Unox ChefTop XVC 055, ChefTop XVC 205, ChefTop XVC 105, ChefTop XVC 105P, ChefTop XVC 305 Instruction Manual

...Page 1

EnglishItaliano

XVC-XBC

Notice d’Utilisation

FRANÇAIS

Manuale d'istruzione

DEUTSCH

Manual Instrucciones

ESPAÑOL

Bedienungsanweisung

Instruction manual

ENGLISH

ITALIANO

Инструкция по эксплуатации

РУССКИЙ

Page 2

English

Explanation of pictograms

2

General pictograms

Danger!

Situation presenting immediate danger, or a hazardous situation which could cause injury or

death.

Danger: fire hazard!

Danger: high voltage!

Danger: corrosive substances.

Danger: risk of burns.

Caution: non-observance may damage property.

Recommendations for everyday use

Information

Page 3

English

BakerTop

™

ChefTop

™

Summary of contents

Explanation of pictograms 2

Summary of contents 3

Introduction 4

INSTRUCTIONS FOR THE USER

- Safety regulations 5-8

Appliance operating instructions and Guarantee 9

ChefTouch-BakerTouch digital control panel 10

- Control panel operation 11

Setting the parameters 12-16

Selecting the cooking steps 17

Setting the cooking programs

- Cooking with a set time and oven cavity temperature 18

- Cooking with the core probe at a set oven cavity temperature 19

- Cooking with the core probe at a set Delta T 20

User programming procedures 21

Standard functions

- LASTP function 22

- Automatic washing programs 22

- "COOL" program for oven cavity cooling 23

- ADAPTIVE.Clima function 24

Pre-set cooking procedures 25

MAXI.Link technology 26

Cooking principles 27

Oven-user communication

- Warning messages: 28-29

- Alarm messages: 29-30

- Maintenance in the event of a malfunction: 30

INSTRUCTIONS FOR THE INSTALLER

- Safety regulations 31

Instructions for appliance transportation 32

Appliance installation 33-34

Positioning 35-41

Electrical connections 42-44

Gas connections 45-51

Plumbing connections 52-53

Oven cavity smoke exhaust 54

Connection of accessories 55

Oven stacking 56

Certification 57

3

Page 4

English

4

Dear Customer,

We would like to congratulate and thank you for choosing to purchase an oven in the ChefTop™/ BakerTop™ range; we

hope this is just the beginning of a fruitful and long-lasting partnership.

As you are aware, the ChefTop™/ BakerTop™ range of ovens and all the complementary accessories designed for it (blast

chiller, holding cabinet, special trays and racks) were specifically created to carry out any cooking process, from beginning

to end, regardless of its level of complexity.

The innovative Chef Touch digital control panel allows you to control all the UNOX equipment connected to the oven

from a single point.

Your ChefTop™ / BakerTop™ oven features exclusive ADAPTIVE.Clima technology, which offers extremely reliable and

consistent results, regardless of the number of trays placed inside.

In fact, the ChefTop™ / BakerTop™ oven constantly monitors all cooking parameters, not only in terms of temperature,

but also the current humidity level inside the cavity. This guarantees the most suitable cooking program is always applied,

to help you achieve perfect results every time. ADAPTIVE.Clima technology also means you can repeat a cooking procedure already stored in the memory countless times, in the certainty that the results will always be the same, regardless

of whether the oven is operating with all trays inserted or with just one tray placed inside.

AIR.Maxi technology, with the option of setting three different motor revolution speeds and three semi-static operating

modes, can be used to adjust the airflow inside the oven cavity to suit your own requirements: from high-speed settings

for quick and intense cooking programs, to low-speed settings used for delicate, slow-cooked food, right through to

semi-static operation which allows you to control even the most challenging pastry and bread cooking procedures.

MULTI.Time technology can also be used to set up to 9 timers, giving you maximum control, even when cooking several

different foods at the same oven cavity temperature and humidity levels for different periods of time.

If your ChefTop™/BakerTop™ oven features two core probes with extra-fine needles (external to the oven), you will also

be able to cook vacuum-packed goods perfectly and steam particularly delicate or small foods.

UNOX S.p.A.

Dealer: Installer:

Installation date:

Introduction

Page 5

English

BakerTop

™

ChefTop

™

5

Caution

Please read this booklet carefully, as it provides important information regarding safe oven operation. Keep it in a safe

place so that the various operators may consult it as necessary.

Safety regulations

Incorrect installation, assistance, maintenance or cleaning procedures, or any modifications made to the

appliance, may damage property or result in injury or even fatal accidents. Read the operating manual carefully

before using the appliance.

General safety regulations

This appliance may only be used by qualified personnel, to cook food in professional and industrial kitchens.

Any other application does not conform to the specified use and is therefore considered hazardous.

The equipment must be used only for its intended purpose; any other application will be considered

improper.

The equipment may be used for the following purposes:

- for cooking all Pastry and Bread products, whether fresh or frozen;

- for cooking all Gastronomic products, whether fresh or frozen;

- for bringing chilled and frozen food back to normal temperatures;

- for steam cooking meat, fish and vegetables;

- for cooking vacuum-packed food in bags which are suited to that type of cooking procedure.

The equipment should not be used by individuals (including children) with reduced physical, mental and sensory

capacities, or by inexperienced or untrained persons, unless they have been given guidance on how to use the

product correctly and are supervised by someone who is responsible for their safety. Children should not be

allowed to play with the equipment.

Do not use foods containing highly flammable ingredients (e.g. alcohol-based foods).

Substances with a low flammability point may burst into flames and therefore constitute a fire and explosion

hazard inside the oven cavity; explosions may cause the door to open suddenly or even violently.

Detergents, limescale removers and the relevant accessories must only be used for the purposes described in

this manual.

Any other application does not conform to the specified use and is therefore considered hazardous.

If the sheets of glass used to construct the door are damaged, have them replaced immediately.

Risk of sudden breakage.

To prevent accidents and to avoid damaging the appliance, all personnel should be informed as to normal safety

procedures and given the necessary training.

INSTRUCTIONS FOR THE USER

Page 6

English

6

Safety regulations for gas appliances

If the appliance is installed below a cooker hood, the hood should be switched on while the operation. – gas combusti!

In case the appliance is connected to a chimney, the exhaust pipe has to be clean and free from obstructions

following the current safety rules – risk of fire! (for further information, please contact your installer).

Do not place any objects on top of the exhaust gas hose connected to the appliance.

The area underneath the appliance should not be blocked or obstructed by any objects.

The appliance may only be operated in a draught-free environment.

If you smell gas:

Cut off the gas supply immediately!

Do not touch any of the electrical switches!

Make sure the room is well ventilated!

Avoid the creation of naked flames and sparks!

Use a telephone outside the building and inform your gas supplier immediately (if you experience problems in

doing so, contact your local fire station)!

Operation: safety regulations

When using the appliance for the first time, make sure that there are no instruction manuals, plastic bags or

accessories inside the oven cavity.

Make sure that any hanging rack frames and tray rack trolleys inside the oven cavity are secured as specified

- Containers holding hot liquids may fall or slip inside the oven cavity - risk of burns!

Before cooking with the appliance, make sure that there are no detergent residues inside the oven cavity.

Remove any detergent residues using a damp cloth while wearing suitable eye, mouth and hand protection,

then rinse thoroughly - Risk of corrosion!

Only use your fingers to operate the control panels; the use of any other objects may cause damage and/or

malfunctioning and will invalidate the guarantee.

Operate the appliance at a room temerature between +5°C and +35°C.

The temperature of the external parts may exceed 60°C: only touch the components used to control the

appliance. Risk of burns!

When the containers are full of liquid or will be filled with liquid during the cooking process, the user must be

able to see inside each container; any racks above eye level may not be used - risk of burns!

Take extra care to avoid drips or spills when removing trays contining hot liquids.

Safety regulations

Page 7

English

BakerTop

™

ChefTop

™

7

Take extra care when moving food containers during and after the cooking process: high temperatures could

cause burns.

Always wear heat-resistant gloves when handling accessories and other objects which have been inside the

hot oven cavity - risk of burns!

Always open the door slowly and carefully: risk of burns caused by hot steam escaping from the oven.

Remove the core probe from the food before taking the tray out of the oven.

Before removing food containers from the oven cavity, make sure that the core probe does not present an

obstacle to the process. Do not leave the core probe hanging out of the oven door, as this could damage the

probe and cause hot steam or liquid to escape from the cavity during the cooking process.

During "COOL" mode operation (cavity cooling), the oven fans run while the oven door is open. Make sure

that the air casing is securely fastened before activating the "COOL" mode. Do not remove the air casing while

the oven is operating in "COOL" mode, and do not under any circumstances touch the fans or heating elements

while the oven is switched on or while the fans are running and/or the heating elements are still hot.

Do not place highly flammable or combustible substances near the appliance - fire hazard!

If mobile appliances and tray rack trolleys do not need to be moved, the wheel lock brake should be applied.

Trolleys may roll away on uneven surfaces - risk of injury!

If the tray rack trolleys need to be moved while in use, always make sure the containers are secured properly.

Close the containers holding liquids so that no hot liquid can spill out - risk of burns!

When loading and unloading the plate rack trolley and the tray rack trolley, the transportation trolley should

be secured to the appliance as directed - risk of injury!

Tray rack trolleys, plate rack trolleys, transportation trolleys and appliances on wheels may tip over when

wheeled along uneven surfaces or when crossing the threshold of a room - risk of injury!

Avoid salting food inside the oven cavity. If it cannot be avoided, clean the oven as soon as possible afterwards

(see relevant sections below).

Safety regulations

Page 8

English

8

Maintenance, inspection and cleaning

We recommend the oven cavity is cleaned on a daily basis, in order to maintain acceptable hygiene standards

and to prevent the stainless steel inside the cavity from being ruined. We would therefore recommend the use

of the Rotor.KLEAN™ washing system, code XC405, which offers automatic washing of the oven cavity.

Caution!

If the appliance is not cleaned or not cleaned thoroughly enough, grease or remnants of food which have

accumulated inside the oven cavity may start to burn - fire hazard!

To prevent corrosion from occurring inside the oven cavity, the appliance should be cleaned every day, even if

it is only used for steam cooking purposes.

Do not clean the appliance with a high-pressure cleaners, jets of hot water or high-pressure steam. Only use

detergents which have been recommeded by the appliance manufacturer.

Detergents from other manufacturers may damage the appliance and therefore invalidate the guarantee. Do

not use abrasive substances or corrosive detergents.

Daily cleaning of the oven cavity seal using a non-abrasive detergent will extend the working life of the appliance.

To clean the oven cavity manually, proceed as follows:

Switch on the oven, set the temperature to 55°C and the steam level to 100%, run for 10 minutes, then leave

to cool and clean with a damp cloth.

Do not use acidic products or abrasive tools and products.

Do not use jets of water or pressurised steam to clean the outer surfaces of the oven. Clean steel areas using

a damp cloth and specially formulated products.

Do not use acidic products, or products containing ammonia.

Installation, inspection, maintenance and repair work

Danger: high voltage!

Installation, inspection, maintenance and repair work should be carried out by qualified, suitably trained

personnel. Before any work is carried out, the appliance should be disconnected from the electricity supply.

If the appliance is placed on a support structure on wheels, make sure that any movement will not damage

electrical wiring, water pipes, exhaust pipes or any other components.

Avoid placing sources of heat near the appliance.

If the appliance is on wheels, its freedom of movement must be limited so that, if shifted, it does not damage

electrical wiring or water pipes in any way.

When moving the appliance, make sure the electrical wiring, water pipes and exhaust ducts have been

disconnected properly. If the appliance is moved back into its original position, make sure that the anti-shift

safety lock is applied, and that all electrical wiring, water pipes and exhaust pipes are connected in compliance

with current standards.

To ensure the appliance remains in perfect technical condition, maintenance work should be carried out at

least once a year, by a partner organisation as recommended by the Assistance Service.

Safety regulations

Page 9

English

BakerTop

™

ChefTop

™

9

Appliance operating instructions

Avoid placing sources of heat (e.g. grills, fryers, etc.) near the appliance.

When the oven door is opened, heating and fan operation stops automatically. The built-in fan brake is activated.

The fan continues to rotate for a short time only.

If the appliance has been on for over 15 minutes without an operating mode or automatic washing being

selected, the standby function is activated automatically in order to minimise energy consumption. To exit

standby mode, simply press the "START/STOP" button.

When using the grilling and roasting functions (e.g. for poultry), a drip tray should always be placed at the

bottom to collect excess fat.

Always clean the accessories before using them.

When the appliance is switched off for long periods of time (e.g. overnight), leave the door ajar.

If the appliance is not used at all for long periods of time (e.g. when the premises is closed), shut off the

electricity and gas supplies.

At the end of its working life, the appliance should not be disposed of using the nomal domestic waste channels,

nor should it be placed in the containers for worn-out household appliances at public recycling centres.

We will be happy to help you dispose of the appliance in the correct manner.

Guarantee

This UNOX product should be installed by an Authorised UNOX Assistance Centre. The installation date

and appliance model must be documented by the end purchaser, by means of written confirmation or an

installation invoice issued by the dealer or the Authorised UNOX Assistance Centre, otherwise this guarantee

will not be valid;

The UNOX guarantee covers all malfunctions which can clearly be traced back to defects resulting from

errors in the manufacturing process. Defects and damage caused by transportation or incorrect product

storage, maintenance or operation, by the application of installation procedures not specified by Unox and by

environmental factors (e.g. the use of dirty and aggressive water, bad quality gas or unsiutable voltage levels)

are not covered. The guarantee does not cover any damage resulting from the application of excess voltage,

or from tampering by unauthorised or unskilled individuals. Guarantee rights will also be diminished in the

event of damage or malfunctioning resulting from the build-up of limescale inside the appliance. Futhermore,

the guarantee does not cover exhaustible parts, namely: seals, light bulbs, glass panels, decorative parts and

consumable components after the appliance has been used.

Guarantee rights will also be invalidated in the event of damage arising as a result of incorrect installation, or

installation which has not been carried out by an Authorised Assistance Centre.

Page 10

English

10

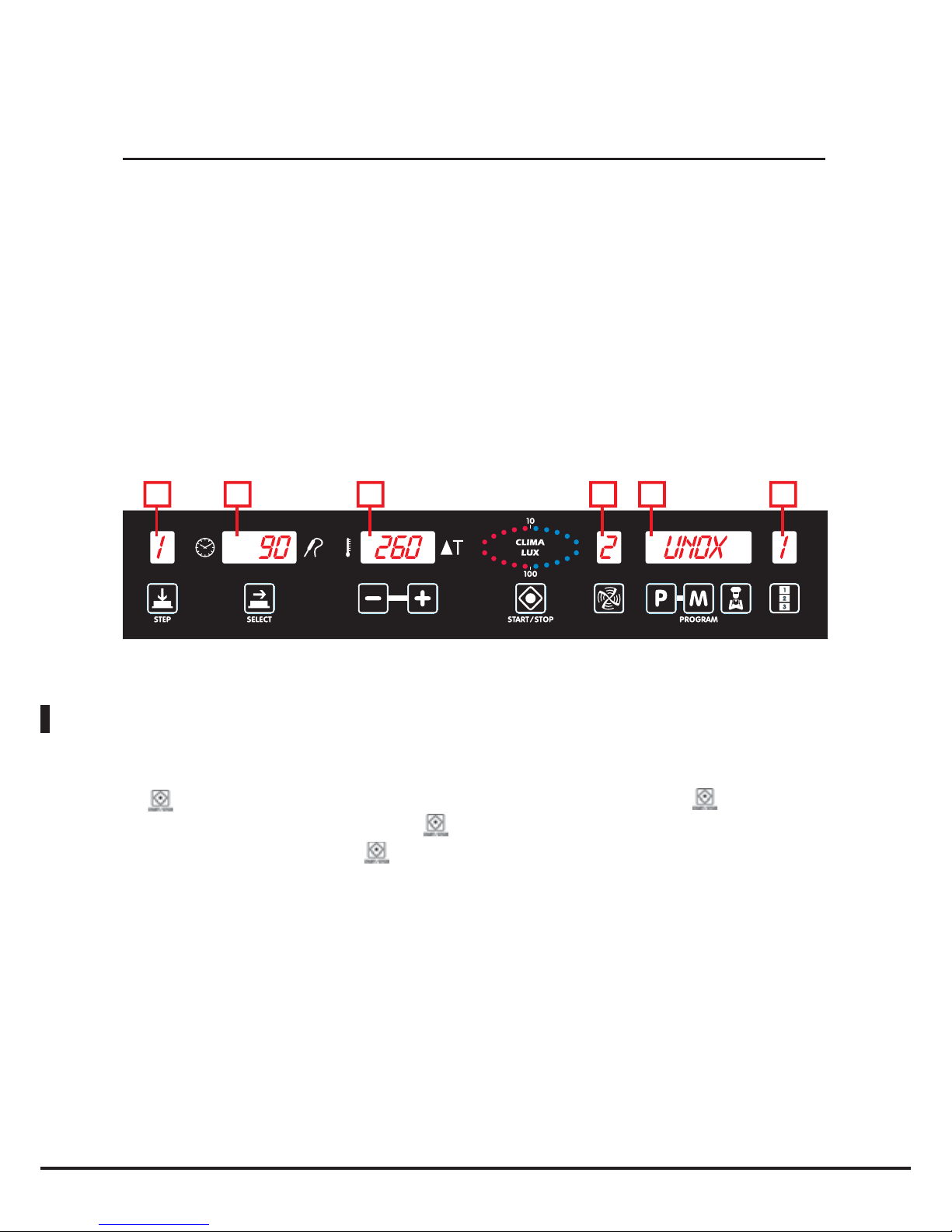

Control panel operation

The “ChefTouch” “BakerTouch” control panel is operated by touching the screen-printed keypad with your

finger (do not use any other objects such as forks, knives, etc.). Functions can thus be activated and values set

as desired.

