Vacon FI9-FI14 service manual

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

user's manual

nx inverters

fi9 – fi14

AT LEAST THE 10 FOLLOWING STEPS OF THE

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

START-UP QUICK GUIDE

MUST BE PERFORMED

DURING THE INSTALLATION AND COMMISSIONING.

IF ANY PROBLEMS OCCUR, PLEASE CONTACT YOUR LOCAL DISTRIBUTOR.

Start-up Quick Guide

1. Check that the delivery corresponds to your order, see Chapter 3.

2. Before taking any commissioning actions, read carefully the safety instructions

in Chapter 1.

3. Before the mechanical installation, check the minimum clearances around the

unit and check the ambient conditions in Chapter 5.

4. Check the size of the motor cable, DC supply cable, and mains fuses, and check

the cable connections. Read Chapters 6.1.1.1 – 6.1.1.6.

5. Follow the installation instructions, see Chapter 6.1.1.8.

6. The sizes and earthing of control connections are explained in Chapter 6.2.1.

7. If the Start-Up wizard is active, select the language you want the keypad and the

application to use and confirm by pressing the enter button. If the Start-Up

wizard is not active, follow the instructions in 7a and 7b below.

8. 7a. Select the language of the keypad from Menu M6, page 6.1. Instructions on

using the keypad are given in Chapter 7.

9. 7b. Select the application you want to use from Menu M6, page 6.2. Instructions

on using the keypad are given in Chapter 7.

10. All parameters have factory default values. To ensure proper operation, check

the rating plate data for the values below and the corresponding parameters of

parameter group G2.1.

• nominal voltage of the motor

• nominal frequency of the motor

• nominal speed of the motor

• nominal current of the motor

• motor cosϕ

All parameters are explained in the All in One Application Manual.

11. Follow the commissioning instructions, see Chapter 8.

12. The Vacon NX Inverter is now ready for use.

Vacon Plc is not responsible for the use of the inverters against the

instructions.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

CONTENTS

VACON NXI USER’S MANUAL

INDEX

1 SAFETY

2 EU DIRECTIVE

3 RECEIPT OF DELIVERY

4 TECHNICAL DATA

5 INSTALLATION

6 CABLING AND CONNECTIONS

7 CONTROL KEYPAD

8 COMMISSIONING

9 FAULT TRACING

4 • vacon

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

ABOUT THE VACON NXI USER'S MANUAL

Congratulations for choosing Vacon NX Inverters!

The User's Manual will provide you with the necessary information about the installation,

commissioning and operation of Vacon NX Inverters. We recommend that you carefully study these

instructions before powering up the inverter for the first time.

In the All in One Application Manual you will find information about the different applications

included in the All in One Application Package. Should these applications not meet the requirements

of your process, please contact the manufacturer for information on special applications.

This manual is available in both paper and electronic editions. We recommend you to use the

electronic version if possible. If you have the electronic version at your disposal, you will be able to

benefit from the following features:

The manual contains several links and cross-references to other locations in the manual, which

makes it easier to move around in the manual. The reader can thus easily find and check things.

The manual also contains hyperlinks to web pages. To visit these web pages through the links, you

must have an internet browser installed on your computer.

Tel: +358-201-2121 • Fax: +358-201-212 205

vacon • 5

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Vacon NXI User's Manual

Index

Date: 18.10.2006

SAFETY............................................................................................................................... 7

1.

1.1 Warnings ..................................................................................................................................... 7

1.2 Safety instructions...................................................................................................................... 7

1.3 Earthing and earth fault protection ........................................................................................... 8

1.4 Running the motor...................................................................................................................... 8

2. EU DIRECTIVE ....................................................................................................................9

2.1 CE marking ................................................................................................................................. 9

2.2 EMC directive .............................................................................................................................. 9

2.2.1 Introduction....................................................................................................................... 9

2.2.2 Technical criteria..............................................................................................................9

2.2.3 Vacon inverter EMC classification ................................................................................... 9

2.2.4 Manufacturer's declaration of conformity....................................................................... 9

Document code: ud01063B

3. RECEIPT OF DELIVERY..................................................................................................... 11

3.1 Type designation code. ............................................................................................................. 11

3.1.1 FI9 – FI14..........................................................................................................................11

3.1.2 The standard features of NXI inverters ..........................................................................12

3.2 Storage...................................................................................................................................... 13

3.3 Maintenance.............................................................................................................................. 13

3.4 Warranty.................................................................................................................................... 14

4. TECHNICAL DATA ............................................................................................................ 15

4.1 Introduction............................................................................................................................... 15

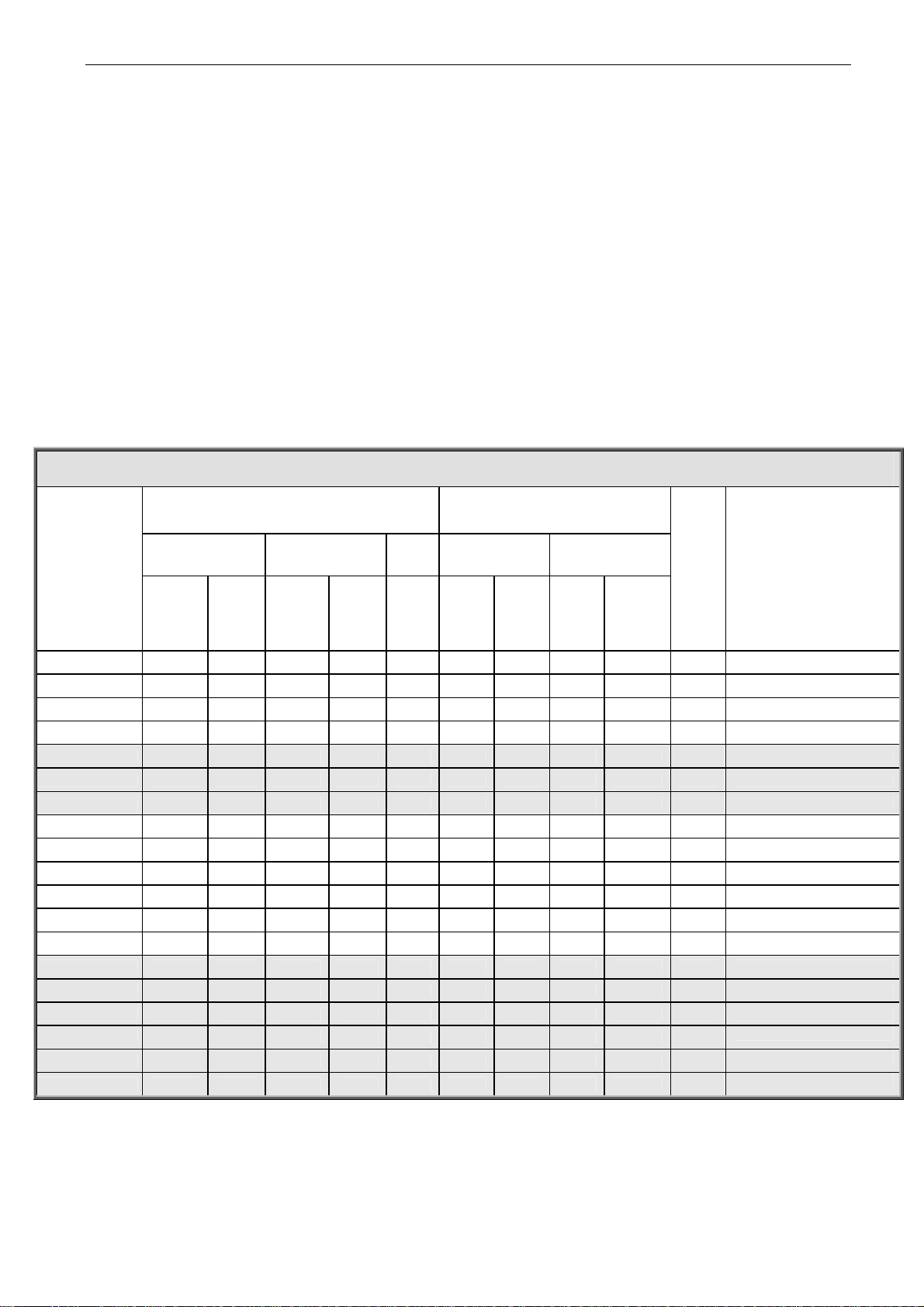

4.2 Power ratings............................................................................................................................ 17

4.2.1 Vacon NXI_xxxx 5 – Supply voltage 465-800 Vdc, Motor voltage 380—500 Vac ............17

4.2.2 Vacon NXI_xxxx 6 – Supply voltage 640-1100 Vdc, Motor voltage 525—690 Vac...........18

4.3 Technical information............................................................................................................... 19

5. INSTALLATION ................................................................................................................. 22

5.1 Mounting ................................................................................................................................... 22

5.2 Fan cooling................................................................................................................................ 29

5.2.1 Frames FI9 to FI14...........................................................................................................29

5.2.2 Arranging ventilation of the enclosure ...........................................................................30

6. CABLING AND CONNECTIONS ......................................................................................... 33

6.1 Power unit................................................................................................................................. 33

6.1.1 Power connections ..........................................................................................................41

6.1.1.1 DC supply and motor cables ...................................................................................41

6.1.1.2 Control cable ...........................................................................................................41

6.1.1.3 Fuses, NXI_xxxx 5....................................................................................................41

6.1.1.4 Fuses, NXI_xxxx 6....................................................................................................42

6.1.1.5 Inverter supply and motor cables , NXI_xxxx 5 ......................................................43

6.1.1.6 Terminal sizes, NXI_xxxx 5 .....................................................................................44

6.1.1.7 Inverter supply and motor cables, NXI_xxxx 6 .......................................................44

6 • vacon

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

6.1.1.8

6.1.2 Installation instructions ..................................................................................................47

6.1.2.1 Vacon NXI frames ...................................................................................................49

6.1.3 Cable installation and the UL standards ........................................................................51

6.1.4 Cable and motor insulation checks ................................................................................51

6.2 Control unit ............................................................................................................................... 52

6.2.1 Control connections ........................................................................................................53

6.2.1.1 Control cables .........................................................................................................54

6.2.1.2 Galvanic isolation barriers ......................................................................................54

6.2.2 Control terminal signals .................................................................................................55

6.2.2.1 Digital input signal inversions.................................................................................56

6.2.2.2 Jumper selections on the OPT-A1 basic board......................................................57

7. CONTROL KEYPAD ........................................................................................................... 59

7.1 Indicators on the keypad display.............................................................................................. 59

7.1.1 Drive status indications...................................................................................................59

7.1.2 Control place indications.................................................................................................60

7.1.3 Status LEDs (green – green – red).................................................................................60

7.1.4 Text lines..........................................................................................................................61

7.2 Keypad push-buttons................................................................................................................ 62

7.2.1 Button descriptions .........................................................................................................62

7.3 Navigation on the control keypad............................................................................................. 63

7.3.1 Monitoring menu (M1) .....................................................................................................65

7.3.2 Parameter menu (M2) .....................................................................................................66

7.3.3 Keypad control menu (M3) ..............................................................................................68

7.3.3.1 Selection of control place .......................................................................................68

7.3.3.2 Keypad reference ....................................................................................................69

7.3.3.3 Keypad direction......................................................................................................69

7.3.3.4 Stop button activated...............................................................................................69

7.3.4 Active faults menu (M4)...................................................................................................70

7.3.4.1 Fault types ...............................................................................................................70

7.3.4.2 Fault codes ..............................................................................................................72

7.3.4.3 Fault time data record.............................................................................................75

7.3.5 Fault history menu (M5) ..................................................................................................76

7.3.6 System menu (M6)...........................................................................................................77

7.3.6.1 Selection of language..............................................................................................80

7.3.6.2 Application selection ...............................................................................................80

7.3.6.3 Copy parameters .....................................................................................................81

7.3.6.4 Parameter comparison ...........................................................................................83

7.3.6.5 Safety .......................................................................................................................84

7.3.6.6 Keypad settings .......................................................................................................86

7.3.6.7 Hardware settings...................................................................................................88

7.3.6.8 System info ..............................................................................................................90

7.3.7 Expander board menu (M7).............................................................................................94

7.4 Further keypad functions ......................................................................................................... 95

Terminal sizes, NXI_xxxx 6 .....................................................................................46

8. COMMISSIONING.............................................................................................................. 96

8.1 Safety......................................................................................................................................... 96

8.2 Commissioning the inverter..................................................................................................... 96

9. FAULT TRACING............................................................................................................... 99

Tel: +358-201-2121 • Fax: +358-201-212 205

SAFETY vacon • 7

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

1. SAFETY

ONLY A COMPETENT ELECTRICIAN MAY CARRY OUT

THE ELECTRICAL INSTALLATION

1.1 Warnings

WARNING

1

2

3

4

5

6

1.2 Safety instructions

1

2

3

4

5

6

7

The components of the power unit of the inverter are live when the Vacon

NX is connected to DC supply. Coming into contact with this voltage is

extremely dangerous and may cause death or severe injury. The

control unit is isolated from mains potential.

