Page 1

Qpivex

SRM60/SRM80

Exacting Standards, Just Like Yours, since 1948

EExxaaccttiinngg SSttaannddaarrddss,, JJuusstt LLiikkee YYoouurrss,, ssiinnccee 11994488

SRM6O/SRM8O

SSRRMM6600//SSRRMM8800

Swing Ring Series

SSwwiinngg RRiinngg SSeerriieess

SRM6O/SRM8O PLANETARY MIXERS

SSRRMM6600//SSRRMM8800 PPLLAANNEETTAARRYY MMIIXXEERRSS

Maintenance & Parts Manual

Maintenance & Parts Manual

Persons under the age of 18 are not permitted to operate or have

Persons under the age of 18 are not permitted to operate or have

accessibility to operate this equipment per U.S. Dept. of Labor Employment

accessibility to operate this equipment per U.S. Dept. of Labor Employment

Standards Administration Fact Sheet No. ESA91-3.

Standards Administration Fact Sheet No. ESA91-3.

UNIVEX CORPORATION -

UNIVEX CORPORATION - 3 Old Rockingham Road - Salem, NH 03079-2140 – Tel (800) 258-6358 – Fax (800) 356-5614

Int'l Tel 603-893-6191 - Int'l Fax 603-893-1249 - Website www.univexcorp.com - E-mail Univex@univexcorp.com

Printed in USA

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Int’l Tel 603-893-6191 – Int’l Fax 603-893-1249 – Website www.univexcorp.com - E-mail Univex@univexcorp.com

3 Old Rockingham Road - Salem, NH 03079-2140 - Tel (800) 258-6358 - Fax (800)356-5614

Printed in USA

Page 2

SRM6O+/SRMSO+

Welcome to Univex

Thank you for purchasing this Univex product.

Your new SRÌvI6O+/SRÌvI8O+ Mixer has been designed with advanced

performance and safetyfeatures that make it an excellent addition to your

foodpreparation equipment. Like all Univex mixers, slicers, meat grinders

and accessories, this mixer is engineered to provide years ofreliable service.

If you have any questions concerning the operation ofthis unit, or ifwe can be

offurther assistance, please call our Customer Service Department.

Univex Customer Service:

USA & Canada 8OO256-6358

Safety is our Top Priority

READ AND MAKE SURE THAT YOU UNDERSTAND THE

INSTRUCTIONS AND SAFETY WARNINGS IN THIS BOOKLET BEFORE

ATTEMPTING TO OPERATE THE MIXER OR ATTACHMENTS.

NEVER PUT FINGERS OR HANDS IN THE BOWL WHILE THE MIXER IS

OPERATING OR SERIOUS INJURY COULD RESULT.

International 603-893-6191

NEVER ATTEMPT TO CLEAR A JAMMED ATTACHMENT OR

STALLED MIXER WITHOUT SHUTTING THE POWER OFF.

DISCONNECT THE ELECTRICAL PLUG FROM ELECTRICAL OUTLET.

ALWAYS REPLACE THE POWER TAKE-OFF (PTO) CAP WHEN

ATTACHMENTS ARE NOT IN USE.

DO NOT OPERATE THIS MIXER WITHOUT THE COWL IN PLACE

WARRANTY

The Univex SRM6O+ISRM8O+ Mixer is warranted by Univex Corporation against defects in materials

ançl workmanship for a period of one year from date of delivery ifdelivered to a destinatìon in the

Contact Univex Customer Service to report any warranty claim. Univex shall not be liable for any

consequential, compensatory, incidental, or specìal damages. damages incurred in transit or from

installation error, accident, alteration, or misuse are not covered. Transit damages should be reported to

Ifthe SRM6O+/SRMSO+ Mixer is deliveredto a country otherthenthe United States or Canada, it is

warranted by Univex's authorized distributor. Contact your distributor directly to report any warranty

claims outside ofthe United States or Canada.

United States or Canada.

the carrier immediately.

Page 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE OF CONTENTS

SRM6O+/SRM8O+

DESCRIPTION

WARRANTY

TABLE OF CONTENTS, LIST OF ILLUSTRATIONS

CHOOSING THE RIGHT LOCATION FOR YOUR NEW MIXER

USER-FRIENDLY SWING RING'TM SAFETY GUARD

OPERATING THE SRM6O+ISRM8O+ MIXER

USING THE POWER TAKE-OFF (PTO)

TABLE OF MIXING CAPACITIES & RECOMMENDED AGITATOR SRM6O+

TABLE OF MIXING CAPACITIES & RECOMMENDED AGITATOR SRM8O+

BEATERS, AGITATORS, BOWLS, & ACCESSORIES SRM6O+

BEATERS, AGITATORS, BOWLS, & ACCESSORIES SRMSO+

CLEANING YOUR MIXER

OPERATOR'S PREVENTIVE MAINTENANCE

TROUBLE SHOOTING GUIDE

REMOVAL OF TOP COVER

MECHANICS MAINTENANCE

REPAIR INSTRUCTIONS

REPLACEMENT PARTS, LISTS

ELECTRICAL CONNECTION AND ROTATION

WIRING DIAGRAMS

LIST OF ILLUSTRATIONS

ILLUSTRATION

OVERALL VIEW OF MIXER

FIGURE

FIGURE 2

FIGURE

FIGURE 4

FIGURE

FIGURE 6

FIGURE 7

FIGURE

FIGURE 9

FIGURE 10

FIGURE 11

1

LUBRICATION INSTRUCTIONS

GEAR BOX TRANSMISSION

3

BEATER HEAD & VERTICAL SHAFT ASSEMBLY

POWER TAKE OFF ASSEMBLY

5

INPUT ASSEMBLY

BOWL LIFT ASSEMBLY

SPEED CONTROL ASSEMBLY

8

BOWL SUPPORT ASSEMBLY

HOUSING ASSEMBLY

DRIVE ASSEMBLY

FIGURE 12A WIRING DIAGRAM 208-240V, 60HZ, 1PH,

220-240V, 50HZ, 1PH

FIGURE l2B WIRING DIAGRAM 208-240V, 60HZ. 3PH, 220V, 50HZ, 3PH

200V, 50/60HZ, 3HP .., .

FIGURE 12C WIRING DIAGRAM 460V, 60HZ, 3PH, 380V, 50HZ, 3PH

PAGE

i

2

3

3 -4

4 - 6

6 - 7

8

9

10

11

13

13

14 - 15

16

16 - 18

19 -24

25 - 37

39

40 -42

PAGE

12

18

25

26

27 -28

29

30 -31

32 -33

34

35 - 36

37 - 38

40

41

42

Page 2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

CHOOSING THE RIGHT LOCATION FOR YOUR NEW MIXER

SRM6O+/SRMSO+

When selecting the best location for the mixer, it is helpful to consider the following:

.

Where is the best location for the operator, both for saving steps and easy

viewing?

s

Is this a good location for product flow as in:

*

Easyto get ingredients to the mixer?

s

Destination ofthe mix alter mixing?

.

Is there existing electrical service at this location?

.

Does this location provide easy access for cleaning and service?

.

Check to be sure that your mixer with attachments does not extend out

into heavy traffic areas.

.

Ifstands and/or portable equipment are used along side ofyour mixer,

can they be moved easily to and from your mixer?

.

Ifunit is not provided with a plug, then the unit is to be fitted with a primary disconnect

device that has a contact separation of at least 3mm in all poles.

IMPORTANT ELECTRICAL SERVICE INFORMATION

Electrical wiring instructions are found in the wiring diagram (Figures l2Athru 12C). Before making

electrical connections, CHECK the specifications on the nameplate to make sure that they agree with

those on your electric service.

USER-FRIENDLY SWING RINGTMSAFETY GUARD

Your SRM6O+/SRMSO+ Mixer features a newly updated, 2-part safety guard. The Swing RingTM

Safety Guard ring is easily be removed and installed, as well as dishwasher safe. It conveniently swings

out ofthe way without having to be removed to place or sample ingredients in the bowl. Only one side

ofthe guard needs to be open when adding ingredients. You'llfindthis twopiece design is easy to

handle and fits conveniently in your sink or dishwasher. It also provides a clear view ofthe product

throughoutthe mixing cycle.

This mixerwifi not operate unless the Swing Ring1M Safety Guard Is properly engaged.

Metal tabs atthe rear ofthe guard activate twin switches that enable the mixer to run only when the

guard is securely closed. These switches protect against accidental operation ofthe mixer when the

safety guard is open or removed from the mixer. The mixer wìll automatically stop ifthe guard is open.

Additional switches in the bowl slide mechanism automatically stop the mixer ifthe bowl is lowered

from the "up" (mixing) position.

To Install the Swing Ring

Safety Guard, insert the pointed end ofthe rod at the rear ofthe guard into

the lower mounting bracket on the mixer housing. Then insert the top end ofthe rod into the upper

bracket by aligning the groove in the rod with the slot inthe bracket Press the rod in and allow it to drop

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

SRM6O+/SRM8O+

down into position. Repeat this for each ofthe two sections ofthe guard. Swing the two halves of the

guard forward. When the guard is properly closed, the switches are now activated and the mixer can be

operated.

To remove the guard, simply reverse the installation procedure. Grip the two halves ofthe guard and

pull it open. Use an upward motion to release each halfofthe guard from the bracket on the machine

body.

To open the guard for access to the bow1 first turn the mixer off by pushing the red stop button

(Fig. i [1 2]). Pull open the two halves ofthe guard and swing one or both outward, It is not necessary to

remove them. Close the guard to resume mixing operations.

OPERATING THE SRM3O+ MIXER

Your Univex Mixer is designed to meet the cook's and Baker's demand for an efficient, dependable

appliance. It should give unfailing performance over a period ofyears when operated and maintained

according to the instructions contained herein.

The mixer drives various agitator attachments through a beater head shalt to beat, mix,

viscous, or dry ingredients. The shaft is driven by a sturdy motor

whose

power is transmitted by a

rugged, cogged belt and a Continuously Variable Transmission (CVT)through a geartrain and

planetary gear set. The speed ofthe beater shaft can be varied from approximately 60 to 270 revolution

per minute (rpm)for SRMSO+ and 75 tO 340rpm for SRM6O+. (See page IO & i i for part numbers of

various agitators, attachments and accessories.)

The SRM6O+/SRM8O+ Mixer is equipped with a power take-off(PTO)that operates other attachments

such as slicers, graters and grinders. The PTO speed can be varied from 85 to

or whip liquid,

385

rpmfor SRMSO+ and

a

SRM6O+. Be sure to read and follow any safety Instructions provided by the manufacturers of

attachments that you operate on the PTO. The PTO hub should be covered with the PTO cap

provided with your mixer when in use.

Warning--Never put hands, spoons, utensils or other objects into the bowl while the mIxer is

operating!

Note: Noise emissions are below 70db (A).

Securing the Bowl & Installing the Mixer Agitator.

Place the bowl on the bowl support (Fig. i [15]). The indentation on the rim ofthe bowl must align with

the corresponding pin on the mixer housing. Align the holes on eighter side ofthe bowl rim

on the bowl support andlower the bowl into position. Secure the bowl by turning the bowl clamps (Fig.

i [16]).

With the bowl in the "down" position, installthe desired agitator by sliding it upward onto the beater

shaft (Fig. 1 [1]). Rotate the agitator counter-clockwise until it is engaged.

Safety Note Serious injusy may result ifthe bowl is not fully secured to the bowl support using the bowl

support pins and firmly closingthe clamps.

over the pins

With the bowl secured, add ingredients. Liquids should be added first. The bowl is

now readyto be

raised to the "up"(mixing)position byturningthe bowl lifthandle (Fig. 1[131) clockwise.

