Page 1

vacon

ac drives

canopen option board opte6

user manual

®

Page 2

Page 3

vacon • 3

TABLE OF CONTENTS

Document: DPD01091C

Release date : 13092017

1. Safety...............................................................................................................5

1.1 Danger................................................................................................................................5

1.2 Warnings ............................................................................................................................6

1.3 Earthing and earth fault protection ...................................................................................7

2. CANopen option board OPTE6 - General ..........................................................8

2.1 Overview .............................................................................................................................8

2.2 Software .............................................................................................................................8

2.2.1 CAN.....................................................................................................................................8

2.2.2 CANopen.............................................................................................................................8

3. CANopen protocol description .........................................................................9

3.1 NMT ....................................................................................................................................9

3.2 Node control protocols ....................................................................................................10

3.3 Error control protocols ....................................................................................................11

3.3.1 Heartbeat protocol ...........................................................................................................11

3.3.2 Node guarding protocol ...................................................................................................12

3.3.3 EMCY object......................................................................................................................12

3.4 SDO protocol ....................................................................................................................14

3.5 PDO protocol ....................................................................................................................15

3.5.1 PDO communication parameter record ..........................................................................15

3.5.2 COB ID ..............................................................................................................................16

3.5.3 Transmission type............................................................................................................17

3.5.4 PDO parameter mapping record .....................................................................................18

3.6 SYNC protocol ..................................................................................................................19

3.6.1 SYNC with counter ...........................................................................................................19

3.7 Communication objects ...................................................................................................21

3.7.1 0X1000 - Device Type .......................................................................................................21

3.7.2 0X1001 - Error Register ...................................................................................................21

3.7.3 0X1003 - Pre-defined Error Field ....................................................................................22

3.7.4 0X1005 - COB ID SYNC .....................................................................................................22

3.7.5 0X100C - Guard Time .......................................................................................................22

3.7.6 0X100D - Life Time Factor ...............................................................................................22

3.7.7 0X1014 - COB ID EMCY.....................................................................................................23

3.7.8 0X1016 - Heartbeat Consumer Entries............................................................................23

3.7.9 0X1017 - Producer Heartbeat Time .................................................................................24

3.7.10 0X1018 - Identify Object ...................................................................................................24

3.7.11 0X1019 - Synchronous counter overflow value ...............................................................24

3.7.12 0X1029 - Error behaviour.................................................................................................25

3.8 Saving and restoring the object dictionary ......................................................................25

3.8.1 0X1010 Store parameter field ..........................................................................................25

3.8.2 0X1011 Restore default parameters................................................................................25

4. CANopen option board OPTE6 - technical data...............................................27

4.1 General.............................................................................................................................27

4.2 CAN cable.........................................................................................................................27

4.2.1 Isolated ground connection .............................................................................................28

4.2.2 Recommended cable .......................................................................................................29

5. OPTE6 layout and connections .......................................................................30

5.1 Layout and connections ...................................................................................................30

5.2 LED Indications ................................................................................................................32

5.3 Jumpers ...........................................................................................................................33

6. Installation.....................................................................................................35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 4

vacon • 4

6.1 Installation in VACON® 100.............................................................................................35

6.2 Prepare for use through fieldbus ....................................................................................37

6.3 Installation in VACON® 20...............................................................................................40

6.3.1 Frames MI1, MI2, MI3 ......................................................................................................40

6.3.2 Frames MI4, MI5 ..............................................................................................................43

6.4 Installation in VACON® 20 X and 20 CP ..........................................................................47

6.5 Installation in VACON® 100 X (Frames MM4-MM6)........................................................49

7. Commissioning ..............................................................................................53

7.1 OPTE6 panel parameters.................................................................................................53

7.1.1 OPTE6 additional panel parameters................................................................................54

7.1.2 Panel parameter change reaction ...................................................................................57

7.1.3 Parameter restore ...........................................................................................................58

7.2 OPTE6 Panel Monitor Values ...........................................................................................59

7.3 Updating the firmware of OPTE6 option board................................................................60

7.4 Quick instructions for controlling the motor...................................................................64

8. CANopen option board interface .................................................................... 65

8.1 Supported drive modes....................................................................................................65

8.2 Velocity mode ...................................................................................................................66

8.2.1 PDS State machine ..........................................................................................................66

8.2.2 CiA-402 objects ................................................................................................................69

8.2.3 PDO configuration ............................................................................................................71

8.3 Bypass mode ....................................................................................................................75

8.3.1 PDO configuration ............................................................................................................75

8.4 Default process data application mapping ......................................................................79

8.4.1 FB Control Word ..............................................................................................................80

8.4.2 FB Control Word Extension (general control word) ........................................................80

8.4.3 FB Speed Reference ........................................................................................................81

8.4.4 FB Process data Input 1...8..............................................................................................81

8.4.5 FB Processdata Input mapping in application ................................................................81

8.4.6 FB Status Word ................................................................................................................82

8.4.7 FB Status Word Extension (general status word) ...........................................................82

8.4.8 FB Actual Speed...............................................................................................................82

8.4.9 FB Processdata Output 1...8 ............................................................................................83

8.4.10 FB Processdata Output mapping in application..............................................................83

8.5 VACON anyparameter service .........................................................................................85

8.5.1 Error responses ...............................................................................................................85

8.5.2 Examples..........................................................................................................................85

9. Fault tracing...................................................................................................87

9.1 Typical fault conditions ....................................................................................................87

9.2 Fieldbus timeout fault (F53).............................................................................................88

9.3 Detailed fault code ...........................................................................................................89

10. Appendix A: Object dictionary ........................................................................90

10.1 Communication segment.................................................................................................90

10.2 Manufacturer Segment....................................................................................................94

10.3 Device Profile Segment....................................................................................................95

11. Appendix B - Fieldbus parametrization .........................................................97

11.1 Fieldbus control and reference selection .......................................................................97

11.1.1 Controlling fieldbus parameter .......................................................................................98

11.2 Response to fieldbus fault ...............................................................................................99

12. Appendix C - Fieldbus Process Data mapping and scaling ...........................100

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 5

Safety vacon • 5

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

Before connecting the AC drive to mains make sure that the front and cable

covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

voltage is present.

Always

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 6

vacon • 6 Safety

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to

standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by the manufacturer can be used.

At power-up, power break or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Start/Stop logic has been selected

Furthermore, the I/O functionalities (including start inputs) may change if

parameters, applications or software are changed. Disconnect, therefore, the

motor if an unexpected start can cause danger.

.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

Wear protective gloves when you do mounting, cabling or maintenance

operations. There can be sharp edges in the AC drive that can cause cuts.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 7

Safety vacon • 7

13006.emf 13006.emf

1.3 Earthing and earth fault protection

CAUTION!

The AC drive must always be earthed with an earthing conductor connected to the earthing terminal

marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

0) The protective conductor must have a cross-sectional area of at least 10 mm

Al, through its total run.

a) Where the protective conductor has a cross-sectional area of less than 10 mm

2

Al, a second protective conductor of at least the same cross-sectional area must be

mm

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm

2

Cu or 16 mm2 Al.

b) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

2

Cu or 1 6 mm2

2

Cu or 16

The cross-sectional area of every protective earthing conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure can cause damage to the product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 8

vacon • 8 CANopen option board OPTE6 - General

2. CANOPEN OPTION BOARD OPTE6 - GENERAL

2.1 Overview

OPTE6 is a CANopen adapter board for VACON® AC drives. The board allows the AC drive to be

controlled by using the CANopen protocol. The board implements the AC drive profile with the

velocity mode.

The option board firmware implements the following protocol specifications:

• CiA-301 CANopen communication specification version 4.2

• CiA-402 CANopen Profile for Drives and Motion Controller version 3.2

Device: AC drive

Operation mode: velocity mode

• CiA-303-3 CANopen indicator specification, implemented by using 2 CANopen status led

indicators

2.2 Software

2.2.1 CAN

The CAN data link layer protocol is standardised in ISO 11898. The standard describes mainly the

data link layer composed of the logical link control (LLC) sub layer and the media access control

(MAC) sub layer, and some aspects of the physical layer of the OSI reference model.

2.2.2 CANopen

CANopen is an application layer protocol on top of the CAN bus.

The protocol specification describes:

• Set of bit rates to support

• Network Management (NMT)

• Service data transmission (SDO)

• Process data transmission (PDO)

• Error message transmission (EMCY)

• Node status monitoring (heartbeat and node guarding)

• Identity information

• Parameter saving and restoring

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 9

CANopen protocol description vacon • 9

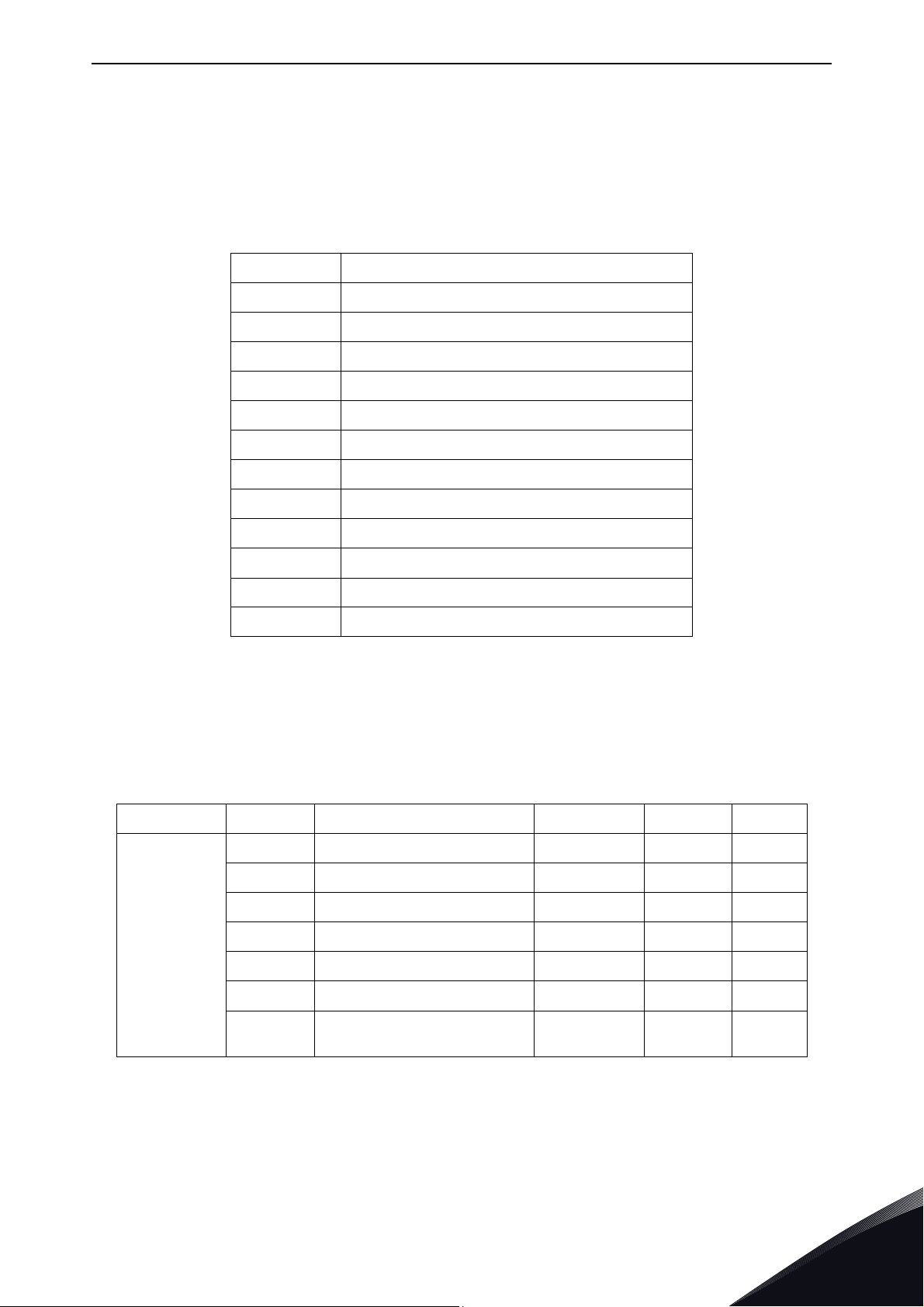

(1)

(2) (11)

(4) (5) (10)

(7)

(3)

(14)

(13)

(12) (8) (9)

