vacon®20

ac drives

quick guide

NOTE! You can download the English and French product manuals with applicable safety, warning

and caution information from www.vacon.com/downloads

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde applicables

sur le site www.vacon.com/downloads

.

.

safety vacon • 1

!

Doc: DPD00511E1 Release: 08.03.2013 Sw Package: FW0107V008.vcx

This quick guide includes the essential steps for easy

installation and setup of your Vacon 20 frequency converter.

Before commissioning your drive, download and read the complete

Vacon 20 User Manual available at:

www.vacon.com -> Downloads

1. SAFETY

ONLY A COMPETENT ELECTRICIAN IS ALLOWED TO

CARRY OUT THE ELECTRICAL INSTALLATION!

This quick guide contains clearly marked warnings which are intended for your personal safety and to avoid any unintentional damage to the product or connected appliances.

Please read these warnings carefully:

The components of the power unit of the frequency converter

are live when Vacon 20 is connected to mains. Coming into

contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W (T1, T2, T3) and the possible brake

resistor terminals - / + are live when Vacon 20 is connected to

mains, even if the motor is not running.

The control I / O-terminals are isolated from the mains potential. However, the relay output terminals may have a dangerous control voltage present even when Vacon 20 is

disconnected from mains.

The earth leakage current of Vacon 20 frequency converters

exceeds 3.5 mA AC. According to standard EN61800-5-1, a

reinforced protective ground connection must be ensured.

See Chapter 7!

If the frequency converter is used as a part of a ma chine, the

machine manufacturer is responsible for providing the

machine with a main switch (EN 60204-1).

If Vacon 20 is disconnected from mains while running the

motor, it remains live if the motor is energized by the process.

In this case the motor functions as a generator feeding energy

to the frequency converter.

After disconnecting the frequency converter from the mains,

wait until the fan stops and the display segments or status

leds on the front panel go out. Wait 5 more minutes before

doing any work on Vacon 20 connections.

The motor can start automatically after a fault situation, if the

autoreset function has been activated.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

1

2 • vacon safety

1

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

installation vacon • 3

=

M5

MI3

MI1

=M4

MI2

=M5

LOC

REM

BACK

RESET

OK

LOC

REM

BACK

RESET

OK

LOC

REM

BACK

RESET

OK

MI4

=M 6

=M 6

MI5

LOC

REM

BACK

RESET

OK

LOC

REM

BACK

RESET

OK

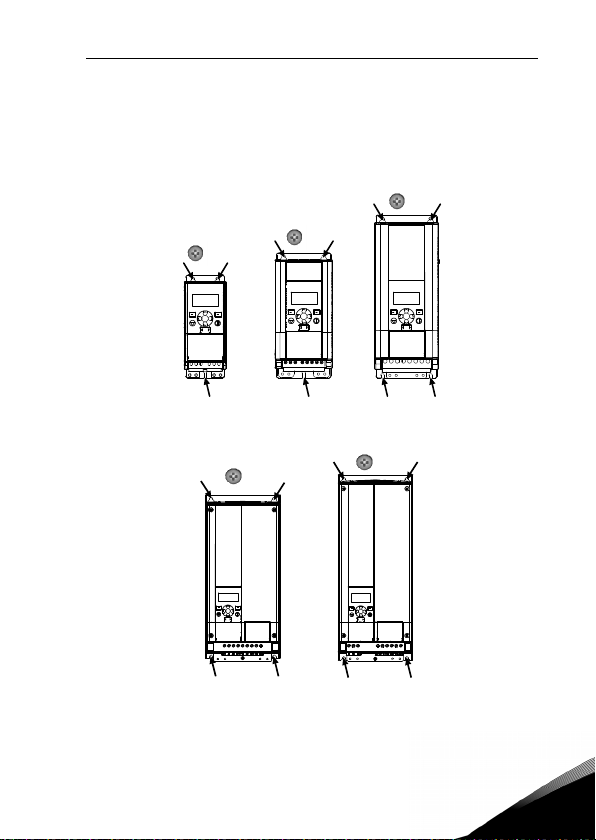

2. INSTALLATION

2.1 Mechanical installation

There are two possible ways to mount Vacon 20 in the wall. For MI1 - MI3, either

screw or DIN-rail mounting; For MI4 - MI5, screw or flange mounting.

Figure 1: Screw mounting, MI1 - MI3

Figure 2: Screw mounting, MI4 - MI5

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

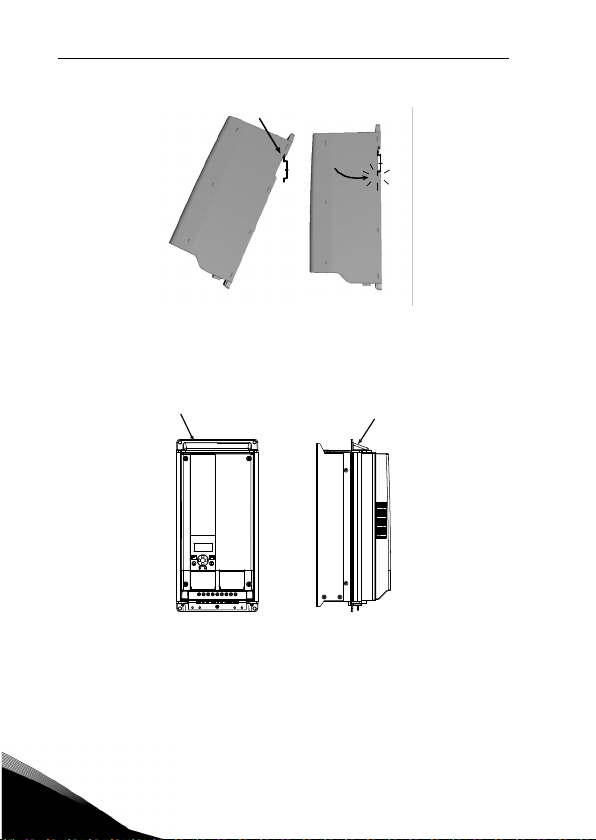

4 • vacon installation

12

LOC

REM

BACK

RESET

OK

Figure 3: DIN-rail mounting, MI1 - MI3

Note! See the mounting dimensions on the back of the drive.

Leave free space for cooling above (100 mm), below (50 mm), and on the si des

(20 mm) of Vacon 20! (For MI1 - MI3, side-to-side installation allowed only if the ambient temperature is below 40 °C; For MI4 - MI5, side-to-side installation is not allowed.

Figure 4: flange mounting, MI4 – MI5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

2

installation vacon • 5

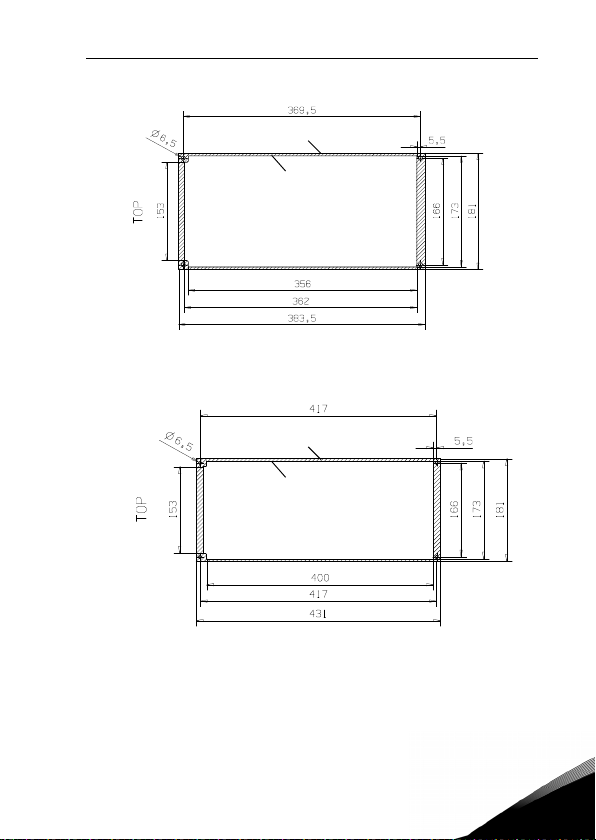

Drive outline

Opening outline

Drive outline

Opening outline

Figure 5: Flange mounting cutout dimensions for MI4 (Unit: mm)

Figure 6: Flange mounting cutout dimensions for MI5 (Unit: mm)

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

6 • vacon installation

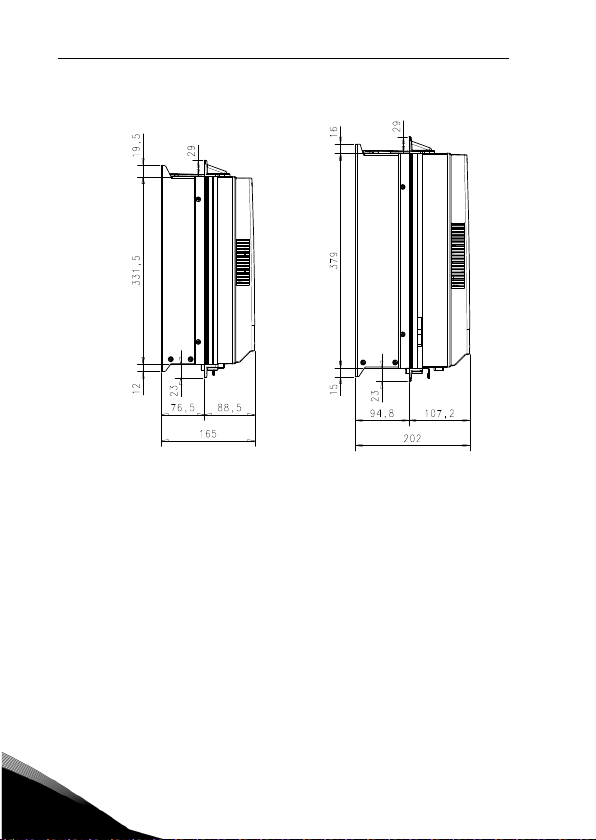

M15

M14

Figure 7: Flange mounting depth dimensions for MI4 and MI5 (Unit: mm)

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

2

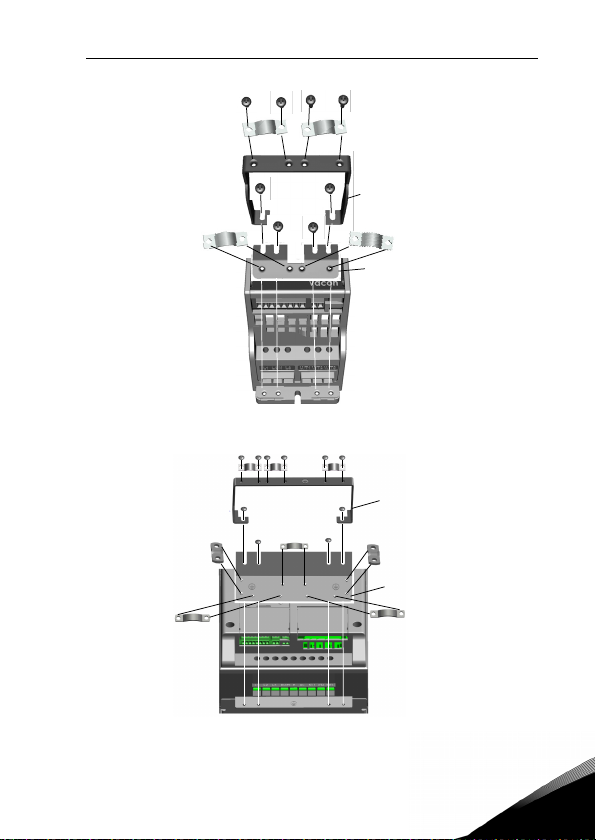

installation vacon • 7

Attachthis plate

BEFORE i nstalling

the p ower cabl es

Attachthe support

AFTER i nstalling

thepower cables

Attach thesupport

AFT ER ins tal lin g

Attac h this plat e

BEFOREinstalling

the p ow er ca bl es

.