When using the wire whip agitator, raise the bowito the "up" position first and then add ingredients

avoid wire whip damage.

Secure and close the Swing

PgTM Safety Guard before proceeding.

to

Page 4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

SRM6O+/SRM8O+

Using the Bowl Lift

The mixer will not operate unless the bowl is inthe "up " position. Raise the bowl by tuming the bowl

lift handle (Fig. i [13]) clockwise. To lowerthe bowl, turnthe handle counterclockwise.

Ifyour mixer is equipped with the power bowilift option(instead ofthe handle)turn the power bowl

switch clockwise to raise the bowl, counter-clockwise to lower the bowl,

It is necessary to lower the bowl to change the agitator. This also makes the

bowl accessible for filling

Setting the Tinier - Start/Stop Controls

This mixer will not operate unless the timer has been set to a specified number ofminutes or set

"HOLD" position. To startthe mixer, firsiturn the timer dial (Fig. i [81)to the desired

Then push the start button(Fig. i [11]). The mixer will automatically stop when the timer reaches "O".

in the

mixing time.

To stop mixing before the timer reaches "O", pushthe red stop button(Fig. i [12]).

The timer may be set for up to 15 minutes ofmixing, or may be set to the "HOLD"

continuous operation. When setting a time ofless then 5 minutes, turn the dial beyond 5 minutes

position for

and

then return itto the desired time.

Safety Note The mìxer will start only when the Swing RingTMSafety Guard is engaged

in the raised position. Do not operate the mixer without the bowl in place.

andthe bowl is

Manual Stop Button

For safety and operational ease, this mixer is equipped with a stop button (Fig.1

oversized, red mushroom-style cap.

Safety Note Although the motor shuts offinstantly when the Swing RingTM Safety Guard is

the bowl is lowered, or the stop button is pushed, the agitator may not come to complete rest

revolutions. Do not put hands or utensils into bowl or near the beater shaft until it Is

Both the start button and stop button are momentary contact type. They provide low

and prevent accidental start-up in the event ofpower interruption.

[12])that has an

opened, or

for several

stopped.

voltage protection

lift

Vail-Speed Control

A major advantage ofUnivex mixers is their Continuously Variable Transmission

mixers, CVT lets you change speed while the mixer Is running. Change speed by

control lever (Fig. 1 [9])to the desiredlevel. The speed indicator (Fig. 1 [10]) shows

Numerous intermediate speeds give the Cook or Backer tremendous flexibility.

Use speed 1 (slow) for heavy mixtures like pizza, bread or roll dough. Speed 1

the Meat and Food Chopper attachment For most mixingtasks, start on speed 1

speeds as needed. Use high speeds for wipping cream, beating eggs, andthin batter. To

your mixer, follow the speed, volume limits and attachments

recommendations shown in the

(CVT). Unlike other

movingthe speed

four speeds.

should also be used with

and progress to higher

avoid damaging

Table ofMixing Capacities on page 8 & 9.

Ifyou notice any slippage during mixing, the mixer may be overloaded. Reduce the load, or

speed until mixing action is smooth. Referto the Trouble- ShootIng Guide on page 14 & 15.

Ifthe mixerjanis and the motor stalls, immediately press the stop button. Take necessary steps

the load. Never put hands in the bowl to clear siam.

Note Always return to speed i before shutting off the mixer. Do not move the

when the mixer is not running, because this will cause belt to become loose and the mixer

operate properly.

Page 5

speed control lever

will not

reduce

to reduce

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

SRM6O+/SRMSO+

If the mixer has been shut off by the timer, or stop button in speed 2, 3 or 4, follow these steps to

avoid belt slippage orjerky start: Empty the bowl. Set the timer to "HOLD". Press the start button.

As the mixer begins to operate, move the speed control lever back to speed i Press the stop button.

Return to "O". Your mixer is now ready for ìts next task.

Using the Ingredients Chute

The ingredients chute provided with your mixer enables you to add ingredients to the bowl while the

mixer is running, and without opening or removing the Swing RingTM Safety Guard. The chute may be

installed on the front or side ofeither halfofthe guard. See below. Once the chute is properly installed,

it can remain in place permanently, if desired.

Ingredients Chute Installation

Slide the bottom ofthe chute between horizontal safety guard rings and engage

the chute onto the safety guard.

Bowl Doffies & Adapter

Dollies (Page 10 & i i [h]), simpliÍj moving large, heavy batches to the next location. To use 40 for SO

bowl or 30 for 60 bowl withthe dolly, you must use a bowl adapter (Page 10 & 11 [i)). To remove

heavy batches from the mixer, first place the dolly underthe bowl. Then open the bowl clamps and

lower the bowl to the dolly. Be sure the bowl support pins clear the bowl mounting brackets before

moving the bowl and dolly.

Using Smaller Bowl

For maximum flexibility, an alternative 30 for 60 quart bowl is available for use on your SRM6O+

Mixer, and a 40 for SO and 60 for 80 for use on your SRM8O+ Mixer. Specially sized agitators must be

used. See page lO & i i for part numbers.

Splash/Extension Ring

A splash/extension ring (page 10 & 11 [j]) mounted to the bowl helps confme ingredients during the

mixing ofcertain recipes. The ring should never be used to overload a mìxer beyond its recommended

capacity. Consultthe Table ofMixing Capacities on page 8 & 9 when you are unsure of appropriate

loads.

USING THE POWER TAKE-OFF (PTO)

The power take-offhub (Fig. 1[5}) accommodates #12 tapered attachments such

and Shredder, or a Meat and Food Chopper. The mixer's speed control lever also controls the PTO drive

speed.

Before installing attachments, turn the mixer off. Remove the PTO cap and loosen the thumb screw (Fig.

i [6]) on the PTO hub. Insertthe attachment with a slighttwist until firmly in place. Tighten the thumb

as a Vegetable Slicer

screw. Be sure to read and follow any safety instructions provided for attaclunents that you

operate on the PTO.

Page 6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

SRM6O+/SRJ48O+

Safety Notes

When grinding meat, chopper attachments must never run faster then speed 1. For vegetables,

attachments may run at higher speed.

Always turn the mixer off to install or remove attachments.

Always return to speed i before shutting off mixer.

Cover the PTO hub with the PTO cap when not In use.

