Vacon 100 ac drives, 100 flow ac drives Installation Manual

vacon 100

®

vacon 100 flow

®

ac drives

installation manual

PREFACE VACON · 3

PREFACE

Document ID: DPD00873E

Date: 3.4.2014

ABOUT THIS MANUAL

This manual is copyright of Vacon Plc. All Rights Reserved.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

VACON · 4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

TABLE OF CONTENTS VACON · 5

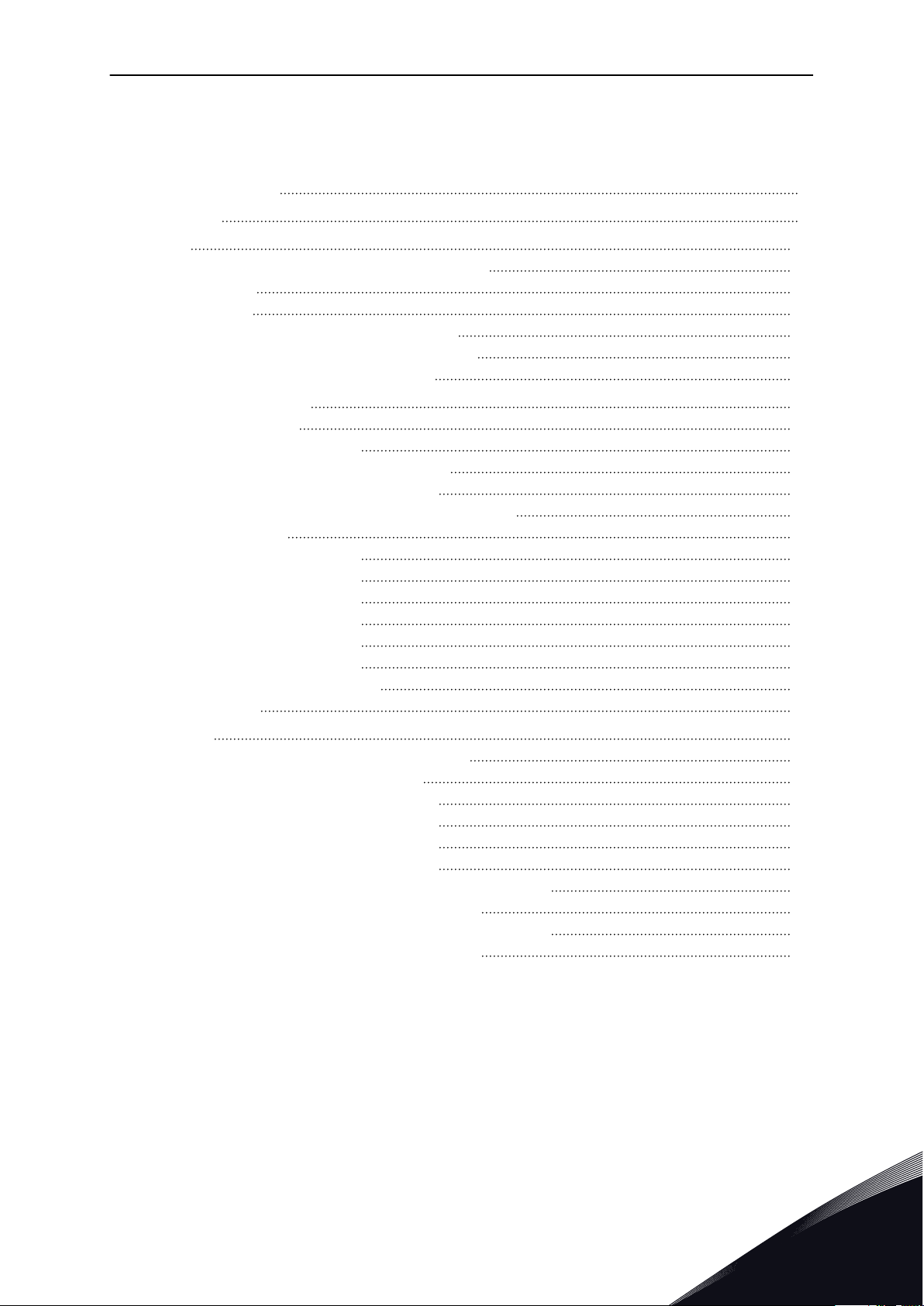

TABLE OF CONTENTS

Preface

About this manual 3

1 Approvals 8

2 Safety 10

2.1 The safety symbols used in the manual 10

2.2 Warning 10

2.3 Caution 11

2.4 Earthing and earth fault protection 12

2.5 Electro-magnetic compatibility (EMC) 13

2.6 Using an RCD or an RCM device 13

3 Receiving the delivery 14

3.1 Package label 14

3.2 Type designation code 14

3.3 Unpacking and lifting the AC drive 15

3.3.1 Weight of the AC drive 15

3.3.2 Lifting the frames MR8 and MR9 15

3.4 Accessories 16

3.4.1 Frame MR4 17

3.4.2 Frame MR5 17

3.4.3 Frame MR6 18

3.4.4 Frame MR7 19

3.4.5 Frame MR8 19

3.4.6 Frame MR9 20

3.5 "Product modified" label 20

3.6 Disposal 20

4 Mounting 21

4.1 General information about mounting 21

4.2 Dimensions for wall mounting 21

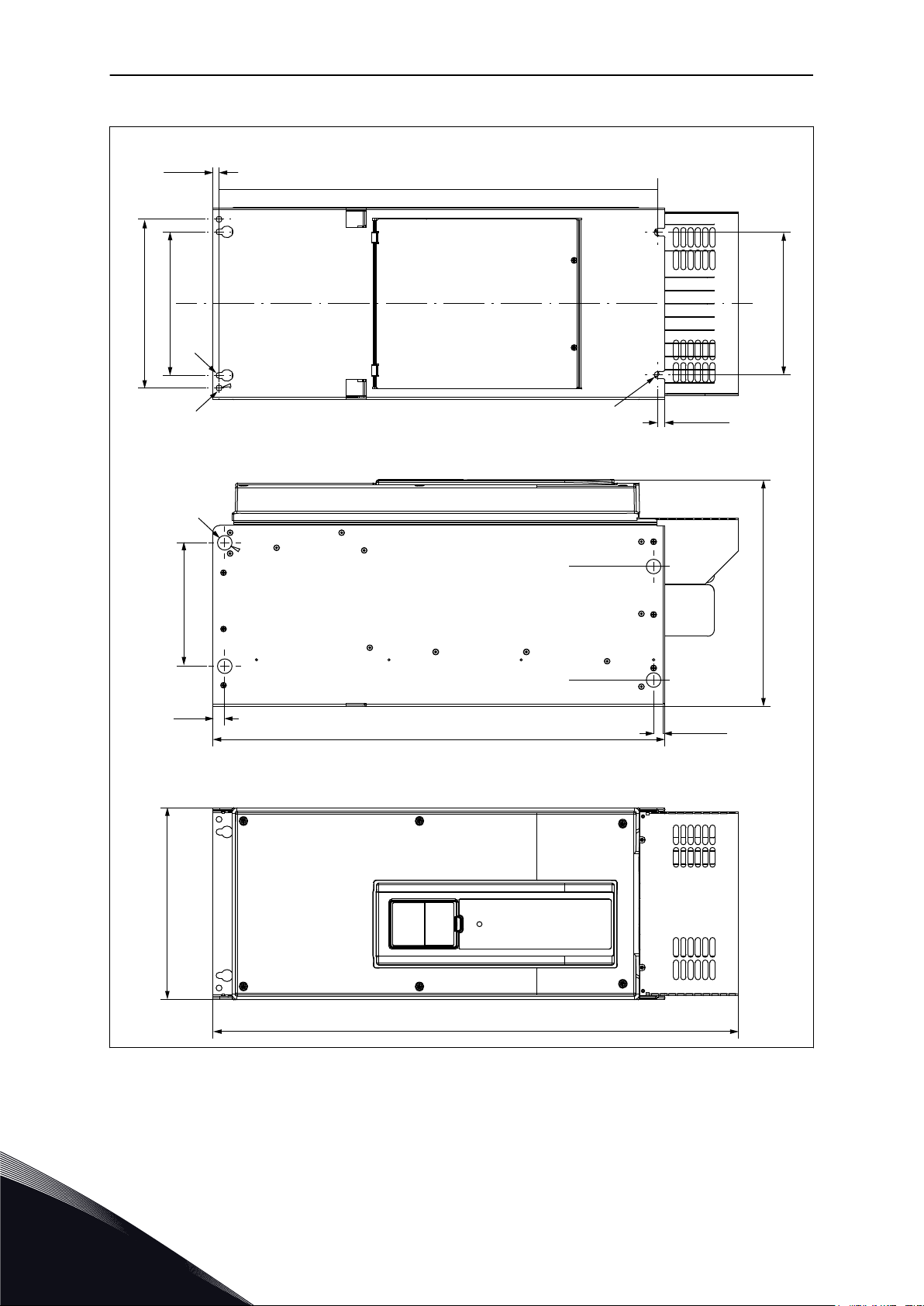

4.2.1 Wall mounting of MR4 21

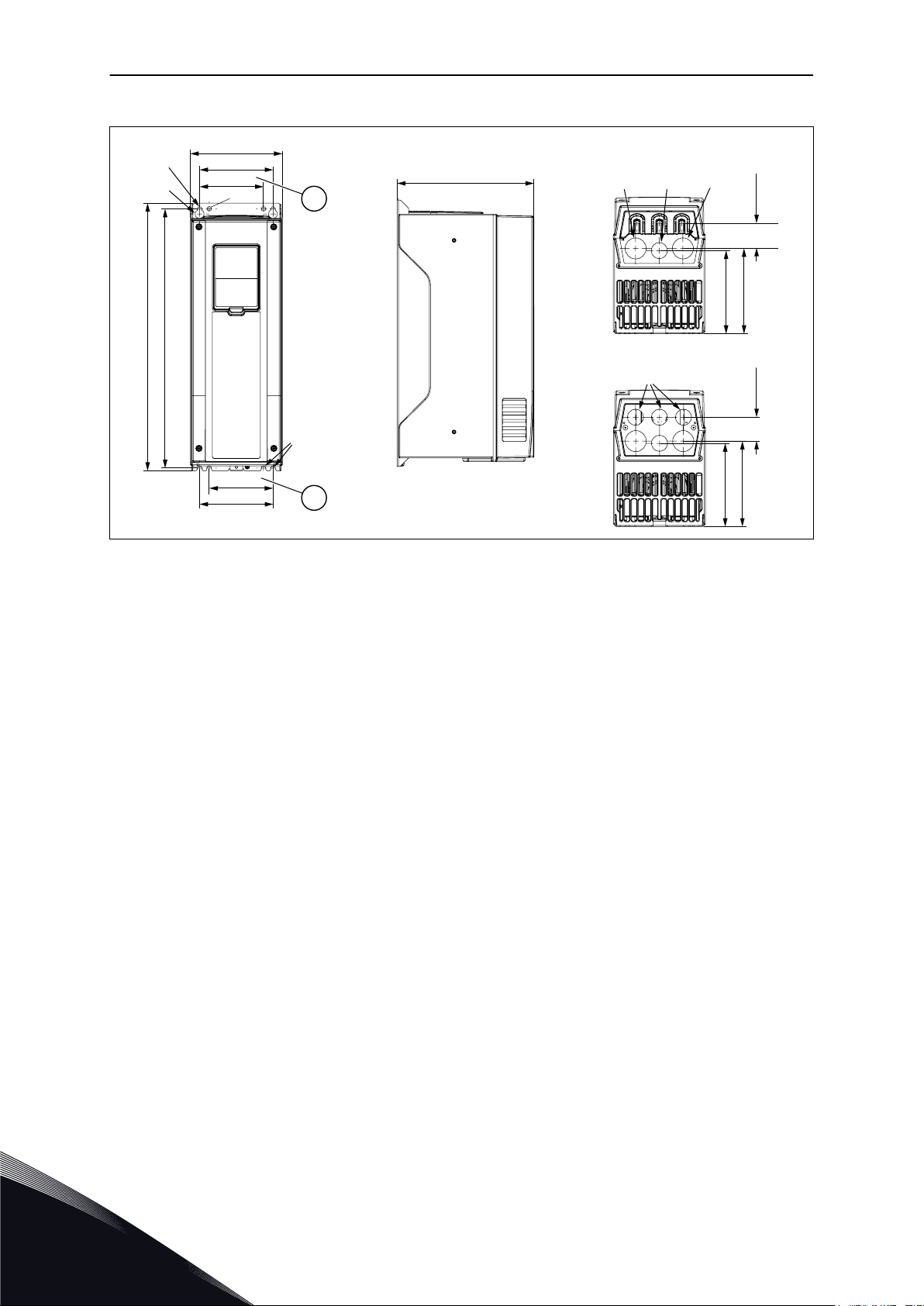

4.2.2 Wall mounting of MR5 22

4.2.3 Wall mounting of MR6 23

