Page 1

OVENS

INSTRUCTION MANUAL AND

TECHNICAL DATAS

FORNI

MANUALE DI ISTRUZIONI E

DATI TECNICI

HORNOS

MANUAL DE INSTRUCCIONES

Y DATOS TECNICOS

ChefTop

™

Gas

BakerTop

™

Gas

ENGLISH

ITALIANO

ESPAÑOL

UNO

R

Page 2

ChefTop™ - BakerTop™

1

ENGLISH

INTRODUCTION

Dear Customer, we would like to thank you and congratulate you on the purchase of your UNOX “ChefTop™”-

“BakerTop™” Convection Oven and we trust this will

be the beginning of a long and lasting relationship.

As you surely know, the UNOX line ”ChefTop™” -

“BakerTop™” and all its complementary equipment

(blast chiller, holding cabinet, special trays and grids) have

been studied to allow you to carry out any cooking process, from the simplest to the most complicated.

Through the innovative digital control panel “ChefTouch”

- “BakerTouch” you will be able to control all UNOX

equipment connected to the oven.

One of the most important features are the “ChefUnox”

- “BakerUnox” AUTOMATIC COOKING PRO-

GRAMS, that will allow you to cook a wide range of different food without setting time, chamber temperature,

core temperature, etc. You simply have to select one

of the following types of cooking SLOW, STEAM, ROAST,

GRILL, and “ChefUnox” - “BakerUnox” will cook for

you delicious and tasty dishes.

“ChefTop™” - “BakerTop™” also allows you the pos-

sibility to choose six automatic cooking settings of differ-

ent product families: BAKE, BREAD, POLLO, PIZZA ITALY,

PIZZA, FRIES.

With “ChefTop™” - “BakerTop™” ovens you can also

add one or two supplementary external core probes,

equipped with extra thin needles, to make perfect vacuum and steam cooking of particularly delicate or small

food.

But the most important chef is You!

On the basis of YOUR personal needs, some of the settings of every automatic cooking process can be adjusted,

in order to let you obtain the results YOU require.

INDEX

A. INSTRUCTIONS FOR THE USER Page 02

1. WARNING Page 02

2. OVEN CLEANING Page 02

3. CONTROL PANEL “ChefTouch”- “BakerTouch” Page 03

4. COOKING PRINCIPLES Page 08

5. CONNECTION WITH THE

EXTERNAL WORLD Page 10

6. ORDINARY MAINTENANCE Page 11

7. SPECIAL MAINTENANCE Page 11

8. TURNING OFF IN CASE OF

MALFUNCTION Page 12

10. MALFUNCTIONS – PROBLEMS

CAUSES AND REMEDIES Page 13

B. INSTRUCTION FOR THE INSTALLER Page 19

1. WARNING Page 19

2. PRELIMINARY OPERATIONS Page 19

3. ELECTRICAL CONNECTION Page 21

4. GAS CONNECTION Page 22

5. WATER CONNECTION Page 24

6. DRAIN CONNECTION Page 24

7. ACCESSORIES CONNECTIONS

(PROVER, HOOD, BLAST CHILLER, ETC.) Page 25

8. REPLACEMENT OF THE DOOR GLASSES

9. OVENS STACKING Page 26

C. CERTIFICATIONS Page 26

Page 3

A. INSTRUCTIONS FOR THE

USER

1. WARNING

ATTENTION :

Carefully read this instruction manual as it provides

important information on the safe installation, operation

and maintenance of your UNOX appliance.

Keep the manual in a safe place for future reference.

In case of need of any further assistance, apply to UNOX or

UNOX service centres. The appliance must be used only for

the purpose it was expressly intended. Any other use is to be

considered improper.

The appliance can be used to:

bake all types of bread and pastry, fresh or frozen;

cook all gastronomy preparations, fresh or frozen;

regenerate refrigerated or frozen food;

steam meat, fish and all kind of vegetables.

Before using the appliance for the first time ensure that

inside the cooking chamber there are no instruction manuals, plastic bags or any other objects.

The control panel should only be operated by hand; any

other object will cause damage or malfunctioning and,

therefore, invalidate the warranty.

The appliance is not intended to be used by persons with

reduced mental, physical and sensory capacities (children

included), or without any expertise and know-how, unless they are informed about how to use the equipment

or they operate under the supervision of who is responsible for their safety.

Children should be watched to make sure they do not

play with the equipment.

At the end of the day or in case the oven is not used for

long period, close the gas cock and disconnect the oven

from the electrical power supply. Regularly air the room

where the oven is installed.

The appliance is intended for professional use and must

by used only by qualified personnel.

The external parts of the appliance must not exceed a

temperature of 60 °C.

Do not install the appliance close to external heat sources

e.g.: fryers, open burners etc.

In the case of cooking food with a very high fat content,

•

•

•

•

place a container on the bottom of the cooking chamber

to collect the fats.

WARNING

Care must be taken to avoid accidents when removing a

tray containing hot liquids.

If the tray contains hot liquids, place it inside the oven, at

a level that allows the operator to monitor it.

Pay particular attention while moving containers of hot

food during and after the cooking: the temperature can

be very high and cause burns.

Open the door of the oven slowly: to avoid burns from

the hot steam.

Use the oven at a room temperature between +5 °C

and +35 °C.

CORE PROBE

Pay particular attention while handling the core probe

inside the oven: use proper protective gloves to avoid

burns.

Do not leave the core probe outside the door of the

oven.

Extract the core probe from the food before removing the tray from the oven.

While the function “COOL” (chamber cooling) is on, the

fans of the oven work with the door of the oven open.

Installation, maintenance and repair must be carried out

by qualified and properly trained personnel. Before carrying out work on the appliance, the electrical supply to

the appliance must be disconnected.

In the event of the appliance being installed on a mobile

support, ensure that the allowed movement is sufficient

as to not cause damage to electrical cables, water pipes,

drain pipes, etc.

In this type of installation, restraining cables must be fitted.

Avoid any operation which leads to cooking salt being

deposited on the steel surfaces of the oven. Should this

happen clean thoroughly and immediately.

Avoid to overheat food such as oils, fats and similar, there

is a risk of fire.

Do not put inside the oven thermo-perishable material,

like plastic of wood.

2. OVEN CLEANING

2.1 FIRST USE OF THE OVEN

Before the first use of the appliance: clean out the oven

carefully with warm water and suitable detergent, then

rinse throughly.

Never use acids or corrosive cleaners, wire wool or

•

•

•

ENGLISH

3

2

ENGLISH

UNO

R

2

Page 4

brushes to clean either the oven chamber or the appliance cabinet.

Leave the cooking chamber empty and heat up the oven for about 30 minutes at the temperature of 200°C to eliminate any

thermic insulation smell.

2.2 CLEANING OF THE COOKING CHAMBER

It is advised to clean the cooking chamber every day in order to maintain a high level of hygiene and to avoid damage to

the stainless steel chamber. For this purpose, it is recommended to use the UNOX Rotor.KLEAN™ washing system, code

XC404, that allows an automatic cleaning of the cooking chamber.

For the manual cleaning of the cooking chamber do not use the following instruments:

• high pressure nozzles

• acidic cleaning products

• abrasive cleaning products or instruments

For the manual cleaning of the cooking chamber please apply the following procedure:

• turn on the oven

• set the temperature at 80°C and the steam at 100%

• let the oven work for ten minutes

• let the oven cool down and clean it with a cloth

If some fat residues remain inside the cooking chamber, please be advised that there is a risk of fire inside the chamber.

2.3 EXTERNAL CLEANING OF THE OVEN

Disconnect the appliance from the mains power supply before carrying out any manual cleaning operations.

Never use pressure washers or excessive water to clean the external part of the oven.

The use of wet cloths is sufficient.

WARNING

Before commencing any maintenance or cleaning operation it is necessary to disconnect the electrical supply and wait for the

appliance to cool down.

3. CONTROL PANEL “ChefTouch” - “BakerTouch”

3.1 OPERATION OF THE “ChefTouch” - “BakerTouch” CONTROL BOARD

The control board “ChefTouch” - “BakerTouch” works by touching the silk-screen printed glass (use only the finger and

no other objects such as knives, forks, etc.). in this way you can set the appliance functions and the required settings.

The advantage of this technology is to avoid any kind of mechanical movement and, therefore, to obtain an high level of reliability.

In addition, this kind of technology allows the quick and easy cleaning of the oven controls.

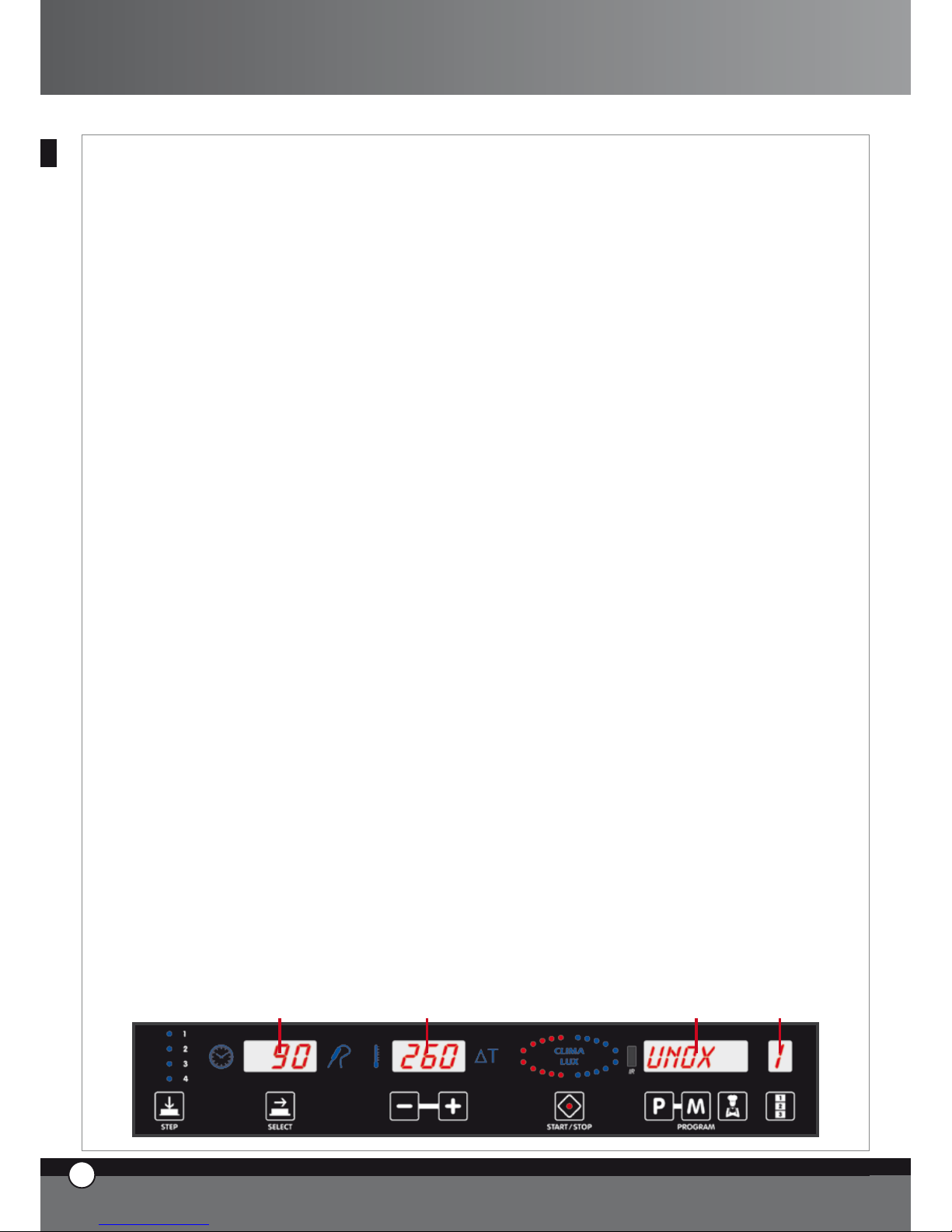

3.2 LAYOUT OF THE CONTROL BOARD

1 2 43

ENGLISH

ENGLISH

4

3

ENGLISH

ChefTop™ - BakerTop™

Page 5

3.3 POWER UP / POWER DOWN

When the power to the oven is supplied, the control

board automatically turns on.

After 15 minutes if any button is not touched and there is

no appliance in use (ovens, blast chillers, holding cabinet)

the control board goes to stand by mode : only the led

“START / STOP” is on.

To return the electronic control to full power again, sim-

ply push the button.

To have the electronic control on stand by, keep the

button pushed for 6 seconds while the control is

on; to return it to full power push the button once

more.

3.4 COOKING CHAMBER LIGHT FUNCTIONING

The lights are normally turned off; every time you touch

one of the buttons they turn on for one minute then, after

one minute, they turn off. To turn them on again, push

any of the electronic control buttons.

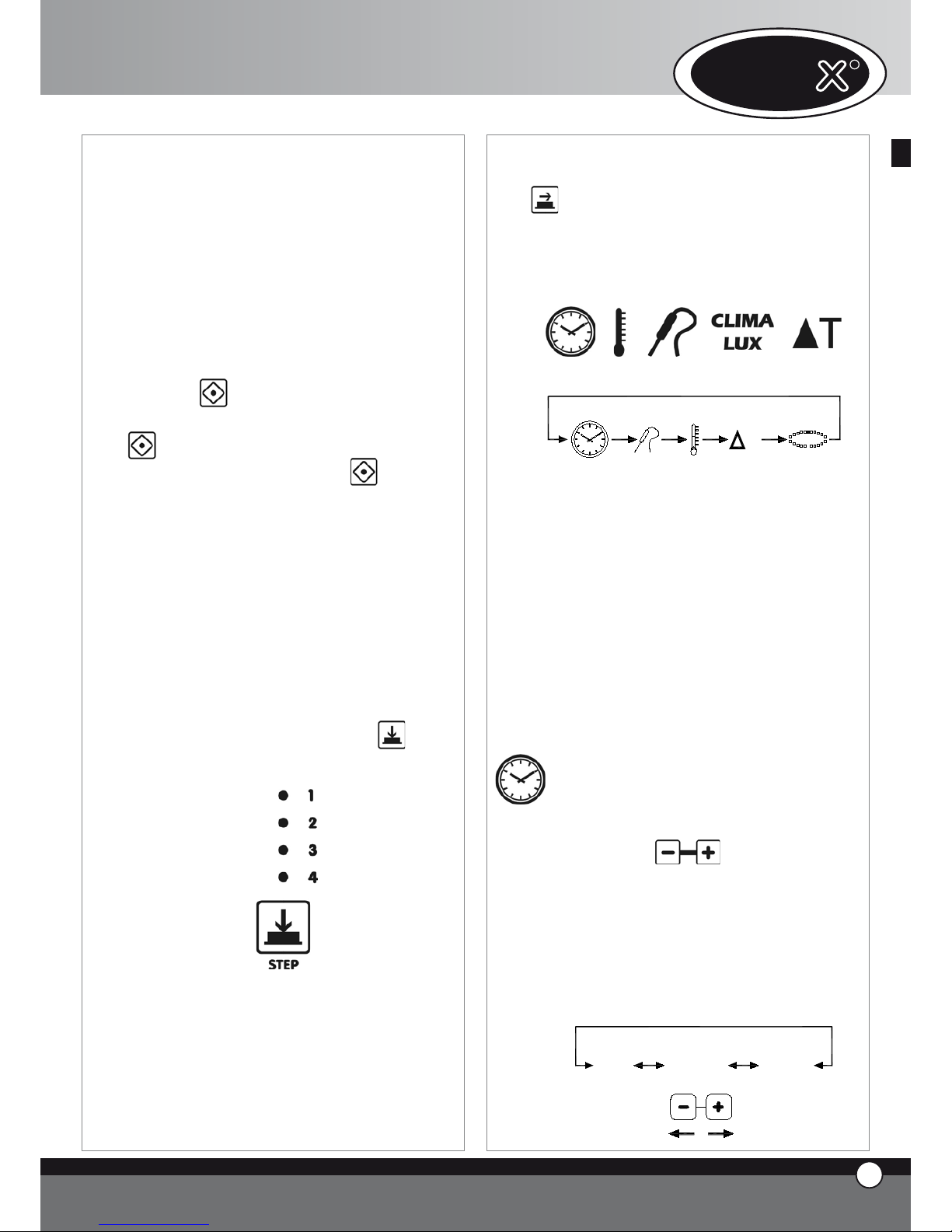

3.5 MANUAL FUNCTIONING

Any cooking program may be composed of 4 steps.