Page 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

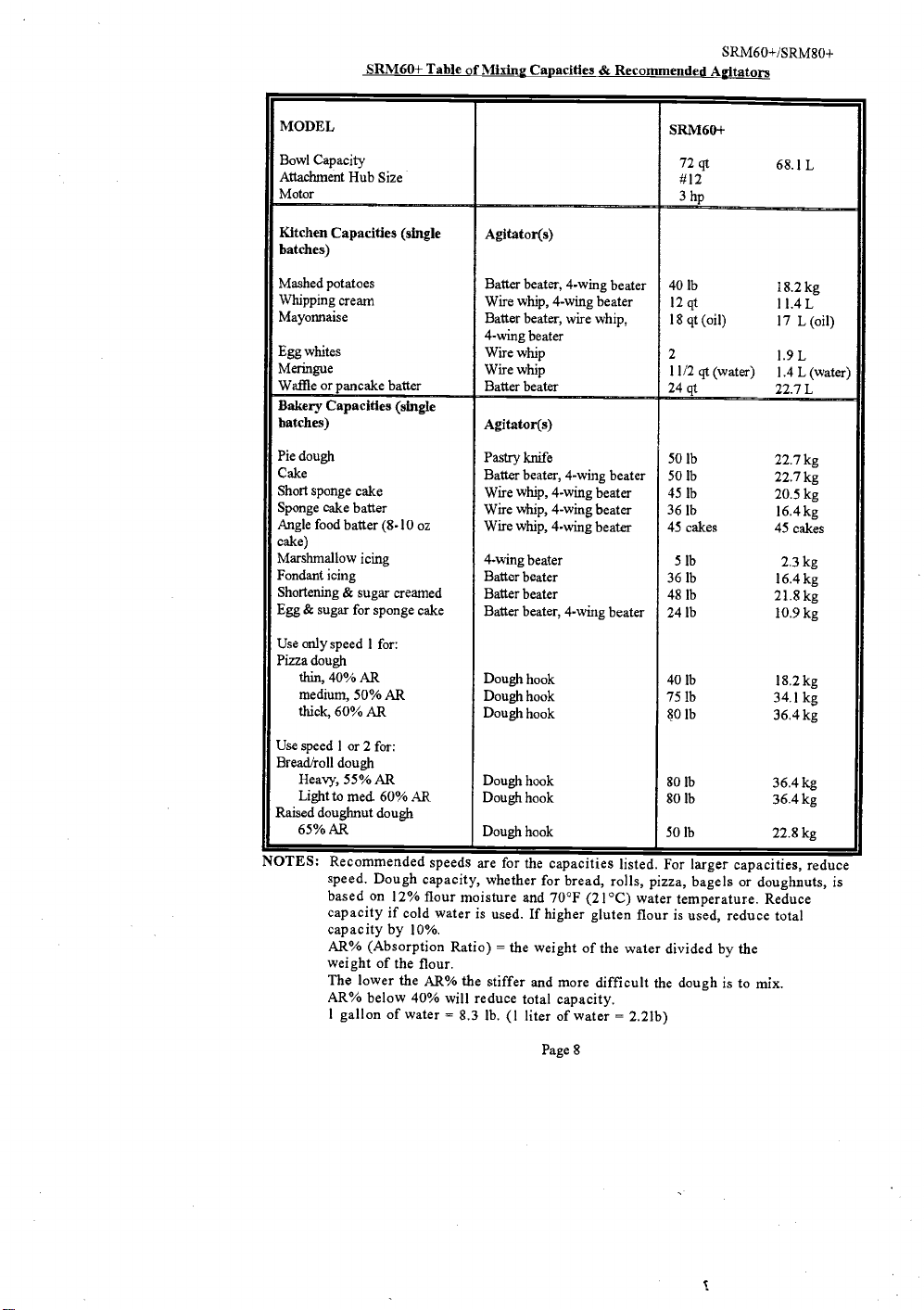

SRM6O+ Table ofMixing Capacities & Recommended Agitators

SRM6O+/SpM8o+

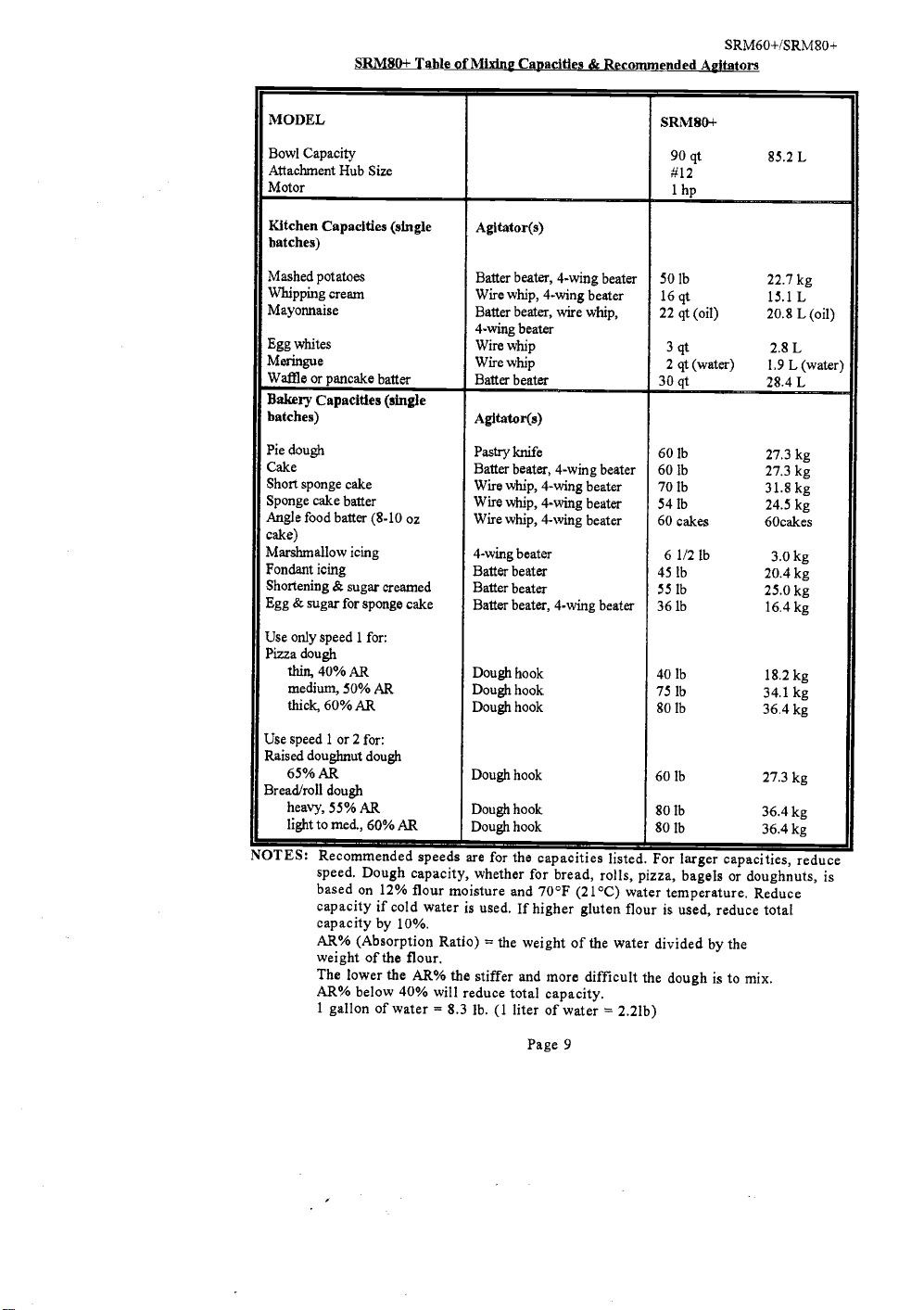

MODEL

Bowl Capacity

Attachment Hub Size

Motor

Kitchen Capacities (single

Agitator(s)

SRM6O+

72 qt

#12

3 hp

68. 1 L

batches)

Mashed potatoes

Whipping cream

Mayonnaise

Egg whites

Meringue

Waffle or pancake batter

Bafter beater, 4-wing beater

Wire whip, 4-wing beater

Batter beater, wire whip,

4-wing beater

Wire whip

Wire whip

Batter beater

40 lb

12 qt

18 qt (oil)

2

11/2 qt(water)

24 qt

18.2 kg

11.4 L

17 L (oil)

1.9 L

1.4 L (water)

22.7 L

Bakery Capacities (single

batches)

Pie dough

Cake

Short sponge cake

Sponge cake batter

Angle food batter (8-10 oz

cake)

Marshmallow icing

Fondant icing

Shortening & sugar creamed

Egg & sugar for sponge cake

Use only speed i for:

Pizza dough

thin, 40% AR

medium, 50% AR

thick, 60% AR

Use speed i or 2 for:

Bread/roll dough

Heavy, 55% AR

Lìghttomed.60%AR

Raised doughnut dough

65% AR

Agitator(s)

Pastry knife

Batter beater, 4-wing beater

Wire whip, 4-wing beater

Wire whip, 4-wing beater

Wire whip, 4-wing beater

4-wing beater

Batter beater

Batter beater

Batter beater, 4-wing beater

Dough hook

Doughhook

Dough hook

Dough hook

Doughhook

Dough hook

50 lb

50 lb

45 lb

36 lb

45 cakes

5 lb

36 lb

48 lb

24 lb

40 lb

75 lb

80 lb

80 lb

8Olb

50 lb

22.7 kg

22.7 kg

20.5 kg

16.4 kg

45 cakes

2.3 kg

16.4 kg

21.8 kg

10.9 kg

18.2 kg

34.1 kg

36.4 kg

36.4 kg

36.4kg

22.8 kg

NOTES: Recommended speeds are for the capacities listed. For larger capacities, reduce

speed. Dough capacity. whether for bread. rolls. nizza. bards or dourhnuts is

based on 12% flour moisture and 70°F (21°C) water temperature. Reduce

capacity if cold water is used. If higher gluten flour is used, reduce total

capacity by 10%.

AR% (Absorption Ratio) = the weight of the water divided by the

weight ofthe flour.

The lower the AR% the stiffer and more difficult the dough is to mix.

AR% below 40% will reduce total capacity.

i gallon of water = 8.3 lb. (1 liter of water

2.21b)

Page 8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

SRM6O+/SRM8O

SRMSO+ Table ofMixing Capacities & Recommended Agitators

MODEL

BowiCapacity

Attachment Hub Size

Motor

Kitchen Capacities (single

Agitator(s)

SRM8O+

9Oqt

#12

i hp

batches)

Mashed potatoes

Whipping cream

Mayonnaise

Egg whites

Meringue

Waffle or pancake batter

Batter beater, 4-wing beater

Wire whip, 4-wing beater

Batter beater, wire whip,

4-wing beater

Wire whip

Wire whip

Batter beater

50 lb

16 qt

22 qt (oil)

3 qt

2 qt (water)

30 qt

Bakery Capacities (single

batches)

Pie dough

Cake

Short sponge cake

Sponge cake batter

Angle food batter (8-10 oz

cake)

Marshmallow icing

Fondant icing

Shortening & sugar creamed

Egg & sugar for sponge cake

Use only speed i for:

Pizza dough

thin,40%AR

medium, 50% AR

thick, 60% AR

Use speed 1 or 2 for:

Raised doughnut dough

65% AR

Bread/roll dough

heavy,55%AR

lightto med., 60% AR

:

Kecommended speeds are for the capacities listed. For larger capacities, reduce

Agitator(s)

Pastryknife

Batter beater, 4-wing beater

Wire whip, 4-wing beater

Wire whip, 4wing beater

Wire whip, 4-wing beater

4-wing beater

Batter beater

Batter beater

Batter beater, 4-wing beater

Doughhook

Dough hook

Dough hook

Dough hook

Doughhook

Dough hook

60 lb

60 lb

70 lb

54 lb

60 cakes

6 1/2 lb

45 lb

55 lb

36 lb

4Olb

75 lb

80 lb

60 lb

801b

80 lb

speed. Dough capacity, whether for bread, rolls, pizza, bagels

based on 12% flour moisture and 70°F (21°C) water temperature. Reduce

capacity if cold water is used. If higher gluten flour is used, reduce total

capacity by 10%.

AR% (Absorption Ratio) = the weight of the water divided by the

weight of the flour.

The lower the AR% the stiffer and more difficult the dough is to mix,

AR% below 40% will reduce total capacity.

i gallon ofwater = 8.3 lb. (1 liter ofwater = 2.2lb)

85.2 L

22.7 kg

15.1 L

20.8 L (oìl)

2.8 L

1.9 L (water)

28.4 L

27.3 kg

27.3 kg

3 1.8 kg

24.5 kg

60cakes

3.0 kg

20.4 kg

25.0 kg

16.4 kg

18.2 kg

34. 1 kg

36.4 kg

27.3 kg

36.4kg

36.4 kg

or doughnuts, is

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

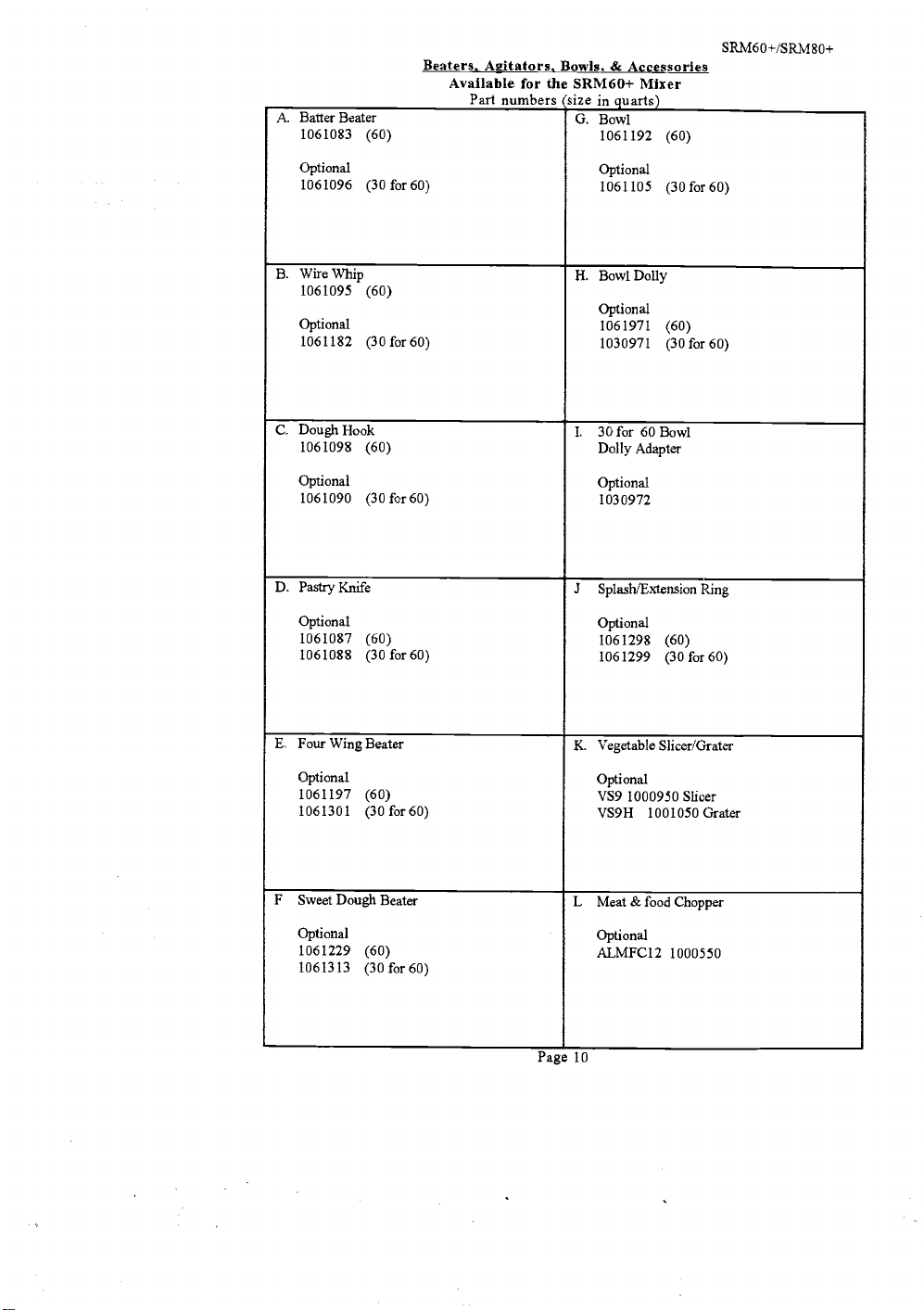

A Batter Beater

1061083

(60)

Beaters Agitators Bow1s & Accessories

SRM6O+/SRM8O+

Available for tile SRM6O+ Mixer

Part numbers (sìze in cuarts

c. Bowl

1061192 (60)

Optional

1061096

B. Wire Whip

1061095

Optional

1061182

C. Dough Hook

1061098

Optional

1061090

D. Pastxy Knife

Optional

1061087

1061088

(3Ofor6O)

(60)

(3Ofor6O)

(60)

(3Ofcr60)

(60)

(3Ofor6O)

Optional

1061105

H. Bowl Dolly

Optional

1061971 (60)

1030971

I.

