Page 1

F O R S M O O T H C O N T R O L

I/O-expander board

installation manual

(Vacon CXS-range)

Subject to changes without notice.

VACON

CX/CXL/CXS

FREQUENCY CONVERTERS

Page 2

Vacon Page 1 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

CONTENTS

1 GENERAL .......................................... 2

1.1 Vacon CX100OPT ...................... 2

1.2 Vacon CX101OPT ...................... 2

1.3 Vacon CX102OPT ...................... 2

1.4 Vacon CX103OPT ...................... 2

1.5 Vacon CX104OPT ...................... 3

1.6 Vacon fieldbus boards ............... 3

2 SPECIFICATIONS ............................ 4

3 INSTALLATION................................. 5

3.1 General ..................................... 5

3.2 Installation ................................ 6

4 CONTROL CONNECTIONS ........1 1

4.1 Vacon CX100OPT .................... 11

4.2 Vacon CX101OPT .................... 12

4.3 Vacon CX102OPT .................... 13

4.4 Vacon CX103OPT .................... 14

4.5 Vacon CX104OPT .................... 15

Page 3

Page 2 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

1 GENERAL

Due to the compact frame size of the Vacon CXS series all I/O-expander boards need

to be installed in a separate box (Vacon CXSOPTBKIT), except the smaller, specifically

for Vacon CXS designed boards (Vacon CX104OPT, CX105OPT, CX107OPT,

CX108OPT). If ordered together with the option board these will be preinstalled.

1.1 Vacon CX100OPT

The available I/O can be increased by using the Vacon CX100OPT I/O-expander

board:

- 5 digital inputs (standard signals)

- 2 analogue inputs (standard signals)

- 3 relay outputs (standard signals)

- analogue output (programmable)

- thermistor input (can be directly connected to the motor

thermistors to monitor the motor temperature)

- encoder input

Typical use: Closed Loop Vector Control

1.2 Vacon CX101OPT

The available I/O can be increased by using the Vacon CX101OPT I/O-expander

board:

- 5 digital inputs (standard signals)

- relay output (standard signal)

- thermistor input (can be directly connected to the motor thermistors to monitor

the motor temperature)

Typical use: thermistor input required

1.3 Vacon CX102OPT

The available I/O can be increased by using the Vacon CX102OPT I/O-expander

board:

- 5 digital inputs (standard signals)

- 2 analogue inputs (standard signals)

- 3 relay outputs (standard signals)

- analogue output (programmable)

- thermistor input (can be directly connected to the motor thermistors to

monitor the motor temperature)

- encoder input

Typical use: Closed Loop Vector Control

1.4 Vacon CX103OPT

The available I/O can be increased by using the Vacon CX103OPT I/O-expander

board:

- 5 digital inputs (standard signals)

- 3 relay outputs (standard signals)

- analogue output (programmable)

- thermistor input (can be directly connected to the motor thermistors to monitor

the motor temperature)

Typical use: thermistor input and additional analogue output required

Page 4

Vacon Page 3 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

1.5 Vacon CX104OPT

The available I/O can be increased by using the Vacon CX104OPT I/O-expander

board:

- encoder input

Typical use: Closed Loop Vector Control

1.6 Fieldbus boards

Vacon fieldbus boards can be installed in the Vacon CXS range frequency converters

as I/O-expander boards. The needed information to install/commission fieldbus

boards can be found in the respective Vacon fieldbus manual.

- Vacon CX 200OPT (Interbus-S)

- Vacon CX 201OPT (Modbus)

- Vacon CX 202OPT (Profibus-DP)

- Vacon CX 203OPT (LonWorks)

- Vacon CX 204OPT (C - b u s )

- Vacon CX 205OPT (SDS-bus)

