Vacon 100 hvac ac drives application manual

vacon 100 hvac

®

ac drives

application manual

vacon • 0

TABLE OF CONTENTS

Document ID: DPD00491H

Order code: DOC-APP02456+DLUK

Revision release date: 19.11.13

Corresponds to application package FW0065V021.vcx

1. Vacon 100 - Startup..........................................................................................2

1.1 Startup Wizard ...................................................................................................................2

1.2 PID Mini-Wizard .................................................................................................................3

1.3 Multi-pump mini-wizard ....................................................................................................4

1.4 Fire Mode wizard................................................................................................................5

2. Keypad of the drive ..........................................................................................6

2.1 Vacon keypad with graphical display .................................................................................7

2.1.1 Keypad display ...................................................................................................................7

2.1.2 Using the graphical keypad ...............................................................................................7

2.2 Vacon keypad with text segment display.........................................................................12

2.2.1 Keypad display .................................................................................................................12

2.2.2 Using the keypad..............................................................................................................13

2.3 Menu structure ................................................................................................................15

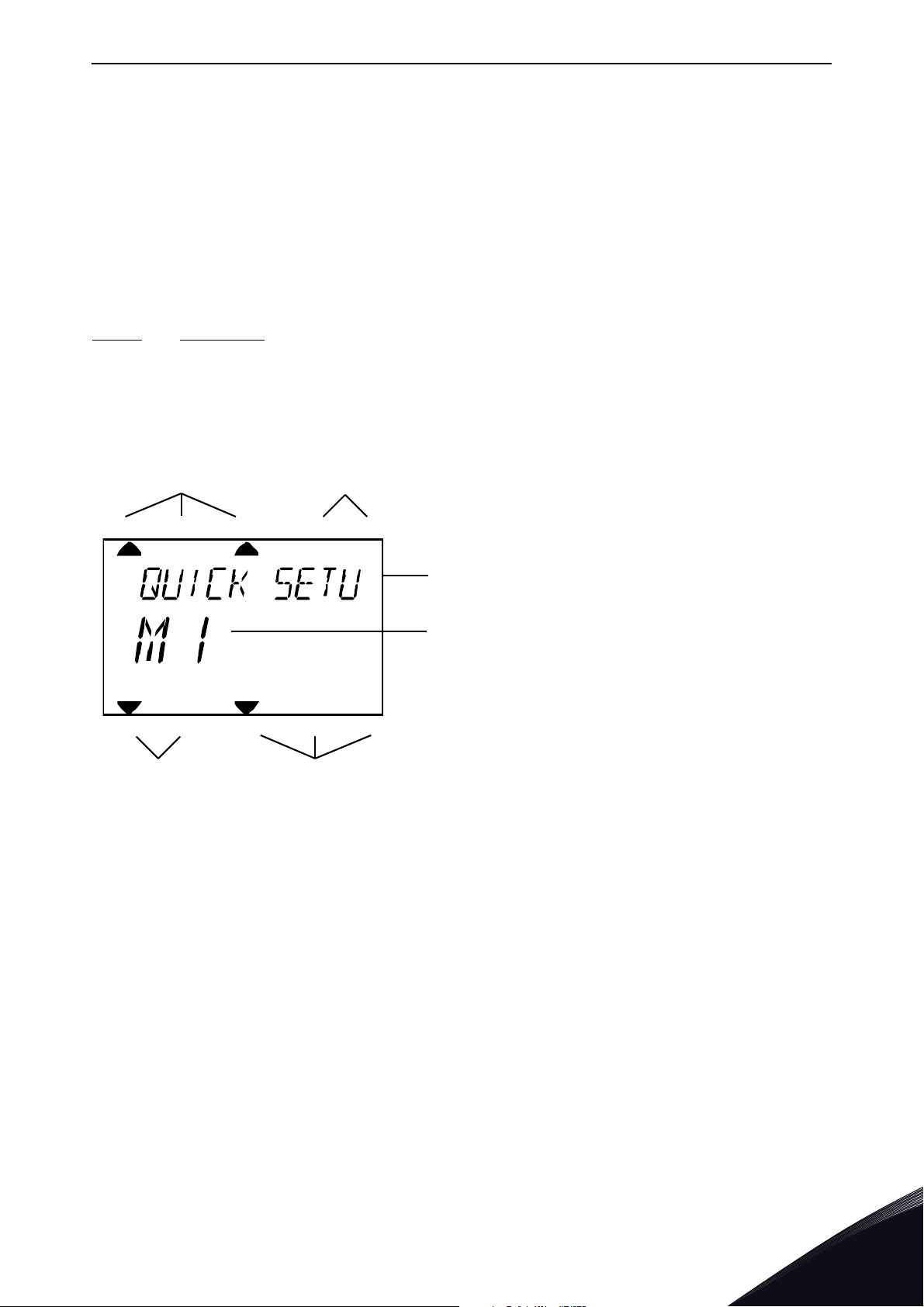

2.3.1 Quick setup.......................................................................................................................16

2.3.2 Monitor .............................................................................................................................16

2.3.3 Parameters ......................................................................................................................17

2.3.4 Diagnostics.......................................................................................................................17

2.3.5 I/O and hardware..............................................................................................................20

2.3.6 User settings ....................................................................................................................28

2.3.7 Favourites.........................................................................................................................29

2.3.8 User levels .......................................................................................................................29

3. Vacon HVAC Application .................................................................................30

3.1 Specific functions of Vacon HVAC application .................................................................30

3.2 Example of control connections ......................................................................................31

3.3 Isolating digital inputs from ground ................................................................................33

3.4 HVAC Application - Quick setup parameter group ..........................................................34

3.5 Monitor group...................................................................................................................36

3.5.1 Multimonitor.....................................................................................................................36

3.5.2 Basic.................................................................................................................................36

3.5.3 Timer functions monitoring .............................................................................................38

3.5.4 PID1 controller monitoring..............................................................................................39

3.5.5 PID2 controller monitoring..............................................................................................39

3.5.6 Multi-pump monitoring....................................................................................................39

3.5.7 Fieldbus data monitoring.................................................................................................40

3.5.8 Temperature inputs monitoring ......................................................................................41

3.6 Vacon HVAC Application - Application parameter lists...................................................42

3.6.1 Column explanations .......................................................................................................43

3.6.2 Parameter programming.................................................................................................44

3.6.3 Group 3.1: Motor settings ................................................................................................48

3.6.4 Group 3.2: Start/Stop setup .............................................................................................51

3.6.5 Group 3.3: Control reference settings.............................................................................52

3.6.6 Group 3.4: Ramp & Brakes Setup....................................................................................54

3.6.7 Group 3.5: I/O Configuration ............................................................................................55

3.6.8 Group 3.6: Fieldbus Data Mapping ..................................................................................62

3.6.9 Group 3.7: Prohibit Frequencies......................................................................................63

3.6.10 Group 3.8: Limit supervisions..........................................................................................64

3.6.11 Group 3.9: Protections .....................................................................................................65

3.6.12 Group 3.10: Automatic reset............................................................................................68

Rev. H

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

vacon • 1

3.6.13 Group 3.11: Timer functions ............................................................................................69

3.6.14 Group 3.12: PID-controller 1............................................................................................73

3.6.15 Group 3.13: PID-controller 2............................................................................................79

3.6.16 Group 3.14: Multi-pump...................................................................................................81

3.6.17 Group 3.16: Fire mode .....................................................................................................81

3.6.18 Group 3.17: Application settings......................................................................................83

3.6.19 Group 3.18: kWh pulse output settings ...........................................................................83

3.7 HVAC Application - Additional parameter information ...................................................84

3.8 HVAC Application - Fault tracing ...................................................................................110

3.8.1 Fault appears .................................................................................................................110

3.8.2 Fault history ...................................................................................................................111

3.8.3 Fault codes.....................................................................................................................112

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from www.vacon.com/downloads

.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site www.vacon.com/downloads

.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Vacon 100 - Startup vacon • 2

OK

BACK

RESET

1. VACON 100 - STARTUP

1.1 Startup Wizard

In the Startup Wizard, you will be prompted for essential information needed by the drive so that

it can start controlling your process. In the Wizard, you will need the following keypad buttons:

Left/Right arrows. Use these to easily move between digits and decimals.

Up/Down arrows. Use these to move between options in menu and to change value.

OK button. Confirm selection with this button.

Back/Reset button. Pressing this button, you can return to the previous question in the

Wizard. If pressed at the first question, the Startup Wizard will be cancelled.

Once you have connected power to your Vacon 100 frequency converter, follow these instructions

to easily set up your drive.

NOTE! You can have your AC drive equipped with a keypad with either a graphical or an LCD display.

1

2

3

4

5

Language selection Depends on language package

Russia

Daylight saving

Time* hh:mm:ss

Day* dd.mm.

Year* yyyy

*

US

EU

OFF

* These questions appear if battery is installed

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

1

vacon • 3 Vacon 100 - Startup

6

Push the OK button unless you want to set all parameter values manually.

7

8

9

10

11

Now the Startup Wizard is done.

The Startup Wizard can be re-initiated by activating the parameter Restore factory defaults (pa-

rameter P6.5.1) in the Parameter backup submenu (M6.5) OR with parameter P1.19 in the Quick

setup menu.

Run Startup Wizard?

Choose your process

Set value for Motor nominal speed

(according to nameplate)

Set value for Motor nominal current

(according to nameplate)

Set value

Set

value

for

Minimum frequency Range: 0.00...50.00 Hz

for

Maximum frequency Range: 0.00...320.00 Hz

Yes

No

Pump

Fan

Range: 24...19,200 rpm

Range: Varies

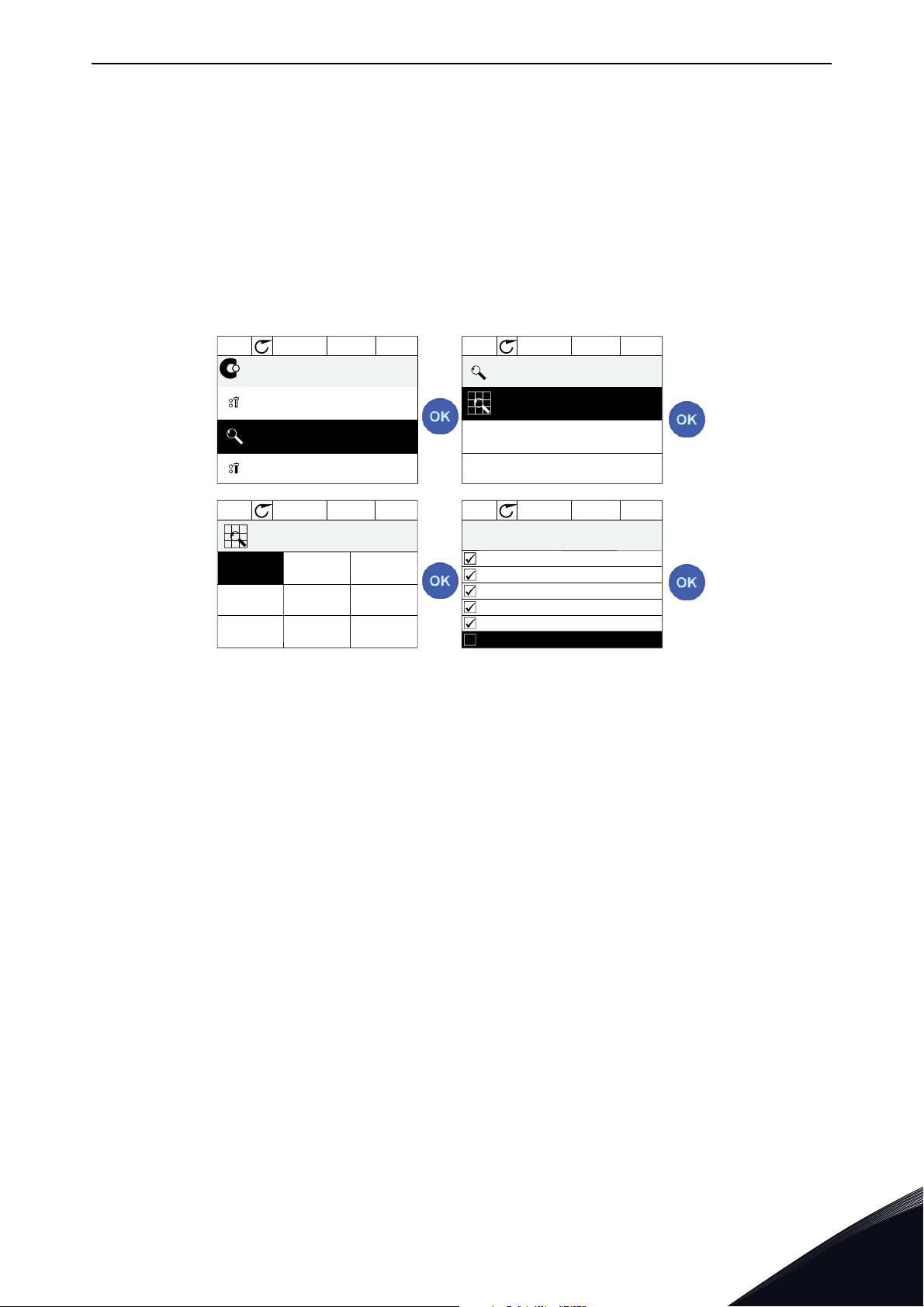

1.2 PID Mini-Wizard

The PID mini wizard is activated in the Quick Setup menu. This wizard presupposes that you are

going to use the PID controller in the "one feedback / one setpoint" mode. The control place will be

I/O A and the default process unit ‘%’.

The PID mini wizard asks for the following values to be set:

1

If any other process unit than ‘%’ is selected the following questions appear: If not the Wizard will

directly jump to step 5

2

3

4

5

If one of the analogue input signals is selected the question 6 appears. Otherwise you will be taken

to question 7.

Process unit selection (Several selections. See par. P3.12.1.4).

.

Process unit min

Process unit max

Process unit decimals 0...4

Feedback 1 source selection

See Chapter 3.6.14.3 on page 71 for

selections.

1

6

Analogue input signal range

0 = 0…10 V / 0…20 mA

1 = 2…10 V / 4…20 mA

See page 57.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Vacon 100 - Startup vacon • 4

7

8

If one of the analogue input signals is selected the question 9 appears. Otherwise you will be taken

to question

If either of the options Keypad Setpoint 1 or 2 is chosen the question 10

9

10

11

If option ‘Yes’ is selected you will be prompted for three more values:

12

13

Error inversion

Setpoint source selection See page 74 for selections.

11.

Analogue input signal range

Keypad setpoint

Sleep function?

Sleep frequency limit 1 0.00...320.00 Hz

Sleep delay 1 0...3000 s

0 = Normal

1 = Inverted

will appear.

0 = 0…10 V / 0…20 mA

1 = 2…10 V / 4…20 mA

See page 57.

No

Yes

14

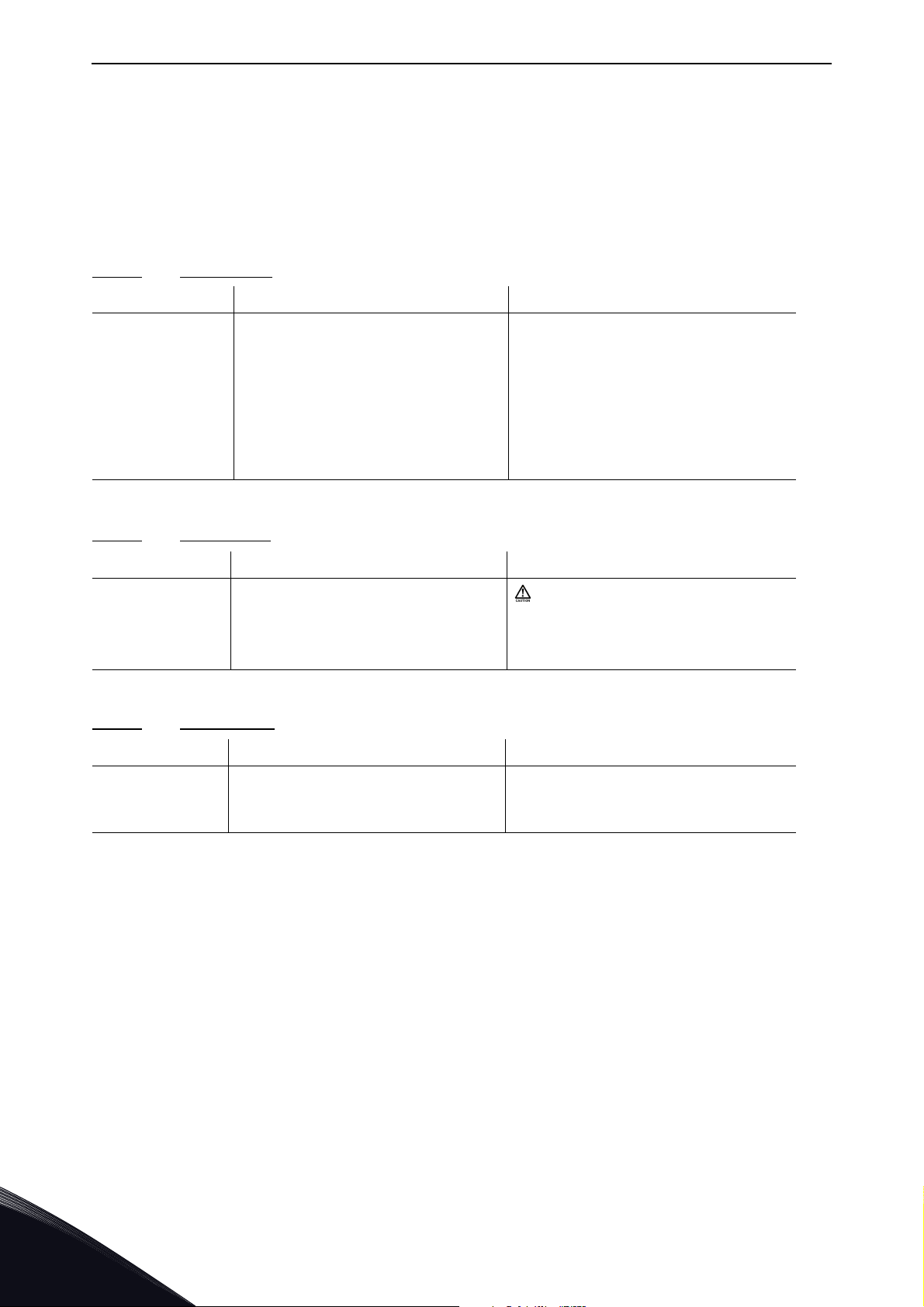

1.3 Multi-pump mini-wizard

The Multi-Pump mini-wizard asks the most important questions for setting up a Multi-Pump system. The PID mini-wizard always precedes the Multi-Pump mini-wizard. The keypad will guide you

through the questions as in Chapter 1.2 then to be followed by the set of questions below:

15

16

17

If Autochange function is enabled the following three questions will appear. If Autochange will not

be used the Wizard jumps directly to question 21.

