Utica Boilers PEG E Series Operation and Installation Manual

|

PEG-E |

|

GAS-FIRED |

Models |

STEAM BOILERS |

PEG075EID |

|

PEG112EID |

INSTALLATION, OPERATION & |

PEG150EID |

MAINTENANCE MANUAL |

PEG187EID |

|

PEG225EID |

|

PEG262EID |

|

PEG299EID |

|

MODEL

PEGEID

Electronic

Intermittent

Ignition

Manufactured by:

ECR International, Inc.

An ISO 9001-2008 Certified Company

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

P/N# 240009937, Rev. B [05/2014]

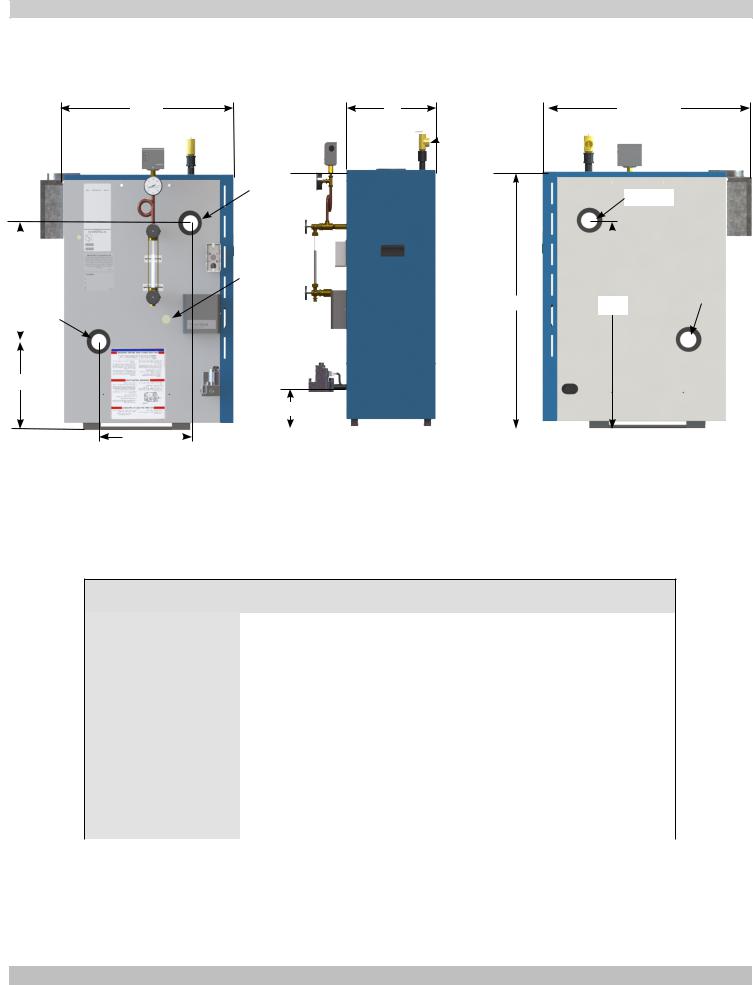

DIMENSIONS

Figure 1 - Dimensions

25" |

A |

Depth C

Safety

Relief

Relief

Valve

2" NPT |

2" NPT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

½" |

|

|

|

|

|

|

|

|

16 |

⅝" |

|

|

NPT |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

2" NPT |

||||

|

|

|

|

|

|

Plug |

|

B |

|

29" |

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

2" NPT |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12⅜"

