Page 1

vacon 100

®

ac drives

application manual

Page 2

Page 3

PREFACE VACON · 3

PREFACE

Document ID: DPD00927F

Date: 30.1.2014

Software version: FW0072V012

ABOUT THIS MANUAL

This manual is copyright of Vacon Plc. All Rights Reserved.

In this manual, you can read about the functions of the Vacon® AC drive and how to use the

drive. The manual has the same structure than the menu of the drive (chapters 1 and 4-8).

Chapter 1, Quick Startup Guide

How to start the work with the control panel.

•

Chapter 2, Wizards

Making a selection of the application configuration.

•

Setting up an application quickly.

•

The different applications with examples.

•

Chapter 3, User Interfaces

The display types and how to use the control panel.

•

The PC tool Vacon Live.

•

The functions of the fieldbus.

•

Chapter 4, Monitoring menu

Data on the monitoring values.

•

Chapter 5, Parameter menu

A list of all the parameters of the drive.

•

Chapter 6, Diagnostics menu

Chapter 7, I/O and Hardware menu

Chapter 8, User settings, favourites and user level menus

Chapter 9, Parameter descriptions

How to use the parameters.

•

Digital and analogue input programming.

•

Application-specific functions.

•

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Page 4

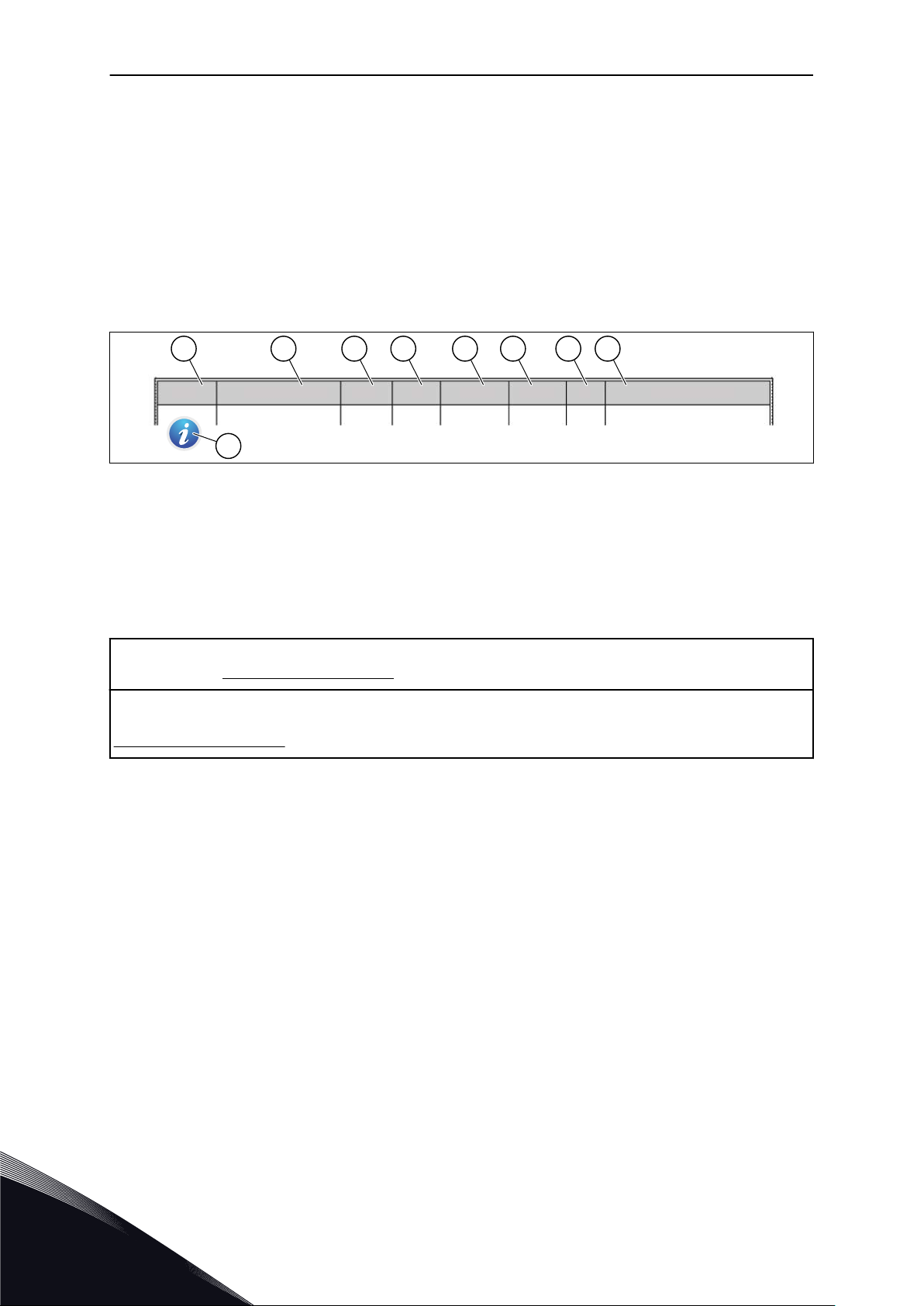

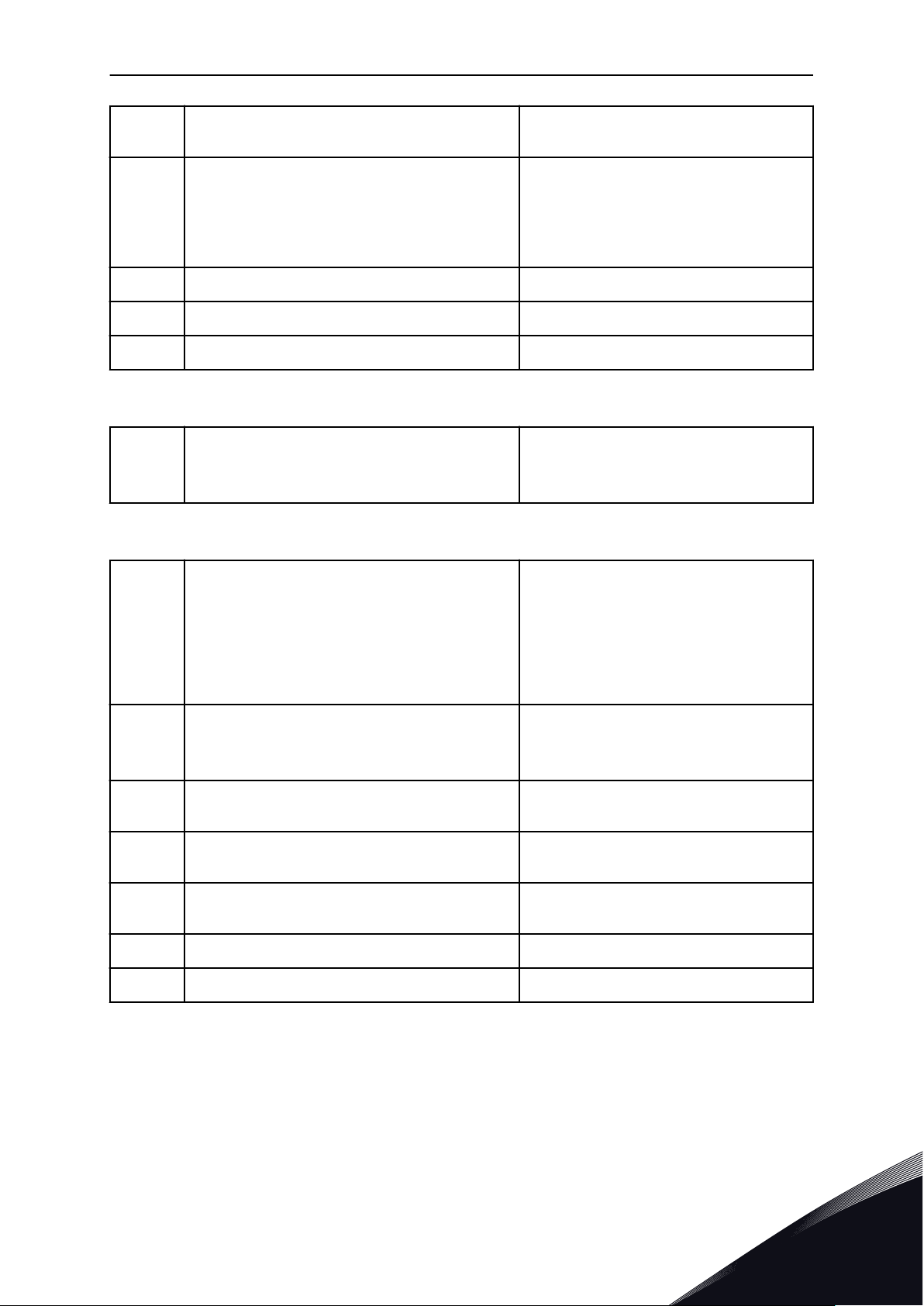

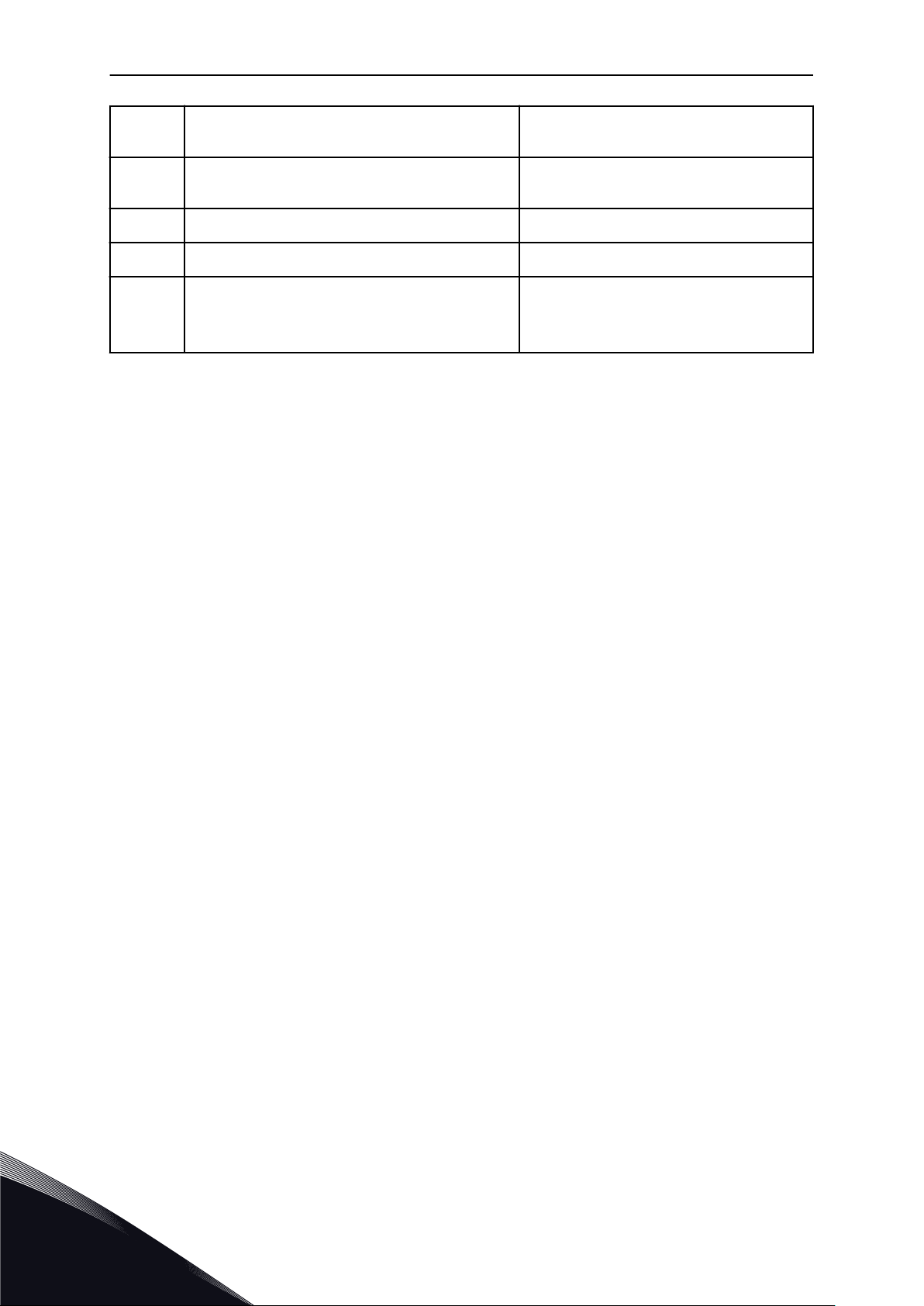

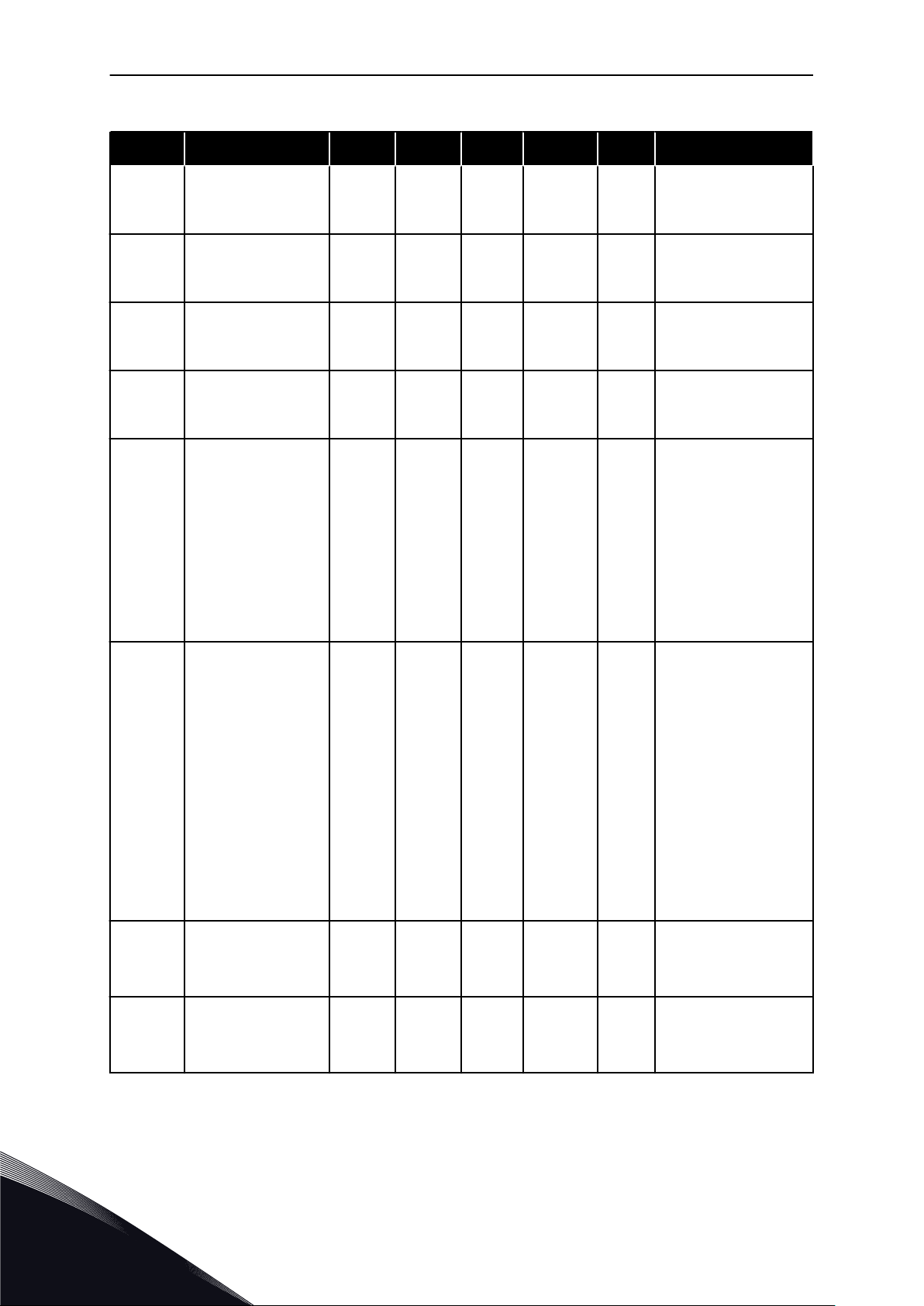

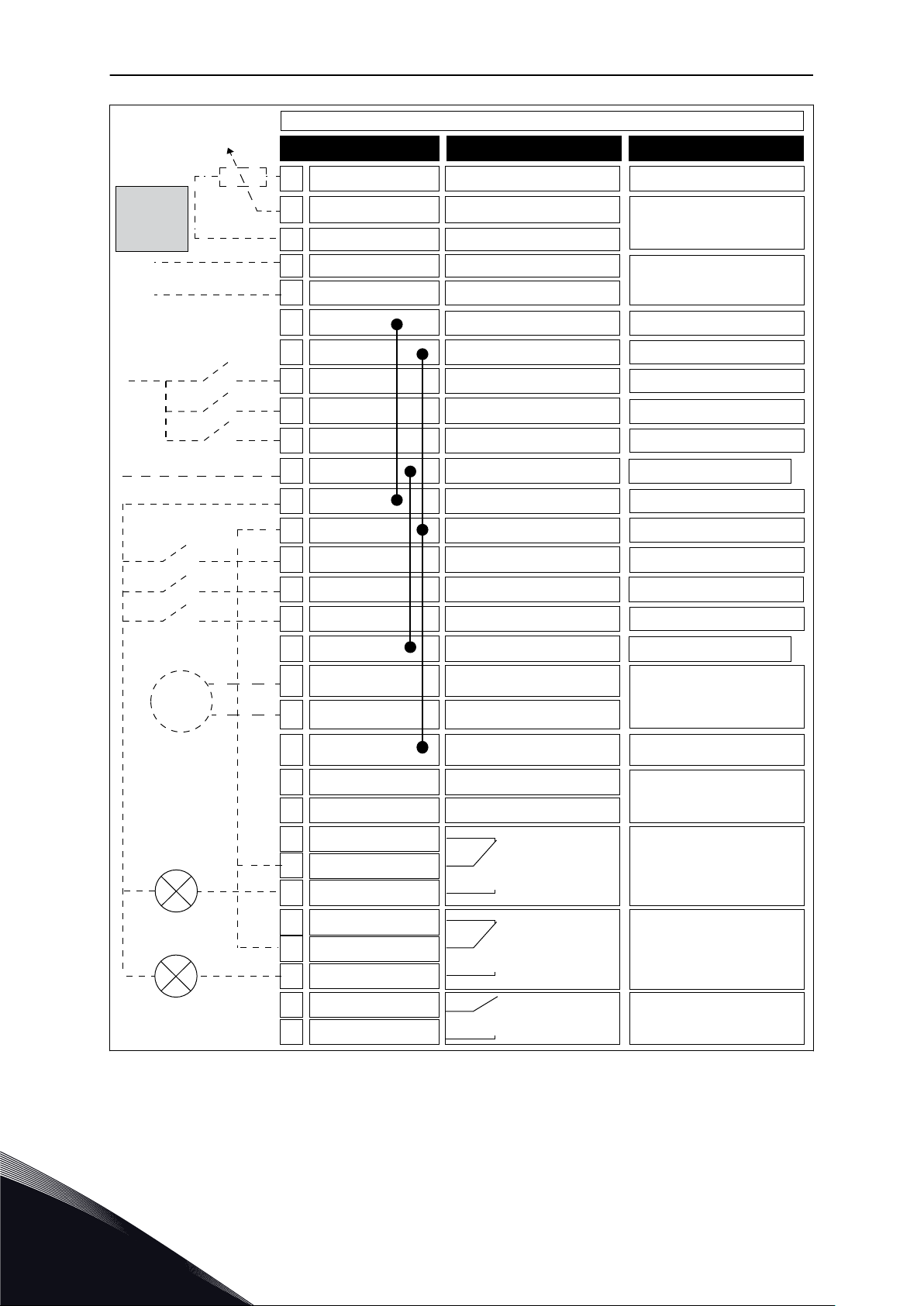

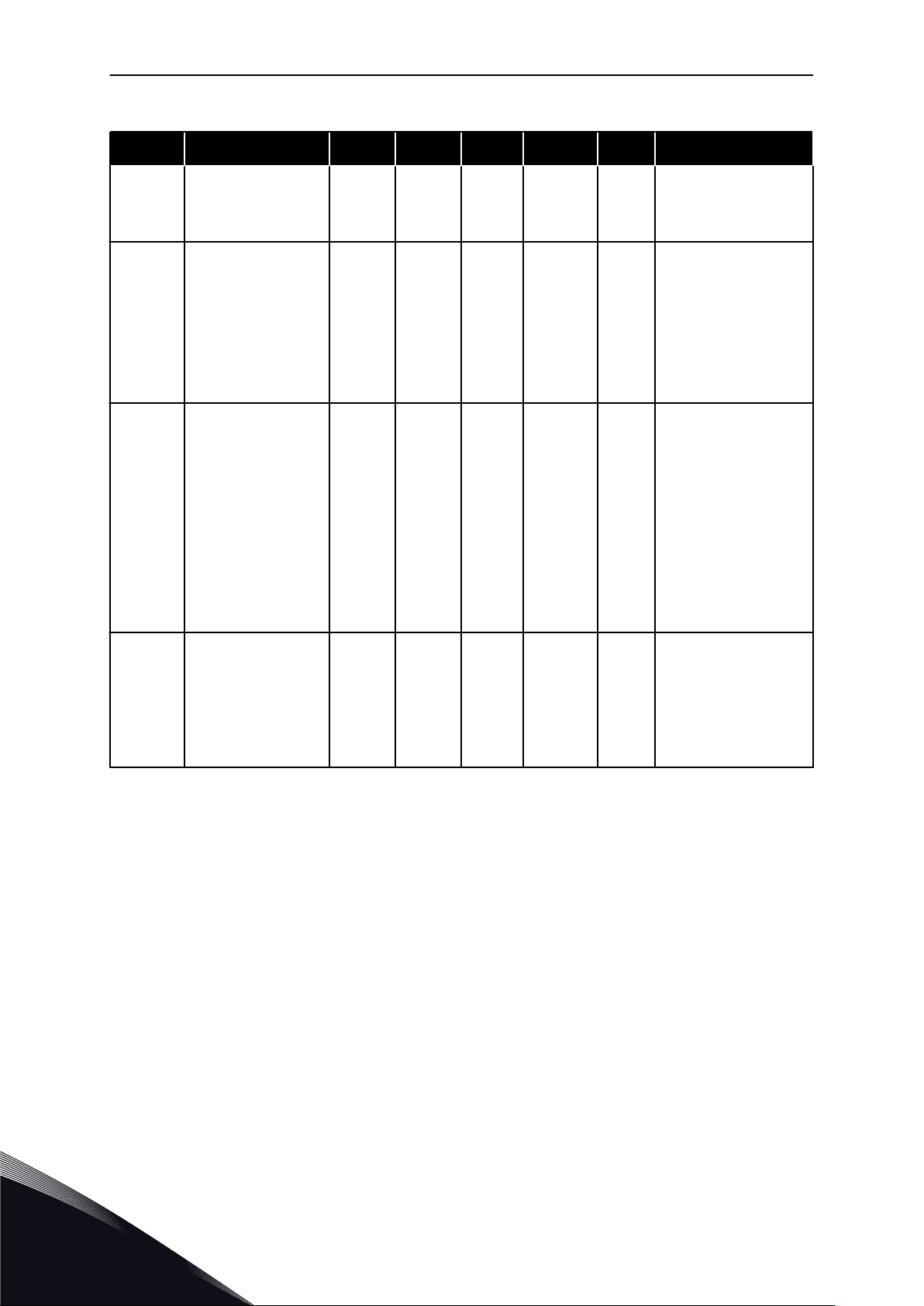

Index Min Max Unit Default ID DescriptionParameter

A

I

B C D E F G H

VACON · 4 PREFACE

Chapter 10, Fault tracing

The faults and their causes.

•

Resetting the faults.

•

Chapter 11, Appendix

Data on the different default values of the applications.

•

This manual includes a large quantity of parameter tables. These instructions tell you how to

read the tables.

A. The location of the parameter in the

menu, that is, the parameter number.

B. The name of the parameter.

C. The minimum value of the parameter.

D. The maximum value of the parameter.

E. The unit of the value of the parameter.

The unit shows if it is available.

NOTE! You can download the English and French product manuals with applicable safety, warning and caution

information from www.vacon.com/downloads.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant

l'ensemble des informations de sécurité, avertissements et mises en garde applicables sur le site

www.vacon.com/downloads.

F. The value that was set in the factory.

G. The ID number of the parameter.

H. A short description of the values of the

parameter and/or its function.

I. When the symbol shows, you can find

more data about the parameter in

Chapter Parameter descriptions.

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 5

PREFACE VACON · 5

FUNCTIONS OF THE VACON® AC DRIVE

Wizards for startup, PID control, multipump and fire mode to make the commissioning

•

easy.

The FUNCT button for an easy change between the local and the remote control place.

•

The remote control place can be I/O or fieldbus. You can make a selection of the remote

control place with a parameter.

8 preset frequencies.

•

Motor pontentiometer functions.

•

A joystick control.

•

A jogging function.

•

2 programmable ramp times, 2 supervisions and 3 ranges of prohibited frequencies.

•

A forced stop.

•

A control page to operate and monitor of the most important values quickly.

•

A fieldbus data mapping.

•

An automatic reset.

•

Different pre-heat modes to prevent condensation problems.

•

A maximum output frequency of 320 Hz.

•

A Real time clock and timer functions (an optional battery is necessary). It is possible to

•

program 3 time channels to get different functions on the drive.

An external PID controller is available. You can use it, for example, to control a valve with

•

the I/O of the AC drive.

A sleep mode function that automatically enables and disables the operation of the drive

•

to save energy.

A 2-zone PID controller with 2 different feedback signals: minimum and maximum

•

control.

2 setpoint sources for the PID control. You can make the selection with a digital input.

•

A function for PID setpoint boost.

•

A feedforward function to make the response to the process changes better.

•

A process value supervision.

•

A multipump control.

•

A maintenance counter.

•

Pump control functions: priming pump control, jockey pump control, pump impeller

•

auto-cleaning, pump input pressure supervision and frost protection function.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Page 6

VACON · 6

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 7

TABLE OF CONTENTS VACON · 7

TABLE OF CONTENTS

Preface

About this manual 3

Functions of the Vacon® AC drive 5

1 Quick Startup Guide 11

1.1 Control panel and keypad 11

1.2 The displays 11

1.3 First start-up 12

1.4 Description of the applications 14

1.4.1 Standard application 14

1.4.2 Local/Remote application 21

1.4.3 Multi-step speed application 28

1.4.4 PID control application 35

1.4.5 Multi-purpose application 45

1.4.6 Motor potentiometer application 55

2 Wizards 63

2.1 Standard application wizard 63

2.2 Local/Remote application wizard 64

