Page 1

MECHANICS

MAINTENANCE

MANUAL

SRM60+/0699001 ED2

0011065

Page 2

SRM60+

TABLE OF CONTENTS

DESCRIPTION PAGE

TROUBLE SHOOTING GUIDE ......................................................................………….. 3

REMOVAL OF TOP COVER AND REAR ACCESS PANEL ............................………. 4

MECHANICS MAINTENANCE ......................................................................………….. 4-6

REPAIR INSTRUCTIONS ...........................................................................……………… 7- 12

REPLACEMENT PARTS, LISTS .................................................................…………….. 13 -24

ELECTRICAL CONNECTIONS AND ROTATION .........................................…………. 25

WIRING DIAGRAMS ..................................................................................……………… 26 -28

LIST OF ILLUSTRATIONS

ILLUSTRATION PAGE

FIGURE 1 OVERALL VIEW OF MIXER ..................................................……... 2

FIGURE 2 LUBRICATION INSTRUCTIONS ............................................…….. 6

FIGURE 3 GEAR BOX ..............................................................................………. 13

FIGURE 4 BEATER HEAD AND VERTICAL SHAFT ASSEMBLY ...........….. 14

FIGURE 5 POWER TAKE OFF ASSEMBLY .............................................…….. 15

FIGURE 6 INPUT ASSEMBLY .................................................................……… 16

FIGURE 7 BOWL LIFT ASSEMBLY ......................................................………. 17-18

FIGURE 8 SPEED CONTROL ASSEMBLY ............................................……… 19 -20

FIGURE 9 BOWL SUPPORT ASSEMBLY .................................................…… 21

FIGURE 10 HOUSING ASSEMBLY .........................................................………. 22 -23

FIGURE 11 DRIVE ASSEMBLY .................................................................…….. 24

FIGURE 12A WIRING DIAGRAM 208-240 V, 60HZ, 1PH,

FIGURE 12B WIRING DIAGRAM 208-240V, 60HZ, 3PH,

FIGURE 12C WIRING DIAGRAM 460V, 60HZ, 3PH, 380V, 50HZ, 3PH……….. 28

220-240V, 50HZ, 1PH, ........…………………………………………. 26

220V, 50HZ, 3PH, 200V, 50/60HZ, 3PH……………………………. 27

PAGE 1

Page 3

SRM60+

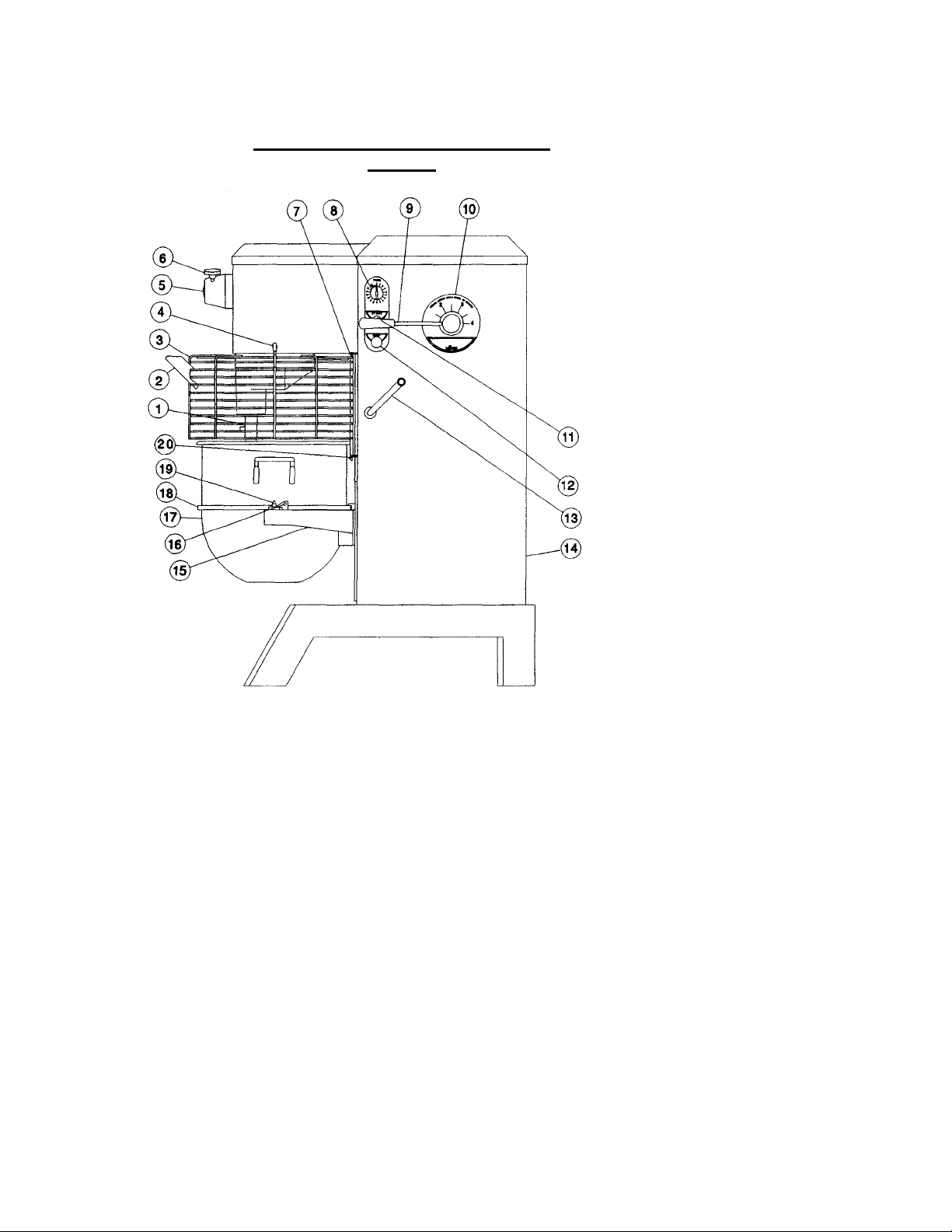

OVERALL VIEW OF FOOD MIXER

Figure 1

1. BEATER SHAFT

2. CHUTE

3. SAFETY RING ASSEMBLY

4. MAGNET

5. NO. 12 HUB

6. THUMB SCREW

7. UPPER MOUNTING BRACKET

8. TIMER

9. SPEED CONTROL LEVER

10. SPEED INDICATOR LABEL

11. START BUTTON

12. STOP BUTTON

13. BOWL LIFT HANDLE

14. REAR ACCESS PANEL

15. BOWL SUPPORT

16. BOWL CLAMP

17. BOWL

18. BOWL RIM

19. BOWL SUPPORT PIN

20. LOWER MOUNTING BRACKET

Page 2

Page 4

SRM60+ TROUBLESHOOTING GUIDE

1 Mixer will not

1.1 Timer not turned on.

1.1 Turn timer on.

2. Mixer runs but

2.1 Drive belt off of pulley.

2.1 Reinstall drive belt on motor

3. Stalling of

3.1 Mixer bowl is overloaded.

3.1 Readjust contents

of bowl per

4. Speeds not

4.1 Loose belt.

4.1 Tighten or replace.

5. Mixer ru

ns but

, 5.1 Bowl overloaded.

5.1 Reduce content of bowl.

6. At

tachments

6.1 Dented bowl.

6.1 remove dent or replace.

7. Attachments

7.1 Dented bowl.

7.1 remove dent or replace.