The DC supply and motor terminals are live when the Vacon NX is

connected to DC supply, even if the motor is not running.

The control I/O-terminals are isolated from the mains potential.

However, the relay outputs and other I/O-terminals may have dangerous

control voltage present even when the Vacon NX is disconnected from the

DC supply.

The inverter has a large capacitive leakage current.

If the inverter is used as a part of a machine, the machine manufacturer

is responsible for providing the machine with a main switch (EN 60204-1).

Only spare parts delivered by Vacon can be used.

The Vacon NX inverter is meant for fixed installations only.

Do not perform any measurements when the inverter is connected to the

DC supply.

After having disconnected the inverter from the DC supply, wait until the

fan stops and the indicators on the keypad go out (if no keypad is

attached see the indicator through the keypad base). Wait 5 more

minutes before doing any work on Vacon NX connections. Do not even

open the cover before this time has expired.

Do not perform any voltage withstand tests on any part of Vacon NX.

There is a certain procedure according to which the tests shall be performed. Ignoring this procedure may result in damaged product.

Prior to measurements on the motor or the motor cable, disconnect the

motor cable from the inverter.

Do not touch the components on the circuit boards. Static voltage discharge may damage the components.

Before connecting the inverter to DC supply, make sure that the Vacon

NX front and cable covers are closed.

1

8 • vacon SAFETY

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.3 Earthing and earth fault protection

The Vacon NX inverter must always be earthed with an earthing conductor connected to the earthing

terminal.

The earth fault protection inside the inverter only protects the inverter against earth faults in the

motor or the motor cable.

Due to the high capacity currents present in the inverter, fault current protective switches may not

function properly. If fault current protective switches are used, they need to be tested with earth

fault currents present during possible fault situations.

1.4 Running the motor

Warning symbols

For your own safety, please pay special attention to the instructions marked with the following

symbols:

WARNING

HOT SURFACE

MOTOR RUN CHECK LIST

WARNING

Dangerous voltage

=

=

General warning

Hot surface – Risk of burn

=

1

2

3

4

5

Before starting the motor, check that the motor is mounted properly and

ensure that the machine connected to the motor allows the motor to be

started.

Set the maximum motor speed (frequency) according to the motor and

the machine connected to it.

Before reversing the motor, make sure that this can be done safely.

Make sure that no power correction capacitors are connected to the

motor cable.

Make sure that the motor terminals are not connected to mains

potential.

Tel: +358-201-2121 • Fax: +358-201-212 205

1

eu directive vacon • 9

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

2. EU DIRECTIVE

2.1 CE marking

The CE marking on the product guarantees the free movement of the product within the EEA

(European Economic Area). It also guarantees that the product complies with applicable directives

(for example, the EMC directive and other possible so-called new method directives).

Vacon NX inverters carry the CE label as a proof of compliance with the Low Voltage Directive (LVD)

and the Electro Magnetic Compatibility (EMC) directive. SGS FIMKO has acted as the Competent

Body.

2.2 EMC directive

2.2.1 Introduction

The EMC Directive provides that the electrical apparatus must not excessively disturb the

environment it is used in, and, on the other hand, it shall have an adequate level of immunity toward

other disturbances from the same environment.

The compliance of Vacon NX inverters with the EMC directive is verified with Technical Construction

Files (TCF) and checked and approved by SGS FIMKO, which is a Competent Body. The Technical

Construction Files are used to authenticate the conformity of Vacon inverters with the Directive

because it is impossible to test such a large product family in a laboratory environment and because

the combinations of installation vary greatly.

2.2.2 Technical criteria

Our basic idea was to develop a range of inverters offering the best possible usability and costefficiency. EMC compliance was a major consideration from the outset of the design.

2.2.3 Vacon inverter EMC classification

Factory delivered Vacon NX inverters are Class T equipment, which fulfil all EMC immunity

requirements (standards EN 50082-1, 50082-2 and EN 61800-3).

Class T:

Class T equipment have a small earth leakage current and can be used with floating DC input.

Warning: This product is of the restricted sales distribution class according to IEC 61800-3. In

residential areas, this product may cause radio interference in which case the user may be required

to take adequate measures.

2.2.4 Manufacturer's declaration of conformity

The following page presents the photocopy of the Manufacturer's Declaration of Conformity assuring

the compliance of Vacon Inverters with the EMC-directives

2

10 • vacon eu directive

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

EU DECLARATION OF CONFORMITY

We

Manufacturer's name: Vacon Oyj

Manufacturer's address: P.O.Box 25

Runsorintie 7

FIN-65381 Vaasa

Finland

hereby declare that the product

Product name: Vacon NX Common DC bus Products

Model designation: Vacon NXI 0004 5… to 2700 5

Vacon NXI 0004 6… to 2250 6

Vacon NXA 0004 5… to 2700 5

Vacon NXA 0004 6… to 2250 6

Vacon NXF 0004 6… to 2700 5

Vacon NXF 0004 6… to 2250 6

Vacon NXN 0400 5… to 0650 5

Vacon NXN 0400 6… to 0650 6

Vacon NXB 0004 5… to 2700 5

Vacon NXB 0004 6… to 2250 6

has been designed and manufactured in accordance with the following standards:

Safety: EN61800-5-1 (2003)

EMC: Factory delivered Vacon NX inverter modules comply with

the requirements of category 4 equipment according to

EN 61800-3 (2004).

It is ensured through internal measures and quality control that the product conforms at all

times to the requirements of the current Directive and the relevant standards.

In Vaasa, 3

Vesa Laisi

President

The year the CE marking was affixed: 2005

rd

of April, 2006

Tel: +358-201-2121 • Fax: +358-201-212 205

2

receipt of delivery vacon • 11

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

3. RECEIPT OF DELIVERY

Vacon NX inverters have undergone scrupulous tests and quality checks at the factory before they

are delivered to the customer. However, after unpacking the product, check that no signs of

transportation damage is to be found on the product and that the delivery is complete (compare the

type designation of the product to the code below, see Figure 3-1

Should the drive have been damaged during the shipping, please contact primarily the cargo

insurance company or the carrier.

If the delivery does not correspond to your order, contact the supplier immediately.

3.1 Type designation code.

3.1.1 FI9 – FI14

2A

T 0 C S S A1A2000000

V

I

AAAA

NX

Option boards; each slot is represented by two characters where:

A = basic I/O board, B = expander I/O board,

C = fieldbus board, D = special board

Hardware modifications; Module type - S - Boards

S = Direct connection, standard boards, FR4...8

V = Direct connection, varnished boards, FR4...8

F= Fiber connection, standard boards

G = Fiber connection, varnished boards

S = Standard air cooled drive

A = Standard air cooled power unit - transformer supply for main fan

U = Standard air cooled power unit - external supply for main fan

C = INU - with integrated charging circuit

I = INU - no charging circuit

N = Standard 6-pulse - no chokes

S = Standard 6-pulse connection with chokes

2 = AFE module

5 = AFE module + LCL filter

3 = FFE module

6 = FFE module + AC choke

8 = BCU Brake chopper unit

0 = N/A (no brake chopper)

EMC emission level:

T = fulfils standard EN61800-3 for IT networks

Enclosure class:

2 = IP21, FR4...7

0 = IP00, FR8, FI9...14

Control keypad:

A = standard (alpha-numeric)

B = no local control keypad

F = dummy keypad

G = graphic display

Nominal supply voltage (3-phase):

5 = 380–500Vac / 465–800Vdc

6 = 525–690Vac / 640–1100Vdc

Nominal current (low overload)

0004 = 4A, 0520 = 520A, etc.

Module type:

