Page 1

LineMicro

™

UNO

R

INSTRUCTION MANUAL

MANUEL DES INSTRUCTIONS

BEDIENUNGSANWEISUNG

MANUALE DI ISTRUZIONI

MANUAL DE INSTRUCCIONES

ENGLISH

FRANÇAIS

DEUTSCH

ITALIANO

ESPANOL

Page 2

LineMicro™

1

ENGLISH

I. INSTRUCTION FOR THE

INSTALLER

Dear Customer, we would like to thank you and congratulate you on the purchase of one of UNOX products.

The instructions and suggestions that follow concern the

phases of a proper installation, as well as the use and

maintenance for your safety and for the best use of the

appliance.

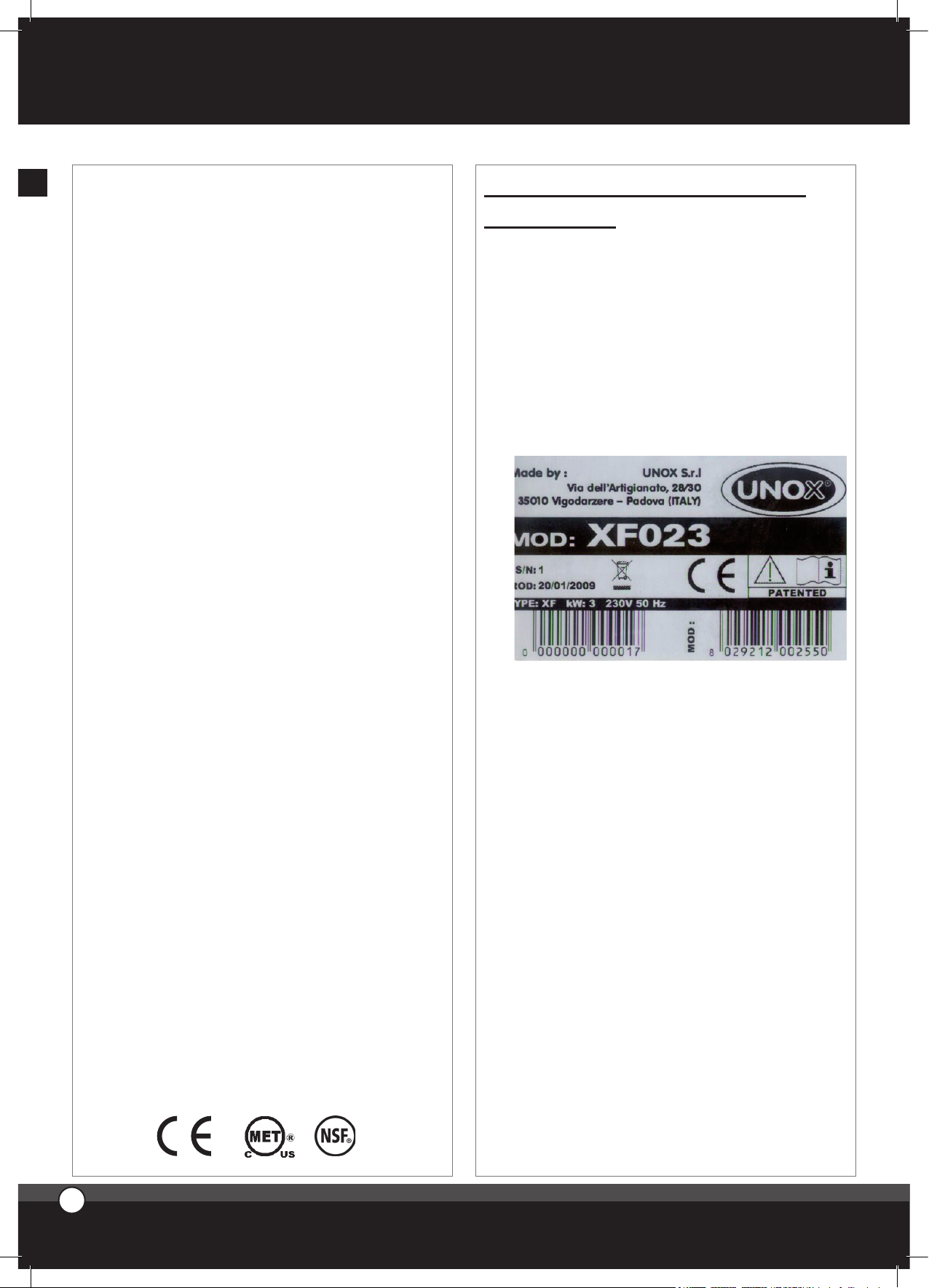

1. DATA PLATE

2. CERTIFICATION

The “CE” brand you find on our labels and on our user

manual refers to the following directives:

ELECTRIC CONVECTION OVENS - SERIES XF:

• Low Tension Directive DBT EC 2006/95,

according to rule EN60335-2-42+A1 and according to

rule EN60335-2-46+A1

• Electromagnetic Compatibility Directive EC 2004/108,

according to rules EN6555-3, EN55014 and EN55104.

The ovens of the XAF series carry MET and NSF for

U.S.A.

INDEX

I. Instructions for the installer

1. DATA PLATE

2. CERTIFICATION

3. INSTALLATION

- Preliminary operations

4. INSTALLATION

- Electrical connection

II. Instructions for the user

1. INSTRUCTION FOR THE OPERATOR

2. NOTES FOR THE USE

3. CONTROL PANEL

4. CLEANING OF THE OVEN

5. TURNING OFF IN CASE OF BREAKDOWN

III. Cooking principles

1. COOKING TYPOLOGIES

2. COOKING VARIABLES

3. USE OF PANS - GRIDS

IV. Maintenance

1. ORDINARY MAINTENANCE

2. SPECIAL MAINTENANCE

3. MORE FREQUENT BREAKDOWNS

Page 3

3. INSTALLATION

PRELIMINARY OPERATIONS

All the electrical connections and installation operations

must be done by qualified personnel according to actual

laws.

3.1 CHECK THE LOCATION OF INSTAL

LATION

Before placing the appliance, please verify the overall

measurements and the exact position of the electrical and

water connections looking at the pictures on the attached

file “TECHNICAL DATA”.

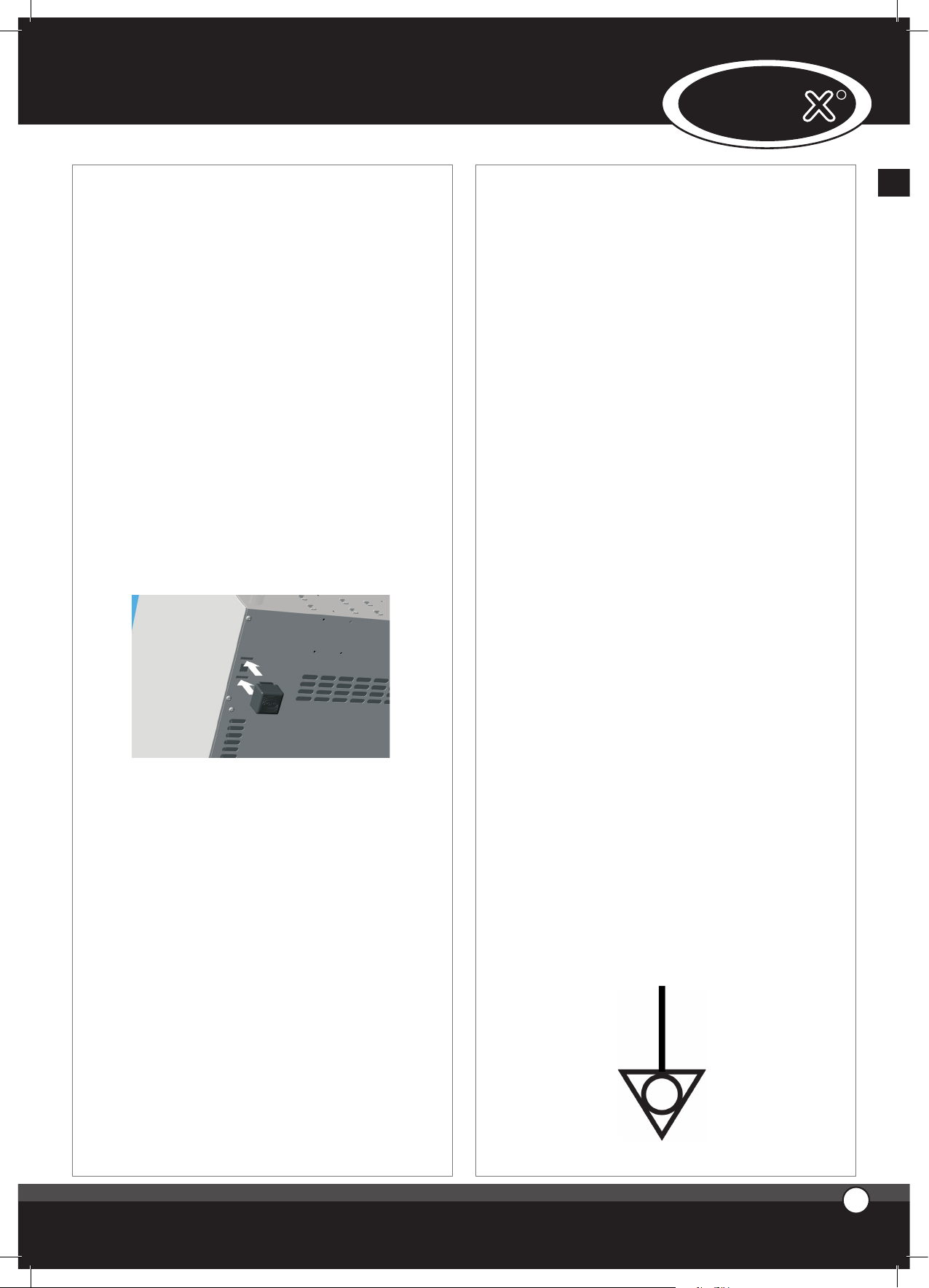

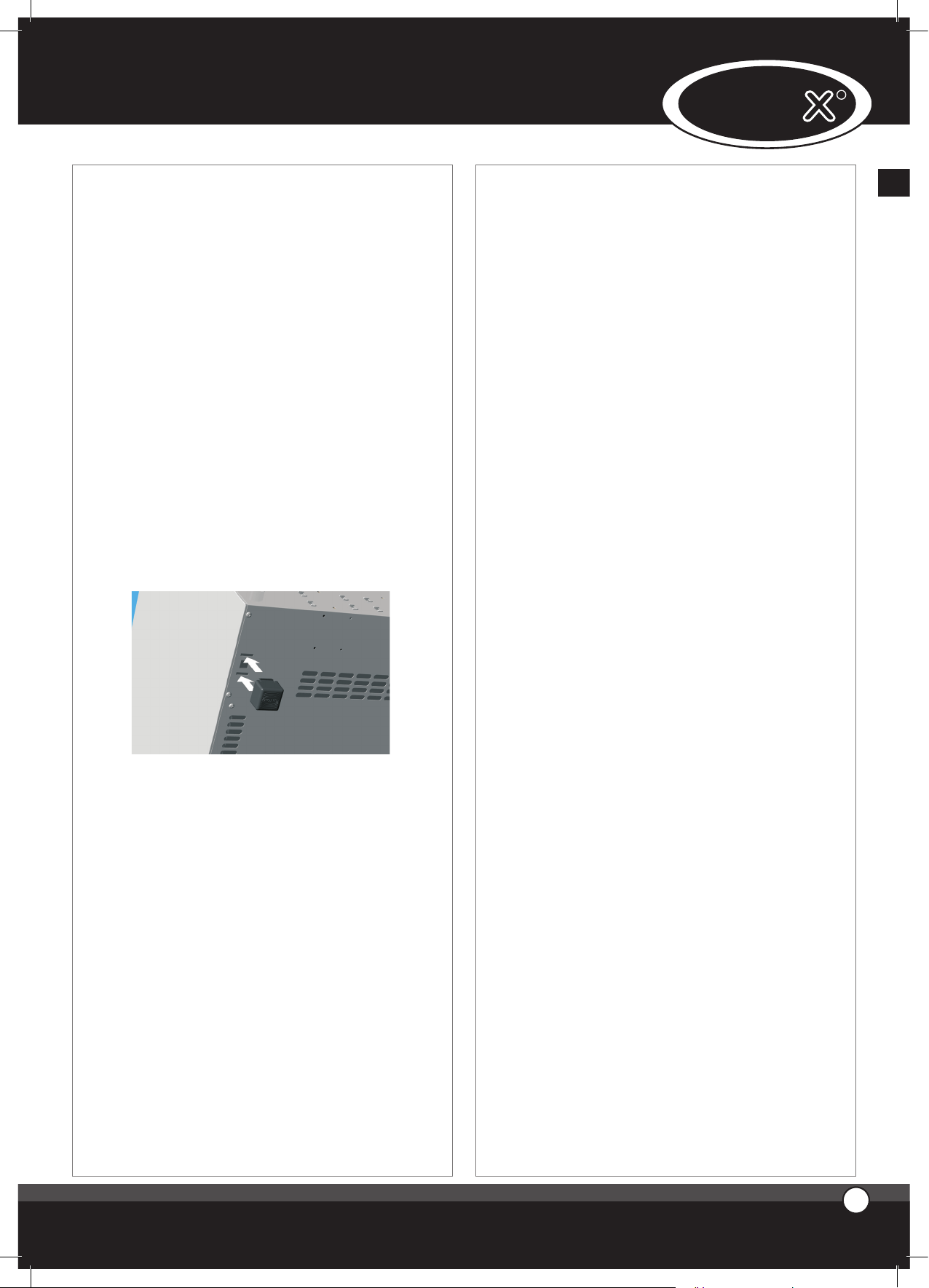

3.2 FEET ASSEMBLY

You find the feet inside the appliance. The feet must

absolutely be assembled on the oven.

