UTICA BOILERS SFM7275W, SFM27275W, SFM24150W, SFM36225W, SFM25175W Installation, Operation And Maintenance Manual

...

R

sFm constellation series

modUlar oil Fired cast iron Boilers

UTICA BOILERS

installation, operation and maintenance manUal

P.O. Box 4729

Utica, NY 13504-4729

www.uticaboilers.com

An ISO 9001-2000 Certied Company

P/N 27513401, Rev. A [01/09]

SFM SERIES MODULAR OIL FIRED CAST IRON BOILERS

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Safety Symbols ................................................ 2

Dimensions ..................................................... 4

Boiler Ratings & Capacities ............................5

Introduction ...................................................... 6

Connecting Supply & Return Piping............... 11

Primary Secondary Piping ..........................9-11

Ventilation & Combustion Air .........................7-8

Venting System Inspection & Installation ......12

Oil Tank Installation & Piping ....................12-13

Thermostat Installation ................................... 13

Operating Instructions .................................... 14

Control System .........................................16-17

Service Check List ......................................... 17

REPLACEMENT PARTS LISTS

Swing Door & Mounting Door Components ... 28

Jacket ............................................................. 28

Hardware .......................................................28

Controls & Hardware ...................................... 28

KEEP THIS MANUAL NEAR BOILER AND

RETAIN FOR FUTURE REFERENCE.

CAUTION

Indicates a potential hazardous situation which,

if not avoided, MAY result in minor or moderate injury. It may also be used to alert against

unsafe practices.

IMPORTANT: Read the following instructions

COMPLETELY before installing!

WARNING

1. Keep boiler area clear and free from combus-

tible materials, gasoline and other ammable

vapors and liquids.

2. DO NOT obstruct air openings to the boiler

room.

3. Modication, substitution or elimination of factory equipped, supplied or specied compo-

nents may result in property damage, personal

injury or the loss of life.

4. TO THE OWNER: Installation and service of

this boiler must be performed by a qualied

installer.

SAFETY SYMBOLS

The following dened symbols are used throughout

this manual to notify the reader of potential hazards

of varying risk levels.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or

serious injury.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, COULD result in death

or serious injury.

5. TO THE INSTALLER: Leave all instructions

with the boiler for future reference.

6. When this product is installed in the Commonwealth of Massachusetts the installation must be performed by a Licensed

Plumber or Licensed Gas Fitter.

