Page 1

INSTALLATION AND

OPERATION MANUAL

“REGAL” SERIES

SALAMANDER BROILERS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1844033 Rev3 (02/22/08) © 2004 Garland Commercial Industries, Inc.

Part # Rev 3 1844033 (02/22/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # Rev 3 1844033 (02/22/08)Page 2

Page 3

Part # Rev 3 1844033 (02/22/08) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION..........................................2

INTRODUCTION.....................................................4

Uncrating........................................................................4

Rating Plate......................................................................4

INSTALLATION......................................................4

Clearances.......................................................................4

Position and Setup...............................................................4

Wall Mounting...............................................................4

Range Mounting............................................................. 5

Counter Installation ..........................................................5

Air Supply and Ventilation........................................................5

Gas Supply ......................................................................5

National Code Requirements .....................................................6

Manual Shut-O Valve...........................................................6

Pressure Regulator...............................................................6

Rigid Connections ...............................................................6

Flexible Couplings & Connectors..................................................6

Manual Pilot Valve...............................................................7

Testing and Adjustments.........................................................7

INITIAL OPERATION.................................................8

Initial Pilot Light .................................................................8

Final Preparation.................................................................8

CLEANING AND MAINTENANCE......................................9

General Cleaning ................................................................9

Cleaning Stainless Steel ..........................................................9

SERVICE AND PARTS ................................................9

Page 4

INTRODUCTION

All units are shipped completely assembled, with wall

mounting clips and pressure regulator packed inside the unit

with the broiler grates. These are individually wrapped and

secured to the oor of the broiler. All units are inspected at

the factory prior to shipment.

The appliance should be given regular care and

maintenance. Periodic inspections by your dealer or a

qualied service agency are recommended.

Uncrating

After uncrating, immediately check the equipment for visible

signs of shipping damage.

If such damage has occurred, do not refuse shipment, but

contact the shipper and le the appropriate freight claims.

Rating Plate

The rating plate is attached to the Salamander’s body, behind

the upper stainless steel trim. It is accessible after removing

that trim (two screws at each end).

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

Other information on this plate is the BTU/hr input to the

burners, outlet gas pressure in inches WC, and whether

oriced for natural or propane gas.

WARNING All U.S. Range Salamander broilers must be

connected only to the type of gas identied on the rating

plate! Installation must be in accordance with ANSI 283.11

(latest edition) of the American national Standards Institute,

Inc.

INSTALLATION

Clearances

The appliance area must be kept free and clear of all

combustibles.

These units are design-certied for the following

installations:

1. Intended for other than household use.

2. For use in non combustible locations only.

Type of Construction

Minimum Clearance

Combustible Non-Combustible

Rear 6” (152mm) Rear 0”

Sides 12” (304mm) Sides 0”