8. Excessive noise.

8.1 Gears need to be repacked

8.1 Locate source by inspection

TROUBLE POSSIBLE CAUSE REMEDY

operate. 1.2 Burned switch contacts. 1.2 Clean or replace.

1.3 Electrical service down. 1.3 Check electrical service.

Replace fuse or reset circuit

breaker as necessary.

1.4 Motor capacitor defective 1.4 Replace.

(1PHonly).

1.5 Burned out motor. 1.5 Remove, test, repair or

replace.

1.6 Magnetic starter tripped due 1.6 Wait several minutes and

to overload.

1.7 SAFETY RING not mounted 1.7 Install SAFETY RING.

and closed.

1.8 Bowl not raised. 1.8 Raise bowl completely.

push start button.

SRM60+

beater will not

turn.

2.2 Key or pin sheared on bevel 2.2 Locate by step inspection and

pinion, vertical shaft or beater

shaft.

2.3 Shifting with mixer not 2.3 With mixer running, slowly

running.

agitator during

mixing. 3.2 Speed is set too high for the 3.2 Shift speed lower till action

changing 4.2 Vari-speed pulley inoperative. 4.2 Remove, clean & lubricate or

properly.

keeps cutting out 5.2 Speed set too high for bowl 5.2 Reduce speed

and stops.

mix.

3.3 Loose belt. 3.3 Readjust pulley center

3.4 Contamination of belt with 3.4 Clean pulleys and replace

grease.

contents.

5.3 Service voltage is too low or 5.3 Check electrical voltage.

fluctuating.

pulley and adjust mount

center distance.

replace defective parts.

move shift lever fully forward

then backward in order to

re-engage belt.

Capacity Chart.

rotates smoothly.

distance to tighten belt.

belt.

replace

contact bottom of 6.2 Bowl height set too high. 6.2 Reset bowl height.

bowl.

contact side of 7.2 Insufficient clearance between 7.2 readjust bowl height.

bowl.

bottom of bowl and beater.

with grease, or oil level is

low.

8.2 Badly worn or frayed drive 8.2 Replace belt.

belt.

8.3 Attachments hitting bowl. 8.3 Inspect for cause. Ref. 6 & 7

8.4 Overloaded mixing bowl. 8.4 Readjust contents of bowl per

and repack with grease or top

off oil level.

Table of Mixing Capacities.

Page 3

Page 5

REMOVAL OF TOP COVER AND REAR ACCESS PANEL

SRM60+

a. The top cover (Fig. 10 [17]) must be removed in order to perform the

A mechanic should perform the following inspection and maintenance as required

depending on severity of use, but at least yearly.

1. CVT BELT DRIVE

maintenance operations. It is secured by a spring clip at its front end and a screw

at its rearward end. First, DISCONNECT THE ELECTRICAL POWER FOR

SAFETY. Then, remove the screw in the rear (Fig. 10 [20]), lift rear of cover,

push forward about 3 inches and lift cover off. Re-install in reverse procedure

using care to insure that the cover sits squarely and uniformly on the mixer

housing.

b. Remove rear access panel (Fig. 10 [27]) by removing eight screws and

washers (Fig. 10 [23, 24])

MECHANICS MAINTENANCE

a. Start mixer and shift speed control (Fig. 1 [9]) to the slowest speed (Low, 1).

Stop mixer.

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER. Place

tag or sign on electrical supply warning that MIXER IS BEING

WORKED ON; DO NOT TURN ON.

b. Remove rear access panel (Fig. 10 [22]) and top cover (Fig. 10 [17]) as

described above.

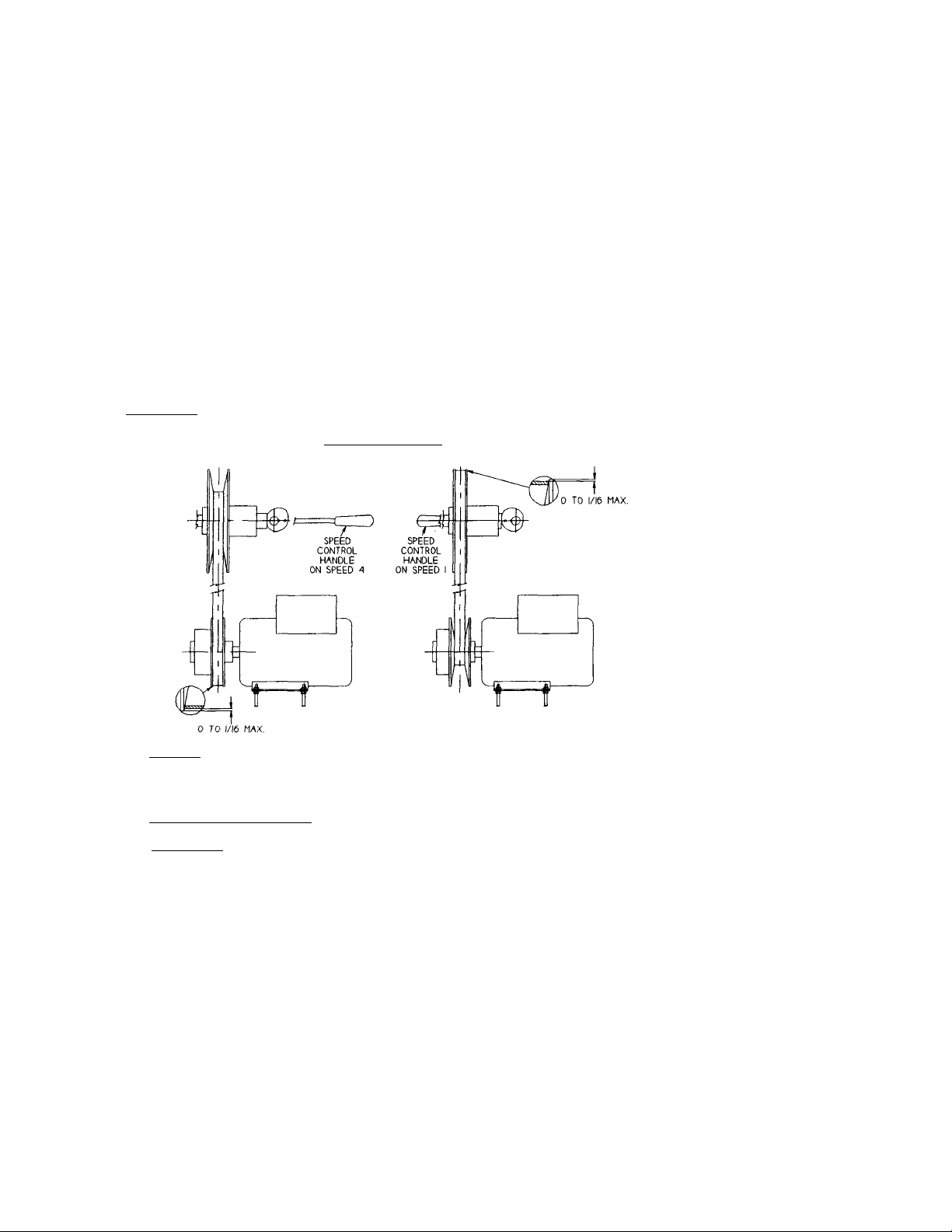

c. Inspect drive belt (Fig. 11 [2]) for proper adjustment. Outer surface of belt

should be approximately flush to 1/16" below the outer edges of the input pulley

flanges (Fig. 11 [5]) when mixer has been shut off in first speed (see Pg. 5). If

drive belt is excessively frayed or has a heavily glazed surface, replace it.