2.3 Multi-step speed application wizard 65

2.4 PID control application wizard 66

2.5 Multi-purpose application wizard 68

2.6 Motor potentiometer application wizard 69

2.7 Multipump wizard 70

2.8 Fire mode wizard 72

3 User interfaces 74

3.1 Navigation on the keypad 74

3.2 Using the graphical display 76

3.2.1 Editing the values 76

3.2.2 Resetting a fault 79

3.2.3 The FUNCT button 79

3.2.4 Copying the parameters 83

3.2.5 Comparing the parameters 85

3.2.6 Help texts 86

3.2.7 Using the Favourites menu 87

3.3 Using the text display 87

3.3.1 Editing the values 88

3.3.2 Resetting a fault 89

3.3.3 The FUNCT button 89

3.4 Menu structure 93

3.4.1 Quick setup 94

3.4.2 Monitor 94

3.5 Vacon Live 96

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Page 8

VACON · 8 TABLE OF CONTENTS

4 Monitoring menu 97

4.1 Monitor group 97

4.1.1 Multimonitor 97

4.1.2 Trend curve 98

4.1.3 Basic 101

4.1.4 I/O 103

4.1.5 Temperature inputs 103

4.1.6 Extras and advanced 105

4.1.7 Timer functions monitoring 107

4.1.8 PID controller monitoring 108

4.1.9 External PID controller monitoring 109

4.1.10 Multipump monitoring 109

4.1.11 Maintenance counters 110

4.1.12 Fieldbus data monitoring 111

5 Parameters menu 113

5.1 Group 3.1: Motor settings 113

5.2 Group 3.2: Start/stop setup 121

5.3 Group 3.3: References 124

5.4 Group 3.4: Ramps and brakes setup 134

5.5 Group 3.5: I/O configuration 137

5.6 Group 3.6: Fieldbus data mapping 151

5.7 Group 3.7: Prohibit frequencies 153

5.8 Group 3.8: Supervisions 154

5.9 Group 3.9: Protections 155

5.10 Group 3.10: Automatic reset 166

5.11 Group 3.11: Application settings 168

5.12 Group 3.12: Timer functions 169

5.13 Group 3.13: PID controller 172

5.14 Group 3.14: External PID controller 188

5.15 Group 3.15: Multipump 193

5.16 Group 3.16: Maintenance counters 195

5.17 Group 3.17: Fire mode 196

5.18 Group 3.18: Motor preheat parameters 198

5.19 Group 3.20: Mechanical brake 200

5.20 Group 3.21: Pump control 201

6 Diagnostics menu 204

6.1 Active faults 204

6.2 Reset faults 204

6.3 Fault history 204

6.4 Total counters 204

6.5 Trip counters 206

6.6 Software info 207

7 I/O and hardware menu 208

7.1 Basic I/O 208

7.2 Option board slots 210

7.3 Real time clock 211

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 9

TABLE OF CONTENTS VACON · 9

7.4 Power unit settings 211

7.5 Keypad 213

7.6 Fieldbus 213

8 User settings, favourites and user level menus 218

8.1 User settings 218

8.1.1 Parameter backup 219

8.2 Favourites 219

8.2.1 Adding an item to the Favourites 220

8.2.2 Removing an item from the Favourites 220

8.3 User levels 221

8.3.1 Changing the access code of the user levels 222

9 Parameter descriptions 224

9.1 Motor settings 224

9.1.1 I/f start function 232

9.1.2 Torque stabilator function 233

9.2 Start/Stop setup 234

9.3 References 241

9.3.1 Frequency reference 241

9.3.2 Torque reference 241

9.3.3 Preset frequencies 243

9.3.4 Motor potentiometer parameters 246

9.4 Joystick parameters 248

9.5 Jogging parameters 249

9.6 Ramps and brakes setup 251

9.7 I/O configuration 252

9.7.1 Programming of digital and analogue inputs 252

9.7.2 Default functions of programmable inputs 263

9.7.3 Digital inputs 263

9.7.4 Analogue inputs 264

9.7.5 Digital outputs 269

9.7.6 Analogue outputs 271

9.8 Prohibit frequencies 274

9.9 Supervisions 275

9.9.1 Motor thermal protections 276

9.9.2 Motor stall protection 279

9.9.3 Underload protection 280

9.10 Automatic reset 285

9.11 Timer functions 286

9.12 PID controller 290

9.12.1 Feedforward 291

9.12.2 Sleep function 291

9.12.3 Feedback supervision 293

9.12.4 Pressure loss compensation 294

9.12.5 Soft fill 296

9.12.6 Input pressure supervision 297

9.12.7 Frost protection 298

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Page 10

VACON · 10 TABLE OF CONTENTS

9.13 Multipump function 299

9.14 Maintenance counters 305

9.15 Fire mode 305

9.16 Motor preheat function 307

9.17 Mechanical brake 308

9.18 Pump control 311

9.18.1 Auto-cleaning 311

9.18.2 Jockey pump 312

9.18.3 Priming pump 313

9.19 Total and trip counters 314

9.19.1 Operating time counter 314

9.19.2 Operating time trip counter 315

9.19.3 Run time counter 315

9.19.4 Power on time counter 316

9.19.5 Energy counter 316

9.19.6 Energy trip counter 317

10 Fault tracing 319

10.1 A fault comes into view 319

10.1.1 Resetting with the Reset button 319

10.1.2 Resetting with a parameter in the graphical display 319

10.1.3 Resetting with a parameter in the text display 320

10.2 Fault history 321

10.2.1 Examining the Fault history in the graphical display 321

10.2.2 Examining the Fault history in the text display 322

10.3 Fault codes 324

11 Appendix 1 337

11.1 The default values of parameters in the different applications 337

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 11

A B C

I

H D

G F E

QUICK STARTUP GUIDE VACON · 11

1 QUICK STARTUP GUIDE

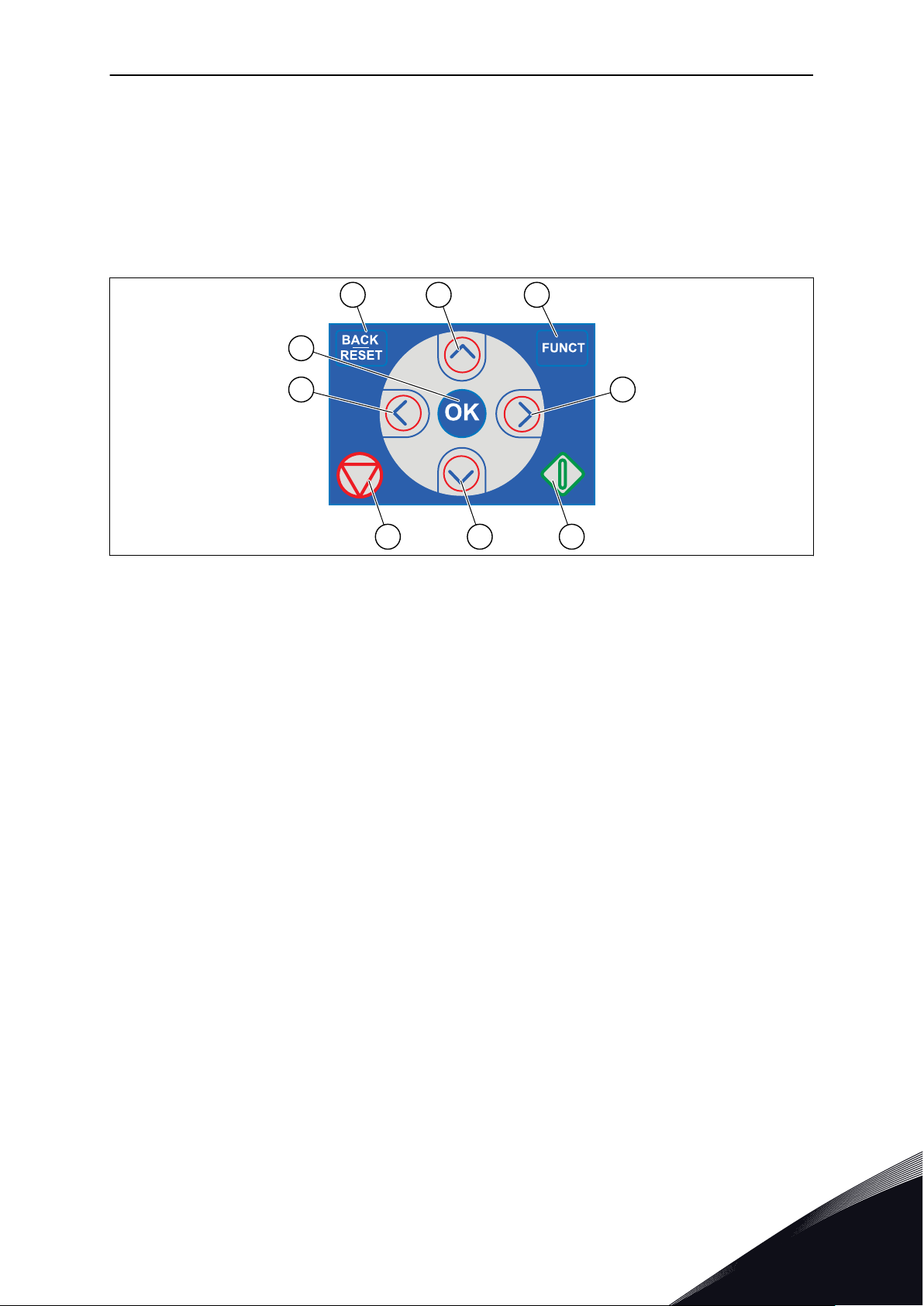

1.1 CONTROL PANEL AND KEYPAD

The control panel is the interface between the AC drive and the user. With the control panel,

you can control the speed of a motor and monitor the status of the AC drive. You can also set

the parameters of the AC drive.