To pass from one step to another touch the button:

the selected step is indicated by the illuminated led.

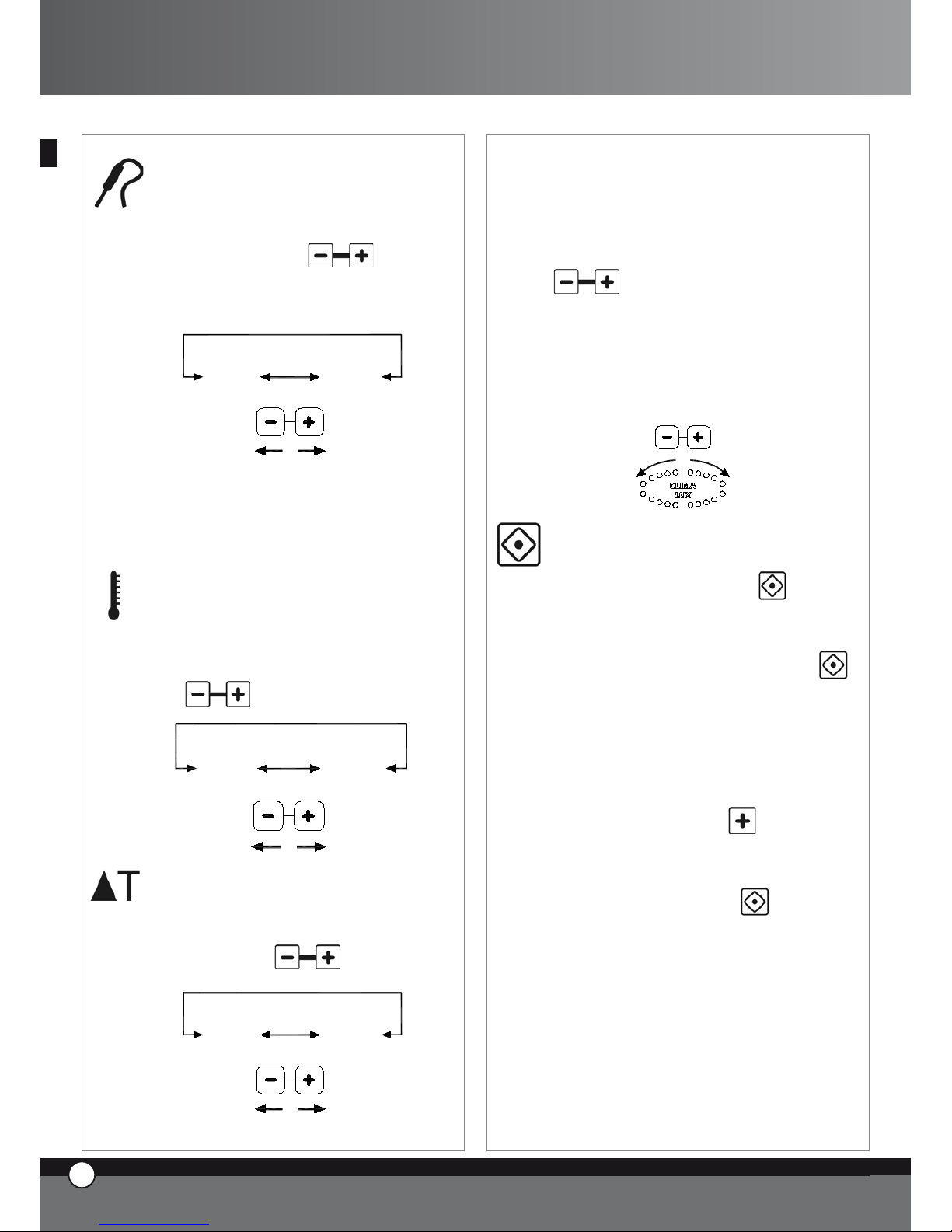

For each step the user can set the following settings:

time or, as an alternative, core temperature

chamber temperature or, as an alternative, Delta T

(available only if core temperature is set)

climate inside the cooking chamber (STEAM.Maxi™

•

•

•

/ DRY.Maxi™).

To pass from one setting to another press the

button

.

The selected setting is indicated by one of the illuminated

icons:

T

TIM E

CO RE

TE MP ER A TU RE

CA VI TY

TE MP ER A TU RE

DE LT A T

CLIM A

LUX

CL IM A L U X

Time

Core

Temperature

Cavity

Temperature

Delta T CLIMA

LUX

The settings “TIME” and “CORE TEMPERATURE” are

self cancelling: when selecting the “TIME”, the “CORE

TEMPERATURE” setting will be inoperable; vice versa, when selecting the “CORE TEMPERATURE” , the

“TIME” setting will be inoperable.

The “CHAMBER TEMPERATURE” and “Delta T” settings are also self cancelling: when selecting the “CHAMBER

TEMPERATURE”, the “Delta T” setting will be inoperable

; vice versa, when selecting “Delta T”, the “CHAMBER

TEMPERATURE” setting will be inoperable.

It is essential to select either the “TIME” or the “CORE

TEMPERATURE” setting: if none of these selections are

set, the control board does not allow the user to select any

of the following (cavity temperature, Delta T, Climate).

Time setting

The time is shown on the display panel1 and is set

with the buttons

.

When the display panel shows “inF”, the oven will

work continuously until it is manually stopped by

the user. On cooking steps 2, 3 or 4, if the HOLD

“HLD” function is selected, only when the burner is

on. Every time the fans start, the direction of rota-

tion reverses.

S T E P 1

0 h 0 0 ' 9h 5 9'

in F

ENGLISH

UNO

R

4

ENGLISH

Page 6

Core temperature setting

The core temperature is shown on display panel 1

and is set with the buttons

.

As soon as the set core temperature is reached, the

co

oking step finishes and the following step (if selected) starts.

0 °C 1 0 0 °C

External core probe kit, XC240, is available to allow

you to connect a further small core probe, suitable

to vacuum cooking and small pieces of food.

Chamber temperature setting

The temperature inside the cooking chamber is

shown on the display panel 2 and is set with the but-

tons

.

2 60 °C0 °C

Delta T setting

Delta T value is shown on the display panel 2 and is

set with the buttons

.

0 °C 1 0 0 °C

CLIMA LUX Climate setting

The setting of the climate inside the cooking cham-

ber (STEAM.Maxi™ / DRY.Maxi™) is shown

by CLIMA LUX ellipse and is set with the buttons

.

The 10 blue led’s indicate the percentage of steam

inside the cooking chamber (STEAM.Maxi™); the

10 red led’s indicate the percentage of dry air

(DRY.Maxi™).

S TE AM

M ax i

D RY

M ax i

Cooking start / stop

To start a cooking cycle touch the

button.

When the cooking starts, the led “START STOP”

turns on.

To stop the cooking cycle touch the button

.

When the cooking cycle has finished, both in ma-

nual and program mode, the oven makes an audible

alarm for 15 seconds and the display 1 flashes for 45

seconds. During this 45 seconds time the “START /

STOP” led remains on:

if you touch the button

you increase the

set cooking time. The oven automatically starts

again (with the last cooking cycle settings)

if you touch the button

the “START /

STOP” led turns off and all settings are reset.

if none of the buttons are touched, after 45 sec-

onds have passed, “START / STOP” led turns off

and all settings are reset

•

•

•

ENGLISH

5

ENGLISH

ChefTop™ - BakerTop™

Page 7

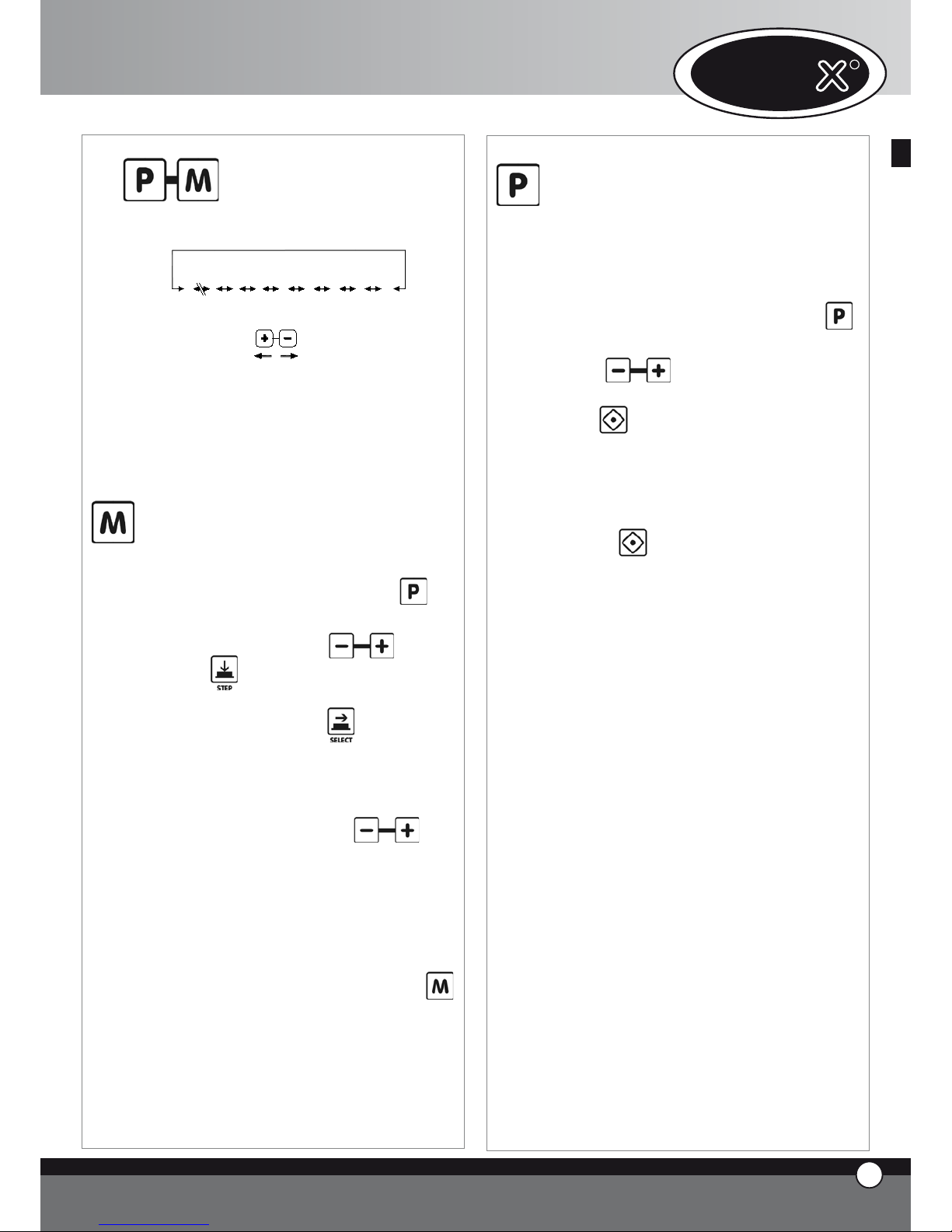

3.6

Working with programs

LP UM P

L3

L2

L1

P0 1

P7 0

P0 2

P0 0

CO O L

The electronic control board allows the user to set,

and select, up to 70 cooking programs.

The electronic control board is already set with the

cooling program (COOL) and the cooking chamber

washing programs (L1, L2, L3, LH2O), for use with

the automatic washing system XC404 if connected.

Program setting - by the user

To set a program proceed as follows:

• the first display shows “Prg”, by pushing but-

ton it is possible to select the type you need to chan-

ge; to change the type push buttons.

• push button and the first display on your

left will show “PRE” message and all the 4 step

leds turns off. By pushing button, you set

the temperature as absolute value or as difference:

the backlighted chamber temperature icon or the

backlighted Delta T icon turns on, and you can set

the required value by pushing

but-

tons.

• select the required cooking settings (time, core

temperature, cavity temperature, Delta T, clima-

te); as for manual working, every cooking pro-

gram can be composed by 1 to 4 steps

• to save the program press and hold the

button for 5 seconds (after 5 seconds have pas-

sed you will hear a bleep) the program is now

saved.

ENGLISH

7

ENGLISH

UNO

R

6

ENGLISH

Use of saved programs, cooling pro

-

gram

To call up a program saved by the user, the cooling

program or a washing program follow the procedure below :

• enter program mode by touching the button

• select the required program by touching the but-

tons

• start the selected program by touching the but-

ton

• when the selected program starts, the led “START

STOP” turns on

• while the cooking program is in operation it is not

possible to modify the program settings.

• it is possible to stop the program by touching the

button

When you start the cooking program, the oven starts

the pre-heating phase: the cooking chamber is heated up to 30°C more than the chamber temperature originally set in the first cooking step. While the

pre-heating phase is on, all the leds and display panels remain turned off apart from: “START / STOP”

led, the display panel 1 which shows the message

“PRE”, and the display panel 3 which shows the selected program. When the required temperature is

reached (step 1 chamber temperature + 30°C) the

oven will make a continuous audible bleep and the

display panels show the settings of the first cooking

step. After you’ve opened the door of the oven,

loaded the food and closed the door, the cooking

program automatically starts.

Once the cooking cycle is finished, both in manual

and programmed mode, if you push “P” button the

5 types display will show “LASTP” message: by pushing “START / STOP” button last cooking cycle

that was used will start again.

Washing programs

The control board is pre-set with 3 washing programs (L1 short, L2 medium, L3 long) + a rinsing

program LH2O + a program for the pre-loading of

the detergent and rinse aid pumps. (LPUMP).

Page 8

Cooking chamber cooling down program

“COOL”

“COOL”, this program is used for cooling down the

cooking chamber, it allows the fans inside the chamber

to rotate whilst the heating elements remain off. The

program works also with the door of the oven open.

While “COOL” program is working, the display shows

cooking chamber temperature.

Important!

It is not possible to remove the fan guard without

the proper removal tool, thanks to the presence of

a fixing screw. If it is necessary to remove the fan

guard for service, do not forget to disconnect the

appliance from the electrical supply.