Page 5

Page 4 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

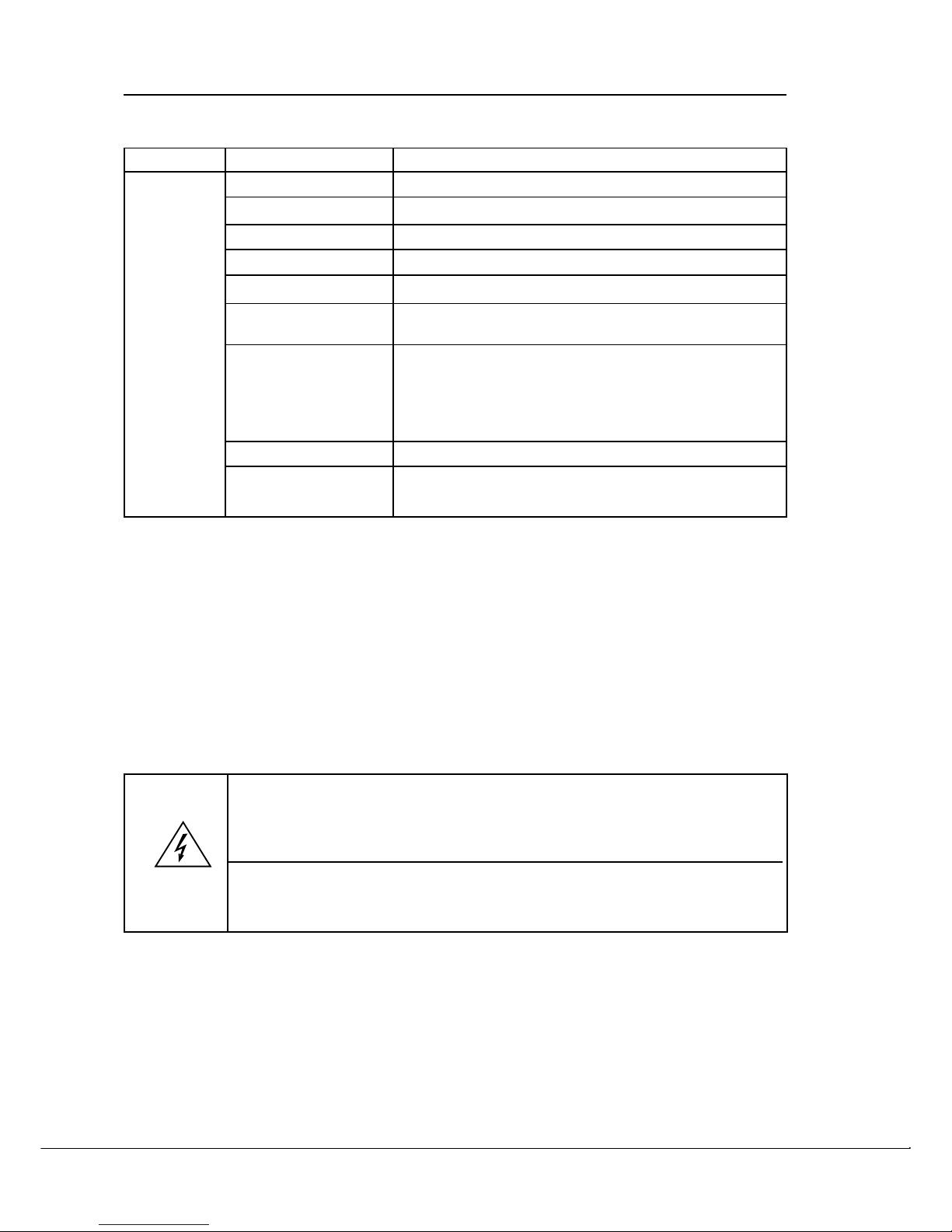

2 SPECIFICATIONS

Safety Fulfills EN50178, C-UL and EN60204-1 standards

Control Analogue voltage, input 0—± 10 V, Ri ≥ 200 kΩ

connections Analogue current, input 0(4)—20 mA, Ri = 250 Ω

Digital input 24 V: "0" ≤10 V, "1" ≥18 V , Ri > 5 kΩ

Aux. voltage 24 V (±20%), max. 50 mA

Reference voltage 10 V ±3 %, max. 10 mA

Analogue current, output 0(4)—20 mA, RL = 500 Ω , resolution 10 bit, accuracy ≤±2%

Analogue voltage, output 0(2)—10 V, RL ≥ 1 kΩ , resolution 10 bit, accuracy ≤±2%

Relay output Max. switching voltage: 300 V DC, 250 V AC

Max. switching load: 8A / 24 V DC

0,4 A / 300 V DC

2 kV A / 250 V AC

Max. continuous load: 2 A rms

Thermistor input R

trip

= 4.7 kΩ

Encoder input 24 V: "0" ≤10 V, "1" ≥18 V, Ri = 2.2 kΩ

5 V: "0" ≤ 2 V, "1" ≥ 3 V, Ri = 330 Ω

Table 2-1 Specifications. (All the control connections are not found on every I/O-expander board, for

specific information see Chapters 1 and 4.)