Position and Setup

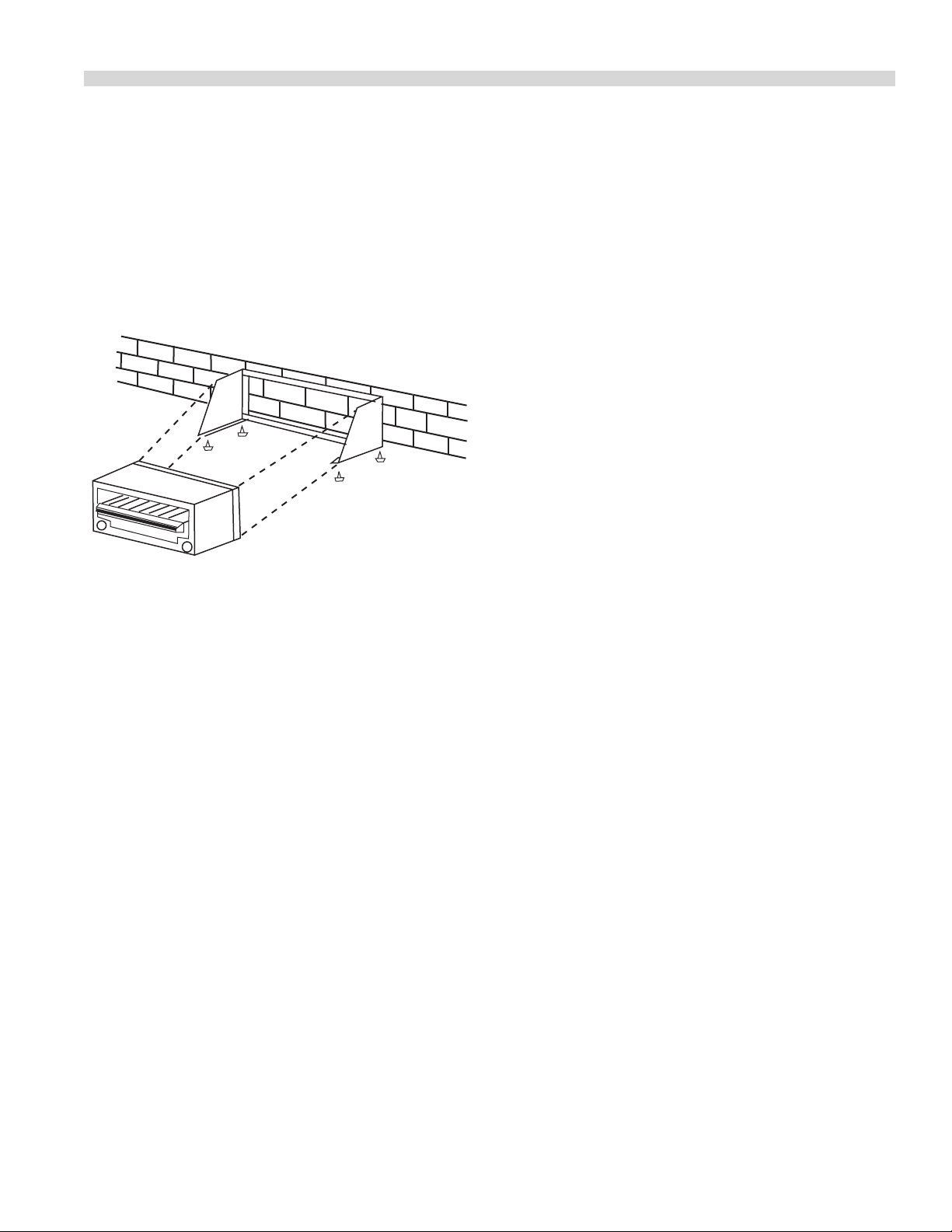

Wall Mounting

1. If the unit is to be mounted on a non-combustible wall

contact the local building department for local codes.

2. Each gas appliance must be located with respect to

building construction and other equipment so as to

permit access to the appliance, Such access and clearance

may be necessary for servicing and cleaning.

3. Salamanders intended for wall mounting are shipped

with the mounting kit already attached.

4. Provisions for gas connections, bottom or rear should be

taken into consideration.

. Position, level, and mark location of assembled wall

mount kit.

Part # Rev 3 1844033 (02/22/08)Page 4

Page 5

Part # Rev 3 1844033 (02/22/08) Page 5

INSTALLATION Continued

. Drill wall (locating wall studs if necessary) to accept

suitable fastening devices.

. Drill angle iron bars of wall mounting kit to match holes

drilled in wall.

. Install wall mounting kit to wall.

. Install and secure broiler with bolts supplied.

Range Mounting

Salamanders my not be mounted onto an already existing

high shelf or high riser with out internally bracing the vertical

panel. The back sheet of a range is not designed to carry that

much weight, and the outside body panels of a salamander

intended for wall mounting are dierent. It is important that

the factory be notied at the time of order/purchase that

the salamander is intended for range mount retrot. Range

mounted Salamanders are normally mounted at the factory

during manufacture.

A salamander intended for eld installation onto an existing

high shelf or high riser will be delivered with two pieces

of at bar steel, each of which has one end bent into a tab.

Install in the fallowing sequence.

1. Slide the at bars into the ue of the high riser (or shelf)

ush to the outside ends with the tabs facing to the

center.

2. Secure these stieners to the sides of the ue with bolts

or heavy self-tapping screws, with the top of the stiener

extending 18” (457mm) above the shelf or 16” (406mm)

above the top of the high riser.

3. Slide the Salamander down over the at bars and secure

with bolts from the at bar tab onto the Salamander.

Counter Installation

Salamanders intended for counter use are manufactured

with leg couplings in the bottom corners and are furnished

with 4” (102mm) legs. Units are not to be installed without

the legs, as the bottom clearance is necessary for heat

dissipation. Level the unit with a carpenter’s level, using the

screw thread of the legs for minor adjustments.

Air Supply and Ventilation

The area around the appliance must be kept clear to avoid

any obstruction to the ow of combustion and ventilation

air, as well as, for ease of maintenance and service. Under

no conditions should anything be stored on top or over the

Salamander, as ue gas temperatures are in the vicinity of

500°-700°F (260°-371°C).

Means must be provided for any commercial, heavy-duty

cooking appliance to exhaust combustion waste products to

the outside of the building. Usual practice is to place the unit

under an exhaust hood; the minimum should be an exhaust

fan mounted above the unit. Filters and drip troughs should

be part of any industrial hood, but consult local codes before

constructing and installing a hood.

Strong exhaust fans in this hood or in the overall air

conditioning system can produce a slight vacuum in the

room and/or cause air drafts, either of which can interfere

with pilot or burner performance and be hard to diagnose.

Air movement should be checked during installation; if

pilot/burner outage problems persist make-up air openings

or baes may have to be provided in the room.

Gas Supply

1. Installation of the equipment should be made by a

licensed plumber.

2. A gas shut-o valve must be installed in the gas supply

line ahead or the appliance for safety and for ease of

future service.

3. A gas pressure regulator must be installed at the

appliance prior to connecting the equipment to the gas

line. Failure to install a regulator will void the equipment

warranty.

NOTE: The gas supply (service) line must be the same size

or greater than the inlet line of the appliance. U.S. Range

Salamander use a 3/4” NPT inlet. Sealant on all pipe joints

must be resistive to LP gas.

Page 6

INSTALLATION Continued

National Code Requirements

Safe and satisfactory operation of your equipment depends,

to a great extent, on its proper installation. Installation must

conform to local codes or, in the absence of local codes with

the National Fuel code, ANSI Z223.1, Natural Gas Installation

Code, CAN/CGA-B149.1, or the Propane Installation Code,

CAN/CGA-B149.2, as applicable, including:

1. The appliance and its individual shuto valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shuto

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi

(3.45 kPa)

Manual Shut-O Valve

This installer-supplied valve must be installed in the gas

service line ahead of the appliance and regulator in the gas

stream and in a position where it can be reached quickly

in the event of an emergency. If the Salamander is ranged

mounted, a separate shut-o valve should be on the line to

the unit.

