ChefTop

™

™

ChefTop

English

ChefTop

™

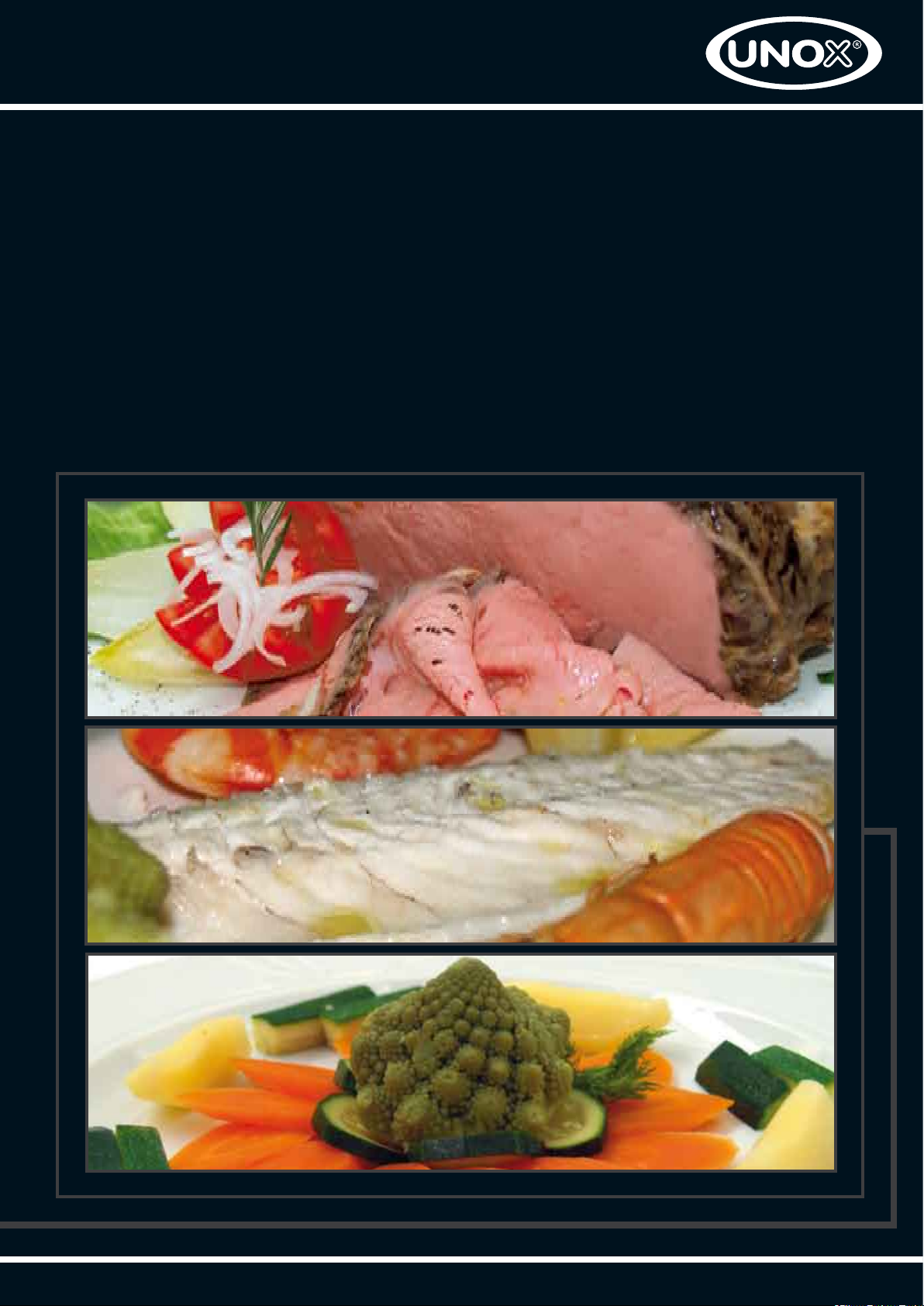

The result of the cooking is

always perfect!

™

ChefTop

Choose the cooking process most

suitable for your demands!

1

Preparing, cooking and serving

Cooking and serving

immediately is undoubtedly the

easiest working process that a

Chef has to face.

For this kind of operation,

UNOX offers you the new ChefTop™ line, characterised by

a wide range of modular ovens of different sizes and powers,

to satisfy any type of demand.

For kitchens with small working areas the option of a stand

with a pull-out shelf is invaluable.

4

2

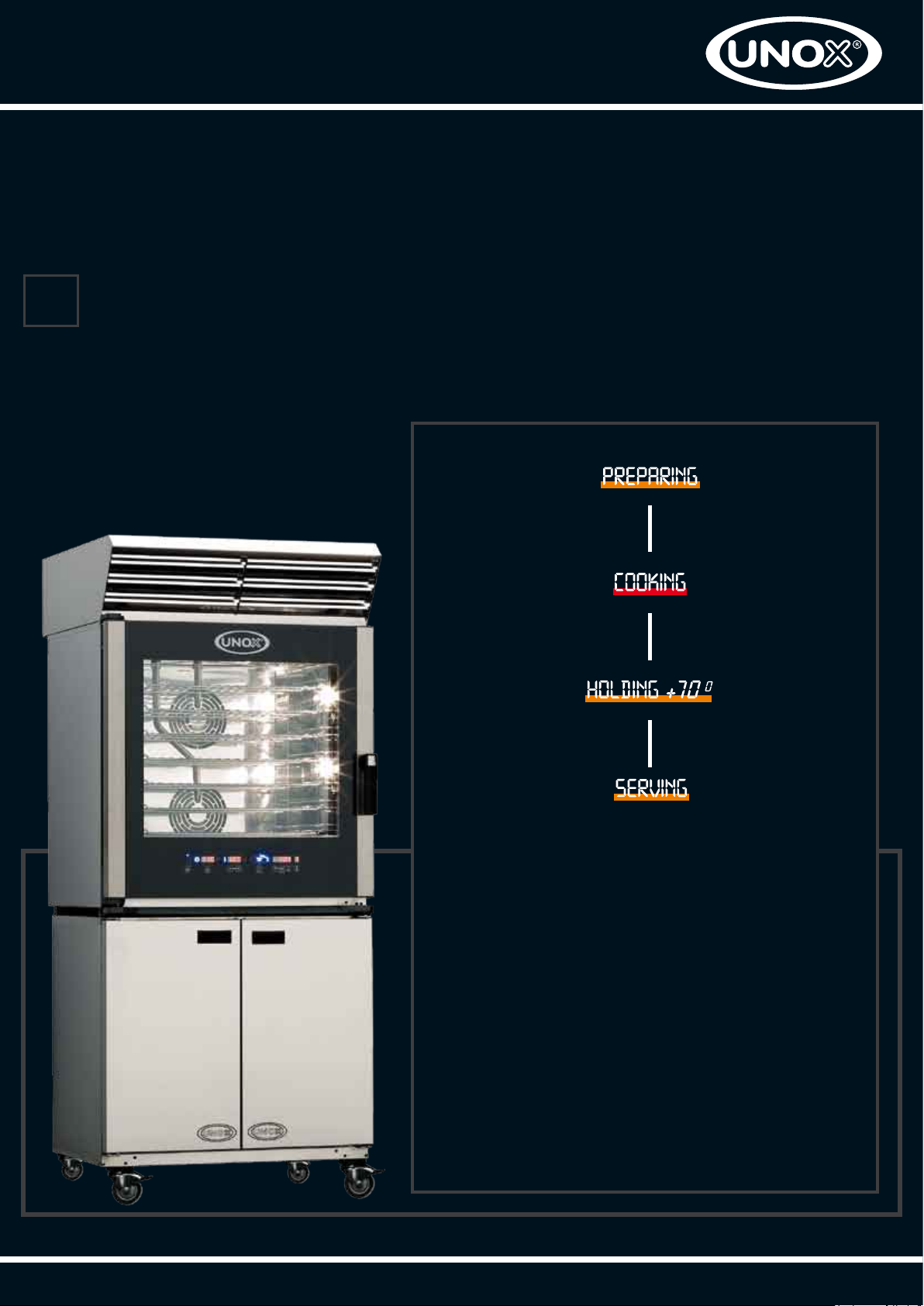

Preparing, cooking, holding and serving

More and more frequently, the modern catering

establishment requires the possibility to cook in

advance large quantities of food and to serve them in

the space of a few hours, depending on the demands.

From here starts the need to combine with the various

ovens in the ChefTop™ range, a Holding Cabinet that

preserves the cooked foods at a temperature higher

than 70°C.

In this way, the growth of bacteria will be avoided, as

required by the HACCP regulation.

