Page 1

user's manual

nxl frequency converters

alfiff28

nxl lift application

application manual

Page 2

2 • vacon

NXL Lift Application (Software ALFIFF28) Version 2.03 or higher

INDEX

1. Introduction ....................................................................................................................... 3

2. Control I/O ......................................................................................................................... 4

3. Lift Application – Parameter lists ......................................................................................5

3.1 Monitoring values (Control keypad: menu M1).......................................................................... 5

3.2 Motor Parameters (Control keypad: Menu P2 Æ P2.1)............................................................. 6

3.3 Speed control (Control keypad: Menu P2 Æ P2.2) .................................................................... 6

3.4 Mechanical Brake control parameters (Control keypad: Menu M2 Æ P2.3)............................ 7

3.5 Drive Control (Control keypad: Menu M2 Æ P2.4)..................................................................... 8

3.6 Motor control parameters (Control keypad: Menu P2 Æ P2.5) ................................................ 8

3.7 Input Signals (Control keypad: Menu P2 Æ P2.6)...................................................................... 9

3.8 Output signals (Control keypad: Menu P2 Æ P2.7) ................................................................. 10

3.9 Protections (Control keypad: Menu P2 Æ P2.8) ...................................................................... 11

3.10 Autorestart parameters (Control keypad: Menu P2 Æ P2.9).................................................. 12

3.11 Keypad control (Control keypad: Menu K3) ............................................................................. 12

3.12 System menu (Control keypad: Menu S6)................................................................................ 12

3.13 Expander boards (Control keypad: Menu E7) .......................................................................... 12

Document code: ud00973C

Date 30.5.2006

4. Description of parameters ............................................................................................... 13

2.1 MOTOR PARAMETERS.............................................................................................................. 13

2.2 SPEED CONTROL...................................................................................................................... 14

2.3 MECHANICAL BRAKE CONTROL ............................................................................................. 18

2.4 DRIVE CONTROL ....................................................................................................................... 24

2.5 MOTOR CONTROL..................................................................................................................... 25

2.6 INPUT SIGNALS ........................................................................................................................ 28

2.7 OUTPUT SIGNALS..................................................................................................................... 30

2.8 PROTECTIONS........................................................................................................................... 33

2.9 AUTO RESTART PARAMETERS ................................................................................................ 39

2.10 KEYPAD CONTROL PARAMETERS ........................................................................................... 40

2.11 CONTROL SIGNALS IN LIFT APPLICATION ............................................................................. 41

2.12 FAULT TRACING ....................................................................................................................... 42

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 3

Introduction vacon • 3

lift application for nxl

1. INTRODUCTION

The NXL Lift Application can be used with modern Lift systems. There are functions included that

are required to achieve a smooth ride in the lift car. The I/O interface table includes the most

commonly needed signals in lift applications.

In the application, constant speeds are presented in [m/s], acceleration and deceleration are

presented in [m/s

Mechanical brake control logic is designed to achieve smooth departures from and landings to

floor level. The brake can be set in various ways to meet the different requirements of lift motors

and lift control logic.

The used hardware can be any Vacon NXL frequency converter.

NXL supports only open loop operation.

Evacuation is not supported by NXL.

Choose NXS or NXP if evacuation is required.

All outputs are freely programmable. The inputs DIN3, DIN4 (AI1) and DIN5 (AI2) are also freely

programmable.

Start forward and reverse signals are fixed to input DIN1 and DIN2 (see next page).

An Expander board, OPT-AA will be needed to get the external inputs signals DIE1-DIE3.

These are as default settings used as speed reference selection inputs when digital inputs are

used as speed reference inputs. The relay output on this board (or the internal R01) can be used

for mechanical brake control.

It is possible to run without OPT-AA if DIN3, DIN4 and DIN5 are programmed as speed references.

But then there is no input signal available for other functions such as fault reset.

OPT-AI can be used in place of OPT-AA if thermistor input is needed.

OPT-AI is similar to OPT-AA board but the transistor output DO1 is not available on this board.

2

] and jerks are presented in [s].

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 4

4 • vacon Control I/O

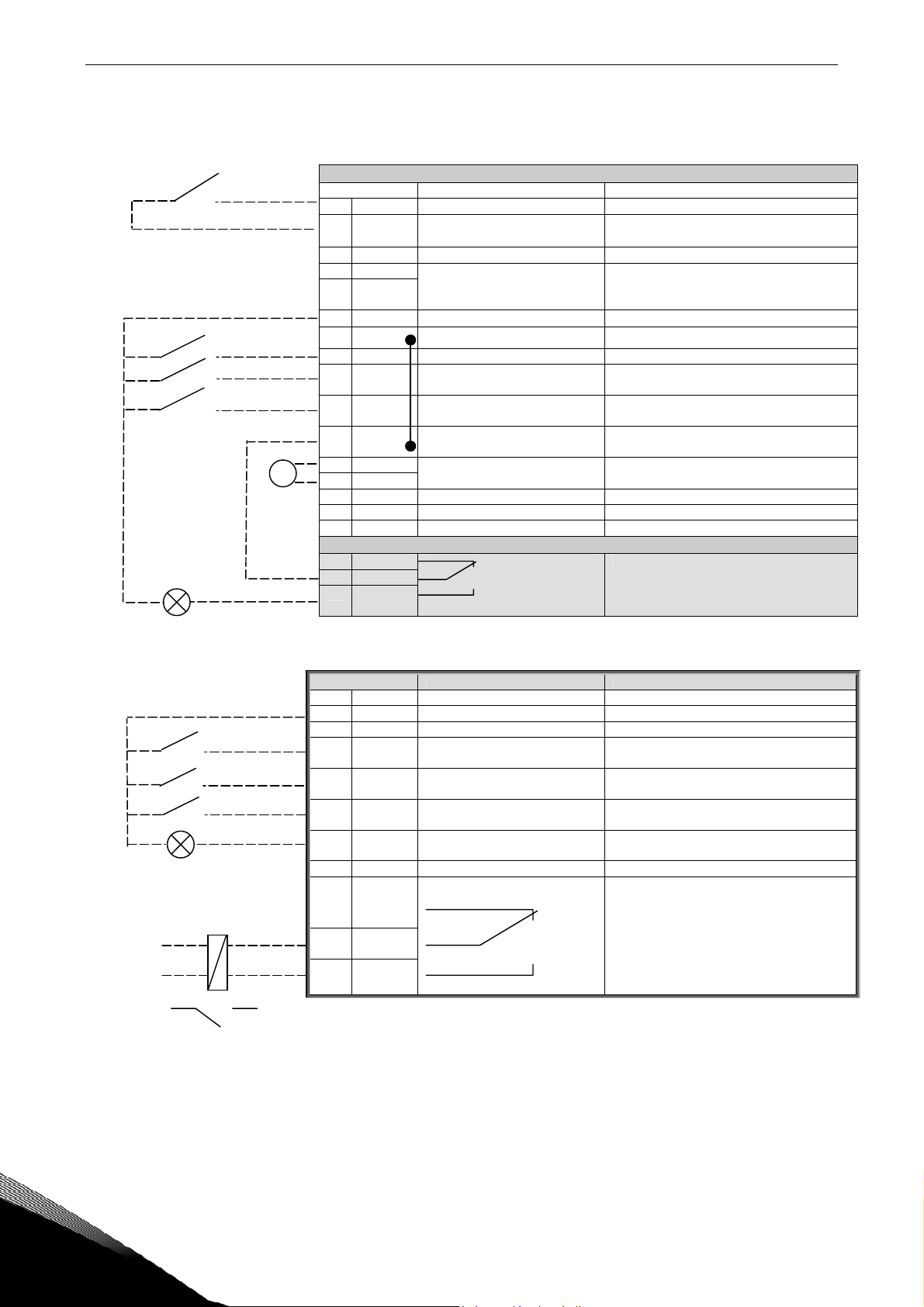

2. CONTROL I/O

NXL internal I/O board

Terminal Signal Description

1 +10V

AI1+

DIN4

3 AI1- I/O Ground Ground for reference and controls

4 AI2+

5 AI2-

/GND

6 +24V Control voltage output Voltage for switches, etc. max 0.1 A

7 GND

8 DIN1 Start forward (programmable) Contact closed = start forward

9 DIN2 Start reverse (programmable) Contact closed = start reverse

10 DIN3 Fault Reset

11 GND I/O ground Ground for reference and controls

Reference output Voltage for potentiometer, etc.

ref

Analogue input, voltage range

0—10V DC.

Analogue input, voltage range

0—10V DC, or current range

0/4—20mA

I/O ground Ground for reference and controls

(programmable)

Voltage input

Used as digital input DIN4

Used as digital input DIN5

Contact open = No Reset

Contact closed = Reset

220

VAC

mA

18 AO1+

19 AO1-

A RS 485 Serial bus Differential receiver/transmitter

B RS 485 Serial bus Differential receiver/transmitter

30 +24V 24V aux. input voltage Control power supply backup

Output frequency

Analogue output

Programmable. Can be used as DO2

Range 0—20 mA/R

, max. 500Ω

L

21 RO1

22 RO1

23 RO1

Relay output 1

RUN

Programmable

Table 2-1. Lift application default I/O configuration.

I/O terminals on option board OPT-AA

Terminal Signal in application Description

X3

1 +24V Control voltage output Voltage for switches etc, max. 150 mA

2 GND I/O ground Ground for reference and controls

3 DIN1 DIE1 Speed reference selection

4 DIN2 DIE2 Speed reference selection

5 DIN3 DIE3 Speed reference selection

6 DO1 Exp. D01, Ready Open collector output, 50mA/48V,

X5

24 RO1

25 RO1

26 RO1

Exp R01, Mechanical brake Relay output 1 (NO),

(programmable)

(programmable)

(programmable)

programmable

function programmable

Switching capacity:

24VDC/8A

250VAC/8A

125VDC/0,4A

Table 2-2. I/O terminals of option board NXOPTAA

Note! The +24 V control voltage terminal can also be used to power the control module (but not the

power module).