The control connections are isolated from the mains potential and the I/O ground is

connected to the frame of the inverter via a 1-MΩ resistor and 4,7-nF capacitor*). The

control I/O ground can be connected directly to the frame by changing the position of the

jumper X4 (GND ON/OFF) to the ON-position. Digital inputs and relay outputs are also

isolated from the I/O ground.

*) Default value (X4 is GND OFF- position).

NOTE!

Internal components and circuit boards (except the isolated I/O terminals) are at

mains potential when the frequency converter is connected to the mains. This

voltage is extremely dangerous and may cause death or severe injury if you

come into contact with it.

The control I/O terminals are isolated from the mains potential, but the relay

outputs and other I/O's may have a dangerous voltage connected even if the

power is disconnected from the frequency converter.

Page 6

Vacon Page 5 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

1

3 INSTALLATION

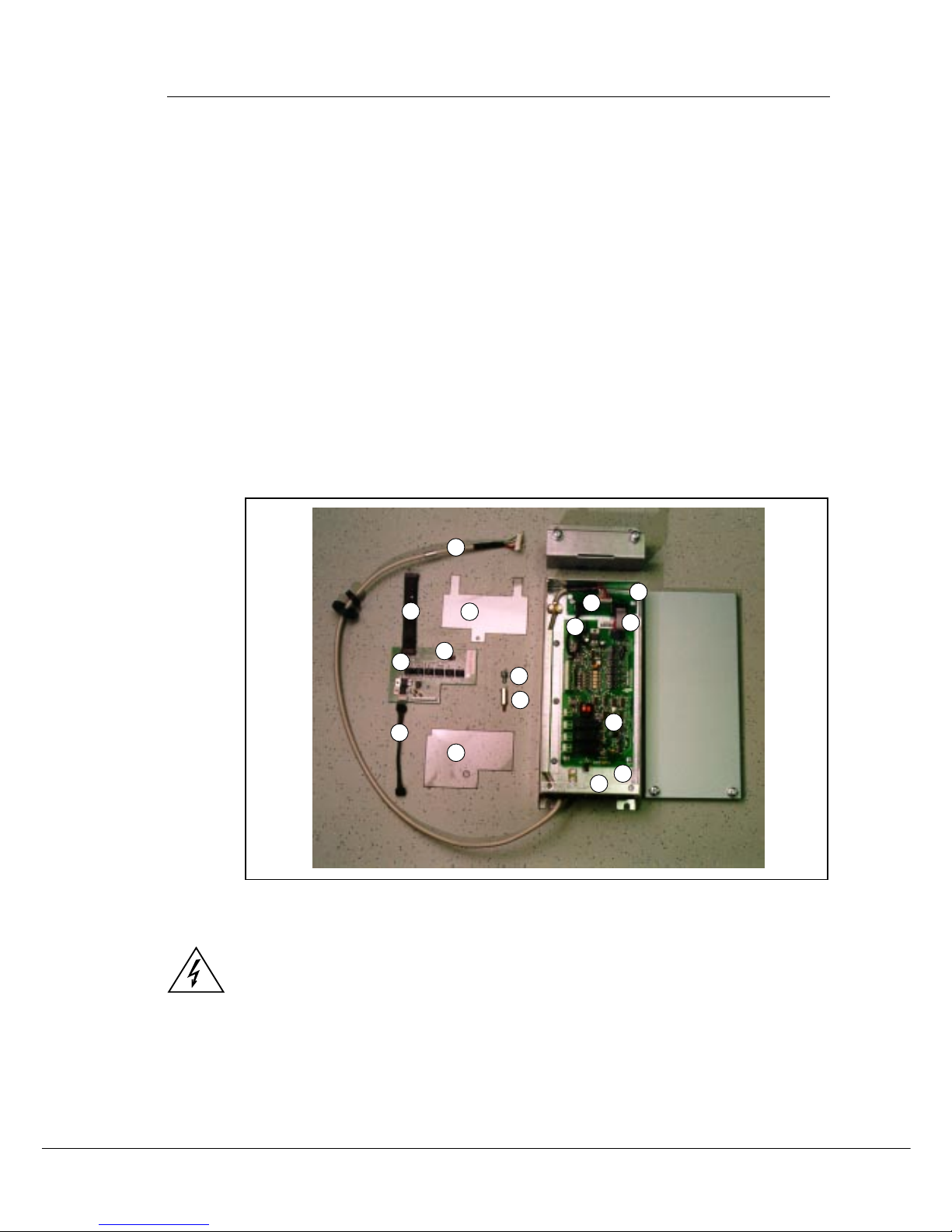

3.1. General

Check that your have received all the required parts (Figure 3-1):

