US Range 836-1414-1 Installation Manual

U.S. Range/ALCO

A Division of ALCO Foodservice Equipment Company

INSTALLATION INSTRUCTIONS

"CUISINE77 Deep Fat Fryers

Models 836/841-1414-1 & -2

All U.S. Range equipment is manufactured for use with the type of gas specified on

the rating plate and for installation in accordance with ANSI Z-223.1 (latest edition) of

the National Fuel Gas Code. Copies may be obtained from the American Gas

Association, 1515 Wilson Blvd., Arlington, VA - 22209.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

Instructions to be followed in case the user smells gas are to be posted in a prominent location. This information shall be obtained by contacting the local gas company or gas supplier.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

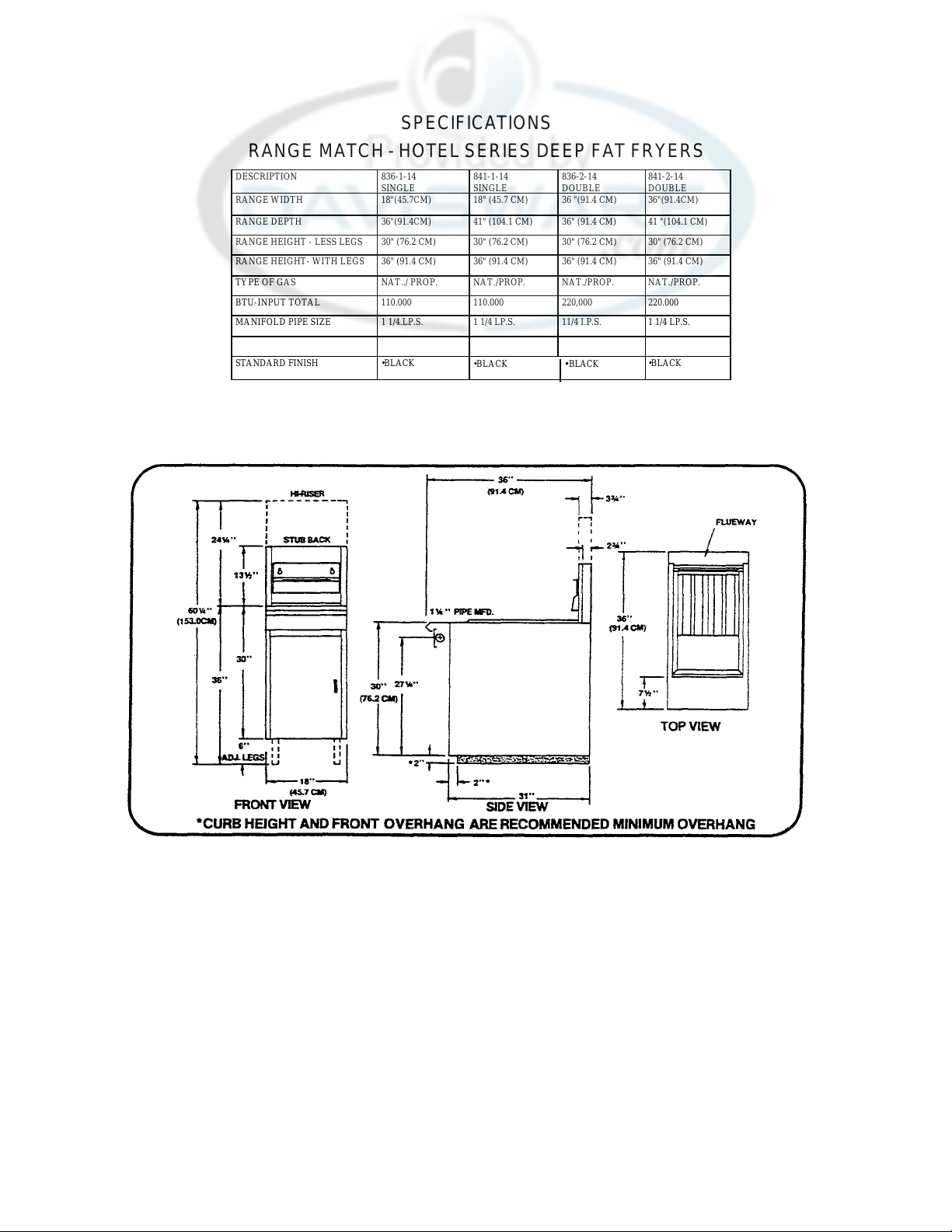

SPECIFICATIONS

SINGLE

SINGLE

DOUBLE

DOUBLE

RANGE MATCH - HOTEL SERIES DEEP FAT FRYERS

DESCRIPTION 836-1-14

RANGE WIDTH 18"(45.7CM) 18" (45.7 CM) 36 "(91.4 CM) 36"(91.4CM)

RANGE DEPTH 36"(91.4CM) 41" (104.1 CM) 36" (91.4 CM) 41 "(104.1 CM)

RANGE HEIGHT - LESS LEGS 30" (76.2 CM) 30" (76.2 CM) 30" (76.2 CM) 30" (76.2 CM)

RANGE HEIGHT- WITH LEGS 36" (91.4 CM) 36" (91.4 CM) 36" (91.4 CM) 36" (91.4 CM)

TYPE OF GAS NAT../ PROP. NAT./PROP. NAT./PROP. NAT./PROP.

BTU-INPUT TOTAL 110.000 110.000 220,000 220.000

MANIFOLD PIPE SIZE 1 1/4.LP.S. 1 1/4 LP.S. 11/4 I.P.S. 1 1/4 LP.S.

STANDARD FINISH •BLACK

•SILVERCO FINISH OPTIONAL AT NO EXTRA COST. STAINLESS STEEL AVAILABLE AT NOMINAL ADDITIONAL COST.

841-1-14

•BLACK •BLACK

836-2-14

841-2-14

•BLACK

IMPORTANT

Safe and satisfactory operation of your equipment

depends to a great extent on its proper installation.

Installation must conform to local codes or, in the absence

of local codes, with the National Fuel Code, ANSI Z-223.1-

1980 (or latest edition).

U.S. Range manufactures the "Cuisine" Deep Fat Fryer in either a single or double tank model, either of

which can be 36" or 41" deep overall. Internal parts are all interchangeable and there are no differences in