Pressure Regulator

All heavy-duty, commercial cooking equipment must have

a pressure regulator in the incoming service line for safe and

ecient operation, since service pressure may uctuate with

local demand. The manual shut-o valve is normally supplied

by the installer, but pressure regulators are shipped from U.S.

Range with every hot plate.

Regulators are pre-set at the factory for 5” WC (natural gas)

or 10” WC (propane) according to the customer’s ordering

instructions.

Prior to connecting the regulator, check the incoming line

pressure, as these regulators can withstand a maximum

pressure of 1/2 psi (14” WC). If the Line pressure is beyond

this limit, a step-down regulator will be required. Doublecheck the arrow forged onto the bottom of the regulator

body which shows gas ow directions; it should point

downstream to the appliance. The red air-vent cap is part of

the regulator and should not be removed unless local codes

require external venting.

Regulators can be adjusted in the eld, but it is

recommended that they not be tampered with unless that

part is known to be out of adjustment or serious pressure

uctuations are found to exist and can be solved no other

way. Any adjustments to regulators must be made by

qualied service personnel with proper test equipment.

WARNING Do not connect the regulator inside the unit’s

body or directly on top of the salamander, as temperatures

are high enough in these areas to destroy the regulator.

Failure to install a pressure regulator will void the

equipment warranty!

Rigid Connections

Double-check any installer-supplied intake pipes visually

and clear any dirt particles, threading chips, or other foreign

matter before installing in a service line. Those particles will

clog orices when gas pressure is applied.

WARNING All connections must be sealed with a joint

compound suitable for LP gas, and all connections must be

tested with a soapy solution before lighting any pilots!

Flexible Couplings & Connectors.

If the unit is to be installed with exible couplings and/or

quick-disconnect ttings, for an appliance equipped with

casters, the installation shall be made with a connector that

complies with the Standard for Connectors for Movable Gas

Appliances, ANSI Z21.69 /CSA 6.16, and a quick-disconnect

device that complies with the Standard for Quick-Disconnect

Devices for Use With Gas Fuel, ANSI Z21.41 / CSA 6.9, and

adequate means must be provided to limit the movement

of the appliance without depending on the connector and

the quick-disconnect device or its associated piping to limit

the appliance movement and the location(s) where the

restraining means may be attached to the appliance shall be

specied.

Further, if the unit is to be installed on a non-combustible

surface that is equipped with casters, means must be

provided to limit the movement of the unit on this surface.

Manual Pilot Valve

Part # Rev 3 1844033 (02/22/08)Page 6

Page 7

Part # Rev 3 1844033 (02/22/08) Page 7

INSTALLATION Continued

All burners are equipped with constant-burning pilots. These

should be manually lighted immediately after the gas is

turned on and the system is checked for leaks. An adjustment

screw for each pilot is located on the gas manifold and can

be accessed through openings in the valve panel between

the valve knobs.

Testing and Adjustments

Check all gas connections for leaks using a soapy solution

before lighting any pilots. DO NOT USE OPEN FLAME

TO CHECK FOR LEAKS! Putting open ame beside a new

connection is not only dangerous, but will often miss small

leaks that a soapy solution would nd.

All U.S. Range appliances are adjusted and tested before

leaving the factory, eectively matching them to sea

level conditions. Adjustments and calibrations to assure

proper operation may be necessary on installation to meet

local conditions, low gas pressure, dierences in altitude;

variations in gas characteristics, to correct possible problems

caused by rough handling or vibration during shipment, and

are to be performed only by qualied service personnel.

These adjustments are the responsibility of the customer,

installer and/or dealer and are not covered by the U.S. Range

warranty.

Page 8

INITIAL OPERATION

Initial Pilot Light

Initial pilot light is in the following sequence:

1. Turn the manual shut-o valve on the incoming service

line “OFF”.

2. Turn all burner valves “OFF”.

3. Close all pilot adjusting screws (clockwise turn all the

way in).

4. Wait for any accumulated gas to disperse.

5. Open the manual shut-o valve.

6. Apply a lighted match or taper to a pilot burner and open

that pilot’s adjustment screw gradually until the pilot

lights.

7. Adjust the pilot ame for the desired characteristics.

8. Turn “ON” that main burner and watch to make sure it

lights from the pilot, then turn the burner “OFF”.

9. Repeat steps 6 through 8 to light all remaining pilots.

If only one pilot has gone out, it is not necessary to follow

the entire procedure outlined above. Merely apply a lighted

match or taper to the pilot until it lights, then adjust the pilot

valve. If the pilot will not light, close the adjustment valve

completely, do not use that burner, and call for service.

NOTE: It may be necessary to re-light the pilots several

times until the new lines are purged of any trapped air and

constant gas ow is attained.

WARNING

The tiles on the face of an infrared burner are porous and

extremely delicate when hot. If these tiles are bumped

roughly with normal hand tools, they can easily crack,

destroying the eectiveness of the burner. The only repair

to a cracked tile is to replace the entire burner.

Final Preparation

New units are wiped clean with solvent at the factory to

remove any visible signs of dirt, oil, grease, etc., remaining

from the manufacturing process. They should be washed

with hot, soapy water to remove any solvent or oil residue or

installation dust or debris before using for food preparation.