5½"

|

|

|

Floor |

13½" |

|

|

|

|

Table 1 - Physical Data

Models |

075 |

|

112 |

|

150 |

|

187 |

|

|

225 |

|

262 |

|

299 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Width (A) |

10 |

7/ |

" |

14 |

1/ |

" |

17 |

3/ |

" |

20 |

5/ |

" |

23 |

7/ |

" |

27 |

1/ |

" |

30 |

3/ |

" |

||

|

|

|

8 |

|

|

8 |

|

|

8 |

|

|

8 |

|

|

|

8 |

|

|

8 |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height (B) |

|

|

|

|

|

|

|

|

|

35 |

7/ |

" |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Depth (C) |

28 |

3/ |

" |

28 |

3/ |

" |

29 |

3/ |

" |

30 |

3/ |

" |

30 |

3/ |

" |

30 |

3/ |

" |

30 |

3/ |

" |

||

|

|

|

8 |

|

|

8 |

|

|

8 |

|

|

8 |

|

|

|

8 |

|

|

8 |

|

|

8 |

|

Gas |

Size (G) |

½ NPT |

½ NPT |

½ NPT |

¾ NPT |

¾ NPT |

¾ NPT |

¾ NPT |

|||||||||||||||

Connection |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Flue Diameter |

5" |

|

5" |

|

6" |

|

7" |

|

|

7" |

|

7" |

|

7" |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

BOILER RATINGS AND CAPACITIES

Table 2 Ratings and Capacities

Natural Gas & Propane (LP)

Boiler Model |

Input |

Heating |

Net AHRI Rating (2) |

|

No. of |

Vent Pipe |

||

|

|

|

||||||

Capacity |

Steam, |

Steam, |

AFUE, % |

|||||

Number |

MBH (1) |

Sections |

Size |

|||||

MBH (1) |

|

|||||||

|

|

MBH |

Sq. Ft. |

|

|

|

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

PEG075EID |

75 |

62 |

47 |

195 |

82.2 |

3 |

5" |

|

|

|

|

|

|

|

|

|

|

PEG112EID |

112 |

93 |

70 |

292 |

82.4 |

4 |

5" |

|

|

|

|

|

|

|

|

|

|

PEG150EID |

150 |

125 |

94 |

391 |

82.6 |

5 |

6" |

|

|

|

|

|

|

|

|

|

|

PEG187EID |

187 |

156 |

117 |

488 |

82.8 |

6 |

7" |

|

|

|

|

|

|

|

|

|

|

PEG225EID |

225 |

188 |

141 |

587 |

83.0 |

7 |

7" |

|

|

|

|

|

|

|

|

|

|

PEG262EID |

262 |

219 |

164 |

685 |

83.2 |

8 |

7" |

|

|

|

|

|

|

|

|

|

|

PEG299EID |

299 |

250 |

188 |

782 |

83.4 |

9 |

7" |

|

|

|

|

|

|

|

|

|

|

Heating Capacity and AFUE are based on DOE (Department of Energy) test procedures.

1.Input rating for sea level to 2,000 ft. above sea level. Altitudes over 2000 ft. above sea level, reduce input rate 4% for every 1000 ft.

2.Net AHRI steam ratings shown are based on a piping and pickup allowance of 1.333. Consult manufacturer before selecting a boiler for installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping systems, etc.

3

TABLE OF CONTENTS

Important Safety Information....................... |

5 |

Locating the Boiler...................................... |

6 |

Hydronic Piping........................................... |

8 |

Fresh Air for Combustion............................. |

12 |

Chimney and Vent Pipe Connection............... |

13 |

Vent Damper Operation............................... |

15 |

Gas Supply Piping...................................... |

16 |

Electrical Wiring......................................... |

17 |

Operating Instructions................................ |

18 |

Operating Your Boiler.................................. |

19 |

Checking and Adjusting............................... |

20 |

Start-up Cleaning....................................... |

22 |

General Maintenance.................................. |

23 |

Troubleshooting......................................... |

24 |

Wire Diagrams........................................... |

25 |

Optional Hydronic Piping............................. |

28 |

Introduction

Boiler is designed for use in closed heating systems where all steam is returned as condensate and make-up water is minimal. Boiler is not designed for or intended for use in open systems using 100% make-up water.

Prior to Installation

•Verify correct boiler for type of gas being used natural or propane. See Rating Plate.

•Verify boiler size and dimensions. See Figure 1 and Table 1, page 2.

•Verify ratings and capacity data for natural gas. See Table 2.

Installation Requirements

•Supply boiler with correct gas (natural or propane), fresh air for combustion, and suitable electrical supply.