18

19

Wake-up level 1

Number of motors 1...4

Interlock function

Autochange

Include FC

Autochange interval 0.0...3000.0 h

Range depends on selected process

unit.

0 = Not used

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

20

21

22

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

Autochange: Frequency limit 0.00...50.00 Hz

Bandwidth 0...100%

Bandwidth delay 0...3600 s

1

vacon • 5 Vacon 100 - Startup

Start Fire Moode

Wizard

Fire Mode already

Enabled ?

Ask: Continue

Wizard?

Continue Wizard?

Ask parameter:

Fire Mode Freq Reference

Source

FireModeFrequency

selected to Frequency

Reference ?

Ask parameter:

Fire Mode Frequency

Ask parameter:

Activation Signal Type

Activation signal type?

(Open / Close)

Ask parameter:

Fire Mode Activ. Close

Ask parameter:

Fire Mode Activ. Open

Ask parameter:

Fire Mode Reverse

Ask parameter:

Fire Mode Password

Finished!

YES

NO

NO

YES

OPEN

CLOSE

NO

YES

7073.emf

After this, the keypad will show the digital input and relay output configuration done by the

application (graphical keypad only). Write these values down for future reference.

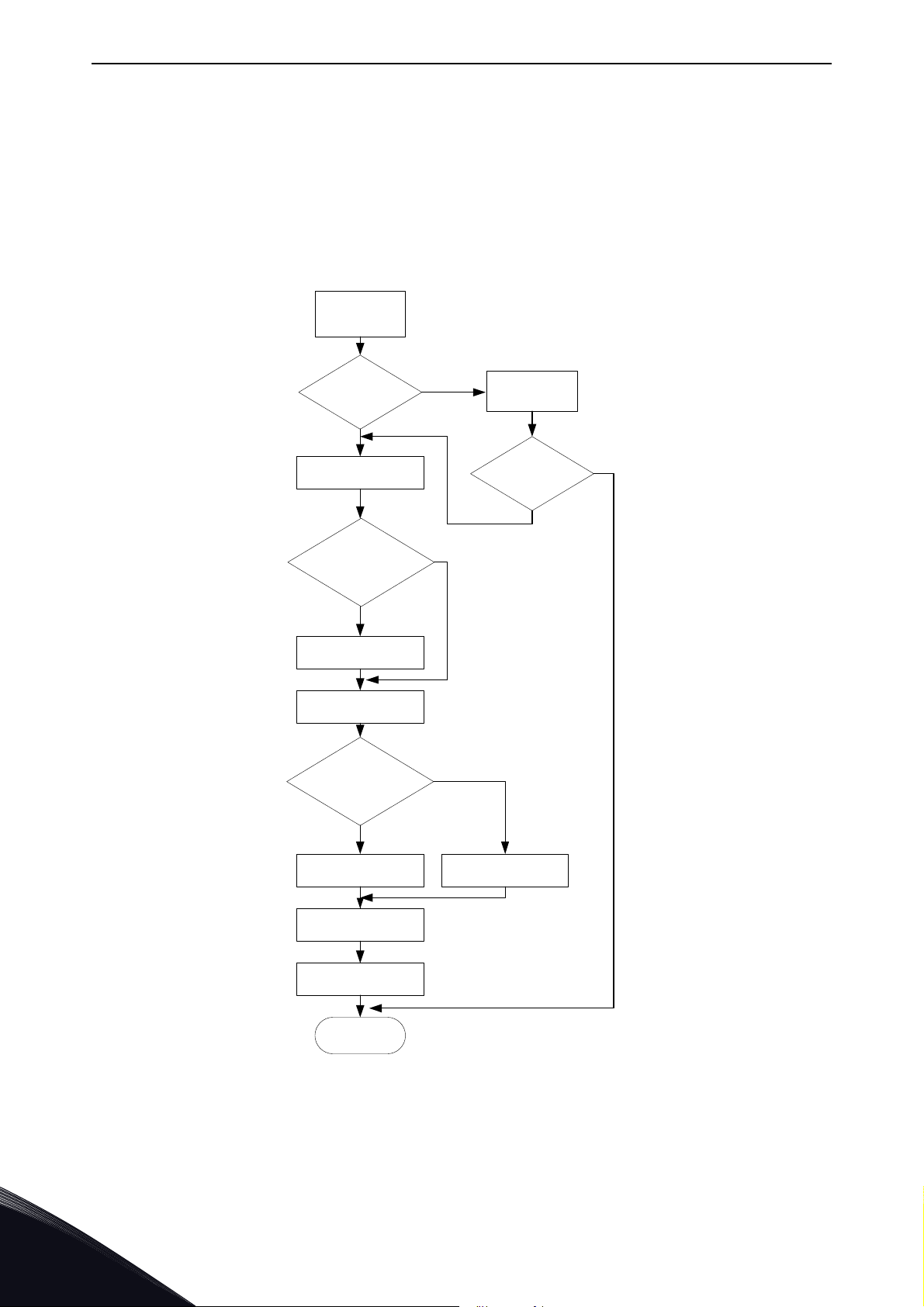

1.4 Fire Mode wizard

The Fire Mode wizard is intended for easy commissioning of the Fire Mode function. The Fire Mode

wizard can be initiated by choosing Activate for parameter P1.20 in the Quick setup menu. Fire Mode

wizard asks the most important questions for setting up a Fire Mode function.

1

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 6

LOC

REM

9086.emf

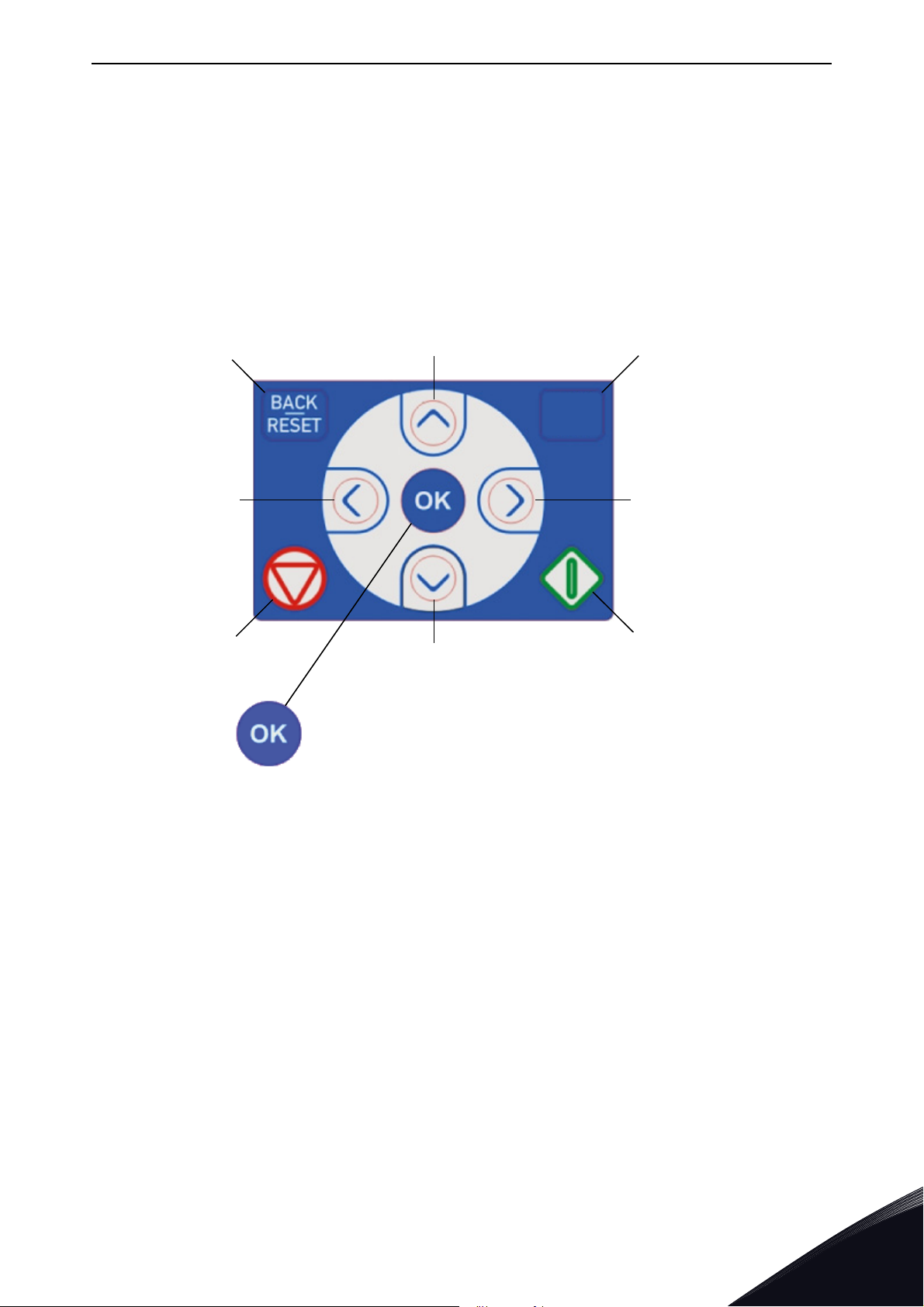

Scroll menu up

Increase value

Scroll menu down

Decrease value

Move cursor left Move cursor right

Move backward in menu

Exit edit mode

Reset faults with long press

Change control place

Access control page

Change direction

See ch. 2.2.1.3 for

more information

Stop button Start button

Enter active level/item

Confirm selection

Enter edit mode

Bypass property page

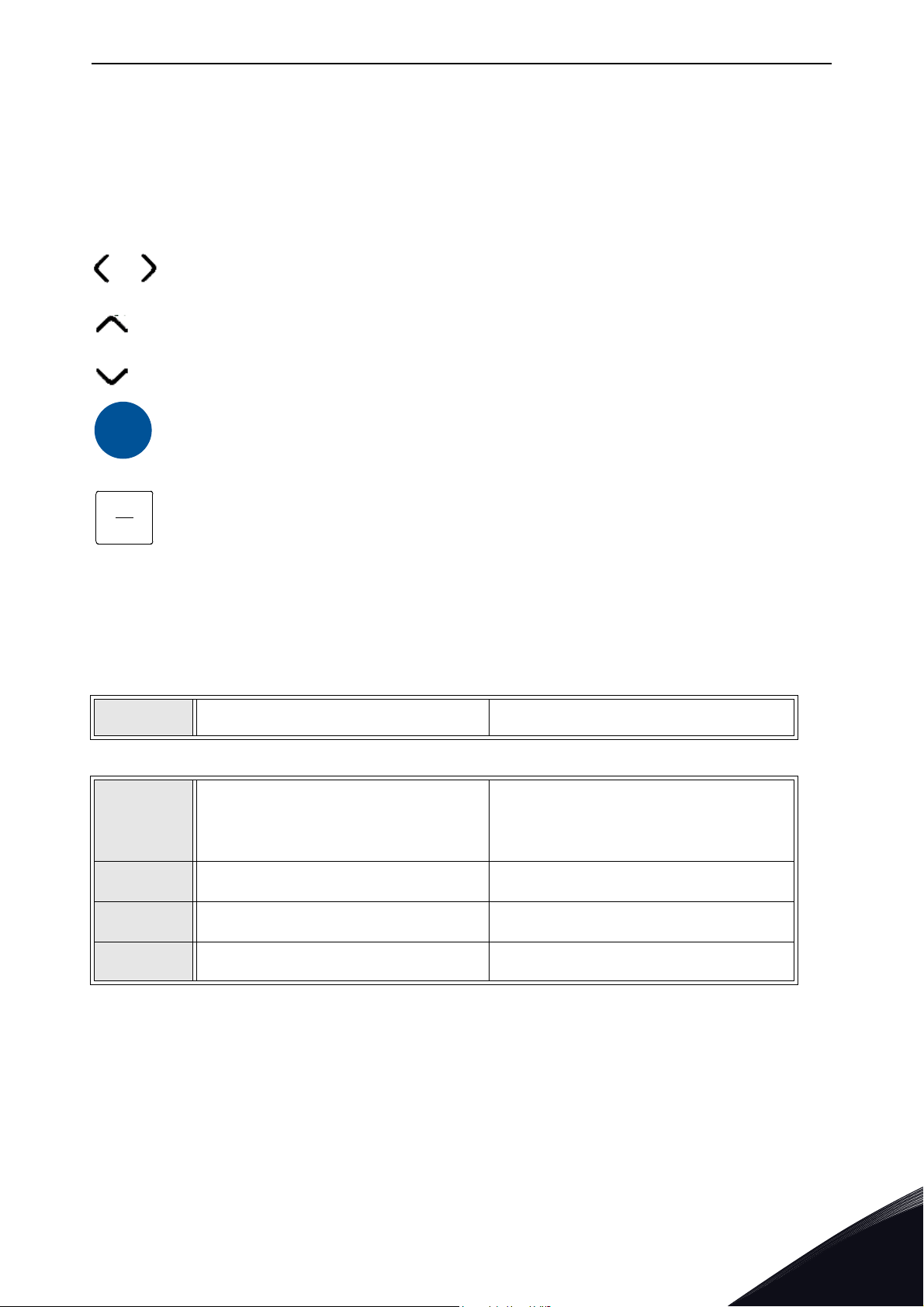

2. KEYPAD OF THE DRIVE

The control keypad is the interface between the Vacon 100 frequency converter and the user. With

the control keypad it is possible to control the speed of a motor, to supervise the state of the

equipment and to set the frequency converter's parameters.

There are two keypad types you can choose for your user interface: Keypad with graphical display

and keypad with text segment display (text keypad).

The button section of the keypad is identical for both keypad types.