This technology also makes cleaning the control panel quick and easy, while guaranteeing maximum reliability

and durability and avoiding any type of mechanical shifting.

Control panel layout:

1 2 3 4 5 6

Switching the appliance on / off

When the oven is connected to the power supply, the control panel switches on automatically.

After 15 minutes, if none of the buttons have been pressed and if none of the devices connected to the

electronic control panel (ovens, blast chiller, holding cabinet) are in operation, it will enter standby mode: only

the

LED will remain lit. To reactivate the electronic control panel, simply press the

button.

To activate standby mode, press and hold the

button for 6 seconds while the electronic control panel is

on; to reactivate the panel, press the button again.

ChefTouch-BakerTouch digital control panel

Page 11

English

BakerTop

™

ChefTop

™

11

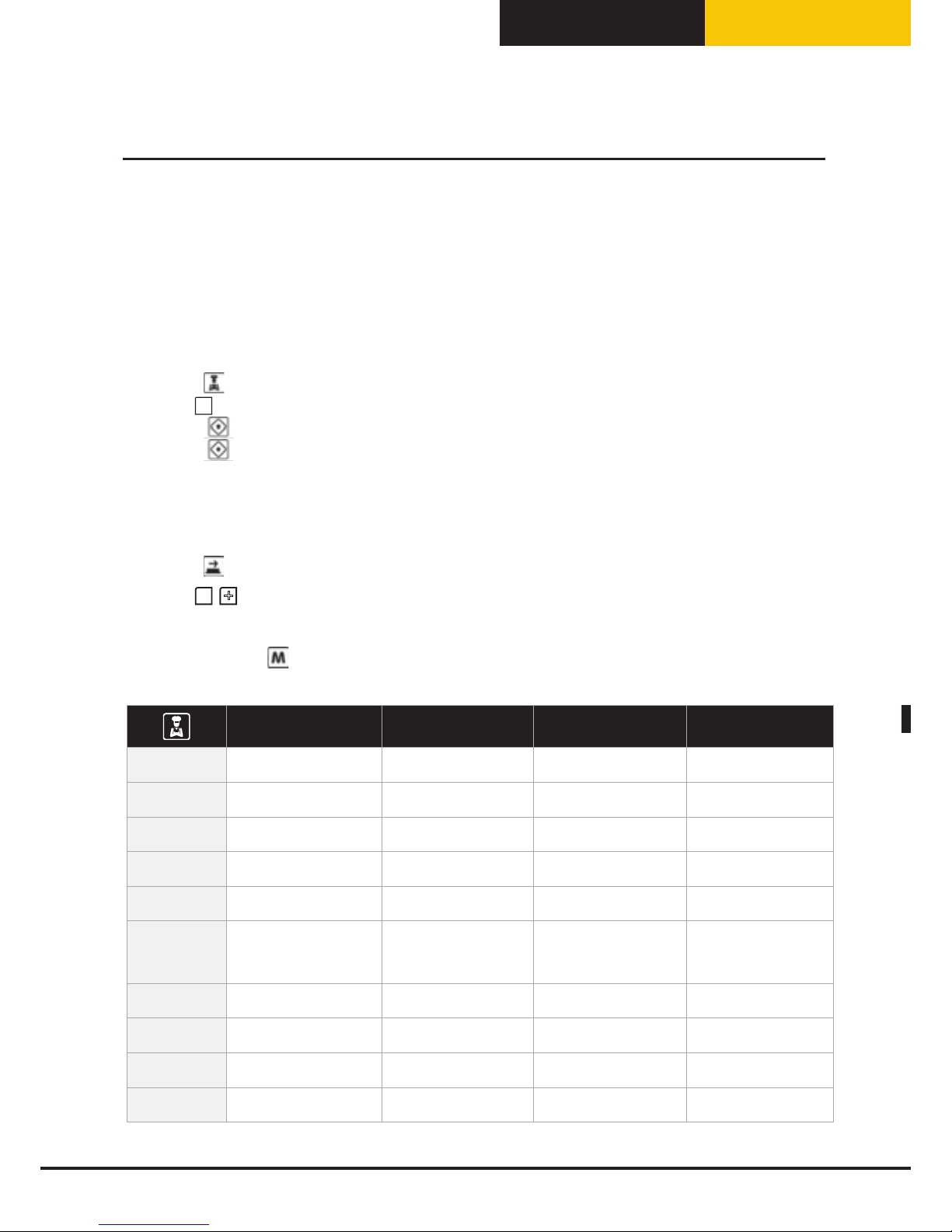

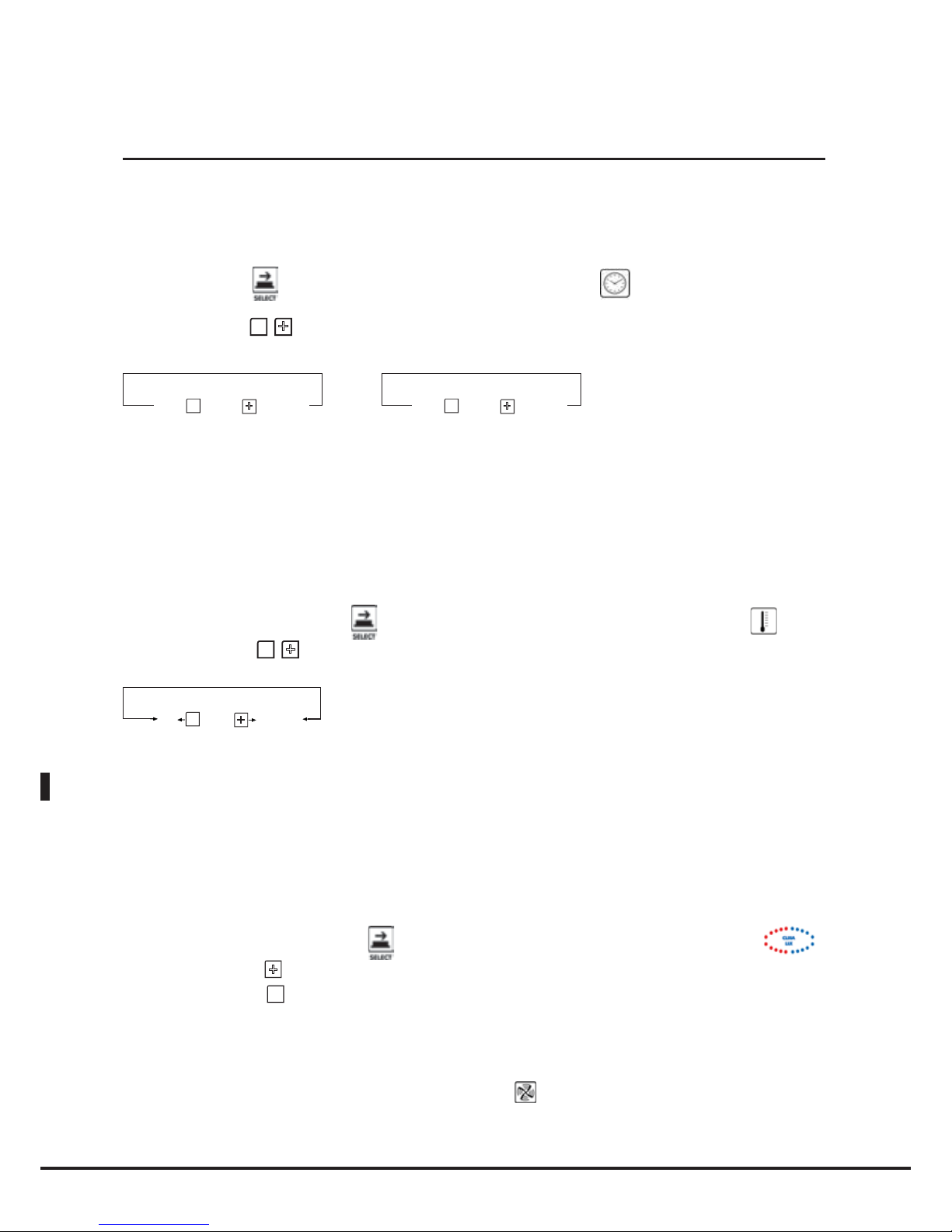

Manual operation

Selecting cooking parameters

The following parameters may be set for each step:

Time or core temperature (these two parameters cancel each other out: if the time is set, the core temperature

parameter will automatically become inoperable, and vice-versa);

Cavity temperature, or alternatively Delta T (Delta T is available only if the core temperature has been set);

CLIMA LUX, if necessary, to set the humidity extraction percentage (DRY.Maxi™) or the steam release

percentage (STEAM.Maxi™);

Use the

button to pass from one parameter to the next; the active parameter is indicated by one of the

five icons lighting up.

It is also possible to select the speed of the airflow inside the oven cavity (3 continuous speeds and 3 semistatic operating modes).

To adjust the airflow speed, press the

button; the active speed level is indicated on display 4.

N.B.

A complete cooking cycle does not necessarily require the implementation of all four steps.

Only the desired steps should be set. This will not compromise oven performance.

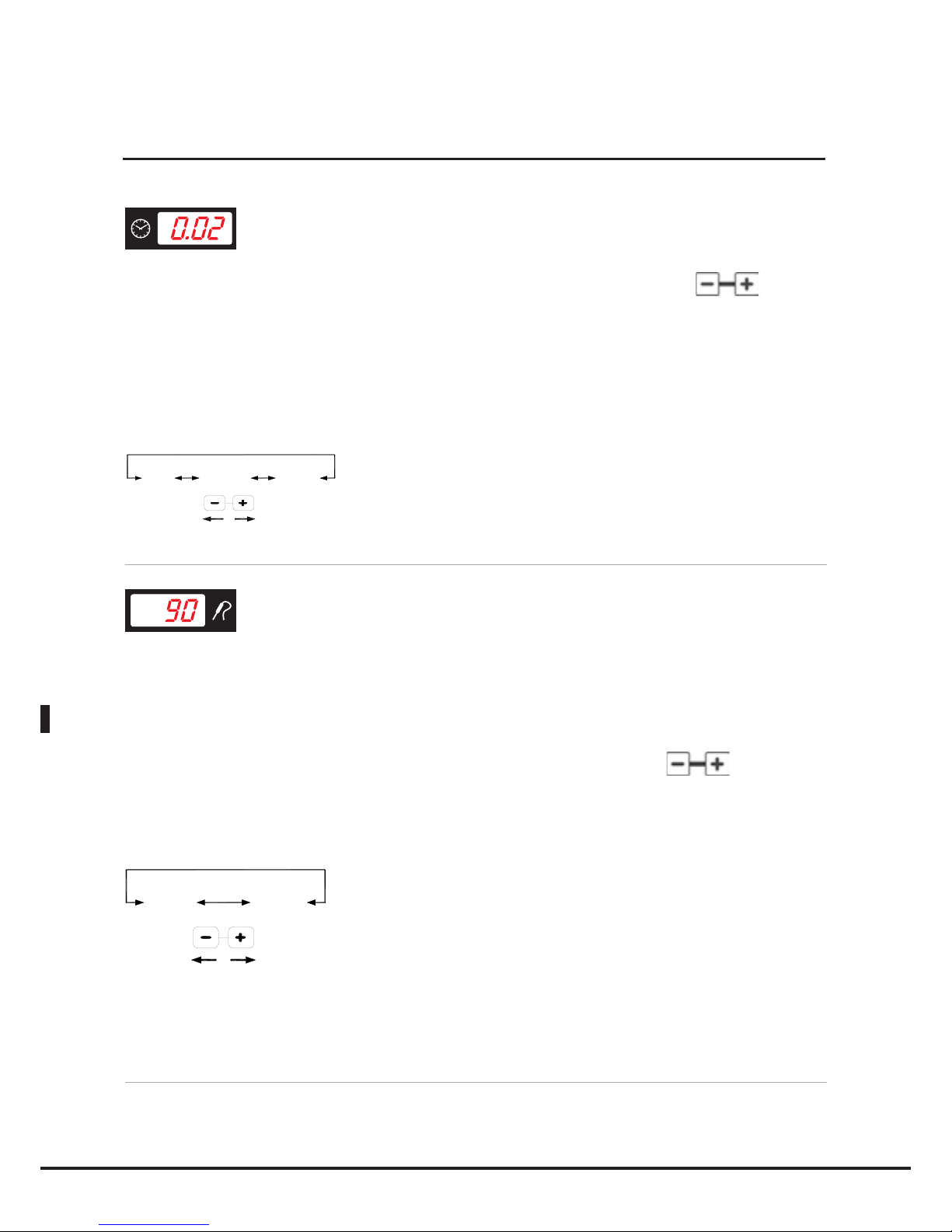

Setting the cooking duration or core temperature

The cooking duration and core temperature parameters control the length of each cooking step.

In general, the more food placed in the oven, the longer the period of time required to complete the cooking

process and vice-versa.

Instead of a cooking duration, it is possible to set a temperature value for the core probe. Once this value is

reached, the next cooking step will begin or the cooking program will end as required.

In this case, the cooking duration is automatically adjusted to suit the amount of food placed inside the oven

cavity.

A shorter duration than is required by the food - or a core temperature which is too low - will result in the

food not being cooked properly.

A longer cooking duration than that required by the food - or a core temperature which is too high - will result

in the food drying out and burning on the surface.

The time and core temperature parameters are mutually exclusive: if a duration is set, the core temperature

parameter will be inoperable, and if the core temperature is set the time parameter will be inoperable.

It will therefore be necessary to set either the time parameter or the core temperature parameter: if neither

parameter is selected, the control panel will not allow any further parameters to be set (cavity temperature,

Delta T, Climate).

Control panel operation

Page 12

English

12

Setting the cooking duration

The time parameter is indicated via display 2, in hours.minutes, and can be set using the buttons.

If cooking step 1 is selected and the text "INF" (INFINITE) appears on display 2, the oven will operate

continuously until it is stopped manually by the user.

When the HOLD ("HLD") function is selected in subsequent cooking steps, the fans only operate when the

heating elements are on.

inF

9h 59'0h 00'

Setting the core temperature

The core probe measures the increase in temperature inside the product during the entire cooking procedure,

and should be inserted into the thickest part of the food, with the very tip at the centre. You must make

sure that this probe is correctly positioned before beginning the cooking cycle: incorrect positioning may

compromise the end result.

The core temperature parameter is indicated via display 2, and can be set using the

buttons.

When the set core temperature is reached, that cooking step is considered complete and the next step begins

(where applicable).

0°C 100°C

The XC249 external core probe kit can be used to connect an extra, smaller core probe which is suitable for

cooking vacuum-packed goods and products which come in smaller pieces.

Setting the parameters

Page 13

English

BakerTop

™

ChefTop

™

13

Setting the cavity temperature or the Delta T value

The exact setting of the temperature inside the cavity ensures the food is cooked properly, both inside and

outside.

A lower temperature than the specified value dries the food out instead of cooking it.

A higher temperature than the specified value burns the surface while the core remains uncooked (sometimes

this is the desired result, especially where meat is concerned).

Cooking with the DELTA-T parameter is only possible during cooking steps which use the core probe to

control the cooking duration. By DELTA-T, we mean the difference between the temperature inside the oven

cavity and the value detected by the core probe inside the product.

The cavity temperature and Delta T parameters are mutually exclusive: if the cavity temperature is set, the

Delta T parameter is inoperable, and if the Delta T is set, the cavity temperature parameter is inoperable.

Setting the parameters

Caution!

Protect your arms and

hands - Risk of injury!

Always position the core probe as instructed.

Risk of damage!

Do not leave the probe hanging out of the

oven cavity.

Risk of damage!

Remove the probe from the food before

taking the pan or the dish out of the oven.

Risk of damage!

Page 14

English

14

Setting the cavity temperature

The temperature inside the cavity is indicated via display 3, and can be set using the buttons.

When the text "PAU" appears on display 3, the oven enters pause mode: the fans and heating elements remain

inactive. To postpone oven activation or to apply a pause period (useful for letting certain products rise), set

the pause duration on display 2 and the "PAU" symbol on display 3.

-

+

PAU

0° C

260° C

Setting the Delta T value

The Delta T value is indicated via display 3, and can be set using the buttons.