5

ChefTop

™

3

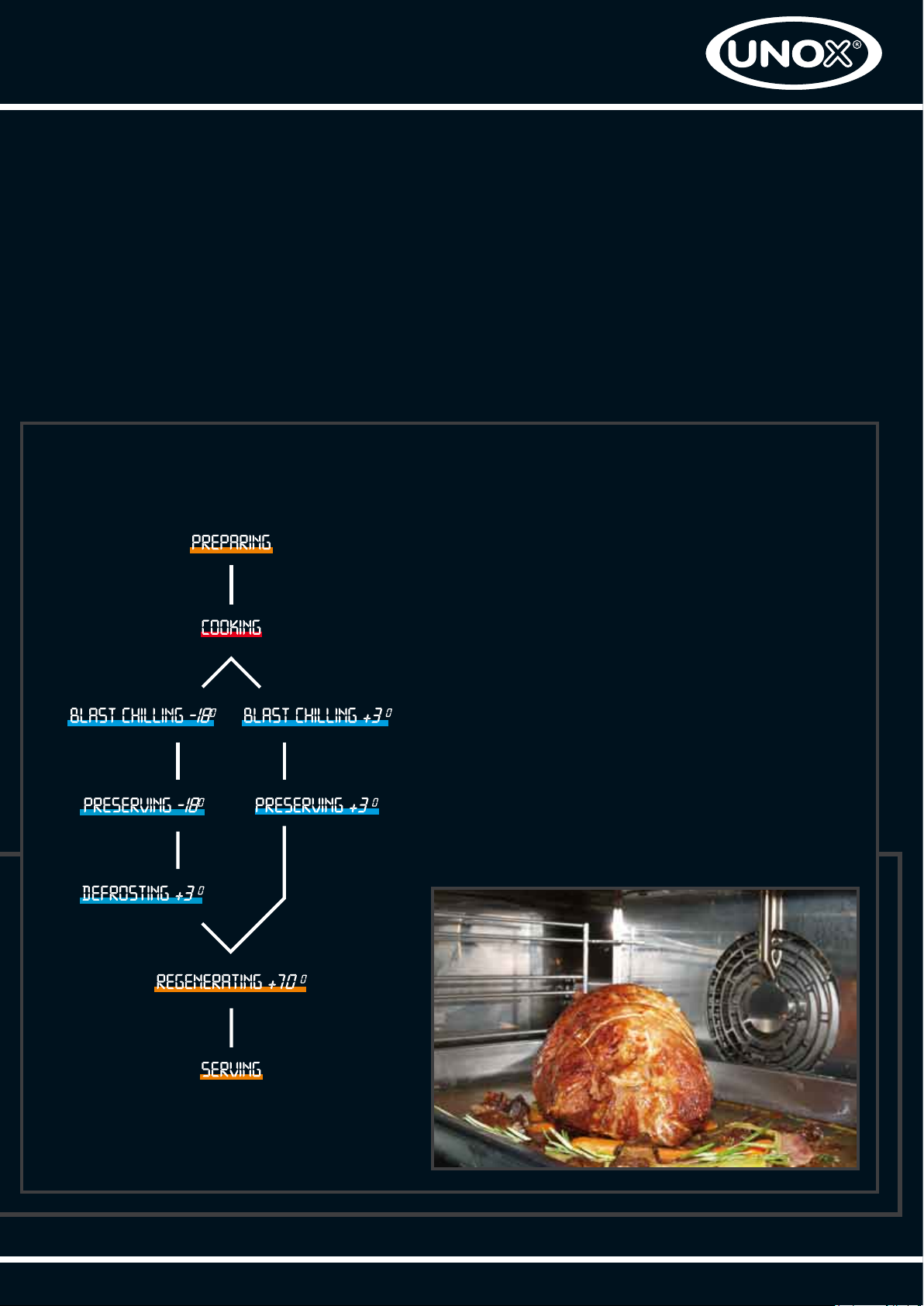

Preparing, cooking, chilling, regenerating

and serving

6

This is the most complex process that a Chef can face during his work.

This system allows the chef to cook foods in advance then, thanks to the blast chiller it is possible to preserve

the cooked foods, even for long periods and then regenerate in the oven and serve when required.

The complete process is composed of 4 working

steps:

• Cooking in advance even large quantities of food with

one or more ChefTop™ ovens.

• Blast chilling cooked food in the UNOX blast chiller

controlled by the digital control panel of the oven.

• Regenerating, the chilled food in the oven, as

required. Avoiding wastage of food and drastically

reducing operating costs.

• Serving! Your dish is now ready to be served,

maintaining the same quality of fresh and just-cooked

food.

7

™

ChefTop

ChefTouch

A single control for all the equipment

• Easy and intuitive

• Manual and pre-programmed

The digital control panel ChefTouch allows the operator to control all the UNOX appliances of the ChefTop™

line which are linked to the oven. In addition, the introduction of the system MASTER & SLAVE permits the

operator to manage, with a single digital control, one or more ovens. The oven that is used to control all the

other equipment, becomes the MASTER oven. The ovens controlled by the MASTER oven become SLAVE ovens,

and their digital control is inactive. The MASTER and SLAVE digital controls are, interchangeable.

• Glazed controls

• Hygienic and easy to clean

MASTER OVEN

1

BLAST CHILLER

2

3

7

8

HOOD

SLAVE OVEN

54

8

HOLDING CABINET

REVERSE OSMOSIS KIT

OVEN/OVENS CONTROL

• Manual mode by setting all the parameters of the functions (time, temperatures, climate);

•

Programmed mode by using up to 70 cooking programs, pre-set and saved by the user;

•

Programmed mode by using ChefUnox automatic cooking settings, pre-set and saved by

UNOX inside the digital panel. Thanks to ChefUnox, the operator chooses the type and intensity of

the desired cooking for various types of food.

BLAST CHILLER CONTROL

• Manual mode by setting all the parameters of functions (time, temperatures);

•

Programmed mode by using up to 10 chilling programs, pre-set and saved by the user;

•

Programmed mode by using chilling settings, pre-set and saved by UNOX inside the digital panel;

CONDENSER HOOD CONTROL

• Automatic suction of the fumes, with two speeds;

•

Condensation of cooking fumes;

HOLDING CABINET CONTROL

• Manual mode, by setting all the parameters of functions (time, temperature, humidity).

“REVERSE OSMOSIS” SYSTEM CONTROL

• Automatic production of demineralised water;

•

Message displayed when replacement cartridge is necessary;

•

Alert message displayed in case of lack of inlet water.

9

™

ChefTop

ChefTouch

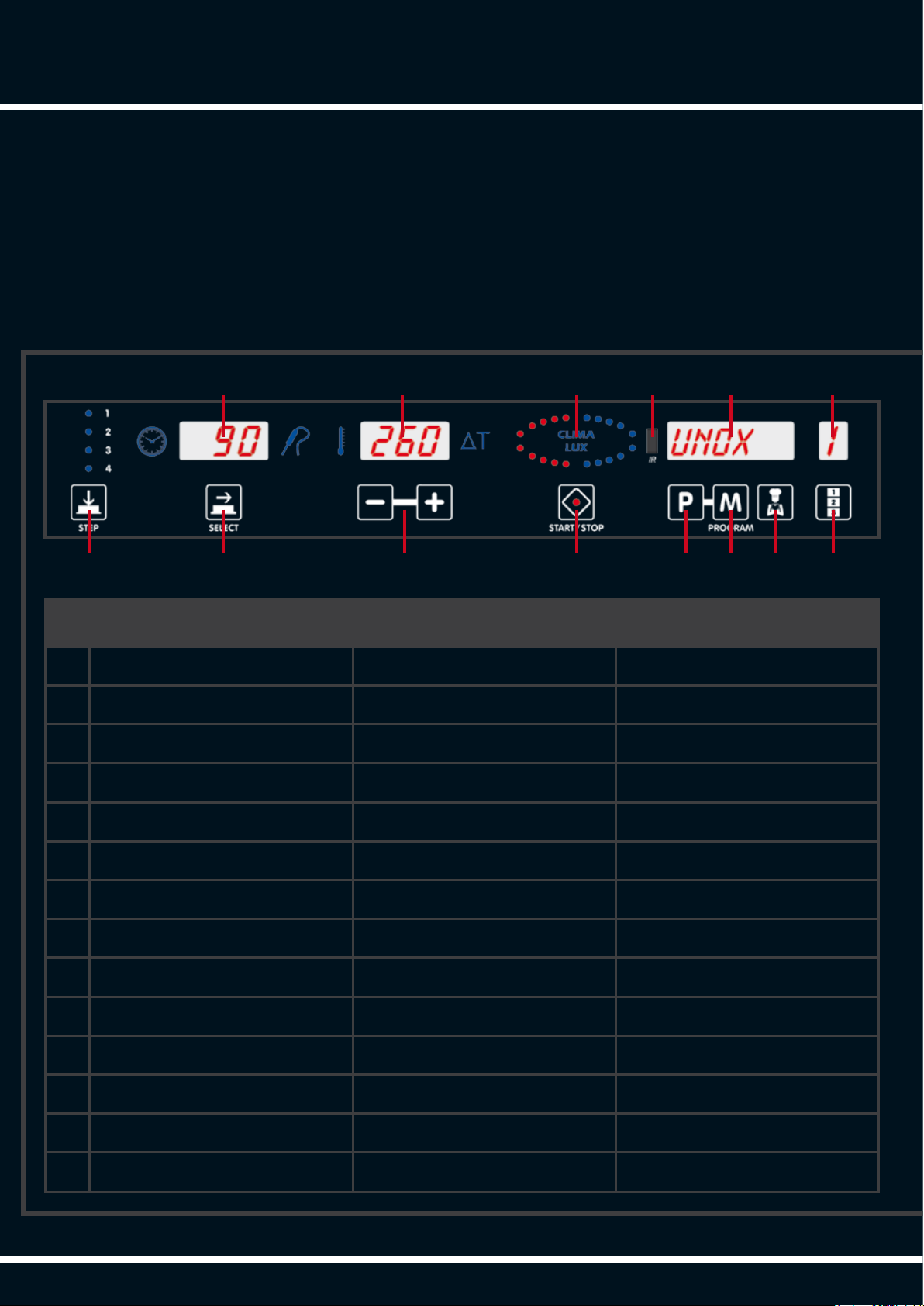

Digital control panel

2

1

1

2

3

4

5

Display Cavity Temperature / Delta T Display chamber temperature / Delta T Display chamber Temperature

Set cooking parameters / Select programs Set blast chilling / frosting parameters cycle Set parameters

Select cooking step Select phase blast chilling / frosting X

Display Time / Core temperature Display time / core temperature Display Time

Select Cooking Parameters

3

Oven Blast chiller Holding cabinet

4

5

Select blast chilling cycle /

frosting parameter

6

7

8

Select holding parameters

11

1312

149 10

10

6

7

8

9

10

11

12

13

14

Display CLIMA LUX X Display humidity

Start / stop cooking Start/stop blast chilling / frosting Start/ Stops cycles

Infrared interface Infrared interface Infrared interface

Saved programs / cooling down program /

washing programs

Cooking programs saving Saving blast chilling / frosting programs X

Pre-set cooking curves selections

Display programs / Autodiagnosis Blast chilling / display frosting programs X

Display controlled equipment Display controlled equipment Display controlled equipment

Selection of equipment to control Selection of equipment to control Selection of equipment to control

Saved programs X

Pre-set blast chilling /

frosting cycles selection

X

Oven digital panel: main functions

• Convection Cooking with variable temperature

from 30°C to 260°C

• Mixed Convection+Steam Cooking

variable temperature from 30°C to 260°C steam

variable from 30% to 90%

• Convection + Humidity Cooking

temperature from 30°C to 260°C steam variable

from 10% to 20%

• Steaming

to 130°C steam 100%

• Convection + Dry Air Cooking

temperature from 30°C to 260°C dry air variable

from 10% to 100%

• Cooking with Core Probe

temperature from 0°C to 100°C

with variable temperature from 48°C

with variable

with variable

with variable

with

• Cooking with Core Probe + Delta T with

variable temperature from 0°C to 260°C

• ChefUnox Automatic Cooking settings

• ChefUnox Automatic Cooking settings

for specific products

• 4 programmable cooking steps

• 70 programs memory

• Hold function “HLD”