A “J” hook reaching to the rear is built into the carriage

assembly, which supports the cast iron broiling grates. This

hook normally catches onto the front cross bar connecting

the right and left-hand grid runners. When the Salamander

is packed for shipment this “J” hook is latched onto the rear

connecting cross bar to limit accidental travel of the carriage.

This can be seen only with the grates removed.

Lift the “J” hook and cautiously slide the carriage out a few

inches, then let the hook drip. Slide the carriage the rest of

the way out and make sure the “J” hook catches on the front

cross bar. If this is not done, the carriage will move only

about two or three inches; if the “J” hook misses the front bar,

the carriage assembly will slide completely out.

Part # Rev 3 1844033 (02/22/08)Page 8

Page 9

Part # Rev 3 1844033 (02/22/08) Page 9

CLEANING AND MAINTENANCE

WARNING If gas odors are detected, the gas supply must

be turned “OFF’ at the main shut-o valve and the local

gas company or authorized service agency contacted for

service.

General Cleaning

Any piece of equipment works better and lasts longer when

maintained properly and kept clean. Cooking equipment is

no exception. Your U.S. Range hot plate must be kept clean

during the working day and thoroughly cleaned at the end

of each day.

Daily

1. Remove the broiler grates. Wire brush them clean of any

encrusted materials and wash in hot, soapy water.

2. The drip pan should be cleaned regularly in the course

of the working day, wiping up spills as they occur. At the

end of the day, remove the pan and wash in hot, soapy

water.

3. Wash the reminder of the Salamander’s interior while the

drip pan and grates are removed, then reassemble.

4. Wipe the outside of the Salamander’s body.

CAUTION The drawer assembly is spring loaded to carry

the eight of the carriage and grates. If the handle is released

without the grates on the carriage, the carriage will slam to

the “UP” position.

Periodic

Your U.S. Range Salamander should be checked and adjusted

periodically by qualied service personnel as part of a regular

kitchen maintenance program.

Cleaning Stainless Steel

All stainless steel body parts should be wiped regularly with

hot, soapy water during the day, and with a liquid cleaner

designed for this material at the end of each day. Do not

use steel wool, abrasive cloths, cleansers, or powders! If it

is necessary to scrape stainless steel to remove encrusted

materials, soak the encrusted area with wet cloths to loosen

the material, then use a wood or nylon scraper. Do not use

a metal knife, spatula, or any other metal tools to scrape

stainless steel. Scratches are almost impossible to remove.

SERVICE AND PARTS

Installation, maintenance and repairs should be performed

by your local authorized U.S. Range service agency listed in

your information manual pamphlet.

Page 10

Page 11

Page 12

Pièce n° Rev 3 1844033 (02/22/08) Page 9

sur la liste du manuel.

par l’agence de service locale autorisée U.S. Range, gurant

L’installation, l’entretien et les réparations doivent être faits

SERVICE ET PIECES DE RECHANGE

rayures sont presque impossibles à retirer.

autre outil métallique pour gratter l’acier ixodydable. Les

N’utilisez pas de couteau ni de spatule en métal ni aucun

décoller et utilisez ensuite un grattoir en bois ou en nylon.

trempez le produit incrusté avec un chi on mouillé pour le

gratter l’acier inoxydable pour retirer des produits incrustés,

abrasifs ni de poudres de nettoyage! S’il est nécessaire de

n de chaque journée. N’utilisez pas de laine d’acier, de tissus

journée et avec un produit de nettoyage liquide spécial à la

régulièrement avec de l’eau chaude savonneuse pendant la

Toutes les pièces en acier inoxydable devront être lavées

Nettoyage De L’acier Inoxydable

cuisine.

dans le cadre d’un programme d’entretien régulier de la

réglée périodiquement par du personnel d’entretien quali é

Votre gril à Salamandre U.S. Range devra être véri ée et

Périodique

position “UP”.

lâchée sans les grilles sur le chariot, le chariot va se fermer en

supporter le poids du chariot et des grilles. Si la poignée est

ATTENTION : L’ensemble de tiroir est muni d’un ressort pour

4. Essuyer l’extérieur de la carrosserie de la salamandre.

place.

lèchefrites et les grilles sont enlevées, puis les remettre en

3. Laver le reste de l’intérieur de la salamandre lorsque les

et la laver à l’eau savonneuse chaude.

se produisent. À la n de la journée, enlever la lèchefrite

journée de travail et les déversements essuyés dès qu’ils

2. La lèchefrite doit être régulièrement nettoyée durant la

laver dans l’eau savonneuse chaude.

métallique pour en enlever tout aliment incrusté. Les

1. Enlever les grilles du gril. Les nettoyer à la brosse

Quotidien

jour.

journée de travail et être nettoyée à fond à la n de chaque

Salamandre U.S. Range doit être maintenue propre durant la

L’équipement de cuisson ne fait pas exception. Votre gril à

s’il est correctement entretenu et maintenu propre.