However, it is generally the best judgment to leave a drive belt in a machine if it

is performing well, even it if shows moderate wear. Inspect gripping surfaces of

drive belt for excessively glazed surfaces or contamination by grease or oil.

To replace belt, run mixer in 1st speed. Disconnect electrical supply. Shift

machine to 4th speed. Unwrap belt from top pulley. Slide belt between top

pulley nose and cam (Fig. 8 [8]). Remove belt from lower pulley.

WARNING: Lower pulley flanges are spring loaded. Keep fingers away while

removing belt.

The bowl must be lowered in order for the belt to clear the nose of the lower

pulley when removing belt. To install new belt wrap belt around lower pulley.

Pull belt into the spring loaded flanges. A pry bar will help separate the flanges.

Continue replacement in reverse order from belt removal. Adjustment of the belt

drive will most likely be required.

d. Readjustment of the drive belt, where a slight stretching or normal seating has

caused outer surface of the belt to exceed the acceptable limit of flush to 1/16"

below the input pulley flanges (see Pg. 5) is as follows:

Loosen kep nuts (Fig. 8 [12]) securing the bracket (Fig. 8 [15]) and holder(Fig. 8

[1]) to the housing. If the belt was riding outside the pulley flanges, tap the speed

control assembly lightly towards the rear of the mixer. If the belt was riding

more than 1/16" below the pulley flanges, tap the speed

Page 4

Page 6

control assembly towards the front of the machine (shifting to 2nd second speed will

help).

Note: The assembly must remain perpendicular to the mixer housing walls. Failure to do

so will result in the binding of the shaft (Fig. 8 [10]) in the bearing (Fig. 8 [21]).

Retighten the kep nuts and run mixer in 1st speed and check belt position. Repeat

procedure if necessary.

e. Once the upper pulley (Fig. 11 [5]) has been adjusted, the lower pulley must be checked.

Start mixer and shift to 4th speed. Turn mixer off and check position of belt. The belt

should be flush to 1/16" below outer edges of the pulley flanges. If adjustment is needed,

loosen kep nuts (Fig. 11 [14]) and raise or lower the motor using the kep nuts on the

under side of motor. Retighten top kep nuts and run mixer in 4th speed to check new belt

position.

Note: The motor must remain level with the mixer base (Fig. 10 [1]). If not, poor shifting

and belt life will result.

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER.

DRIVE BELT SETUP

SRM60+

2. MOTOR

Check motor (Fig. 11 [16]) for overheating and excessive noise. If defective, send to a local

electrical repair shop.

3. BOWL LIFT ADJUSTMENT

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER.

a. Check adjustment by placing a 60 quart bowl on the lowered bowl support, and place a

60 quart batter beater on the beater shaft (Fig. 1 [1]).

b. Raise bowl support to the upper position.

c. Check clearance between bottom of the bowl and the adjacent underside of the batter beater.

Clearance should be 3/16" ± 1/16".

Page 5

Page 7

d. If adjustment is required, loose jam nut (Fig. 7 [25]) and turn threaded bowl stop rod

(Fig.7 [24]) until the desired clearance is obtained, then tighten the jam nut.

4. DRIVE BELT REPLACEMENT (See CVT Belt Drive)

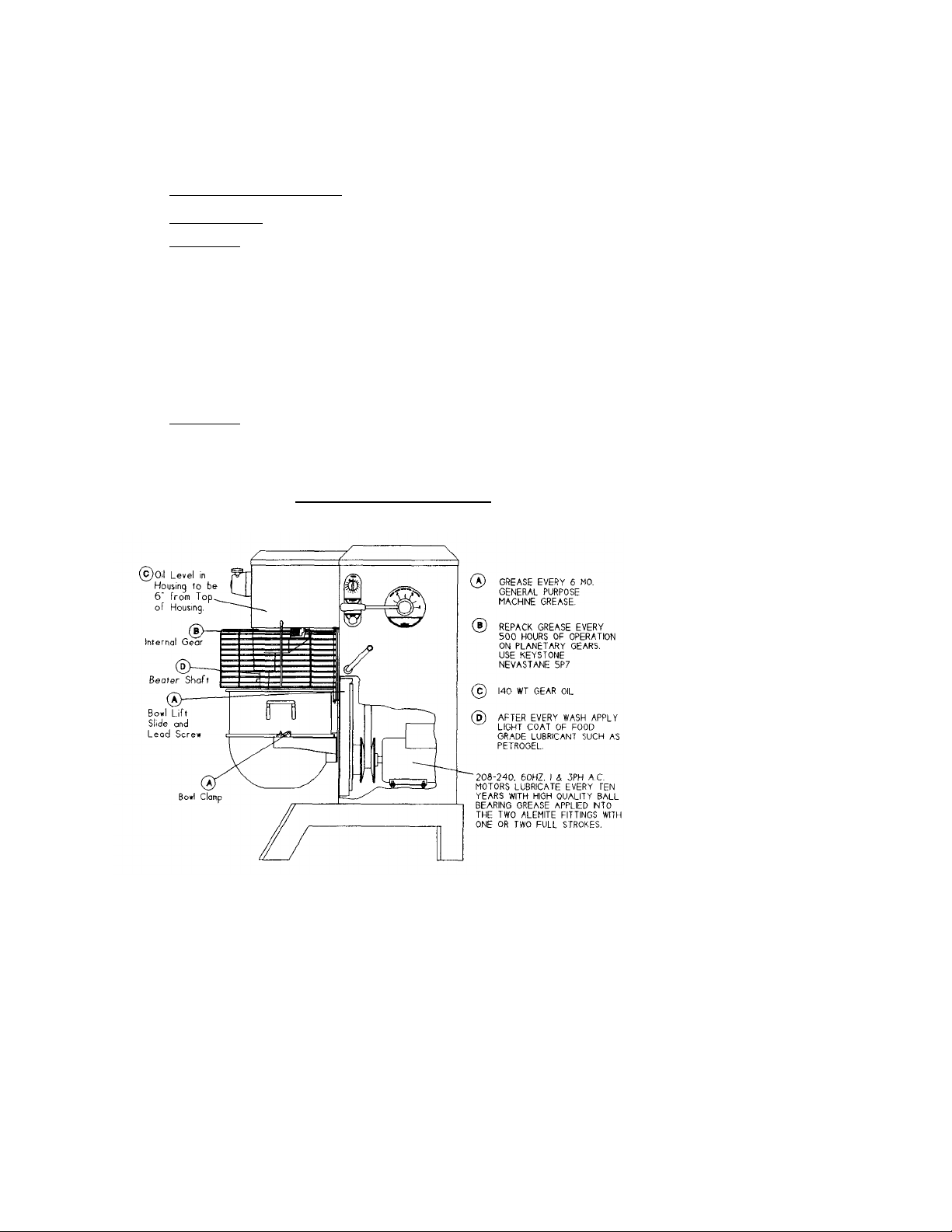

5. LUBRICATION

WARNING: FOR SAFETY, DISCONNECT ELECTRICAL POWER TO THE MIXER.

a. The lubrication instructions are listed in Figure 2.

b. Remove access panel (Fig. 10 [22]), top cover (Fig. 10 [17]) per page 4.

c. In order to service the gearbox, it will be necessary to further remove the gearbox cover

(Fig. 3 [2]). A thin blade putty knife will prove helpful in separating the silicone sealant

between this cover and the gearbox. Do not bend cover. Thoroughly remove all dried

sealant before applying new sealant when reinstalling the cover. Do not allow dried

sealant to enter gearbox. Silicone rubber sealant such as Dow Corning Silastic 732RTV or

Permatex Form-A-Gasket are recommended.

