Page 1

PEG-C

GAS FIRED BOILERS

FOR STEAM HEATING

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS

Utica Boilers P.O. Box 4729 Utica, NY 13504

Page 2

TABLE OF CONTENTS

Safety Symbols & Warnings ................................................................................. Page 1

Installation Procedure ........................................................................................... Page 2

Ventilation and Combustion Air ...................................................................... Pages 3-4

Connecting Supply and Return Piping ............................................................... Page 5-6

Vent Installation .................................................................................................... Page 7

Vent System Modification ..................................................................................... Page 8

Vent Damper Installation and Instructions ........................................................... Page 9

Connecting Gas Service ..................................................................................... Page 10

Electrical Wiring .................................................................................................. Page 10

Thermostat Installation ....................................................................................... Page 11

Lighting Instructions ................................................................................... Pages 11-13

Normal Sequence of Operation .......................................................................... Page 14

Connecting Supply And Return Piping Water-Chilled Medium ........................... Page 15

General Instructions .................................................................................... Pages 16-20

Replacement Parts Lists ............................................................................. Pages 20-25

Ratings, Data and Dimensions .......................................................................... Page 26

KEEP THIS MANUAL NEAR BOILER

RETAIN FOR FUTURE REFERENCE

SERIES PEG-C

CAST IRON

GAS FIRED BOILERS

INSTALLATION MANUAL AND

OPERATING INSTRUCTIONS

Published April 1997

Printed in USA

Made in USA

C.S.A. Certified

for Natural gas

or Propane

Tested for 100 lbs.

ASME Working

Pressure

Page 3

Safety Symbols

The following defined symbols are used throughout this manual to notify the

reader of potential hazards of varying risk levels.

DANGER

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

WARNING

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury

CAUTION

CAUTION - Indicates a potential hazardous situation which, if not avoided, MAY result

in minor or moderate injury. It may also be used to alert against unsafe practices.

IMPORTANT! READ ALL INSTRUCTIONS BEFORE INSTALLING.

WARNING:

1. Keep boiler area clear and free from combustible materials, gasoline and other

flammable vapors and liquids.

2. DO NOT obstruct air openings to the boiler room.

3. Modification, substitution or elimination of factory equipped, supplied or specified

components may result in property damage, personal injury or the loss of life.

4. To the owner: Installation and service of this boiler must be performed by a qualified

installer.

5. To the installer: Leave all instructions with the boiler for future reference.

6. When this product is installed in the Commonwealth of Massachusetts the installation

must be performed by a Licensed Plumber or Licensed Gas Fitter.

WARNING: ALL INSTALLATIONS OF BOILERS AND VENTING

SHOULD BE DONE ONLY BY A QUALIFIED EXPERT AND IN

ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL.

INSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCE

WITH IMPROPER METHODS OR MATERIALS MAY RESULT IN SERIOUS

INJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION FROM

POISONOUS GASES SUCH AS CARBON MONOXIDE WHICH IS

ODORLESS AND INVISIBLE.

PAGE 1

Page 4

INSTALLATION PROCEDURE

WARNING:

maintenance can cause injury or property damage.

1. The installation must conform to the requirements of the authority having jurisdiction

or, in absence of such requirements, to the latest revision of the National Fuel Gas Code,

ANSI Z223.1. (Available from the American Gas Association, Pleasant Valley Road,

Cleveland, Ohio 44134.) Reference should also be made to local gas utility regulations and

other codes in effect in the area that the installation is to be made.

2. Where required by the authority having jurisdiction, the installation must conform to

American Society of Mechanical Engineers Safety Code for Controls and Safety Devices

For Automatically Fired Boilers, No.CSD-1.

3. This boiler is classified as a Category 1 appliance and the vent installation shall be

in accordance with Part 7 & 11 of the latest revision of the National Fuel Gas Code noted

above or applicable provisions of the local building codes. See Vent Installation on page 7.

4. This boiler meets safe lighting and other preference criteria with the gas manifold and

control assembly provided on the boiler per the latest revision of ANSI Z21.13b.

5. This boiler shall be installed such that the gas ignition system components are

protected from water (dripping, spraying, rain, etc.) during appliance operation and service,

(circulator replacement, condensate trap, control replacement, etc.).

Improper installation, adjustment, alteration, service or

6. LOCATE BOILER on level, solid base as near chimney as possible and centrally

located with respect to the heat distribution system as practical.

7. ALLOW 24 inches at the front and right side for servicing and cleaning.

8. When installing in a utility room, the door should be wide enough to allow the largest

boiler part to enter, or to permit replacement of another appliance such as a water heater.

9. FOR INSTALLATION ON NONCOMBUSTIBLE FLOORS ONLY. *The boiler must

not be installed on carpeting. Minimum clearances to combustible construction are:

TOP.................................................................... 24 IN.

FRONT .......................................................... ALCOVE

FLUE COLLECTOR ............................................. 6 IN.

REAR ................................................................... 8 IN.

SIDES .................................................................. 6 IN.

NOTE: GREATER CLEARANCES FOR ACCESS SHOULD SUPERSEDE FIRE

PROTECTION CLEARANCE.

PAGE 2

Page 5

VENTILATION & COMBUSTION AIR

WARNING:

AIR OPENINGS TO COMBUSTION AREA MUST NOT BE

OBSTRUCTED. BY FOLLOWING THE INSTRUCTIONS BELOW, ADEQUATE

COMBUSTION AIR CAN BE MAINTAINED

* Unconfined area: A space whose volume is not less than 50 cubic feet per 1000

BTU per hour of all appliances installed in that space (cubic feet of space = height x

width x length).

** Confined area: A space whose volume is less than 50 cubic feet per 1000 BTU per

hour of all appliances installed in that space (cubic feet of space = height x width x

length).

1. Ventilation of the boiler room must be adequate to provide sufficient air to properly

support combustion per the latest revision of the National Fuel Gas Code, ANSI Z223.1

section 5.3.

2. When a boiler is located in an unconfined space in a building or conventional construction

frame, masonry or metal building, infiltration normally is adequate to provide air for

combustion and ventilation. However, if the equipment is located in a building of unusually tight

construction (See the national Fuel Gas Code, Ansi Z223.1 section 1.7), the boiler area

should be considered as a confined space. In this case air for combustion and ventilation shall

be provided according to part 5 on page 4. If there is any doubt, install air supply provisions

in accordance with the latest revision of the National Fuel Gas Code.

3. When a boiler is installed in an unconfined

space, in a building of unusually tight

construction, air for combustion and ventilation

must be obtained from outdoors or from

spaces freely communicating with the

outdoors. A permanent opening or openings

having a total free area of not less than 1

square inch per 5,000 BTU per hour of total

input rating of all appliances shall be provided.

Ducts may be used to convey makeup air

from the outdoors and shall have the same

cross-sectional area of the openings to which

they are connected.

4. When air for combustion and ventilation

is from inside buildings, the confined space

shall be provided with two permanent

openings, one starting 12 inches from the top

FIGURE 1

and one 12 inches from the bottom of the

enclosed space. Each opening shall have a

minimum free area of 1 square inch per one thousand (1000) BTU per hour of the total input

rating of all appliances in the enclosed space, but must not be less than one hundred (100)

square inches. These openings must freely communicate directly with other spaces of

sufficient volume so that the combined volume of all spaces meets the criteria for an

unconfined space.

PAGE 3

Page 6

5. When the boiler is installed in a confined space and all air is provided from the outdoors

the confined space shall be provided with one or two permanent openings according to

methods A or B. When ducts are used, they shall be of the same cross sectional area as the

free area of the area of the openings to which they connect. The minimum dimension of

rectangular air ducts shall be not less than 3 x 3 inches or 9 square inches.

A. When installing two openings, one must commence within 12 inches from the top and

FIGURE 3FIGURE 2

the other within 12 inches from the bottom of

the enclosure. The openings shall

communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely

communicate with the outdoors. One of the

following methods must be used to provide

adequate air for ventilation and combustion.