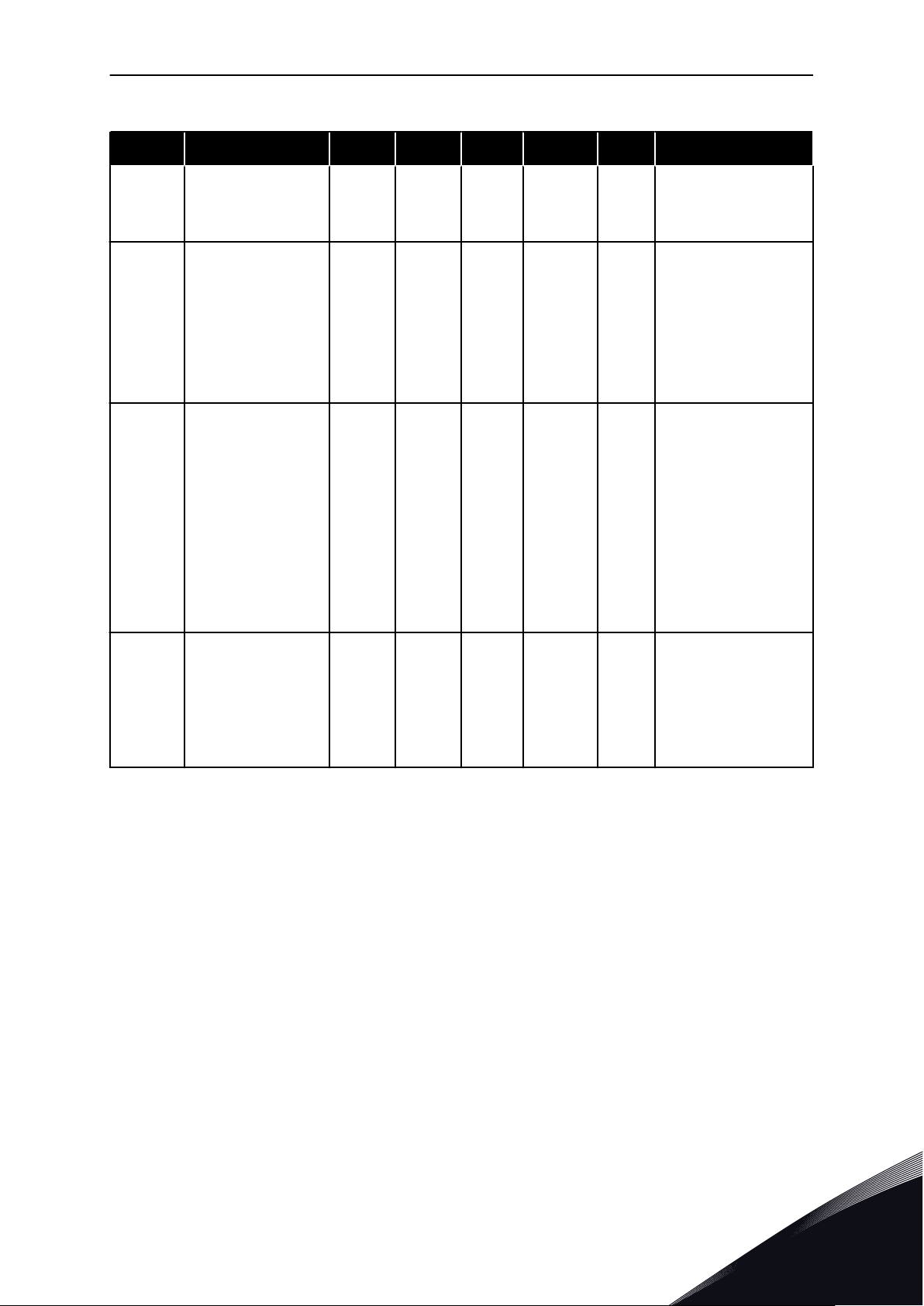

Fig. 1: The buttons of the keypad

A. The BACK/RESET button. Use it to move

back in the menu, exit the Edit mode,

reset a fault.

B. The arrow button UP. Use it to scroll the

menu up and to increase a value.

C. The FUNCT button. Use it to change the

rotation direction of the motor, access

the control page, and change the control

place. See more in Table 38 Frequency

reference parameters.

D. The arrow button RIGHT.

E. The START button.

F. The arrow button DOWN. Use it to scroll

the menu down and to decrease a value.

G. The STOP button.

H. The arrow button LEFT. Use it to move

the cursor left.

I. The OK button. Go into an active level or

item, accept a selection.

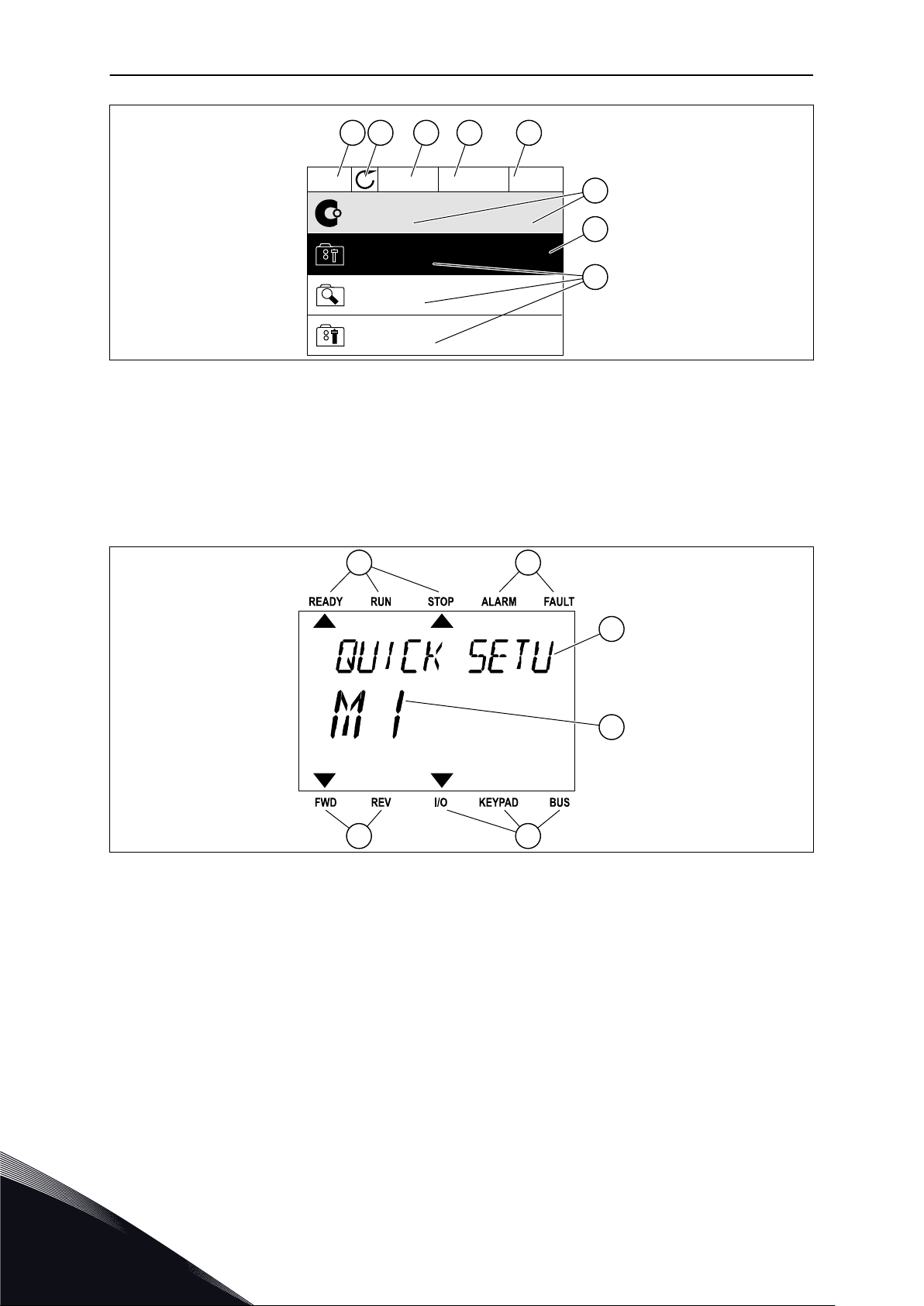

1.2 THE DISPLAYS

There are 2 display types: the graphical display and the text display. The control panel always

has the same keypad and buttons.

The display shows this data.

The status of the motor and the drive.

•

Faults in the motor and in the drive.

•

Your location in the menu structure.

•

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 12

STOP

READY I/O

Main Menu

A B C D E

F

H

G

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

( 12 )

M1ID:

A B

F

C

D

E

VACON · 12 QUICK STARTUP GUIDE

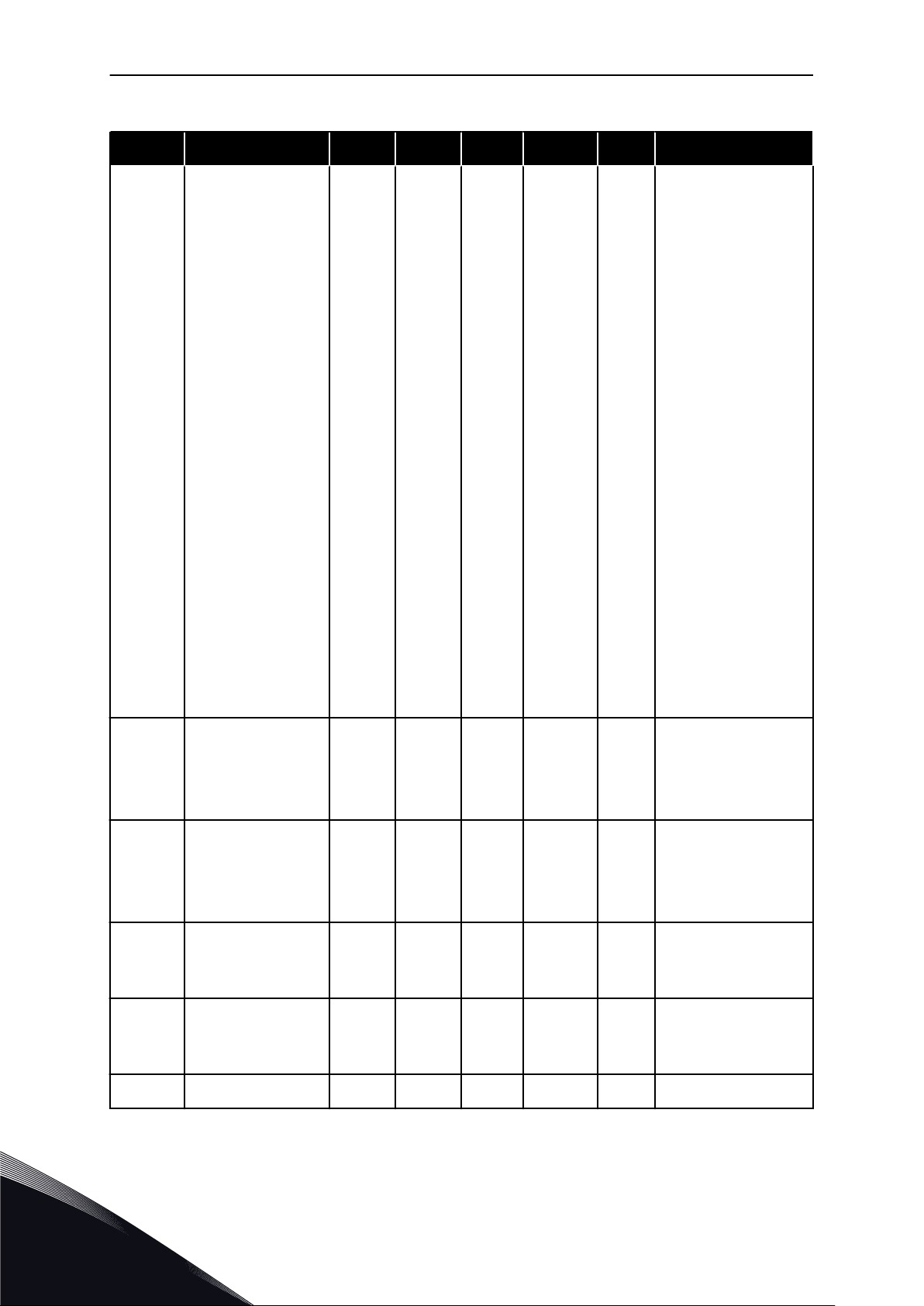

Fig. 2: The graphical display

A. The first status field: STOP/RUN

B. The rotation direction of the motor

C. The second status field: READY/NOT

READY/FAULT

D. The alarm field: ALARM/E. The control place field: PC/IO/KEYPAD/

F. The location field: the ID number of the

parameter and the current location in

the menu

G. An activated group or item

H. The number of items in the group in

question

FIELDBUS

Fig. 3: The text display. If the text is too long to show, the text scrolls automatically on the display.

A. The indicators of status

B. The indicators of alarm and fault

C. The name of the group or item of the

current location

1.3 FIRST START-UP

1

The Start-up wizard tells you to give necessary data for the drive to control your procedure.

D. The current location in the menu

E. The indicators of the control place

F. The indicators of the rotation direction

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 13

QUICK STARTUP GUIDE VACON · 13

1

2

3 Time* (P5.5.2) hh:mm:ss

4 Year* (P5.5.4) yyyy

5 Date* (P5.5.3) dd.mm.

Language selection (P6.1) The selection is different in all the language

packages

Daylight saving* (P5.5.5)

Russia

US

EU

OFF

* If a battery is installed, you see these questions.

Run Startup wizard?

6

Yes

No

To set the parameter values manually, make the selection No and push the OK button.

Make a selection of an application (P1.2 Application,

ID212)

7

Set a value for P3.1.2.2 Motor Type (so that it agrees

8

9

10

11

12 Set a value for P3.1.1.4 Motor Nominal Current Range: Varies

13 Set a value for P3.1.1.5 Motor Cos Phi Range: 0.30-1.00

with the nameplate)

Set a value for P3.1.1.1 Motor Nominal Voltage (so

that it agrees with the nameplate)

Set a value for P3.1.1.2 Motor Nominal Frequency

(so that it agrees with the nameplate)

Set a value for P3.1.1.3 Motor Nominal Speed (so

that it agrees with the nameplate)

Standard

Local/Remote

Multi-step speed

PID control

Multi-purpose

Motor potentiometer

PM motor

Induction motor

Range: Varies

Range: 8.00...320.00 Hz

Range: 24...19200

If you set Motor Type to Induction Motor, you see the next question. If your selection is PM

Motor, the value of parameter P3.1.1.5 Motor Cos Phi is set to 1.00 and the wizard goes

directly to question 14.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 14

VACON · 14 QUICK STARTUP GUIDE

14

15

16 Set a value for P3.4.1.2 Acceleration Time 1 Range: 0.1...300.0 s

17 Set a value for P3.4.1.3 Deceleration Time 1 Range: 0.1...300.0 s

18

Set a value for P3.3.1.1 Minimum Frequency

Reference

Set a value for P3.3.1.2 Maximum Frequency

Reference

Run the Application wizard?

