US Range RHPA-1112A, Regal Installation Manual

INSTALLATION AND

OPERATION MANUAL

“REGAL” SERIES

HOT PLATES

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1382698 (02/26/08) © 2005 Garland Commercial Industries, Inc.

Part # 1382698 (02/26/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 1382698 (02/26/08)Page 2

Part # 1382698 (02/26/08) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION..........................................2

SPECIFICATIONS....................................................4

INTRODUCTION.....................................................4

Uncrating........................................................................4

Rating Plate......................................................................4

INSTALLATION......................................................5

Clearances.......................................................................5

Positioning and Setup............................................................5

Air Supply and Ventilation........................................................5

Gas Supply ......................................................................5

Statutory Regulations ............................................................5

Manual Shut-O Valve...........................................................5

Pressure Regulator...............................................................5

Rigid Connections ...............................................................6

Flexible Couplings & Connectors..................................................6

Manual Pilot Valve...............................................................6

Testing and Adjustments.........................................................6

INITIAL OPERATION.................................................7

Initial Pilot Light .................................................................7

Final Preparation.................................................................7

CLEANING AND MAINTENANCE......................................7

General Cleaning ................................................................7

Cleaning Stainless Steel ..........................................................7

SERVICE AND PARTS ................................................8

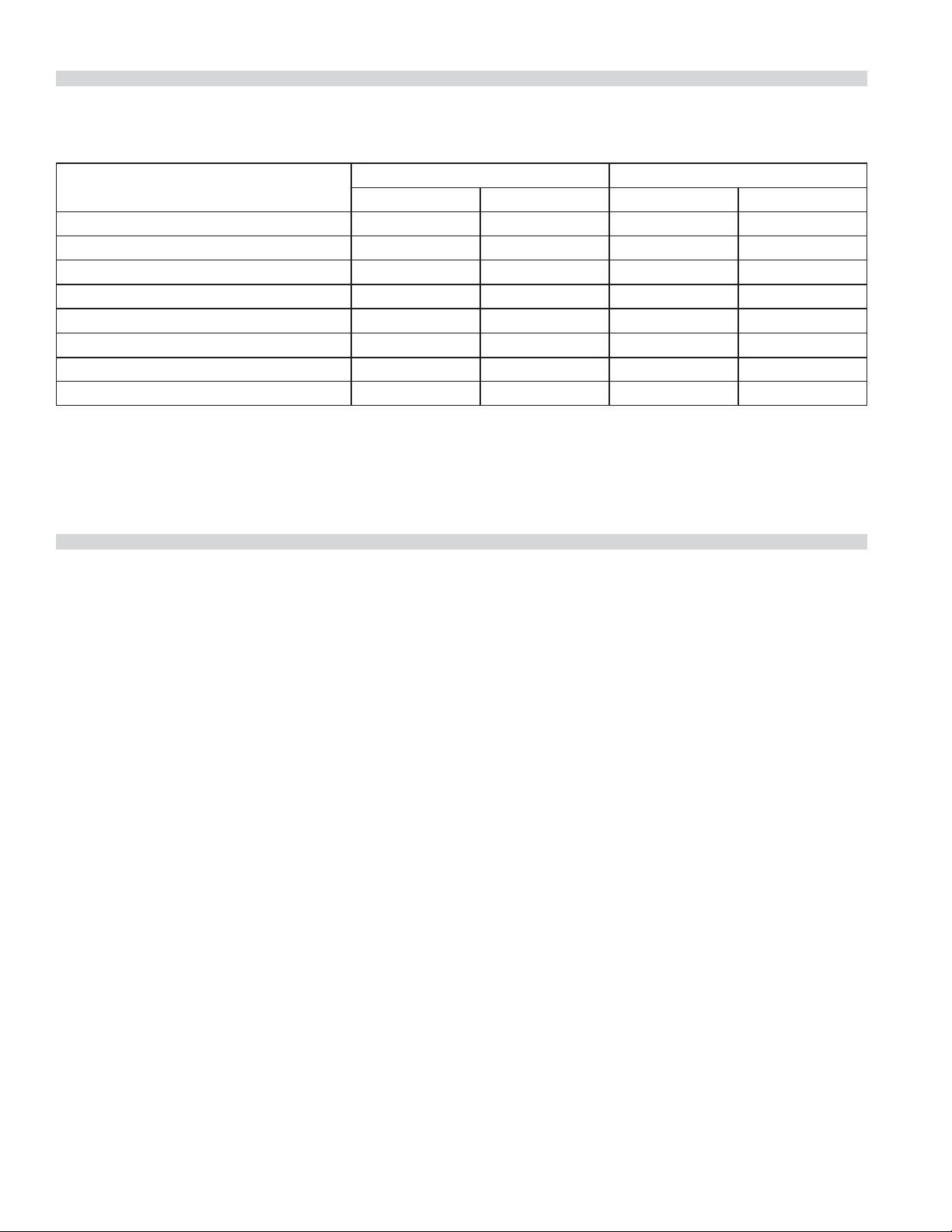

SPECIFICATIONS

MODEL NUMBER

RHPA-1112A 46 20,000 BTU 56 17,500 BTU

RHPA-212A & RHPR-12 46 40,000 BTU 56 35,000 BTU

RHPA-224A 46 40,000 BTU 56 35,000 BTU

RHPA-336A 46 60,000 BTU 56 52,500 BTU

RHPA-424A &RHPR-24 46 80,000 BTU 56 70,000 BTU

RHPA-448A 46 80,000 BTU 56 70,000 BTU

RHPA-636A & RHPR-36 46 120,000 BTU 56 105,000BTU

RHPA-848A & RHPR-48 46 160,000 BTU 56 140,000 BTU

Operating pressure is 5” WC for Natural Gas and 10” WC for LP Gas.