1. When directly communicating

with the outdoors, each opening shall have a

minimum free area of 1 square inch per 4,000

BTU per hour of total input rating of all

equipment in the enclosure. See figure 2

above.

2. When communicating with the

outdoors by means of vertical ducts, each

FIGURE 4

opening shall have a minimum free area 1

square inch per 4,000 BTU per hour of total input rating of all appliances in the enclosed

space. See figure 3 above.

3. If horizontal ducts are used, each opening and duct shall have a minimum free

area 1 square inch per 2,000 BTU per hour of total input rating of all appliances in the enclosed

space. See figure 4 at right.

B. One permanent opening, commencing within 12 inches of the top of the enclosure,

shall be permitted where the equipment has clearances of at least 1 inch from the sides, 1

inch from the back, and 6 inches from the front of the boiler. The opening shall directly

communicate with the outdoors or shall communicate through a vertical or horizontal duct to

the outdoors or spaces (crawl or attic) that freely communicate with the outdoors. The

openings must have a minimum free area of 1 square inch per 3000 Btu per hour of the total

PAGE 4

Page 7

input rating of all equipment located in the enclosure. The free area must be no less than the

sum of the areas of all vent connectors in the confined space.

6. In calculating free area using louvers, grilles or screens for the above, consideration

shall be given to their blocking effect. Screens used shall not be smaller than 1/4 inch mesh.

If the free area through a design of louver or grill is known, it should be used in calculating

the size opening required to provide the free area specified. If the design and free area is

not known, it may be assumed that wood louvers will have 20-25% free area and metal

louvers and grilles will have 60-75% free area. Louvers and grilles should be fixed in the open

position or interlocked with the boiler so they are opened automatically during the boiler

operation.

CONNECTING SUPPLY AND RETURN PIPING

1. Suggested piping for steam heating system can be seen in figure 5 below. Actual

piping may vary based on system design and local conditions.

2. Suggested piping for a modular steam boiler using pumped returns may be seen in

figures 6a and 6b on page 6. Actual piping may vary based on system design and local

conditions.

3. Refer to pages 17 & 18 for procedures on cleaning and skimming off impurities.

4. "Near Boiler Piping" is crucial for proper performance of a replacement steam boiler

and should always be considered as part of the boiler installation. Always be sure to include

cleanout and skimming tees in the near boiler piping. These "Tees" are necessary for proper

cleaning and servicing of the boiler.

5. For further piping information refer to the I=B=R installation piping guide.

SUGGESTED PIPING FOR A SINGLE STEAM

BOILER HEATING SYSTEM

FIGURE 5

PAGE 5

Page 8

SUGGESTED PIPING FOR A MODULAR STEAM BOILERS

PUMPED RETURNS

FIGURE 6a

GRAVITY RETURNS

FIGURE 6b

PAGE 6

Page 9

VENT INSTALLATION

WARNING:

draft system operating under positive pressure.

1. The vent pipe must slope upward from the boiler not less than 1/4 inch for every 1 foot

to the vent terminal.

2. Horizontal portions of the venting system shall be supported rigidly every 5 feet and

at elbows. No portion of the vent pipe should have dips or sags.

3. This boiler series is classified as a Category 1 appliance and the vent installation shall

be in accordance with Part 7 & 11 of the latest revision of the National Fuel Gas Code or

applicable provisions of the local building codes.

4. Inspect chimney to make certain it is constructed according to National Board of Fire

Underwriters.

5. Attach draft hood to flue collector at rear of boiler, (See figure 7, below), with sheet

metal screw(s) through hole(s) provided. The vent or vent collector shall be Type B or metal

pipe having resistance to heat and corrosion not less than that of galvanized sheet steel or

aluminum not less than 0.016 inch thick (No. 28 GA).

6. Connect flue pipe same as draft hood to chimney. Bolt or screw joints together to avoid

sag. Flue pipe should not extend beyond inside wall of chimney. Do not install manual

damper in flue pipe or reduce size of flue outlet except as provided by the latest revision of

ANSI Z223.1. Protect combustible ceiling and walls near flue pipe with fireproof insulation.

Where two or more appliances vent into a common flue, the area of the common flue must

be at least equal to the area of the largest flue plus 50 percent of the areas of each additional

flue.

This boiler shall not be connected to any portion of a mechanical

WARNING: ALL

INSTALLATIONS OF BOILERS

AND VENTING SHOULD BE

DONE ONLY BY A QUALIFIED

EXPERT AND IN ACCORDANCE

WITH THE APPROPRIATE UTICA

BOILERS MANUAL. INSTALLING

OR VENTING A BOILER OR ANY

OTHER GAS APPLIANCE WITH

IMPROPER METHODS OR

MATERIALS MAY RESULT IN

SERIOUS INJURY OR DEATH

DUE TO FIRE OR TO

ASPHYXIATION FROM

POISONOUS GASES SUCH AS

CARBON MONOXIDE WHICH IS

ODORLESS AND INVISIBLE.

FIGURE 7

PAGE 7

Page 10

VENT SYSTEM MODIFICATION

When an existing boiler is removed from a common venting system, the common venting

system is likely to be too large for the proper venting of the appliances remained connected

to it. If this situation occurs, the following test procedure must be followed:

At the time of removal of an existing boiler, the following steps shall be followed with

each appliance remaining connected to the common venting system placed in operation,

while the other appliances remaining connected to the common venting system are not in

operation.

A. Seal any unused openings in the common venting system.

B. Visually inspect the venting system for proper size and horizontal pitch and determine

there is no blockage or restriction, leakage, corrosion and other deficiencies which could

cause an unsafe condition.

C. Insofar as is practical, close all building doors and windows and all doors between

the space in which the appliances remaining connected to the common venting system are

located and other spaces in the building. Turn on clothes dryers and any appliance not

connected to the common venting system. Turn on any exhaust fans, such as range hoods

and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace damper.

D. Place in operation the appliance being inspected. Follow the lighting instructions.

Adjust thermostat so appliance will operate continuously.

E. Test for spillage at the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle, or smoke from a cigarette, cigar or pipe.

F. After it has been determined that each appliance remaining connected to the common

venting system properly vents when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas burning appliance to their previous

conditions of use.

G. Any improper operation of the common venting system should be corrected so the

installation conforms with the latest revision of the National Fuel Gas Code, ANSI Z223.1.

When resizing any portion of the common venting system, the common venting system

should be resized to approach the minimum size as determined using the appropriate tables

in appendix G in the latest revision of the National Gas Fuel Code, ANSI Z223.1.

PAGE 8

Page 11

VENT DAMPER INSTALLATION

AND INSTRUCTIONS

INSTALLATION

NOTE: REFER TO FIGURE 8 BELOW FOR STEPS 1-7

1. Place Vent Damper on or as close to vent outlet of boiler as possible.

2. Remove Locknut from connector at the free end of the Damper wire harness.

3. Feed Damper connector and Damper wire harness through bracket hole on Damper Motor

frame.

4. Replace and tighten locknut onto Damper wire harness connector.

5. Plug Damper connector into socket on Damper Motor frame.

INSTRUCTIONS

FIGURE 8

1. Ensure that only the boiler is serviced by the Vent Damper. See figure 9 above.

2. Clearance of not less than 6 inches between Vent Damper and combustible

construction must be maintained. Additional clearance should be allowed for service

of the Vent Damper.

3. Vent Damper must be in open position when appliance main burners are operating.

4. The Vent Damper position indicator must be in a visible location following installation.

5. The thermostats heat anticipator must be adjusted to match the total current draw of

all controls associated with the boiler during a heating cycle.

6. The Vent Damper wire harness may be removed and installed in flexible metal conduit

if local codes or jurisdiction requires. If this is necessary, the flexible metal conduit

must be mounted to a J-box and all appropriate connections must be made to this J-

box.