• Continuous operation “INF”

• Oven pause program “PAU”

• Oven chamber cool down program with

door open. “COOL”

• 3 washing programs L1 / L2 / L3

• Rinsing programme L H2O

• Autodiagnosis / alarm

Blast chiller digital control: main functions

• 4 blast chilling / freezing programmable steps

• Chamber temperature programmable to -35°C

• Possibility to set the duration of the blast

chilling / freezing process or the desired core

temperature

• Possibility to work with core probe + Delta T

• Continuous operation “

INF”

• Possibility to save up to 10 blast chilling

/ freezing programs

• 4 pre-set programs:

- soft blast chilling

- hard blast chilling

- soft freezing

- hard freezing

Holding cabinet digital control: main functions

• Variable humidity control• Chamber temperature programmable from

20°C to 100°C

• Continuous operation “INF”

11

™

ChefTop

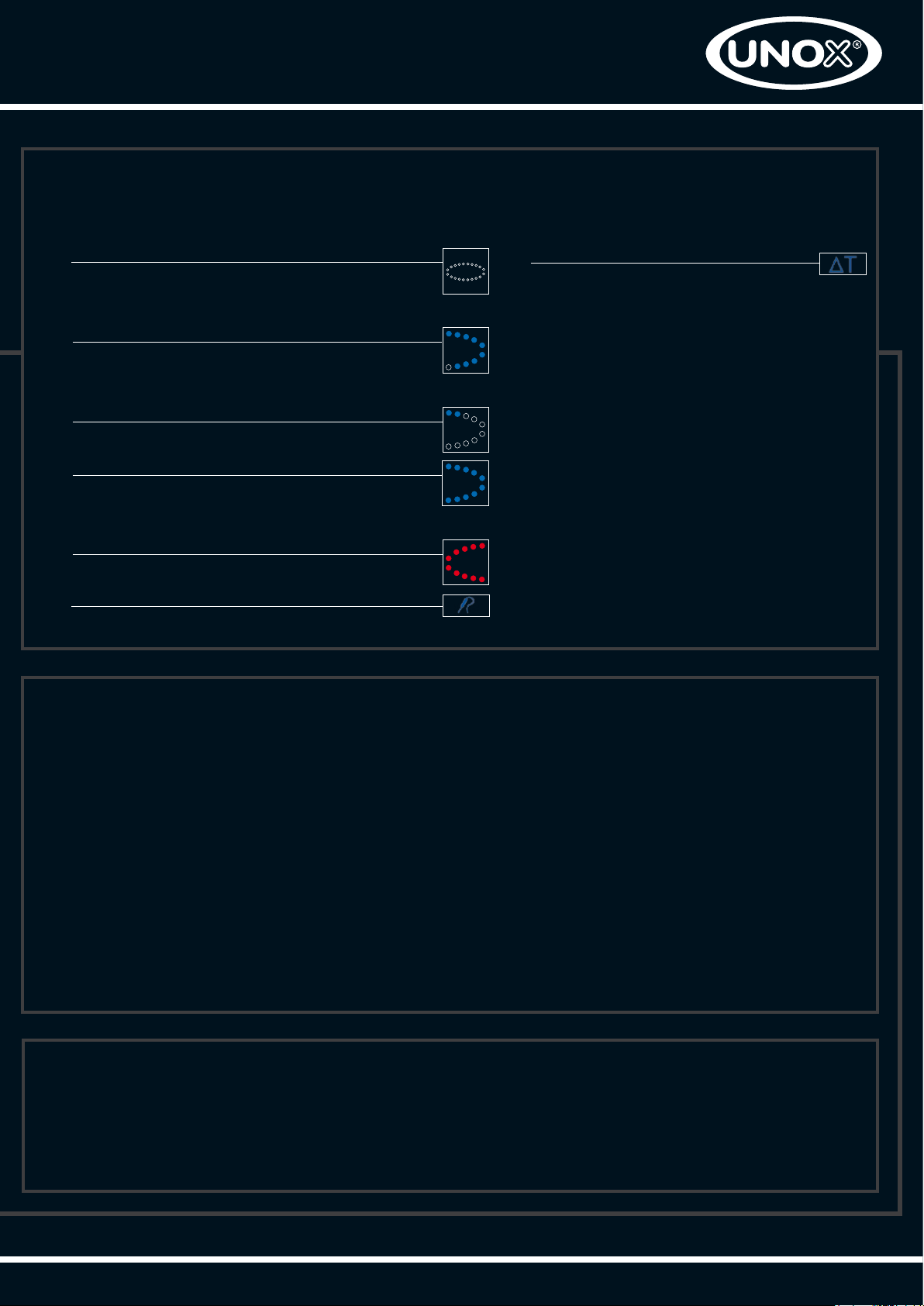

ChefUnox

Automatic Cooking settings...

For an endless range of foods

Unox

Chef

The digital control ChefTouch contains inside its memory a set of automatic

cooking settings proposed by ChefUnox.

It is sufficient to simply select the required kind of cooking to prepare,

automatically, an endless range of foods.

But the most important Chef is you!

Inside every kind of Automatic Cooking setting, you have the possibility

to personalise some parameters in order to obtain, according to your own

demands, the best level of cooking.

SLOW COOKING

This type of cooking is related to the most ancient type of cooking,

simple roasting. Slow cooking increases the tenderness of the meat

and reduces the weight loss. The external crust formed by the heat

prevents the leakage of the natural juices, thus allowing the internal

part of the food to cook in a gradual, even and delicate way.

12

Ideal for the cooking of large joints of meat.

The automatic SLOW cooking cycle, proposed by

ChefUnox, can be personalised by changing the

temperature at the core of the food.

STEAMING

This kind of cooking, who’s origins go back to ancient China, is the

simplest and most nutritional form of cooking. Minimizing weight loss

and locking in colour, flavour, vitamins and minerals. Therefore offering

tasty and delicate food.

Ideal for the cooking of vegetables, potatoes, fish.

The automatic STEAM cooking cycle, proposed by

ChefUnox, can be personalised by changing its

time on the basis of the type of food or on its size.

ROASTING

This kind of cooking uses two elements as heat conductors: the fats

that are naturally found in the food, and hot air.

Ideal for the cooking of meat, fish, poultry and game (with Pollo grid),

skewers (with Spido tray).

It is possible to improve the cooking level by

changing the temperature at the core of the

product.

13

ChefTop

ChefUnox

Automatic Cooking settings...

For an endless range of foods

Unox

Chef

™

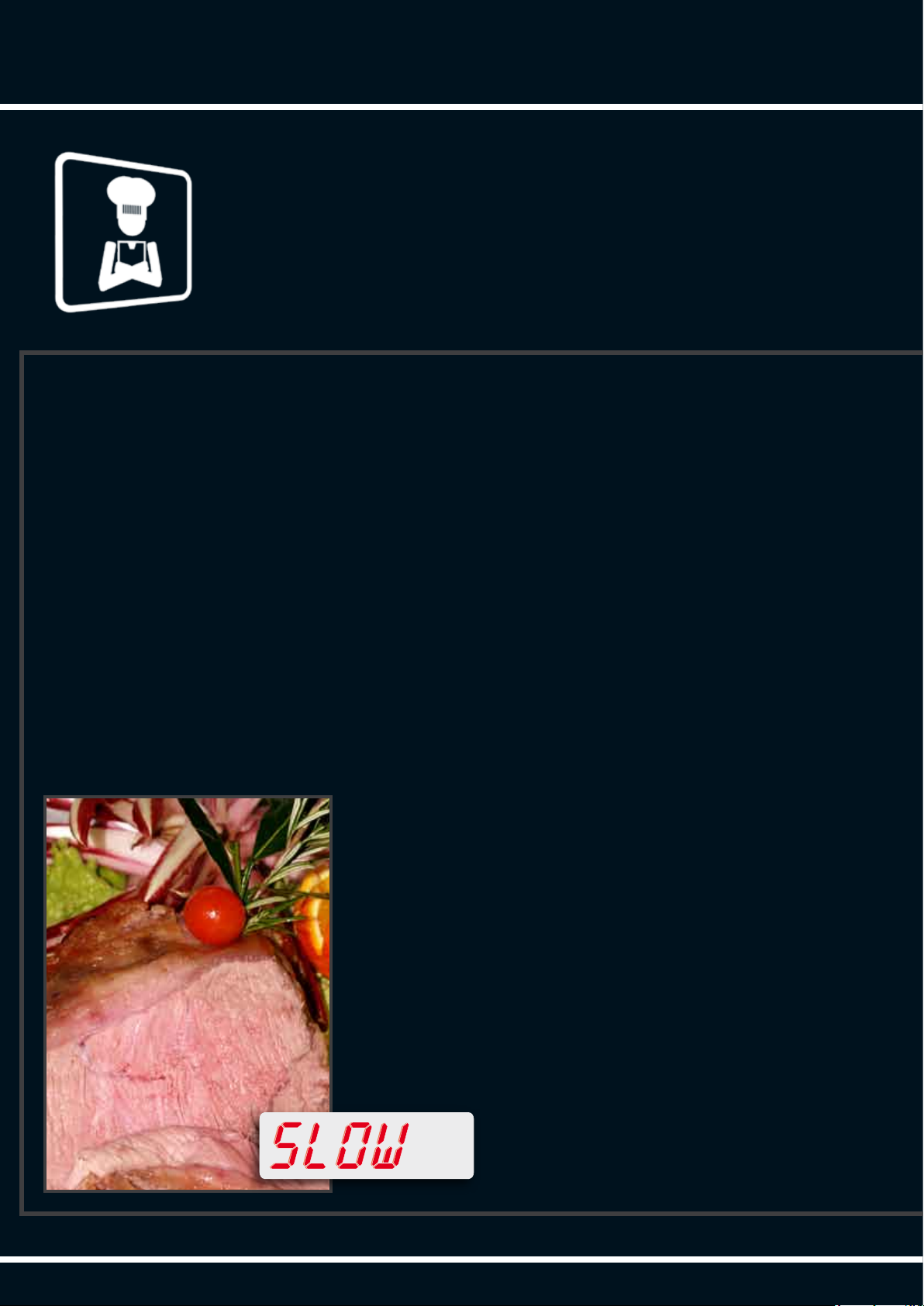

GRILLING

Very ancient and quick size of cooking, for the perfect grilling of meat

fish and vegetables:

• The surface of the grill plate must be very hot before placing the food

on it;

T-bone steaks and fillets… absolutely perfect thanks to the inimitable

griddle-plate FAKIRO™ Grill.