4.2.4 Wall mounting of MR7 24

4.2.5 Wall mounting of MR8, IP21 and IP54 25

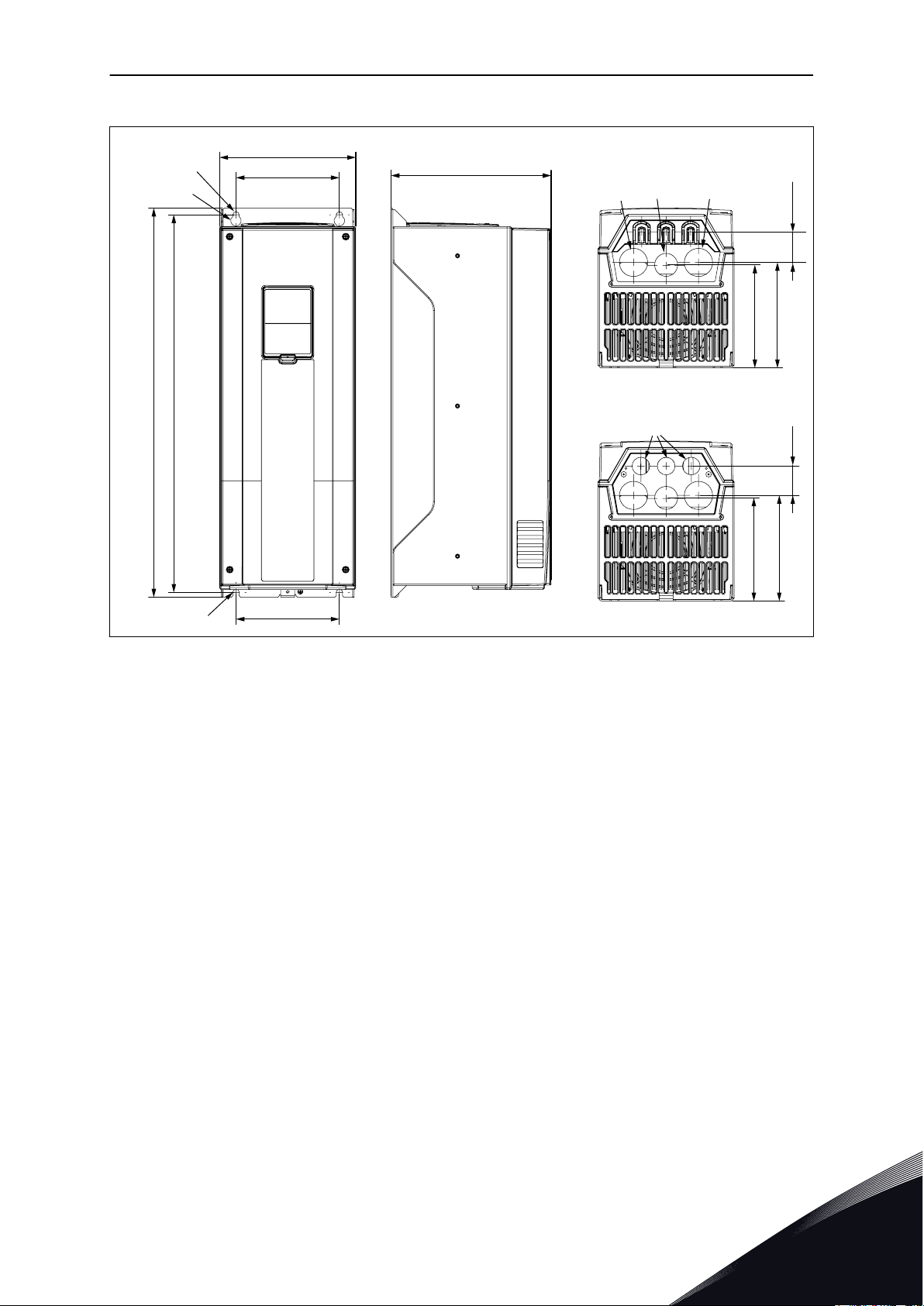

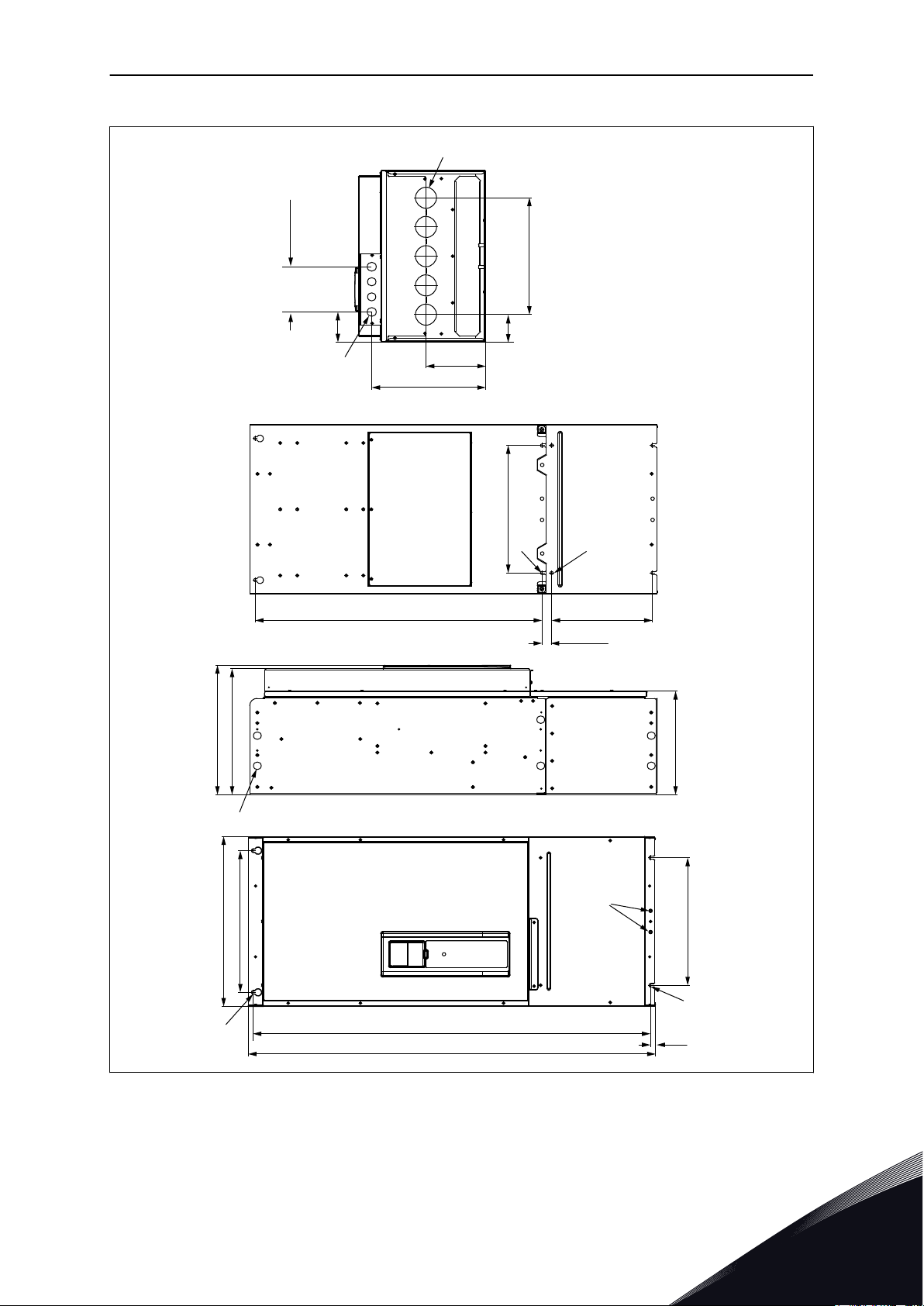

4.2.6 Wall mounting of MR8, IP00 26

4.2.7 Wall mounting of MR9, IP21 and IP54 27

4.2.8 Wall mounting of MR9, IP00 28

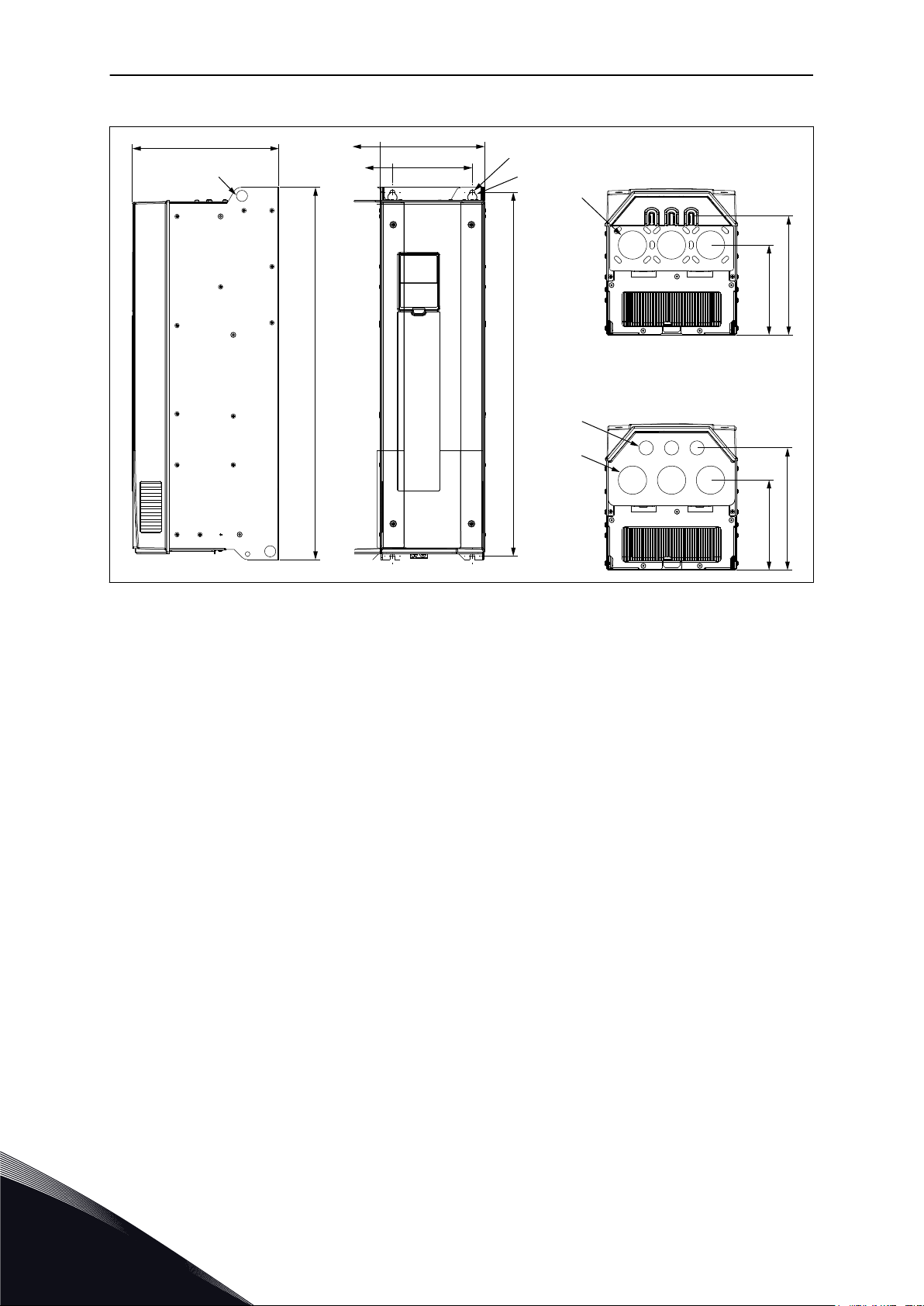

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

VACON · 6 TABLE OF CONTENTS

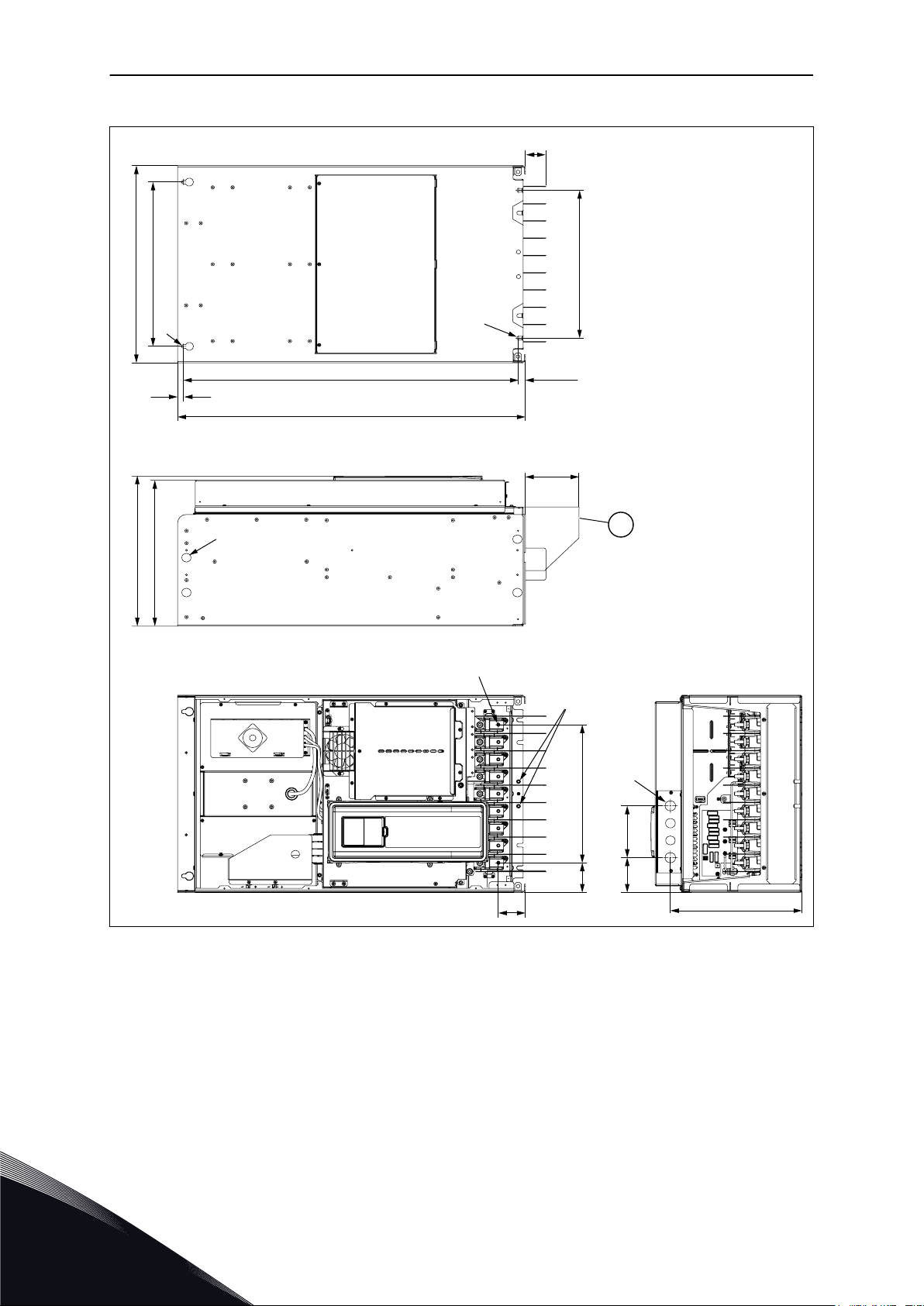

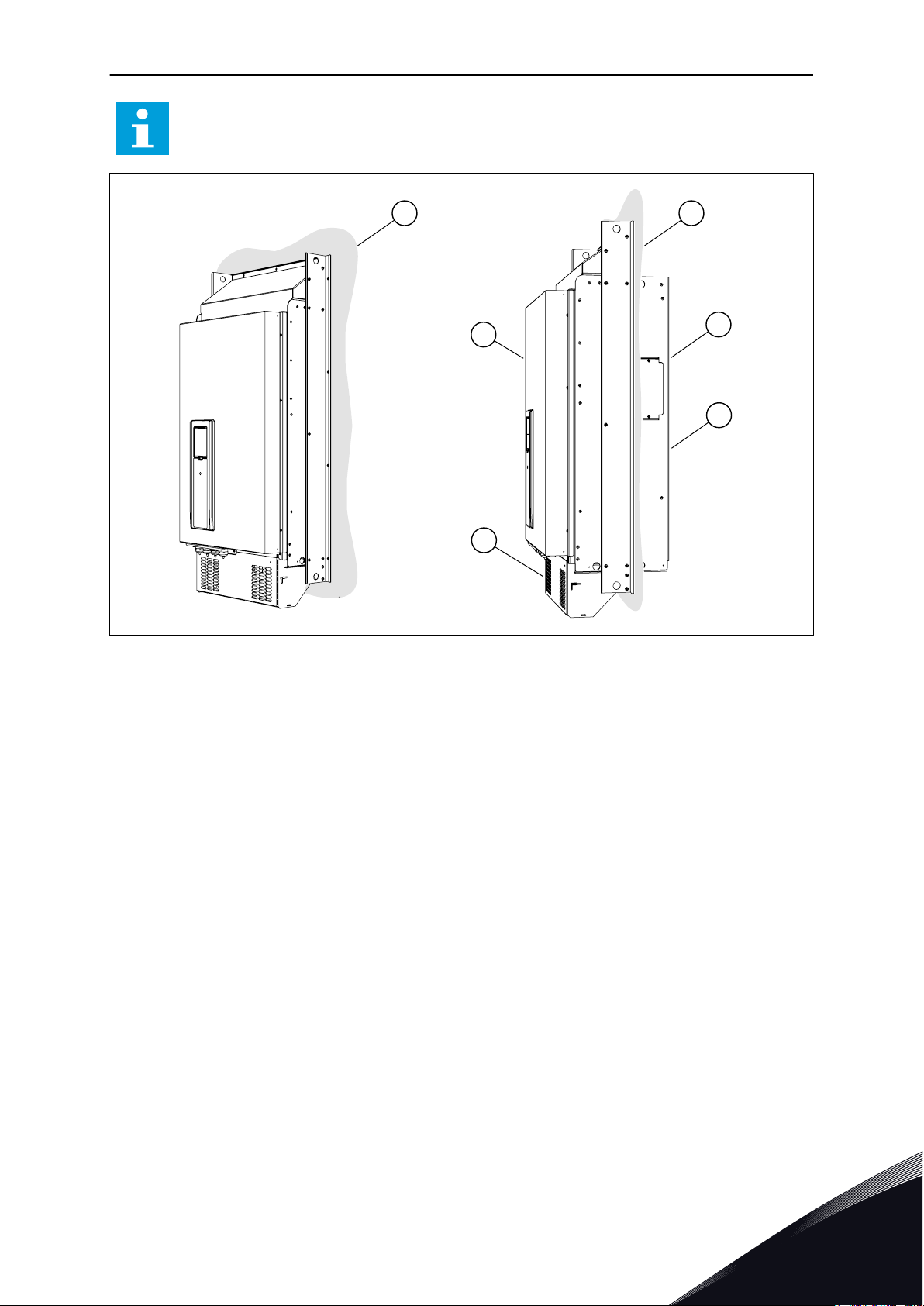

4.3 Dimensions for flange mounting 28

4.3.1 Flange mounting of MR4 32

4.3.2 Flange mounting of MR5 33

4.3.3 Flange mounting of MR6 34

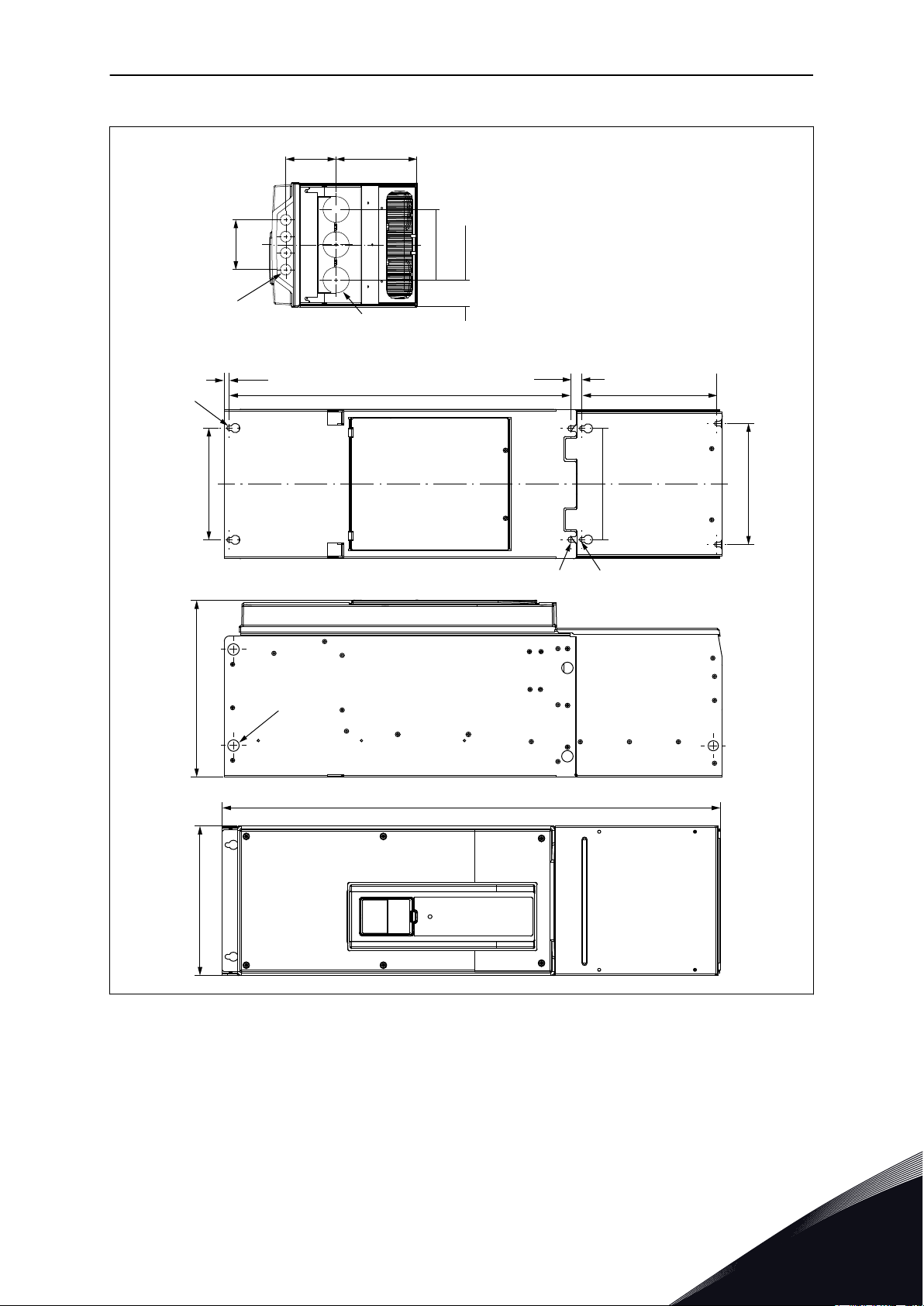

4.3.4 Flange mounting of MR7 35

4.3.5 Flange mounting of MR8 36

4.3.6 Flange mounting of MR9 37

4.4 Cooling 38

5 Power cabling 41

5.1 Cable connections 41

5.2 UL standards on cabling 42

5.3 Cable dimensioning and selection 42

5.3.1 Cable and fuse sizes 43

5.3.2 Cable and fuse sizes, North America 45

5.4 Brake resistor cables 49

5.5 Preparing for the cable installation 49

5.6 Cable installation 50

5.6.1 Frames MR4 to MR7 50

5.6.2 Frames MR8 to MR9 56

5.7 Installation in a corner-grounded network 68

6 Control unit 69

6.1 Control unit components 69

6.2 Control unit cabling 70

6.2.1 Selection of the control cables 70

6.2.2 Control terminals and DIP switches 70

6.3 Fieldbus connection 74

6.3.1 Using fieldbus through an Ethernet cable 75