Range: 0.00...P3.3.1.2 Hz

Range: P3.3.1.1...320.00 Hz

Yes

No

To continue to the application wizard, set the selection to Yes and push the OK button. See

the description of the different application wizards in Chapter 2 Wizards.

After these selections, the Start-up wizard is completed. To start the Start-up wizard again,

you have 2 alternatives. Go to the parameter P6.5.1 Restore Factory Defaults or to the

parameter B1.1.2 Start-up Wizard. Then set the value to Activate.

1.4 DESCRIPTION OF THE APPLICATIONS

Use the parameter P1.2 (Application) to make a selection of an application for the drive.

Immediately when the parameter P1.2 changes, a group of parameters get their preset

values.

1.4.1 STANDARD APPLICATION

You can use the Standard application in speed-controlled processes where no special

functions are necessary, for example pumps, fans, or conveyors.

It is possible to control the drive from the keypad, Fieldbus or I/O terminal.

When you control the drive with the I/O terminal, the frequency reference signal is connected

to AI1 (0…10V) or AI2 (4…20mA). The connection depends the type of the signal. There are

also 3 preset frequency references available. You can activate the preset frequency

references with DI4 and DI5. The start/stop signals of the drive are connected to DI1 (start

forward) and DI2 (start reverse).

It is possible to configure all the drive outputs freely in all the applications. There are 1

analogue output (Output Frequency) and 3 relay outputs (Run, Fault, Ready) available on the

basic I/O board.

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 15

RUN

FAULT

READY

Reference output+10 Vref

Terminal

Standard I/O board

Signal

1

24V auxiliary voltage24Vout6

Analogue input 1 +AI1+2

AI1-3

Analogue input 2 +

AI2+4

AI2-5

Analogue output 1 +

AO1+

RUN

18

Analogue output 1 -

AO1-19

+24Vin

30

24V auxiliary voltage24Vout

12

I/O groundGND7

I/O groundGND13

Digital input 1DI18

Digital input 2DI29

Digital input 3DI310

Digital input 4DI414

Digital input 5DI515

Digital input 6DI616

Relay output 1

RO1/1 NC21

22

RO1/2 CM

RO1/3 NO23

Common for DI1-DI6CM11

Common for DI1-DI6CM

17

Serial bus, negativeRS485A

Serial bus, positiveRS485

B

Relay output 2

Relay output 3

RO2/1 NC24

25

RO2/2 CM

RO2/3 NO26

32

RO3/2 CM

RO3/3 NO33

Description

Frequency reference

(default 0...10V)

Frequency reference

(Default 4...20mA)

Start forward

Start reverse

External fault

DI4

DI5

Freq. ref.

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Analog input 1

Preset Freq. 1

Preset Freq. 2

Preset Freq. 3

Fault reset

Output frequency

(default: 0...20mA)

Modbus RTU

N2, BACnet

Analogue input 1 -

FAULT

Analogue input 2 -

Reference

potentiom-

eter

1...10kΩ

mA

*)

*)

**)

24V auxiliary

input voltage

QUICK STARTUP GUIDE VACON · 15

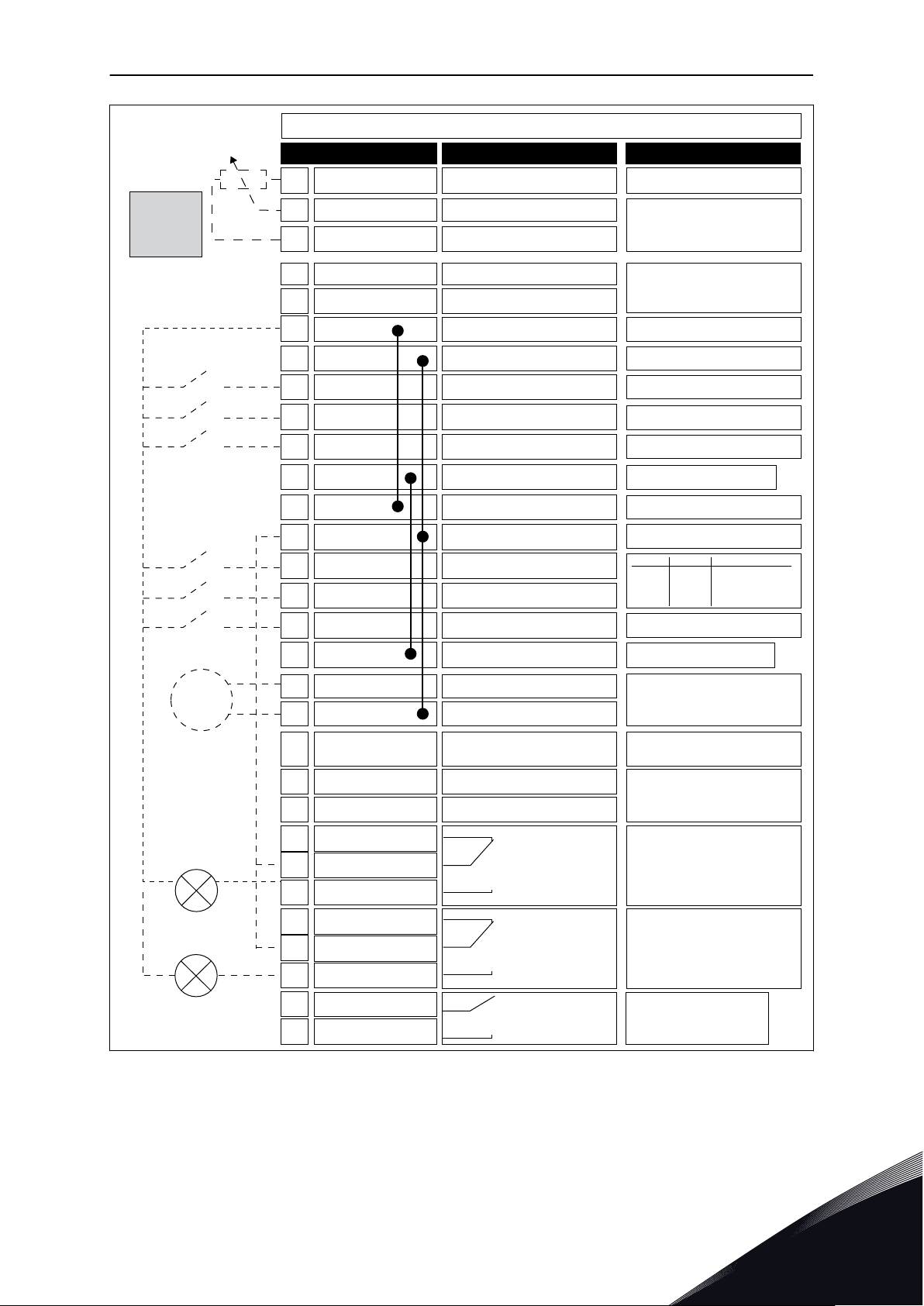

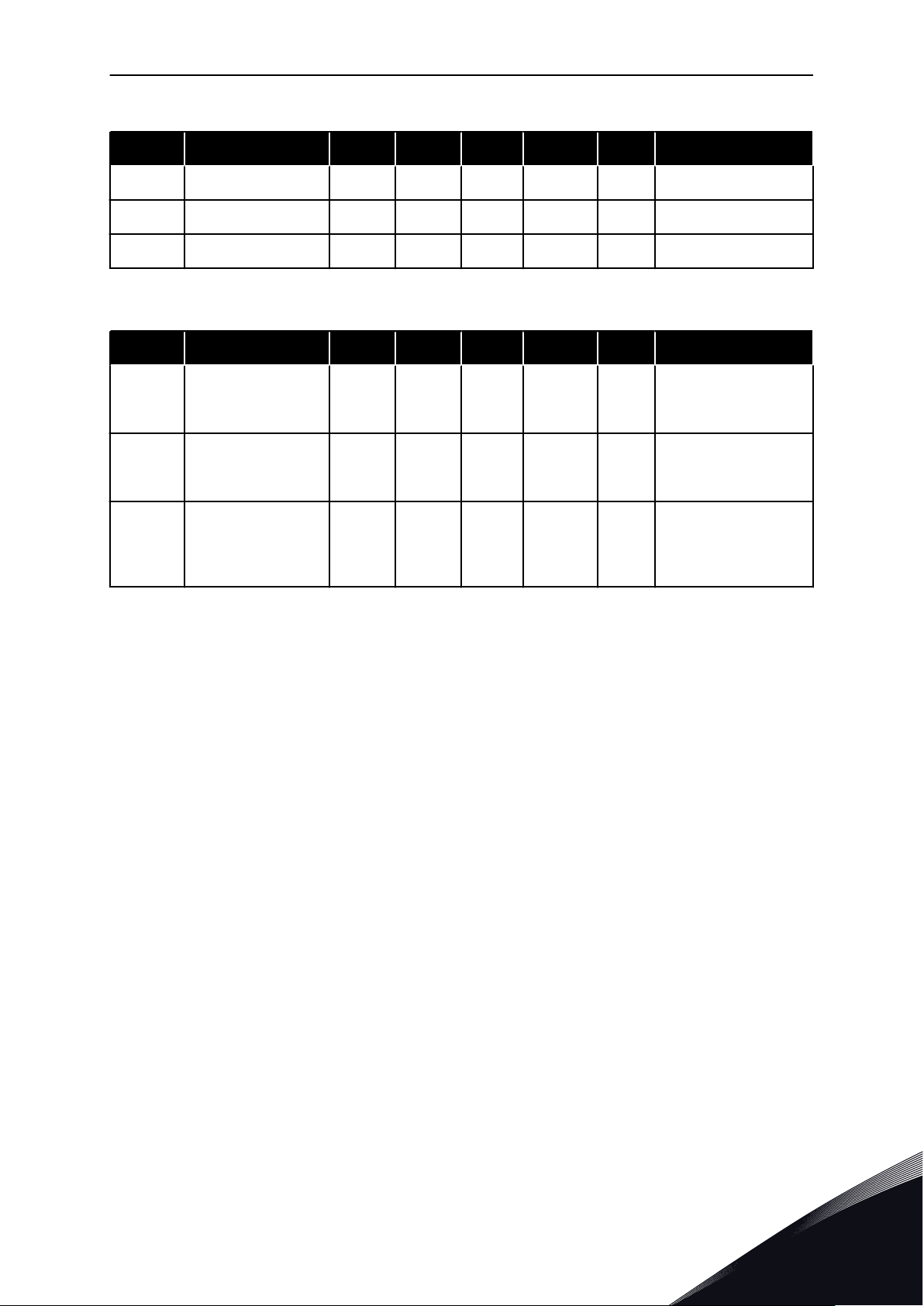

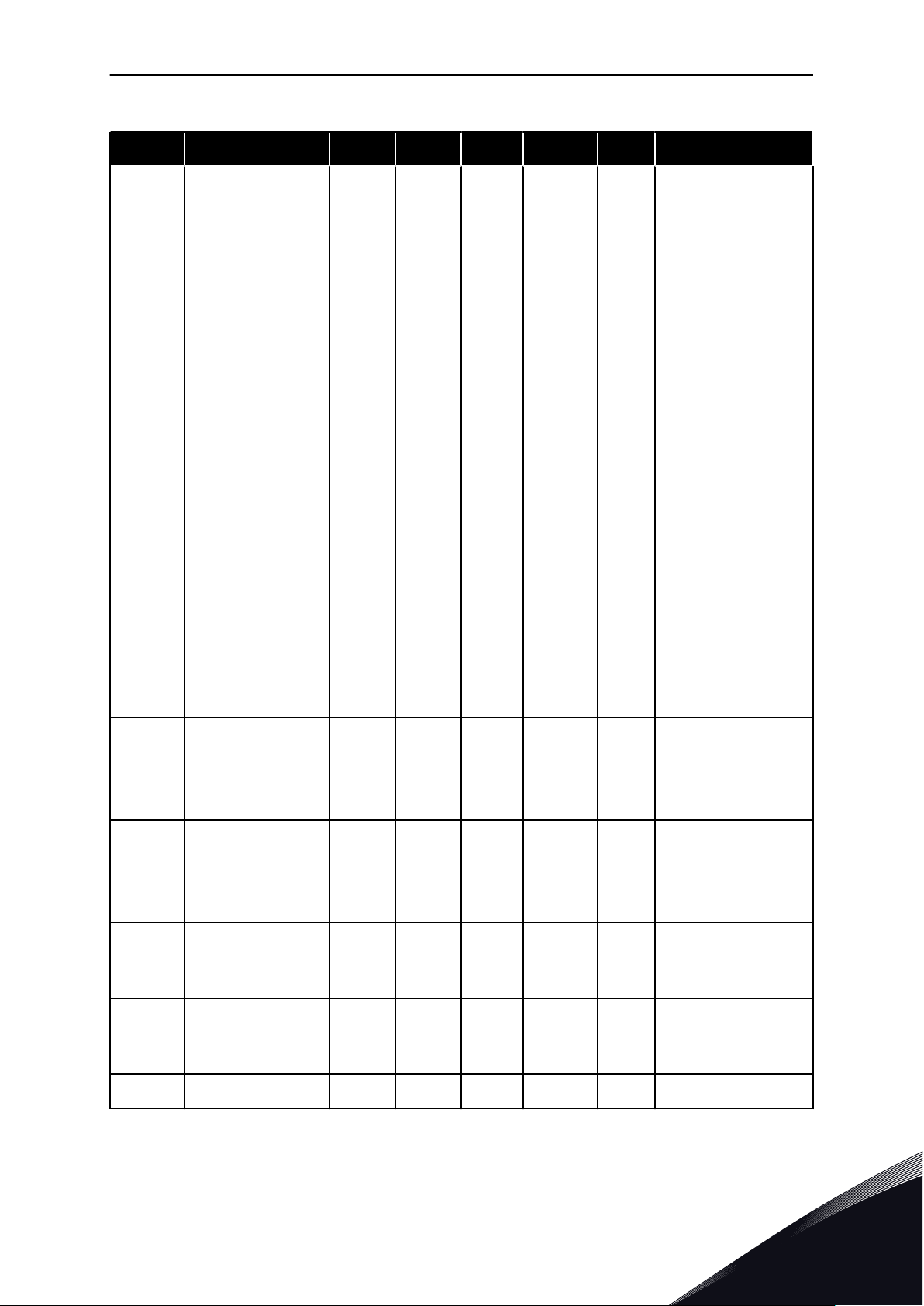

Fig. 4: The default control connections of the Standard application

* = You can isolate the digital inputs from the ground with a DIP switch.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 16

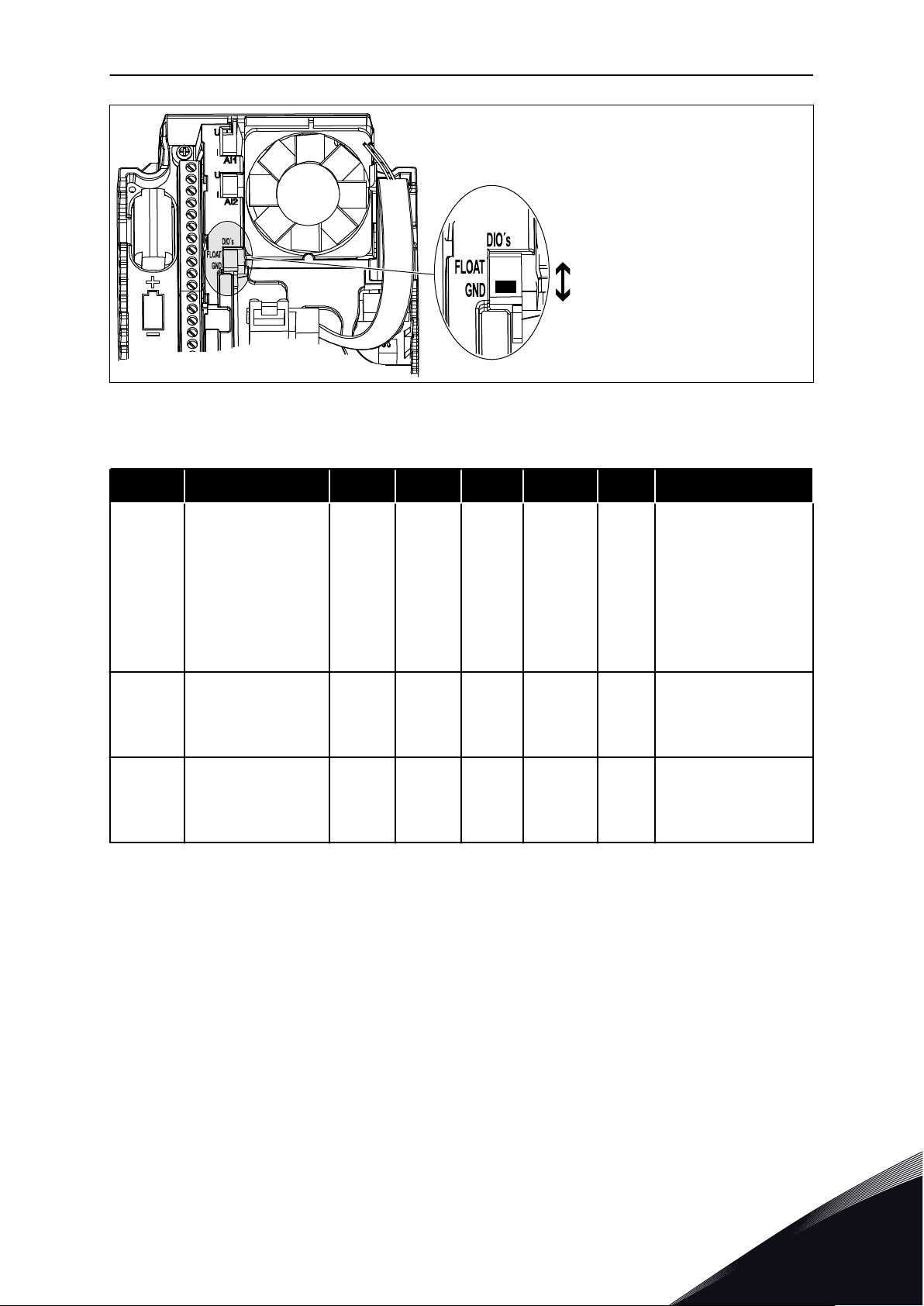

Digital inputs

Floating

Connected to GND

(Default!)