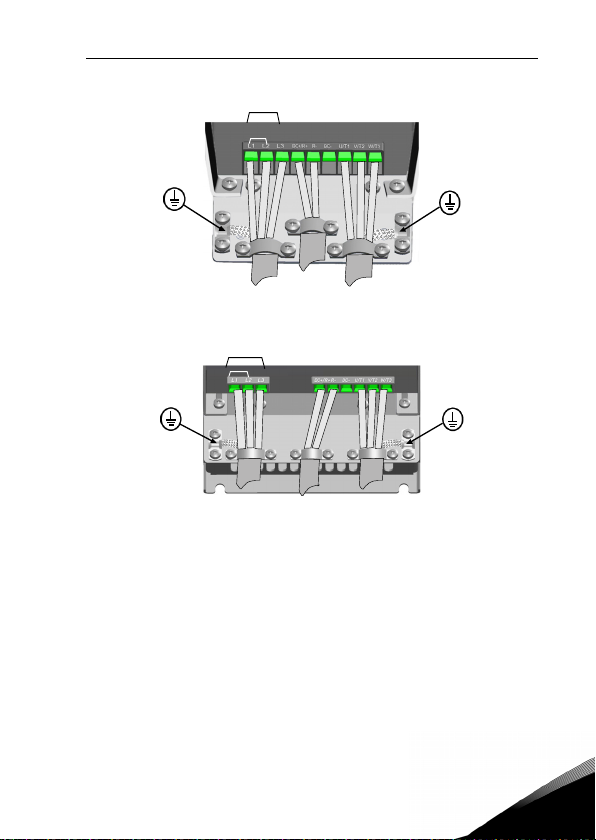

Figure 8: Attaching the PE-plate and API cable support, MI1 - MI3

Figure 9: Attaching the PE-plate and API cable support, MI4 - MI5

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

8 • vacon installation

1~ (230V)

3~ (230V, 400V)

Motor out

MAINS

MOTOR

Strip the

plastic cable

coating f or

360° earthing

L1 L 2/N L3 U/T1 V/T2 W/T3R+ R-

1~ (230V)

3~(230V,400V,575V)

1~ (115V)

MAINS

MOTOR

BRAKE

RESISTOR

Externalbrakeresistor

Motor out

Strip t he

plastic

cable

coating

for 360°

earthing

3~(230V, 400V,575V)

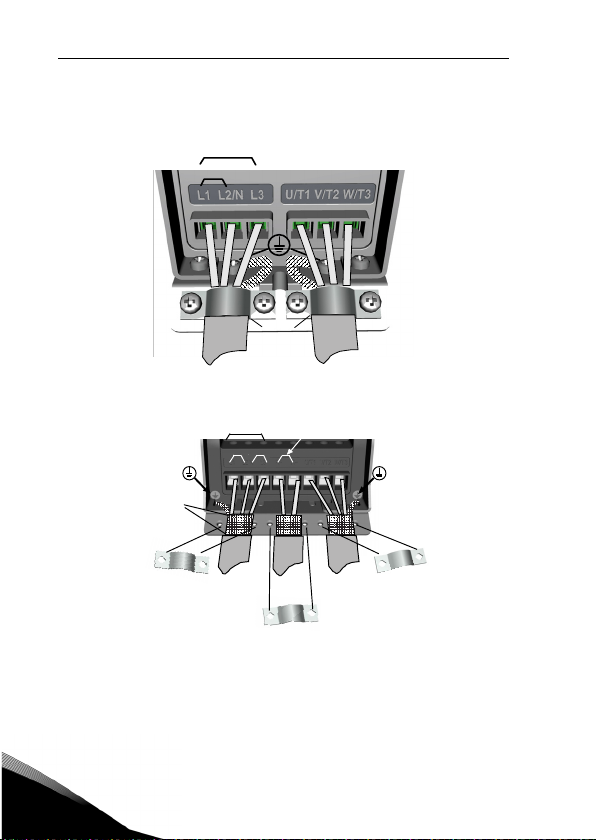

2.2 Cabling and connections

2.2.1 Power cabling

Note! Tightening torque for power cables is 0.5 - 0.6 Nm (4-5 in.lbs).

Figure 10: Vacon 20 power connections, MI1

Figure 11: Vacon 20 power connections, MI2 - MI3

2

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

installation vacon • 9

MAINS

MOTOR

Motor out

Brake

RESISTOR

3~ (380, 480V)

MAINS

MOTOR

Motor out

Brake

RESISTOR

3~ (380, 480V)

Figure 12: Vacon 20 power connections, MI4

Figure 13: Vacon 20 power connections, MI5

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

10 • vacon installation

2.2.2 Control cabling

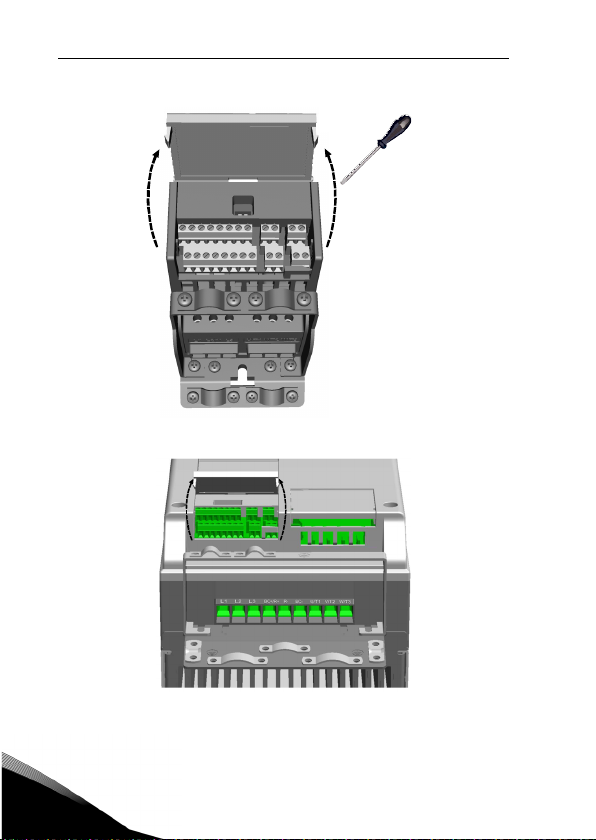

Figure 14: Open the lid MI1 - MI3

2

Figure 15: Open the lid MI4 - MI5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

installation vacon • 11

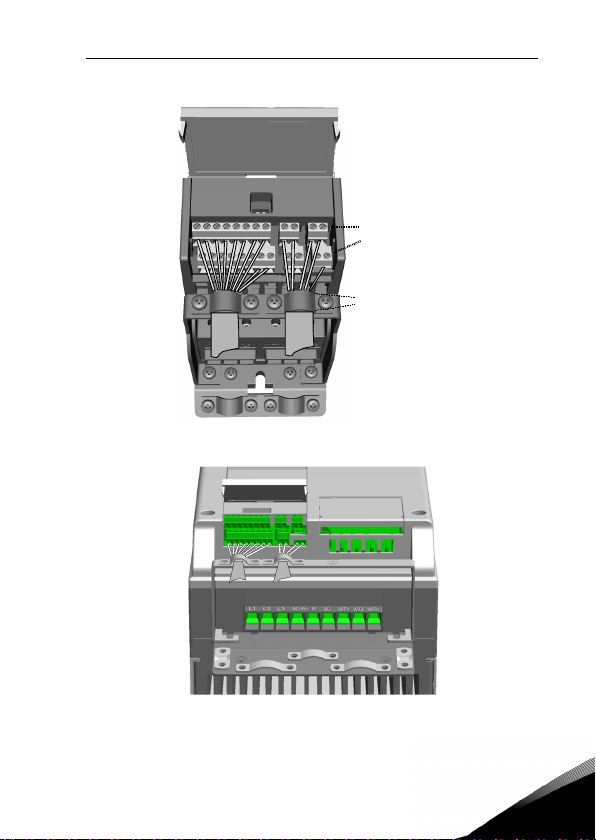

Strip the plastic

cable coating for

360°earthing

Control cable

tightening

torque: 0.4 Nm

Figure 16: Install the control cables, MI1 - MI3

Figure 17: Install the control cables, MI4 - MI5

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

12 • vacon installation

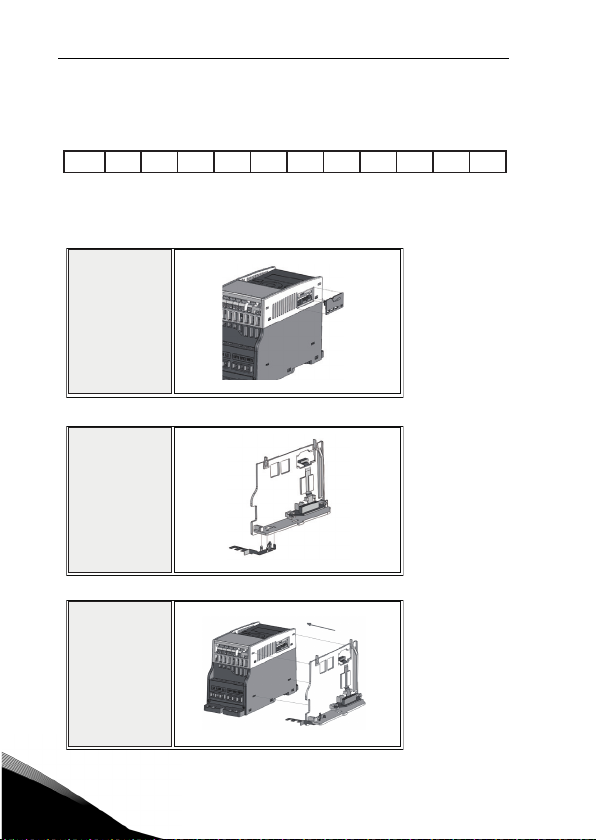

2.2.3 Allowed option boards in Vacon20

See below for the allowed option boards in the slot:

6/27 ( ( ( ( % % % % % %+ %)

Note! OPT-B1 and OPT-B4 only support external power supply.