- I/O-repeater board (1) and I/O-pole shielded data cable (2)

- check that you have also received the jumper for I/O- repeater board

terminal X5 (3)

- 4-pole power cable (4)

- protection foil below (5) and above (6) the I/O-reapeater board

- stand sleeve (7)

- screw for fixing I/O-repeater board (8)

- 12-pole communication cable (9)

- opition box (10)

- I/O-expander board (11) (check that the typecode is corresponds to

your order)

- I/O-interface board (12)

- 10-pole data cable (13)

- 4-pole power cable (14)

- screws for I/O-expander board (15)

- screws for I/O-interface board (16)

Figure 3-1. I/O-expander board parts.

If the delivery does not match your order, please contact the supplier immediately. Only

a competent electrician should carry out the electrical installation.

Before doing any commissioning, carefully read the safety instructions in the "USER'S

MANUAL, V ACON CX/CXL/CXS", Chapter 1, SAFETY.

Disconnect the frequency converter from the mains. NOTE: Also the control circuits!

Wait further 5 minutes before opening the cover of the frequency converter. Verify by

measuring that the frequency converter is safe to touch.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 7

Page 6 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Table 3-2. I/O-expander board installation (continues ...).

1

2

4

Remove the control panel, control panel base (4 screws) and the jumper X4 from the

control board.

3

3.2 INSTALLATION

I/O-repeater board (1) should be installed above the control board inside the frequency converter. The I/O-expander board (10) and I/O-inter face board (11) should be installed in the

option box. Follow the instructions below (see Table 3-2).

Check that the jumper for I/O-repeater board (1) is in the right position in terminal X5 (3).

The position of the jumper must be chosen according to the I/O-expander board (11)

:

- If I/O-expander board CX101OPT or 103OPT

is in use, jumper must be in position A.

- If I/O-expander board CX100OPT or 102OPT

is in use, jumper must be in position B.

- If one of the following fielbus boards is in use:

CX200OPT , CX201OPT, CX202OPT or

CX203OPT, jumper must be in position C.

(Positon D is not in use).

X5

X4

Make sure that the cable of the control panel

cover is connected to the control board X1 terminal. Connect the 4-pole power cable (4) to

the control board X5 terminal (The power cable

can also be connected to the X6-terminal, if the

power cable from the power board is connected

to the X5-terminal.)

Set the protection foil (5) above the control

board as shown in the picture. Make sure that

the protection foil is correctly located, the hole

in the foil will must be located above the stand

sleeve.

X5

Remove the fixing screw from the control board

and replace it with the stand sleeve (7).

5

7

Page 8

Vacon Page 7 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Connect the shielded data cable for I/

O-repeater board (2) to the control

board terminal X14.

7

5

Set the protection foil (6) above the I/O-repeater board as shown in the picture. Make sure

that the protection foil is correctly located, push the "arms" of the protection foil under the

control panel cover. Fasten the I/O-repeater board and protection foil to the stand sleeve (7)

with the screw .

X14

Install the control panel cover with 4

screws.

6

8

Connect the power cable (4) to the I/O-repeater terminal X1 and communication cable (9) to

the I/O-repeater terminal X3. Uncover carefully the shield of the communication cable (max.

1,5 cm), tighten up to the metal clamp (of the cable) and earth the cable to the frequency

converter ground as shown in the picture.

Table 3-2. I/O-expander board installation (continues ...).

4

9

6

7

Page 9

Page 8 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Check the connections and make sure that there are no foreign objects inside the frequency

converter.

Close the cover of the frequency converter.

9

10

Install the jumper removed from the control board X4 terminal into the I/O-expander board

terminal X9. Note: the jumper can be connected in ON or OFF position,see V acon CX/CXL/

CXS User's manual, Chapter 6.2.2.

13

If you have the option box with the I/O-expander (11) and I/

O-interface boards (12) pre-installed, jump to section 17.

Mount the I/O-expanderboard (11) and I/O-interface board

(12) in the option box (10) with the screws.

11

Connect data cable (13) between terminal X14 in

the I/O-interface board (12) and terminal X14 in

the I/O-expander board (11)).