The level of cooking can be personalised, according

to your requirements, by changing the temperature

at the core of the food.

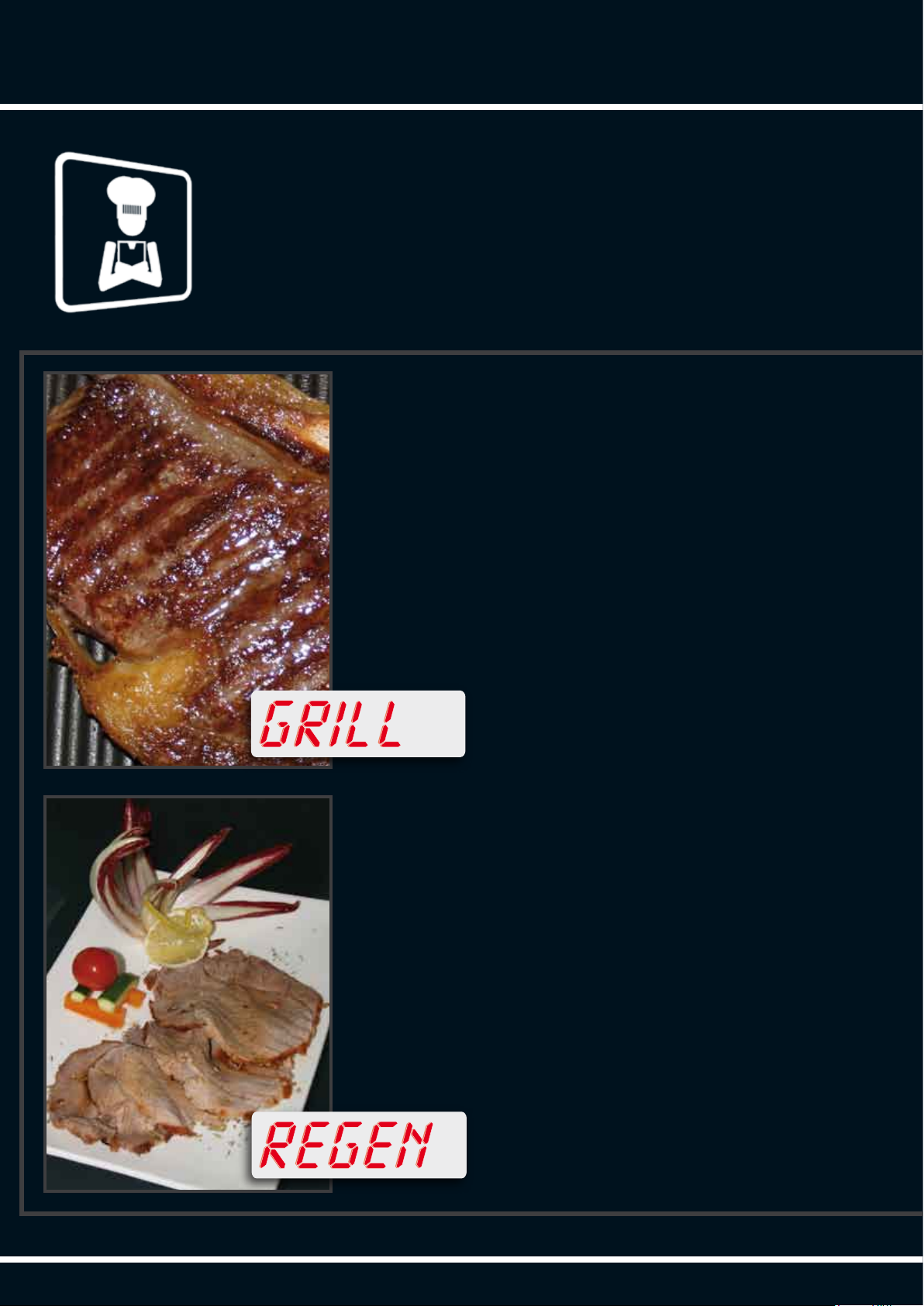

REGENERATING

The combined use of an UNOX oven and blast chiller allows the

operators to optimize their time by preparing food in advance, then

regenerating as and when required.

14

The level of cooking can be personalised, according

to Your demands, by changing the time of the

regeneration process.

AUTOMATIC COOKING

SETTINGS FOR GROUPS OF FOODS

CROIS, PANE, POLLO:

ChefUnox Automatic

Cooking settings for specific

products with the use of the

core probe. It is possible

to personalise the cooking

settings of the specific product

by setting different core

temperatures.

PIZZA ITALY, PIZZA,

FRIES: ChefUnox

Automatic Cooking settings

for specific products.

The use of COOKING

TECHNOLOGIES

FAKIRO™ for pizza and

NoFry, for fried products,

will greatly improve their

cooking and flavour.

It is possible to personalise the

cooking settings of the specific

product by setting different

cooking times.

External core probe...

For supplementary automatic cooking settings

VACUUM-COOKING SETTINGS

This innovative technology presents numerous advantages in the cooking of the

foods: unaltered nutritional value, better organoleptic quality, easier and more durable

conservation of the foods, in their regeneration process.

This kind of cooking is performed through a probe, external to the oven, equipped with

an extra-fine needle (in order not to damage the vacuum pack).

Ideal for the cooking of dishes based on fish, white and red meat and

vegetables.

STEAMING WITH PROBE

Thanks to the external probe, equipped with an extra-fine needle, it is possible to obtain

optimum steaming of particularly delicate foods, such as sausages, fish and vegetables.

OPTIONAL

15

™

ChefTop

Cooking Technologies

UNOX research has dedicated a special study on cooking processes, including all oven accessories that are

necessary to improve the functions of the oven.

For this purpose, a complete range of innovative trays and grids have been especially manufactured to allow types

of cooking usually only possible with specialist equipment.

Thanks to this range of accessories, the applications of UNOX ovens become multiple while the number of

necessary equipment in the kitchen decreases with a considerable saving of money and space.

TG 845

TG 860

FAKIRO

NO MORE UNPLEASANT SMELLS AND SMOKE!

NOW IT IS POSSIBLE TO GRILL IN THE OVEN!

Delicious grilled meat, fish and vegetables with the patented

aluminium Teflon coated FAKIRO™ Grill. Extremely

easy to clean, it allows you to grill different types of food

in a very short time preserving the room from unpleasant

smells & smoke.

™

Grill

™

FAKIRO

PIZZA IN 3 MINUTES, AND A LOT MORE!

Aluminium FAKIRO™ plate is an accessory specifically

studied to bake pizza, bread and pastries, in convection

ovens. The particular pin structure in the lower surface

and the thickness with which it is manufactured, give

FAKIRO™ a great capacity of heat transmission.

Practically, baking times are cut in half and the food is

evenly baked both on the upper and on the lower

surface.

16

No Fry

LIGHT BUT TASTY!

Stainless steel grid No Fry, to prepare crispy and healthy

French fries, vegetables and fish, without any use of oils.

Also particularly useful to steam all kinds of vegetables.

In addition, two grids (one as a base and another, turned

upside down, as a cover) allow the easy steaming of leaf

vegetables.

GRP 815

TG 865

Spido

SKEWERS, WHAT A PASSION!

10 fish, meat or vegetable skewers, quickly roasted in the

oven. With an integral drain off tray to collect the excess

fats, making Spido an excellent tool in gastronomy.

Pollo

CHICKENS AND FOWL IN LARGE QUANTITIES!

The stainless-steel grid Pollo has been studied in every

single detail to roast simultaneously up to 8 chickens on

the spit. Thanks to the particular shape of the supports,

the achieved result is an even roasting both inside and

outside, with a fine golden-brown skin.

GRP 810

TG 835

Black

NO MORE STICKING!

The enamelled tray Black, developed by UNOX,

prevents cooked food from sticking to the surface and

improves the cooking results. It is perfect for the cooking

of roasts, pre-fried foods such as veal chops, stuffed

olives, battered vegetables.

17

ChefTop

™

DRY.Maxi™

System for humidity extraction!

UNOX World Patent

18

Which of these croissants would you like

to taste?

DRY.Maxi™ technology allows the rapid extraction of the humidity

produced by STEAM.Maxi™ and the moisture from the food.

The use of DRY.Maxi™ at low temperature allows also to reduce in

a considerable way the time to dry different types of food.

In Gastronomy the use of DRY.Maxi™ at high temperature gives

a better external browning to the cooked food, like meat, fish, and

vegetables.

The use of DRY.Maxi™ at low temperature allows also to reduce in

a considerable way the time to dry different types of food.

PATENTED

STEAM.Maxi™

Revolutionary system for the

best steaming!

This revolutionary system studied by UNOX marks the beginning of a

new era for steaming in Combi Ovens.

STEAM.Maxi™, compared to traditional Boiler technology,

guarantees the capacity to produce steam immediately and the

reliability that the simplicity of its design allows.

The combination of STEAM.Maxi™ and AIR.Maxi™ allows

UNOX Ovens to transform in steam a quantity of water that is up to

three times higher than traditional direct-injection ovens.

19

™

ChefTop

AIR.Maxi™

System for a perfect

uniform cooking

20

Air is the medium for the heat transmission and the means used to cook

the product.

The performance of the air flow is fundamental to obtain a uniformity

of cooking in all the points of a single tray and in all the trays.

For this reason the study of air flow inside the chamber plays a leading

role in the design of all UNOX Ovens.

The AIR.Maxi™ Technology has been studied by UNOX to obtain a

perfect distribution of the air and the heat inside the chamber.

Multiple fans in the design of UNOX ovens ensures perfect uniformity

on all the trays, from the top to the bottom one.