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 5

Lift Application – Parameter lists vacon • 5

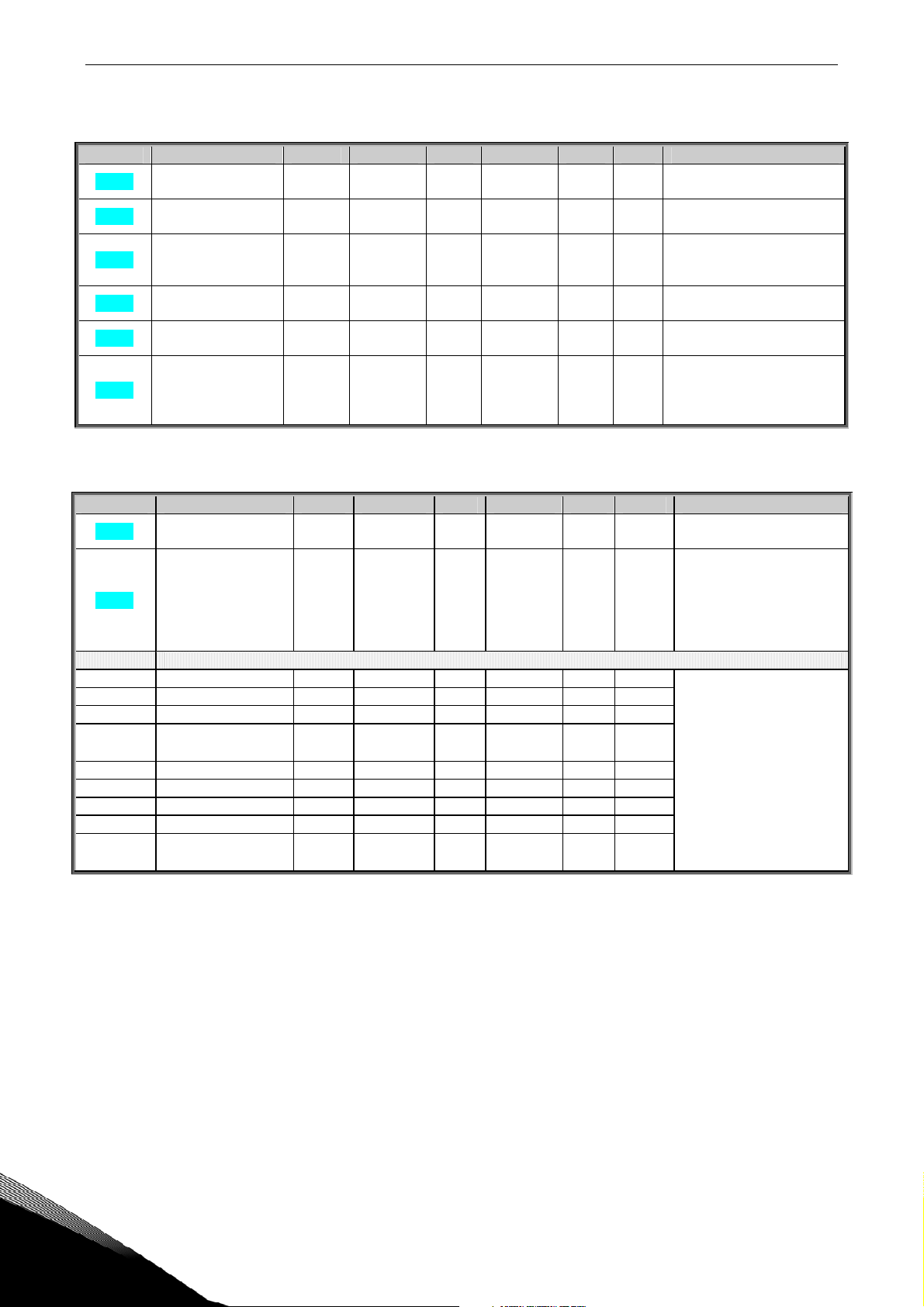

3. LIFT APPLICATION – PARAMETER LISTS

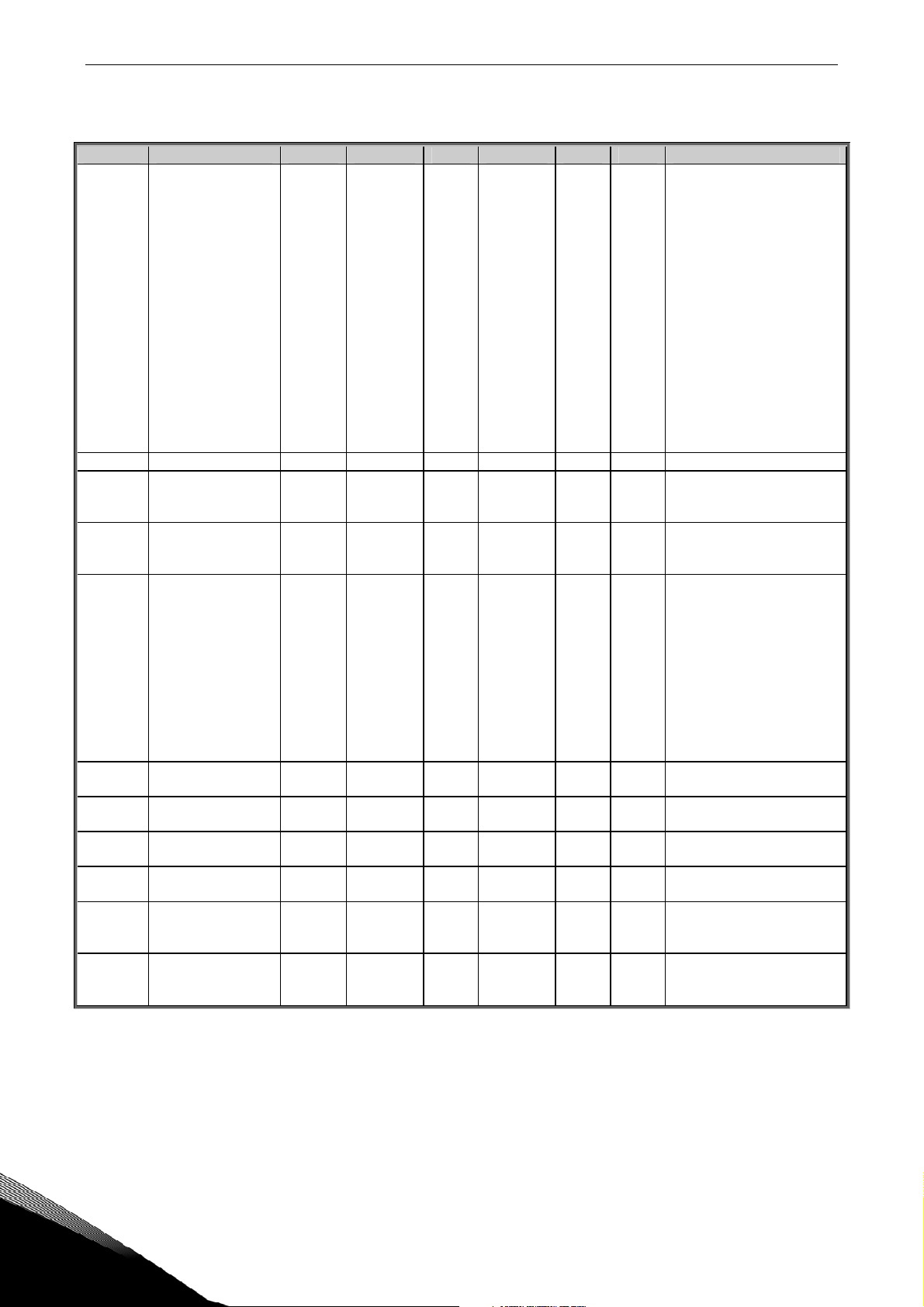

On the next pages you will find the lists of parameters within the respective parameter groups. The

parameter descriptions are given on pages 13 to 40.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present param.

Number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust = Customer’s own setting

ID = ID number of the parameter (used with PC tools)

= On the parameter code: parameter value can only be changed after the FC has

been stopped.

3.1 Monitoring values (Control keypad: menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses and

measurements. Monitoring values cannot be edited.

See Vacon NXL User’s Manual, Chapter 7.4.1 for more information.

Code Parameter Unit ID Description

V1.1 Output frequency Hz 1 Output frequency to motor

V1.2 Frequency reference Hz 25 Frequency reference to motor control

V1.3 Motor speed rpm 2 Motor speed in rpm

V1.4 Motor current A 3 Measured motor current

V1.5 Motor torque % 4 In % of the nominal motor torque

V1.6 Motor power % 5 Motor shaft power

V1.7 Motor voltage V 6 Calculated motor voltage

V1.8 DC link voltage V 7 Measured DC-link voltage

V1.9 Unit temperature

V1.10 Analogue input 1

V1.11 Analogue input 2 14 AI2, used as digital input DIN5

V1.12 Analogue I

V1.13 DIN1, DIN2, DIN3 15 Digital input statuses

V1.14 DIE1, DIE2, DIE3 33 I/O Expander board: Digital input statuses

V1.15 RO1, ROE1, DOE1 1720 Relay and digital output statuses

V1.16 Lift Speed m/s 1719 Lift speed in m/s

mA 26 AO1

out

°C

8 Heatsink temperature

13 AI1, used as digital input DIN4

Table 3-1. Monitoring values

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 6

6 • vacon Lift Application – Parameter lists

3.2 Motor Parameters (Control keypad: Menu P2 Æ P2.1)

Code Parameter Min Max Unit Default Cust ID Note

P2.1.1

P2.1.2

P2.1.3

P2.1.4

P2.1.5

P2.1.6 Current limit 0,1 x IL 1,5 x IL A IL

Nominal voltage of

the motor

Nominal frequency

of the motor

Nominal speed of the

motor

Nominal current of

the motor

Motor cosϕ

180 690 V

0,00 320,00 Hz 50,00

0 20 000 Rpm rpm

0,3 x IL 1,5 x IL A IL

0,30 1,00 0,85

NXL2:230V

NXL5:400V

110

Check the rating plate of

111

the motor

The default applies for a 4-

112

pole motor and a nominal

size frequency converter.

Check the rating plate of

113

the motor

Check the rating plate of

120

the motor

NOTE: Formulas apply

approx. up to MF3. For

107

greater sizes consult the

factory.

Table 1-2. Motor parameters P2.1

3.3 Speed control (Control keypad: Menu P2 Æ P2.2)

Code Parameter Min Max Unit Default Cust ID Note

P2.2.1

P2.2.2

P2.2.3.x Speed Reference [m/s]