X14

X14

12

Connect power cable (14) between terminal X6

in the I/O-interface board (12) and terminal

X6 in the I/O-expander board (11).

X6

X6

Table 3-2. I/O-expander board installation (continues ...).

X9

Page 10

Vacon Page 9 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Connect the communication cable (9) to the I/O-expander board

X15 terminal (12). Earth the communication cable to the option box

ground.

X15

14

15

Connect the necessary control signals. If a fieldbus board is in use, see separate manual for

more specific information.

X8

16

If an encoder input (closed loop control) is to

be used and the encoder works at a 5V level,

move three jumpers from terminal X5 to terminal

X8. If the encoder works at 24V, then terminal

X8 should be left free.

Check the connections and make sure that there are no foreign objects inside the option box.

Before connecting the mains make sure that the cover of the option box and frequency converter are closed.

Set the parameters of I/O-expander board according to the Vacon "Five in One+" -application manual (parameter group 3).

17

18

T able 3-2. I/O-expander board installation.

Page 11

Page 10 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Figure 3-2. Frequency converter and external I/O-expander box installation (unit sizes M3 and M4B).

I/O-expander box can also be installed beside the frequency converter (unit sizes M3, M4B and M5B).

Page 12

Vacon Page 11 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

4 CONTROL CONNECTIONS

4.1 Vacon CX100OPT

Signal from

motor thermistors *)

Figure 4-1 Control connections of V acon CX100OPT.

Ter minal Signal Description

201 +10V

ref

Reference output Voltage for a potentiometer, etc.

202 U

in

+ Analogue input, voltage Not in use

range 0—10 V DC

203 GND I/O ground Ground for reference and controls

204 I

in

+ Analogue input, current Not in use

205 I

in

- range 0—20 mA

206 +24V Control voltage output Voltage for switches, etc. max. 50 mA

207 GND I/O ground Ground for reference and controls

208 CMC Common for DIC1-DIC5 Connect to GND or + 24 V

209 DIC1 External fault Contact open = no fault

(closing contact) Contact closed = fault

210 DIC2 Run disable Cont. open = start of motor enabled

Cont. closed= start of motor disabled

211 DIC3 Acceler. / Decel. time Contact open = time 1 selected

selection Contact closed = time 2 selected

212 DIC4 Jogging speed selection Contact open = no action

Contact closed = jogging speed

213 DIC5 Fault reset Contact open = no action

Contact closed = fault reset

214 DI6A+ Pulse input A

215 DI6A- (differential input)

216 DI7B+ Pulse input B 90 degrees phase shift compared

217 DI7B- (differential input) to pulse input A

218 D I 8 Z + Pulse input C one pulse per one revolution

219 DI8Z- (differential input)

220 I

out

+ Analogue output Programmable

0—20 mA/RL max. 500 Ω (Motor current as default value)

221 T I + Thermistor input

222 TI223 RO3/1 Relay output 3 READY

224 RO3/2

225 RO4/1 Relay output 4 RUN

226 RO4/2

227 RO5/1 Relay output 5 FAULT

228 RO5/2

*) NOTE! Thermistor input (terminals 221 and 222) must be shorted if not used.

Enco der

Page 13

Page 12 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Ter minal Signal Description

206 +24V Control voltage output V oltage for switches, etc. max. 50 mA

207 GND I/O ground Ground for reference and controls

208 CMC Common for DIC1-DIC5 Connect to GND or + 24 V

209 DIC1 External fault Contact open = no fault

(closing contact) Contact closed = fault

210 DIC2 Run disable Cont. open = start of motor enabled

Cont. closed= start of motor disabled

211 DIC3 Acceler. / Decel. time Contact open = time 1 selected

selection Contact closed = time 2 selected

212 DIC4 Jogging speed selection Contact open = no action

Contact closed = jogging speed

213 DIC5 Fault reset Contact open = no action

Contact closed = fault reset

214 N.C. Not connected

215 N.C. Not connected

221 TI+ Thermistor input

222 TI+

225 RO4/1 Relay output 4 RUN

226 RO4/2

4.2 Vacon CX101OPT

Signal from

motor thermistors *)

*) NOTE! Thermistor input (terminals 221 and 222) must be shorted if not used.

Figure 4-2 Control connections of V acon CX101OPT.

Page 14

Vacon Page 13 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Ter minal Signal Description

201 +10V

ref

Reference output Voltage for a potentiometer, etc.