Do not ever use the appliance without its feet.

Assemble the feet as showed in picture:

3.3 POSITIONING

Place the appliance respecting the safety standards in

force that you find here following described.

Place the appliance so that its back and sides can be easily

reached in order to make the electrical connections and

provide the needed service.

The appliance is not suitable for built-in installation and

side by side positioning, therefore, in case of use of more

than one oven, the appliances can not to be stacked.

It is suggested to leave a distance of 10 cm. Between the

eventual wall on the back of the oven and the chimney.

With particular reference to the ovens, all models must

be placed upon a support, for example a prover, a stand

or on the top of a table built with non-combustible mate-

rial.

Never install the appliance on the floor.

If the appliance is placed near walls, dividers, kitchen cabinets, decorated edges, etc., it is recommended that this

be of non combustible material.

Otherwise, they must be coated with non combustible

thermal insulating material and you must be very respectful of the fire prevention standards.

3.4 REMOVE THE PROTECTIVE FILM

Carefully remove all the protective film from the exter-

nal walls of the appliance. Pay attention not to leave any

rest of glue on the sides.

If there should be any residue, please remove it with an

appropriate solvent (ex.: ethyl denatured alcohol).

4. INSTALLATION ELECTRICAL CONNECTION

a-The connection to the electrical power supply system

must be done according to the standard in force.

Use the oven at a room temperature between +5 °C and

+35 °C.

Before connecting the appliance, make yourself sure that

the voltage and the frequency correspond to those stated on the data plate of the appliance. The appliance must

be placed so that the connection plug to the network can

be easily reached.

Place an omni-polar switch between the appliance and

the network. The switch must be easily accessible after

installation. The contacts of this switch must have a minimum opening distance of 3 mm and the switch must have

an appropriate input. It is suggested to use a differential

magneto-thermal switch.

When the appliance is working, the power supply voltage

must not diverge from the value of the nominal voltage,

written on the technical data plate, by more than ± 10%.

The protective cover of thermal cut out should be tight so

cannot be removed without the use of a tool.

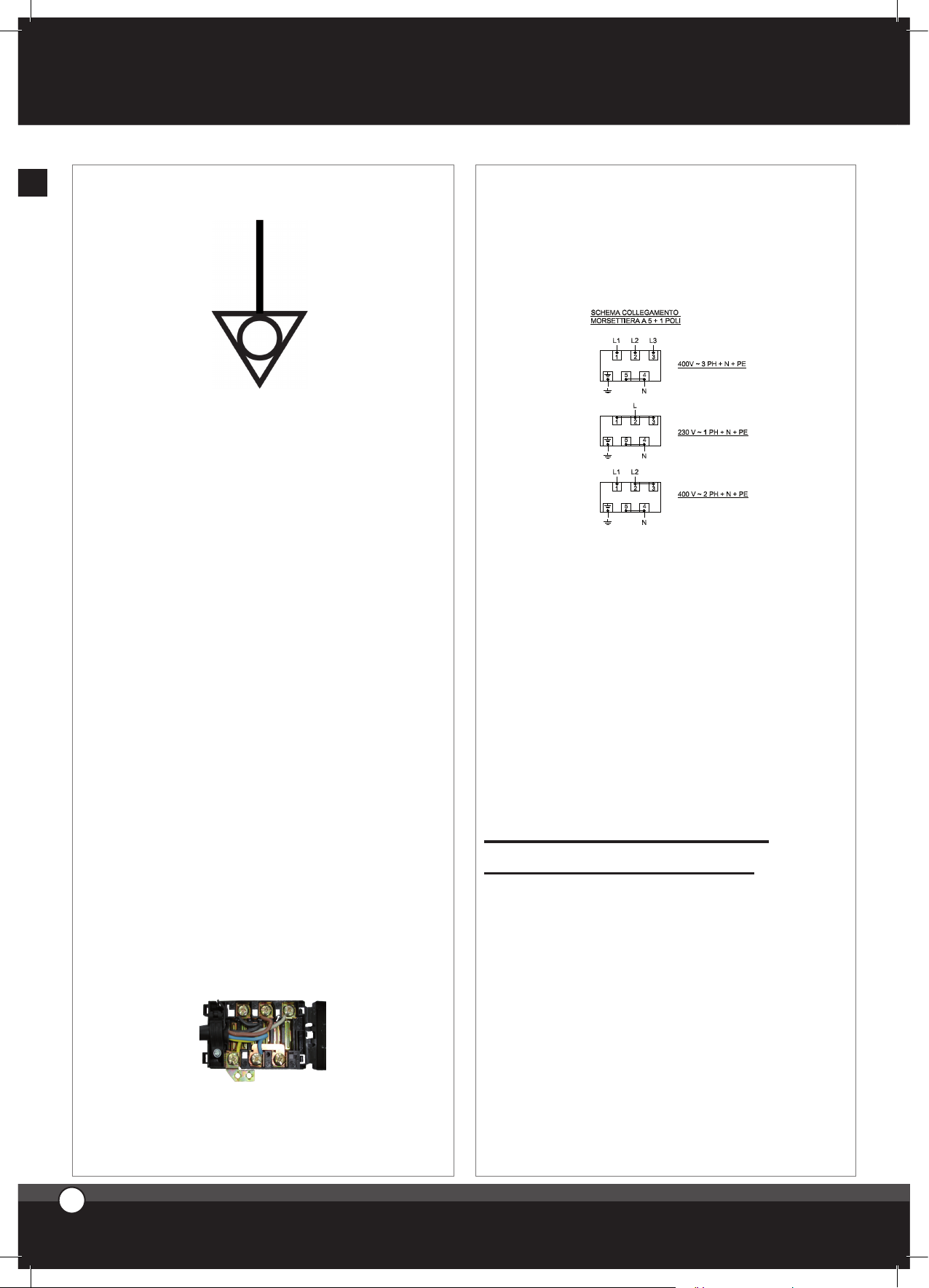

b- The appliance must be connected to the ground line of

the network.

Moreover, the appliance must be included in an equipo-

tential system whose efficiency must be properly checked

according to the current law. This connection must be

done between the different appliances using the terminal

marked with the symbol:

ENGLISH

3

2

ENGLISH

UNO

R

2

Page 4

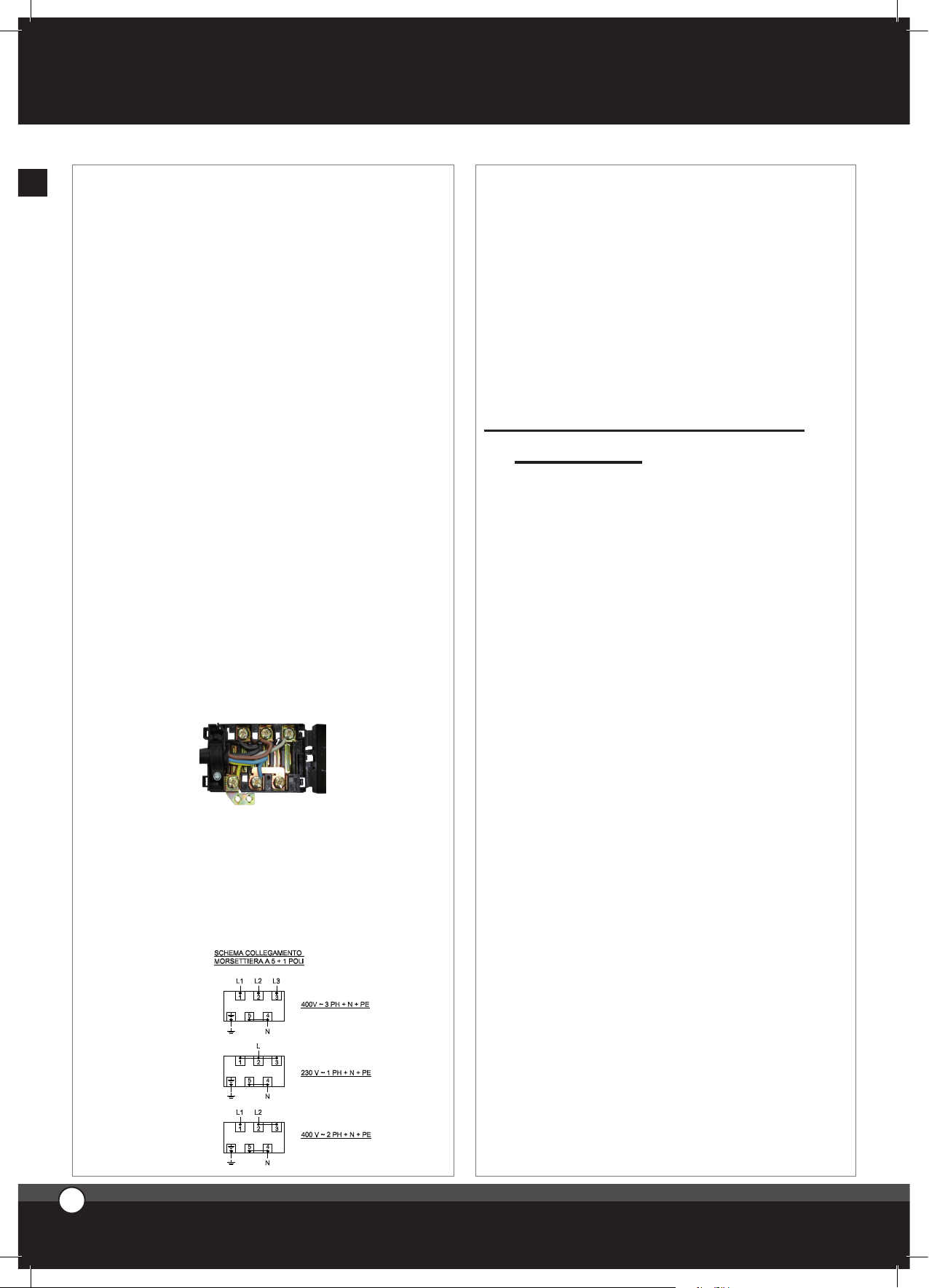

The equipotential conductor must have a minimum sec-

tion of 10 mm2.

1- Ovens equipped with cordset and Schuko plug (single

phase 230V) or Nema pyug ) single pfare 120 or 230 v.):

is sufficient to insert the plug in the proper socket (the

socket must be suitable for the plug assembled in the

oven)

2- Ovens equipped with cordset (three phases 400V + Neu-

tral): these ovens are equipped with electrical cord with 5

conductors: it is necessary to connect the proper threephase 5 poles plug with suitable capacity or you can connect the cord directly to the electrical panel.

In those ovens equipped with a cord with 5 conductors it

is possible to substitute the power cord to adapt the appliance to the available type of current.

To replace the power cord proceed as follows:

• Open the cover of the terminal board levering the two

lateral small wings with a proper screw-driver (1)

• Unscrew the screws that lock the conductors (2)

• Unscrew the screw that locks the cordstopper (3)

• Remove the supplied cord

• Connect the conductors that you would like to use according to the chosen connection drawing; be sure to fix

properly the screws of the clamps.

• Block the cord using the proper cordstopper

• Close the cover of the terminal board.

WARNING:

Connect the electrical cable to the terminal board as shown on

the drawing: insert screw-wise the copper bridge and the electrical cable together under the screw. Tighten the screw paying

attention that the cable and the copper bridge are well fixed

under the screw. A wrong connection can cause the overheating of the terminal board which can also melt.

FUMES EXIT FROM CAVITY

In the back side of the oven you find a fume chimney from

which the fumes that come from the cavity are ejected.

During each cooking cycle you will have hot and wet fumes

coming out from this chimney (temperature and humidity

of the fumes depend on the cooking parameters set on the

oven and on the type and quantity of food put inside the

oven).

The fumes that come out from the chimney can be guided

outside the room where the oven is installed or can be

condensated.

11. INSTRUCTIONS FOR

THE USER

The appliance cannot be cleaned with a jet of water.

Never wash the cavity with acids or aggressive detergents. Use only water and soap.

The appliance is made for a specific professional use and

must be used by qualified personnel only.