30 for 60 Bowl

Dolly Adapter

Optional

1030972

J

Splash/Extension Ring

Optional

1061298

1061299 (3Ofor6O)

(60)

(3Ofor6O)

(3Ofor6O)

E. Four Wing Beater

Optional

1061197

1061301

F

Sweet Dough Beater

Optional

1061229

1061313

(60)

(3Ofor6O)

(60)

(3Ofor6O)

K. Vegetable Slicer/Grater

Optional

VS9 1000950 Slicer

VS9H 1001050 Grater

L Meat & food Chopper

Optional

ALMFC12 1000550

Page 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

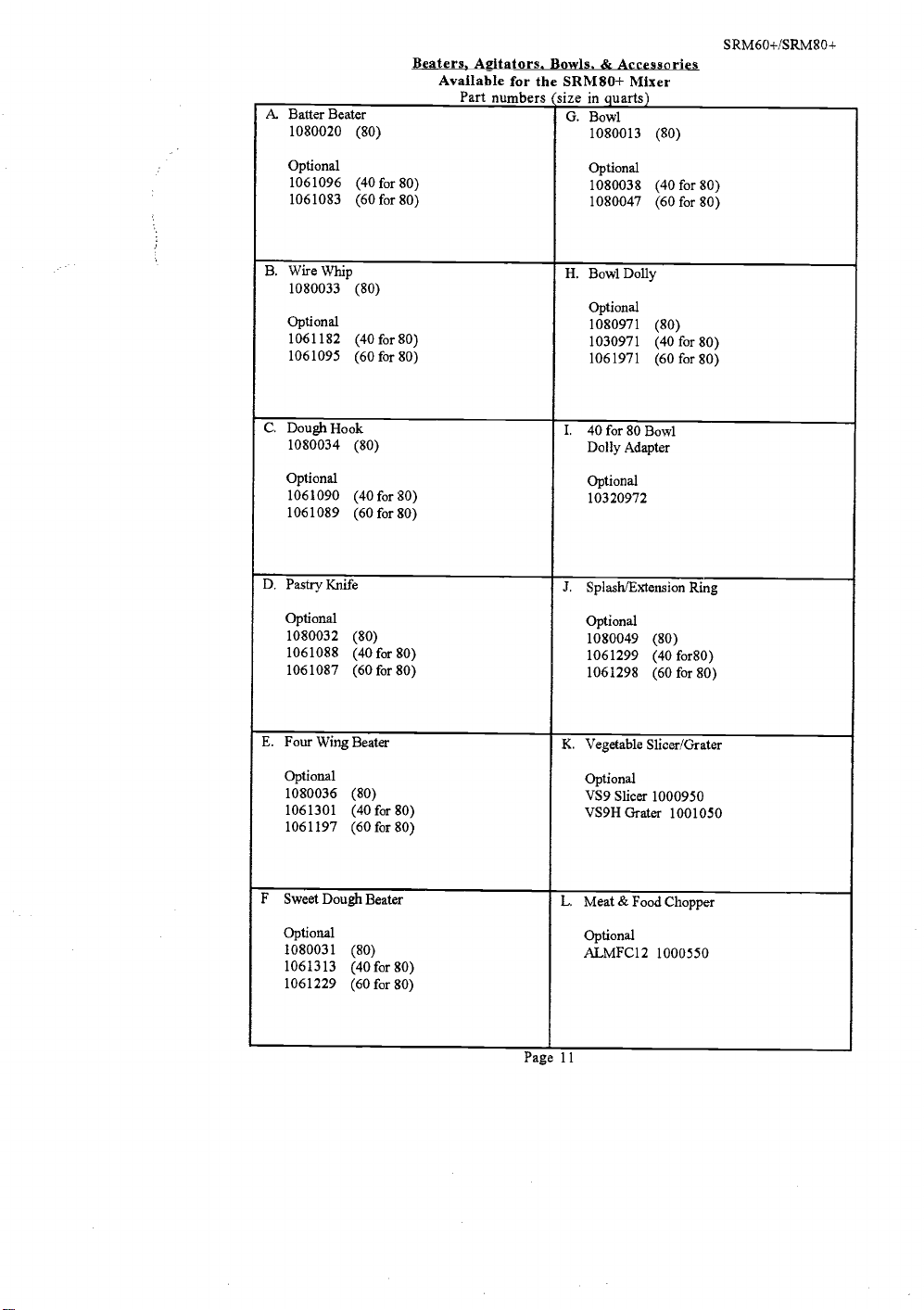

A. Batter Beater

1080020

(80)

Beaters, AgItators Bowls, & Accessories

Available for the SRM8O+ Mixer

Part numbers (size in auarts

)

G. Bowl

1080013

(80)

SRM6O+/SRM8O+

Optional

1061096

1061083

B. Wire Whip

1080033

Optional

1061182

1061095

C. Dough Hook

1080034

Optional

1061090

1061089

D. Pastry Knife

Optional

1080032

1061088

1061087

(40f'or8O)

(6OforSO)

(80)

(4Ofor8O)

(6OforSO)

(80)

(4Ofor8O)

(6OforSO)

(80)

(4Ofor8O)

(6Ofor8O)

Optional

1080038

1080047

H. Bowl Dolly

Optional

1080971

1030971

1061971

L

40 for 80 Bowl

Dolly Adapter

Optional

10320972

J.

Splash/Extension Ring

Optional

1080049

1061299

1061298

(80)

(4Ofor8O)

(6Ofor8O)

(4Ofor8O)

(6Ofor8O)

(80)

(4OforSO)

(6Ofor8O)

E. Four Wing Beater

Optional

1080036

1061301

1061 197

F

Sweet Dough Beater

Optional

1080031

1061313

1061229

(80)

(4Ofor8O)

(60 for 80)

(80)

(40for80)

(6OforSO)

K. Vegetable Slicer/Grater

Optional

VS9 Slicer 1000950

VS9HGrater 1001050

L. Meat & Food Chopper

Optional

ALMFCl2 1000550

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

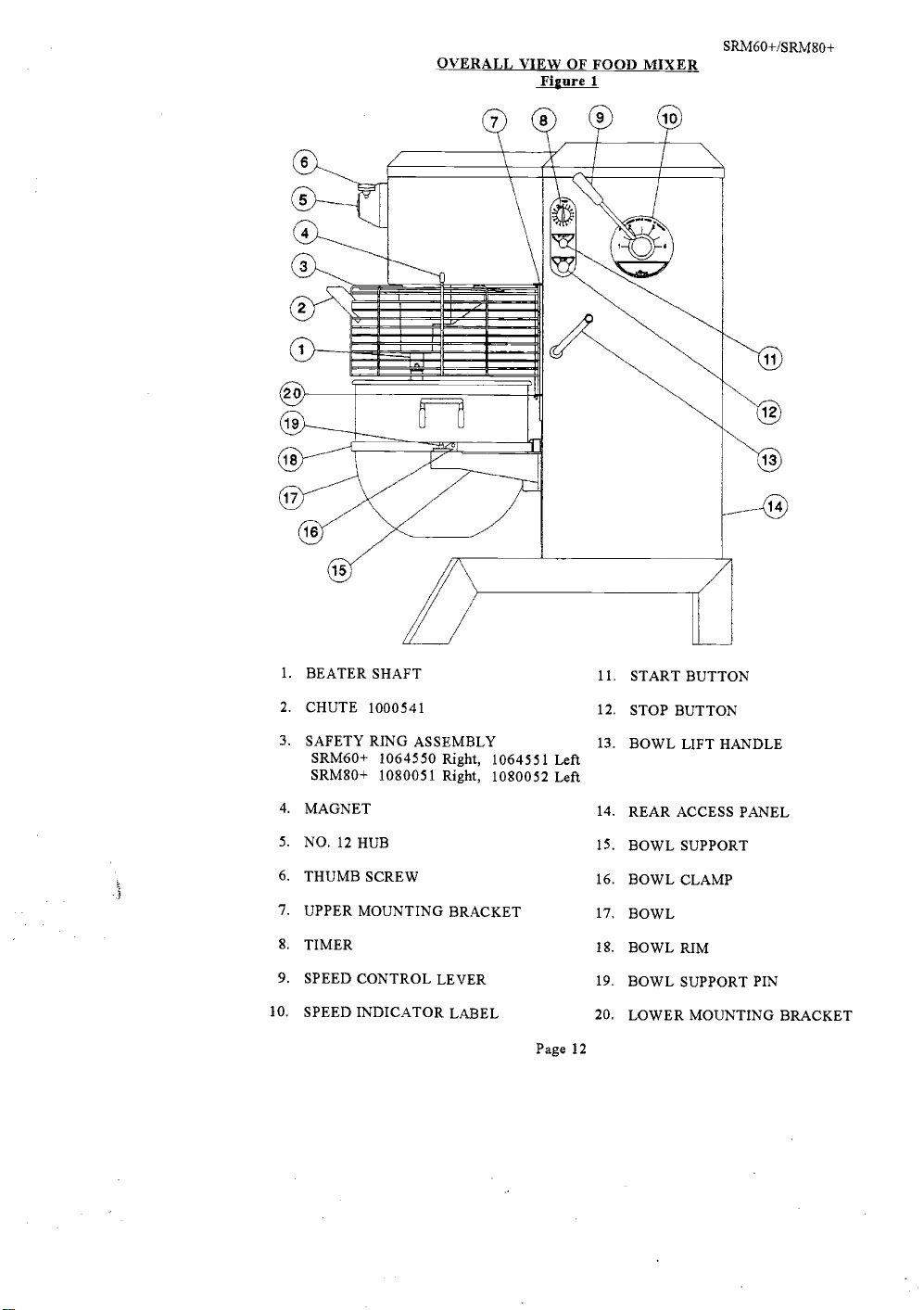

OVERALL VIEW OF FOOD MIXER

Figure 1

SRM6O+/SRM8O+

1.

BEATER SHAFT

2.

CHUTE 1000541

3.

SAFETY RING ASSEMBLY

SRM6O+ 1064550 Right, 1064551 Left

SRM8O+ 1080051 Right, 1080052 Left

4. MAGNET

5.

NO. 12 HUB

6. THUMB SCREW

7.

UPPER MOUNTING BRACKET

8.

TIMER

9.

SPEED CONTROL LEVER

10.

SPEED INDICATOR LABEL

Page 12

11.

START BUTTON

12.

STOP BUTTON

13. BOWL LIFT HANDLE

14. REAR ACCESS PANEL

15. BOWL SUPPORT

16. BOWL CLAMP

17. BOWL

18. BOWL RIM

19. BOWL SUPPORT PIN

20. LOWER MOUNTING BRACKET

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

CLEANING YOUR MIXER

SRM6O+/SRM8O+

Consistent use ofthe following procedures will

condition,

s

Warning -- Disconnect electric power supply before

.

Wash the body of the mixer, the bowl support, and beater

ensure that your mixer is in optimum

mild soap.

e

Avoid excess water in the area ofthe safety switch that

where the Swing RingTM Safety Guard is mounted.

u

Do not rinse with a hose,

e

Do not use abrasive pads.

e

Dry the mixer thoroughly using a soft cloth.

e

Wash the bowl and beater immediately after

been used, rinse the bowl and batter with cold

Wash the Swing RingTM Safety Guard in the

u

Dry bowls, agitators and safety guard thoroughly.

use. If egg mixtures or flour batter have

water before washing with hot water,

same manner, or in your dishwasher.