FIGURE 9

PAGE 9

Page 12

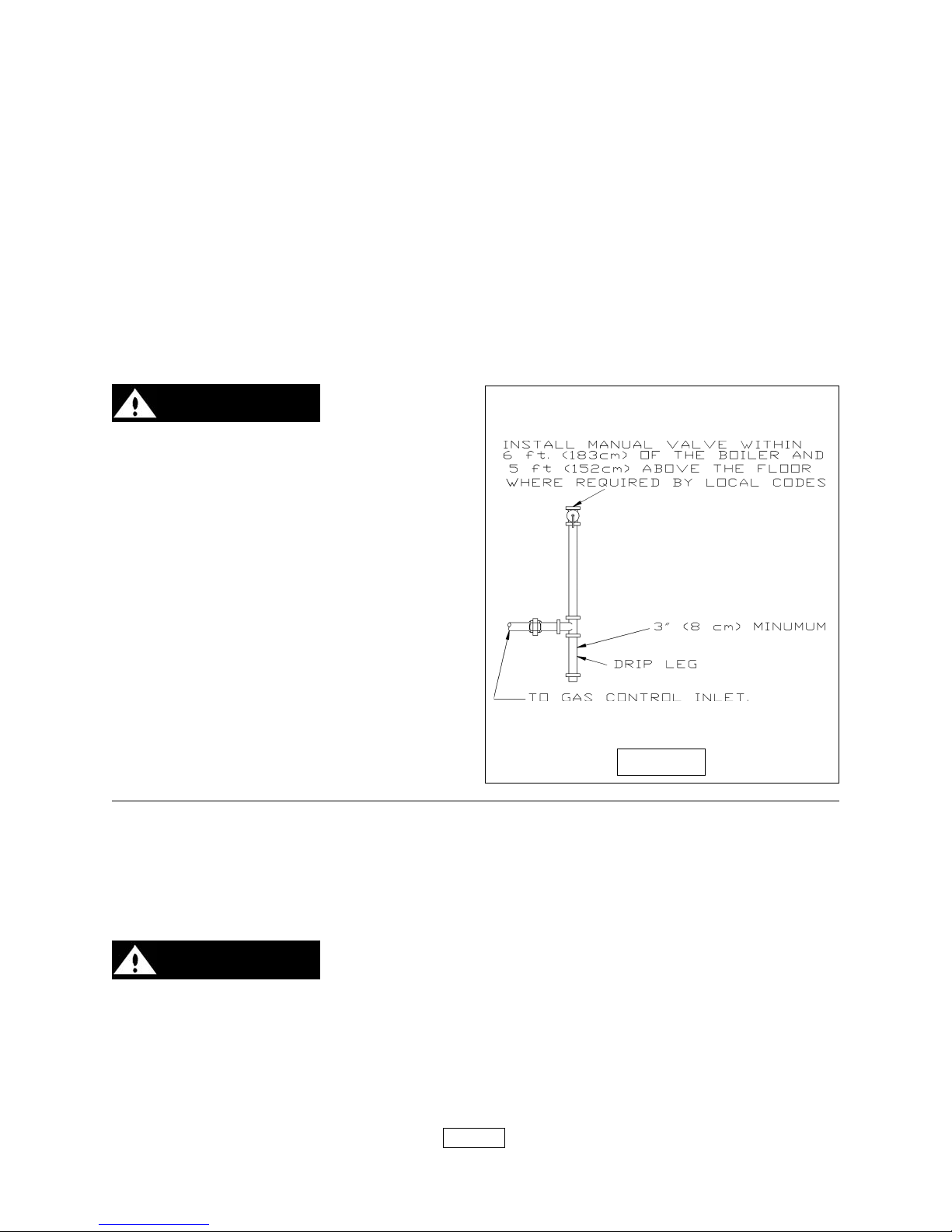

CONNECTING GAS SERVICE

Connect gas service meter to control assembly in accordance with the latest revision of

ANSI Z223.1 and local codes or utility. A ground joint union should be installed for easy

removal of gas control for servicing. A drip or trap must be installed at the bottom of a vertical

section of piping at the inlet to the gas valve. A pipe compound resistant to the action of

liquefied petroleum gases must be used on all threaded pipe connections. Check with the

local utility for location of manual shutoff valve if required. See figure 10 below.

1. The gas line should be of adequate size to prevent undue pressure drop and never

smaller than the pipe size of the main gas control valve.

2. The boiler and its gas connection must be leak tested before placing the boiler in

operation. To check for leaks in gas piping, use a soap and water solution or other approved

method.

WARNING: DO NOT USE

AN OPEN FLAME.

3. The boiler and its individual shutoff

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa). The boiler must

be isolated from the gas supply piping system

by closing its individual manual shutoff valve

during any pressure testing of the gas supply

piping system at test pressures equal to or

less than 1/2 psig (3.5 kPa).

FIGURE 10

ELECTRICAL WIRING

SEE ADDENDUM "A" FOR WIRING DIAGRAMS AND COMPONENT CODING

Electrical wiring must conform with the latest revision of the National Electrical Code, ANSI/

NFPA No. 70 and/or local authority having jurisdiction.

WARNING: 1. The boiler, when installed, MUST BE electrically grounded

in accordance with these requirements.

2. Install a fused disconnect switch between boiler and meter at a convenient location.

PAGE 10

Page 13

THERMOSTAT INSTALLATION

1. Thermostat should be installed on an inside wall at least two feet from an uninsulated

or outside wall, approximately four feet above the floor.

2. NEVER install a thermostat on an outside wall.

3. Do not install a thermostat where it will be affected by:

A. Drafts

B. Hot or cold pipes

C. Sun light

D. Lighting fixtures

E. Television

F. Fireplace or chimneys

4. Check thermostat operation by raising and lowering thermostat as required to start

and stop the burners.

5. Instructions for the final adjustment of the thermostat are packaged with the

thermostat ( adjusting heating anticipator, calibration, etc.).

LIGHTING INSTRUCTIONS

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EX-

ACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

Before any procedures are attempted on this appliance, it is necessary to

determine if the ignition system is intermittent or continuous pilot system. If you are

uncertain, contact the manufacturer before proceeding.

CAUTION: Before operating, make certain steam boiler is full of water

to water line and system is vented of air. See the operating lighting instructions.

LIGHTING PROCEDURE FOR BOILER WITH

INTERMITTENT PILOT SYSTEM.

FOR YOUR SAFETY READ BEFORE OPERATING.

A. This appliance is equipped with an ignition system which automatically lights the pilot.

Do not try to light the pilot by hand.

B. Before operating smell all around the appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than air and will settle on the floor.

CAUTION: WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electrical switch.

* Do not use any phone in your building.

* Immediately call your gas supplier from a neighbor's phone.

* Follow your gas supplier's instructions.

* If you cannot reach your gas supplier, call the fire department.

PAGE 11

Page 14

C. Use only your hand to push in or turn gas control knob. NEVER USE TOOLS. If t he

knob will not push in or turn by hand, dont try to repair it, call a qualified service technician.

Force or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water. Immediately call a

qualified service technician to inspect the appliance and to replace any part of the control

system and gas control which has been under water.

OPERATING INSTRUCTIONS FOR

INTERMITTENT PILOT SYSTEMS

1. STOP! Read the safety information in the users information manual.

2. Set thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device which automatically lights the pilot.

DO NOT try to light the pilot by hand. See figure 11, below.

5. Remove access panel (if present)

6. Push in gas control knob slightly and

INTERMITTENT PILOT GAS VALVE

turn clockwise to "OFF."

7. Wait five (5) minutes to clear out any

gas. If you then smell gas, STOP, Follow B

in the safety information What To Do IF You

Smell Gas. If you dont smell gas, go to the

next step.

8. Turn gas control knob

counterclockwise to ON.

9. Replace control access panel (IF

PRESENT).