6.3.2 Using fieldbus through an RS485 cable 78

6.4 Installation of option boards 82

6.4.1 The installation procedure 83

6.5 Installation of a battery for the Real Time Clock (RTC) 85

6.6 Galvanic isolation barriers 85

7 Commissioning and additional instructions 87

7.1 Commissioning safety 87

7.2 Commissioning of the drive 87

7.3 Operation of the motor 88

7.3.1 Checks before starting the motor 88

7.4 Measuring the cable and motor insulation 88

7.5 Installation in an IT system 89

7.5.1 Frames MR4, MR5, and MR6 89

7.5.2 Frames MR7 and MR8 91

7.5.3 Frame MR9 94

7.6 Maintenance 95

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

TABLE OF CONTENTS VACON · 7

8 Technical data, Vacon® 100 96

8.1 AC drive power ratings 96

8.1.1 Mains voltage 208-240 V 96

8.1.2 Mains voltage 380-500 V 98

8.1.3 Overload capability 99

8.1.4 Brake resistor ratings 100

8.2 Vacon® 100 - technical data 103

9 Technical data, Vacon® 100 FLOW 107

9.1 AC drive power ratings 107

9.1.1 Mains voltage 208-240 V 107

9.1.2 Mains voltage 380-500 V 108

9.1.3 Overload capability 109

9.2 Vacon® 100 FLOW - technical data 110

10 Technical data on control connections 114

10.1 Technical data on control connections 114

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

VACON · 8 APPROVALS

1 APPROVALS

Here are the approvals that have been granted to this Vacon product.