Figure 1. Keypad buttons

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 7 Keypad of the drive

9159.emf

( 17 )

( 12 )

STOP READY I/O

ID: M1

( 5 )

Main Menu

Quick Setup

Parameters

Monitor

Status field

STOP/RUN

Direction

ALARM

Status field

READY/NOT READY/FAULT

Control place:

PC/IO/KEYPAD/FIELDBUS

Activated group/item:

Press OK to enter

Number of items

in the group

Location field

(Parameter ID number and

current menu location

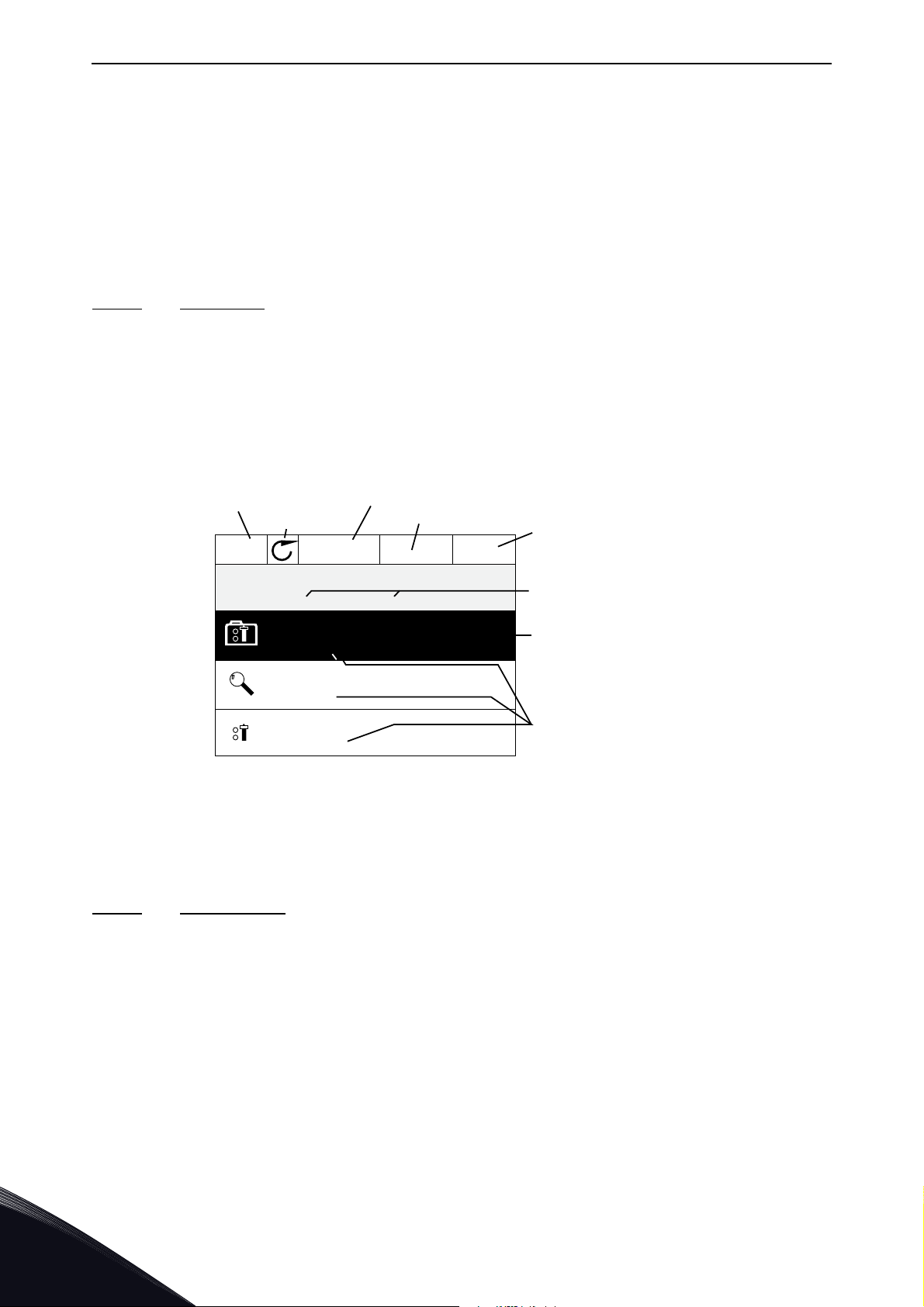

2.1 Vacon keypad with graphical display

The graphical keypad features an LCD display and 9 buttons.

2.1.1 Keypad display

The keypad display indicates the status of the motor and the drive and any irregularities in motor or

drive functions. On the display, the user sees information about

structure and the item displayed.

See the attached Keypad Navigation Map to get a comprehensive idea of the menu structure.

his present

location in the menu

2.1.1.1

The data on the control keypad are arranged in menus and submenus. Use the Up and Down arrows

to move between the menus. Enter the group/item by pressing the OK button and

mer level by pressing the Back/Reset button.

The Location field indicates your current location. The Status field gives information about the

present status of the drive. See Figure 1.

Main menu

return

to the for-

2.1.2 Using the graphical keypad

2.1.2.1

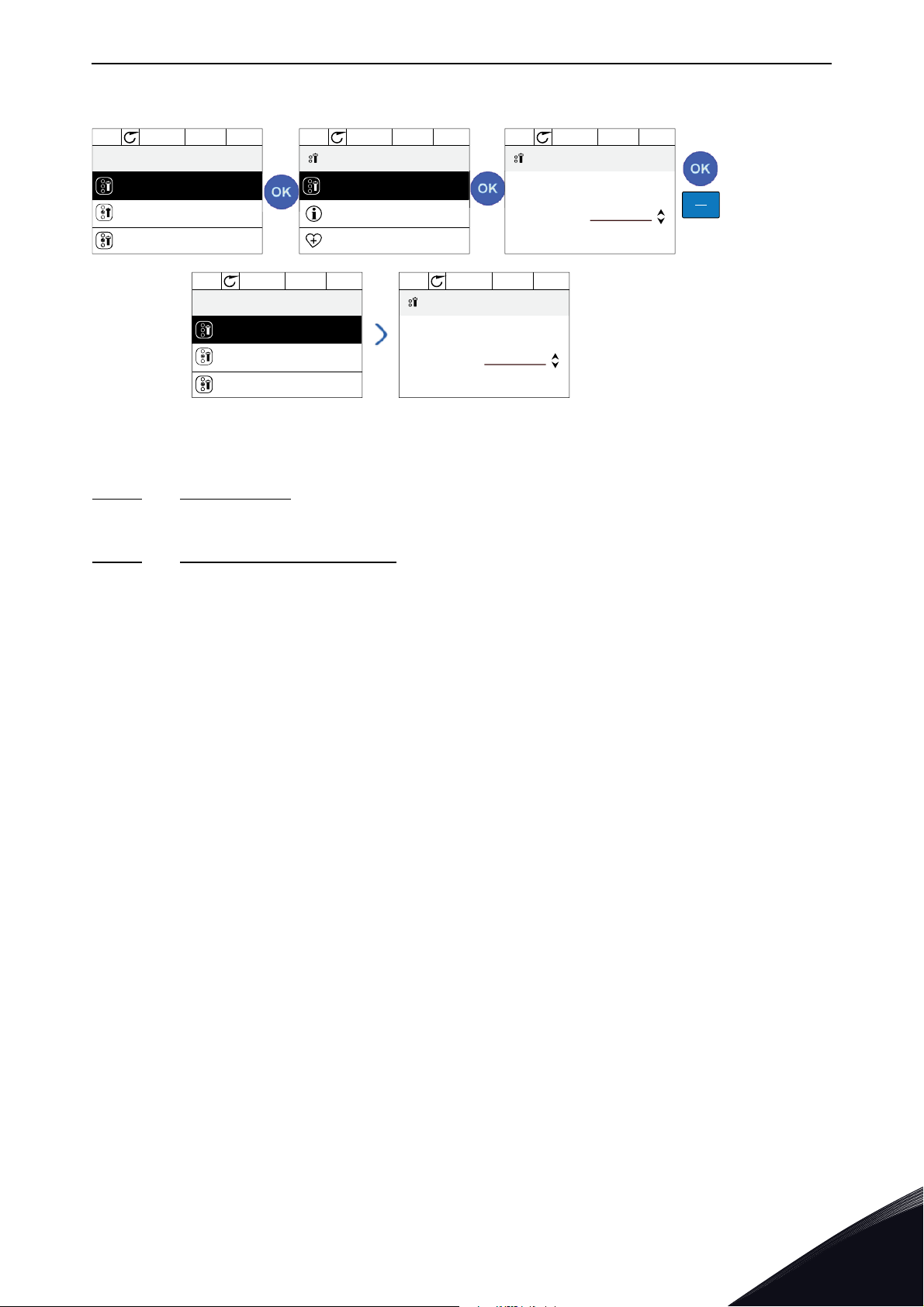

Change value of a parameter following the procedure below:

1. Locate the parameter.

2. Enter the Edit mode.

2

3. Set new value with the arrow buttons up/down. You can also move from digit to digit with the

arrow buttons left/right if the value is numerical and change then the value with the arrow buttons up/down.

4. Confirm change with OK button or ignore change by returning to previous level with Back/

Reset button.

Editing values

Figure 2. Main menu

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 8

STOP READY I/O

ID:172 M3.2.1

STOP READY I/O

ID: M3.2.1

STOP READY I/O

M3.2.1

STOP READY I/O

ID:172 M3.2.1

STOP READY I/O

M3.2.1

9160.emf

BACK

RESET

OR:

Start/Stop Setup

Rem Control Place

I/O Control

KeypadStopButton

Yes

Start Function

Ramping

Edit

Help

Add to favorites

Rem Control Place Rem Control Place

I/O Control

FieldbusCTRL

Start/Stop Setup

Rem Control Place

I/O Control

KeypadStopButton

Yes

Start Function

Ramping

Rem Control Place

I/O Control

FieldbusCTRL

Figure 3. Editing values on graphical keypad

2.1.2.2 Resetting fault

Instructions for how to reset a fault can be found in Chapter 3.8.1 on page 110.

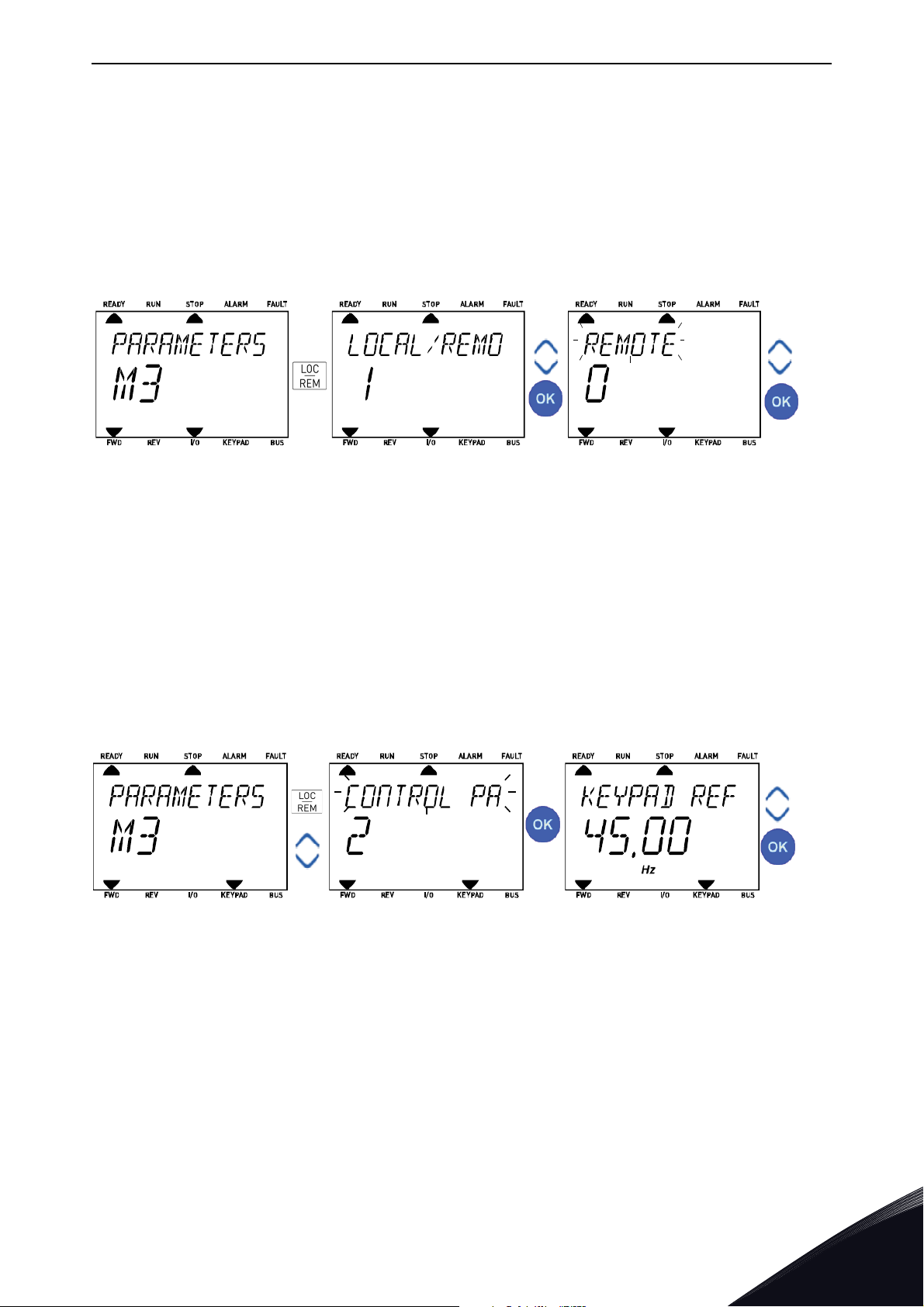

2.1.2.3

Local/Remote control button

The LOC/REM button is used for two functions: to quickly access the Control page and to easily

change between the Local (Keypad) and Remote control places.

Control places

The control place is the source of control where the drive can be started and stopped. Every

control place has its own parameter for selecting the frequency reference source. In the HVAC

drive, the Local control place is always the keypad. The Remote control place is determined by

parameter P1.15 (I/O or Fieldbus). The selected control place can be seen on the status bar of the

keypad.

Remote control place

I/O A, I/O B and Fieldbus can be used as remote control places. I/O A and Fieldbus have the lowest

priority and can be chosen with parameter P3.2.1 (Rem Control Place). I/O B, again, can bypass

the remote control place selected with parameter P3.2.1 using a digital input. The digital input is

selected with parameter P3.5.1.5 (I/O B Ctrl Force).

Local control

Keypad is always used as control place while in local control. Local control has higher priority than

remote control. Therefore, if, for example, bypassed by parameter P3.5.1.5 through digital input

while in Remote, the control place will still switch to Keypad if Local is selected. Switching

between Local and Remote Control can be done by pressing the Loc/Rem-button on the keypad or

by using the "Local/Remote" (ID211) parameter.

Change of control place from Remote to Local (keypad).

1. Anywhere in the menu structure, push the Loc/Rem button.

2. Push the Arrow up or the Arrow down button to select Local/Remote and confirm with the

OK button.

3. On the next display, select Local or Remote and again confirm with the OK button.

4. The display will return to the same location as it was when the Loc/Rem button was pushed.

Changing control places

However, if the Remote control place was changed to Local (Keypad) you will be prompted for

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 9 Keypad of the drive

( 21 )

STOP READY Keypad

ID: M1

( 12 )

( 6 )

ID:

STOP Ready Keypad

ID:1805

?

ID:

STOP READY Keypad

ID:211

( 21 )

STOP READY I/O

ID: M1

( 12 )

( 6 )

11114.emf

Remote

Main Menu

Parameters

Diagnostics

Monitor

Choose action

Local/Remote

Control page

Local/Remote

Remote

Local

Main Menu

Parameters

Diagnostics

Monitor

( 21 )

STOP READY I/O

ID: M1

( 12 )

( 6 )

ID:

STOP Ready Keypad

ID:1805

STOP READY Keypad

( 6 )

0.00 Hz

0.00Hz

0.00A

0.00%

0.00%

ID:184

0.00 Hz

0.00Hz

0.00A

0.00%

0.00%

STOP READY Keypad

( 6 )

ID:168

0.00 Hz

0.00Hz

0.00A

0.00%

0.00%

11115.emf

Keypad Reference

Main Menu

Parameters

Diagnostics

Monitor

Choose action

Local/Remote

Control page

Output Frequency

Motor Current

Motor Torque

Motor Power

Keypad Reference

Output Frequency

Motor Current

Motor Torque

Motor Power

keypad reference.

Figure 4. Changing control places

Accessing the control page

The Control page is meant for easy operation and monitoring of the most essential values.

1. Anywhere in the menu structure, push the Loc/Rem button.

2. Push the Arrow up or the Arrow down button to select Control page and confirm with the

OK button.

3. The control page appears.

If keypad control place and keypad reference are selected to be used you can set the Keypad

reference after having pressed the OK button. If other control places or reference values are

used the display will show Frequency reference which is not editable. The other values on the

page are Multimonitoring values. You can choose which values appear here for monitoring (for

this procedure, see page 16).