1. INSTRUCTIONS FOR THE OPERATOR

WARNING: carefully read this user manual befo-

re starting to operate with the appliance as it gives

you important information regarding safety during

installation, use and maintenance of the appliance

itself.

Keep the manual in a safe place where the different operators that work with the appliance can easily find and read it.

Before using the appliance for the first time ensure that

inside the cooking chamber there are no instruction manuals, plastic bags or any other objects.

The appliance is not intended to be used by persons with

reduced mental, physical and sensory capacities (children

included), or without any expertise and know-how, unless they are informed about how to use the equipment

or they operate under the supervision of who is responsible for their safety.

Children should be watched to make sure they do not

play with the equipment.

For any eventual repair, please apply only to authorized service centres. Always require original UNOX spare parts.

Failure to observe the above suggestions can compromise safety of the appliance and the guarantee

will not be recognized anymore.

4

3

ENGLISH

LineMicro™

Page 5

2. NOTES FOR USE

In case you need to open the door while the oven is

working, it is suggested to open it completely in order

to let the heat coming easily out of the cooking chamber,

avoiding to damage the lateral columns

This appliance must be used only in the way in which

it was expressly intended. The ovens were designed to

cook food as here below described. Every other use is to

be considered improper.

The oven allows you to work on temperature between 0

and 300 °C (0 - 572 °F). It can be used to:

• bake all types of bread and pastry, both fresh and fro

zen;

• cook all gastronomy preparations, fresh or frozen;

• regeneration of refrigerated or frozen food;

•cook meat, fish and all kind of vegetables.

When placing the food in the cooking chamber, leave at least 20 mm between the trays in order to

allow the hot air to circulate inside the cavity.

Please avoid to put salt on the food inside the cavity

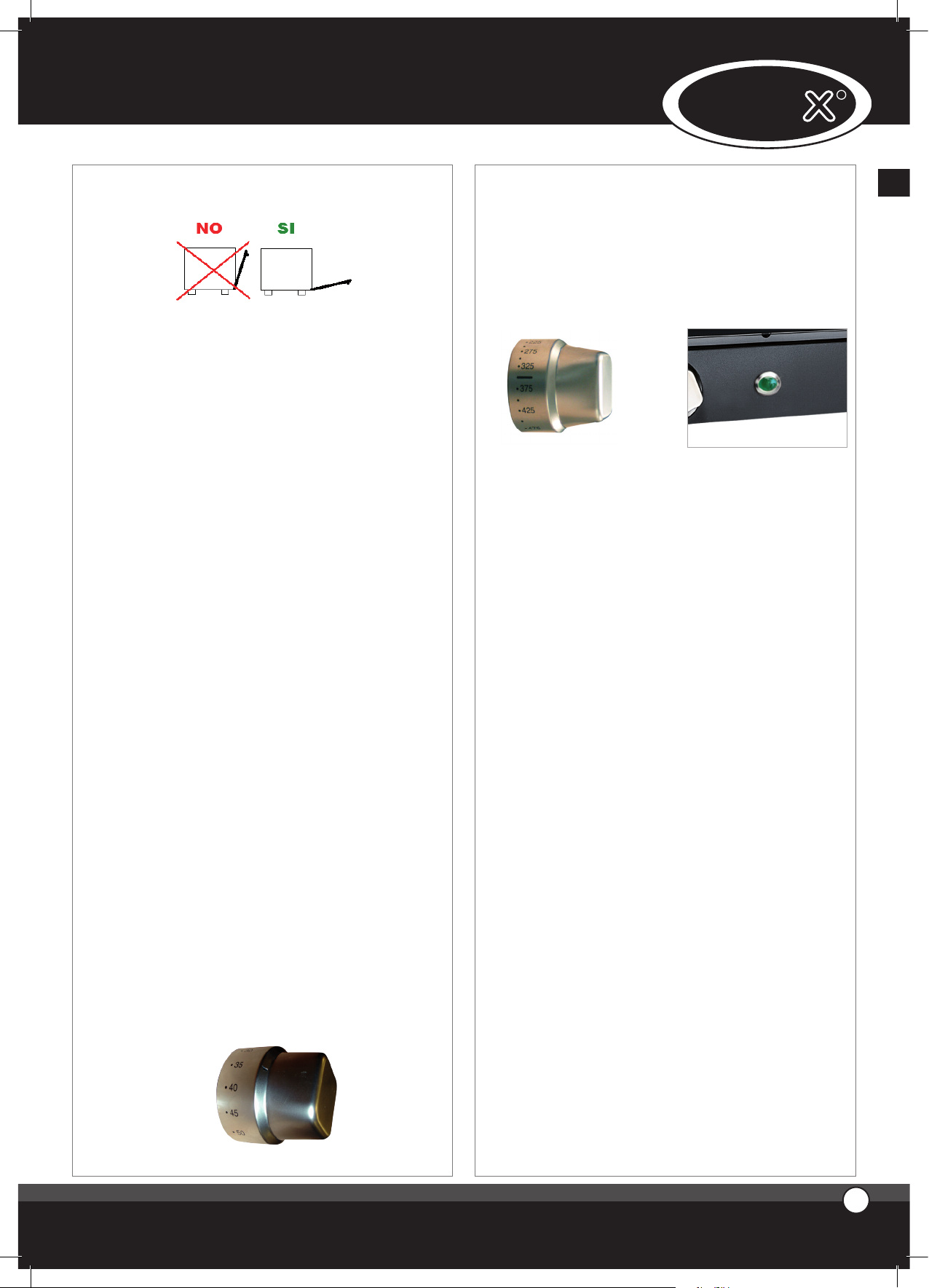

3. CONTROL PANEL

COOKING TIME SETTING

Time of cooking can be set by turning clockwise the knob

situated on left side of the control board:

time range is 0 - 60 minutes.

By turning the knob anti-clockwise the oven works continuously.

By turning the knob you start the oven: the fan spins and

internal light, if present, turns on.

When cooking time is over, the knob turns to “0” positio-

nand the oven turns off.

Attention! The oven is off when the timer knob is set at

zero “0”. To check the oven is correctly turned off, wait 5

minutes before leaving the equipment unattended.

4

ENGLISH

COOKING TEMPERATURE SETTING

The cooking temperature inside cooking chamber is set through the temperature knob (on right side of control board): temperature range is 0 - 300 °C (0 - 572 °F).

Temperature green light on indicates that heating element is

on; when set temperature is reached turns off.

4. CLEANING

WARNING:

Before starting any maintenance or cleaning operation it is necessary to disconnect the electrical power

supply and wait for the appliance to cool down.

4.1 FIRST USE OF THE OVEN

Before the first use of the appliance: clean the metal part

with hot water and soap and rinse it. Never wash the inner

part of the oven with acids or aggressive detergents.

With the empty cavity, heat the oven up for about 30 min-

utes at a temperature of 200 °C (392 °F) to eliminate any

thermic insulation smell.

4.2 CAVITY CLEANING

At the end of each cooking cycle, clean the cavity using only

proper products.

Never clean the stainless steel with acids, aggressive deter-

gents or other product containing chlorine (sodic hypochlorite, hydrochloric acid, etc.), even though they are diluted.

4.3 CLEANING OF THE EXTERNAL PART OF

THE OVEN

Never use a jet of water in pressure to clean the external

part of the oven. Only use wet clothes and proper products

for stainless steel cleaning.

To clean the glass of the oven use water and neutralsoap.

Never use alcohol or other type of solvent.

UNO

R

Page 6

ChefTop™

LineMicro™

5. TURNING OFF IN CASE OF BREAKDOWN

If there is a breakdown, deactivate the appliance:

a- disconnect the electrical power supply automatic circuit

breaker placed upstream from the appliance or, in case of

no circuit breaker, unplug the appliance.

b- consult a technical service centre authorized by the man

facturer where you can find trained personnel.

III. COOKING PRINCIPLE

1. COOKING TYPOLOGIES

The types of cooking you can realize with the appliance

described on this manual are Bread, Pastry professional

baking and Gastronomy professional cooking with CONVECTION, that means the baking is realized through hot air.

WARNING:

a- Before any use, heat up the oven setting a cavity tem-

perature 30 °C (54 °F) higher than the desired cooking

temperature.

This allows you to obtain the best baking uniformity.

b- Use of higher temperatures than those needed by the

product causes an uneven baking.

c- Bread and Pastry baking: do not use trays with a height of

more than 20 mm and avoid that the single units on the

tray get in touch.

d- Do not overload the trays.

In convection ovens the cooking is done by hot air that

circulates round and round inside the cooking chamber.

This allows to realize an even cooking, also because in

this way the heat is homogeneously distributed.

An even baking is guaranteed also when the oven is fully

loaded. The food is perfectly baked both on the surface,

with a golden crust, and in the internal part, with a uni-

form structure and a constant residual humidity.

The main advantage is the possibility to cook at the same

time different types of food without mixing their flavours

( as long as the required cooking temperature is the same

for all the cooked products).

2. COOKING VARIABLES

TEMPERATURE

The exact setting of the temperature grants a proper

cooking of the food, both inside and outside.

A lower temperature than the proper one dries the food

rather than cook it.

A higher temperature than the proper one burns the sur-

face while the core of the food remains uncooked (some-

times this is desired, especially with meat dishes).

TIME

This variable depends a lot on the quantity of food put in

the oven. The bigger the quantity of food, the longer the

cooking time and vice versa.

A shorter cooking time than that required by the food

does not allow to have completely cooked food.

A longer cooking time than that required by the food

causes the burning of the food surface.

QUANTITY OF FOOD

The quantity of food affects the cooking time.

The bigger the quantity of food, the longer the cooking

time and vice versa.

An overload of the oven can give, as a result, an uneven

cooking.

3. USE OF TRAYS – WIRE GRIDS

It is recommended the use of:

• Aluminium trays: Pastry, non-frozen bread

• Stainless steel trays: first courses, meat, fish, potatoes

• Wire grids: meat to be finished such as steaks, hot-dogs,

sausages, frozen bread, frozen pizza

IV. MAINTENANCE

1. ORDINARY MAINTENANCE

All maintenance operations must be done only by quali-

fied personnel.

Before starting any maintenance operation, you need to

disconnect the appliance from the electrical power supply and wait for the appliance to cool down.

The parts that need ordinary maintenance can be reached

removing the front control panel and the back of the oven.

The appliance must be regularly controlled (at least once

a year). A specialized technician has to control the complete machine

2. SPECIAL MAINTENANCE

All maintenance operations must be done only by quali-

fied personnel.

Before starting any maintenance operation, you need to

disconnect the appliance from the electrical power supply and wait for the appliance to cool down.

The parts that need special maintenance can be reached

removing the front control panel and the back of the oven.

2.1 REPLACEMENT OF INTERNAL LAMP (IF

PRESENT)

5

ENGLISH

Page 7

UNO

R

UNO

R

7

6

ENGLISH

To replace the internal lamp, please operate as follows:

• Disconnect the appliance from the power supply system and let it cool down.

• Remove the lateral supports.

• Unscrew the glass cover and replace the lamp with one

with the same characteristics.

• Screw the glass cover back in.

• Reassemble the lateral supports.

2.2 REFIT OF THE SAFETY THERMOSTAT

The appliance is equipped with a safety thermostat with

manual recovery. This safety thermostat is needed to protect the appliance from overheating. In case it is needed,

it turns the appliance off.

This safety thermostat can be reached removing the black

cap you find on the bottom part of the back of the oven:

in case you need to refit it, push the key you have in the

center of the thermostat so that it starts working again.