VACON · 16 QUICK STARTUP GUIDE

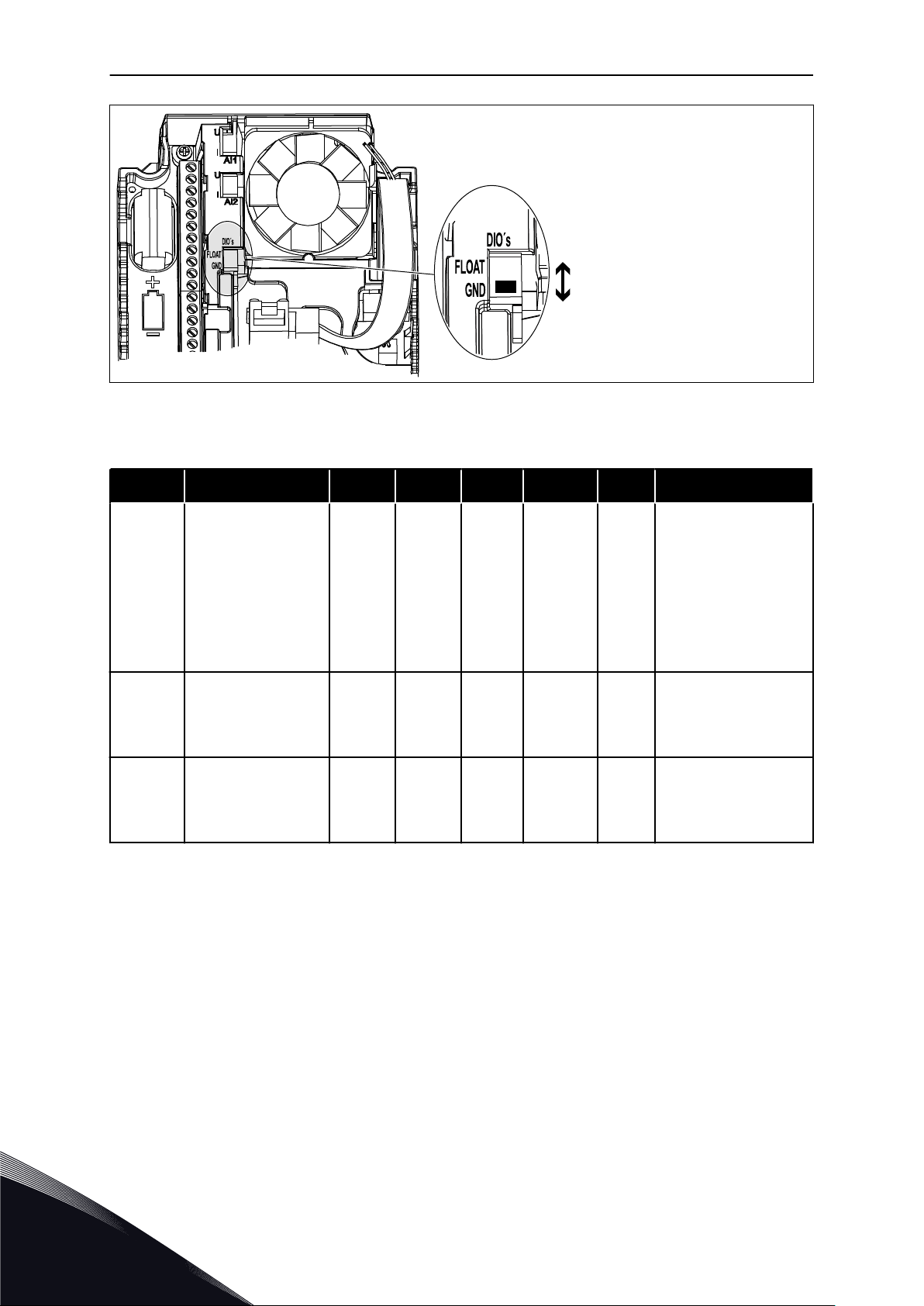

Fig. 5: The DIP switch

Table 2: M1.1 Wizards

Index Parameter Min Max Unit Default ID Description

1.1.1 Startup wizard 0 1 0 1170

1.1.3 Multi-pump Wizard 0 1 0 1671

1.1.4 Fire mode Wizard 0 1 0 1672

0 = Do not activate

1 = Activate

The selection Activate

starts the Start-up

wizard (see Chapter

Table 1 The Start-up

wizard.

The selection Activate

starts the Multipump

wizard (see Chapter

2.7 Multipump wizard).

The selection Activate

starts the Fire mode

wizard (see Chapter

2.8 Fire mode wizard).

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 17

QUICK STARTUP GUIDE VACON · 17

Table 3: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

0 = Standard

1.2

Application 0 5 0 212

1 = Local/Remote

2 = Multi-Step Speed

3 = PID Control

4 = Multi-Purpose

5 = Motor

Potentiometer

1.3

1.4

1.5 Acceleration Time 1 0.1 300.0 s 5.0 103

1.6 Deceleration Time 1 0.1 300.0 s 5.0 104

1.7 Motor Current Limit IH*0.1 I

Minimum Frequency

Reference

Maximum Frequency

Reference

0.00 P1.4 Hz 0.0 101

P1.3 320.0 Hz

S

A Varies 107

50.0 /

60.0

102

The minimum

frequency reference

that is acceptable.

The maximum

frequency reference

that is acceptable.

Gives the quantity of

time that is necessary

for the output

frequency to increase

from zero frequency to

the maximum

frequency.

Gives the quantity of

time that is necessary

for the output

frequency to decrease

from the maximum

frequency to zero

frequency.

The maximum motor

current from the AC

drive.

1.8 Motor Type 0 1 0 650

1.9

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Motor Nominal

Voltage

Varies Varies V Varies 110

0 = Induction Motor

1 = Permanent Magnet

Motor

Find this value Un on

the rating plate of the

motor.

NOTE!

Find out if the motor

connection is Delta or

Star.

1

Page 18

VACON · 18 QUICK STARTUP GUIDE

Table 3: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.10

1.11

1.12

1.13

1.14 Energy Optimization 0 1 0 666

Motor Nominal

Frequency

Motor Nominal

Speed

Motor Nominal

Current

Motor Cos Phi

(Power Factor)

8.0 320.0 Hz 50 / 60 111

24 19200 Rpm Varies 112

IH * 0.1 IH * 2 A Varies 113

0.30 1.00 Varies 120

Find this value fn on

the rating plate of the

motor.

Find this value nn on

the rating plate of the

motor.

Find this value In on

the rating plate of the

motor.

Find this value on the

rating plate of the

motor.

The drive searches for

the minimum motor

current to save energy

and to lower the motor

noise. Use this function

with, for example, fan

and pump processes.

0 = Disabled

1 = Enabled

1.15 Identification 0 2 0 631

1.16

1.17 Stop Function 0 1 0 506

Start Function 0 1 0 505

The identification run

calculates or measures

the motor parameters

that are necessary for

a good control of the

motor and speed.

0 = No action

1 = At standstill

2 = With rotation

Before you do the

identification run, you

must set the motor

nameplate parameters.

0 = Ramping

1 = Flying Start

0 = Coasting

1 = Ramping

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 19

QUICK STARTUP GUIDE VACON · 19

Table 3: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.18 Automatic Reset 0 1 0 731

1.19

1.20

1.21

Response to External

Fault

Response to AI Low

Fault

Remote Control

Place

0 3 2 701

0 5 0 700

0 1 0 172

0 = Disabled

1 = Enabled

0 = No action

1 = Alarm

2 = Fault (Stop

according to stop

mode)

3 = Fault (Stop by

coasting)

0 = No action

1 = Alarm

2 = Alarm+preset fault

frequency (P3.9.1.13)

3 = Alarm + previous

frequency

4 = Fault (Stop

according to stop

mode)

5 = Fault (Stop by

coasting)

The selection of the

remote control place

(start/stop).

0 = I/O control

1 = Fieldbus control

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 20

VACON · 20 QUICK STARTUP GUIDE

Table 3: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

The selection of the

frequency reference

source when the

control place is I/O A.

0 = Preset Frequency 0

1 = Keypad Reference

2 = Fieldbus

3 = AI1

4 = AI2

5 = AI1+AI2

6 = PID Reference

7 = Motor

Potentiometer

8 = Joystick Reference

9 = Jogging Reference

10 = Block Out.1

11 = Block Out.2

12 = Block Out.3

13 = Block Out.4

14 = Block Out.5

15 = Block Out.6

16 = Block Out.7

17 = Block Out.8

18 = Block Out.9

19 = Block Out.10

1.22

I/O Control

Reference A

Selection

0 9 5 117

The application that

you set with parameter

1.2 gives the default

value.

The selection of the

1.23

1.24

1.25 AI1 Signal Range 0 1 0 379

1.26 AI2 Signal Range 0 1 1 390

1.27 RO1 Function 0 51 2 1101 See P3.5.3.2.1

Keypad Control

Reference Selection

Fieldbus Control

Reference Selection

0 9 1 121

0 9 2 122

frequency reference

source when the

control place is keypad.

See P1.22.

The selection of the

frequency reference

source when the

control place is

fieldbus. See P1.22.

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 21

QUICK STARTUP GUIDE VACON · 21

Table 3: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.28 RO2 Function 0 51 3 1104 See P3.5.3.2.1

1.29 RO3 Function 0 51 1 1107 See P3.5.3.2.1

1.30 AO1 Function 0 31 2 10050 See P3.5.4.1.1

Table 4: M1.31 Standard

Index Parameter Min Max Unit Default ID Description

Make the selection of a

1.31.1 Preset Frequency 1 P1.3 P1.4 Hz 10.0 105

1.31.2 Preset Frequency 2 P1.3 P1.4 Hz 15.0 106

preset frequency with

the digital input DI4.

Make the selection of a

preset frequency with

the digital input DI5.

Make the selection of a

1.31.3 Preset Frequency 3 P1.3 P1.4 Hz 20.0 126

preset frequency with

the digital input DI4

and DI5.

1.4.2 LOCAL/REMOTE APPLICATION

Use the Local/Remote application when, for example, it is necessary to switch between 2

different control places.

To change between the Local and the Remote control place, use DI6. When Remote control is

active, you can give the start/stop commands from Fieldbus or from I/O terminal (DI1 and

DI2). When Local control is active, you can give the start/stop commands from the keypad,

Fieldbus or I/O terminal (DI4 and DI5).

For each control place, you can make a selection of the frequency reference from the

keypad, Fieldbus or I/O terminal (AI1 or AI2).

It is possible to configure all the drive outputs freely in all the applications. There are 1

analogue output (Output Frequency) and 3 relay outputs (Run, Fault, Ready) available on the

basic I/O board.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 22

REMOTE:

Frequency reference

(default: 4...20mA)

RUN

FAULT

READY

Analogue input 1 +

Analogue input 1 -

Analogue input 2 +

Analogue input 2 -

Reference output+10 Vref

Terminal Signal

1

24V auxiliary voltage24Vout6

Remote reference

(4...20mA)

AI1+2

AI1-

3

AI2+4

AI2-5

AO1+

RUN

18

AO1-/GND19

+24Vin

30

24V auxiliary voltage24Vout

12

I/O groundGND7

I/O groundGND13

Digital input 1DI18

Digital input 2DI29

Digital input 3DI310

Digital input 4DI414

Digital input 5DI515

Digital input 6DI616

Relay output 1RO1/1 NC21

22

RO1/2 CM

RO1/3 NO23

Common for DI1-DI6CM11

Common for DI1-DI6CM

17

Serial bus, negativeRS485A

Serial bus, positiveRS485

B

Relay output 2

Relay output 3

RO2/1 NC24

25

RO2/2 CM

RO2/3 NO26

32

RO3/2 CM

RO3/3 NO33

Description

REMOTE: Start forward

REMOTE: Start reverse

External fault

Output frequency

(default: 0...20mA)

Modbus RTU

BACnet, N2

LOCAL: Start forward

LOCAL: Start reverse

LOCAL/REMOTE

selection

Remote

control ground

Analogue output 1 +

Analogue output 1 -

FAULT

Reference

potentiom-

eter

1...10kΩ

Remote

control

(+24V)

mA

*)

*)

24V auxiliary

input voltage

LOCAL:

Frequency reference

(default: 0...10V)

Standard I/O board

VACON · 22 QUICK STARTUP GUIDE

1

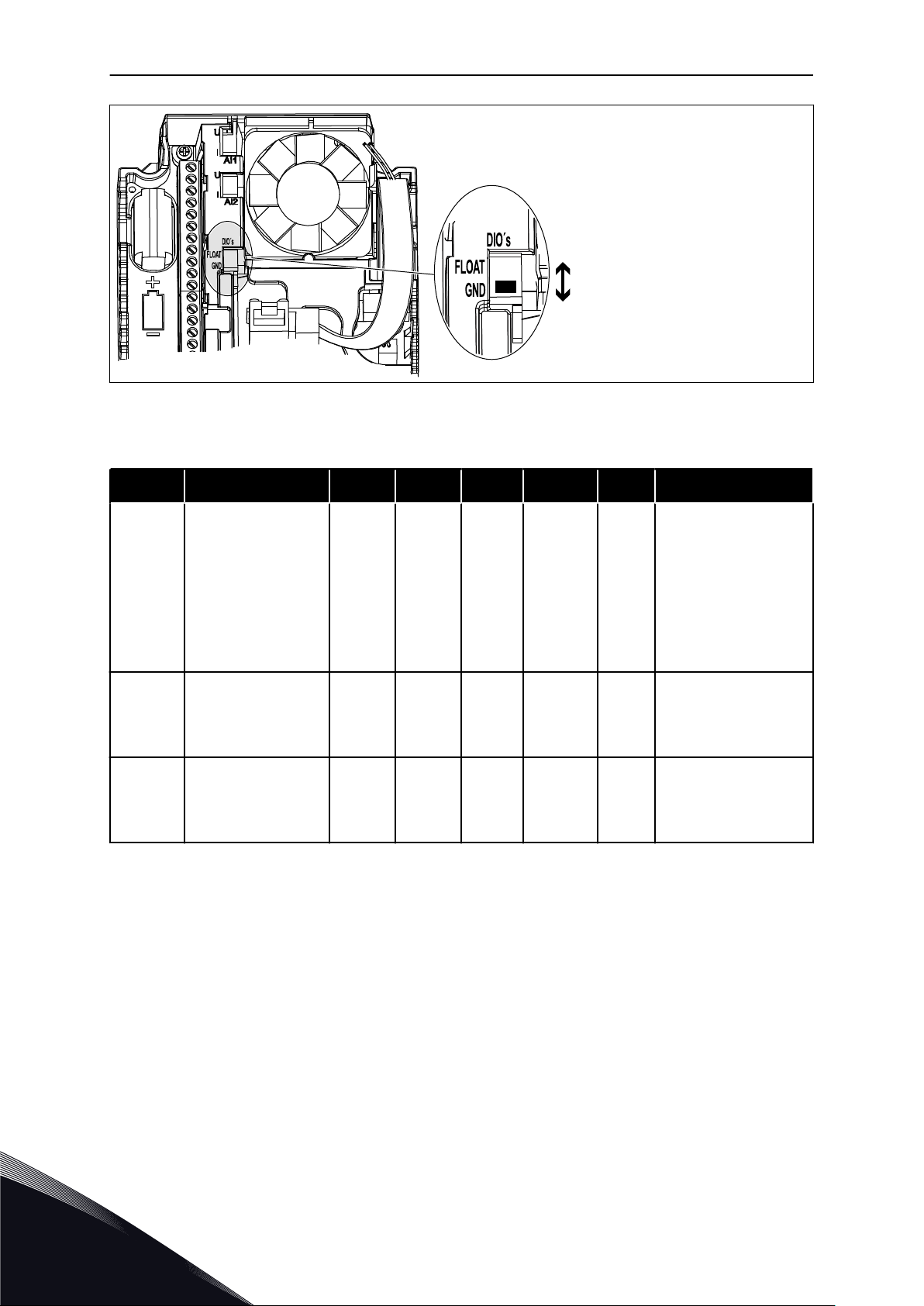

Fig. 6: The default control connections of the Local/Remote application

* = You can isolate the digital inputs from the ground with a DIP switch.

