Page 1

UL STANDARDS ON CABLING

To obey the UL (Underwriters Laboratories)

regulations, use a UL-approved Class 1

copper wire with a minimum heat

resista nce of +158 or +167 °F (+70 or +75°C).

You can use the drive on a circuit that gives

a maximum of 50 000 rms symmetrical

amperes, and a maximum of 500 V AC,

when the drive is protected by Class T and

J fuses.

CABLE AND FUSE SIZES,

NORTH AMERICA

The recommended fuse types are class

T (UL & CSA). The fuse voltage rating

should be selected according to the supply

network. The final selection should be

made according to local regulations,

cable installation conditions and cable

specifications. Bigger fuses than those

recommended below shall not be used.

Check that the fuse operating time is less

than 0.4 seconds. Operating time depends

on used fuse type and impedance of the

supply circuit. Consult the factory about

faster fuses. VACON® also recommends

for high speed J (UL & CSA) fuse ranges.

THE TECHNICAL DATA OF THE VACON® 20 X AC DRIVE

VACON® 20 X AC DRIVES

INSTALLATION

IN US AND CANADA

Download and read VACON® 20 X Installation Manual,

wall-mounted drives at:

http://drives.danfoss.com/knowledge-center/

technical-documentation/

The dimensions of the cables must agree

with the requirements of the UL508C.

• The cables must be PVC-isolated.

• The maximum ambient temperature

is +104 °F (+40°C).

• The maximum temperature of the

cable surface is +158 or +167 °F

(+70 or +75°C).

• Use only cables with a concentric

copper shield.

• The maximum number of parallel

cables is 9.

When you use parallel cables, make sure

that you obey the requirements of the

cross-sectional area and the maximum

number of cables.

For important information on the

requirements of the grounding conductor,

see the UL508C.

For the correction factors for each

temperature, see the instructions of the

UL508C.

QUICK GUIDE

DPD01821B

Technical item or function Technical data

Mains

connection

Input voltage U

in

3AC 208…240V

1AC 208...240V

3AC 380...480V

Input voltage tolerance -15%…+10% continuously

Input frequency 50/60 Hz

Input frequency tolerance 45…66 Hz

Protection class I

Connection to mains Once per minute or less

Starting delay 4 s

Supply network

IT and TN-networks

(cannot be used with corner earthed

networks)

Short-circuit current

Maximum short-circuit current

has to be <50kA

DC connection

Available as standard in

MU2 single-phase frames and MU3

Motor

connection

Output voltage 3AC 0…U

in

Rated output current IN: Ambient temperature max. +40°C

Overload output current 1.5 x IN (1 min/10 min)

Starting current IS for 2 s every 20 s (IS = 2.0 * IN)

Output frequency 0…320 Hz

Frequency resolution 0.01 Hz

Protection class I

Motor characteristics

AC squirrel cage motors

Permanent magnet motors

Cable type Screened motor cable

Cable maximum length 30 m

Control

characteristics

Switching frequency

Programmable 2…16 kHz;

Default 6 kHz.

Automatic switching frequency

derating in case of overheating

Frequency reference:

Analogue input

Panel reference

Resolution ±0.05% (11-bit),

accuracy ±1% Resolution 0.01 Hz

Field weakening point 8…320 Hz

Acceleration time 0.1…3000 sec

Deceleration time 0.1…3000 sec

Braking

Brake chopper standard in all three-phase

frames. External brake resistor optional.

Page 2

THE CABLE AND FUSE SIZES FOR VACON® 20 X IN NORTH AMERICA,

MAINS VOLTAGE 208240 V AND 380500 V

THE TIGHTENING TORQUES OF CABLE TERMINALS

Frame Type

IL

[A]

Fuse

(class T)

[A]

Mains and

motor cable

Cu

Terminal cable size

Main terminal Earth terminal

MU2

0004 2

0003 4 - 0004 4

4.3

3.2 - 4.0

6 AWG14 AWG24-AWG12 AWG17-AWG10

0005 2 - 0007 2

0005 4 - 0006 4

6.8 - 8.4

5.6 - 7.3

10 AWG14 AWG24-AWG12 AWG17-AWG10

0008 4 9.6 15 AWG14 AWG24-AWG12 AWG17-AWG10

MU2

1-phase

0004 2 8.3 20 AWG14 AWG24-AWG12 AWG17-AWG10

0005 2 11.2 20 AWG14 AWG24-AWG12 AWG17-AWG10

0007 2 14.1 25 AWG14 AWG24-AWG12 AWG17-AWG10

MU3

0011 2

0009 4

13.4

11.5

15 AWG14 AWG20-AWG6 AWG17-AWG10

0012 2

0012 4

14.2

14.9

20 AWG12 AWG20-AWG6 AWG17-AWG10

0017 2

0016 4

20.6

20.0

25 AWG10 AWG20-AWG6 AWG17-AWG10

Frame Type

Tightening torque

Power and motor

terminals

Tightening torque

EMC grounding clamps

Tightening torque

Grounding

terminals

[Nm] lb-in. [Nm] lb-in. [Nm] lb-in.