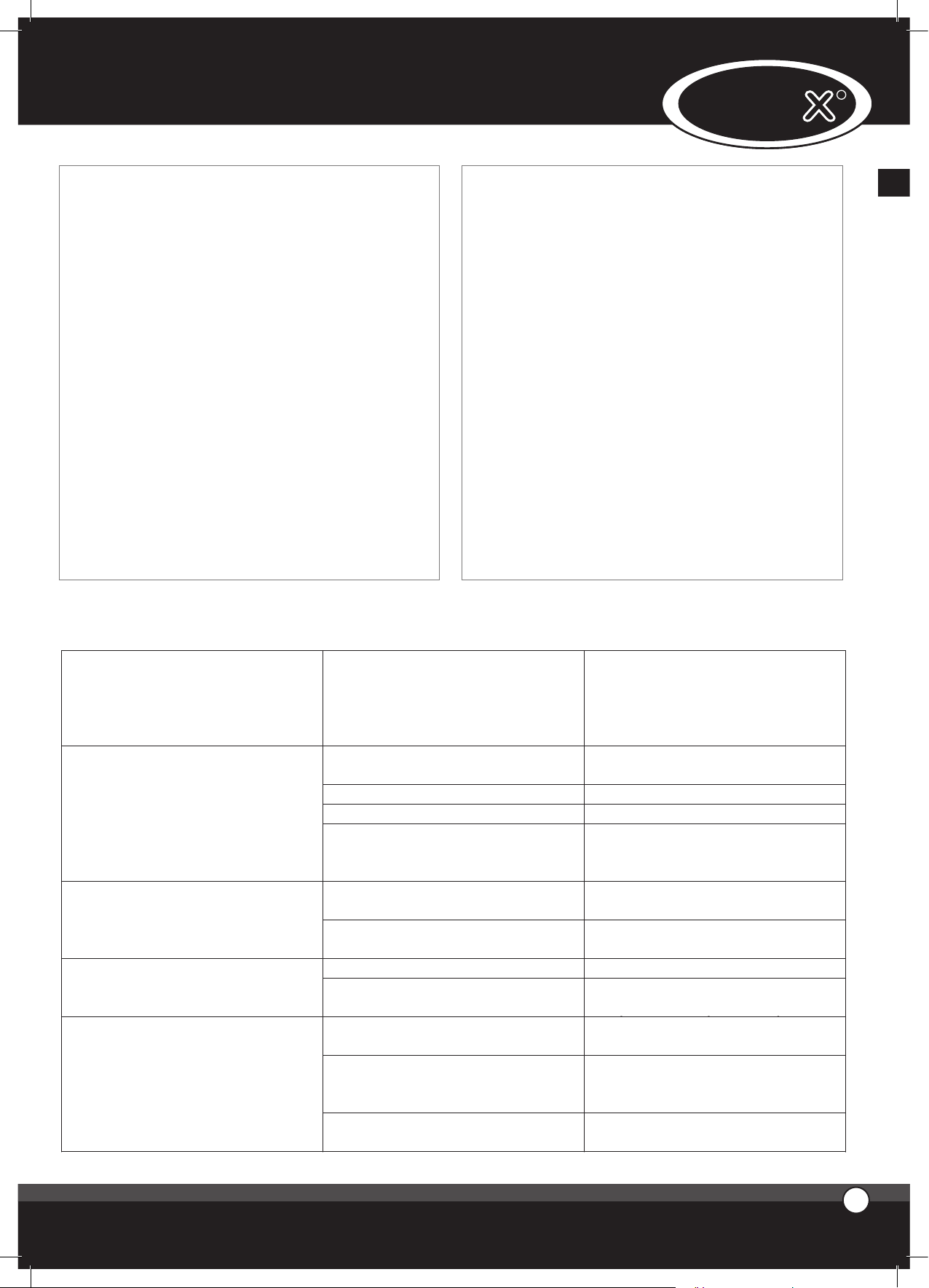

3. MORE FREQUENT

BREAKDOWNS

CAUSE SOLUTION

BREAKDOWN

The tension of the electrical

system is missing

Restore the tension

Safety thermostat intervention Refit the safety thermostat

The oven is completely turned

off

The connection to the electrical

system not made in the correct

way

Control the connection of the

appliance to the electrical

system

Damaged door basket Contact a specialized

technician for reparation

There is water coming out of

the cavity from the door

gasket, even though the door

is closed

Loosened door mechanism Contact a specialized

technician for reparation

Burnt lamp Sostituire la lampadina

The oven light (if present) does

not turn on

Loosened lamp Inserire in maniera corretta la

lampadina nel portalampade

The fans do not reverse the

rotating direction

Contact a specialized

technician for reparation

One of the fans do not work (in

case that you have an oven

with more than one motor)

Contact a specialized

technician for reparation

The cooking results are even

The heating element is broken Contact a specialized

technician for reparation

Substitute the lamp

Fix the lamp in the lamp holder cor-

rectly

3. MORE FREQUENT BREAKDOWNS

CAUSE SOLUTION

Page 8

LineMicro™

1

FRANÇAIS

I. LES INSTRUCTIONS

POUR L’INSTALLATEUR

Gentil Client, nous la remercions et nous nous complimentons pour avoir acheté un produit UNOX.

Les avertissements et les conseils qui suivent concernent

les phases pour la correcte installation, l’usage et la maintenance de l’équipement, pour sauvegarder sa sûreté et

pour une meilleure utilisation de l’appareil.

1. ÉTIQUETTE DES DONNÉES

2. CERTIFICATION

Le marquage “CE” rapportée sur les appareillages

insérés dans ce manuel fait référence aux suivantes

directives :

FOURS À CONVECTION ELETTRIQUES-SERIE XF :

• Directive de la Basse Tension

DBT EC 2006/95,

selon la norme EN60335-2-42+A1 et

selon la norme EN60335-2-46+A1

• Directive de la Compatibilité Electromagnétique EC

2004/108,

selon les normes EN60555-3, EN55014, EN55104

Le fours du la series XAF sont approuvé avec MET et

NSF mark.

INDEX

I. Les Instructions pour l’installateur

1. ETIQUETTE DES DONNÉES

2. CERTIFICATION

3. INSTALLATION

- les opérations préliminaires

4. INSTALLATION

- Branchement elettrique

II. Les Instructions pour l’utilisateur

1. INSTRUCTIONS POUR L’UTILISATEUR

2. INDICATIONS D’EMPLOI

3. TABLEAU DES COMMANDES

4. NETTOYAGE DU FOUR

5. ETEIGNEMENT EN CAS DE DEGÂT

III. Les Principes de cuisson

1. TYPOLOGIES DE CUISSON

2. VARIABLES DE CUISSON

3. UTILISATION DES PLAQUES ET DES GRILLES

IV. La maintenance

1. MAINTENANCE ORDINAIRE

2. MAINTENANCE EXTRAORDINAIRE

3. LES DÉGÂTS PLUS FRÉQUENTS

Page 9

3. L’INSTALLATION

- LES OPERATIONS PRÉLIMINAIRES

Toutes les opérations d’installation et de branchement

électrique doivent être faites par des personnes qualifiées

selon les normes en vigueur.

3.1 LA VÉRIFICATION DU LIEU

D’INSTALLATION

Avant de positionner l’appareil vérifiez les mesures d’en-

combrement et l’exacte position des branchements

électriques selon la figure rapportée dans le dossier cijoint «Données Techniques».

3.2 LE MONTAGE DES PIEDS DES FOURS

Les pieds sont posés à l’intérieur de l’appareillage et

doivent être péremptoirement montés. Ne pas utiliser

l’équipement sans les pieds. Insérer les pieds à déclenchement comme montré dans la figure.

3.3 LE POSITIONNEMENT

Positionnez l’appareil en respectant les normes de sûreté

indiquées comme suit:

1. disposez l’appareil en mode que les parties postérieures

et latérales soient facilement accessibles pour effectuer

le branchement électrique e pour permettre la maintenance de l’appareillage.

2. L’appareillage n’est pas adéquat pour être encastrer ou

positionner en batterie.

3. On conseille de laisser une distance de 10 cm entre la

partie postérieure et la cheminée du four.

Tous les modèles doivent être positionnés au dessus d’un

support, pas ex. une étuve, un support ou bien une table

faite par un matériel incombustible.

Non jamais installer les fours sur le sol directement.

Si l’appareil est positionné à coté d’un mur, diviseurs,

meubles de cuisine, bordures décorées etc., on vous recommande que ceux-ci soient faites d’un matériel incombustible.

En cas contraire ils doivent être revêtus avec un matériel

isolant thermique incombustible, et il faut bien sur prêter

l’ attention aux règles de prévention incendie.

3.4 L’ENLÈVEMENT DES FEUILS DE PROTECTION

Enlevez complètement le feuil de protection des parties

externes de l’appareil attentivement et évitez de laisser

des résidus de colle.

Si malgré cela ces résidus persistent, enlevez-les avec un

solvant approprié.

4. L’INSTALLATION

4.1 BRANCHEMENT ELETTRIQUE

a- Le branchement au réseau électrique doit être

effectué par des personnes qualifiées

selon les normatives en vigueur.

Utiliser le four avec une température ambiante comprise

entre +5 °C et +35 °C.

Avant d’effectuer le branchement, contrôlez que la ten-

sion et la fréquence correspondent aux données rapportées sur l’étiquette de l’appareil. L’appareil doit être

positionné de sorte que l’épine de connexion au réseau,

soit accessible.

Interposer entre l’appareillage et le réseau, un interrup-

teur omnipolaire. Cet Interrupteur doit être facilement

accessible après l’installations.

Les contacts de cet interrupteur doivent avoir une dis-

tance minimale d’ouverture de 3mm et il doit avoir aussi

une portée appropriée. On vous conseille d’utiliser un

interrupteur differential magneto-thermal switch.

La tension d’alimentation, lorsque l’appareil est en fonc-

tion, ne doit pas s’écarter de la valeur nominale de la

tension rapportée sur l’étiquette données du four, de

±10%.

Le couvercle de le thermostat du protection doit être

serré ne peut pas êntre enlevé sans l utilisation d-un outil

b- L’appareillage doit être lié à la ligne de terre

du réseau. En outre l’appareillage doit être inclus dans un

système équipotentiel duquel l’efficacité doit être opportunément vérifiée selon combien rapporté dans la réglementation en vigueur.

ENGLISH

3

2

FRANÇAIS

UNO

R

2

Page 10

ChefTop™

Cette liaison doit être effectuée entre les différents appareil-

lages avec la borne marquée du symbole :

Le conducteur équipotentiel doit avoir une section mini-

male de 10 mm2.

1- Fours doués de câble et fiche Schuko (monophase 230V) :

il est suffisant d’insérer la fiche dans l’appropriée prise (la

prise doit être apte à l’épine fournie en dotation).

2- Fours doués de câble (des tri phase 400V Neutre) : les

fours en question sont doués d’un câble électrique à 5

conducteurs : il est nécessaire de relier l’appropriée fiche

tri phase aux 5 pôles de portée appropriée ou bien de

relier le câble directement à un cadre électrique.

Dans les fours doués de câble à 5 conducteurs il est possible

substituer le câble d’alimentation pour adapter le four à la

typologie de fourniture de courant électrique disponible.

Pour substituer le câble d’alimentation procédez

comme il suit :

• Ouvrir le couvercle de la boite à bornes en faisant levier,

avec un tournevis adapté, sur les deux ailettes latérales (1)

• Dévisser les vis de blocage des conducteurs (2)

• Dévisser les vis du fixe-câble (3)

• Ôter le câble en dotation

• Relier les conducteurs du câble qu’on veut utiliser selon

le schéma de liaison choisie en serrant opportunément les

vies des boites à bornes

• Bloquer le câble à travers l’approprié fixe câble

• Enfermer le couvercle de la boite à bornes

PRÉCAUTION :

Effectuer la connexion électrique de la boîte à bornes comme

indiqué dans le dessin: introduire le pont de cuivre et le câble

électrique ensemble sous la vis, dans le sens de vissage, dans la

façon que, en serrant la vis, le câble et le pont soient strictement fixés.

Une connexion incorrecte peut causer le surchauffage de la

boîte à bornes, jusqu’ à la faire fondre.

LA SORTIE DES VAPEURS DE LA CHAMBRE DE CUISSON

Une cheminée d’évacuation des vapeurs provenant

de la chambre de cuisson est présente dans la partie

postérieure du four:

pendant la cuisson, les vapeurs chaudes et humides sortent

à travers cette cheminée (la température et l’humidité

des vapeurs dépendent des paramètres de fonctionnement du four et du type et de la quantité de produit inséré à l’intérieur du four). Les vapeurs qui sortent de la

cheminée peuvent être canalisées vers l’extérieur ou bien

condensées.

II. LES INSTRUCTIONS

POUR L’UTILISATEUR

L’appareillage ne doit pas être nettoyé avec un jet d’eau

en pression. Ne lavez jamais l’intérieur de la chambre de

cuisson avec des acides ou des produits agressifs, mais

seulement avec du savon et de l’eau. L’appareillage est

destiné à l’emploi professionnel spécifique et doit être

utilisé seulement par des personnes qualifiées.

1. LES INSTRUCTIONS POUR

L’UTILISATEUR

ATTENTION!

Lisez attentivement le présent livret puisqu’il vous

fournit des importantes indications en ce qui concerne la sûreté de l’installation, de l’emploi et de la

maintenance.

4

3

FRANÇAIS

LineMicro™

Page 11

UNO

R

Conservez avec soin ce livret pour chaque ultérieure consultation des divers opérateurs.

En phase de première utilisation, faire attention que le

notice d’utilisation, des sacs en plastic ou n’importe quel

autre objet, ne soient pas présents à l’intérieur de la

chambre de cuisson.

L’appareil n’est pas conçu pour une utilisation de part de

personnes (inclus les enfants) avec des capacités mental,

physique et sensoriales réduites, ou une absence de expérience ou de connaissance de l’appareil, au moins q’îles

sont surveillées par une personne responsable pour la

leur sécurité ou qui louer donne des instructions pour

l’utilisation de l’appareil.

Les enfants doit être surveillées, pour être sur que il ne

jeux pas avec l’appareil.

Pour une éventuelle réparation il faut s’adresser seulement à un centre d’assistance technique et exiger des

pièces détachées UNOX originales.

Le non- respect de ce qui est écrit là-dedans peut

compromettre la sûreté de l’appareillage et vous

risquez d’être déchus de la garantie.