10. Turn on all electric power to the

appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate,

FIGURE 11

follow the instructions To Turn Off Gas To

Appliance and call a qualified service

technician or your gas supplier.

LIGHTING PROCEDURE FOR BOILER WITH

CONTINUOUS PILOT.

FOR YOUR SAFETY READ BEFORE LIGHTING

A. Read warning at the beginning of this instruction.

B. This appliance has a pilot which must be lighted by hand. When lighting the pilot,

follow these instructions exactly.

C. Before lighting, smell all around the appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air and will settle on the floor. Follow B in the

lighting instructions for safety information for what to do if you smell gas on page 10.

D. Use only your hand to push in or turn the gas control knob or reset button. Never use

tools. If the knob or reset button will not push in or the knob will not turn by hand, dont try

to repair it. Call a qualified service technician. Force or attempted repair may result in fire

or explosion. See figure 12, on page 13.

PAGE 12

Page 15

E. Do not use this appliance if any part has

CONTINUOUS PILOT GAS VALVE

been under water. Immediately call a qualified

service technician to inspect the appliance

and to replace any part of the control system

and any gas control which has been under

water.

LIGHTING INSTRUCTIONS FOR

CONTINUOUS PILOT SYSTEM

1. Stop! Read the safety information at

the beginning of this manual.

2. Set thermostat to lowest setting.

3. Turn off all electric power to the

appliance.

4. Remove manifold cover and burner

FIGURE 12

door, (figures 13 & 15 on pages 14 & 16).

5. Turn gas control knob clockwise to off (See Note #1).

NOTE #1: Some gas control knobs cannot be turned from pilot to off unless knob is

pushed in slightly. Do not force.

6. Wait (5) minutes to clear out any gas. If you smell gas, stop! Follow safety information

What to do if you smell gas, located on page 10 of this manual. If you dont smell gas, go

to the next step.

7. Find pilot. Follow metal tube from gas control. Depending on the model of the boiler,

pilot is mounted on the base or on one of the burner tubes.

8. Turn gas control knob counterclockwise to pilot.

9. Push in gas control knob, or reset button if so equipped, all the way in and hold.

Immediately Light the pilot with a match. Continue to hold the gas control knob or reset button

for about one (1) minute after the pilot is lit. Release knob or button and it will pop back up.

Pilot should remain lit. If it goes out, repeat steps 5 through 10.

* If knob or button does not pop up when released, stop and immediately call your

service technician or gas supplier.

* If the pilot will not stay lit after several tries, turn the gas control knob clockwise

to off (see note #1 above) and call a service technician or gas supplier.

10. Replace burner door and manifold cover, (figures 13 & 15 on pages 14 & 16).

11. Turn gas control knob counterclockwise to "on".

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Remove access panel (if present)

4. Turn gas control knob clockwise to off. (See note #1) in the lighting

instructions. Do not force.

PAGE 13

Page 16

NORMAL SEQUENCE OF OPERATION

On a call for heat:

1.) The thermostat will actuate completing the circuit between T and T.

2.) The damper will then open thus closing the end switch completing the circuit, and

ignition will begin.

3.) In the event that the boiler steam pressure exceeds the pressure control setting,

the pressure control will interrupt the circuit to the boiler ignition system. The power will

remain off until the steam pressure drops below the pressure control setting.

4.) In the event a low water condition occurs, an automatic low water cut-off device

will interrupt the circuit to the ignition system until the low water condition is satisfied,

(i.e., manually restore the water or utilize an electric water feeding device which will

automatically restore boiler water to its normal operating level).

5.) In the event the flow of combustion products through the boiler venting system

becomes blocked, a blocked vent safety switch will shut the main burner gas off (See figure

13 below).

6.) In the event the flow of combustion products through the flueways becomes blocked

a flame rollout switch will shut the main burner gas off (See figure 13 below).

FIGURE 13

PAGE 14

Page 17

CONNECTING SUPPLY AND

RETURN PIPING, WATER CHILLED MEDIUM

1. When the boiler is used in connection with refrigerated system, connect supply and

return piping as suggested in figure 14 below.

A. The chilled medium MUST BE IN PARALLEL with the boiler.

B. Use appropriate valves to prevent the chilled medium from entering the heating

boiler.

a. During heating cycle open valves A and B. Close valves C and D.

b. During cooling cycle open valves C and D. Close valves A and B.

C. Maintain a minimum clearance of one inch between combustible materials and

hot water pipes.

* Reduced pressure backflow preventer must be present under provisions required by

the Environmental Protection Agency, (EPA).

2. When the boiler is connected to heating coils located in air handling units where they

may be exposed to refrigerated air circulation, the boiler piping system MUST be supplied

with flow control valves or other automatic means to prevent gravity circulation of the boiler

water during the cooling cycle.

3. A hot water boiler installed above radiation level must be provided with a low water

cutoff device either as a part of the boiler or at the time of boiler installation.

4. Suggested piping for steam heating system can be seen in figure 5 on page 5. Actual

piping may vary based on system design and local conditions.

FIGURE 14

PAGE 15

Page 18

GENERAL INSTRUCTIONS

Before seasonal start up it is advisable to have a competent service agency check the

boiler for soot and scale in the flues, clean the burners, and check the gas input rate to

maintain high operating efficiency.

On steam boilers make certain the boiler is filled to the water line as indicated in figure

15. The gauge cocks should be normally open. To remove dirt from the gauge glass the

petcock may be opened to flush out the glass.

WARNING: DISCHARGE WILL BE BOILING HOT WATER.

The radiator valves on a one-pipe steam system must be either wide open or tightly shut.

Do not attempt to regulate room temperature by partially closing the radiator valve.

Air vents on steam radiators and the supply main release air from the system. If radiators

do not heat satisfactorily, make sure the air vents are clean and operational.

The lever of the safety valve, shown in figure 15 below, on the boiler should be operated

periodically to make sure that it is functioning properly.

WARNING: DISCHARGE WILL BE BOILING HOT WATER AND STEAM.

The safety valve should open before the steam pressure exceeds the 15 lb. reading on the

gauge, (figure 15 to right). If this pressure is

exceeded and the safety valve does not

open, it must be replaced. If the safety valve

leaks steam when the boiler is operating at

normal pressures, it should be immediately

replaced. Corrosion can build up rapidly at

the valve seat and prevent its functioning as

a safety device.

During the heating season the drain cock,

on the bottom rear of the boiler, should be

opened once a month to flush out the boiler

so the device will be free to function properly.

Use a pail to catch the discharge.

WARNING: DISCHARGE

FIGURE 15

WILL BE BOILING HOT WATER.

If the water in a steam boiler appears to be dirty or oily, or the water level in the gauge

glass fluctuates considerably, the boiler should be cleaned and skimmed (See page 18 for

instructions). A competent service person will use approved cleaning compounds and

properly clean and flush out the boiler. He/she should also clean or replace air vents and traps,

clean flue passages and check for proper operation of all controls and safety devices.

The venting system should be inspected at the start of each heating season. Check the

vent pipe from the boiler to the chimney for signs of deterioration by rust or sagging joints.

Repair if necessary. Remove the vent pipe at the base of the chimney or flue and, using

a mirror, check for obstruction.

The boiler flue gas passageways may be inspected by a light and mirror. Remove the

burner access door, (figure 15 above). Place a trouble lamp in the flue collector through the

draft-hood relief opening. With the mirror positioned above the burners, the flue gas

passageways can be checked for soot or scale.

PAGE 16

Page 19

TO CLEAN THE BOILER FLUEWAYS:

1. Remove the burners from the combustion chamber by raising the burners upward

from the manifold orifices and pulling toward the front of the boiler. To remove the burner

with the pilot burner attached, first disconnect the pilot line tubing and thermocouple or pilot

generator leads at the main electric gas valve. Do not remove the pilot line tubing at the pilot

as the pilot burner orifice may drop out and become damaged or lost.