Tested for 75 PSI ASME

Working Pressure

3

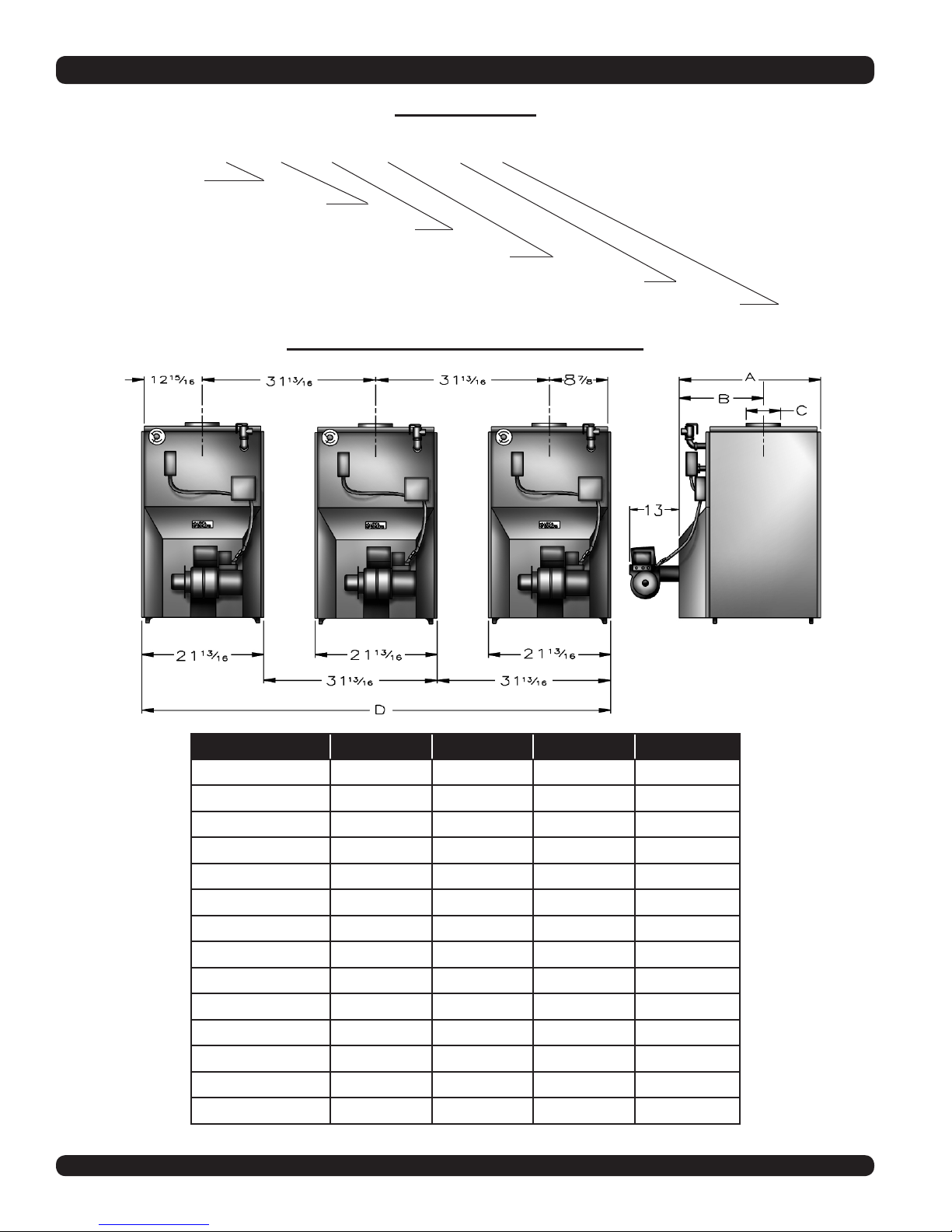

DIMENSIONS

MODEL # CODE

SF M 2 6 225 W

SERIES

MODULAR DESIGN

NO. OF PACKED BOILERS

SECTIONS PER BOILER

G.P.H. INPUT EACH FOR BOILER

TYPE OF UNIT

MULTIPLE BOILER DIMENSIONAL DATA

MODEL NO. A B C D

SFM6225W * 29 ¼” 13 ⅝” 8” ———

SFM7275W * 32 ⅞” 13 ⅝” 8” ———

SFM24150W 21 ½” 12 ⅝” 6” 53 13⁄16”

SFM25175W 25 ⅛” 14 ¼” 7” 53 13⁄16”

SFM25200W 25 ¼” 14 ¼” 7” 53 13⁄16”

SFM26225W 29 ¼” 13 ⅝” 8” 53 13⁄16”

SFM27275W 32 ⅞” 13 ⅝” 8” 53 13⁄16”

SFM36225W 29 ¼” 13 ⅝” 8” 85 7⁄16”

SFM37275W 32 ⅞” 13 ⅝” 8” 85 7⁄16”

SFM47275W 32 ⅞” 13 ⅝” 8” 87 13⁄16”

SFM57275W 32 ⅞” 13 ⅝” 8” 149 1⁄16”

SFM67275W 32 ⅞” 13 ⅝” 8” 181 13⁄16”

SFM77275W 32 ⅞” 13 ⅝” 8” 212 11⁄16”

SFM87275W 32 ⅞” 13 ⅝” 8” 245 ⅝”