0°C 100°C

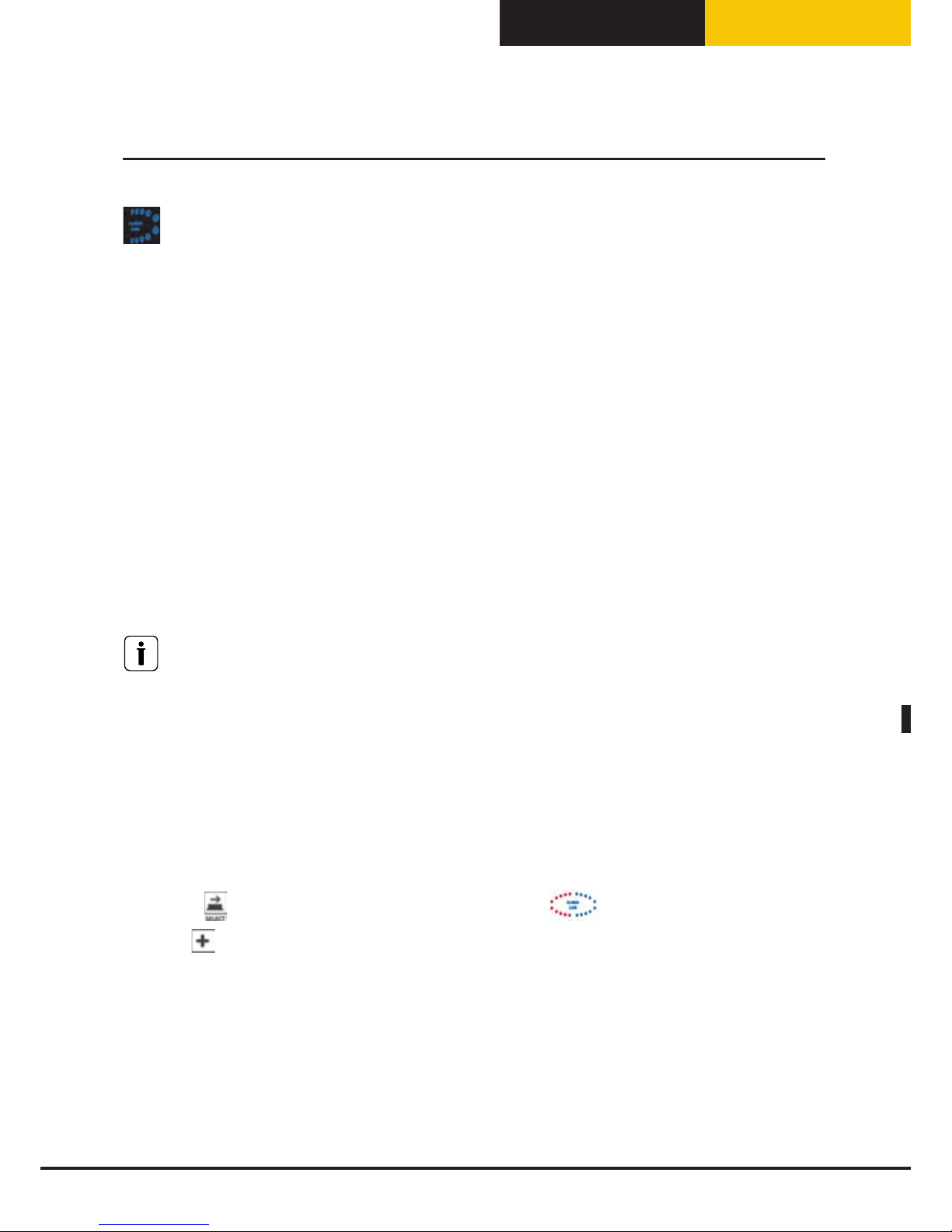

Setting the climate

The oven cavity internal climate setting (STEAM.Maxi / DRY.Maxi) is indicated by the CLIMA LUX ellipse and

is set using the

buttons.

The 10 blue LEDs indicate the percentage of humidity or steam inside the oven cavity (STEAM Maxi);

The 10 red LEDs indicate the drying percentage (DRY Maxi).

STEAM

Maxi

DRY

Maxi

N.B.

The two systems cannot be used simultaneously. Setting the CLIMA LUX parameter is optional. If this

parameter is not set the oven operates in "CONVECTION" mode.

Setting the parameters

Page 15

English

BakerTop

™

ChefTop

™

15

Steam / Humidity release inside the oven cavity: STEAM.Maxi™

Your oven is equipped with exclusive STEAM.Maxi technology for the generation of steam inside the oven cavity.

This innovative technology allows you to carry out any kind of steam cooking, starting from a temperature of

48°C, while guaranteeing maximum accuracy in terms of steam production temperature control.

STEAM.Maxi™ introduces adjustable amounts of steam in conjunction with various temperatures, allowing

different types of cooking to take place:

• Steaming (only steam);

• Mixed convection-steam cooking (air+steam).

Through the ADAPTIVE.Clima technology, BakerTop™ and ChefTop™ ovens constantly monitor all cooking

parameters, not only in terms of temperature, but also the current humidity level inside the cavity. This

ensures the most suitable cooking program is always applied, to help each user achieve perfect results every

time, regardless of the number of trays placed inside.

The ADAPTIVE.Clima function will release the amount of steam required to create the humidity percentage

set by the user.

Caution!

During the cooking process, the product inside the oven releases a certain amount of steam: it may happen,

therefore, that the appliance does not produce any steam, if the moisture released by the food is sufficient to

achieve the value requested by the user. In this case the lack of steam production is not due to an appliance

malfunction, but is the result of oven monitoring and control procedures taking place correctly.

To set the desired humidity level inside the oven cavity, proceed as follows:

• Press the

button repeatedly until the CLIMA LUX display

flashes;

• Use the

button to set the desired steam release percentage (STEAM.Maxi™).

The 10 blue LEDs indicate the humidity percentage level inside the cavity requested by the user, which can

vary from 10% to 90% for each step in the cooking cycle. If 100% is selected - and for temperatures below

130°C - the oven will automatically activate its steam only mode.

Setting the parameters

Page 16

English

16

Extracting humidity/steam from the oven cavity: DRY.Maxi™

The patented DRY.Maxi™ technology makes it possible to quickly extract all the humidity from the oven

cavity, whether it was released by the products in the oven or generated by the STEAM.Maxi™ system in

a previous cooking step.

The DRY.Maxi™ technology means that ChefTop™ and BakerTop™ ovens guarantee enhanced flavours,

whether cooking restaurant dishes or baking pastry and bread products.

To set the desired humidity extraction level inside the oven cavity, proceed as follows:

• Press the button repeatedly until the CLIMA LUX display

y,

p

flashes;

• Use the button to set the desired humidity extraction percentage (DRY.Maxi™).

The 10 red LEDs indicate the variable humidity percentage (between 10% and 100%) which needs to be

extracted from the oven cavity.

Setting the airflow speed

The option of setting 3 airflow speeds inside the oven cavity, in addition to the 3 semi-static operating modes,

means it is possible to cook any product, from delicate and light foods to those which require a great deal of

heat.

The button can be used to set the motor revolution speed and operating mode. There are 3 continuous

revolution speeds and 3 semi-static operating modes.

The semi-static mode only activates the motors when the heating elements are on, which accurately reproduces

the effects of a traditional static oven. The fan is activated for a few moments, in order to evenly distribute the

heat produced by the heating elements and to ensure the temperature remains uniform throughout the oven

cavity. The speed selected previously is indicated on display 4 and can be selected using the

button, in the

following sequence:

• 1: indicates that the revolution speed is set to minimum

• 2: indicates that the revolution speed is between the minimum and maximum settings

• 3: indicates that the revolution speed is set to maximum

• 1P: indicates semi-static operation, with the revolution speed set to minimum

• 2P: indicates semi-static operation, with the revolution speed set to the medium value

• 3P: indicates semi-static operation, with the revolution speed set to maximum

Starting / stopping the cooking process

Once you have set all the cooking parameters, press

to start the cooking cycle.

To stop the cooking cycle, press the

button again.

When the cooking cycle has finished, both in manual and programmed mode, the oven emits an audible alarm

for 15 seconds and the display flashes for 45 seconds.

During this 45-second period, the “START / STOP” LED remains on.

If you press the

button during this period, the set cooking time will be increased and the oven will

automatically start again (using the most recent cooking parameters).

If you press the

button the “START / STOP” LED will switch off and all operating parameters will be

reset.

If none of the buttons are pressed within 45 seconds, the “START / STOP” LED will switch off and all operating

parameters will be reset.

Setting the parameters

Page 17

English

BakerTop

™

ChefTop

™

17

Starting / stopping the cooking process

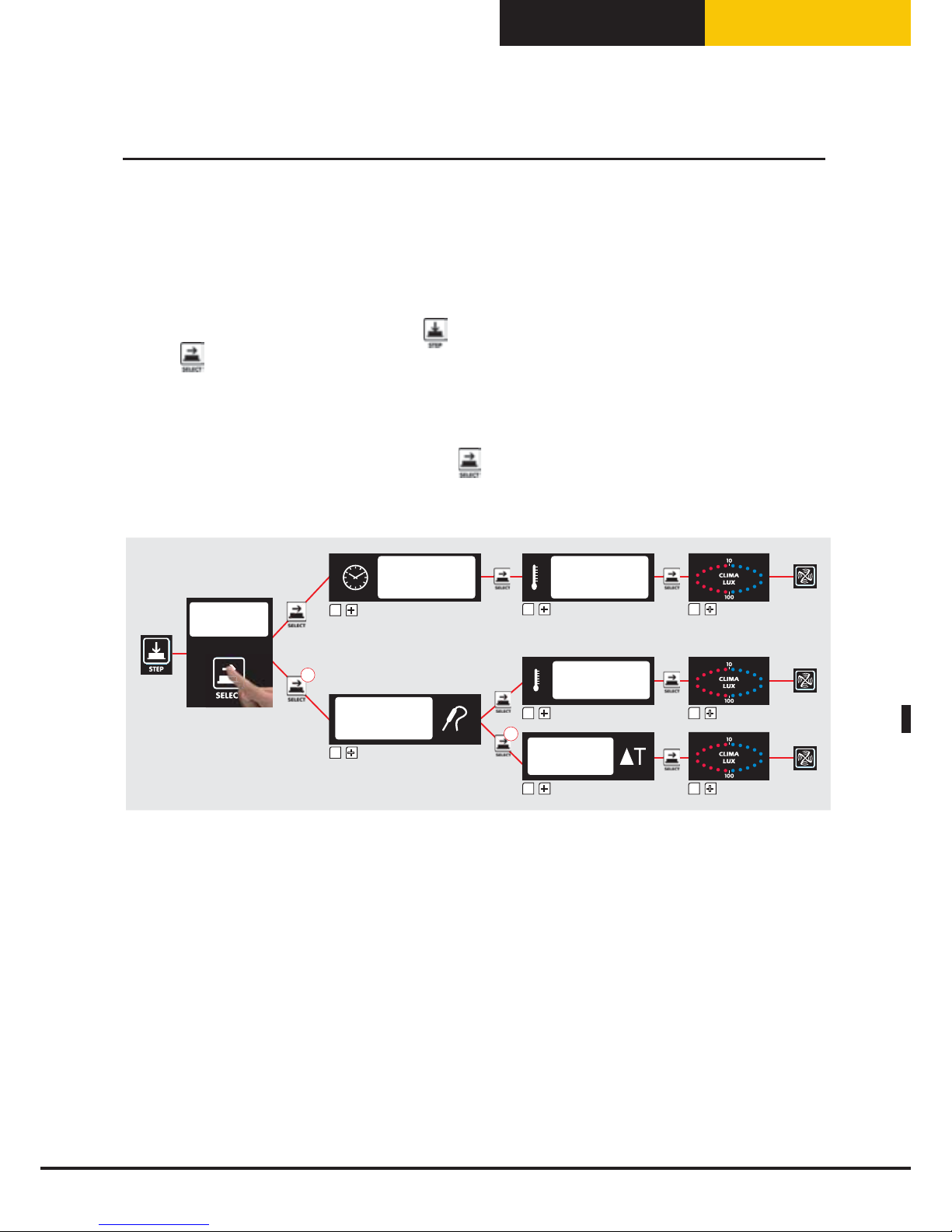

Selecting the cooking steps

Each cooking process consists of up to 9 steps.

To move from one step to the next, press the

button; the active step will be indicated on display 1.

Use the

button to pass from one parameter to the next; the active parameter is indicated by one of the

five icons lighting up.

Caution: the parameter displayed by pressing the

button may vary, depending on the selections made

when using the control panel to set the cooking duration (see diagam below):

-

+

-

x2

x2

-

+

-

-

+

-

-

+

-

-

+

-

-

+

-

-

+

-

-

+

-

It is therefore not possible to cook with the DELTA-T function if the cooking step duration has been set using

the COOKING DURATION function.

Selecting the cooking steps

Page 18

English

18

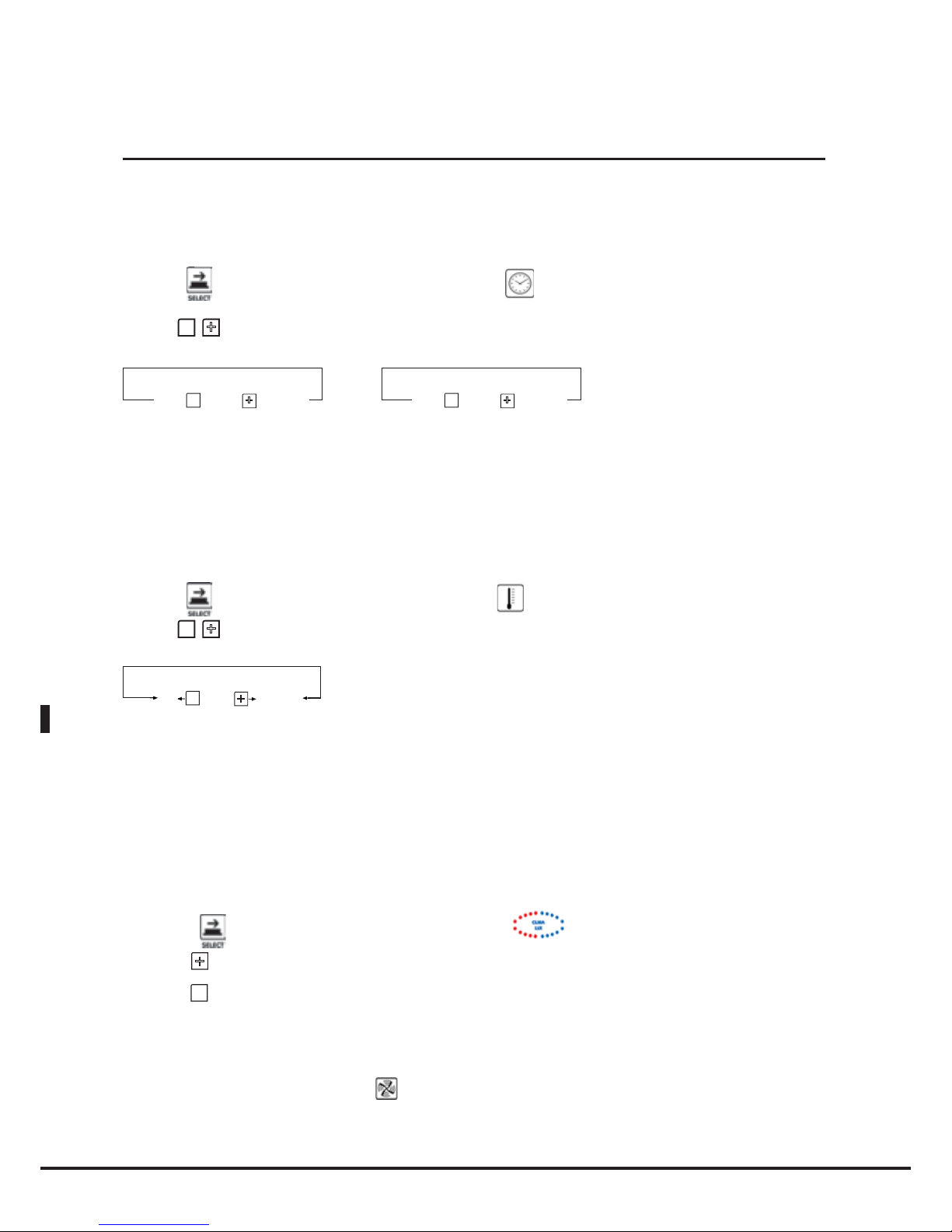

Cooking with a set duration and cavity temperature

First step:

Press the

button until the timer display begins to flash ;

Use the

-

+

-

buttons to set the duration as desired.

-

+

1° STEP

INF

INF

9h 59’

-

+

2° 3° 4°... STEP

HLD

HLD

0h 00’

9h 59’

0h 00’

N.B.

During cooking step 1, an indefinite duration "INF" may be set; in this case the oven will maintain the temperature

and humidity parameters indefinitely and will have to be stopped manually by the user. During cooking steps

2/3/4, the "HLD" function may be selected in order to maintain a constant cavity temperature of 70°C until the

oven is switched off manually; this keeps the food inside the oven hot and ready to be served.

Second step:

Press the

button again, until the temperature display begins to flash;

Use the

-

+

-

buttons to set the desired cavity temperature.

-

+

PAU

0° C

260° C

N.B.

The pause function, "PAU", may be selected at any time. During this time, the oven will remain in Standby

mode, with the fans, heating elements and burner switched off. This is a useful function for many types of

cooking, particularly if you wish to limit "Thermal pressure" on the product.

Third step:

CLIMA LUX, if necessary, with a humidity extraction percentage (DRY.Maxi™) or steam release percentage

(STEAM.Maxi™):

• Press the button again, until the CLIMA LUX display

begins to flash;

• Use the

+

button to set the desired steam

release percentage (STEAM.Maxi™)

;

•

Use the - button to set the desired humidity extraction percentage (DRY.Maxi™);

• Leave the setting as Ø for convection-only cooking, without releasing or extracting steam.

Fourth step:

To change the airflow speed, press the

button;

the current speed level is indicated on display 4.