•Connect boiler to adequate venting and piping systems.

•Provide boiler with properly located and adjusted thermostat.

Installation of boiler in building under construction, use precaution to insure clean combustion air supply during construction process. Airborne particulate from construction materials can clog burner ports and cause incomplete combustion and sooting.

Complete all steps for safe and proper heating system operation.

KEEP THIS MANUAL NEAR BOILER

RETAIN FOR FUTURE REFERENCE

GAS FIRED STEAM BOILERS

Check our website frequently for updates: www.ecrinternational.com

Information and specifications outlined in this manual in effect at the time of printing of this manual. ECR International reserves the right to discontinue, change specifications or system design at any time without notice and without incurring any obligation, whatsoever.

4

IMPORTANT SAFETY INFORMATION

General

Boiler and venting installation shall be completed by qualified agency.

! WARNING

Fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read this manual and understand all requirements before beginning installation.

Become familiar with symbols identifying potential hazards.

This is the safety alert symbol. Symbol alerts you to potential personal injury hazards. Obey all safety messages following this symbol to avoid possible injury or death.

Installation shall conform to requirements of authority having jurisdiction or in absence of such requirements to the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

Where required by authority having jurisdiction, installation shall conform to Standard for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1. Controls can be added to make this boiler CSD-1 compliant. Check with your local

codes for requirements.

Requirements for Commonwealth of Massachusetts:

Boiler installation must conform to Commonwealth of Massachusetts code 248 CMR which includes but is not limited to installation by licensed plumber or gas fitter.

!DANGER

Indicates a hazardous situation which, if not avoided, WILL result in death or serious injury.

! WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

! CAUTION

Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE

Used to address practices not related to personal injury.

! WARNING

Installing or venting a boiler or any other gas appliance with improper methods or materials could result in death or serious injury due to fire or to asphyxiation from poisonous gases such as carbon monoxide which is odorless and invisible.

! WARNING

Fire, explosion, asphyxiation hazard. Keep boiler area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

Modification, substitution or elimination of factory equipped, supplied or specified components could result in death or serious injury.

5

LOCATING THE BOILER

Locating the Boiler

1.Select level location as centralized with piping system, and as near chimney as possible.

2.Place crated boiler at selected location. Remove all crate material. Please recycle responsibly.

!WARNING

Fire hazard. Do not install boiler on combustible flooring or carpeting. Failure to follow these instructions could result in death or serious injury.

3.Do not install boiler on carpeting. For installation on non-combustible floors only. For installation on combustible flooring, special base must be used. (See Replacement Parts Manual.)

4.Use metal shims under boiler base legs for final leveling if needed.

5.Install boiler in location that permits satisfactory combustion of gas, proper venting, and maintenance of ambient temperature at safe limits under normal conditions of use. Boiler location should not interfere with proper circulation of air. Introduce outside air if normal infiltration does not provide necessary air.“Fresh Air for Combustion” on page 12.

6.Notify owner to keep air passages free of obstruction. Ventilating and combustion air must enter boiler room without restrictions.

Table 3 -

Minimum Clearance Dimensions

Top |

6" |

Rear |

6" |

Control Side |

7" |

Opposite Side |

6" |

Front |

Alcove |

Flue/Vent |

6" |

Connector |

|

Near Boiler Piping |

1/2" |

7.Install boiler so automatic gas ignition system components are protected from water (dripping, spraying, rain, etc.) during appliance operation and service.

Draft Hood Installation

! WARNING

Asphyxiation, carbon monoxide hazard. Failure to follow these instructions could result in improper combustion and possible leakage of combustion products into the living space.

Follow directions given in Figure 3. Attach draft diverter, and blocked vent switch. Mount vent damper. See "Connecting Vent Damper and Vent Connector" page 13. See Wiring Diagrams pages 26 and 27.