Power on or hardware reset

Pre-operational

Initialisation

Operational

Stopped

11651_uk

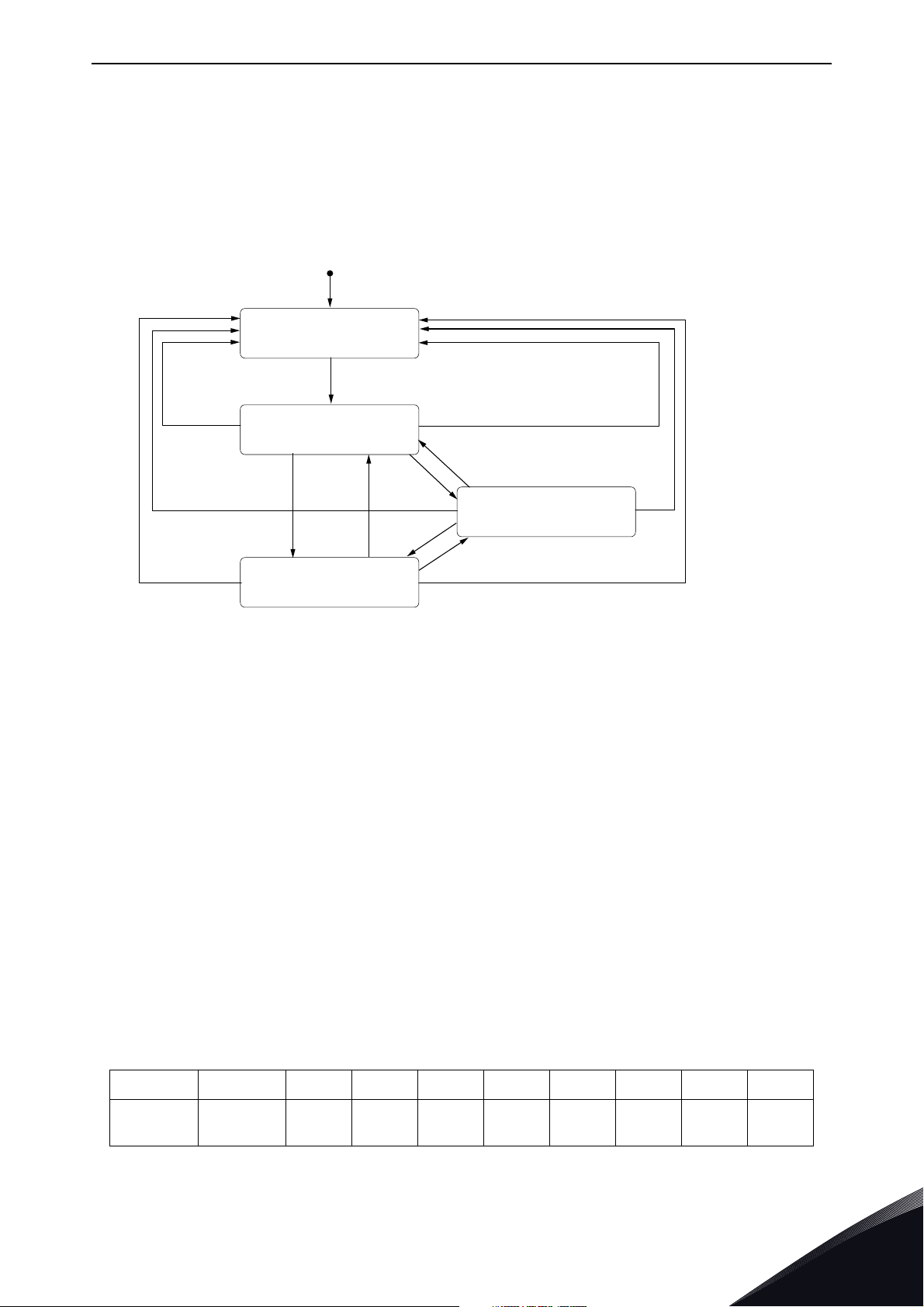

3. CANOPEN PROTOCOL DESCRIPTION

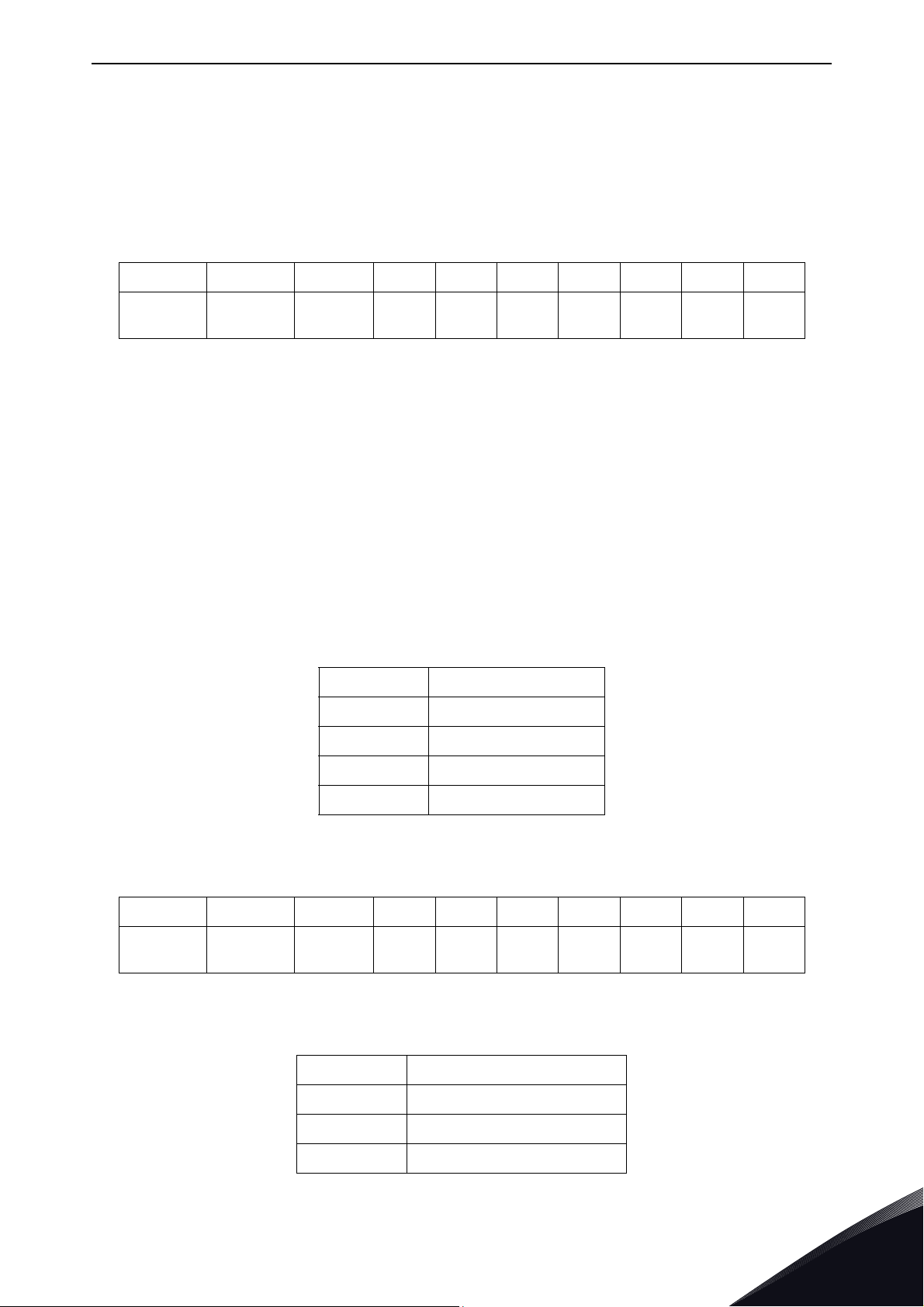

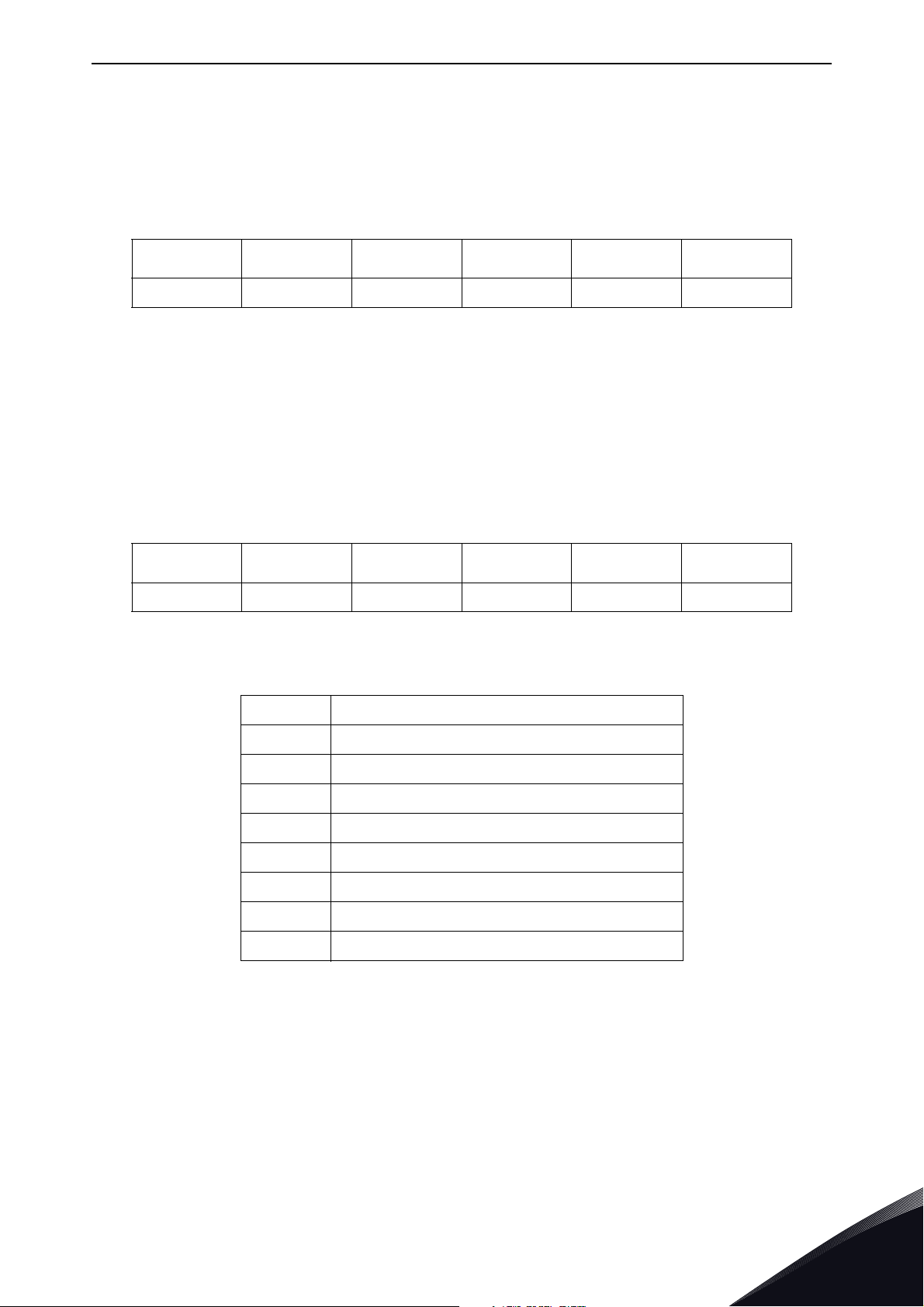

3.1 NMT

NMT network management manages CANopen, and is a mandatory, common feature for all

devices. The protocol describes several node control services and the state machine.

1 = When the power is on, the NMT state is entered autonomously

2= The NMT state initialisation is finished, the NMT pre-operational state is entered

automatically

3 = NMT service starts with remote node indication or by local control

4 and 7 = NMT service enters pre-operational indication

5 and 8 = NMT service stops remote node indication

6 = NMT service starts remote node indication

9, 10 and 11 = NMT resets node indication

12, 13 and 14 = Indication of NMT service reset communication

Boot-up protocol

After a node starts, it will enter automatically into the pre-operational state. Always when this

transition occurs, a boot-up message is sent into the bus.

Table 1: Boot-up message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA 5 DATA 6 DATA7

Figure 1. NMT state machine

0x700 +

Node ID

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

10

3

Page 10

vacon • 10 CANopen protocol description

3.2 Node control protocols

Protocol start remote node

The start remote node message sets the node(s) into operational state. See Figure 1. NMT state

machine. If the node ID in the message is set to ‘0’, the message affects all nodes (broadcast).

Table 2: Start remote node message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x0 0x2 0x1

NODE

ID

Protocol stop remote node

The stop remote node message sets the node(s) into stopped state. See Figure 1 NMT state

machine. If the node ID in the message is set to ‘0’, the message affects all nodes (broadcast). When

the node is in stopped state, it will not answer to SDO or PDO messages.

Table 3: Stop remote node message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x0 0x2 0x2

NODE

ID

Protocol enter pre-operational

The enter pre-operational message sets the node(s) into pre-operational state. See Figure 1. NMT

state machine. If the node ID in the message is set to ‘0’, the message affects all nodes (broadcast).

When the node is in pre-operational state, it will not answer to PDO messages.

Table 4: Enter pre-operational message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x0 0x2 0x80

NODE

ID

Protocol reset node

The reset node message makes the node(s) apply application reset. See Figure 1. NMT state

machine. Application reset sets the whole object dictionary back to the default or previously saved

values. If the node ID in the message is set to ‘0’, the message affects all nodes (broadcast). After

the node has made the application reset, it will enter the pre-operational state automatically from

the initialising state. This also creates a boot-up event and the boot-up message is sent after the

reset.

Table 5: Reset node message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x0 0x2 0x81

NODE

ID

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 11

CANopen protocol description vacon • 11

Protocol reset communication

The reset communication message makes the node(s) apply communication reset. See Figure 1.

NMT state machine. Communication reset does not affect the object dictionary values. If the node

ID in the message is set to ‘0’, the message affects all nodes (broadcast). After the node has made

the communication reset, it will enter the pre-operational state automatically from the initialising

state. This also creates a boot-up event and the boot-up message is sent after the reset.

Table 6: Reset communication message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x0 0x2 0x82

NODE

ID

3.3 Error control protocols

It is not allowed to use guarding protocol and heartbeat protocol on one NMT slave at the same

time. If the heartbeat producer time is unequal 0, the heartbeat protocol is used.

3.3.1 Heartbeat protocol

Heartbeat protocol defines the producer and consumer. The producer node sends its NMT status

that is then available for any consumer node. The consumer node is the receiver of heartbeat

messages. The producer node has a timing parameter that indicates how often the heartbeat

message should be sent. The consumer node has a relative parameter that indicates how often the

heartbeat message should be received. If the consumer does not receive the heartbeat message

within the time defined in the heartbeat object entry, an error event occurs.

Table 7: Node status description

Value Description

0x0 Boot-up

0x4 Stopped

0x5 Operational

0x7F Pre-operational

Table 8: Heartbeat message

CAN ID LENGTH DATA0 DATA 1 DATA2 DATA3 DATA4 DATA 5 DATA6 D ATA7

0x700 +

Node ID

0x1 Status

Table 9: Heartbeat-related objects in OD

Index Description

0x1016 Consumer heartbeat time

0x1017 Producer heartbeat time

0x1029 Error behaviour

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 12

vacon • 12 CANopen protocol description

3.3.2 Node guarding protocol

Node guarding protocol is a NMT master driver protocol, where the master sends a remote

transmission request, which is answered by the slave. The slave response includes one data byte

that consists of a NMT slave state, and a toggle bit that toggles every response.

NOTE! The CiA application note 802 recommends that the node guarding protocol should not be

used, because of different handling of RTR frames in CAN controllers.

OPTE6 option board does not have a hardware-triggered automatic response to the RTR frame. RTR

information is handled by software, and the response data always consists of updated information.

Table 10: Node guarding RTR frame (remote request)

CAN ID LENGTH RTR DATA0 DATA1 DATA2 DATA3 DATA 4 DATA5 DATA6 DATA7

0x700 +

Node ID

Table 11: Node guarding response

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x700 +

Node ID

0x0 1

0x1 t Status

Table 12: Node guarding slave status

Status

Value Description

0x4 Stopped

0x5 Operational

0x7F Pre-operational

3

Table 13: Node guarding related objects in OD

Index Description

0x100C Guard time

0x100D Life time factor

3.3.3 EMCY object

Option board works as an EMCY producer. The EMCY object is transmitted when a fault occurs in

the drive or option board. To switch off the EMCY producer, disable the EMCY COB-id by writing MSB

to 1 (object 0x1014).

When an error occurs, the EMCY message is transmitted with the current value of the error

register and the error code is inserted into the pre-defined error field list. The newest error code is

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 13

CANopen protocol description vacon • 13

always the first sub-index on the error field list. When all active errors are cleared, an empty EMCY

object is transmitted.

If a drive-internal fault occurs, the MSEF field contains the drive fault code. See the application and

user manual for possible fault codes. The ER field holds a bit coded value of the error type. See

object 0x1001 for more details.