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 23

Digital inputs

Floating

Connected to GND

(Default!)

QUICK STARTUP GUIDE VACON · 23

Fig. 7: The DIP switch

Table 5: M1.1 Wizards

Index Parameter Min Max Unit Default ID Description

1.1.1 Startup wizard 0 1 0 1170

1.1.3 Multi-pump Wizard 0 1 0 1671

1.1.4 Fire mode Wizard 0 1 0 1672

0 = Do not activate

1 = Activate

The selection Activate

starts the Start-up

wizard (see Chapter

Table 1 The Start-up

wizard.

The selection Activate

starts the Multipump

wizard (see Chapter

2.7 Multipump wizard).

The selection Activate

starts the Fire mode

wizard (see Chapter

2.8 Fire mode wizard).

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 24

VACON · 24 QUICK STARTUP GUIDE

Table 6: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

0 = Standard

1.2

Application 0 5 1 212

1 = Local/Remote

2 = Multi-Step Speed

3 = PID Control

4 = Multi-Purpose

5 = Motor

Potentiometer

1.3

1.4

1.5 Acceleration Time 1 0.1 300.0 s 5.0 103

1.6 Deceleration Time 1 0.1 300.0 s 5.0 104

1.7 Motor Current Limit IH*0.1 I

Minimum Frequency

Reference

Maximum Frequency

Reference

0.00 P1.4 Hz 0.0 101

P1.3 320.0 Hz

S

A Varies 107

50.0 /

60.0

102

The minimum

frequency reference

that is acceptable.

The maximum

frequency reference

that is acceptable.

Gives the quantity of

time that is necessary

for the output

frequency to increase

from zero frequency to

the maximum

frequency.

Gives the quantity of

time that is necessary

for the output

frequency to decrease

from the maximum

frequency to zero

frequency.

The maximum motor

current from the AC

drive.

1

1.8 Motor Type 0 1 0 650

1.9

Motor Nominal

Voltage

Varies Varies V Varies 110

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

0 = Induction Motor

1 = Permanent Magnet

Motor

Find this value Un on

the rating plate of the

motor.

NOTE!

Find out if the motor

connection is Delta or

Star.

Page 25

QUICK STARTUP GUIDE VACON · 25

Table 6: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.10

1.11

1.12

1.13

1.14 Energy Optimization 0 1 0 666

Motor Nominal

Frequency

Motor Nominal

Speed

Motor Nominal

Current

Motor Cos Phi

(Power Factor)

8.0 320.0 Hz 50 / 60 111

24 19200 Rpm Varies 112

IH * 0.1 IH * 2 A Varies 113

0.30 1.00 Varies 120

Find this value fn on

the rating plate of the

motor.

Find this value nn on

the rating plate of the

motor.

Find this value In on

the rating plate of the

motor.

Find this value on the

rating plate of the

motor.

The drive searches for

the minimum motor

current to save energy

and to lower the motor

noise. Use this function

with, for example, fan

and pump processes.

0 = Disabled

1 = Enabled

1.15 Identification 0 2 0 631

1.16

1.17 Stop Function 0 1 0 506

Start Function 0 1 0 505

The identification run

calculates or measures

the motor parameters

that are necessary for

a good control of the

motor and speed.

0 = No action

1 = At standstill

2 = With rotation

Before you do the

identification run, you

must set the motor

nameplate parameters.

0 = Ramping

1 = Flying Start

0 = Coasting

1 = Ramping

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 26

VACON · 26 QUICK STARTUP GUIDE

Table 6: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.18 Automatic Reset 0 1 0 731

1.19

1.20

1.21

Response to External

Fault

Response to AI Low

Fault

Remote Control

Place

0 3 2 701

0 5 0 700

0 1 0 172

0 = Disabled

1 = Enabled

0 = No action

1 = Alarm

2 = Fault (Stop

according to stop

mode)

3 = Fault (Stop by

coasting)

0 = No action

1 = Alarm

2 = Alarm+preset fault

frequency (P3.9.1.13)

3 = Alarm + previous

frequency

4 = Fault (Stop

according to stop

mode)

5 = Fault (Stop by

coasting)

The selection of the

remote control place

(start/stop).

0 = I/O control

1 = Fieldbus control

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 27

QUICK STARTUP GUIDE VACON · 27

Table 6: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

The selection of the

frequency reference

source when the

control place is I/O A.

0 = Preset Frequency 0

1 = Keypad Reference

2 = Fieldbus

3 = AI1

4 = AI2

5 = AI1+AI2

6 = PID Reference

7 = Motor

Potentiometer

8 = Joystick Reference

9 = Jogging Reference

10 = Block Out.1

11 = Block Out.2

12 = Block Out.3

13 = Block Out.4

14 = Block Out.5

15 = Block Out.6

16 = Block Out.7

17 = Block Out.8

18 = Block Out.9

19 = Block Out.10

1.22

I/O Control

Reference A

Selection

0 9 3 117

The application that

you set with parameter

1.2 gives the default

value.

The selection of the

1.23

1.24

1.25 AI1 Signal Range 0 1 0 379

1.26 AI2 Signal Range 0 1 1 390

1.27 RO1 Function 0 51 2 1101 See P3.5.3.2.1

Keypad Control

Reference Selection

Fieldbus Control

Reference Selection

0 9 1 121

0 9 2 122

frequency reference

source when the

control place is keypad.

See P1.22.

The selection of the

frequency reference

source when the

control place is

fieldbus. See P1.22.

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 28

VACON · 28 QUICK STARTUP GUIDE

Table 6: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.28 RO2 Function 0 51 3 1104 See P3.5.3.2.1

1.29 RO3 Function 0 51 1 1107 See P3.5.3.2.1

1.30 AO1 Function 0 31 2 10050 See P3.5.4.1.1

Table 7: M1.32 Local/Remote

Index Parameter Min Max Unit Default ID Description

I/O Control

1.32.1

1.32.2 I/O B Control Force

1.32.3

1.32.4 Control Signal 1 B

1.32.5 Control Signal 2 B

1.32.6

1.32.7

1.32.8

Reference B

Selection

I/O B Reference

Force

Keypad Control

Force

Fieldbus Control

Force

External Fault

(Close)

1 20 4 131

DigIN

SlotA.6

DigIN

SlotA.6

DigIN

SlotA.4

DigIN

SlotA.5

DigIN

SlotA.1

DigIN

Slot0.1

DigIN

SlotA.3

425

343

423

424

410

411

405

See P1.22

TRUE = Force control

place to I/O B

TRUE = Used frequency

reference is specified

by I/O Reference B

parameter (P1.32.1)

Start signal 1 when

control place is I/O B

Start signal 1 when

control place is I/O B

Force Control to

Keypad

Force Control to

Fieldbus

FALSE = OK

TRUE = External fault

1

1.32.9 Fault Reset (Close)

DigIN

Slot0.1

Resets all active faults

414

when TRUE

1.4.3 MULTI-STEP SPEED APPLICATION

You can use the Multi-step speed application with processes where more than 1 fixed

frequency reference is necessary (for example test benches).

It is possible to use 1 + 7 frequency references: 1 basic reference (AI1 or AI2) and 7 preset

references.

Make a selection of the preset frequency references with digital signals DI4, DI5 and DI6. If

none of these inputs are active, the frequency reference is removed from the analogue input

(AI1 or AI2). Give the start/stop commands from the I/O terminal (DI1 and DI2).

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 29

*)

*)

mA

DI4DI5

1

FAULT

DI6

000

1

0

0

1

00

1

1

1

1

1

0

0

0

RUN

0

1

1

1

10

1

6

2

3

4

5

AO1+

RUN

18

AO1-19

+24Vin30

24Vout

12

GND7

GND13

DI18

DI29

DI310

DI414

DI515

DI616

RO1/1 NC21

22

RO1/2 CM

RO1/3 NO23

CM11

CM

17

RS485A

RS485

B

RO2/1 NC24

25

RO2/2 CM

RO2/3 NO26

32

RO3/2 CM

RO3/3 NO33

Reference

potentiometer

1...10 kΩ

Standard I/O board

Terminal Signal Description

+10Vref

AI1+

AI1-

AI2+

AI2-

24Vout

Reference output

Analogue input 1 +

Analogue input 1 -

Analogue input 2 +

Analogue input 2 -

Frequency

reference

(default 0...10V)

Frequency

reference

(default 4...20mA)

24V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Start forward

Start reverse

External fault

Common for DI1-DI6

Common for DI1-DI6

24V auxiliary voltage

I/O ground

Analogue output 1 +

Analogue output 1 -

24V auxiliary

input voltage

Output

frequency

(default:

0...20mA)

Modbus RTU,

BACnet, N2

READY

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

Analog input

Preset Freq. 1

Preset Freq. 2

Preset Freq. 3

Preset Freq. 4

Preset Freq. 5

Preset Freq. 6

Preset Freq. 7

Freq. ref.

FAULT

QUICK STARTUP GUIDE VACON · 29

It is possible to configure all the drive outputs freely in all the applications. There are 1

analogue output (Output Frequency) and 3 relay outputs (Run, Fault, Ready) available on the

basic I/O board.

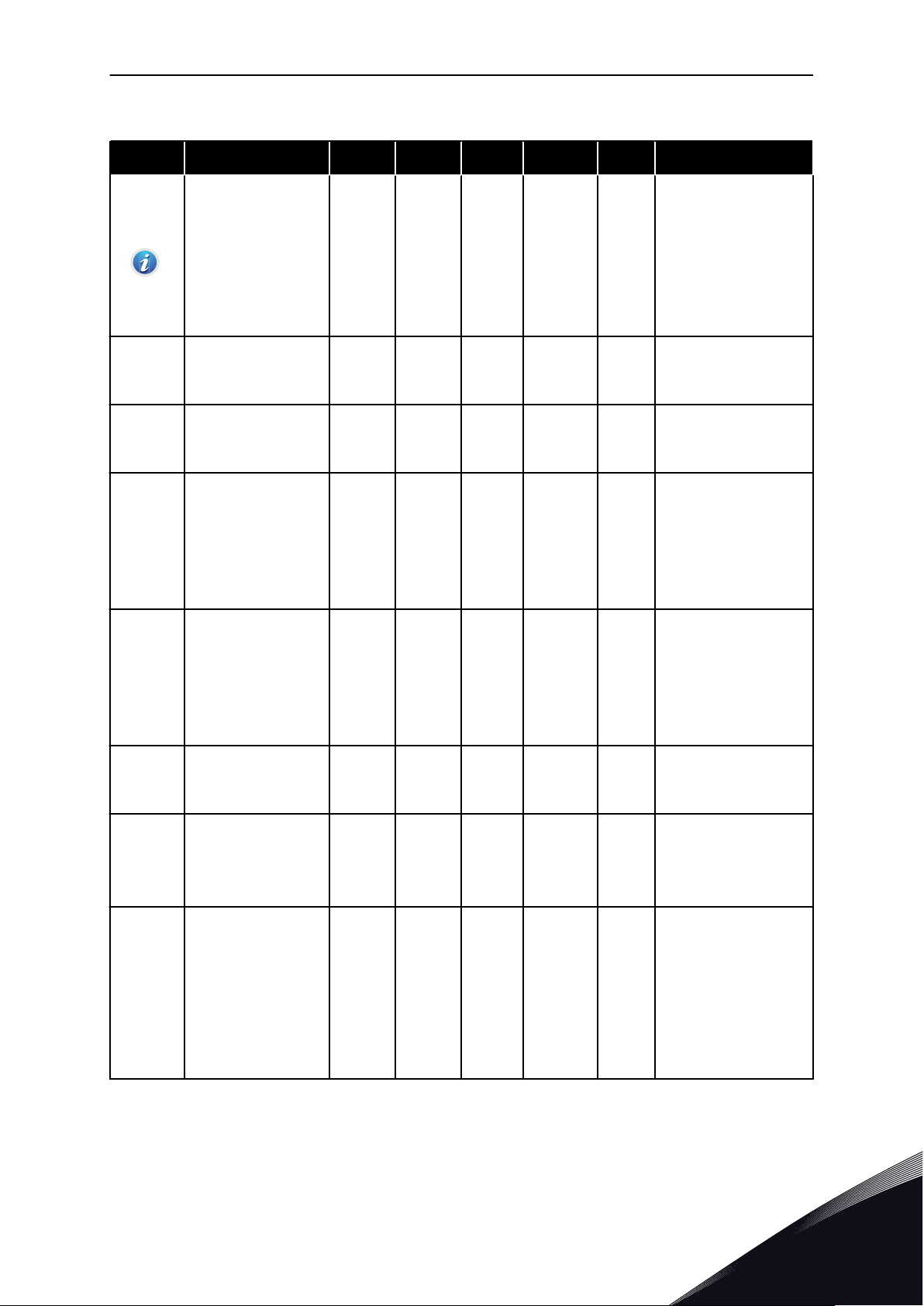

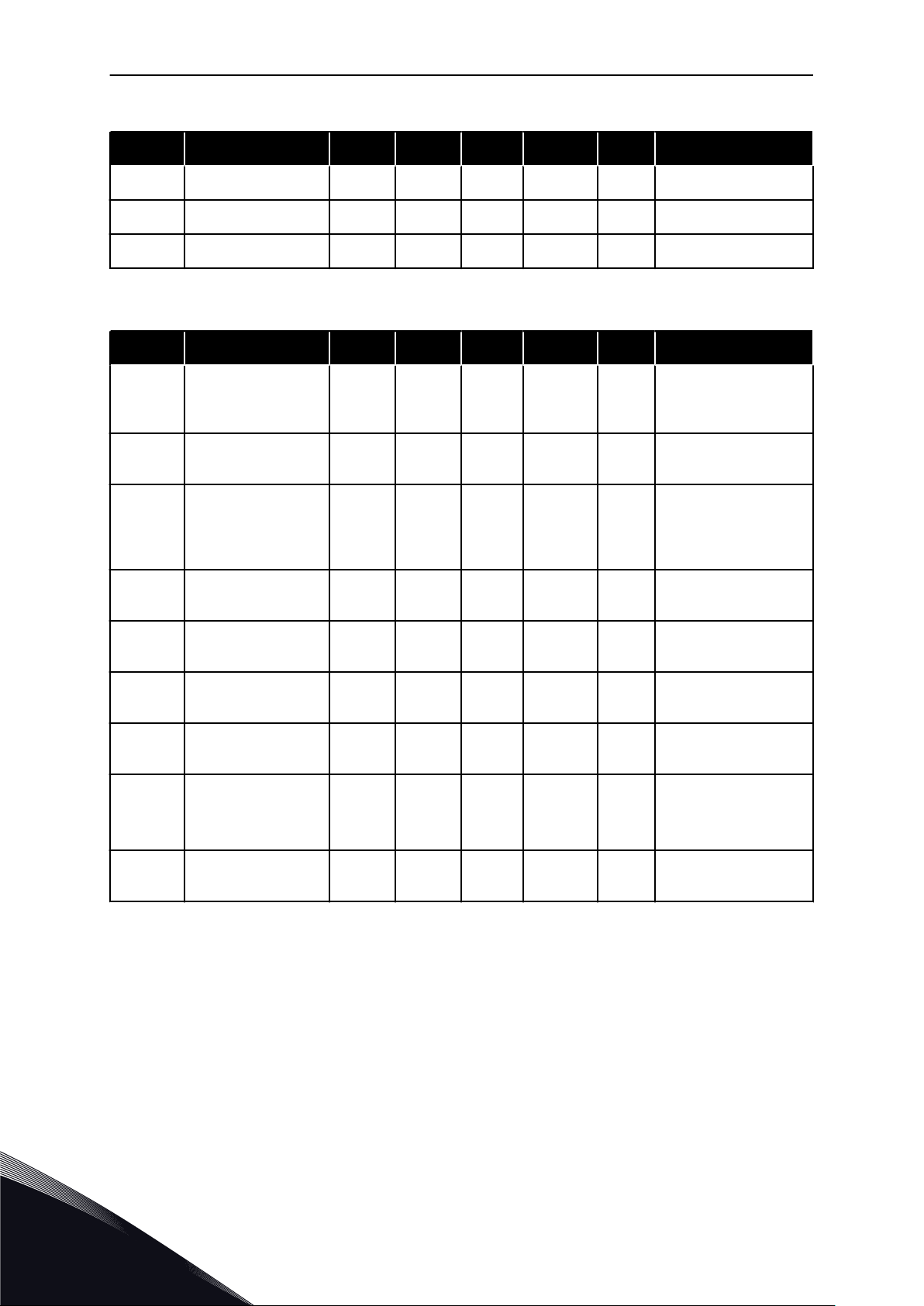

Fig. 8: The default control connections of the Multi-step speed application

* = You can isolate the digital inputs from the ground with a DIP switch.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 30

Digital inputs

Floating

Connected to GND

(Default!)