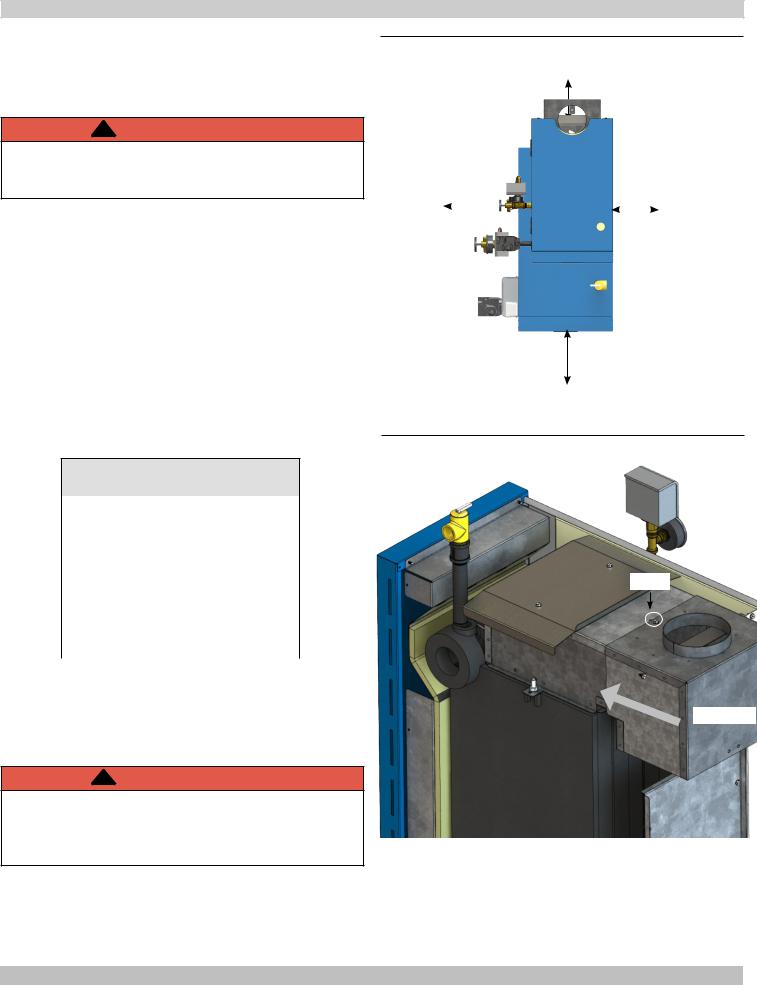

Figure 2 - Minimum Clearances To Combustible

Construction

6” (152mm)

View from top of boiler

Rear

7” |

|

Control Side |

Boiler |

OppositeideS |

|

6” |

|

||||||

|

|

|||||

(178mm) |

(152mm) |

|||||

|

|

|

|

|

||

Front

ALCOVE

Figure 3 - Draft Hood Installation

Screw

Draft Hood

Top and side panels not shown for clarity.