Option board assembly structure:

1

2

2

3

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

installation vacon • 13

4

5

6

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

14 • vacon installation

2

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

vacon 20 api vacon • 15

20

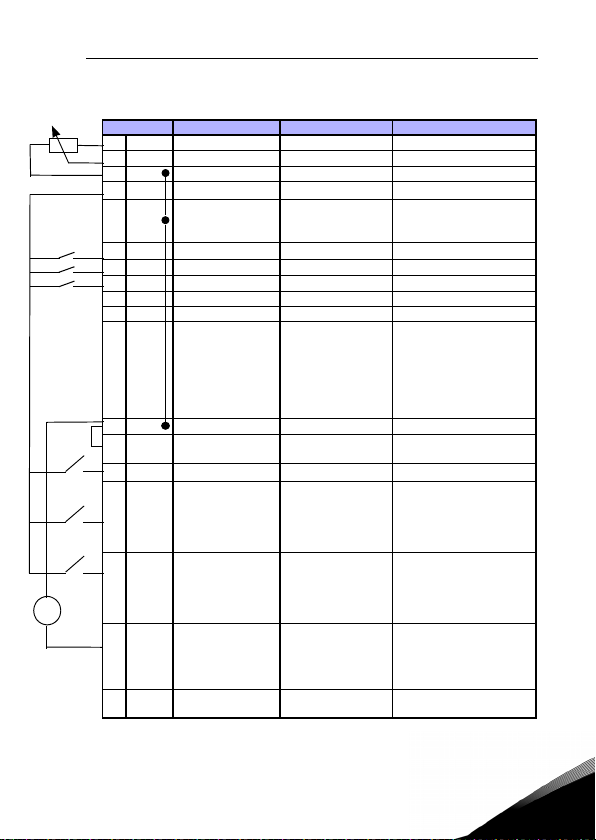

3. CONTROL I / O AND TERMINALS

Vacon 20

1-10 k

mA

Terminal Signal Factory preset Description

1 +10 Vref Ref voltage out Maximum load 10 mA

2 AI1 Analogue signal in 1

3 GND I / O signal ground

6 24 Vout 24 V output for DI's

7DI_C

8 DI1 Digital input 1

9 DI2 Digital input 2

10 DI3 Digital input 3

A A RS485 signal A FB Communication Negative

B B RS485 signal B FB Communication Positive

4AI2

5 GND I / O signal ground

13 DO-

14 DI4 Digital input 4

15 DI5 Digital input 5

16 DI6 Digital input 6

18 AO Analogue Output

20 DO Digital signal out

Table 1: Vacon 20 General purpose application default I / O configuration and

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

Digital Input Common

Analogue signal in

2

Digital Output

Common

connections for control boar d

P) = Programmable function, See User Manual: parameter lists and

descriptions for detail

Freq re ference

Start forward P)

Start reverse P)

Fault reset P)

PID actual value and

Freq re ference P)

Preset speed B0 P)

Preset speed B1

External Fault

Output frequency P)

Active = READY P)

P)

0 - 10 V, Ri >= 200 k

%, max load 50 mA

Digital Input for DI1- DI6,

refer to Table 2 for DI sink

type

18 - 30 V, Ri > 5 k

Default:

0(4) - 20 mA, Ri <= 250

Other:

0 - 10 V, Ri >= 200 k

Selectable through micro-

switch

Digital Output Common

18 - 30 V, Ri > 5 k

As DI,

Other: Encoder Input A

P)

(frequency up to 10 kHz)

Selectable through microswitch

As DI,

Other: Encoder Input B

P)

(frequency up to 10 kHz),

Pulse Train Input (frequency up to 5 kHz)

0 - 10 V, RL >1 K

0(4) - 20 mA, RL < 500

Selectable through micro-

switch

Open collector, max load

48 V / 50 mA

3

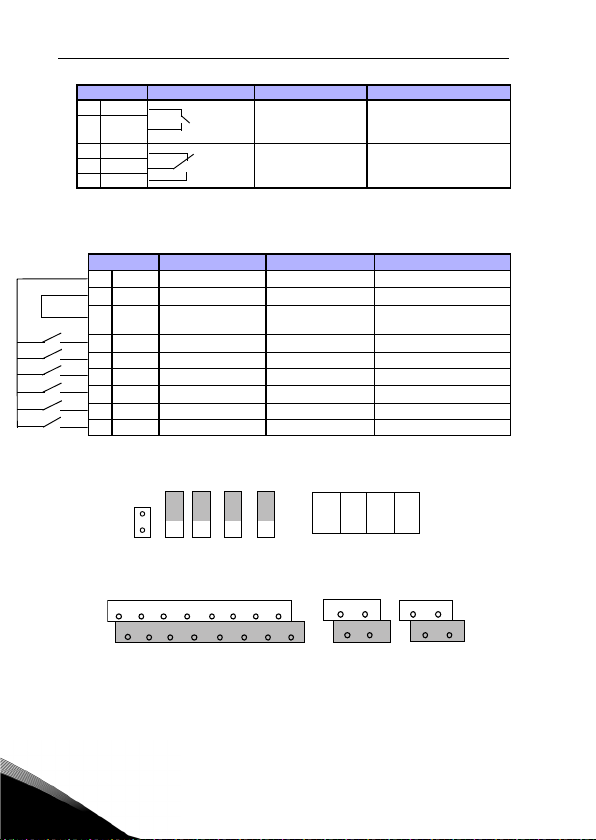

16 • vacon vacon 20 api

20

DI

Enco Nor

AO

VmA

AI2

VmA

RS485

-term

ON

S1S2S3S4

J500

OFF

4 5 13 14 15 16 2018

123678910

22 23 26

2425

AI2 G ND DO- DI 4 DI5 DI6 AO DO+ R13 R14 * R24

+10V AI1 G ND 24V DI -C DI1 DI 2 D I3 A B R21 R22

Terminal Signal Factory preset Description

22 RO 13 Relay out 1

23 RO 14

24 RO 22

25 RO 21

26 RO 24

Table 1: Vacon 20 General purpose application default I / O configuration and

connections for contro l board

P) = Programmable function, See User Manual: parameter lists and

descriptions for detail

Relay out 2

Active = RUN P)

Active = FAULT

Terminal Signal Factory preset Description

3 GND I / O signal ground

6 24 Vout 24 V output for DI's

7DI_C

8 DI1 Digital input 1

9 DI2 Digital input 2

10 DI3 Digital input 3

14 DI4 Digital input 4

15 DI5 Digital input 5

16 DI6 Digital input 6

Table 2: DI Sink Type, remove jumper J500 and connect the wire using table 2

Digital Input Common

Start forward P)

Start reverse P)

Fault reset P)

Preset speed B0 P)

Preset speed B1

External Fault

Max switching load:

250 Vac / 2 A or 250 Vdc /

0.4 A

Max switching load:

P)

250 Vac / 2 A or 250 Vdc /

0.4 A

%, max load 50 mA

Digital Input Common

for DI1-DI6

18 - 30 V, Ri > 5 k

18 - 30 V, Ri > 5 k

P)

Only for DI.

P)

Only for DI.

Vacon 20 I / O terminals:

Figure 18: Microswitchs

3

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

navigation & startup vacon • 17

FWD REV I/O KEY PAD BUS

REF

MON

PAR

SYS SYS

SYS SYS

SYS SYS

SYS SYS

FAULTALARMSTOPREADY RUN

FWD REV I/O KEYPAD BUS

REF

PA R

FAULTALARMSTOPREADY RUN

MON

FW D R EV I/O KEY PAD BU S

REF

PAR

FAUL TALARMSTOPREADY RUN

MON

FWD REV I/O KEYPAD BUS

REF

PAR

FAULTALARMSTOPREADY RUN

MON

FWD REV I/O KEYPAD BUS

REF

PAR

FAULTALARMSTOPRE ADY RUN

MON

FWD REV I/O KEYPAD BUS

REF

PAR

FAULTALAR MSTOPREADY RUN

MON

FWD REV I/O KEYPAD BUS

REF

PAR

FAU LTALARMST OPREADY RUN

MON

PRESS

PRESS

PRESS

PRESS

PRESS

FWD REV I/O KEY PA D BUS

REF

MON

PAR

FAU LTALARMSTOPREADY R UN

PRESS

PRESS

OK

OK

OK

OK

OK

In this m enu

you can

browsethe

monitoring

values.

In this m enu

you can

browse and

editthe

parameters.

Dispalysthe

keypad reference

value

regardlessof

the sel ected

contron place.

Hereyou will be

able tobrowse

system parameter

and fault

submenu.

MONI TO RING

MENU

REFERENCE

MENU

PARAMETER

MENU

SYSTEM

MENU

Hz

Hz

4. NAVIGATION AND STARTUP

4. 1 The main menus of Vacon 20

Figure 19: The main menu of Vacon 20

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

4

18 • vacon navigation & startup

FAULTALARMSTOPREADY

RUN

REF

MON

PAR

SYS

FAULTALARMSTOPREADY RUN

REF

MON

PAR

SYS

FAULTALARMSTOPREADY RUN

REF

MON

PAR

SYS

FWD REV I/O KEY PAD BUS

FWD REV I/O KEYPAD BUS

FWD REV I/O KEY PAD BUS

FWD REV I/O KEY PAD BUS

2

1

4

3

Change

P1.3

value

with Up/Down button

and press O K to

comfir m

Perform t he same

procedure for P1.4,

motor nominal curr ent

Press OK enter

edit mode

Enter Par. menu, select

P1.3 motor nomi nal speed

FAULTALARMSTOPREADY RUN

REF

MON

PAR

SYS

OK

OK

rpm

4.2 Commissioning and startup wizard

4.2.1 Commissioning steps:

1. Read safety instructions on page 1

2. Secure the grounding and check that cables

comply with requirements

3. Check quality and quantity of cooling air 9. Perform an identification run (Par. ID631)

4. Check that all start / stop switches are in

STOP position

5. Connect the drive to mains 11. Vacon 20 is now ready for use

6. Run the Startup wizard and set all necessary

parameters

Table 3: Commissioning steps

4.2.2 Startup wizard

Vacon 20 runs the startup wizard in first power-up. The wizard can be run by setting

SYS Par.4.2 =1. The following figures show the procedure.

NOTE! Running the startup wizard will always return all parameter

settings to their factory defaults!

7. Perform test run without motor, see the

User Manual at www.vacon.com

8. Run no-load tests without motor bei ng connected to the process

10. Connect the motor to the process and perform test run once again

4

Figure 20: Vacon 20 startup wizard (standard application)

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

navigation & startup vacon • 19

1

2

3

4

Selections:

Parameters

affected:

P1.7 Current limit(A)

P1.8 Motorcontrol mode

P1.15 Torque boost

P2.2 Start function

P2.3 Stop fun ction

P3.1 Min frequency

P4.2 Acc. ti me (s)

P4.3 Dec time (s)

Startup wizard

showns par17.1

numbe r.

Press OK to enter

edit mode.

Press OK to

confirm

drive setup

Select between

0-3, see below!

OK

OK

READY RUN STOP ALARMFAULT

REF

MON

PAR

SYS

READY RUN STOP ALARMFAULT

FWD REV I/O KEYPAD BU S FWD R EV I/O KEYPAD BU S FWD REV I/O KEYPAD BU S

READY RUN STOP ALARMFAULT

REF

MON

PA R

SYS

REF

MON

PAR

SYS

READY RUN STOP ALARM FAULT

REF

MON

PA R

SYS

FWD REV I/O KEYPAD BU S

1.7 P1.8 P1.15 P2.2 P4.3

0=Basic

1=Pumpdrive

2=Fandrive

0=

Not

used

0=

Frequecny

control

0=

Frequecny

control

0=

Frequecny

control

1=Open

loop speed

ontrol

0=

Not

used

0=

Not

used

1=

used

0=

Ramp

0=

Ramp

1=

Flying

0=

Ramp

P2.3

1=

Ramp

0=

Coast

0=

Coast

0=

Coast

P3.1

0Hz

0Hz

20 Hz

20 Hz

3s

5s

1s

20s

P4.2

3s

5s

1s

20s

P

1.1 x

I

NMOT

1.1 x

I

NMOT

1.5 x

I

NMOT

1.5 x

I

NMOT

3 = High Torque drive

Figure 21: Drive setup

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

4

20 • vacon navigation & startup

4

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 21

5. MONITORING AND PARAMETERS

NOTE! This guide is for Vacon 20 standard application, if you need parameter descriptions for detail, please download the user manual on: www.vacon.com ->

Support & downloads.