Auto-reversing motors combined with high speed revolving fans ensures

perfect uniformity within every single pan.

MAXI.Link

XVC 704

10 GN 1/1

XR 114

+

XR 714

8 GN 1/1

10 GN 1/1

XVC 304

5 GN 1/1

XC 680

XVC 704

10 GN 1/1

XVC 304

5 GN 1/1

XC 680

XVC 504

7 GN 1/1

XR 104

12 GN 1/1

XVC 504

7 GN 1/1

XC 680

XVC 504

7 GN 1/1

XVC 104

3 GN 1/1

XC 680

XVC 104

3 GN 1/1

XC 680

XVC 104

3 GN 1/1

XR 104

XVC 104

3 GN 1/1

XC 680

XVC 104

3 GN 1/1

XL 314

7 GN 1/1

XVC 704

10 GN 1/1

XR 314

8 GN 1/1

XVC 504

7 GN 1/1

XK 304

5 GN 1/1

9 GN 1/1 10 GN 1/16 GN 1/1 7 GN 1/1

XVC 714 G

10 GN 1/1

XC 680

XVC 304

5 GN 1/1

XVC 514 G

7 GN 1/1

XC 680

XVC 504

7 GN 1/1

XVC 514 G

7 GN 1/1

XC 680

XVC 304

5 GN 1/1

XVC 1204 P

6 GN 2/1

XC 682

XVC 1204 P

6 GN 2/1

XR 104

XR 644

15 GN 1/1

XR 644

XR 644

14 GN 1/1 15 GN 1/1 12 GN 1/1 12 GN 2/114 GN 1/1

XR 644

The goal of MAXI.Link Technology is to simplify and to make easier the work inside the modern professional

kitchen.

The MAXI.Link Technology, thanks to possibility of creating cooking columns with two or three stacked

ChefTop™ ovens, allows to:

• Cook at the same time meals that need different temperature, humidity and time thanks to the use of

different ovens in the same footprint;

• Reduce operating costs using only the strictly necessary ovens;

• Increase the available space in the kitchen thanks to the optimum use of the vertical space;

• Control with one electronic panel “ChefTouch” all the equipment of the column, for example an oven,

a blast chiller or a holding cabinet.

21

™

ChefTop

Electric combi ovens

GN 2/1 Power

XVC 4004 P trolley included 20 GN 2/1

XVC 3204 P trolley included 16 GN 2/1

XVC 4004 P XVC 3204 P XVC 4004 PL XVC 3204 PL

Capacity 20 GN 2/1 16 GN 2/1 20 GN 2/1 16 GN 2/1

Pitch 66 mm 78 mm 66 mm 78 mm

Voltage 400 V~ 3N 400 V~ 3N 400 V~ 3N 400 V~ 3N

Frequency 50 / 60 Hz 50 / 60 Hz 50 / 60 Hz 50 / 60 Hz

Electrical power 46,5 kW 46,5 kW 46,5 kW 46,5 kW

Max temperature (cooking)

Max temperature (preheating)

Dimensions 869x1206x1857 WxDxH mm 869x1206x1857 WxDxH mm 869x1206x1857 WxDxH mm 869x1206x1857 WxDxH mm

Weight 190 kg 190 kg 190 kg 190 kg

22

260 °C 260 °C 260 °C 260 °C

300 °C 300 °C 300 °C 300 °C

XVC 4004 PL trolley included 20 GN 2/1

XVC 3204 PL trolley included 16 GN 2/1

left-to-right door opening

XVC 2004 P

XVC 1204 P

10 GN 2/1

Capacity 10 GN 2/1 6 GN 2/1

Pitch 80 mm 80 mm

Voltage 400 V~ 3N 400 V~ 3N

Frequency 50 / 60 Hz 50 / 60 Hz

Electrical power 28 kW 18,5 kW

Max temperature (cooking)

Max temperature (preheating)

Dimensions 860x1152x1208 WxDxH mm 860x1152x888 WxDxH mm

Weight 155 kg 120 kg

6 GN 2/1

XVC 2004 P XVC 1204 P

260 °C 260 °C

300 °C 300 °C

23

™

ChefTop

Electric combi ovens

GN 1/1 Power

24

XVC 1004 P

trolley included 20 GN 1/1

XVC 1004 P XVC 1004 PL

Capacity 20 GN 1/1 20 GN 1/1

Pitch 66 mm 66 mm

Voltage 400 V~ 3N 400 V~ 3N

Frequency 50 / 60 Hz 50 / 60 Hz

Electrical power 31,6 kW 31,6 kW

Max temperature (cooking)

Max temperature (preheating)

Dimensions 866x962x1857 WxDxH mm 866x962x1857 WxDxH mm

Weight 177 kg 177 kg

XVC 1004 PL

left-to-right door opening

trolley included 20 GN 1/1

260 °C 260 °C

300 °C 300 °C

For public sector catering (bulk production) and wherever

maximum power is needed for constant use fully loaded

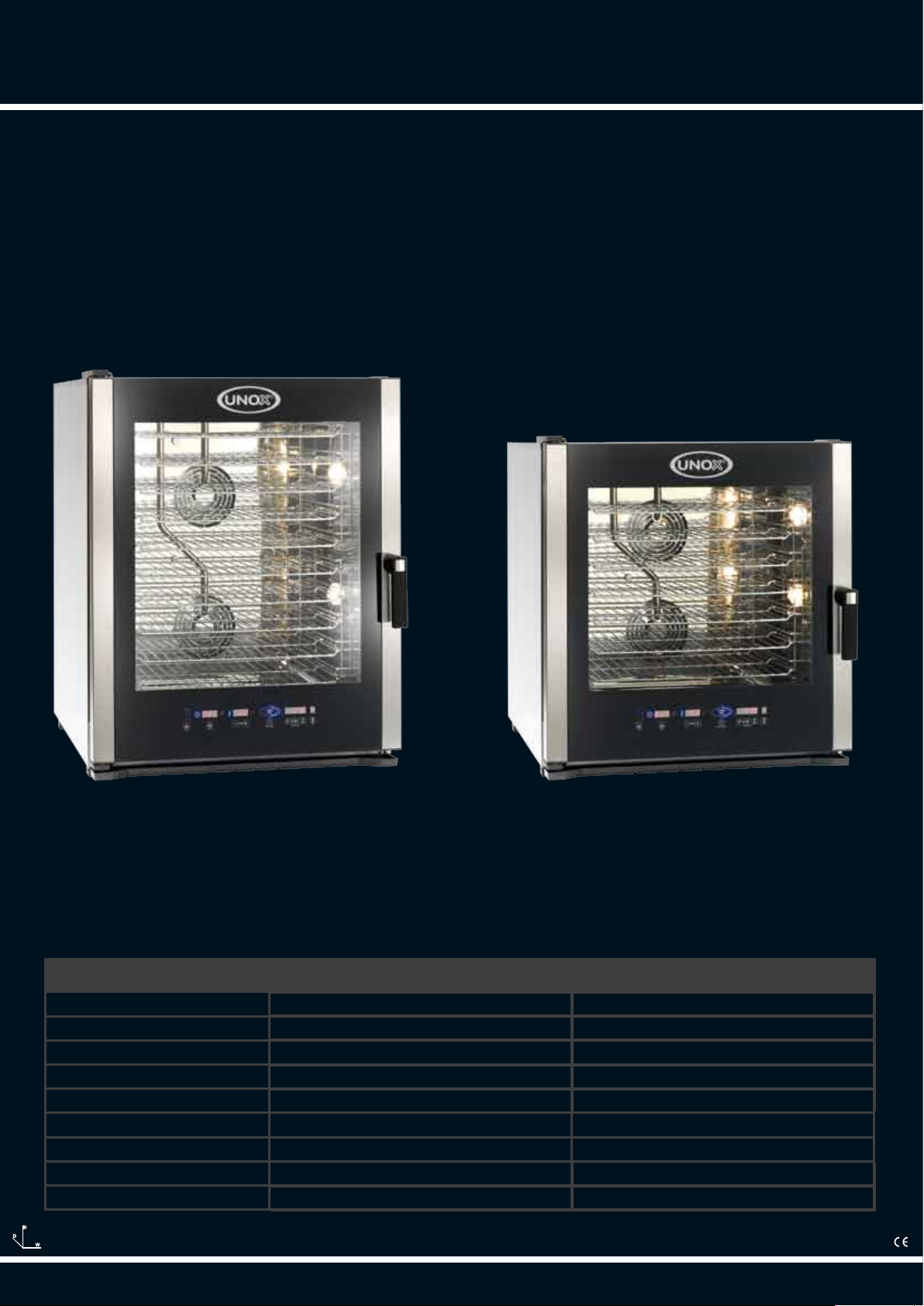

XVC 704 P

10 GN 1/1

Capacity 10 GN 1/1 7 GN 1/1

Pitch 67 mm 67 mm

Voltage 400 V~ 3N 400 V~ 3N

Frequency 50 / 60 Hz 50 / 60 Hz

Electrical power 18,6 kW 10,6 kW

Max temperature (cooking)

Max temperature (preheating)

Dimensions 750x752x960 WxDxH mm 750x752x813 WxDxH mm

Weight 77 kg 70 kg

XVC 504 P

7 GN 1/1

XVC 704 P XVC 504 P

260 °C 260 °C

300 °C 300 °C

25

™

ChefTop

Electric combi ovens

GN 1/1

26

XVC 704

10 GN 1/1

Capacity

Pitch

Voltage

Frequency

Electrical power

Max temperature (cooking)

Max temperature (preheating)

Dimensions

Weight

XVC 504

7 GN 1/1

XVC 704 XVC 504

10 GN 1/1 7 GN 1/1

67 mm 67 mm

230 V~ IN / 400 V~ 3N 230 V~ IN / 400 V~ 3N

50 / 60 Hz 50 / 60 Hz

10,6 kW 7,6 kW

260 °C 260 °C

300 °C 300 °C

750x752x960 WxDxH mm 750x752x813 WxDxH mm

77 kg 70 kg

The best for restaurants and medium kitchens!