WARNING: NEVER WORK ON THE GEARBOX WITH THE MIXER

RUNNING.

d. Use care to avoid getting lubricant of any kind on the drive belt and pulleys as this would

seriously deteriorate the belt grip and mixer performance.

LUBRICATION INSTRUCTIONS

FIGURE 2

SRM60+

Page 6

Page 8

(Including Disassembly, Replacement and Reassembly)

REPAIR INSTRUCTIONS

A. GEARBOX (Fig. 3)

GEARBOX REMOVAL:

1. Run mixer and shift to first speed then turn off.

2. WARNING: FOR SAFETY, DISCONNECT ELECTRICAL SUPPLY.

3. Remove set screw (Fig. 3 [16]) and drain oil.

4. Remove rear access panel (Fig. 10 [22]), top cover (Fig. 10 [17]), detailed on page 4.

5. Remove drive belt per instructions (1) in Mechanic's Maintenance.

6. Remove speed control assembly (Fig. 8) See Speed

Control Disassembly.

7. Loosen two allen set screws (Fig. 11 [4]) that secure input pulley (Fig. 11 [5]) and

remove pulley completely from input shaft (Fig. 6 [12]).

8. Remove gearbox cover (Fig. 3 [2]). Remove remaining oil from gearbox.

9. WARNING - FOR SAFETY! The gearbox is very heavy, weighing

approximately 225 pounds and must, therefore, be supported safely before starting step

number (10). It is recommended that a portable hydraulic crane of sufficient capacity be

used. A chain may be attached to t he P.T.O. shaft (Fig. 5 [11]) at mid-length. Use care

not to rub or scrape the gears.

10. Remove four cap screws (Fig. 3 [11]) securing gearbox housing to mixer housing.

Remove gear box assembly and place on work bench.

11. Rotate gear train by hand and inspect for worn or chipped gears, bent shaft, worn

bearings and excessive backlash. Backlash measured at gear teeth exceeding 1/32" is

considered excessive. After trouble has been isolated, proceed to disassemble.

SRM60+

GEARBOX DISASSEMBLY:

1. Beater Head (Fig. 4)

a. Remove cap screw (Fig. 4 [21]) and remove beater head assy. If beater head does not

drop easily, use the two jacking screws (Fig. 4 [19]) to assist in removal. Do not pry

against outer rim of beater head housing (may cause breakage).

b. Remove top retaining ring [9], gear [II], bottom retaining ring [9], key [7], seal [10],

retaining ring [9], retaining ring [8], and press shaft [2] (at gear end) from housing

[1].

c. Press bearings [4 & 6] along with spacer [5] from housing [1].

Page 7

Page 9

2. Power Take Off (Fig. 5)

a. Remove three cap screws (Fig. 5 [5]) and washers [6] holding P.T.O.

housing [3] to gearbox housing (Fig. 3 [1]).

b. Remove retaining ring [8] from helical gear end of P.T.O. shaft [11].

Remove gear [14] and key [15].

c. Using two cap screws as Jacking screws (Fig. 5 [5]) in the tapped

holes of gearbox housing (Fig. 3 [1]), dislodge and remove the P.T.O.

assembly from the gearbox housing.

d. Remove retaining ring [8] and slide bevel gear [13] away from P.T.O.

housing [3].

e. Remove internal retaining ring [9], P.T.O. adaptor [2] and press shaft,

bearing, and gear assembly from P.T.O. housing [3].

f. Remove four retaining rings [8] and key [15] from P.T.O. shaft [II], and

press ball bearings [10] and P.T.O. bevel gear [13] off P.T.O. shaft [11].

g. Remove P.T.O. oil seal [7] from P.T.O. housing [3] and discard.

3. Input (Fig. 6)

a. Remove four cap screws (Fig. 6 [11] from flange of input housing [9].

b. Thread two of the cap screws [11] into the two threaded jacking holes in

the flange [9]. Turn these two screws in evenly until the input housing is

pushed free of the gear box housing.

SRM60+

c. Remove sleeve [14] and proceed to remove input shaft [12] out of input

housing [9] by pressing from opposite the gear end of the shaft.

d. Remove retaining ring [5] at gear end of the shaft, and press off

bearing [7].

e. Remove rubber seal [4] from housing or shaft. Seal must be replaced.

f. Remove retaining rings [6] and bearing [7] from housing.

4. Vertical Shaft (Fig. 4)

a. Remove beater head as covered in Gearbox Disassembly (1) a-c. b.

Remove P.T.O. assembly as covered in Gearbox Disassembly (2) a-g.

c. Remove key (Fig. 4 [18]) and retaining ring [9] from vertical shaft [13].

d. Drive vertical shaft downward into the gearbox. A brass drift will be

necessary to drive shaft completely free from the gear box. Lift bevel gear

[12] and key [14] from gear box.

e. Insert drift through top of bearing [15] in gearbox and drive seal [16] out

bottom of bore.

Page 8

Page 10

f. Reach up into bore from bottom opening with snap ring pliers and

remove retaining ring [8] from bore.

g. Carefully drive upper bearing [15] out bottom of bore.

h. Press bearing [17] from shaft [13].

GEARBOX ASSEMBLY

SRM60+

1. Clean all components (except bearings) with safety approved cleaning

2. If shafts have become slightly scored during the disassembly process, it is

3. Always fit new rubber seals when rebuilding the gearbox. Use special

4. Reassembly should be carried out in reverse of the disassembly procedure

solvent. Inspect components for defects and replace those found to be

defective.

NOTE: If planetary pinion gear (Fig. 4 [11]) requires replacement, it is

likely that the planetary gear (Fig. 3 [20]) requires replacement also.

necessary to polish the shafts with fine machinist's crocus cloth. An

especially smooth finish is necessary in the working seal area of the shafts.

Use care to avoid excessive removal of shaft surface or proper fit of

components will be lost.

attention in examining the end of the shafts over which the seals will be

pushed. The slightest burring or scoring will abrade or cut the delicate seal

lips. A light polish of the shaft ends with crocus cloth is recommended.

see exception below. Successful reassembly is very dependent on the

cleanliness of all surfaces, particularly the bores of housings, gears, and

bearings, as well as the outer surface of shafts. It is good to recheck each

component for cleanliness as it is picked up for reassembly.

THE ASSEMBLY OF THE INPUT IS AS FELLOWS.

a Install retaining ring (Fig. 6 [6]) into housing [9], press in bearing [7] and

install remaining retaining ring [6].

b. Slide seal [4], with spring facing gear, along length of shaft opposite the

gear (be careful when sliding seal over retaining ring groove not to damage

the seal). Install bearing [7] and retaining rings [5] onto gear end of shaft.

c Press shaft into bearing [7] mounted in housing [9] until the retaining ring

[5] seats against the bearing.

d Press seal OD flush with end of housing.

5. Transmission should be progressively checked for smooth operation while

on the workbench by hand turning each assembly as it is installed.

6. Lubrication of the gear box should be done following its installation on the

mixer. The helical and bevel housing compartments are filled to a level 6"

(10 qts.) from the top edge of the gear box with SAE 140 gear oil.

Page 9

Page 11

B. BOWL LIFT & SLIDE (Fig. 7)

BOWL LIFT & SLIDE DISASSEMBLY & REMOVAL

CAUTION: FOR SAFETY, DISCONNECT ELECTRICAL SUPPLY.