OPERATOR'S PREVENTIVE MAINTENANCE

For best long-term performance, operators should follow

e

Lightly lubricate the beater shaft (Fig. 1 [1]) after

food grade lubricant should be used.

e

Do not cover the unit with a plastic bag,

e

If the electrical supply cord is damaged, it

assembly available from Univex directly

u

Do not overload the mixer. Overloading Is the #1

the Table of Mixing Capacities on

table adjacent to the mixer.

e

Keep the mixer properly lubricated, Lack of

failure. Key mixer components require lubrication

as this traps humidity in your mixer.

must be replaced by a special cord or

or from a Univex service agent,

page 8 &9. It may be helpful to post a copy of this

lubrication is #2 cause of mixer

(Instructions on frequency and method of lubricating

e

Only change speed with the mixer running. Changing

loosen, and the mixer will not turn (see Trouble-Shooting

speed 1 before shutting the mixer off. Use the procedure

speed i ifmixer is shut offin a higher speed.

cleaning.

shaft with warm water and

protrude from the housing

these simple practices.

washing. Petro-Gel or equivalent

cause ofmixer failure, Follow

after each 500 hours of operation.

are on page 1 8).

speed with mixer offwffl cause belts to

Guide on page 14 & 15). Return to

described on page 6 to return the mixer to

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

TROUBLE

1 , Mixer will not

operate.

SRM6O+/SRMSO+ TROUBLESHOOTING GUIDE

SRM6O+/SRM8O+

POSSIBLE CAUSE

1 . i Timer not turned on.

1.2 Burned switch contacts

1 . 1 Turn timer on.

1.2 Clean or replace contacts.

REMEDY

2. Mixer runs but

agitator will not

turn.

3. Agitator stalls

during mixing

1.3 Electrical service down.

1,4 Motor capacitor defective.

(1 PH Only)

1.5 Burned out motor.

1.6 Magnetic starter tripped

due to overload

1.7 SAFETY RING not

mounted and closed.

1.8 Bowl not raised.

2. 1 Drive belt off pulley

2.2 Key or Pin sheared on input

shaft, input gear, bevel

pinion, bevel gear, vertical

shaft or beater shaft.

2.3 Shifting speed with mixer

not running.

3.1 Mixer bowl is overloaded

1.3 Check electrical service.

Replace fuse or reset

circuit breaker if necessary.

1.4 Replace. *

1.5 Remove, test, repair or

replace. *

1.6 Wait several minutes and

push start button

1.7 Install SAFETY RING.

1.8 Raise bowl comnletelv

2.1 Reinstall drive belt on

motor pulley and adjust

mount center distance. *

2.2 Locate by step inspection

and replace defective part.*

2.3 With mixer running, slowly

move speed control lever

slowly fully forward then

backward to re-engage belt

3. 1 Adjust contents ofbowl per

Mixing Capacities Table

4. Speeds do not

3.2 Speed is settoo high forthe mix

3.3 Loose belt

3.4 Contamination ofbelt with

grease

4.1 Loose belt.

3.2 Shift speedlower till action

rotates smoothly

3.3 Readjust pulley center distance

to tighten belt.

3.4 Clean pulleys and replace belt *

'

4.1 Tighten or replace belt. *

change properly

4.2 Van-Speed pulley

inoperative

4.2 Remove, clean & lubricate,

or replace. '

Page 14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

SRM6O+/SRM8O+ TROUBLESHOOTING GUIDE

'

5. Mixer runs, but

repeatedly cuts

out and stops

s. i

Bowl overloaded

5.2 Speed is set too high for

the mix

SRM6O+/SRM8O+

(CONT'D).

5. 1 Adjust contents of bowl

per Mixing Capacities

Table

5.2 Reduce speed

5.3 Service voltage too low or

5.4 Starter improperly set

f

6. Attachments

6.1 Dented bowl.

contact bottom

of bowl.

6.2 Bowl height is set too high

7. Attachments

contact side of

bowl

7.1 Dented bowl

7.2 Insufficient clearance

between bottom of bowl and

beater.

8. Excessive

noise.

8.1 Gears need to be repacked

8.2 Badly worn or frayed drive

8.3 Attachments hitting bowl

8.4 Overloaded mixing bowl

* Remedies designated with

fluctuating

5.3 Check electrical voltage. *

5.4 Adjust amp setting on

starter.

6.1 Remove dent or replace

bowl.

6.2 Reset bowl height. *

7. 1 Remove dents or replace bowl

7.2 Adjust bowl height. *

with grease, or oil level is

low.

belt.

8.1 Locate source by

inspection and repack

with grease, or top off oil

level. *

8.2 Replace belt.

8.3 Inspect for cause in items

6 and 7 above.

8.4 Adjust contents of bowl

per Mixing Capacities

Table

a

require the services of an authorized service agent.

Page 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

REMOVAL OF TOP COVER AND REAR ACCESS PANEL

SRM6O+/SRJ8o+

The top cover (Fig. 10 [17]) must be removed in order to perform the

maintenance operations.

It is secured by a spring clip at its front end and a

screw at its rearward end. First, DISCONNECT THE ELECTRICAL

POWER FOR SAFETY. Then, remove the screw in the rear (Fig. 10 [20J),

lift rear of cover, push forward about 3 inches and lift cover off.

Reinstall in reverse procedure using care to insure that the cover sits squarely

and uniformly on the mixer housing.

Remove rear access panel (Fig. 10 [22]) by removing eight screws and

washers (Fig. 10 [23, 24}).

A mechanic should perform the following inspection and maintenance as required

depending on severity of use, but at least yearly.

MECHANICS MAINTENANCE

CVT BELT DRIVE

1.

a.

Start mixer and shift speed control (Fig. i

Stop mixer.

to the slowest speed (Low, 1).

[91)

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER. Place

tag or sign on electrical supply warning that MIXER IS BEING

WORKED ON: DO NOT TURN ON.

Remove rear access panel (Fig. 10 [22]) and top cover (Fig. 10 [17]) as

described above.

Inspect drive belt (Fig. lI [21) for proper adjustment. Outer surface of belt

should be approximately flush to 1/16' below the outer edges ofthe input

pulley flanges (Fig. 1 1 [5]) when mixer has been shut off in first speed (see

Pg. 17).

replace it.

If drive belt is excessively frayed or has a heavily glazed surface,

However, it is generally the best judgment to leave a drive belt in

a machine if it is performing well, even it if shows moderate wear. Inspect

gripping surfaces of drive belt for excessively glazed surfaces or

contamination by grease or oil.

To replace belt, run mixer in ist speed. Disconnect electrical supply. Shift

machine to 4th speed. Unwrap belt from top pulley. Slide belt between top

pulley nose and cam (Fig. S [8]). Remove belt from lower pulley.

WARNING: Lower pulley flanges are spring loaded. Keep fingers away while

removing belt.

The bowl must be lowered In order for the belt to clear the nose of the

lower pulley when removing belt. To install new belt wrap belt around

lower pulley. Pull belt into the spring loaded flanges. A pry bar will help

separate the flanges. Continue replacement in reverse order from belt

removal. Adjustment ofthe belt drive will most likely be required.

Readjustment of the drive belt, where a slight stretching or normal seating has

caused outer surface of the belt to exceed the acceptable limit of flush to

1116 below the input pulley flanges (see Pg. 17) is as follows:

Loosen Kep nuts (Fig. 8 [12]) securing the bracket (Fig. 8 [15]) and holder

(Fig. 8 [1]) to the housing. Ifthe belt was riding outside the pulley flanges,

tap the speed control assembly lightly towards the rear of the mixer. If the belt

was riding more than 1/16" below the pulley flanges, tap the

Page i6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

Speed control assembly towards the front ofthe machine (shifting to 2nd

SRM6O+/SRM8O+

second speed will help).

Note: The assembly must remain perpendicular to the mixer housing walls.

Failure to do so will result in the binding ofthe shaft (Fig. 8 [10]) in the

bearing (Fig. S [21}). Retighten the Kep nuts and run mixer in ist speed and

check belt position. Repeat procedure if necessary.

e.

Once the upper pulley (Fig. i i [5}) has been adjusted, the lower pulley

be checked. Start mixer and shift to 4th speed. Turn mixer off and

position ofbelt. The belt should be flush to 1/16" below outer edges of the

pulley flanges. Ifadjustment is needed, loosen Kep nuts (Fig. li [14])

raise or lower the motor using the Kep nuts on the under side of

Retighten top Kep nuts and run mixer in 4th speed to check

new belt position.

must

check

and

motor.

Note: The motor must remain level with the mixer base (Fig. 10

poor shifting and belt life will result.

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER.

DRIVE BELT SETUP

O TO VIE MAX.

o

TO I/IS MAX.

SPEED

CONTROL

HÑ'DLE

ON SPEED 4

SPEED

CONTROL

HANDLE

ON SPEED

MOTOR

Check motor (Fig. 11 [16)) for overheating and excessive noise.

to a local electrical repair shop.

[1]).

If not,

Ifdefective, send

BOWL LIFT ADJUSTMENT

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER.

Check adjustment by placing the bowl on the lowered bowl

a batter beater on the beater shaft (Fig. i [11).

support, and place

Raise bowl support to the upper position,

Check clearance between bottom of the bowl and the adjacent underside of

batter beater. Clearance should be 3/16" ± 1116".

the

Page 17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

d.

If adjustment is required, loose jam nut (Fig. 7 [26]) and turn threaded

SRM6O+/SR8O+

stop rod (Fig. 7 [25}) until the desired clearance is obtained, then tighten

jam nut.

DRIVE BELT REPLACEMENT (See CVT Belt Drive)

LUBRICATION

bowl

the

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER TO

MIXER.

a.

The lubrication instructions are listed in Figure 2.

b,

Remove access panel (Fig. 10 [22]), top cover (Fig. 10 [17])

In order to service the gearbox, it will be necessary to flirther

gearbox cover (Fig. 3 [2]). A thin blade putty knife will

separating the silicone sealant between this cover and the gearbox. Do

bend cover. Thoroughly remove all dried sealant before applying

when reinstalling the cover. Do not allow dried sealant to enter gearbox.

Silicone rubber sealant such as Dow Corning Silastic 732RTV

Form-A-Gasket are recommended.

WARNING: NEVER WORK ON THE GEARBOX WITH THE MIXER

RUNNING.

Use care to avoid getting lubricant of any kind on the drive belt and pulleys

this would seriously deteriorate the belt grip and mixer performance.

LUBRICATION INSTRUCTIONS

FIGURE 2

©

Oil Level n

Housing fo be

6 from Top

of Housin9.

Internal Gear

Beater Shaft

-. TTi!It Vj

® GREASE EVERY 6 MO.

® REPACK GREASE EVERY 500

® 140 WT GEAR OIL

THE

per page 4.

remove the

prove helpful in

new sealant

or Permatex

GENERAL PURPOSE

MACHINE GREASE.

HOURS OF OPERATION

ON PLANETARY GEARS.

USE KEYSTONE

NEVASTANE 5P7.

not

as

Bowl Lift

Slide and

Lead Screw

Bowl Clamp

AFTER EVERY WASH APPLY

LIGHT COAT OF FOOD-GRADE

LUBRICANT SUCH AS. PETROGEL.

208-240V. 50HZ. I & 3PH AC,

Motors. Lubricate every ten years

with hiqh quality ball beans9 grease

oppliedinto the two Alemite fittings.

with ose or two full strokes.