1. Slide draft hood over flue collector.

2. Through holes in jacket top, secure with 1 or 2 screws, based on boiler size.

6

LOCATING THE BOILER

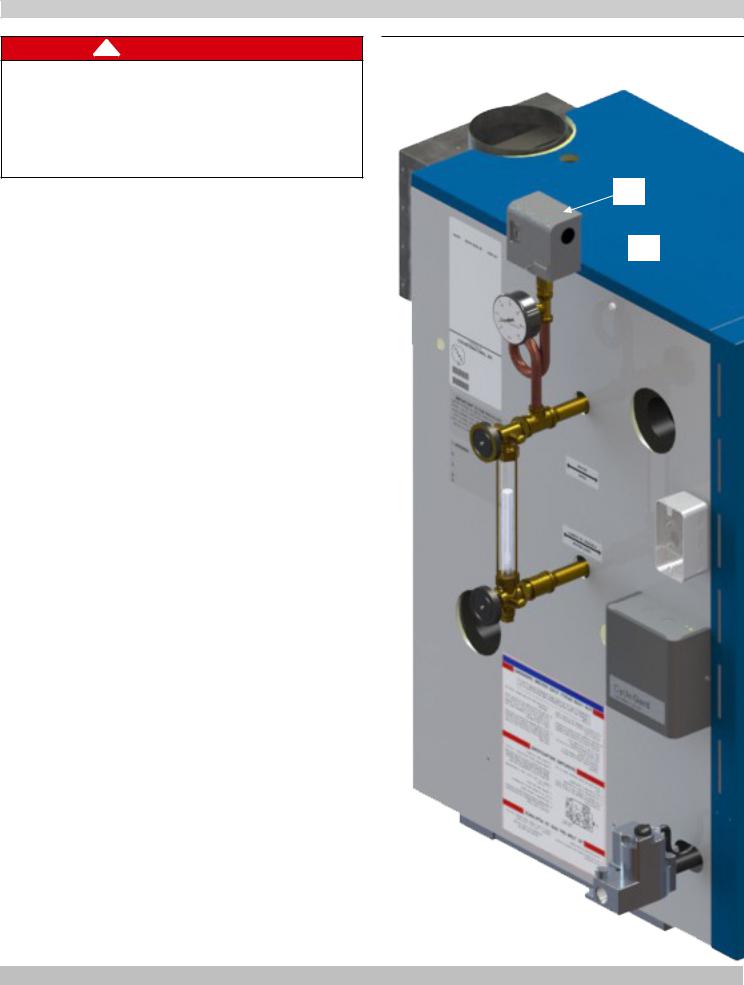

!DANGER

Burn, scald hazard. Pressuretrol must be installed by a qualified service agency in accordance with manufacturer’s instructions, all applicable codes and

requirements of authority having jurisdiction. Failure to follow the information in these instructions exactly will result in death or serious injury. Qualified service agency is responsible for proper installation.

Pressuretrol Assembly

Installation Instructions: See Figure 4.

1.Attach pressuretrol assembly (A) to site glass assembly, using proper pipe sealant.

2.Remove pressuretrol cover.

3.Route wire harness through black plastic bushing (B).

4.Attach two wires. Wires are not polarity sensitive, can place on either terminal.

5.Replace pressuretrol cover.

