Page 1

XAV905P-208

16 - 18”x26” Full Sheet Pans

Description:

• Standard o Optional - Not available

COOKING MODES

Convection cooking from 86 °F - 500 °F

Mixed steam and convecti on cooking from 118 °F - 500 °F, with STEAM.Maxi™ settings between 30% to 90%

•

Mixed humidity and convec tion cooking from 118 °F - 500 °F, with STE AM.Maxi™ settings between 10% to 20%

•

Steaming from 118 °F - 266 °F w ith STEAM.Maxi™ technology

•

Dry air cooking from 86 °F - 500 °F with DRY.Maxi™ technology, with settings between 10% to 100%

Maximum pre-heating temperature is 57 2 °F

•

Delta-T cooking with core probe

•

MULTI-Point core probe

SOUS-VIDE core pro be

o

AIR DISTRIBUTION WITH IN THE COOKING CHAMBER

AIR.Maxi™ Technology: multiple fans with reversing g ear

•

AIR.Maxi™ Technology: 3 air spee ds, programmable

AIR.Maxi™ Technology : 3 semi-static cooking modes, programmable

•

AIR.Maxi™ Technology: pulse functio n

•

CLIMATE MANAGEMENT WIT HIN THE COOKING CHAMBER

DRY.Maxi™ Technology: high performance moisture and humidity extraction, programmable by t he operator

•

DRY.Maxi™ Technology: cooking with humidity ext raction from 86 °F - 500 ° F

•

STEAM.Maxi™ Technology: steaming at 118 °F - 266 °F

STEAM.Maxi™ Technology: allows for a comb ination of moist air and dry air from 118 °F - 266 °F

•

ADAPTIVE.Clima Technology: for oven cav ity humidity measurement and regulation

•

ADAPTIVE.Clima Technology: repeating of the exact desired cooking process t hrough memorizing the act ual cooking process

ADAPTIVE.Clima Technology: 20 ADAPTIV E.Clima process m emory

•

THERMAL INSULATION AND SAFETY

Protek.SAFE™ Technology: maximum thermal efficiency and safe working conditions (cold glass doo r and external surfaces)

•

Protek.SAFE™ Technology: brake to prevent energy loss at door opening

•

Protek.SAFE™ Technology: electrical power absorption relat ed to the required needs

Protek.SAFE™ Technology: gas power absorption related t o the required needs

-

AUTOMATIC CLEANING

Rotor.KLEAN™ XC405: 3 automatic and 2 semi-automatic washing programs

•

PATENTED DOOR

Door hinges ma de of highly durable, self -lubricating techno-polymer

Reversible door , even after installation

•

Door stopping posit ions at 60°-120°-180°

•

AUXILIARIES FUNCTIONS

99 cooking programs memory, each one capable of 9 cooking s teps

Ability to assign a name to each stored program

•

Preheating temperature up t o 572 °F (manually controlled by operato r)

•

Display of the remaining c ooking time (when cooking without the co re probe)

•

Cooking Hold mode: «HOLD »

Continuous functioning: «INF»

•

Display of dat a: actual cooking time, c ore probe temperature, ca vity temperature and level of humidity

•

«COOL» function for rapid cavity cool-dow n

Temperatures cap tured in °C or °F

•

TECHNICAL DETAILS

Rounded-edge stainle ss steel (DIN 1.4301) cav ity for proper sanitation a nd ease of cleaning

•

Cavity lightin g through external LED lig hts

Steam-proof sealed ChefTouch control panel

•

Highly-durable c arbon fiber door lock

•

Door drip pan, for cont inuous drainage, even when the door is ope n

High capacity drip pan co nnectable to appliance drain

•

Light weight, heavy duty structure using innovative raw materials

•

Proximity door contact switch

•

2-stage safety door l ock

o

Self-diagnostic system

•

Safety temperature switch

Accessible inte rnal glass, for ease of c leaning

•

Stainless st eel / C-shaped rack rails with notched re cesses for easy loading

•

Certifications

Integrated tecnologies

AIR.Maxi Multiple fa ns in the design of UNOX ovens ensure perfect uniformity

very high heat transfer.