Page 18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

REPAIR INSTRUCTIONS

(Including Disassembly, Replacement and Reassembly)

A2 GEARBOX (Fig. 3)

GEARBOX REMOVAL:

Run mixer and shift to first speed then turn off.

WARNING; FOR SAFETY, DISCONNECT ELECTRICAL SUPPLY.

Remove set screw (Fig. 3 [16]) and drain oil.

Remove rear access panel (Fig. 10 [22]), top cover (Fig. 10 [17)),

instruction on page 4.

Remove drive belt per instructions (1) in Mechanics Maintenance.

Remove speed control assembly (Fig. 8)

See Speed Control Disassembly.

Loosen two allen set screws (Fig. 1 1 [4)) that secure input pulley (Fig. i 1

[5)) and remove pulley completely from input shaft (Fig. 6 [10)).

Remove gearbox cover (Fig. 3 [2]). Remove remaining oil from gearbox.

WARNING - FOR SAFETY! The gearbox is very heavy, weighing

approximately 261 pounds and must, therefore, be supported safely before

starting step number (10),

crane of sufficient capacity be used. A chain may be attached to the PTO.

shaft (Fig. 5 [1 1)) at mìd-length. Use care not to rub or scrape the gears.

SRM6O+/SRM8O+

It is recommended that a portable hydraulìc

Remove four cap screws (Fig. 3 [1 1]) securing gearbox housing to mixer

housing. Remove gear box assembly and place on work bench.

i i .

Rotate gear train by hand and inspect for worn or chipped gears, bent shaft,

worn bearings and excessive backlash. Backlash measured at gear teeth

exceeding 1/32" is considered excessive. After trouble has been isolated,

proceed to disassemble.

GEARBOX DISASSEMBLY:

1.

Beater Head (Fig. 4)

Remove cap screw (Fig. 4 [21]) and remove beater head assy. If beater

head does not drop easily, use the two jacking screws (Fig.

assist in removal. Do not pry against outer rim of beater head housing

(may cause breakage).

Remove top retaining ring [9], gear [1 1], bottom retaining ring [9),

key [7], seal [10), retaining ring [9), retaining ring [S), and press shaft

[2] (at gear end) from housing [1].

C.

Press bearings [4 & 6] along with spacer [5) from housing [1).

Page

4 [19]) to

19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

2. Power Take Off (Fig. 5)

Remove three cap screws (Fig. 5 [5}) and washers [6] holding PTO.

housing [3] to gearbox housing (Fig. 3 [1]).

Remove retaining ring 8} from helical gear end of PTO shaft [1 1].

Remove gear [13} and key [14].

Using two cap screws as jacking screws (Fig. 5 [5]) in the tapped

holes of gearbox housing (Fig. 3 [1]), dislodge and remove the P.T.O.

assembly from the gearbox housing.

Remove and slide bevel gear [12] away from PTO. housing [3] and

remove key [15].

Remove internal retaining rìng [9], PTO. adapter [2] and press shaft,

bearing, and gear assembly from P.T.O. housing [3].

Remove four retaining rings [8] from PTO. shaft [1 1], and press ball

bearings [10] and P.T.O. bevel gear [12] off PTO. shaft [1 1}.

Remove PTO. oil seal [7] from PLO. housing [3] and discard.

3.

IILP.g.t (Fig. 6)

Remove four cap screws (Fig. 6 [8] from flange of input housing [6].

Thread two of the cap screws [8] into the two threaded jacking holes

in the flange [6]. Turn these two screws in evenly until the input

housing is pushed free ofthe gear box housing.

SRM6O+/SRMSO+

Remove retaining ring [2] at gear end of the shaft, and press off

bearing [4].

Remove retaining ring [3] and proceed to remove input shaft [10] with

bearing [4], out of input housing [6] by pressing from the gear end of

the shaft.

Remove rubber seal [4] from housing. Seal must be replaced.

Remove remaining retaining ring [3] from housing.

4.

Vertical Shaft (Fig. 4)

Remove beater head as covered in Gearbox Disassembly (1) a-c.

Remove P.T.O. assembly as covered in Gearbox Disassembly (2) a-g.

C.

Remove key (Fig. 4 [18]) and retaining ring [9] from vertical shaft

[13].

d. Drive vertical shaft downward into the gearbox. A brass drift will be

necessary to drive shaft completely free from the gear box. Lift bevel

gear [12] and key [14] from gear box.

Page 20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 22

e.

Insert drift through top ofbearing [15] in gearbox and drive seal [16] out bottom of

bore.

SRM6O+/SRM8O+

Reach up into bore from bottom opening with snap ring pliers and

remove retaining ring [8] from bore.

Carefully drive upper bearing [15] out bottom of bore.

Press bearing [17] from shaft [13].

GEARBOX ASSEMBLY

1 .

Clean all components (except bearings) with safety approved cleaning

solvent. Inspect components for defects and replace those found to be

defective.

NOTE: Ifplanetary pinion gear (Fig. 4 [11]) requires replacement, it is

likely that the planetary gear (Fig. 3 [20]) requires replacement also.

2.

If shafts have become slightly scored during the disassembly process, it is

necessary to polish the shafts with fine machinist's crocus cloth. An

especially smooth finish is necessary in the working seal area of the shafts.

Use care to avoid excessive removal of shaft surface or proper fit of

components will be lost.

3,

Always fit new rubber seals when rebuilding the gearbox. Use special

attention in examining the end of the shafts over which the seals will be

pushed. The slightest burring or scoring will abrade or cut the delicate seal

lips. A light polish of the shaft ends with crocus cloth is recommended.

Reassembly should be carried out in reverse ofthe disassembly procedure

stated above. Successful reassembly is very dependent on the cleanliness of

all surfaces, particularly the bores of housings, gears, and bearings,

as the outer surface of shafts.

It is good to recheck each component for

as well

cleanliness as it is picked up for reassembly.

Transmission should be progressively checked for smooth operation while

on the workbench by hand turning each assembly as it is installed.

Lubrication of the gear box should be done following its installation

mixer. The helical and bevel housing compartments are filled to

on the

a level 6"

(10 qt. SRM6O±) (16 qt. SRM8O+) from the top edge ofthe gear box with

SAE 140 gear oil.

B. BOWL LIFT & SLIDE (Fig. 7)

BOWL LIFT 8 SLIDE DISASSEMBLY & REMOVAL

CAUTION: FOR SAFETY, DISCONNECT ELECTRICAL SUPPLY.

Remove top cover and rear access panel as detailed on page 4.

Remove drive belt from motor pulley as stated in Mechanic's Maintenance

Section 1 (c).

Remove drive assembly (Fig. i 1) from mixer housing as follows:

Page 21

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 23

Remove the top 4 Kep nuts (Fig. i i [14]) that secure motor assembly to

SRM6O+/SRM8O+

mixer base.

Remove motor electrical leads (Fig. i i [13}) from magnetic starter (Fig. 10

[26]). Remove motor ground lead from stud.

i 1.

C.

Lift motor assembly from mixer housing.

CAUTION: Drive assembly can weight in excess of 100 lb. depending on

type ofmotor. Use mechanical lift assistance.

Remove bowl from bowl support.

Remove two screws (Fig. 9 [121).

Remove 4 screws (Fig. 7 [321).

CAUTION: Someone should be holdìng bowl support (Fig. 9 [1}) while

the screws are being removed, so that it does not fall and get damaged.

Remove slide cover (Fig. 9 [10J).

Loosen set screws (Fig. 7 [2)) and Fìg. 7 [8]).

Withdraw handle assy. (Fig. 7 [38]) from the outside ofmixer housing.

Collect gear [9], key

washers [4 & 42] and collar [3].

[391,

Remove 8 nuts (Fig. 7 [3 1]) and pull slide/frame assembly from studs and

remove from mixer housing.

CAUTION: Assembly is heavy.

Remove 2 hex head cap screws (Fig. 7 [15]). This allows for removal of

yoke (Fig. 7 [7]).

Drive roll pin (Fig. 7 [1 1)) from miter gear (Fig. 7 [12]). Remove miter

gear and thrust washer (Fig. 7 [4]) from lead screw (Fig. 7 [10]).

Press lead screw (Fig. 7 [10]) through hole in frame [1].

Loosen set screws (2). Remove collar [3] and thrust washer (Fig. 7 [4]) by

pulling them from lead screw.

Unscrew lead screw from floating nut (Fig. 7 [28]) and remove.

Remove 4 screws (Fig. 7 [27]) and remove gibbs (Fig. 7 [29)). The slide

may now be removed from the frame.

NOTE: Save any shim strips that may have been used between the frame

and the gibbs.

It is recommended that the location be marked at this time

with a pencil to facilitate reinstallation.

BOWL LIFT & SLIDE. REASSEMBLY & INSTALLATION (Fig. 7)

Grease sliding surfaces of slide & frame. See Lubrication page 18.

Keeping shims in place (if any), position slide in frame as shown in Fig. 7.

Page 22

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 24

SRM6O+/SRM8O

Secure slide (Fig. 7 {34}) in frame [1) by bolting gibbs [29] to frame with

four hex head cap screws [15]. Check to insure that slide moves freely in

frame. If not, remove gibbs and shim where needed.

Screw lead screw [10] into floating nut [28] and push slide to bottom of

frame so that the lead screw does not protrude through hole in frame.

Place the collar [3] and then thrust washer [4] over top of lead screw [10].

Push slide and lead screw up so that the lead screw protrudes through hole

in frame.

Place thrust washer [4} and then miter gear [12] on top of lead screw [10].

Drive roll pin [11] through miter gear [12] and into lead screw [10].

Push slide & lead screw down as far as possible. Slide collar [3] and thrust

washer [4] up against frame and tighten set screws [2] in collar against

corresponding flats on lead screw [10].

Check DU bearings in yoke for burrs (Fig. 7 [6]). Install yoke [7] to frame

[1] (do not tighten bolts).

Lift assembly into mixer housing. Place assembly on S weld studs.

Tighten assembly to mixer housing using washers and Kep nuts.

Insert bowl lift lever assembly (Fig. 7 [35-38,40,41]) through hole in mixer

housing. Slide collar [3] and thrust washer [42] over end of lever. Insert

lever through yoke while holding the thrust washer

position. Continue to slide lever through until miter gear seats against

shoulder on the lever shaft. Align key ways of miter gear and lever, insert

and miter gear [9] in

[41

key [39]. Tighten set screw [8]. Squeezing miter gear [9] and collar [42],

tighten set screw [2].

li.

With yoke bolts [15] lightly tightened, tap yoke back and forth until the

miter gears mesh smoothly. Tighten bolts [15]. Adjust hub [40] so that it

is positioned 1/32" from mixer housing. Tighten set screw [41].

Lubricate the miter gears and lead screw with general purpose machine

grease.

Raise and lower bowl lift by turning the bowl lift lever [37]. The

mechanism should turn freely.

Raise bowl all the way. Check clearance between bottom of bowl and

batter beater attachment. The clearance should be 3/16 ± 1/16. If the

clearance is not sufficient, adjust bowl stop (Fig. 7 [25]). Loosen jam nut

[26}, raise or lower bowl stop as needed and tighten jam nut.

Make sure bowl lift safety switch (Fig. 7 [19]) is actuated by the retainer

plate [24] when the bowl is raised completely. Ifthe switch is not actuated,

or the lever on the switch is being bent, adjust the bracket [17] by

loosening screws [23] and raising or lowering until the switch actuates.

Note: The bowl should continue to raise 1/8' after switch actuates.

Page 23

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ç

Page 25

SPEED CONTROL (Fig. 8)

SRM6O+/SRM8O+

i

Run mixer and shift to first speed then turn mixer off.

Warning: For safety disconnect electrical supply.