Figure 4 - Pressuretrol Assemly

A

B

B

7

HYDRONIC PIPING

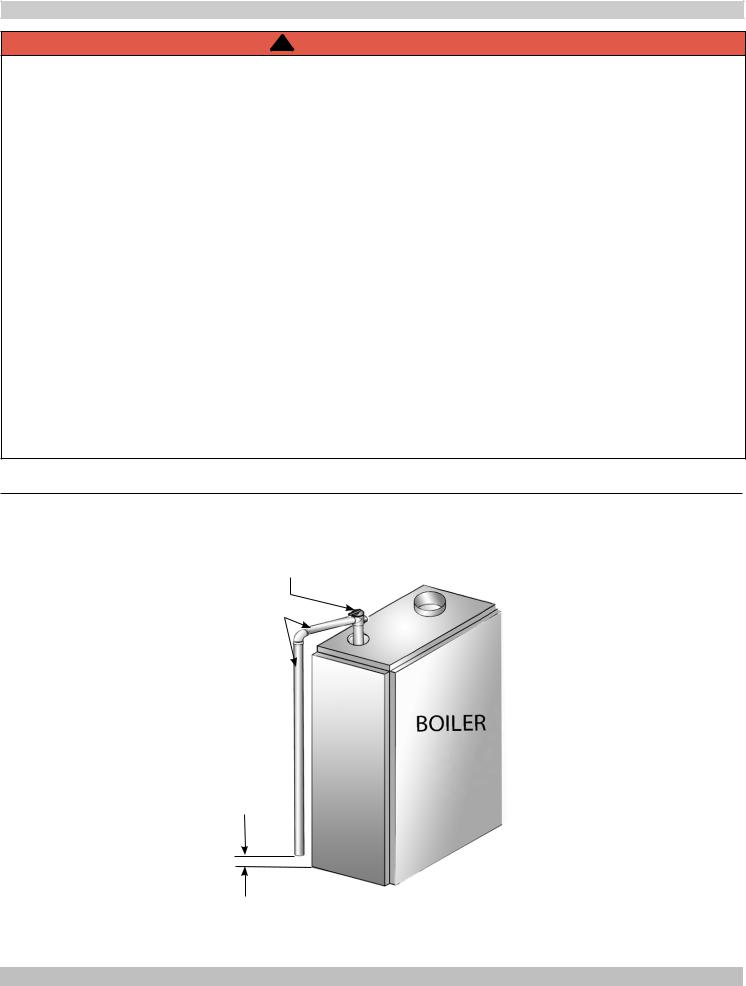

!WARNING

Burn or Scald Hazard. Discharge line shall be installed to relief valve outlet connection to avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation.

Discharge line shall:

•Connect to safety valve outlet. Piped down to safe point of disposal. Check local codes for maximum distance from floor or allowable safe point of discharge.

•Pipe size be of equal to or greater than of safety valve outlet over entire length of discharge line.

•Have no intervening shutoff valve between safety valve and discharge to atmosphere. Do not plug or place any obstruction in discharge line.

•Terminate freely to atmosphere where any discharge will be clearly visible and at no risk of freezing.

•Allow complete drainage of valve and discharge line.

•Install safety valve with spindle in vertical position.

•Do not install shutoff valve between boiler and safety valve.

•Support safety valve discharge piping.

•Be short and straight as possible.

•Terminate with plain end, not threaded.

•Constructed of material suitable for exposure to temperatures of 375° F (191°C); or greater.

Refer to local codes and appropriate ASME Boiler and Pressure Vessel Code for additional installation requirements.

Figure 5 - Safety Valve

Safety Valve

Discharge

Piping

Check local codes for maximum distance from floor or other allowable safe point of discharge

6" Above Floor

8

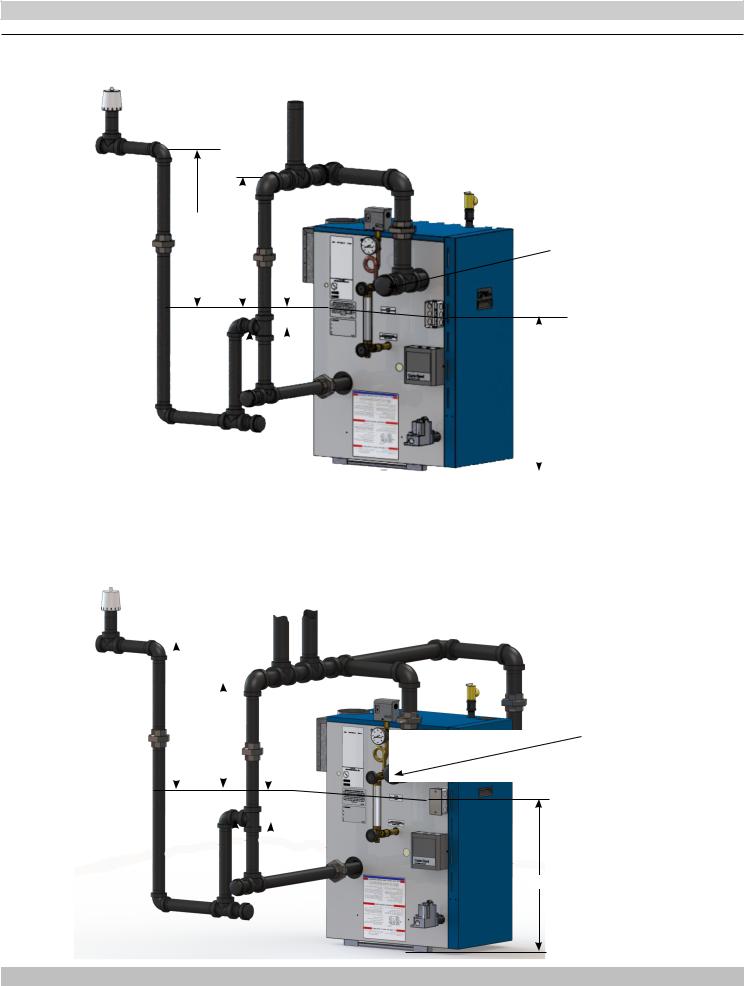

HYDRONIC PIPING

Consider near boiler piping as part of the boiler for proper water level control and to produce dry steam.