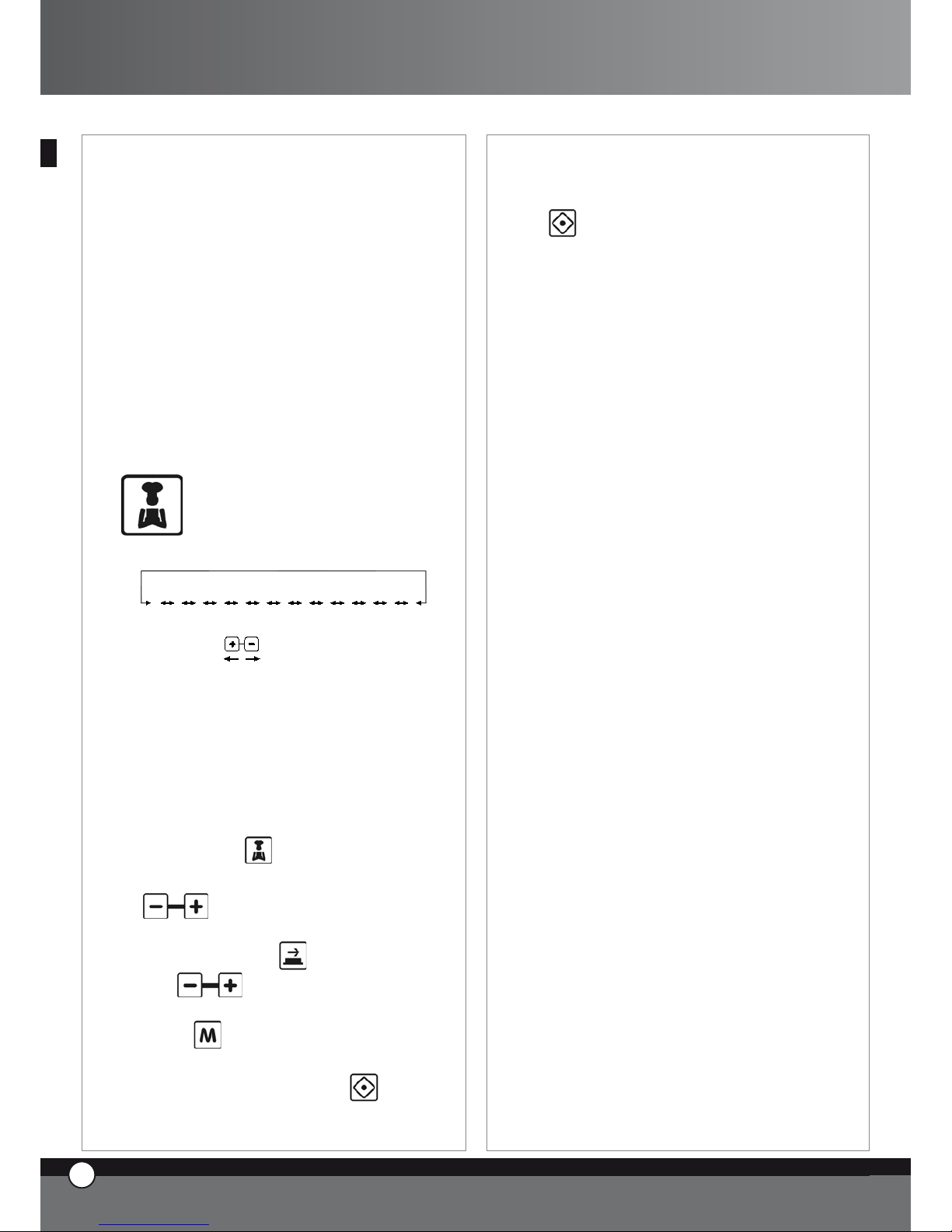

3.7

“ChefUnox™” - “BakerUnox™”

COOKING CYCLES

PIZ ZA

BR EA D

BA KE

PO LL O

FR IE S

ST EA M

ST EA M PR B1

RO AS T

GR IL L

SL OW

VA CU O

RE GE N

PIZ ZA IT AL Y

The electronic control board “ChefTouch™” - “BakerTouch™” is programmed with a series of automatic

cooking cycles pre-set at the UNOX factory: by simply

selecting the required cooking cycle, it is possible to automatically cook an endless range of food.

For every cooking program, you have the possibility to

modify some of the settings in order to personalise the

required cooking results.

To use one of the pre-set programs, proceed as indicated below:

touch the button

select the required program by using the buttons

it is possible to modify the value of the flashing set-

ting by touching the button and, afterwards,

the

buttons (If this new value needs to

be saved in the selected cooking program, touch and

hold the button for 5 seconds until you hear the

confirmation bleep).

start the program by touching the button

when the program starts, the led “START / STOP”

turns on

•

•

•

•

•

while the cooking program is in operation it is not

possible to modify the program settings.

it is possible to stop the program by touching the

button

AUTOMATIC COOKING PROGRAMS FOR DIFFERENT PRODUCTS

“PIZZA ITALY” Cooking program

Progr am for the cooking of “thin” based pizza.

Variable setting: cooking time.

It is recommended to use the UNOX “FAKIRO™” plate

TG860 especially studied for this purpose by Unox.

“PIZZA” Cooking program

Program for the cooking of “thick” based pizza.

Variable setting: cooking time.

“PANE” Cooking program

Program for the cooking of bread and similar products.

The core probe is used to check the cooking level of the product.

Variable setting: core temperature, in order to obtain a variation in the finished product.

“BAKE” Cooking program

Program for the cooking of pastry products.

The core probe is used to check the cooking level of the

product.

Variable setting: core temperature, in order to obtain a variation in the finished product.

“POLLO” Cooking program (only for ChefTop™ series)

Program for the cooking of roast chicken, poultry and

game.

Variable setting: core temperature, in order to obtain a variation in the finished product.

The program is composed by a pre-heating step at 210°C

and in 4 steps with temperature from 180 to 250°C.

It is recommended to use the UNOX “Pollo” grid

GRP810, especially studied for this purpose by UNOX.

“FRIES” Cooking program (only for ChefTop™ series)

Program for the cooking of french fries.

Variable setting: core temperature, in order to obtain a variation in the finished product.

•

•

ENGLISH

8

ENGLISH

7

ENGLISH

ChefTop™ - BakerTop™

Page 9

It is recommended to use the Unox “NoFry” tray

GRP815 especially studied for this purpose by UNOX.

AUTOMATIC COOKING PROGRAMS FOR

DIFFERENT TYPE OF COOKING

“REGEN” Regeneration program (only for ChefTop™ series)

Regeneration program allows the user to regenerate previously cooked and preserved foods.

Variable setting: time of the regeneration process.

“VACUO” Cooking program (available only if the exter-

nal core probe kit XC240 is connected) (only for

ChefTop™ series)

Program for the cooking of vacuumed food.

Variable setting: core temperature in order to adapt the

cooking to different kinds of food.

The use of the very thin core probe XC240 avoids damage to the plastic vacuum bags.

“STEAM” Cooking program (only for ChefTop™ series)

Suitable for meat, fish, vegetables and other products.

Variable setting: core temperature, in order to obtain a variation in the finished product

With this cooking program the fans inside the cooking

chamber turn only clockwise (there is no reversing gear).

(there is no reversing gear).

The amount of water released inside the cooking chamber depends on the set temperature: higher is the temperature, lower is the quantity of water. The oven automatically calculates the right amount of water to release

on the basis of the set temperature.

“STEAM PRB1” Cooking program (available only if the

external core probe kit XC240 is connected) (only

for ChefTop™ series)

The external core probe is required.

Suitable for delicate or small products such as sausages,

fish and steamed vegetables thanks to the use of the external core probe which checks the cooking level.

Variable setting: core temperature, in order to obtain a variation in the finished product

With this cooking program the fans inside the cooking

chamber turns only clockwise (there is no reversing gear).

“SLOW” Cooking program (only for ChefTop™ series)

The core probe is required.

Suitable for slow cooking at low temperatures, ideal for

ENGLISH

UNO

R

8

ENGLISH

large joints of meat.

Variable setting: core temperature, in order to obtain a variation in the finished product from rare to well done, when

the cooking has finished, the product is maintained at a temperature of 70 °C.

“ROAST” Cooking program (only for ChefTop™ series)

The core probe is required.

Suitable for the cooking of roast meat or fish.

Variable setting:. core temperature, in order to obtain a variation in the finished product

It is recommended to use the UNOX “Black” tray

TG835 especially studied for this purpose by UNOX.

“GRILL” Cooking program (only for ChefTop™ series)

Suitable for grilling of meat, fish and vegetables.

Important note: to cook fish it is suggested to use the

ROAST++ cooking program.

Variable setting: core temperature, in order to obtain a variation in the finished product from rare to well done

It is recommended to use the UNOX “FAKIRO™ Grill”

plate TG845 especially studied for this purpose by UNOX.

3.8

MANAGEMENT OF MULTIPLE

APPLIANCES USING THE SAME

CONTROL PANEL

The digital control panel “ChefTouch” - “Baker-

Touch” allows the user to control a variety of UNOX

ChefTop™ - BakerTop™ appliances connected to

the oven. In addition , the introduction of the MASTER

& SLAVE system allows the management , with a single

digital control, multiple ovens. The oven that is used to

control all other appliances, becomes the MASTER oven.

The ovens controlled by the MASTER oven become

SLAVE ovens, and their digital control is inactive. The

MASTER and SLAVE digital control boards are, in case of

emergency, interchangeable.

The selection of the appliance to control is made with the

button and the controlled appliance is shown by the

display panel 4.

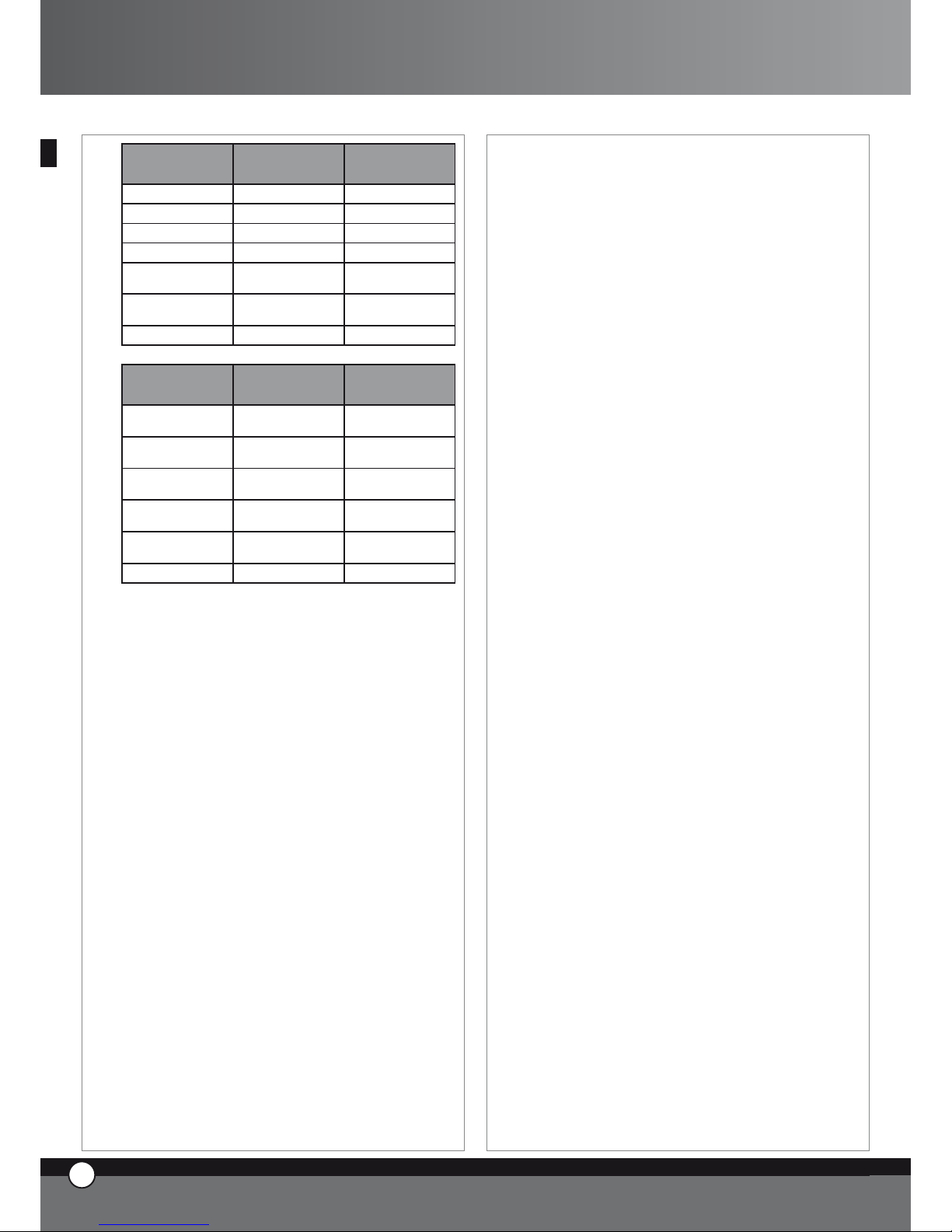

Number – corrensponding appliance chart

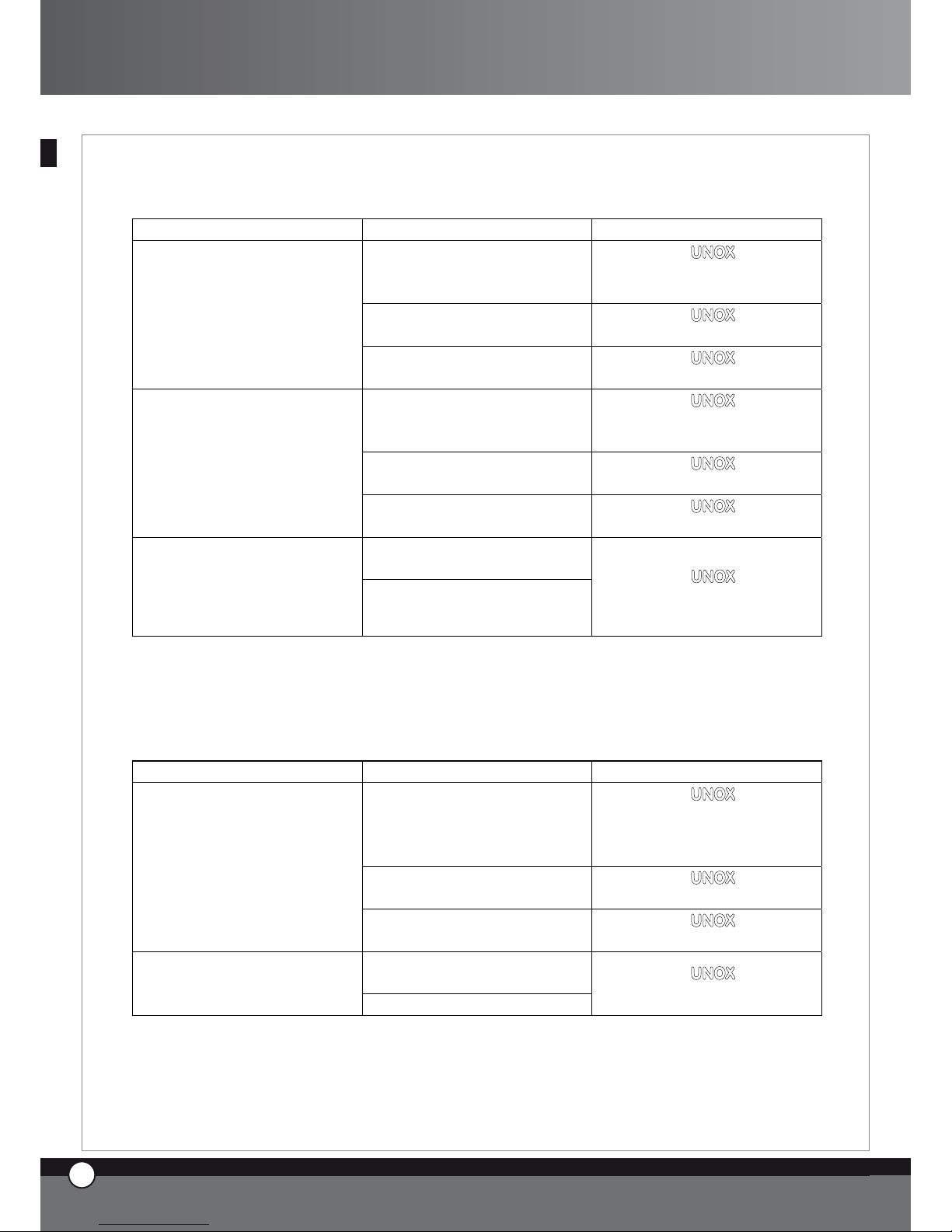

Page 10

Appliance

number

Appliance

code

Device

1 ChefTop™ Oven - master

2 ChefTop™ Oven - slave 2

3 ChefTop™ Oven - slave 3

4 XK304 Blast chiller

5 XL314

Holding cabinet

7 XC 314 Hood

8 XC224 Reverse osmosis system

Appliance

number

Appliance

code

Device

1

BakerTop™ Oven

- master

2

BakerTop™ Oven

- slave 2

3

BakerTop™ Oven

- slave 3

5 XL 404

Prover

7 XC 414 Hood

8 XC224 Reverse osmosis system

When installing UNOX appliances in a column, this kind of

technology allows the user to work in a very ergonomic

way, by using the same working logic.