VACON · 30 QUICK STARTUP GUIDE

Fig. 9: The DIP switch

Table 8: M1.1 Wizards

Index Parameter Min Max Unit Default ID Description

1.1.1 Startup wizard 0 1 0 1170

1.1.3 Multi-pump Wizard 0 1 0 1671

1.1.4 Fire mode Wizard 0 1 0 1672

0 = Do not activate

1 = Activate

The selection Activate

starts the Start-up

wizard (see Chapter

Table 1 The Start-up

wizard.

The selection Activate

starts the Multipump

wizard (see Chapter

2.7 Multipump wizard).

The selection Activate

starts the Fire mode

wizard (see Chapter

2.8 Fire mode wizard).

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 31

QUICK STARTUP GUIDE VACON · 31

Table 9: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

0 = Standard

1.2

Application 0 5 2 212

1 = Local/Remote

2 = Multi-Step Speed

3 = PID Control

4 = Multi-Purpose

5 = Motor

Potentiometer

1.3

1.4

1.5 Acceleration Time 1 0.1 300.0 s 5.0 103

1.6 Deceleration Time 1 0.1 300.0 s 5.0 104

1.7 Motor Current Limit IH*0.1 I

Minimum Frequency

Reference

Maximum Frequency

Reference

0.00 P1.4 Hz 0.0 101

P1.3 320.0 Hz

S

A Varies 107

50.0 /

60.0

102

The minimum

frequency reference

that is acceptable.

The maximum

frequency reference

that is acceptable.

Gives the quantity of

time that is necessary

for the output

frequency to increase

from zero frequency to

the maximum

frequency.

Gives the quantity of

time that is necessary

for the output

frequency to decrease

from the maximum

frequency to zero

frequency.

The maximum motor

current from the AC

drive.

1.8 Motor Type 0 1 0 650

1.9

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Motor Nominal

Voltage

Varies Varies V Varies 110

0 = Induction Motor

1 = Permanent Magnet

Motor

Find this value Un on

the rating plate of the

motor.

NOTE!

Find out if the motor

connection is Delta or

Star.

1

Page 32

VACON · 32 QUICK STARTUP GUIDE

Table 9: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.10

1.11

1.12

1.13

1.14 Energy Optimization 0 1 0 666

Motor Nominal

Frequency

Motor Nominal

Speed

Motor Nominal

Current

Motor Cos Phi

(Power Factor)

8.0 320.0 Hz 50 / 60 111

24 19200 Rpm Varies 112

IH * 0.1 IH * 2 A Varies 113

0.30 1.00 Varies 120

Find this value fn on

the rating plate of the

motor.

Find this value nn on

the rating plate of the

motor.

Find this value In on

the rating plate of the

motor.

Find this value on the

rating plate of the

motor.

The drive searches for

the minimum motor

current to save energy

and to lower the motor

noise. Use this function

with, for example, fan

and pump processes.

0 = Disabled

1 = Enabled

1.15 Identification 0 2 0 631

1.16

1.17 Stop Function 0 1 0 506

Start Function 0 1 0 505

The identification run

calculates or measures

the motor parameters

that are necessary for

a good control of the

motor and speed.

0 = No action

1 = At standstill

2 = With rotation

Before you do the

identification run, you

must set the motor

nameplate parameters.

0 = Ramping

1 = Flying Start

0 = Coasting

1 = Ramping

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 33

QUICK STARTUP GUIDE VACON · 33

Table 9: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.18 Automatic Reset 0 1 0 731

1.19

1.20

1.21

Response to External

Fault

Response to AI Low

Fault

Remote Control

Place

0 3 2 701

0 5 0 700

0 1 0 172

0 = Disabled

1 = Enabled

0 = No action

1 = Alarm

2 = Fault (Stop

according to stop

mode)

3 = Fault (Stop by

coasting)

0 = No action

1 = Alarm

2 = Alarm+preset fault

frequency (P3.9.1.13)

3 = Alarm + previous

frequency

4 = Fault (Stop

according to stop

mode)

5 = Fault (Stop by

coasting)

The selection of the

remote control place

(start/stop).

0 = I/O control

1 = Fieldbus control

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 34

VACON · 34 QUICK STARTUP GUIDE

Table 9: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

The selection of the

frequency reference

source when the

control place is I/O A.

0 = Preset Frequency 0

1 = Keypad Reference

2 = Fieldbus

3 = AI1

4 = AI2

5 = AI1+AI2

6 = PID Reference

7 = Motor

Potentiometer

8 = Joystick Reference

9 = Jogging Reference

10 = Block Out.1

11 = Block Out.2

12 = Block Out.3

13 = Block Out.4

14 = Block Out.5

15 = Block Out.6

16 = Block Out.7

17 = Block Out.8

18 = Block Out.9

19 = Block Out.10

1.22

I/O Control

Reference A

Selection

0 9 5 117

The application that

you set with parameter

1.2 gives the default

value.

The selection of the

1.23

1.24

1.25 AI1 Signal Range 0 1 0 379

1.26 AI2 Signal Range 0 1 1 390

1.27 RO1 Function 0 51 2 1101 See P3.5.3.2.1

Keypad Control

Reference Selection

Fieldbus Control

Reference Selection

0 9 1 121

0 9 2 122

frequency reference

source when the

control place is keypad.

See P1.22.

The selection of the

frequency reference

source when the

control place is

fieldbus. See P1.22.

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 35

QUICK STARTUP GUIDE VACON · 35

Table 9: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.28 RO2 Function 0 51 3 1104 See P3.5.3.2.1

1.29 RO3 Function 0 51 1 1107 See P3.5.3.2.1

1.30 AO1 Function 0 31 2 10050 See P3.5.4.1.1

Table 10: M1.33 Multi-step speed

Index Parameter Min Max Unit Default ID Description

1.33.1 Preset Frequency 1 P1.3 P1.4 Hz 10.0 105

1.33.2 Preset Frequency 2 P1.3 P1.4 Hz 15.0 106

1.33.3 Preset Frequency 3 P1.3 P1.4 Hz 20.0 126

1.33.4 Preset Frequency 4 P1.3 P1.4 Hz 25.0 127

1.33.5 Preset Frequency 5 P1.3 P1.4 Hz 30.0 128

1.33.6 Preset Frequency 6 P1.3 P1.4 Hz 40.0 129

1.33.7 Preset Frequency 7 P1.3 P1.4 Hz 50.0 130

0 = Binary Coded

1 = Number of inputs.

1.33.8

1.33.9

1.33.10 Fault Reset (Close)

Preset Frequency

Mode

External Fault

(Close)

0 1 0 128

DigIN

SlotA.3

DigIN

Slot0.1

405

414

Preset frequency is

selected according to

how many of preset

speed digital inputs

are active.

FALSE = OK

TRUE = External fault

Resets all active faults

when TRUE

1.4.4 PID CONTROL APPLICATION

You can use the PID control application with processes where you control the process

variable (for example pressure) through control of the speed of the motor.

In this application, the internal PID controller of the drive is configured for 1 setpoint and 1

feedback signal.

It is possible to use 2 control places. Make the selection of the control place A or B with DI6.

When control place A is active, the start/stop commands are given by DI1, and the PID

controller gives the frequency reference. When control place B is active, start/stop

commands are given by DI4, and AI1 gives the frequency reference.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 36

VACON · 36 QUICK STARTUP GUIDE

It is possible to configure all the drive outputs freely in all the applications. There are 1

analogue output (Output Frequency) and 3 relay outputs (Run, Fault, Ready) available on the

basic I/O board.

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 37

RUN

FAULT

READY

Analogue input 1 +

Reference output+10 Vref

Terminal

Standard I/O board

Signal

1

24V auxiliary voltage24Vout6

Actual

value

2-wire

transmitter

I =

(0)4...20mA

AI1+

2

AI1-3

AI2+4

AI2-

5

AO1+

RUN

18

AO1-/GND19

+24Vin30

24V auxiliary voltage24Vout

12

I/O groundGND7

I/O groundGND13

Digital input 1DI18

Digital input 2DI29

Digital input 3DI310

Digital input 4DI414

Digital input 5DI515

Digital input 6DI616

Relay output 1

RO1/1 NC21

22

RO1/2 CM

RO1/3 NO23

Common for DI1-DI6CM11

Common for DI1-DI6CM

17

Serial bus, negativeRS485A

Serial bus, positiveRS485

B

Relay output 2

Relay output 3

RO2/1 NC24

25

RO2/2 CM

RO2/3 NO26

32

RO3/2 CM

RO3/3 NO33

Description

Place A: Start forward

(PID controller)

External fault

Preset frequency 1

Output frequency

(default: 0...20mA)

Modbus RTU

N2, BACnet

Fault reset

Place B: Start forward

(Freq. reference P3.3.1.6)

Control place A/B selection

-

Analogue input 1 Analogue input 2 +

Analogue input 2 -

Analogue output 1 +

Analogue output 1 -

FAULT

+

1...10kΩ

mA

*)

*)

24V auxiliary

input voltage

PID feedback

(actual value)

(default: 4...20mA)

Place A: PID setpoint

(reference)

Place B: Frequency

reference

(default: 0...10V)

Reference

potentiom-

eter

QUICK STARTUP GUIDE VACON · 37

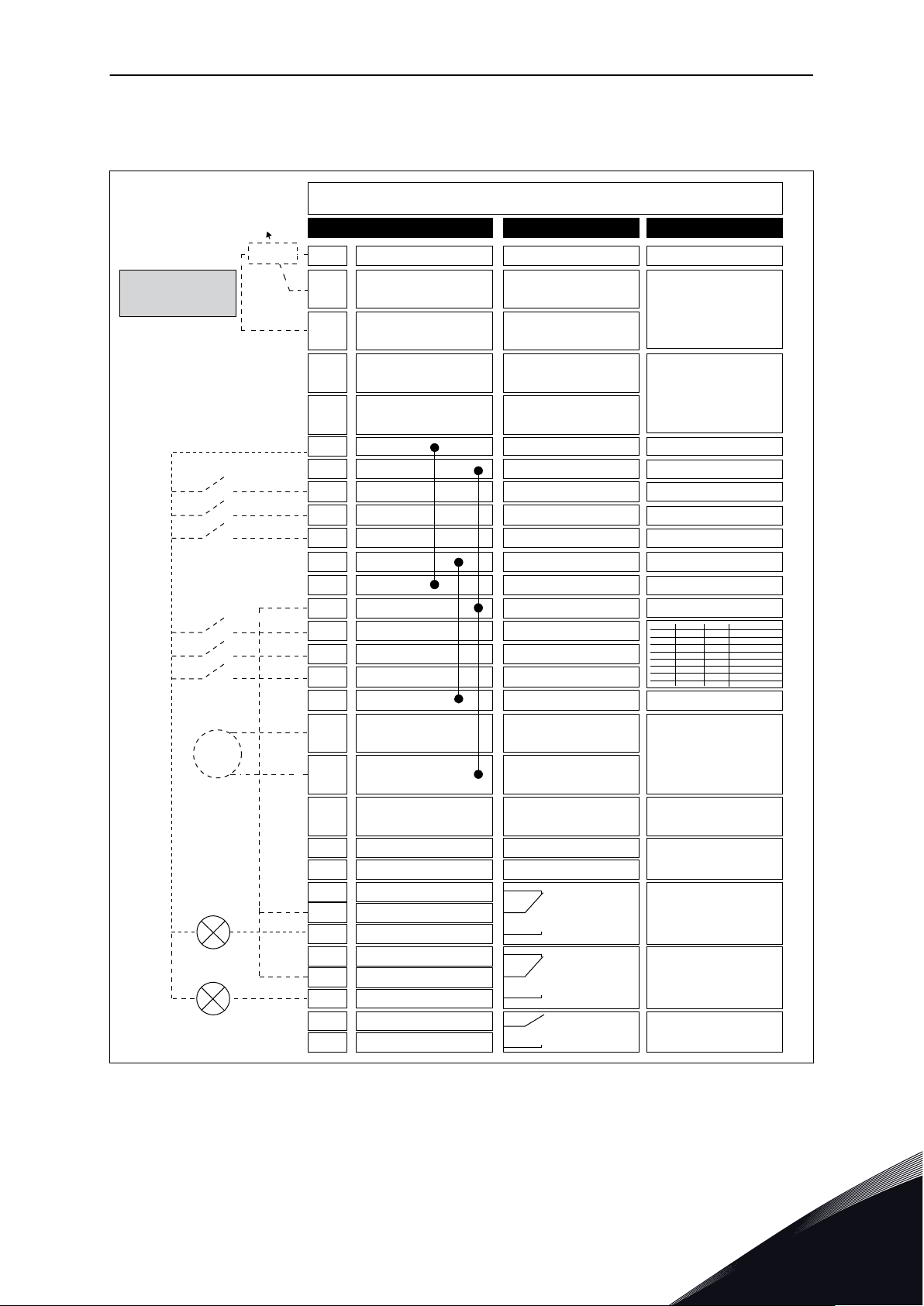

Fig. 10: The default control connections of the PID control application

* = You can isolate the digital inputs from the ground with a DIP switch.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 38

Digital inputs

Floating

Connected to GND

(Default!)

VACON · 38 QUICK STARTUP GUIDE

Fig. 11: The DIP switch

Table 11: M1.1 Wizards

Index Parameter Min Max Unit Default ID Description

1.1.1 Startup wizard 0 1 0 1170

1.1.3 Multi-pump Wizard 0 1 0 1671

1.1.4 Fire mode Wizard 0 1 0 1672

0 = Do not activate

1 = Activate

The selection Activate

starts the Start-up

wizard (see Chapter

Table 1 The Start-up

wizard.

The selection Activate

starts the Multipump

wizard (see Chapter

2.7 Multipump wizard).

The selection Activate

starts the Fire mode

wizard (see Chapter

2.8 Fire mode wizard).

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 39

QUICK STARTUP GUIDE VACON · 39

Table 12: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

0 = Standard

1.2

Application 0 5 3 212

1 = Local/Remote

2 = Multi-Step Speed

3 = PID Control

4 = Multi-Purpose

5 = Motor

Potentiometer

1.3

1.4

1.5 Acceleration Time 1 0.1 300.0 s 5.0 103

1.6 Deceleration Time 1 0.1 300.0 s 5.0 104

1.7 Motor Current Limit IH*0.1 I

Minimum Frequency

Reference

Maximum Frequency

Reference

0.00 P1.4 Hz 0.0 101

P1.3 320.0 Hz

S

A Varies 107

50.0 /

60.0

102

The minimum

frequency reference

that is acceptable.

The maximum

frequency reference

that is acceptable.

Gives the quantity of

time that is necessary

for the output

frequency to increase

from zero frequency to

the maximum

frequency.

Gives the quantity of

time that is necessary

for the output

frequency to decrease

from the maximum

frequency to zero

frequency.

The maximum motor

current from the AC

drive.

1.8 Motor Type 0 1 0 650

1.9

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Motor Nominal

Voltage

Varies Varies V Varies 110

0 = Induction Motor

1 = Permanent Magnet

Motor

Find this value Un on

the rating plate of the

motor.

NOTE!

Find out if the motor

connection is Delta or

Star.

1

Page 40

VACON · 40 QUICK STARTUP GUIDE

Table 12: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.10

1.11

1.12

1.13

1.14 Energy Optimization 0 1 0 666

Motor Nominal

Frequency

Motor Nominal

Speed

Motor Nominal

Current

Motor Cos Phi

(Power Factor)

8.0 320.0 Hz 50 / 60 111

24 19200 Rpm Varies 112

IH * 0.1 IH * 2 A Varies 113

0.30 1.00 Varies 120

Find this value fn on

the rating plate of the

motor.

Find this value nn on

the rating plate of the

motor.

Find this value In on

the rating plate of the

motor.

Find this value on the

rating plate of the

motor.

The drive searches for

the minimum motor

current to save energy

and to lower the motor

noise. Use this function

with, for example, fan

and pump processes.

0 = Disabled

1 = Enabled

1.15 Identification 0 2 0 631

1.16

1.17 Stop Function 0 1 0 506

Start Function 0 1 0 505

The identification run

calculates or measures

the motor parameters

that are necessary for

a good control of the

motor and speed.

0 = No action

1 = At standstill

2 = With rotation

Before you do the

identification run, you

must set the motor

nameplate parameters.

0 = Ramping

1 = Flying Start

0 = Coasting

1 = Ramping

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 41

QUICK STARTUP GUIDE VACON · 41

Table 12: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.18 Automatic Reset 0 1 0 731

1.19

1.20

1.21

Response to External

Fault

Response to AI Low

Fault

Remote Control

Place

0 3 2 701

0 5 0 700

0 1 0 172

0 = Disabled

1 = Enabled

0 = No action

1 = Alarm

2 = Fault (Stop

according to stop

mode)

3 = Fault (Stop by

coasting)

0 = No action

1 = Alarm

2 = Alarm+preset fault

frequency (P3.9.1.13)

3 = Alarm + previous

frequency

4 = Fault (Stop

according to stop

mode)

5 = Fault (Stop by

coasting)

The selection of the

remote control place

(start/stop).