Tout équipement fonctionne mieux et dure plus longtemps

Nettoyage Général

ou un service de réparation autorisé.

principal et l’on doit contacter la compagne locale de gaz

l’alimentation en gaz doit être coupée au robinet d’arrêt

AVERTISSEMENT : Si l’on détecte une odeur de gaz,

NETTOYAGE ET ENTRETIEN

Page 13

Pièce n° Rev 3 1844033 (02/22/08)Page 8

complètement à l’extérieur.

ne s’engage pas dans la barre transversale, le chariot sortira

déplacera que de deux ou trois pouces. Si le crochet en “J”

transversale avant. Si ce n’est pas le cas, le chariot ne se

et s’assurer que le crochet en “J” s’engage dans la barre

crochet. Tirer sur toute sa course le chariot vers l’extérieur

vers l’extérieur de quelques pouces, puis laisser tomber le

Soulever le crochet en “J” et faire doucement glisser le chariot

fois les grilles enlevées.

déplacement accidentel du chariot. On ne peut le voir qu’une

en “J” est xé à la barre transversale arrière pour limiter tout

de l’emballage de la salamandre pour l’expédition, ce crochet

avant reliant les coulisseaux gauche et droit des grilles. Lors

crochet s’engage normalement dans la barre transversale

l’ensemble de chariot, qui soutient les grilles en fonte. Ce

Un crochet en “J” orienté vers l’arrière est intégré dans

cuisson d’aliments.

d’huile et de solvant ou les débris avant de les utiliser pour la

être lavés à l’eau chaude savonneuse pour retirer les résidus

etc., restant du processus de fabrication. Ils devront donc

pour éliminer toute trace visible de saleté, d’huile, de graisse,

Les appareils neufs sont nettoyés avec du solvant en usine

réparateur.

soupape de réglage, n’utilisez pas ce brûleur et appelez le

Si la veilleuse ne s’allume pas, fermez complètement la

la veilleuse jusqu’à ce qu’elle s’allume, puis réglez la veilleuse.

simplement une allumette ou une mèche en ammée près de

suivre toute la procédure indiquée ci-dessus. Appliquez

Si une seule veilleuse s’est éteint, il est nécessaire de

restantes.

9. Répéter les étapes 6 à 8 pour allumer toutes les veilleuses

bout d’environ trente secondes.

être di cile à voir, mais qui deviendra rouge cerise au

début, le brûleur brûle avec une amme bleue qui peut

brûleur s’allume par la veilleuse, puis arrêter le brûleur. Au

8. Mettre le brûleur infrarouge sur “ON” et s’assurer que le

souhaitées.

7. Régler la amme de veilleuse pour les caractéristiques

réglage de cette veilleuse jusqu’à ce qu’elle s’allume.

brûleur infrarouge) et ouvrez progressivement la vis de

xée sur le côté de l’appareil, juste dessous et à droite du

veilleuse (ceci est monté sur une languette fabriquée,

6. Appliquez une allumette ou une mèche près d’une

Préparation Finale

5. Ouvrez le robinet d’arrêt manuel.

un carreau ssuré est de remplacer tout le brûleur.

annulera l’e cacité du brûleur. La seule façon de réparer

de cuisine, elles peuvent se ssurer facilement, ce qui

chaudes. Si ces carreaux subissent le choc d’un ustensile

poreuses et extrêmement fragiles lorsqu’elles sont

Les carreaux de la façade du brûleur à infrarouge sont

4. Attendez que le gaz accumulé se disperse.

vissant complètement à droite).

3. Fermez toutes les vis de réglage des veilleuses (en les

2. Fermez tous les robinets de brûleurs.

AVERTISSEMENT

gaz constant.

purgées de toute trace d’air et qu’on obtienne une débit de

plusieurs fois jusqu’à ce que les nouvelles conduites soient

NOTA : Il peut être nécessaire de réallumer les veilleuses

d’alimentation en gaz.

1. Fermez le robinet d’arrêt manuel sur la conduite

Procédez à l’allumage des veilleuses dans l’ordre suivant :

Allumage Initial Des Veilleuses

UTILISATION INITIALE

Page 14

Pièce n° Rev 3 1844033 (02/22/08) Page 7

la garanties U.S. Range.

l’installateur et/ou du revendeur et ne sont pas couverts par

Ces réglages sont de la responsabilité du client, de

e ectués par du personnel d’entretien quali é.

ou des vibrations pendant le transport, et ils doivent être

du gaz, a n de corriger des problèmes causés par des chocs

di érences d’altitude, aux variations des caractéristiques

aux conditions locales, à une faible pression du gaz, aux

peuvent être nécessaire lors de l’installation pour répondre

réglages et étalonnages pour fonctionner correctement

quitter l’usine, pour correspondre au niveau de la mer. Des

Tous les appareils U.S. Range sont réglés et testés avant de

que l’eau savonneuse pourrait détecter.

dangereux, mais on manquera souvent ainsi de petites fuites

nue près d’une nouvelle connexion est non seulement

LA PRÉSENCE DE FUITES! Le fait de placer une amme

veilleuses. N’UTILISEZ PAS DE FLAMME NUE POUR VÉRIFIER

en utilisant une solution savonneuse avant d’allumer les

Véri ez toutes les connexions du gaz pour déceler les fuites

robinets entre les boutons.

peut y accéder par les ouvertures dans le panneau des

chaque veilleuse est situé dans le collecteur de gaz et on

système comportait des fuites. Une vis de réglage pour

immédiatement après avoir ouvert le gaz et véri é si le

constante. Elles devront être allumées manuellement

Tous les brûleurs sont équipés de veilleuses à amme

Robinet Manuel De Veilleuse

surface.