2

Figure 5. Accessing Control page

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 10

STOP READY Keypad

( 0 )

( 4 )

ID: M6

( 8 )

STOP READY Keypad

( 3 )

ID: M6. 5M6.5

STOP READY Keypad

ID: P6.5.2

11088.emf

Main Menu

Favourites

User settings

I/O and Hardware

Parameter compare

( 4 )

User settings

Language selection

English

Parameter backup

Restore from keypad

Restore factory defaults

Save to keypad

Parameter backup

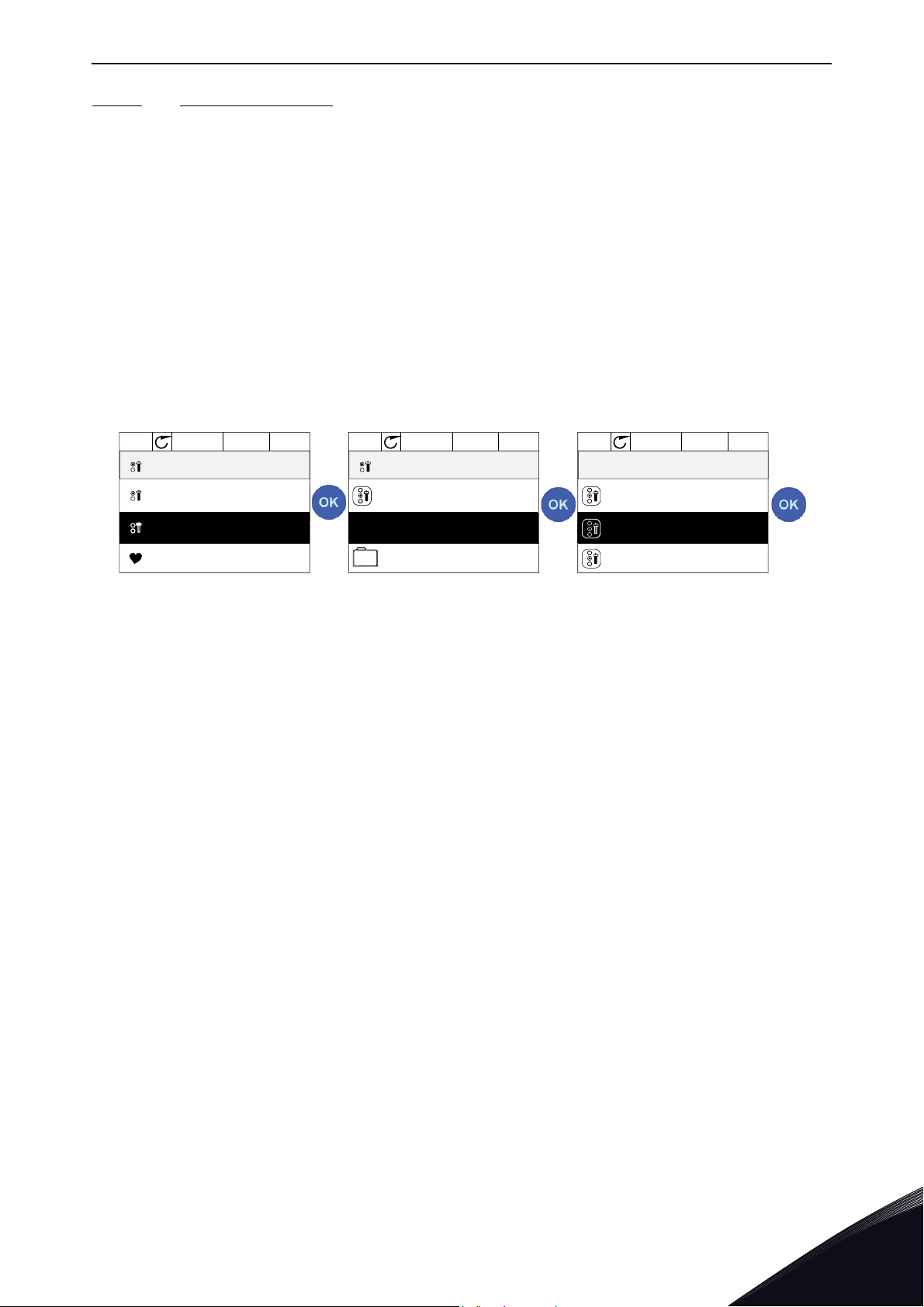

2.1.2.4 Copying parameters

NOTE! This feature is available in graphical keypad only.

The parameter copy function can be used to copy parameters from one drive to another.

The parameters are first saved to the keypad, then the keypad is detached and connected to another

drive. Finally the parameters are downloaded to the new drive restoring them from the keypad.

Before any parameters can successfully be copied from one drive to another the drive has to be

stopped when the parameters are downloaded.

• First go into User settings menu and locate the Parameter backup submenu.

In the Parameter backup submenu, there are three possible functions to be selected:

• Restore factory defaults will re-establish the parameter settings originally made

at the factory.

•By selecting Save to keypad you can copy all parameters to the keypad.

• Restore from keypad will copy all parameters from keypad to a drive.

Figure 6. Parameter copy

NOTE! If the keypad is changed between drives of different sizes, the copied values of these

parameters will not be used:

Motor nominal current (P3.1.1.4)

Motor nominal voltage (P3.1.1.1)

Motor nominal speed (P3.1.1.3)

Motor nominal power (P3.1.1.6)

Motor nominal frequency (P3.1.1.2)

Motor cos phii (P3.1.1.5)

Switching frequency (P3.1.2.1)

Motor current limit (P3.1.1.7)

Stall current limit (P3.9.5)

Stall time limit (P3.9.13)

Stall frequency (P3.9.14)

Maximum frequency (P3.3.2)

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 11 Keypad of the drive

( 6 )

STOP READY I/O

ID:403 P3.5.1.1

( 6 )

STOP READY I/O

ID:403 P3.5.1.1

STOP READY I/O

ID:403

P3.5.1.1

9165.emf

Digital Inputs

Ctrl Signal 1 A

Ctrl Signal 1 B

Ctrl Signal 2 A

Add to favorites

Ctrl signal 1 A

Edit

Help

Start Signal 1 for control Place

I/O A. Start Signal 1

functionality chosen with I/O A

Logic in Start/Stop Setup Menu.

Ctrl signal 1 A

230.00 V

1430 rpm

STOP READY I/O

50.00 Hz

STOP READY I/O STOP READY I/O

9166.emf

Basic Settings

Motor Nom Voltg

Motor Nom Speed

Motor Nom Freq

Edit

Help

Motor Nom Freq

Add to favorites

Motor Nom Freq

was added to

favorites. Press OK

to continue.

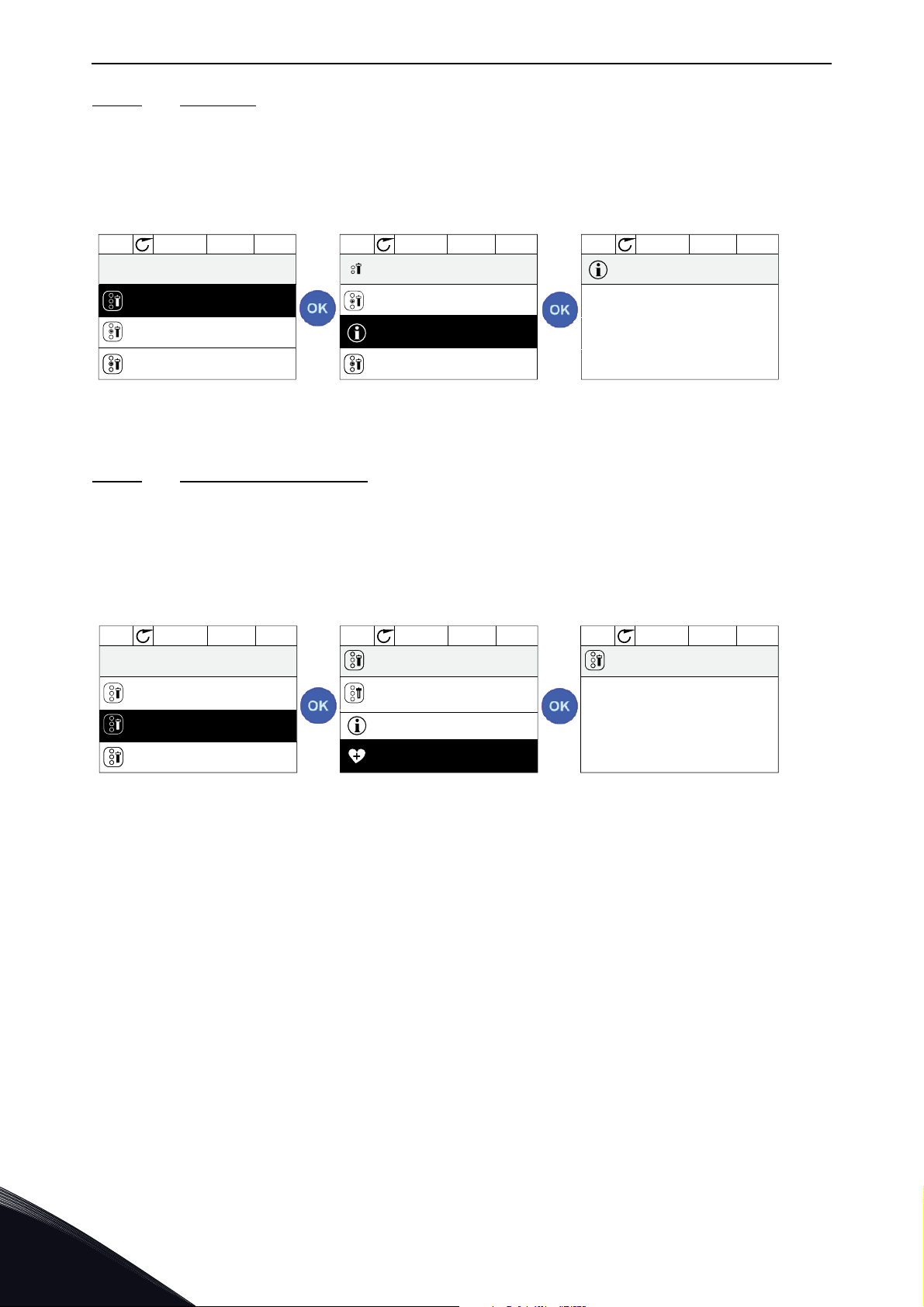

2.1.2.5 Help texts

The graphical keypad features instant help and information displays for various items.

All parameters offer an instant help display. Select Help and press the OK button.

Text information is also available for faults, alarms and the startup wizard.

Figure 7. Help text example

2.1.2.6 Adding item to favourites

You might need to refer to certain parameter values or other items often. Instead of locating them

one by one in the menu structure, you may want to add them to a folder called Favourites where

they can easily be reached.

To remove an item from the Favourites, see Chapter 2.3.7.

Figure 8. Adding item to Favourites

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 12

9167.emf

READY RUN STOP ALARM FAULT

FWD REV I/O BUSKEYPAD

Indicators:

Status

Indicators:

Alarm, Fault

Indicators:

Direction

Indicators:

Control place

Group or parameter name

Menu location

2.2 Vacon keypad with text segment display

You can also choose a Keypad with text segment display (Text keypad) for your user interface.

It has mainly the same functionalities as the keypad with graphical display although some of these

are somewhat limited.

2.2.1 Keypad display

The keypad display indicates the status of the motor and the drive and any irregularities in motor or

drive functions. On the display, the user sees information about

structure and the item displayed. If the text on the text line is too long to fit in the display, the text

will scroll from left to right to reveal the whole text string.

his present

location in the menu

2.2.1.1

Main menu

The data on the control keypad are arranged in menus and submenus. Use the Up and Down arrows

return

to move between the menus. Enter the group/item by pressing the OK button and

to the

former level by pressing the Back/Reset button.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 13 Keypad of the drive

9168.emf

BACK

RESET

2.2.2 Using the keypad

2.2.2.1

Editing values

Change value of a parameter following the procedure below:

1. Locate the parameter.

2. Enter the Edit mode by pressing OK.

3. Set new value with the arrow buttons up/down. You can also move from digit to digit with the

arrow buttons left/right if the value is numerical and change then the value with the arrow buttons up/down.

4. Confirm change with OK button or ignore change by returning to previous level with Back/

Reset button.

Figure 9. Editing values

2.2.2.2 Resetting fault

Instructions for how to reset a fault can be found in Chapter 3.8.1 on page 110.

2.2.2.3

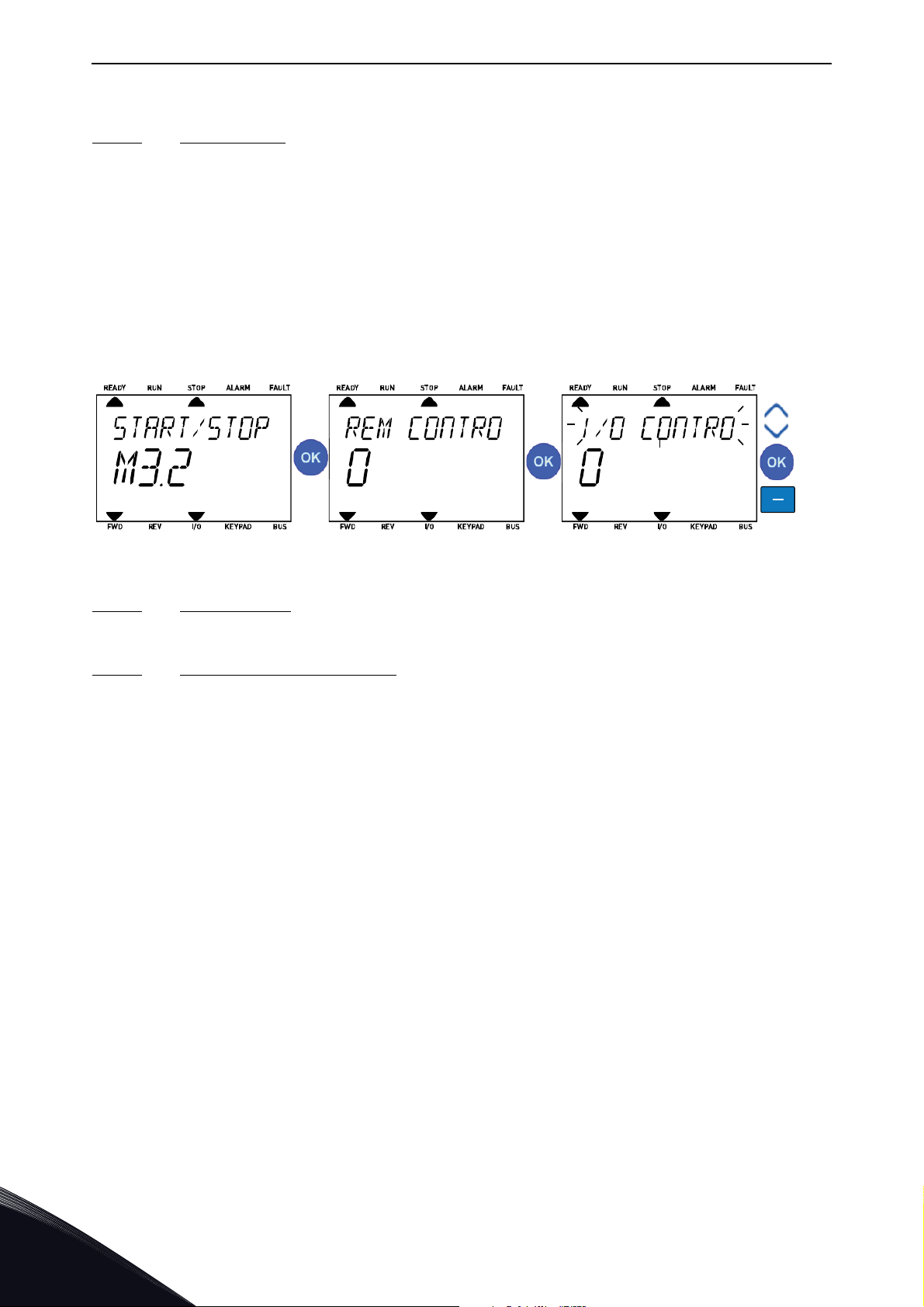

Local/Remote control button

The LOC/REM button is used for two functions: to quickly access the Control page and to easily

change between the Local (Keypad) and Remote control places.

Control places

The control place is the source of control where the drive can be started and stopped. Every

control place has its own parameter for selecting the frequency reference source. In the HVAC

drive, the Local control place is always the keypad. The Remote control place is determined by

parameter P1.15 (I/O or Fieldbus). The selected control place can be seen on the status bar of the

keypad.

Remote control place

I/O A, I/O B and Fieldbus can be used as remote control places. I/O A and Fieldbus have the lowest

priority and can be chosen with parameter P3.2.1 (Rem Control Place). I/O B, again, can bypass

the remote control place selected with parameter P3.2.1 using a digital input. The digital input is

selected with parameter P3.5.1.5 (I/O B Ctrl Force).

Local control

Keypad is always used as control place while in local control. Local control has higher priority than

remote control. Therefore, if, for example, bypassed by parameter P3.5.1.5 through digital input

while in Remote, the control place will still switch to Keypad if Local is selected. Switching

between Local and Remote Control can be done by pressing the Loc/Rem-button on the keypad or

by using the "Local/Remote" (P3.2.2) parameter.