2. NOTE POUR L’USAGE

L’appareillage devra être destiné seulement à l’emploi

pour lequel il a été expressément conçu.

Les fours ont été projetés pour la cuisson « au four » des

aliments comme rapporté ci-dessous. On retient impropre chaque autre emploi.

Le four vous permet des températures d’exercice comprises entre 0 - 300 °C (0 - 572 °F).

Vous pouvez l’utiliser pour :

• Les cuissons de tous les produits de la pâtisserie et du

pain, frais ou congelés.

• Les cuissons de tous les produits de la gastronomie,

frais ou congelés.

• Pour le reconditionnement des aliments réfrigérés et

congelés.

• Pour la cuisson de la viande, des poissons et des verdures.

En disposant les aliments dans la chambre de cuisson, laissez une espace d’au moins 20 mm entre

les bassinets pour permettre la circulation de l’air

chaud.

Évitez de saler les aliments dans la chambre de cuisson.

4

FRANÇAIS

3. LE TABLEAU DES COMMANDES

L’ETABLISSEMENT DU TEMPS DE CUISSON

On établit le temps de cuisson au moyen de la poignée

destinée à cet usage (poignée à gauche sur le tableau des

commandes): le temps peut être établi entre 0 - 60 min.

En tournant la poignée en sens horaire, on établit le temps

de cuisson; en tournant la poignée en sens contraire aux

aiguilles d’une montre (position manuelle), le four fonctionne sans arrêt.

La rotation de la poignée fait partir le four en activant la

rotation des turbines et en allumant la lumière interne (si

présente).

Attention! La condition du four éteint se vérifie seulement quand la poignée du Timer est mise exactement à

zéro “0”. Pour être sûr de l’éteignement correcte du four,

il faut attendre 5 minutes avant de laisser l’appareil.

L’ETABLISSEMENT DE LA TEMPERATURE DE CUISSON

On établit la température de cuisson au moyen de la

poignée destinée à cet usage (poignée à droite sur le

tableau des commandes):

la température peut être établie entre 0 - 300 °C (0 - 572 °F) .

Feu vert de la température lorsque qu’il est allumé, signale

que la résistance est active; quand la température désirée

est rejointe s’éteint.

4. LE NETTOYAGE DU FOUR

NOTICE:

Avant d’effectuer n’importe quelle intervention

d’entretien ou nettoyage, débranchez l’alimentation

électrique et attendez le refroidissement de

l’appareil.

UNO

R

Page 12

ChefTop™

LineMicro™

4.1 LA PREMIÈRE UTILISATION DU FOUR

Avant d’utiliser l’équipement pour la première fois il est

obligatoire nettoyer la partie interne en métal avec de

l’eau chaude et du savon et ensuite la rincer bien.

Ne lavez jamais l’intérieur de la chambre avec des acides

ou des produits agressifs.

Il est nécessaire ensuite réchauffer l’appareil à vide pour 3

minutes environ à la température de 200 ºC (392 ºF) pour

éliminer des éventuelles odeurs causées par l’isolation

thermique.

4.2 LE NETTOYAGE DE LA CHAMBRE DE

CUISSON

Il est nécessaire nettoyer l’intérieur de la chambre de cuis-

son en utilisant des produit adéquats à la fin de chaque

cycle de cuisson.

N’utilisez pas pour le nettoyage de l’acier des acides, des

produits agressifs ou bien des produits qui contiennent le

chlore (hypochlorite sodique, acide chlorique etc.), néanmoins s’ils sont dilués.

4.3 LENETTOYAGE EXTERNE DU FOUR

On vous recommande de ne pas utiliser un jet d’eau en

pression pour le lavage extérieur du four. Utilisez seulement des tissus humides et des produits convenables

pour le nettoyage de l’acier inoxydable .

Pour nettoyer le vitre du four, utilisez de l’eau avec

du savon neutre. Ne jamais utiliser de l’alcool ou bien

d’autres types de produits.

5. L’EXTINCTION EN CAS DE DÉGÂT

En cas de dégât vous êtes priés de désactiver

l’appareillage :

•débrancher l’interrupteur automatique de l’alimentation

électrique.

•s’adresser à un centre d’assistance technique ayant un

personnel qualifié.

III. LES PRINCIPES DE

CUISSON

1. LES TYPOLOGIES DE CUISSON

Les typologies de cuisson qui peuvent être effectuées

avec les équipements indiqués dans ce manuel sont la

Cuisson Professionnelle de Pain et Pâtisserie et la Cuisson

Professionnelle de la Gastronomie en modalité à CON-

VECTION, c.à.d à travers la circulation de l’air chaud.

PRÉCAUTION :

a- Réchauffez le four en fixant une température supérieure

à la température de cuisson de 30°C (54°F) avant toute

utilisation pour obtenir une cuisson uniforme.

b- L’utilisation de températures plus élevées par rapport au

standard demandé d’un produit cause une cuisson non

pas uniforme.

c- Pour la cuisson du pain et de la pâtisserie: n’utilisez pas

des plaques avec une hauteur supérieure à 20 mm et

évitez que les produits placés sur la plaque se touchent.

d- Ne surchargez pas les plaques de produit.

Dans les fours à Convection (fours à air pulsé), la cuis-

son se produit à travers la circulation de l’air chaud à

l’intérieur de la chambre de cuisson. Ceci permet de cuisiner les aliments uniformément grâce à une distribution

homogène de la température.

L’uniformité de cuisson est garantie même si le four est

complètement chargé.

Le produit est cuit parfaitement que se soit en superfi-

cie, avec une dorure homogène, ou bien dans la partie

interne, avec une structure uniforme et une humidité restante constante.

L’avantage se présente dans la possibilité de pouvoir cuire

en même temps des produits de nature différente (pourvu que la température de cuisson soit la même) sans mélanger les saveurs.

2. LES VARIABLES DE CUISSON

LA TEMPÉRATURE

L’exacte position de la température garantit une cuisson

correcte des aliments que se soit dans la partie externe

ou bien dans la partie interne.

• Une température basse par rapport à celle correcte

tend plus à dessécher qu’à cuire la nourriture.

• Une température supérieure à celle correcte tend à

brûler la partie extérieure et à laisser l’intérieur non cuit

(ce phénomène parfois est voulu par exemple dans la cuisson de la viande).

LE TEMPS

Cette variable dépend beaucoup de la quantité des ali-

ments introduite dans le four. Les temps de cuisson

s’allongent quand les quantités augmentent et vice-versa.

Des temps plus courts par rapport à ceux correctes ne

permettent pas une cuisson complète des aliments.

Des temps plus longs, toujours par rapport à ceux cor-

rectes, créent des phénomènes de brûlure extérieure des

aliments.

5

FRANÇAIS

Page 13

UNO

R

UNO

R

7

6

FRANÇAIS

LA QUANTITÉ DES ALIMENTS

La quantité des aliments influence le temps de cuisson.

Des quantités majeures signifient des temps de cuisson

plus longs et vice-versa. Une quantité des aliments excessive peut provoquer une aggravation de l’uniformité de

cuisson.

3. L’UTILISATION DES PLAQUES – GRILLES

On vous conseille d’utiliser des:

•Plaques en aluminium: pâtisserie, pain non surgelé.

•Plaques en acier: premiers plats, viandes, poissons,

pommes de terre

•Grilles: pour rissoler la viande comme les biftèques,

würstel, saucisse, pain surgelé, pizza surgelée.

IV. LA MAINTENANCE

1. LA MAINTENANCE ORDINAIRE

N’importe quelle opération d’entretien doit être ef-

fectuée seulement par des personnes qualifiées. Avant

d’effectuer n’importe quel type d’entretien il est nécessaire débrancher l’alimentation électrique et attendre le

refroidissement de l’appareil.

Les composants qui nécessitent d’entretien ordinaire

sont accessibles en enlevant le tableau des commandes

frontal et le dos du four.

Périodiquement (au moins une fois par an), soumettre

l’appareillage à un contrôle total de la part d’un technicien

spécialisé.

2. LA MAINTENANCE EXTRAORDINAIRE

N’importe quelle opération d’entretien doit être ef-

fectuée seulement par des personnes qualifiées. Avant

d’effectuer n’importe quel type d’entretien il est nécessaire débrancher l’alimentation électrique et attendre le

refroidissement de l’appareil. Les composants qui nécessitent d’entretien ordinaire sont accessibles en enlevant le

tableau des commandes frontal et le dos du four.

2.1 LE REMPLACEMENT DE LA LAMPE

D’ÉCLAIRAGE (SI PRÉSENTE)

Pour substituer la lampe d’éclairage, procédez comme

il suit :

•Débranchez électriquement l’appareillage et laissez-le

refroidir.

•Enlevez les grilles latérales.

•Dévissez le couvercle en verre et substituez la lampe

par une autre ayant les mêmes caractéristiques.

•Revissez le verre ( couvre lampe ).

•Remontez les grilles latérales.

2.2 LE RÉÉQUIPEMENT DU DISPOSITIF

THERMIQUE DE SICURITÉ

L’appareillage est doué d’un dispositif thermique

d’interruption à rééquipement manuel pour la protection contre les sur températures. Dans le cas

d’intervention il éteint l’appareillage. Tel dispositif est

accessible en enlevant le bouchon noir posé en bas dans

le côté postérieur de l’équipement : en cas de rééquipement manuel, pressez le bouton au centre du dispositif

pour réactiver l’appareillage.

DÉGÂT CAUSE SOLUTION

Manque de tension du

réseau électrique

Rétablir la tension

d’alimentation

Intervention du dispositif

thermique de sécurité

Rétablir le dispositif

thermique de sécurité

Le four est

complètement éteint

Branchement au réseau

électrique fait

incorrectement

Vérifier le branchement

au réseau électrique

Joint endommagé Il faut s’adresser à un

technicien spécialisé

pour la réparation

Avec la porte fermée,

l’eau sort à travers le

joint

Système de fermeture

endommagé

Il faut s’adresser à un

technicien spécialisé

pour la réparation

Lampe brûlée Remplacez la lampe

Lumière du four (si

présente) est éteinte

Lampe détendue et pas

bien fixée

Insérer correctement la

lampe dans le porte-lampe

Les Turbines n’effectuent

pas l’inversion de marche

Il faut s’adresser à un

technicien spécialisé

pour la réparation

Un des turbines ne

fonctionne pas ( au cas où

le four a plus d’un moteur)

Il faut s’adresser à un

technicien spécialisé

pour la réparation

La cuisson n’est pas

uniforme

La résistance est

endommagée

Il faut s’adresser à un

technicien spécialisé

pour la réparation

3. LES DEGÂTS PLUS FRÉQUENTS

Page 14

LineMicro™

1

DEUTSCH

I. ANLEITUNG FÜR DEN

INSTALLATEUR

Lieber Kunde, wir möchten Ihnen zu dem Erwerb eines

LineMicro™ Heissluftofens gratulieren und danken.

Achtung: Lesen Sie bitte vor dem Gebrauch, die Bedienungsanleitung gründlich durch. Bewahren Sie die Bedienungsanleitung bitte sehr sorgfältig auf.

1. TYPENSCHILD

2. ZERTIFIKAT

Das CE-Kennzeichen an den Geräten und in

dieser Betriebsanleitung unterliegen den folgenden

EG –Richtlinien:

ELEKTRO HEISSLUFTÖFEN - SERIE XF:

- Niederspannungsrichtlinie

DBT EC 2006/95,

nach EN60335-2-42+A1 und

EN60335-2-46+A1

- Richtlinie der Elektromagnetischen Verträglichkeit

2004/108/CE,

nach EN6555-3, EN55014 und EN55104.

Die Öfen der XAF-Serie von MET und NSF für U.S.A.

INDEX

I. Anleitung für den installateur

1. TYPENSCHILD

2. ZERTIFIKAT

3. INSTALLATION

- Erste schritte

4. INSTALLATION

- Elektrischer anschluß

II. Hinweise für den Benutzer

1. HINWEISE FÜR DEN BENUTZER

2. ANWEISUNGEN FÜR DEN BETRIEB

3. BESCHREIBUNG UND ANWENDUNG DES BEDIENPANELS

4. REINIGUNG DES OFENS

5. ANWEISUNGEN BEI STÖRUNGEN

III. KOCHMETHODEN

1. BETRIEBSARTEN

2. EINSTELLUNG DER PARAMETER

3. GEBRAUCH VON BLECHEN UND ROSTEN

IV. Wartung

1. GEWÖHNLICHE WARTUNG

2. SPEZIELLE WARTUNG

3. STÖRUNGEN UND DEREN BEHEBUNG

Page 15

UNO

R

7

2

DEUTSCH

3. INSTALLATION

ERSTE SCHRITTE

Alle elektrischen Anschlüsse und Installationsarbeiten

müssen von qualifizierten Fachleuten entsprechend den

Richtlinien ausgeführt werden.