prévus pour limiter les déplacements de l’appareil sur cette

combustible équipée de roulettes., des moyens doivent être

De plus, si l’appareil doit être installé sur une surface non

l’appareils seront spéci és.

emplacements où les moyens de retenue peuvent être xés à

connexe pour limiter les déplacements de l’appareil et les

et le dispositif de débranchement rapide ou sa tuyauterie

le déplacement de l’appareil sans utiliser le connecteur

ANSI Z21.41 / CSA 6.9, et un dispositif sera prévu pour limiter

pour les Dispositifs à débranchement rapide pour le gaz,

dispositif de débranchement rapide conforme à la norme

pour appareils mobiles, ANSI Z21.69 / CSA 6.16, et un

connecteur conformément à la norme pour connecteurs

équipés de roulettes, l’installation doit être faite avec un

exibles et/ou des raccords rapides pour les appareils

Si l’unité doit être installée avec des accouplements

Essais Et Réglages

Raccords Et Connecteurs Souples

INSTALLATION suite

Page 15

Pièce n° Rev 3 1844033 (02/22/08)Page 6

savonneuse avant d’allumer les vielleuses!

le GPL et toutes connexions doivent être testées à l’eau

étanchéi ées, avec un composé à joint convenable pour

AVERTISSEMENT : Toutes les connexions doivent être

boucheront les ori ces une fois la pression de gaz appliquée.

d’installer une conduite d’alimentation. Ces particules

copeaux de letage et autres matières étrangères avant

par l’installateur et nettoyez toutes les particules de saleté,

Véri ez bien visuellement les tuyaux d’alimentation fournis

Connexions Rigides

annulera la garantie de l’équipement!

le régulateur. Toute absence de régulateur de pression

su samment élevées dans ces endroits pour détruire

la Salamandre étant donné que les températures sont

l’intérieur de l’appareil ou directement au-dessus de

AVERTISSEMENT : Ne branchez pas le régulateur à

l’équipement d’essai approprié.

doit être e ectué par du personnel d’entretien quali é avec

être résolu d’une autre façon. Tout réglage du régulateur

uctuations de pression et que le problème ne puisse pas

que le régulateur est déréglé ou qu’il existe d’importantes

recommandé de ne pas les modi er à moins que l’on sache

Les régulateurs peuvent être ajustés sur place, mais il est

une mise à l’air libre extérieure.

ne devra pas être retiré à moins que les codes locaux exigent

Le bouchon d’évent d’air rouge fait partie du régulateur et

sens du débit du gaz; elle devra être orientée vers l’appareil.

bien la èche forgée sur le corps du régulateur qui montre le

régulateur abaissseur de pression sera nécessaire. Véri ez

pression de la conduite est supérieure à cette limite, un

à une pression maximale de 0,5 lb/po2 (14 po C.E.). Si la

du gaz, étant donné que ces régulateurs peuvent résister

Avant de brancher le régulateur, véri ez la pression d’arrivée

conduite de gaz à l’appareil.

unité autonome, prévoir une soupape d’arrêt séparée sur la

facilement en cas d’urgence. Si la salamandre est montée en

régulateur de pression, à un endroit où on peut l’atteindre

la conduite d’alimentation en gaz avant l’appareil et le

Le robinet fourni par l’installateur doit être monté sur

Robinet D’arrêt Manuel

inférieures à 0,5 lb/po2 (3,45 kPa).

essai de pression du système à des pressions égales ou

gaz en fermant son robinet d’arrêt individuel lors de tout

2. L’appareil doit être isolé du système d’alimentation en

(3,45 kPa).

pression du système à des pressions dépassant 0,5 lb/po2

débranchés de l’alimentation en gaz lors de tout essai de

1. L’appareil et son robinet d’arrêt individuel doivent être

y compris :

Code d’installation du propane CAN/CGA-B149.2, selon le cas,

Code d’installation du gaz naturel, CAN/CGA-B149.1 ou au

l’absence de codes locaux, au National Fuel code, ANSI Z223.1,

L’installation doit être conforme aux codes locaux ou, en

dépend, dans une grande mesure, de son installation correcte.

Le fonctionnement sécuritaire et satisfaisant de l’équipement

Exigences Des Codes Nationaux

appliqué sur tous les raccords doivent résister au GPL.

utilisent une entrée 3/4 po NPT. Le produit d’étanchéité

d’entrée de l’appareil. Des grils U.S. Range à Salamandre

diamètre ou d’un diamètre supérieur à celui de la conduite

NOTA : La conduite d’alimentation de gaz doit être du même

du client.

naturel) ou 10 po C.E. (propane) en fonction de la commande

Les régulateurs sont préréglés en usine pour 5 po C.E. (gaz

expédiés par U.S. Range avec chaque Salamandre.

fourni par l’installateur, mais les régulateurs de pression sont

de la demande. Le robinet d’arrêt manuel est normalement

donné que la pression d’alimentation peut varier en fonction

en gaz pour un fonctionnement sécuritaire et e cace, étant

d’un régulateur de pression sur la conduite d’alimentation

Tout gros équipement de cuisson commercial doit être doté

Régulateur De Pression

l’équipement.

de gaz. L’absence de régulateur annulera la garantie sur

l’appareil avant de brancher l’équipement à la conduite

3. Un régulateur de pression du gaz doit être installé sur

sécurité et pour faciliter les réparations ultérieures.

conduite d’alimentation en amont de l’appareil pour la

2. Un robinet de fermeture du gaz doit être installé sur la

plombier licencié..