P2.2.3.1 Levelling Speed 0,00 par2.2.1 m/s 0,10 1602

P2.2.3.2 Nominal Speed 0,00 par2.2.1 m/s 1,00 1603

P2.2.3.3 Limited Speed 0,00 par2.2.1 m/s 0,25 1604

P2.2.3.4 Inspection Speed 0,00

P2.2.3.5 Speed Reference 4 0,00 par2.2.1 m/s 0,10 1606

P2.2.3.6 Speed Reference 5 0,00 par2.2.1 m/s 1,00 1607

P2.2.3.7 Speed Reference 6 0,00 par2.2.1 m/s 0,25 1608

P2.2.3.8 Speed Reference 7 0,00 par2.2.1 m/s 0,50 1609

P2.2.3.9 Override speed 0,00

Nominal Linear

Speed

Speed Reference

Selection

0,20 5,00 m/s 1,00

0 4 0

1,5 x

par2.2.1

1,5 x

par2.2.1

m/s 0,50

m/s 0,10

1600 Nominal speed for lift

1601

1605

1610

0=Activity Reference

1=Activity Reference with

direction

2=Binary reference

3=Fieldbus

4=Keypad

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 7

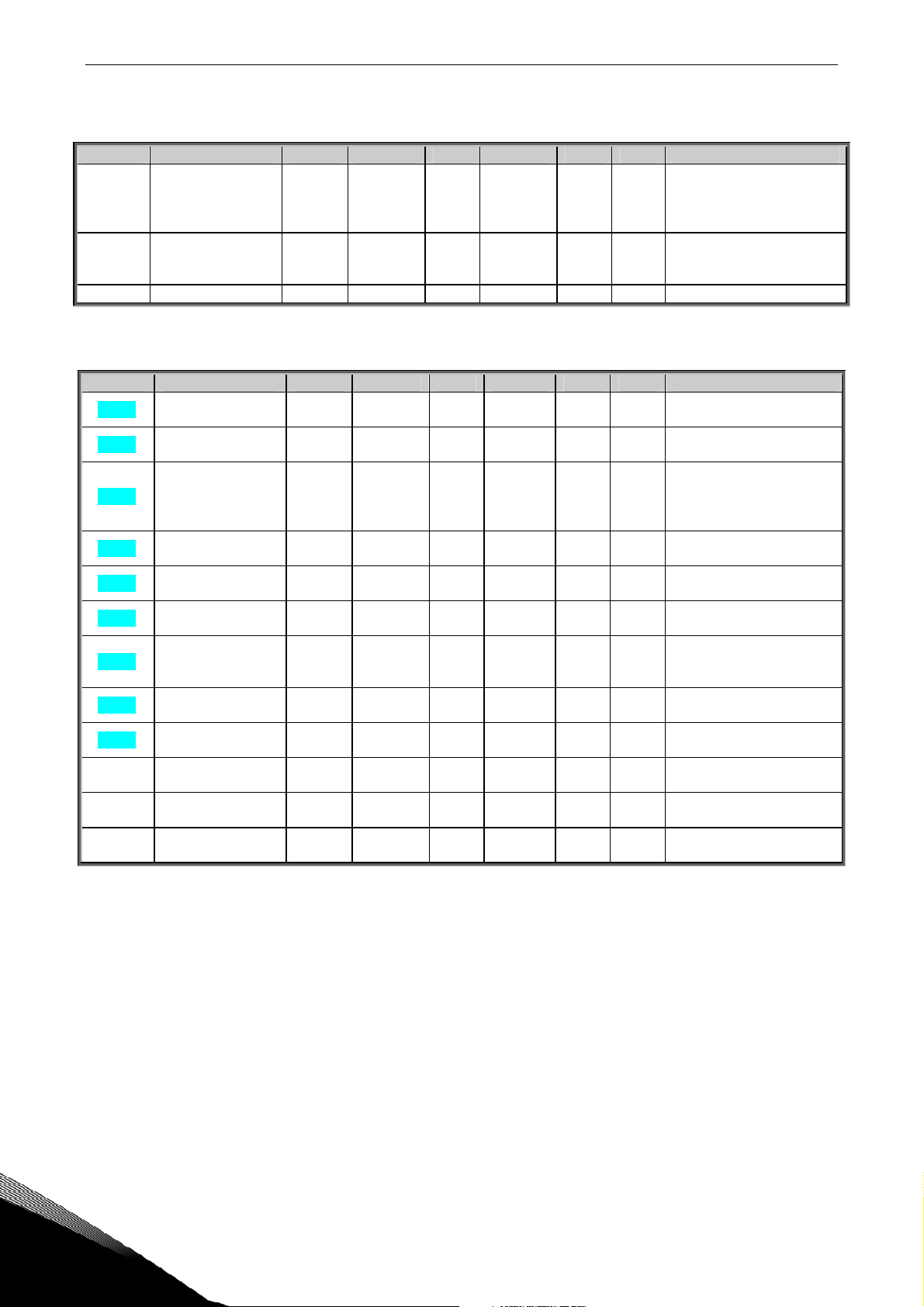

Lift Application – Parameter lists vacon • 7

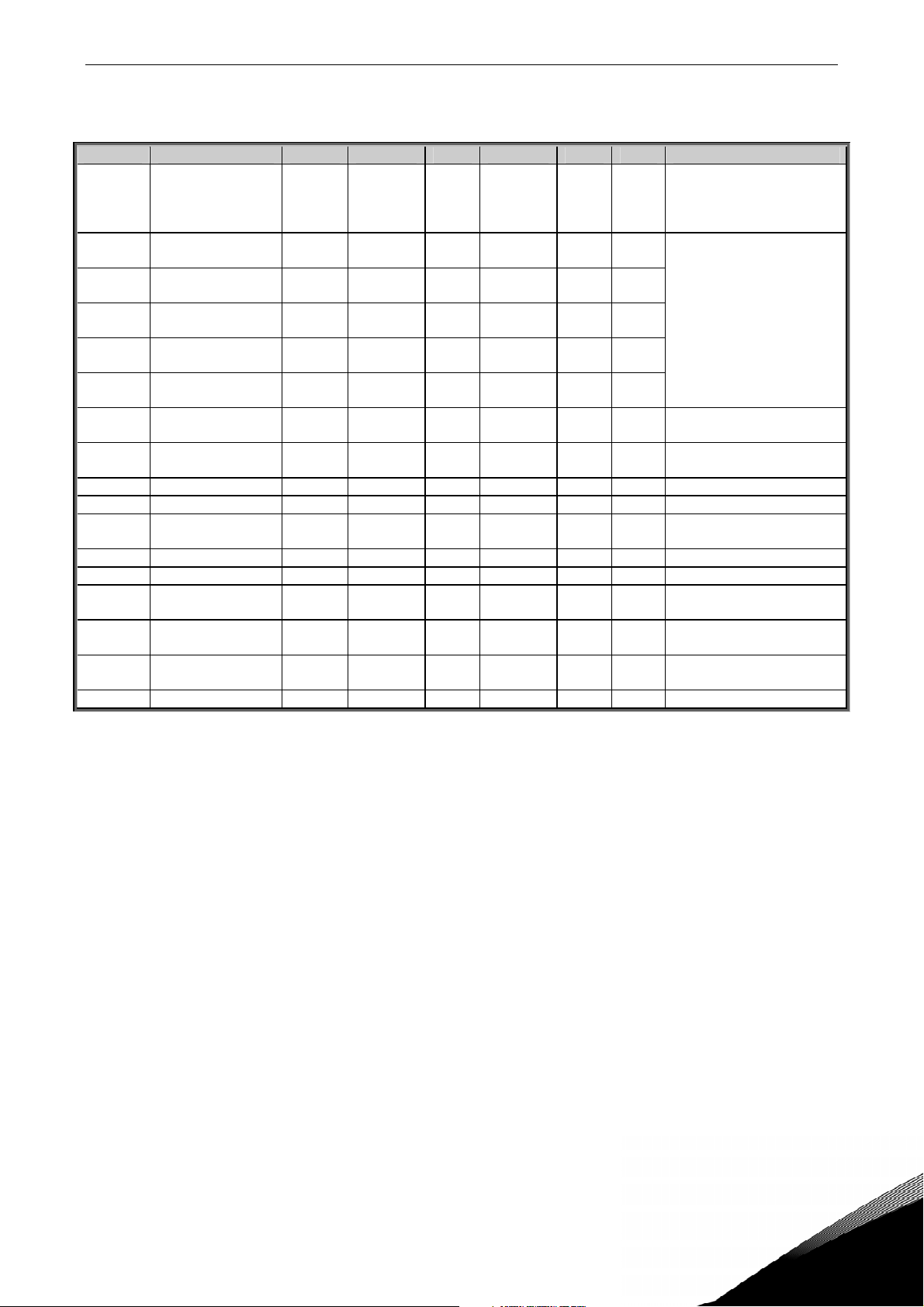

Code Parameter Min Max Unit Default Cust ID Note

P2.2.4.x SPEED CURVE 1

P2.2.4.1 Acceleration 1 0,20 2,00 m/s2 0,70 103

P2.2.4.2 Deceleration 1 0,20 2,00 m/s2 0,70 104

P2.2.4.3

P2.2.4.4

P2.2.4.5

P2.2.4.6

P2.2.5.x SPEED CURVE 2

P2.2.5.1

P2.2.5.2 Acceleration 2 0,20 2,00 m/s2 0,20 1711

P2.2.5.3 Deceleration 2 0,20 2,00 m/s2 0,20 1712

P2.2.5.4

P2.2.5.5

P2.2.5.6

P2.2.5.7

Acceleration increase

jerk 1

Acceleration

Decrease jerk 1

Deceleration increase

jerk 1

Deceleration

decrease jerk 1

Internal Ramp

Switch

Acceleration increase

jerk 2

Acceleration

decrease jerk 2

Deceleration increase

jerk2

Deceleration

decrease jerk 2

0,01 3,00 S 0,50

0,01 3,00 S 0,25

0,01 3,00 S 0,25

0,01 3,00 S 0,50

0 MaxFreq Hz 0

0,01 3,00 S 0,50

0,01 3,00 S 0,50

0,01 3,00 S 0,50

0,01 3,00 S 0,50

1611

1612

1613

1614

1710

1713

1714

1715

1716

Table 3-3. Speed control parameters P2.2

3.4 Mechanical Brake control parameters (Control keypad: Menu M2 Æ P2.3)

Code Parameter Min Max Unit Default Cust ID Note

G2.3.1.x

P2.3.1.1 Current limit FWD 0 par2.1.4 A 0 1700

P2.3.1.2 Current limit REV 0 par2.1.4 A 0 1701

P2.3.1.3 Torque limit FWD 0 100,0 % 30 1702

P2.3.1.4 Torque limit REV 0 100,0 % 30 1703

P2.3.1.5 Frequency limit FWD 0 par2.1.2 Hz 1,00 1704

P2.3.1.6 Frequency limit REV 0 par2.1.2 Hz 1,00 1705

P2.3.1.7 Brake Open Delay 0 10,00 s 0,15 1706

P2.3.1.8 MecBr React Time 0 10,0 s 0,05

P2.3.1.9 MaxFreqBrClosed 0 MaxFreq Hz 4,0

G2.3.2.x

P2.3.2.1 Freq. Limit close 0,01 par2.1.2 Hz 2,00

P2.3.2.2 Brake close delay 0 10,0 s 0,0 1708

OPENING BRAKE

CLOSING BRAKE

1622

1621

1707

Mechanical brake

physical reaction time

Maximum allowed

frequency reference

when brake is closed

Frequency limit for

closing brake when

stopping

Table 3-4. Mechanical brake control parameters G2.3.

G2.3.3.x

P2.3.3.1 DC brake current

P2.3.3.2 Start DC-brake time 0 600,00 S 1,00 1750 0=DC brake is off at start

P2.3.3.3 Stop DC-brake time 0 600,00 S 1,00 1717 0=DC brake is off at stop

P2.3.3.4

DC BRAKE

Stop DC-brake

frequency

MinCurr

ent

0,10 10,00 Hz 3,00

1,5 x IN A Varies

1740

515

Table 3-5. DC brake control parameters G2.3.3

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 8

8 • vacon Lift Application – Parameter lists

3.5 Drive Control (Control keypad: Menu M2 Æ P2.4)

Code Parameter Min Max Unit Default Cust ID Note

P2.4.1 Brake chopper 0 3 1

0=Disabled

1=Used in Run state

504

2=Used in Run state

3=Ready

P2.4.2 Stop Function 0 2 2

506

0=Coasting

1=Ramping

2=Stop type by Freq. Limit

P2.4.3 Frequency limit 0 MaxFreq Hz 5,00 1623 Used only if par 4.2=2

Table 3-6. Drive control parameters P2.4

3.6 Motor control parameters (Control keypad: Menu P2 Æ P2.5)

Code Parameter Min Max Unit Default Cust ID Note

P2.5.1 Motor control mode 0 1 1

P2.5.2 U/f Optimization 0 1 0

P2.5.3 U/f ratio selection 0 3 0

0=Frequency control

600

1=Speed control

0=None

109

1=Automatic torque boost

0=Linear

1=Squared

108

2=Programmable

3=Linear with flux optim.

P2.5.4

P2.5.5

P2.5.6

P2.5.7

P2.5.8

P2.5.9 Switching frequency 1,0

P2.5.10

P2.5.11

Field weakening

point

Voltage at field

weakening point

U/f curve midpoint

frequency

U/f curve midpoint

voltage

Output voltage at

zero frequency

Overvoltage

controller

Undervoltage

controller

30,00 320,00 Hz 50,00

10,00 200,00 % 100,00

0,00

par.

P2.5.4

Hz 50,00

0,00 100,00 % 100,00

0,00 40,00 % 0,00

Max

SwFreq.