EC Declaration of conformity

1.

Find the EC Declaration of Conformity on the next page.

•

UL approval

2.

cULus approval file number E171278.

•

C-tick approval

3.

C-tick approval file number N16307.

•

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

EC DECLARATION OF CONFORMITY

We

Manufacturer’s name: Vacon Oyj

Manufacturer’s address: P.O. Box 25

Runsorintie 7

FIN-65381 Vaasa

Finland

hereby declare that the product

Product name: Vacon 100 AC drive

Model designation: Vacon 0100-3L-0003-5...0310-5

Vacon 0100-3L-0003-2...0310-2

has been designed and manufactured in accordance with the following standards:

Safety: EN 61800-5-1: 2007

EN 60204-1: 2009 (as relevant)

EMC: EN 61800-3: 2004 + A1: 2012

EN 61000-3-12

and conforms to the relevant safety provisions of the Low Voltage Directive

(2006/95/EC) and EMC Directive 2004/108/EC.

It is ensured through internal measures and quality control that the product

conforms at all times to the requirements of the current Directive and the relevant

standards.

In Vaasa, 26th of February, 2014

Vesa Laisi

President

The year the CE marking was affixed: 2012

APPROVALS VACON · 9

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

VACON · 10 SAFETY

2 SAFETY

2.1 THE SAFETY SYMBOLS USED IN THE MANUAL

This manual contains warnings and cautions, which are identified with safety symbols. The

warnings and cautions give important information on how to prevent injury and damage to

the equipment or your system.

Read the warnings and cautions carefully and obey their instructions.

Table 1: The safety symbols

The safety symbol Description

WARNING!

2.2 WARNING

WARNING!

Do not touch the components of the power unit when the drive is connected to

mains. The components are live when the drive is connected to mains. A contact

with this voltage is very dangerous.

WARNING!

Do not touch the motor terminals U, V, W or the brake resistor terminals when the

drive is connected to mains. These terminals are live when the drive is connected to

mains, also when the motor does not operate.

WARNING!

CAUTION!

HOT SURFACE!

2

Do not touch the relay outputs or the I/O terminals. They can have a dangerous

voltage also when the drive is disconnected from mains.

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

SAFETY VACON · 11

WARNING!

Before you do electrical work, make sure that there is no voltage in the

components of the drive.

WARNING!

To do work on the terminal connections of the drive, disconnect the drive from

mains and make sure that the motor has stopped. Wait 5 minutes before you open

the cover of the drive. Then use a measuring device to make sure that there is no

voltage. The terminal connections and the components of the drive are live 5

minutes after it is disconnected from mains and the motor has stopped.

WARNING!

Before you connect the drive to mains, make sure that the front cover and the cable

cover of the drive are closed. The connections of the AC drive are live when the

drive is connected to mains.

WARNING!

Disconnect the motor from the drive if an accidental start can be dangerous. When

there is a power-up, a power brake or a fault reset, the motor starts immediately if

the start signal is active, unless the pulse control for Start/Stop logic is selected. If

the parameters, the applications or the software change, the I/O functions

(including the start inputs) can change.

2.3 CAUTION

CAUTION!

Do not move the AC drive. Use a fixed installation to prevent damage to the drive.

CAUTION!

Do not make measurements when the AC drive is connected to mains. It can cause

damage to the drive.

CAUTION!

Make sure that there is reinforced protective ground connection. It is mandatory,

because the touch current of the AC drives is more than 3.5 mA AC (refer to EN

61800-5-1). See chapter 2.4 Earthing and earth fault protection.

CAUTION!

Do not use spare parts that are not from the manufacturer. Using other spare parts

can cause damage to the drive.

CAUTION!

Do not touch the components on the circuit boards. Static voltage can cause

damage to these components.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

2

VACON · 12 SAFETY

CAUTION!

Make sure that the EMC level of the AC drive is correct for your mains. See chapter

7.5 Installation in an IT system. An incorrect EMC level can cause damage to the

drive.

CAUTION!

Prevent radio interference. The AC drive can cause radio interference in a domestic

environment.

NOTE!

If you activate the autoreset function, the motor starts automatically after an

automatic fault reset. See the Application Manual.

NOTE!

If you use the AC drive as a part of a machine, the machine manufacturer must

supply a mains disconnection device (refer to EN 60204-1).

2.4 EARTHING AND EARTH FAULT PROTECTION

CAUTION!

The AC drive must always be earthed with an earth conductor that is connected to

the earth terminal that is identified with the symbol . Not using an earth

conductor can cause damage to the drive.

The touch current of the drive is more than 3.5 mA AC. The standard EN 61800-5-1 tells that

1 or more of these conditions for the protective circuit must be true.

The connection must be fixed.

The protective earth conductor must have a cross-sectional area of minimum 10 mm2 Cu

a)

or 16 mm2 Al. OR

There must be an automatic disconnection of the mains, if the protective earth conductor

b)

breaks. See chapter 5 Power cabling. OR

There must be a terminal for a second protective earth conductor in the same cross-

c)

sectional area as the first protective earth conductor.

Table 2: Protective earthing conductor cross-section

Cross-sectional area of the phase conductors (S)

[mm2]

S ≤ 16 S

The minimum cross-sectional area of the protective

earthing conductor in question [mm2]

16 < S ≤ 35 16

35 < S S/2

The values of the table are valid only if the protective earthing conductor is made of the same

metal as the phase conductors. If this is not so, the cross-sectional area of the protective

2

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

SAFETY VACON · 13

earthing conductor must be determined in a manner that produces a conductance equivalent

to that which results from the application of this table.

The cross-sectional area of each protective earthing conductor that is not a part of the mains

cable or the cable enclosure, must be a minimum of:

2.5 mm2 if there is mechanical protection, and

•

4 mm2 if there is not mechanical protection. If you have cord-connected equipment,

•

make sure that the protective earthing conductor in the cord is the last conductor to be

interrupted, if the strain-relief mechanism breaks.

Obey the local regulations on the minimum size of the protective earthing conductor.

NOTE!

Because there are high capacitive currents in the AC drive, it is possible that the

fault current protective switches do not operate correctly.

CAUTION!

Do not do voltage withstand tests on the AC drive. The manufacturer has already

done the tests. Doing voltage withstand tests can cause damage to the drive.

2.5 ELECTRO-MAGNETIC COMPATIBILITY (EMC)

The drive must obey the standard IEC 61000-3-12. To obey it, the short-circuit power SSC

must be a minimum of 120 RSCE at the interface point between your mains and the public

mains. Make sure that you connect the drive and the motor to mains with a short-circuit

power SSC that is a minimum of 120 RSCE. If necessary, contact your mains operator.

2.6 USING AN RCD OR AN RCM DEVICE

The drive can cause a current in the protective earthing conductor. You can use a residual

current-operated protective (RCD) device, or a residual current-operated monitoring (RCM)

device to give protection against a direct or an indirect contact. Use a type B RCD or RCM

device on the mains side of the drive.

NOTE! You can download the English and French product manuals with applicable safety, warning and caution

information from

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'ensemble des informations de sécurité, avertissements et mises en garde applicables sur le site www.vacon.com/

downloads.