5.1 Monitoring values

Code Monitoring s ignal Unit ID Description

V1.1 Output frequency Hz 1 Output frequency to motor

V1.2 Frequency reference Hz 25

V1.3 Motor speed rpm 2 Calculated motor speed

V1.4 Motor current A 3 Measured motor current

V1.5 Motor torque % 4

V1.6 Motor shaft power % 5

V1.7 Motor voltage V 6 Motor voltage

V1.8 DC-link voltage V 7 Measured DC-link voltage

V1.9 Unit temperature °C 8 Heatsink temperature

V1.10 Motor temperature % 9 Calculated motor temperature

V1.11 Output Power KW 79 Output power from drive to motor

V2.1 Analogue input 1 % 59

V2.2 Analogue input 2 % 60

V2.3 Analogue output % 81

Digital input status DI1,

V2.4

DI2, DI3

Digital input status DI4,

V2.5

DI5, DI6

V2.6 RO1, RO2, DO 17 Relay / digital output status

Pulse train / encoder

V2.7

input

V2.8 Encoder rpm rpm 1235

Table 4: Monitoring values

% 1234 0 - 100% scale value

Frequency reference to motor control

Calculated actual / nominal torque

of the motor

Calculated actual / nominal power

of the motor

AI1 signal range in percent of used

range

AI2 signal range in percent of used

range

AO signal range in percent of used

range

15 Digital input status

16 Digital input status

Scaled according to Encoder

pulses / revolution parameter

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

22 • vacon monitoring & parameters

Code Monitoring signal Unit ID Description

V2.11 Analogue input E1 % 61

V2.12 Analogue output E1 % 31

V2.13 Analogue output E2 % 32

V2.14 DIE1, DIE2, DIE3 33

V2.15 DIE4, DIE5, DIE6 34

V2.16 DOE1,DOE2,DOE3 35

V2.17 DOE4,DOE5,DOE6 36

V2.18 Temperature input 1 50

V2.19 Temperature input 2 51

V2.20 Temperature input 3 52

Table 4: Monitoring values

Analogue input signal 1 in % from

option board, hidden until an

option board is connected

Analogue output signal 1 in % from

option board, hidden until an

option board is connected

Analogue output signal 2 in % from

option board, hidden until an

option board is connected

This monitor value shows status of

the digital inputs 1-3 from option

board, hidden until an option board

is connected

This monitor value shows status of

the digital inputs 4-6 from option

board, hidden until an option board

is connected

This monitor value shows status of

the relay outputs 1-3 from option

board, hidden until an option board

is connected

This monitor value shows status of

the relay outputs 4-6 from option

board, hidden until an option board

is connected

Measured value of Temperature

input 1 in temperature unit ( Celsius or Kelvin) by parameter setting, hidden until an option board

is connected

Measured value of Temperature

input 2 in temperature unit ( Celsius or Kelvin) by parameter setting, hidden until an option board

is connected

Measured value of Temperature

input 3 in temperature unit ( Celsius or Kelvin) by parameter setting, hidden until an option board

is connected

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 23

Code Monitoring s ignal Unit ID Description

V3.1 Drive status word 43

V3.2 Application status word 89

V3.3 DIN status word 56

V4.1 PID set point % 20 Regulator setpoint

V4.2 PID feedback value % 21 Regulator actual value

V4.3 PID error % 22 Regulator error

V4.4 PID output % 23 Regulator output

V4.5 Process 29

Table 4: Monitoring values

Bit codes status of drive

B0 = Ready

B1 = Run

B2 = Reverse

B3 = Fault

B6 = RunEnable

B7 = AlarmActive

B12 = RunRequest

B13 = MotorRegulatorActive

Bit codes status of application:

B3 = Ramp 2 Active

B5 = Remote CTRL Place 1 active

B6 = Remote CTRL Place 2 active

B7 = Fieldbus Control Active

B8 = Local Control Active

B9 = PC Control Active

B10 = Preset Frequencies Active

B0 = DI1

B1 = DI2

B2 = DI3

B3 = DI4

B4 = DI5

B5 = DI6

B6 = DIE1

B7 = DIE2

B8 = DIE3

B9 = DIE4

B10 = DIE5

B11 = DIE6

Scaled process variable

see par. 15.18

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

24 • vacon monitoring & parameters

P1.1

P1.2

P1.3

P1.4

P1.5

P1.7

P1.15

P2.2

P2.3

P3.1

P3.2

5.2 Quick setup parameters (Virtual menu, shows when par. 17.2 = 1)

Code Parameter Min Max Unit Default ID Note

Motor nominal

voltage

Motor nominal

frequency

Motor nominal

speed

Motor nominal

current

Motor cos

Current limit

Torque boost 0 1 0 109

Remote control

P2.1

place 1 selection

Start function

Stop function

Min frequency 0.00 P3.2 Hz 0.00 101 Minimum freq reference

Max frequency P3.1 320.00 Hz

Remote Control

Place 1 frequency

P3.3

refere nce

selection

Table 5: Quick setup parameters

180 690 V Varies 110

30.00 320.00 Hz

30 20000 rpm

2.0 x

0.2 x

I

I

Nunit

Nunit

0.30 1.00 0.85 120

2.0 x

0.2 x

I

I

Nunit

Nunit

0 2 0 172

0

1 0 505

0

1 0 506

1 Varies 7 117

50.00 /

60.00

1440 /

1720

I

A

Nunit

1.5 x

A

I

Nunit

50.00 /

60.00

Check rating plate on the

motor.

Check rating plate on the

111

motor.

Default a pplies for a 4-

112

pole motor.

Check rating plate on the

113

motor.

Check rating plate on the

motor.

107 Maximum motor current

0 = Not used

1 = Used

0 = I / O terminal

1 = Fieldbus

2 = Keypad

0 = Ramp

1 = Flying start

0 = Coasting

1 = Ramp

Maximum freq refer-

102

ence

1 = Preset speed 0

2 = Keypad

3 = Fieldbus

4 = AI1

5 = AI2

6 = PID

7 = AI1 + AI2

8 = Motor potentiometer

9 = Pulse train / Encoder

10 = AIE1

11 = Temperature input 1

12 = Temperature input 2

13 = Temperature input 3

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 25

P4.2

P4.3

P14.1

Code Parameter Min Max Unit Default ID Note

P3.4 Preset speed 0 P3.1 P 3.2 Hz 5 .00 180

P3.5 Preset speed 1 P3.1 P3.2 Hz 10.00 10 5

P3.6 Preset speed 2 P3.1 P3.2 Hz 15.00 10 6

P3.7 Preset speed 3 P3.1 P3.2 Hz 20.00 12 6

Acceleration

time 1

Deceleration

time 1

P6.1 AI1 Signal range 0 1 0 379

P6.5 AI2 Signal range 0 1 0 390

Automatic reset 0 1 0 731

Parameter

P17.2

conceal

Table 5: Quick setup parameters

0.1 3000.0 s 3.0 103

0.1 3000.0 s 3.0 104

01 1 115

Preset speed 0 is used

as frequency reference

when P3.3 = 1

Activated by digital

inputs

Activated by digital

inputs

Activated by digital

inputs

Acceleration time from

0 Hz to maximum frequency.

Deceleration time from

maximum frequency to

0 Hz.

0 = 0 - 100%

1 = 20% - 100%

20% is the same as 2 V

minimum signal level.

0 = 0 - 100%

1 = 20% - 100%

20% is the same as 2 V

or 4 mA minimum signal

level.

0 = Disable

1 = Enable

0 = All parameters visi-

ble

1 = Only quick setup

parameter group visible

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

26 • vacon monitoring & parameters

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

P1.8

P1.9

P1.10

P1.11

P1.12

P1.13

P1.14

P1.15

P1.16

5.3 Motor settings (Control panel: Menu PAR -> P1)

Code Parameter Min Max Unit Default ID Note

Motor nominal

voltage

Motor nominal

frequency

Motor nominal

speed

Motor nominal

current

Motor cos

(Power Factor)

Motor type 0 1 0 650

Current limit

Motor control

mode

U / f ratio 0 2 0 108

Field weakening

point

Field weakening

point voltage

U / f mid point

frequency

U / f mid point

voltage

Zero freq voltage 0.00 40.00 % Varies 606

Torqu e Bo ost 0 1 0 1 09

Switching

frequency

Table 6: Motor settings

180 690 V Varies 110

30.00 320.00 Hz

30 20000 rpm

2.0 x

0.2 x

I

Nunit

0.30 1.00 0.85 120

0.2 x

I

Nunit

01 0600

8.00

10.00 200.00 % 100.00 603

0.00 P1.10 Hz

0.00 P1.11 % 100.00 605

1.5 16.0 kHz 4.0 / 2.0 601

I

Nunit

2.0 x

I

Nunit

320.00 Hz

A

A

50.00 /

60.00

1440 /

1720

I

Nunit

1.5 x

I

Nunit

50.00 /

60.00

50.00 /

60.00

Check rating plate on the

motor

Check rating plate on the

111

motor

Default applie s for a 4-pole

112

motor.

Check rating plate on the

113

motor

Check rating plate on the

motor

0 = Induction

1 = Permanent magnet

107 Maximum motor current

0 = Frequency control

1 = Open loop speed control

0 = Linear

1 = Square

2 = Programmable

Field weakening point fre-

602

quency

Voltage at field weakening

point as % of U

Mid point frequency for

604

programmable U / f

Mid point voltage for programmable U / f as % of

U

nmot

Voltage at 0 Hz as % of

U

nmot

0 = Disabled

1 = Enabled

PWM frequency. If values

are higher than default,

reduce the current capacity

nmot

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 27

P1.17

P1.18

P1.19

P1.20

P1.21

P1.22

P1.23

P1.24

Code Parameter Min Max Unit Default ID Note

Brake Chopper 0 2 0 504

Brake chopper

level

Motor

identification

Rs voltage drop 0.00 100.00 % 0.00 662

Overvoltage

controller

Undervoltage

controller

Sine filter 0 1 0 522

Modulator type 0 65535 28928 648

Table 6: Motor settings

0 911 V varies 1267

01 0631

02 1607

01 1608

0 = Disabled

1 = Enabled: Always

2 = Run state

Brake chopper control activation level in volt.

For 240V Supply:

240*1.35*1.18 = 382V

For 400V Supply:

400*1.35*1.18 = 638V

Please note that when

brake chopper is used the

overvoltage controller can

be switched off or the overvolt age refere nce level can

be set above the brake

chopper level.

0 = Not active

1 = Standstill identification

(need run command within

20 s to activate)

Voltage drop over motor

windings as % of U

nominal current.