Setting the cooking programs

Page 19

English

BakerTop

™

ChefTop

™

19

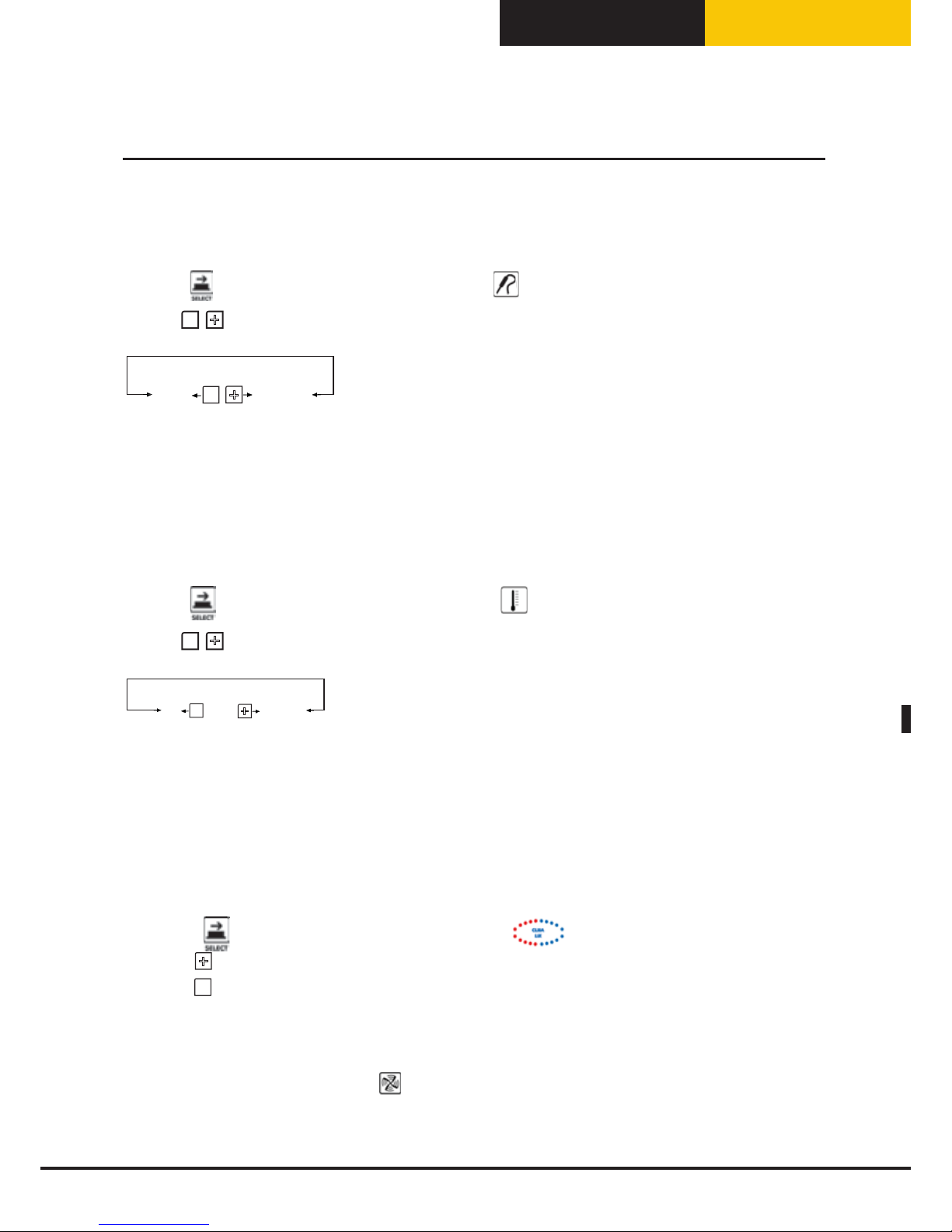

Cooking with the core probe at a set oven cavity temperature

First step:

Press the

button until the core temperature symbol begins to flash;

Use the

-

+

-

buttons to set the desired core temperature.

-

+

0° C

120° C

N.B.

By setting the core temperature, the cooking duration is set automatically.

As soon as the set core temperature is reached, the oven moves on to the following step (if selected) or the

cooking cycle ends.

Second step:

Press the

button again, until the temperature display begins to flash;

Use the

-

+

-

buttons to set the desired core temperature.

-

+

PAU

0° C

260° C

N.B.

The pause function, "PAU", may be selected at any time. During this time, the oven will remain in Standby

mode, with the fans, heating elements and burner switched off. This is a useful function for many types of

cooking, particularly if you wish to limit "Thermal pressure" on the product.

Third step:

CLIMA LUX, if necessary, with a humidity extraction percentage (DRY.Maxi™) or steam release percentage

(STEAM.Maxi™):

• Press the ) button again, until the CLIMA LUX display

begins to flash;

• Use the

+

button to set the desired steam

release

percentage (STEAM.Maxi™);

•

Use the - button to set the desired humidity extraction percentage (DRY.Maxi™);

• Leave the setting as Ø for convection-only cooking, without releasing or extracting steam.

Fourth step:

To change the airflow speed, press the

button;

the current speed level is indicated on display 4.

Setting the cooking programs

Page 20

English

20

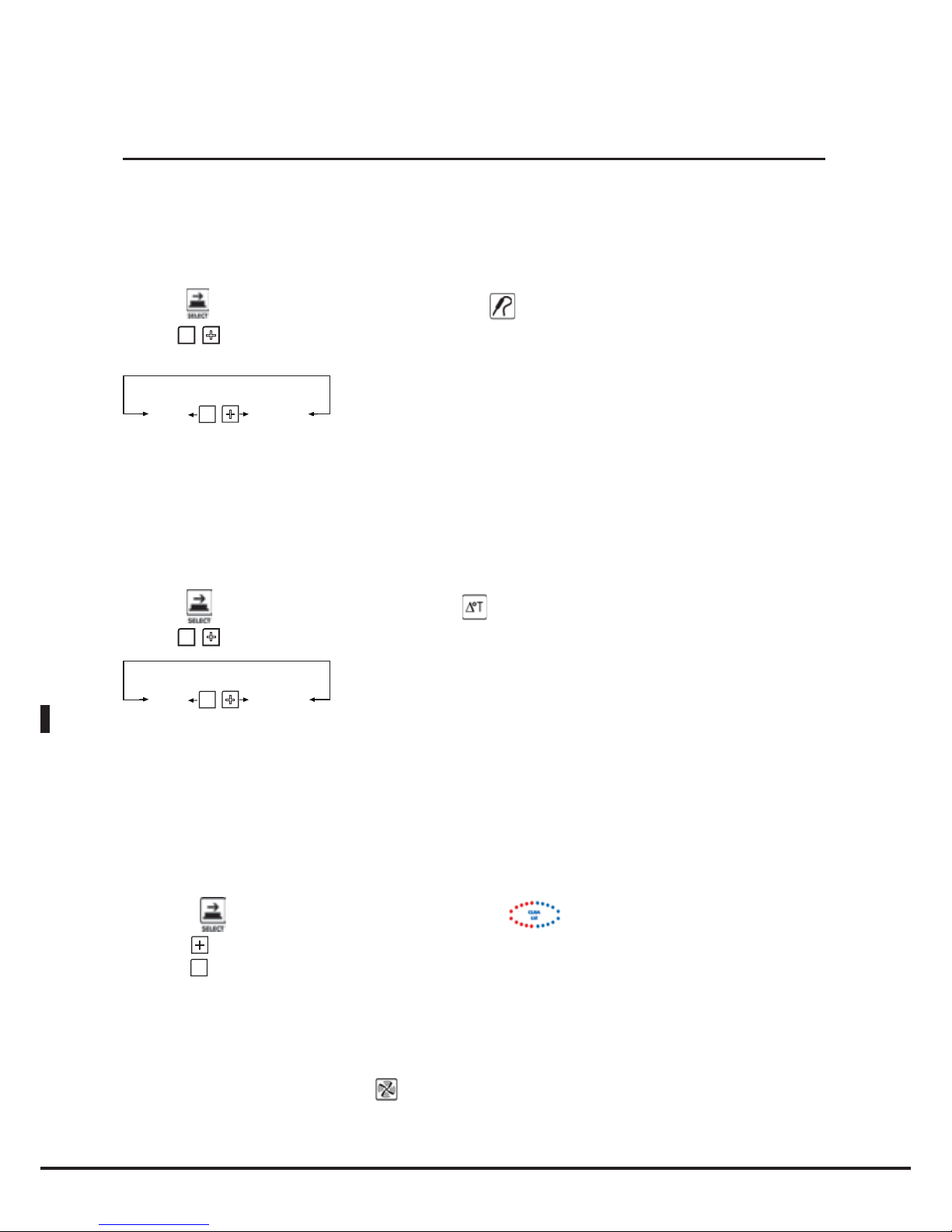

Cooking with the core probe at a set Delta T

First step:

Press the

button until the core temperature symbol

begins to flash;

Use the

-

+

-

buttons to set the desired core temperature.

-

+

0° C

120° C

N.B.

By setting the core temperature, the cooking duration is set automatically.

As soon as the set core temperature is reached, the oven moves on to the following step (if selected) or the

cooking cycle ends.

Second step:

Press the

button again, until the Delta T display begins to flash;

Use the

-

+

-

buttons to set the desired Delta T.

-

0° C

260° C

+

N.B.

7KH RYHQ Z LOO QHYHU XQGHUDQ\ FLUFXP VWDQFHV RSHUDWH DW WHP SHUDWXUHV DERYH

Third step:

CLIMA LUX, if necessary, with a humidity extraction percentage (DRY.Maxi™) or steam release percentage

(STEAM.Maxi™):

• Press the

button again, until the CLIMA LUX display

begins to flash;

• Use the

+

button to set the desired steam release percentage (STEAM.Maxi™);

• Use the - button to set the desired humidity extraction percentage (DRY.Maxi™);

• Leave the setting as Ø for convection-only cooking, without releasing or extracting steam.

Fourth step:

To change the airflow speed, press the

button;

the current speed level is indicated on display 4.

Setting the cooking programs

Page 21

English

BakerTop

™

ChefTop

™

21

Operation using programs

The ChefTouch/BakerTouch electronic control panel allows the user to save up to 99 cooking

programs, each assigned with a name up to 25 letters long.

Access the programming menu by pressing the

button;

Select the location in which you wish to save the program (from P01 to P99) using the

-

+

-

buttons indicated

on display 5; press

and use the

-

+

-

buttons to select the first letter of the name as desired;

Press

again and use the

-

+

-

buttons to select the second letter;

Repeat this procedure for subsequent letters;

Finally, press the

button to select the oven preheating temperature. The text "PRE" will appear;

Use the

button to select either an absolute preheating temperature

or a temperature

difference

between the preheating value and the value for the first cooking step of program;

Use

-

+

-

to set the desired value, expressed in degrees;

Press the

button to move to the next step and set the desired operating parameters (Duration, Core

Temperature, Cavity Temperature, Delta T, Climate) for the step;

Press the

button and set the parameter governing airflow speed inside the oven cavity;

Press and hold the

button for 5 seconds to store the program in the memory (after 5 seconds a confirmation

beep will sound).

Using saved programs:

Access the programming menu by pressing the

button;

Press the

-

+

-

buttons until the number correpsonding to the desired program appears on display 5;

Press the

button to start the selected program;

Press the

button again to stop the program.

N.B.

When a saved cooking program is started, the oven preheats automatically to the setted preheating temperature.

When a cooking program is started, the oven begins the set preheating step. During this step, all the LEDs

and displays remain off except the "START / STOP" LED, display 2 (which shows the text "PRE") and display 4

(which indicates the program being used). When the desired temperature has been reached and is maintained,

the oven beeps and the data corresponding to the first cooking step appears on the display. After the door has

been opened, the food placed inside and the door closed again, the cooking program begins automatically.

User programming procedures

SHORT WASHING

LH2O WASHING

COOL

SEMI-AUTO WASHING

RESTART

LAST P

P01

P02

...

P99

MED WASHING

LONG WASHING

PUMP LOADING

P

- +

Page 22

English

22

LASTP function

This can be used to quickly select the most recently used cooking cycle, whether it was activated manually or

in programmed mode.

When the cooking cycle has finished, press the

button. The text "LASTP" will appear on display 5;

Press the

button to start the most recently used cooking cycle again.

Automatic washing programs

The Rotor.KLEAN™ washing system, code XC405, offers automatic washing of the oven cavity. Automatic

washing programs can only be used if the appliance features this option. The Rotor.KLEAN™ washing system

may also be installed after the appliance has been commissioned.

3 washing programs (SHORT WASHING, MED WASHING and LONG WASHING) are stored in the control

P.C.B. memory, as well as a pre-loading program for the detergent and rinse aid pipes (PUMP LOADING).

There are another two semi-automatic programs: "LH2O", which can be used to rinse and dry the oven cavity

at a temperature of 120°C, without the use of chemicals and “SEMI-AUTOMATIC WASHING” which can

wash the oven cavity using a pre setted temperature and chemicals products manually.

Access the programming menu by pressing the

u

u

button;

Press the

-

+

-

buttons repeatedly until the LH2O, SHORT WASHING, MED WASHING, LONG WASHING

or PUMP LOADING washing programs appear on display 5;

Press the

button to start the selected program;

N.B.

The first time the washing system is used, it is advisable to run the PUMP LOADING program to remove any

air inside the detergent and rinse aid pipes, so that the quality of the wash is not compromised.

These programs are only used if the Rotor.KLEAN™ washing system (XC405) is installed.

Caution!

Never open the oven cavity door while a cleaning cycle is in progress - chemical cleaning substances and hot air may escape

- risk of corrosion and burns! When the cleaning cycle implemented by the Rotor.KLEAN™ system is complete, make sure

that there is no detergent residue remaining in the oven cavity (including the area behind the air channel panelling). Remove

any residue and rinse the entire oven cavity thoroughly (including the area behind theair channel panelling) using a hand-held

shower head - risk of corrosion!

Standard functions

Caution!

We recommend the oven cavity is cleaned on a daily basis, in order to maintain acceptable hygiene standards and

to prevent the stainless steel inside the cavity from being ruined. We would therefore recommend the use of the

Rotor.KLEAN™ washing system, code XC405, which offers automatic washing of the oven cavity. Caution!

If the appliance is not cleaned or not cleaned thoroughly enough, grease or remnants of food which have accumulated

inside the oven cavity may start to burn - fire hazard!

To prevent corrosion from occurring inside the oven cavity, the appliance should be cleaned every day, even if it is only

used for steam cooking purposes.

Only use detergents which have been recommeded by the appliance manufacturer. Detergents from other manufacturers

may damage the appliance and therefore invalidate the guarantee.

Page 23

English

BakerTop

™

ChefTop

™

"COOL" program for oven cavity cooling

The “COOL” program is used for oven cavity cooling; it allows the fans inside the cavity to rotate whilst the

heating elements remain off. The program can also be started with the door open, to accelerate the cavity

cooling process. During this program, the temperature inside the oven cavity is displayed.

• Access the programming menu by pressing the

button;

• Press the

-

+

-

buttons until the LCOOL program appears on display 5;

• Press the

button to start the selected program.

23

Standard functions

Page 24

English

24

ADAPTIVE.Clima function

Through the ADAPTIVE.Clima technology, ChefTop™ and BakerTop™ ovens constantly monitor all cooking

parameters, not only in terms of temperature, but also the current humidity level inside the cavity. This

ensures the most suitable cooking program is always applied, to help each user achieve perfect results every

time, regardless of the number of trays placed inside.

The amount of steam released inside the oven cavity varies in accordance with the amount of food placed

inside the appliance, even when the same program is used. As a general rule, the greater the amount of food

placed inside the oven, the less steam will be produced by the oven.

The ADAPTIVE.Clima technology can also be used to store the most recently used cooking process in the

memory of the appliance. For this use we recommend to use the MULTI.Point core probe in order to prevent

positioning mistakes.

The constant monitoring of all cooking parameters allows ChefTop™ and BakerTop™ ovens to acquire

information regarding changes in the temperature and humidity level during the entire cooking process,

while gathering information on the effects of any manual interventions from the user (opening the door, for

example).

Once the desired result has been achieved, the ADAPTIVE.Clima technology also allows the user to store

the implemented process in the memory of the appliance so that it can be repeated as often as necessary in

the knowledge that the results will always be the same, without any user intervention or supervision being

required.

The oven will automatically reproduce the effects of the user's actions during the "pilot" process (the one you

wish to repeat): if, for example, the door was opened in the third minute, causing the temperature to drop by

20°C and the humidity inside the cavity to disperse, the oven will also simulate these effects in the subsequent

cooking processes.

Caution: to store an ADAPTIVE.Clima program in the memory correctly, the core probe must have been

inserted correctly during the “pilot” cooking process, even if the program set on the control panel did not

require its application.

To store the cooking process you have just completed in the memory of the appliance using the ADAPTIVE.

Clima technology, proceed as follows:

• At the end of the cooking process, press the

button;

• Use the

+

button to select the program memory slot in which you would like to store the “pilot” cooking

process. For example ACM01, ACM02, …ACM20

• Press

and use the

-

+

-

buttons to select the first letter of the name you wish to assign to the

program;

• Press

again and use the

-

+

-

buttons to select the second letter;

• Repeat this procedure for subsequent letters;

• Press and hold the

button for 5 seconds to store the program in the memory (after 5 seconds a

confirmation beep will sound).

Caution: it is not possible to modify any of the parameters for a stored ADAPTIVE.Clima program.

Standard functions

Page 25

English

BakerTop

™

ChefTop

™

25

ChefUnox - BakerUnox automatic cooking processes

The ChefTouch - BakerTouch digital control panel has a set of suggested automatic cooking settings devised by

ChefUnox - BakerUnox stored in its memory.

Simply select the desired type of cooking to automatically prepare an endless range of foods.

Every type of automatic cooking program offers the option of customising certain parameters, in order to

achieve the optimal level of browning and cooking in line with your own requirements.

• Press the

button;

• Use the

-

button to select the desired program;

• Press the

button to start the program;

• Press the

button again to stop the program.

N.B.