1. Remove top cover and rear access panel as stated on page 4.

2. Remove drive belt from motor pulley as stated in Mechanics Maintenance Section 1 (c).

3. Remove drive assembly (Fig. 11) from mixer housing as follows:

a. Remove the top 4 kep nuts (Fig. 11 [14]) that secure motor assembly to mixer base.

b. Remove motor electrical leads (Fig. 11 [13]) from magnetic starter (Fig. 10 [26]).

Remove motor ground lead from stud.

c. Lift motor assembly from mixer housing.

CAUTION: Drive assembly can weight in excess of 100 Ibs. depending on type of

motor. Use mechanical lift assistance.

4. Remove bowl from bowl support.

5. Remove two screws (Fig. 9 [10]).

6. Remove 4 screws (Fig. 7 [30]).

CAUTION: Someone should be holding bowl support (Fig. 9 [1]) while the screws are

being removed, so that it does not fall and get damaged. Remove slide cover (Fig. 9 [8]).

SRM60+

7. Loosen set screws (Fig. 7 [41]) and Fig. 7 [8]).

8. Withdraw handle assy. (Fig. 7 [36]) from the outside of mixer housing. Collect gear [9],

key [37], washers [4 & 42] and collar [40].

9. Remove 8 nuts (Fig. 7 [29]) and pull slide/frame assembly from studs and remove from

mixer housing.

CAUTION: Assembly is heavy.

10. Remove 2 hex head cap screws (Fig. 7 [15]). This allows for removal of yoke (Fig. 7 [7]).

11. Drive roll pin (Fig. 7 [11]) from miter gear (Fig. 7 [12]). Remove miter gear and thrust

washer (Fig. 7 [4]) from lead screw (Fig. 7 [10]).

12. Press lead screw (Fig. 7 [10]) through hole in frame [1].

13. Loosen set screws (2). Remove collar [3] and thrust washer (Fig. 7 [4]) by pulling them

from lead screw.

14. Unscrew lead screw from floating nut (Fig. 7 [26]) and remove.

15. Remove 4 screws (Fig. 7 [15]) and remove gibbs (Fig. 7 [27]). The slide may now be

removed from the frame.

Page 10

Page 12

SRM60+

NOTE: Save any shim strips that may have been used between the frame and the

gibbs. It is recommended that the location be marked at this time with a pencil to

facilitate reinstallation.

BOWL LIFT & SLIDE. REASSEMBLY & INSTALLATION (Fig. 7)

1. Grease sliding surfaces of slide & frame. See Lubrication page 6.

2. Keeping shims in place (if any), position slide in frame as shown in Fig. 7.

3. Secure slide (Fig. 7 [32]) in frame [1] by bolting gibbs [27] to frame with four hex

head cap screws [15]. Check to insure that slide moves freely in frame. If not, remove

gibbs and shim where needed.

4. Screw lead screw [10] into floating nut [26] and push slide to bottom of frame so that

the lead screw does not protrude through hole in frame.

5. Place the collar [3] and then thrust washer [4] over top of lead screw [10]. Push slide

and lead screw up -so that the lead screw protrudes through hole in frame.

6. Place thrust washer [4] and then miter gear [12] on top of lead screw [10]. Drive roll

pin [11] through miter gear [12] and into lead screw [10].

7. Push slide & lead screw down as far as possible. Slide collar [3] and thrust washer [4]

up against frame and tighten set screws [2] in collar against corresponding flats on

lead screw [10].

8. Check DU bearings in yoke for burrs (Fig. 7 [6]). Install yoke [7] to frame [1] (do not

tighten bolts).

9. Lift assembly into mixer housing. Place assembly on 8 weld studs. Tighten

assembly to mixer housing using washers and kep nuts.

10. Insert bowl lift lever assembly (Fig. 7 [33-36,38,39]) through hole in mixer housing.

Slide collar [40] and thrust washer [42] over end of lever. Insert lever through yoke

while holding the thrust washer [4] and miter gear [9] in position. Continue to slide

lever through until miter gear seats against shoulder on the lever shaft. Align

keyways of miter gear and lever, insert key [37]. Tighten set screw [8]. Squeezing

miter gear [9] and collar [40], tighten set screw [41].

11. With yoke bolts [15] lightly tightened, tap yoke back and forth until the

miter gears mesh smoothly. Tighten bolts [15]. Adjust hub [38] so that it is

positioned 1/32" from mixer housing. Tighten set screw [39].

12. Lubricate the miter gears and lead screw with general purpose machine grease.

13. Raise and lower bowl lift by turning the bowl lift lever [36]. The

mechanism should turn freely.

14. Raise bowl all the way. Check clearance between bottom of bowl and batter beater

attachment. The clearance should be 3/16 ± 1/16". If the clearance is not sufficient,

adjust bowl stop (Fig. 7 [24]). Loosen jam nut [25], raise or lower bowl stop as

needed and tighten jam nut.

Page 11

Page 13

15. Make sure bowl lift safety switch (Fig. 7 [18]) is actuated by the retainer plate [23]

when the bowl is raised completely. If the switch is not actuated the lever on the switch

is be ing bent, adjust the bracket [17] by loosening screws [22] and raising or lowering

until the switch actuates.

Note: The bowl should continue to raise 1/8" after switch actuates.

SPEED CONTROL (Fig. 8)

1. Run mixer and shift to first speed then turn mixer off.

2. Warning: For safety disconnect electrical supply.

3. Remove rear access panel (Fig. 10 [22]) and top cover (Fig. 10 [17]) detailed on page 4.

4. Remove drive belt per instructions 1 in mechanics maintenance.

5. Warning: Handle (Fig. 8 [25]) has spring loaded rotation. Hold handle to prevent injury.

While holding handle (Fig. 8 [25]) remove set screws [20] and rotate handle counter

clockwise two full turns. This disengages the spring [11]. Note: The ball [3] and spring

[4] may fall out of block [6].

6. Loosen set screws (Fig. 9 [5]), drive roll pin [22] from hub [23] and pull hub from shaft

[10]. Unscrew hub [23] and handle [25] from lever [24].

7. Slide retaining rings [9], cam [8] and spring [11] towards locating block

[6]. Remove key [19] from shaft, loosen nuts [12] securing detent housing [11.

8. Drive shaft [10] inward until it contacts the left side housing wall. Pull detent housing

[1] and shaft assembly [10] towards rear of machine and remove assembly from

mounted bearing [18].

9. Slide spring [11] retaining ring [9], cam [8] and belleville washer [2] from shaft [10].

Drive roll pin [7] from block [6]. Slide block [6] from shaft [10].

10. Remove nuts [12], washers [13 & 14] and bracket [15] from housing. Remove bolts

(16 & 17] securing bearing [18] to bracket [15].

SRM60+

Reassemble in reverse order of above Adjust assembly as described in

Mechanics Maintenance 1d, & e.

If speed handle creeps during operation tighten the two set screws (Fig. 8 [5]) which push

against the belleville washer [2] until creeping stops.

HOUSING (Fig 10)

For the remaining parts which have not been discussed pertain to electrical components, and

the housing, Figures 10, 12A, 12B, and 12C should provide adequate guidance for the

disassembling and reassembling of these parts.

Page 12

Page 14

GEAR BOX

FIGURE 3

SRM60+

ILLUS PART NO. DESCRIPTION QTY.