0 = Disabled

1 = Enabled, Standard

mode

2 = Enable d, Shock load

mode

0 = Disable

1 = Enable

0 = Not in use

1 = In use

Modulator configuration word:

B1 = Discontinuous modulation (DPWMMIN)

B2 = Pulse dropping in

overmodulation

B6 = Under modulation

B8 = Instantaneous DC volt-

age compensation *

B11 = Low noise

B12

= Dead time compensation *

B13

= Flux error compensation *

* Enabled by default

NOTE! These parameters are shown, when P17.2 = 0.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

nmot

at

5

28 • vacon monitoring & parameters

P2.2

P2.3

P2.9

5.4 Start / stop setup (Control panel: Menu PAR -> P2)

Code Param eter Min Max Unit Default ID Note

Remote Control

P2.1

Place Selection

Start function

Stop function

I / O Start / Stop

P2.4

P2.5 Local / Remote 0 1 0 211

P2.6

P2.7

P2.8

Table 7: Start / stop setup

logic

Keypad control

direction

Keypad stop but-

ton

Remote Control

Place 2 Selection

keypad button

lock

0

2 0 172

0

1 0 505

0

1 0 506

0 4 2 300

0 1 0 123

0 1 1 114

0

2 0 173

0

1 0 15520

0 = I / O terminals

1 = Fieldbus

2 = Keypad

0 = Ramp

1 = Flying start

0 = Coasting

1 = Ramp

I / O control I / O control

signal 1 signal 2

0 Forward Reverse

1 Fw d(e dge ) In ver ted Sto p

2 Fwd(edge) Bwd(edge)

3 Start Reverse

4 Start(edge) Reverse

0 = Remote control

1 = Local control

0 = Forward

1 = Reverse

0 = Keypad control only

1 = Always

0 = I / O terminals

1 = Fieldbus

2 = Keypad

0 = unlock all keypad button

1 = Loc/Rem button locked

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 29

P3.1

P3.2

5.5 Frequency references (Control panel: Menu PAR -> P3)

Code Parameter Min Max Unit Default ID Note

Min frequency 0.00 P3.2 Hz 0.00 101

Max frequency P3.1 320.00 Hz

Remote Control

Place 1

P3.3

frequency

refere nce

selection

P3.4 Preset speed 0 P3.1 P3.2 Hz 5.00 180

P3.5 Preset speed 1 P3.1 P3.2 Hz 10.00 105 Activated by digital inputs

P3.6 Preset speed 2 P3.1 P3.2 Hz 15.00 106 Activated by digital inputs

P3.7 Preset speed 3 P3.1 P3.2 Hz 20.00 126 Activated by digital inputs

P3.8 Preset speed 4 P3.1 P3.2 Hz 25.00 127 Activated by digital inputs

P3.9 Preset speed 5 P3.1 P3.2 Hz 30.00 128 Activated by digital inputs

P3.10 Preset speed 6 P3.1 P3.2 Hz 40.00 129 Activated by digital inputs

P3.11 Preset speed 7 P3.1 P3.2 Hz 50.00 130 Activated by digital inputs

Remote Control

Place 2 fre-

P3.12

quency refer-

ence selection

Motor Poten-

P3.13

tionmeter Ramp

Motor Poten-

P3.14

tionmeter Reset

Table 8: Frequency references

1 Varies 7 117

1 Varies 5 131 See P3.3

1 50 Hz/s 5 331 Speed variation rate

0 2 2 367

50.00 /

60.00

NOTE! These parameters are shown, when P17.2 = 0.

Minimum allowed

frequency reference

Maximum allowed

102

frequency reference

1 = Preset speed 0

2 = Keypad

3 = Fieldbus

4 = AI1

5 = AI2

6 = PID

7 = AI1 + AI2

8 = Motor potentiometer

9 = Pulse train / Encoder

10 = AIE1

11 = Temperature input 1

12 = Temperature input 2

13 = Temperature input 3

Preset speed 0 is used as

frequency reference when

P3.3 = 1

0 = No Reset

1 = Reset if stopped

2 = Reset if powered down

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

30 • vacon monitoring & parameters

P4.1

P4.2

P4.3

P4.4

P4.5

P4.6

P4.7

P4.8

P4.9

P4.10

P4.11

P4.12

5.6 Ramps and brakes setup (Control panel: Menu PAR -> P4)

Code Para meter Min Max Unit Default ID Note

Ramp S-shape 1 0.0 10.0 s 0.0 500

Acceleration time 1 0.1 3000.0 s 3.0 103

Deceleration time 1 0.1 3000.0 s 3.0 104

Ramp S-shape 2 0.0 10.0 s 0.0 501 See the parameter P4.1

Acceleration time 2 0.1 3000.0 s 10.0 502 See the parameter P4.2

Deceleration time 2 0.1 3000.0 s 10.0 503 See the parameter P4.3

Flux Braking 0 3 0 520

2.0 x

Flux Braking

Current

DC Braking Current

Stop DC current

time

Stop DC current

frequency

Start DC current

time

Table 9: Ramps and brakes setup

0.5 x

I

I

Nunit

Nunit

2.0 x

0.3 x

I

I

Nunit

Nunit

0.00 600.00 s 0.00 508

0.10 10.00 Hz 1.50 515

0.00 600.00 s 0.00 516 0.00 = Not active

I

A

Nunit

I

A

Nunit

0 = Linear

>0 = S-curve ramp time

Defines the time

required for the output

frequency to increase

from zero frequency to

maximum frequency.

Defines the time

required for the output

frequency to decrease

from maximum frequency to zero frequency.

0 = Off

1 = Deceleration

2 = Chopper

3 = Full Mode

Defines the current level

519

for flux b raking.

Defines the current

507

injected into the motor

during DC brakeing.

Determines if braking is

ON or OFF and the braking time of the DC-brake

when the motor is stopping.

0.00 = Not active

The output frequency at

which the DC-braking is

applied.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 31

Code Parameter Min Max Unit Default ID Note

Accel2 Frequency

P4.13

Threshold

Decel2 Frequency

P4.14

Threshold

External Brake:

P4.15

Open Delay

External Brake:

P4.16

Open Frequency

limit

External Brake :

P4.17

Close Frequency

limit

External Brake :

P4.18

Close Frequency

limit in Reverse

External Brake :

P4.19

Open/Close Cur-

rent l imit

Table 9: Ramps and brakes setup

0.00 P3.2 Hz 0.00 527 0.00 = disabled

0.00 P3.2 Hz 0.00 528 0.00 = disabled

0.00 320.00 s 0.20 1544

0.00 P3.2 Hz 1.50 1535

0.00 P3.2 Hz 1.00 1539

0.00 P3.2 Hz 1.50 1540

0.0 200.0 % 20.0 1585

Delay to open brake

after Open frequency

limit is reached.

Opening frequency from

forward and reverse

direction.

Close frequency from

positive direction if no

run command active.

Close frequency from

negative direction if no

run command active.

The brake is not opened

if the current does not

exceed this value, and is

closed immediately if

current goes below.

This parameter is set as

a percent of Motor nominal current.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

32 • vacon monitoring & parameters

5.7 Digital inputs (Control panel: Menu PAR -> P5)

Code Parameter Min Max Unit Default ID Note

P5.1 I / O control signal 1 0 Varies 1 403

P5.2 I / O control signal 2 0 Varies 2 404 See 5.1

P5.3 Reverse 0 Varies 0 412 See 5.1

P5.4 Ext. fault Close 0 Varies 6 405 See 5.1

P5.5 Ext. fault Open 0 Varies 0 406 See 5.1

P5.6 Fault reset 0 Varies 3 414 See 5.1

P5.7 Run enable 0 Varies 0 407 See 5.1

P5.8 Preset speed B0 0 Varies 4 419 See 5.1

P5.9 Preset speed B1 0 Varies 5 420 See 5.1

P5.10 Preset speed B2 0 Varies 0 421 See 5.1

Ramp time 2 selec-

P5.11

P5.12

P5.13

P5.14

P5.15

Table 10: Digital inputs

tion

Motor potentiome-

ter up

Motor potentiome-

ter down

Remote control

place 2

Remote control

plece freq refer-

ence 2

0 Varies 0 408 See 5.1

0 Varies 0 418 See 5.1

0 Varies 0 417 See 5.1

0 Varies 0 425

0 Varies 0 343

0 = Not used

1 = DI1

2 = DI2

3 = DI3

4 = DI4

5 = DI5

6 = DI6

7 = DIE1

8 = DIE2

9 = DIE3

10 = DIE4

11 = DIE5

12 = DIE6

Activates control place 2

See 5.1

Activates control place 2

See parameter 5.1

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 33

Code Parameter Min Max Unit Default ID Note

P5.16 PID setpoint 2 0 Varies 0 1047

Motor Preheat

P5.17

Table 10: Digital inputs

Active

0 Varies 0 1044

Activates reference 2

See 5.1

Activates the Motor Preheat (DC-Current) in

stop state when parameter Motor Preheat function is set to 2

See 5.1

5.8 Analogue inputs (Control panel: Menu PAR -> P6)

Code Parameter Min Max Unit Default ID Note

144

145

0.1

142

0 = 0 - 100% ( 0 - 10 V)

1 = 20% - 100% ( 2 - 10 V)

See P6.1, hidden until an

option board is connected

See P6.2, hidden until an

option board is connected

See P6.3, hidden until an

option board is connected

See P6.4, hidden until an

option board is connected

P6.1 AI1 Signal range 0 1 0 379

-100.00

P6.2 AI1 Custom min

P6.3 AI1 Custom max

P6.4 AI1 filter time 0.0 10.0 s 0.1 378 0 = no filtering

P6.5 AI2 signal range 0 1 0 390 See P6.1

P6.6 AI2 Custom min

P6.7 AI2 Custom max

P6.8 AI2 filter time 0.0 10.0 s 0.1 389 See P6.4

P6.9 AIE1 Signal range 0 1 0 143

P6.10 AIE1 Custom Min

P6.11 AIE1 Custom Max

P6.12 AIE1 Filter time

Table 11: Analogue inputs

100.00 % 0.00 380 0.00 = no min scaling

-100.00

300.00 % 100.00 381 100.00 = no max scaling

-100.00

100.00 % 0.00 391 See P6.2

-100.00

300.00 % 100.00 392 See P6.3

-100.00 100.00

-100.00 300.00

0.0 10.0

0.00

%

100.00

%

s

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

34 • vacon monitoring & parameters

P7.7

5.9 Pulse train / Encoder (Control panel: Menu PAR -> P7)

Code Parameter Min Max Unit Default ID Note

Min pulse fre-

P7.1

quency

Max pulse fre-

P7.2

quency

Freq ref at mi n

P7.3

pulse freq

Freq ref at max

P7.4

pulse freq

Encoder direc-

P7.5

P7.6

Table 12: Pulse train/Encoder

tion

Encoder pulses

/ revolution

Config DI5 and

DI6

0 10000 Hz 0 1229

0.0 10000 Hz 10000 1230

0.00

P3.2 Hz 0.00 1231

0.00

P3.2 Hz

0 2 0 1233

1 65535 ppr 256 629

0

2 0 1165

50.00 /

60.00

Pulse frequency to be

interpreted as a 0% signal.

Pulse frequency to be

interpreted as a 100%

signal.

Frequency corresponding to 0% if used as frequency reference.

Frequency correspond-

1232

ing to 100% if used as

frequency reference.

0 = Disable

1 = Enable / Normal

2 = Enable / Inverted

Pulse count of encoder

per round. Used for scaling encoder rpm monitor

value only.