KHz 6,0

0 1 0

0 1 0

P2.5.12 Meas.RsVolt Drop 0 10000

602

603 n% x U

604

n% x U

605

Parameter max. value =

par. 2.5.5

606 n% x U

601 Depends on kW

1721

0=Not used

607

1=Used

0=Not used

608

1=Used

Measured Voltage drop at

stator resistance

nmot

nmot

nmot

Table 3-7. Motor control parameters P2.5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 9

Lift Application – Parameter lists vacon • 9

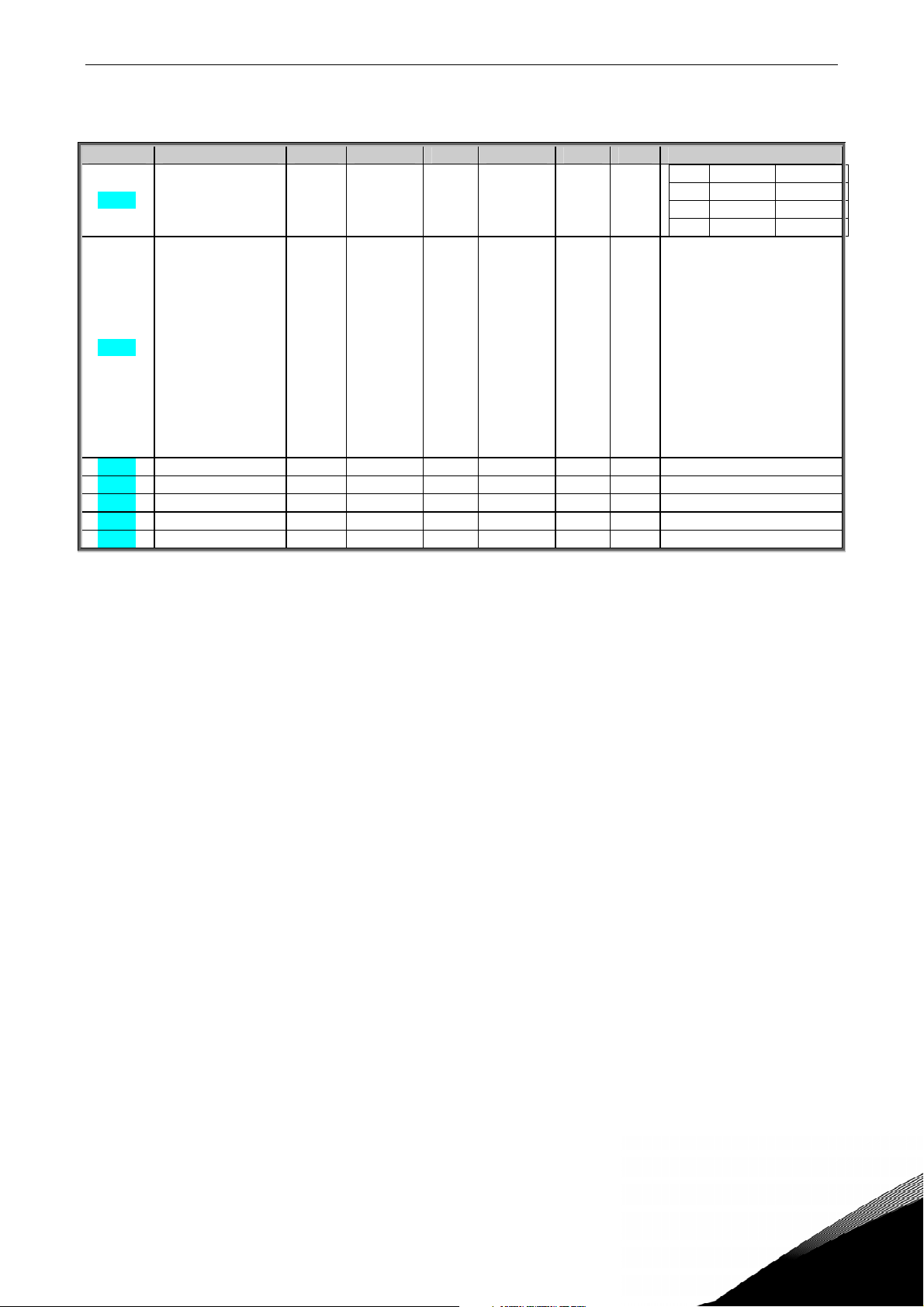

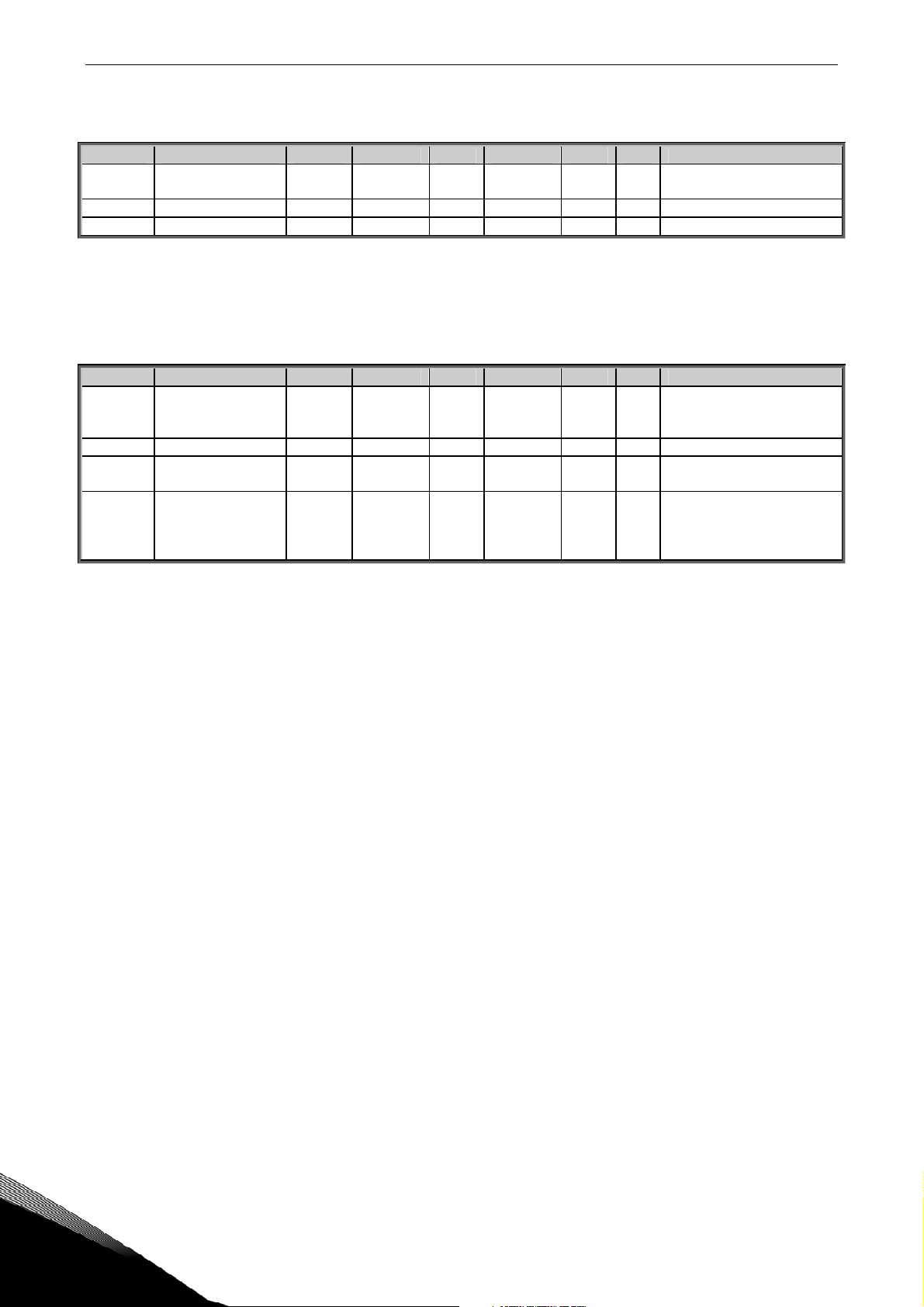

3.7 Input Signals (Control keypad: Menu P2 Æ P2.6)

Code Parameter Min Max Unit Default Cust ID Note

P2.6.1 Start/stop Logic 0 2 0

P2.6.2

P2.6.3 DIN4 (AI1)Function 0 12 2 499 As parameter 2.6.2

P2.6.4 DIN5 (AI2)Function 0 12 0

P2.6.5 DIE1 Function 0 12 10 368 As parameter 2.6.2

P2.6.6 DIE2 Function 0 12 11 330 As parameter 2.6.2

P2.6.7 DIE3 Function 0 12 12 369 As parameter 2.6.2

DIN3

Function

0 12 4

300

301

1500

DIN1 DIN2

0 ForwP RevP

1 Start Rev

2 Forw Rew

0=Not used

1=Speed curve 2

2=Ext Fault close

3=Ext Fault open

4=Fault Reset

5=Run Enable

6=Emergency stop CC

7=Emergency stop OC

8=Override speed

9=Brake open Enable

10=Speed Reference 1

11=Speed Reference 2

12=Speed Reference 3

As parameter 2.6.2

Table 3-8. Input signals P2.6

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 10

10 • vacon Lift Application – Parameter lists

3.8 Output signals (Control keypad: Menu P2 Æ P2.7)

Code Parameter Min Max Unit Default Cust ID Note

0=Not used

1=Ready

2=Run

3=Fault

4=Fault inverted

5=FC overheat warning

6=Ext. fault or warning

P2.7.1

Relay output 1

function

0 16 2

313

7=Not Used

8=Warning

9=Reversed

10=Preset speed

11=At speed

12=Mot. regulator active

13=OP freq. limit superv.1

14=Control place: IO

15=Thermistor fault/ warn

16=Mechanical brake

P2.7.2 DO2 (AO1) function 0 16 3 490 As parameter 2.7.1

P2.7.3

Expander board

relay output 1

0 16 16

314 As parameter 2.7.1

function

312 As parameter 2.7.1

P2.7.4

Expander board

digital output 1

0 16 1

function

0=Not used

1=Output freq. (0—f

max

2=Freq. reference (0—f

)

)

max

3=Motor speed (0–Motor

nominal speed)

4=Output current (0—I

5=Motor torque (0—T

6=Motor power (0—P

7=Motor voltage (0--U

nMotor

nMotor

nMotor

nMotor

)

)

)

)

P2.7.5

Analogue output

function

0 9 1

307

8=DC-link volt (0—1000V)

9=Digital output 2

P2.7.6

P2.7.7

P2.7.8

P2.7.9

P2.7.10

P2.7.11

Analogue output

filter time

Analogue output

inversion

Analogue output

minimum

Analogue output

scale

Output frequency

limit 1 supervision

Output frequency

limit 1;

0,00 10,00 S 1,00

0 1 0

0 1 0

10 1000 % 100

0 2 0

0,00 Max Freq Hz 0,00

308 0=No filtering

309

310

311

315

316

0=Not inverted

1=Inverted

0=0 mA

1=4 mA

0=No limit

1=Low limit supervision

2=High limit supervision

Supervised value

Table 3- 9. Output signals, P2.7

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 11

Lift Application – Parameter lists vacon • 11

3.9 Protections (Control keypad: Menu P2 Æ P2.8)

Code Parameter Min Max Unit Default Cust ID Note

P2.8.1

Response to external

fault

0 3 0

0=No response

1=Warning

701

2=Fault,stop acc. to 2.4.2

3=Fault,stop by coasting

P2.8.2

P2.8.3

P2.8.4

P2.8.5

P2.8.6

P2.8.7

Response to

undervoltage fault

Output phase

supervision

Earth fault

protection

Thermal protection

of the motor

Motor ambient

temperature factor

Motor cooling factor

at zero speed

P2.8.8 Motor thermal time

constant

1 3 2

0 3 2

0 3 2

0 3 2

–100,0 100,0 % 0,0

0,0 150,0 % 40,0

1 200 Min 45

727

702

0=No response

1=Warning

703

2=Fault,stop acc. to 2.4.2

3=Fault,stop by coasting

704

705

706

707

P2.8.9 Motor duty cycle 0 100 % 100 708

P2.8.10 Stall protection 0 3 1 709 As par. 2.7.1

P2.8.11

Stall current limit 0 2x I

A

nmotor

I

nmotor

x1.3

710

P2.8.12 Stall time limit 1,00 120,00 S 15,00 711

P2.8.13 Stall frequency limit 1,0 P 2.1.2 Hz 25,0 712

P2.8.14

Response to

thermistor fault

P2.8.15 Response to

fieldbus fault

P2.8.16 Response to slot

fault

0 3 0

0 3 2

0 3 2

732 As par. 2.7.1

733 As par. 2.7.1

734 As par. 2.7.1

P2.8.17 Min. Current Limit 0 P 2.1.4 A 1760

Table 3-10. Protections, P2.8

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 12

12 • vacon Lift Application – Parameter lists

3.10 Autorestart parameters (Control keypad: Menu P2 Æ P2.9)

Code Parameter Min Max Unit Default Cust ID Note

P2.9.1 Enable/Disable 0 1 0

P2.9.2 Wait time 0,10 10,00 s 0,50 717

P2.9.3 Trial time 0,00 60,00 s 30,00 718

731

0=Disabled

1=Enabled

Table 3-11. Autorestart parameters, P2.9

3.11 Keypad control (Control keypad: Menu K3)

The parameters for the selection of control place and direction on the keypad are listed below. See

the Keypad control menu in the Vacon NXL User’s Manual.