www.vacon.com/downloads.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

2

A B

C

H

I

D

F

G

E

VACON · 14 RECEIVING THE DELIVERY

3 RECEIVING THE DELIVERY

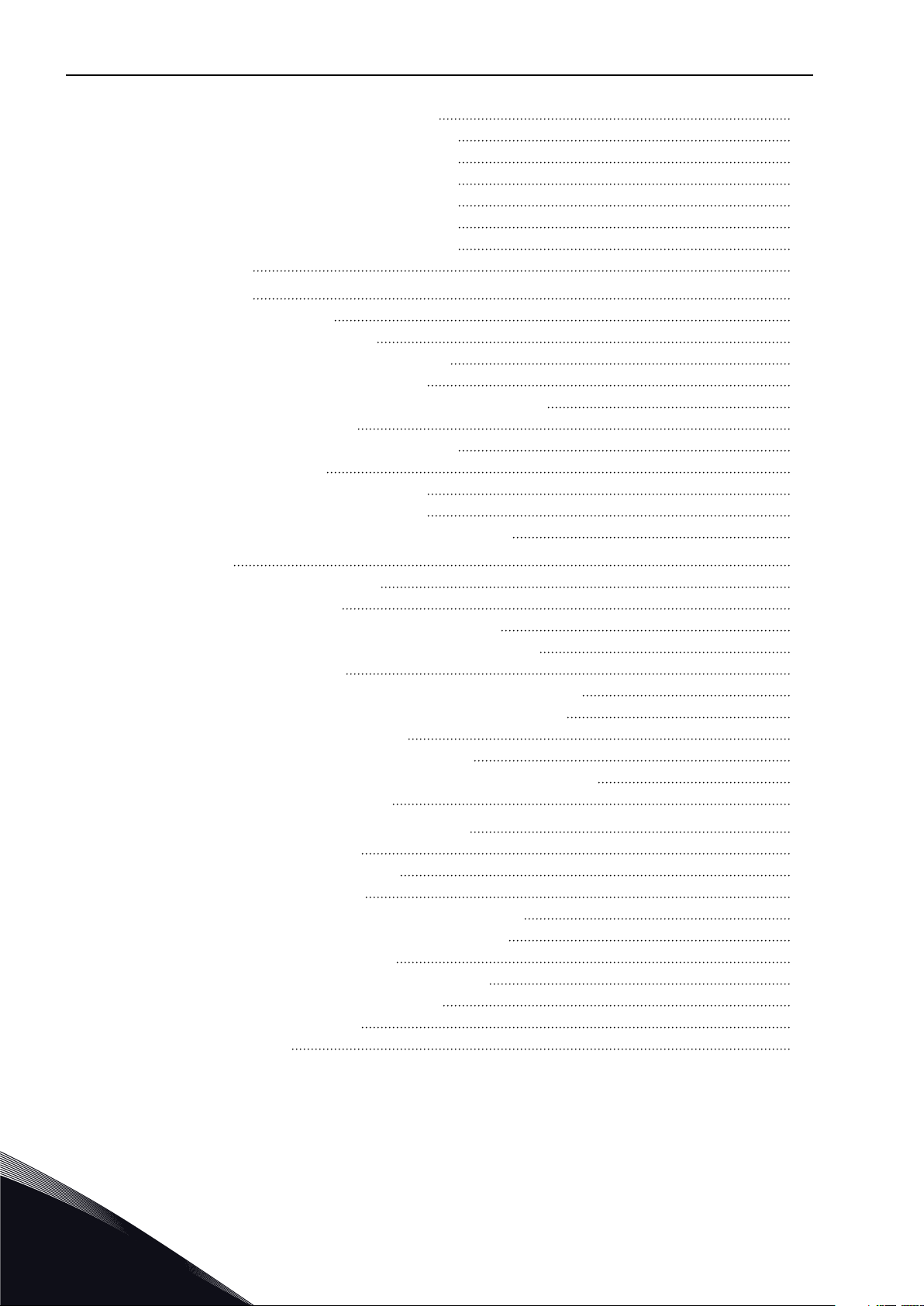

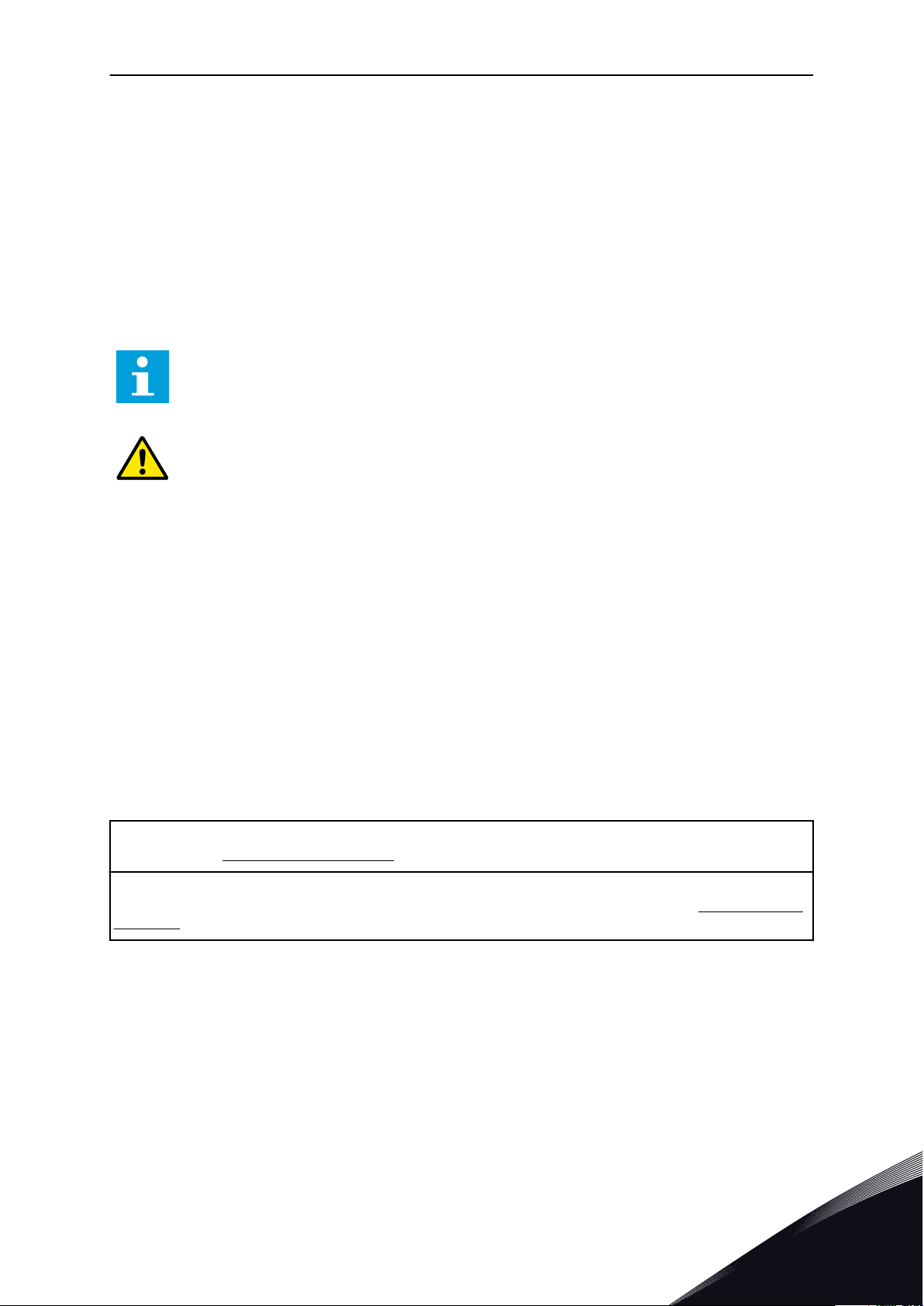

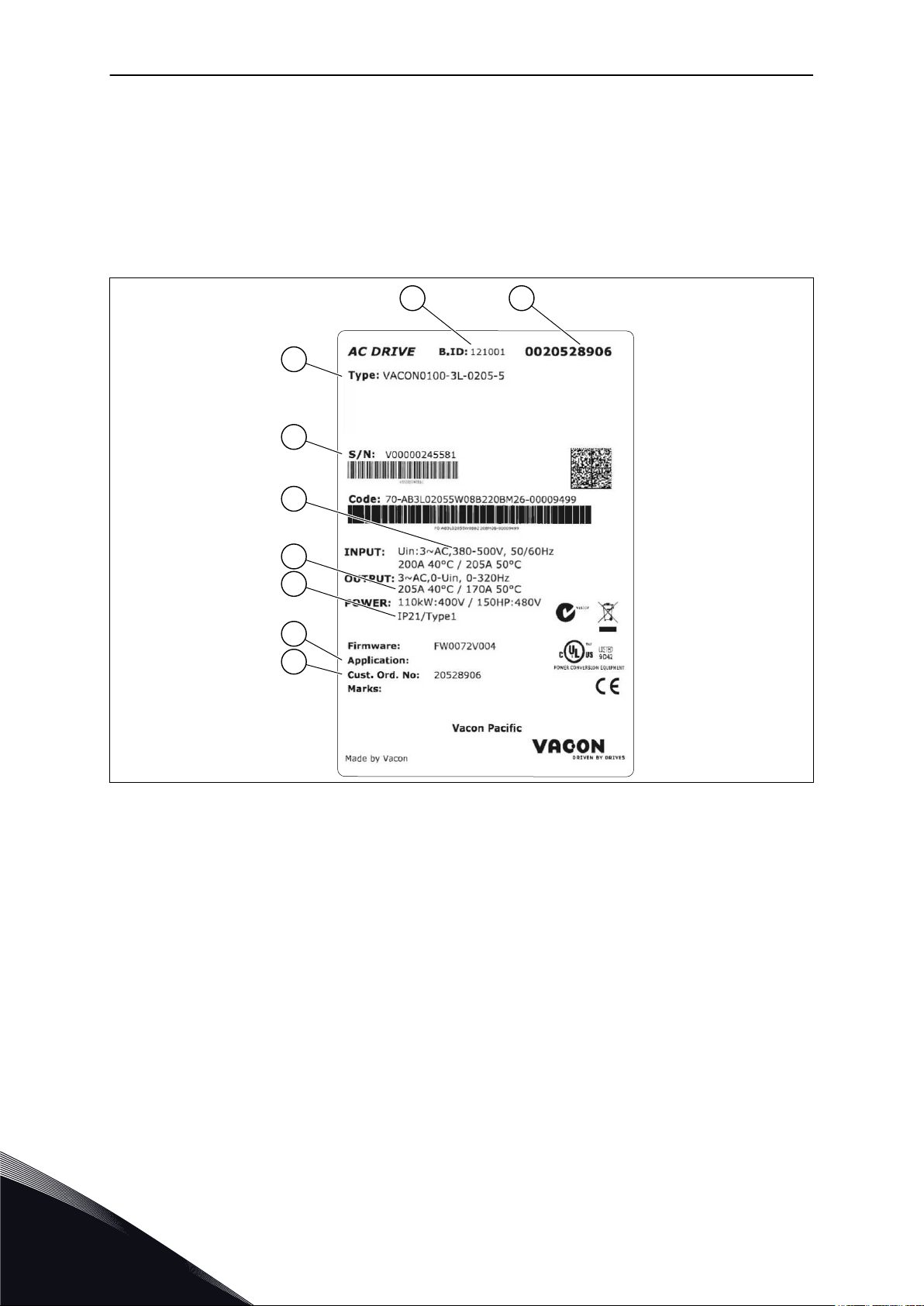

3.1 PACKAGE LABEL

To make sure that the delivery is correct, compare your order data to the data on the

package label. If the delivery does not agree with your order, speak to the vendor

immediately.

Fig. 1: The package label of Vacon AC drives

A. The batch ID

B. The order number of Vacon

C. The type designation code

D. The serial number

E. The mains voltage

F. The rated output current

G. The IP class

H. The application code

I. The order number of the customer

3.2 TYPE DESIGNATION CODE

The type designation code of Vacon is made of standard codes and optional codes. Each part

of the type designation code agrees to the data in your order. The code can have this format,

for example:

VACON0100-3L-0061-5+IP54

VACON0100-3L-0061-5-FLOW

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

RECEIVING THE DELIVERY VACON · 15

Table 3: The description of the parts in the type designation code

Code Description

VACON This part is same for all the products.

0100 The product range: 0100 = Vacon 100

3L Input/Function: 3L = A 3-phase input

0061 The drive rating in amperes. For example, 0061 = 61 A

5 The mains voltage:

2 = 208-240 V

5 = 380-500 V

FLOW The Vacon 100 FLOW AC drive

+IP54 The optional codes. There are many options, for example +IP54 (an AC drive with

the IP protection class IP54)

3.3 UNPACKING AND LIFTING THE AC DRIVE

3.3.1 WEIGHT OF THE AC DRIVE

The weights of AC drives of different frames are very different. It can be necessary for you to

use a lifting device to move the drive from its package.

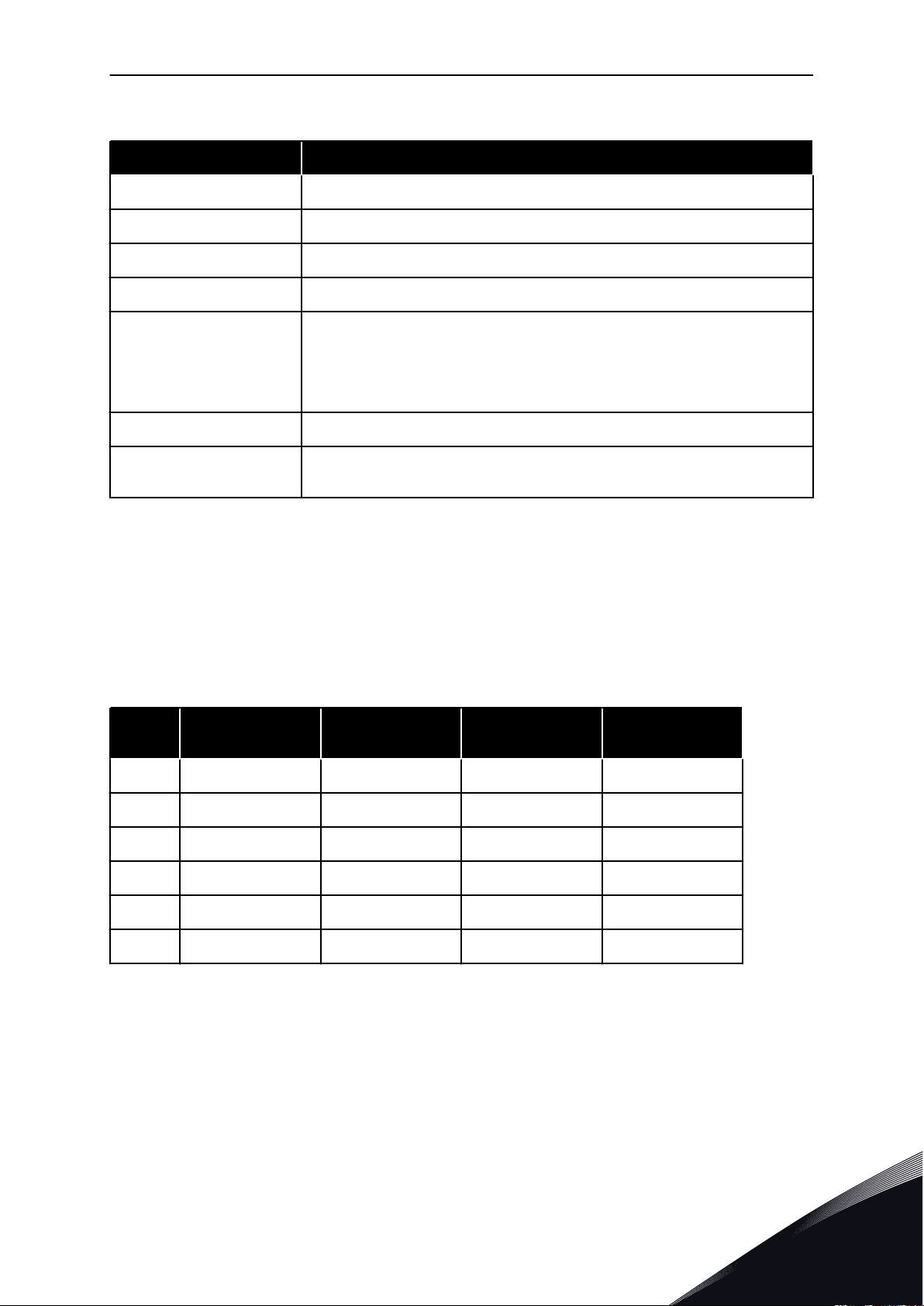

Table 4: The weights of the different frames

Frame Weight, IP21/IP54

[kg]

MR4 6.0 13.2

MR5 10.0 22.0

MR6 20.0 44.1

MR7 37.5 82.7

MR8 66.0 62.0 145.5 136.7

MR9 119.5 103.5 263.5 228.2

Weight, IP00 [kg] Weight, UL Type 1 /

Type 12 [lb.]