Remove rear access panel (Fig. 10 [22)) and top cover (Fig. 10 [17])

instructions on page 4.

Remove drive belt per instructions 1 in mechanics maintenance.

Warning: Handle (Fig. 8 [25]) has spring loaded rotation. Hold handle to

prevent injury.

While holding handle (Fig. 8 [25]) remove set screws [20] and rotate

handle counter clockwise two full turns. This disengages the spring [1 11.

Note: The ball [3] and spring [4] may fall out of block [6].

Loosen set screws (Fig. 8 [1), drive roll pin [22] from hub [23] and pull

hub from shaft [10]. Unscrew hub [23] and handle [25] from lever [24].

Slide retaining rings [9], cam [8] and spring [1 1] towards locating block

[6]. Remove key [19] from shaft, loosen nuts [12] securing detent housing

[11

Drive shaft [10] inward until it contacts the left sìde housing wall. Pull

detent housing [1] and shaft assembly [10] towards rear of machine and

remove assembly from mounted bearing [18].

Slide spring [1 1] retaining ring [9], cam [8] and belleville washer [2] from

shaft [10]. Drive roll pin [7] from block [6].

[10].

Slide block [6] from shaft

Remove nuts [12], washers [13 & 14] and bracket [15] from housing.

Remove bolts [16 & 17] securing bearing [18] to bracket [15].

Reassemble in reverse order of above

Adjust assembly as described in Mechanics Maintenance 1 d, & e.

If speed handle creeps during operation tighten the two set screws (Fig. 8 [5]) which

push against the belleville washer [2] until creeping stops.

HOUSING (Fig 10)

For the remaining parts which have not been discussed pertain to electrical

components, and the housing, Figures 10, 12A, l2B, and 12C should provide

adequate guidance for the disassembling and reassembling oftbese parts.

Page 24

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 26

GEAR BOX

FIGURE 3

ILLUS. NO.

i 1064530 HOUSING, TRANSMISSION-SRM6O+ I

PART NO.

1080054

2

1064417 COVER, TRANSMISSION-SRM6O+

1080022

3 1200008 SCREW, PHILLIPS PAN HEAD 8-32 X 3/S 8

4

5

6 4400065 LOCK WASHER #10

7

8

9

10 1064418 TUBING, TRANSMISSION

11

12 1200085 LOCK WASHER 1/2

13

14 1200403

15 1061990

1024041

1200076

1200012

1200378 SCREW, CUP POINT SET 8-32 X 1/4

1064507 PLUG, OILING TUB

1200057

1200084

1080039

16 1200329

17 1200365

18

19 1061002

4400269

20 1061111

21 4400345

4400327

22

23 1012439

1012438

DESCRIPTION

HOUSING, TRANSMISSION-SRM8O+ I

COVER, TRANSMISSION-SRMSO+

SPRING CLIP 1

FLAT WASHER #10

SCREW, PHILLIPS PAN HEAD 10.32 X 1/2

SCREW, HEX HEAD CAP 1/2-20 X 1 4

FLAT WASHER 1/2

PIN, DOWEL 3/8 DIA. . X 1/2

PLUG, OIL.SRM6O+

PLUG, OIL-SRM8O±

DRAIN PLUG, l/4NPT HEX HD SOCKET

SCREW, SOCKET HEAD CAP 114-20 X 1/2

LABEL, ROTATION

SPLASH RING

GEAR,INTERNAL

LABEL, UNIVEX-SRM6O+

LABEL, UNIVEX-SRMSO+

HOLDER, MAGNET 2

MAGNET

SRM6O+/SRM8O+

QTY.

1

1

2

2

2

1

2

1

4

4

2

i

1

I

8

i

1

1

i

1

2

Page 25

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 27

SRM6O+/SRM8O+

BEATER HEAD AND VERTICAL SHAFT ASSEMBLY

FIGURE 4

ILLUS. NO. PART NO. DESCRIPTION.

i

2

3

4

5 1064426

6

7

8 i200354

9 1200353

lo 1064509

11 1061003

12

13

14

15

i6

17

i8

19

20

21

1064423

1064424

1200310

106i959

1061917

4400231

1064420

1080016

1064422

10800 1 4

1200314

1064513

1064512

i064500

1200315

1200405

1064448

1200379

HOUSING, BEATER HEAD

SHAFT, BEATER HEAD

PIN, DOWEL

BEARING, BALL

SPACER, BEATER HEAD

BEARING,BALL

KEY 1/4 SQ. X 1, CL 1, ROUNDED BOTH ENDS

RETAINING RING, INTERNAL

RETAINING RING, EXTERNAL

SEAL,

GEAR, PINION, BEATER HEAD

GEAR, BEVEL, VERTICAL SHAFT-SRM6O+

GEAR, BEVEL, VERTICAL SHAFT-SRMSO+

SHAFT, VERTICAL-SRM6O+

SHAFT, VERTICAL-SRM8O+

KEY, 3/8 SQ. X 1-1/2, CL 1, ONE END ROUNDED

BEARING, BALL, VERTICAL

SEAL,

BEARING, BALL, VERTICAL

KEY, 3/8 SQ. X 2, CLASS 1, ONE END ROUNDED

SCREW, SET 5/16-18 X i-3/4

WASHER, 1/2

SCREW, HEX HEAD CAP, 1/2-20, SS, L.H.

o

QE,

o

D

D

o

o

o

o

o

o

o

,__

Q

'-w.

Lii

_)

o

LI

Q

o

OTY.

i

i

i

i

i

i

i

2

4

i

i

1

i

1

i

i

i

i

i

i

2

i

i

18

o

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

'a

\

Page 26

Q

Page 28

P.T.O. ASSEMBLY

FIGURE 5

SRM6O+/SRM8O+

ILLUS. NO.

i

2

3

4

5

6

7

S

9

lo

II

12

13

14

15

16

17

18

19

20

PART NO.

8800033

8800012

1061107

1080018

1064514

1080041

4400220

1200077

1064510

1080040

1200253

1200316

i2OO54

1061909

1030148

1064501

1064458

i0800i9

1064459

1080017

1064428

1080015

4400231

4400231

4400500

4400006

4400016

4400229

4400210

8900019

DESCRIPTION

CAP, CHROME, PTO

ADAPTER, PTO

HOUSING, PTO-SRM6O+

HOUSING, PTO-SRM8O+

O-RING SRM6O+

O-RING SRM8O+

SCREW, HEX HD CAP, 5/16-18 X i 3

WASHER, LOCK, 5/16 3

SEAL, OIL, PTO-SRM6O+

SEAL, OIL, PTO-SRMSO+

RETAINING RING, EXT.-SRM6O+ 6

RETAINING RING, EXT.-SRM8O+

RETAINING RING, INT.-SRM6O+

RETAINING RING, INT.SRM8O+

BEARING, BALL-SRM6O+ 2

BEARING, BALL-SRMSO+

SHAFT, PTO-SRM6O+

SHAFT, PTO-SRMSO+

GEAR, BEVEL, PTO-SRM6O+

GEAR, BEVEL, PTO-SRMSO+

GEAR, HELICAL, PTO-SRM6O+

GEAR, HELICAL, PTO-SRMSO+

KEY, 1/4 SQ. X i, CL 1, RND ENDS

KEY, 1/4 SQ. X i, CL i, RND ENDS SRM6O+

KEY 1/4 SQ. X 1 1/2 LG CL i, RND ENDS

SRM8O+

SPRING, 1/4 OD., COMPRESSION

BALL, STEEL, 1/4 DIA. i

KNOB ASSEMBLY, PTO

WASHER, PTO

SCREW SFHD 6-32 X 3/4

I

1

1

i

i

i

i

1

6

i

1

2

1

1

i

1

1

1

i

i

1

i

i

I

2

Page 27

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 29

P.T.O. ASSEMBLY

FIGURE 5

SRM6O+/SRM8O+

Page 28

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 30

INPUT ASSEMBLY

FIGURE 6

SRM6O+/SRMSO+

ILLUS. NO.

i

2

3

4

5

6

7

8

9

io

PART NO.

1064511

1200316

DESCRIPTION

SEAL, INPUT

RETAINING RING, EXTERNAL

1061909 RETAININGRING,INTERNAL

1064501

1064515

1064430

1200077

1200039

BEARING, INPUT HOUSING

O-RING, INPUT HOUSING

HOUSING, INPUT

WASHER, LOCK, 5/16

SCREW, HX HD CAP, 5/16-18 X 3/4, ZINC PLTD

i064433 SLEEVE, INPUT SHAFT

i064532

GEAR/SHAFT, INPUT

QTY.

i

2

2

2

i

i

4

4

i

i

Page 29

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 31

BOWL LIFT ASSEMBLY

FIGURE 7

SRM6O+/SRM8O+

ILLUS. NO.

i

2

3

4

5

6

7

8

9

io

i i

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

PART NO.

1062190

4400407

1062193

1061821

1200403

1061820

1064452

1200036

10622i7

i064457

4400004

i062970

i200078

1200077

1200369

1200433

i06441 i

7100023

7100103

1200432

1200076

4400065

i2000i2

i062i87

1200431

1200063

4400220

1064444

1062191

1200083

1200388

1200402

1200085

1062189

1200325

1064416

i0645i6

1080025

4400232

1064450

4400154

1000517

DESCRIPTION.

FRAME

SCREW, SET, 51i6-i8 X 1/4 LOE

COLLAR, LEAD SCREW (COMES WITH

ILLUSTRATION # 2)

WASHER,THRUST

PIN, DOWEL, 3/S DIA. X 1/2 LO.

BEARING

YOKE

SCREW, SET, 5/16-24 X 3/S LO.

GEAR, MITER, HANDLE SHAFT

SHAFT, LEAD SCREW

PIN, ROLL, i/4 DIA. X i-1/8 LO.

GEAR, MITER, LEAD SCREW

WASHER, 5/16

WASHER, LOCK, 5/16

SCREW, HEX HD CAP 5/i6-18 X I 1/4

NUT, ELASTIC STOP, 4-40

BRACKET, BOWL LIFT SWITCH

INSULATIONBARRIER

SWITCH, BOWL LIFT

SCREW, HEX HD 4-40 X 314

WASHER, #iO

WASHER, LOCK, #10

SCREW, PHILLIPS PAN HD., 10-32 X 1/2

PLATE, RETAINER

SCREW, SET, 5/16.18 X 2

NUT, KEP, 5/16-iS

SCREW, HEX HD CAP 5/16.18 X i

NUT, FLOATING

GIBB

WASHER, 3/8

NUT, ELASTIC STOP, 3/8-16

SCREW, HEX HD CAP 1/22O X 2-3/4

WASHER, LOCK, 1/2

SLIDE

SCREW, FLAT HD SCK CAP, 1/4-20 X 3/4, SS

CAP, BL. HANDLE

HANDLE

LEVER, BL.

KEY, 3/i6 SQ. X 1 LO., CL ONE, RND ENDS

HUB, BL.

SCREW, SET, #10-32 X 1/4

WASHER, BRONZE, 3/4 I.D X i-1/8 OD. X i/S

i

4

2

3

2

3

i

i

i

i

i

i

i

7

2

2

i

i

i

2

2

2

2

i

1

i

5

i

2

8

8

4

4

i

i

1

i

i

i

i

1

i

Page 30

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 32

BOWL LIFT ASSEMBLY

FIGURE 7

SRM6O+/SRMSO+

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 33

SPEED

CONTROL ASSEMBLY

FIGURE 8

ILLUS. NO. PART NO. DESCRIPTION

SRM6O+/SRMSO+

I 1064436 HOUSING, DETENT

2 1200324

3 4400016

4 4400006

5 1200036 SCREW, SET, 5/16-24 X 3/8

6 1064437 BLOCK, S.C. LOCATING

7

8

9

1200321

1064438

1200317

lo 1064434

WASHER, BELLEVILLE

BALL, STEEL, 1/4' DIA.