1. L’installation de l’équipement devra être faite par un

Alimentation En Gaz

INSTALLATION suite

Page 16

ouvertures ou dé ecteurs d’air dans la pièce.

brûleurs persistent, il est possible que l’on doive prévoir des

véri é lors de l’installation; si les problèmes de veilleuses/

di ciles à diagnostiquer. Tout mouvement d’air devra être

avec les performances des brûleurs ou des veilleuses et être

dans la pièce et/ou des courants d’air, qui peuvent interférer

le système d’air conditionné peuvent causer un léger vide

Des ventilateurs d’extraction puissants dans la hotte ou dans

les codes locaux avant de construire une hotte.

de ltres et d’ori ce d’écoulement, mais vous devez consulter

est un minimum. Toute hotte industrielle devrait être dotée

présence d’un ventilateur d’extraction au-dessus de l’appareil

On place généralement l’unité une hotte d’extraction; la

d’évacuer les produits de cuisson à l’extérieur du bâtiment.

Pour tout appareil de cuisson commercial, il est nécessaire

conduit de fumée est voisine de 500°-700°F (260°-371°C).

ou au dessus de la salamandre car la température des gaz du

réparations. En aucun cas, il ne faut rien poser sur le dessus

de ventilation, ainsi que pour faciliter l’entretien et les

éviter toute obstruction du ux d’air de combustion et

La zone autour de l’appareil doit être dégagée pour

Pièce n° Rev 3 1844033 (02/22/08) Page 5

fabrication.

sont normalement montées en usine au moment de la

autonome. Les salamandre montées en unités autonomes

achat que la salamandre est destinée à un montage en unité

important de noti er à l’usine au moment de la commande/

salamandre destinée au montage mural sont di érents . Il est

important et les panneaux de carrosserie extérieurs d’une

d’une cuisinière n’est pas conçue pour soutenir un poids

renforcer intérieurement le panneau vertical. La paroi arrière

étagères hautes ou des colonnes montantes existantes sans

Les salamandres ne doivent pas être montées sur des

Montage en unité autonome

Alimentation En Air Et Ventilation

charpentier et les vis des pieds pour le réglage.

faut mettre l’appareil de niveau en utilisant un niveau de

inférieur est nécessaire pour la dissipation de la chaleur. Il

doivent pas être installées sans les pieds, parce que l’espace

inférieurs et sont livrées avec des pieds de 4 po. Ces unités ne

sont fabriquées avec des supports de pieds dans les coins

Les salamandres destinées à être utilisées sur un comptoir

Installation Sur Comptoir

plat vers la salamandre.

et xer les boulons depuis la languette de la pièce d’acier

3. Faire glisser la salamandre vers le bas sur les barres plates

haut de la colonne montante.

dessus de l’étagère ou de 16 po (406 mm) au dessus du

dessus du raidisseur dépassant de 18 po (457 mm) au

des boulons ou de grosses vis autotaraudeuses, avec le

2. Fixer ces raidisseurs aux côtés du conduit de fumée avec

vers le centre.

avec les bords extérieurs, avec les languettes orientées

fumée de la colonne montante ou de l’étagère de niveau

1. Faire glisser les pièces d’acier plat dans le conduit de

languette. Procéder au montage dans l’ordre suivant :

pièces en acier plat ayant chacune une extrémité pliée en

ou une colonne montante existants seront livrées avec deux

Une salamandre destinée au montage sur une étagère haute

9. Installer et xer le grilloir avec des boulons fournis

8. Installer le nécessaire d’accrochage au mur sur le mur.

perforés dans le mur.

d’accrochage au mur pour correspondre aux trous

7. Perforer les barres de fer d’angle du nécessaire

appropriés.

nécessaire) pour accepter les dispositifs d’attache

6. Perforer le mur (en localisant des goujons de mur si

nécessaire d’accrochage au mur assemblé.

5. Position, niveau, et emplacement de la marque du

dessous ou de l’arrière devraient être prises en compte.

4. Des dispositions pour des raccordements du gaz, du

transportées avec le nécessaire d’accrochage déjà joint.

3. Des salamandres prévues pour l’accrochage au mur sont

entretenir et nettoyer.

tel accès et dégagement peuvent être nécessaires pour

équipements a n de permettre l’accès à l’appareil. Un

respectant la construction de bâtiments et d’autres

2. Chaque appareil d’utilisation du gaz doit être situé en

INSTALLATION suite

Page 17

Pièce n° Rev 3 1844033 (02/22/08)Page 4

pour des codes locaux.

contactez le service des bâtiments et de l’entretien local

1. Si l’unité doit être montée sur un mur non combustible

Accrochage au Mur

Côtés 0 po

Arrière 0 po

combustible:

Construction non-

(304 mm)

12 po

(152 mm)

6 po

Dégagement minimum

Type de construction

Positionnement Et Installation

Côtés

Arrière

Construction combustible:

combustibles uniquement.

2. Pour une utilisation dans des emplacements non

1. Pour une utilisation autre que ménagère

installations suivantes ;

Ces appareils sont homologués par conception pour les

combustibles.