3.1 ÜBERPRÜFUNG DER AUFSTELLUNGS-

FLÄCHE

Vor der Aufstellung des Gerätes überprüfen Sie bitte die

Abmessungen und die Position des Elektrischen Anschlusses etc. unter Berücksichtigung der nachfolgenden Seiten

“TECHNISCHE DATEN“.

3.2 MONTAGE DER GERÄTEFÜßE

Die Füße liegen innen im Gerät und müssen unter dem

Ofen angeschraubt werden.

Bitte nutzen Sie das Gerät niemals ohne Füße.

Montage wie im Bild abgebildet.

3.3 POSITIONIERUNG

Das Gerät muss entsprechend den Sicherheitsvorschrif-

ten und Normen wie nachfolgend

beschrieben, aufgestellt werden.

Die Seiten und Oberflächen des Gerätes müssen so auf-

gestellt werden, sodass ein einfacher

elektrischer Anschluss, die normale Wartungen und

Reparaturen möglich sind.

Das Gerät ist nicht einbaufähig, und nicht für Reihenauf-

stellung geeignet.

Es ist wichtig, dass ein Abstand von mindestens 10 cm

zwischen der Geräte Oberfläche bzw.

dem Abluftkamin des Gerätes und der nächsten Möbel

oder dem nächsten Gerät gewährleistet ist.

Alle Geräte müssen auf einem Unterbau, Gärschrank

oder einem geeigneten Tisch aufgestellt

werden. Bitte auf keinen Fall den Ofen auf den Boden

stellen.

Falls das Gerät in der Nähe von Mauern, Wänden,

Küchenschränken, Deko-Materialien aufgestellt werden

muss, ist es wichtig dass diese Teile aus einem nicht brennbaren Material bestehen.

Bitte prüfen Sie dies genau, falls die Teile aus brennbarem

Material bestehen, verkleiden Sie diese mit nicht brennbarer Isolierung oder entfernen Sie diese Teile aus dem

Umfeld des Gerätes. Bitte prüfen Sie hier den Schutzvorschriften vor Feuer und Rauch genau.

Andernfalls, müssen diese mit nicht brennbarem Material

abisoliert werden.

Bitte beachten Sie die Feuerschutzvorschriften.

3.4 ABZIEHEN DES SCHUTZFILMS

Ziehen Sie unbedingt den weißen Schutzfilm von den

Außen und Innenseiten des Gerätes ab, Dies ist wichtig

um ein verbrennen des Schutzfilms während des Betriebes zu verhindern!

Falls ein Rückstand verbleibt, entfernen Sie den Rück-

stand mit einem Lösungsmittel.

4. INSTALLATION

ELEKTRISCHER ANSCHLUß

a- Die Installation zum Stromversorgungsnetz muss vom

qualifizierten Personal gemacht werden und sie muss den

Vorschriften des Netzbetreibers vor Ort entsprechen.

Der Ofen sollte nur bei einer Raumtemperatur von +5

bis +35°C genutzt werden.

Der Installateur ist für den richtigen elektrischen An-

schluss des Ofens und der Beachtung der Sicherheitsnormen verantwortlich.

Vor dem Anschluss stellen Sie bitte sicher das die Voltzahl

und die Stromfrequenz des Stromnetzes mit den Angaben auf dem Typenschild des Gerätes übereinstimmen.

Plazieren Sie den Stecker zwischen dem Gerät und dem

Stromversorgungsnetz nach der Installation, die Kontakte dürfen nur ein Minimum Öffnungs- Abstand von

3 mm von der Zuleitung (z.B.: ein magnetthermischer

Trennschalter).

Wenn das Gerät arbeitet darf die Spannung nicht mehr als

± 10 % von der normalen Spannung abweichen.

b- Das Gerät muss über das Stromnetz geerdet sein.

Zusätzlich muss das Gerät an ein System für einen Äqui-

potential Ausgleich angeschlossen sein.

Der Anschluss für den Äquipotential Ausgleich ist durch

Page 16

ChefTop™

LineMicro™

3

DEUTSCH

dieses Symbol gekennzeichnet:

Die Aquipotential Ausgleichsleitung muss einen Quer-

schnitt von 10 mm2 haben.

1- Ofen mit Zuleitungskabel und Schukostecker (Eine Phase

230 Volt): es ist ausreichend, nur den Stecker in die Steck-

dose zu stecken (der Stecker muss zu der Steckdose pas-

send sein)

2- Ofen mit Zuleitungskabel (drei Phasen 400V): diese Öfen

haben ein elektrisches Zuleitungskabel mit 5 Leiter:

es ist notwendig, den dreiphasigen Starkstromstecker an-

zuschließen oder das Kabel direkt anschließen.

In den Öfen, die ein elektrisches Zuleitungskabel mit 5

Leitern haben, ist es möglich das Kabel auszuwechseln,

und dem verfügbaren elektrischen Strom anzupassen.

Die Auswechslung der elektrischen Kabel( im Fall eines

Kabelschadens) muss durch einen technischen Fachmann

oder durch eine Person die ähnliche Qualifikationen bes-

itzt, vorgenommen werden.

Um die Stromzuleitung auszuwechseln, verfahren Sie wie

folgt:

• Schrauben Sie die Plastikabdeckung der Anschlussleiste mit

einem Schraubenzieher ab(1).

• Schrauben Sie die Befestigungsschrauben der Stromleiter(2) ab.

• Lösen Sie die Befestigungsschraube der Zugentlastung ab (3).

• Entfernen Sie das Kabel.

• Verbinden Sie die Leiter wie auf dem gewählten Schema

beschrieben.

• Befestigen Sie das Kabel durch die Zugentlastung.

• Montieren Sie die Plastikabdeckung der Anschlussleiste

HINWEISE:

Nehmen Sie die Verbindung des Elektrokabels nach der Zeichnung vor:

stecken Sie die Kupferbrücke und den Stromleiter unter die Schraube.

Die Kabel müssen in die Richtung der Verschraubung ange

-

bracht werden, so dass beim Verschrauben der Schraube, der

Stromleiter und die Kupfer-Brücke festgemacht werden:

eine falsche Verbindung kann die Überhitzung der Klemmleiste

bis auf das Schmelzen bewirken.

ABLUFT AUS DEM BACKRAUM

Auf der Rückseite des Ofens finden Sie ein Abluftrohr, aus

welchem die Backraumabluft entweicht. Während eines

Backvorgangs entsteht kontinuierlich Abluft (Hitze und

Beschwadung, abhängig von den Einstellungen und der

Menge der zubereitenden Gerichte).

Die entstehende Abluft kann aus dem Raum abgeführt

werden.

II. HINWEISE FÜR DEN BE-

NUTZER

Dies Gerät ist nicht für die Reinigung mit einem Dampfstrahler geeignet.

Reinigen Sie die Backkammer mit Wasser und Spülmittel,

bitte benutzen Sie keine aggressiven

Reinigungsmittel oder Säuren.

Das Gerät ist speziell entwickelt für die gewerbliche Nutzung in Großküchen, Bäckereien, und muss vom qualifizierten Personal bedient werden.

1. ANWEISUNGEN FÜR DEN BETRIEB

HINWEIS: Bitte lesen Sie gründlich die Bedienun-

gsanleitung, bevor Sie das Gerät in Betrieb nehmen.

Bewahren Sie die Anleitung an einem Platz auf, wo jeder Bediener des Gerätes drauf Zugriff hat.

Vor der ersten Inbetriebnahme des Gerätes vergewissern

Sie sich bitte, dass alles aus dem Garraum entfernt wurde.

Dieser Apparat kann nicht von Leute (und Kinder auch)

mit Kapazitaetsabbau (geistig, koerperlich und sensor-

Page 17

UNO

R

UNO

R

7

4

DEUTSCH

isch), oder ohne Erfahrung und Erkenntniss benutzt sein.

Die Kinder muessen beaufsichtigt sein, damit sie spielen

nicht mit dem Apparat.

Für etwaige Reparaturen rufen Sie nur den vom Werk

autorisierten Kundendienst an und verwenden Sie nur

Original UNOX - Ersatzteile für das Gerät.

All diese Hinweise gewährleisten den sicheren

Gebrauch des Gerätes und die Gültigkeit der Garantie.

2. NOTIZEN ZUR BEDIENUNG

Das Gerät darf nur für den Verwendungszweck für den es

konstruiert wurde, benutzt werden.

Der Verwendungszweck für die Geräte das Backen und

wie weiter unten angegeben.

Für eine andere Nutzung ist das Gerät ungeeignet.

Der Ofen erlaubt Betriebstemperaturen von (0 -300 °C

oder 0 - 572 °C) . Es kann verwendet werden für:

• alle Brot - und Backwarenprodukte, frisch oder gefroren

• Kochen von allen Gastronomieprodukten, frisch oder

gefroren

• regenerieren von gekühlten oder gefrorenen Speisen

• Kochen von Gemüse, Kartoffeln, Fisch und Fleisch.

Wenn Sie die Lebensmittel in die Backkammer einführen, lassen Sie einen Abstand von

mindestens 20 mm zwischen den Blechen, um eine

ausreichende Luftzirkulation der Heißluft zu

gewährleisten.

Führen Sie kein Salz in die Speisen in der Backkammer ein.

3. BESCHREIBUNG UND ANWENDUNG

DES BEDIENPANELS

ZEITEINSTELLUNG

Die Backzeit kann durch das Drehen des linken Knopfes im

Uhrzeigersinn von 0 - 60 Minuten eingestellt werden.

Drehen Sie den Knopf gegen den Uhrzeigersinn, stellen Sie

den Dauerlauf ein.

Beim Drehen des Knopfes starten Sie den Ofen: die Lüf-

terräder drehen sich und das Licht im Backraum geht an.

Achtung!! Der Ofen ist ausgeschaltet wenn die Zeitschlatuhr auf „0“ gestellt ist. Mann muss 5 Minuten warten um

sicherzugehen, dass der Oven korrekt abgeschaltet ist, um

die Ausrüstung unbeaufsichtigt lassen zu können.

EINSTELLUNG DER TEMPERATUR

Die Garraumtemperatur (0 -300 °C oder 0 - 572 °C)

können Sie über den Knopf( rechts auf der Bedienung)

einstellen.

Das grüne Temperaturwarnlicht signalisiert den Heizvor-

gang im Backraum.

Sobald die eingestellte Temperatur erreicht ist, schaltet

sich die Heizung.

4. REINIGUNG

HINWEIS:

Unterbrechen Sie vor der Durchführung jeglicher

Wartungs- oder Reinigungsarbeiten die Stromzufuhr zum Gerät und warten Sie ab bis das Gerät abgekühlt ist.

4.1 ERSTE BENUTZUNG DES GERATES

Vor der ersten Inbetriebnahme des Gerätes: Reinigen Sie

die Metallteile mit warmen Wasser und Seife und spülen

Sie gründlich nach.

Bitte verwenden Sie keine chlorhaltigen Reinigungsmittel

oder Säuren.

Heizen Sie das Gerät nun für ca. 30 Minuten mit einer

Temperatur von 200°C (392° F) auf, um eventuelle

störende Gerüche, die von der Wärmeisolierung ent-

standen sind, zu beseitigen.

4.2 REINIGUNG DES BACKRAUMS

Reinigen Sie den Backraum nach Beendigung jedes Back-

vorgangs in nachfolgend beschriebener Weise:

Page 18

ChefTop™

LineMicro™

5

DEUTSCHDEUTSCH

Verwenden Sie zur Reinigung des Stahls keine chlorhalti-

gen Mittel (Hypochlorit, Salzsäure usw.) auch wenn diese

verdünnt sind.

4.3 ÄUßERE REINIGUNG DES OFENS

Für die äußere Reinigung des Ofens, verwenden Sie auf

keinen Fall einen Dampfstrahler.

Reinigen Sie das Gerät mit einem feuchten Tuch.

Zum Reinigen der Glasscheibe, verwenden Sie Wasser

und Seife.

5. ANWEISUNGEN BEI STÖRUNGEN

Schalten Sie das Gerät im Störfall ab:

a- trennen Sie als erstes die Stromzufuhr

b- kontaktieren Sie einen autorisierten, technischen Fach-

mann der Fa. UNOX.

III. KOCHMETHODEN

1. BETRIEBSARTEN

Die Produkte die mit dem Gerät produziert werden kön-

nen finden Sie hier nachfolgend:

• Brot / Brötchen / Backwaren gewerbliches Backen,

gewerbliches Kochen mit Umluft

HINWEIS:

a- Heizen Sie den Ofen vor jeder Benutzung gut auf, bis zum

einer Temperatur über 30 °C (54 °F) höher als die Ko-

chtemperatur, damit erreichen Sie ein gleichmäßiges Back-

ergebnis.

b- Durch die Einstellung einer Temperatur, die höher als der

normale Standard ist, erreichen

Sie kein gleichmäßiges Backergebnis.

c- Backwaren und Snacks: benutzen Sei keine Bleche die

höher als 20 mm sind und lassen Sie einen Abstand

zwischen den Backwaren, damit die nicht verkleben können.

d- Bitte die Bleche nicht überladen

Das Kochen in einem Ofen mit Ventilator ist möglich

durch die Zirkulation der Heißluft in der Backkammer.