Code Parameter Min Max Unit Default Cust ID Note

P3.1 Control place 1 3 1

R3.2 Freq reference 0 MaxFreq Hz 0

P3.3 Direction (on keypad) 0 1 0

R3.4 Stop button 0 1 1

1 = I/O terminal

125

2 = Keypad

3 = Fieldbus

0 = Forward

123

1 = Reverse

0=Limited function of Stop

114

button

1=Stop button always

enabled

Table 3 12. Keypad control parameters, K3

3.12 System menu (Control keypad: Menu S6)

For parameters and functions related to the general use of the frequency converter, such as

customised parameter sets or information about the hardware and software, see Chapter 7.4.6 in

the Vacon NXL User’s Manual.

3.13 Expander boards (Control keypad: Menu E7)

The E7 menu shows the expander boards attached to the control board and board-related

information. For more information, see Chapter 7.4.7 in the Vacon NXL User’s Manual.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 13

description of parameters vacon • 13

4. DESCRIPTION OF PARAMETERS

2.1 MOTOR PARAMETERS

2.1.1 Nominal voltage of the motor

Find this value Un on the rating plate of the motor. This parameter sets the voltage at

the field weakening point (parameter 2.5.5) to 100% x U

nmotor

.

2.1.2 Nominal frequency of the motor

Find this value fn on the rating plate of the motor. This parameter sets the field

weakening point (parameter 2.5.4) to the same value.

2.1.3 Nominal speed of the motor

Find this value nn on the rating plate of the motor.

2.1.4 Nominal current of the motor

Find this value In on the rating plate of the motor.

2.1.5 Motor cos phi

Find this value “cos phi” on the rating plate of the motor.

2.1.6 Current limit

This parameter determines the maximum motor current from the frequency converter.

To avoid motor overload, set this parameter according to the rated current of the

motor. The current limit is equal to the rated converter current (I

) by default.

L

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 14

14 • vacon description of parameters

2.2 SPEED CONTROL

2.2.1 Nominal Linear Speed

Nominal linear speed corresponds to the lift speed at nominal frequency of the motor

(parameter 2.1.2)

Speed parameters in group 2.2.3 are entered in linear magnitudes.

2.2.2 Speed reference selection

Defines which frequency reference source is selected when controlled from the I/O

control place. Default value is 0.

0 = Activity coding

1 = Activity coding with direction

2 = Binary coding

4 = Fieldbus

5 = Keypad

Speed reference can be determined in three different ways with the external digital

inputs on option board.

The first column contains the state of the digital inputs (marked as DIE1, DIE2 and

DIE2).

The second column contains the parameter and the next column the corresponding

speed reference. The priority column defines which speed is activated if more than one

digital input is activated. If Speed reference is different when running to different

direction the direction is defined in direction column.

0 = Activity coding

Four different constant speeds can be selected.

DIE

[1,2,3]

[0;0;0] 2.2.3.1 (levelling speed) 0 low irrelevant

[1;0;0]

[0;1;0]

[0;0;1]

Parameters SpeedRef Priority Direction

2.2.3.2 (nominal speed) 1 medium irrelevant

2.2.3.3 (limited speed) 2 high irrelevant

2.2.3.4 (inspection speed) 3 highest irrelevant

Table 4-1. Activity reference.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 15

description of parameters vacon • 15

1 = Activity coding with direction

The constant speeds are selected according to the state of digital inputs and motor

direction. Four different speeds per direction are available.

DIE

[1,2,3]

[0;0;0] 2.2.3.1 (levelling speed) 0 low forward

[1;0;0]

[0;1;0]

[0;0;1]

[0;0;0] 2.2.3.5 (preset speed 4) 0 low reverse

[1;0;0]

[0;1;0]

[0;0;1]

Parameters SpeedRef Priority Direction

2.2.3.2 (nominal speed) 1 medium forward

2.2.3.3 (limited speed) 2 high forward

2.2.3.4 (inspection speed) 3 highest forward

2.2.3.6 (preset speed 5) 1 medium reverse

2.2.3.7 (preset speed 6) 2 high reverse

2.2.3.8 (preset speed 7) 3 highest reverse

Table 4--2. Activity reference with direction.

2 = Binary coding

Eight different constant speeds are selected according to binary word formed through

digital inputs.

DIE

[1,2,3]

[0;0;0] 2.2.3.1 (levelling speed) - irrelevant

[1;0;0]

[0;1;0]

[1;1;0]

[0;0;1]

[1;0;1]

[0;1;1]

[1;1;1]

Parameters SpeedRef Priority Direction

2.2.3.2 (nominal speed) - irrelevant

2.2.3.3 (limited speed) - irrelevant

2.2.3.4 (inspection speed) - irrelevant

2.2.3.5 (preset speed 4) - irrelevant

2.2.3.6 (preset speed 5) - irrelevant

2.2.3.7 (preset speed 6) - irrelevant

2.2.3.8 (preset speed 7) - irrelevant

Table 4-3. Binary reference.

Speed reference [m/s] parameters (M2 -> G2.2.3)

Parameters in group 2.2.3 define the speed reference in linear magnitudes [m/s].

2.2.3.1 Levelling Speed

2.2.3.2 Nominal Speed

2.2.3.3 Limited Speed

2.2.3.4 Inspection Speed

2.2.3.5 Speed reference 4

2.2.3.6 Speed reference 5

2.2.3.7 Speed reference 6

2.2.3.8 Speed reference 7

2.2.3.9 Override Speed

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 16

16 • vacon description of parameters

Speed Curve 1 parameters (M2 -> G2.2.4)

Speed curve 1 is used as the default values for acceleration and deceleration and jerks.

2.2.4.1 Acceleration time 1

2.2.4.2 Deceleration time 1

Acceleration and deceleration of the lift car are presented in [m/s2]. Acceleration and

deceleration curves are affected by the jerk time settings, too.

2.2.4.3 Acc inc jerk 1

Acceleration increase jerk1.

Jerk times are presented in [ms].

Speed [m/s]

acceleration

2

[m/s

]

P2.2.4.1

Figure 1. Jerks related to speed and acceleration

2.2.4.4 Acc dec jerk 1

Acceleration decrease jerk 1.

2.2.4.5 Dec inc jerk 1

Deceleration increase jerk 1.

2.2.4.6 Dec dec jerk 1

Deceleration decrease jerk 1.

P2.2.4.3

t [s]

P2.2.4.4

t [s]

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 17

description of parameters vacon • 17

Speed Curve 1 parameters (M2 -> G2.2.5)

Parameters in group Speed curve 2 are used when internal ramp switch function is

activated (see parameter P2.2.5.1). Then the Speed curve 1 parameters will be

replaced by Speed curve 2 parameters.

2.2.5.1 Internal Ramp switching frequency

0 = Not used

The ramp set 2 (Speed Curve2 parameters) can be activated internally. The update is

done when the speed is decelerated below the internal ramp switch frequency and the

reference frequency is reached.

Ramp set 1 (Speed Curve1 parameters) is changed back when the Run request of the

frequency converter is inactivated.

2.2.5.2 Acceleration time 2

2.2.5.3 Deceleration time 2

Acceleration and deceleration of the lift car are presented in [m/s2]. Acceleration and

deceleration curves are affected by the jerk time settings, too.

2.2.5.4 Acc inc jerk 2

Acceleration increase jerk 2. See Figure 1. Jerks related to speed and acceleration.

2.2.5.5 Acc dec jerk 2

Acceleration decrease jerk 2.

2.2.5.6 Dec inc jerk 2

Deceleration increase jerk 2.

2.2.5.7 Dec dec jerk 2

Deceleration decrease jerk 2.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 18

18 • vacon description of parameters

2.3 MECHANICAL BRAKE CONTROL

The mechanical brake control parameters affect the mechanical brake control, the

smooth start and stop function and the safety functions.

The mechanical brake can be set to release on current, on torque or on frequency.

These parameters can be set individually for forward and reverse direction

DIN3 or DIN4 can be programmed for brake open Enable.

The closing is performed by frequency and by Run request signal. In case of fault the

brake closes immediately without delay.

f/Hz

Max Freq

Brake closed

P2.3.1.9

Cur/Freq lim

P2.3.1.1-6

Run Request

signal

DC- Brake

P2.3.3.1-4

Br Open Del

P2.3.1.7

BR Mec Delay

P2.3.1.8

Brake Cl Del

P2.3.2.2

Brake Open

R02

P2.2.3.1

Levelling Speed

*)

P2.3.3.4

StopDC Freq

P2.3.2.1

FreqCloseLim

Figure 2. Mechanical brake control logic.

*) Start signal to Brake open delay when current, freq. and torque exceed limits defined by

parameters.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 19

description of parameters vacon • 19

Mechanical Brake Control Logic

BRAKE OPENING LOGIC

MOTOR CURRENT

P2.3.1.1/2.3.1.2

.CURRENT LIMIT

MOTOR TORQUE

P2.3.1.3/2.3.1.4

TORQUE LIMIT

MOTOR FREQ

P2.3.1.5/2.3.1.6

FREQ LIMIT

DIN3/DIN4

BRAKE CLOSING LOGIC

V1.1

OUTPUT FREQ

P2.3.2.1

FREQ CLOSE LIMIT

EXT. BR INPUT SIGNAL

MOTOR RUNNING

P2.3.1.7

P2.3.2.2

BRAKE OPEN DELAY

A N D

BRAKE CLOSE DELAY

A N D

To n

To n

FAULT ACTIVE

O R

S E T

R E S E T

P2.7.1

or

P2.7.2

or

P2.7.3

MEC. BRAKE

CONTROL SIGNAL

RUN REQUEST

MOTOR RUNNING

Figure 3. Mechanical brake control logic.

Mechanical brake control signal can be selected to any digital or relay output to control the

external mechanical brake.

In the upper section of Figure 3 you can find the mechanical brake opening logic. Five signals and

the delay are required for the mechanical brake to open. If current, torque or frequency signal is

not needed for brake opening, then these parameters can be set to zero. The external brake input

signal is programmable for digital input DIN3 or DIN4.

In the lower section of Figure 3 you can find the mechanical brake closing logic. The brake close

circuit has higher priority than the open circuit. So if closing signal is active the mechanical brake

will be closed.