4. COOKING PRINCIPLES

4.1 Cooking variables

Time

This variable depends a lot on the quantity of food you

put in the oven.

The larger the quantity of food, the longer the cooking

time and vice versa.

A shorter cooking time than that required by the food

results in the food being under cooked. A longer cooking

time than that required by the food causes the burning of

the food surface.

Cavity temperature

The exact setting of the temperature inside the cavity

guarantees a proper cooking of the food, both inside and

outside.

A lower temperature than the proper one dries the

food rather than cooking it.

A higher temperature than the proper one burns the

surface while the core remains uncooked (sometimes

this result is desired, especially with meat).

Hot dry air

Hot dry air system “DRY.Maxi™”, patented by UNOX,

•

•

allows the user to extract the humidity, created by the

product while cooking, from the chamber, thus maintaining a dry environment. In this way the product becomes crispy and crumbly outside (for example: bread,

croissants), while the internal part is dry with an even

structure.

Steam

The introduction of the variable steam (STEAM.Maxi™)

and its different combinations with the temperature allow different types of cooking:

steaming (only steam);

mixed convection-steam cooking (air + steam).

4.2 Chef’s suggestions for even cooking

Preheating

It is always better to pre-heat the oven to a temperature

at least 30-50°C higher than the one required for cooking, in order to reduce the effects of heat loss due to the

opening of the door.

Type of trays and pans

To obtain a perfect cooking quality and an even browning

of the product, it is better not to use high sided containers,

as they do not allow the correct circulation of hot air.

Free space between pans

For even cooking it is important to check that you have

at least 3 cm of free space between the product and the

upper pan.

Quantity of food

To obtain the best results it is important not to overload

the oven, and to check, in the case of bread and pastry,

the orientation of the food on the trays compared with

the air flow.

Core probe positioning

For its correct functioning, it is essential to insert the core

probe, from the top to the bottom, in the thickest part of

the product, until you reach the centre.

In case of foods with reduced thickness, the core probe

should be inserted horizontally to the support surface.

IMPORTANT

Convection ovens need lower cooking temperatures (2040°C less) than those normally used in static ovens.

Pay attention when opening the door!!!

Heat and steam could cause burns.

4.3 Convection cooking

Temperatures from 30°C to 260°C

Convection cooking is done by hot dry air that circulates

around the oven chamber. This allows the heat to be perfectly

distributed, consequently, it is possible to have even cooking.

•

•

ENGLISH

10

ENGLISH

9

ENGLISH

ChefTop™ - BakerTop™

Page 11

The results are perfectly cooked food both on the surface, with a golden crust, and internally.

Suitable for: Cooking au gratin, Roasting and Grilling.

Advantages: Possibility to cook at the same time different

types of food such as vegetables, meat, fish, without the

cross transfer of flavours (as long as the required cooking

temperature is the same for all the cooked dishes).

Foods with free running juices should always be placed at

the bottom of the oven chamber.

4.4 Mixed Steam-Convection Cooking

Temperatures from 30°C to 260°C

Steam from 30% to 90%

The cooking is made by the combination of hot dry air and

steam, evenly distributed inside the chamber. It is surely

the most profitable and efficient of the cooking methods

used today. Cooking times and weight loss are considerably reduced. At the same time, the food remains tender

and flavoursome.

Suitable for: Roasting meats, Braising, Stewing,Cooking

of Fish.

Chef’s suggestions:

For roasting it is better to use a perforated pan or a grid,

this way it will not be necessary to turn the food continually.

By placing a non-perforated pan on the bottom of the oven

chamber,you will be able to collect the meat juices.These

can be used at a later time to make a stock,gravy or sauce.

4.5 Steaming

Temperature from 48°C to 130°C

Steam 100%

The use of ventilated steam is one of the most delicate

ways of cooking food. With this kind of cooking the food

does not lose any liquid; therefore the nutritional contents, the appearance and the weight of the food remain

unaltered.

Suitable for :

Low temperature steaming: Vegetables, Fruit,

Fish,Terrines, Soufflés, Pâtés, Vacuum-Cooking.

Steaming: Vegetables, Fruit, Eggs, Meat,

Fish,Seafood.

Intensive steaming: Potatoes,Root Vegetables

Chef’s Suggestions:

To cook leaf vegetables with steam, it is suggested to initially slightly

moisten the food, in order to avoid the drying out of the leaves.

In addition, to avoid the dispersion of the food, inside the

chamber due to air flow, you can use two baskets (No Fry,

one as a base and another, turned upside down, as a cover).

•

•

•

ENGLISH

11

ENGLISH

UNO

R

10

ENGLISH

4.6 Convection Baking

Temperature from 30°C to 260°C

Convection baking is done by hot dry air that circulates

around the oven chamber. This allows the heat to be perfectly distributed, consequently, it is possible to have even

baking results at all the points of a single pan and on all

the pans. Even baking is also guaranteed when the oven

is fully loaded.

Pastry is perfectly baked both on the surface, with a golden crust, and in the internally, with a uniform structure

and a constant residual humidity.

Suitable for:

Baking of Short Pastry, Puff Pastry, Tart Pastry,

Ccream-puff Pastry

Baking of Sponge cake

Baking of Cookies

Chef’s suggestions:

To obtain the best results in pastry it is necessary to have

a higher distance between the trays, and a higher distance

between the products on the trays.

For products with a light mass ie; meringues it is preferable

to use the air reduction kit, in order to prevent their movement on the trays.

4.7 Convection + Humidity Baking

Temperature from 30°C to 260°C

Humidity from 10% to 20%

The baking is made by hot air with the addition of a variable percentage of humidity, according to the type of food

that has to be baked.

Suitable for:

Baking of leavened dough, such as bread

Baking of sponge cakes, panettone, croissants ,pain

au chocolate.

Chef’s suggestions:

The use of the humidity at the beginning of the baking makes

leavening easier; subsequently, the humidity should be reduced, or even completely eliminated, to obtain the final

crispness and golden surface.

4.8 Convection + Dry Air Baking

“DRY.Maxi™” System (UNOX Worldwide Patent)

Temperatures from 30°C to 260°C

Dry air from 10% to 100%

This is an innovative system that allows the humidity, generated by the product when baking, to be extracted from

the chamber, thus maintaining a dry environment.

The product, thanks to its dry and even internal structure, appears crispy and crumbly.

Suitable for:

Baking of Croissants

Baking of Cookies

Baking of Bread

•

•

•

•

•

•

•

•

Page 12

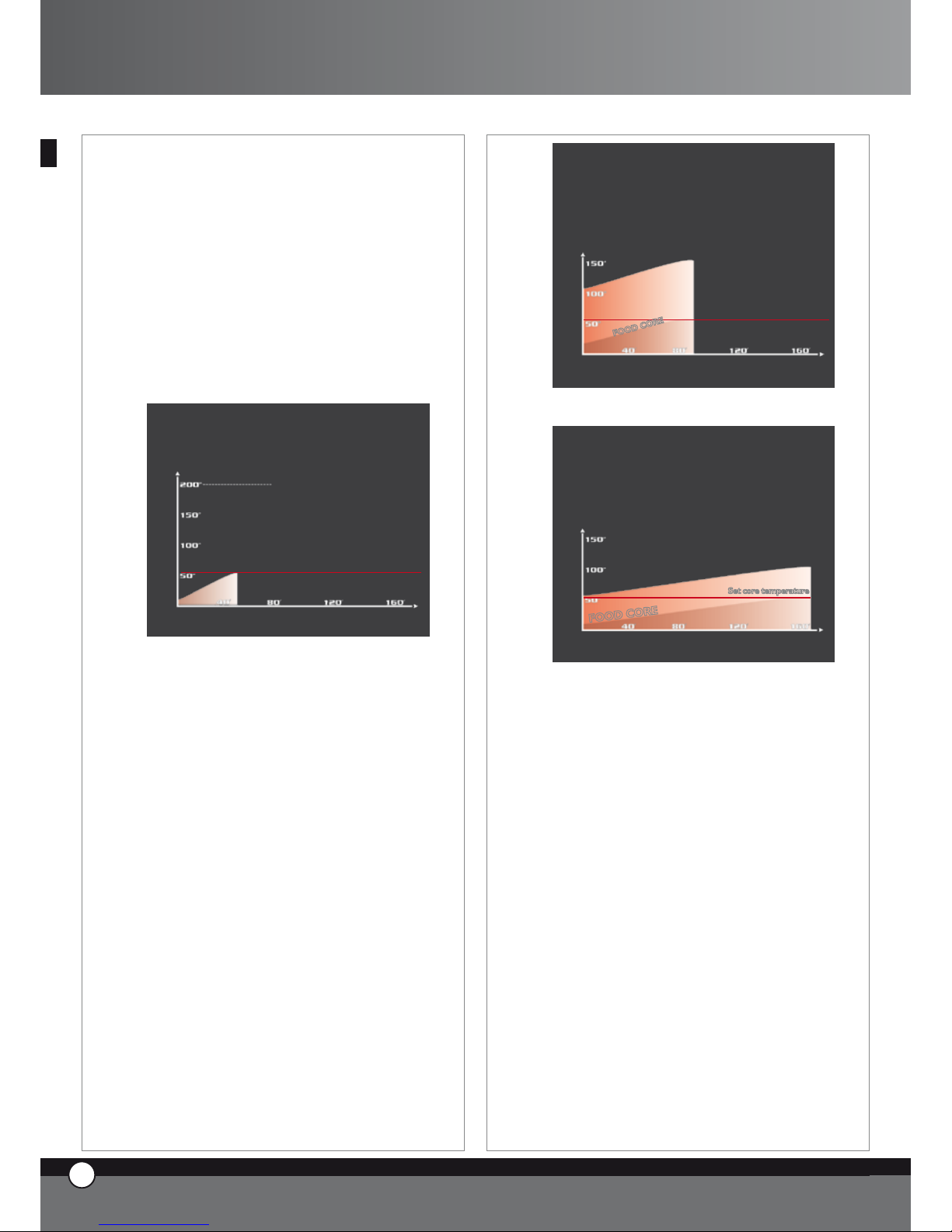

4.9 Cooking with Core Probe + Chamber Temperature

With this kind of cooking, the core temperature and the

chamber temperature have to be set.

The core probe measures the rise of the temperature

inside the product during the cooking process, the end

of the probe has to be inserted in the thickest part of the

food in the centre.With this system, it is no longer necessary to set the time, the oven, will automatically turn off

when the set core temperature is reached, or it will pass

to the following programmed step.

Core Probe cooking is useful to optimise the cooking of

different foods and avoid to continuously checking the

food during its various cooking stages.

Core probe + 100°C ∆T

Sonda al cuore + ∆T a 100°C

Core probe + Cavity temperature

cavity

Set core temperature

C

A

V

I

T

Y

Time in minutes

Temperature

4.10 Cooking with Core Probe + Delta T

In this case you have to set the desired temperature

at the core of the food and the Delta T (difference between the core and the chamber temperature)

CHAMBER TEMPERATURE =

CORE TEMPERATURE + SET DELTA T

In this way the chamber temperature will increase gradually, keeping the difference between the product core

temperature and the chamber temperature you set constant during the cooking cycle. This kind of cooking will

allow you to obtain very soft and delicate cooking, especially useful for large joints of meat.

ENGLISH

11

ENGLISH

Core probe + 100°C ∆T

C

A

V

I

T

Y

Time in minutes

Temperature

Set core temperature

F

O

O

D

C

O

R

E

Core probe + 50°C ∆T

F

O

O

D

C

O

R

E

C

A

V

I

T

Y

Set core temperature

Time in minutes

Temperature

5. CONNECTION WITH THE EXTERNAL

WORLD

The digital control panel of the “ChefTop™” -

“BakerTop™” ovens has been preset to easily connect

the oven to the external world through the present and

future systems of communication: USB, Bluetooth, serial

connections, etc.

The USB interface kit XC226 is available, and allows the

following functions:

Insertion of cooking programs.

Changes in operational parameters (ex: probe setting).

Diagnostics of problems.

Saving of the trends with regard to temperatures

inside the oven chamber or inside the blast chiller

chamber (necessary data for HACCP system)

Connection to a printer (HACCP)

You can find further information included in the kit.

•

•

•

•

•

11

ENGLISH

ChefTop™ - BakerTop™

Page 13

ENGLISH

12

ENGLISH

UNO

R

12

ENGLISH

6. ORDINARY MAINTENANCE

The appliance must be regularly serviced (at least once a

year) by a qualified UNOX service technician.

Any maintenance operations must be carried only by a

qualified UNOX technician.

Before starting any maintenance operation, it is necessary

to disconnect the appliance from the electrical power

supply and allow it to cool down.

The service is needed on:

Combustion

To check if the combustion is correctly made an unburnt

meter (like TESTO 300M or similar) is required. In the

combustion exhaust fumes the percentages of CO in ppm

and of CO2 must be below the maximum values allowed

by the regulations (approx. the CO value must be below

300 ppm).

If the CO value is over le maximum level allowed, proceed with the further check over described here below

to find out the cause of the problem.

Condition of the of the burner flame surface

Remove the burner box from the back of the oven, open it

by removing the upper cover and check the burner surface

is clean and free from any dirt by.

Check the burner surface is not damaged or cracked, otherwise, in case of damage, it is necessary to find out and remove the cause of the problem (too high gas pressure, gas

injector not suitable for the type of gas on use, oven placed

on a non flat surface, water leakage on the burner surface,

etc.) and to have immediately the burner replaced.

Condition of the heat exchanger

Check the heat exchangers are not strained, cracked or

damaged, otherwise it is necessary to remove the cause

of the damage (too high gas pressure, gas injector not

suitable for the type of gas on use, oven placed on a non

flat surface, water leakage on the burner surface, etc.)

and to have immediately the heat exchangers replaced.