Table 14: EMCY message

CAN ID LENGTH DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x80 +

Node ID

0x8 EEC ER MSEF

Table 15: EMCY message data fields

EEC Emergency error code

ER Error register value

MSEF

Manufacturer-specific

error code

Table 16: Used EMCY error codes and description MSEF fields

DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

0x0000

0x1000 Drive fault codes

0x8110 -

0x8120 -

0x8130

ER

0x8140 -

3: N umb er of remai ning error s ource s

3: Heartbeat consumer subindex

4: Heartbeat consumer node-ID

0x8210 -

0x8220 -

0x8240 -

0x8250 -

Table 17: Description and behavior of different error situations

EEC Description Error behaviour Err LED

0x0000

0x1000

0x8120

0x8130

Error Reset or No Error

Generic Error

CAN in Error Passive

Mode

Life Guard Error

Heartbeat Error

If MSEF field is empty all error sources are cleared and drive

fault is cleared.

Drive fault codes have changed. -

EMCY is sent after CAN driver goes back to active state. This

also clears the fault.

Error is reset when a RTR is received or either of the life

guard objects (0x100C, 0x100D) is written to zero.

Error is reset when a HB message is received by the HB consumer, or the consumer entry is changed (either Node-ID or

Heartbeat Time).

Single flash

-

Double

flash

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 14

vacon • 14 CANopen protocol description

Table 17: Description and behavior of different error situations

0x8140 Recovered from Bus-Off

0x8250

PDO timer expired

EMCY is sent after CAN driver goes back to active state. This

also clears the fault.

Error is cleared when a PDO is received (in expired PDO).

On

Quadruple

flash

All communication errors are reset if a reset command is given. This does not however reset drive

faults if there are active error sources.

EMCYs are also created in some cases, even though a fault is not created. These are for notification

only.

Table 18: Notification EMCY objects

EEC Description

0x8110 CAN overrun (objects lost)

0x8210 PDO not processed due to length error

0x8220 PDO length exceeded

0x8240 Unexpected SYNC data length

Table 19: EMCY-relate objects in OD

Index Description

0x1001 Error register

0x1003

0x1014 EMCY object COB-ID

Pre-defined error field

list

3.4 SDO protocol

The Option board contains one SDO server. The SDO protocol provides a direct access to the object

entries of the object dictionary of the CANopen device. Each message is acknowledged by the

server. The protocol is mostly used to set and read parameters from the object dictionary at the

pre-operational state. Some objects have limitations for SDO usage at the operational state.

Up to four bytes can be transferred by using the expedited transfer, where the data fits into one CAN

message. For bigger than 4-byte object sizes, segmented transfer must be used. Optionally, block

transfer is also possible with bigger data types. Block transfer is most efficient with big data sizes.

Table 20: SDO-related objects in OD

Index Description

3

0x1200

SDO server parameter

object

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 15

CANopen protocol description vacon • 15

3.5 PDO protocol

Process data objects PDOs are used to transmit real-time data with no protocol overhead. Each

PDO has its mapping and communication parameter record.

There are two different types of PDOs. Transmit PDOs for producing data into network and Receive

PDOs for consuming data from network. OPTE6 board supports 3 receive and 3 transmit PDOs.

Table 21: PDO-related objects in OD

Index Description

0x1400 1st rxPDO communication parameter record

0x1401 2nd rxPDO communication parameter record

0x1402 3rd rxPDO communication parameter record

0x1600 1st rxPDO mapping parameter record

0x1601 2nd rxPDO mapping parameter record

0x1602 3rd rxPDO mapping parameter record

0x1800 1st txPDO communication parameter record

0x1801 2nd txPDO communication parameter record

0x1802 3rd txPDO communication parameter record

0x1A00 1st txPDO mapping parameter record

0x1A01 2nd txPDO mapping parameter record

0x1A02 3rd txPDO mapping parameter record

3.5.1 PDO communication parameter record

PDO communication parameter record defines the COB-id, transmission type and how often the

PDO is transmitted. The fields can be modified during the pre-operational state.

Table 22: PDO communication parameter record

Indexes Sub-index Name Data type RX PDO TX PDO

0 Highest sub-index supported UNSIGNED8 ro ro

1 COB ID UNSIGNED32 r/w r/w

0x1400

0x1401

0x1402

0x1800

0x1801

0x1802

2 Transmission type UNSIGNED8 r/w r/w

3 Inhibit time UNSIGNED16 ro r/w

4 Reserved UNSIGNED8 ro ro

5 Event timer UNSIGNED16 r/w r/w

6 SYNC start value UNSIGNED8

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Not

available

r/w

3

Page 16

vacon • 16 CANopen protocol description

3.5.2 COB ID

COB ID determines whether the PDO is valid (active) and using 11-bit or 29-bit frames.

Table 23: COB ID

31 30 29 28 11 10 0

Valid Reserved Frame

Table 24: COB ID data fields

Bit(s) Value Description

Valid

Reserved x Not applicable

Frame

29-bit CAN-ID x

11-bit CAN-ID x

0x00000 11-bit CAN-ID

29-bit CAN-ID

0 PDO exists / enabled

1

0 11-bit CAN-ID valid

1 20-bit CAN-ID valid

PDO does not exist /

disabled

29-bit CAN-ID of the CAN

extended frame

11-bit CAN-ID of the CAN

base frame

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 17

CANopen protocol description vacon • 17

3.5.3 Transmission type

Table 25: PDO transmission types

Value Description

0x00

0x01

0x02

0x03

0x04

... ...

0xF0

0xF1

... ... - -

0xFB

0xFC

0xFD

0xFE

Synchronous (acyclic)

Synchronous (cyclic every sync)

Synchronous (cyclic every 2nd sync)

Synchronous (cyclic every 3rd sync)

Synchronous (cyclic every 4th sync)

Synchronous (cyclic every 240th sync)

Reserved

Reserved

RTR-only (synchronous)

RTR-only (Event-driven)

Event-driven (manufacturer-specific)

Receive

PDO

XX

X

1

X

1

X

1

X

1

X

1

X

1

--

--

-X

-X

XX

Transmit

PDO

X

X

X

X

X

X

0xFF

For receive PDO, each sync transmission mode equals the same. Each sync always activates the latest

1

Event-driven (device and application profile)

XX

received PDO value.

Synchronous means that the PDO is transmitted after the SYNC. The CANopen device starts

sampling the data with the reception of the SYNC. If the transmission mode of the PDO is acyclic,

the CANopen device gives an internal event, the sampling starts with the next SYNC and the PDO is

transmitted afterwards. If the transmission mode is cyclic, the sampling starts with the reception

of every SYNC, every second SYNC, every third SYNC etc. depending on the given value, and the PDO

is transmitted afterwards.

RTR-only means that the PDO is requested via RTR. If the transmission mode of the PDO is

synchronous, the CANopen device starts sampling with the reception of every SYNC and will buffer

the PDO. If the mode is event-driven, the CANopen device starts the sampling with the reception of

the RTR and transmits the PDO immediately.

Event-driven means that the PDO can be transmitted at any time based on the occurrence of the

internal event of the CANopen device. An event that triggers the OPTE6 transmission occurs when

the data mapped into the PDO is changed. Also, an event timer can be used to create transmit

events.

Inhibit time

For transmit PDOs, the inhibit time defines the minimum transmission interval, when 0xFE or 0xFF

transmission types are selected. For receive PDOs, the inhibit time is disabled. The inhibit time is

16bit unsigned value that is given as multiple of 100μs. Zero value means that the inhibit time is

disabled.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 18

vacon • 18 CANopen protocol description

Event timer

For a transmit PDO event, the timer defines the maximum interval between the transmissions, if

the transmission type is set to 0xFE or 0xFF.

For a receive PDO event, the timer activates the deadline monitoring. The deadline monitoring is

activated at the first received PDO. If the time between the after the last PDO received is longer

than defined in the event timer, a fault will occur.

Event timer is 16bit unsigned value that is given as multiple of 1ms. Zero value means that the event

timer is disabled.

Sync start value

Sync start value gives the possibility to compensate network peak traffic in case of sync

transmission mode. If the sync start value is zero, the normal sync behaviour for the PDO is used.

If the sync start value is greater than zero, the PDO waits for the SYNC message that contains the

counter value. When the counter value of a SYNC message equals the SYNC start value, the first

SYNC message is regarded as received. The sync start value must not be changed while the PDO

exists. See the SYNC message format in Table 29.

3.5.4 PDO parameter mapping record

Each PDO consists of a maximum of 8 bytes of mapped data. To data map the PDO, use a

corresponding mapping record that consists of index, sub-index and the length of the mapped

object.

Table 26: PDO mapping structure

31 16 15 8 7 0

Index Sub-index Length

Table 27: PDO mapping parameter record

Indexes Sub-index Name Data type Access

0x1600

0x1601

0x1602

0x1A00

0x1A01

0x1A02

0

1

2

3

4

Number of mapped objects in

PDO

1st object to be mapped UNSIGNED32 r/w

2nd object to be mapped UNSIGNED32 r/w

3rd object to be mapped UNSIGNED32 r/w

4th object to be mapped UNSIGNED32 r/w

UNSIGNED8 r/w

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 19

CANopen protocol description vacon • 19

To data map the PDOs, first disable the related PDO COB ID in the pre-operational state. In the

mapping structure, write the sub-index 0 to zero (number of mapped objects). Then write the

mapping structures on the mapping parameter record, starting from the sub-index 1. When you

have written all the necessary structures, write the sub-index 0 to correspond to the mapped

objects.

Example on how to write a dummy object to RPDO1 4th entry (when using Bypass mode) is explained

below:

Table 28. RPDO mapping example

Transfer data (hex) Interpretation

23 00 14 01

2F 00 16 00

23 00 16 04

2F 00 16 00

23 00 14 01

01 02 00 80 Write RPDO1 COB-ID (1400:01) to invalid (0x8000 0201)

00 00 00 00 Write RPDO1 mapping number of entries (1600:00) to 0

10 00 06 00

Write RPDO1 4

th

entry (1600:04) to Dummy object (00060010)

04 00 00 00 Write RPDO1 mapping number of entries (1600:00) to 4

01 02 00 00 Write RPDO1 COB-ID (1400:01) as valid (0x201)

3.6 SYNC protocol

Sync protocol is used by PDOs when the transmission is synchronous. The sync object that is

defined by COB ID in the object 0x1005 triggers the transmission of the txPDOs, or activates the

previously received data of the rxPDO. At the default sync message the CAN-ID is 0x80. The sync

message is a zero-length message but optionally it can consist of an 8bit counter.