STEAM.Maxi

3000 rotations/mi n.

DRY.Maxi

surface.

ADAPTIVE.Clima:

while allowing the operator to obtain a perfect f inished product, each and every time.

Cooking Essentials

Bake (Art.: TG515)

Perforated aluminum pan

Grid (Art.: TG560)

Stainless st eel grid

Black.Bake (Art.: TG520)

aluminum pan

Pollo (Art.: TG570)

stainless steel grid

Optional

Art.: XAC 515

Hood with steam condenser

Art.: XC 249

External core probe SOUS-VIDE

Art.: XC 236

Ovex.net 3.0 with USB interface kit

ChefTop™: “Total Cooking Solutions” (Combi Oven) comes with the most advanced patented UNOX t echnologies.

ChefTop™: Differentiates itself from all other combi ovens, because it has been designed and de veloped through extensive

collaboration among a team of professional chefs and the most advanced research institutes across the globe.

ChefTop™: 0vens have a wide ra nge of available accessories to make this an extremely versatile machine, for ease of use within

all commercial kitchens.

Features:

•

•

Note: Lateral support in the cavity of the oven

(accommodates 16 – 18” x 26” Full Sheet Pans)

throughout all trays, fr om the top to the bottom. Auto-reversing motors , combined with

high-speed revolving fans , ens ure perfect uniformity within ev ery single pan. The ability

to select 3 air flow speeds within the chamber, and 3 semi-static modes, allows you to

cook any kind of product, from the l ightest and most delicate, to those which require a

due to the specia l design, high-speed fans which o perate upwards to

from the cooking chamber (both the humidity relea sed by the food and the same

eventually generated throug h all previous cooking steps). In gourmet and pastry this

technology ensures the exaltation of flavors, while allowing for a dry finished product

with an internal a lveolar-shaped s tructure, characterized by a crisp and crumbly external

including the chamber an d core temperature along with the level of humidity ( steam), the

oven can then adjust the cooking pr ogram to the number o f pans placed in the oven,

Production of “dens e and thin” steam from 118 °F

Patented UNOX technology, which provides rapid extraction of the humidity

Through the continuous monitoring of all the c ooking parameters,

•

•

•

•

•

•

•

•

•

•

Teflon-coated perforated

Pan.Fry (Art.: TG525)

Enamel-coated pan

Grill (Art.: TG530)

Teflon-coated aluminum pan

Baguette (Art.: TG565)

6 channel chromium plate d grid

8 bird capacity

No.fry (Art.: TG575)

Stainless steel basket

•

•

Page 2

TECHNICAL SPECIFICATIONS

Capacity

Pan Spacing / Pitch

Frequency

Voltage

Electrical power

Dimensions

Weight

XAV 905 P – 208

16

3

60 Hz

208V 3~ 60 Hz

38.5 kW

34

404 lbs (183 kg)