A = AFE Active Front End

B = BCU Brake Chopper Unit

F = FFE Fundamental Front End

I = INU Inverter

N = Non regenerative Front End

Product generation

Figure 3-1 Vacon NX type designation code, FI9 – FI14

3

12 • vacon receipt of delivery

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

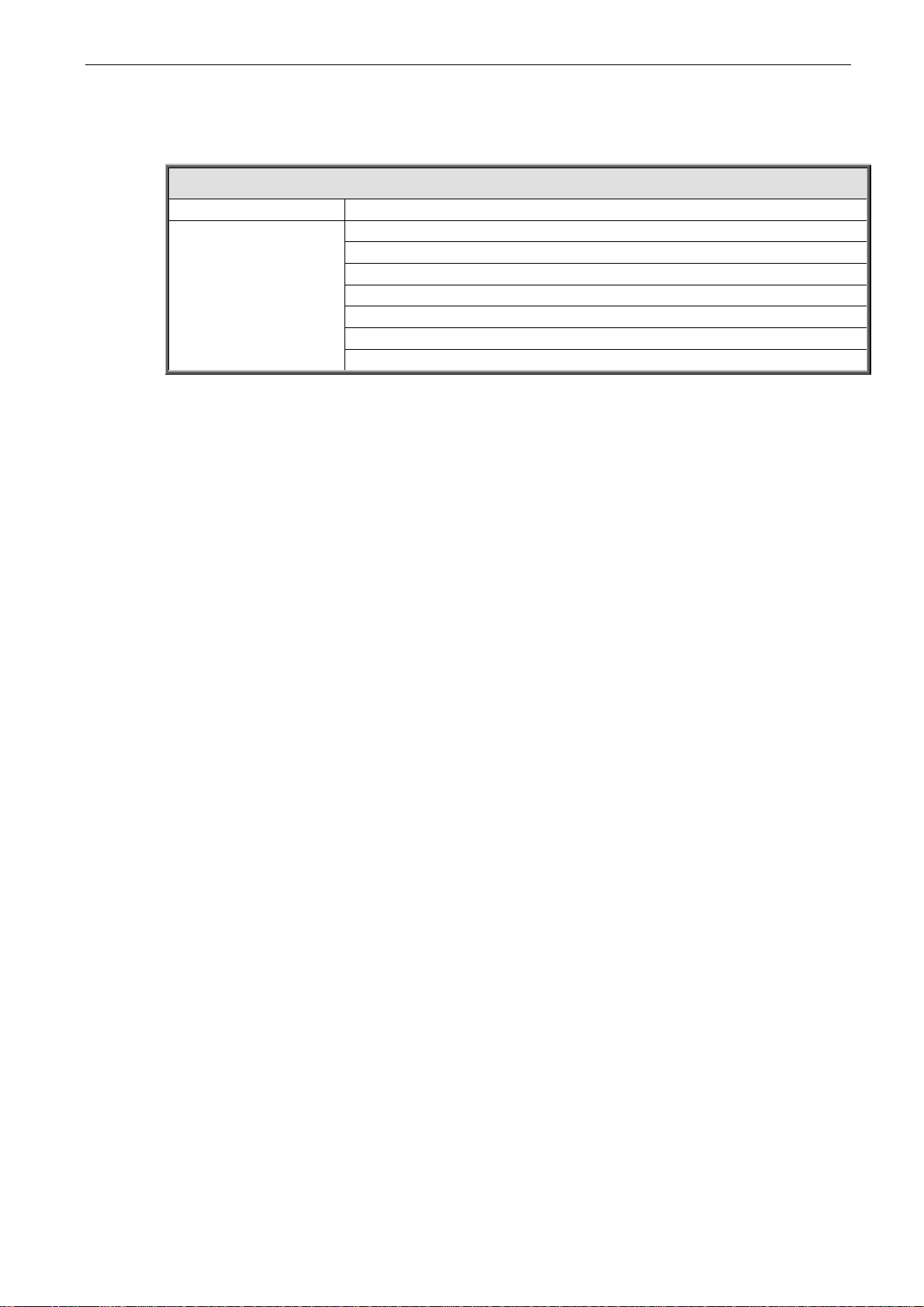

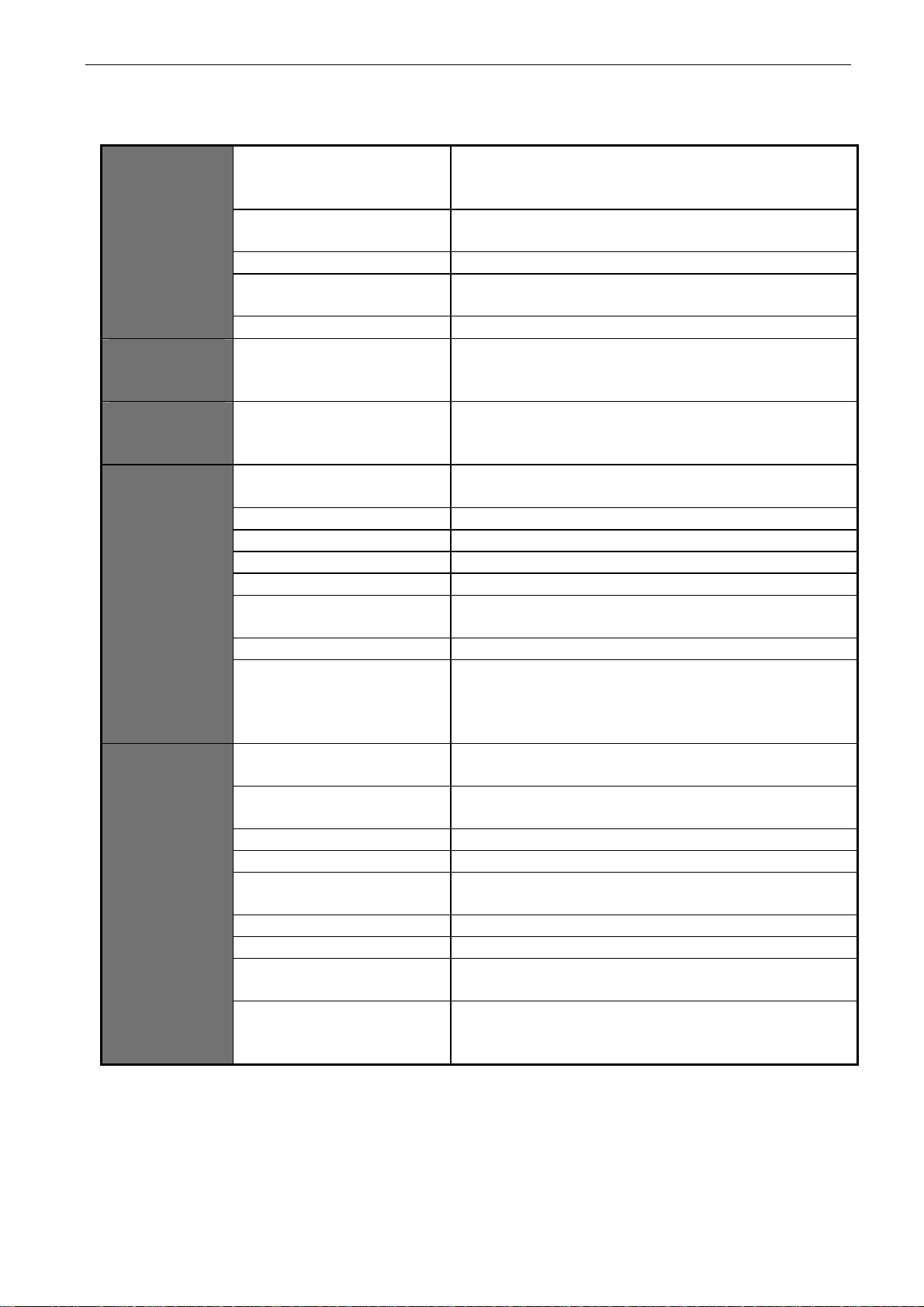

3.1.2 The standard features of NXI inverters

INVERTER

Sales code NXI_AAAA 5/6

Air cooling

Alphanumeric control panel with fiber connection

Standard features of

FI9, FI10, FI12,

FI13 and FI14

Table 3-1. The standard features of NXI inverters

EMC class T (EN 61800-3 for IT networks)

Safety CE / UL

External charging required

I/O modules A1 & A2

IP00

Tel: +358-201-2121 • Fax: +358-201-212 205

3

receipt of delivery vacon • 13

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.2 Storage

If the inverter is to be stored before use, make sure that the ambient conditions are acceptable:

Storage temperature –40…+70°C

Relative humidity <95%, no condensation

When inverter units are stored without voltage being applied, the recharging of the capacitors

should be done at least once a year by connecting voltage into the unit and keeping it powered at

least for 1 hour.

If the storing time is much longer than one year, the recharging of the capacitors has to be carried

out so that the possible high leakage current through the capacitors is limited. The best alternative

is to use DC-power supply with adjustable current limit. Current limit has to be set for example to

300…500mA and DC-power supply has to be connected to the B+/B- terminals (DC supply terminals).

DC-voltage must be adjusted up to nominal DC-voltage level of the unit (1.35*Un ac) and shall be

supplied at least for 1 hour.

If DC-voltage is not available and unit has been stored much longer than 1 year de-energized,

consult factory before connecting the power.

3.3 Maintenance

All technical devices, drives as well, need a certain amount of care-taking and failure preventive

maintenance. To maintain trouble-free operation of the drive, environmental conditions, as well as

load, line power, process control, etc. have to be within specifications, determined by manufacturer.

If all conditions are in accordance with the manufacturer's specifications, there are no other

concerns, but to provide a cooling capacity high enough for the power- and control circuits. This

requirement can be met by making sure, that the cooling system works properly. Operation of

cooling fans and cleanness of the heat sink should be verified regularly.

Regular maintenance is recommended to ensure trouble free operation and long lifetime of the

drive. At least the following things should be included in the regular maintenance.

3

14 • vacon receipt of delivery

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

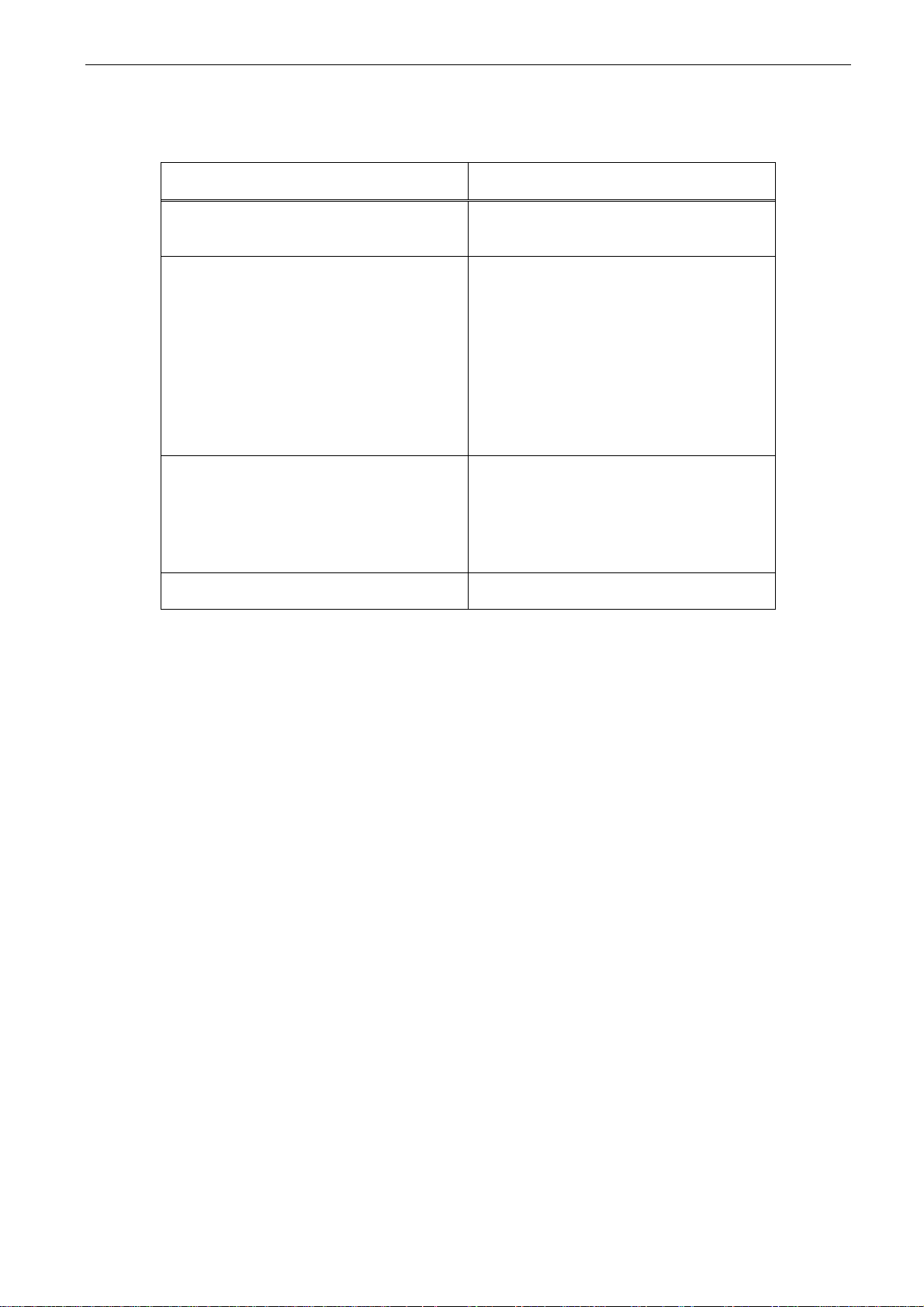

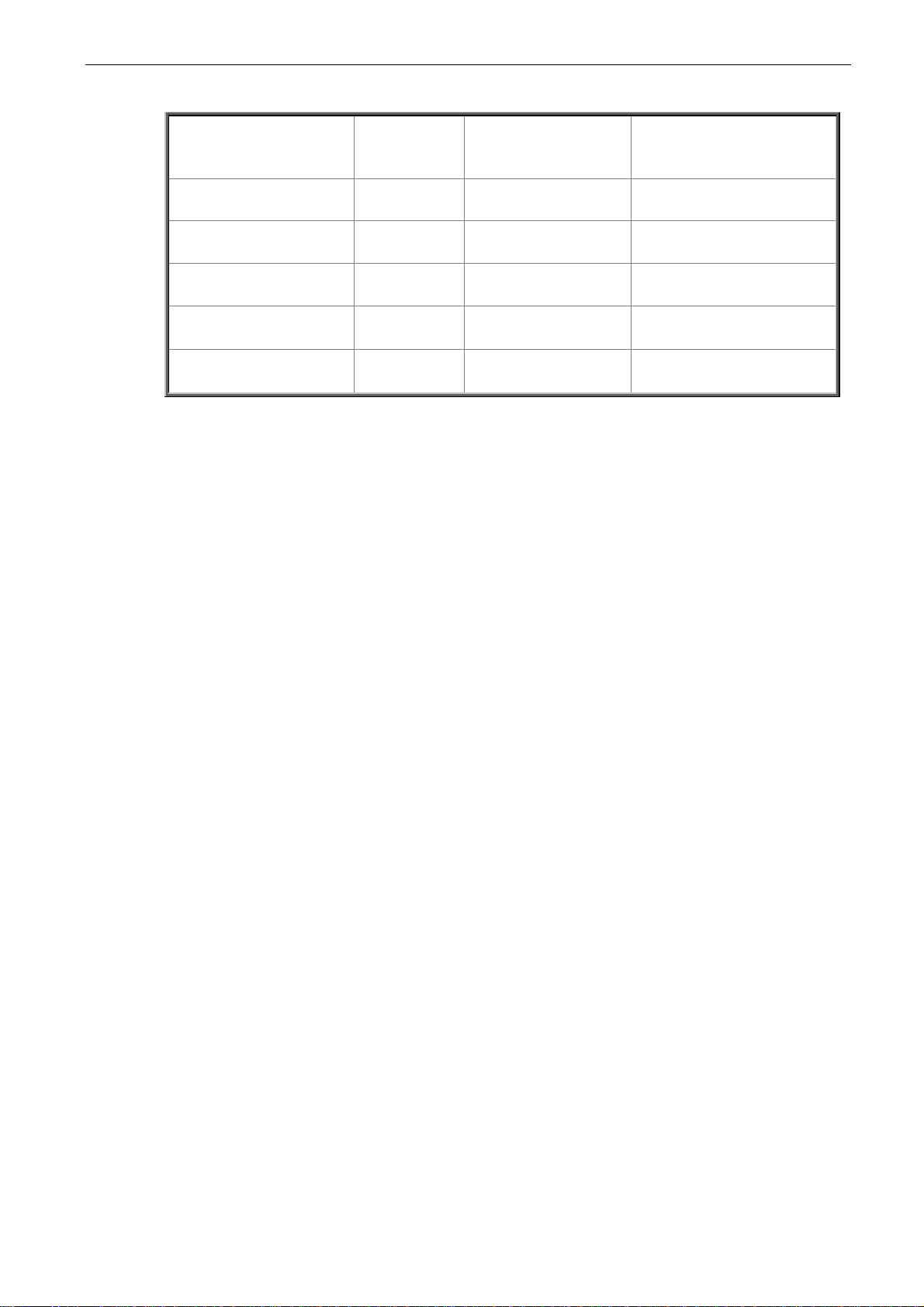

TABLE 5. Maintenance interval

Interval Maintenance

12 months (if unit stored)

6 - 24 months (depending on

environment)

5 - 7 years Change the cooling fans

5 - 10 years Change the DC bus capacitors

Capacitor reforming, see separate

instructions

Check the input and output terminals

and control I/O-terminals.