Before starting the program, you may change the value of a parameter which can be used to adjust the cooking

level as desired. The oven will adjust its cooking performance accordingly, in order to gurantee a perfect

result.

• Press the

button until the parameter you want to modify flashes;

• Use the

-

+

-

buttons to set the new value as desired.

If you want to make this change permanent:

• Press and hold the

button for 5 seconds (you will then hear a beep to indicate the program has been

saved).

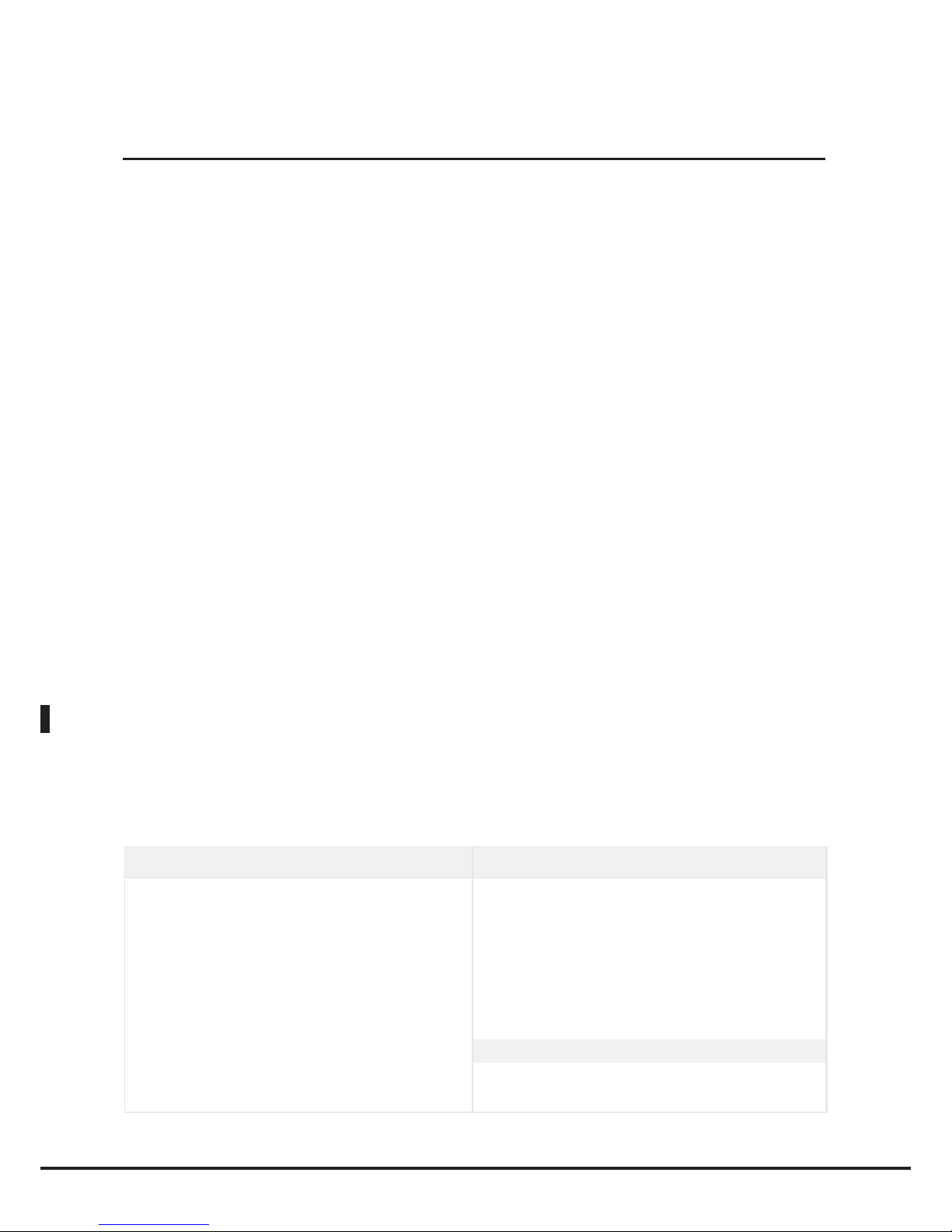

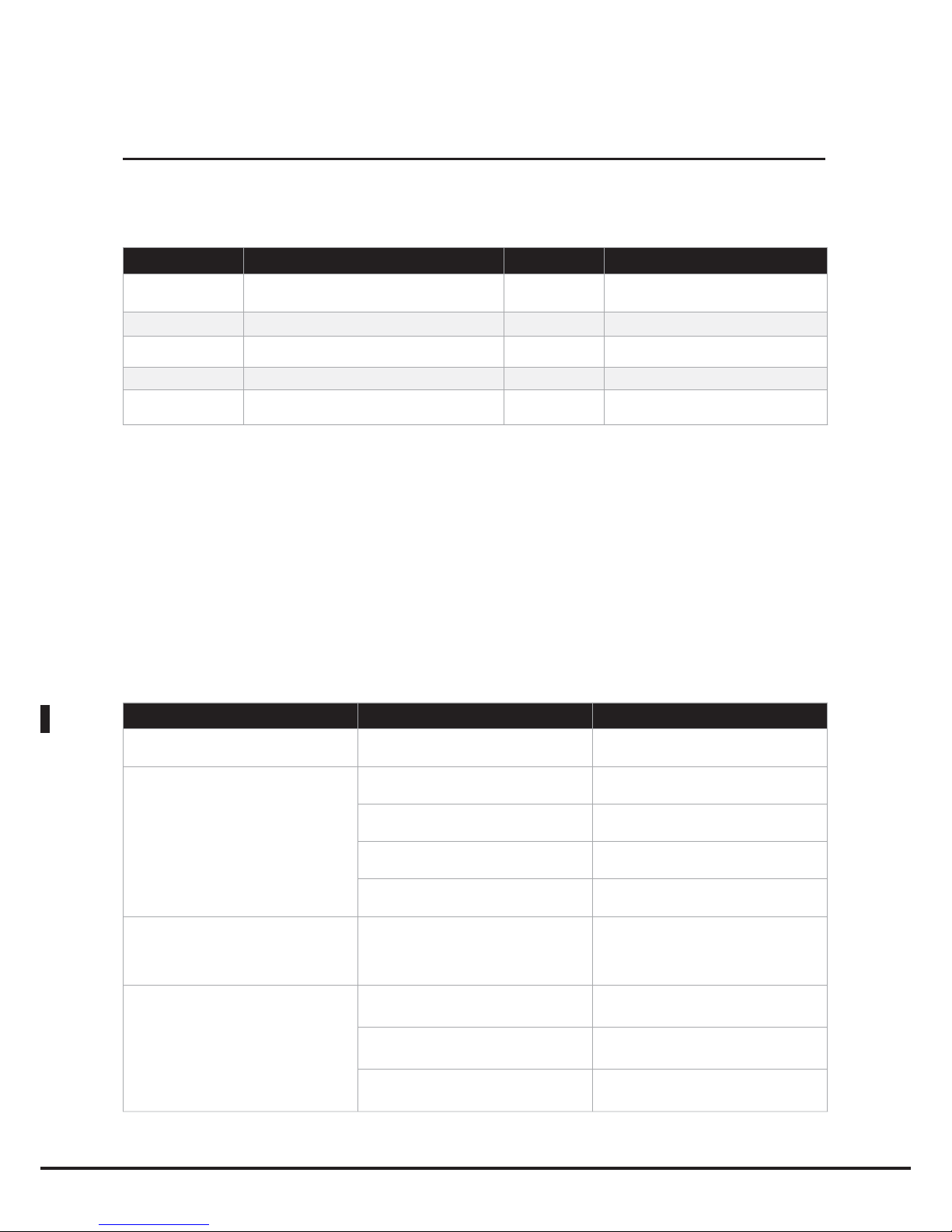

DESCRIPTION

ADJUSTABLE

PARAMETER

WHEN TO INCREASE WHEN TO DECREASE

ROASTING Roasting meats Core probe 54°C Increase the cooking level Decrease the cooking level

CRISPY ROAST Roasting meats with a crust Core probe 54°C Increase the cooking level Decrease the cooking level

NIGHT ROAST

Roasting meats overnight

Core probe 54°C Increase the cooking level Decrease the cooking level

BRAISE Braising and stewing meats Cooking time 1 h Increase the cooking level Decrease the cooking level

GRILL Grilling vegetables and meats

9 Timers can be set, use

FAKIRO Grill

--

MULTI TIME

Simultaneous cooking of

several products for various

periods of time

Set temperature and

CLIMALUX, press Start and

use the step button to set the

9 timers

--

CHICKEN

Cooking chicken, birds,

poultry, game

Time 5 min Increase external browning Decrease external browning

ROAST POTATO Roast potatoes Time 5 min Increase external browning Decrease external browning

BAKING

Cooking frozen baked goods

Time 5 min Increase the cooking level Decrease the cooking level

+3 REGEN Regeneration from 3°C Core probe 65°C

Increase the temperature of

the dish for service

Decrease the temperature

of the dish for service

Pre-set cooking procedures

Page 26

English

26

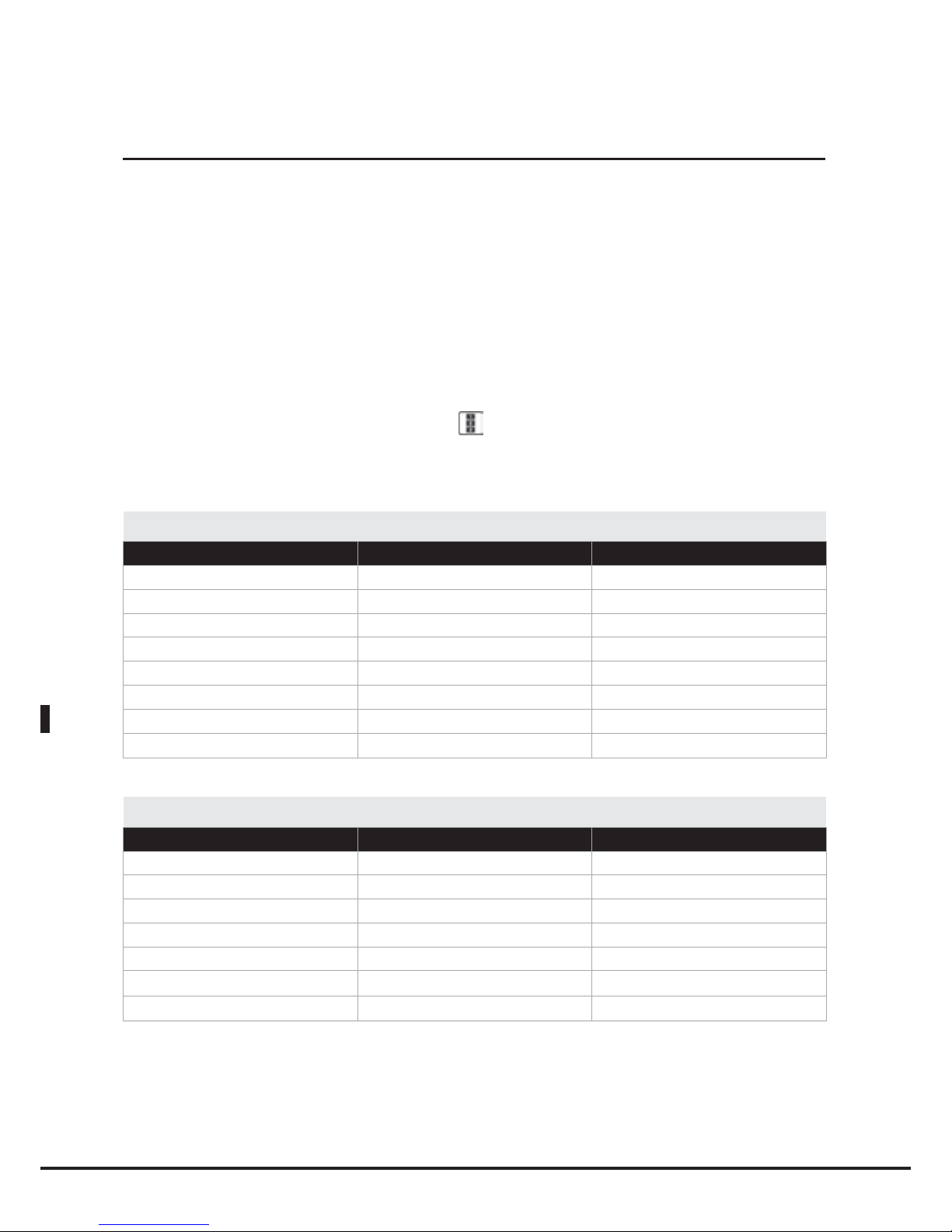

MAXI.Link technology:

controlling several appliances using the same control panel

The ChefTouch – BakerTouch digital control panel allows the user to control a variety of UNOX ChefTop™

- BakerTop™ appliances connected to the oven. The MAXI.Link technology also allows the user to control

several ovens with a single digital control panel. The oven used to control all the other appliances becomes

the MASTER oven. The ovens controlled by the MASTER oven become SLAVE ovens, and their digital control

panels remain inactive. The MASTER and SLAVE digital control panels are interchangeable in the event of an

emergency.

The appliance to be controlled is selected using the

button; this selection is indicated by display 6.

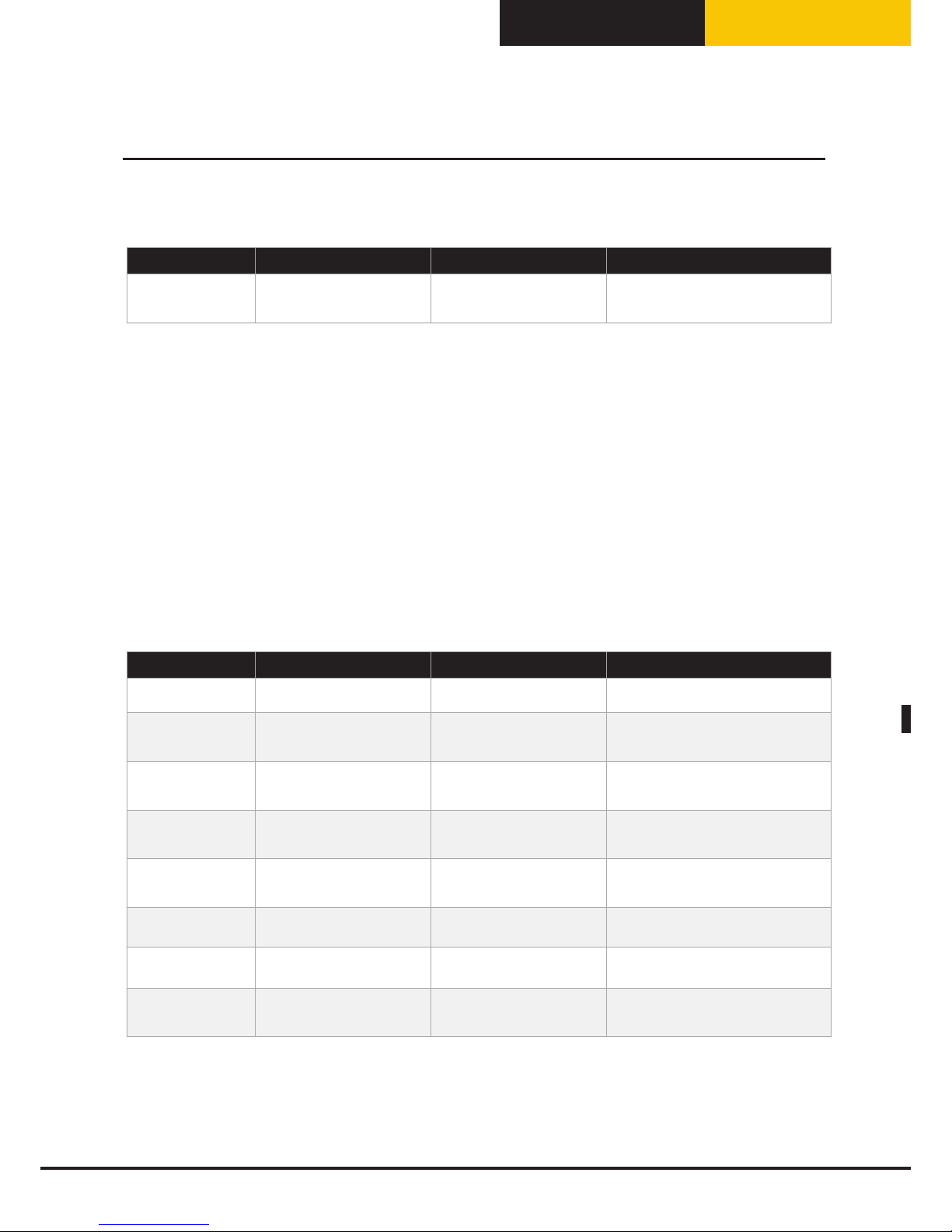

Number / appliance correspondence table

ChefTop™

Appliance number Appliance code Device

1 ChefTop™ master oven

2 ChefTop™ slave oven 1

3 ChefTop™ slave oven 2

4 ChefTop™ slave oven 3

5 XK305 Blast chiller

6 XVL575 - XVL375 Holding cabinet / Slow cooking oven

7 XC235 Reverse osmosis system

9 XC236 Kit OVEX.Net 2.0

BakerTop™

Appliance number Appliance code Device

1 Forno BakerTop™ master

2 Forno BakerTop™ slave 1

3 Forno BakerTop™ slave 2

4 Forno BakerTop™ slave 3

6 XL405 Prover

7 XC235 Reverse osmosis system

9 XC236 Kit OVEX.Net 2.0

MAXI.Link technology

Page 27

English

BakerTop

™

ChefTop

™

27

Chef’s recommendations for even cooking

Preheating

It is always better to preheat the oven to a temperature at least 30-50°C higher than is required for cooking,

in order to reduce the effects of heat lost when opening the door.