2

Changing control places

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 14

11089.emf

11090.emf

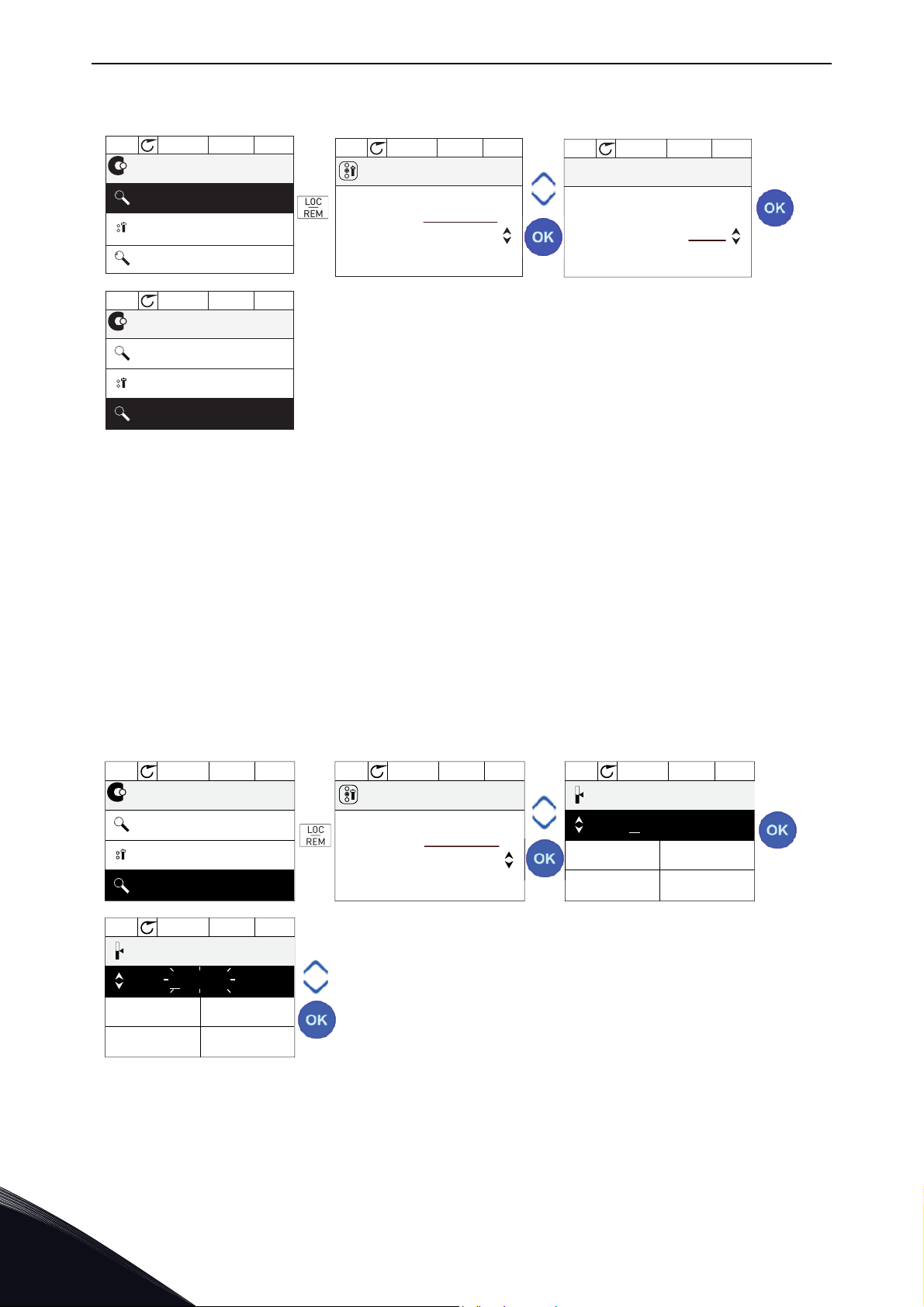

Change of control place from Remote to Local (keypad).

1. Anywhere in the menu structure, push the Loc/Rem button.

2. Using the arrow buttons, select Local/Remote and confirm with the OK button.

3. On the next display, select Local or Remote and again confirm with the OK button.

4. The display will return to the same location as it was when the Loc/Rem button was pushed.

However, if the Remote control place was changed to Local (Keypad) you will be prompted for

keypad reference.

Figure 10. Changing control places

Accessing the control page

The Control page is meant for easy operation and monitoring of the most essential values.

1. Anywhere in the menu structure, push the Loc/Rem button.

2. Push the Arrow up or the Arrow down button to select Control page and confirm with the

OK button.

3. The control page appears.

If keypad control place and keypad reference are selected to be used you can set the Keypad

reference after having pressed the OK button. If other control places or reference values are

used the display will show Frequency reference which is not editable.

Figure 11. Accessing Control page

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 15 Keypad of the drive

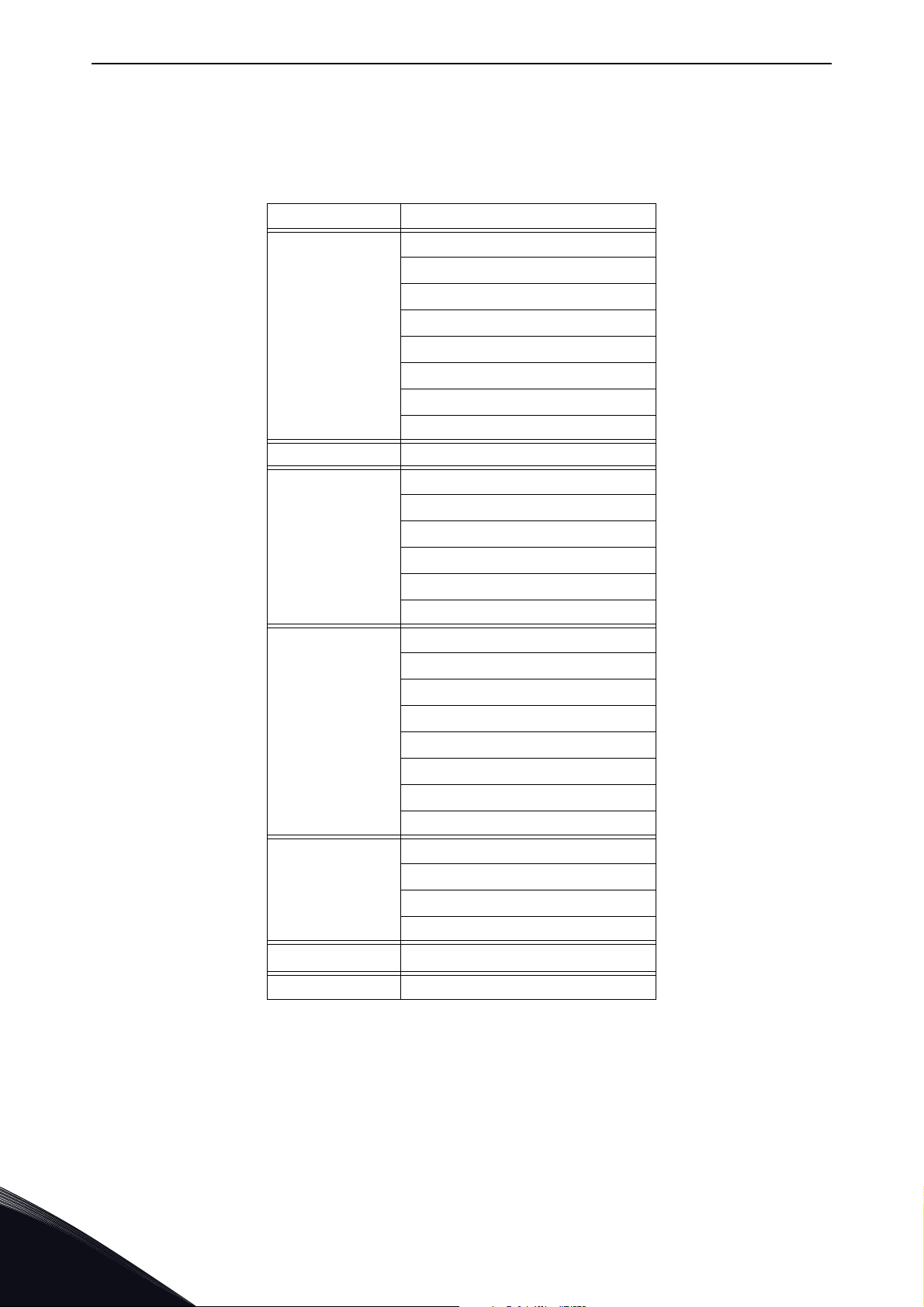

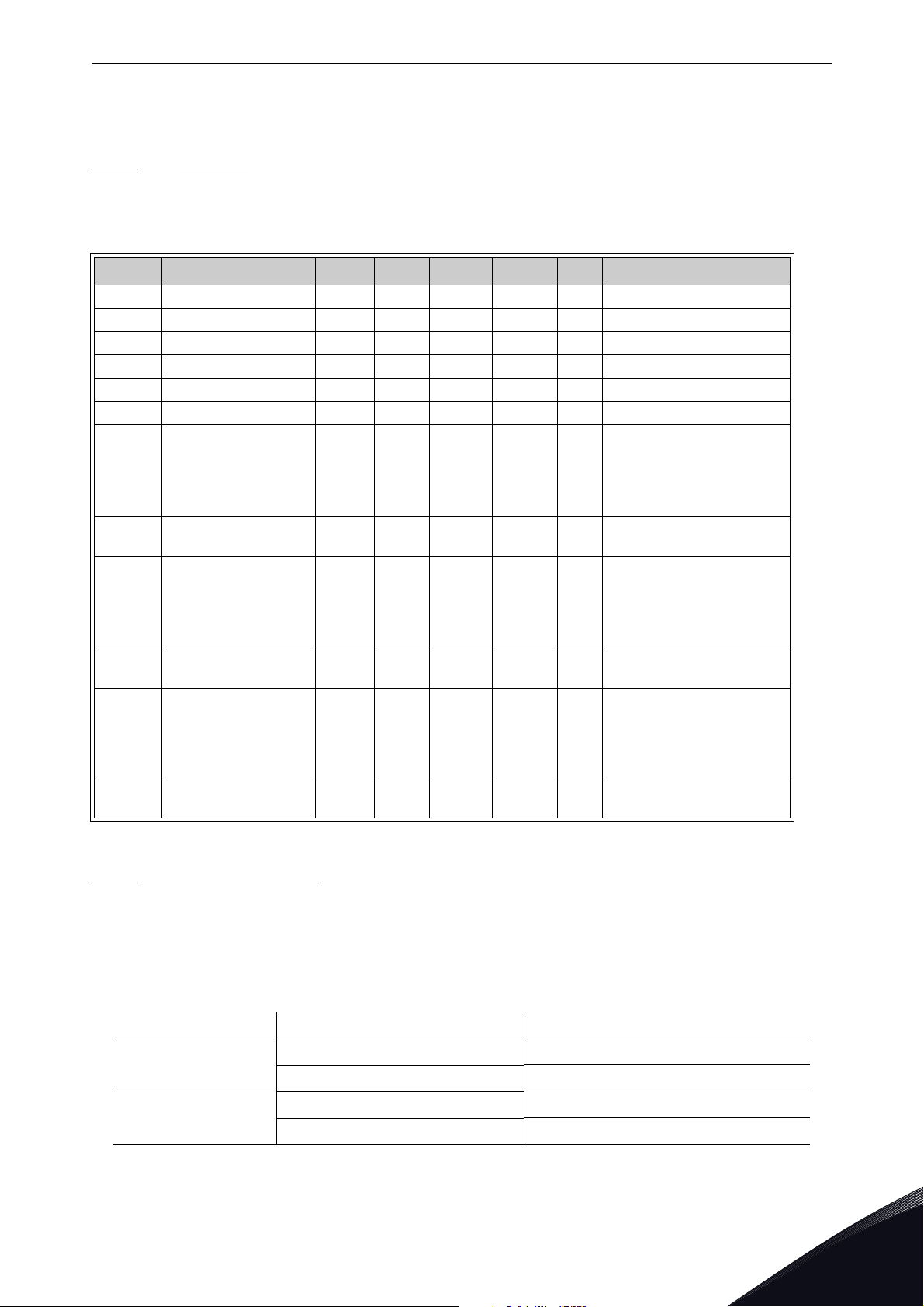

2.3 Menu structure

Click on and select the item you wish to receive more information about (electronic manual).

Table 1. Keypad menus

Quick setup See Chapter 3.4.

Monitor Multi-monitor*

Basic

Timer functions

PID Controller 1

PID Controller 2

Multi-Pump

Fieldbus data

Temperature inputs

Parameters See Chapter 3.

Diagnostics Active faults

Reset faults

Fault history

Total counters

Trip counters

Software info

I/O and

hardware

User settings Language selections

Favourites

*

Basic I/O

Slot D

Slot E

Real time clock

Power unit settings

Keypad

RS-485

Ethernet

Application selection

Parameter backup*

Drive name

See Chapter 2.1.2.6.

2

User levels See Chapter 2.3.8.

* Not available in text keypad

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 16

( 4 )

( 12 )

ID: M1

STOP READY I/O

( 5 )

(13)

(10)

STOP READY I/O

ID: M2.1

0.0rpm

STOP READY I/O

0.00 Hz

ID25

0.00Hz

0.00A

0.00%

20.0 Hz

0.0V

0.0V 81.9°C 0.0%

ID:1 M2.1.1.1

STOP Ready I/O

0.00 Hz

10.00 Hz

0.00 rpm

0.00 A

0.00 %

0.00 %

11116.emf

(13)

Main Menu

Quick Setup

Parameters

Monitor

Monitor

Multimonitor

Basic

Timer functions

Multimonitor

FreqReference

Output Freq

Motor Curre

Motor Torque

Motor Voltage

Motor Speed

Motor TemperaUnit TemperaDC-link volt

FreqReferenc

FreqReference

Output frequency

Motor Power

FreqReference

Motor Speed

Motor Current

Motor Torque

2.3.1 Quick setup

The Quick Setup Menu includes the minimum set of most commonly used parameters during installation and commissioning. More detailed information on the parameters of this group you will

find in Chapter 3.4.

2.3.2 Monitor

Multi-monitor

NOTE!This menu is not available in text keypad.

On the multi-monitor page, you can collect nine values that you wish to monitor.

Change the monitored value by activating the value cell (with arrow buttons left/right) and clicking

OK. Then choose a new item on the Monitoring values list and click OK again.

Basic

The basic monitoring values are the actual values of selected parameters and signals as well as

statuses and measurements. Different applications may have different and different number of

monitoring values.

Timer functions

Monitoring of timer functions and the Real Time Clock. See Chapter 3.5.3.

PID Controller 1

Monitoring of PID controller values. See Chapter and Chapter 3.5.5.

PID Controller 2

Monitoring of PID controller values. See Chapter and Chapter 3.5.5.

Multi-Pump

Monitoring of values related to the use of several drives. See Chapter 3.5.6.

Fieldbus data

Fieldbus data shown as monitor values for debugging purposes at e.g. fieldbus commissioning. See

Chapter 3.5.7.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

Figure 12. Multi-monitoring page

2

vacon • 17 Keypad of the drive

2.3.3 Parameters

Through this submenu, you can reach the application parameter groups and parameters. More information on parameters in Chapter 3.

2.3.4 Diagnostics

Under this menu, you can find Active faults, Reset faults, Fault history, Counters and Software info.

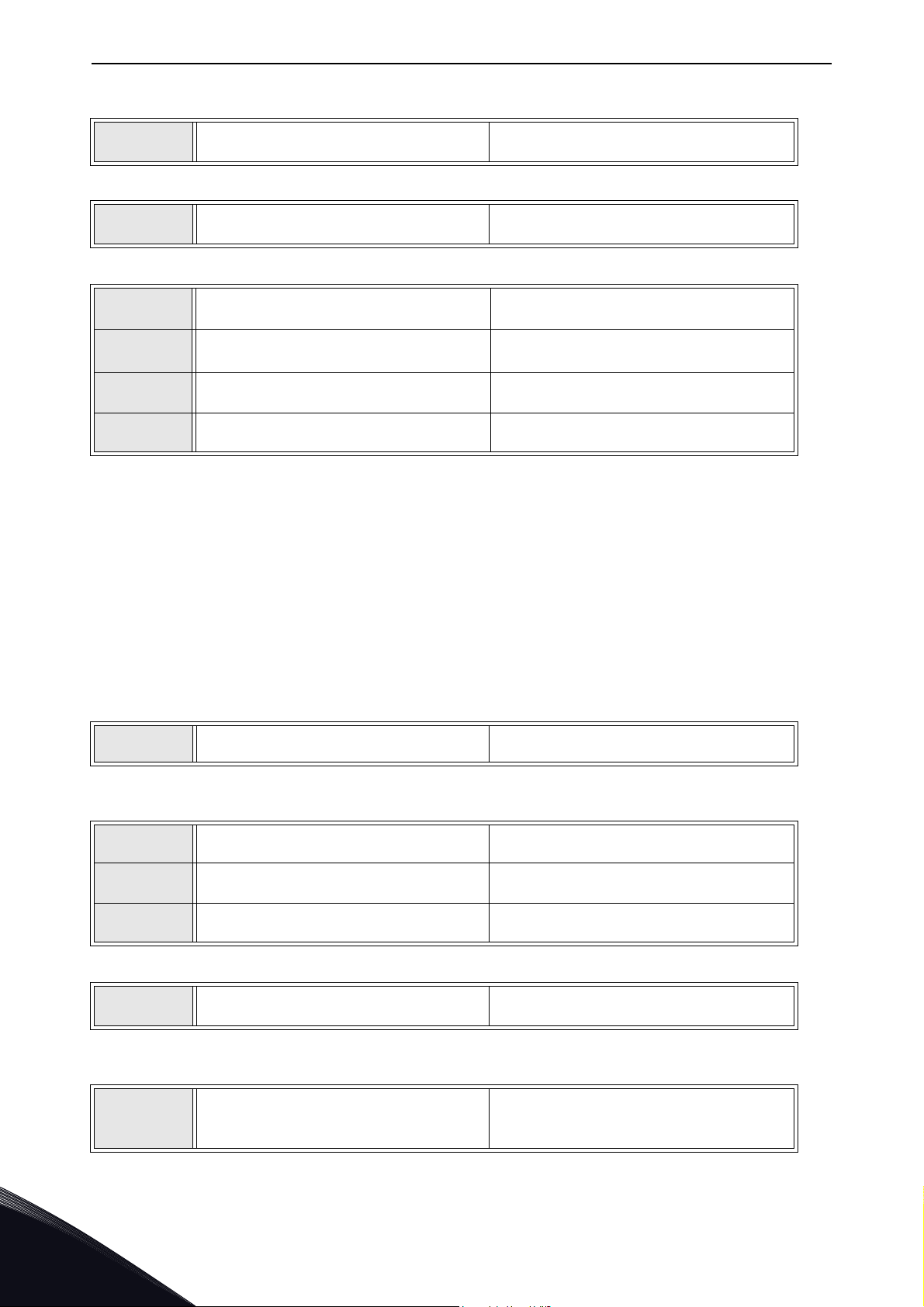

2.3.4.1

Menu Function Note

Active faults When a fault/faults appear(s), the

2.3.4.2 Reset faults

Menu Function Note

Reset faults

Active faults

display with the name of the fault

starts to blink. Press OK to return

to the Diagnostics menu. The

Active faults submenu shows the

number of faults. Select the fault

and push OK to see the fault-time

data.