0 = I/O control

1 = Fieldbus control

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 42

VACON · 42 QUICK STARTUP GUIDE

Table 12: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

The selection of the

frequency reference

source when the

control place is I/O A.

0 = Preset Frequency 0

1 = Keypad Reference

2 = Fieldbus

3 = AI1

4 = AI2

5 = AI1+AI2

6 = PID Reference

7 = Motor

Potentiometer

8 = Joystick Reference

9 = Jogging Reference

10 = Block Out.1

11 = Block Out.2

12 = Block Out.3

13 = Block Out.4

14 = Block Out.5

15 = Block Out.6

16 = Block Out.7

17 = Block Out.8

18 = Block Out.9

19 = Block Out.10

1.22

I/O Control

Reference A

Selection

0 9 6 117

The application that

you set with parameter

1.2 gives the default

value.

The selection of the

1.23

1.24

1.25 AI1 Signal Range 0 1 0 379

1.26 AI2 Signal Range 0 1 1 390

1.27 RO1 Function 0 51 2 1101 See P3.5.3.2.1

Keypad Control

Reference Selection

Fieldbus Control

Reference Selection

0 9 1 121

0 9 2 122

frequency reference

source when the

control place is keypad.

See P1.22.

The selection of the

frequency reference

source when the

control place is

fieldbus. See P1.22.

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 43

QUICK STARTUP GUIDE VACON · 43

Table 12: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.28 RO2 Function 0 51 3 1104 See P3.5.3.2.1

1.29 RO3 Function 0 51 1 1107 See P3.5.3.2.1

1.30 AO1 Function 0 31 2 10050 See P3.5.4.1.1

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 44

VACON · 44 QUICK STARTUP GUIDE

Table 13: M1.34 PID control

Index Parameter Min Max Unit Default ID Description

If the value of the

parameter is set to

100% a change of 10%

1.34.1 PID Gain 0.00 100.00 % 100.00 18

1.34.2 PID Integration Time 0.00 600.00 s 1.00 119

1.34.3 PID Derivation Time 0.00 100.00 s 0.00 1132

in the error value

causes the controller

output to change by

10%.

If this parameter is set

to 1,00s a change of

10% in the error value

causes the controller

output to change by

10.00%/s.

f this parameter is set

to 1,00s a change of

10% in the error value

during 1.00 s causes

the controller output to

change by 10.00%.

1.34.4

1.34.5

1.34.6 Keypad Setpoint 1 Varies Varies Varies 0 167

1.34.7

1.34.8 Sleep Delay 1 0 3000 s 0 1017

1.34.9 Wake-up Level 1 Varies Varies Varies Varies 1018

Feedback 1 Source

Selection

Setpoint 1 Source

Selection

Sleep Frequency

Limit 1

0 30 2 334

0 32 1 332

0.0 320.0 Hz 0.0 1016

See P3.13.3.3

See P3.13.2.6

Drive goes to sleep

mode when the output

frequency stays below

this limit for a time

greater than that

defined by parameter

Sleep delay.

The minimum amount

of time the frequency

has to remain below

the Sleep level before

the drive is stopped.

Defines the level for

the PID feedback value

wake-up supervision.

Uses selected process

units.

1

1.34.10 Preset Frequency 1 P1.3 P1.4 Hz 10.0 105

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Preset Frequency

selected by digital

input DI5.

Page 45

QUICK STARTUP GUIDE VACON · 45

1.4.5 MULTI-PURPOSE APPLICATION

You can use the Multi-purpose application for different processes (for example conveyors)

where a wide range of motor control functions is necessary.

It is possible to control the drive from the keypad, Fieldbus or I/O terminal. When you use I/O

terminal control, the start/stop commands are given through DI1 and DI2, and the frequency

reference from AI1 or AI2.

There are 2 acceleration/deceleration ramps available. The selection between Ramp1 and

Ramp2 is made by DI6.

It is possible to configure all the drive outputs freely in all the applications. There are 1

analogue output (Output Frequency) and 3 relay outputs (Run, Fault, Ready) available on the

basic I/O board.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 46

RUN

FAULT

READY

Analogue input 1 +

Reference output+10 Vref

Terminal

Standard I/O board

Signal

1

24V auxiliary voltage24Vout6

2-wire

transducer

(0)4...20mA

AI1+

2

AI1-3

AI2+

4

AI2-

5

AO1+

RUN

18

AO1-/GND19

24V auxiliary

input voltage

+24Vin30

24V auxiliary voltage24Vout

12

I/O groundGND7

I/O groundGND13

Digital input 1DI18

Digital input 2DI29

Digital input 3DI310

Digital input 4DI414

Digital input 5DI515

Digital input 6DI616

Relay output 1RO1/1 NC21

22

RO1/2 CM

RO1/3 NO23

Common for DI1-DI6CM11

Common for DI1-DI6CM

17

Serial bus, negativeRS485A

Serial bus, positiveRS485

B

Relay output 2

Relay output 3

RO2/1 NC24

25

RO2/2 CM

RO2/3 NO26

32

RO3/2 CM

RO3/3 NO33

Description

Preset frequency 1

Modbus RTU,

BACnet, N2

Fault reset

Ramp 1/Ramp 2 selection

+

-

Analogue input 1 Analogue input 2 +

Analogue input 2 -

Analogue output 1 +

Analogue output 1 -

FAULT

Frequency reference

(default 0...10V)

Frequency reference

(Default 4...20mA)

Start forward

Start reverse

External fault

Reference

potentiometer

1...10kΩ

mA

*)

*)

Output frequency

(0...20mA)

VACON · 46 QUICK STARTUP GUIDE

Fig. 12: The default control connections of the Multi-purpose application

* = You can isolate the digital inputs from the ground with a DIP switch.

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 47

Digital inputs

Floating

Connected to GND

(Default!)

QUICK STARTUP GUIDE VACON · 47

Fig. 13: The DIP switch

Table 14: M1.1 Wizards

Index Parameter Min Max Unit Default ID Description

1.1.1 Startup wizard 0 1 0 1170

1.1.3 Multi-pump Wizard 0 1 0 1671

1.1.4 Fire mode Wizard 0 1 0 1672

0 = Do not activate

1 = Activate

The selection Activate

starts the Start-up

wizard (see Chapter

Table 1 The Start-up

wizard.

The selection Activate

starts the Multipump

wizard (see Chapter

2.7 Multipump wizard).

The selection Activate

starts the Fire mode

wizard (see Chapter

2.8 Fire mode wizard).

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 48

VACON · 48 QUICK STARTUP GUIDE

Table 15: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

0 = Standard

1.2

Application 0 5 4 212

1 = Local/Remote

2 = Multi-Step Speed

3 = PID Control

4 = Multi-Purpose

5 = Motor

Potentiometer

1.3

1.4

1.5 Acceleration Time 1 0.1 300.0 s 5.0 103

1.6 Deceleration Time 1 0.1 300.0 s 5.0 104

1.7 Motor Current Limit IH*0.1 I

Minimum Frequency

Reference

Maximum Frequency

Reference

0.00 P1.4 Hz 0.0 101

P1.3 320.0 Hz

S

A Varies 107

50.0 /

60.0

102

The minimum

frequency reference

that is acceptable.

The maximum

frequency reference

that is acceptable.

Gives the quantity of

time that is necessary

for the output

frequency to increase

from zero frequency to

the maximum

frequency.

Gives the quantity of

time that is necessary

for the output

frequency to decrease

from the maximum

frequency to zero

frequency.

The maximum motor

current from the AC

drive.

1

1.8 Motor Type 0 1 0 650

1.9

Motor Nominal

Voltage

Varies Varies V Varies 110

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

0 = Induction Motor

1 = Permanent Magnet

Motor

Find this value Un on

the rating plate of the

motor.

NOTE!

Find out if the motor

connection is Delta or

Star.

Page 49

QUICK STARTUP GUIDE VACON · 49

Table 15: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.10

1.11

1.12

1.13

1.14 Energy Optimization 0 1 0 666

Motor Nominal

Frequency

Motor Nominal

Speed

Motor Nominal

Current

Motor Cos Phi

(Power Factor)

8.0 320.0 Hz 50 / 60 111

24 19200 Rpm Varies 112

IH * 0.1 IH * 2 A Varies 113

0.30 1.00 Varies 120

Find this value fn on

the rating plate of the

motor.

Find this value nn on

the rating plate of the

motor.

Find this value In on

the rating plate of the

motor.

Find this value on the

rating plate of the

motor.

The drive searches for

the minimum motor

current to save energy

and to lower the motor

noise. Use this function

with, for example, fan

and pump processes.

0 = Disabled

1 = Enabled

1.15 Identification 0 2 0 631

1.16

1.17 Stop Function 0 1 0 506

Start Function 0 1 0 505

The identification run

calculates or measures

the motor parameters

that are necessary for

a good control of the

motor and speed.

0 = No action

1 = At standstill

2 = With rotation

Before you do the

identification run, you

must set the motor

nameplate parameters.

0 = Ramping

1 = Flying Start

0 = Coasting

1 = Ramping

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 50

VACON · 50 QUICK STARTUP GUIDE

Table 15: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.18 Automatic Reset 0 1 0 731

1.19

1.20

1.21

Response to External

Fault

Response to AI Low

Fault

Remote Control

Place

0 3 2 701

0 5 0 700

0 1 0 172

0 = Disabled

1 = Enabled

0 = No action

1 = Alarm

2 = Fault (Stop

according to stop

mode)

3 = Fault (Stop by

coasting)

0 = No action

1 = Alarm

2 = Alarm+preset fault

frequency (P3.9.1.13)

3 = Alarm + previous

frequency

4 = Fault (Stop

according to stop

mode)

5 = Fault (Stop by

coasting)

The selection of the

remote control place

(start/stop).

0 = I/O control

1 = Fieldbus control

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 51

QUICK STARTUP GUIDE VACON · 51

Table 15: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

The selection of the

frequency reference

source when the

control place is I/O A.

0 = Preset Frequency 0

1 = Keypad Reference

2 = Fieldbus

3 = AI1

4 = AI2

5 = AI1+AI2

6 = PID Reference

7 = Motor

Potentiometer

8 = Joystick Reference

9 = Jogging Reference

10 = Block Out.1

11 = Block Out.2

12 = Block Out.3

13 = Block Out.4

14 = Block Out.5

15 = Block Out.6

16 = Block Out.7

17 = Block Out.8

18 = Block Out.9

19 = Block Out.10

1.22

I/O Control

Reference A

Selection

0 9 5 117

The application that

you set with parameter

1.2 gives the default

value.

The selection of the

1.23

1.24

1.25 AI1 Signal Range 0 1 0 379

1.26 AI2 Signal Range 0 1 0 390

1.27 RO1 Function 0 51 2 1101 See P3.5.3.2.1

Keypad Control

Reference Selection

Fieldbus Control

Reference Selection

0 9 1 121

0 9 2 122

frequency reference

source when the

control place is keypad.

See P1.22.

The selection of the

frequency reference

source when the

control place is

fieldbus. See P1.22.

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

0= 0..10V / 0..20mA

1= 2..10V / 4..20mA

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 52

VACON · 52 QUICK STARTUP GUIDE

Table 15: M1 Quick Setup

Index Parameter Min Max Unit Default ID Description

1.28 RO2 Function 0 51 3 1104 See P3.5.3.2.1

1.29 RO3 Function 0 51 1 1107 See P3.5.3.2.1

1.30 AO1 Function 0 31 2 10050 See P3.5.4.1.1

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 53

QUICK STARTUP GUIDE VACON · 53

Table 16: M1.35 Multi-purpose

Index Parameter Min Max Unit Default ID Description

0 = U/f Freq Control

open loop

1.35.1 Control Mode 0 2 0 600

1 = Speed control open

loop

2 = Torque Control

open loop

1.35.2 Auto Torque Boost 0 1 0 109

1.35.3 Acceleration Time 2 0.1 300.0 s 10.0 502

1.35.4 Deceleration Time 2 0.1 300.0 s 10.0 503

1.35.5 Preset Frequency 1 P1.3 P1.4 Hz 5.0 105

1.35.6 U/f Ratio Select 0 2 0 108

0 = Disabled

1 = Enabled

Defines the time that is

necessary for the

output frequency to

increase from zero

frequency to maximum

frequency.

Defines the time that is

necessary for the

output frequency to

decrease from

maximum frequency to

zero frequency.

Preset Frequency

selected by digital

input DI4.

Type of U/f curve

between zero

frequency and the field

weakening point.

1.35.7

1.35.8

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

Field Weakening

Point Frequency

Voltage at Field

Weakening Point

8.00 P1.4 Hz Varies 602

10.00 200.00 % 100.00 603

0 = Linear

1 = Squared

2 = Programmable

The field weakening

point is the output

frequency at which the

output voltage reaches

the field weakening

point voltage

Voltage at field

weakening point in %

of motor nominal

voltage

1

Page 54

VACON · 54 QUICK STARTUP GUIDE

Table 16: M1.35 Multi-purpose

Index Parameter Min Max Unit Default ID Description

Provided that the

programmable U/f

1.35.9

1.35.10 U/f Midpoint Voltage 0.0 100.00 % 100.0 605

1.35.11

U/f Midpoint

Frequency

Zero Frequency

Voltage

0.0 P1.35.7 Hz Varies 604

0.00 40.00 % Varies 606

curve has been

selected (par. P1.35.6),

this parameter defines

the middle point

frequency of the curve.

Provided that the

programmable U/f

curve has been

selected (par. P1.35.6),

this parameter defines

the middle point

voltage of the curve.

This parameter defines

the zero frequency

voltage of the U/f

curve. The default

value varies according

to unit size.

1.35.12

1.35.13

1.35.14 DC Brake Current Varies Varies A Varies 507

1.35.15

1.35.16

Start Magnetizing

Current

Start Magnetizing

Time

DC Braking time at

stop

Frequency to start

DC braking at ramp

stop

0.00 Varies A Varies 517

0.00 600.00 s 0.00 516

0.00 600.00 s 0.00 508

0.10 50.00 % 0.00 515

Defines the DC current

fed into motor at start.

Disabled if set to 0.

This parameter defines

the time for how long

DC current is fed to

motor before

acceleration starts.

Defines the current

injected into the motor

during DC braking.

0 = Disabled

Determines if braking

is ON or OFF and the

braking time of the DCbrake when the motor

is stopping.

The output frequency

at which the DCbraking is applied.

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page 55

QUICK STARTUP GUIDE VACON · 55

Table 16: M1.35 Multi-purpose

Index Parameter Min Max Unit Default ID Description

The drooping function

enables speed drop as

a function of load.

1.35.17 Load Drooping 0.00 50.00 % 0.00 620

1.35.18 Load Drooping Time 0.00 2.00 s 0.00 656

Drooping will be

defined in percent of

nominal speed at

nominal load.

Load drooping is used

in order to achieve a

dynamic speed

drooping because of

changing load. This

parameter defines the

time during which the

speed is restored to

the level it was before

the load increase.

0 = Normal; Load

drooping factor is

constant through the

1.35.19 Load Drooping Mode 0 1 0 1534

whole frequency range

1 = Linear removal;

Load drooping is

removed linearly from

nominal frequency to

zero frequency

1.4.6 MOTOR POTENTIOMETER APPLICATION

Use the Motor potentiometer application for the processes where the frequency reference of

the motor is controlled (that is, increased and decreased) through digital inputs.

In this application, the I/O terminal is set to the default control place. the start/stop

commands are given with DI1 and DI2. The frequency reference of the motor is increased

with DI5 and decreased with DI6.

It is possible to configure all the drive outputs freely in all the applications. There are 1

analogue output (Output Frequency) and 3 relay outputs (Run, Fault, Ready) available on the

basic I/O board.

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: VACON@VACON.COM

1

Page 56

*)

*)

mA

FAULT

RUN

1

6

2

3

4

5

RUN

18

AO1-/GND19

+24Vin30

24Vout

12

GND7

GND13

DI18

DI29

DI310

DI414

DI515

DI616

RO1/1 NC21

22

RO1/2 CM

RO1/3 NO23

CM11

CM

17

RS485A

RS485

B

RO2/1 NC24

25

RO2/2 CM

RO2/3 NO26

32

RO3/2 CM

RO3/3 NO33

Standard I/O board

Terminal Signal Description

+10Vref

AI1+

AI1-

AI2+

AI2-

24Vout

Reference output

Analogue input 1 +

Analogue input 1 -

Analogue input 2 +

Analogue input 2 -

Not used

Not used

24V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Start forward

Start reverse

External fault

Common for DI1-DI6

Common for DI1-DI6

24V auxiliary voltage

I/O ground

Analogue output 1 +

Analogue output 1 -

24V auxiliary

input voltage

Output

frequency

0...20mA)

Modbus RTU,

BACnet, N2

READY

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

FAULT

Preset frequency 1

Frequency reference UP

Frequency reference DOWN

AO1+

VACON · 56 QUICK STARTUP GUIDE

Fig. 14: The default control connections of the Motor potentiometer application

1