Clean the cooling tunnel

Check operation of cooling fan, check

for corrosion on terminals, busbars

and other surfaces

Check the door filters in the case of

cabin installation

Main fan

Internal IP54 fan

Cabinet cooling fan/filter

It is also recommended to record all actions and counter values with dates and time for follow up of

maintenance.

3.4 Warranty

Only manufacturing defects are covered by the warranty. The manufacturer assumes no

responsibility for damages caused during or resulting from transport, receipt of the delivery,

installation, commissioning or use.

The manufacturer shall in no event and under no circumstances be held responsible for damages

and failures resulting from misuse, wrong installation, unacceptable ambient temperature, dust,

corrosive substances or operation outside the rated specifications.

Neither can the manufacturer be held responsible for consequential damages.

The Manufacturer's warranty period is 18 months from the delivery or 12 months from the

commissioning whichever expires first (General delivery terms NL92/Orgalime S92).

The local distributor may grant a warranty time different from the above. This warranty time shall be

specified in the distributor's sales and warranty terms. Vacon assumes no responsibility for any

other warranties than that granted by Vacon itself.

In all matters concerning the warranty, please contact your distributor first.

Tel: +358-201-2121 • Fax: +358-201-212 205

3

technical data vacon • 15

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

4. TECHNICAL DATA

4.1 Introduction

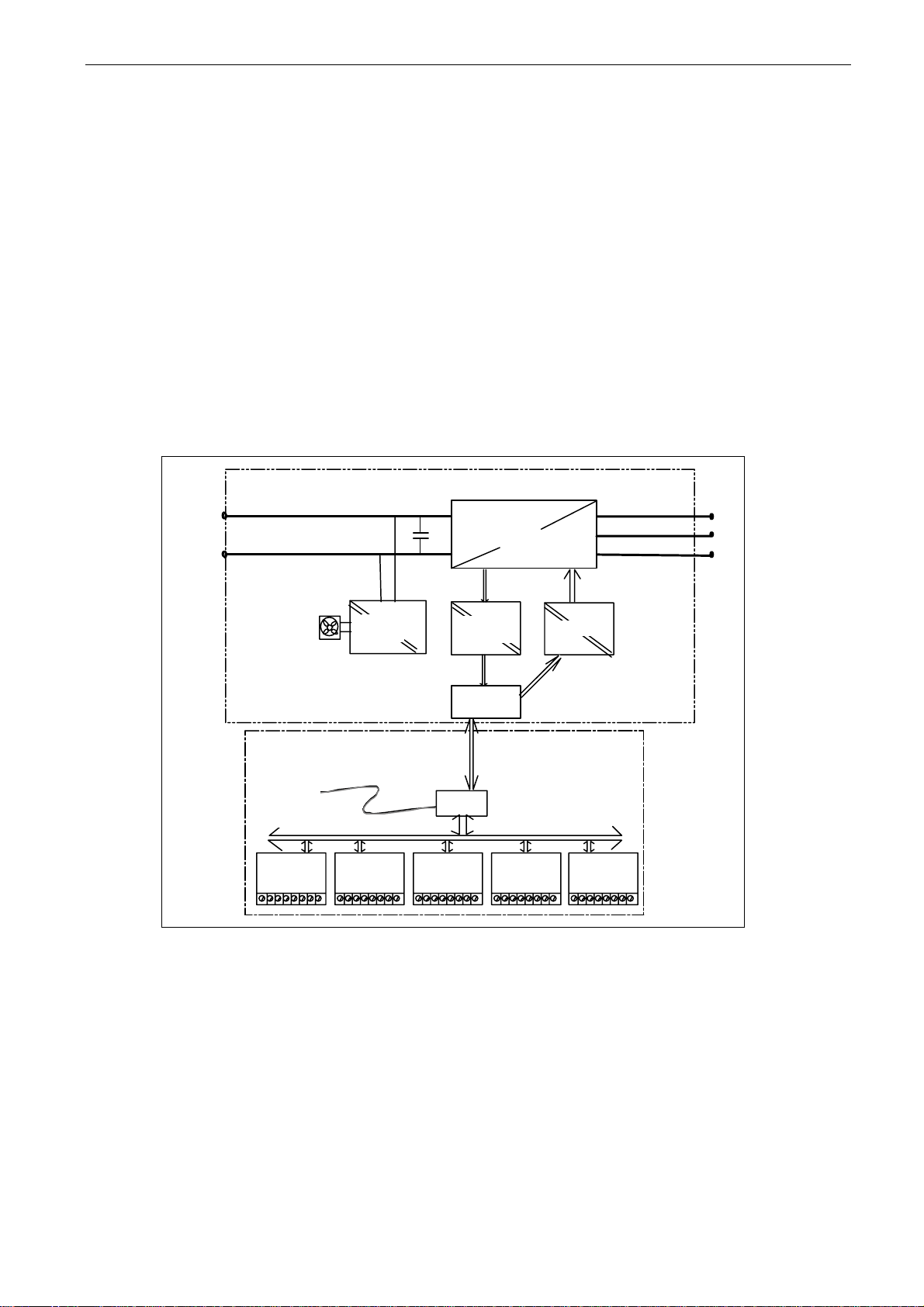

The figure below presents the block diagram of the Vacon NX inverter. The inverter mechanically

consists of two units, the Power Unit and the Control Unit.

The Power Unit contains an inverter bridge which consists of IGBT switches and produces a

symmetrical, 3-phase PWM-modulated AC voltage to the motor.

The Motor and Application Control Block is based on microprocessor software. The microprocessor

controls the motor based on the information it receives through measurements, parameter settings,

control I/O and control keypad. The motor and application control block controls the motor control

ASIC which, in turn, calculates the IGBT positions. Gate drivers amplify these signals for driving the

IGBT inverter bridge.

Power

module

B+

B-

IGBT

bridge

U

V

W

Fa n

Control

module

Control

Keypad

I/O

Slot A

Power

Supply

RS 232

I/O

Slot B

Control

I/O

Slot C

Measurements

ASIC

I/O

Slot D

Figure 4-1. The block diagram of Vacon NXI inverter

Driver

I/O

Slot E

NK4 _1

4

16 • vacon technical data

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

The control keypad constitutes a link between the user and the inverter. The control keypad is used

for parameter setting, reading status data and giving control commands. It is detachable and can be

operated externally and is connected via a cable to the inverter. Instead of the control keypad, a PC

can be used to control the inverter if connected through a similar cable (VACON RS232PC –1.5M).

The basic control interface and the parameters (the Basic Application) are easy to use. If a more

versatile interface or parameters are required, a more suitable application can be chosen from the

"All in One+" Application Package. See the "All in One+" Application Manual for more information on

the different applications.

Optional I/O expander boards that increase the number of inputs and outputs to be used are also

available. For more information, contact the Manufacturer or your local distributor (see back cover).

Tel: +358-201-2121 • Fax: +358-201-212 205

4

technical data vacon • 17

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

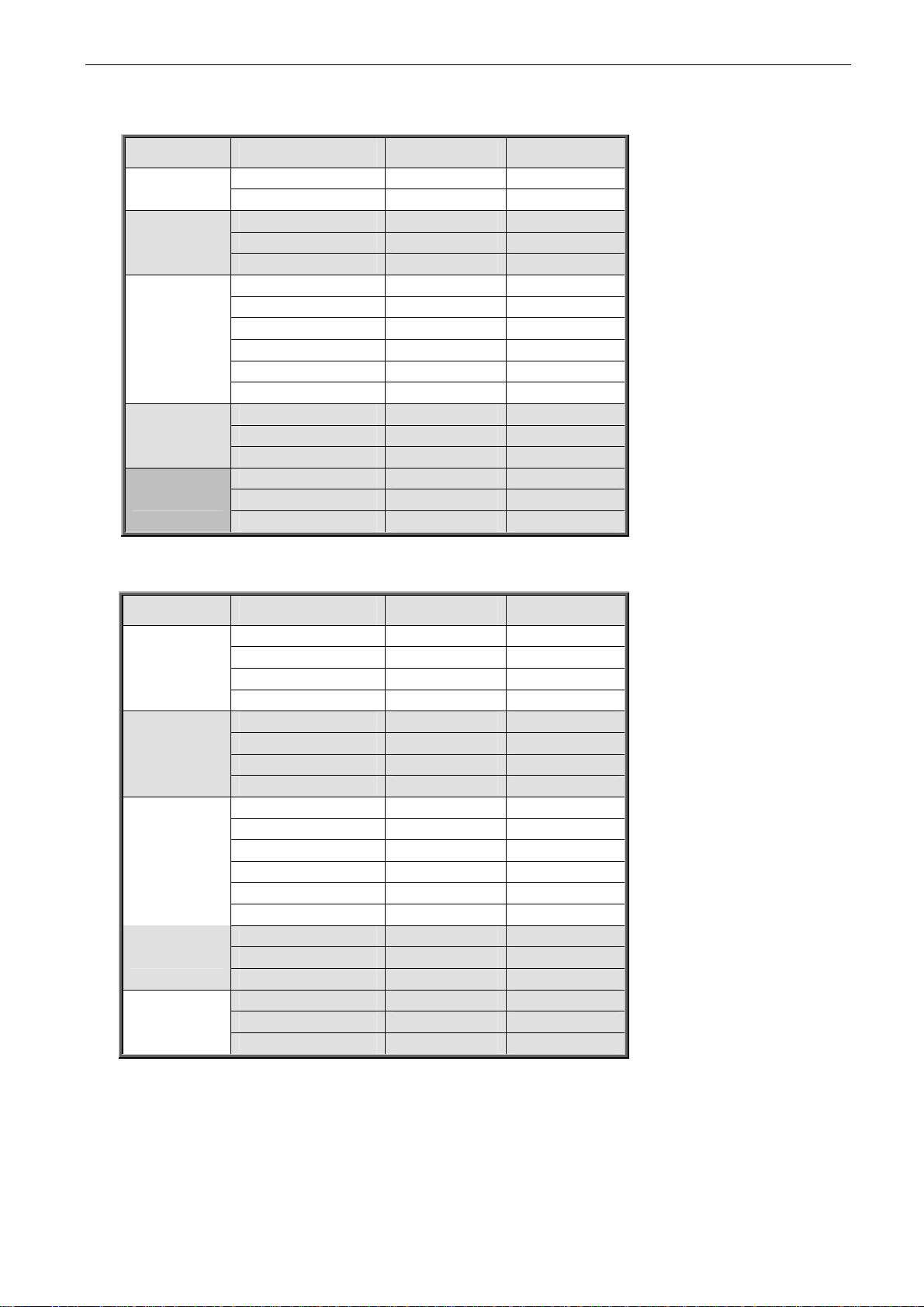

4.2 Power ratings

4.2.1 Vacon NXI_xxxx 5 – Supply voltage 465-800 Vdc, Motor voltage 380—500 Vac

High overload = Max current I

; 2 sec/20 sec, 150% overloadability; 1 min/10 min

S

Following continuous operation at rated output current, 150 % rated

output current (I

) for 1 min, followed by a period of load current less

H

than rated current, and of such duration that the r.m.s output current,

over the duty cycle, does not exceed rated output current (I

)

H

Low overload = Max current I

, 2 sec/20 sec, 110% overloadability; 1 min/10 min

S;

Following continuous operation at rated output current, 110% rated

output current (I

) for 1 min, followed by a period of load current less

L

than rated current, and of such duration that the r.m.s output current,

over the duty cycle, does not exceed rated output current (I

)

