has been selected as the active control place.

Loading...

Loading...