2. Disconnect the vent pipe from the draft hood.

3. Remove the draft hood. The draft hood is attached to the flue collector at the top by

sheet metal screw(s).

4. Remove the top jacket panel. It is attached to the jacket by sheet metal screws.

5. Remove the flue collector from the boiler casting by loosening the nuts on the J bolts

at either side of the flue collector.

6. Place a sheet of heavy paper or similar material over the bottom of the combustion

chamber and brush down the flue passageways. The soot and scale will collect on the paper

and is easily removed with the paper.

7. With the paper still in place in the combustion chamber, clean the top of the boiler

castings of the boiler putty or silicone used to seal between the castings and the flue

collector. Make certain chips are not lodged in the flueways.

When the cleaning process is completed, restore the boiler components to their original

position. Use boiler putty or GE IS-808 silicone to seal around the flue collector and castings.

Make certain the burner ends are inserted in the slots at the back of the combustion chamber

and well down in position over the burner orifices. Follow the lighting instructions on the

boiler to put the burners back in operation.

CHECK SAFETY CONTROL CIRCUIT, after burner adjustments are made, for

satisfactory operation.

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after service.

1. Pilot: with main burner operating turn the pilot gas adjusting screw clockwise

until pilot gas is turned off. See figures 11 and 12 on pages 12 & 13. Within 90 seconds the

main gas control should close, shutting off the gas to the main burner. After, check pilot

operation. Relight following lighting instructions on pages 10-12.

2. Pressure control - on steam boilers - remove cover and note pressure setting. With

the boiler operating, decrease the setting. When setting is lower than boiler pressure, the

control will open, closing the automatic main gas valve. After checking pressure control,

reset control to original setting.

3. Mechanical Low water cut-off: Operation may checked by opening the blow-off valve

located in the lower portion of the body. This will drain water quickly from the cut-off body

and break circuit to automatic main gas valve. Owner should blow off this control at least

once each month of the heating season.

WARNING: WATER WILL BE BOILING HOT.

PAGE 17

Page 20

4. Electronic Low Water Cut-off: Operation may be checked by opening the drain valve

in the back side of the boiler. This will drain the water from the boiler and break the electronic

circuit to the automatic gas valve.

IMPURITIES IN BOILER WATER of a steam boiler may cause foaming and an unsteady

water line, or prevent steam generation. They may result in objectionable odors escaping

from the vents on water boilers. This condition is caused by oil, grease, and sediment from

pipe fittings collecting within the boiler and can be remedied only by giving the boiler a

thorough cleaning.

BOILERS CAN BE CLEANED by skimming or blowing down.

CAUTION: The boiler should not be left unattended during the cleaning

process.

SKIMMING OFF IMPURITIES

Some of the impurities in the boiler water will float on the water and must be skimmed off.

With the boiler empty and cool, slowly begin to add water. After water has entered boiler

- never before - turn on main gas burners and adjust flame at main manual shut-off valve

so that the water being added is kept just below boiling point. Avoid boiling and turbulence.

Gradually raise hot water level to skimming tee, see figure 5 on page 5, installed at the

supply outlet piping of the boiler being careful not to raise it above the opening of the tee.

Skim until there are no impurities. Repeat the process if necessary.

Water may be checked to make sure it is free from oil by drawing off a sample at the

skimming tee. If the sample is reasonably free from oil, it will not froth when boiled on stove.

This test does not indicate the amount of sediment which may lay in the bottom of the boiler.

It is therefore necessary that the boiler be further cleaned by blowing down.

BLOWING DOWN BOILER

Before blowing down the boiler, fill it to the water line. Light burners and allow five pounds

of steam pressure to build up. Run a temporary connection from one of the drain valves to

a nearby sewer. Connect to a drain valve on the opposite end of the boiler from feed water

inlet, if possible. Shut off the gas burners, open drain valve and blow down the entire

contents of boiler.

Allow boiler to thoroughly cool and slowly refill to water line. Repeat step 2 as many times

as required until blow off water is clear. Owner should blow down boiler at least once each

month of the heating season.

WARNING: WATER WILL BE BOILING HOT.

USING CLEANING COMPOUND

If an exceptional amount of dirt or sludge seems to be present in the boiler, a boiler

cleaning compound made by a reputable manufacturer may be used according to the

instructions of the manufacturer of the compound. When any type of cleaning compound

is used, care must be taken to thoroughly flush all traces of the compound out of the boiler.

Following blow down allow the boiler to cool. Add fresh water slowly. Be certain to blow

enough times as required to remove compounds from system.

PAGE 18

Page 21

CHECKING AND ADJUSTING THE GAS IGNITION COMPONENTS

The gas input to the boiler can be adjusted by removing the protective cap on the

pressure regulator, see figure 16 on page 19 , and turning screw clockwise t o

increase input and counterclockwise to decrease input. Natural gas manifold

pressure should be set at approximately 3.5 inches water column. Propane gas manifold

pressure should be set at approximately 10 inches water column. Manifold pressure is taken

at the pressure tap on the outlet side of the gas valve, see figures 11 and 12 on pages 12

and 13. Burner orifices should be changed if the final manifold pressure varies more than

plus or minus 0.3 inch water column from the specified pressure.

To check for proper flow of natural gas to boiler divide the input rate on the rating plate

by heating value of the gas as obtained from the local gas company. This will determine the

number of cubic feet of gas required per hour. With all other gas appliances off, determine

FIGURE 16

FIGURE 17

the flow of gas through the meter for two minutes and multiply by 30 to get the hourly rate.

Make minor adjustments to the gas input as described above.

Primary air adjustment is not necessary, therefore air shutters are not furnished as

standard equipment. Air shutters can be furnished on request when required by local codes

or conditions.

A visual check of the main burners and pilot flames should be made at the start of the

heating season and again at mid-season.

The main burner flame should have a well defined inner blue mantel with a lighter blue

outer mantel. If the flame does not appear this way, check the burner throats and burner

orifices for lint or dust obstruction. See figure 17 above.

The pilot flame should envelop 3/8 to 1/2 inch of the tip of the pilot sensor. See figure

18 on page 20. To adjust the pilot flame, remove the pilot adjustment screw and turn the

inner adjustment screw clockwise to decrease or counterclockwise t o

increase pilot flame. See figures 11 and 12 on pages 12 & 13. Be sure to replace cover screw

after adjustment to prevent possible gas leakage.

The burners and pilot should be checked for signs of corrosion, rust or scale build-up.

The area around the boiler should be kept clear and free of combustible materials, gasoline

and other flammable vapors and liquids.

PAGE 19

Page 22

The free flow of combustion and

ventilation air to the boiler and boiler room

should not be restricted or blocked.

It is suggested that a qualified service

agency be employed to make an annual

inspection of the boiler and heating system.

They are experienced in making the

inspections outlined above and, in the event

repairs or corrections are necessary, can

make the proper changes for safe operation

of the boiler.

Optional parts

WC-001.00 # 67 - U LWCO

WC-004.01 # 101 Water Feeder

WC-005.00 # 47-2 LWCO & Feeder

PEG-C REPLACEMENT PARTS - PILOT

FIGURE 18

24 VOLT

ITEM # PART # DESCRIPTION OTY.

1 PB01301 PILOT-Q350A 24 VOLT 1

2 HW-024.01 SCREW #10-32X3/16 2

3 MS-003.05 PILOT TUBE 1/4"X24.1/4" 1

4 1520001 THERMOCOUPLE Q309A

SPARK

ITEM # PART # DESCRIPTION OTY.