Condition of the baffles

Check the baffles are not damaged or cracked by taking

them out from the heat exchangers and check also there

is no soot on them. In case of cracks or soot on the baffles

it is necessary to find out and remove the cause (too high

gas pressure, gas injector not suitable for the type of gas

on use, oven placed on a non flat surface, water leakage

on the burner surface, etc.) and to have immediately the

baffles replaced.

Once the check over and the replacements described

here above have been made repeat the check on the

combustion.

6.1 REPLACEMENT OF THE INTERNAL LAMP

To replace the internal lamp:

disconnect the appliance from the power supply and

allow it cool down.

remove the lateral supports

unscrew the glass cover and replace the lamp with

one with the same characteristics.

Inspect the lamp glass seal and replace if required.

screw the glass cover back in

reassemble the lateral supports

7. SPECIAL MAINTENANCE

All maintenance operations must be only be carried out

by a qualified UNOX technician.

Before starting any maintenance operation it is necessary

to disconnect the appliance from the electrical power

supply and allow it to cool down.

Removal of the back panel will allow access to all internal

components for service and maintenance.

•

•

•

•

•

•

Page 14

ChefTop™

7.1 RESETTING OF THE SAFETY THERMOSTAT

The appliance is supplied with a safety thermostat with a

manual reset. This safety thermostat is needed to protect

the appliance from overheating. When activated, close

gas supply to the burner and the display panel shows the

message “EF4”.

This safety device can be found on the bottom part of the

back panel of the oven: to reset the thermostat,remove

the black cover and push in the small central pin.

If the safety thermostat activates again, contact your nearest UNOX service centre.

7.2 RE-SETTING OF THE LIGHTER DEVICE

In case the burner stops the display 1 shows “GAS”

message, the button flashes and the buzzer bleeps:

it is necessary to push button and wait for the burner

to light again.

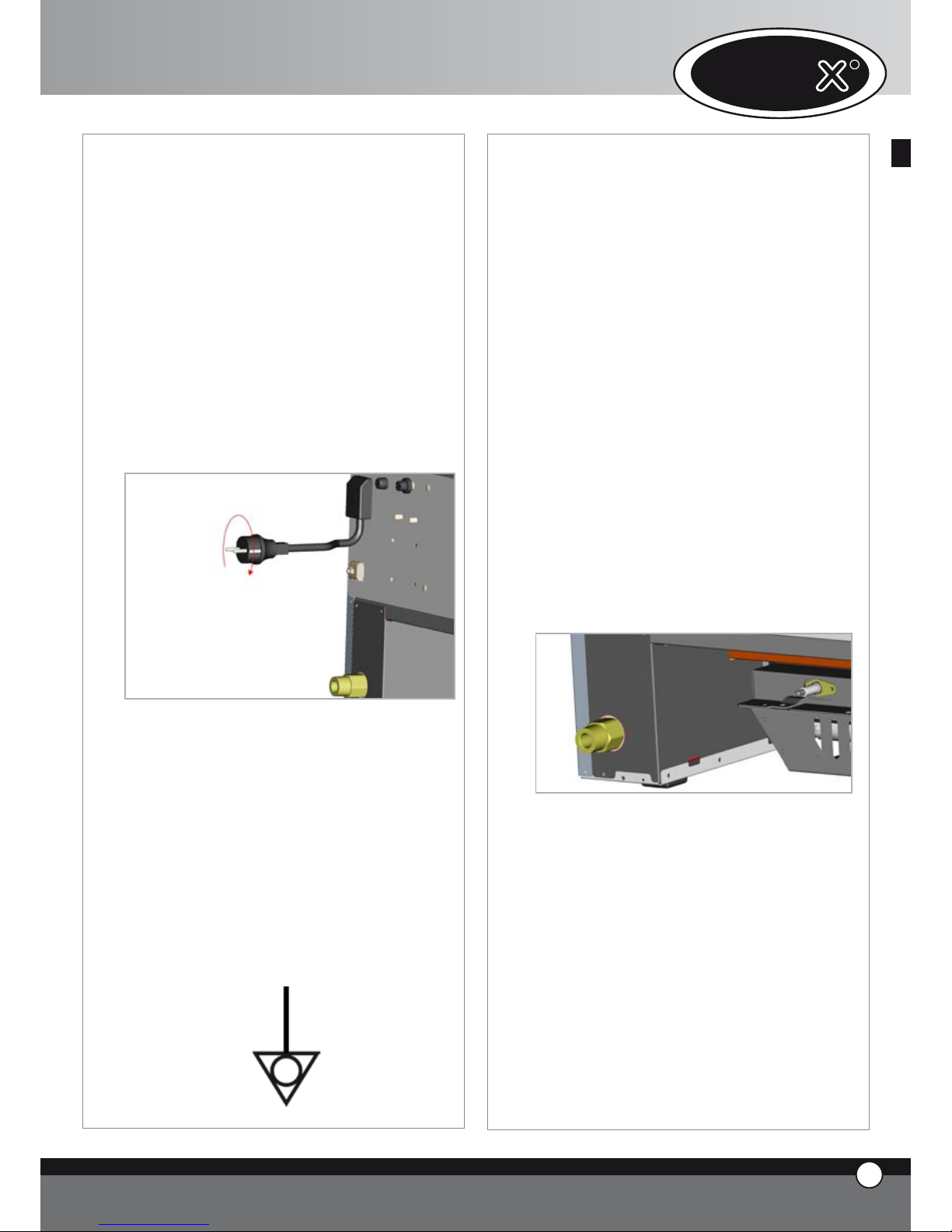

7.3 REPLACEMENTE OF THE FLAME CONTROL FUSE

In case the burner starting system does not work, it is

necessary to check the flame control fuse is not burnt. If

this is the case, the fuse must be replaced.

The flame control fuse is placed on the back of the oven,

below the round black cap indicated by “FUSE” plate.

ENGLISH

11

ENGLISH

WARNING!! Disconnect the oven from the electric

supply before removing the fuse!

To replace the fuse proceed as follows:

• open the round black cap by pushing it and at the same

time turn it counter clockwise of around 20 degrees

• remove the cap of the fuse holder

• remove the fuse from the fuse holder cap

• replace the fuse with a new one with similar technical

characteristics (Fast 1,6A – 250V)

• place the fuse holder cap back

• close the round black cap by pushing it and at the same

time turn it clockwise of around 20 degrees

8. TURNING OFF IN CASE OF

MALFUNCTION

In case of malfunction it is necessary to disconnect the

appliance:

switch off the electrical power supply isolator switch,

that is between the appliance and the network.

close the gas cock

contact your nearest UNOX service centre.

•

•

•

13

ENGLISH

ChefTop™ - BakerTop™

Page 15

ENGLISH

12

ENGLISH

UNO

R

14

ENGLISH

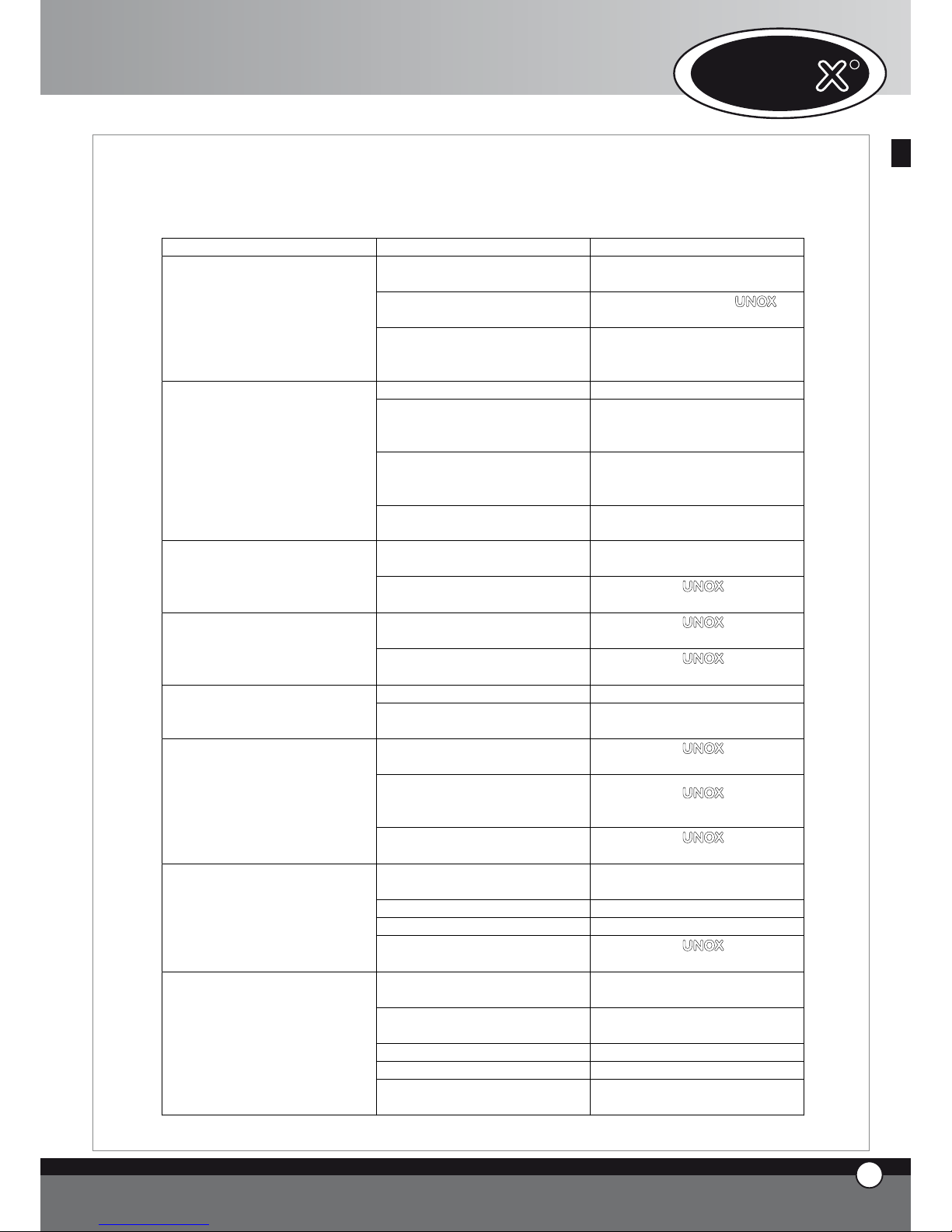

9. MALFUNCTIONS – PROBLEMS CAUSES AND REMEDIES

The guide below will help the user rectify minor faults.

BREAKDOWN CAUSE SOLUTION

The supply mains voltage is

missing

Restore the voltage

Intervention of one of the fuses on

the power board

Apply to a qualified UNOX

technician for service

The oven is completely turned off

The electrical connection to the

mains has not been made in the

correct way

Check the connection of the

appliance to the mains

The water inlet valve is closed Open the water inlet valve

The connection to the water

supply or to the tank has not been

made in the correct way

Check the connection to the

water supply or to the tank

The tank is empty (in case the

appliance is connected to an

external tank)

Pour water in the tank

The humidity control of the oven

is on, but the water does not

come out of the pipes

The filter on the water inlet is

blocked

Clean the filter

The door of the oven is open or

not properly closed

Close the door in the correct way

The oven does not start even

though you have set the time or

the core temperature and pressed

START / STOP button

Damaged door magnetic micro

switch

Apply to a UNOX qualified

technician for service

Damaged door seal

Apply to a UNOX qualified

technician for service

There is water coming out though

the door and the sealing even

though the door is closed

Loose door mechanism

Apply to a UNOX qualified

technician for service

Blown lamp Replace the lamp

The oven light does not turn on

Loose lamp

Place correctly the lamp in the

lamp holder

The fans do not reverse their

rotation

Apply to a UNOX qualified

technician for service

One of the fans is not rotating (in

case of oven with more than one

motor)