0 = DI5 and DI6 are for

normal digital input

1 = DI6 is for pulse train

2 = DI5 and DI6 are for

encoder frequence mode

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 35

5.10 Digital outputs (Control panel: Menu PAR -> P8)

Code Parameter Min Max Unit Default ID Selections

RO1 signal

P8.1

selection

RO2 signal

P8.2

selcetion

DO1 signal

P8.3

selcetion

P8.4 RO2 inversion 0 1 0 1588

P8.5 RO2 ON delay 0.00 320.00 s 0.00 460 0.00 = No delay

P8.6 RO2 OFF delay 0.00 320.00 s 0.00 461 0.00 = No delay

P8.7 RO1 inversion 0 1 0 1587

P8.8 RO1 ON delay 0.00 320.00 s 0.00 458 0.00 = No delay

P8.9 RO1 OFF delay 0.00 320.00 s 0.00 459 0.00 = No delay

DOE1 signal

P8.10

selection

DOE2 signal

P8.11

selection

DOE3 signal

P8.12

selection

Table 13: Digital outputs

0 Varies 2 313

0 Varies 3 314 See 8.1

0 Varies 1 312 See 8.1

0 Varies 0 317

0 Varies 0 318

0 Varies 0 1386

0 = Not used

1 = Ready

2 = Run

3 = Fault

4 = Fault Inverted

5 = Warning

6 = Reversed

7 = At Speed

8 = Motor regula tor active

9 = FB C ontrol Wo rd.B13

10 = FB C ontrol Wo rd.B14

11 = FB C ontrol Wo rd.B15

12 = Output freq superv.

13 = Output torque superv.

14 = Unit temperature superv.

15 = Analogue input superv.

16 = Preset Speed Active

17 = External Brake ctrl

18 = Keypad control active

19 = I / O control active

20 = Temperature supervision

0 = No inversion

1 = Inverted

0 = No inversion

1 = Inverted

See 8.1, hidden until an

option board is connected

See 8.1, hidden until an

option board is connected

See 8.1, hidden until an

option board is connected

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

36 • vacon monitoring & parameters

Code Parameter Min Max Unit Default ID Selections

DOE4 signal

P8.13

selection

DOE5 signal

P8.14

selection

DOE6 signal

P8.15

selection

Table 13: Digital outputs

0 Varies 0 1390

0 Varies 0 1391

0Varies 0 139

5.11 Analogue outputs (Control panel: Menu PAR -> P9)

Code Parameter Min Max Unit Default ID Selections

Analogue output

P9.1

signal selection

Analogue output

P9.2

minimum

Analogue output

P9.3

scaling

Analogue output

P9.4

filter time

Analogue output

P9.5

E1 signal selec-

tion

Analogue output

P9.6

E1 minimum

Table 14: Analogue outputs

0 14 1 307

0 1 0 310

0.0 1000.0 % 100.0 311 Scaling factor

0.00

10.00 s 0.10 308 Filter time

0

14 0 472

0

1 0 475

See 8.1, hidden until an

option board is connected

See 8.1, hidden until an

option board is connected

See 8.1, hidden until an

option board is connected

0 = Not used

1 = Output freq (0-f

2 = Output current (0-I

3 = Motor torque (0-T

4 = PID output (0 - 100%)

5 = Freq refer. (0-f

6 = Motor speed (0-n

7 = Motor power (0-P

8 = Motor Voltage (0-U

9 = DC-link Voltage

(0 - 1000 V)

10 = Process Data In1

(0 - 10000)

11 = Process Data In2

(0 - 10000)

12 = Process Data In3

(0 - 10000)

13 = Process Data In4

(0 - 10000)

14 = Test 100%

0 = 0 V / 0 mA

1 = 2 V / 4 mA

See P9.1, hidden until an

option board is connected

See P9.2, hidden until an

option board is connected

max

max

nMotor

)

max

nMotor

)

nMotor

)

nMotor

)

)

)

)

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 37

Code Parameter Min Max Unit Default ID Selections

Analogue output

P9.7

E1 scaling

Analogue output

P9.8

E1 filter time

Analogue output

P9.9

E2 signal selec-

tion

Analogue output

P9.10

E2 minimum

Analogue output

P9.11

E2 scaling

Analogue output

P9.12

E2 filter time

Table 14: Analogue outputs

0.0 1000. 0

0.00 1 0.00

0.0 1000. 0

0.00 1 0.00

%

s

0

14 0 479

0

1 0 482

%

s

100.0

0.10

100.0

0.10

See P9.3, hidden until an

476

option board is connected

See P9.4, hidden until an

473

option board is connected

See P9.1, hidden until an

option board is connected

See P9.2, hidden until an

option board is connected

See P9.3, hidden until an

483

option board is connected

See P9.4, hidden until an

480

option board is connected

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

38 • vacon monitoring & parameters

5.12 Fieldbus Data-Mapping (Control panel: Menu PAR -> P10)

Code Parameter Min Max Unit Default ID Note

FB Data Output 1

P10.1

selection

FB Data Output 2

P10.2

selection

FB Data Output 3

P10.3

selection

FB Data Output 4

P10.4

selection

FB Data Output 5

P10.5

selection

FB Data Output 6

P10.6

selection

FB Data Output 7

P10.7

selection

FB Data Output 8

P10.8

selection

Aux CW Data In

P10.9

selection

Table 15: Fieldbus Data-Mapping

0 Varies 0 852

0

Varies 1 853 Variable mapped on PD2

0

Varies 2 854 Variable mapped on PD3

0

Varies 4 855 Variable mapped on PD4

0

Varies 5 856 Variable mapped on PD5

0

Varies 3 857 Variable mapped on PD6

0

Varies 6 858 Variable mapped on PD7

0

Varies 7 859 Variable mapped on PD8

0

5 0 1167

0 = Frequency reference

1 = Output reference

2 = Motor speed

3 = Motor current

4 = Motor voltage

5 = Motor torque

6 = Motor power

7 = DC link voltage

8 = Active fault code

9 = Analogue AI1

10 = Analogue AI2

11 = Digital input state

12 = PID feedback value

13 = PID setpoint

14 = Pulse train /

encoder input(%)

15 = Pulse train /

encoder pulse()

16 = AIE1

PDI for Aux CW

0 = Not used

1 = PDI1

2 = PDI2

3 = PDI3

4 = PDI4

5 = PDI5

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 39

5.13 Prohibited Frequencies (Control panel: Menu PAR -> P11)

Code Parameter Min Max Unit Default ID Note

Prohibit Frequency

P11.1

Range 1 Low Limit

Prohibit Frequency

P11.2

Range 1 High Limit

Prohibit Frequency

P11.3

Range 2 Low Limit

Prohibit Frequency

P11.4

Range 2 High Limit

Table 16: Prohibited Frequencies

0.00 P3.2 Hz 0.00 509

0.00 P3.2 Hz 0.00 510

0.00 P3.2 Hz 0.00 511

0.00 P3.2 Hz 0.00 512

5.14 Limit Supervisions (Control panel: Menu PAR -> P12)

Code Parameter Min Max Unit Default ID Note

Output freq

P12.1

supervision

function

Output freq

P12.2

supervision limit

Torqu e su perv i-

P12.3

sion function

Torqu e su perv i-

P12.4

sion limit

Unit Temperature

P12.5

Supervision

Unit Temperature

P12.6

Supervision Limit

Analogue input

P12.7

superv signal

P12.8 AI superv ON level 0.00 100.00 % 80.00 357 ON threshold AI superv.

AI superv OFF

P12.9

Table 17: Limit Supervisions

level

0 2 0 315

0.00 P3.2 Hz 0.00 316

0 2 0 348

0.0 300.0 % 0.0 349

0 2 0 354

-10 100

0 Varies 0 356

0.00 100.00 % 40.00 358 OFF threshold AI superv.

40 355

°C

Low Limit

0.00 = Not used

High Limit

0.00 = Not used

Low Limit

0.00 = Not used

High Limit

0.00 = Not used

0 = Not used

1 = Low limit

2 = High limit

Output frequency supervision threshold

0 = Not used

1 = Low limit

2 = High limit

Torque supervision

Threshold

0 = Not used

1 = Low limit

2 = High limit

Unit temperature supervision threshold

0 = AI1

1 = AI2

2 = AIE1

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

40 • vacon monitoring & parameters

P13.2

P13.3

P13.4

P13.5

P13.6

P13.7

Code Para meter Min Max Unit Default ID Note

Binary-coded selection

of signals to use for temperature supervision

Tem pe rat ur e

P12.10

supervision input

Tem pe rat ur e

P12.11

supervision

function

Tem pe rat ur e

P12.12

supervision limit

Table 17: Limit Supervisions

1 7 1 1431

0 2 2 1432

-50.0/

223.2

200.0/

473.2

80.0 1433

B0 = Temperature input 1

B1 = Temperature input 2

B2 = Temperature input 3

NOTE! Hidden until an

option board is connected

See 12.1, hidden until an

option board is connected

Temperature supervision

threshold, hidden until

an option board is connected

5.15 Protections (Control panel: Menu PAR -> P13)

Code Parameter Min Max Unit Default ID Note

0 = No action

Analogue Input

P13.1

low fault

Under voltage

fault

Earth fault

Output Phase

Faul t

Stall protection

Under load pro-

tection

Motor thermal

protection

Table 18: Protections

0 4 1 700

1 2 2 727

0

3 2 703

0

3 2 702 See 13.3

0

3 0 709 See 13.3

0

3 0 713 See 13.3

0

3 2 704 See 13.3

1 = Alarm

2 = Alarm, preset alarm

frequency

3 = Fault: Stop function

4 = Fault: Coast

1 = No response (no fault

generated but drive still

stops modulation)

2 = Faul t:Coa st

0 = No action

1 = Alarm

2 = Fault: Stop function

3 = Fault: Coast

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 41

P13.8

P13.9

P13.10

P13.11

P13.12

P13.13

P13.14

P13.15

P13.16

P13.18

Code Parameter Min Max Unit Default ID Note

Mtp:Ambient

temperature

Mtp:Zero speed

cooling

Mtp:Thermal time

constant

Stall Current

Stall time

Stall frequency

UL:Field weaken-

ing load

UL:Zero freq load

UL:Time limit

Analogue Input

P13.17

low fault delay

External fault

P13.19 Fieldbus fault 0 4 3 733 See 13.1

Preset alarm

P13.20

frequency

Parameters edit

P13.21

P13.22 Thermistor Fault 0 3 2 732

P13.23

Table 18: Protections

lock

FWD/REV conflict

supervision

-20

100

0.0

150.0 % 40.0 706 Cooling as % at 0 speed

1

200 min Varies 707

2.0 x

0.00

I

Nunit

0.00

300.00 s 15.00 711 Stall time limited

0.10

320.00 Hz 25.00 712 Stall min frequency

10.0

150.0 % 50.0 714

5.0

150.0 % 10.0 715 Minimum torque at f0

1.0

300.0 s 20.0 716

0.0

10.0 s 0.5 1430

0

3 2 701

P3.1 P3.2 Hz 25.00 183

0 1 0 819

0 3 1 1463 See P13.3

40 705

°C

I

A

Nunit

Environment temperation

Motor thermal time constant

For a stall stage to

710

occur, the current must

have exceeded this limit

Minimum torque at field

weakening

This is the maximum

time allowed for an

underload state to exist

Delay time for analogue

input low fault

0 = No action

1 = Alarm

2 = Fault: Stop function

3 = Fault: Coast

Frequency used when

fault respo nse is Alar m +

preset Frequency

0 = Edit enabled

1 = Edit disabled

0 = No action

1 = Alarm

2 = Fault: Stop function

3 = Fault: Coast

Hidden until an option

board is connected

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

42 • vacon monitoring & parameters

P14.1

P14.2

P14.3

P14.4

P14.5

Code Parameter Min Max Unit Default ID Note

P13.24 Temperature fault 0 3 0 740

Temperature fault

P13.25

P13.26

P13.27

Table 18: Protections

input

Temperature fault

mode

Temperature fault

limit

1 7 1 739

0 2 2 743

-50.0/

223.2

200.0/

473.2

100.0 742

See P13.3, hidden until

an OPTBH board is connected

Binary-coded selection

of signals to use for

alarm and fault triggering

B0 = Temperature input 1

B1 = Temperature input 2

B2 = Temperature input 3

NOTE! Hidden until an

OPTBH board is connected

0 = Not used

1 = Low limit

2 = High limit

Temperature fault

threshold, hidden until

an OPTBH board is connected

NOTE! These parameters are shown, when P17.2 = 0.