1 PB-001.02 PILOT-Q345A SPARK 1

2 HW-024.01 SCREW #10-32X3/16 2

3 MS-003.05 PILOT TUBE 1/4"X24.1/4" 1

4 PB00702 PILOT IGNITION CABLE 1

FIGURE 19

FIGURE 20

PAGE 20

Page 23

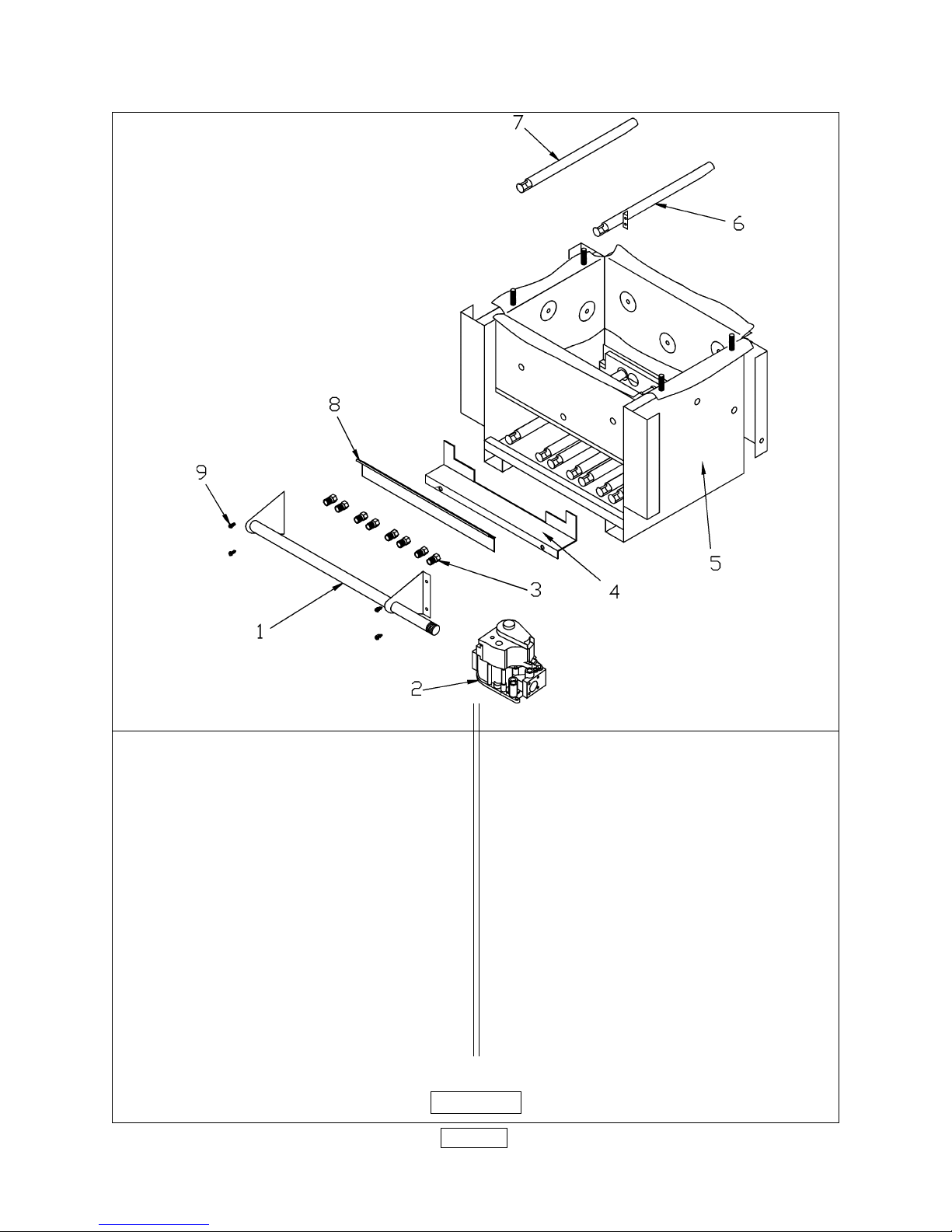

PEG-C REPLACEMENT PARTS - BASE

ITEM # PART # DESCRIPTION OTY. ITEM # PART # DESCRIPTION OTY.

1 3542202 MANIFOLD PEG112C 1

3542203 MANIFOLD PEG150C

3542204 MANIFOLD PEG187C

3542205 MANIFOLD PEG225C

3542206 MANIFOLD PEG262C

3542207 MANIFOLD PEG300C

2 VG-008.07 GAS VALVE VR8200H-3000 1

PEG112 & 150 24V

VG01102 GAS VALVE VR8204-3010

PEG112&150 SPARK

VG01103 GAS VALVE VR8304H4206

PEG187 - 300 SPARK

VG01201 VR8300H4006 PEG262C

PEG187 - 300 24V

3 352-1-1.03 GAS ORIFICE #47-NATURAL

352-1-1.04 GAS ORIFICE #56-LP

PEG112C - (6), PEG150 - (8), PEG187 - (10),

PEG 225 -(12), PEG262 - (14), PEG300 - (16)

4 32425301 BASE PLATE PEG112C

32425302 BASE PLATE PEG150C

32425303 BASE PLATE PEG187C

32425304 BASE PLATE PEG225C

32425305 BASE PLATE PEG262C

32425306 BASE PLATE PEG300C

5 5612501 BASE WITH INSUL PEG112C 1

5612502 BASE WITH INSULPEG150C

5612503 BASE WITH INSUL PEG187C

5612504 BASE WITH INSUL PEG225C

5612505 BASE WITH INSUL PEG262C

5612506 BASE WITH INSUL PEG300C

6 3342701 BURNER ASSY. W/ PILOT 1

BRACKET & SHUTTER

7 3342601 BURNER ASSY. W/SHUTTER

PEG112C - (5), PEG150 - (7), PEG187 - (9),

PEG 225 -(11), PEG262 - (13), PEG300 - (15)