L

Motor voltage 380-500 Vac, 50/60 Hz, 3~

Loadability

@ 40 °C ambient temperature

Inverter type

NXI_0168 5 170 187 140 210 238 90 75 110 90 FI9 239 × 1030 × 372/65

NXI_0205 5 205 226 170 255 285 110 90 132 110 FI9 239 × 1030 × 372/65

NXI_0261 5 261 287 205 308 349 132 110 160 132 FI9 239 × 1030 × 372/65

NXI_0300 5 300 330 245 368 444 160 132 200 160 FI9 239 × 1030 × 372/65

NXI_0385 5 385 424 300 450 540 200 160 250 200 FI10 239 × 1030 × 552/100

NXI_0460 5 460 506 385 578 693 250 200 315 250 FI10 239 × 1030 × 552/100

NXI_0520 5 520 572 460 690 828 250 250 355 315 FI10 239 × 1030 × 552/100

NXI_0590 5 590 649 520 780 936 315 250 400 355 FI12 2×239 × 1030 × 552/200

NXI_0650 5 650 715 590 885 1062 355 315 450 400 FI12 2×239 × 1030 × 552/200

NXI_0730 5 730 803 650 975 1170 400 355 500 450 FI12 2×239 × 1030 × 552/200

NXI_0820 5 820 902 730 1095 1314 450 400 560 500 FI12 2×239 × 1030 × 552/200

NXI_0920 5 920 1012 820 1230 1476 500 450 630 560 FI12 2×239 × 1030 × 552/200

NXI_1030 5 1030 1133 920 1380 1656 560 500 710 630 FI12 2×239 × 1030 × 552/200

NXI_1150 5 1150 1265 1030 1545 1854 630 560 800 710 FI13 708 × 1030 × 553/302

NXI_1300 5 1300 1430 1150 1725 2070 710 630 900 800 FI13 708 × 1030 × 553/302

NXI_1450 5 1450 1595 1300 1950 2340 800 710 1000 900 FI13 708 × 1030 × 553/302

NXI_1770 5 1770 1947 1600 2400 2880 1000 1200 FI14

NXI_2150 5 2150 2365 1940 2910 3492 1200 1500

NXI_2700 5 2700 2970 2300 3287 3933 1500 1800

Low High

L

10%

overload

current

(A)

Rated

continuous

current I

(A)

Rated

continuous

current

I

(A)

H

50%

overload

current

(A)

Max

current

I

S

Motor shaft power

513Vdc

supply

10%

overload

40°C

P(kW)

50%

overload

40°C

P(kW)

675Vdc

supply

10%

overload

40°C

P(kW)

50%

overload

40°C P(kW)

Frame

FI14 2×708 × 1030 × 553/302

FI14 2×708 × 1030 × 553/302

Dimensions and weight

W×H×D/kg

2×708 × 1030 × 553/302

Table 4-1. Power ratings and dimensions of Vacon NXI, supply voltage 465—800Vdc

Note: The rated currents in given ambient temperatures are achieved only when the switching

frequency is equal to or less than the factory default.

4

18 • vacon technical data

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

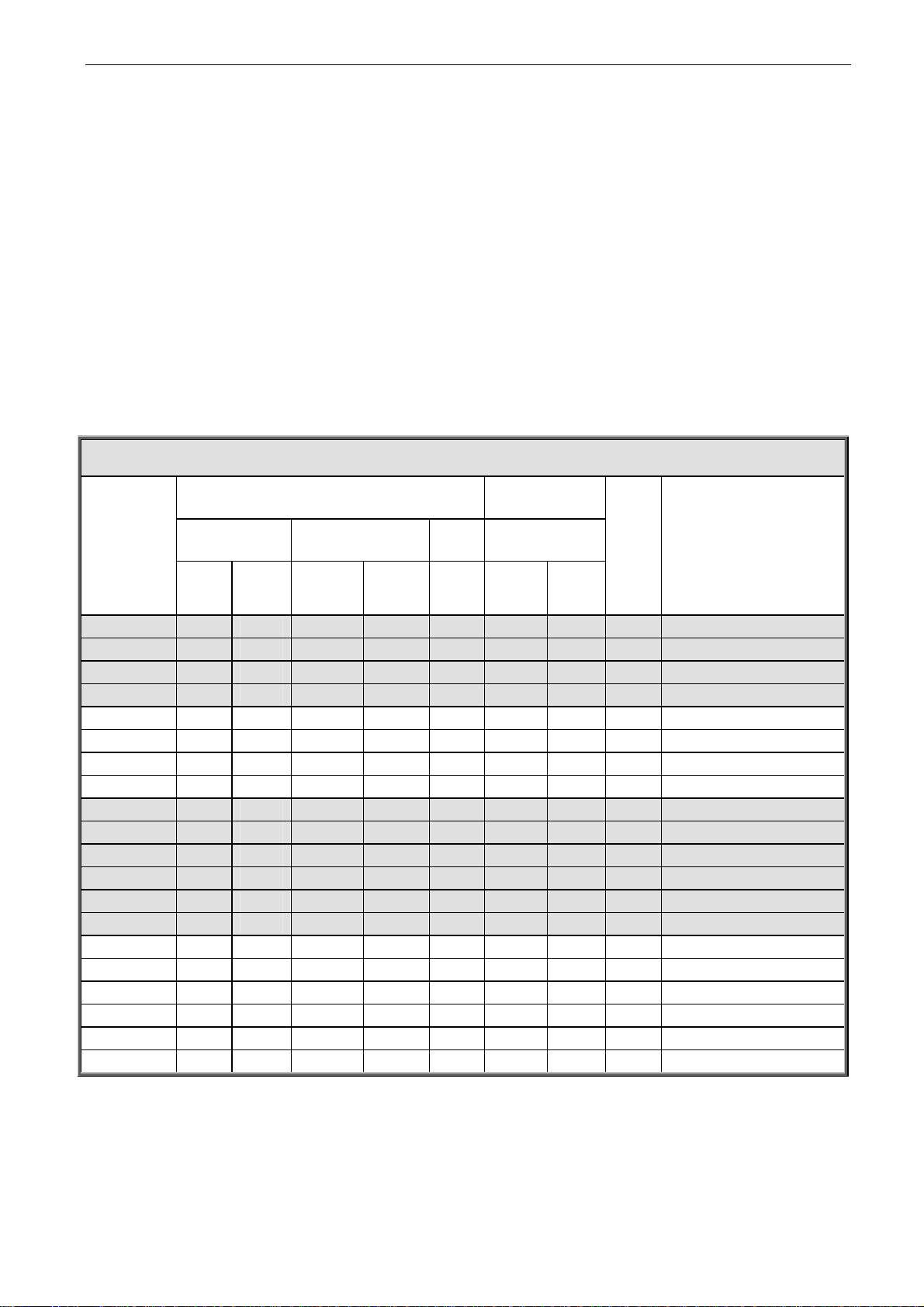

4.2.2 Vacon NXI_xxxx 6 – Supply voltage 640-1100 Vdc, Motor voltage 525—690 Vac

High overload = Max current IS; 2 sec/20 sec, 150% overloadability; 1 min/10 min

Following continuous operation at rated output current, 150 % rated

output current (I

) for 1 min, followed by a period of load current less

H

than rated current, and of such duration that the r.m.s output current,

over the duty cycle, does not exceed rated output current (I

)

H

Low overload = Max current I

, 2 sec/20 sec, 110% overloadability; 1 min/10 min

S

Following continuous operation at rated output current, 110% rated

output current (I

) for 1 min, followed by a period of load current less

L

than rated current, and of such duration that the r.m.s output current,

over the duty cycle, does not exceed rated output current (I

)

L

All frames are available as IP21 and IP54.

Motor voltage 525-690 Vac, 50/60 Hz, 3~

I

S

40°C P(kW)

Motor shaft

power

930Vdc

supply

10%

overload

50%

overload

40°C

P(kW)

Frame

Dimensions and weight

W×H×D/kg

Loadability

@ 40 °C ambient temperature

Inverter type

NXI_0125 6 125 138 100 150 200 110 90 FI9 239 × 1030 × 372/65

N×I_0144 6 144 158 125 188 213 132 110 FI9 239 × 1030 × 372/65

N×I_0170 6 170 187 144 216 245 160 132 FI9 239 × 1030 × 372/65

NXI_0208 6 208 229 170 255 289 200 160 FI9 239 × 1030 × 372/65

NXI_0261 6 261 287 208 312 375 250 200 FI10 239 × 1030 × 552/100

NXI_0325 6 325 358 261 392 470 315 250 FI10 239 × 1030 × 552/100

NXI_0385 6 385 424 325 488 585 355 315 FI10 239 × 1030 × 552/100

NXI_0416 6 416 458 325 488 585 400 355 FI10 239 × 1030 × 552/100

NXI_0460 6 460 506 385 578 693 450 400 FI12 2×239 × 1030 × 552/200

NXI_0502 6 502 552 460 690 828 500 450 FI12 2×239 × 1030 × 552/200

NXI_0590 6 590 649 502 753 904 560 500 FI12 2×239 × 1030 × 552/200

NXI_0650 6 650 715 590 885 1062 630 560 FI12 2×239 × 1030 × 552/200

NXI_0750 6 750 825 650 975 1170 710 630 FI12 2×239 × 1030 × 552/200

NXI_0820 6 820 902 650 975 1170 800 710 FI12 2×239 × 1030 × 552/200

NXI_0920 6 920 1012 820 1230 1476 900 800 FI13 708 × 1030 × 553/302

NXI_1030 6 1030 1133 920 1380 1656 1000 900 FI13 708 × 1030 × 553/302

NXI_1180 6 1180 1298 1030 1464 1755 1200 1000 FI13 708 × 1030 × 553/302

NXI_1500 6 1500 1650 1300 1950 2340 1500 1300 FI14 2×708 × 1030 × 553/302

NXI_1900 6 1900 2090 1500 2250 2700 1800 1500 FI14 2×708 × 1030 × 553/302

NXI_2250 6 2250 2475 1900 2782 3335 2000 1800 FI14 2×708 × 1030 × 553/302

Low High

Rated

continuou

s current

(A)

I

L

10%

overload

current

(A)

continuous

Rated

current

IH (A)

50%

overload

current

(A)

Max

current

Table 4-2. Power ratings and dimensions of Vacon NXI, supply voltage 640—1100Vdc

Note: The rated currents in given ambient temperatures are achieved only when the switching

frequency is equal to or less than the factory default.

Tel: +358-201-2121 • Fax: +358-201-212 205

4

technical data vacon • 19

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

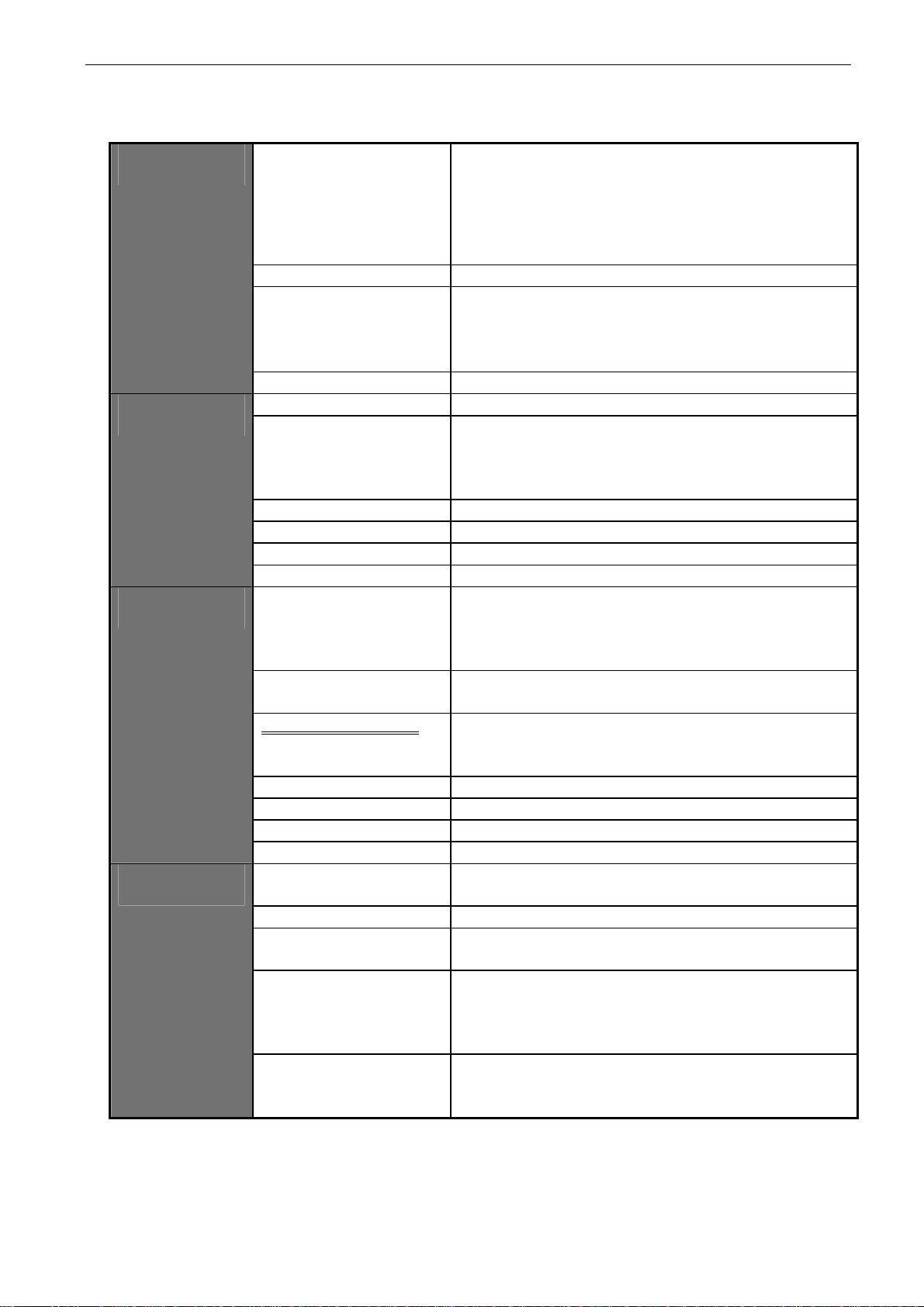

4.3 Technical information

Supply

connection

Motor

connection

Control

characteristics

Ambient

conditions

(Continues on next page)

Input voltage U

in

465...800Vdc ( 380-500 Vac)

640...1100Vdc ( 525-690 Vac)

The waviness of the inverter supply voltage, which

is formed in rectification of the electric network's

alternating voltage in basic frequency, must be less

than 50V peak-to-peak.