installation between models.

All "Cuisine" Deep Fat Fryers are shipped completely assembled, with the legs or optional casters

packed inside the fryer tank. All units are adjusted, tested, and inspected at the factory prior to crating for

shipment.

After uncrating, immediately check the equipment for visible signs of

shipping damage. If such damage has occurred, do not refuse shipment, but

contact the shipper and file the appropriate freight claims.

General

1. Installation of the equipment should be made by a licensed plumber.

2. A manual gas shut-off valve must be installed in the gas supply line ahead of

the appliance in the gas stream for safety and for ease of future service.

Rating Plate

This is riveted to the inside of the fryer-door.

Information on this plate includes the model and serial numbers ... when

communicating with the factory about a unit or requesting special parts or

Form CU-DFF 08/84

information, this data is essential for proper identification. Other information on this plate is the BTU/hr

output of the burners, outlet gas pressure in inches WC, and whether orificed for natural or propane

gas.

"CUISINE" DEEP FAT FRYERS MUST BE CONNECTED

ONLY TO THE TYPE OF GAS IDENTIFIED ON THE RATING PLATE!

Clearances

The appliance area must be kept free and clear of all combustibles. This unit is design-certified

for the following installations:

1. For locations having non-combustible walls;

2. For installation on a combustible floor when equipped with six inch legs or casters;

3. For installation without legs on a non-combustible curb or platform; and

4. For battery installation with other "Cuisine" appliances.

Mechanical

Legs or optional casters should be installed near where the appliance is to be used, as neither

are secure for long transit. After uncrating, tilt the body only high enough (or raise it about a foot) to

permit the legs or casters to be screwed into their couplings, and lower it gently to keep any undue

strain from the legs. It is strongly recommended that a pallet or lift jack be used rather than tilting.