8 32411302 BRN ACCESS DOOR PEG112C 1

32411303 BRN ACCESS DOOR PEG150C

32411304 BRN ACCESS DOOR PEG187C

32411305 BRN ACCESS DOOR PEG225C

32411306 BRN ACCESS DOOR PEG262C

32411307 BRN ACCESS DOOR PEG300C

9 HW-005.01 SCREW 1/4-20X1/2 SELF TAP

FIGURE 21

PAGE 21

32425303 BASE PLATE PEG187C

Page 24

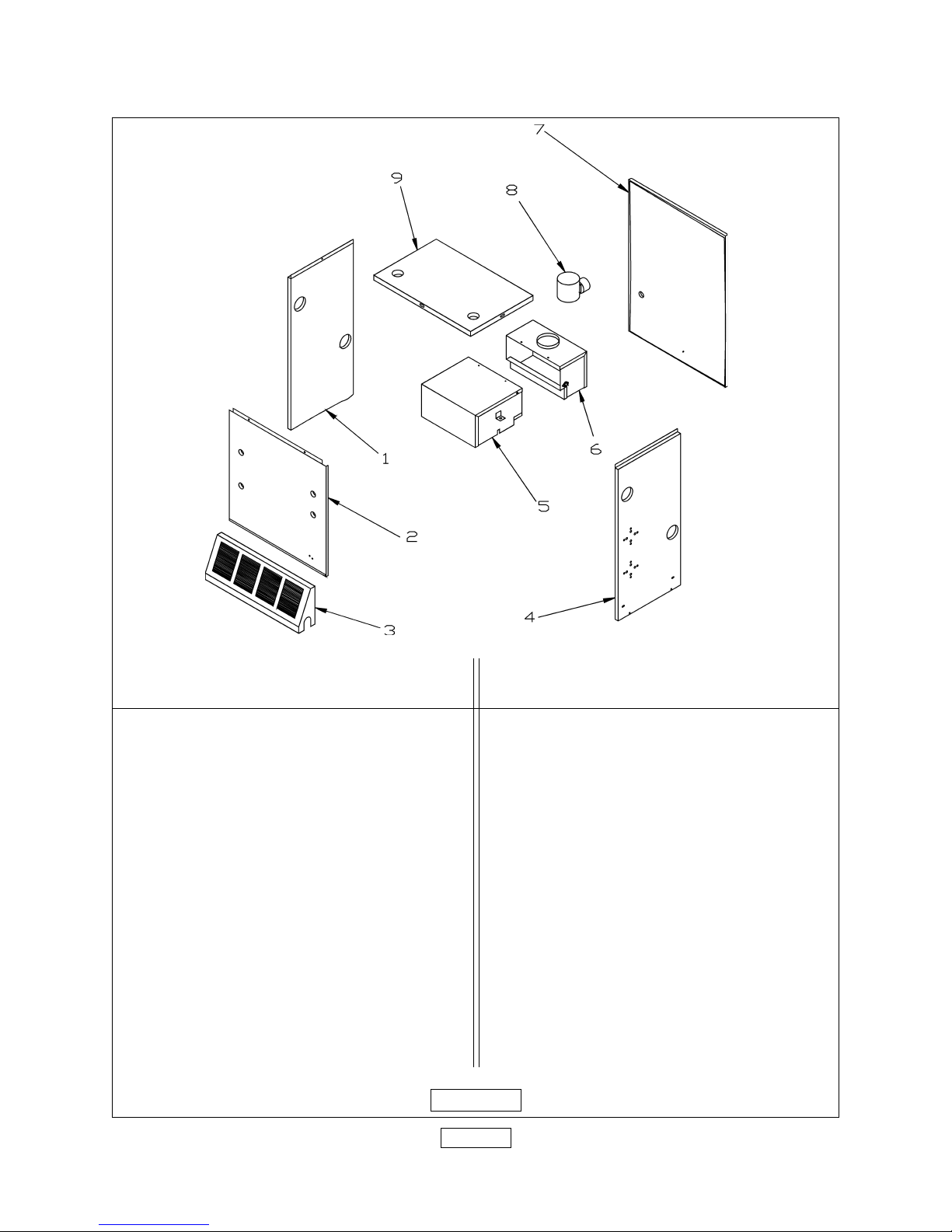

PEG-C REPLACEMENT PARTS - JACKETS

ITEM PART ITEM PART

# NUMBER DESCRIPTION OTY. # NUMBER DESCRIPTION OTY.

1 31423001 SIDE PANEL LEFT (ALL) 1

2 31422802 FRONT PANEL PEG112C 1

31422803 FRONT PANEL PEG150C

31422804 FRONT PANEL PEG187C

31422805 FRONT PANEL PEG225C

31422806 FRONT PANEL PEG262C

31422807 FRONT PANEL PEG300C

3 31421002 MANIFOLD COVER PEG112C 1

31421003 MANIFOLD COVER PEG150C

31421004 MANIFOLD COVER PEG187C

31421005 MANIFOLD COVER PEG225C

31421006 MANIFOLD COVER PEG262C

31421007 MANIFOLD COVER PEG300C

4 31423002 SIDE PANEL RIGHT (ALL) 1

5 3442702 FLUE COLLECTOR PEG112C 1

3442703 FLUE COLLECTOR PEG150C

3442704 FLUE COLLECTOR PEG187C

3442705 FLUE COLLECTOR PEG225C

3442706 FLUE COLLECTOR PEG262C

3442707 FLUE COLLECTOR PEG300C

FIGURE 22

6 344-2-1.02 DRAFT HOOD PEG112C 1

344-2-1.03 DRAFT HOOD PEG150C

344-2-1.04 DRAFT HOOD PEG187C

344-2-1.05 DRAFT HOOD PEG225C

344-2-1.06 DRAFT HOOD PEG262C

344-2-1.07 DRAFT HOOD PEG300C

7 31423302 REAR PANEL PEG112C 1

31423303 REAR PANEL PEG150C

31423304 REAR PANEL PEG187C

31423305 REAR PANEL PEG225C

31423306 REAR PANEL PEG262C

31423307 REAR PANEL PEG300C

8 1182005 DAMPER PEG112C 5" 1

1182006 DAMPER PEG150C 6"

1182007 DAMPER PEG187C 7"

1182008 DAMPER PEG225C&262C 8"

1182009 DAMPER PEG300C 9"

9 31423502 TOP PANEL PEG112C 1

31423503 TOP PANEL PEG150C

31423504 TOP PANEL PEG187C

31423505 TOP PANEL PEG225C

31423506 TOP PANEL PEG262C

31423507 TOP PANEL PEG300C

PAGE 22

Page 25

PEG-C REPLACEMENT PARTS - HEAT EXCHANGER

ITEM PART

# NUMBER DESCRIPTION OTY.

1 100-2-15.01 E-Left Hand Section 1

2 100-2-14.01 E-Center Section

PEG112C - (2), PEG150 - (3), PEG187 - (4),

PEG 225 -(5), PEG262 - (6), PEG300 - (7)

3 100-2-13.02 E-Right Hand Section 1

4 HW06901 NUT-5/16-18 WISLOCK 4

5 HW-011.10TIE ROD 1/4X10.25 PEG112 2

HW-011.02 TIE ROD 1/4X13 PEG150

HW-011.04 TIE ROD 1/4X17 PEG187

HW-011.05 TIE ROD 1/4X19 PEG225

HW-011.07 TIE ROD 1/4X23 PEG262

HW-011.08 TIE ROD 1/4X25 PEG300

6 PF-007.02 PIPE FIT PLG 2" 1

7 251-1-2.00 J-BOLT 1/4-20X3.5/16 2

8 43300976 NIPPLE 2" MACH.

PEG112C - (4), PEG150 - (6), PEG187 - (8),

PEG 225 -(10), PEG262 - (12), PEG300 - (14)

9 HW-016.02 DRAIN LONG 1

10 1570001 VALVE, POP SAFETY 3/4" 1

11 1150001 COUPLING 3/4" 1

12 PF-005.10 PIPE FIT NPL 3/4"X 6" 1

ITEM PART

# NUMBER DESCRIPTION OTY.

13 HW-003.02 NUT-1/4-20 HEX SLT 4

14 HW-008.01 WASH 5/16 FLAT STL ZP 2

(Fully assembled heat exchangers.)

10022802 4 SECTION PEG112C 1

10022803 5 SECTION PEG150C 1

10022804 6 SECTION PEG187C 1

10022805 7 SECTION PEG225C 1

10022806 8 SECTION PEG262C 1

10022807 9 SECTION PEG300C 1

FIGURE 23

PAGE 23

Page 26

PEG-C REPLACEMENT PARTS

FRONT PANEL CONTROLS

ITEM PART

# NUMBER DESCRIPTION OTY.

1 GA-004.00 GAUGE WTR LEVEL 1

2 PF-033.02 PIPE FIT NPL 1/2"X4" 1

3 WCO1901 ELWCO PS-802U-24 1

WITH PROBE

4 HW-006.02 POP RIVIT FLUE 3/16" 2

5 32421901 SENSOR BRACKET 1

6 AQ02101 CONTROL FIXED TEMP 2

(ONE ON DRAFT HOOD)

7 37513301 WIRE - ROLL OUT 1

8 HW06501 SCR 6X1/4" SLOT 2

ITEM PART

# NUMBER DESCRIPTION OTY.

9 753-1-3.00 90° SYPHON 1

10 PF-025.01 1/4" TEE 1

11 PF-026.05 1/4" X 3" NIPPLE 1

12 GA-003.00 PRESSURE GAUGE 1

13 PF-027.01 1/4" ELBOW 90° 1

14 SS-001.01 PRESSURE SWITCH 1

15 PF-026.01 CLOSE NIPPLE 1/4" NPL 1

16 PF05601 PIPE FIT NPL 1/2"X3" 1

17 PF-034.01 1/2" BRASS COUPLING 2

FIGURE 24

PAGE 24

Page 27

PEG-C REPLACEMENT PARTS - ELECTRICAL

ITEM PART

NUMBER NUMBER DESCRIPTION OTY.