5.16 Fault autoreset parameters (Control panel: Menu PAR -> P14)

Code Parameter Min Max Unit Default ID Note

Automatic Reset 0 1 0 731

Wait time 0.10 10.00 s 0.50 717 Waiting time after fault

Trial time 0.00 60.00 s 30.00 718 Maximum time for trials

Trials number 1 10 3 759 Maximum trials

Restart Function 0 2 2 719

Table 19: Fault autoreset parameters

0 = Disabled

1 = Enable

0 = Ramping

1 = Flying

2 = From Start Function

NOTE! These parameters are shown, when P17.2 = 0.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 43

5.17 PID control parameters (Control panel: Menu PAR -> P15)

Code Parameter Min Max Unit Default ID Note

0 = Fixed setpoint %

1 = AI1

2 = AI2

3 = ProcessDataIn1

(0 -100%)

4 = ProcessDataIn2

(0 -100%)

Setpoint source

P15.1

selection

P15.2 Fixed setpoint 0.0 100.0 % 50.0 167 Fixed setpoint

P15.3 Fixed setpoint 2 0.0 100.0 % 50.0 168

Feedback

P15.4

source selection

Feedback value

P15.5

minumum

Feedback value

P15.6

maximum

P15.7 P gain 0.0 1000.0 % 100.0 118 Proportional gain

P15.8 I time 0.00 320.00 s 10.00 119 Integrative time

Table 20: PID control parameters

0 Varies 0 332

0 Varies 1 334

0.0 50.0 % 0.0 336 Value at minimum signal

10.0 300.0 % 100.0 337 Value at maximum signal

5 = ProcessDataIn3

(0 -100%)

6 = ProcessDataIn4

(0 -100%)

7 = Pulse train/encoder

8 = AIE1

9 = Temperature input 1

10 = Temperature input 2

11 = Temperature input 3

Alternative fixed setpoint,

selecta ble with DI

0 = AI1

1 = AI2

2 = ProcessDataIn1

(0 -100%)

3 = ProcessDataIn2

(0 -100%)

4 = ProcessDataIn3

(0 -100%)

5 = ProcessDataIn4

(0 -100%)

6 = AI2-AI1

7 = Pulse train / encoder

8 = AIE1

9 = Temperature input 1

10 = Temperature input 2

11 = Temperature input 3

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

44 • vacon monitoring & parameters

P15.16

P15.17

Code Para meter Min Max Unit Default ID Note

P15.9 D time 0.00 10.00 s 0.00 132 Derivative time

0 = Direct (Feedback < Setpoint ->Increase PID out-

P15.10 Error inversion 0 1 0 340

Sleep minimum

P15.11

frequency

P15.12 Sleep delay 0 3600 s 30 1017 Delay for enter sleep

P15.13 Wake up error 0.0 100.0 % 5.0 1018 Threshold for exit sleep

Sleep setpoint

P15.14

P15.15

P15.18

P15.19

P15.20

P15.21

Table 20: PID control parameters

boost

Setpoint boost

time

Sleep maxi-

mum loss

Sleep loss check

time

Process unit

source select

Process unit

decimal digits

Process unit

minimum value

Process unit

maximum value

0.00 P3.2 Hz 25.00 1016

0.0 50.0 % 10.0 1071 Referred to setpoint

0 60 s 10 1072 Boost time after P15.12

0.0 50.0 % 5.0 1509

1 300 s 30 1510 After boost time P15.15

0 6 0 1513

0 3 1 1035 Decimals on display

0.0 P15.21 0.0 1033 Process min value

P15.20 3200.0 100.0 1034 Process max value

put)

1 = Inverted (Feedback >

Setpoint ->Decrease PID

output)

Drive goes to sleep mode

when the output frequency

stays below this limit for a

time greater than that

defined by parameter Sleep

delay

Referred to feedback value

after boost

0 = PID feedback value

1 = Output frequency

2 = Motor speed

3 = Motor torque

4 = Motor power

5 = Motor current

6 = Pulse Train / Encoder

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

monitoring & parameters vacon • 45

P17.1

Code Parameter Min Max Unit Default ID Note

Tem pe rat ur e

P15.22

min value

Tem pe rat ur e

P15.23

max value

Table 20: PID control parameters

-50.0/

P15.23 0.0 1706

223.2

200.0/

P15.22

473.2

100.0 1707

NOTE! These parameters are shown, when P17.2 = 0.

5.18 Motor c (Control panel: Menu PAR -> P16)

Code Parameter Min Max Unit Default ID Note

Motor Preheat

P16.1

Functio n

Motor Preheat

P16.2

Table 21: Motor Preheat

Current

0 2 0 1225

0.5 x

0

I

Nunit

A 0 1227

5.19 Easy usage menu (Control panel: Menu PAR -> P17)

Code Parameter Min Max Unit Default ID Note

Application Type 0 3 0 540

Parameter

P17.2

conceal

Tem pe ra tur e

P17.3

Table 22: Easy usage menu parameters

unit

01 1115

01 01197

Temperature min value for

PID and frequency reference scale, hidden until an

OPTBH board is connected

Temperature max value for

PID and frequency reference scale, hidden until an

OPTBH board is connected

0 = Not used

1 = Always in stop state

2 = Controlled by digital

input

DC current for preheating

of motor and drive in stop

state. Acti ve in stop state

or by digital input while in

stop state.

0 = Basic

1 = Pump

2 = Fan dr ive

3 = High Torque

NOTE! Visible only when

Startup wizard is active.

0 = All parameters visible

1 = Only quick setup

parameter group visible

0 = Celsius

1 = Kelvin

NOTE! Hidden until an

OPTBH board is connected

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

46 • vacon monitoring & parameters

5.20 System parameters

Code Parameter Min Max Default ID Note

Software information (MENU PAR -> V1)

V1.1 API SW ID 2314

V1.2 API SW version 835

V1.3 Power SW ID 2315

V1.4 Power SW version 834

V1.5 Application ID 837

V1.6 Application revision 838

V1.7 System load 839

When no field bus Option Board or no OPT-BH Board has been installed, the Modbus comm.

V2.1 Communication status 808

P2.2 Fieldbus protocol 0 1 0 809

P2.3 Slave address 1 255 1 810

P2.4 Baud rate 0 8 5 811

Table 23: System parameters

parameters are as follows

Status of Modbus

communication.

Format: xx.yyy

where xx = 0 - 64

(Number of error

messages)

yyy = 0 - 999

(Number of good

messages)

0 = Not used

1 = Modbus used

0 = 300

1 = 600

2 = 1200

3 = 2400

4 = 4800

5 = 9600

6 = 19200

7 = 38400

8 = 57600

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 47

Code Parameter Min Max Default ID Note

0 = None

1 = Even

2 = Odd

14004

The Stop Bit is 2-bit

When Parity type is

0 = None;

The Stop Bit is 1-bit

When Parity type is

1 = Even or 2 = Odd

0 = Not used

1 = 1 sec

2 = 2 secs, etc

0 = Initialising

4 = Stopped

5 = Operational

6 = Pre_Operational

7 = Reset_Application

8 = Reset_Comm

9 = Unknow

1 = Driver Profile

2 = Bypass

1 = 10 kbaud

2 = 20 kbaud

3 = 50 kbaud

4 = 100 kbaud

5 = 125 kbaud

6 = 250 kbaud

7 = 500 kbaud

8 = 1000 kbaud

P2.6 Parity type 0 2 0 813

P2.7 Communication time out 0 255 10 814

Reset communication

P2.8

When Canopen E6 board has been installed, the comm. parameters are as follows

V2.1

P2.2 Canopen operation mode 1 2 1 14003

P2.3 Canopen Node ID 1 127 1 14001

P2.4 Canopen baud rate 1 8 6 14002

When DeviceNet E7 board has been installed, the comm. parameters are as follows

Table 23: System parameters

status

Canopen communication

status

0 1 0 815

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

48 • vacon monitoring & parameters

Code Parameter Min Max Default ID Note

Status of Modbus

communication.

Forma t:

XXXX.Y, X = DeviceNet

msg counter

V2.1 Communication status 14014

P2.2 Output assembly type 20 111 21 14012 20, 21, 23, 25, 101, 111

P2.3 MAC ID 0 63 63 14010

P2.4 Baud rate 1 3 1 14011

P2.5 Input assembly type 70 117 71 14013

When ProfidBus E3/E5 board has been installed, the comm. parameters are as follows

V2.1 Communication status 14022

V2.2 Fieldbus protocol status 14023

V2.3 Active protocol 14024

V2.4 Active buad rate 14025

V2.5 Telegram type 14027

P2.6 Operate mode 1 3 1 14021

P2.7 Slave address 2 126 126 14020

When OPT-BH board has been installed, the comm. parameters are as follows

P2.1 Sensor 1 type 0 6 0 14072

Table 23: System parameters

Y = DeviceNet status

0 = Non-existent or no

bus power

1 = Configuring state

2 = Established

3 = Timeout

1 = 125 kbit/s

2 = 250 kbit/s

3 = 500 kbit/s

70, 71, 73, 75, 107,

117

1 = Profidrive

2 = Bypass

3 = Echo

0 = No Sensor

1 = PT100

2 = PT1000

3 = Ni1000

4 = KTY84

5 = 2 x PT100

6 = 3 x PT100

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

monitoring & parameters vacon • 49

P4.2

P4.5

P4.6

Code Parameter Min Max Default ID Note

0 = No Sensor

1 = PT100

P2.2 Sensor 2 type 0 6 0 14073

P2.3 Sensor 3 type 0 6 0 14074

Other information

V3.1 MWh counter 827 Million Watt Hour

V3.2 Power on days 828

V3.3 Power on hours 829

V3.4 Run counter: Days 840

V3.5 Run counter: Hours 841

V3.6 Fault counter 842

Panel parameter set

V3.7

status monitor

Restore factory defaults 0 1 0 831

P4.3 Password 0000 9999 0000 832

Time for panel and lcd

P4.4

backlight active

Save parameter set to

panel

Restore parameter set

from panel

F5.x Active Fault menu

F6.x Fault History menu

Table 23: System parameters

0 99 5 833

01 0

01 0

2 = PT1000

3 = Ni1000

4 = KTY84

5 = 2 x PT100

6 = 3 x PT100

0 = No Sensor

1 = PT100

2 = PT1000

3 = Ni1000

4 = KTY84

5 = 2 x PT100

6 = 3 x PT100

Hidden when connect

with PC.