* SFM6225W & SFM7275W are Single Module Units

4

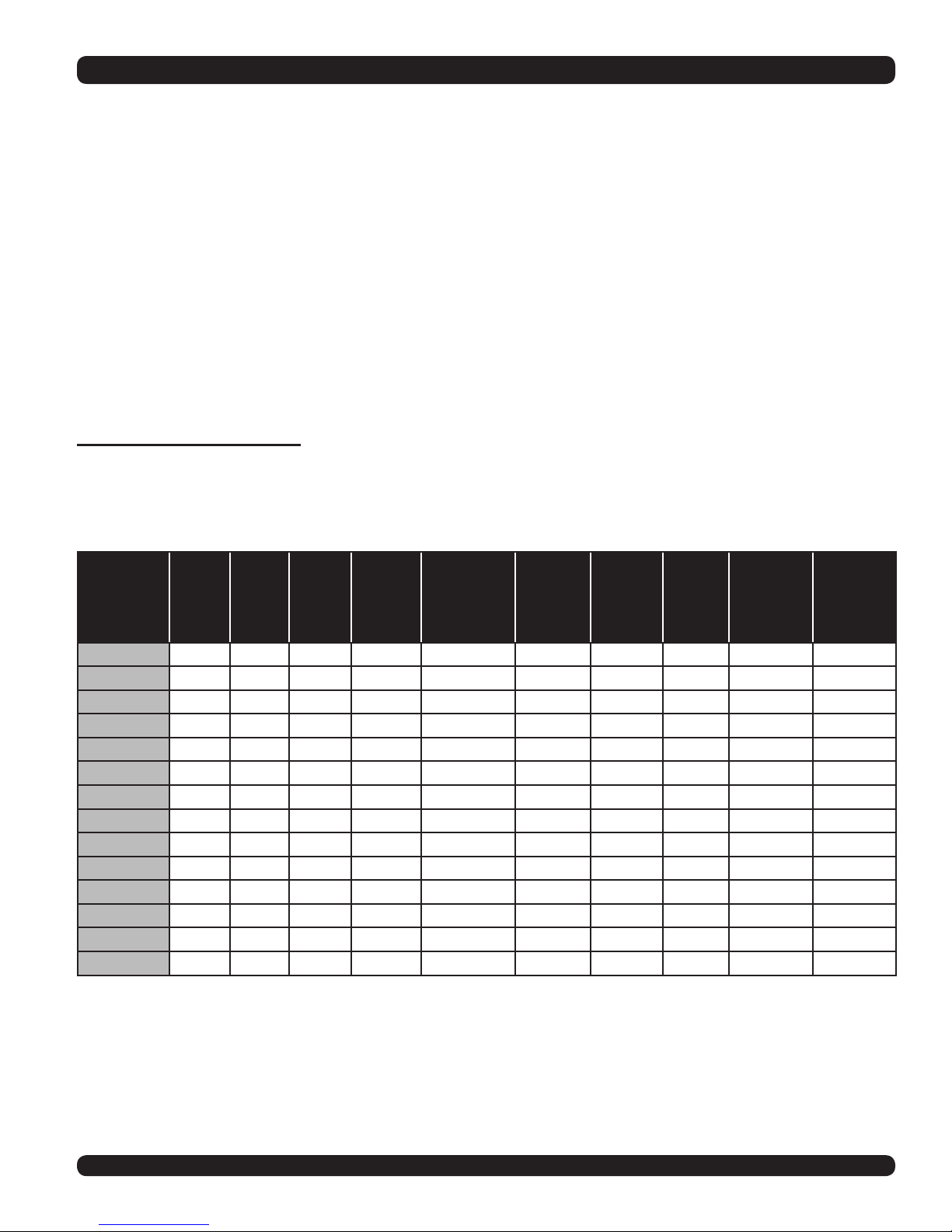

BOILER RATINGS, CAPACITIES & DIMENSIONS

NOTES:

1. Add sufx “T” to denote boiler with tankless heater.

2. I=B=R burner capacity is based on an oil heating value of 140,000 Btu/gal. and with 13% CO2.

3. For equivalent square feet of radiation, divide I=B=R output by 150.

4. Net ratings based on 170 0 F temperature in radiators and include 15% allowance for normal piping and pick-up load. Consult manufacturers for unusual piping and pick-up requirements.

5. Nozzle listed is for use with Beckett burner. When alternate burner is used, consult burner manufacturer’s recommendations.

6. Electrical service to be 120 Volts, 15 Amps, 60 Hz. (Each Boiler).

7. The MEA number for the SFM series is 182-86E.

8. The MEA number for the AFG burner is 213-83-E.

STANDARD EQUIPMENT: Crated Boiler, Flush Jacket, Oil Burner, Target Wall/Liner, ASME Relief Valve, Theralitimeter Gauge, Drain Cock, Wiring Harness, Burner Electrical Disconnect, Plastic

Cover, Supply Tapping - 2”, Return Tapping - 1 ¼”, High Limit and Circulator Control, Primary Control. For Tankless Heater Units-add Tankless Hot Water Coil.

TOTAL

FIRING

MODEL NO.