1 1064453 HOUSING, TRANSMISSION 1

2 1064417 COVER, TRANSMISSION 1

3 1200008 SCREW, PHILLIPS PAN HEAD 8-32 X 3/8 8

4 1024041 SPRING CLIP 1

5 1200076 FLAT WASHER #10 3

6 4400065 LOCK WASHER #10 2

7 1200012 SCREW, PHILLIPS PAN HEAD 10-32 X 1/2 2

8 1200378 SCREW, CUP POINT SET 8-32 X 1/4 1

9 1064507 PLUG, OILING TUB 2

10 1064418 TUBING, TRANSMISSION 1

11 1200057 SCREW, HEX HEAD CAP 1/2-20 X 1 4

12 1200085 LOCK WASHER 1/2 4

13 1200084 FLAT WASHER 1/2 4

14 1200403 PIN, DOWEL 3/8 DIA.. X 1/2 2

15 1061990 PLUG, OIL 1

16 1200329 SCREW, CUP POINT SET 1/4 NPT 1

17 1200365 SCREW, SOCKET HEAD CAP 1/4-20 X 1/2 8

18 4400269 LABEL, ROTATION 1

19 1061002 SPLASH RING 1

20 1061111 GEAR, INTERNAL 1

21 4400345 LABEL, UNIVEX 1

22 1012438 HOLDER, MAGNET 2

23 1012439 MAGNET 2

Page 13

Page 15

BEATER HEAD AND VERTICAL SHAFT ASSEMBLY

FIGURE 4

SRM60+

ILLUS

PART NO. DESCRIPTION QTY

1 1064423 HOUSING, BEATER HEAD 1

2 1064424 SHAFT, BEATER HEAD 1

3 1200310 PIN, DOWEL 1

4 1061959 BEARING, BALL 1

5 1064426 SPACER, BEATER HEAD 1

6 1061917 BEARING, BALL 1

7 4400231 KEY 1/4 SQ. X 1, CLASS 1, ROUNDED BOTH ENDS 1

8 1200354 RETAINING RING, INTERNAL 2

9 1200353 RETAINING RING, EXTERNAL 4

10 1064509 SEAL 1

11 1061003 GEAR, PINION, BEATER HEAD 1

12 1064420 GEAR, BEVEL, VERTICAL SHAFT 1

13 1064422 SHAFT, VERTICAL 1

14 1200314 KEY, 3/8 SQ. X 1-1/2, CLASS 1, ONE END ROUNDED 1

15 1064513 BEARING, BALL, VERTICAL 1

16 1064512 SEAL 1

17 1064500 BEARING, BALL, VERTICAL 1

18 1200315 KEY, 3/8 SQ. X 2, CLASS 1, ONE END ROUNDED 1

19 1200405 SCREW, SET 5/16-18 X 1-3/4 2

20 1064448 WASHER, 1/2 1

21 1200379 SCREW, HEX HEAD CAP, 1/2-20, SS, L.H. 1

Page 14

Page 16

1

1

P.T.O. ASSEMBLY

FIGURE 5

SRM60+

ILLUS

PART NO. DESCRIPTION QTY.

1 8800033 CAP, CHROME, P.T.O 1

2 8800012 ADAPTOR, P.T.O 1

3 1061104 HOUSING, P.T.O 1

4 1064514 O-RING, 1

5 4400220 SCREW, HX HD CAP, 5/16-18 X 1 3

6 1200077 WASHER, LOCK, 5/16 3

7 1064510 SEAL, OIL, P.T.O, 1

8 1200253 RETAINING RING, EXT. 6

9 1200254 RETAINING RING, INT. 1

10 1030148 BEARING, BALL, 2

11 1064458 SHAFT, P.T.O 1

12

RESERVED

13 1064459 GEAR, BEVEL, P.T.O 1

14 1064428 GEAR, HELICAL, P.T.O 1

15 4400231 KEY, 1/4 SQ. X 1, CLASS 1, ROUNDED ENDS 2

16 4400006 SPRING, 1/4 O.D., COMPRESSION 1

17 4400016 BALL, STEEL, 1/4 DIA. 1

18 4400229 KNOB ASSEMBLY, P.T.O

19 4400210 WASHER, P.T.O.

20 8900019 SCREW SFHD 6-32 x 3/8 2

Page 15

Page 17

3

INPUT ASSEMBLY

FIGURE 6

SRM60+

ILLUS. PART NO. DESCRIPTION QTY.

1

2

RESERVED

RESERVED

RESERVED

4 1064511 SEAL, INPUT 1

5 1200316 RETAINING RING, EXTERNAL 2

6 1061909 RETAINING RING, INTERNAL 2

7 1064501 BEARING, INPUT HOUSING 2

8 1064515 O-RING, INPUT HOUSING 1

9 1064430 HOUSING, INPUT 1

10 1200077 WASHER, LOCK, 5/16 4

11 1200039 SCREW, HX HD CAP, 5/16-18 X 3/4, ZINC PLATED 4

12 1064532 GEAR/SHAFT, INPUT 1

13

RESERVED

14 1064433 SLEEVE, INPUT SHAFT 1

Page 16

Page 18

BOWL LIFT ASSEMBLY

40 1064517

COLLAR, B.L. (Comes with

5/16-18x1/4

cup point set screw)

FIGURE 7

SRM60+

ILLUS

PART NO. DESCRIPTION QTY.

1 1062190 FRAME 1

2 4400407 SCREW, SET, 5/16-18 X 1/4 LG. 2

3 1062193 COLLAR, LEAD SCREW 1

4 1061821 WASHER, THRUST 3

5 1200403 PIN, DOWEL, 3/8 DIA. X 1/2 LG. 2

6 1061820 BEARING 3

7 1064452 YOKE 1

8 1200036 SCREW, SET, 5/16-24 X 3/8 LG. 1

9 1062217 GEAR, MITER, HANDLE SHAFT 1

10 1064457 SHAFT, LEAD SCREW 1

11 4400004 PIN, ROLL, 1/4 DIA. X 1-1/8 LG. 1

12 1062970 GEAR, MITER, LEAD SCREW 1

13 1200078 WASHER, 5/16 2

14 1200077 WASHER, LOCK, 5/16 7

15 4400220 SCREW, HEX HD CAP 5/16-18 X 1 5

16 1200433 NUT, ELASTIC STOP, 4-40 2

17 1064411 BRACKET, BOWL LIFT SWITCH 1

18 7100103 SWITCH, BOWL LIFT 1

19 1200432 SCREW, HEX HD 4-40 X 3/4 2

20 1200076 WASHER, #10 2

21 4400065 WASHER, LOCK, #10 2

22 1200012 SCREW, PHILLIPS PAN HD., 10-32 X 1/2 2

23 1062187 PLATE, RETAINER 1

24 1200431 SCREW, SET, 5/16-18 X 2 1

25 1200063 NUT, KEP, 5/16-18 1

26 1064444 NUT, FLOATING 1

27 1062191 GIBB 2

28 1200083 WASHER, 3/8 8

29 1200388 NUT, ELASTIC STOP, 3/8-16 8

30 1200402 SCREW, HEX HD CAP 1/2-20 X 2-3/4 4

31 1200085 WASHER, LOCK, 1/2 4

32 1062189 SLIDE 1

33 1200325 SCREW, FLAT HD SOCKET CAP, 1/4-20 X 3/4, S.S. 1

34 1064416 CAP, B.L. HANDLE 1

35 1064516 HANDLE 1

36 1064441 LEVER, B.L. 1

37 4400232 KEY, 3/16 SQ. X 1 LG., CLASS ONE, ROUNDED ENDS 1

38 1064450 HUB, B.L. 1

39 4400154 SCREW, SET, #10-32 X 1/4 1

41 1200369 SCREW, HEX HD CAP 5/16-18 X 1 1/4LG 2

42 1000517 WASHER, BRONZE, 3/4 I.D. X 1-1/8 O.D. X 1/8 1

43 7100023 INSULATING BARRIER 1

44 1200369 SCREW, HEX HD CAP 5/16-18 X 1 1/4 2

Page 17

1

Page 19

BOWL LIFT ASSEMBLY

FIGURE 7 (CONT)7

SRM60+

Page 18

Page 20

SPEED CONTROL ASSEMBLY FIGURE 8

SRM60+

ILLUS. PART

DESCRIPTION QTY.