Input current I

in

DC bank capacitance

(sqrt3 × U

FI9_5 : 4950µF; FI9_6 : 3733µF

mot

× I

× cosϕ) / ( Uin × 0,98)

mot

FI10_5: 9900µF; FI10_6: 7467µF

FI12_5: 19800µF; FI12_6: 14933µF

FI13_5: 29700µF; FI13_6: 22400µF

Starting delay 5 s (FI9 and greater)

Output voltage 3 ~ 0 – Uin / 1,4

Continuous output

current

IH: Ambient temperature max. +40°C,

overload 1.5 × I

I

: Ambient temperature max. +40°C,

L

overload 1.1 × I

(1 min./10 min.)

H

(1 min./10 min.)

L

Starting torque IS for two seconds, torque motor dependent

Peak current IS for 2 s every 20 s

Output frequency 0…320 Hz ; 7200 Hz (Special)

Frequency resolution Application dependent

Control method Frequency control U/f

Open Loop Sensorless Vector Control

Closed Loop Frequency Control

Switching frequency

(see parameter 2.6.9)

Frequency reference

Analogue input

Panel reference

Closed Loop Vector Control

NXI_5:

NXI_6:

1…10 kHz; Factory default 3.6 kHz

1…6 kHz; Factory default 1.5 kHz

Resolution 0.1% (10-bit), accuracy ±1%

Resolution 0.01 Hz

Field weakening point 30…320 Hz

Acceleration time 0…3000 sec

Deceleration time 0…3000 sec

Braking torque DC brake: 30% * TN (without brake)

Ambient operating

temperature

Storage temperature

–10°C (no frost)…+40°C

–40°C…+70°C

Relative humidity 0 to 95% RH, non-condensing, non-corrosive,

no dripping water

Air quality:

- chemical vapours

IEC 721-3-3, unit in operation, class 3C2

IEC 721-3-3, unit in operation, class 3S2

- mechanical

particles

Altitude 100% load capacity (no derating) up to 1,000 m

1-% derating for each 100m above 1000.; max.

2000m

4

20 • vacon technical data

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Vibration

EN50178/EN60068-2-6

Shock

EN50178, EN60068-2-27

Heat loss P

Cooling air required FI9 1150 m3/h, FI10 1400 m3/h,

Unit enclosure class IP00

EMC

Immunity Fulfil all EMC immunity requirements,

(at default

settings)

Safety

Control

Analogue input voltage

connections

Analogue input current

Digital inputs (6) Positive or negative logic; 18…30VDC

Auxiliary voltage +24V, ±15%, max. 250mA

Output reference voltage +10V, +3%, max. load 10mA

Analogue output

Digital outputs Open collector output, 50mA/48V

Relay outputs 2 programmable change-over relay outputs

Protections

Overvoltage protection

Undervoltage protection

Earth fault protection In case of earth fault in motor or motor cable, only

Motor phase supervision Trips if any of the output phases is missing

Overcurrent protection Yes

Unit overtemperature

protection

Motor overload protection Yes

Motor stall protection Yes

Motor underload

protection

Short-circuit protection of

+24V and +10V reference

voltages

Table 4-3. Technical information

Displacement amplitude 0.25 mm (peak) at 5…31

Hz

Max acceleration 1 G at 31…150 Hz

UPS Drop Test (for applicable UPS weights)

Storage and shipping: max 15 G, 11 ms (in package)

[kW] approx. P

loss

FI12 2800 m

3

/h, FI13 4200 m3/h, FI14 2×4200 m3/h

[kW] × 0,02

mot

Level T

CE, UL, CUL

EN 61800-5-1 (2003); (see unit nameplate for more

detailed approvals)

0…+10V, R

= 200kΩ, (–10V…+10V joystick control)

i

Resolution 0.1%, accuracy ±1%

0(4)…20 mA, R

0(4)…20mA; R

= 250Ω differential

i

max. 500Ω; Resolution 10 bit;

L

Accuracy ±2%

Switching capacity: 24VDC/8A, 250VAC/8A,

125VDC/0.4A

Min.switching load: 5V/10mA

NX_5: 911VDC; NX_6: 1200VDC

NX_5: 333VDC; NX_6: 460 VDC

the inverter is protected

Yes

Yes

Yes

Tel: +358-201-2121 • Fax: +358-201-212 205

4

technical data vacon • 21

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Structure IN (output) Motor P.F. IDC (input)

FI9

FI10

FI12

FI13

FI14

Table 4- 4 DC currents and dimensions of Vacon NXI, supply voltage 465 - 800Vdc

261 0,89 304

300 0,89 350

385 0,9 454

460 0,9 542

520 0,9 613

590 0,9 695

650 0,9 766

730 0,91 870

820 0,91 977

920 0,91 1096

1030 0,91 1227

1150 0,91 1370

1300 0,91 1549

1450 0,91 1727

1770 0,92 2132

2150 0,92 2590

2700 0,92 3252

Structure IN (output) Motor P.F. IDC (input)

125 0,89 146

FI9

FI10

F12

FI13

FI14

Table 4- 5. DC currents and dimensions of Vacon NXI, supply voltage 640 - 1100Vdc

144 0,89 168

170 0,89 198

208 0,9 245

261 0,9 308

325 0,9 383

385 0,9 454

416 0,9 490

460 0,91 548

502 0,91 598

590 0,91 703

650 0,91 774

750 0,91 894

820 0,91 977

920 0,91 1096

1030 0,91 1227

1180 0,92 1421

1500 0,92 1807

1900 0,93 2313

2250 0,93 2739

4

22 • vacon installation

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

5. INSTALLATION

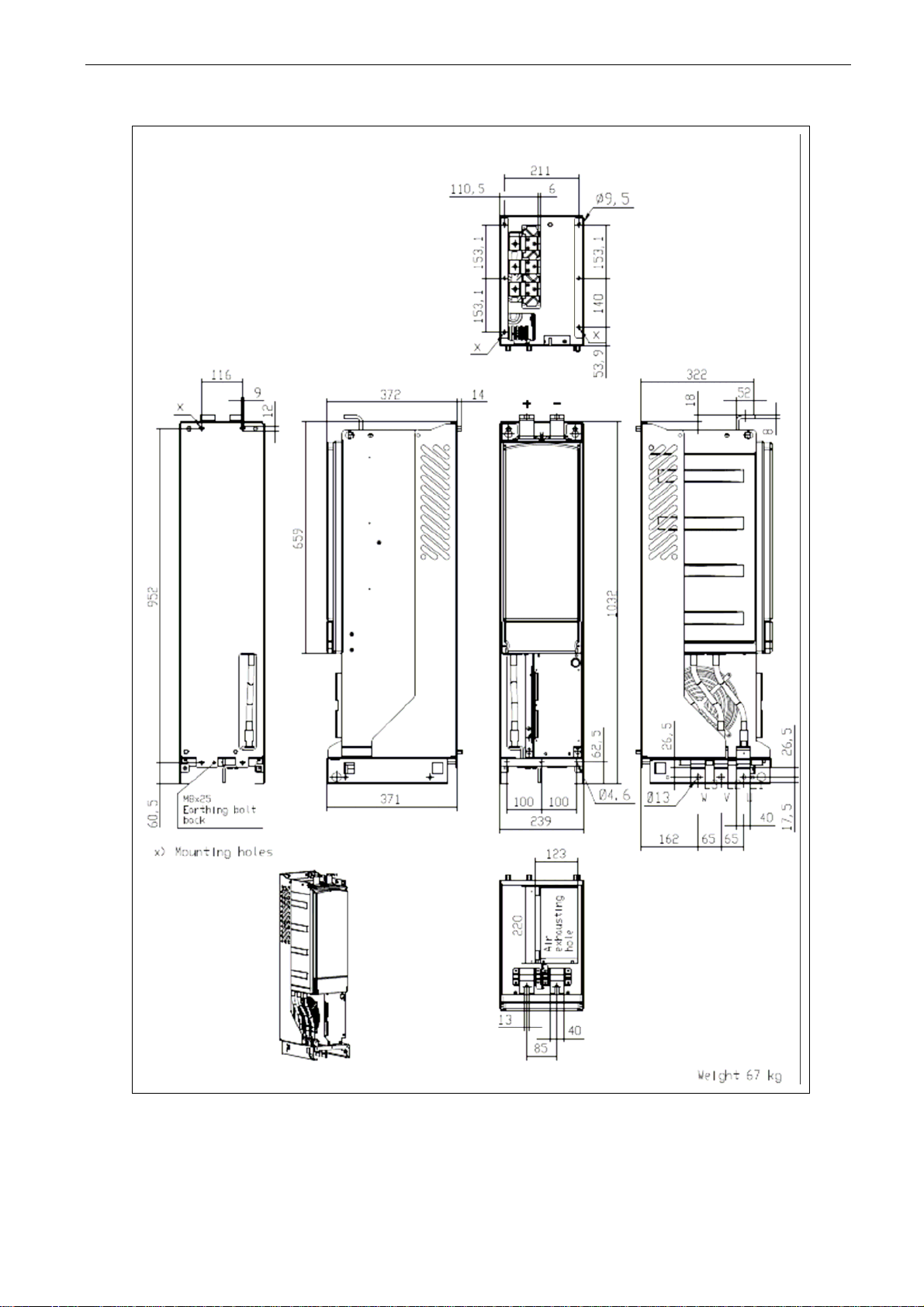

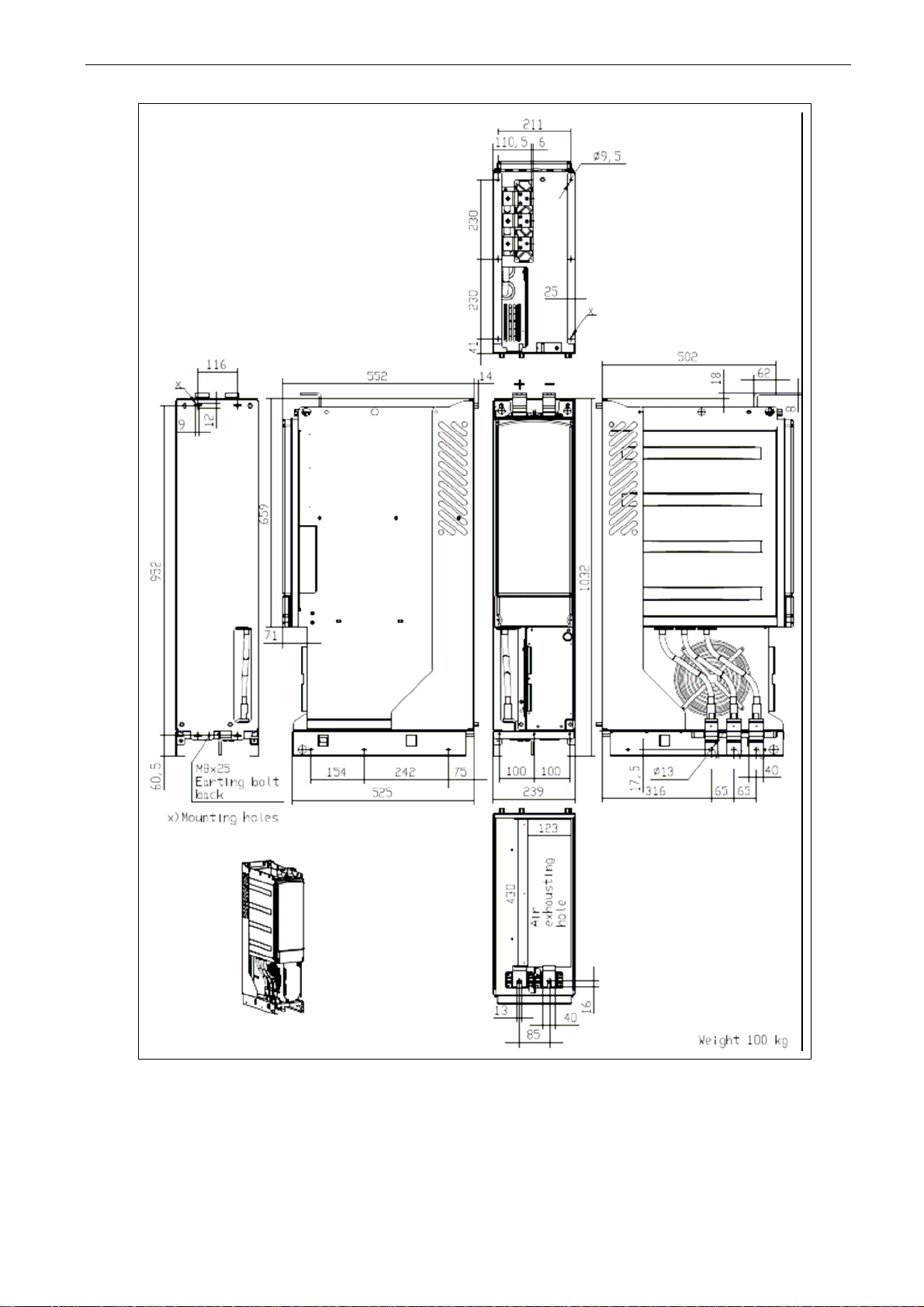

5.1 Mounting

The inverter can be mounted in a vertical position on the back plane of a cubicle. Enough space must