SFH6225W 2.25 315 254 221 SFM6225W 1 19.5 915 140 2.00 45B

SFH7275W 2.75 385 307 267.1 SFM7275W 1 22.5 1058 140 2.25 45B

SFM24150W 3.00 420 350 304 SFM4150W 2 27.0 1251 140 1.25 80B

SFM25175W 3.50 490 412 358 SFM5175W 2 33.0 1546 140 1.50 80B

SFM25200W 4.00 560 462 402 SFM5200W 2 33.0 1546 140 1.75 80B

SFM26225W 4.50 630 508 442 SFM6225W 2 39.0 1831 140 2.00 45B

SFM27275W 5.50 770 614 534.2 SFM7275W 2 45.0 2116 140 2.25 45B

SFM36225W 6.75 945 762 663 SFM6225W 3 58.5 2745 140 2.25 45B

SFM37275W 8.25 1155 921 801.3 SFM7275W 3 67.5 3174 140 2.25 45B

SFM47275W 11.00 1540 1228 1068.4 SFM7275W 4 90.0 4232 140 2.25 45B

SFM57275W 13.75 1925 1535 1335.5 SFM7275W 5 112.5 5290 140 2.25 45B

SFM67275W 16.50 2310 1842 1602.6 SFM7275W 6 135.0 6347 140 2.25 45B

SFM77275W 19.25 2695 2149 1869.7 SFM7275W 7 157.5 7905 140 2.25 45B

SFM87275W 22.00 3080 2456 2136.8 SFM7275W 8 180.0 8464 140 2.25 45B

RATE

G.P.H.

INPUT

M.B.H.

DOE

OUTPUT

M.B.H.

IBR

OUTPUT

M.B.H.

MODEL NO.

OF MODULES

NO. OF

MODULES

BOILER

WATER

VOLUME

GAL

BOILER

WEIGHT

LBS.

PUMP

PRESSURE

P.S.I

NOZZLE

FURNISHED

5

INTRODUCTION

All installations must conform to the requirements

of the authority having jurisdiction. Such applicable

requirements take precedence over the general

instructions of this manual.

Where required by the authority having jurisdiction, the installation must conform to the American

Society of Mechanical Engineers Safety Code for

Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME No. CSD-1.

LOCATE BOILERS in front of nal position before

removing crate. Provide a level solid base as near

the chimney as possible, and centrally located

with respect to the heat distribution system as

practical.

WARNING

BOILER MAY NOT BE INSTALLED ON

COMBUSTIBLE FLOORING.

Allow 24 inches in the front and top for servicing and

cleaning, or removing tankless water heating coil.

When installed in a utility room, the door should

be wide enough to allow the largest boiler part to

enter, or to permit replacement of another appliance such as a water heater.

FOR INSTALLATION ON NON-COMBUSTIBLE

FLOORS ONLY. The boiler must not be installed

on carpeting or vinyl ooring. Minimum clearances

to combustible construction are:

TOP .............................................24 IN.

FRONT ........................................24 IN.

FLUE CONNECTOR .....................9 IN.

REAR ............................................6 IN.

SIDES .........................................12 IN.

NOTE: Clearance for access should exceed

fore protection clearance.

REMOVE CRATE and plastic protective wrapper

and inspect for damage. All equipment is carefully

manufactured, inspected and packaged by experienced workers. Our responsibility ceases upon

delivery of the crated boiler to the carrier in good

condition. Any claims for damage or shortage in

shipment must be led immediately against the

carrier by the cosigner. Move boiler to permanent

position by sliding or walking.