Apply to a UNOX qualified

technician for service

The cooking is not even

One of the heating elements is

broken

Apply to a UNOX qualified

technician for service

The fuse of the ligher device is

damaged

Replace the fuse placed on the

back of the oven

No gas supplì Apply to the gas company

Low gas pressure Apply to the gas company

The flame goes out

Defective gas electrovalve

Apply to a UNOX qualified

technician for service

Inverted Phase and Neutral

Togliere la spina e reinserirla

ruotata di 180 gradi

Lighter device fuse is damaged

Replace the fuse placed on the

back of the oven

No gas supply Apply to the gas company

Low gas pressure Apply to the gas company

No flame lighting

Defective gas electrovalve

Apply to a Unox qualified

technician for service

Page 16

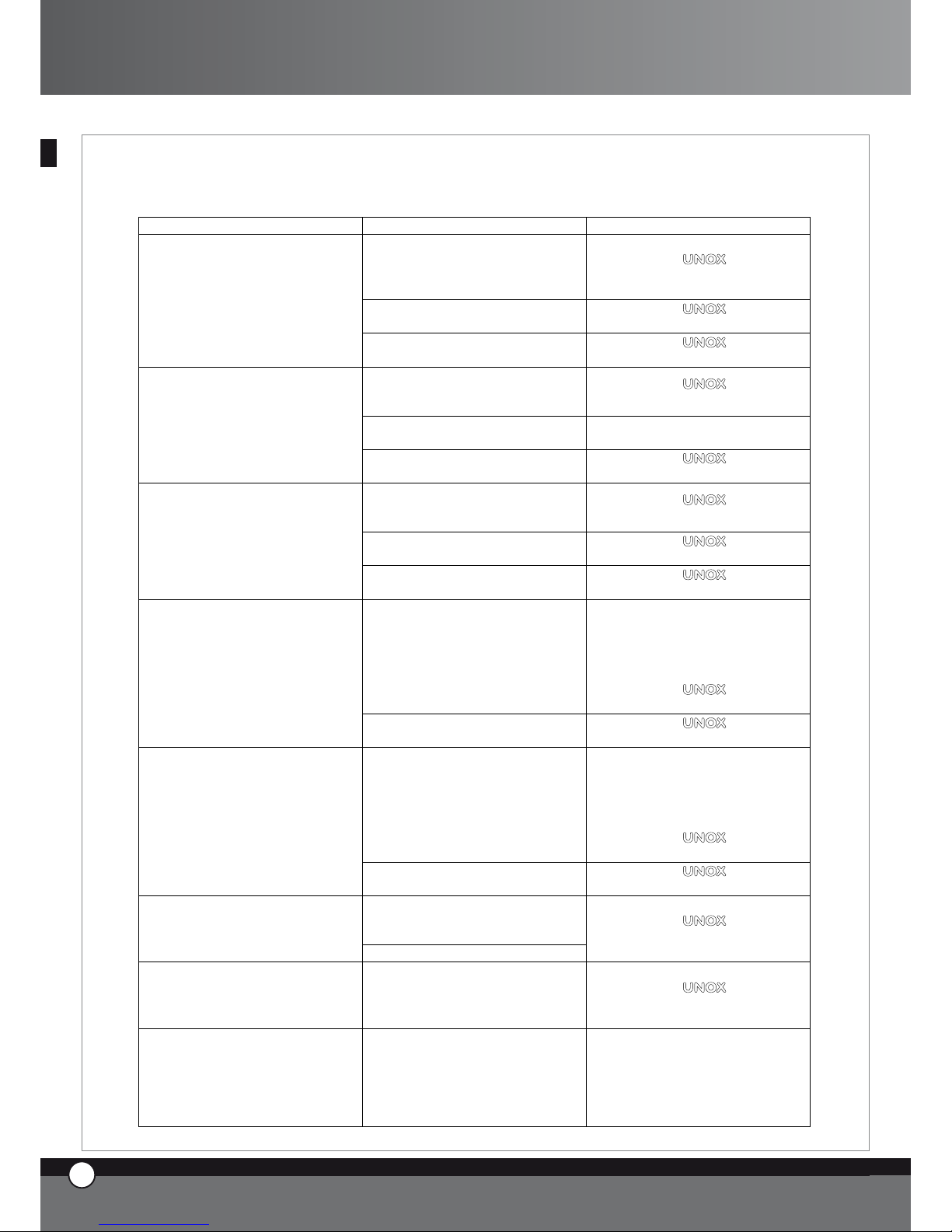

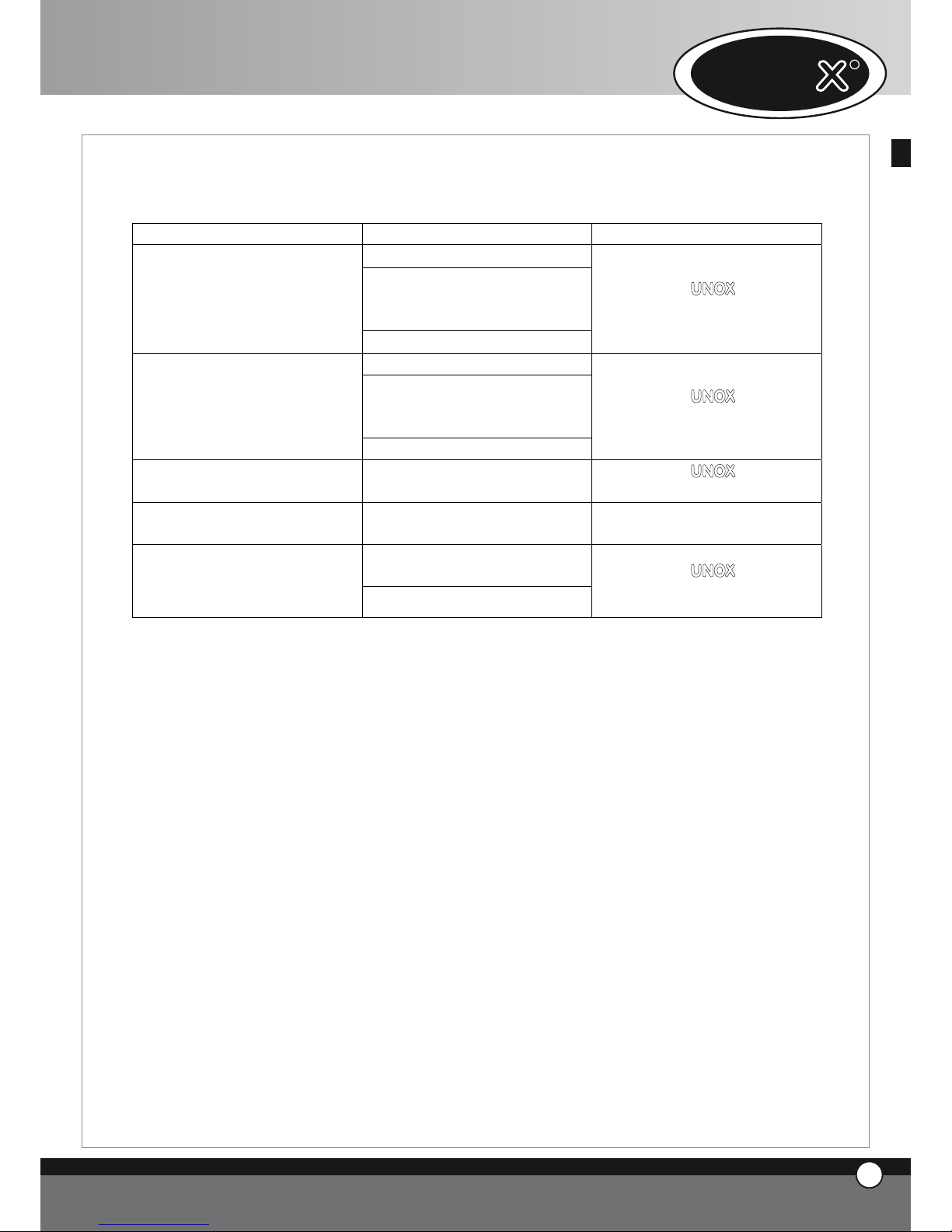

10. ERROR MESSAGES

10.1 OVEN ERROR MESSAGES

BREAKDOWN CAUSE SOLUTION

The connection wires of the

chamber probe 1 are

disconnected from the power

card

Apply to a UNOX qualified

technician for service

Damaged cavity probe 1

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EF1

Damaged power card

Apply to a UNOX qualified

technician for service

The connection wires of the cavity

probe 2 are disconnected from

the power board

Apply to a UNOX qualified

technician for service

Damaged cavity probe 2

Apply to a Unox qualified

technician for service

The display panel 1 shows

continuously the message EF2

Damaged power card

Apply to a UNOX qualified

technician for service

The connection wires of the core

probe 2 are disconnected from

the power card

Apply to a UNOX qualified

technician for service

Damaged core probe

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EF3

Damaged power card

Apply to a UNOX qualified

technician for service

Intervention of the thermic

protection of one of the motors

Disconnect the oven from power

supply, wait for the appliance to

cool down and restart the oven: if

the display shows again the

message EF4

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EF4

Damaged power card

Apply to a UNOX qualified

technician for service

Intervention of the safety thermic

device

Disconnect the oven from power

supply, wait for the appliance to

cool down and restart the oven: if

the display shows again the

message EF5

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EF5

Damaged power card

Apply to a UNOX qualified

technician for service

Control board / Power card

connecting cable is damaged or

disconnected

Display no. 1 shows continuously

EF6 message

Oven power card is damaged

Apply to a UNOX qualified

technician for service

Display no. 1 shows continuously

EF7 message

Lost of communication between

the oven and connected

accessories

Apply to a UNOX qualified

technician for service

Display 1 shows “GAS” message,

“START/STOP” led flashes and

the buzzer bleeps

The burner does not ignite

Push “START/STOP” button and

wait for the burner to ignite again.

If after several tries, the burner is

still not igniting, invert the phase

and the neutral by turning the plug

of 180 degrees.

ENGLISH

11

ENGLISH

15

ENGLISH

ChefTop™ - BakerTop™

Page 17

ENGLISH

12

ENGLISH

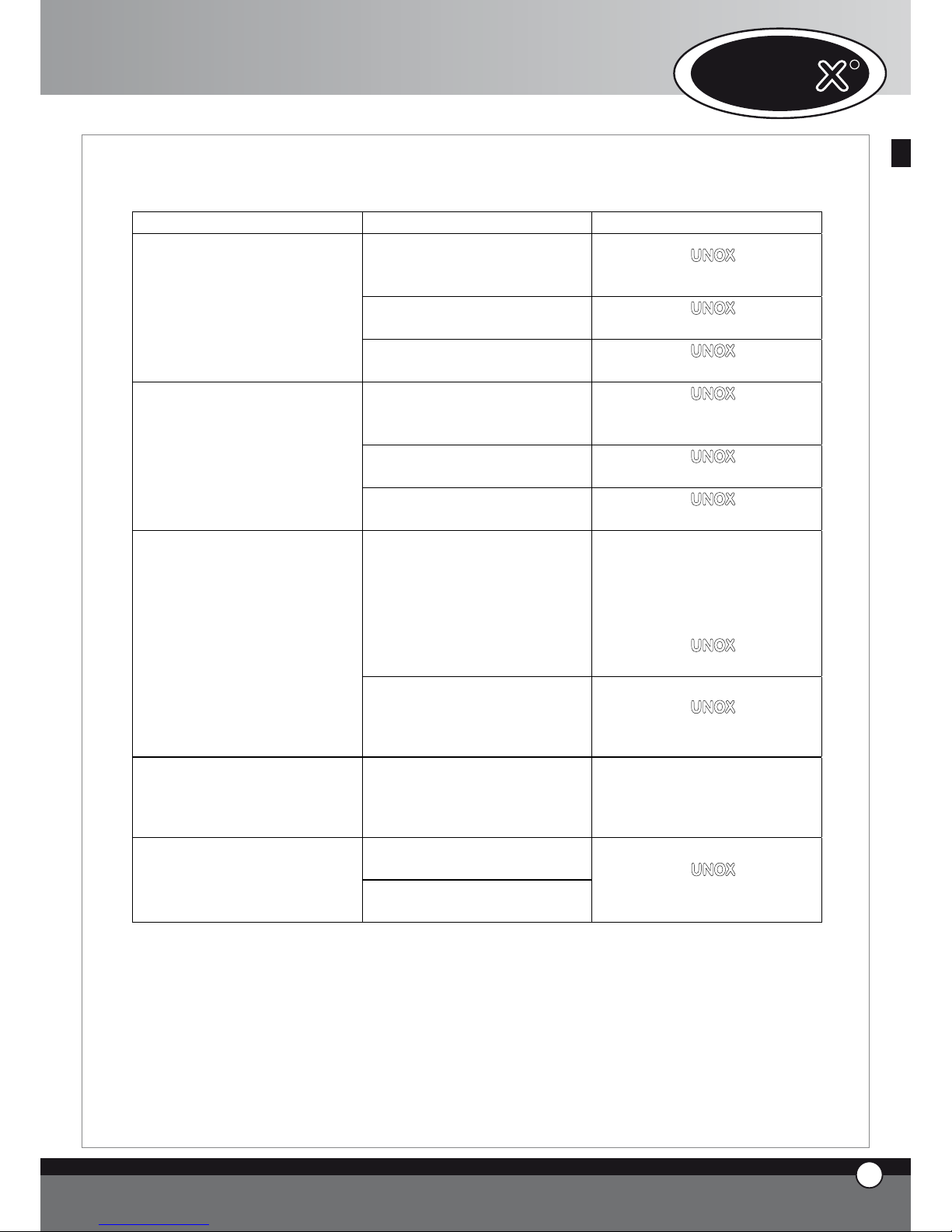

10.2 BLAST CHILLER ERROR MESSAGES

BREAKDOWN CAUSE SOLUTION

The connection wires of the cavity

probe are disconnected from the

power card

Apply to a UNOX qualified

technician for service

Damaged chamber probe

Apply to a UNOX qualified

technician for service

The display panel 1 shows the

message EA1

Damaged blast chiller power card

Apply to a UNOX qualified

technician for service

The connection wires of the core

probe are disconnected from the

power card

Apply to a UNOX qualified

technician for service

Damaged core probe

Apply to a UNOX qualified

technician for service

The display panel 1 shows the

message EA2

Damaged blast chiller power card

Apply to a UNOX qualified

technician for service

Overpressure in the refrigeration

circuit

Disconnect the blast chiller from

the power supply, wait for about

20 minutes, and connect again the

appliance: if the display shows

again the message EA3

Apply to a UNOX qualified

technician for service

The display panel 1 shows the

message EA3

Damaged blast chiller power card

Apply to a UNOX qualified

technician for service

Display no. 1 shows continuously

EA4 message

Filters working limit reached Take out the filter and wash it

Oven / blast chiller connecting

cable is damaged or disconnected

Display no. 1 shows continuously

EA5 message

Blast chiller power card is

damaged

Apply to a UNOX qualified

technician for service

UNO

R

16

ENGLISH

Page 18

10.3 HOLDING CABINET ERROR MESSAGES

BREAKDOWN CAUSE SOLUTION

The connection wires of the

chamber probe are disconnected

from the power card

Apply to a UNOX qualified

technician for service

Damaged chamber probe

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EL1

Damaged holding cabinet power

card

Apply to a UNOX qualified

technician for service

The connection wires of the

humidity probe are disconnected

from the power card

Apply to a UNOX qualified

technician for service

Damaged humidity probe

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EL2

Damaged holding cabinet power

card

Apply to a UNOX qualified

technician for service

Oven / holding cabinet connecting

cable is damaged or disconnected

Display no. 1 shows continuously

EL3 message

Holding cabinet power card is

damaged

Apply to a UNOX qualified

technician for service

10.4 HOOD ERROR MESSAGES

BREAKDOWN CAUSE SOLUTION

The connection wires of the

temperature probe are

disconnected from the power

card

Apply to a UNOX qualified

technician for service

Damaged temperature probe

Apply to a UNOX qualified

technician for service

The display panel 1 shows

continuously the message EC1

Damaged hood power card

Apply to a UNOX qualified

technician for service

Oven / hood connecting cable is

damaged or disconnected

Display no. 1 shows continuously

EC2 message

Hood power card is damaged

Apply to a UNOX qualified

technician for service

ENGLISH

11

ENGLISH

17

ENGLISH

ChefTop™ - BakerTop™

Page 19

ENGLISH

12

ENGLISH

10.5 OSMOSIS SYSTEM ERROR MESSAGES

BREAKDOWN CAUSE SOLUTION

Pressure transducer is damaged

Transducer / power card

connecting cable is damaged or

disconnected

Display no. 1 shows continuously

EO1 message

Osmosis power card is damaged

Apply to a UNOX qualified

technician for service

Liter-counter is damaged

Liter-counter / power card

connecting cable is damaged or

disconnected

Display no. 1 shows continuously

EO2 message

Osmosis power card is damaged

Apply to a UNOX qualified

technician for service

Display no. 1 shows continuously

EO3 message

Filters working limit reached

Apply to a UNOX qualified

technician for service

Display no. 1 shows continuously

EO4 message

Inlet water pressure is too low

Verificare che arrivi acqua

all’ingresso dell’osmosi

Oven / osmosis connecting cable

is damaged or disconnected

Display no. 1 shows continuously

EO5 message

Osmosis power card is damaged

Apply to a UNOX qualified

technician for service

UNO

R

18

ENGLISH

Page 20

B. INSTRUCTION FOR THE IN-

STALLER

1. WARNING

All the operations of installation, assembly, service and

assistance must be carried out by qualified personnel according to current laws and regulations.

Please read carefully the instruction manual before the

installation and commissioning of the appliance.

The appliance must be unaltered (check for any transport damage). Remove all informative material from the

chamber.

Avoid to modify the components sealed by the producer

with the intention of improving the performances of the

equipment; the producer refuses all responsibility for any

damage to persons or things that may be caused by an

improper use of the appliance and the warranty is automatically invalidated.

The settings, the gas supply pressure values and the

technical data are indicated on CHART A of every oven

model.

2. PRELIMINARY OPERATIONS

2.1 INSTALLATION SITE

Before placing the appliance, please verify the overall dimensions and the exact position of the electrical and water connections and of the fumes exhaust as indicated on

the attached file “Technical Data”.

In particolar, check the earthing and the exhaust fumes

scavenging are in compliance with the safety.

Avoid to install the oven on places where there is a risk

of explosion.

Avoid to install the oven outdoor without a proper and

complete rain proof protection.

Avoid to install and use the oven inside small rooms where

there is insufficient air change.

2.2 PRESETTING FOR POSITIONING

You will find the feet inside the appliance.They must be

fitted to the oven.

Never use the appliance without its feet.

Remove the drip tray from the back of the oven by using

a screwdriver.

Place the oven on one side.

Insert the feet in the indicated positions and the tray

guides as shown in the picture.

2.3 REMOVAL OF THE PROTECTIVE FILM

Carefully remove all the protective film from the external

walls of the appliance.

Pay attention not to leave any residue of glue.If there

should be any residue of glue please remove it with an

appropriate solvent.