Weight, UL Open

Type [lb.]

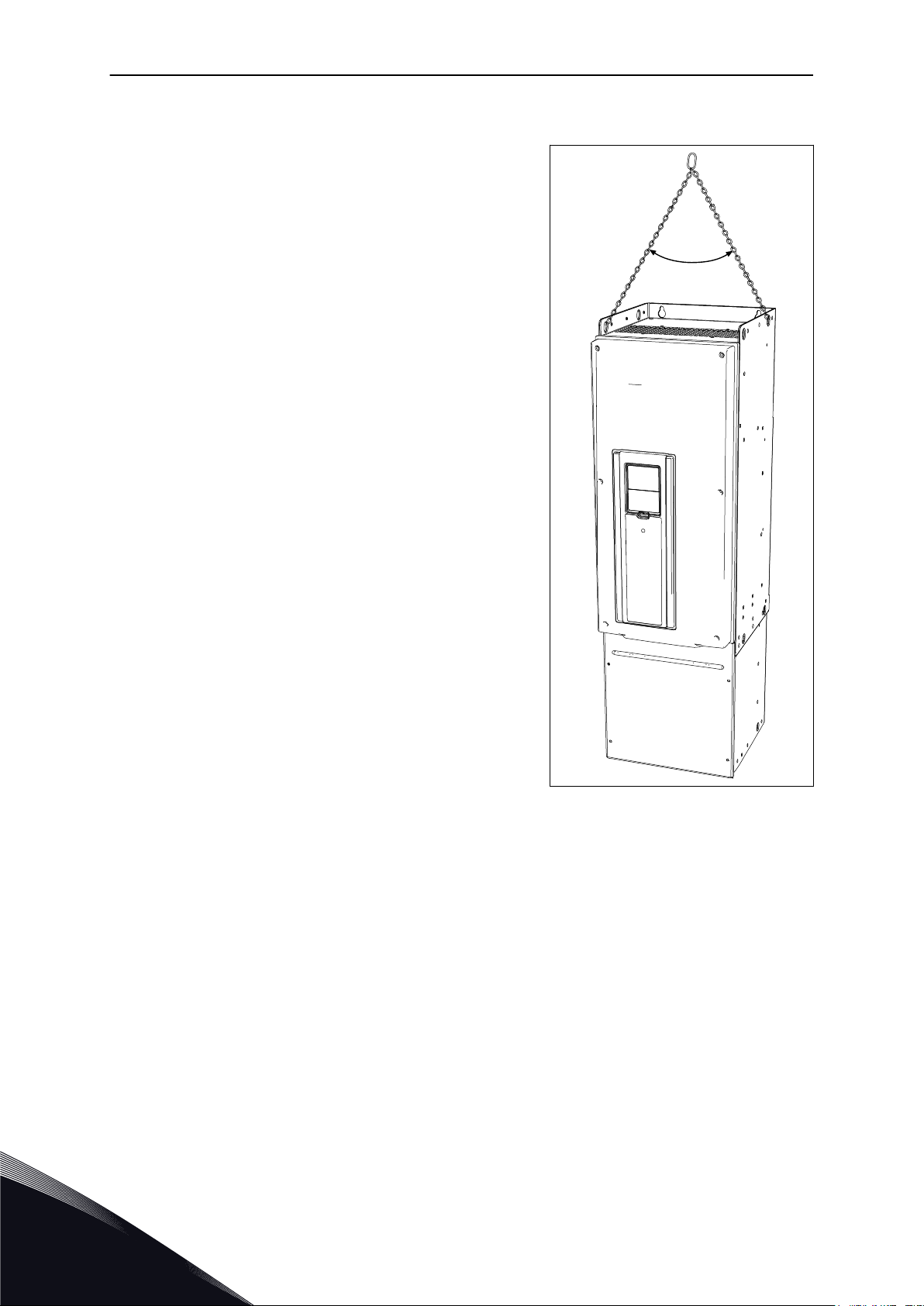

3.3.2 LIFTING THE FRAMES MR8 AND MR9

1 Remove the drive from the pallet where it was

bolted to.

2 Use a lifting device that is sufficiently strong for the

weight of the drive.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

3

≤45°

VACON · 16 RECEIVING THE DELIVERY

3 Put the lifting hooks symmetrically in a minimum of

2 holes.

4 The maximum lifting angle is 45 degrees.

Before a Vacon® AC drive is sent to the customer, the manufacturer makes many tests on

the drive. After you lift the drive, do a check for signs of damage on the drive. Make sure that

the contents of the package are correct.

If the drive was damaged during the shipping, speak to the cargo insurance company or the

carrier.

3.4 ACCESSORIES

After you open the package and lift the drive out, make sure that you received all the

accessories. The content of the accessories bag is different for the different frames and

protection classes.

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

RECEIVING THE DELIVERY VACON · 17

3.4.1 FRAME MR4

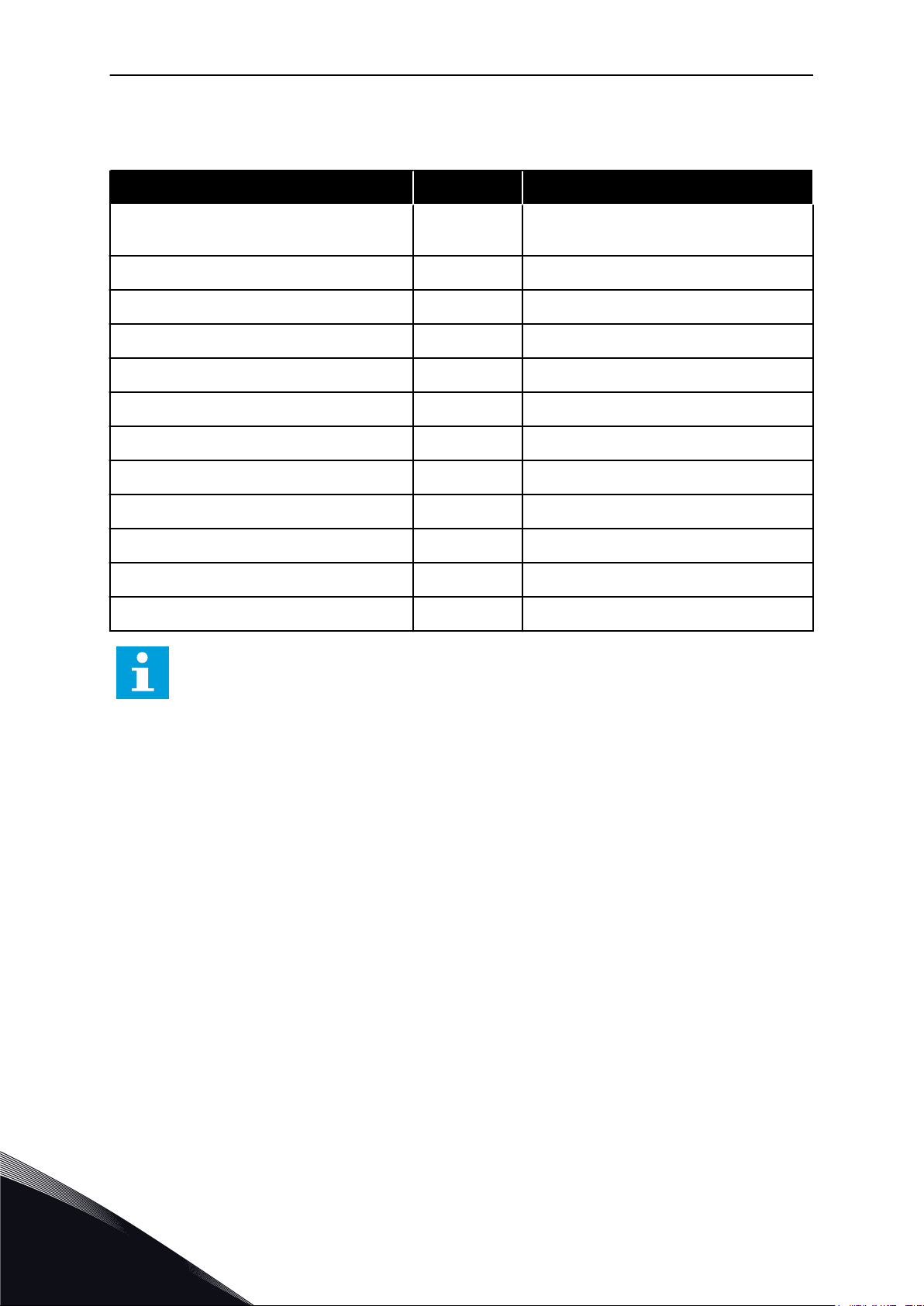

Table 5: The content of accessories bag

Item Quantity Description

M4x16 screw 11 Screws for the power cable clamps (6), the

control cable clamps (3), and the grounding

clamps (2)

M4x8 screw 1 Screw for the optional grounding

M5x12 screw 1 Screw for the external grounding of the drive

Control cable grounding lamella 3 Control cable grounding

EMC cable clamp, size M25 3 Clamping the power cables

Grounding clamp 2 Power cable grounding

"Product modified" label 1 Data about changes

IP21: Cable grommet 3 Sealing for the cables

IP54: Cable grommet 6 Sealing for the cables

3.4.2 FRAME MR5

Table 6: The content of the accessories bag

Item Quantity Description

M4x16 screw 13 Screws for the power cable clamps (6), the

control cable clamps (3), and the grounding

clamps (4)

M4x8 screw 1 Screw for the optional grounding

M5x12 screw 1 Screw for the external grounding of the drive

Control cable grounding lamella 3 Control cable grounding

EMC cable clamps, size M25 1 Clamping brake cable

EMC cable clamps, size M32 2 Clamping power cables

Grounding clamp 2 Power cable grounding

"Product modified" label 1 Data about changes

IP21: Cable grommet, hole diameter 25.3 mm 1 Sealing for the cables

IP54: Cable grommet, hole diameter 25.3 mm 4 Sealing for the cables

Cable grommet, hole diameter 33.0 mm 2 Sealing for the cables

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

3

VACON · 18 RECEIVING THE DELIVERY

3.4.3 FRAME MR6

Table 7: The content of the accessories bag

Item Quantity Description

M4x20 screw 10 Screws for the power cable clamps (6), and

the grounding clamps (4)

M4x16 screw 3 Screws for the control cable clamps

M4x8 screw 1 Screw for the optional grounding

M5x12 screw 1 Screw for the external grounding of the drive

Control cable grounding lamella 3 Control cable grounding

EMC cable clamps, size M32 1 Clamping the brake resistor cable

EMC cable clamps, size M40 2 Clamping the power cables

Grounding clamp 2 Power cable grounding

"Product modified" label 1 Data about changes

Cable grommet, hole diameter 33.0 mm 1 Sealing for the cables

Cable grommet, hole diameter 40.3 mm 2 Sealing for the cables

IP54: Cable grommet, hole diameter 25.3 mm 3 Sealing for the cables

NOTE!

The Vacon® 100 FLOW software does not have the dynamic braking or the brake

resistor functions.