Table 29: SYNC message

CAN ID LENGTH

0x80 0x0

Table 30: SYNC message with counter

CAN ID LENGTH DATA0

0x80 0x1 Counter

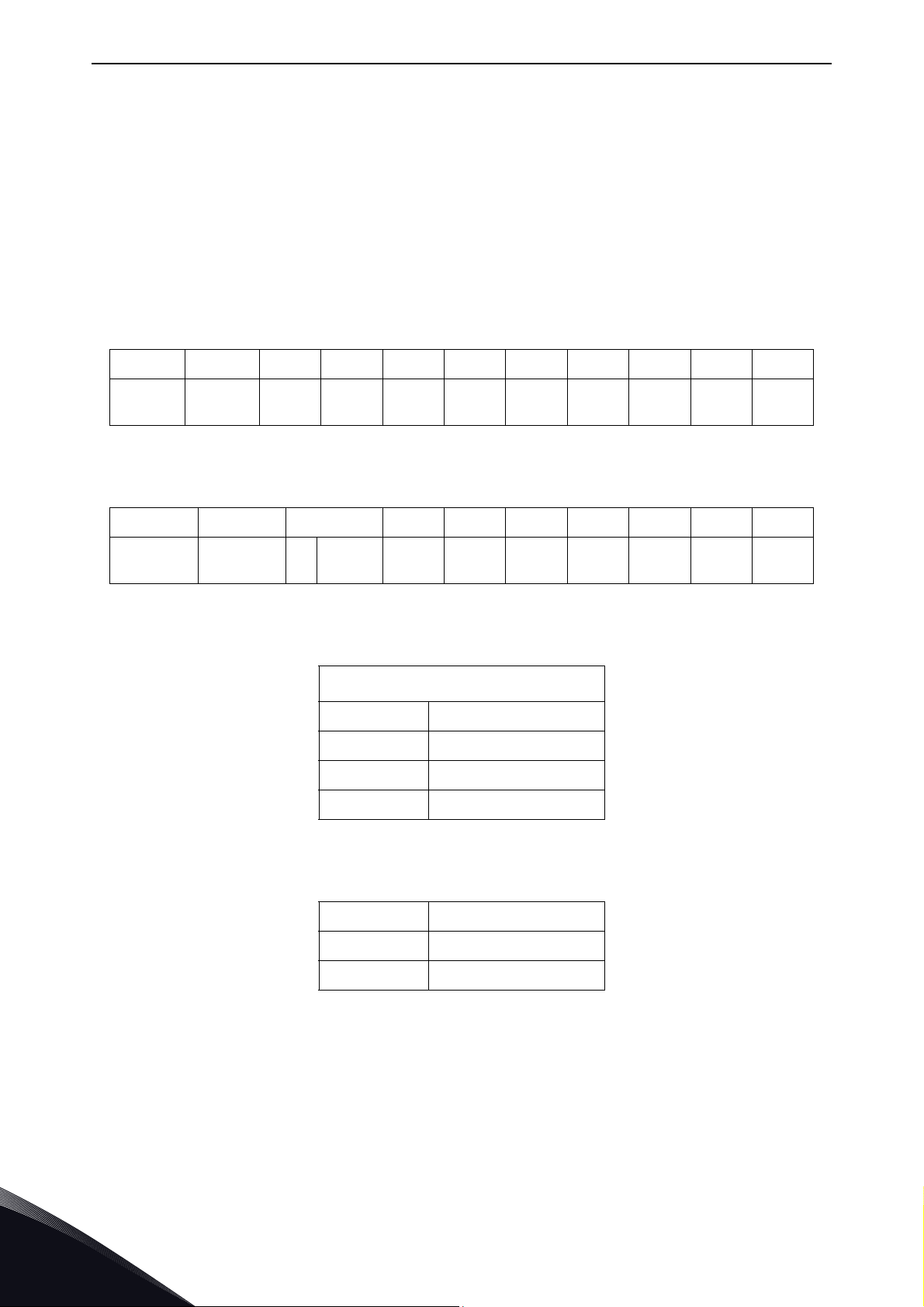

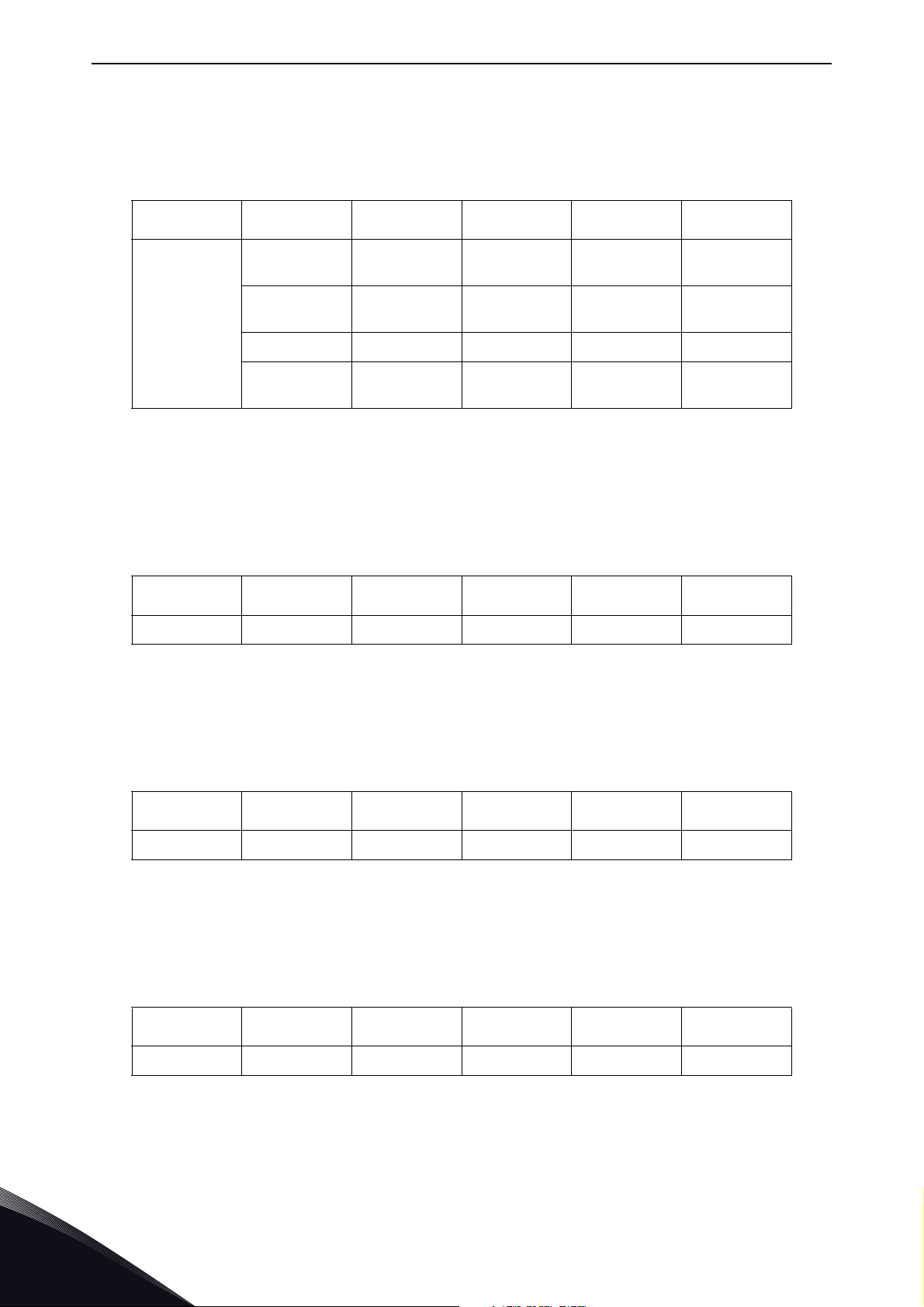

3.6.1 SYNC with counter

When a counter is used in a sync message, the PDOs that have a defined sync start value compare

the value against the sync message counter. The sync producer counter will overflow after it

reaches the value defined in its ‘synchronous counter overflow value’ at the object 0x1019. Also, the

sync consumer has the object 0x1019 even when the value itself is ignored. When the value of the

sync consumer is greater than zero, the sync counter handling and expecting of the sync messages

with counter are activated.

When the sync start value and the sync counter value match, the first sync message is regarded as

received.

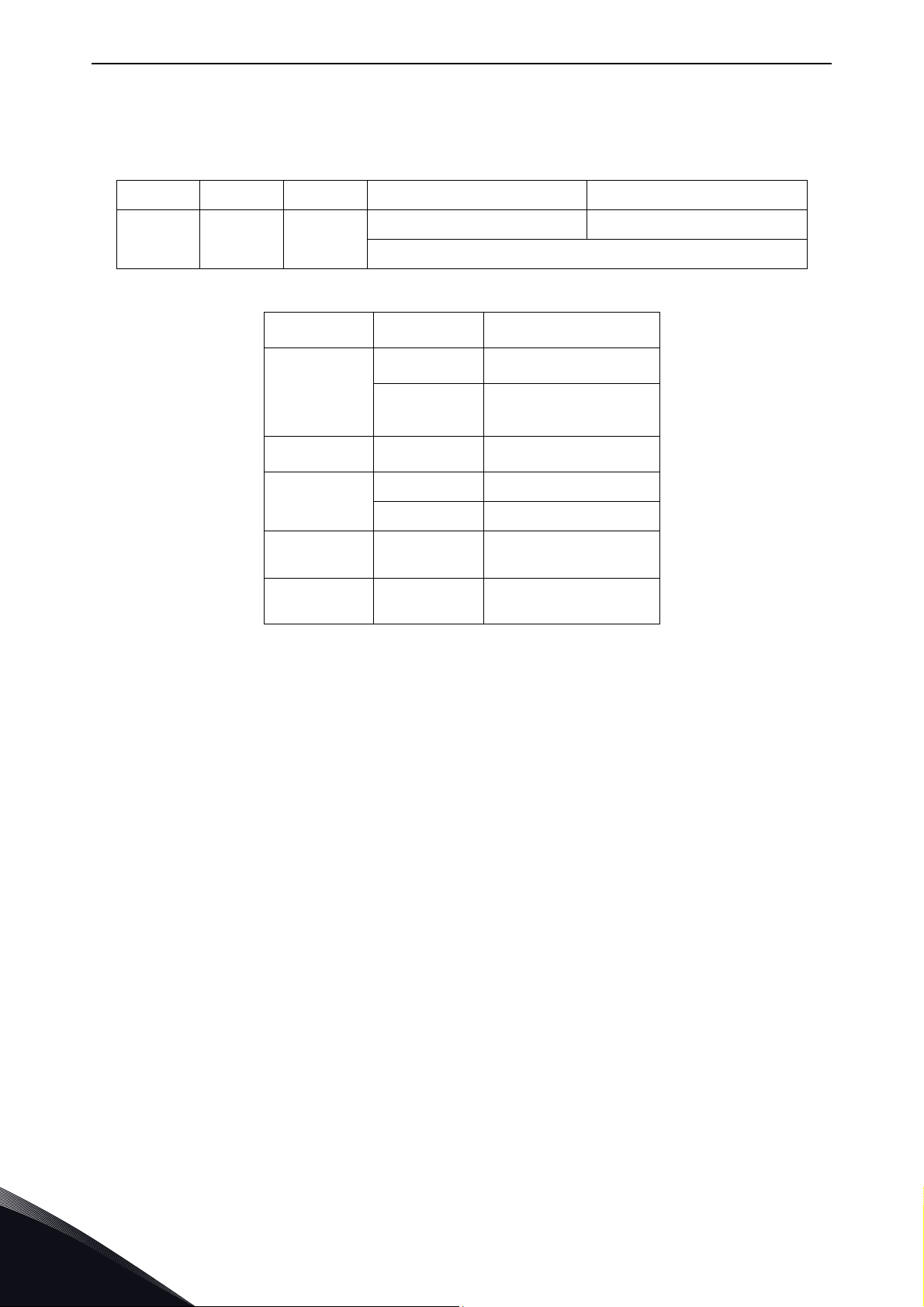

The following figure shows an example of SYNC messaging, when the slave is configured with:

• 0x1019 - Synchronous counter 128

• 0x1800,2 - Transmission type = 2 (Cyclic, No. of SYNCs = 2)

• 0x1800,6 - Sync start value = 4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 20

vacon • 20 CANopen protocol description

(1) (2) (3) (4) (5) (6) (7) (8)

SYNC

time

txPDO

Figure 2. txPDO responses to SYNC messages

Table 31: Sync-related object in OD

Index Description

0x1005 COB ID SYNC

0x1019 Synchronous counter

0x1014 EMCY object COB ID

0x1400 1st rxPDO communication parameter record

0x1401 2nd rxPDO communication parameter record

0x1402 3rd rxPDO communication parameter record

0x1800 1st txPDO mapping parameter record

0x1801 2nd txPDO mapping parameter record

0x1802 3rd txPDO mapping parameter record

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 21

CANopen protocol description vacon • 21

3.7 Communication objects

3.7.1 0X1000 - Device Type

The device type object indicates basic information about the device, including the supported device

profile and the profile settings.

Table 32: 0x1000 Device type

Index Sub-index Value Name Data type Access

0x1000 - 0x00010192 Device type UNSIGNED32 const

Value description:

0x0192 = 402 (Drive profile)

0x0001 = AC drive with PDO set for a generic drive device

3.7.2 0X1001 - Error Register

Error register indicates the active error code.

Table 33: 0x1001 Error register

Index Sub-index Value Name Data type Access

0x1001 - 0x0 Error register UNSIGNED8 ro

Table 34: Error register bit descriptions

Bit Meaning

0 Generic error

1Current

2Voltage

3Temperature

4 Communication error (overrun, error state)

5 Device profile-specific*

6Reserved*

7 Manufacturer-specific*

* Not used/supported

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 22

vacon • 22 CANopen protocol description

3.7.3 0X1003 - Pre-defined Error Field

Pre-defined error field is a list of errors signaled with an EMCY object, listing the error history of

up to 9 error entries. Sub-index 1 contains the latest error.

Table 35: 0x1003 Pre-defined error field

Index Sub-index Value Name Data type Access

00x0

10x0

0x1003

.. .. .. .. ..

90x0

Number of

errors

Sta ndard error

field

Sta ndard error

field

UNSIGNED8 ro

UNSIGNED32

UNSIGNED32

ro

ro

3.7.4 0X1005 - COB ID SYNC

Defines the synchronisation message COB ID. Receiving the sync message causes actions in the

PDOs that have a synchronous transmission mode.

Table 36: 0x1005 COB ID sync

Index Sub-index Value Name Data type Access

0x1005 - 0x00000080 COB ID sync UNSIGNED32 r/w

3.7.5 0X100C - Guard Time

The object contains the guard time in milliseconds. As a default, guarding is disabled.

Table 37: 0x100C Guard time

Index Sub-index Value Name Data type Access

0x100C - 0x0000 Guard time UNSIGNED16 r/w

3.7.6 0X100D - Life Time Factor

Life time factor is used together with guard time, which is multiplied with the life time factor.

Table 38: 0x100D Guard time

Index Sub-index Value Name Data type Access

0x100D - 0x00 Guard time UNSIGNED8 r/w

Node life time = life time factor x guard time. If node life time is zero, guarding is disabled.

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 23

CANopen protocol description vacon • 23

3.7.7 0X1014 - COB ID EMCY

The object defines the emergency message COB ID.

Table 39: 0x1014 COB ID EMCY

Index Sub-index Value Name Data type Access

0x1014 -

0x00000080+

node id

COB ID EMCY UNSIGNED32 r/w

Setting MSB (bit 31) to 1 will disable sending of EMCY messages.

3.7.8 0X1016 - Heartbeat Consumer Entries

The device can act as the heartbeat consumer. Up to 8 devices can be monitored, as defined in the

table below. If the heartbeat transmission delay of a defined node ID exceeds the heartbeat time,

the error behaviour is activated according to the error behaviour object.

Table 40: 0x1016 Heartbeat consumer entries

Index Sub-index Value Name Data type Access

0 0x08 Number of entries UNSIGNED8 ro

1 0x0000 0000

2 0x0000 0000

3 0x0000 0000

Consumer heart beat

time 1

Consumer heart beat

time 2

Consumer heart beat

time 3

UNSIGNED32 r/w

UNSIGNED32 r/w

UNSIGNED32 r/w

Consumer heart beat

time 4

Consumer heart beat

time 5

Consumer heart beat

time 6

Consumer heart beat

time 7

Consumer heart beat

time 8

UNSIGNED32 r/w

UNSIGNED32 r/w

UNSIGNED32 r/w

UNSIGNED32 r/w

UNSIGNED32 r/w

0x1016

4 0x0000 0000

5 0x0000 0000

6 0x0000 0000

7 0x0000 0000

8 0x0000 0000

Table 41: Consumer heartbeat time entry

31 24 23 16 15 0

Not used, must be

zeroes.

Node ID Heartbeat time

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 24

vacon • 24 CANopen protocol description

3.7.9 0X1017 - Producer Heartbeat Time

Heartbeat producer object consists of the time in milliseconds (ms) that it takes to transmit the

heartbeat message into the network. If the value is zero, the heartbeat is not used.

Table 42: 0x1017 Producer heartbeat time

Index Sub-index Value Name Data type Access

0x1017 - 0x0000

Table 43: Heartbeat message

CAN ID LENGTH DATA0

0x700 + node 0x1 Node state

Producer

heartbeat time

UNSIGNED16 r/w

3.7.10 0X1018 - Identify Object

The object gives information about the option board

Table 44: 0x1018 Identify object

Index Sub-index Value Name Data type Access

0 0x04 Number of entries UNSIGNED8 ro

1 0x90 Vendor ID UNSIGNED32 ro

0x1018

2 - Product code UNSIGNED32 ro

3 - Revision number UNSIGNED32 ro

4 - Serial number UNSIGNED32 ro

3.7.11 0X1019 - Synchronous counter overflow value

The synchronous counter overflow value defines whether a counter is mapped into the SYNC message, as well as the highest value the counter can reach. 0 disables the sync counter.

Table 45: 0x1019 Synchronous counter

Index Sub-index Value Name Data type Access

0x1019 - 0x00

Synchronous

counter

UNSIGNED8 r/w

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 25

CANopen protocol description vacon • 25

3.7.12 0X1029 - Error behaviour

Error behaviour allows a change in the default error behaviour if there is a communication

error.