be reserved around the inverter to ensure sufficient cooling, see Figure 5-7. Follow the minimum

dimensions for installation, see Table 5-1 and Table 5-2. Also make sure that the mounting plane is

relatively even. The inverter is fixed with four screws (or bolts, depending on the unit size). The

dimensions for installation are presented in Figure 5-7 and Table 5-1.The following pages show the

dimensions for IP00 power module.

Tel: +358-201-2121 • Fax: +358-201-212 205

5

installation vacon • 23

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

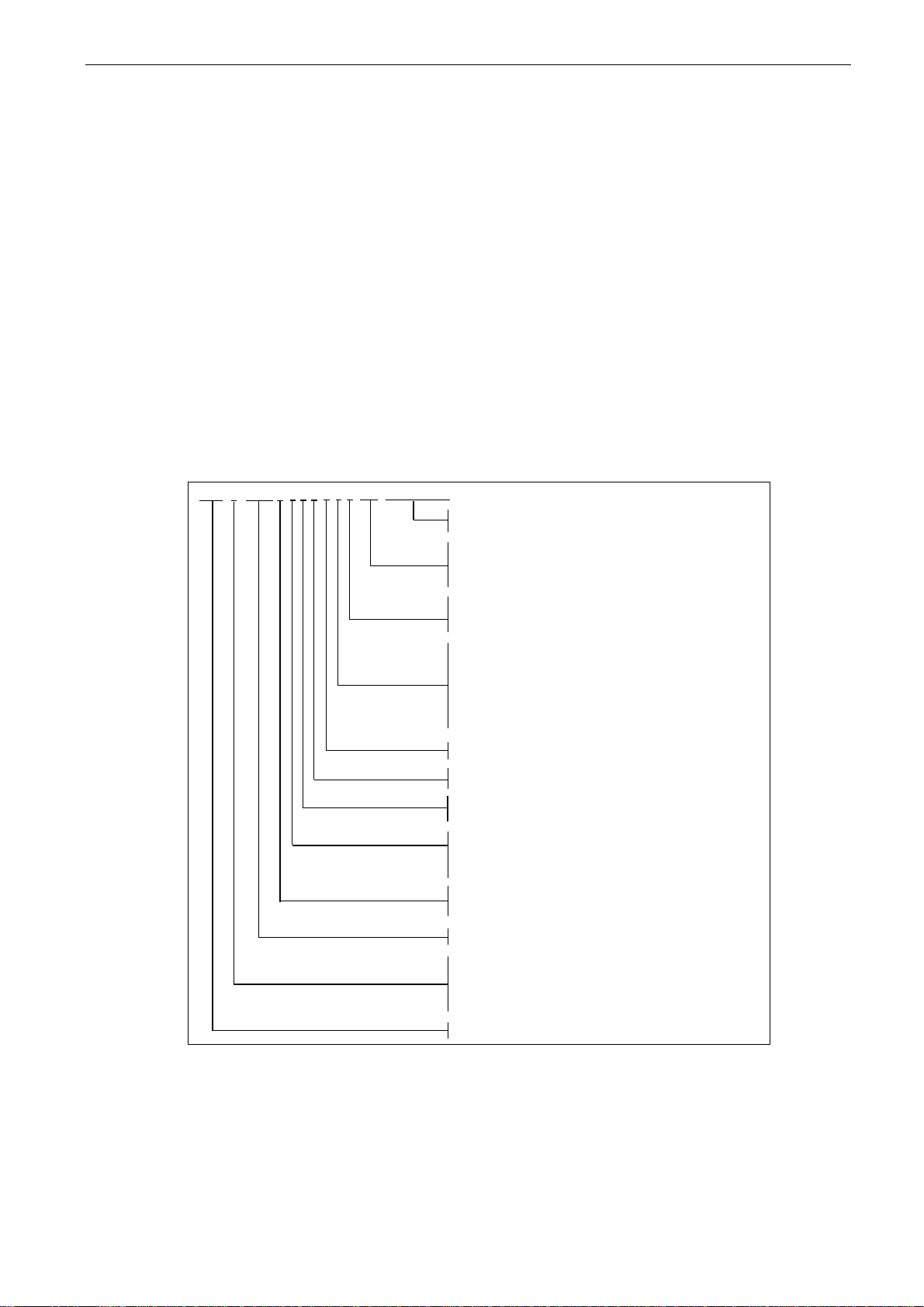

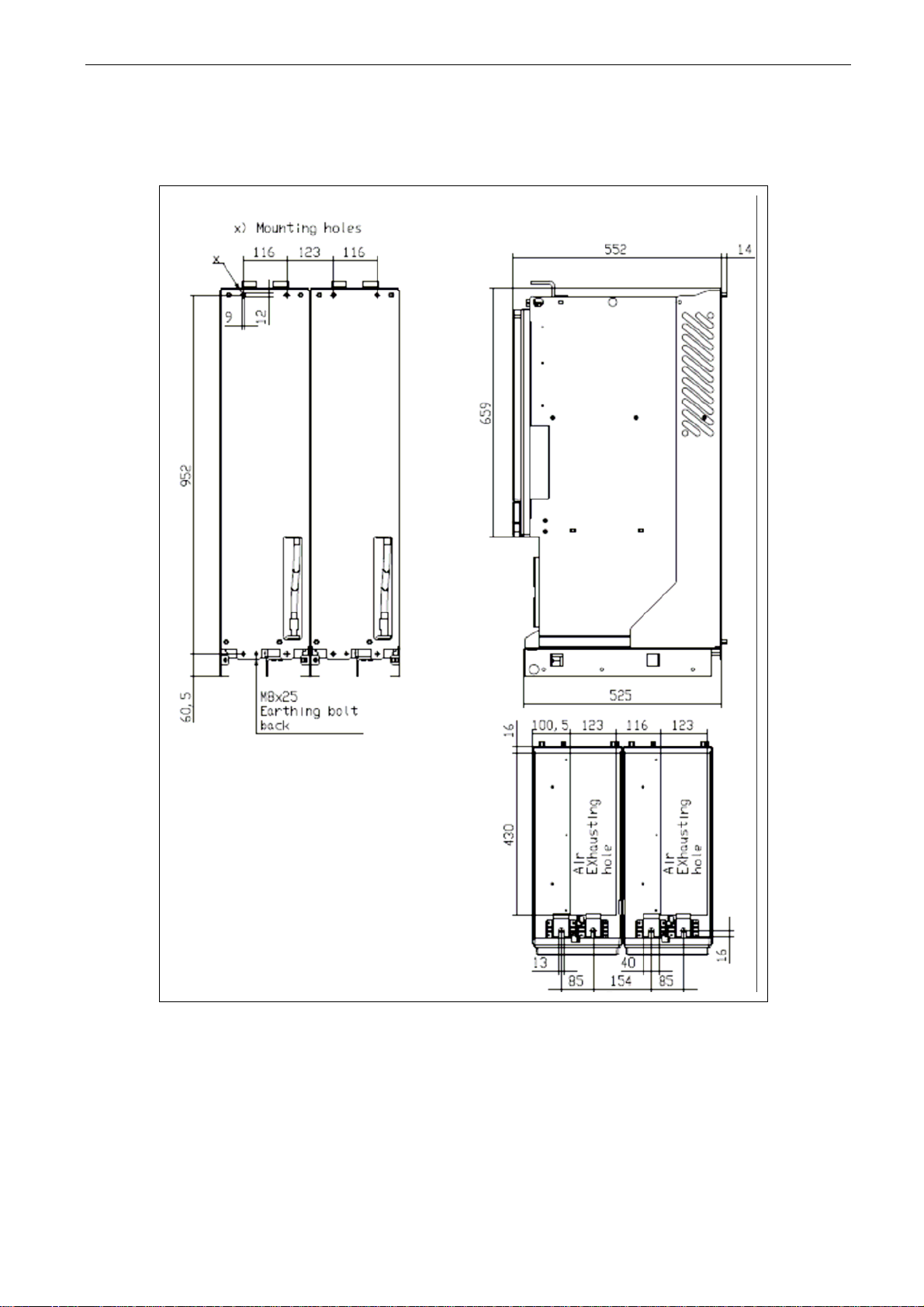

Figure 5-1. The dimensions of Vacon NXI FI9

5

24 • vacon installation

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

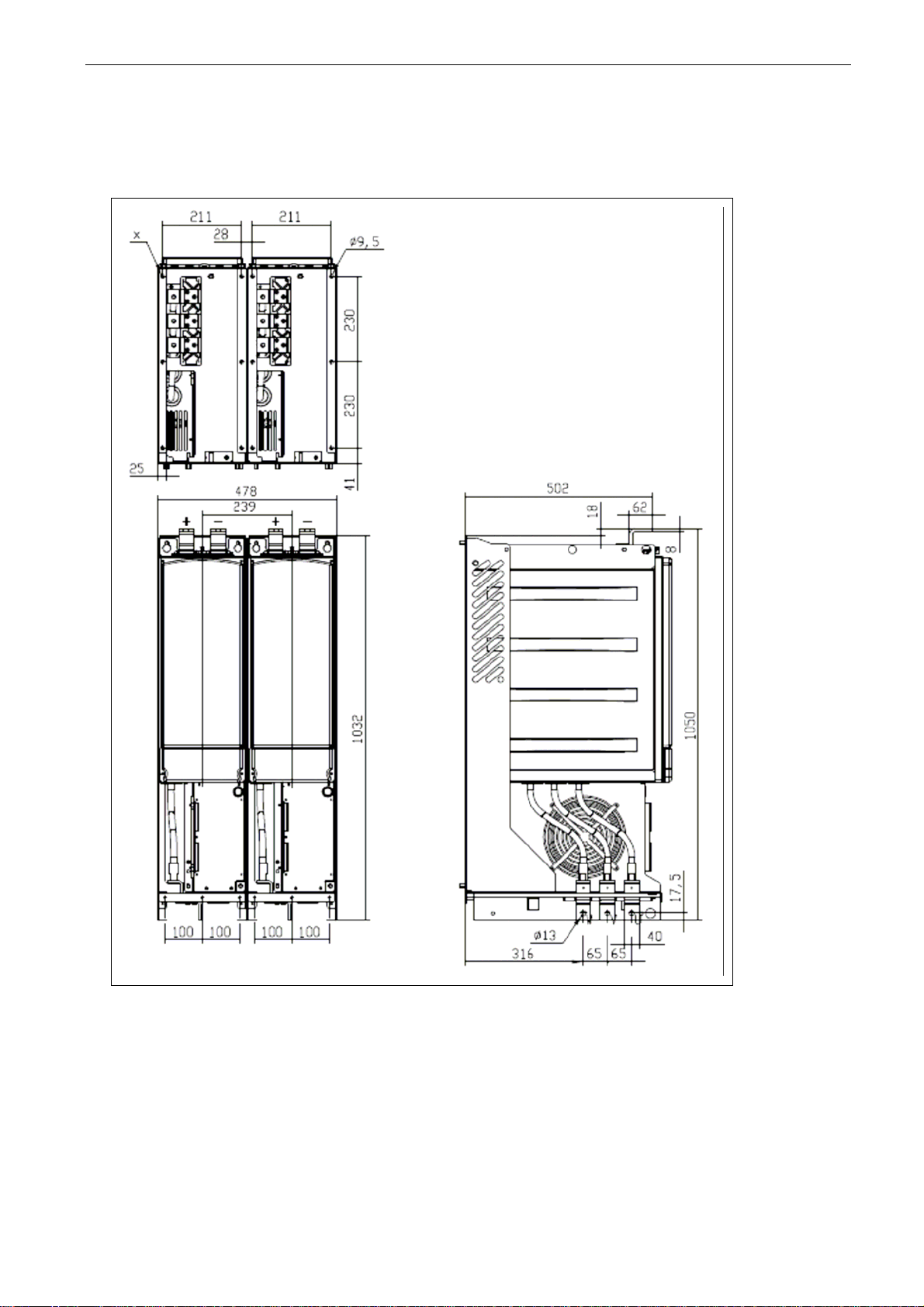

Figure 5-2. Vacon NXI dimensions, FI10

installation vacon • 25

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

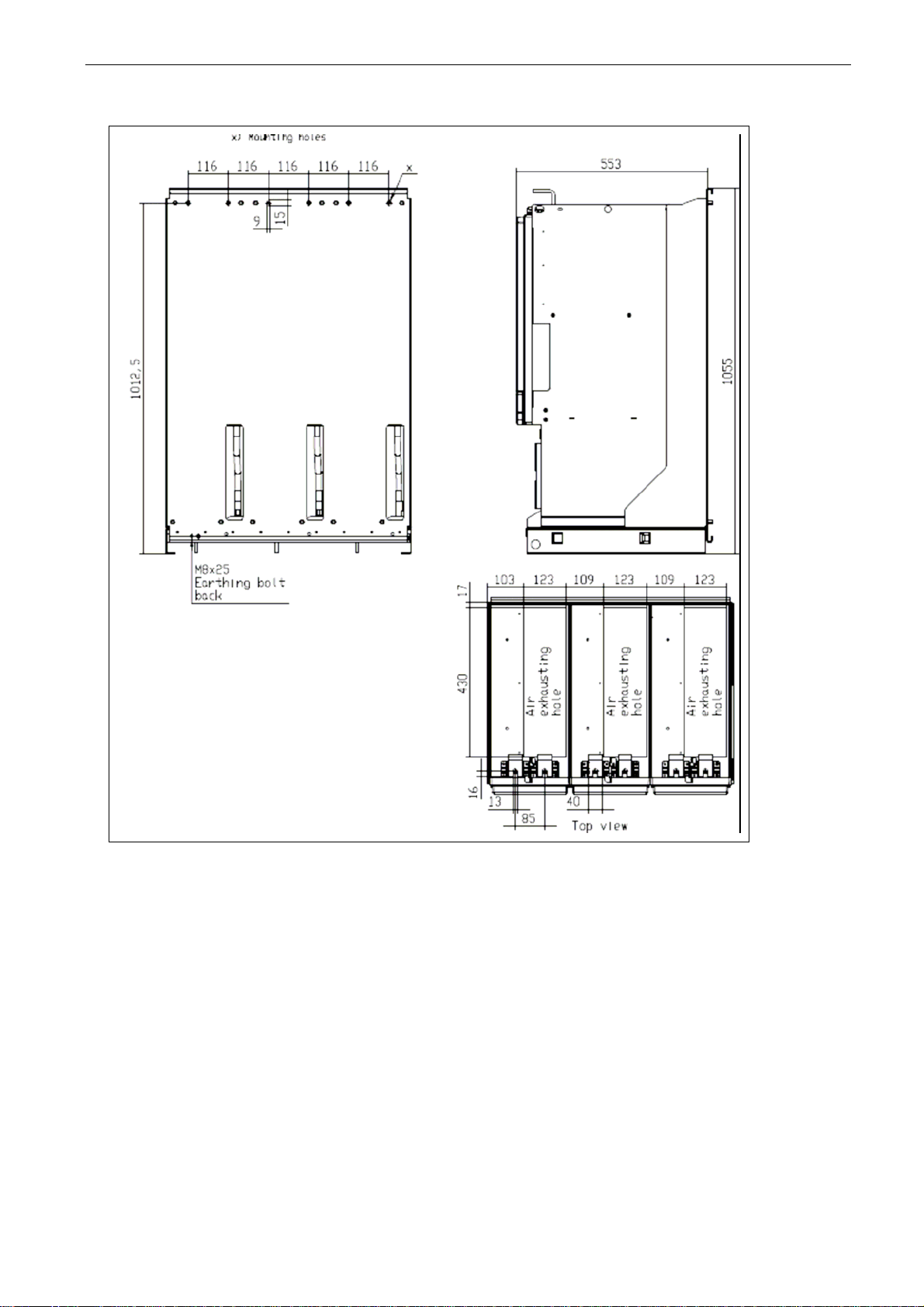

Figure 5-3. Vacon NXI dimensions, FI12 back view.

5

26 • vacon installation

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Figure 5-4. Vacon NXI dimensions, FI12 front view

Tel: +358-201-2121 • Fax: +358-201-212 205

5

installation vacon • 27

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Figure 5-5. Vacon NXI dimensions, FI13 back view. Note, FI14 is a douple FI13

5

28 • vacon installation

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Figure 5-6. Vacon NXI dimensions, FI13 front view. Note, FI14 is a douple FI13

Tel: +358-201-2121 • Fax: +358-201-212 205

5

installation vacon • 29

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

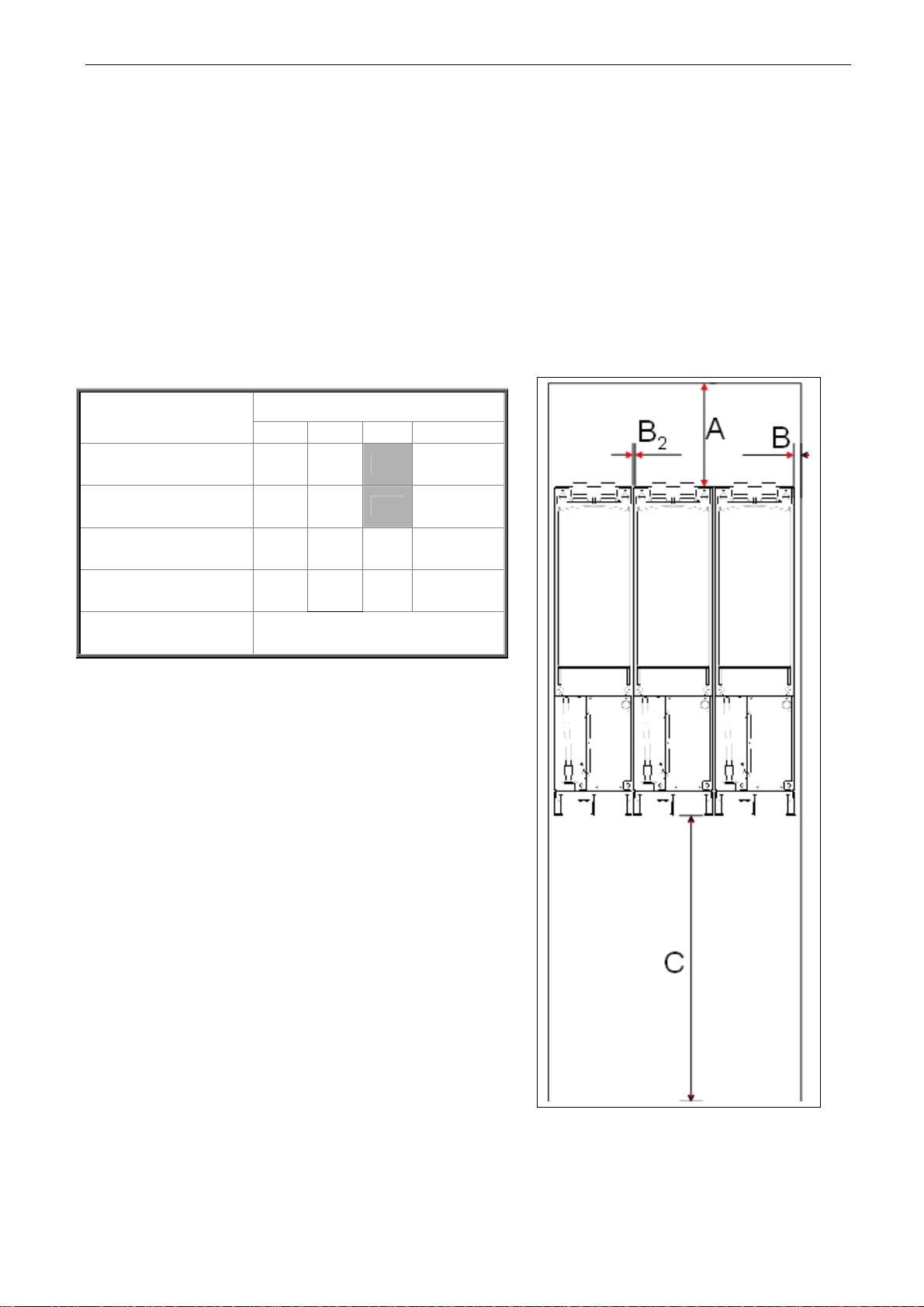

5.2 Fan cooling

5.2.1 Frames FI9 to FI14

Enough free space must be left around the inverter to ensure sufficient air circulation and cooling.

You will find the required dimensions for free space in the table below.

If several units are mounted on top of each other, the required free space equals 2 * C (see figure

below). Moreover, the outlet air used for cooling by the lower unit must be directed away from the air

intake of the upper unit. When planning the cooling for the space, take into consideration that the

inverter’s heat loss is approx. 2.5% of the nominal capacity.

Type Dimensions [mm]

A

NXI_0168 – 0300 5

NXI_0125 – 0208 6

NXI_0385 – 0520 5