1 EF-013.01 ELEC. J-BOX 4X4X1/2 2

2 37414401 WIRE PRES. SWITCH TO J-BOX 34" 1

3 37424501 HARNESS-ELWCO TO J-BOX 18" 1

4 PB00702 IGN WIRE 30" CIDE MODELS ONLY 1

5 37413602 HARNESS IGN. MOD. TO GAS VALVE 12" 1

6 PB00604 SPK CTL S8600M1013 1

7 37413201 WIRE SPILL SWITCH 47" 1

8 37413801 WIRE J-BOX TO CONTROLS 27" 1

9 EF03601 WIRE CLAMP #3600 WHITE 1

10 37413002 WIRE TRANSFORMER (WHITE) 15" 1

11 37413001 WIRE TRANSFORMER (BROWN) 15" 1

12 3641601 TRANSFORMER ASSEMBLY 24V 1

13 37413101 DAMPER CABLE 53" 1

14 3641501 ELEC 4"X4" COVER/TERM STRIP 1

FIGURE 25

PAGE 25

Page 28

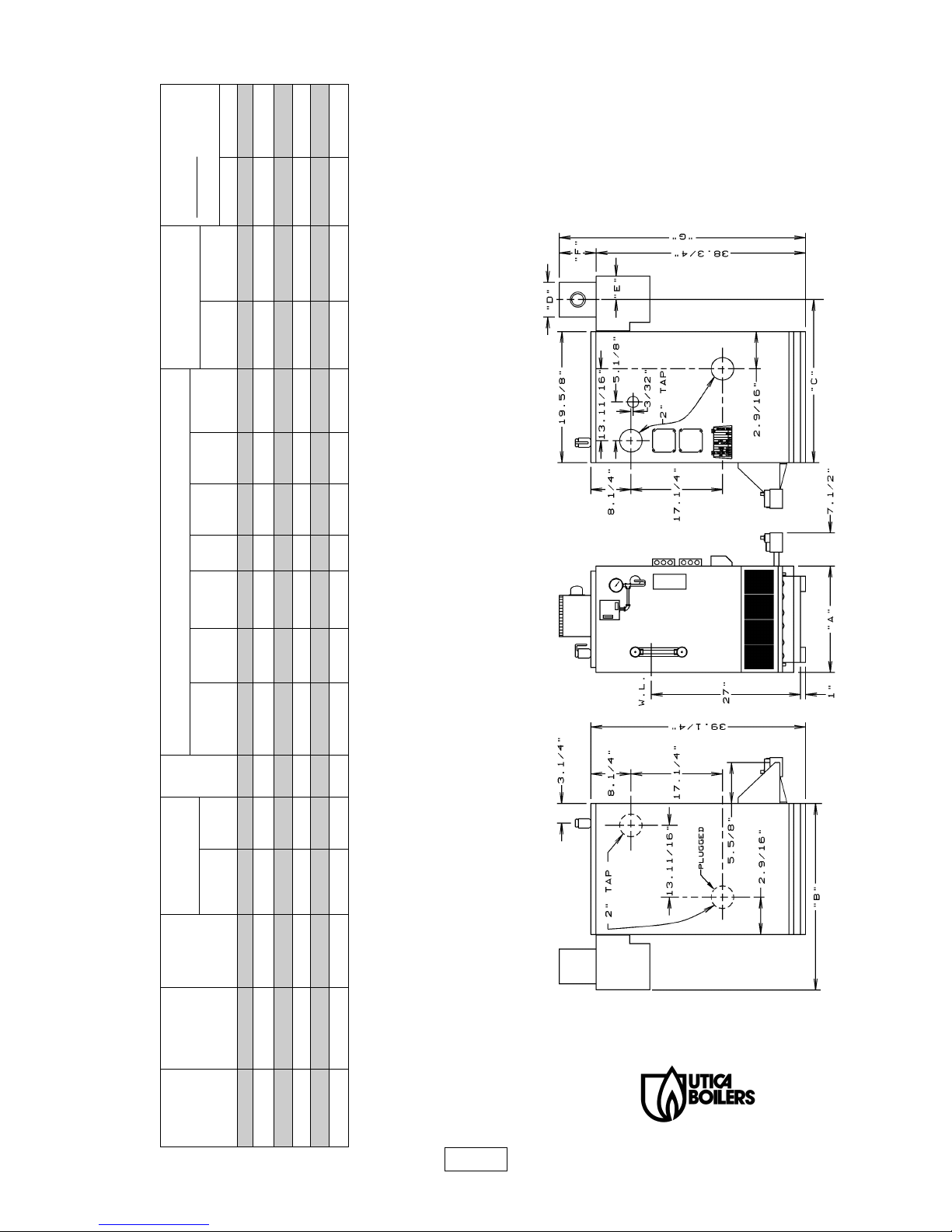

Utilization Efficiency

NATURAL GAS STEAM BOILERS

RATINGS, DATA, AND DIMENSIONS

*A.G.A Heating Net I=B=R** Gas Dimensions WATER CONTENT Annual Fuel

The MEA number for the PEG series is 17-79.

Electrical service to be 120 Volts, 15 Amps, 60 Hz.

**For equivalent square feet of radiation, divide I=B=R output by 240.

Blocked Vent and Roll-Out Safety Switches, Gas Valve, Pilot, Pressure High Limit Control, 2-2" Supply Tapping-L.H. Plugged, 2-2" Return Tappings-L.H. Plugged.

Packed in Separate Carton:Pop Safety Valve and Boiler Drain.

Net I=B=R Steam Ratings shown are based on a piping and pickup allowance of 1.333. Proper allowance has been made for piping and pickup in accordance with the

OPTIONAL EQUIPMENT: Electronic water feeder

The Ratings marked Net I=B=R indicate the amount of equivalent direct cast iron radiation each boiler will take care of under normal conditions and thermostatic control. The

factors shown in the I=B=R Standard as published by The Hydronics Institute.

Selection of boiler size should be based upon Net BTU per Hour of the connected radiation and piping.

The manufacturer should be consulted before selecting a boiler for installations having unusual piping and pickup requirements.

In line with it's policy of product improvement, Utica Boilers reserves the right to make changes without notice.

Boiler Input Capacity Steam Rating Inlet (GALLON CAPACITY)

Number Btu/Hr. Btu/Hr. Btu/Hr. Sq. Ft. Size A B C D E F G To Water To LWCO (AFUE)

& Damper & Damper Line Line Elect Ign Std. Pilot

PEG112C 112,500 90,000 67,500 281 1/2 14.1/4 27.5/8 24.1/8 5 3.1/2 6 44.3/4 4.8 3.0 81.0 78

PEG150C 150,000 120,000 90,000 375 1/2 17.1/8 28.5/8 24.5/8 6 4 6.1/2 45.1/4 6.0 3.7 81.0 78

PEG187C 187,000 151,000 113,300 472 1/2 20 29.5/8 25.1/8 7 4.1/2 7 45.3/4 7.0 4.4 81.0 78

PEG225C 225,000 181,000 135,800 556 3/4 22.13/16 30.5/8 25.5/8 8 5 8 46.3/4 8.4 5.0 81.0 78

PEG262C 262,500 212,000 159,000 663 3/4 25.5/8 30.5/8 25.5/8 8 5 8 46.3/4 9.5 5.8 81.0 78

PEG300C 299,999 243,000 182,300 760 3/4 28.1/8 31.5/8 26.1/8 9 5.1/2 10 48.3/4 10.7 6.4 81.0 78

NOTE: For altitudes above 2,000 ft. ratings should be reduced at the rate of 4% for each 1,000 ft. above sea level,

3741801 PAGE 26 REV: 15, July 2003

STANDARD EQUIPMENT: Crafted Boiler, Drafthood, Low Water Cut-off (Probe Type), Deluxe Jacket, Wiring, Automatic Vent Damper, Ported Stainless Steel Burners,

FRONT VIEWLEFT SIDE VIEW RIGHT SIDE VIEW

Loading...

Loading...