Table 46: 0x1029 Error behaviour

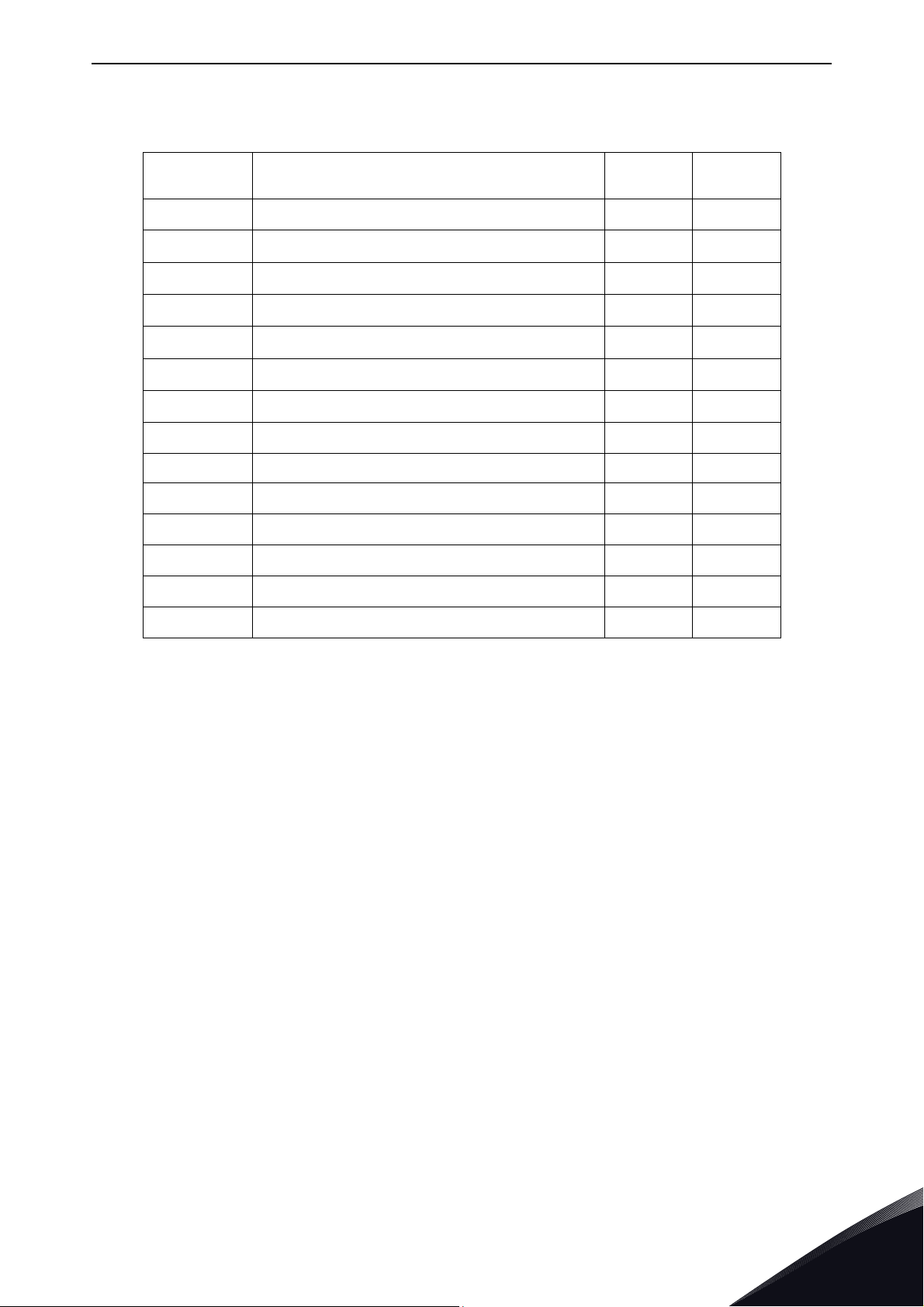

Index Sub-index Value Name Data type Access Min Max

0 0x01 Number of entries UNSIGNED8 ro 2 2

0x1029

1 0x00 Communication error UNSIGNED8 r/w 0 2

2 0x01 Internal error UNSIGNED8 r/w 1 1

Table 47: Error behaviour

Value Description

0 Pre-operational

1 No change in state

2 Stopped

3..127 Reserved

3.8 Saving and restoring the object dictionary

CANopen defines a way of restoring the values in an object dictionary to the defaults and saving the

values if the modified values must be valid after the power cycle. The manufacturer-specific bypass

configuration can be restored to the object dictionary.

3.8.1 0X1010 Store parameter field

To save the object dictionary, use the object 0x1010 ‘Store Parameter Field’.

The option board only saves the parameters in the object dictionary with a command. Autonomous

saving is not supported. To save the parameters in the object dictionary, write the value 0x65766173

(ASCII “save”) into the sub-index by using the SDO protocol.

Table 48: 0x1010 Store parameter field

Index Sub-index Name Data type Access

0x1010

0

1 Save all parameters UNSIGNED32 r/w

Highest sub-index

supported

UNSIGNED8 ro

3.8.2 0X1011 Restore default parameters

The object values of the object dictionary are restored to defaults by using the object 0x1011. Option

board supports restoring All parameters (sub index 1) and manufacturer-specific Bypass mode defaults (sub index 4).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 26

vacon • 26 CANopen protocol description

To restore parameters, write 0x64616F6C (ASCII "load") into the sub-index by using the SDO

protocol. Default object values are selected after reset. Restore all default parameter restores CiA402 default parameters (refer to Chapter 8.2.2.2). Bypass parameter set is described in Chapter 8.3.

Table 49: 0x1011 Restore default parameters

Index Sub-index Name Data type Access

0 Highest sub-index supported UNSIGNED8 ro

Restore all default

parameters

Restore bypass parameter

set*

Restore Puller parameter

set

Restore Co-Extruder parameter set

UNSIGNED32 r/w

UNSIGNED32

UNSIGNED32

UNSIGNED32

r/w

r/w

r/w

0x1011

1

4

5

6

* The bypassed set disables the CIA- 402 drive profile and resets the PDO mapping to the vendor specific

configuration. See Chapter 8.2 and Chapter 8.3 for more information.

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 27

CANopen option board OPTE6 - technical data vacon • 27

4. CANOPEN OPTION BOARD OPTE6 - TECHNICAL DATA

4.1 General

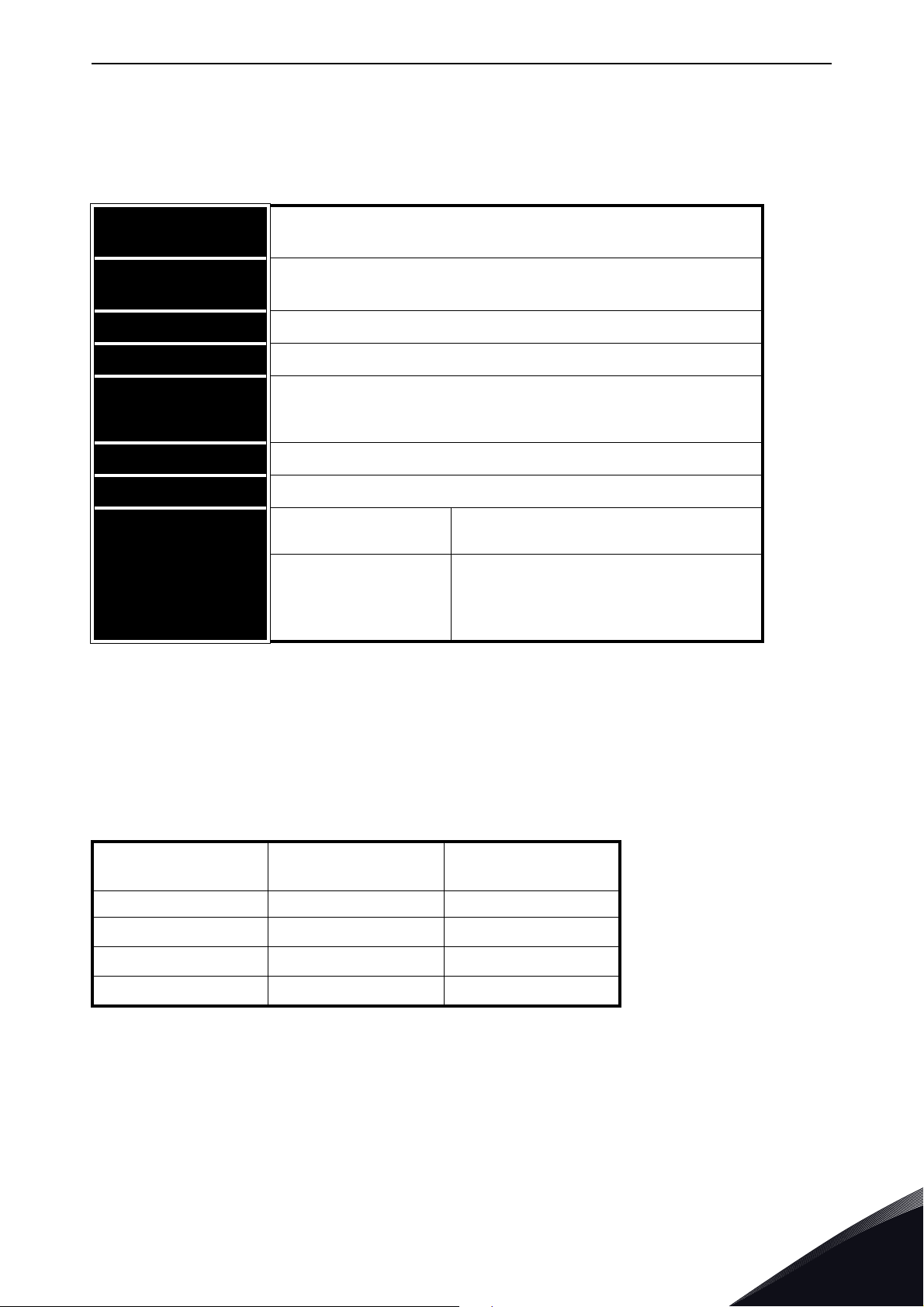

Table 50. Technical data of CANopen opt ion board

CAN bus electrical

isolation

Ambient

temperature

Storing temperature As specified in drive specification (-40°C … 70°C)

Humidity 0-95%, non-condensing, corrosive

Vibration and

electrical safety

Emission C2 level, EN 61800-3 (2004)

Immunity C2 level, EN 61800-3 (2004)

CAN Interface

500 VDC

As specified in drive specification (-10°C … 40°C)

EN 61800-5-1 (2007)

5… 15.8 Hz 1mm (peak)

15.8 ...150 Hz 1 G

Isolation

Protection

2500 V rms isolation with a less than

10-ns propagation delay

±8kV ESD IEC 61000-4-2 Contact

Discharge

±80V Fault Protection

greater than ±12V common Mode Range

4.2 CAN cable

The recommended cables for installations are 4 wires twisted and a shielded cable with an

impedance of 120 Ohm. The network topology is a 2-wire bus line that is terminated at both ends by

resistors representing the characteristic impedance of the bus line. The typical CAN cable

impedance is 120 Ohm, and so for the termination resistors of ~120 Ohm must be used. For long

networks a higher resistor value must be used (150-300 Ohm).

Table 51. Bus parameter relation to cable length

Cable length Max bit rate [kbit/s]

0-40 m 1000 Max 70

100 m 500

500 m 100

1 km 50

Max cable resistance

[m

Ω/m]