MU2

0003 4—0008 4

0004 2—0007 2

0.5—0.6 4.5—5.3 1.5 13.3 2.0 17.7

MU3

0009 4—0016 4

0011 2—0017 2

1.2—1.5 10.6—13.3 1.5 13.3 2.0 17.7

TIGHTENING TORQUE OF NPT ADAPTERS TO METRIC THREADS CABLE ENTRIES

Frame

Thread male

metric

Thread male

NPT

Tightening torque

[Nm] lb-in.

MU2

M20 1/2” 2.0 17.7

M25 3/4” 4.0 35.5

MU3 M25 3/4” 4.0 35.5

M20x1.5

M25x1.5

M16x1.5

M25x1.5

M16x1.5

M25x1.5

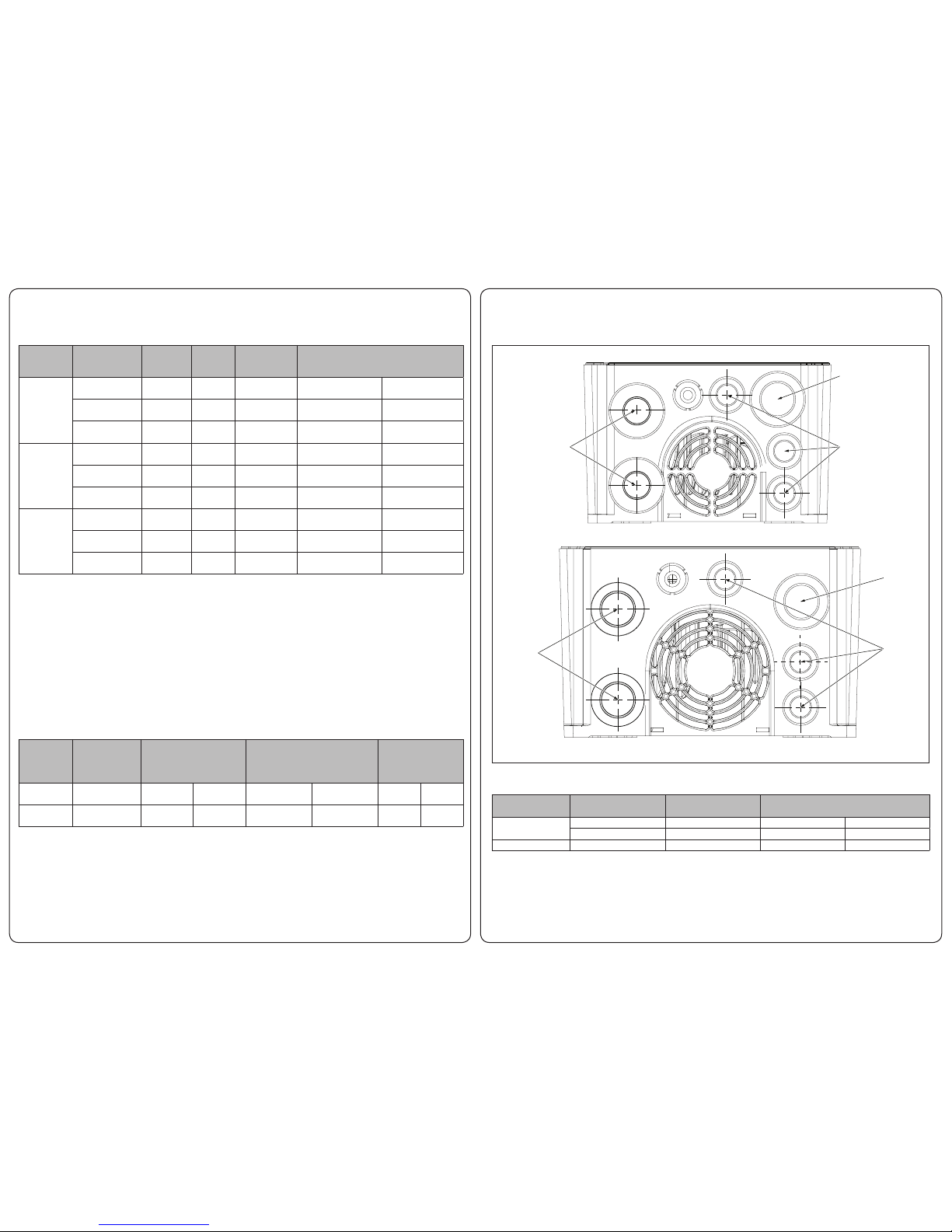

CABLE ENTRIES, MU2 AND MU3 INSTALLATIONS

MU2

MU3

NPT adapter order information

M20: ADEC M20-T12

M25: ADEM M25-T34

Loading...

Loading...