NXI_0261 – 0416 6

NXI_0590 – 1030 5

NXI_0460 – 0820 6

NXI_1150 – 1450 5

NXI_0920 – 1180 6

NXI_1770 – 2700 5

NXI_1500 – 2250 6

Table 5-1. Mounting space dimensions

200

200

200

200 20 0 Min. 300

The dimensions as per FI13

module

B B

C

2

20 Min. 300

20 Min. 300

20 0 Min. 300

A = free space above the inverter

B = distance between inverter and cabinet wall

B

= distance between two inverters

2

C = free space underneath of the inverter

Figure 5-7. Installation space.

5

30 • vacon installation

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Type Frame Cooling air

required

3

(m

/h)

NXI_0168 – 0300 5

NXI_0125 – 0208 6

NXI_0385 – 0520 5

NXI_0261 – 0416 6

NXI_0590 – 1030 5

NXI_0460 – 0820 6

NXI_1150 – 1450 5

NXI_0920 – 1180 6

NXI_1770 – 2700 5

NXI_1500 – 2250 6

Table 5-2. Required cooling air

FI9 1.150

FI10 1.400

FI12 2.800

FI13 4.200

FI14 2 × 4.200

Minimum air holes on

2

switchgear (mm

)

Inlet: 55.000

Outlet: 30.000

Inlet: 65.000

Outlet: 40.000

Inlet: 130.000

Outlet: 70.000

Inlet: 195.000

Outlet: 105.000

Inlet: 2 × 195.000

Outlet: 2 × 105.000

5.2.2 Arranging ventilation of the enclosure

The enclosure door must be provided with air gaps for air intake. To achieve sufficient cooling inside

the cabinet, the dimensions for the total area of free openings for incoming air given in Table 5-2

must be followed. For instance, there could be two screened gaps as presented in Figure 5-7

(Vacon's recommendation). This layout ensures a sufficient air flow to the module fans as well as

cooling of the additional components.

Air outlet gaps must be situated on top of the cabinet. The minimum effective air outlet area per

converter frame is given in Table 5-2. The cooling arrangements inside the cabinet must be such

that they prevent hot output air from mixing with the incoming fresh air (see page 32).

The ventilation gaps must fulfil the requirements set by the selected IP class. The examples in this

manual apply to protection class IP21.

During operation, air is sucked in and circulated by a fan blower at the bottom of the power unit. If

the power unit is placed in the upper part of the cabinet, the fan blower will be in the mid of the

cabinet, at the height of the upper ventilation grid.

See Figure 5-7 on page 29.

Tel: +358-201-2121 • Fax: +358-201-212 205

5

Loading...

Loading...