In this menu you can reset faults.

For closer instructions, see

Chapter 3.8.1.

The fault remains active until it is

cleared with the Reset button (push

for 2 s) or with a reset signal from the

I/O terminal or fieldbus or by

choosing Reset faults (see below).

The memory of active faults can store

the maximum of 10 faults in the order

of appearance.

Control signal before resetting the

fault to prevent unintentional restart

of the drive.

CAUTION! Remove external

2.3.4.3 Fault history

Menu Function Note

Fault history

40 latest faults are stored in the

Fault history.

Entering the Fault history and clicking

OK on the selected fault shows the

fault time data (details).

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 18

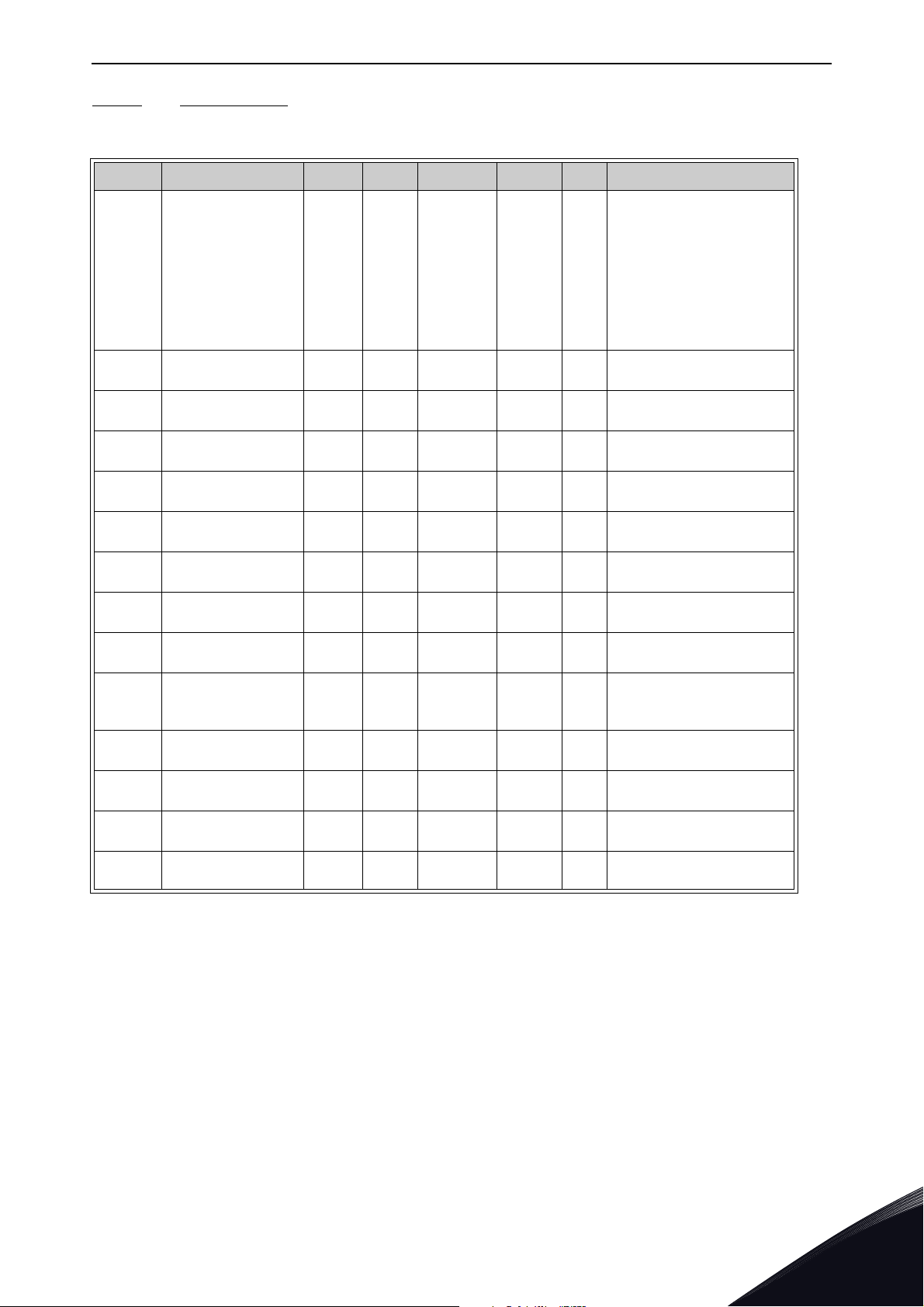

2.3.4.4 Total counters

Table 2: Diagnostics menu, Total counters parameters

Index Parameter Min Max Unit Default ID Description

Amount of energy taken from

supply network. No reset.

NOTE FOR TEXT KEYPAD:

The highest energy unit

V4.4.1 Energy counter Varies 2291

V4.4.3

V4.4.4

V4.4.5

V4.4.6

V4.4.7

V4.4.8

V4.4.9

V4.4.10

V4.4.11

V4.4.12

V4.4.13

V4.4.14

V4.4.15

Operating time

(graphical keypad)

Operating time

(text keypad)

Operating time

(text keypad)

Operating time

(text keypad)

Run time

(graphical keypad)

Run time

(text keypad)

Run time

(text keypad)

Run time

(text keypad)

Power on time

(graphical keypad)

Power on time

(text keypad)

Power on time

(text keypad)

Power on time

(text keypad)

Start command

counter

a d hh:min 2298 Control unit operating time.

a

d

hh:min:ss

a d hh:min 2293 Motor running time.

a

d

hh:min:ss

a d hh:min 2294

a Power on time in total years.

d Power on time in total days.

hh:min:ss

shown on the standard keypad is MW. Should the

counted energy exceed 999.9

MW, no unit is shown on the

keypad.

Control unit operating time in

total years.

Control unit operating time in

total days.

Control unit operating time in

hours, minutes and seconds.

Motor running time in total

years.

Motor running time in total

days.

Motor running time in hours,

minutes and seconds

Amount of time the power

unit has been powered so far.

No reset.

Power on time in hours,

minutes and seconds.

The number of times the

2295

power unit has been started.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 19 Keypad of the drive

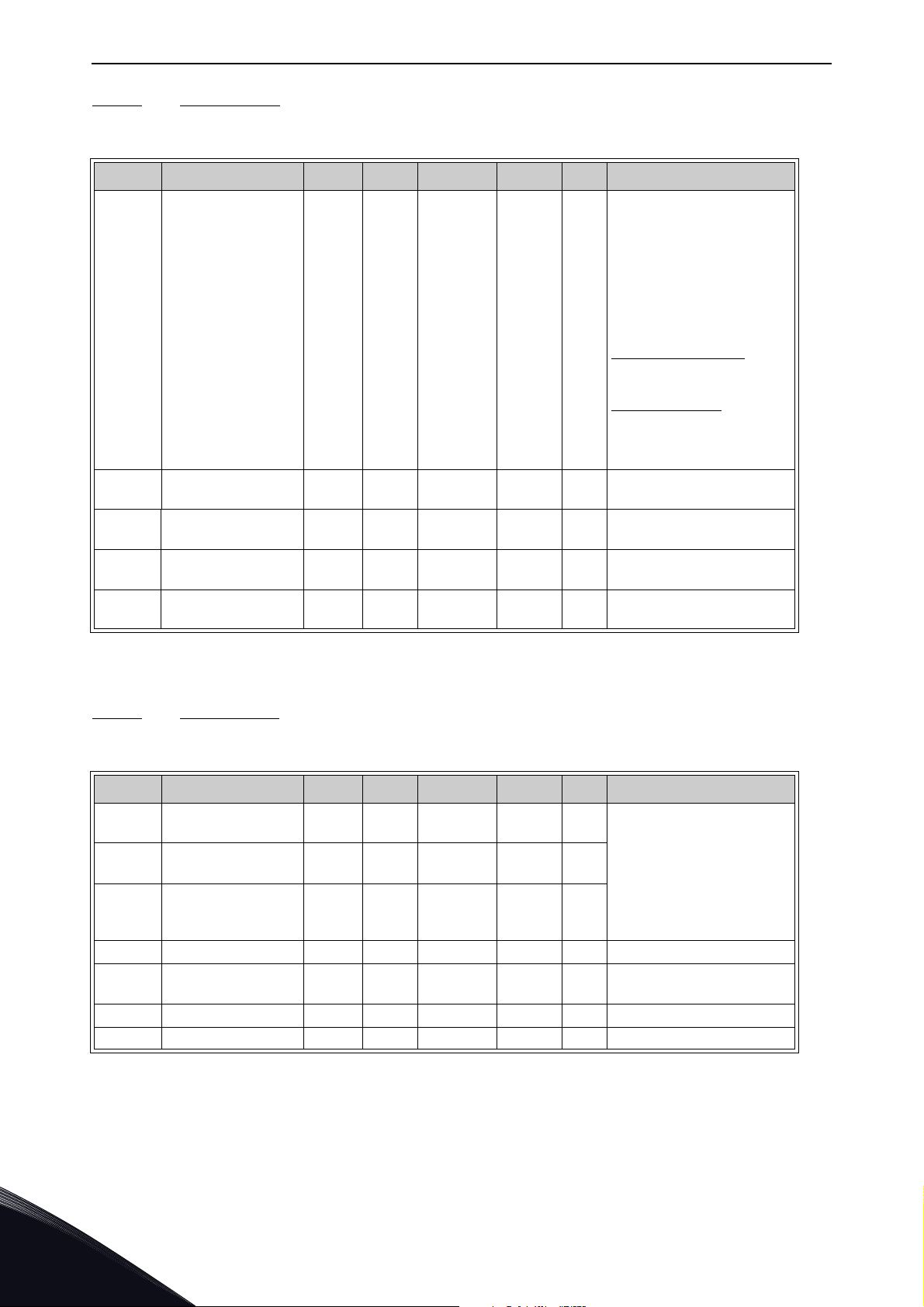

2.3.4.5 Trip counters

Table 3: Diagnostics menu, Trip counters parameters

Index Parameter Min Max Unit Default ID Description

Resettable energy counter.

NOTE FOR TEXT KEYPAD:

The highest energy unit

shown on the standard

keypad is MW. Should the

counted energy exceed 999.9

MW, no unit is shown on the

P4.5.1 Energy trip counter Varies 2296

P4.5.3

P4.5.4

P4.5.5

P4.5.6

Operating time

(graphical keypad)

Operating time

(standard keypad)

Operating time

(standard keypad)

Operating time

(standard keypad)

a d hh:min 2299 Resettable. See P4.5.1.

a Operating time in total years.

d Operating time in total days.

hh:min:ss

keypad.

To reset the counter:

Standard text keypad:

Apply a long (4 s) push on the

OK button.

Graphical keypad:

Push OK once.

counter

Push OK once again.

Operating time in hours,

minutes and seconds.

Reset

page will appear.

2.3.4.6 Software info

Table 4: Diagnostics menu, Software info parameters

Index Parameter Min Max Unit Default ID Description

V4.6.1

V4.6.2

V4.6.3

V4.6.4 System load 0 100 % 2300 Load on control unit CPU.

V4.6.5

V4.6.6 Application ID 837 Application code.

V4.6.7 Application version 838

Software package

(graphical keypad)

Software package ID

(text keypad)

Software package

version

(text keypad)

Application name

(graphical keypad)

2524

Code for software

identification.

2525 Name of application.

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 20

2.3.5 I/O and hardware

Various options-related settings are located in this menu.

2.3.5.1

Basic I/O

Monitor here the statuses of inputs and outputs.

Table 5: I/O and Hardware menu, Basic I/O parameters

Index Parameter Min Max Unit Default ID Description

V5.1.1 Digital input 1 0 1 2502 Status of digital input signal

V5.1.2 Digital input 2 0 1 2503 Status of digital input signal

V5.1.3 Digital input 3 0 1 2504 Status of digital input signal

V5.1.4 Digital input 4 0 1 2505 Status of digital input signal

V5.1.5 Digital input 5 0 1 2506 Status of digital input signal

V5.1.6 Digital input 6 0 1 2507 Status of digital input signal

Shows the selected (with

V5.1.7 Analogue input 1 mode 1

V5.1.8 Analogue input 1 0 100 % 2509

V5.1.9 Analogue input 2 mode 1

V5.1.10 Analogue input 2 0 100 % 2511

V5.1.11

V5.1.12 Analogue output 1 0 100 % 2513

Analogue output 1

mode

-30...

+200°C

-30...

+200°C 2510

-30...

1

+200°C 2512

jumper) mode for Analogue

2508

input signal

1 = 0...20 mA

3 = 0...10 V

Status of analogue input

signal

Shows the selected (with

jumper) mode for Analogue

input signal

1 = 0...20 mA

3 = 0...10 V

Status of analogue input

signal

Shows the selected (with

jumper) mode for Analogue

otuput signal

1 = 0...20 mA

3 = 0...10 V

Status of analogue output

signal

2.3.5.2

Option board slots

The parameters of this group depend on the option board installed. If no option board is placed in

slots D or E, no parameters are visible. See Chapter 3.6.2 for the location of the slots.

As an option board is removed, info text F39 Device removed will appear on the display. See

Table 74.

Menu Function Note

Slot D Settings Option board related settings.

Monitoring Monitor option board-related info.

Slot E Settings Option board related settings.

Monitoring Monitor option board-related info.

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 21 Keypad of the drive

2.3.5.3 Real time clock

Table 6: I/O and Hardware menu, Real time clock parameters

Index Parameter Min Max Unit Default ID Description

Status of battery.

M5.5.1 Battery state 1 3 2 2205

M5.5.2 Time hh:mm:ss 2201 Current time of day

M5.5.3 Date mm.dd. 2202 Current date

M5.5.4 Year yyyy 2203 Current year

M5.5.5 Daylight saving 1 4 1 2204

1 = Not installed

2 = Installed

3 = Change battery

Daylight saving rule

1 = Off

2 = EU

3 = US

4 = Russia

2.3.5.4 Power unit settings

Fan

The fan operates in optimized or always-on mode. In the optimized mode, fan speed is controlled

according to the drive‘s internal logic that receives data from temperature measurements (if

supported by the power unit) and the fan stops within 5 minutes when the drive is in Stop state. In

always-on mode, the fan runs at full speed, without stopping.

Table 7: Power unit settings, Fan

Index Parameter Min Max Unit Default ID Description

V5.5.1.1 Fan control mode 0 1 1 2377

M5.6.1.5 Fan lifetime N/A N/A 0 849 Fan lifetime

M5.6.1.6

M5.6.1.7 Fan lifetime reset N/A N/A 0 823 Fan lifetime reset

Fan lifetime alarm

limit

0 200 000 h 50 000 824 Fan lifetime alarm limit

0 = Always on

1 = Optimized

Brake chopper

Table 8: Power unit settings, Brake chopper

Index Parameter Min Max Unit Default ID Description

0 = Disabled

P5.6.2.1 Brake chopper mode 0 3 0 2526

1 = Enabled (Run)

2 = Enabled (Run & Stop)

3 = Enabled (Run, no testing)

2

Sine filter

Sine filter support restricts overmodulation depth and prevents thermal management functions

from decreasing switching frequency.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 22

Table 9: Power unit settings, Sine filter

Index Parameter Min Max Unit Default ID Description

P5.6.4.1 Sine filter 0 1 0 2507

0 = Disabled

1 = Enabled

2.3.5.5 Keypad

Table 10: I/O and Hardware menu, Keypad parameters

Index Parameter Min Max Unit Default ID Description

Time after which the display

P5.7.1 Timeout time 0 60 min 0 804

P5.7.2 Default page 0 4 0 2318

P5.7.3 Menu index 2499

P5.7.4 Contrast* 30 70 % 50 830

P5.7.5 Backlight time 0 60 min 5 818

returns to page defined with

parameter P5.7.2.

0 = Not used

0 = None

1 = Enter menu index

2 = Main menu

3 = Control page

4 = Multimonitor

Set menu index for desired

page and activate with

parameter P5.7.2 = 1.

Set contrast of the display

(30...70%).

Set the time until the

backlight of the display turns

off (0...60 min). If set to 0 s,

backlight is always on.