The brake will be closed immediately in case of fault or when the motor is stopped.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 20

20 • vacon description of parameters

In normal operation the brake will be closed when frequency falls below the Frequency close limit

(P2.3.2.1) AND when the Run Request signal is switched OFF. If the Frequency close limit signal is

not needed for the closing logic it can be set to zero. After the conditions are true there is a brake

close delay (P2.3.2.2) after which the brake will be closed.

Opening Brake Parameters (M2 -> G2.3.1)

Please note that there are limitations parameters for both Forward (FWD) and Reverse (REV)

direction.

Different values for FWD and REV can be set when application requires.

For example when counter weight is not used (e.g. Mechanical Brake Control application)

2.3.1.1 Current Limit FWD

Parameter defines the actual current limit that has to be exceeded for a brake release.

If set to zero this condition is excluded. The value is updated always when the nominal

current of the motor (parameter 2.1.4) is set (see Figure 3).

2.3.1.2 Current Limit REV

Parameter defines the actual current limit that has to be exceeded for a brake release.

If set to zero this condition is excluded. The value is updated always when the nominal

current of the motor (parameter 2.1.4) is set (see Figure 3).

2.3.1.3 Torque limit FWD

Parameter defines the actual torque limit that has to be exceeded for a brake release.

If set to zero this condition is excluded.

100 % corresponds to the calculated nominal torque of the motor (see Figure 3).

2.3.1.4 Torque limit REV

Parameter defines the actual torque limit that has to be exceeded for a brake release.

If set to zero this condition is excluded.

100 % corresponds to the calculated nominal torque of the motor (see Figure 3).

2.3.1.5 Frequency limit FWD

Parameter defines the actual frequency limit that has to be exceeded for brake

release. If set to zero this condition is excluded (see Figure 3).

2.3.1.6 Frequency limit REV

Parameter defines the actual frequency limit that has to be exceeded for brake

release. If set to zero this condition is excluded (see Figure 3).

2.3.1.7 Brake open delay

Delay which starts when the opening conditions (see parameters 2.3.1.1-2.3.1.6) are

TRUE (see Figure 3).

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 21

description of parameters vacon • 21

2.3.1.8 Mechanical brake reaction time

Mechanical brake reaction time will hold the speed reference for the defined time by

this parameter. This hold time should be set according to the mechanical brake

reaction time (see figure 2)

2.3.1.9 Maximum frequency brake closed

Output frequency does not exceed this value when mechanical brake is closed. When

modifying this parameter make sure that the brake release by frequency (see

parameter 2.3.1.5/2.3.1.6) is possible with new value.

Closing Brake Parameters (M2 -> G2.3.2)

2.3.2.1 Frequency limit closing

The output frequency limit for the brake closing. The run request signal needs to be

disabled to allow the signal to affect.

2.3.2.2 Closing delay

The brake closing is delayed with defined time. If set to zero there is no delay between

the brake closing condition and the actual brake closing.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 22

22 • vacon description of parameters

DC Brake Parameters (M2 -> G2.3.3)

2.3.3.1 DC-brake current

Defines the current injected into the motor during DC-braking.

2.3.3.2 DC-braking time at start

DC-brake is activated when the start command is given. This parameter defines the

time before the brake is released.

2.3.3.3 DC-braking time at stop

Determines if braking is ON or OFF and the braking time of the DC-brake when the

motor is stopping. The function of the DC-brake depends on the stop function,

parameter 2.4.2.

0 DC-brake is not used

>0 DC-brake is in use and its function depends on the Stop function,

(par. 2.4.2). The DC-braking time is determined with this parameter

Par. 2.4.2 = 0; Stop function = Coasting:

After the stop command, the motor coasts to a stop without control of the frequency

converter.

With DC-injection, the motor can be electrically stopped in the shortest possible time,

without using an optional external-braking resistor.

The braking time is scaled according to the frequency when the DC-braking starts. If

the frequency is ≥ the nominal frequency of the motor, the set value of parameter

2.3.3.3 determines the braking time. When the frequency is ≤10% of the nominal, the

braking time is 10% of the set value of parameter 2.3.3.3.

f

o u t

f

n

R U N

S T O P

O u t p u t

f r e q u e n cy

M

s p e e d

D

bra k i n g

C -

o t o r

O N

0,1 x f

t

f

n

n

RUN

STOP

f

out

Figure 4. DC-braking time when Stop mode = Coasting.

Output frequency

Motor speed

DC-braking ON

t = 1 x par. 2.3.3.3 t = 1 x par. 2.3.3.3

NX1 2 K 2 1

t

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 23

description of parameters vacon • 23

Par. 2.4.2 = 1; Stop function = Ramp

After the Stop command, the speed of

the motor is reduced according to the

set deceleration parameters, as fast

as possible, to the speed defined with

f

out

M o t o r

s p e e d

O u t p u t

f r e q u e n c y

parameter 2.3.3.4, where the DC-

braking starts.

The braking time is defined with

parameter 2.3.3.3. If high inertia

exists, it is recommended to use an

external braking resistor for faster

deceleration. See Figure 5.

P2.3.3.4

RUN

STOP

D C - b r a k i n g

t

t=1 x par. 2.3.3.3

NX12K23

Par. 2.4.2 = 2; Stop function = Stop by frequency. limit

Stop mode depends on the actual frequency of the motor. If frequency is above the

frequency limit (par. 2.4.3) then the stop mode is coasting (see Figure 4). If frequency is

even or below the frequency limit then the stop mode is ramp (see Figure 5).

2.3.3.4 DC-braking frequency at stop

The output frequency which the DC-braking is applied. See Figure 5

Figure 5. DC-braking time when Stop mode = Ramp

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 24

24 • vacon description of parameters

2.4 DRIVE CONTROL

2.4.1 Brake chopper

0 = No brake chopper used

1 = Brake chopper in use when running

2 = Brake chopper in use when running

3 = Used drive is ready

When the frequency converter is decelerating the motor, the inertia of the motor and

the load are fed into an external brake resistor. This enables the frequency converter

to decelerate the load with a torque equal to that of acceleration (provided that the

correct brake resistor has been selected). See separate Brake resistor installation

manual.

2.4.2 Stop function

Coasting:

0 The motor coasts to a halt without any control from the frequency converter,

after the Stop command.

Ramp:

1 After the Stop command, the speed of the motor is decelerated according to

Frequency limit

2 Coasting Stop if the motor frequency is above the frequency limit (par. 2.4.3)

the set deceleration parameters.

If the regenerated energy is high it may be necessary to use an external

braking resistor for faster deceleration.

when stop request is given. Stop by ramp if the motor frequency is the same

or below this parameter when stop request is given.

2.4.3 Frequency limit

Defines the frequency limit for the stop function if selected as the frequency limit (par.

2.4.2=2).

If the motor frequency is above the frequency limit the motor costs to stop and if it is

below or the same as the frequency limit the stop function is ramp.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 25

description of parameters vacon • 25

2.5 MOTOR CONTROL

2.5.1 Motor control mode

0 Frequency control: The I/O terminal and keypad references are frequency

references and the frequency converter controls the output

frequency (output frequency resolution = 0.01 Hz)

1 Speed control: The I/O terminal and keypad references are speed references

and the frequency converter controls the motor speed

(accuracy ± 0,5%).

2.5.2 U/f optimisation

Automatic

torque boost

NOTE!

2.5.3 U/f ratio selection

Linear: The voltage of the motor changes linearly with the frequency in the constant

0 flux area from 0 Hz to the field weakening point where the nominal voltage is

supplied to the motor. Linear U/f ratio should be used in constant torque

applications. This default setting should be used if there is no special

need for another setting.

Squared: The voltage of the motor changes following a squared curve form

1 with the frequency in the area from 0 Hz to the field weakening point where

the nominal voltage is also supplied to the motor. The motor runs under

magnetised below the field weakening point and produces less

torque and

electromechanical noise. Squared U/f ratio can be used in applications

where torque demand of the load is proportional to the square of the speed,

e.g in centrifugal fans and pumps.

The voltage to the motor changes automatically which makes the

motor produce sufficient torque to start and run at low

frequencies. The voltage increase depends on the motor type and

power. Automatic torque boost can be used in applications where

starting torque due to starting friction is high, e.g. in conveyors.

In high torque - low speed applications - it is likely that the motor

will overheat. If the motor has to run a prolonged time under these

conditions, special attention must be paid to cooling the motor. Use

external cooling for the motor if the temperature tends to rise too

high.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 26

26 • vacon description of parameters

U[V]

Un

par.2.5.5

Default: Nominal

voltage of the m otor

Linear

Field w eakening

point

Squared

Default: Nominal

frequency of the

motor

NX12K07

f[Hz]

Figure 6. Linear and squared change of motor voltage

Programmable U/f curve:

2 The U/f curve can be programmed with three different points.

Programmable U/f curve can be used if the other settings do not satisfy the

needs of the application.

U

[ V ]

D e f a u l t :

v

o l t a g e

N o m i n al

o f

t h e

motor

Field weakening point

P a r

U n

2 . 5 . 5

a r .

2 . 5 . 7

P

( D e f .

1 0 % )

8

2 . 5

1 . 3 % )

.

P a r .

( D e f .

P a r .

( D e f .

Figure 7. Programmable U/f curve.

Linear with flux optimisation:

3 The frequency converter starts to search for the minimum motor current in

order to save energy, lower the disturbance level and the noise. This function

can be used in applications with constant motor load, such as fans, pumps

etc.

2.5.4 Field weakening point

The field weakening point is the output frequency at which the output voltage reaches

the set (par. 2.5.5) maximum value.

2 . 5

5

H z)

Default: Nominal

frequency of the moto

.

6

Par. 2.5.4

r

f[H z ]

NX12 K 0 8

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 27

description of parameters vacon • 27

2.5.5 Voltage at field weakening point

Above the frequency at the field weakening point, the output voltage remains at the set

maximum value. Below the frequency at the field weakening point, the output voltage

depends on the setting of the U/f curve parameters. See parameters 2.5.2, 2.5.3, 2.5.6

and 2.5.7.

When the parameters 2.1.1 and 2.1.2 (nominal voltage and nominal frequency of the

motor) are set the parameters 2.5.4 and 2.5.5 are automatically given the

corresponding values. If you need different values for the field weakening point and the

maximum output voltage, change these parameters after setting the parameters 2.1.1

and 2.1.2.

2.5.6 U/f curve, middle point frequency

If the programmable U/f curve has been selected with the parameter 2.5.3 this

parameter defines the middle point frequency of the curve. See Figure 7.

2.5.7 U/f curve, middle point voltage

If the programmable U/f curve has been selected with the parameter 2.5.3 this

parameter defines the middle point voltage of the curve. See Figure 7.

2.5.8 Output voltage at zero frequency

If the programmable U/f curve has been selected with the parameter 2.5.3 this

parameter defines the zero frequency voltage of the curve. See Figure 7.

2.5.9 Switching frequency

Motor noise can be minimised using a high switching frequency. Increasing the

switching frequency reduces the capacity of the frequency converter unit.

The range of this parameter depends on the size of the frequency converter:

2.5.10 Overvoltage controller

2.5.11 Undervoltage controller

These parameters allow the under-/overvoltage controllers to be switched out of

operation. This may be useful, for example, if the mains supply voltage varies more

than –15% to +10% and the application will not tolerate this over-/undervoltage. In this

case, the regulator controls the output frequency taking the supply fluctuations into

account.

Note: Over-/undervoltage trips may occur when controllers are switched out of

operation.

0 Controller switched off

1 Controller switched on

2.5.12. Measured RS voltage drop

Measured Voltage drop at stator resistance between two phases of the motor with

nominal current of motor.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 28

28 • vacon description of parameters

2.6 INPUT SIGNALS

2.6.1 Start/Stop logic selection

0 DIN1: closed contact = start forward (rising edge pulse is required)

DIN2: closed contact = start reverse (rising edge pulse is required)

FWD

t

REV

DIN1

DIN2

1

2

Figure 8. Start forward/Start reverse

c If both DIN switches are ON at the same time the second input is ignored.

d The drive can be re-started when both DIN switches are in OFF position.