SPRING, 1/4' O.D.

PIN, ROLL, 1/4 DIA. X 1-1/2, PLAIN FINISH

CAM, S.C.

RETAININGRING

SHAFT, S.C. CAM-SRM6O+

1080026 SHAFT, S.C. CAM-SRM8O+

11 1064439

12

13 1200078 WASHER, 5/16

14 1200083

15 1080027

16 i200327

17 1200039

18

19

20

21

1200063 NUT, KEP

1064508 BEARING, FLANGE

440023i

1200319 SCREW, SOCKET HD SET, 5/16.18 X 1

1064502

SPRING, TORSION

WASHER, 5/16 LO. OD.

BRACKET, S.C. BEARING HOLDER

SCREW, HEX HD 5/1648X2, FULLY THD

SCREW, HEX HD 5/16-18 X 3/4

KEY, ROUND END, 1/4" SQ. X i

BEARING, BRONZE FLANGE

22 1200361 PIN, ROLL, 1/4 DIA. X 3

23

24 1020048

1064435 HUB, S.C.

LEVER, S.C.

25 4400202 KNOB, S.C.

26 1064456

27

1200434

STRAP, SPEED CONTROL

SCREW, SET, 5/16-23 X I

1

1

1

1

1

1

2

i

2

i

I

1

10

8

8

i

1

2

1

i

2

I

i

i

i

i

i

1/8 2

Page 32

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 34

SPEED CONTROL ASSEMBLY

FIGURE 8

SRM6O+/SRMSO+

Page 33

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 35

BOWL SUPPORT ASSEMBLY

FIGURE 9

SRM6O+/SRM8O+

ILLUS. NO. PART NO. DESCRIPTION

i

2

1061028

1080028

SUPPORT, BOWL-SRM6O+

SUPPORT, BOWL,-SRM8O+

1064454 PINS, BOWL SUPPORT-SRM6O+

1080030 PINS, BOWL SUPPORT-SRM8O+

3

4 1200091

5

6 1200093

7 1200449

s

9

io

il 1020040

12 1200008

*

i3 1200382

*

14

*

15 1200075

1200388

NUT, ELASTIC STOP 3/8-16

WASHER, BELLEVILLE

1064322 CLAMP, BOWL

SHIM, WASHER

SCREW HEX HD 3/8-16 X 3

1064455 CLAMP, BOWL, REAR-SRM6O+

1080029

1200322

i200439

1080037

CLAMP, BOWL, REAR-SRM8O+

SCREW, SOCKET HD, 1/4-20 X I -SRM6O+

SCREW, SOCKET HD, 1/4-20 X i 1/2-SRM8O+

COVER, SLIDE, MOVEABLE

STRIP, RUBBER, 2i"

SCREW, PHILLIPS PAN HD. #8-32 X 3/8'

SCREW, 1!4.2OUNC-2B X 7/8

4400005

LOCK WASHER, 1/4

WASHER, 1/4

* INCLUDED ON SRMSO+ ONLY.

QTY.

i

I

2

2

2

4

2

2

2

I

i

2

2

i

2

2

2

2

2

Page 34

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 36

HOUSING ASSEMBLY

FIGURE 10

SRM6O+/SRMSO+

ILLUS. NO.

i

2

PART NO. DESCRIPTION

1064552

1080053

1200060 NUT, HEX 10-32

HOUSING, MIXER SRM6O+

HOUSING, MIXER SRM8O+

WITH TRANSFORMER CONTROL

1200076

3

WASHER, FLAT #10

WITH TRANSFORMER CONTROL

1064554

4

i080055

7100028 KNOB, TIMER

5

12003i8

6

4400413

7

4400003

8

9 i0i2441

COVER, FIXED SLIDE-SRM6O+

COVER, FIXED SLIDE-SRM8O+

SCREW, M4 X .7 MM, CHZ. HD X 8MM LONG

BOLT, CARR 1/4-20 X 3/4 SS

SPACER

BRACKET, UPPER

io 4400141 NUT, KEP i/4-20

7100027

li

4400001

12

1200008 SCREW, PHILLIPS PAN HD #8-32 X 3/8

13

4400183 WASHER, LOCK, #8

14

i200092 WASHER, FLAT, #8

15

1024042 SPRING, TOP COVER

16

10644i2

i7

1080023

4400 i i 3

i S

4400 i i4

19

1200422

20

1200451 SCREW (SECURITY OPTION)

4400065 WASHER, LOCK, 1iO

2i

i0644i9

22

4400208

23

1200453 SCREW (SECURITY OPTION) 8

1200075 WASHER, 1/4 ID.

24

1033326

25

7100005 STARTER, 220-240V, 50HZ, 3PH

26

7100006

7100007

TIMER

NUT, TINNERMAN

COVER, TOP-SRM6O+

COVER, TOP-SRM8O+

LABEL, STOP, UNPLUG (Not for Europe)

LABEL, COVER REMOVAL (Not for Europe)

SCREW, SHEET METAL, TOP COVER

WITHTRANSFORMER

PANEL, REAR

SCREW, PHILLIPS HD. 1/4-20 X 1/2

TRANSFORMER, 440V i

STARTER, 208-240V, 60HZ 3PH

STARTER, 350V, 50HZ, 3PH, 460V, 60HZ, 3PH

7100008 STARTER, 220-240V, 50HZ, IPH

7100009

7100ii4

7100010 BRACKET, DIN RAIL

27

4400350

28

4400336

1064453

29

4400005

30

i200328

31

7100101

32

7i00 102

33

44003 i i

34

4400015

35

1200331

36

37 1064461

i064460 ISOLATOR, MOTOR, 3/8 ID

38

STARTER, 208-240V, 60HZ, iPH i

STARTER, 200V, 50/60HZ, 3PH

LABEL, SPEED INDICATOR-SRM6O+

LABEL, SPEED INDICATOR-SRM8O+

PANEL, REINFORCEMENT

LOCK WASHER 1/4

SCREW, HEX HD 1/4-20 X 5/16

SWITCH, PUSH BUTTON, START

SWITCH, PUSH BUTTON, STOP

LABEL, START/STOP/TIMER

NUT, KEP 3/8-16

WASHER, 3/8

MOUNT, MOTOR, 3/8 ID

QLY

i

i

2

6

2

6

i

i

i

2

4

4

2

4

i

i

2

2

2

i

i

i

i

i

i

i

2

6

i

8

8

i

i

i

i

i

i

i

i

i

4

4

i

i

i

4

8

8

4

Page 35

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 37

39

40

41

42

43

1200330

8800053

1012442

7100123

1200450

SRM6O+/SRMSO+

BOLT, MOTOR MOUNT 3/8-16 X 4-1/2

PLUG, BOWL LIFT SWITCH

BRACKET, LOWER 2

SWITCH, GUARD 2

TOOL KIT (SECURITY OPTION)

HOUSING ASSEMBLY

FIGURE 10

4

Page 36

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ç

Page 38

DRIVE ASSEMBLY

FIGURE 11

SRM6O+/SRM8O+

ILLUS, NO, PART NO.

i

1064504

2

1064505

i080035

3

4400214

4

5

6

7

8

9

lo

ii

12

13

1064503

4400231

4400101

i200060

4400065

1061967

4400402

4400401

8800206

8800207

i4

15

16 1064520

17

18

19

20

*

*

*

*

4400015

4400i27

1064521

1064522

1064523

i064524

1061973

8800230

880023 1

8800098

7100107

* INCLUDES 1/4 SQ. X 2 KEY

DESCRIPTION

OTY.

PULLEY, VARIABLE, MOTOR (COMES WITH

(2) 5116-18X3/8 SET SCREWS)

BELT, VARIABLE-SRM6O+

BELT, VARIABLE-SRM8O+

BUSHING, HEYCO

RESERVED

PULLEY, VARIABLE, INPUT (COMES WITH (2)

5/1648X3/8 SET SCREWS)

KEY, i/4 SQ. X i

CLAMP, CORD

NUT, HEX #10-32

WASHER, LOCK #1Q

RING, TERMINAL, #10, i2 GAUGE

WASHER, CABLE CONNECTOR

CONNECTOR, CABLE, 3/8

CORD, MOTOR, i PHASE

CORD, MOTOR, 3 PHASE

NUT, KEP 3/846

WASHER, 3/8

MOTOR, 208-240V, 60HZ, i PH

MOTOR, 220-240V, 50HZ, i PH

MOTOR, 208-240/460V, 60HZ, 3 PH

MOTOR, 220/380/440V, 50HZ, 3 PH

MOTOR, 200V, 50/60HZ, 3PH

WIRE NUT (NOT SHOWN) 1PH, 3PH LOW VOLT 4

3PH HIGH VOLT

CORD, POWER, 230V, 50HZ, IPH

(CE & BRITISH) (NOT SHOWN)

CORD, POWER, 400V, 50HZ, iPH

(CE & BRITISH) (NOT SHOWN)

PLUG, POWER i PH (EUROPE) (NOT SHOWN)

STRAIN RELIEF (EUROPE) (NOT SHOWN)

i

i

i

4

i

i

2

5

2

i

2

1

1

i

8

8

1

1

1

1

i

6

I

1

1

i

Page 37

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 39

PART OF HOUSING

TO SAFETY

RING SWITCHES

TO BOWL LIFT

SWITCH

DRIVE ASSEMBLY

FIGURE 11

SRM6O+ISRM8O+

POWER-IN

FOR

GRO UNO

Page 38

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 40

ELECTRICAL CONNECTIONS

Electrical connections should be made my

qualified workmen who will observe all

applicable safety codes and the National

Electrical Code.

Before making electrical connections, check

the specifications on the data plate (located on

the rear access panel) to assure they agree with

those ofyour electrical service.

SINGLE PHASE

GROUND

STUD

SRM6O+/SRMSO+

PIGTML

LEADS

WARNING: DISCONNECT ELECTRICAL

POWER SUPPLY AT THE MAIN

CIRCUIT BOX AND PLACE A TAG

INDICATING THE CIRCUIT IS BEING

WORKED ON.

A hole of 112" conduit is located in the left

surface of the housing in the rear uppermost

location. Connect the input power leads to the

pigtail leads for the motor controller. A solder

less lug is provided for the service ground lead.

Secure service ground to the grounding stud

located to the left ofthe conduit hole.

Three-phase machines must be connected so the

beater head (planetary) turns in the direction of

the arrow (left to right). To check the direction

of rotation, turn the power disconnect switch

'ON". Place timer on 'HOLD". Energize

machine momentarily by pushing "START'

then "STOP" and verify the direction of

rotation.

WARNING: DISCONNECT

ELECTRICAL POWER SUPPLY AT THE

FUSED DISCONNECT SWITCH AND

PLACE A TAG INDICATING THE

CIRCUIT IS BEING WORKED ON.

LUG

THREE PHASE

GROUND

STUD

LUG

MIXER ROTATION

PIGTAIL

LEADS

If motor rotation is incorrect, interchange any

two ofthe power supply leads.

NOTE: It is not necessary to remove the top

cover ofthe mixer in order to perform the

electrical installation. Only the rear access

panel (FiglO [22]) need be removed,

BEATER HEAD

DIRECTION

Page 39

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 41

(208-240V, 60HZ, 1PH) (220-240V, 50HZ, 1PH)

WIRING DIAGRAM

Figure 12A

SRM6O+/SRM8O+

LEFT GUARD1

SWITCH

RIGHT GUARD

SWITCH

r

L°i

W5

STOP