1 1064436 HOUSING, DETENT 1

2 1200324 WASHER, BELLEVILLE 1

3 4400016 BALL, STEEL, 1/4" DIA. 1

4 4400006 SPRING, 1/4" O.D. 1

5 1200036 SCREW, SET, 5/16-24 X 3/8 3

6 1064437 BLOCK, S.C. LOCATING 1

7 1200321 PIN, ROLL, 1/4 DIA. X 1-1/2, PLAIN FINISH 2

8 1064438 CAM, S.C. 1

9 1200317 RETAINING RING 2

10 1064434 SHAFT, S.C. CAM 1

11 1064439 SPRING. TORSION 1

12 1200063 NUT, KEP 10

13 1200078 WASHER, 5/16 8

14 1200083 WASHER, 5/16 LG. O.D. 8

15 1064440 BRACKET, S.C. BEARING HOLDER 1

16 1200327 SCREW, HEX HD 5/16-18 X 2, FULLY THREADED 1

17 1200039 SCREW, HEX HD 5/16-18 X 3/4 2

18 1064508 BEARING, FLANGE 1

19 4400231 KEY, ROUND END, 1/4" SQ. X 1 1

20 1200319 SCREW, SOCKET HD SET, 5/16-18 X 1 2

21 1064502 BEARING, BRONZE FLANGE 1

22 1200361 PIN, ROLL, 1/4 DIA. X 3 1

23 1064435 HUB, S.C. 1

24 1020048 LEVER, S.C. 1

25 4400202 KNOB, S.C 1

26 1064456 STRAP, SPEED CONTROL 1

Page 19

Page 21

SPEED CONTROL ASSEMBLY

FIGURE 8

SRM60+

Page 20

Page 22

BOWL SUPPORT ASSEMBLY

1 1061028

SUPPORT, BOWL

1

2 1064454

PINS, BOWL SUPPORT

2 3

1200388

NUT, ELASTIC STOP

3/8-16 2 4 1200091

WASHER, BELLEVILLE

4 5

1064322

CLAMP, BOWL

2 6

1064455

CLAMP, BOWL, REAR

1 7

1200322

SCREW, SOCKET HD CAP,

1/4-20 X 1 2 8 1064445

COVER, SLIDE, MOVEABLE

1 9

1020040

STRIP, RUBBER,

21" 2 10 1200008

SCREW, PHILLIPS PAN HD.

#8-32 X

2 11 1200449

SCREW, HX HD

3/8-16 X 3.5 2 12 1200093

SHIM, WASHER

2

FIGURE 9

SRM60+

ILLUS. PART NO.

DESCRIPTION QTY.

Page 21

Page 23

SRM60+

1

1

1

1

1

1

1

1

1

1

1

1

4

4

1

1

HOUSING ASSEMBLY

FIGURE 10

ILLUS. PART NO. DESCRIPTION QTY

1 1064552 HOUSING, MIXER 1

2 1200060 NUT, HEX 10-32 4

WITH TRANSFORMER CONTROL 8

3 1200076 WASHER, FLAT #10 4

WITH TRANSFORMER CONTROL 8

4 1064554 COVER, FIXED SLIDE 1

5 7100027 KNOB, TIMER 1

6 1200318 SCREW, M4 X .7MM, CHZ. HD X 8MM LONG 2

7 4400413 BOLT, CARR 1/4-20 X 3/4 SS 4

8 4400003 SPACER 4

9 1012441 BRACKET, UPPER 2

10 4400141 NUT, KEP 1/4-20 4

11 7100027 TIMER 1

12 4400001 NUT, TINNERMAN 1

13 1200008 SCREW, PHILLIPS PAN HD. #8-32 X 3/8 2

14 4400183 WASHER, LOCK, #8 2

15 1200092 WASHER, FLAT, #8 2

16 1024042 SPRING, TOP COVER

17 1064412 COVER, TOP 1

18 4400113 LABEL, STOP, UNPLUG (Not for Europe)

19 4400114 LABEL, COVER REMOVAL (Not for Europe) 1

20 1200422 SCREW, SHEET METAL, TOP COVER 1

1200451 SCREW (SECURITY OPTION) 1

21 4400065 WASHER, LOCK, #10 2

WITH TRANSFORMER 6

22 1064419 PANEL, REAR 1

23 4400208 SCREW, PHILLIPS HD. 1/4-20 X 1/2 8

1200453 SCREW (SECURITY OPTION) 8

24 1200075 WASHER, 1/4 I.D. 8

25 1033326 TRANSFORMER, 440V

26 7100005 STARTER, 220-240V, 50HZ, 3PH

7100006 STARTER, 208-240V, 60HZ 3PH

7100007 STARTER, 380V, 50HZ, 3PH, 460V, 60HZ, 3PH

7100008 STARTER, 220-240V, 50HZ, 1PH

7100009 STARTER, 208-240V, 60HZ, 1PH

7100114 STARTER, 200V, 50/60HZ, 3PH

27 7100010 BRACKET, DIN RAIL

28 4400316 LABEL, SPEED INDICATOR

29 1064453 PANEL, REINFORCEMENT

30 4400005 LOCKWASHER 1/4

31 1200328 SCREW, HEX HD 1/4-20 X 5/16

32 7100101 SWITCH, PUSH BUTTON, START

33 7100102 SWITCH, PUSH BUTTON, STOP

34 4400311 LABEL, START/STOP/TIMER 1

35 1200063 NUT, KEP 5/16-18 4

36 1200320 WASHER 8

37 1064447 MOUNT, MOTOR 8

38 1064446 ISOLATOR, MOTOR 4

39 1200323 BOLT, MOTOR MOUNT 5/16-18 X 4-1/2 4

40 8800053 PLUG, BOWL LIFT SWITCH 1

41 1012442 BRACKET, LOWER 2

42 7100123 SWITCH, GUARD 2

43 1200450 TOOL KIT (SECURITY OPTION) 1

Page 22

Page 24

HOUSING ASSEMBLY

FIGURE 10 (CONT)

SRM60+

Page 23

Page 25

SRM60+

DRIVE ASSEMBLY

FIGURE 11

ILLUS. PART NO. DESCRIPTION QTY.