<60

<40

<26

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 28

vacon • 28 CANopen option board OPTE6 - technical

E6 Option Board E6 Option Board E6 Option Board

9384.emf

E6 Option Board E6 Option Board Non isolated node

9385.emf

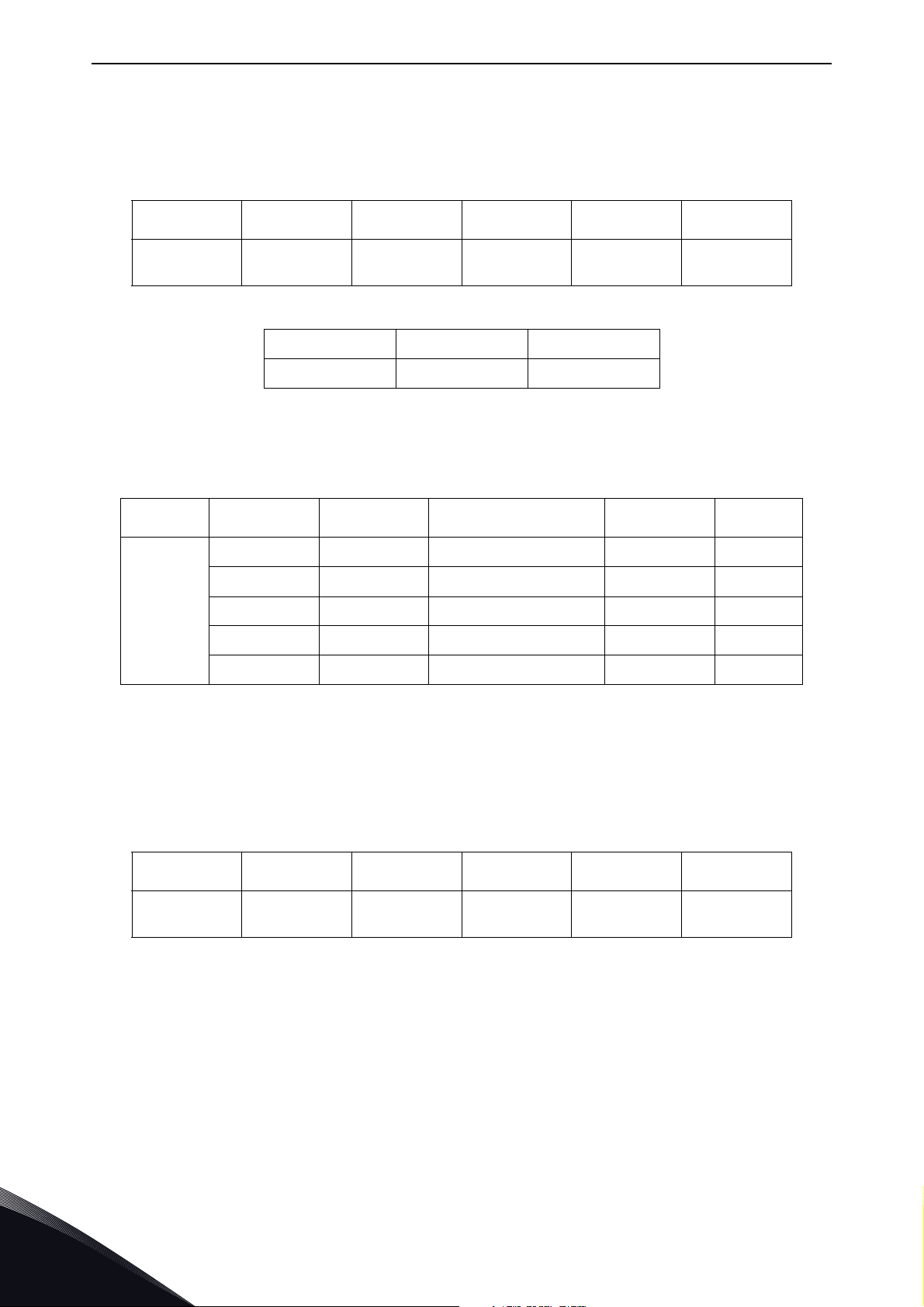

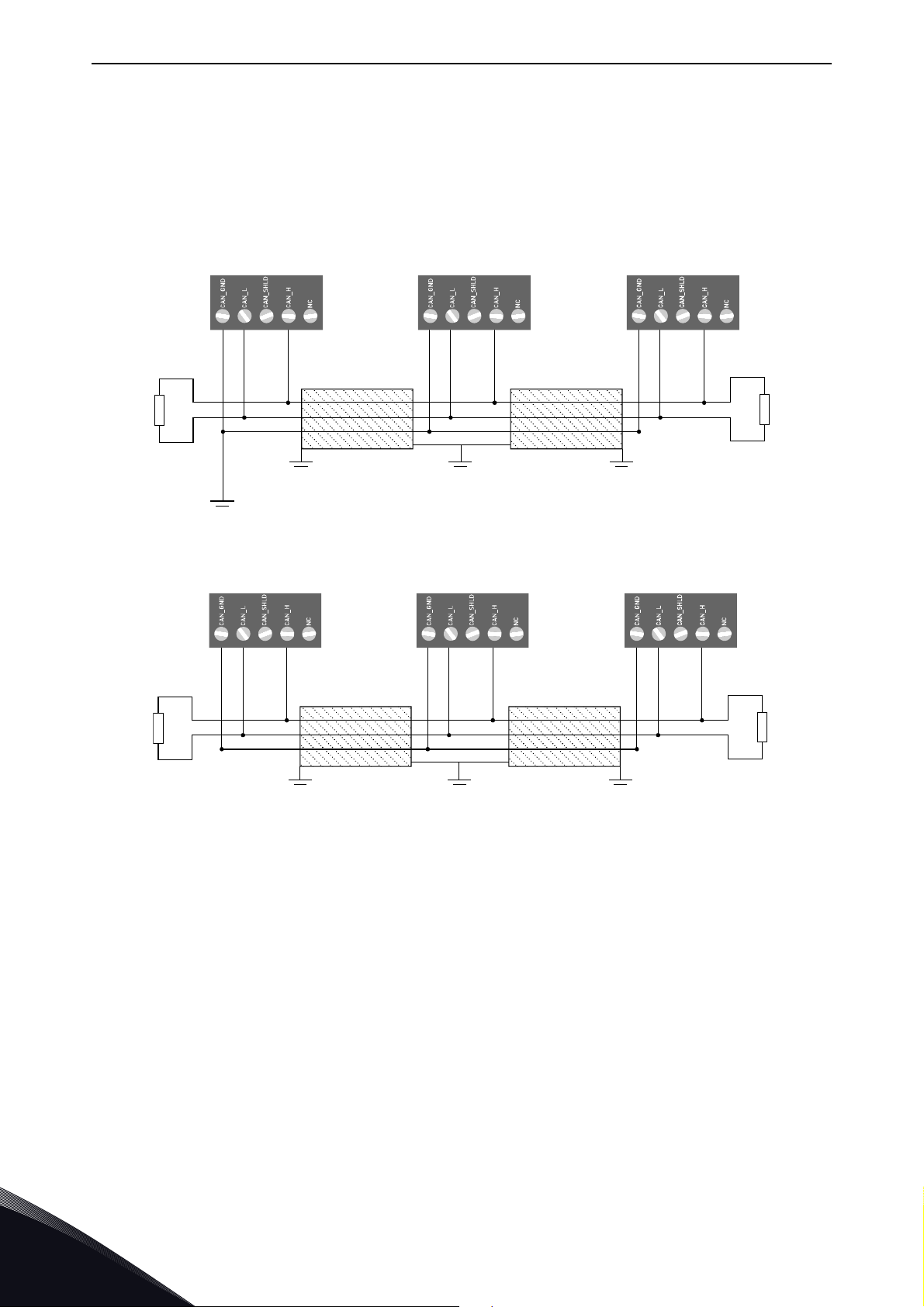

4.2.1 Isolated ground connection

The OPTE6 option board is galvanically isolated. In CANopen networks that are completely galvanically isolated the CAN ground signal is carried in the cable line. It is connected at only one point

into common ground potential. If one CAN device with not galvanically isolated interface is connected to the network, the potential for isolated CAN ground is given. Therefore only one device with not

galvanically isolated interface may be connected to the network.

Figure 3. Completely isolated nodes

Figure 4. CAN network with one non-isolated node

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 29

CANopen option board OPTE6 - technical data vacon • 29

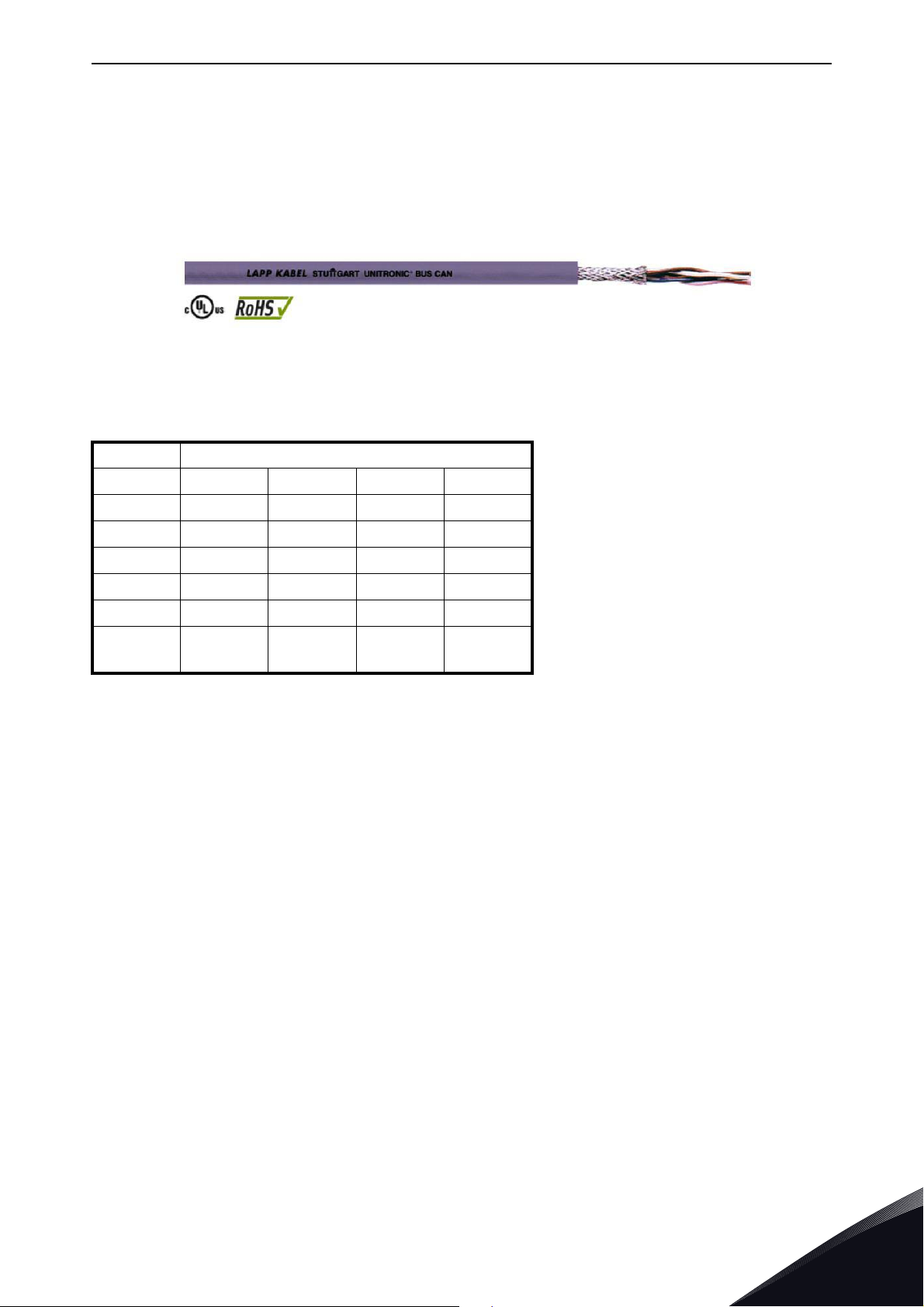

4.2.2 Recommended cable

For all OPTE6 installations the use of 4-wire cable is recommended. 4 wires enable the connection

of isolated digital grounds with nodes.

VACON

UNITRONIC

Colour-coded in accordance with DIN 47100

Table 52. Cable thickness, length and baud rate relation

®

recommends the following cable:

®

BUS CAN FD P

Figure 5. Recommended cable

Bit rate Min cable thickness

1 Mbit/s 0.25

500 kbit/s 0.25 0.34

250 kbit/s 0.25 0.34 0.6

125 kbit/s 0.25 0.34 0.6

100 kbit/s 0.25 0.34 0.6 0.6

50 kbit/s 0.25 0.34 0.6 0.6

Cable

length

25 100 250 500

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 30

vacon • 30 OPTE6 layout and connections

M/N A N/M

1

2

3

4

5

6

7

product code

serial no.