L’appareil doit être tenu à l’écart de tous les produits

Dégagements

INSTALLATION

l’American national Standards Institute, Inc.

conforme à la norme ANSI 283.11 (dernière édition) de

identi é sur la plaque signalétique ! L’installation doit être

Range doivent être branchées uniquement au type de gaz

AVERTISSEMENT : Toutes les rôtissoires salamandre U.S.

ou le propane.

de sortie de gaz en pouces C.E. et ori ces pour le gaz naturel

suivantes : débit calori que des brûleurs en BTU/h, pression

Les autres informations gurant sur cette plaque sont les

signalétique xée à l’appareil contient ces renseignements.

et du su xe) et le numéro de série de garantie. La plaque

modèle correct (comprenant les lettres et chi res du pré xe

rechange, bien faire référence à l’appareil avec le numéro de

local concernant des problèmes de service ou des pièces de

Pour correspondre avec l’usine ou le centre de service agréé

transport appropriées.

contacter l’expéditeur et remplir les réclamations de

En cas de dommages, ne pas refuser l’expédition, mais

dommages dus au transport sur l’équipement.

Après le déballage, véri er immédiatement les signes de

Déballage

par le concessionnaire ou une agence de services quali ée.

recommandé de faire e ectuer des inspections périodiques

L’appareil doit être nettoyé et entretenu régulièrement. Il est

chaque extrémité).

est accessible après avoir retiré cette garniture (deux vis à

derrière la garniture supérieure en acier inoxydable. Elle

La plaque signalétique est xée au corps de la salamandre,

Plaque Signalétique

usine avant l’expédition.

à la sole de la rôtissoire. Tous les appareils sont inspectés en

rôtissoire. Ces articles sont emballés individuellement et xés

emballés à l’intérieur de l’appareil avec les grilles de la

les clips de montage mural et les régulateurs de pression

Tous les appareils sont expédiés complètement montés, avec

INTRODUCTION

Page 18

Pièce n° Rev 3 1844033 (02/22/08) Page 3

SERVICE ET PIECES DE RECHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Nettoyage De L’acier Inoxydable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Nettoyage Général . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

NETTOYAGE ET ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Préparation Finale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Allumage Initial Des Veilleuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

UTILISATION INITIALE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Essais Et Réglages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Robinet Manuel De Veilleuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Raccords Et Connecteurs Souples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Connexions Rigides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Régulateur De Pression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Robinet D’arrêt Manuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Exigences Des Codes Nationaux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Alimentation En Gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Alimentation En Air Et Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Sur Comptoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Montage en unité autonome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Accrochage au Mur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Positionnement Et Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Dégagements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plaque Signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INFORMATIONS IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE DES MATIÈRES

Page 19

Pièce n° Rev 3 1844033 (02/22/08)Page 2

AVERTISSEMENT

dégagés et ne pas y stocker de produits combustibles

Maintenir les abords de l’appareil

d’autres problèmes reproductifs.

est reconnue par l’état de Californie comme pouvant causer des malformations congénitales ou

exposer au monoxyde de carbone en cas de mauvais réglage. L’inhalation de monoxyde de carbone

est reconnue par l’état de Californie comme causant le cancer. L’utilisation de ce produit peut vous

verre/fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

INFORMATIONS IMPORTANTES

Page 20

Pièce n° Rev 3 1844033 (02/22/08) Page 1

Pièce nº 1844033 Rev 3 (02/22/08) © 2004 Garland Commercial Industries, Inc.

Télécopieur : 081-848-0041

Téléphone : 081-561-0433

ANGLETERRE

Swallow eld Way, Hayes, Middlesex UB3 1DQ

Enodis UK LTD.

.

être obtenue auprès du fournisseur de gaz local

détectée par l’utilisateur. Cette information peut

instructions à suivre en cas d’odeur de gaz

Placer dans un endroit bien en vue les

Pour votre sécurité

D’AUTORISATION : G-1-07-05-28

MONTEUR D’INSTALLATION AU GAZ. NUMÉRO

DOIT ÊTRE INSTALLÉ PAR UN PLOMBIER OU UN

DANS L’ÉTAT DU MASSACHUSETTS, CE PRODUIT

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

L’ÉQUIPEMENT.

AVANT D’INSTALLER OU DE RÉPARER

D’UTILISATION ET D’ENTRETIEN

MENT LES INSTRUCTIONS D’INSTALLATION,

SURES OU LA MORT. LIRE SOIGNEUSE-

DES DOMMAGES MATÉRIELS, DES BLES-

ENTRETIEN MAL FAITS PEUVENT CAUSER

MODIFICATIONS, DES RÉPARATIONS OU UN

UNE INSTALLATION, DES RÉGLAGES, DES

AVERTISSEMENT

Télécopieur : (570) 636-3903

Téléphone : (570) 636-1000

Freeland, Pennsylvanie 18224

185 East South Street

GARLAND COMMERCIAL INDUSTRIES

conception et les spéci cations des pièces) peuvent être remplacés ou modi és sans préavis.

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modi é ou réparé avec des pièces non autorisées

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être e ectués par un agent

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

ULTÉRIEUREMENT.

MANUEL ET LE CONSERVER POUR S’Y REPORTER

APPAREIL OU DE TOUT AUTRE APPAREIL

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

POUR VOTRE SÉCURIT:

LIRE TOUTES LES SECTIONS DU PRÉSENT

»

SÉRIE «REGAL

GRILS À SALAMANDRE

ET D’INSTALLATION

MANUEL D’UTILISATION

Loading...

Loading...