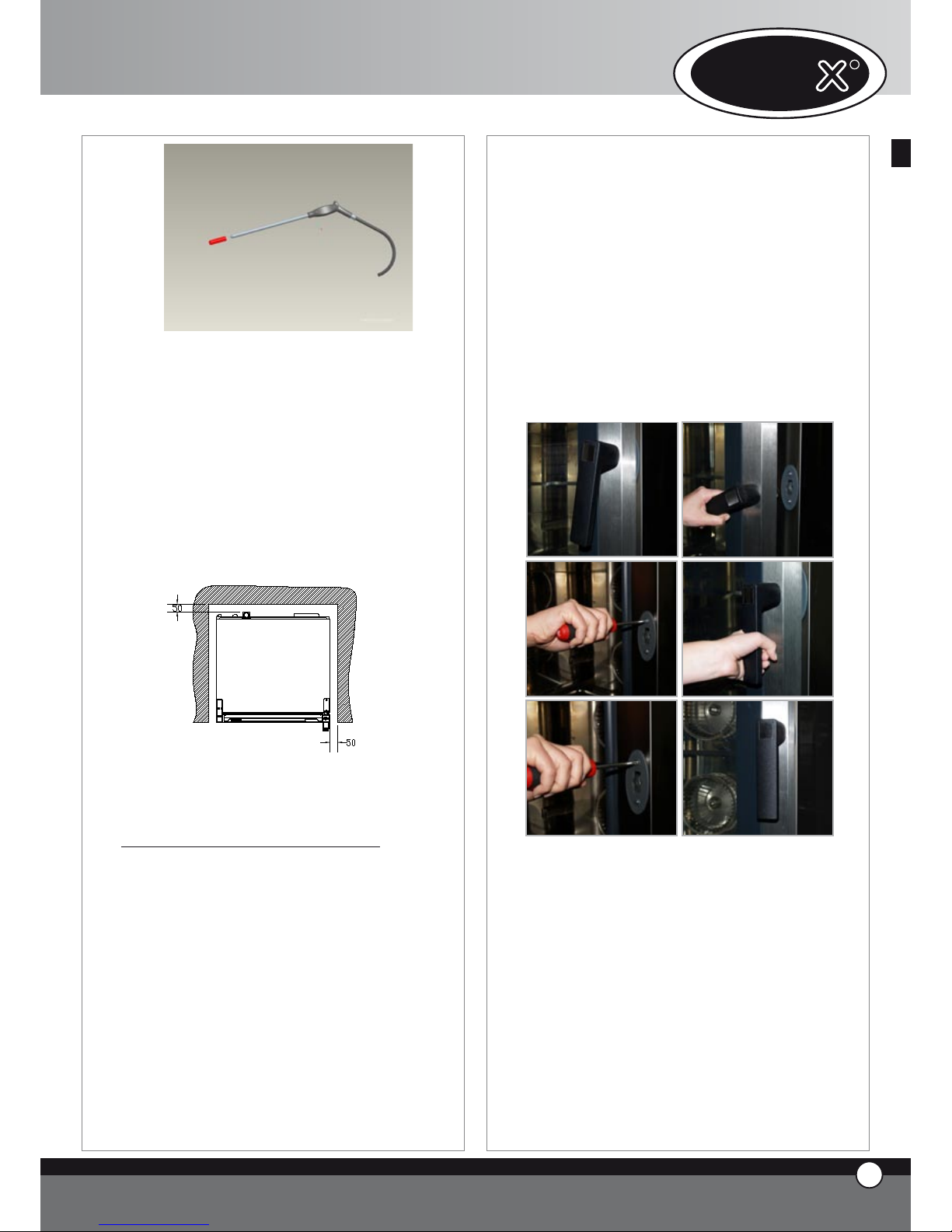

Remove the probe protection.

13

ENGLISH

19

ENGLISH

ChefTop™ - BakerTop™

Page 21

2.4 POSITIONING

Place the appliance respecting the safety standards indicated below.

Place the appliance so that its back can be easily reached

in order to make the electrical connections and to provide the necessary service.

Avoid to install the oven near heat sources.

The appliance is not suitable for built-in installation

or side by side positioning.

It is recommended to leave 10 cm cm of free room all

around the appliance.

With particular reference to the ovens, all models must

be placed upon a support, such as a prover, a stand or a table.

Never install the appliance on the floor.

If the appliance is placed near walls, partitions, kitchen

cabinets, decorated edges, etc., it is recommended these

are made of non combustible material.

Otherwise, they must be coated with non combustible

thermal insulating material and the fire prevention standards must be respected.

Do not install the appliance near a fryer. because some fat

may enter inside the oven and settle on the electric parts,

causing malfuncitoning of the equipment, or enter inside

the burner box and cause problems on the gas combustoin.

Avoid to install the appliance near inflammable substances

containers, eg.: gas cylinders.

Verify that the appliance is installed on a flat and

level surface.

In case, once the oven is placed, the door handle does not

properly close the door, it is necessary to accommodate

the handle latch, as described here below:

• open the door of the oven (pic.1), slightly unloose the

fixing screws of the door latch (pic.2)

• close the door and turn the handle to lock it (pic.3)

• if the door remained closed and the handle is perfectly

in vertical position, open the door and tightly fix the fixing

screws of the latch (pic.4).

• in case the problem is not solved, repeat the procedure

unloosing more the latch fixing screws.

WARNING! In case the oven is placed on a non perfectly flat surface, the handle does not properly close: if

the surface is only lightly deformed, it is possible to solve

the problem by following the latch accomodation procedure described here above; this procedure can not be

used to solve the problem in case the surface shows big

deformations.

Install the appliance inside rooms where there is a sufficient air

change in order to avoid the formation of toxic substances.

Attention! Keep free the exhaust fumes chimney

placed on the top of the oven.

For the installation, the exhaust fumes conveying and the

minimum wall ventilation, refer to installation and safety national standards in force in the country where the oven is

14

ENGLISH

UNO

R

20

ENGLISH

Page 22

installed. Make sure the air volume needed for combustion

is not blocked by objects placed under or around the oven,

especially near holes or slots.

A correct air change grants a proper combustion of the oven

burner and a healthy room for the users.

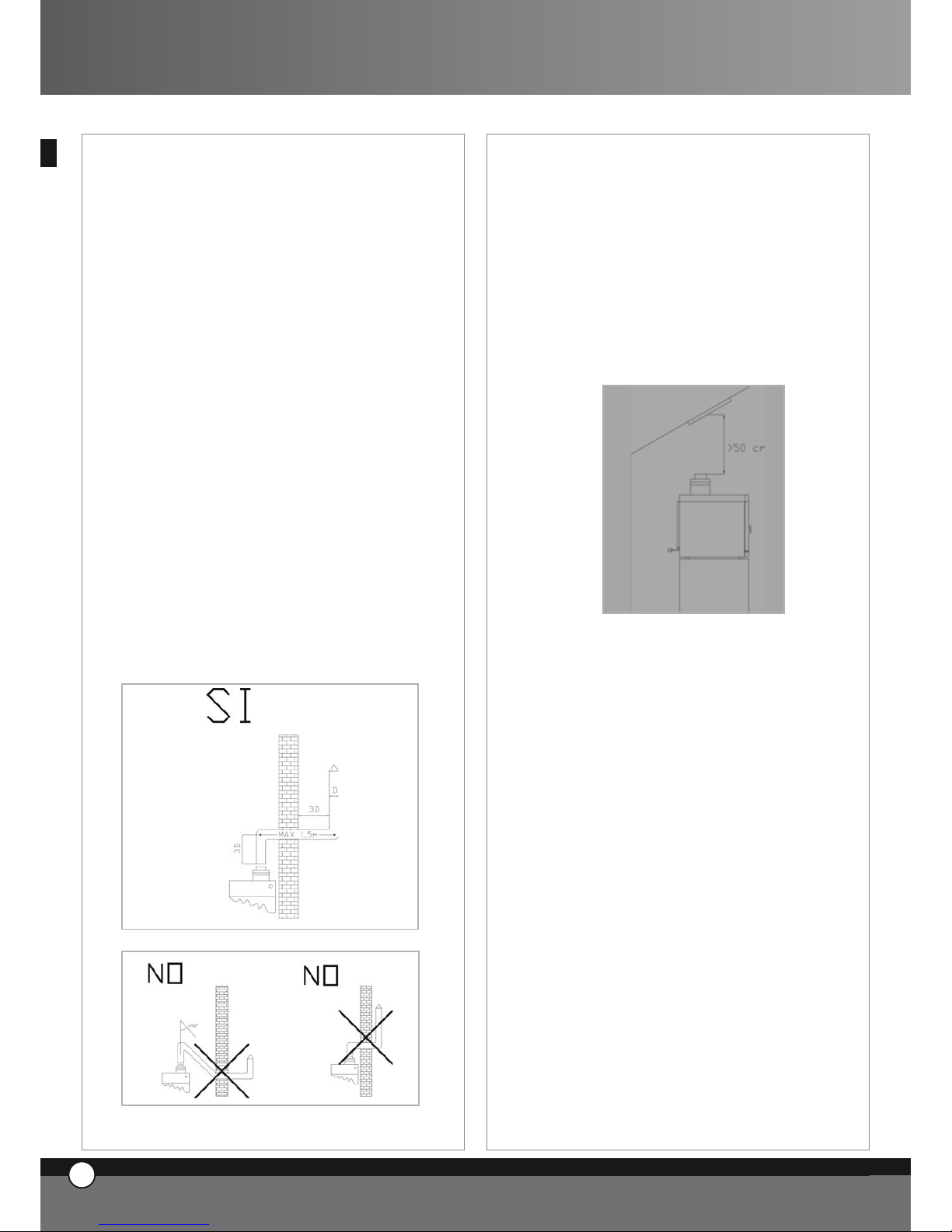

On the basis of to the scavenging system used, the gas oven

models are classifiable as follows:

Type A1 (ovens with thermic power < 14kW): exhaust

gasses are scavenged in the room where the oven is installed.

Type B11 (ovens with thermic power < 14kW): Exhaust

fumes are scavenged to the outside through a natural draught

chimney. In this type of installation, make sure that, for all its

length, the section of the chimney is larger than the section of

the oven exhaust pipe. Above the draught breaker there must

be a vertical length longer at least three times the diameter of

the pipe. The exhaust system must have for all its length an ascending path with a minimum slope of 10%. Moreover, there

mustn’t be any angle smaller than 90”. Avoid the horizontal

part of the connection exceed the approximate length of 1,5

meters. In case the connection is not possible, install a hood at

least at 50 cm from the oven draught breaker.

Attention! Placing a hood too near the draught breaker may

cause an over depression on the draught breaker that would,

then, attract a greater gas quantity inside the burner with consequent blasts and leave harmful unburnt gasses.

It is recommended to install a chimney cover on the external

top part of the flue in order to avoid the rain to get inside the

oven and to limit the Venturi effect depressions that may occur

in case the chimney is exposed to strong external draughts.

Type B21 (ovens with thermic power > 14kW): Exhaust

fumes are scavenged to the outside through the hood. The

hood must be at, at least, 50 centimetres from the draught

breaker: if the hood is placed to close to the draught breaker

it may cause an over depression on the draught breaker that

would, then, attract a greater gas quantity inside the burner

with consequent blasts and leave harmful unburnt gasses.

It is recommended to install a chimney cover on the external

top part of the flue in order to avoid the rain to get inside the

oven and to limit the Venturi effect depressions that may occur

in case the chimney is exposed to strong external draughts.

The choice about the type of gasses scavenging must be made

accordingly to local laws on gas appliances installation.

All UNOX gas ovens are supplied with an anti-wind chimney,

incorporated to the gasses scavenging system, to avoid obstructions and not proper draught: it has never to be removed

because it is integral part of the oven.

3. ELECTRICAL CONNECTION

3.1 WARNING

The connection to the electrical power supply system

must be carried out according to the current local regulations.

Before connecting the appliance, make sure that the voltage and the frequency correspond to those stated on the

data plate of the appliance.

The appliance must be placed in such a way that the connecting plug to the network can be easily reached.

Place an omni-polar switch between the appliance and

the network in such a way that it will be easily accessible after the installation. The contacts of this switch must

have a minimum opening distance of 3 mm and the switch

must have an appropriate input (for example: thermalmagnetic switch).

21

ENGLISH

ChefTop™ - BakerTop™

Page 23

UNO

R

22

ENGLISH

The use of a safety switch for fault current is suggested.

When the appliance is working, the power supply voltage

must not diverge from the value of the nominal voltage,

indicated on the data plate, by more than ± 10%.

3.2 CONNECTION TO THE ELECTRICAL SUPPLY

MAINS

UNOX gas ovens are equipped with electrical cable and

Schuko plug (monophase 230V) that has to be simply

plugged in a proper outlet (check the outlet is suitable to

the supplied Schuko plug).

Pay attention on plugging in the equipment: in case the

oven locks at any time the flame lighting starts try to turn

the plug of 180 degrees (on board safety system that

avoid Phase-Neutral polarity inversion).

The electric supply outlet must be clean, in good

conditions and far from fats, oils and other substances that may compromise the electric connection.

3.3 EQUIPOTENTIAL SYSTEM

The appliance must be included in an equipotential system

whose efficiency must be properly checked according to

the current laws. This connection must be done between

different appliances through the terminal marked with

the symbol: simbolo morsetto equipotenziale

The equipotential conductor must have a minimum section of 10 mm2.

4. GAS C0NNECTION

4.1 WARNING

Before proceeding with the gas connection, the qualified

installer must check the data indicated on the technical

data plate match with the available gas type.

The equipment is set and tested in production for LPG

gas, G30 type (butane/propane G30/G31) at a nominal

pressure value of 28-30/37 mbar.

In case the gas available to be connected to the equipment is different from the gas the oven is set to, see paragraph 4.3.

4.2 CONNECTIONS

The equipment has to be connected to the gas accordingly to the standard in force.

Install an interception gas cock between the equipment

and the gas supply in an accessible position.

The connection to the gas main, through the ¾” ISO 71 type fitting placed on the back left panel of the oven,

can be made by using flexible or not flexible pipes and by

placing an approved interceptiongas cock between the

equipment and the gas supply.

In case flexible pipes are used, make sure they are made

in stainless steel, not placed close to external heat sources

(e.g.: fryers, open burners etc.) and not subject to twisting and/or traction.

In case non metallic material are used, e.g.: sealing, they

must be certified and complying with the European standards in force.

Check the gas circuit seal by putting on the fittings a suds

solution or non corrosive specific foaming products.

Important: never use a flame to check possible gas leaks.

4.3 SET AND ADJUSTMENT TO DIFFERENT GAS TYPES

Before carrying out work on the appliance, close the gas

cock and disconnect the electrical supply.