202 U

in

+ Analogue input, voltage Not in use

range 0—10 V DC

203 GND I/O ground Ground for reference and controls

204 U

in

+ Analogue input, voltage Not in use

205 U

in

- range 0—10 V DC

206 +24V Control voltage output Voltage for switches, etc. max. 50 mA

207 GND I/O ground Ground for reference and controls

208 CMC Common for DIC1-DIC5 Connect to GND or + 24 V

209 DIC1 External fault Contact open = no fault

(closing contact) Contact closed = fault

210 DIC2 Run disable Cont. open = start of motor enabled

Cont. closed= start of motor disabled

211 DIC3 Acceler. / Decel. time Contact open = time 1 selected

selection Contact closed = time 2 selected

212 DIC4 Jogging speed selection Contact open = no action

Contact closed = jogging speed

213 DIC5 Fault reset Contact open = no action

Contact closed = fault reset

214 DI6A+ Pulse input A

215 DI6A- (differential input)

216 DI7B+ Pulse input B 90 degrees phase shift compared

217 DI7B- (differential input) to pulse input A

218 DO1 Encoder direction output

21 9 DO2 Encoder divider 1/64 output

220 U

out

+ Analogue output Programmable

0—10 V DC/RL ≥ 1 kΩ (Motor voltage as default value)

221 T I + Thermistor input

222 TI223 RO3/1 Relay output 3 READY

224 RO3/2

225 RO4/1 Relay output 4 RUN

226 RO4/2

227 RO5/1 Relay output 5 FAULT

228 RO5/2

4.3 Vacon CX102OPT

Figure 4-3 Control connections of V acon CX102OPT.

Signal from

motor thermistors *)

*) NOTE! Thermistor input (terminals 221 and 222) must be shorted if not used.

Enco der

Page 15

Page 14 (15) Vacon

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

4.4 Vacon CX103OPT

*) NOTE! Thermistor input (terminals 221 and 222) must be shorted if not used.

Figure 4-4 Control connections of V acon CX103OPT.

Te rminal Signal Description

206 +24V Control voltage output V oltage for switches, etc. max. 50 mA

207 GND I/O ground Ground for reference and controls

208 CMC Common for DIC1-DIC5 Connect to GND or + 24 V

209 DIC1 External fault Contact open = no fault

(closing contact) Contact closed = fault

210 DIC2 Run disable Cont. open = start of motor enabled

Cont. closed= start of motor disabled

211 DIC3 Acceler. / Decel. time Contact open = time 1 selected

selection Contact closed = time 2 selected

212 DIC4 Jogging speed selection Contact open = no action

Contact closed = jogging speed

213 DIC5 Fault reset Contact open = no action

Contact closed = fault reset

21 4 GND I/O ground

215 I

out

+ Analogue output Programble

0—20 mA/RL max. 500 Ω (Motor current as default value)

221 TI+ Thermistor input

222 TI 223 RO3/1 Relay output 3 READY

224 RO3/2

225 RO4/1 Relay output 4 RUN

226 RO4/2

227 RO5/1 Relay output 5 FAULT

228 RO5/2

Signal from

motor thermistors *)

Page 16

Vacon Page 15 (15)

I/O-expander board installation (Vacon CXS-range)

Vacon Plc Tel: +358-201 2121 Fax: +358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

http://www.vacon.com

Ter minal Signal Description

201 +5 V Control voltage output Voltage for switches, max load

100-150 mA

203 GND I/O ground Ground for controls

206 +24V Control voltage output

207 GND I/O ground Ground for controls

214 DI6A+ Pulse input A

215 DI6A- (differential input)

216 DI7B+ Pulse input B

217 DI7B- (differential input)

218 DI R Encoder direction

21 9 DIV Encoder divider 1/1024

4.5 Vacon CX104OPT

More information on the Vacon CX104OPT encoder option board you will find in a

separate manual (ud318). Ask your distributor for more information.

Figure 4-5 Control connections of V acon CX104OPT.

Enco der

Page 17

VACON PLC

P.O. Box 25

Runsorintie 7

FIN-65381 VAASA

FINLAND

Phone: +358-201 2121

Fax: +358-201 212 205

Service: +358-40-8371 150

E-mail: vacon@vacon.com

http://www.vacon.com

Distributor:

U

D 00244C1, 19.10.2000

Loading...

Loading...