The oven may be preheated to 300°C.

Do not heat the oven to a temperature over 260°C for periods of longer than 10 minutes.

Tray types

To achieve perfect cooking quality and even browning of the product, it is better not to use recipients which

are too tall and prevent correct air circulation.

Tray spacing

For even cooking it is important to make sure there is at least 3 cm of free space between the product once

it has risen and the tray above.

Quantity of food

To achieve the best results, it is important not to overload the oven; you should also make sure, when baking

bread and pastry, the food on the trays is facing the right direction in relation to the airflow.

Core probe positioning

For correct operation, it is essential that the core probe is inserted from top to bottom, at the thickest point

of the food, until the tip reaches the centre.

When cooking thinner foods, the core probe should be inserted horizontally to the support surface.

Be careful when opening the door!!!

Heat and steam could cause burns.

Cooking principles

Page 28

English

The digital control panel used in ChefTop™ - BakerTop™ ovens is designed to offer a straightforward interface

between the oven and the outside world, by means of existing communication systems and those to be used in the

future: USB, Bluetooth, serial port etc.

The USB XC236 interface kit can be used to carry out the following functions:

• entering cooking programs

• modifying operating parameters (e.g. probe calibration)

• diagnosing malfunctions

• storing oven cavity or blast chiller temperature changes in the memory of the appliance (data required for the HACCP system)

Further information is supplied with the kit.

Warning messages:

When a malfunction is detected which allows the appliance to continue operating, abeit in a limited manner, a

WARNING message is displayed.

The device continues to run and the WARNING message remains on the display until the button is pressed.

Warning messages oven:

Display message Description Effect Problem solution

WF01

An error has been detected in the data recorded by

cavity probe 1

The oven contines to operate, using the data

from cavity probe 2 only

Contact the Customer Assistance Service

WF02

An error has been detected in the data recorded by

cavity probe 2

The oven contines to operate, using the data

from cavity probe 1 only

Contact the Customer Assistance Service

WF03

An error has been detected in the data recorded by

the core probe

It is not possible to set steps or activate

programs which use the core probe; if a step

which uses the core probe is in progress, the

following step will begin

Contact the Customer Assistance Service

WF04

Non correct fan rotation speed Turn off the motor breaking system

Contact the Customer Assistance Service

WF05

An error has been detected in the cooling system for

the electronic components

The cooling fan for the electronic components

may not work

Contact the Customer Assistance Service

WF06

The temperature of the oven power P.C.B. is too

high

There is a risk of permanent

damage to the power P.C.B.

Make sure the positioning standards

specified in the installation manual have

been observed. Contact the Customer

Assistance Service

WF08

Gas board detected while the oven is set as electric

The oven keeps on working but is controlled

as electric

Contact the Customer Assistance Service

WF09

Error on the motor breaking system

The oven keeps on operating but the motor

breaking system is not working

Contact the Customer Assistance Service

WF10

Non basic power board setting error

The oven keeps on working (with some

limitations due to the setting involved on the

error)

Contact the Customer Assistance Service

WF11

Not correct temperature on the gas board The oven keeps on operating

Contact the Customer Assistance Service

WF12

Too high temperature on the external thermocouples

board

The oven keeps on operating

Contact the Customer Assistance Service

WF13

The external sous-vide probe takes non correct data

The oven keeps on working but it is not possible

to use external sous-vide probe

Contact the Customer Assistance Service

WF14

Error on the data taken by the Multi.point core probe

(totally not working)

The oven keeps on working but it is not possible

to use cooking programs with the core probe

Contact the Customer Assistance Service

WF15

Error on the board-thermocouples communication

system

The oven keeps on working but it is not possible

to use external sous-vide probe

Contact the Customer Assistance Service

WF17

Error on the data taken by the Multi.point core probe

(partially not working)

The oven keeps on working but the core

temperature may be not precisely taken

Contact the Customer Assistance Service

28

Oven-user communication

Page 29

English

BakerTop

™

ChefTop

™

Warning messages (attention) panel control board:

Display message Description Effect Problem solution

WD10

Non basic control board

setting error

The oven keeps on working (with

some limitations due to the setting

involved on the error)

Contact the Customer

Assistance Service

Alarm messages:

When a condition arises which prevents the appliance from operating at all, an ALARM signal is displayed and

the appliance must be switched to its STOP status.

The device stops operating and the ALARM! message appears on the oven display until the problem is resolved.

If the device is operating when the ALARM status occurs, it will shut down and the alert corresponding to the

detected problem will be displayed.

To resolve a problem of this type, contact an Authorised Assistance Centre.

Once the problem has been resolved, the appliance can be reactivated by pressing the "START/STOP"

button.

If any other devices/accessories are connected to the oven, these will continue to operate normally unless the

alarm corresponds to a specific device that prevents its continued operation.

Alarm messages oven:

Display message Description Effect Problem solution

AF01

The motors have overheated Oven shutdown Contact the Customer Assistance Service

AF02

The safety thermostat has

overheated

Oven shutdown Contact the Customer Assistance Service

AF03

An error has been detected

in the data recorded by both

cavity probes

Oven shutdown Contact the Customer Assistance Service

AF04

Communication between the

control P.C.B. and the power

P.C.B. has been cut off

Oven shutdown Contact the Customer Assistance Service

AF05

Communication between the gas

P.C.B and the power P.C.B. has

been cut off

Oven shutdown Contact the Customer Assistance Service

AF06

Gas oven exhaust fumes reach too

high temperature

Oven shutdown Contact the Customer Assistance Service

AF10

Power card settings error Oven shutdown Contact the Customer Assistance Service

GAS

There is no flame in the

burner

The burner is deactivated. Ignition

may be attempted again by ressing

the “START/STOP” button

In case it is not possible to re-start the oven,

immediately close the gas cock

N.B.

Every time the oven is started electrically, and every time the control P.C.B. exits STANDBY mode, the control

P.C.B. is scanned for ALARM / WARNING conditions (which appear on the display, if present).

Oven-user communication

29

Page 30

English

Alarm messages panel control board:

Display message Description Effect Problem solution

AD01

An error has been detected in the control

board memory

Oven shutdown Contact the Customer Assistance Service

AD02

An error has been detected on the keyboard

Oven shutdown Contact the Customer Assistance Service

AD03

An error has been detected in the display

Oven shutdown Contact the Customer Assistance Service

AD04

Communication has been cut off

Oven shutdown Contact the Customer Assistance Service

AD10

Basic control board setting error

Oven shutdown Contact the Customer Assistance Service

Maintenance in the event of a malfunction:

In the event of a malfunction, deactivate the appliance:

Disconnect the appliance from the electricity supply.

For gas appliances

Cut off the gas supply immediately.

Contact a Technical Assistance Centre with specially trained personnel.

Before calling the Customer Assistance Service:

Malfunction Possible cause Solution

The oven is completely switched off No mains power

Make sure the appliance is connected to

the electricity mains

No steam is produced inside the oven

cavity

Water inlet closed Open water inlet

Appliance plumbed into the water mains

or the tank incorrectly

Make sure the appliance is plumbed into

the water mains or the tank correctly

No water in the tank (if water is taken

from the tank)

Fill the tank with water

Water inlet filter blocked Clean the filter

After the duration or core

temperature has been set and the

START / STOP button pressed, the

oven does not start

Door open or not shut properly Make sure the door is shut

Water escapes from the seal while

the door is shut

Seal dirty Clean the seal using a damp cloth

Seal damaged

Contact a specialised technician to

request the necessary repair work

The handle mechanism is loose

Contact a specialised technician to

request the necessary repair work

Oven-user communication

30

Page 31

English

BakerTop

™

ChefTop

™

Safety regulations

All installation, assembly, assistance and maintenance procedures must be performed by qualified personnel in

accordance with current regulations.

These technicians must, nevertheless, be aware of and apply the regulations relating to the safety of repaired

products and safety in the workplace.

Appliance installation by qualified personnel not authorised by UNOX will invalidate the guarantee.

In light of the above information, UNOX accepts no responsibility for any situation resulting from work carried

out in an unprofessional manner, or from the incorrect intepretation or application of regulations or the

instructions supplied in this manual.

Caution!

Incorrect installation, assistance, maintenance or cleaning procedures, or any modifications made to the

appliance, may damage property or result in injury or even fatal accidents.

Read the installation instructions carefully before installing the appliance.

This appliance may only be used to cook food in industrial kitchens.

Any other application does not conform to the specified use and is therefore considered hazardous.

Gas appliances only

If the appliance is installed below a cooker hood, the hood should be switched on while the operation.

In case the appliance is connected to a chimney, the exhaust pipe has to be clean and free from obstructions

following the current safety rules – risk of fire! (for further information, please contact your installer).

Do not place any objects on top of the exhaust gas hose connected to the appliance - Fire hazard!

The area underneath the appliance should not be blocked or obstructed by any objects - Fire hazard!

The appliance may only be operated in a draught-free environment - Fire hazard!

If you smell gas:

Cut off the gas supply immediately;

Do not touch any of the electrical switches;

Make sure the room is well ventilated;

Avoid the creation of naked flames and sparks;

Use a telephone outside the building and inform your gas supplier immediately.

------

Read the manual carefully before installing and commissioning the appliance.

Make sure the appliance has not been damaged during the transportation process.

If you suspect any damage may have occurred during transportation, inform your local authorised dealer or

the shipping agent.

31

INSTRUCTIONS FOR THE INSTALLER

Page 32

English

Make sure the unit will fit through all doors, corridors or other passageways required to reach the installation site.