The accommodation has to be made by qualified person-

Page 24

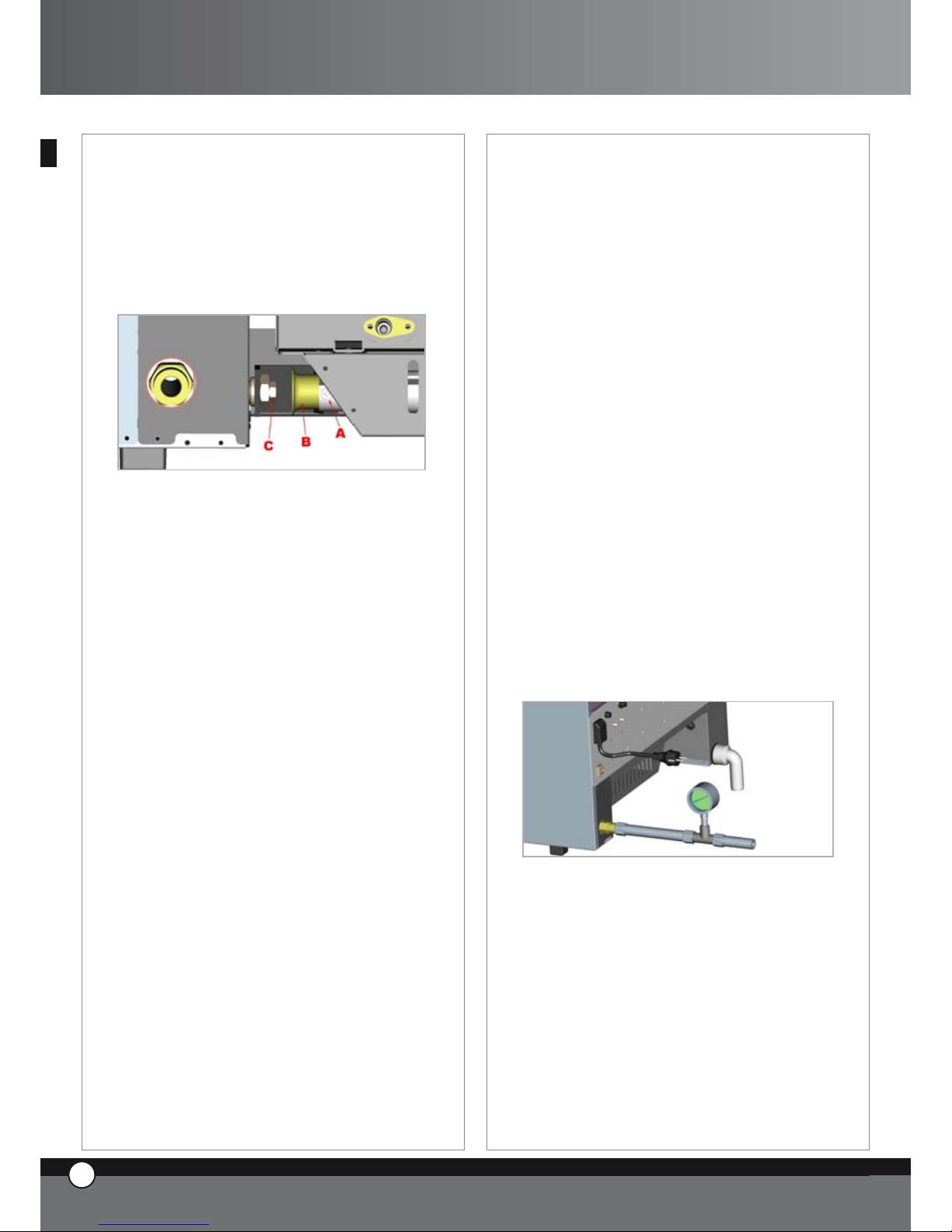

ChefTop™

nel. Referring to the attached technical data sheet, replace

the main nozzle and adjust the primary air by setting the

referred bush.

Check the diameter of the nozzle, printed on the nozzle,

that has to be replaced is 1/100 mm.

The nozzle is placed on the lower left back side of the

equipment. To replace the nozzle and adjust the primary

air setting, proceed as follows (see the picture here below):

• loose screw A

• move the bush B as indicated on the attached chart

• unfix and take off the nozzle C by using a 13 mm spanner

• install the nozzle suitable to the gas type available on

the main (see proper technical data sheet)

• place the bush B at the right distance H (see proper

technical data sheet).

• screw the screw A

Warning!

After the equipment has been set to a different

type of gas:

• place on the equipment place a inerasable sticker with

the new setting data.

• Seal again the adjusted parts.

• Proceed with gas circuit seal test procedure.

• Make a general working test on the whole system.

4.4 CHECK OF THE NOMINAL THERMAL POWER

RATE

The nominal thermal power rate has to be checked by

authorized personnel or by the company in charge on the

basis of the information indicated on this manual.

This check is required at any new installation, transformation or adjustment to different gas types and after any

maintenance work.

The nominal thermal power rate and the connection pressure values are indicated on the technical data sheet.

Do not remove the parts sealed with red paint.

The required nominal thermal power rate is set by using

the nozzles as indicated on the respective chart of the

technical data sheet and by setting the specific connection

pressure value indicated per gas type.

In case you need a further test to be made on the nominal

thermal power rate, proceed with the volumetric method by using a counter and a chronometer.

The exact volume that has to pass per time unit is indicated on the respective chart on the technical data sheet.

This value for the connection has to be respected with

a tolerance of ±5%. In case a difference value is found,

check the diameter of the used nozzles and inlet pressure

are correctly set.

4.5 CHECK OF THE SERVICE PIPE PRESSURE

The service pipe pressure is measured, with the equipment turned on, by using a pressure gauge for fluids (e.g.:

a “U” type manometer with resolution 0,1 mbar or an

electronic manometer): make sure the taken pressure

value matches with the value indicated on the respective

chart.

To check the inlet pressure proceed as follows: close the

gas cock installed between the equipment and the gas

main, remove the gas feeding pipe and insert between

the pipe and the oven gas inlet a T fitting; connect on the

free end of the T fitting a manometer suitable to check

the pressure.

In case the taken pressure value is lower than the value

indicated on the ” CHART A”,(more than 0,2 mbar below

indicated value), apply to local gas company.

Warning!

Never tamper the gas solenoid valve parts set and sealed

by the producer.

23

ENGLISH

ChefTop™ - BakerTop™

Page 25

UNO

R

24

ENGLISH

4.6 CHECK OF CORRECT FUNCTIONING

Turn on the equipment following the instructions indicated here below.

Check the equipment gas circuit is correctly seal and

there are no gas leaks, as indicated on paragraph 4.2

Check the burner flames are evenly lighted by looking

through the burner aeration slots; in details, the flames

have to be blazing and blue without yellows ends.

4.7 SUGGESTIONS FOR THE USER

The technician responsible for the installation has to inform the user about the safety on the use of the equipment, with reference to the information contained in this

manual that has to be delivered together with the equipment. Any special maintenance work (replacement of a

damaged component, adjustment to a different type of

gas, etc.) has to be made by authorized and qualified personnel; after any maintenance work a general check of

the equipment functioning is required.

It is suggested to draw up a service contract in order to

have the equipment checked and tested at least twice a

year, in particular on electric, water and gas connections.

The user is in charge only of the use and daily cleaning of

the equipment.

4.8 TEST OF THE FIRST USE

Turn on the equipment following the instructions indicated here below.

Pay attention while turning on the oven for the first time

because, due to some air bubbles inside the gas circuit,

it may lock; the oven lock is indicated buy the START/

STOP button flashing and intermittent buzzer sound:

keep START/STOP button pushed until the oven starts

again. Repeat this procedure until the air inside gas circuit

is completely bleeded.

In case despite several turning on tries the flame (after

the sparking) keeps on turning off and making the oven

lock, invert the phase with the neutral of the plug (plug

out, turn the plug of 180 degrees and plug in).

Once the oven has been turned on, check the flames

through the aeration slots placed on the back of the

oven.

The technician informs the user about the functioning and

the turning on of the equipment referring to the instructions contained on this manual.

5. WATER CONNECTION

5.1 WARNING

It is necessary to place a mechanical filter and a shut-off

valve between the water system and the appliance.

As required by current laws, the appliance is equipped

with 2 metres of pipe, the respective pipe fitting (3/4”)

with non-return valve and mechanical filter.

Before connecting the water pipe to the appliance please

let some water flow to clear the pipe of any obstructions.

The water used in the appliance must have a pressure

value between 1 and 3 bar and a maximum temperature

of 30°C.

5.2 TREATMENT OF WATER

The water must have a maximum hardness of 5 °FH (this

avoids formation of limestone inside the chamber of the

oven).

It is strongly recommended to use a demineralising appliance (reverse osmosis unit) in order to avoid limestone

and/or other minerals depositing inside the oven.

The UNOX reverse osmosis system, code XC224 is available for this purpose. This system is directly controlled

by the control board of the oven through a self•diagnosis

system.

6. DRAIN CONNECTION

6.1 WARNING

The water coming our from the waste outlet pipe can be

very hot (90°C).

Proper pipes for high temperature must be used for this

connection.

Page 26

ChefTop™

6.2 WATER DRAIN

You find the waste outlet pipe on the rear of the oven. It

has to be connected to an open tundish drain in compliance with current regulations through a rigid or flexible

heat resistant pipe; the diameter of the pipe cannot be

smaller than diameter of the drain connection. The length

of the pipe cannot be longer than one metre.

Avoid reductions in diameter and tight bends along the

whole length of the waste pipe run.

The waste pipe must remain at least 20 cm below the

drain connection to allow the liquids to drain.

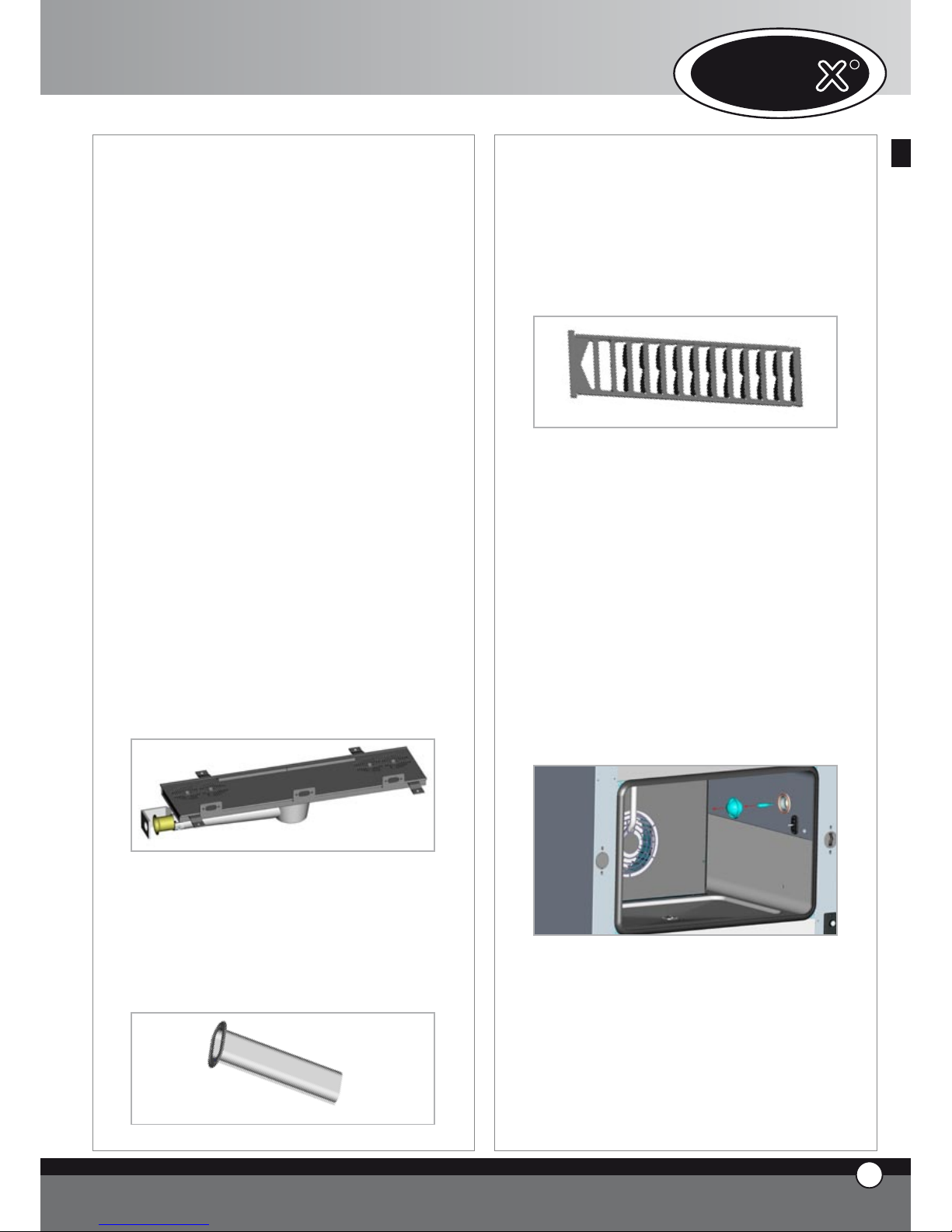

6.3 COOKING CHAMBER EXHAUST

The exhaust outlet of the cooking chamber is positioned

on the rear of the oven, at the top.

Do not stack any object and or material on the outlet as

this could cause a blockage of the fumes. Please ensure

that the exhaust outlet is correctly vented and the vicinity

of the outlet is clear of objects and materials that may be

damaged by the fumes.

It is suggested to place the oven below an extraction

hood or to install the UNOX aspiration hood, code

XC314 for ChefTop™- XC414 for BakerTop™, or the

UNOX steam condenser, code XC114. In all installations

please extract the fumes through the UNOX tube, code

TB1520A0, avoiding tight bends in the pipework run.

7. ACCESSORIES CONNECTIONS (PROVER, HOOD, BLAST CHILLER, ETC.)

The digital board of the oven controls all the accessories

(hood, holding cabinet, blast chiller, reverse osmosis system).

The accessories controlled by the oven are connected

through RJ45 connectors that are positioned on the rear

of the oven.

To connect the cables proceed as follows:

• remove the protection cover to enter the electrical

system

• by using a cutter make a vertical cut on one of the rubber caps placed on the panel on the back of the oven

• enter an end of the RJ45 cable through the cut on the

rubber cap

• connect the cable end with the proper female connector on the power card (you can use any one of the three

connectors)

• replace the protection cover by fixing the screw

Now the accessory is recognized and connected to the

oven

Please refer to relevant instructions manual for the correct use ot the connected accessory

25

ENGLISH

ChefTop™ - BakerTop™

Page 27

UNO

R

26

ENGLISH

8.

REPLACEMENT OF THE DOOR GLASSES

7.1 WARNING

The internal glass of the door is a low emissive tempered

glass.

The glass surface towards the cooking chamber is covered by a transparent metallic film that reduces the heat

transfer to the interspace between the two glasses and

reflects the heat inside the chamber.

If you need to replace the internal glass, pay attention

to correctly place the glass with the low emissive side

towards the cooking chamber.

If the low emissive side is wrongly turned towards the

outside, the temperature of the external door surface will

rise with risk of burns for the user and possible blowing

of the glass!

To check the low emissive side you need to use a proper

tester set at a maximum range of

2 KOhm. Point the two test prods on the glass surface at

5 cm one from the other: the low emissive surface will

show around 50 Ohm of resistance, while the other side

will show infinite resistance.

8. OVENS STACKING

In the event of stacking multiple ovens it is essential

to assemble the UNOX stacking kit, code XC680 for

ChefTop™ - XC681 for BakerTop™, which will main-

tain the correct distance between the ovens.

C. CERTIFICATIONS

Producer: UNOX S.p.A.

Address: Via Dell’Artigianato 28/30

I-35010 Vigodarzere, Padova, Italy

Product: GAS Combi Ovens for professional use

Family: ChefTop™ - BakerTop™

REFERENCE LAWS

The “CE” marking on the appliances indicated in this

manual refers to following UE directives:

ELECTRIC MIXED STEAM CONVECTION OVENS

XVC - XBC SERIES:

Low Voltage Directive 2006/95/EC

following the rules and current updating:

• CEI EN 60335-2-42

• CEI EN 60335-1

Electromagnetic Compatibility Directive 2004/108/EC