* Only available with graphical keypad

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 23 Keypad of the drive

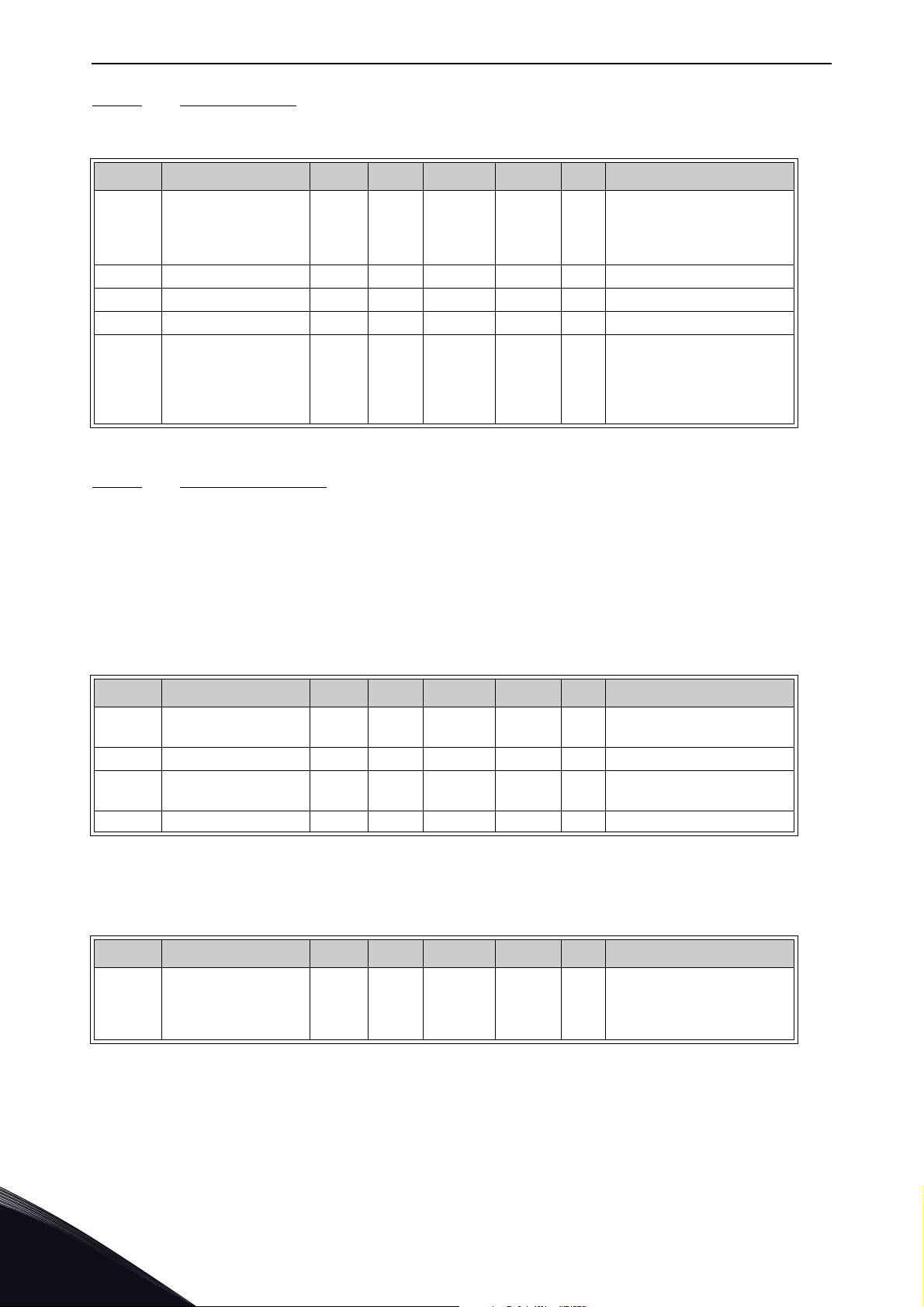

2.3.5.6 Fieldbus

Parameters related to different fieldbus boards can also be found in the I/O and Hardware menu.

These parameters are explained in more detail in the respective fieldbus manual.

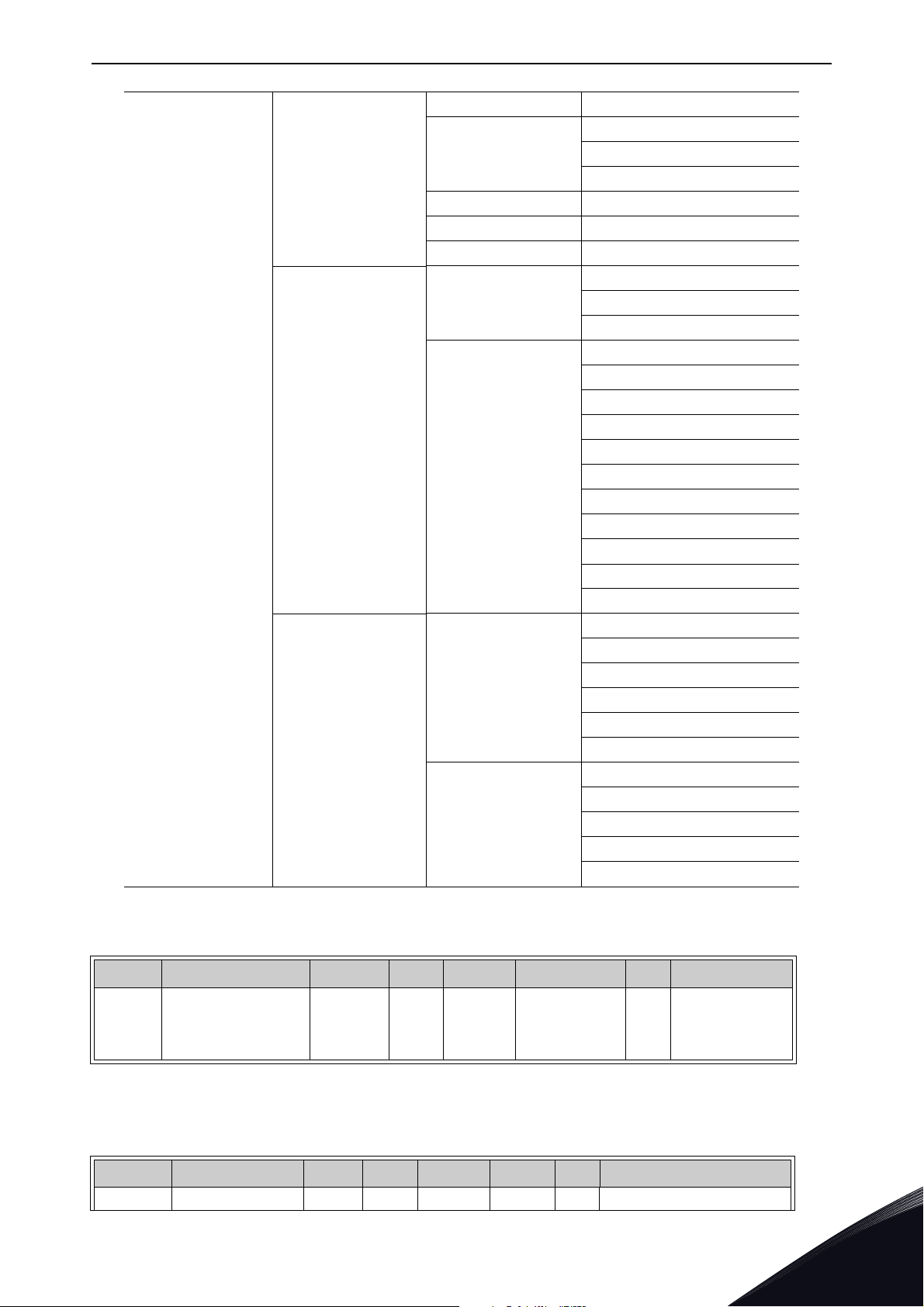

Submenu level 1 Submenu level 2 Submenu level 3 Submenu level 4

RS-485 Common settings Protocol Modbus/RTU

N2

BACnet MS/TP

Modbus/RTU Parameters Slave address

Baud rate

Parity type

Stop bits

Communication timeout

Operate mode

Monitoring Fieldbus protocol status

Communication status

Illegal functions

Illegal data addresses

Illegal data values

Slave device busy

Memory parity error

Slave device failure

Last fault response

Control word

Status word

N2 Parameters Device address

Communication timeout

Monitoring Fieldbus protocol status

Communication status

Invalid data

Invalid commands

Command not accepted

Control word

Status word

RS-485 BACnet MS/TP Parameters Baud rate

Autobauding

MAC address

Instance number

Communication timeout

Monitoring Fieldbus protocol status

Communication status

Actual instance number

Fault code

Control word

Status word

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 24

Ethernet Common settings IP address mode

Fixed IP

IP address

Subnet mask

Default gateway

Modbus/TCP Common settings Connection limit

Monitoring* Fieldbus protocol status

BACnet/IP Settings Instance number

Monitoring Fieldbus protocol status

* Will appear only after connection has been established

IP address

Subnet mask

Default gateway

Slave address

Communication timeout

Communication status

Illegal functions

Illegal data addresses

Illegal data values

Slave device busy

Memory parity error

Slave device failure

Last fault response

Control word

Status word

Communication timeout

Protocol in use

BBMD IP

BBMD Port

Time to live

Communication status

Actual instance number

Control word

Status word

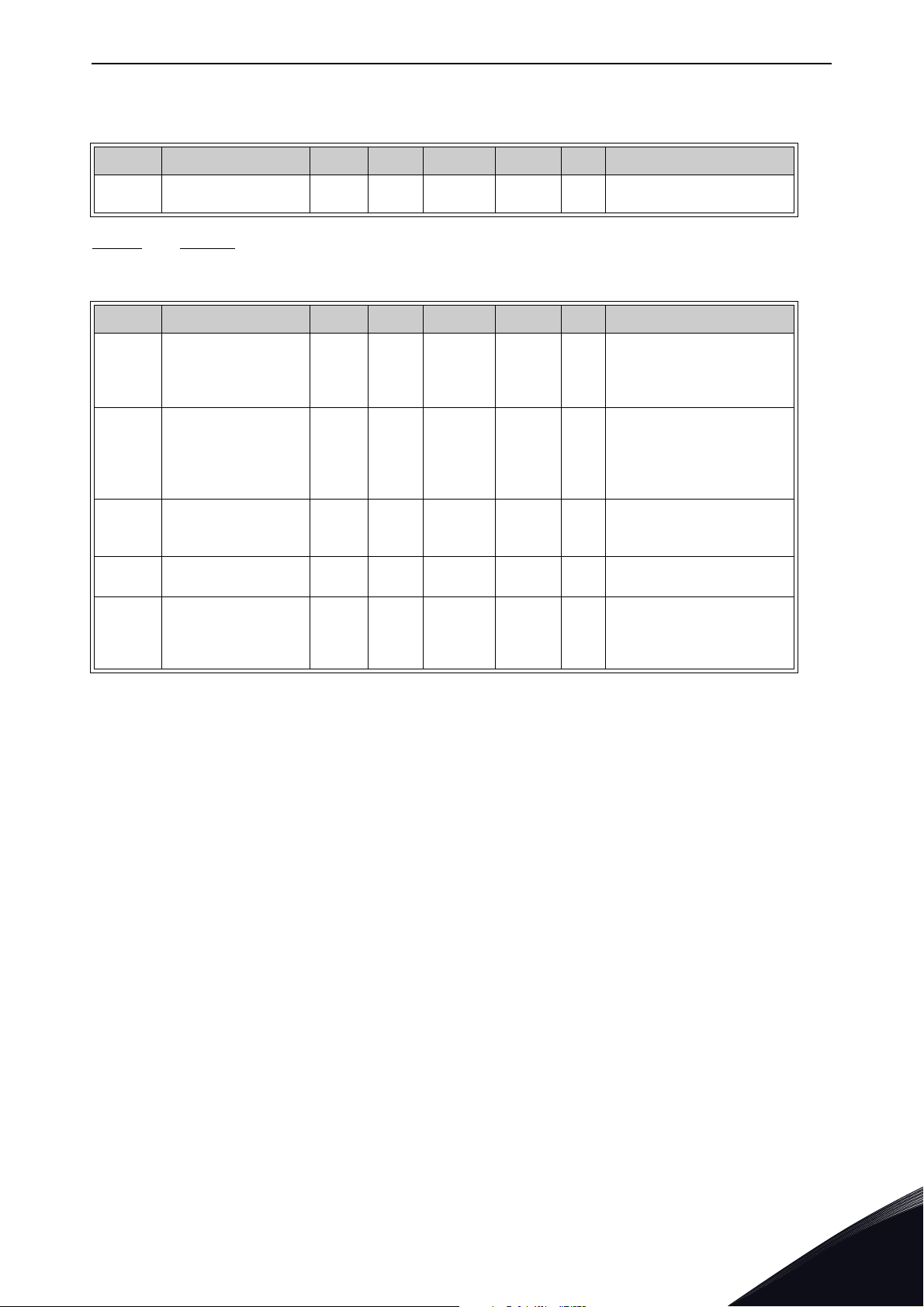

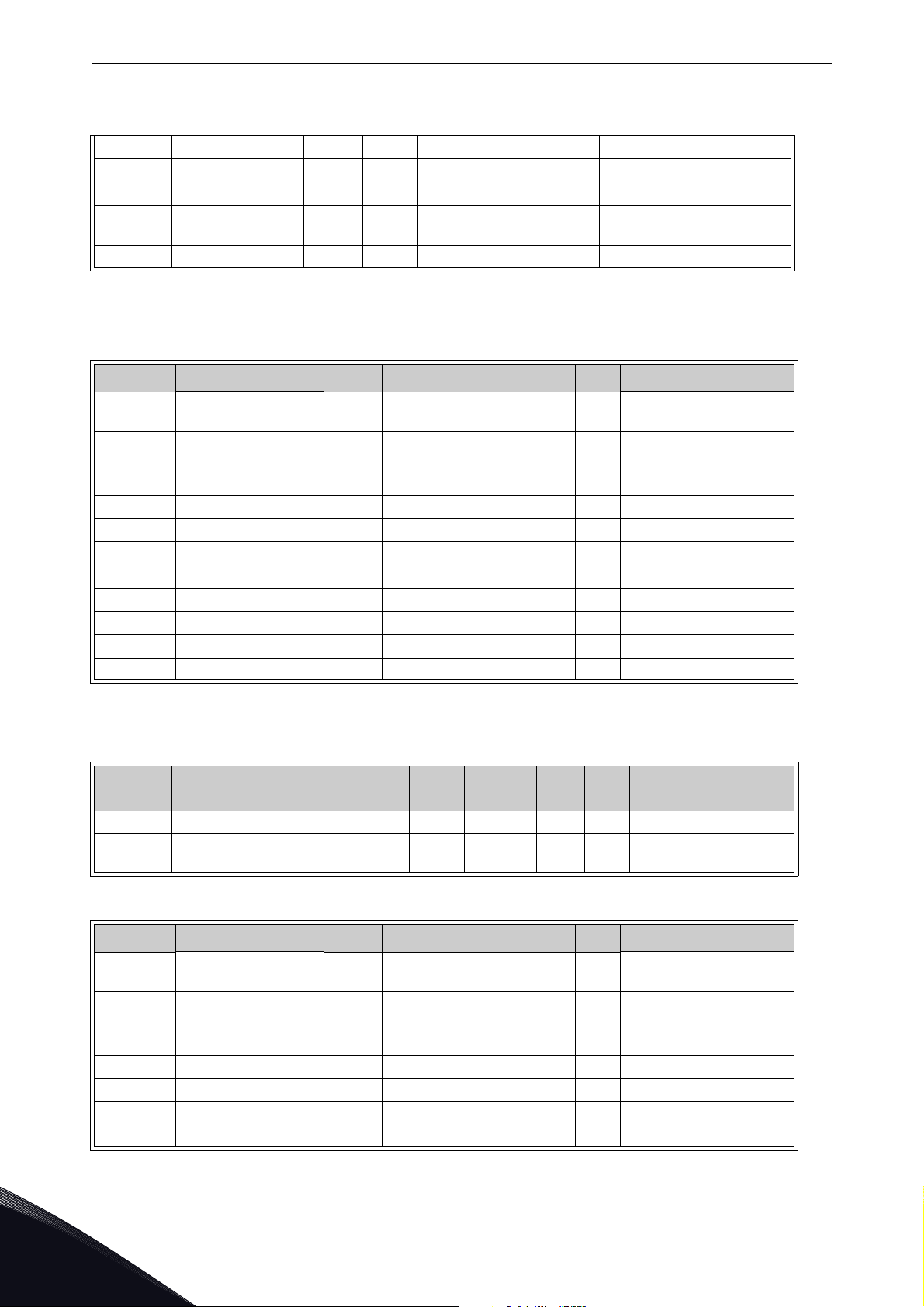

Table 11: RS-485 common settings

Index Parameter Min Max Unit Default ID Description

0 = No protocol

P5.8.1.1 Protocol 0 9 0 2208

Table 12: ModBus RTU parameters (This table is only visible when P5.8.1.1 Protocol = 4/

Modbus RTU)

Index Parameter Min Max Unit Default ID Description

P5.8.3.1.1 Slave address 1 247 1 2320 Slave address

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

4 = Modbus RTU

5 = N2

9 = BACnet MSTP

2

vacon • 25 Keypad of the drive

Table 12: ModBus RTU parameters (This table is only visible when P5.8.1.1 Protocol = 4/

Modbus RTU)