6

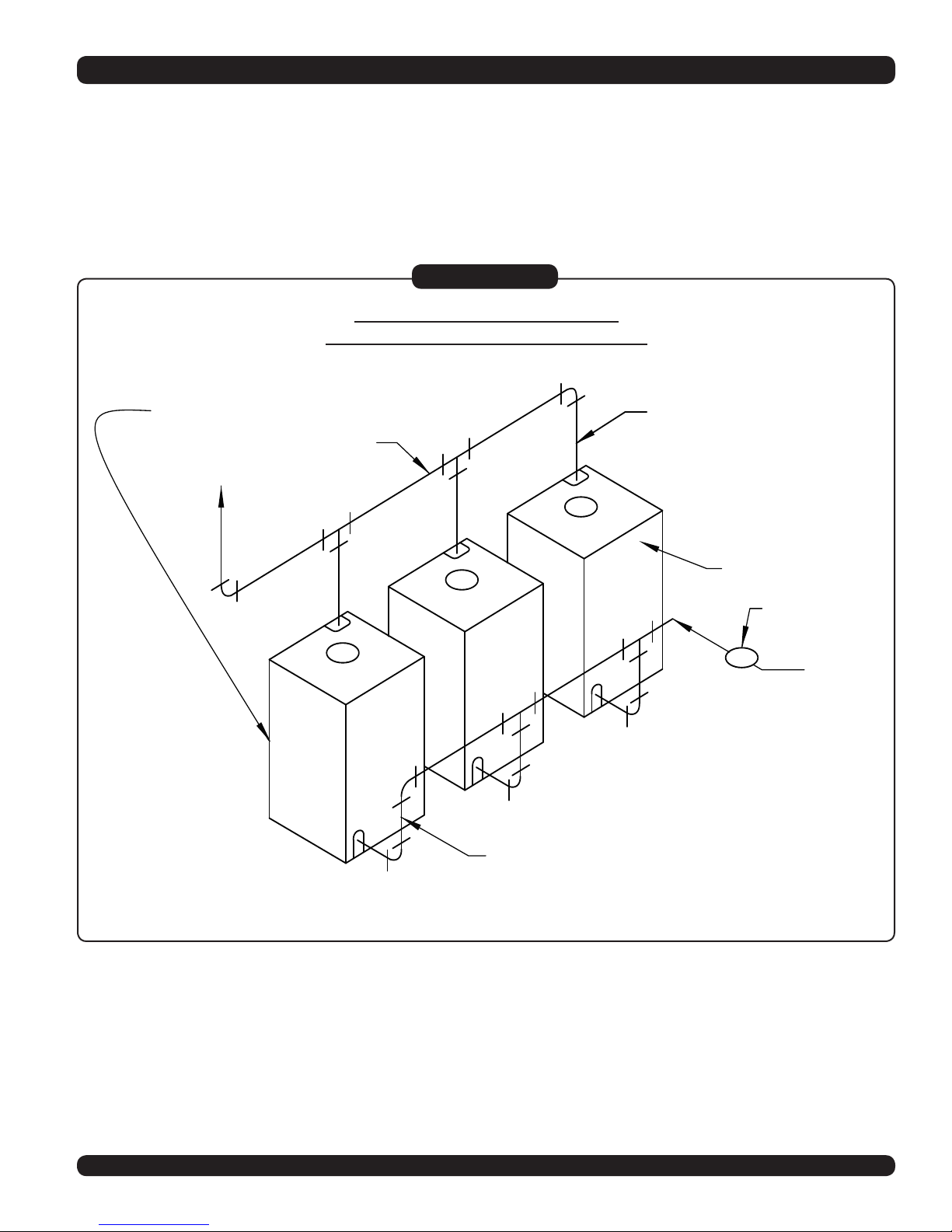

RETURN

SUPPLY

CIRCULATOR

REAR OF BOILER

FRONT OF BOILER

BRANCH

BRANCH

MAIN

CONNECTING SUPPLY AND RETURN PIPING

The recommended method of connecting the supply and return piping can be seen in

Figure #1 below.

(For detailed piping recommendations refer to the engineering manual)