Correct near boiler piping is crucial to proper operation of boiler and heating system.

Follow these recommendations carefully.

1.Place boiler in selected location as near chimney as possible.

2.Install safety valve. Figure 5 and Warning on Page 8.

•Install union, if used, close to safety valve outlet.

•Install elbows close to safety valve outlet and downstream of union (if used).

3.Boiler is equipped with two 2" supply connections and two 2" return connections, one each on both left and right sides of boiler. Plug unused connections with furnished 2" plug and 2 x ¾ " bushing for drain valve.

4.When using both supply tappings to pipe system as shown in Figure 6b , Page 10.

•Fit headers with header offsets, swing joints, or equip with expansion joints, so thermal expansion and contraction of header does not damage boiler. Do not weld headers.

•Place system takeoffs from header between equalizer and riser to header nearest equalizer. System takeoffs must never be between two risers. If steam main goes in two directions, place two takeoffs from header, one for each main.

5.Recommended near boiler piping for gravity return systems is shown in Figure 8 page 11. For gravity return systems, bottom of lowest steam carrying pipe, dry return or end of steam main, must be at least 28” above normal water level line on left side of boiler.

6.Equip all boilers in gravity return systems with Hartford Loop as shown in Figure 6a and 6b page 10.

7.Piping vertical risers from boiler to header, risers must be minimum of 24" high above water line.

8.Steam riser(s) and header shall be 2" pipe.

9.Equalizer line shall be minimum 1-1/2" pipe size.

10.Near boiler piping shall include 2" tee with female adapter and cap located on supply line as shown for skimming (i.e. surface blow-down).

11.For pumped return systems, follow condensate pump or boiler feed pump manufacturer’s instructions for proper installation and hookup. See Table 4 and Figure 7 page 11.

12.Connecting cold water supply to water inlet valve, verify clean water supply is available. When water supply is from well or pump, install sand strainer at pump.

Table 4 - Steam Flow Rates (Gross)

Sections |

Flow Rates LBS/HR |

3 |

63.4 LBS/HR |

494.7 LBS/HR

5126.8 LBS/HR

6158.1 LBS/HR

7190.2 LBS/HR

8221.5 LBS/HR

9252.8 LBS/HR

9

HYDRONIC PIPING

Figure 6a - Recommended Near Boiler Piping Using One Supply Tapping

Main Vent |

|

|

|

|

|

Sections |

Risers |

Headers |

Equalizers |

||

|

|||||

|

|

|

|

|

|

|

3 |

2" |

2" |

1½ |

|

|

4 |

2" |

2" |

1½ |

Header

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

28" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

24" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cap To |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Skimmer Tee |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water Line |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Hartford Loop |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2" |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Close Nipple |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24" |

|

|

|

|

|

|

|

|

|

||

Equalizer 1½" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

For Alternate Piping Configurations |

|

|

|

|

|

|

|

|

|

|

|

|

Floor |

|

|

|

|

||||||||||||||||||||||

|

See Page 28 and 29 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Figure 6b - Recommended Near Boiler Piping Using Two Supply Tappings |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sections |

|

|

|

Risers |

|

Headers |

Equalizers |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

(2) 2" |

|

2" |

1½ |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Main Vent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

(2) 2" |

|

2" |

1½ |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

(2) 2" |

|

2½" |

1½ |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

(2) 2" |

|

3 |

1½ |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Header |

9 |

|

|

|

|

|

(2) 2" |

|

3 |

1½ |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cap To |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

24" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Skimmer Tee |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water Line |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

Hartford Loop |

2" |

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Close Nipple |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Equalizer 1½"

24"

For Alternate Piping Configurations

Floor

See Pages 28 and 29

10

Loading...

Loading...