1 1064504 PULLEY, VARIABLE, MOTOR

(COMES WITH (2) 5/16-18X3/8 SET SCREWS) 1

2 1064505 BELT, VARIABLE, 1

3 4400214 BUSHING, HEYCO 4

4

Reserved

5 1064503 PULLEY, VARIABLE, INPUT

(COMES WITH (2) 5/16-18X3/8 SET SCREWS) 1

6 4400231 KEY, 1/4 SQ. X 1 1

7 4400101 CLAMP, CORD 2

8 1200060 NUT, HEX #10-32 5

9 4400065 WASHER, LOCK #10 2

10 1061967 RING, TERMINAL, #10, 12 GAUGE 1

11 4400402 WASHER, CABLE CONNECTOR 2

12 4400401 CONNECTOR, CABLE, 3/8 1

13 8800206 CORD, MOTOR, 1 PHASE 1

8800207 CORD, MOTOR, .3 PHASE 1

14 1200063 NUT, KEP 5/16-18 8

15 1200078 WASHER, 5/16 8

16 1064520 MOTOR, 208-240V, 60HZ, 1 PH

(COMES WITH 1/4SQ. X 2 KEY) 1

1064521 MOTOR, 220-240V, 50HZ, 1 PH 1

1064522 MOTOR, 208-240/460V, 60HZ, 3 PH 1

1064523 MOTOR, 220/380/440V, 50HZ, 3 PH 1

1064524 MOTOR, 200V, 50/60HZ, 3PH 1

17 1061973 WIRE NUT (NOT SHOWN) 1PH, 3PH (LOW VOLT) 4

3PH, (HIGH VOLT) 6

18 8800230 CORD, POWER, 230V, 50HZ, 1PH

(CE & BRITISH) (NOT SHOWN) 1

8800231 CORD, POWER, 400V, 50HZ, 1PH

(CE & BRITISH) (NOT SHOWN) 1

19 8800098 PLUG, POWER 1 PH (EUROPE) (NOT SHOWN) 1

20 7100107 STRAIN RELIEF (EUROPE) (NOT SHOWN) 1

Page 24

Page 26

SRM60+ ELECTRICAL CONNECTIONS

Electrical connections should be made by a

qualified workmen who will observe all applicable

safety codes and the National Electrical Code.

Before making electrical connections, check the

specifications on the data plate (located on the rear

access panel) to assure they agree with those of

your electrical service.

WARNING: DISCONNECT ELECTRICAL

POWER SUPPLY AT THE MAIN CIRCUIT

BOX AND PLACE A TAG INDICATING THE

CIRCUIT IS BEING WORKED ON.

A hole of 1/2" conduit is located in the left surface

of the housing in the rear uppermost location.

Connect the input power leads to the pigtail leads

for the motor controller. A solderless lug is

provided for the service ground lead. Secure service

ground to the grounding stud locat ed to the left of

the conduit hole.

Three-phase machines must be connected so the

beater head (planetary) turns in the direction of the

arrow (left to right). To check the direction of

rotation, turn the power disconnect switch "ON".

Place timer on "HOLD". Energize machine

momentarily by pushing "START" then "STOP"

and verify the direction of rotation.

SRM60+

WARNING: DISCONNECT ELECTRICAL

POWER SUPPLY AT THE FUSED

DISCONNECT SWITCH AND PLACE A TAG

INDICATING THE CIRCUIT IS BEING

WORKED ON.

If motor rotation is in correct, interchange any

two of the power supply leads.

NOTE; It is not necessary to remove the lop cover

of the mixer in order to perform the electrical

installation. Only the rear access panel (Fig. 10

[22]) need be removed.

Page 25

Page 27

WIRE TABLE

NOTE

NOTE

W1 16 3 39 1 2 WHITE

W2 16 3 22 2 2

WHITE

W3 16 3 10 2 2

BLACK

W4 16 3 19 2 2

BLACK

W5 16 3 8 1 2

RED W6 16 3 2 1/2 1 1 RED W7 16 3 45 1 1 BLACK

W8 16 3 42 1 1 RED W9 18 3 5 1 1 RED W10 18 3 5 1 1 RED W11 12 3 10 1 1 B

LACK

W12 18 3 9 1 1 RED 8800206

W13 CORD

SRM60+

(208-240V, 60HZ, 1PH)(220-240V, 50HZ, 1PH)

WIRING DIAGRAM

Figure 12A

PART

NUMBER

8800237

PART OF

STARTER

IMPORTANT: Before making electrical connections, check the specifications on the data plate

(located on the rear access panel) to assure they agree with those of your electrical service.

WARNING: Whenever maintenance is being performed, or whenever the top cover or rear

access panel have been removed, DISCONNECT electrical cord and place a tag on it indicating

the mixer is being worked on.

WIRE

NO.

NOTES: 1. ATTACH DOUBLE CRIMP FERRULE.

GA

2. ATTACH DOUBLE CRIMP 1/4- FEMALE

3. MATERIAL: 1015 TEW CSA AND UL APPROVED.

SEE

NOTE

QUICK DISCONNECT FULLY INSULATED.

LENGTH IN

INCHES

Page 26

END A

SEE

END B

SEE

COLOR

Page 28

INCHES

NOTE

NOTE

W1 16 3 39 1 2 WHITE

W2 16 3 22 2 2

WHITE

W3 16 3 10 2 2

BLACK

W4 16 3 19 2 2

BLACK

W5 16 3 8 1 2

RED W6 16 3 2 1/2 1 1 RED W7 16 3 45 1 1 BLACK

W8 16 3 42 1 1 RED W9 18 3 5 1 1 RED W10 18 3 5 1 1 RED

W11 18 3 9 | |

RED

8800207

W12 CORD

SRM60+

(208-240V, 60HZ, 3PH)(220V, 50HZ, 3PH)

WIRING DIAGRAM

(200V, 50/60HZ, 3PH) Figure 12B

PART

NUMBER

8800237

PART OF

STARTER

IMPORTANT: Before making electrical connections, check the specifications on the data

plate (located on the rear access panel) to assure they agree with those of your electrical

service.

WARNING: Whenever maintenance is being performed, or whenever the top cover of rear

access panel have been removed, DISCONNECT electrical cord and place a tag on it

indicating the mixer is being worked on.

WIRE

NO.

NOTES: 1. ATTACH DOUBLE CRIMP FERRULE.

GA

NOTE

2. ATTACH DOUBLE CRIMP 1/4- FEMALE QUICK

DISCONNECT FULLY INSULATED.

3. MATERIAL: 1015 TEW CSA AND UL APPROVED.

SEE

LENGTH

IN

Page 27

END A

SEE

END B

SEE

COLOR

Page 29

INCHES

NOTE

NOTE

1

1

1 1

1

1

1

PART

NUMBER

8800237

PART OF

STARTER

8800207 W14 CORD

WIRE

NO.

W1 16 3 39 4 2 WHITE

W2 16 3 22 2 2 WHITE

W3 16 3 10 2 2 BLACK

W4 16 3 19 2 2 BLACK

W5 16 3 8

W6 16 3 2 1 /2

W7 16 3 45

W8 16 3 42

W9 16 3 5

W10 16 3 5

W11 16 3 9 1 4 RED

W12 16 3 1 1 1 4 BLACK

W13 16 3 1 1 1 4 WHITE

NOTES: I. ATTACH DOUBLE CRIMP FERRULE.

2. ATTACH DOUBLE CRIMP 1/4- FEMALE QUICK

DISCONNECT FULLY INSULATED.

3. MATERIAL: 1015 TEW CSA AND UL APPROVED.

4. NO. 10 RING TERMINAL. AMP 60772-1

(460V, 60HZ, 3PH) (380V, 50HZ, 3PH)

GA

NOTE

WIRING DIAGRAM

WIRE TABLE

SEE

LENGTH

Figure 12C

IN

END A

SEE

END B

SEE

2 RED

1 RED

1 RED

1 RED

1 RED

COLOR

BLACK

IMPORTANT: Before making electrical connections, check the specifications on the data

plate (located on the rear access panel) to assure they agree with those of your electrical

service.

WARNING: Whenever maintenance is being performed, or whenever the top cover or rear

access panel have been removed, DISCONNECT electrical cord and place a tag on it

indicating the mixer is being worked on.

Page 28

Loading...

Loading...