A carpenter's spirit level should be placed across the top of the fryer and the unit levelled both

front-to-back and side-to-side. If it is not level, burner combustion may be erratic, the unit will not

function efficiently, and (in a line-up) it will not match the line visually.

If the floor is smooth and level, level the unit with the screw thread of the legs or casters; adjust

to the high corner and measure with the spirit level. If the floor is uneven or has a decided slope, level

the unit with metal shims; the adjustment required may exceed the thread available in the leg or caster

and/or a castered unit will probably not return to exactly the same position after being moved,

requiring relevelling after each move.

Form CU-DFF 08/84

Do not push against any edges of the unit in an attempt to adjust its

position! Although all metal parts are deburred during manufacture, accidents

could occur if the fryer should move suddenly while being pushed into position by

hand. Pushing a unit into position (rather than using a lift jack) also increases

the probability of bending the leg or caster spindles or the internal coupling

connectors.

Battery Assembly

The "Cuisine" standard 36" width and front manifold open on both ends were

designed to facilitate joining the units into a cooking line. This unit can be

added to an already existing line or be part of a new line-up. Once inserted into

its proper position and levelled, installation is the same as if it were standing

alone.

NOTE: The "Cuisine" Deep Fat Fryer does not have a removable front landing ledge!

That piece is part of the one-piece top. Installation will require an

off-set wrench to to able to tighten the union collar which connects to a

neighboring manifold.

NOTE: Local building codes will usually not permit a Deep Fat Fryer (with its

open tank of hot grease) to be mounted immediately next to an open flame

of any type, whether a broiler or the open burner of a range. Check the

local codes before beginning installation.

Adding a unit to a cooking line is in the following sequence:

1. Place all units to be batteried in their approximate locations in the line, or

open an existing line at the appropriate position and insert the fryer.

2. Remove the valve covers of adjacent units.

3. Level the fryer to match the units on either side at the front manifold.

4. Connect these units loosely at the front manifold ends.

5. Level the rear of the fryer to match adjacent units.

6. Secure the front manifold.

7. Plumb the feed lines as necessary. Cap the open end of the manifold if

exposed. The half-union supplied on the end of the manifold must be removed in

order to cap that end.

8. Replace all valve covers, landing ledges, and knobs.

Form CU-DFF 08/84

Air Supply & Ventilation

5

The area around the appliance must be kept clear to avoid any obstruc tion to the flow of

combustion and ventilation air as well as for ease of maintenance and service. Under no conditions is

the interior of the fryer's cabinet to be used for storage!

Means must be provided for any commercial, heavy-duty cooking appliance to exhaust

combustion waste products to the outside of the building. It is essential that a Deep Fat Fryer be set

under a powered exhaust hood or that an exhaust fan be provided in the wall above the unit, as

exhaust gas temperatures are in the vicinity of 1400 degrees. These temperatures, in addition to the

open tank of hot oil, make the storage of anything on shelving behind or over the fryer unsafe. Filters

and drip troughs should be part of any industrial hood, but consult local codes before constructing

and installing a hood.

Strong exhaust fans in this hood or in the overall air conditioning system can produce a slight

vacuum in the room and/or cause air drafts, either of which can interfere with pilot or burner

performance and be hard to diagnose. Air movement should be checked during installation; if

pilot/burner outage problems persist, make-up air openings or baffles nay have to be provided in the

room.

Gas Connection

NOTE: The gas supply (service) line must be the same size or greater than the inlet line of the

appliance. "Cuisine" Deep Fat Fryers use a 1-1/4" NPT (Sch40) inlet. Sealant on all

pipe joints must be resistive to LP gas.

Manual Shut -off Valve

This installer-supplied valve must be installed in the gas service line ahead of the appliance and

regulator in the gas stream and in a position where it can be reached quickly in the event of an

emergency.

Pressure Regulator

All heavy-duty, conmercial cooking equipment must nave a pressure regulator on the incoming

service line for safe and efficient operation, since

Form CU-DFF 08/84

Loading...

Loading...