1 DIN1: closed contact = start open contact = stop

DIN2: closed contact = reverse open contact = forward

FWD

t

REV

DIN1

DIN2

Figure 9. Start, Stop, Reverse

2 DIN1: closed contact = start forward

DIN2: closed contact = start reverse

Same as selection 0 except rising edge pulse is not required.

Fault is not activated if both DIN switches are on.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 29

description of parameters vacon • 29

2.6.2 DIN3 function

This parameter has 8 selections. If digital input DIN3 need not be used, set the

parameter value to 0.

1 Speed curve2

2 Ext Fault close

3 Ext Fault open

4 Fault reset

5 Run enable

6 Emergency stop CC

7 Emergency stop OC

8 Override speed

9 Brake open enable

2.6.3 DIN4 (Analog input 1) function

The analog input 1 is used as digital input DIN4.

Selections are the same as for Parameter 2.6.2

2.6.4 DIN5 (Analog input 2) function

The analog input 2 is used as digital input DIN5.

Selections are the same as for Parameter 2.6.2

2.6.5 Expander board DIE1 function

Function selection for Expander board digital input DIE1.

Selections are the same as for Parameter 2.6.2

2.6.6 Expander board DIE2 function

Function selection for Expander board digital input DIE2.

Selections are the same as for Parameter 2.6.2

2.6.7 Expander board DIE3 function

Function selection for Expander board digital input DIE3.

Selections are the same as for Parameter 2.6.2

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 30

30 • vacon description of parameters

2.7 OUTPUT SIGNALS

2.7.1 Relay output 1 function

2.7.2 Digital output 2 (Analogue output 1) function

2.7.3 Expander board relay output 1 function

2.7.4 Expander board digital output 1 function

Setting value Signal content

0 = Not used Out of operation

1 = Ready The frequency converter is ready to operate

2 = Run The frequency converter operates (motor is running)

3 = Fault A fault trip has occurred

4 = Fault inverted A fault trip not occurred

5 = Frequency converter overheat

warning

6 = External fault or warning Fault or warning depending on par. 2.8.1

Relay output RO1 and expander board

programmable relays (RO1, D01) are activated when:

The heat-sink temperature exceeds +70°C

7 = Not Used Not Used

8 = Warning Always if a warning exists

9 = Reversed The reverse command has been selected

10 = Preset speed A preset speed has been selected

11 = At speed The output frequency has reached the set reference

12 = Motor regulator activated Overvoltage or overcurrent regulator was activated

13 = Output frequency limit 1

supervision

14 = Control from I/O terminals

15 = Thermistor fault or warning

16 = Mechanical brake

Table 4-4. Output signals via RO1, DO2 and expander board RO1, and DO1.

2.7.5 Analogue output function

This parameter selects the desired function for the analogue output signal.

See the table on page 10 for the parameter values. Maximum analogue output is

activated when output selected by P2.7.2 is true.

Not used in this application

Selected control place (Menu K3; par. 3.1) is “I/O

terminal”

The thermistor input of option board indicates

overtemperature. Fault or warning depending on

parameter 2.8.14

External brake ON/OFF control

(see parameter Group G2.3)

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 31

description of parameters vacon • 31

A

A

A

A

A

2.7.6 Analogue output filter time

Defines the filtering time of the analogue

output signal.

If you set value 0 for this parameter, no

filtering takes place.

2.7.7 Analogue output invert

Inverts the analogue output signal:

Maximum output signal = 0 %

Minimum output signal = Maximum set value (parameter 2.7.9)

0 Not inverted

1 Inverted

See parameter 2.7.9.

%

Unfiltered s i g n a l

F i l t e r e d s i g n a l

Par. 2.7.

5

Figure 10. Analogue output filtering

20 m

12 m

10 m

4 m

P a r a m . 2 . 7 . 8

=

2 0 0 %

0 m

0

0 . 5

t [s]

NX12K16

Param. 2.7.8

= 50%

Param. 2.7.8

= 100%

1.0

NX12K17

Figure 11. Analogue output invert

2.7.8 Analogue output minimum

Sets the signal minimum to either 0 mA or 4 mA (living zero). Note the difference in the

analogue output scaling in parameter 2.7.9.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 32

32 • vacon description of parameters

2.7.9 Analogue output scale

Scaling factor for the analogue output.

Signal Max. value of the signal

Output frequency 100% x f

max

Motor speed 100% x Motor nom. speed

Output current 100% x I

Motor torque 100% x T

Motor power 100% x P

Motor voltage 100% x U

nMotor

nMotor

nMotor

nmotor

DC-link voltage 1000 V

Table 1- 1. Analogue output scaling

Analogue

output

current

20 mA

12 mA

10 mA

Par. 2.7.7 = 1

Par. 2.7.7 = 0

4 mA

0 mA

a r . 2 . 7 . 8 =

P

2 0 0 %

0

0 . 5

P a r . 2 .7.8=

0 0 %

1

Par.2.7.8=

50%

Max. value of signal

selected by param. 2.7.4

1 .0

n x l k 4 9.fh8

Figure 12. Analogue output scaling

2.7.10 Output frequency limit 1 supervision function

0 No supervision

1 Low limit supervision

2 High limit supervision

If the output frequency goes under/over the set limit (par. 2.7.10) this function

generates a warning message via the relay outputs depending on the settings of

parameters 2.7.1 – 2.7.3

2.7.11 Output frequency limit 1 supervised value

Selects the frequency value supervised by parameter 2.7.9

P a r 2 . 7 . 1 0

E x a m p l e :

f[ H z ]

21 R O 1

22 R O 1

23 R O 1

Par 2.7.9 = 2

21 RO1

22 RO1

23 RO1

t

21 RO1

22 RO1

23 RO1

NX12K19

Figure 13. Output frequency supervision

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 33

description of parameters vacon • 33

2.8 PROTECTIONS

I/O Faults parameters (M2 -> G2.8.1)

2.8.1 Response to external fault

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2.

3 = Fault, stop mode after fault always by coasting

A warning or a fault action and message is generated from the external fault signal

in the programmable digital inputs. The information can also be programmed into relay

outputs.

2.8.2 Response to undervoltage fault

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2.

3 = Fault, stop mode after fault always by coasting

For the undervoltage limits see Vacon NXL User’s Manual. Table 4-3.

Note: This protection can not be inactivated.

2.8.3 Output phase supervision

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2.

3 = Fault, stop mode after fault always by coasting

Output phase supervision of the motor ensures that the motor phases have an

approximately equal current.

2.8.4 Earth fault protection

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2.

3 = Fault, stop mode after fault always by coasting

Earth fault protection ensures that the sum of the motor phase currents is zero. The

overcurrent protection is always working and protects the frequency converter from

earth faults with high currents.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 34

34 • vacon description of parameters

Motor Faults parameters

Parameters 2.8.5—2.8.8, Motor thermal protection:

General

The motor thermal protection is to protect the motor from overheating. The Vacon drive is capable

of supplying higher than nominal current to the motor. If the load requires this high current there

is a risk that the motor will be thermally overloaded. This is the case especially at low frequencies.

At low frequencies the cooling effect of the motor is reduced as well as its capacity. If the motor is

equipped with an external fan the load reduction at low speeds is small.

The motor thermal protection is based on a calculated model and it uses the output current of the

drive to determine the load on the motor.

The motor thermal protection can be adjusted with parameters. The thermal current I

the load current above which the motor is overloaded. This current limit is a function of the output

frequency.

!

CAUTION!

The calculated model does not protect the motor if the airflow to the

motor is reduced by blocked air intake grill.

specifies

T

2.8.5 Motor thermal protection

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2.

3 = Fault, stop mode after fault always by coasting

If tripping is selected the drive will stop and activate the fault stage.

Deactivating the protection, i.e. setting parameter to 0, will reset the thermal stage of

the motor to 0%.

2.8.6 Motor thermal protection: Motor ambient temperature factor

When the motor ambient temperature must be taken into consideration, it is

recommended to set a value for this parameter. The value of the factor can be set

between –100.0% and 100.0% where –100.0% corresponds to 0

maximum running ambient temperature of the motor. Setting this parameter value to

0% assumes that the ambient temperature is the same as the temperature of the

heatsink at power-on.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

°C and 100.0% to the

Page 35

description of parameters vacon • 35

2.8.7 Motor thermal protection: Cooling factor at zero speed

The cooling power can be set between

0—150.0% x cooling power at nominal

frequency. See Figure 14.

100%

par.

2.8.7=40%

Figure 14. Motor cooling power

2.8.8 Motor thermal protection: Time constant

This time can be set between 1 and 200 minutes.

This is the thermal time constant of the motor. The bigger the motor, the bigger the

time constant. The time constant is the time within which the calculated thermal model

has reached 63% of its final value.

The motor thermal time is specific to the motor design and it varies between different

motor manufacturers.

If the motor's t6–time (t6 is the time in seconds the motor can safely operate at six

times the rated current) is known (given by the motor manufacturer) the time constant

parameter can be set basing on it. As a rule of thumb, the motor thermal time constant

in minutes equals to 2xt6. If the drive is in stop state the time constant is internally

increased to three times the set parameter value. The cooling in the stop state is based

on convection and the time constant is increased. See also Figure 10.

Note: If the nominal speed (par. 2.1.3) or the nominal current (par. 2.1.4) of the motor

are changed this parameter is automatically set to the default value (45).

0

f

N X 1 2 k 6 2

f

n

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 36

36 • vacon description of parameters

Θ

j

w

2.8.9 Motor thermal protection: Motor duty cycle

Defines how much of the nominal motor load is applied.

The value can be set to 0%…100%.

M o t o r

t emp e r a t u r e

1 0 5 %

M

c u r r e n t

I / I

o t o r

T

T r i p

a r e a

arning

Fault/

par. 2.8.3.1

M

o t o r

Time constant T

t e m p erature

*)

Changes by motor size and

ad

ustedwith parameter 2.8.8.

=

(I/I

*)

2

)

T

-t/T

)

(1-e

x

Time

NX12k82

Figure 15. Motor temperature calculation

Parameters 2.8.10-2.8.13, Stall protection:

General

The motor stall protection protects the motor from short time overload situations such as one

caused by a stalled shaft. The reaction time of the stall protection can be set shorter than that of

motor thermal protection. The stall state is defined with two parameters, 2.8.11 (Stall current) and

2.8.13 (Stall frequency). If the current is higher than the set limit and output frequency is lower

than the set limit, the stall state is true. There is actually no real indication of the shaft rotation.

Stall protection is a type of overcurrent protection.

2.8.10 Stall protection

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2

3 = Fault, stop mode after fault always by coasting

Setting the parameter to 0 will deactivate the protection and reset the stall time

counter.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 37

description of parameters vacon • 37

2.8.11 Stall current limit

The current can be set to 0.0…I

For a stall stage to occur, the current

must have exceeded this limit. See

Figure 1- 20. The software does not

allow entering a greater value than

I

*2. If the parameter 2.1.4 Nominal

nMotor

current of motor is changed, this

parameter is automatically restored to

the default value (I

2.8.12 Stall time limit

This time can be set between 1.0 and

120.0s.

This is the maximum time allowed for a

stall stage. The stall time is counted by

an internal up/down counter.

If the stall time counter value goes above

this limit the protection will cause a trip

(see parameter 2.8.10).

nMotor

*1.3).

nMotor

*2.

I

Stal l a r e a

Par. 2.8.11

a r .