1 = Restores factory

defaults for all

parameters

Hidden when connect

with PC.

Hidden when connect

with PC.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

5

50 • vacon monitoring & parameters

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

FAULT TRACING vacon • 51

6. FAULT TRACING

Fault code Fault name Fault code Fault name

Overcurrent

1

Overvoltage

2

Earth fault

3

System fault

8

Undervoltage

9

Output phase fault

11

Frequency converter

13

undertemperature

Frequency converter

14

overtemperature

Motor stalled

15

Motor overtemperature

16

Motor underload

17

EEPROM checksum fault

22

Microcontroller watchdog

25

Table 24: Fault codes. See User Manual for detailed fault descriptions.

fault

Back EMF protection

27

Thermistor fault

29

Internal bus communica-

34

tion

Application fault

35

IGBT Overtemperature

41

Analogue input select 20%

- 100% (selected signal

50

range 4 to 20 mA or 2 to

10 V)

External fault

51

Door Panel fault

52

Fieldbus fault

53

Slot fault

54

Wrong run fault

55

Idenfication fault

57

Temperature fault

111

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

6

52 • vacon FAULT TRACING

6

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

general data vacon • 53

7. GENERAL DATA

Dimensions

and weight

Supply

network

Motor

connection

Ambient

conditions

EMC

Standards

Certificates

and manufacturer’s declarations o f

conformi ty

Frame Height(mm) Width(mm) Depth (mm) Weight (kg)

MI1 157 6.2 66 2.6 98 3.9 0.5 1.1

MI2 195 7.7 90 3.5 102 4 0.7 1.5

MI3 262 10.3 100 3.9 109 4.3 1 2.2

MI4 370 14.6 165 6.5 165 6.5 8 17.6

MI5 414 16.3 165 6.5 202 8 10 22

Networks

Short circuit current

Output voltage

Output current

Ambient operating temperature

Storage temperature

Relative humidity 0…95% RH, non-condensing, non-corrosive, no dripping water

Altitude

Enclosure class IP20 / IP21 / Nema1 for MI1-3, IP21/Nema 1 for MI4-5

Pollution degree PD2

Immunity Complies with EN50082-1, -2, E N61800-3

Emissions(See

detailed descriptions in Vacon 20

User Manual at:

www.vacon.com)

mm inch mm inch mm inch kg lb.

Vacon 20 units with other than EMC4 filter combinations cannot be

used on delta power networks (corner grounded)

Maximum short circuit current has to be < 50 kA, For MI4 without

DC-choke, maximum short circuit current has to be < 2.3 kA, for

MI5 without DC-choke, maximum short circuit current has to be <

3.8 kA

0 - U

in

Continuous rated cu rrent I

(depends on the unit size), overload

1.5 x I

max 1 min / 10 min

N

-10 °C (no frost)…+40 / 50 °C (depends on the unit size): rated

loadability I

N

Side by side installation for MI1-3 it is always 40 °C; For IP21/

Nema1 option in MI1-3 the maximum temparture is also 40 °C

-40 °C…+70 °C

100% load capacity (no derating) up to 1000 m. 1% derating for

each 100 m above 1000 m; max 2000 m

230V : Complies with EMC category C2; With an internal RFI filter.

MI4 and 5 complies C2 with an optional DC choke and CM choke.

400V: Complies with EMC category C2; With an internal RFI filter

MI4 and 5 complies C2 with an optional DC choke and CM choke.

Both: No EMC emission protection (Vacon level N): Without RFI filter

For EMC: EN61800-3,

For safety: UL508C, EN61800-5

For safety: , CE, UL, cUL,

For EMC: CE

(see unit nameplate for more detailed approvals)

at ambient temperature max +50 ºC

N

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

54 • vacon general data

Terminal cable min-max

2

)

2

)

(mm

Main Earth

2.5-50

2.5-35

Cu / Al

1.5-4

Control

and relay

0.5-1.5

Frame Fuse (A)

Cable and fuse

requ iremen ts

(See detailed data

in Vacon 20 User

Manual at:

www.vacon.com)

380 - 480 V, 3~

208 – 240 V, 3~

115 V, 1~

208 – 240, 1~

575V

- With above-mentioned fuses, the drive can be connected to power supply the short

circuit current of which is max 50 kA

- Use cables with heat resistance of at least +70 °C.

- The fuses function also as cable overload protection.

- These instructions apply only to cases with one motor and one cable connection

from the frequency converter to the motor.

- To fulfil standard EN61800-5-1, the protective conductor should be at lea st 10 mm2

Cu or 16 mm2 Al. Another possibility is to use an additional protective conductor of

at least the same size as the original one.

MI1 6

MI2 10

MI3 20 3*2.5+2.5 1.5-6

MI4

MI5 40 3*10+10

MI2 20 2*2.5+2.5

MI3 32 2*6+6

MI1 10 2*1.5+1.5

MI2 20 2*2.5+2.5

MI3 32 2*6+6 1.5-6

MI3 6

MI3 10

MI3 20 3*2.5+2.5 1.5-6

20

25

40

(20 and 40 is

only for 208 240 V, 3~)

Mains cable

Cu (mm

3*1.5+1.5 1.5-4

3*6+6 1-10Cu 1-10

3*1.5+1.5 1.5-4

7

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

general data vacon • 55

Vacon 20 power ratings

Mains voltage 208 - 240 V, 50 / 60 Hz, 1~ series

Rated loadability

Fre-

quency

converte r

100% contin.

type

current I

0001 1.7 2.6 0.33 0.25 4.2 MI1 0.55

0002 2.4 3.6 0.5 0.37 5.7 MI1 0.55

0003 2.8 4.2 0.75 0.55 6.6 MI1 0.55

0004 3.7 5.6 1 0.75 8.3 MI2 0.7

0005 4.8 7.2 1.5 1.1 11.2 MI2 0.7

0007 7 10.5 2 1.5 14.1 MI2 0.7

0009* 9.6 14.4 3 2.2 22.1 MI3 0.99

Table 25: Vacon 20 power ratings, 208 - 240 V

[A]

N

150% overload cu rrent

[A]

Motor shaft

power

P

[HP]P[KW]

* The maximum ambient operating temperature of this drive is 40 °C!

Mains voltage 208 - 240 V, 50 / 60 Hz, 3~ series

Rated loadability

Fre-

quency

converte r

100% contin.

type

current I

0001 1.7 2.6 0.33 0.25 2.7 MI1 0.55

0002 2.4 3.6 0.5 0.37 3.5 MI1 0.55

0003 2.8 4.2 0.75 0.55 3.8 MI1 0.55

0004 3.7 5.6 1 0.75 4.3 MI2 0.7

0005 4.8 7.2 1.5 1.1 6.8 MI2 0.7

0007* 7 10.5 2 1.5 8.4 MI2 0.7

0011* 11 16.5 3 2.2 13.4 MI3 0.99

0012 12.5 18.8 4 3 14.2 MI4 9

0017 17.5 26.3 5 4 20.6 MI4 9

0025 25 37.5 7.5 5.5 30.3 MI4 9

0031 31 46.5 10 7.5 36.6 MI5 11

0038 38 57 15 11 44.6 MI5 11

Table 26: Vacon 20 power ratings, 208 - 240 V, 3~

[A]

N

150% overload current

[A]

*The maximum ambient operating temperature of this drive is +40°C !

Motor shaft

power

P

[HP]P[KW]

Nominal

input

current

[A]

Nominal

input

current

[A]

Mechanical

size

Mechanical

size

Weigh t

(kg)

Weigh t

(kg)

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

56 • vacon general data

Mains voltage 115 V, 50 / 60 Hz, 1~ series

Rated loadability

Fre-

quency

converte r

100% contin.

type

current I

0001 1.7 2.6 0.33 0.25 9.2 MI2 0.7

0002 2.4 3.6 0.5 0.37 11.6 MI2 0.7

0003 2.8 4.2 0.75 0.55 12.4 MI2 0.7

0004 3.7 5.6 1 0.75 15 MI2 0.7

0005 4.8 7.2 1.5 1.1 16.5 MI3 0.99

Table 27: Vacon 20 power ratings, 115 V, 1~

[A]

N

150% overload current

[A]

Motor shaft

power

P

[HP]P[KW]

Mains voltage 380 - 480 V, 50 / 60 Hz, 3~ series

Rated loadability

Fre-

quency

converter

100% contin.

type

current I

0001 1.3 2 0.5 0.37 2.2 MI1 0.55

0002 1.9 2.9 0.75 0.55 2.8 MI1 0.55

0003 2.4 3.6 1 0.75 3.2 MI1 0.55

0004 3.3 5 1.5 1.1 4 MI2 0.7

0005 4.3 6.5 2 1.5 5.6 MI2 0.7

0006 5.6 8.4 3 2.2 7.3 MI2 0.7

0008 7.6 11.4 4 3 9.6 MI3 0.99

0009 9 13.5 5 4 11.5 MI3 0.99

0012 12 18 7.5 5.5 14.9 MI3 0.99

0016 16 24 10 7.5 17.1 MI4 9

0023 23 34.5 15 11 25.5 MI4 9

0031 31 46.5 20 15 33 MI5 11

0038 38 57 25 18.5 41.7 MI5 11

Table 28: Vacon 20 power ratings, 380 - 480 V

[A]

N

150% overload current

[A]

Motor shaft

power

P

[HP]P[ KW ]

Nominal

input

current

[A]

Nominal

input

current

[A]

Mechanical

size

Mechanical

size

Weig ht

(Kg)

Weigh t

(kg)

7

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

general data vacon • 57

Mains voltage 575 V, 50 / 60 Hz, 3~ series

Rated loadability

Fre-

quency

converter

100% contin.

type

current I

0002 1.7 2.6 1 0.75 2 MI3 0.99

0003 2.7 4.2 2 1.5 3.6 MI3 0.99

0004 3.9 5.9 3 2.2 5 MI3 0.99

0006 6.1 9.2 5 3.7 7.6 MI3 0.99

0009 9 13.5 7.5 5.5 10.4 MI3 0.99

Table 29: Vacon 20 power ratings, 575 V

[A]

N

150% overload current

[A]

Motor shaft

power

P

[ HP]P[KW]

Note: The input currents are calculated values with 100 kVA line transformer supply.

Quick Modbus setup

A: Select Fieldbus as remote control place: P2.1 to1 – Fieldbus

1

B: Set Modbus RTU protocol to “ON”: SYS P2.2 to 1 – Modbus

A. Set Control Word to “0” (2001)

B. Set Control Word to “1” (2001)

C. Frequency converter status is RUN

D. Set Reference value to “5000” (50.00%) (2003)

2

E. Actual Speed is 5000 (25.00 Hz if MinFreq is 0.00 Hz and MaxFreq is 50.00 Hz)

F. Set Control Word to “0” (2001)

G. Frequency converter status is STOP

Nominal

input

current

[A]

Mechanical

size

Weig ht

(kg)

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

7

Find your nearest Vacon office

on the Internet at:

www.vacon.com

Manual authoring:

documentation@vacon.com

Vacon Plc.

Runsorintie 7

65380 Vaasa

Finland

Subject to change without prior notice

© 2013 Vacon Plc.

Document ID:

Rev. E1

Loading...

Loading...