9338A_00

Pin 1

Pin 5

9340.emf

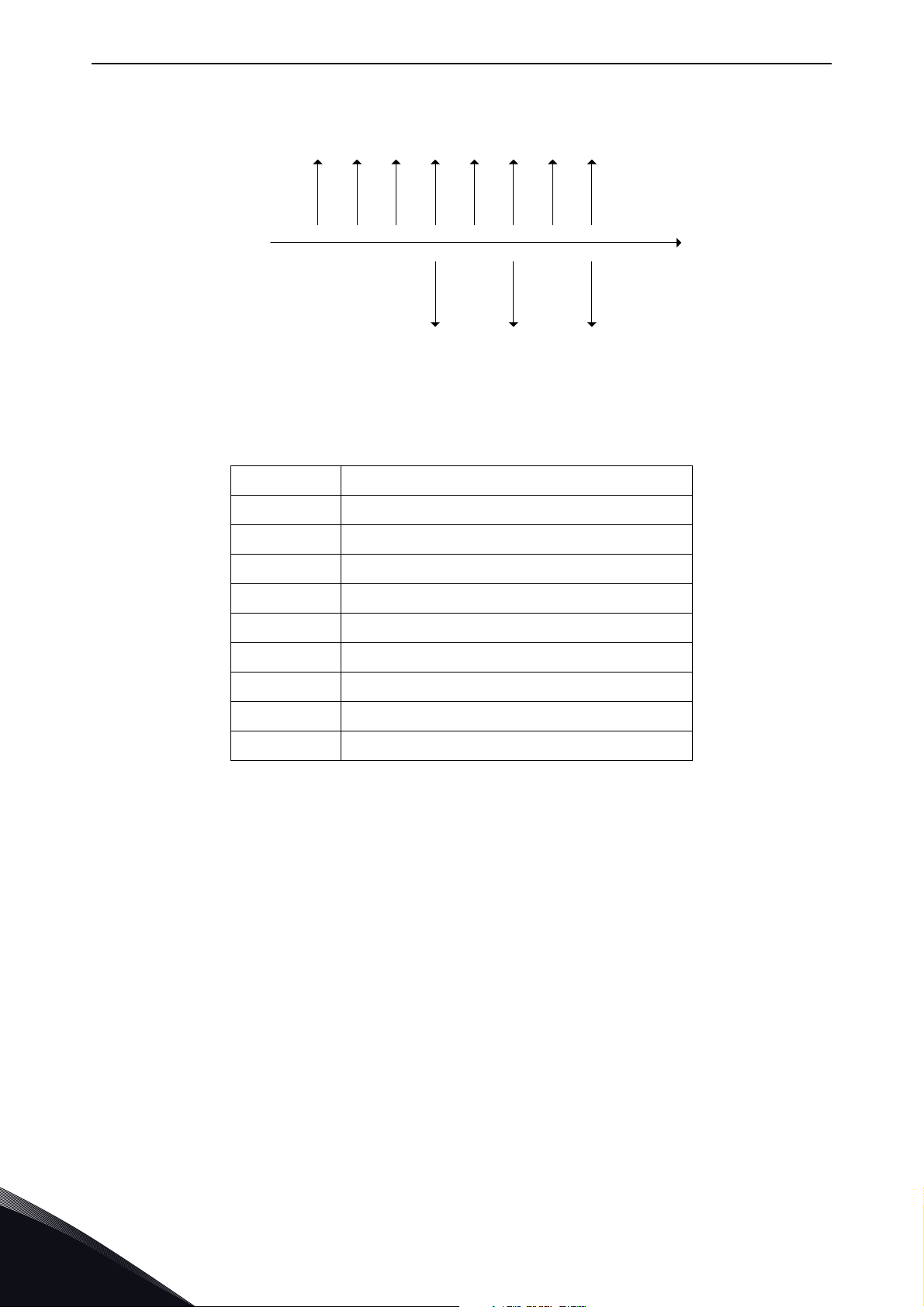

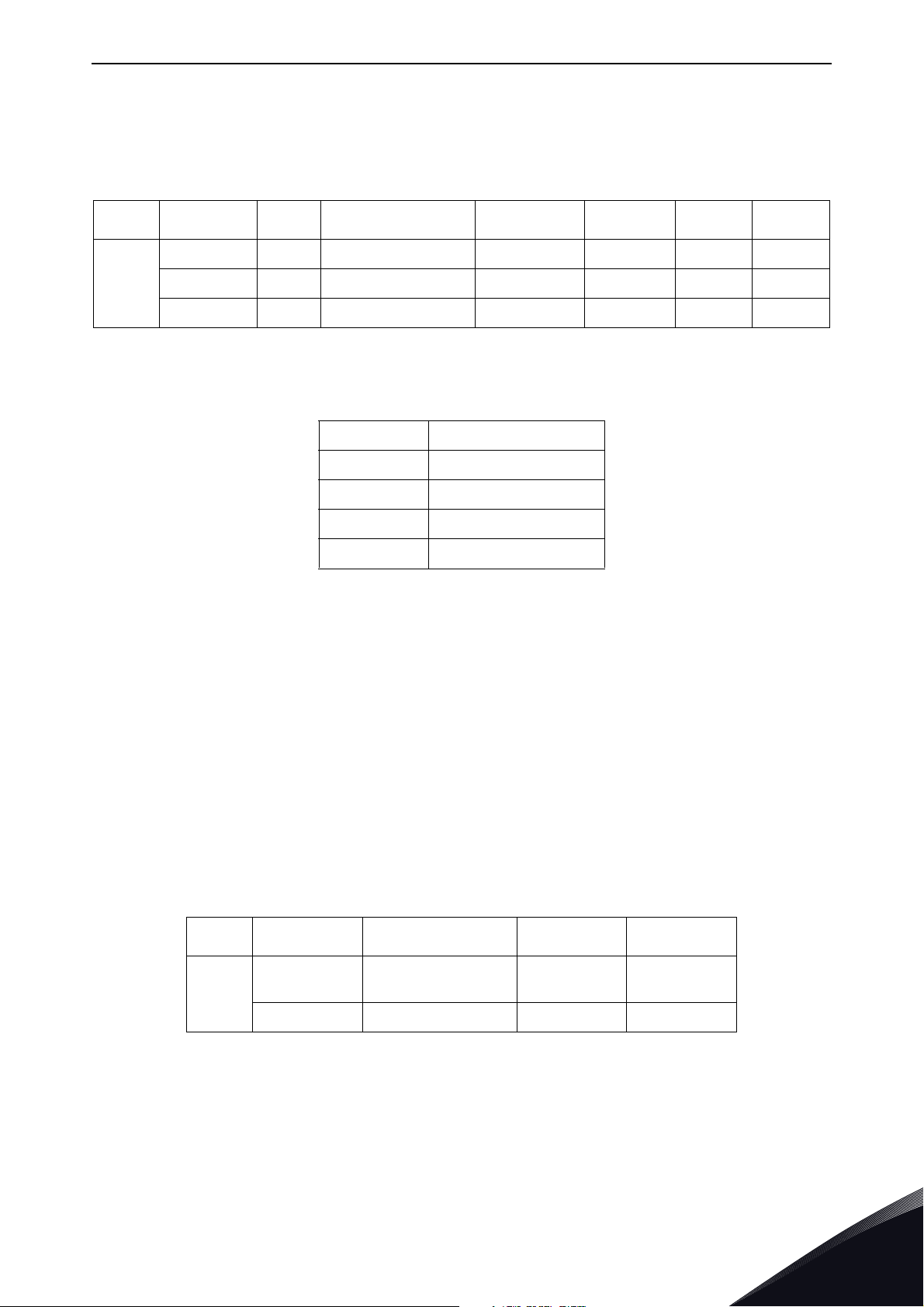

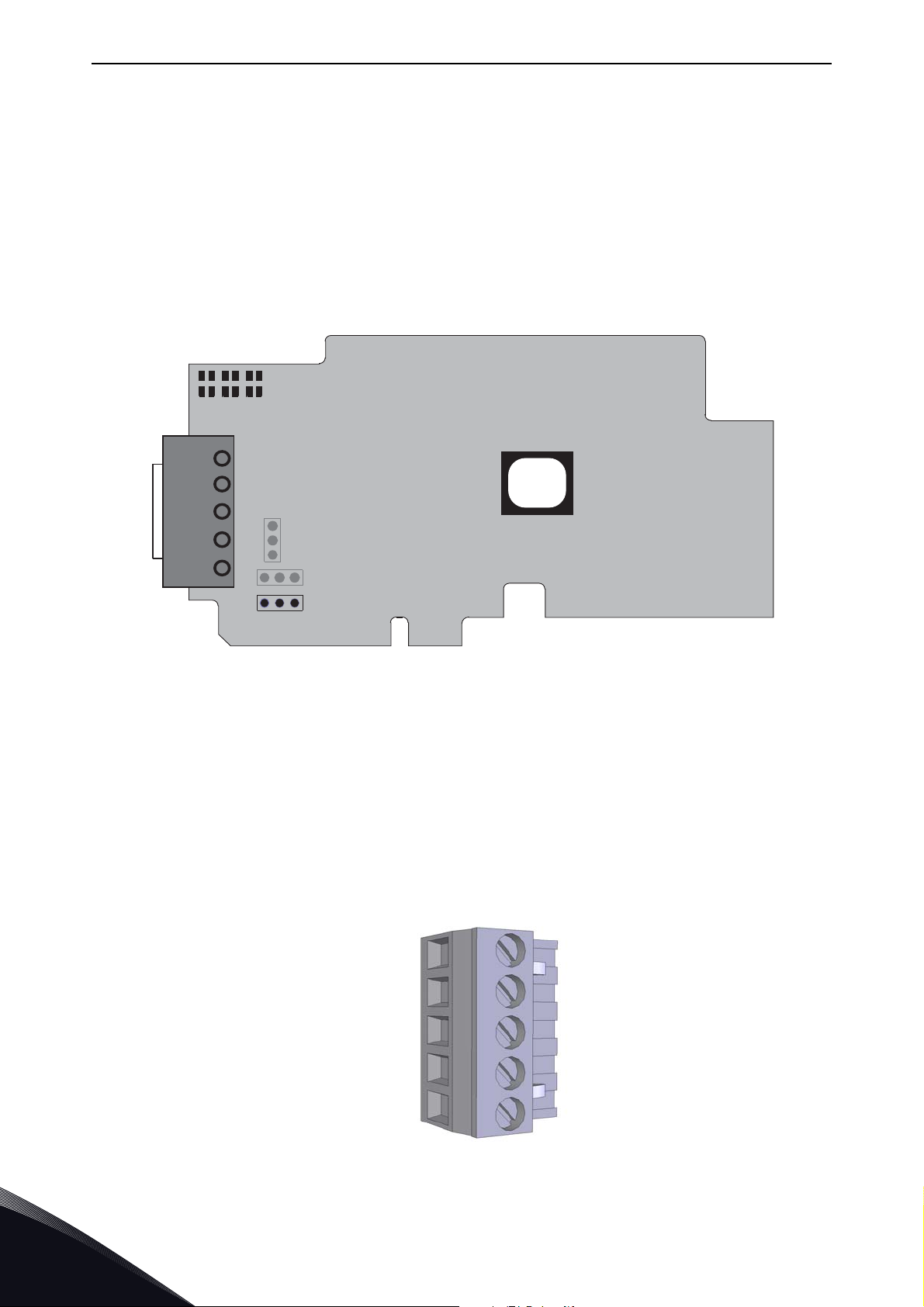

5. OPTE6 LAYOUT AND CONNECTIONS

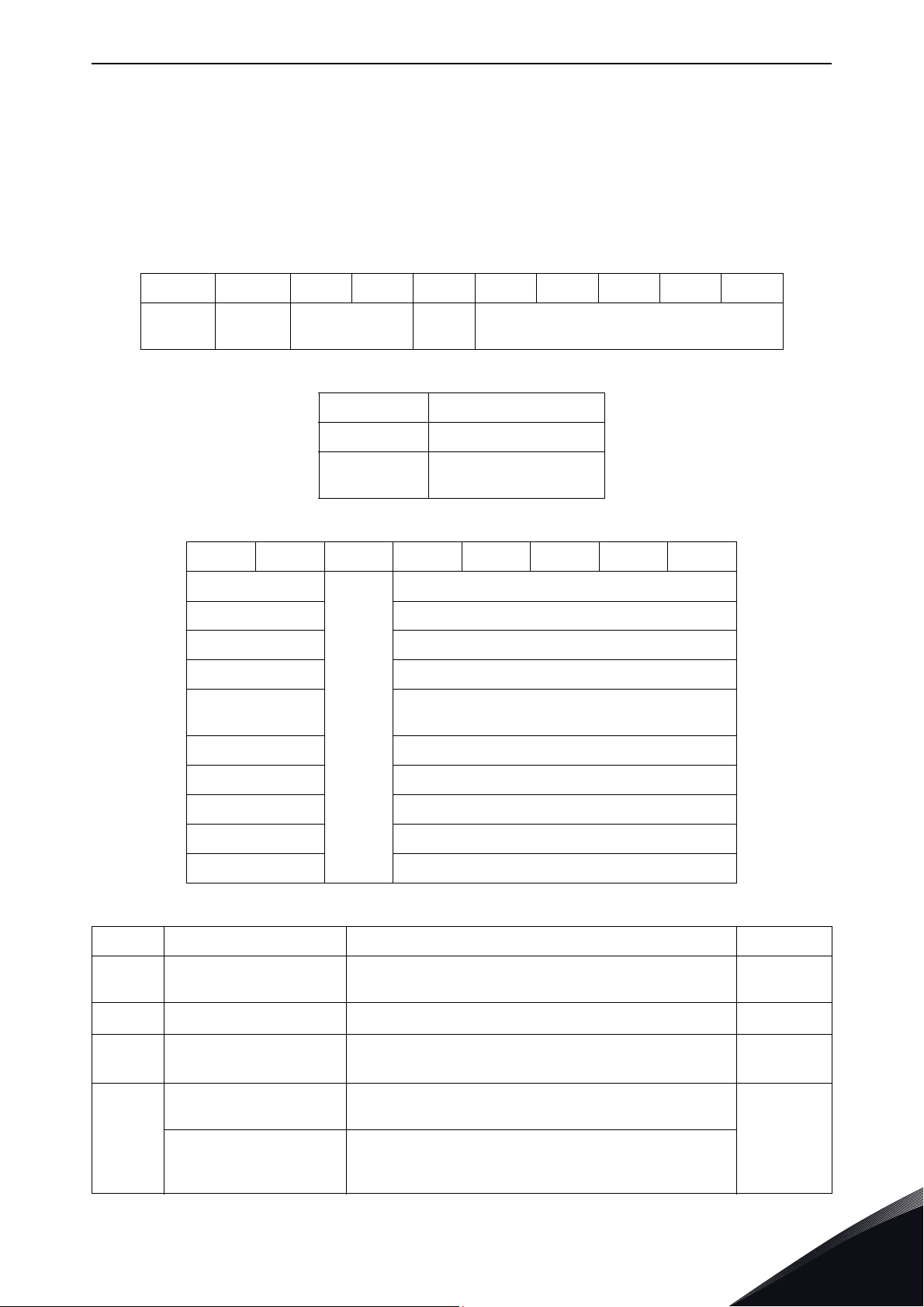

5.1 Layout and connections

OPTE6 has two different hardware revisions with slightly different layout. Layout is different in LED

arrangement and termination resistor orientation.

The two hardware revisions are marked with different product codes, and this product code can be

located from the sticker on the top side (location marked in Figure 6).

The two hardware revisions are named 70CVB01605 and 70CVB01124.

1 = CAN GND (isolated digital ground reference)

2 = CAN L

3 = SHIELD (shield connector)

4 = CAN H

5 = NC (No connection)

6 = Grounding option jumper

7= Bus termination resistor

5

Figure 6. OPTE6 board layout

Figure 7. CAN connector

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 31

OPTE6 layout and connections vacon • 31

CAN connector pinout

Pin out

1 CAN GND, isolated digital ground reference

2CAN LO

3 Shield connector

4CAN HI

5 No connection

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 32

vacon • 32 OPTE6 layout and connections

9339A_00

N A MM A N

70CVB01605 70CVB01124

5.2 LED Indications

Figure 8. LED indicators

M = CANopen run led

A = CANopen err led

N = Board status

CANopen run led (green)

LED is Description

Blinking The CANopen device is in the pre-operational state.

Single flash The CANopen device is in the stopped state.

ON The CANopen device is in the operational state.

CANopen err led (red)

LED is Description

OFF No error

Blinking Invalid configuration

Single flash

Double flash

Quadruple flash

ON The CAN controller is bus-off.

Board status led (green)

LED is Description

At least one of the error counters of the CAN controller has

reached or exceeded the warning level (too many error frames).

A guard event (NMT slave or NMT master) or a heartbeat event

(heartbeat consumer) has occurred.

An expected PDO was not received before the event timer

elapsed.

OFF Option board is not activated.

ON

Blinking (once/

1s)

Option board is in initialization state, waiting activation com-

mand from the AC drive.

Option board is activated and in RUN state. Option board is

ready for external communication.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 33

OPTE6 layout and connections vacon • 33

3

1

2

3

2

1

1

2

3

A

B

C

9341A_00

70CVB0112470CVB01605

3

1

2

3

2

1

1

2

3

A

B

C

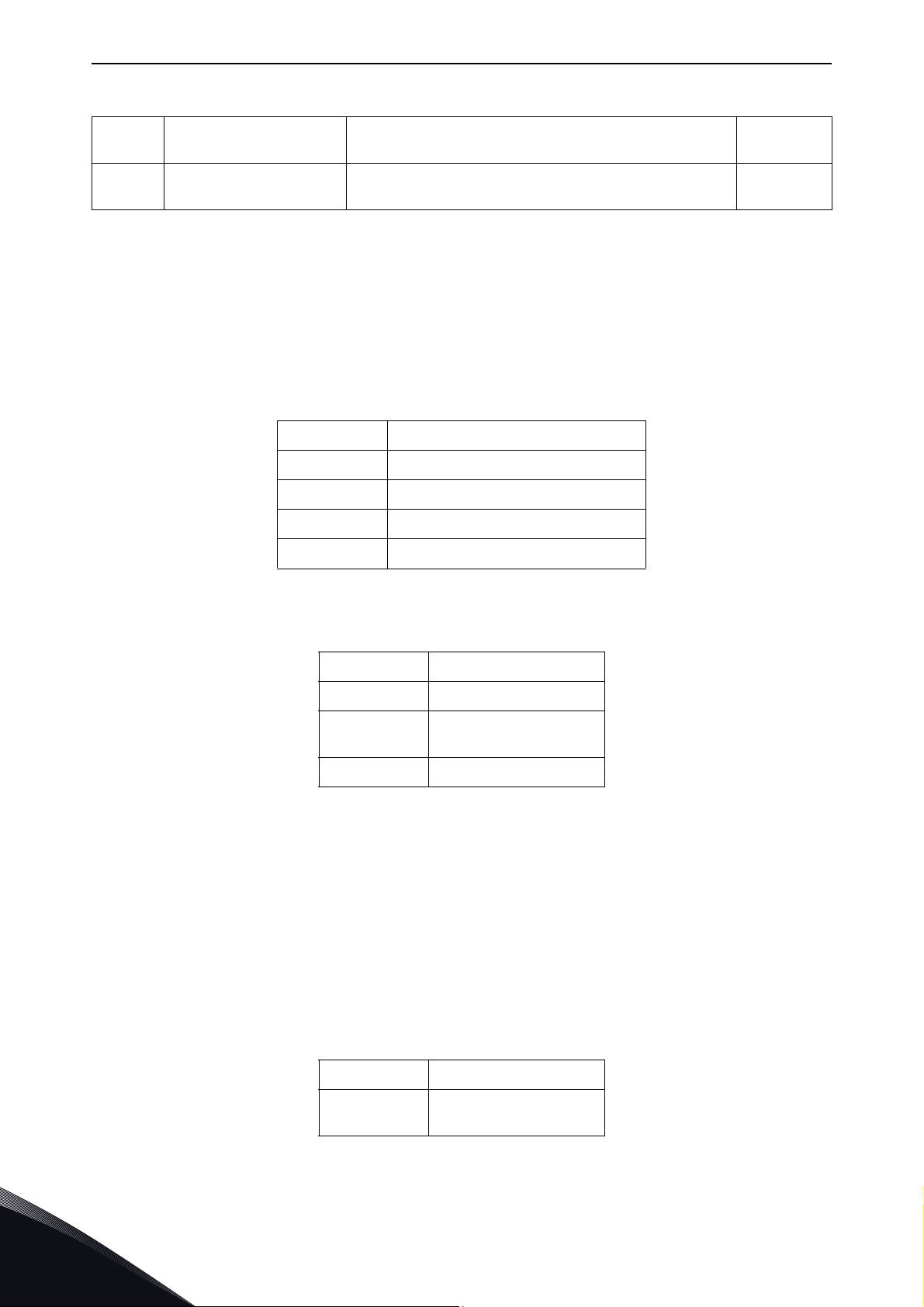

5.3 Jumpers

The termination resistor jumper location differs on used hardware version. The jumper locations

can be seen from figure below.