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

RECEIVING THE DELIVERY VACON · 19

3.4.4 FRAME MR7

Table 8: The content of the accessories bag

Item Quantity Description

M6x30 slotted nut 6 Nuts for the power cable clamps

M4x16 screw 3 Screws for the control cable clamps

M6x12 screw 1 Screw for the external grounding of the drive

Control cable grounding lamella 3 Control cable grounding

EMC cable clamps, size M25 3 Clamping the power cables

Grounding clamp 2 Power cable grounding

‘Product modified’ label 1 Data about changes

IP21: Cable grommet 3 Sealing for the cables

IP54: Cable grommet 3 Sealing for the cables

3.4.5 FRAME MR8

Table 9: The content of accessories bag

Item Quantity Description

M4x16 screw 3 Screws for the control cable clamps

Control cable grounding lamella 3 Control cable grounding

Cable lugs KP40 3 Clamping power cables

Cable insulator 11 To prevent contact between cables

Cable grommet, hole diameter 25.3 mm 4 Sealing for the cables

IP00: Touch shield 1 To prevent contact with live parts

IP00: M4x8 screw 2 To attach the touch protection shield

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

3

Product modified

Date:

Date:

Date:

VACON · 20 RECEIVING THE DELIVERY

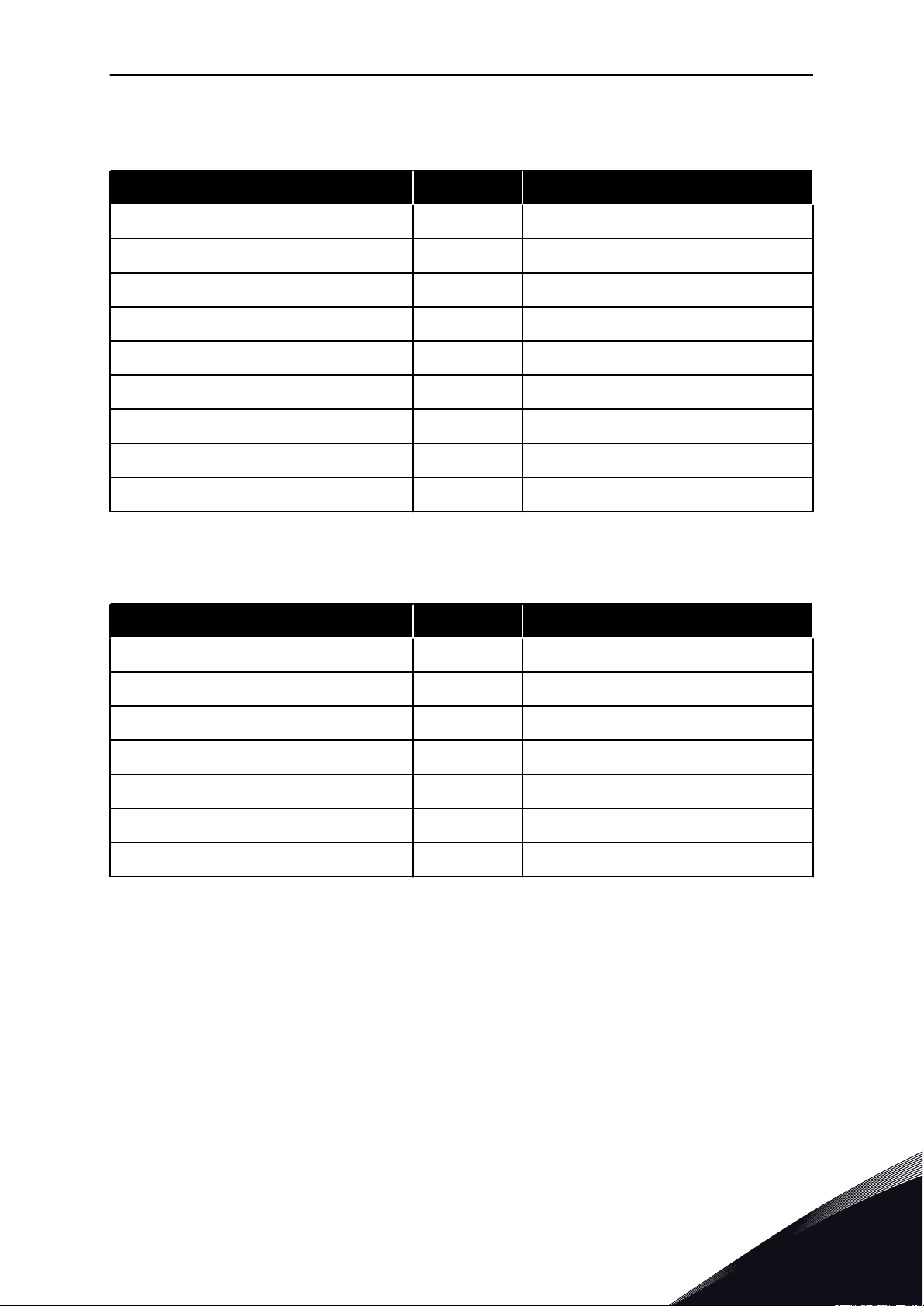

3.4.6 FRAME MR9

Table 10: The content of the accessories bag

Item Quantity Description

M4x16 screw 3 Screws for the control cable clamps

Control cable grounding lamella 3 Control cable grounding

Cable lugs KP40 5 Clamping power cables

Cable insulator 10 To prevent contact between cables

Cable grommet, hole diameter 25.3 mm 4 Sealing for the cables

IP00: Touch shield 1 To prevent contact with live parts

IP00: M4x8 screw 2 To attach the touch protection shield

3.5 "PRODUCT MODIFIED" LABEL

In the accessories bag, there is also a "product modified" label. The function of the label is to

tell the service personnel about the changes that are made in the AC drive. Attach the label

on the side of the AC drive to know where to find it. If you make changes in the AC drive, write

the change on the label.

3.6 DISPOSAL

When the drive is at the end of its operation life, do not discard it as a part of municipal

waste. You can recycle the primary components of the drive. You must disassemble

some components before you can remove the different materials. Recycle the electrical

and electronic components as waste.

To make sure that the waste is recycled correctly, send the waste to a recycling centre.

You can also send the waste back to the manufacturer.

Obey the local and other applicable regulations.

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Ø25

Ø25

Ø7

Ø13

IP21

IP54

112

147

128

100

313

100

328

190

151

112

MOUNTING VACON · 21

4 MOUNTING

4.1 GENERAL INFORMATION ABOUT MOUNTING

Install the AC drive in a vertical position on the wall. If you install the drive in a horizontal

position, it is possible that some functions with the nominal values that are found in chapter

8 Technical data, Vacon® 100 or 9 Technical data, Vacon® 100 FLOW are not available.

Attach the AC drive with the screws and other components that you received in the delivery.

4.2 DIMENSIONS FOR WALL MOUNTING

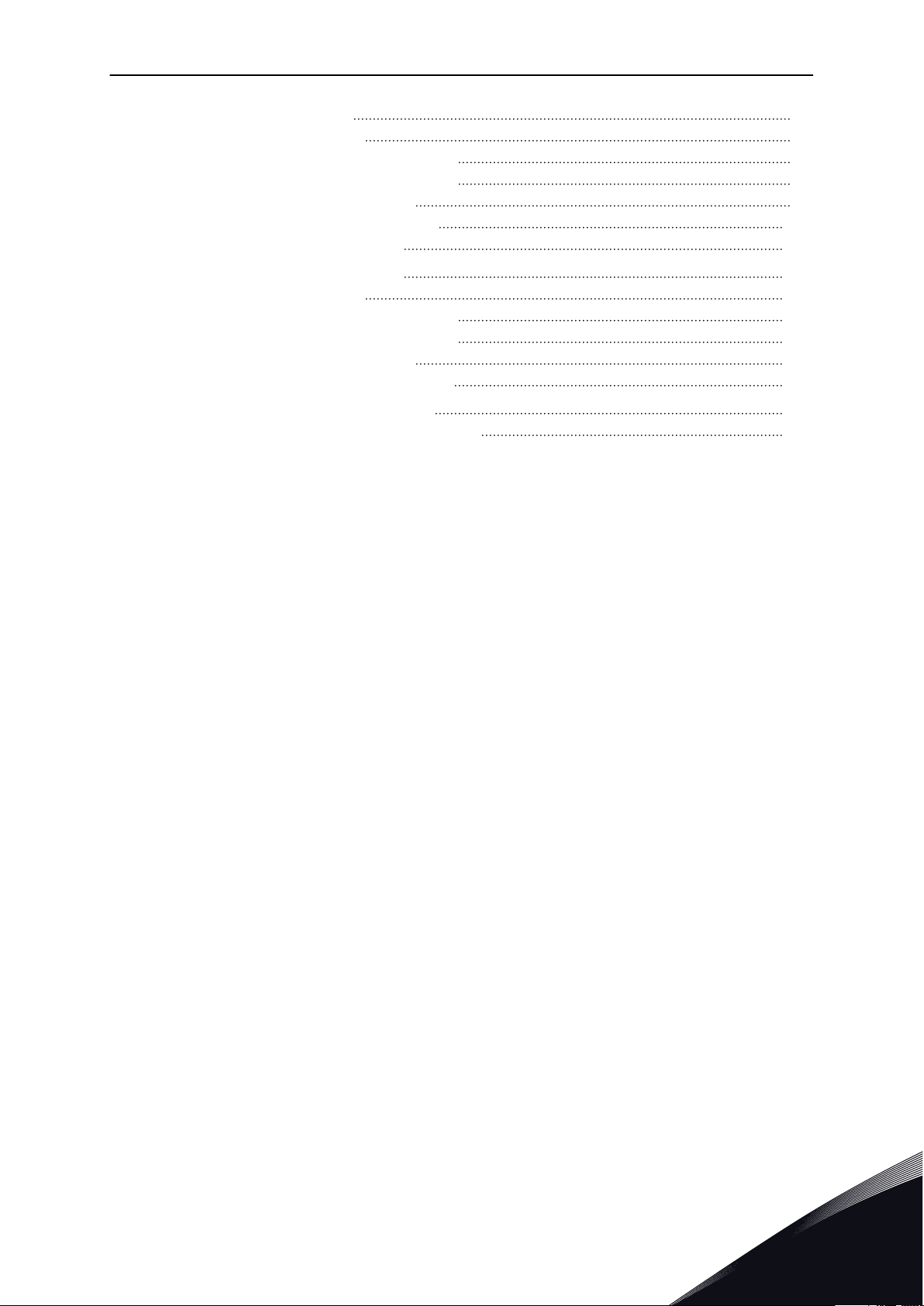

4.2.1 WALL MOUNTING OF MR4

Fig. 2: The dimensions of the AC drive, MR4

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

4

Ø7

Ø33 Ø25

Ø25

Ø33

A

A

214

144

115

Ø7

Ø14

Ø7

100*

419

406

115

100*

IP21

39

37.5

130

134

130

134

IP54

VACON · 22 MOUNTING

4.2.2 WALL MOUNTING OF MR5

Fig. 3: The dimensions of the AC drive, MR5

A. Use these mounting holes when you

replace your Vacon® NX AC drive with a

Vacon® 100 or Vacon® 100 FLOW AC

drive.