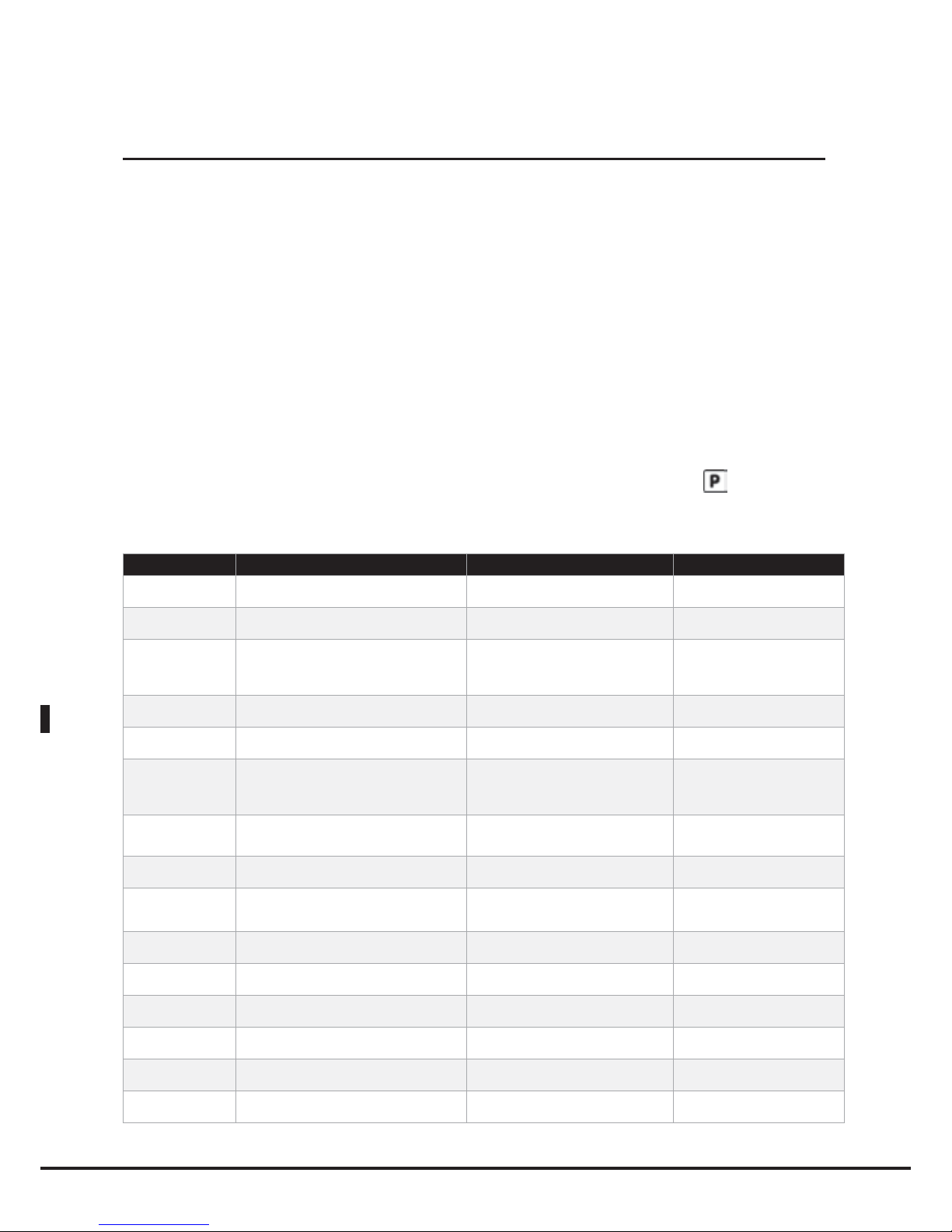

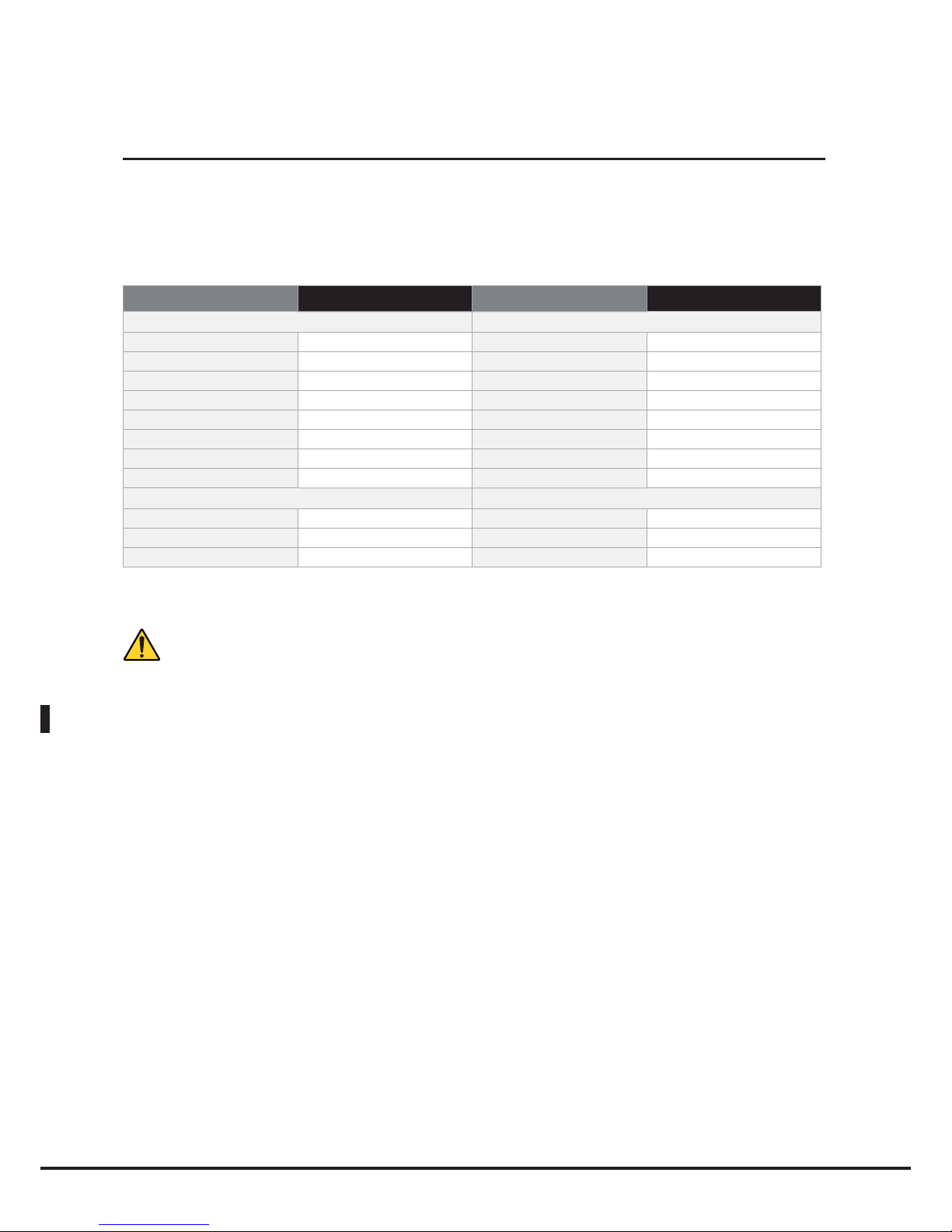

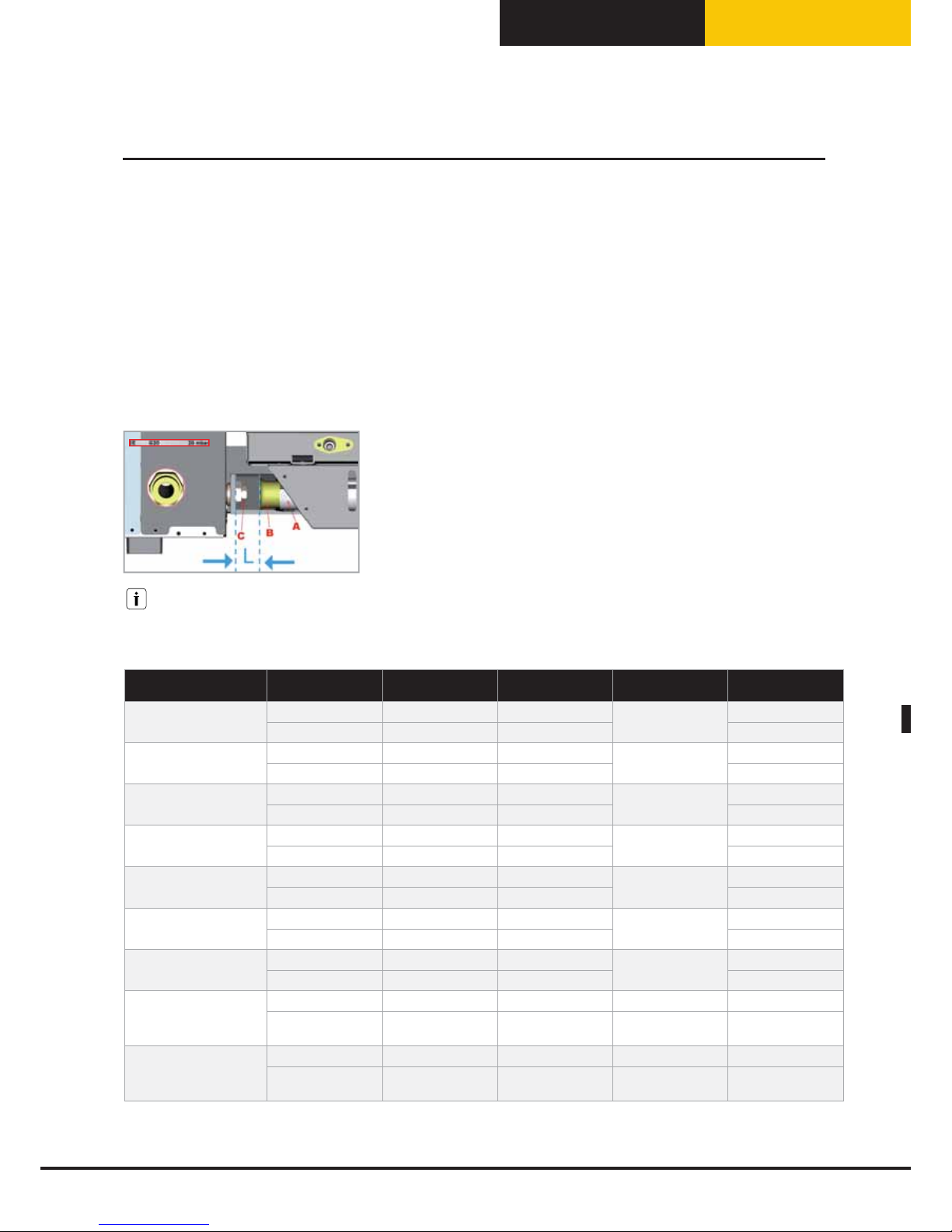

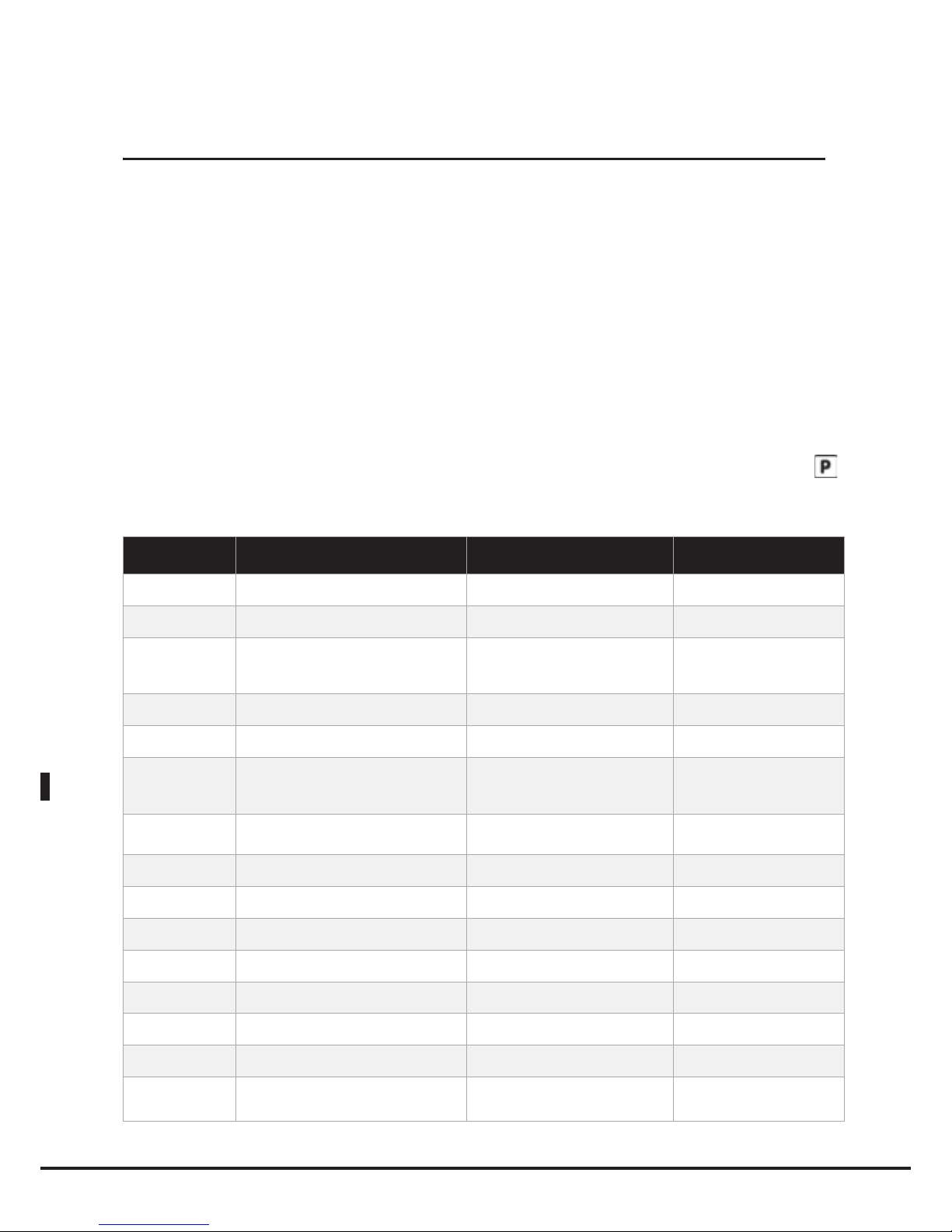

The table lists the measurements of the models, with and without packaging:

UNIT/MODEL No packaging

LxDxH mm

With packaging

LxDxH mm

UNIT/MODEL No packaging

LxDxH mm

With packaging

LxDxH mm

ChefTop™ electric ChefTop™ gas

XVC 055 574x737x498 740x800x640 - - -

XVC 105/ 105P 750x782x498 880x880x640 - - -

XVC 205 574x758x632 740x800x780 - - -

XVC 305/ 305P 750x792x625 880x880x780 XVC 315G 750x796x840 870x870x1000

XVC 505/ 505P 750x792x813 880x880x970 XVC 515G 750x796x1028 870x870x1200

XVC 705/ 705P 750x792x960 880x880x1120 XVC 715G 750x796x1175 870x870x1400

XVC 1005P/ 905P 866x972x1866 980x1140x2000 XVC 1015G/ 915G 866x970x2072 980x1140x2250

XVC 1205 860x1160x888 990x990x1300 XVC 1215G 860x1160x1028 -

XVC 2005 860x1160x1208 980x1300x1310 XVC 2015G 860x1160x1348 -

XVC 4005P/ 3205P 869x1206x1857 985x130x2000 XVC 4015G/ 3215G 869x1206x2072 -

BakerTop™ electric BakerTop™ gas

XBC 405 860x900x624 980x1060x772 - - -

XBC 605 860x900x820 980x1060x960 XBC 615G 860x900x1028 950x1030x1180

XBC 805 860x900x1140 980x1060x1280 XBC 815G 860x900x1348 980x1060x1470

XBC 1005/ 905 866x972x1866 980x1140x2000 XBC 1015G/ 915G 866x970x2072 980x1140x2250

The appliance should only be transported using pallets supplied by UNOX.

Caution!

Make sure that the appliance is not in danger of tipping over during transportation.

Take the weight of the appliance into account. Use suitable supports.

Wear protective shoes during the installation process.

32

Instructions for appliance transportation

Page 33

English

BakerTop

™

ChefTop

™

Oven installation is divided into 5 stages:

1) Preliminary and positioning procedures

2) Electrical connection / Gas connection

3) Plumbing: water supply

4) Plumbing: water drainage

5) Smoke exhaust outlet

2

3

5

1

4

Preliminary and positioning procedures

Installation site

Before positioning the appliance, check the measurements and the exact position of the electrical, plumbing

and smoke exhaust connections, in accordance with the figures provided in the enclosed "Technical Data"

booklet.

Caution!

Do not install the appliance near flammable materials.

If the appliance is positioned near walls, partitions, kitchen cabinets, decorative trim, etc., these items must be

made from non-flammable material.

If this is not the case, they must be coated with a non-flammable heat insulating material, and all fire prevention

regulations must be strictly observed.

33

Appliance installation

1. Positioning

2. Electrical connection

3. Water supply

4. Water drainage

5. Smoke exhaust outlet

Page 34

English

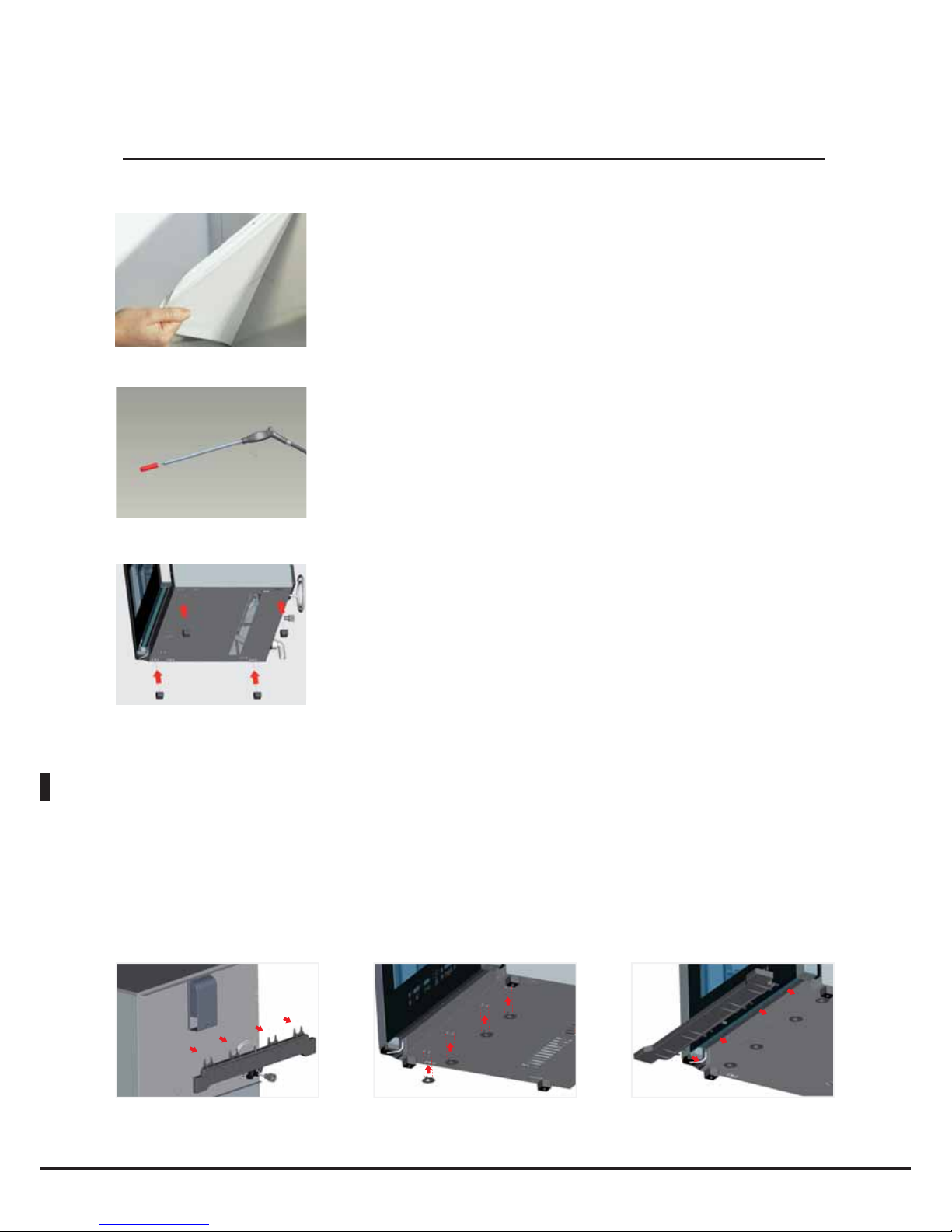

Removing the protective film

Carefully remove the protective film from the outer surfaces of the appliance,

so that no glue residue is left behind. Any remaining residue can be removed

using a suitable solvent product.

Removing the protective silicone from the tip of the core probe

Fitting the fixed appliance feet

The feet supplied in the bag inside the packaging ensure sufficient airflow for

the cooling of electronic components and the outer surfaces of the oven. It is

therefore essential that they are fitted correctly. Install the feet at the points

indicated in the illustration.

Caution! Do not use the oven without feet; this could cause the electronic

components to overheat, damaging them beyond repair.

Drip drawer

The drip drawer fixed to the back panel of the oven collects any liquids deposited on the inside of the oven

door, thereby preventing them from dripping onto the floor when the door is opened.

Remove the drip drawer from the rear of the oven using a screwdriver, slide the runners (supplied in the bag

inside the oven) into position and insert the drawer as illustrated in the figure.

34

Appliance installation

Page 35

English

BakerTop

™

ChefTop

™

Warning

Position the appliance so that the back panel is easily accessible when performing electrical connection and

carrying out maintenance work. The appliance is not suitable for recessed installation, or for use as part of a

series of appliances. A minimum gap of 50 mm must be left around the entire perimeter of the appliance.

If any fryers or other potential sources of hot liquid spills are used in the kitchen, they should be placed at least

45 cm away from the sides and 70 cm away from the back of the oven.

450 mm

700 mm

50 mm

50 mm

For safety reasons, tabletop appliances must only be placed on supporting structures or cabinets from the

appliance manufacturer. The maximum operating height for the top shelf level is 1600 mm.

1600 mm

The safety labels «max. height of thelast

shelf for containers holding liquids» can be

found in the starter kit.

After installing theappliance, apply thelabel

at aheight of 1600 mm.

(see example)

Tabletop ovens require the use of special stands, leavening devices or tray racks, or should be placed on top

of a stainless steel table.

Do not install ovens directly on the floor.

35

Positioning

Page 36

English

Align the appliance horizontally.

Make sure the appliance is level.

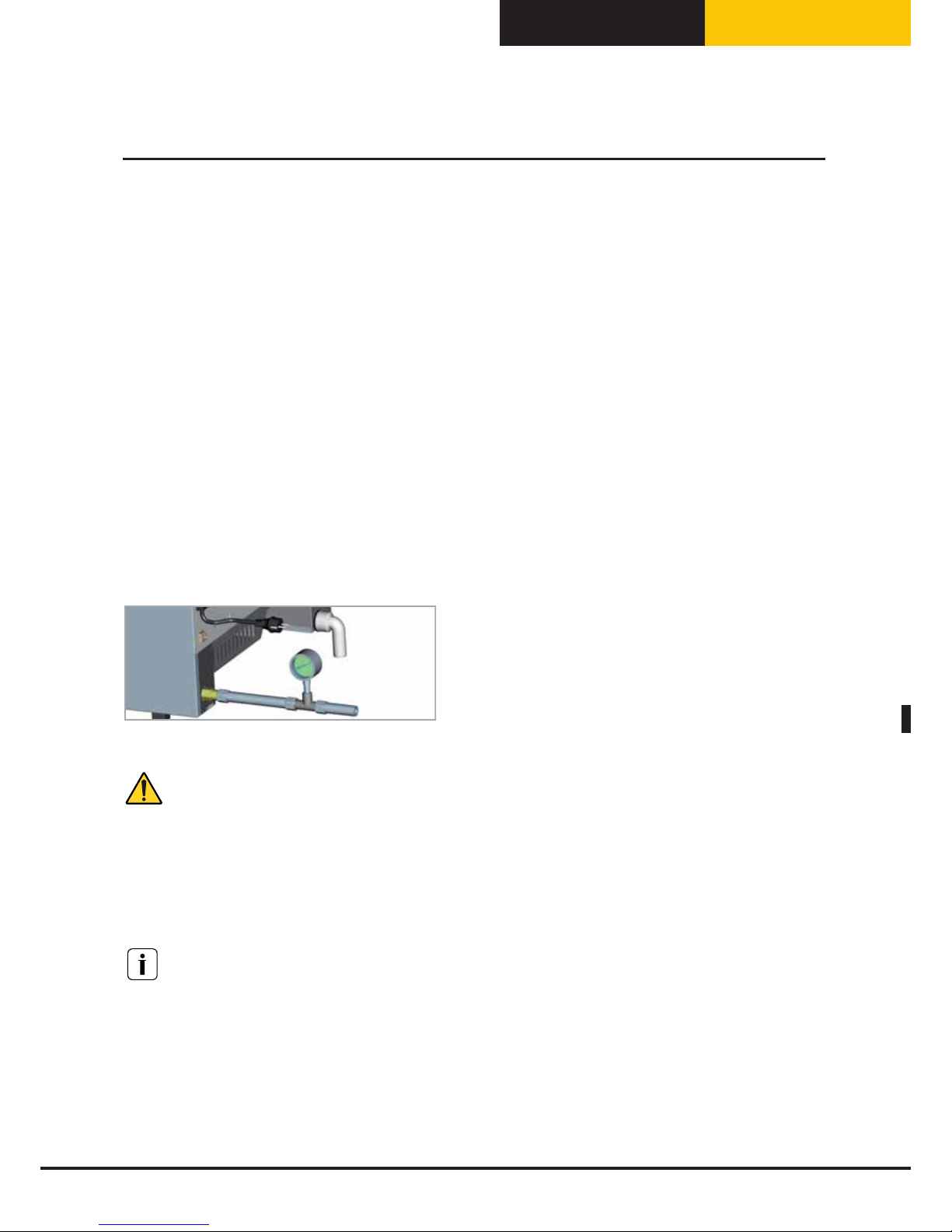

During cooking, hot smoke is produced, along with other odours which need to be removed from the flue;

it is therefore advisable to position the oven underneath a suitable cooker hood, or to use the special UNOX

hoods and ensure the fumes are channelled outside.