Durch die gleichmäßige Wärmeverteilung wird das Ko-

chen von allen Lebensmitteln möglich gemacht.

Die gleichmäßigen Backergebnisse sind garantiert, auch

wenn der Ofen voll beschickt wurde. Die Produkte be-

kommen eine goldene Kruste auf der Oberfläche und

eine gleichmäßige Struktur im inneren Bereich.

Der größte Vorteil ist die Möglichkeit, in der gleichen Zeit

verschiedene Arten von Lebensmitteln ohne Vermischung deren Aromen (solange die erforderliche Temperatur gleich ist)zu produzieren.

2. EINSTELLUNG DER PARAMETER

TEMPERATUR

Die genaue Einstellung der Temperatur gewährleistet eine

ordnungsgemäße Zubereitung der Lebensmittel, sowohl

innerhalb als auch außerhalb.

• Eine niedrigere Temperatur als die benötigte, trocknet

das Produkt aus, anstatt es zu kochen.

• Eine höhere Temperatur als die benötigte, verbrennt

die Oberfläche, während der Kern der Lebensmittel

roh bleibt(manchmal ist dies gewünscht, vor allem bei

Fleisch).

ZEIT

Diese Variable hängt allerdings stark von der Menge der

zubereitenden Produkte. Je größer die Menge der Lebensmittel, desto länger die Zeit und umgekehrt.

Bei einer kürzeren Zeiteinstellung wird das Produkt nicht

fertig gekocht bzw. gebacken.

Eine längere Zeiteinstellung als normal benötigt, verbren-

nt die Oberfläche des Produktes.

MENGE DES PRODUKTES

Die Menge beeinflusst die länge der Back- bzw.Kochzeit.

Je höher die Menge, desto länger die Zubereitungszeit.

Eine Überladung des Ofens, kann zu einem ungleichmäßi-

gen Ergebnis führen.

3. GEBRAUCH VON BLECHEN UND ROSTEN

Es wird empfohlen, der Einsatz von:

• Aluminium Backblech: Snacks, frisches Brot

• Edelstahl Backblech: für erste Zubereitungen, Fleisch,

Fisch, Kartoffeln

• Gitterroste: Steaks, hot-dogs, Wurstwaren, TK-Brot,

TK-Pizza

IV. WARTUNG

1. GEWÖHNLICHE WARTUNG

Jede Wartung muss von einem qualifizierten Fachmann

durchgeführt werden.

Bevor Sie Wartungsarbeiten durchführen ist es notwendig

immer die Stromzufuhr zu trennen. Das Gerät soll vor

den Wartungsarbeiten abgekühlt werden. Die Kompo-

Page 19

UNO

R

UNO

R

7

6

DEUTSCHDEUTSCH

nenten die der Wartung bedürfen befinden sich hinter

dem Kontrollpanel oder sind über die Rückwand des

Gerätes zugänglich. Das Gerät sollte durch den Kundendienst alle 12 Monate einmal gewartet werden.

2. SPEZIELLE WARTUNGEN

Jede Wartung muss von einem qualifizierten Fachmann

durchgeführt werden.

Bevor Sie Wartungsarbeiten durchführen ist es notwendig

immer den Netzstecker zu ziehen und das Gerät Stromlos zu machen. Das Gerät soll vor den Wartungsarbeiten

abgekühlt werden.

Die Komponenten die der Wartung bedürfen befinden

sich hinter dem Kontrollpanel oder sind über die Rückwand des Gerätes zugänglich.

2.1 AUSWECHSELUNG DER GARRAUMBELEUCHTUNG

Gehen Sie zum Austausch der Lampe, wie nachfolgend

beschrieben vor:

• Unterbrechen Sie die Stromzufuhr zum Gerät und lassen Sie das Gerät abkühlen

• Entfernen Sie die seitlichen Einschubleisten

• Schrauben Sie das Schutzglas ab und ersetzten Sie die

Lampe durch eine, die über dieselben

technischen Eigenschaften verfügt.

• Zur Montage, bitte die eben erwähnten Arbeitsschritte

in umgekehrter Reihenfolge vornehmen.

2.2 Reseten des Sicherheitsthermostaten

Einige Geräte sind mit einem manuellen Sicherheitsther-

mostat ausgestattet.

Dieses Thermostat dient zum Schutz vor Überhitzung

und trennt das Gerät vom Netz.

Sollte dieses Thermostat auslösen, muss das kein Zeichen

für einen Defekt sein. Sie finden Es an der Rückseite des

Gerätes im unteren Bereich. Von außen ist eine schwarze

runde Kappe zu sehen. Diese Kappe drehen Sie bitte ab

und drücken den darunter befindlichen Stift wieder ein.

Sollte das Sicherheitsthermostat sehr oft auslösen, liegt

eine Fehlfunktion vor. Sollte dies der Fall sein, wenden Sie

sich an den UNOX Kundendienst.

Bevor Sie Wartungsarbeiten durchführen ist es notwendig immer den Netzstecker zu ziehen und

das Gerät Stromlos zu machen. Das Gerät soll vor den Wartungsarbeiten abgekühlt werden.

Die Komponenten die der Wartung bedürfen befinden sich hinter dem Kontrollpanel oder sind

über die Rückwand des Gerätes zugänglich.

2.1 Auswechselung der Garraumbeleuchtung

Gehen Sie zum Austausch der Lampe, wie nachfolgend beschrieben vor:

- Unterbrechen Sie die Stromzufuhr zum Gerät und lassen Sie das Gerät abkühlen

- Entfernen Sie die seitlichen Einschubleisten

- Schrauben Sie das Schutzglas ab und ersetzten Sie die Lampe durch eine, die über dieselben

technischen Eigenschaften verfügt.

- Zur Montage, bitte die eben erwähnten Arbeitsschritte in umgekehrter Reihenfolge vornehmen.

2.3 Reseten des Sicherheitsthermostaten

Einige Geräte sind mit einem manuellen Sicherheitsthermostat ausgestattet.

Dieses Thermostat dient zum Schutz vor Überhitzung und trennt das Gerät vom Netz.

Sollte dieses Thermostat auslösen, muss das kein Zeichen für einen Defekt sein. Sie finden Es

an der Rückseite des Gerätes im unteren Bereich. Von außen ist eine schwarze runde Kappe zu

sehen. Diese Kappe drehen Sie bitte ab und drücken den darunter befindlichen Stift

wieder ein. Sollte das Sicherheitsthermostat sehr oft auslösen, liegt eine Fehlfunktion vor. Sollte

dies der Fall sein, wenden Sie sich an den UNOX Kundendienst.

3. STÖRUNGEN UND DEREN BEHEBUNG

STÖRUNG

URSACHE LÖSUNG

Es liegt keine Spannung an. Kontrollieren Sie die Sicherung

Sicherheitsthermostat hat

ausgelöst.

Reaktivieren Sie das

Sicherheitsthermostat.

Das Gerät lass sich nicht

einschalten oder hat ohne

ersichtlichen Grund

abgeschaltet.

Die Stromverbindung ist nicht

korrekt hergestellt.

Überprüfen Sie die

Stromverbindung

Defekte Türdichtung

Kontaktieren Sie einen

autorisierten Fachmann

Wasser tritt trotz

geschlossener Tür aus dem

Garraum aus

Defekter Türkontakt.

Kontaktieren Sie einen

autorisierten Fachmann

Defektes Leuchtmittel. Wechseln Sie das Leuchtmittel.

Die Garraumbeleuchtung lässt sich

nicht einschalten.

Lockeres Leuchtmittel. Überprüfen Sie den richtigen Sitz

des Leuchtmittels.

Die Motoren führen keinen

Drehrichtungswechsel durch.

Kontaktieren Sie einen

autorisierten Fachmann

Ein Lüfterrad dreht sich nicht ( bei

mehrmotorigen Geräten).

Kontaktieren Sie einen

autorisierten Fachmann

Das Koch-/ Backergebnis ist

ungleichmäßig.

Ein Heizelement ist defekt.

Kontaktieren Sie einen

autorisierten Fachmann

3. STÖRUNGEN UND DEREN BEHEBUNG

Page 20

1

ITALIANO

I. ISTRUZIONI PER

L’INSTALLATORE

Gentile Cliente, La ringraziamo e ci complimentiamo per

aver acquistato un nostro prodotto.

Le avvertenze e i consigli che seguono riguardano le fasi

per la corretta installazione, l’uso e la manutenzione

dell’attrezzatura, a tutela della Sua sicurezza e per un

miglior utilizzo dell’apparecchio.

1. TARGHETTA DATI

2. CERTIFICAZIONE

La marcatura “CE” riportata sulle apparecchiature inserite in questo manuale fa riferimento alle seguenti direttive:

FORNI CONVEZIONE ELETTRICI - SERIE XF :

• Direttiva Bassa Tensione

DBT EC 2006/95,

secondo la norma EN60335-2-42+A1 e

secondo la norma EN60335-2-46+A1

•Direttiva Compatibilità Elettromagnetica EC 2004/108,

secondo le norme EN60555-3, EN55014 e EN55104.

I forni della serie XAF riportano i marchi MET e NSF per

gli Stati Uniti.

INDICE

I. Istruzioni per l’installatore

1. TARGHETTA DATI

2. CERTIFICAZIONE

3. INSTALLAZIONE

- operazioni preliminari

4. INSTALLAZIONE

- collegamento elettrico

II. Istruzioni per l’utilizzatore

1. ISTRUZIONI PER L’UTENTE

2. NOTE PER L’USO

3. PANNELLO COMANDI

4. PULIZIA FORNO

5. SPEGNIMENTO IN CASO DI GUASTO

III. Principi di cottura

1. TIPOLOGIE DI COTTURA

2. VARIABILI DI COTTURA

3. USO DI TEGLIE - GRIGLIE

IV. Manutenzione

1. MANUTENZIONE ORDINARIA

2. MANUTENZIONE STRAORDINARIA

3. GUASTI PIU’ FREQUENTI

LineMicro™

Page 21

7

2

ITALIANO

3. INSTALLAZIONE

Operazioni Preliminari

Tutte le operazioni di installazione e di allacciamento elet-

trico devono essere fatte da personale qualificato secondo le norme in vigore.

3.1 CONTROLLARE IL LUOGO DI INSTALLAZIONE

Prima di posizionare l’apparecchio verificare le misure

d’ingombro e l’esatta posizione dei collegamenti elettrici

ed idrici secondo le figure riportate nell’allegato fascicolo

“Dati Tecnici”.

3.2 MONTARE I PIEDINI

I piedini sono posti all’interno dell’apparecchiatura e dev-

ono essere tassativamente montati.

Non utilizzare l’attrezzatura senza piedini.

Inserire i piedini a scatto come mostrato nella figura

3.3 POSIZIONAMENTO

Posizionare l’attrezzatura rispettando le norme di sicurezza indicate qui di seguito.

Posizionare l’attrezzatura in modo che la parete posteriore e laterale siano facilmente accessibili per effettuare

l’allacciamento elettrico e per consentire la manutenzione dell’apparecchiatura.

L’apparecchiatura non è adatta all’incasso e al posizionamento in batteria, pertanto, nel caso di utilizzo di più forni, essi non vanno mai sovrapposti.

Si consiglia di lasciare una distanza di 10 cm tra la parete

posteriore e il camino del forno.

Con particolare riferimento ai forni, tutti i modelli devono essere posizionati sopra un supporto tipo lievitatore,

porta-teglie, oppure sopra un tavolo di materiale non

combustibile.

Non installare i forni sul pavimento.

Se l’apparecchio é posizionato vicino a pareti, divisori,

mobili da cucina, bordure decorate ecc., si raccomanda

che questi siano di materiale non combustibile.

In caso contrario devono essere rivestiti con materiale

isolante termico non combustibile, e occorre prestare la

massima attenzione alle norme di prevenzione incendi.

3.4 RIMUOVERE LE PELLICOLE DI

PROTEZIONE

Togliere completamente la pellicola protettiva dalle

pareti esterne dell’apparecchio con attenzione ed evitare

che rimangano residui di colla.

Se nonostante ciò dovessero rimanervi ancora residui di

colla toglierli con un solvente appropriato (ad. Es. alcool

etilico denaturato).

4. INSTALLAZIONE

Collegamento Elettrico

a- Il collegamento alla rete d’alimentazione elettrica deve

essere effettuato secondo le normative vigenti.

Utilizzare il forno con una temperatura ambiente

compresa tra +5 °C e +35 °C.

Prima di effettuare il collegamento accertarsi che la ten-

sione e la frequenza corrispondano a quanto riportato

sulla targhetta apposta sull’apparecchio.

L’apparecchio deve essere posto in modo che la spina di

connessione alla rete, sia accessibile.