4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

195

148

Ø15.5

Ø9

557

541

Ø9

148

229

148

151

IP21

IP54

42 43.7

148

151

Ø40 Ø33 Ø40

Ø25

MOUNTING VACON · 23

4.2.3 WALL MOUNTING OF MR6

Fig. 4: The dimensions of the AC drive, MR6

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

4

259

Ø20

660

645

237

190

IP21

IP54

160

211

160

217

Ø9

Ø16

Ø51

Ø25

Ø50

VACON · 24 MOUNTING

4.2.4 WALL MOUNTING OF MR7

Fig. 5: The dimensions of the AC drive, MR7

4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

9

3 x 38

114

117

188

62.5

164

290

343

216

663

996

22

262

235

217

Ø25

Ø60

Ø11

Ø22

Ø9

Ø9

MOUNTING VACON · 25

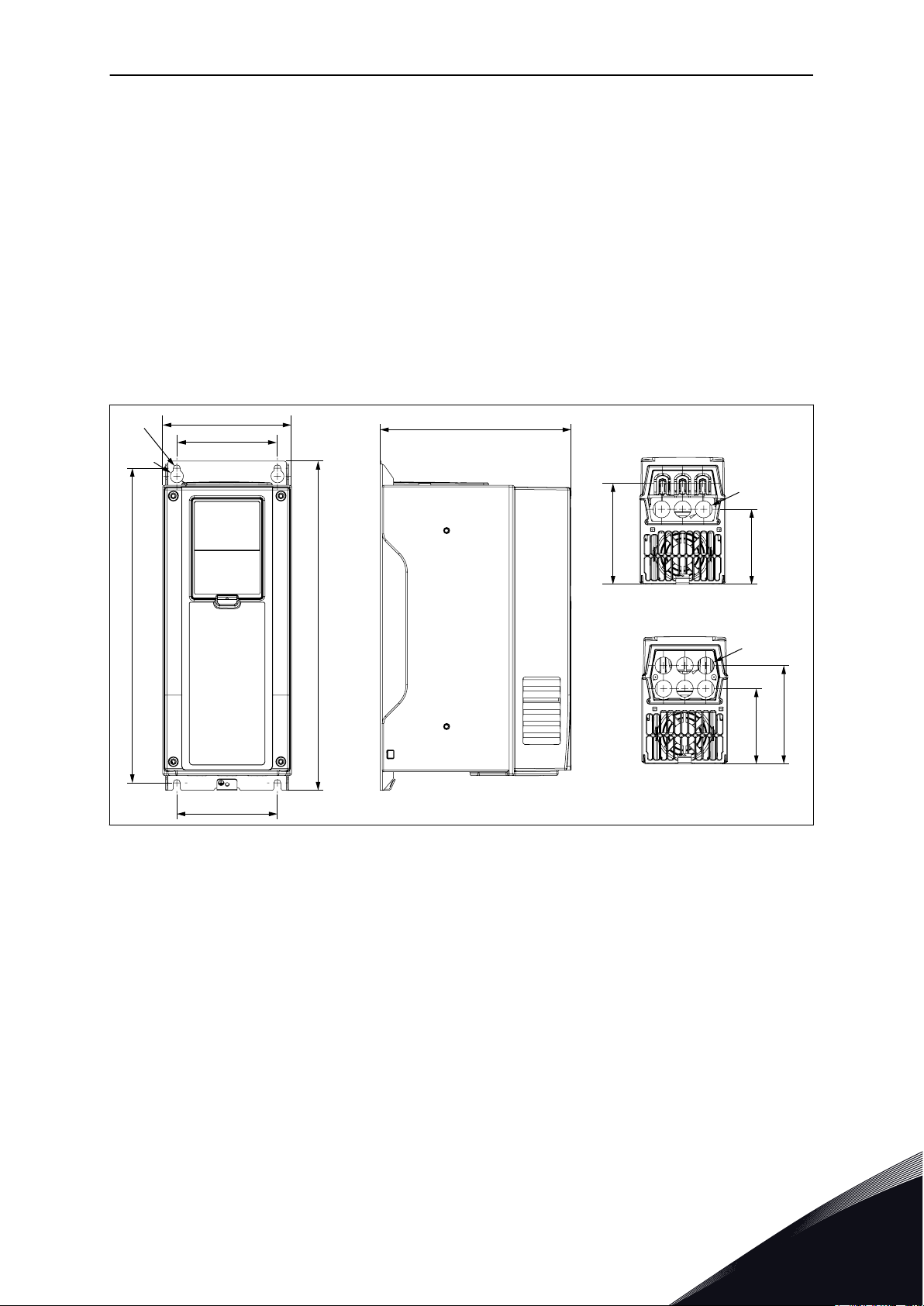

4.2.5 WALL MOUNTING OF MR8, IP21 AND IP54

Fig. 6: The dimensions of the AC drive, MR8, IP21 and IP54

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

4

9.3

290

186.5

255

217

794

683

663

18

171.5

343

215.7

10.8

15.1

Ø9

Ø9

Ø22

Ø11

VACON · 26 MOUNTING

4.2.6 WALL MOUNTING OF MR8, IP00

4

Fig. 7: The dimensions of the AC drive, MR8, IP00

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Ø25

Ø59

Ø22

84

3 x 42

126

318

166

77

4 x 81.5

326

1122

1150

Ø9

14

480

400

355

365

292

284

27,5

360

810

360

M8 GND

Ø9

Ø9Ø9

MOUNTING VACON · 27

4.2.7 WALL MOUNTING OF MR9, IP21 AND IP54

Fig. 8: The dimensions of the AC drive, MR9, IP21 and IP54

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

4

130

810

840.5

16.5

65

50

360

8 x 42

72

M8

GND

318

3 X 42

84.5

14

Ø9

Ø22

400

480

355

365

Ø9

M8

A

Ø25

126

336

VACON · 28 MOUNTING

4.2.8 WALL MOUNTING OF MR9, IP00

Fig. 9: The dimensions of the AC drive, MR9, IP00

A. An optional main connector cover for the

cabinet installation

4.3 DIMENSIONS FOR FLANGE MOUNTING

You can also install the AC drive into the cabinet wall with a flange mounting option.

4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

A

B

D

A

C

E

MOUNTING VACON · 29

NOTE!

The protection classes are different in different sections of the drive.

Fig. 10: Example of flange mounting (frame MR9)

A. The cabinet wall or other surface

B. The front

C. The rear

D. IP00 / UL Open Type

E. IP54 / UL Type 12

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

4

G

F

A E

B

D

C

H

VACON · 30 MOUNTING

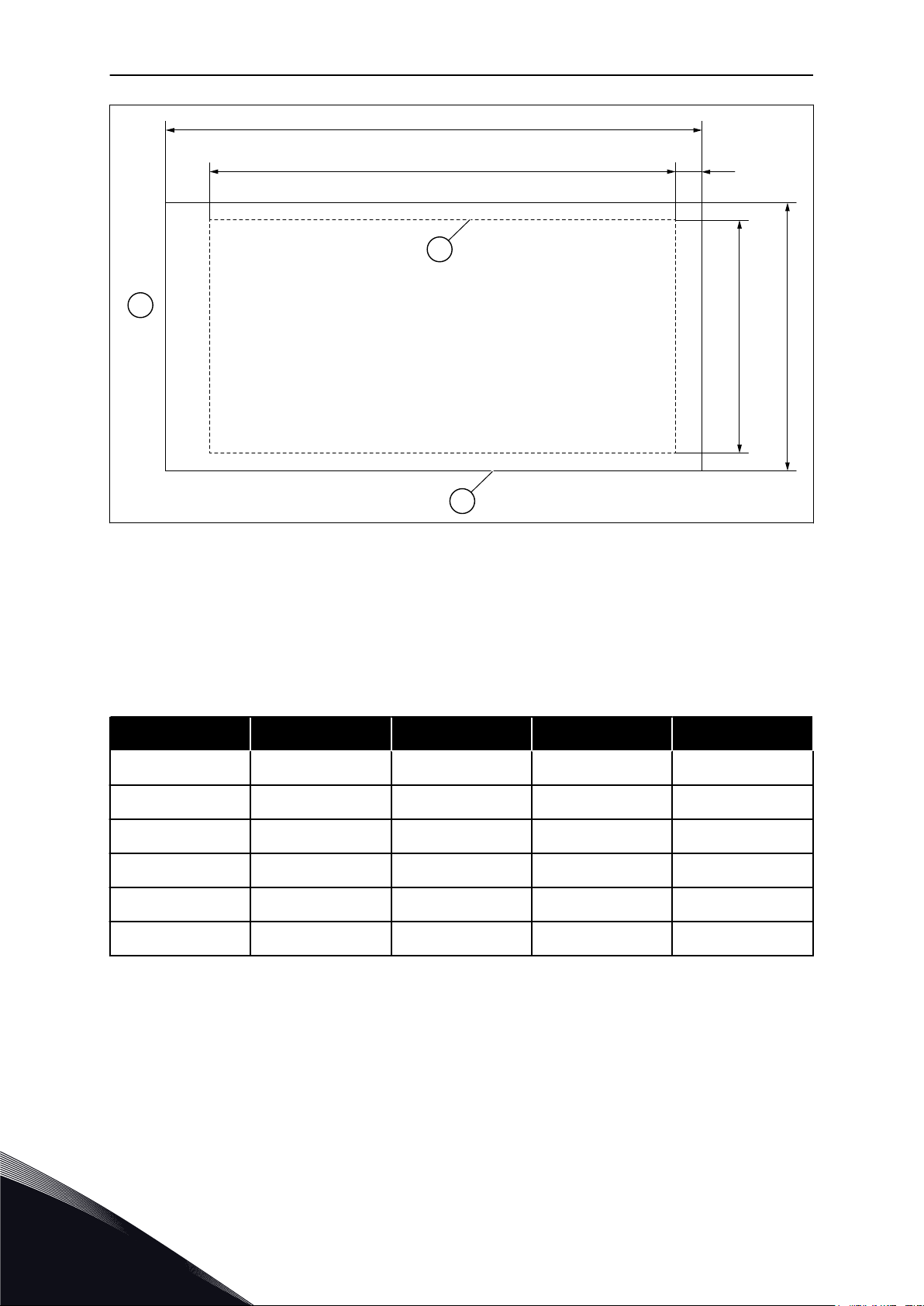

Fig. 11: The dimensions of the opening and drive outline with flange

A. The height of the opening for the flange

mounting

B. The width of the opening

C. The height of the drive

D. The width of the drive

E. The distance between the bottom of the

drive and the bottom of the opening

F. The outline of the opening

G. The outline of the drive

H. The top of the drive

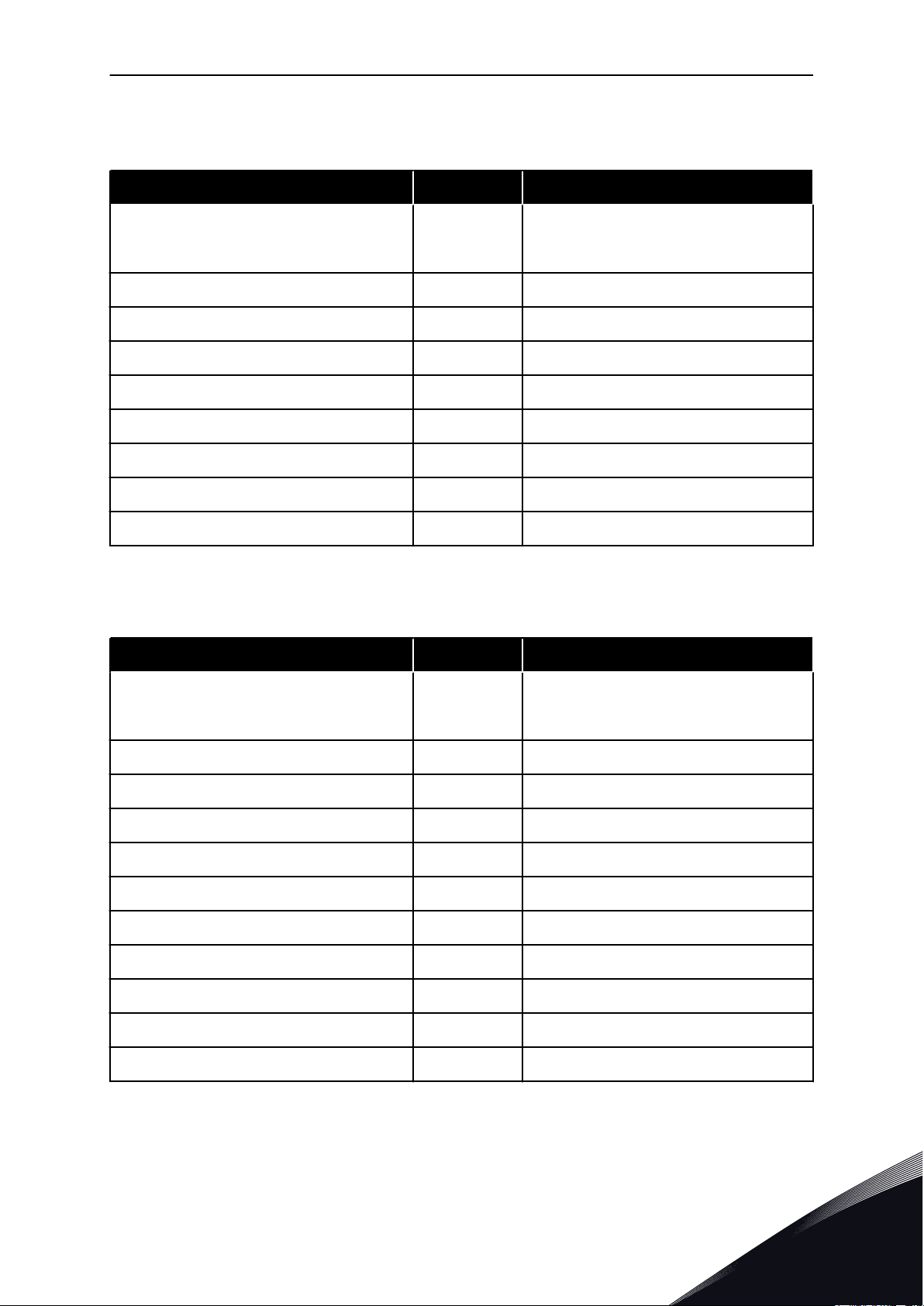

Table 11: The dimensions of the drive, frames MR4 to MR9

Frame C [mm] D [mm] C [in] D [in]

MR4 357 152 14.1 6.0

MR5 454 169 17.9 6.7

MR6 580 220 22.8 8.7

MR7 680 286 26.8 11.3

MR8 898 359 35.4 14.1

MR9 1060 550 41.7 21.7

4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Loading...

Loading...