Figure #1

MODULAR BOILER HOOK-UP

RECOMMENDED PARALLEL PIPING

7

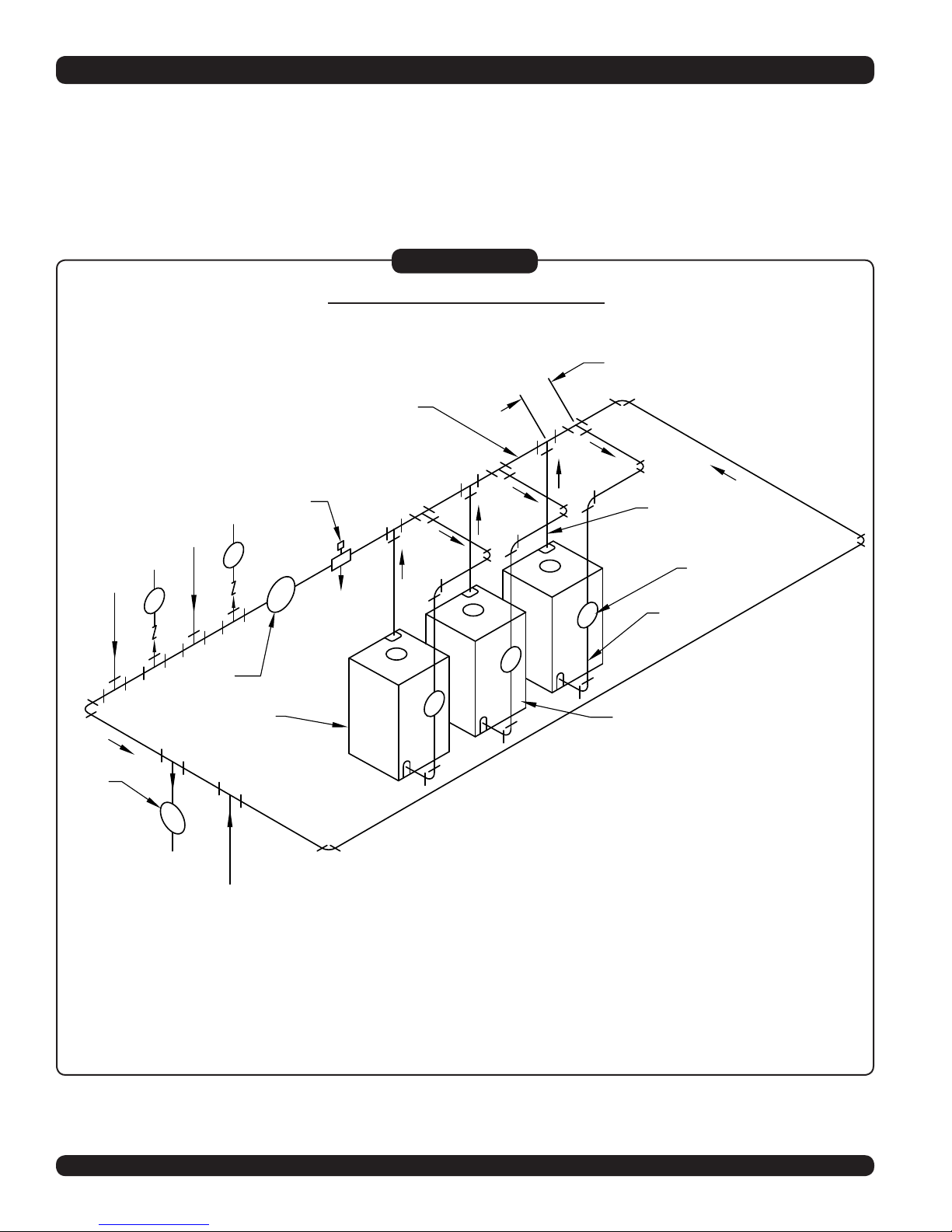

ZONE 1

ZONE2

ZONE 3

REAR OF

BOILER

BRANCH

BRANCH

12"

MAX

FRONT OF

BOILER

AIR

ELIMINATOR &

EXPANSION

TANK

PRIMARY

PUMP

PRIMARY

LOOP

SECONDARY

PUMP

LOAD

PUMPS

TO

EXPANSION

TANK &

SYSTEM

FILL

PRIMARY SECONDARY PIPING

An alternate method of connecting the supply and return piping can be seen in Figure #2

below.

(Refer to the engineering manual for detailed piping recommendations.)

Figure #2

PRIMARY SECONDARY PIPING

Note: The tapping sizes for the supply and return piping are 2” and 1 ½” respectively.

It is recommended that the main piping be 3” and the branches 1 ½”.