36

Positioning

Page 37

English

BakerTop

™

ChefTop

™

Positioning

Door closure regulation

Models without trolley

If, once the oven is in position, the door handle does not remain in its correct closed position (Fig. 1), the

closure latch probably needs to be adjusted; proceed as follows:

• while the oven door is open (Fig. 2), slightly loosen the screws fixing the latch in place (Fig. 3);

• close the door again and turn the handle to stop it from opening (Fig. 3);

• if the door stays shut with the handle in a perfectly vertical position, open the door again (Fig. 4) and tighten

the latch fixing screws (Fig. 5);

• if the problem persists, repeat this procedure, loosening the latch fixing screws further.

2 3 451

Trolley models

In case, once the oven has been placed, the door handle of the oven does not correctly close in vertical

position (pic.1), it may be necessary to fix the door spring latch position. Proceed as follows:

• open the oven door and loose the upper and lower spring latch fixing screws (pictures 2 and 3)

• lightly loose the 2 central spring latch fixing screws (picture 4)

• draw the door up to the spring latch and move vertically the position of the latch in order to make it

perfectly lined up with the door closing pin (picture 5)

• tight the upper, lower and central spring latch fixing screws and try to close the door.

• if the door closes properly and the handle perfectly stays in vertical position, open the door and tightly

fix the fixing screws of the latch.

• in case the problem is not solved, repeat the procedure and loose more the spring latch fixing screws .

23451

N.B

A support surface which is not perfectly even will not allow the door handle to close correctly: if the surface is

only slightly uneven, the problem may be overcome by adjusting the closure latch using the method described

previously; there is no way of compensating for a highly uneven floor or oven support surface.

37

Page 38

English

The support surface must be flat and level. The installation site must be able to withstand the weight of the

appliance and the maximum load. Please refer to the table below:

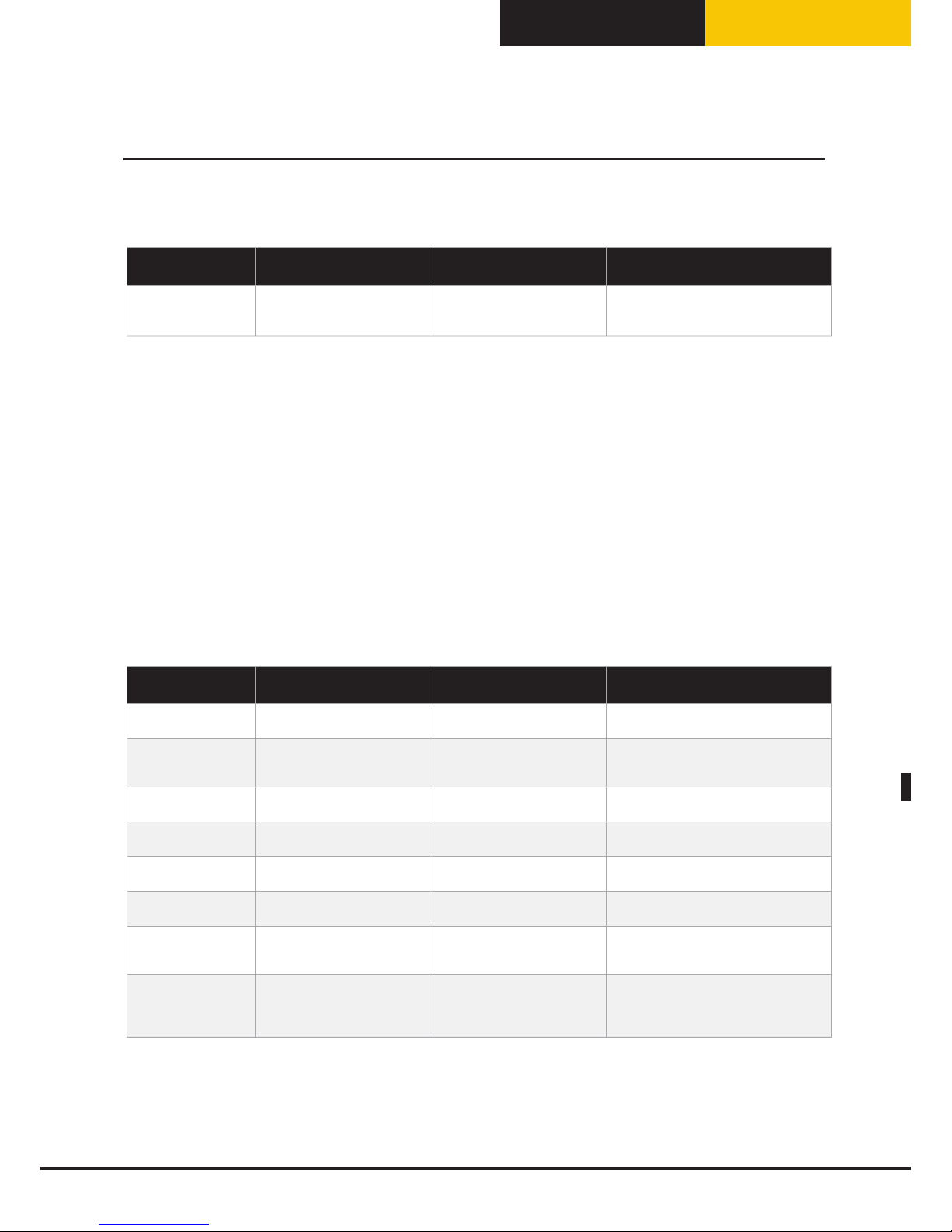

UNIT/MODEL Weight (without load) UNIT/MODEL Weight (without load)

ChefTop™ elettrici ChefTop™ gas

XVC 055 35 kg - -

XVC 105/ 105P 45 kg - -

XVC 205 41 kg - -

XVC 305/ 305P 59 kg XVC 315G 73 kg

XVC 505/ 505P 76 kg XVC 515G 90 kg

XVC 705/ 705P 83 kg XVC 715G 97 kg

XVC 1205 150 kg XVC 1215G 170 kg

XVC 2005 165 kg XVC 2015G 185 kg

BakerTop™ elettrici BakerTop™ gas

XBC 405 60 kg - -

XBC 605 86 kg XBC 615G 106 kg

XBC 805 118 kg XBC 815G 132 kg

Once the appliance has been positioned, make sure that there is no danger of it slipping or tipping over.

Caution!

If the appliance is to be mounted on a mobile support frame or cabinet, it should be secured with an extra

chain or rope to stop it from rolling around and damaging the electricity or gas supply lines.

Positioning

38

Page 39

English

BakerTop

™

ChefTop

™

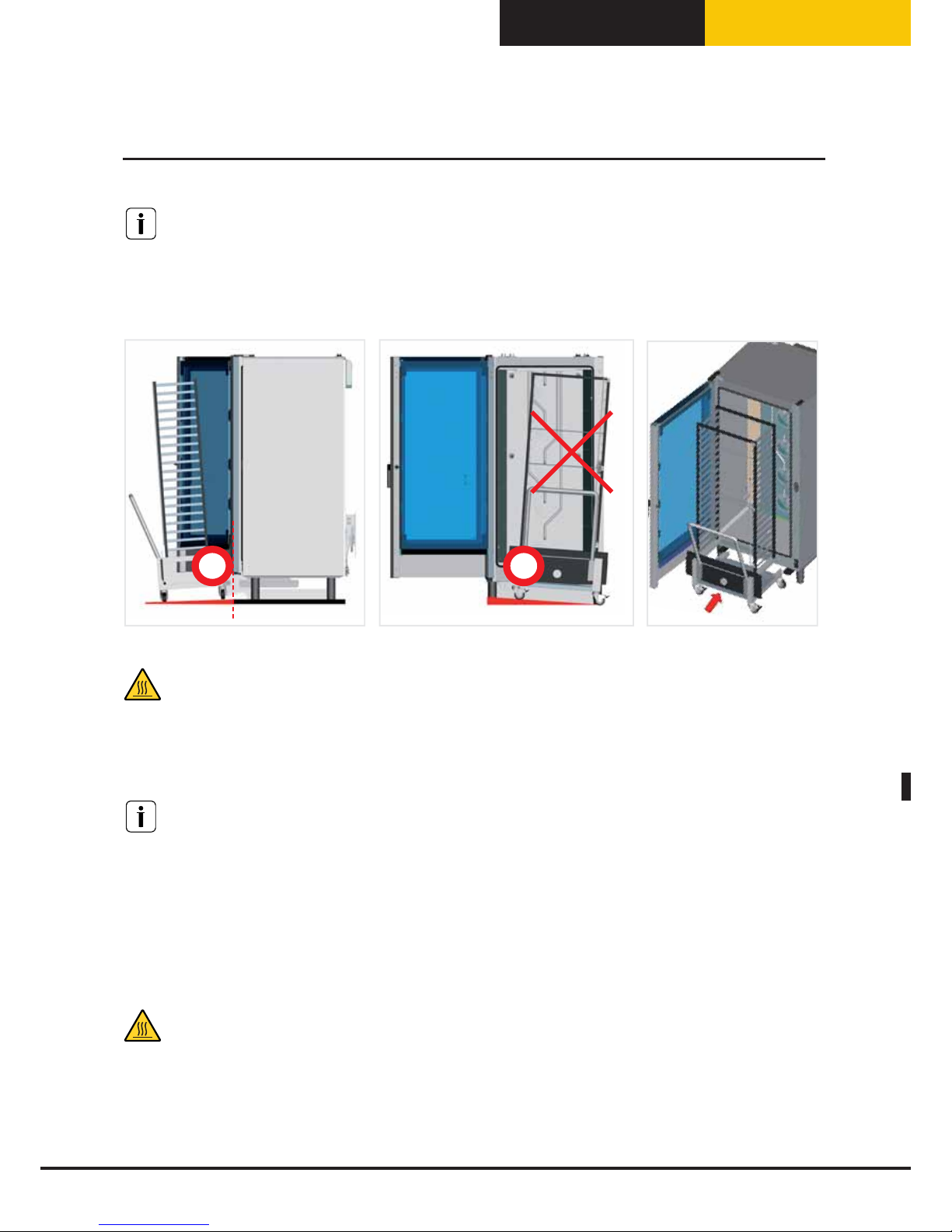

Trolley models

Preliminary action – Trolley Extraction

The trolley is positioned inside the oven and fixed with two lateral screws in order to ensure a safe

transport. Before removing the trolley, unfix the two screws as shown on the picture:

Feet adjusting for trolley inserting

To ensure the correct positioning of the trolley inside the oven it’s necessary to check and possibly adjusting

the feet height.

One of the two frontal feet must be fixed to ensure the basic height already pre setted to 173 mm. Looking

one of the frontal fixed foot the other three can be therefore adjusted. See the example bellow:

173 mm

-12

+12

Make sure that the diagonal lengths of the oven opening are identical.

If they are not, fix the adjustable feet as necessary.

Caution!

Make sure that the tray rack trolley can move easily and that there is no

obstruction when sliding it into and out of the oven: sudden movements

may result in hot liquid or food spilling out, which could cause burns.

Positioning

39

Page 40

English

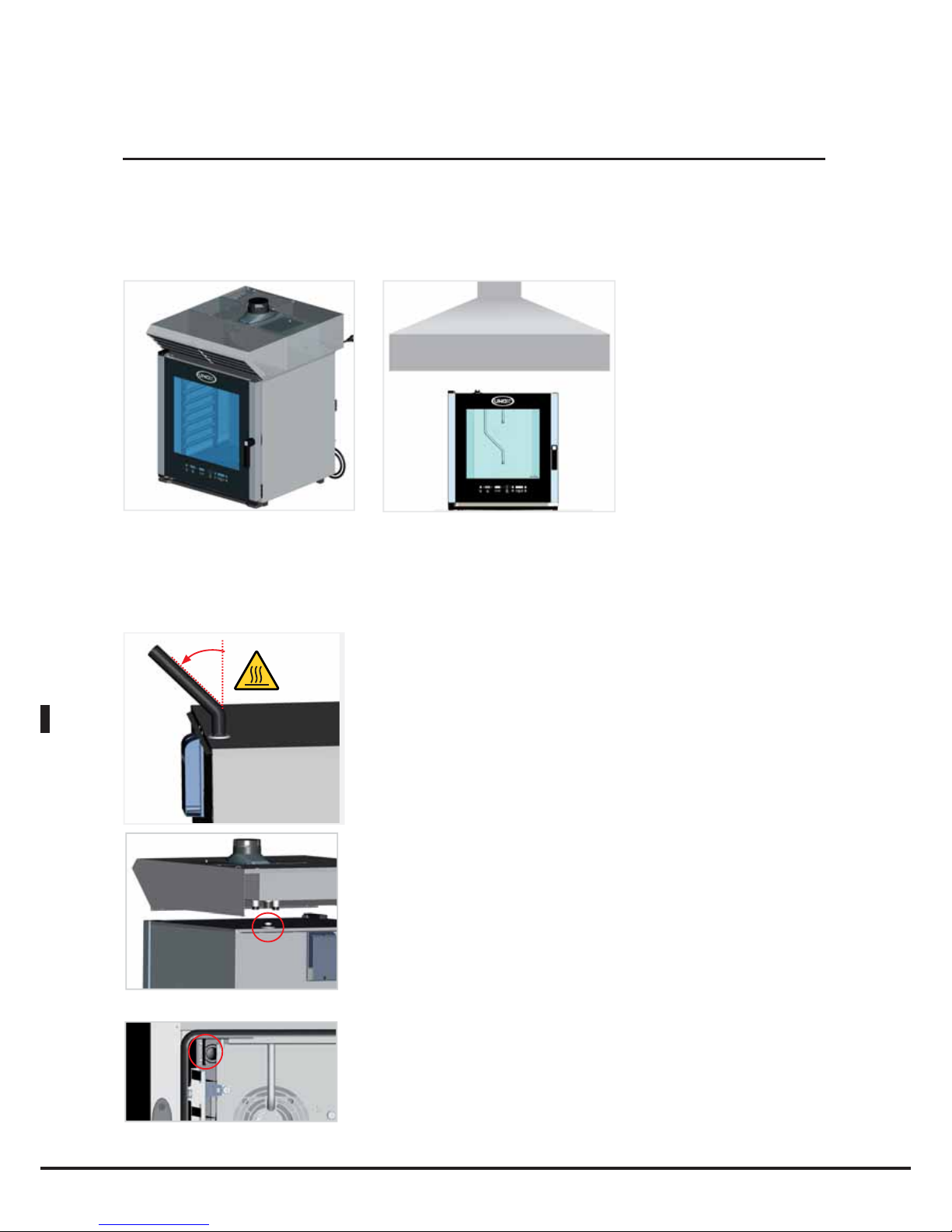

Inserting the trolley and positioning the door closure panel:

To insert the tray rack trolley into the oven, slide it in using the runners on the underside of the oven.

Caution!

The trolley may be hot, and should only be handled while wearing suiable protective garments.

On the central lower part of the oven front there is a micro switch; the oven turns of only when the trolley is

placed inside the cooking chamber or when the door closing panel is placed as described here above.

It is suggested to use the door closing panel during pre-heating or washing programs.

To the door closing panel positioning proceed as follows:

A B C D

1

3

2 4

- Open the oven door and hook the panel (1) by making the lateral holes (2) matching the hooks (3) on the

lower front of the oven (Pictures A, B, C).

- As the drip tray is full, wait for the oven to cool down, grasp the drip tray by the hand grip (4) and empty it

over the drain placed on the bottom of the oven cooking chamber (Picture D).

Caution! the drip tray back surface may be hot and cause burns.

BakerTop trolleys are not equipped with drip tray while ChefTop trolleys have the drip tray as standard

feature. For this reasong it is suggested to use the door closing panel, being equipped with a drip tray collects

the liquids that condense on the internal glass of the oven door.

40

Positioning

Page 41

English

BakerTop

™

ChefTop

™

Caution!

If the floor is not flat, use an entrance ramp with a maximum angle of 4 degrees.

Max.

4°

Max.

2°

Caution!

If the entrance ramp angle is exceeded, hot liquid may spill out of the containers.

Risk of burns!

Caution!

A tray rack trolley which has not been positioned correctly may cause the appliance to malfunction.