Interporre tra l’apparecchiatura e la rete, un interrut-

tore omnipolare accessibile dopo l’installazione, i

cui contatti abbiano una distanza minima d’apertura di 3

mm, di portata appropriata. Si consiglia l’utilizzo di un in-

terruttore magnetotermico differenziale.

La tensione di alimentazione, quando l’apparecchio è in

funzione, non deve discostarsi dal valore della tensione

nominale, riportata sulla targhetta dati del forno, di ± 10%.

La protezione del termostato di sicurezza deve essere av-

vitata stretta in modo da non poter essere rimossa senza

l´utilizzo di un utensile.

b- L’apparecchiatura deve essere connessa alla linea di terra

della rete.

Inoltre l’apparecchiatura deve essere inclusa in un sistema

equipotenziale la cui efficacia deve essere opportunamente verificata secondo quanto riportato nella normativa in vigore. Questo collegamento deve essere effettuato

tra apparecchiature diverse con il morsetto contrassegnato dal simbolo :

UNO

R

Page 22

LineMicro™

3

ITALIANO

Il conduttore equipotenziale deve avere una sezione minima

di 10 mmq.

1- Forni dotati di cavo e spina Schuko (monofase 230V): è

sufficiente inserire la spina nell’apposita presa (la presa

deve essere adatta alla spina fornita in dotazione)

2- Forni dotati di cavo (trifase 400V + Neutro): i forni in

questione sono dotati di cavo elettrico a 5 conduttori: è

necessario collegare l’apposita spina trifase a 5 poli di portata appropriata oppure collegare il cavo direttamente ad

un quadro elettrico.

Nei forni dotati di cavo a 5 conduttori è possibile sostituire il

cavo di alimentazione per adattare il forno alla tipologia di

fornitura di corrente elettrica disponibile.

Per sostituire il cavo di alimentazione procedere come segue:

- Aprire il coperchio della morsettiera facendo leva, con

un cacciavite adeguato, sulle due alette laterali (1)

- Svitare le viti di bloccaggio dei conduttori (2)

- Svitare la vite del fermacavo (3)

- Rimuovere il cavo in dotazione

- Collegare i conduttori del cavo che si vuole utilizzare secondo lo schema di collegamento scelto serrando opportunamente le viti dei morsetti

- Bloccare il cavo attraverso l’apposito fermacavo

- Richiudere il coperchio della morsettiera

AVVERTENZA :

Effettuare il collegamento della morsettiera come indicato dal

disegno: inserire il ponte di rame e il cavo elettrico insieme

sotto la vite, nel senso di avvitamento, in modo che serrando la

vite, il cavo e il ponte siano strettamente fissati.

Un collegamento errato può causare il surriscaldamento della

morsettiera, fino a farla fondere.

USCITA FUMI CAMERA COTTURA

Nella parte posteriore del forno è presente un camino

di uscita fumi provenienti dalla camera di cottura: da tale

camino, durante la cottura, escono fumi caldi e umidi

(temperatura e umidità dei fumi dipendono dai parametri

di funzionamento del forno e dal tipo e dalla quantità di

prodotto inserito all’interno del forno).

I fumi che escono dal camino possono essere incanalati

verso l’esterno oppure condensati.

11. ISTRUZIONI PER

L’UTILIZZATORE

ATTENZIONE:

L’apparecchiatura non va pulita con getto d’acqua.

Non lavare mai l’interno della camera di cottura con

acidi o prodotti aggressivi, ma solo con sapone e acqua.

L’apparecchiatura è destinata solo all’uso professionale

specifico e deve essere utilizzato da personale qualificato.

1. ISTRUZIONI PER L’UTENTE

ATTENZIONE: leggere attentamente il presente libretto in quanto fornisce importanti

indicazioni riguardanti la sicurezza d’installazione, d’uso e di manutenzione.

Conservare con cura questo libretto per ogni ulteriore

consultazione dei vari operatori.

In fase di primo utilizzo assicurarsi che all’interno della

camera di cottura non siano presenti libretti di istruzioni,

sacchetti in plastica o quant’altro.

L’apparecchiatura non è adatta all’utilizzo da parte di

persone (inclusi i bambini) con ridotte capacità fisiche,

mentali e sensoriali, e con mancanza di esperienza e

conoscenza, a meno che essi non siano stati istruiti sul

corretto utilizzo del prodotto da una persona responsabile della loro sicurezza.

Assicurarsi che i bambini non giochino con

l’apparecchiatura.

Per l’eventuale riparazione rivolgersi solamente ad un

centro assistenza tecnica ed esigere parti di ricambio originali.

Il mancato rispetto di quanto sopra può compromettere la sicurezza dell’apparecchiatura e la garanzia viene a

decadere.

Page 23

UNO

R

7

4

ITALIANO

2. NOTE PER L’USO

Durante il normale funzionamento del forno, qualora si vo-

lesse aprire la porta, per preservare l’integrita’ di questa si

consiglia di aprirla completamente per far sì che il calore

venga facilmente smaltito all’esterno e non vada a danneggiare le colonnine laterali.

Premessa:

L’apparecchiatura dovrà essere destinata solo all’uso per il

quale è stata espressamente concepita.

I forni sono stati progettati per la cottura al forno di cibi

come sotto riportato. Ogni altro impiego è da ritenersi improprio.

Il forno permette temperature d’esercizio comprese tra i

valori di 0 - 300 °C (0 - 572 °F).

L’apparecchiatura può essere utilizzata per i seguenti im-

pieghi:

• per le cotture di tutti i prodotti di Pasticceria e Pane, fre

schi o congelati;

• per le cotture di tutti i prodotti di Gastronomia, freschi

o congelati

• per ricondizionamento di cibi refrigerati e congelati

• per la cottura di carni, pesce e verdure.

Nel disporre il cibo in camera di cottura mantenere uno

spazio di almeno 20 mm tra una bacinella e l’altra per permettere la circolazione dell’aria calda.

Evitare di effettuare la salatura dei cibi nella camera di cottura.

3. DESCRIZIONE E USO PANNELLO

COMANDI

IMPOSTAZIONE TEMPO DI COTTURA

Il tempo di cottura è impostabile mediante l’apposita ma-

nopola (manopola a sx): il tempo è impostabile in un range

di 0 - 60 min.

Ruotando la manopola in senso orario si imposta il tempo

di cottura; ruotando la manopola in senso antiorario (posizione manuale) il forno funziona in continuo.

La rotazione della manopola avvia il forno attivando la rota-

zione del ventilatore ed accendendo l’eventuale luce interna.

A fine cottura la manopola si porta sulla posizione di zero e

il forno si spegne.

La condizione di forno spento é verificata solamente quan-

do la manopola del timer è posta esattamente sullo zero

“0”. Per accertarsi del corretto spegnimento, attendere 5

minuti prima di abbandonare l’apparecchio.

IMPOSTAZIONE TEMPERATURA DI COTTURA

La temperatura all’interno della camera di cottura è imposta-

bile mediante l’apposita manopola (manopola a dx):

la temperatura è impostabile in un range di 0 - 300 °C

(0 - 572 °F).

la spia verde della temperatura, quando accesa, segnala che

la resistenza è attiva; raggiunta la temperatura desiderata si

spegne.

4. PULIZIA FORNO

AVVERTENZA:

Prima di effettuare qualsiasi intervento di ma-

nutenzione o pulizia è necessario disinserire

l’alimentazione elettrica e aspettare il raffreddamento dell’apparecchio.

4.1 PRIMA UTILIZZAZIONE DEL FORNO

Per la prima utilizzazione dell’attrezzatura: pulire la parte

in metallo con acqua calda e sapone e risciacquarlo. Non

lavare mai l’interno della camera con acidi o prodotti aggressivi.

Riscaldarlo quindi a vuoto per 30 minuti circa alla tem-

peratura di 200 °C (392 °F) per eliminare eventuali odori

dell’isolamento termico.

4.2 PULIZIA CAMERA DI COTTURA

Ogni fine ciclo di cottura pulire l’interno della camera di

cottura usando prodotti adatti allo scopo.

Non usare per la pulizia dell’acciaio acidi, prodotti

aggressivi o prodotti contenenti cloro (ipoclorito

sodico, acido cloridrico etc.) nemmeno se diluiti.

Page 24

LineMicro™

5

ITALIANO

4.3 PULIZIA ESTERNA FORNO

Non utilizzare un getto d’acqua in pressione per il lavaggio

esterno del forno.

Utilizzare panni inumiditi e prodotti idonei per la pulizia

dell’acciaio inox.

Per il vetro utilizzare acqua e sapone neutro. Non utiliz-

zare alcool o altri solventi.

5. SPEGNIMENTO IN CASO DI GUASTO

In caso di guasto disattivare l’apparecchiatura:

- disinserire l’interruttore automatico di alimentazione elettrica, posto a monte dell’apparecchiatura o se non previsto dall’impianto elettrico, staccare la spina.

- rivolgersi ad un centro di assistenza tecnica con personale

addestrato.

III. PRINCIPIO DI COTTURA

1. TIPOLOGIE DI COTTURA

Le tipologie di cottura effettuabili con l’attrezzatura indi-

cata in questo manuale sono esclusivamente limitate alla

Cottura Professionale di Pane, Pasticceria e Gastronomia

varia in modalità CONVEZIONE, ovvero mediante utilizzo di aria calda come mezzo di cottura.

AVVERTENZA :

a- Riscaldare il forno impostando una temperatura 30 °C

(54 °F) superiore alla temperatura di cottura prima di

qualsiasi utilizzo per ottenere il massimo di uniformità di

cottura.

b- L’utilizzo di temperature più elevate rispetto allo standard

richiesto da un prodotto porta ad una cottura non uniforme.

c- Cottura di pane e pasticceria: non utilizzare teglie con un

altezza superiore ai 20 mm ed evitare che i prodotti posti

nella teglia si tocchino.

d- Non sovraccaricare le teglie di prodotto

La cottura nel forno ventilato avviene per mezzo del

ricircolo di aria calda all’interno della camera di cottura.

Questo permette di cucinare il cibo in modo uniforme

grazie ad una distribuzione omogenea della temperatura.

L’uniformità di cottura é garantita anche a pieno carico del

forno. Il prodotto è cotto perfettamente sia in superficie,

con una doratura omogenea, che nella parte interna, con

una struttura uniforme e una umidità residua costante.

Il vantaggio è la possibilità di poter cuocere contempora-

neamente pietanze di diversa natura (purché la temperatura di cottura sia la stessa) senza mescolarne i sapori.

2. VARIABILI DI COTTURA

TEMPERATURA

L’esatta impostazione della temperatura garantisce una

cottura corretta del cibo sia nella parte esterna che in

quella interna.

• Una temperatura bassa rispetto e quella corretta tende

più ad essiccare che a cuocere il cibo.

Una temperatura superiore a quella corretta tende a

bruciare la parte esterna e lasciare l’interno non cotto

(fenomeno questa a volte desiderato, per esempio nelle

carni).

TEMPO

Questa variabile dipende molto dalla quantità di cibo in-

trodotto nel forno. Maggiore è la quantità più si allungano

i tempi di cottura e viceversa.

Tempi brevi rispetto a quelli corretti non permettono una

cottura completa del cibo.

Tempi lunghi, sempre rispetto a quelli corretti, creano

fenomeni di bruciatura esterna degli alimenti.

QUANTITA’ DI CIBO

La quantità di cibo influenza il tempo di cottura.

Maggiori quantità significano tempi di cottura più lunghi e

viceversa.

Una quantità di cibo eccessiva può provocare un peggio-

ramento della uniformità di cottura.

3. USO DI TEGLIE – GRIGLIE

Si consiglia l’uso di:

- Teglie in alluminio: pasticceria, pane non surgelato

- Teglie in acciaio: primi piatti, carni, pesce, patate

- Griglie: carni da rosolare come bistecche, wurstel, salsicce, pane surgelato, pizza surgelata

IV. MANUTENZIONE

1. MANUTENZIONE ORDINARIA

Qualsiasi lavoro di manutenzione deve essere effettuato

solamente da personale qualificato.

Prima di effettuare qualsiasi tipo di manutenzione è nec-

essario disinserire l’alimentazione elettrica e aspettare il

raffreddamento dell’apparecchio.

- I componenti che necessitano di manutenzione ordinar-

Page 25

UNO

R

7

6

ITALIANO

ia sono accessibili togliendo il pannello comandi frontale e

la schiena del forno.

Sottoporre l’apparecchiatura periodicamente (almeno

una volta l’anno) ad un controllo totale da parte di un

tecnico specializzato.

2. MANUTENZIONE STRAORDINARIA

Qualsiasi lavoro di manutenzione deve essere effettuato

solamente da personale qualificato.

Prima di effettuare qualsiasi tipo di manutenzione è nec-

essario disinserire l’alimentazione elettrica e aspettare il

raffreddamento dell’apparecchio.

I componenti che necessitano di manutenzione sono ac-

cessibili togliendo il pannello comandi frontale e la schiena

del forno.

GUASTO CAUSA RIMEDIO

Mancanza della tensione di

rete

Ripristinare la tensione di