XVC 304

5 GN 1/1

Capacity

Pitch

Voltage

Frequency

Electrical power

Max temperature (cooking)

Max temperature (preheating)

Dimensions

Weight

XVC 104

3 GN 1/1

XVC 304 XVC 104

5 GN 1/1 3 GN 1/1

67 mm 67 mm

230 V~ IN / 400 V~ 3N 230 V~ 1N

50 / 60 Hz 50 / 60 Hz

5,3 / 3,2 kW 3,2 kW

260 °C 260 °C

300 °C 300 °C

750x752x625 WxDxH mm 750x742x468 WxDxH mm

53 kg 41 kg

27

™

ChefTop

Gas combi ovens

GN 1/1

28

XVC 1014 G

Trolley included 20 GN 1/1

*

XVC 1014 G XVC 1014 GL

Capacity 20 GN 1/1 20 GN 1/1

Pitch 66 mm 66 mm

Voltage 230 V~ 1N 230 V~ 1N

Frequency 50 / 60 Hz 50 / 60 Hz

GAS power 40 kW / 34400 kcal/h 40 kW / 34400 kcal/h

Electrical power 1,6 kW 1,6 kW

Max temperature (cooking)

Max temperature (preheating)

Dimensions 869x962x2089 WxDxH mm 869x962x2089 WxDxH mm

Weight 221 kg 221 kg

*Available from September 2009

XVC 1014 GL

left-to-right door opening

Trolley included 20 GN 1/1

260 °C 260 °C

300 °C 300 °C

*

XVC 714 G

XVC 514 G

XVC 314 G

10 GN 1/1

Capacity 10 GN 1/1 7 GN 1/1 5 GN 1/1

Pitch 67 mm 67 mm 67 mm

Voltage 230 V~ 1N 230 V~ 1N 230 V~ 1N

Frequency 50 / 60 Hz 50 / 60 Hz 50 / 60 Hz

GAS power 19.8 kW / 17100 kcal/h 15 kW / 12900 kcal/h 11.4 kW / 9800 kcal/h

Electrical power 0,7 kW 0,7 kW 0,4 kW

Max temperature (cooking)

Max temperature (preheating)

Dimensions 750x796x1175 WxDxH mm 750x796x1028 WxDxH mm 750x796x840 WxDxH mm

Weight 97 kg 90 kg 73 kg

XVC 714 G

260 °C 260 °C 260 °C

300 °C 300 °C 300 °C

7 GN 1/1

XVC 514 G

5 GN 1/1

XVC 314 G

29

™

ChefTop

Electric combi ovens

GN 2/3

XVC 204

5 GN 2/3

Capacity

Pitch

Voltage

Frequency

Electrical power

Max temperature (cooking)

Max temperature (preheating)

Dimensions

Weight

XVC 054

3 GN 2/3

XVC 204 XVC 054

5 GN 2/3 3 GN 2/3

67 mm 67 mm

230 V~ IN / 400 V~ 3N 230 V~ 1N

50 / 60 Hz 50 / 60 Hz

5,3 / 3,2 kW 3,2 kW

260 °C 260 °C

300 °C 300 °C

574x707x625 WxDxH mm 574x697x468 WxDxH mm

41 kg 35 kg

30

All features are standard!

ChefTouch digital control panel

Possibility to store up to 70 cooking programs

Core probe

Delta-T cooking

Motor reversing gear

Internal lighting with halogen lamps

Reversible door for models XVC 704/ 504/ 304/ 204/ 714G/ 514G/ 314G

DRY.Maxi™ System

STEAM.Maxi™ System

AIR.Maxi™ System

MAXI.Link System

Presetting for Rotor.KLEAN™ washing system

Protek.SAFE™ System

N. 3 Anti-capsizing and anti-pulling out flat grids for XVC 704/ 714G

N. 2 Anti-capsizing and anti-pulling out flat grids for XVC 504/ 304/ 204/ 514G/ 314G

N. 1 Anti-capsizing and anti-pulling out flat grids for XVC 104/054

31

™

CaldoLux

Electric GN 1/1 - Static

XCH 014

3 GN 1/1 - 6 GN 1/2

XCH 014

Capacity 3 GN 1/1 - 6 GN 1/2

Pitch 75 mm

Voltage 230 V~ IN

Frequency 50 / 60 Hz

Electrical power 1 kW

Max temperature 120°C

Dimensions 574x673x468 WxDxH mm

Weight 30 kg

All features are standard!

ChefTouch digital control panel Internal lighting with halogen lamps

Possibility to store up to 70 cooking programs

Core probe

Delta-T cooking

32

Protek.SAFE™ System

DRY.Maxi™ System

MAXI.Link™

System

Modular structure

XCH 014

+

XCH 014

With the slow cooking oven CaldoLux™ XCH 014 it is possibile to create a number of moduli

placing two or more CaldoLux™ XCH 014 one on top of the other and obtaining in this way, the

same capacity of ovens with bigger dimensions. The advantages of UNOX modularity are simple:

• Possibility to cook at the same time types of food with very different cooking requirements

(temperature, time) since more than one appliance are available;

• Reduction of operating costs because, if the amount of work is not vast, the employ of one oven is

enough to achieve a perfect cooking.

Cook

Hold

33

™

ChefTop

Technical features

Door:

1. Reversible without any further modifications or

additional components

2. Strong and compact thanks to the patented

tubular frame

3. Hinged internal glass for an easy cleaning

4. Seal tightness granted by the seal fixed to the

face of the oven chamber

5. Hinges with self-lubrificating brackets to reduce

mechanical wear

6. Special materials for a better mechanical

resistance

7. Carbon fibre handle to improve mechanical

resistance and reduce components wear

Motor fan:

8. Motors with high temperature resistant

bearings and reversing gears, designed for an

extended working life

9. Anti-corrosion fan design.

Better thermal insulation:

10. Important decrease of power consumption

11. Longer life of electrical components

Convenience:

12. High capacity drip tray

13. Drain pipe

14. Simple electrical connection

15. Simple water connection thanks to the flexible

tube

16. Ergonomic core probe with innovative design

17. Easily accessible control board

Easy clean:

18. Preset automatic washing programs

19. Rounded chamber entirely manufactured from

stainless steel

20. Hinged fan guard

21. Easily removable lateral grids

21

20

19

32

17

4

16

5

15

7

12

13

14

34

Standard reversible door

No use of additional components!

The direction of the door opening can be easily changed at any time.

The oven, is already equipped with two handle latches, one on the left side and one on the right.

Rotor.KLEAN™

Integrated washing system

Rotor.KLEAN™ is a washing system studied in minute detail to obtain

maximum cleanliness in the oven chamber. Using a low consumption of

water and detergent , Rotor.KLEAN™ first dissolves the dirt with

water preheated by the oven to 60 °C, then applies detergent to every

corner of the oven chamber via the pressurized rotor in the chamber

ceiling. At the end of the automatic washing cycle the chamber is rinsed

and polish is applied, adding further cleanliness to the oven.

Directly controlled by the oven digital panel ChefTouch,

it is programmed for three different kinds of washing.

PATENTED

IT PD 2004A000235

OPTIONAL

35

™

ChefTop

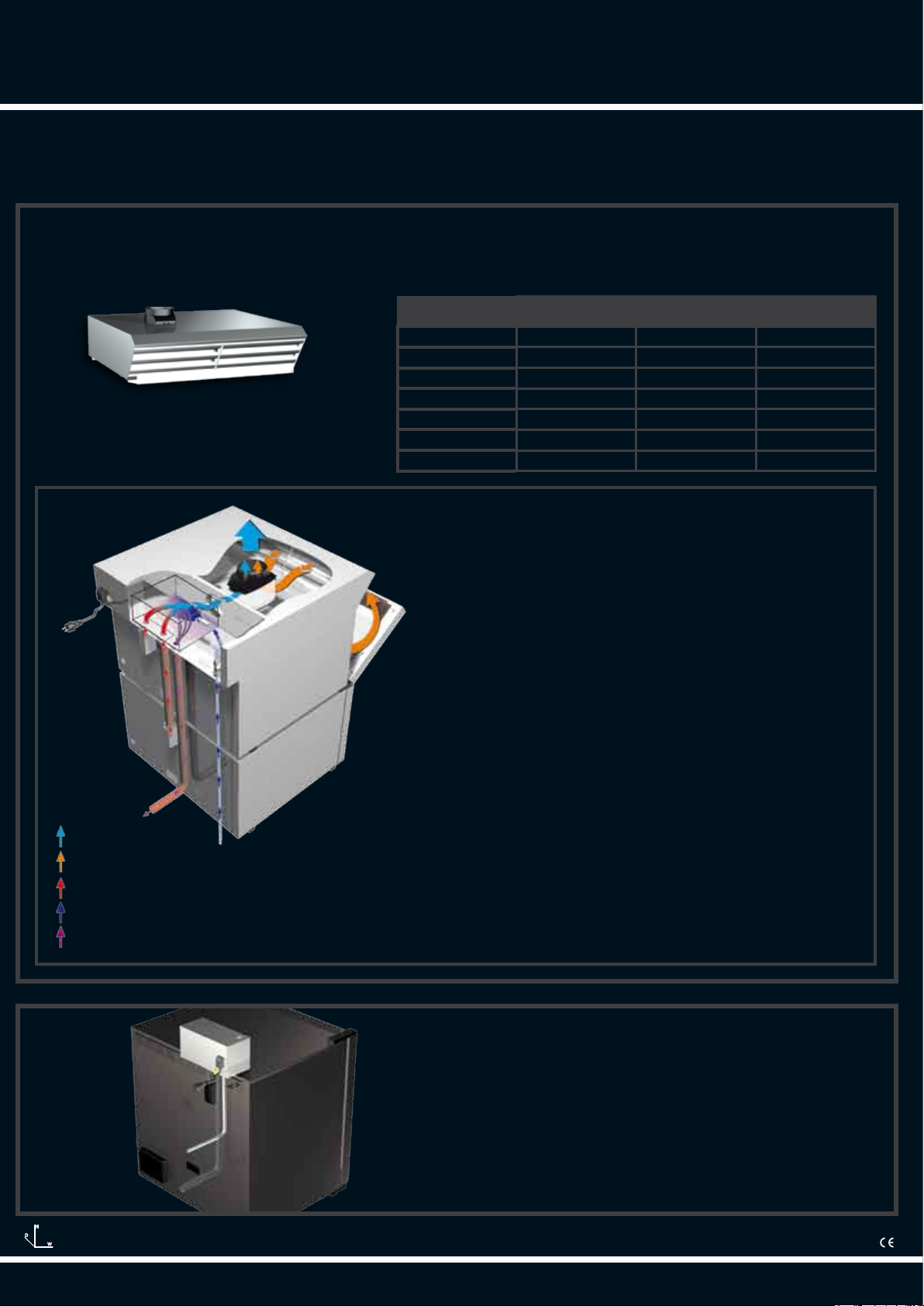

Entry and outlet flow treatments

Hood with steam condenser

Digitally controlled only by ChefTouch digital panel

XC 614 XC 514 XC 314

Voltage 230 V~ 1N 230 V~ 1N 230 V~ 1N

Frequency 50 / 60 Hz 50 / 60 Hz 50 / 60 Hz

Electrical power 200 W 200 W 200 W

XC 614

XC 514

XC 314

For models: XVC 4004P/ 4004PL/ 3204P/ 3204PL

For models

For models

: XVC 1004P/1004PL

: XVC 104/ 304/ 504/ 704

Exhaust chimney diameter

Min. air flow 550 m3/h 550 m3/h 550 m3/h

Max. air flow

Dimensions

121 mm 121 mm 121 mm

750 m3/h 750 m3/h 750 m3/h

868x1295x297 WxDxH mm 868x1060x297 WxDxH mm

750x825x272 WxDxH mm

30ºC

Cold air

Chamber humidity exiting from open door

Chamber humidity exiting from chimney

Cold water entrance

Drainpipe of residual water

200ºC

Functioning:

• Suction of fumes when you open the oven door;

• Condensation of fumes from the exhaust

of the oven with water, thermically controlled by a

temperature sensor;

• Two speed suction (slow when the oven is turned on

and the door is closed, fast when the door is open).

Technical features

• Equipped with twin speed motor;

• Controlled by ChefTouch digital panel;

• Also suitable for stacked ovens.

requires: - Water connection to condensate the fumes;

- Wastepipe for residual water;

- Electric connection.

XC 114

36

Exhaust fume condenser

Condensation of fumes from the exhaust of the oven with

water, thermically controlled by a temperature sensor.

Requires:

- Wastepipe for residual water;

- Electric connection.

Not necessary if the system is equipped with hood XC 614/ XC 514/ XC 314

- Water connection to condensate the fumes;

Reverse osmosis water treatment system

Till 25.000 litres of demineralised water without the necessity to replace resources.

The ChefTouch control checks the litres quantity and indicates the necessity to

substitute them.

It is well-known that the presence of lime scale, minerals and other

water impurities produce scale on the heating elements, ferrous residuals in the cavity, scale on the fans, with consequent loss of balance

WITH KIT

WITHOUT KIT

and problems for the motors. All this will result in a reduced life of

the oven.

The use of the «Reverse Osmosis» system is fundamental to eliminate

the salts contained in the water which are introduced in to the oven,

there by drastically reducing the corrosion phenomena inside the

chamber. As a consequence, the life of the oven will be extended.

Reverse osmosis system XC 224

Mechanical filter: this removes the grit and the sand present in the water. It carries out the roughest filtering.

Activated carbons filter: this eliminates the chlorine present in the inlet water. The removal of the chlorine

is indispensable because this element is an oxidizing agent and would damage the membranes, and as a

consequence it would be necessary to change them frequently.

Pump: this introduces in the chamber the pre-filtered water by passing it through a reverse osmosis membrane.

Membranes with reverse osmosis system: they remove all the salts present in the water, which cause

problems to the ovens.

Expansion tank: this accumulates the water while the electrovalve is closed and it acts as a hydraulic shock

absorber for the system.

SUPPLY

Mechanical

filter

Activated

carbons filter

Pump

Membranes

with reverse

osmosis

Expansion

tank

OUTLET

OVERFLOW WATER

INLET TREATED

WATER

37

™

ChefTop

Complementary equipments

Blast chiller + Shock freezer

Digitally controlled only by the ChefTouch control panel

XK 304

5 GN 1/1

XK 304

Output SOFT blast chilling from +90 °C to +3 °C 20 kg

Output HARD blast chilling from +90 °C to +3 °C 22 kg

Output SOFT blast freezing from +90 °C to -18 °C 15 kg

Output HARD blast freezing from +90 °C to -18 °C 18 kg

Capacity 5 GN 1/1

Pitch 67 mm

Voltage 230 V~ 1N

Frequency 50 / 60 Hz

Electrical power 1,5 kW

Min. temperature - 35 °C

Dimensions 750x812x975 WxDxH mm

Weight 98 kg

38

Blast Chilling

IDEAL TEMPERATURE FOR

CHILLED

TEMPERATURE

BACTERIAL PROLIFERATION

To obtain the perfect and lasting conservation of cooked

food,it is necessary to chill the product quickly.Natural

bacteria growth,the main reason for the deterioration

of food, occurs at a rapid rate between 70 °C and 10 °C.

The most strict international regulations require that

the maximum time to chill the core of the food from a

temperature of +90°C to a temperature of +3°C is 90

minutes.

ChefTop™ blast chillers are built with the most

innovative technology. They grant a blast chilling time

that is fully inside the required limits.

Shock Freezing

MACROCRISTALL

MICROCRISTALL

To extend the storage life for longer periods it is

necessary to freeze the food at a temperature lower

than -18°C.

To maintain the organoleptic characteristics of the food it

is important that the freezing at the core of the product

is completed in no longer than 240 minutes.

It is also important to prevent the formation of

macrocrystals, which are responsible for the

deterioration of the product.

Using ChefTop™ blast chillers intercellular

microcrystals are created preserving the freshness

and flavour of the food.and retaining that “just cooked“

taste.

39

ChefTop

Cycle of Chilling

SOFT BLAST CHILLING

™

Complementary equipments

SOFT Blast Chilling Cycle is recommended for delicate, light, thin or

small portions of food..

The cycle is divided into two steps:

• Blast chilling: the temperature in the chamber never goes below

0°C avoiding superficial freezing of food.

• Conservation: the program goes directly to this second step,

maintaining a temperature of between +3 and +1°C in the

chamber.

HARD BLAST CHILLING

Cycle of Freezing

SOFT FREEZING

HARD Blast Chilling Cycle is ideal for large or dense products or for

food that does not suffer from superficial freezing.

The cycle is divided into two steps:

• Blast chilling: minimum temperature in the chamber is -1°C. This

allows the operator to blast chill the core of the products within 90

minutes.

• Conservation: the program goes directly to this second step,

maintaining a temperature of between +3°C and +1°C in the

chamber.

SOFT Deep Freezing Cycle allows the conservation of small pieces

of food for long periods.

The cycle is divided into two steps:

• Deep Freezing: evenly reducing the temperature of the product

avoiding the formation of superficial ice macrocrystals.

• Conservation: the program directly goes to this second step,

maintaining in the chamber a temperature of between -18°C and

-20°C.

40

HARD FREEZING

HARD Deep Freezing Cycle is recommended for large or thick

pieces of food.

The cycle is divided into two steps:

• Quick deep freezing:

of the product,in the chamber, with a temperature of -35 °C.

• Conservation: the program goes directly to this second step,

maintaining in the chamber a temperature of between -18°C and

-20°C.

rapid and even reduction of the temperature

Holding cabinet

Digitally controlled only by the ChefTouch control panel

XL 314

7 GN 1/1

XL 314

Capacity 7 GN 1/1

Pitch 70 mm

Voltage 230 V~ 1N

Frequency 50 / 60 Hz

Electrical power 1,2 kW

Max temperature 100°C

Dimensions 750x680x772 WxDxH mm

Weight 43 kg

41

™

ChefTop

Complementary equipments

Connection with the external world

The digital control panel of the ChefTop™ ovens has been preset to easily connect the oven to the external

world through the present and future systems of communication.

Accessories now available:

USB INTERFACE

The USB interface allows the user to connect

the oven with a PC to perform these functions:

• Insertion of cooking programs;

• Changes in operational parameters (eg:

probe setting);

• Diagnostics / alarms;

• Saving of the history of the temperatures

inside the oven chamber or inside the blast

chiller chamber (necessary data for HACCP

system);

• Connection to a printer (HACCP).

XC 226

External core probe

It is possible to add a probe, fitted with an extra-fine needle,

external to the oven.

This allows the user to:

• cook at the same time products with different

• obtain different levels of cooking in products with the

dimensions

same dimensions

42

XC 240

Neutral cabinet

XR 314

8 GN 1/1

XR 314

Capacity 8 GN 1/1

Pitch 70 mm

Dimensions 750x625x772 WxDxH mm

Weight 27 kg

Open stand with table

XR 914

XR 914

Capacity 30 kg

Dimension 545 x 552 x 63 WxDxH mm

Weight 5 kg

43

™

ChefTop

Complementary equipments GN 2/1

Trolley

For models: XVC 4004P/ 4004PL

Capacity: 20 GN 2/1

Pitch: 66 mm

Dimensions: 733x774x1691 WxDxH mm

Art.: XCT 4004

Mobile plate trolley

For models: XVC 4004P/ 4004PL/ 3204P/ 3204PL

Capacity: 104 dishes

Dimensions: 733x774x1691 WxDxH mm

Trolley

For models: XVC 3204P/ 3204PL

Capacity: 16 GN 2/1

Pitch: 78 mm

Dimensions: 733x774x1691 WxDxH mm

Art.: XCT 3204

Thermocover for mobile plate trolley

For models: XCP4004/ XCT 4004/ XCT 3204

Art.: XCP 4004

Basket

For model:

Capacity: 10 GN 2/1

Pitch: 80 mm

Dimensions: 622x674x865 WxDxH mm

XVC 2004P

Art.: XCT 2004

Trolley for basket

For models:

Dimensions: 630x750x1114 WxDxH mm

XCT 2004/1204

Art.: XCP 140

Basket

For model:

Capacity: 6 GN 2/1

Pitch: 80 mm

Dimensions: 622x674x545 WxDxH mm

XVC 1204P

Art.: XCT 1204

Hood with steam condenser

For models:

2004P/ 1204P

XVC 4004P/4004PL/ 3204P/ 3204PL/

Voltage: 230 V~ 1N

Frequency: 50 / 60 Hz

Electrical power: 200 W

Exhaust chimney diameter: 121 mm

Min. air flow: 550 m3/h;

Max. air flow : 750 m3/h

Dimensions: 868x1295x297 WxDxH mm

44

Art.: XR 954

Art.: XC 614

Accessories GN 2/1

SL1135A0 Spray Detergent for non-automatic Cleaning

Detergente a spruzzo per la pulizia manuale

Cleaning Product

Detergent for non-automatic cleaning

Distributed by UNOX

Open stand

For models: XVC 2004P/ 1204P

Dimensions:858x980x757 WxDxH mm

Weight:10 Kg

Art.: XR 454

Buzzer kit

It allows to increase the ring’s intensity produced by

the oven to inform you about the end of the cooking.