P

2 . 8 . 1 3

Figure 16. Stall characteristics settings

Par. 2.8.

Stall time cou n t e r

Trip are a

11

T

r i p / w a r n i n g

p a r .

2 . 8 . 10

T i m e

f

NX12k63

2.8.13 Maximum stall frequency

The frequency can be set between 1-f

For a stall state to occur, the output frequency must have remained below this limit.

Figure17. Stall time count

(par. 2.1.2).

max

Stall

No stall

NX12k64

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 38

38 • vacon description of parameters

Parameters 2.8.14-2.8.17, other protections:

2.8.14 Response to thermistor fault

0 = No response

1 = Warning

2 = Fault, stop mode after fault according to parameter 2.4.2.

3 = Fault, stop mode after fault always by coasting

2.8.15 Response to fieldbus fault

Set here the response mode for the fieldbus fault if a fieldbus board is used. For more

information, see the respective Fieldbus Board Manual.

See parameter 2.8.14.

2.8.16 Response to slot fault

Set here the response mode for a board slot fault due to missing or broken board.

See parameter 2.8.14.

2.8.17 Minimum current limit

If actual current of the motor is below the minimum current limit fault is activated. The

fault is activated only when the mechanical brake is open.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 39

description of parameters vacon • 39

A

)

2.9 AUTO RESTART PARAMETERS

2.9.1 Automatic restart: Enable

Set this parameter to 1 to enable the automatic restart function.

Restart function works for following faults:

Undervoltage, Overvoltage, Overcurrent, IGBT overtemperature, Motor

overtemperature and External fault.

2.9.2 Automatic restart: Wait time

Defines the time before the frequency converter tries to automatically restart the

motor after the fault has disappeared.

2.9.3 Automatic restart: Trial time

The Automatic restart function restarts the frequency converter when the faults have

disappeared and the waiting time has elapsed.

Fault trigger

Motor stop signal

Motor start signal

Supervision

Fault active

RESET/

Fault reset

Wait time

Par.2.9.1

Restart 1 Restart 2

Wait time

Par. 2.9.1

Trial time

Par.2.9.2

utoreset function:(Trials = 2

Wait time

Par. 2.9.1

NX12k67

Figure 10. Example of Automatic restart with two restarts.

The time count starts from the first autorestart. If the number of faults occurring

during the trial time exceeds three, the fault state becomes active. Otherwise the fault

is cleared after the trial time has elapsed and the next fault starts the trial time count

again.

If a single fault remains during the trial time, a fault state is true.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 40

40 • vacon description of parameters

2.10 KEYPAD CONTROL PARAMETERS

3.1 Control place

The active control place can be changed with this parameter. For more information,

see Vacon NXL User's Manual, Chapter 7.4.3.

3.2 Keypad frequency reference

The frequency reference can be adjusted from the keypad with this parameter. For

more information, see Vacon NXL User's Manual, Chapter 7.4.3.2.

3.3 Keypad direction

0 Forward: The rotation of the motor is forward, when the keypad is the active

control place.

1 Reverse: The rotation of the motor is reversed, when the keypad is the active

control place.

For more information, see Vacon NXL User's Manual, Chapter 7.4.3.3.

3.4 Stop button activated

If you wish to make the Stop button a "hotspot" which always stops the drive regardless

of the selected control place, give this parameter the value 1 (default). See Vacon NXL

User's Manual, Chapter 7.4.3.

See also parameter 3.1.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 41

description of parameters vacon • 41

3. CONTROL SIGNALS IN LIFT APPLICATION

DIN#

DIE1

DIE2

DIE3

DIN1

DIN2

DIN#

Override Speed selection

Speed Selection:

Inpu t 1

Inpu t 2

Inpu t 3

Speed Reference

parameters:

P2.2.3.x

Fieldbus

Fw

Bw

Programmable

Start/Stop Logic

Run Enable

wit h Run Enable

P2.2.3.9

Override Speed

P2.2.2 Speed

Reference

P3.1

Control Place

Internal

Frequency reference

Reference

Reset Button

Start/Stop

Buttons

Internal

Start / Stop

Internal

Reverse

KeyPad

Start/Stop from Fieldbus

P3.3 Keypad Direction

Direction from Fieldbus

Fault Reset (Programmable)

DIN#

DIN# is Programm able input. Function for input can b e selected.

NOTE! Same function can be programmed for several inputs.

This feature must be used ver y car ef ully .

Figure 19. Control signal logic in the Lift Application

Internal

Fault Reset

1

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 42

42 • vacon fault tracing

3.1 FAULT TRACING

When a fault is detected by the frequency converter control electronics, the drive is stopped and

the symbol F together with the ordinal number of the fault and the fault code appear on the

display. The fault can be reset with the

Reset button

on the control keypad or via the I/O terminal.

The faults are stored in the Fault history menu (H5) which can be browsed. The different fault

codes you will find in the table below.

The fault codes, their causes and correcting actions are presented in the table below. The

shadowed faults are A faults only. The items written in white on black background present faults

for which you can program different responses in the application. See parameter group

Protections.

Fault

code

1 Overcurrent Frequency converter has detected too

2 Overvoltage The DC-link voltage has exceeded the

3 Earth fault Current measurement has detected that

5 Charging switch The charging switch is open, when the

8 System fault - component failure

9 Undervoltage DC-link voltage is under the voltage

11 Output phase

13 Frequency

14 Frequency

Fault Possible cause Correcting measures

) in the motor cable:

n

supervision

converter

undertemperature

converter

overtemperature

high a current (>4*I

− sudden heavy load increase

− short circuit in motor cables

− unsuitable motor

limits defined in.

− too short a deceleration time

− high overvoltage spikes in utility

the sum of motor phase current is not

zero.

− insulation failure in cables or motor

START command has been given.

− faulty operation

− component failure

- faulty operation

limits defined in.

− most probable cause: too low a

supply voltage

− frequency converter internal fault

Current measurement has detected that

there is no current in one motor phase.

Heatsink temperature is under –10°C

Heatsink temperature is over 90°C.

Overtemperature warning is issued when

the heatsink temperature exceeds 85°C.

Check loading.

Check motor size.

Check cables.

Make the deceleration time longer.

Check motor cables and motor.

Reset the fault and restart.

Should the fault re-occur, contact the

distributor near to you.

Reset the fault and restart.

Should the fault re-occur, contact the

distributor near to you.

In case of temporary supply voltage

break reset the fault and restart the

frequency converter. Check the supply

voltage. If it is adequate, an internal

failure has occurred.

Contact the distributor near to you.

Check motor cable and motor.

Check the correct amount and flow of

cooling air.

Check the heatsink for dust.

Check the ambient temperature.

Make sure that the switching frequency

is not too high in relation to ambient

temperature and motor load.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 43

fault tracing vacon • 43

15 Motor stalled Motor stall protection has tripped. Check motor.

16 Motor

overtemperature

17 Motor underload Motor underload protection has tripped.

EEPROM

22

24 Counter fault Values displayed on counters are

25 Microprocessor

29 Thermistor fault The thermistor input of option board has

34 Internal bus

39 Device removed Option board removed.

40 Device unknown Unknown option board or drive. Contact the distributor near to you.

41 IGBT temperature IGBT Inverter Bridge overtemperature

44 Device change Option board changed.

45 Device added Option board added. Reset

51 External fault Digital input fault. Digital input has been

52 Keypad

53 Fieldbus fault The data connection between the

54 Slot fault Defective option board or slot Check board and slot.

58 Minimum

checksum fault

watchdog fault

communication

communication

fault

Current

Motor overheating has been detected by

frequency converter motor temperature

model. Motor is overloaded.

Parameter save fault

− faulty operation

− component failure

incorrect

− faulty operation

− component failure

detected increase of the motor

temperature

Ambient interference or defective

hardware

Drive removed.

protection has detected too high a motor

current.

Option board has default settings.

programmed as external fault input and

this input is active.

The connection between the control

keypad and the frequency converter is

broken.

fieldbus Master and the fieldbus board is

broken

Motor Current is less than set limit of

P2.8.17

Decrease the motor load.

If no motor overload exists, check the

temperature model parameters.

Contact the distributor near to you

Reset the faultand restart.

Should the fault re-occur, contact the

distributor near to you.

Check motor cooling and loading

Check thermistor connection

(If thermistor input of the option board is

not in use it has to be short circuited)

Should the fault re-occur, contact the

distributor near to you.

Reset

Check loading.

Check motor size.

Reset

Check the programming and the device

indicated by the external fault

information. Check also the cabling of

this device.

Check keypad connection and possible

keypad cable.

Check installation.

If installation is correct contact the

nearest Vacon distributor.

Contact the nearest Vacon distributor.

Check motor cables

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 44

Vaasa

Vacon Oyj (Headquarters and Production)

Runsorintie 7, 65380 Vaasa

firstname.lastname@vacon.com

tel. +358 (0) 201 2121

fax: +358 (0) 201 212 205

Helsinki

Vacon Oyj

Äyritie 12, 01510 Vantaa

tel. +358 (0)201 212 600

fax: +358 (0)201 212 699

Tampere

Vacon Oyj

Alasniitynkatu 30, 33700 Tampere

tel. +358 (0)201 2121

fax: +358 (0)201 212 750

sales companies and representative offices:

Austria

Vacon AT Antriebssysteme GmbH

Aumühlweg 21

2544 Leobersdorf

vacon.austria@vacon.com

tel. +43 2256 651 66

fax: +43 2256 651 66 66

Belgium

Vacon Benelux NV/SA

Interleuvenlaan 62

3001 Heverlee (Leuven)

info@vacon.be

tel. +32 (0)16 394 825

fax: +32 (0)16 394 827

France

Vacon France s.a.s.

Batiment le Sextant

462 rue Benjamin Delessert

Zl de Moissy Cramayel

BP 83

77 554 Moissy Cramayel

www.vacon-france.fr

tel. +33 (0)1 64 13 54 11

fax: +33 (0)1 64 13 54 21

Germany

Vacon GmbH

Gladbecker Str. 425

45329 Essen

tel. +49 (0)201/80670-0

fax: +49 (0)201/80670-93

Great Britain

Vacon Drives (UK) Ltd.

18 Maizefield

Hinckley Fields Industrial Estate

Hinckley

LE10 1YF Leicestershire

vacon.uk@vacon.com

tel. +44 (0)1455 611 515

fax: +44 (0)1455 611 517

Italy

Vacon S.p.A.

Via F.lli Guerra, 35

42100 Reggio Emilia

info@vacon.it

tel. +39 0522 276811

fax: +39 0522 276890

The Netherlands

Vacon Benelux BV

Weide 40, 4206 CJ Gorinchem

vacon.benelux@vacon.com

tel. +31 (0)183 642 970

fax: +31 (0) 183 642 971

Norway

Vacon AS

Langgata 2

3080 Holmestrand

vacon@vacon.no

tel. +47 330 96120

fax: +47 330 96130

PR China

Vacon Plc

Beijing Representative Office

A205, Grand Pacific Garden Mansion

8A Guanhua Road

Beijing 100026

www.vacon.com.cn

vacon.china@vacon.com

tel. +86 10 6581 3734

fax: +86 10 6581 3754

Rotatek Finland Oy

Laserkatu 6, 53850 Lappeenranta

tel. +358 (0)5 6243 870

fax: +358 (0)5 6243 871

Vacon Traction Oy

Alasniitynkatu 30, 33700 Tampere

tel. +358 (0)201 2121

fax: +358 (0)201 212 710

Russia

ZAO Vacon Drives

Bolshaja Jakimanka 31

stroenie 18

109180 Moscow

www.ru.vacon.com

tel. +7 (095) 974 1541

fax: +7 (095) 974 1554

ZAO Vacon Drives