P5.8.3.1.2 Baud rate 300 230 400 bps 9600 2378 Baud rate

P5.8.3.1.3 Parity type Even None None 2379 Parity type

P5.8.3.1.4 Stop bits 1 2 2 2380 Stop bits

P5.8.3.1.5

P5.8.3.1.6 Operate mode Slave Master Slave 2374 Operate mode

Communication

timeout

0 65 535 s 10 2321

Communication

timeout

Table 13: ModBus RTU monitoring (This table is only visible when P5.8.1.1 Protocol = 4/

Modbus RTU)

Index Parameter Min Max Unit Default ID Description

M5.8.3.2.1

P5.8.3.2.2

M5.8.3.2.3 Illegal functions 0 2383 Illegal functions

M5.8.3.2.4 Illegal data addresses 0 2384 Illegal data addresses

M5.8.3.2.5 Illegal data values 0 2385 Illegal data values

M5.8.3.2.6 Slave device busy 0 2386 Slave device busy

M5.8.3.2.7 Memory parity error 0 2387 Memory parity error

M5.8.3.2.8 Slave device failure 0 2388 Slave device failure

M5.8.3.2.9 Last fault response 0 2389 Last fault response

M5.8.3.2.10 Control word 16#0 2390 Control word

M5.8.3.2.11 Status word 16#0 2391 Status word

Fieldbus protocol

status

Communication

status

0 2381 Fieldbus protocol status

0 0 0 2382 Communication status

Table 14: N2 parameters (This table is only visible when P5.8.1.1 Protocol = 5/N2)

Index Parameter Min Max Unit

P 5.8.3.1.1 Device address 1 255 1 2350 Device address

P 5.8.3.1.2

Communication

timeout

0 255 10 2351

Defaul

t

ID Description

Communication

timeout

Table 15: N2 monitoring (This table is only visible when P5.8.1.1 Protocol = 5/N2)

Index Parameter Min Max Unit Default ID Description

M5.8.3.2.1

M5.8.3.2.2

M5.8.3.2.3 Invalid data 0 2401 Invalid data

M5.8.3.2.4 Invalid commands 0 2402 Invalid commands

M5.8.3.2.5 Command NACK 0 2403 Command NACK

M5.8.3.2.6 Control word 16#0 2404 Control word

M5.8.3.2.7 Status word 16#0 2405 Status word

Fieldbus protocol

status

Communication

status

0 2399 Fieldbus protocol status

0 0 0 2400 Communication status

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Keypad of the drive vacon • 26

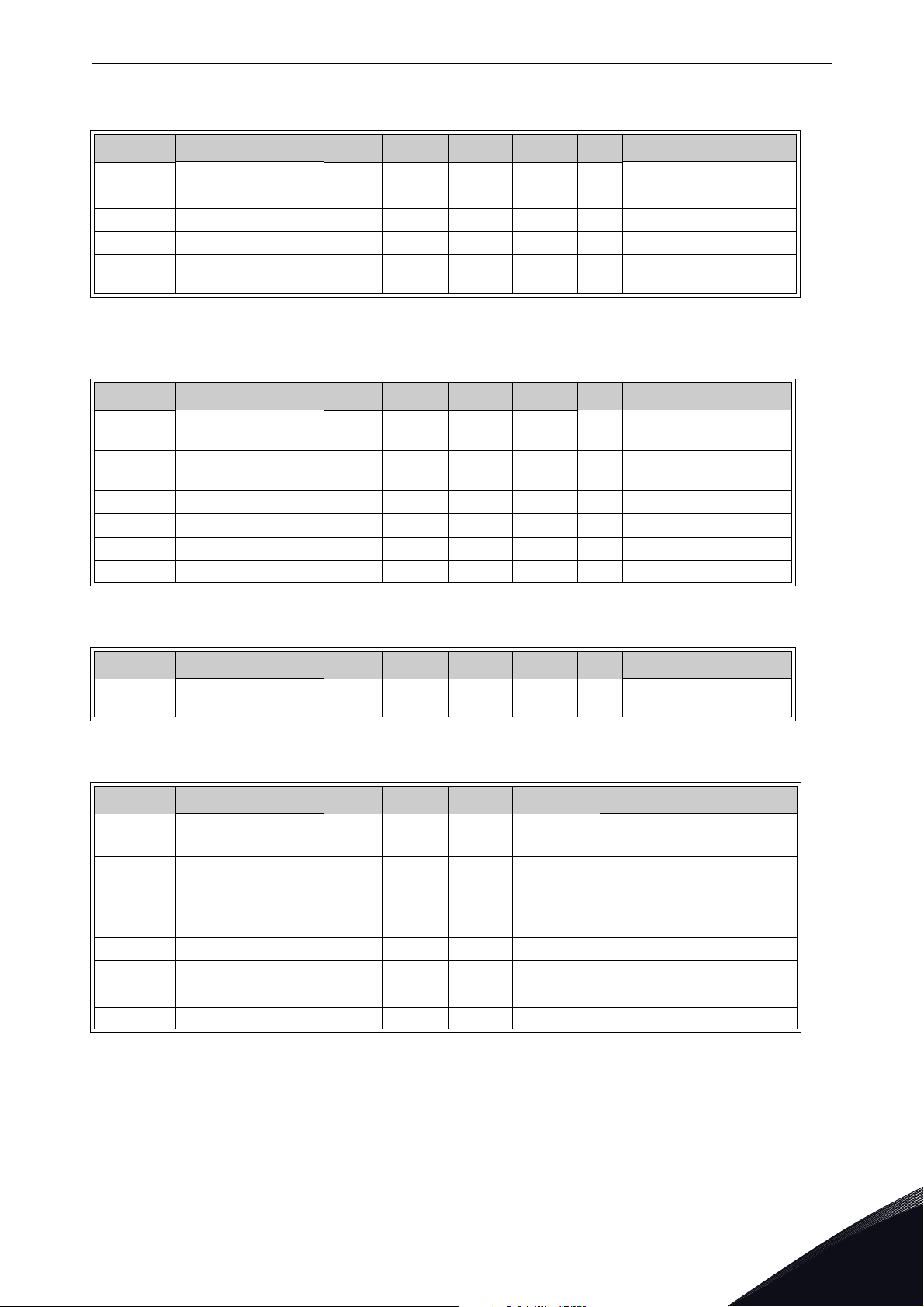

Table 16: BACnet MSTP parameters (This table is only visible when P5.8.1.1 Protocol = 9/

BACNetMSTP)

Index Parameter Min Max Unit Default ID Description

P5.8.3.1.1 Baud rate 9600 76 800 bps 9600 2392 Baud rate

P5.8.3.1.2 Autobauding 0 1 0 2330 Autobauding

P5.8.3.1.3 MAC address 1 127 1 2331 MAC address

P5.8.3.1.4 Instance number 0 4 194 303 0 2332 Instance number

P5.8.3.1.5

Communication

timeout

0 65 535 10 2333

Communication

timeout

Table 17: BACnet MSTP monitoring (This table is only visible when P5.8.1.1 Protocol = 9/

BACNetMSTP)

Index Parameter Min Max Unit Default ID Description

M5.8.3.2.1

M5.8.3.2.2

M5.8.3.2.3 Actual instance 0 2395 Actual instance

M5.8.3.2.4 Fault code 0 2396 Fault code

M5.8.3.2.5 Control word 16#0 2397 Control word

M5.8.3.2.6 Status word 16#0 2398 Status word

Fieldbus protocol

status

Communication

status

0 2393

0 2394

Fieldbus protocol

status

Communication

status

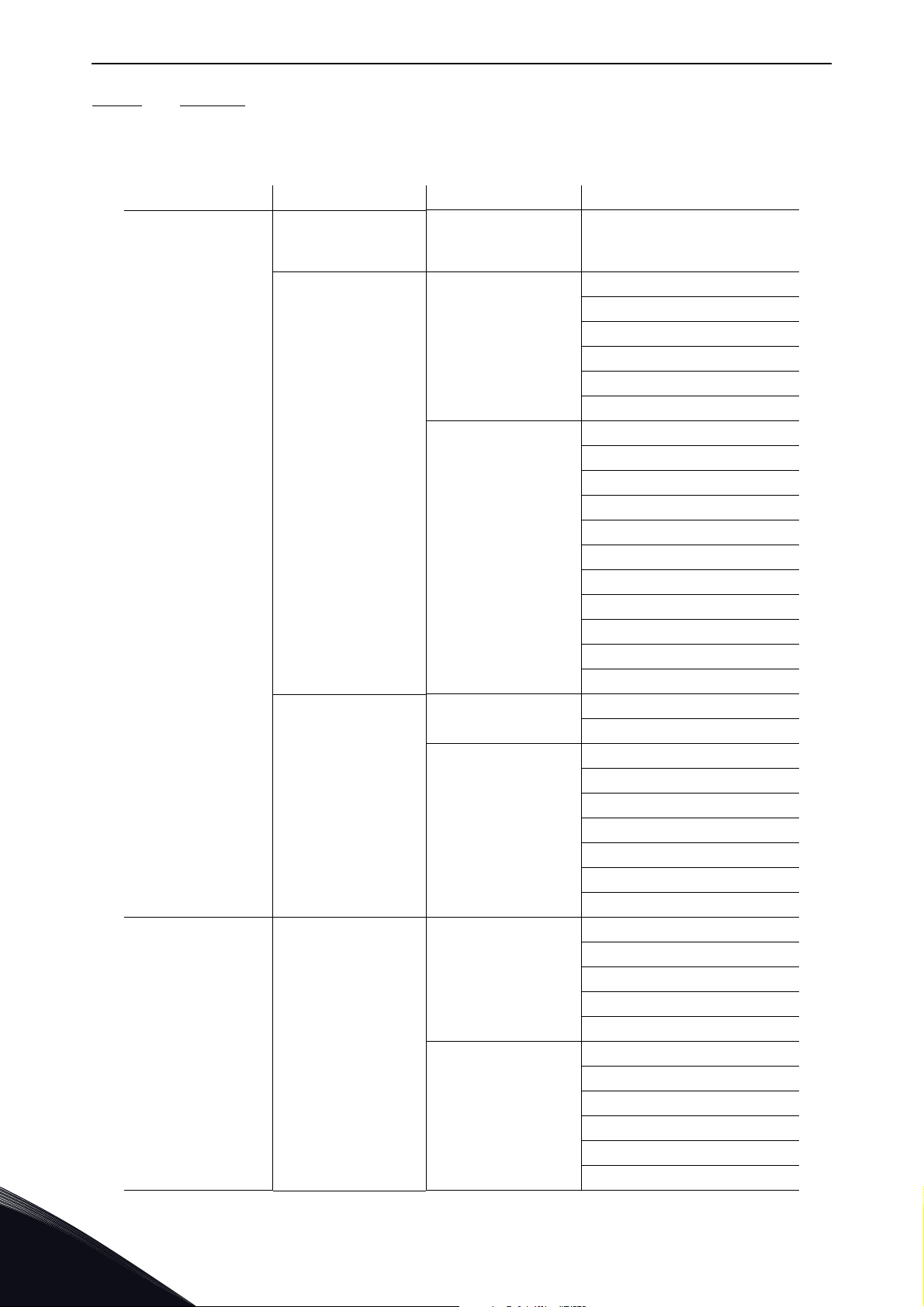

Table 18: Ethernet common settings

Index Parameter Min Max Unit Default ID Description

P5.9.1.1 IP address mode 0 1 1 2482

0 = Fixed IP

1 = DHCP with AutoIP

Table 19: Fixed IP

Index Parameter Min Max Unit Default ID Description

P5.9.1.2.1 IP address 192.168.0.10 2529

P5.9.1.2.2 Subnet mask 255.255.0.0 2530

P5.9.1.2.3 Default gateway 192.168.0.1 2531

M5.9.1.3 IP address 0 2483 IP address

M5.9.1.4 Subnet mask 0 2484 Subnet mask

M5.9.1.5 Default gateway 0 2485 Default gateway

M5.9.1.6 MAC address 2486 MAC address

The parameter is in use

if P5.9.1.1 = 0/Fixed IP

The parameter is in use

if P5.9.1.1 = 0/Fixed IP

The parameter is in use

if P5.9.1.1 = 0/Fixed IP

24-hour support +358 (0)201 212 575 • Email: vacon@vacon.com

2

vacon • 27 Keypad of the drive

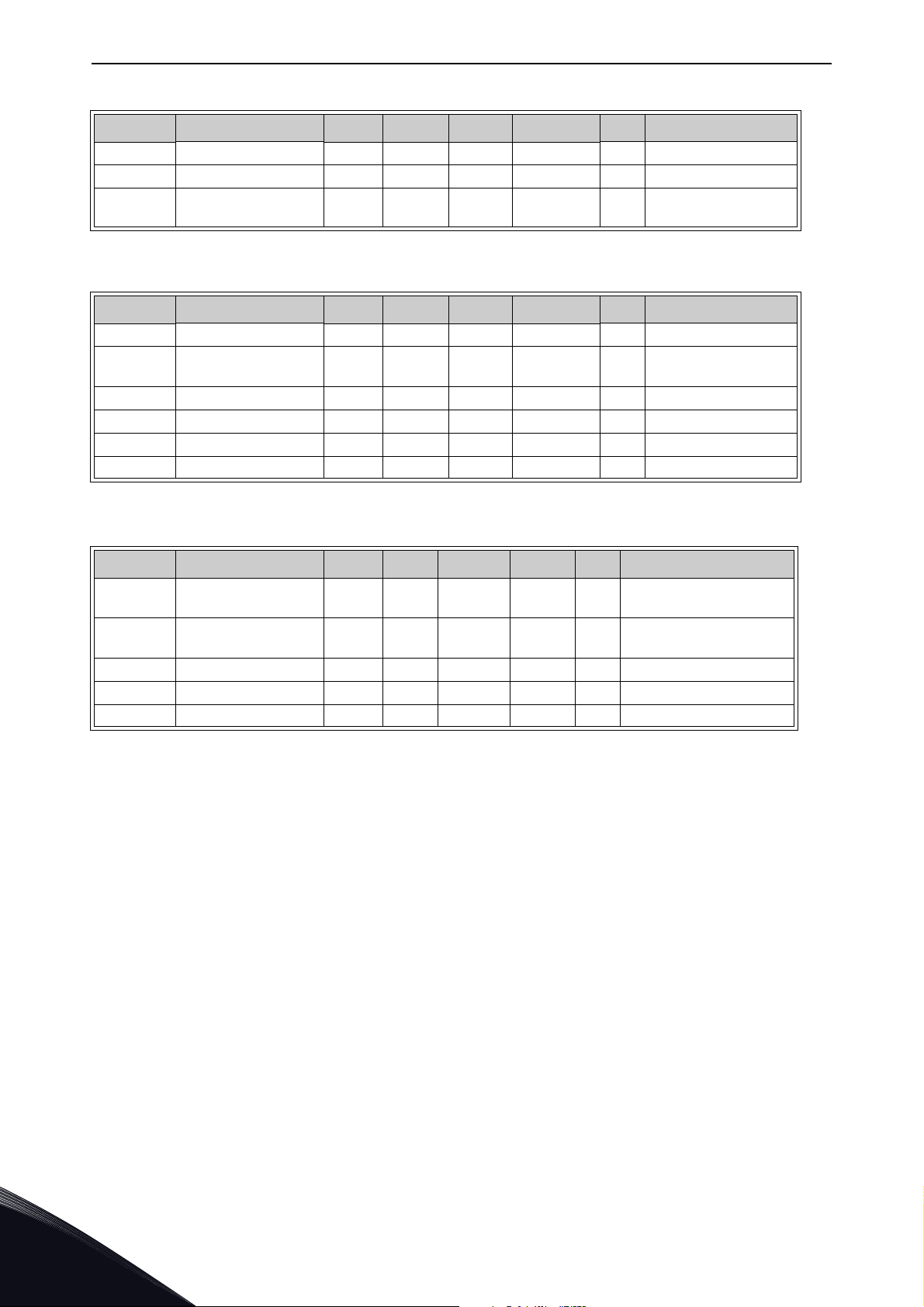

Table 20: ModBus TCP common settings

Index Parameter Min Max Unit Default ID Description

P5.9.2.1.1 Connection limit 0 3 3 2446 Connection limit

P5.9.2.1.2 Slave address 0 255 255 2447 Slave address

P5.9.2.1.3

Communication

timeout

0 65 535 s 10 2448

Communication

timeout

Table 21: BACnet IP settings

Index Parameter Min Max Unit Default ID Description

P5.9.3.1.1 Instance number 0 4 194 303 0 2406 Instance number

P5.9.3.1.2

P5.9.3.1.3 Protocol in use 0 1 0 2408 Protocol in use

P5.9.3.1.4 BBMD IP 192.168.0.1 2409 BBMD IP

P5.9.3.1.5 BBMD Port 1 65 535 47 808 2410 BBMD Port

P5.9.3.1.6 Time to live 0 255 0 2411 Time to live

Communication

timeout

0 65 535 0 2407

Communication

timeout

Table 22: BACnet IP monitoring

Index Parameter Min Max Unit Default ID Description

M5.9.3.2.1

P5.9.3.2.2

M5.9.3.2.3 Actual instance 0 2414 Invalid data

M5.9.3.2.4 Control word 16#0 2415 Control word

M5.9.3.2.5 Status word 16#0 2416 Status word

Fieldbus protocol

status

Communication

status

0 2412 Fieldbus protocol status

0 0 0 2413 Communication status

2

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Loading...

Loading...