For models: XVC 2004P/ 1204P

Art.: XC 705

Reverse osmosis kit with pump

For models:

Voltage:

Electrical power: 220 W

Dimensions: 542x198x449 WxDxH mm

Weight: 16 Kg

XVC 2004P/ 1204P

230 V~ 1N -

Frequency:

50 / 60 Hz

Art.: XC 224

Washing system

For models:

For models: XVC 4004/3204

XVC

2004P/ 1204P

(two pieces required)

Art.: XC 404

Complete installation kit for stacked

ovens. Fixing + water connection +

waste and exhaust pipe

For model

: XVC 1204P

Art.: XC 682

Drip tray - water drain connection kit

For models: XVC 2004P/ 1204P

Art.: XC 692

XC 224 filters and membrane

replacement kit

Up to 25.000 liters of purified water

Art.: KEL 001

Detergent for

Tank 10 L

Art.: SL 1130A0

Polish for

Tank: 10 L

Art.: SL 1125A0

Shower kit

For models:

2004P/ 1204P

XVC 4004P/4004PL/ 3204P/ 3204PL/

Art.: XC 202

Ovex.NET 2.0

with USB interface kit

For models:

3204PL/

XVC 4004P/4004PL/ 3204P/

2004P/ 1204P

Art.: XC 226

Air reduction kit

For models:

2004P/ 1204P

1 plate for each fan. The KIT contains 1 plate

XVC 4004P/4004PL/ 3204P/ 3204PL/

Detergent for non-automatically

cleaning

Box: 6 x 2 L

Art.: SL 1135A0

External core probe + control box

For models:

2004P/ 1204P

XVC 4004P/4004PL/ 3204P/ 3204PL/

Art.: XC 240

Mobile printer

For models:

2004P/ 1204P

Art.: XC 228

XVC 4004P/4004PL/ 3204P/ 3204PL/

Art: XC 605

45

™

ChefTop

Complementary equipments & Accessories

Digitally controlled

only by the ChefTouch

control panel

Blast chiller

For models: XVC 104/304/504/704/314G/514G/714G

Capacity: 5 GN 1/1 - Pitch: 67 mm

Voltage: 230 V~ 1N - Frequency: 50 / 60 Hz

Electrical power: 1,5 kW

Min. temperature: -35 °C

Dimensions: 750x812x975 WxDxH mm

Weight: 98 kg

Art.: XK 304

Trolley

For models: XVC 1004P/1004PL/1014G/1014GL

Capacity: 20 GN 1/1

Pitch: 66 mm

Dimensions: 730x555x1724 WxDxH mm

Weight: 25 Kg

Art.: XR 835

Mobile plate trolley

For models: XVC 1004P/1004PL/1014G/1014GL

Capacity: 54 dishes

Dimensions: 730x555x1716 WxDxH mm

Weight: 25 Kg

Art.: XCP 1004

Digitally controlled

only by the ChefTouch

control panel

Holding cabinet

For models: XVC 104/304/504/704/314G/514G/714G

Capacity: 7 GN 1/1 - Pitch: 70 mm

Voltage: 230 V~ 1N - Frequency: 50 / 60 Hz

Electrical power: 1,2 kW

Max. temperature:100 °C

Dimensions: 750x680x772 WxDxH mm

Weight: 43 kg

Art.: XL 314

Neutral cabinet

For models: XVC 104/304/504/704/314G/514G/714G

Capacity: 8 GN 1/1

Pitch: 70 mm

Dimensions: 750x625x772 WxDxH mm

Weight: 27 kg

Art.: XR 314

Hood with steam condenser

For models: XVC 104/304/504/704

Voltage: 230 V~ 1N - Frequency: 50 / 60 Hz

Electrical power: 200 W

Exhaust chimney diameter: 121 mm

Min. air flow: 550 m3/h;

Max. air flow : 750 m3/h

Dimensions: 750x825x272 WxDxH mm

Art.: XC 314

Thermocover for mobile plate trolley

For models: XCP 1004/ XR 835

Art.: XCP 130

Feet 100 mm

For models: XVC 304/504/704

H: 100 mm

Art.: XR 644

Low open stand

For models: XVC 104/304/504/704/314G/514G/714G

Dimensions: 748x550x278 WxDxH mm

Weight: 5 Kg

Art.: XR 104

High open stand

For models: XVC 104/304/504/704/314G/514G/714G

Dimensions: 748x550x782 WxDxH mm

Weight: 8 Kg

Art.: XR 114

Kit tank-holder

For model: XR 114

Dimensions: 285x515x18 WxDxH mm

Art.: XR 665

Hood with steam condenser

For models: XVC 1004P/1004PL

Voltage: 230 V~ 1N - Frequency: 50 / 60 Hz

Electrical power: 200 W

Exhaust chimney diameter: 121 mm

Min. air flow: 550 m3/h;

Max. air flow : 750 m3/h

Dimensions: 868x1060x297 WxDxH mm

Art.: XC 514

Steam condenser

For models: XVC 054/104/204/304/504/704

Voltage: 230 V~ 1N - Frequency: 50 / 60 Hz

Electrical power: 8 W - Weight: 7 kg

Dimensions: 340x235x170 WxDxH mm

Art.: XC 114

Intermediate open stand

For models: XVC 104/304/504/704/314G/514G/714G

Dimensions: 748x550x494 WxDxH mm

Weight: 7 Kg

Art.: XR 154

Lateral support - Kit for stand

For model: XR 114

Capacity: 8 GN 1/1

Pitch: 70 mm

Weight: 3 Kg

Art.: XR 714

Pull-out table for stand

For model: XR 714

Capacity: 30 Kg

Dimensions: 545x552x63 WxDxH mm

Weight: 5 kg

Art.: XR 914

46

Accessories

SL1135A0 Spray Detergent for non-automatic Cleaning

Detergente a spruzzo per la pulizia manuale

Cleaning Product

Detergent for non-automatic cleaning

Distributed by UNOX

Wheels

For models: XK 304/XL 314/XR 314/XR 114/XR 104/XR 154

H: 104 mm

4 wheels complete Kit:

2 wheels with brake - 2 wheels without brake.

Art.: XR 621

Buzzer kit

It allows to increase the ring’s intensity produced by the

oven to inform you about the end of the cooking.

For models: XVC054/104/204/304/504/704/1004P/

1004PL/314G/514G/714G/1014G/1014GL

Art.: XC 705

Complete installation kit for stacked

ovens. Fixing + water connection +

waste and exhaust pipe

For models: XVC 054/204

Art.: XC 685

Kit for

water connection

For models:

Dimension: 3 m

complementary equipments

XVC 054/104/204/304/504/704

Art.: XC 615

Pump kit to connect the oven with the water

tank (XC 655) if the oven is not connected to the

water supply

For models:

Voltage:

Electrical power:

XVC 054/104/204/304

230 V~ 1N

- Frequency: 50

16 W

/

60 Hz

Art.: XC 665

Reverse osmosis kit with pump

For models:

Voltage:

Electrical power: 220 W

Dimensions: 542x198x449 WxDxH mm

Weight: 16 Kg

XVC 054/104/204/304/504/704/314G/514G/714G

230 V~ 1N -

Frequency:

50 / 60 Hz

Art.: XC 224

Air reduction kit

For models: XVC054/104/204/304/504/704/1004P/

1004PL/314G/514G/714G/1014G/1014GL

1 plate for each fan. The KIT contains 1 plate

Art: XC 605

Kit cooling discharge

For models: XVC 054/104/204/304/504/704/

314G/514G/714G

Art.: XC 695

Complete installation kit for stacked

ovens. Fixing + water connection +

waste and exhaust pipe

For models: XVC 104/304/504/704/314G/514G/714G

Art.: XC 680

Drip tray - water drain connection kit

For models:

XVC 054/104/204/304/504/704

Art.: XC 690

Water tank for ovens with pump

For models:

XVC 054/104/204/304

Art.: XC 655

XC 224 filters and membrane

replacement kit

Up to 25.000 liters of purified water

Art.: KEL 001

Washing system

For models: XVC 054/104/204/304/504/704/314G/514G/714G

For models: XVC 1004/1014 (two pieces required)

Art.: XC 404

Polish for

Tank: 10 L

Minimun order: 60 tanks (one pallet)

Art.: SL 1125A0

Shower kit

For models: XVC 054/104/204/304/504/704/1004P/

1004PL/314G/514G/714G/1014G/1014GL

Art.: XC 202

Ovex.NET 2.0

with USB interface kit

For models: XVC 054/104/204/304/

504/704/1004P/1004PL/314G/514G/

714G/1014G/1014GL

Art.: XC 226

Detergent for

Tank 10 L

Minimun order: 60 tanks (one pallet)

Art.: SL 1130A0

Detergent for non-automatically

cleaning

Box: 6 x 2 L

Minimun order: 44 box (one pallet)

Art.: SL 1135A0

External core probe + control box

For models: XVC 054/104/204/304/504/704/1004P/

1004PL/314G/514G/714G/1014G/1014GL

Art.: XC 240

Mobile printer

For models: XVC 054/104/204/304/504/704/1004P/

1004PL/314G/514G/714G/1014G/1014GL

Art.: XC 228

47

Sale Conditions: Delivery Terms EX - WORKS - Packaging included

THE PICTURES USED IN THIS CATALOGUE ARE ONLY A DEMONSTRATION OF THE PRODUCT.

OV ENS PLANET

®

English

WARNING: All features indicated in this catalogue maybe subject to modification and could be changed without any advice.

www .unox .com

LI1695A4 - Printed: 04-2009

Loading...

Loading...