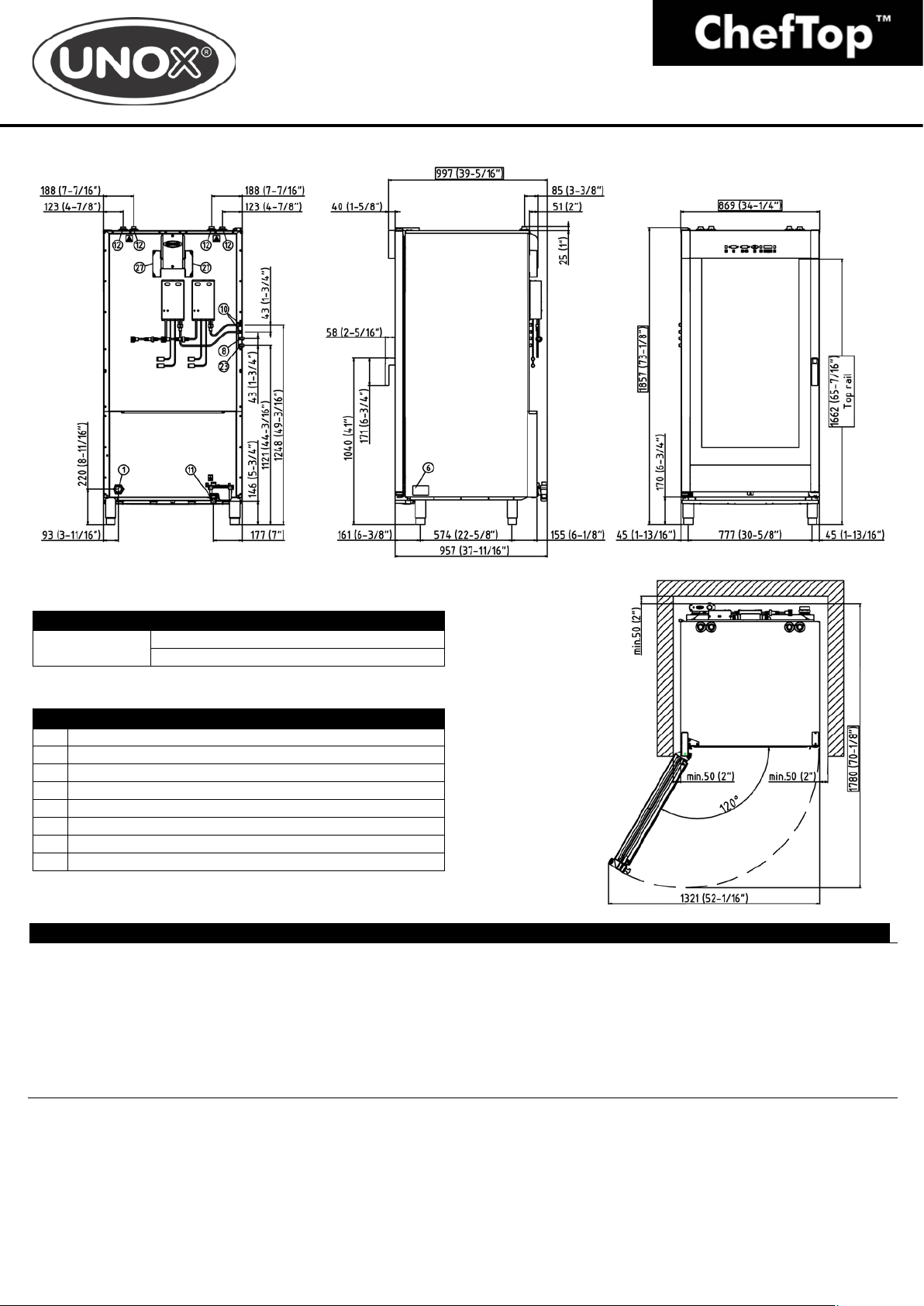

DIMENSIONS

A: mm

B: (in)

DRAWING LEGEND

1

TERMINAL BOARD COVER BOX

6

TECHNICAL DATA PLATE

8

3/4" THREAD WATER INLET

10

Rotor.KLEAN™ CONNECTION

11

OUTLET

12

CHEMNEYS

23

COOLING WATER INLET

27

COOLING AIR OUTLET

A (B)

- 18”x26” Full Sheet Pans

-3/8" (85 mm)

-1/4" (869 mm) x 38-1/4" (972 mm) x 73-15/32" (1866 mm)

UNOX INC.

105 Terry Drive - Suite 119

Newtown, Pennsylvania 18940

Toll Free: 1-800-489-UNOX (8669)

infousa@unox.com

Page 3

www.unox.com

Loading...

Loading...