Orice Size Total Input Orice Size Input

NATURAL GAS LP GAS

INTRODUCTION

U.S. Range manufactures the “Regal” Hot Plate in widths

ranging from two feet to ve feet, and either one or two

burners deep, to be used as free-standing counter units.

All units are shipped completely assembled, with the

pressure regulator and adjustable legs packed on the

drip pan. The burners are tied to their hangers to prevent

vibration damage. All units are inspected at the factory prior

to shipment.

Like any ne, precision built piece of equipment, your

appliance should be given regular care and maintenance.

Periodic inspections by your dealer or a qualied service

agency are recommended.

Uncrating

Rating Plate

The rating plate is attached to the hot plate’s end frame. It

can be viewed by tilting the unit and looking underneath. A

ashlight may be necessary.

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

Other information on this plate is the BTU/hr input to the

burners, outlet gas pressure in inches WC, and whether

oriced for natural or propane gas.

After uncrating, immediately check the equipment for visible

signs of shipping damage.

If such damage has occurred, do not refuse shipment, but

contact the shipper and le the appropriate freight claims.

WARNING All U.S. Range Hot Plates must be connected only

to the type of gas identied on the rating plate! Installation

must be in accordance with ANSI 283.11 (latest edition) of

the American national Standards Institute, Inc.

Part # 1382698 (02/26/08)Page 4

Part # 1382698 (02/26/08) Page 5

INSTALLATION

Clearances

The appliance area must be kept free and clear of all

combustibles.

These units are design-certied for the following

installations:

1. Intended for other than household use.

2. For use in non combustible locations only.

3. For use with 4” (minimum) legs.

Type of Construction

Minimum Clearance

Combustible Non-Combustible

Rear 3” (76mm) Rear 0”

Sides 6” (152mm) Sides 0”

Positioning and Setup

The hot plate should be placed on a solid, level countertop

with ample space to combustible surfaces, as dened under

“CLEARANCES.”

The unit should be leveled with a carpenter’s spirit level from

front to back and side to side. Each leg features an adjustable

foot which can be screwed in or out to facilitate leveling.

Air Supply and Ventilation

The area around the appliance must be kept clear to avoid

any obstruction to the ow of combustion and ventilation

air, as well as, for ease of maintenance and service.

Means must be provided for any commercial, heavy-duty

cooking appliance to exhaust combustion waste products to

the outside of the building. Usual practice is to place the unit

under an exhaust hood; the minimum should be an exhaust

fan mounted above the unit Filters and drip troughs should

be part of any industrial hood, but consult local codes before

construction and installing a hood.

Strong exhaust fans in this hood or in the overall air

conditioning system can produce a slight vacuum in the

room and/or cause air drafts, either of which can interfere

with pilot or burner performance and be hard to diagnose.

Air movement should be checked during installation; if

pilot/burner outage problems persist, make-up air openings

or baes may have to be provided in the room.

Gas Supply

1. Installation of the equipment should be made by a

licensed plumber.

2. A gas shut-o valve must be installed in the gas supply

line ahead or the appliance for safety and for ease of

future service.

3. A gas pressure regulator must be installed at the

appliance prior to connecting the equipment to the gas

line. Failure to install a regulator will void the equipment

warranty.

NOTE: The gas supply (service) line must be the same size or

greater than the inlet line of the appliance. U.S. Range Hot

Plates use a 3/4” NPT inlet. Sealant on all pipe joints must be

resistive to LP gas.

Statutory Regulations

Safe and satisfactory operation of your equipment depends,

to a great extent, on its proper installation. Installation must

conform to local codes or, in the absence of local codes with

the National Fuel code, ANSI Z223.1, Natural Gas Installation

Code, CAN/CGA-B149.1, or the Propane Installation Code,

CAN/CGA-B149.2, as applicable, including:

1. The appliance and its individual shuto valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shuto

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psi (3.45 kPa).

Manual Shut-O Valve

This installer-supplied valve must be installed in the gas

service line ahead of the appliance and regulator in the gas

stream and in a position where it can be reached quickly in

the event of an emergency.

Pressure Regulator

All heavy-duty, commercial cooking equipment must have

a pressure regulator in the incoming service line for safe and

ecient operation, since service pressure may uctuate with

local demand. The manual shut-o valve is normally supplied

by the installer, but pressure regulators are shipped from U.S.

Range with every hot plate.

Loading...

Loading...