8

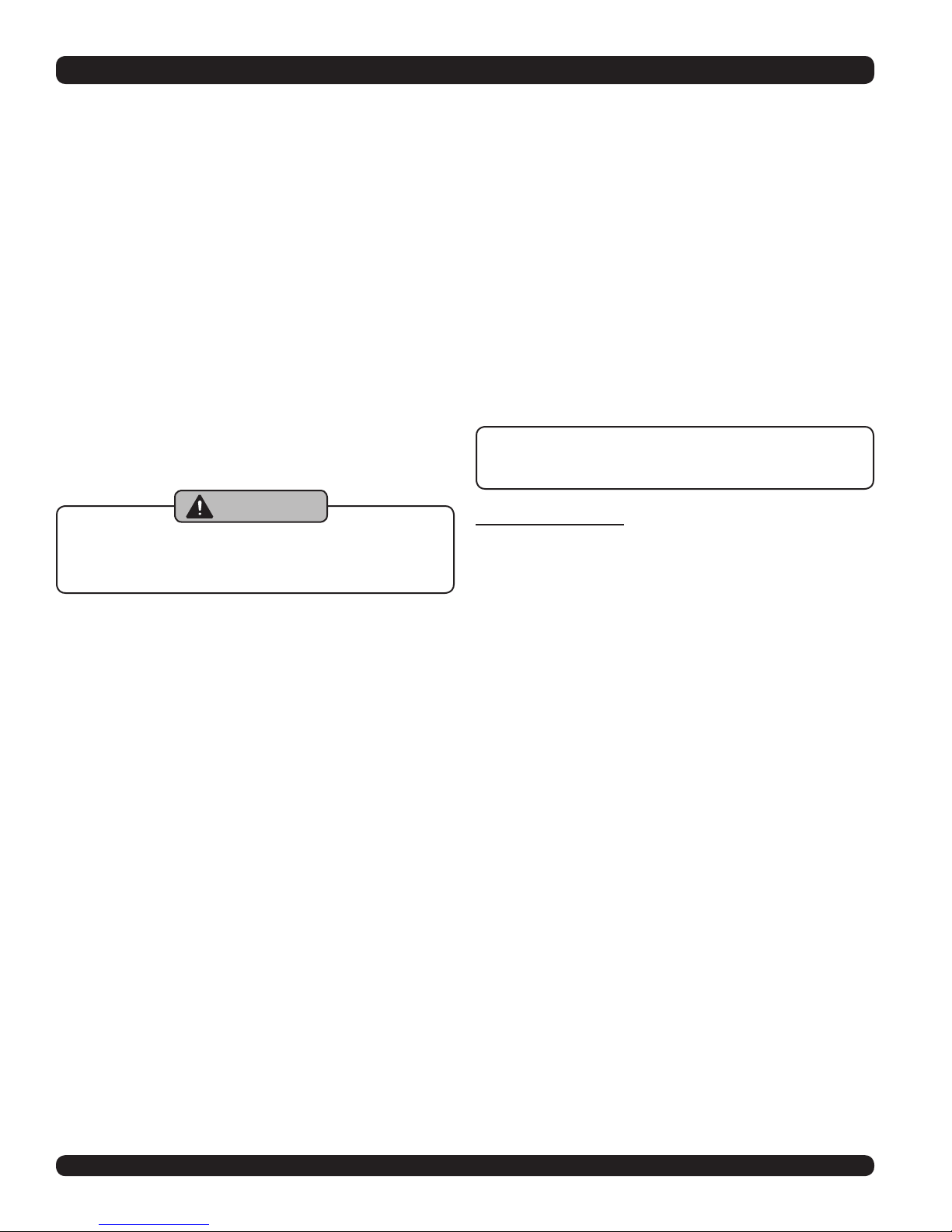

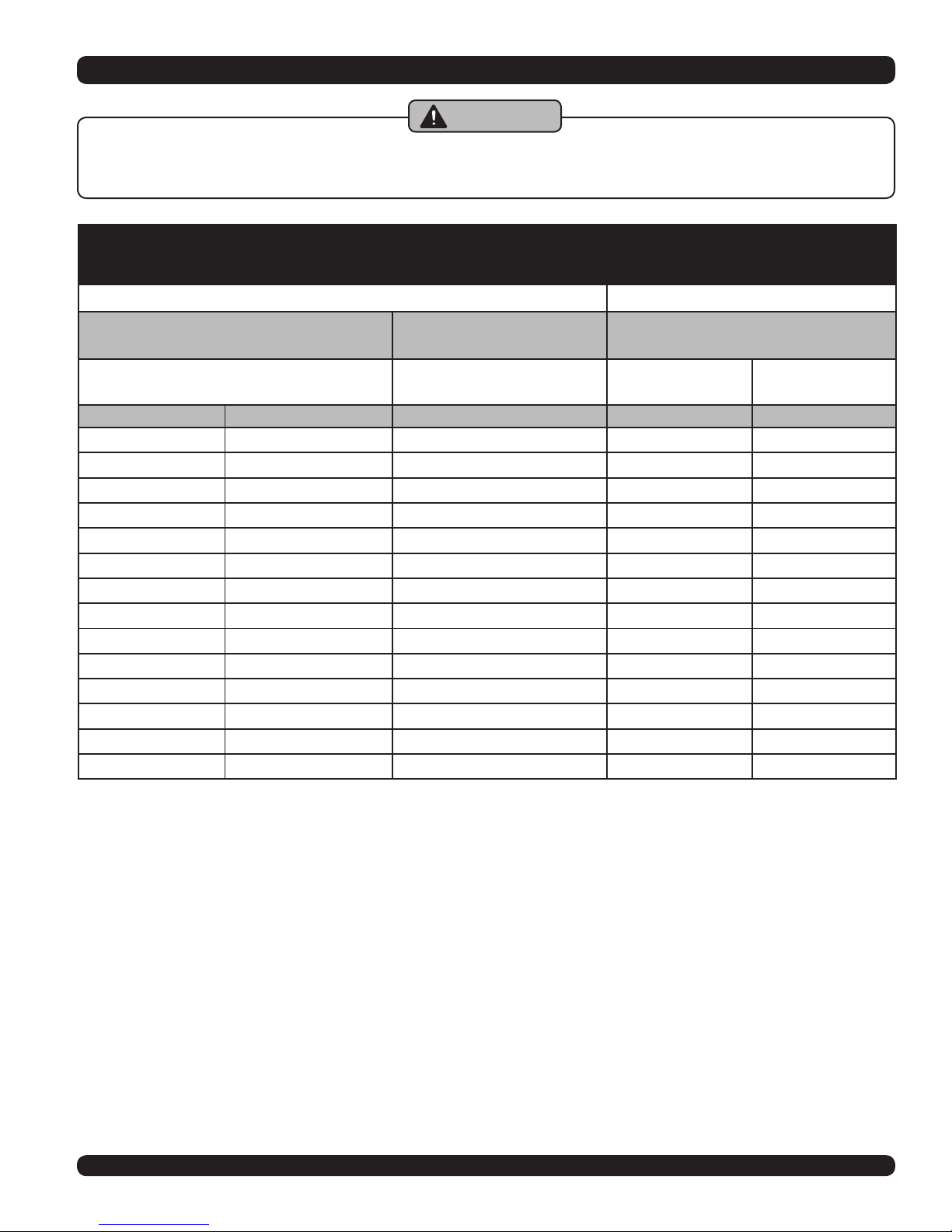

VENTILATION & COMBUSTION AIR

WARNING

AIR OPENINGS TO COMBUSTION AREA MUST NOT BE OBSTRUCTED. FOLLOW THE CHART

BELOW TO OBTAIN AND MAINTAIN ADEQUATE COMBUSTION AIR.

COMBUSTION AIR REQUIRMENTS

(MINIMUM OPENING IN SQUARE INCHES)

*UNCONFINED AREA **CONFINED AREA

OUTSIDE

COMBUSTION AIR

1 IN2/5000BTU

(PARAGRAPH 2)(SQ IN)

BTU/HR INPUT

COMBUSTION AIR

(MIN 100IN2) (FIG 4) (SQ IN)

315,000 63 315 78.75 158

385,000 77 385 96.25 193

420,000 84 420 105 210

490,000 98 490 123 245

560,000 112 560 140 280

630,000 126 630 158 315

770,000 154 770 193 385

945,000 189 945 237 473

1,155,000 231 1155 289 578

1,540,000 308 1540 385 770

1,925,000 385 1925 482 963

2,310,000 462 2310 578 1155

2,695,000 539 2695 675 1348

3,080,000 616 3080 770 1540

* Unconned area: A space whose volume is not less than 50 cubic feet per 1000 BTU per hour of all appliances in-

stalled in that space (cubic feet of space = height x width x length).

** Conned area: A space whose volume is less than 50 cubic feet per 1000 BTU per hour of all appliances installed in

that space (cubic feet of space = height x width x length).

INSIDE

1 IN2/1000 BTU

OUTSIDE

COMBUSTION AIR

1 IN2/4000 BTU

(FIG 3)(SQ IN)

1 IN2/2000 BTU

(FIG 3)(SQ IN)

1. When a boiler is located in an unconned

space in a building of conventional construction

frame, masonry or metal, inltration normally

is adequate to provide air for combustion and

ventilation. However, in any building which

has been altered to conserve energy or to

minimize inltration, the boiler area should

be considered as a CONFINED SPACE. If

there is any doubt, install air supply provisions

for combustion and ventilation in accordance

with section 5.3, Air for Combustion and Ventila-

tion, of the latest revision of the NFPA 54 code,

the recommendations that follow, or applicable

provisions of the local building codes.

2. When a boiler is installed in an unconned space,

in a building of unusually tight construction, air

for combustion and room ventilation must be

obtained from outdoors or from spaces freely

communicating with the outdoors. A permanent

opening or openings having a total free area

of not less than 1 square inch per 5,000 BTU

per hour of total input rating of all appliances

9

Loading...

Loading...