3

4

5

3

4

7

5

7

6

70CVB01605 70CVB01124

Figure 9. Jumper locations

The jumper (7) settings for the CAN bus termination resistor are shown in the figure below.

6

11653_00

Figure 10. CAN bus termination jumper

A = Termination resistor 120 Ohm connected

B = Termination resistor is not connected to the CAN bus. (Factory default setting)

C = Termination resistor is not connected to the CAN bus

The jumper (6) settings for the CAN cable shield grounding are shown in the figure below.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 34

vacon • 34 OPTE6 layout and connections

3

1

2

3

2

1

1

2

3

A

B

C

9342.emf

Figure 11. CAN shield grounding option

A = CAN connector pin 3 (shield) connected to the drive chassis with a high-impedance RC circuit.

Recommended option when equipotential bonding is poor.

B = CAN connector pin 3 (shield) connected directly into the drive chassis. Recommended option

when equipotential bonding is good. (Factory default setting)

C = CAN connector pin 3 is not connected.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 35

Installation vacon • 35

M4x55

9174.emf

DANGER

6. INSTALLATION

6.1 Installation in VACON® 100

Open the cover of the AC drive.

1

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when AC drive is disconnected from mains.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 36

vacon • 36 Installation

3023.emf

DE

3024.emf

Open the inner cover to reveal the option board slots (C,D,E). See Figure below.

2

3

Install the fieldbus board into slot D or E. See figure below.

NOTE: Incompatible boards cannot be installed on the AC drive. Compatible

boards have a slot coding

that enable the placing of the board.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 37

Installation vacon • 37

10

5

6.2 Prepare for use through fieldbus

Strip about 15 mm of the fieldbus cable (see specification in ch. 3.2) and cut off

the grey cable shield. Remember to do this for both bus cables (except for the

last device).

Leave no more than 10 mm of the cable outside the terminal block and strip the

cables at about 5 mm to fit in the terminals. See picture below.

4

5

Also strip the cable now at such a distance from the terminal that you can fix it to

the frame with the grounding clamp. Strip the cable at a maximum length of 15

mm. Do not strip the aluminum cable shield!

Then connect the cable to its appropriate terminals on the OPTE6 CANopen

option board terminal block.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 38

vacon • 38 Installation

Cable clamp

Using the cable clamp included in the delivery of the drive, ground the shield of

the CAN cable to the frame of the AC drive.

NOTE: This can be done in all drives if there is no difference in PE potential

between the drives. However, if there is PE potential difference then the shield

should be connected to PE only at one point in the system. The shields of the

cables shall be joint but not connected to several PE points with different potential.

6

7

8

If the AC drive is the last device on the bus, the bus termination must be set

with jumper X13 (see ch. 4.3.)

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

fieldbus cable (protection class IP21).

NOTE: Cut the opening on the same side you

have installed the board in!

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 39

Installation vacon • 39

9202.emf

Fieldbus

cables

Fieldbus cable

= Bus termination

Termination

activated

Ter min ation

activated with

jumper

Termination

deactivated

Vacon 100 Vacon 100 Vacon 100 Vacon 100 Vacon 100

3007.emf

Remount the AC drive cover and run the cable as

shown in picture.

NOTE: When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm. It is

recommended to route the option board cables

away from the power cables as shown in the picture.

9

The bus termination must be set for the first and the last device of the fieldbus

line. See picture below. See also step 7 on page 38. We recommend that the first

device on the bus and, thus, terminated was the Master device.

10

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 40

vacon • 40 Installation

11649_00

11556A_0

6.3 Installation in VACON® 20

6.3.1 Frames MI1, MI2, MI3

Remove the cable connector lid from the

AC drive.

1

11555A_00

2

3

Select a correct grounding plate and attach it to the

option board mounting frame. The grounding plate is

marked with the supported enclosure size.

Attach an option board mounting frame to

the AC drive.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 41

Installation vacon • 41

11559A_00

Connect the flat cable from the option board mounting frame to VACON® 20.

4

11557A_00

If a cable strain relief is required, attach the parts as shown in the figure.

5

6

11558A_00

Install the option board to the option board

holder. Make sure that the option board is

securely fastened.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 42

vacon • 42 Installation

11560A_00

Cut free a sufficiently wide opening for the

option board connector.

7

11650_00

Attach the option board cover to VACON®

20. Attach the strain relief cable clamp with

screws if needed.

8

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 43

Installation vacon • 43

13006.emf

11562_00

11563_00

6.3.2 Frames MI4, MI5

®

Make sure power is disconnected before opening the VACON

1a: For MI4: Open the cover.

20 cover.

11561_00

1

2

1b: For MI5: Open the cover and release the fan connector.

Attach the option board support.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 44

vacon • 44 Installation

11564_00

11565_00

Connect the flex cable to option board connector PCB.

3

Connect the option board to connector PCB.

4

5

Attach the option board with connector PCB to VACON® 20 and connect the flex

cable.

11566_00

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 45

Installation vacon • 45

MI 04

MI 05

11567_00

11568_00

Attach a suitable grounding plate to VACON® 20. The grounding plate is marked

with supported enclosure size.

6

Assemble a clamp on top of the grounding plate on both sides of the option board.

7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 46

vacon • 46 Installation

11569_00

11570_00

8a: For MI4: Close the cover.

8

8b: For MI5: Remount the fan connector and close the cover.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 47

Installation vacon • 47

13006.emf

13006.emf

6.4 Installation in VACON® 20 X and 20 CP

Do not add or replace option boards or fieldbus boards on an AC

drive with the power switched on. This may damage the boards.

Open the cover of the drive.

1

11643_00

MU3 example

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the drive is disconnected from mains.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 48

vacon • 48 Installation

7089_00

7090_00

7091_007091_00

Remove the option slot cover.

2

Install the option board into the slot as shown in the figure.

3

4

Mount the option slot cover. Remove the plastic opening for the option board terminals.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 49

Installation vacon • 49

11638_00

6.5 Installation in VACON® 100 X (Frames MM4-MM6)

Open the cover of the AC drive.

1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 50

vacon • 50 Installation

11639_00

To get access to the option board slots, remove the screws and open the cover of

the control unit.

2

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 51

Installation vacon • 51

11641_00

Install the option board into the correct slot, D or E.

DE

3

4

5

11640_00

Close the option board cover.

Remove the cable entry plate. If you

installed the option board in the slot

D, use the cable entry plate on the

right side. If you installed the option

board in the slot E, use the cable entry plate on the left side.

NOTE! The cable entry plate at the

bottom of the drive is used only for

mains and motor cables.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 52

vacon • 52 Installation

6

7

Open the necessary holes in the cable entry plate. Do not open the other holes.

See the VACON

Attach a cable gland on the hole in the cable entry plate. Pull the fieldbus cable

through the hole.

NOTE! The fieldbus cable must go through

the correct cable entry plate to avoid going

near the motor cable.

®

100 X Installation Manual for the dimensions of the holes.

11642_00

8

9

Put the cable entry plate back.

Close the cover of the AC drive.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 53

Commissioning vacon • 53

7. COMMISSIONING

This chapter describes how to commission the OPTE6 board for use. For instructions on how to setup the AC drive to be controlled over fieldbus, refer to Chapter 11 Appendix B - Fieldbus parametrization.

7.1 OPTE6 panel parameters

Different number of panel parameters are visible depending on the used AC drive and version. VA-

®

CON

20 family option board parameters are under SYS menu.

Table 53. OPTE6 board basic parameters

Panel code

#

VACON® 100

family

VACON® 20

family

Parameter Min Max Default Description

1 P5.x.3.1 P2.2 Node ID 1 127 1

2 P5.x.3.2 P2.3 Baud Rate 3 8 5

3 P5.x.3.3 P2.4 Operate Mode 1 4 1

5 P5.x.3.4* -

6 P5.x.3.5* -

7 P5.x.3.6* - Mode 0 1 0 Set OPTE6 mode. See Table 56

* From version V26 (INDUSTRIAL) and V18 (FLOW)

Table 54. OPTE6 Baud Rate settings

Comm.

Timeout

Restore from

Set

0 65535 1

01 0

Network-wide unique identifier

for each CANopen device

Data signalling rate. Should be

the same on each node in the

same bus. See Table 54

Selection between OPTE6 operate

modes. See Table 55

Timeout in seconds for CAN

communication faults (PASSIVE,

BUS-OFF)

0'1 All CANopen parameters are

reset to default values based on

Operate Mode.

Value Bit rate

1 10 kbps (not supported)

2 20 kbps (not supported)

3 50 kbps

4100 kbps

5125 kbps

6250 kbps

7500 kbps

8 1000 kbps

Table 55. OPTE6 Operate Mode settings

Value Name Description

1 Drive Profile CiA-402 drive profile, velocity mode active

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 54

vacon • 54 Commissioning

Table 55. OPTE6 Operate Mode settings

Value Name Description

2Bypass

3Puller*

4 Co-Extruder*

*Restricted availability, requires use of special application

VACON

CiA-420 EUROMAP profile, puller mode

active

CiA-420 EUROMAP profile, co-extruder

mode active

®

specific bypass mode active

Baud Rate: used in CANopen communication. Regardless of the selected bitrate, the bit sample

timing is set as close as possible to 87.5 % according to the CANopen specification.

Operate Mode: is used to change the modes of operation between standardized profile modes and

VACON

®

specific Bypass mode.

Different operate modes activate different device profile segment objects. Accessing e.g. CiA-402

velocity profile objects in Bypass mode is not possible. See Chapter 8.2 Velocity mode and Chapter

8.3 Bypass mode.

Comm. Timeout: Fieldbus communication timeout is time in seconds after a fault is created from

CAN bus communication errors (PASSIVE, BUS-OFF). Setting this value to 0 disables CAN bus errors from triggering a fault in AC drive. This does not affect other CANopen faults, e.g. heartbeat

consumer times. This value is the same as object 0x2004 - Communication timeout. See conditions

when fieldbus communication timeout is activated in Chapter 9.2 Fieldbus timeout fault (F53).

Table 56. OPTE6 Mode settings

Value Description Details

0Normal

Anyparameter service behaves same

®

1Pre V008

as version 7 and earlier in VACON

100 family devices. See Chapter 8.5 for

more details.

Mode: compatibility mode(s) can be activated using this parameter. This parameter is the same as

object 0x2005 - Mode.

7.1.1 OPTE6 additional panel parameters

®

From VACON

100 (INDUSTRIAL V027 and FLOW V018) and OPTE6 V009 firmware version forwards,

CANopen bus communication parameters are stored and can also be modified directly from panel

parameters. The stored parameters are modifiable and stored under the "Parameters" menu and

these parameters are restored after power cycle. The active settings are visible under the "Monitor"

menu.

These parameters are separated into sub-folders for easier modification. It is recommended to use

VACON

®

Live PC-tool to modify the parameters.

General Heartbeat RPDO1 Communication RPDO2 Communication

7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 55

Commissioning vacon • 55

Table 57. OPTE6 board CANopen object parameters under General folder

Panel Code

VACON® 100

5.x.3.6.1 COB-ID SYNC 0x80 3.7.4

5.x.3.6.2 Guard Time 0 3.7.5

5.x.3.6.3 Life Time Factor 0 3.7.6

5.x.3.6.4 COB-ID EMCY 0x80 + Node ID 3.7.7

5.x.3.6.5 Sync Counter Ovf. 0 3.7.11

5.x.3.6.6 Error Behaviour 0 3.7.12

5.x.3.7.1 Producer Time 0 3.7.9

5.x.3.7. Consumer Time 1 0

5.x.3.7.3 Consumer Time 2 0

5.x.3.7.4 Consumer Time 3 0

5.x.3.7.5 Consumer Time 4 0

5.x.3.7.6 Consumer Time 5 0

5.x.3.7.7 Consumer Time 6 0

5.x.3.7.8 Consumer Time 7 0

Parameter Default Reference

3.7.8

5.x.3.7.9 Consumer Time 8 0

5.x.3.8.1 COB-ID 0x200 + Node ID 3.5.2

5.x.3.8.2 Transmission Type 0xFE

3.5.35.x.3.8.3 Inhibit Time 0

5.x.3.8.4 Event Timer 0

5.x.3.9.1 COB-ID 0x80000300 + Node ID 3.5.2

5.x.3.9.2 Transmission Type 0xFE

3.5.35.x.3.9.3 Inhibit Time 0

5.x.3.9.4 Event Timer 0

5.x.3.10.1 COB-ID 0x80000400 + Node ID 3.5.2

5.x.3.10.2 Transmission Type 0xFE

3.5.35.x.3.10.3 Inhibit Time 0

5.x.3.10.4 Event Timer 0

5.x.3.11.1 Number of Entries 2

5.x.3.11.2 1

5.x.3.11.3 2

5.x.3.11.4 3

5.x.3.11.5 4

st

Application Obj. 0x60400010

nd

Application Obj. 0x60420010

rd

Application Obj. 0

th

Application Obj. 0

3.5.4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 56

vacon • 56 Commissioning

Table 57. OPTE6 board CANopen object parameters under General folder

Panel Code

VACON® 100

Parameter Default Reference

5.x.3.12.1 Number of Entries 4

st

5.x.3.12.2 1

5.x.3.12.3 2

5.x.3.12.4 3

5.x.3.12.5 4

Application Obj. 0x20000410

nd

Application Obj. 0x20000510

rd

Application Obj. 0x20000610

th

Application Obj. 0x20000710

5.x.3.13.1 Number of Entries 4

5.x.3.13.2 1

5.x.3.13.3 2

5.x.3.13.4 3

5.x.3.13.5 4

st

Application Obj. 0x20000810

nd

Application Obj. 0x20000910

rd

Application Obj. 0x20000A10

th

Application Obj. 0x20000B10

5.x.3.14.1 COB-ID 0x180 + Node ID 3.5.2

5.x.3.14.2 Transmission Type 0xFE

5.x.3.14.3 Inhibit Time 100

5.x.3.14.4 Event Timer 0

3.5.4

3.5.4

3.5.3

5.x.3.14.5 Sync Start Value 0

5.x.3.15.1 COB-ID 0x80000280 + Node ID 3.5.2

5.x.3.15.2 Transmission Type 0xFE

5.x.3.15.3 Inhibit Time 1000

3.5.3

5.x.3.15.4 Event Timer 0

5.x.3.15.5 Sync Start Value 0

5.x.3.16.1 COB-ID 0x80000380 + Node ID 3.5.2