Page 1

MECHANICS

SRM20

MAINTENANCE

MANUAL

SRM20 - SRMF20

(SRM20 - SRMF20) less hub

SRM20/0799 ED2

0011021

Page 2

- SRMF20

TABLE OF CONTENTS

DESCRIPTION PAGE

TROUBLE SHOOTING GUIDE 3

REMOVAL OF TOP COVER 4

MECHANICS MAINTENANCE 4- 5

REPAIR INSTRUCTIONS 6- 10

REPLACEMENT PARTS, LISTS 11-22

WIRING DIAGRAMS 23 -25

LIST OF ILLUSTRATIONS

ILLUSTRATION PAGE

FIGURE 1 OVERALL VIEW OF MIXER 2

FIGURE 2 LUBRICATION INSTRUCTIONS 5

FIGURE 3 TRANSMISSION 11

FIGURE 4 BEATER HEAD ASSEMBLY 12

FIGURE 5 POWER TAKE OFF ASSEMBLY 13

FIGURE 6 INPUT ASSEMBLY 14

FIGURE 7 VERTICAL SHAFT ASSEMBLY 15

FIGURE 8 BOWL LIFT ASSEMBLY 16

FIGURE 9 BOWL SUPPORT ASSEMBLY 17

FIGURE 10 SPEED CONTROL ASSEMBLY 18

FIGURE 11 VARI SPEED AND DRIVE SYSTEM 19 -20

FIGURE 12 HOUSING ASSEMBLY 21 -22

FIGURE 13 A WIRING DIAGRAM 115V, 208-230V 60HZ 1PH,

220-240V, 50HZ, 1PH, 100V, 50/60HZ, 1PH 23

FIGURE 13B WIRING DIAGRAM 115V, 60HZ, 1PH, CANADIAN ONLY

220-240V, 50HZ, 1PH, EUROPE ONLY 24

FIGURE 13C WIRING DIAGRAM 380-400V, 50HZ, 3PH EUROPE ONLY 25

Page 1

Page 3

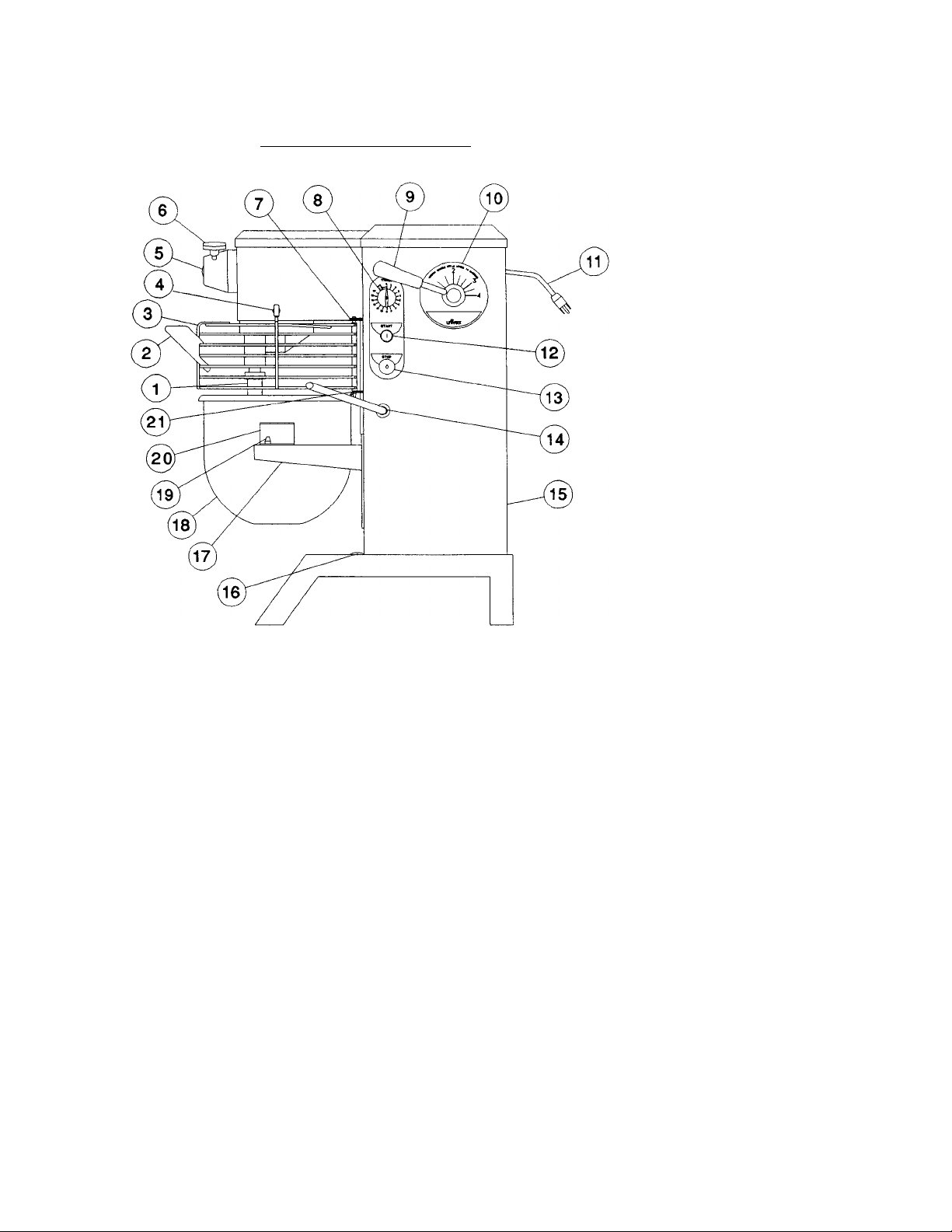

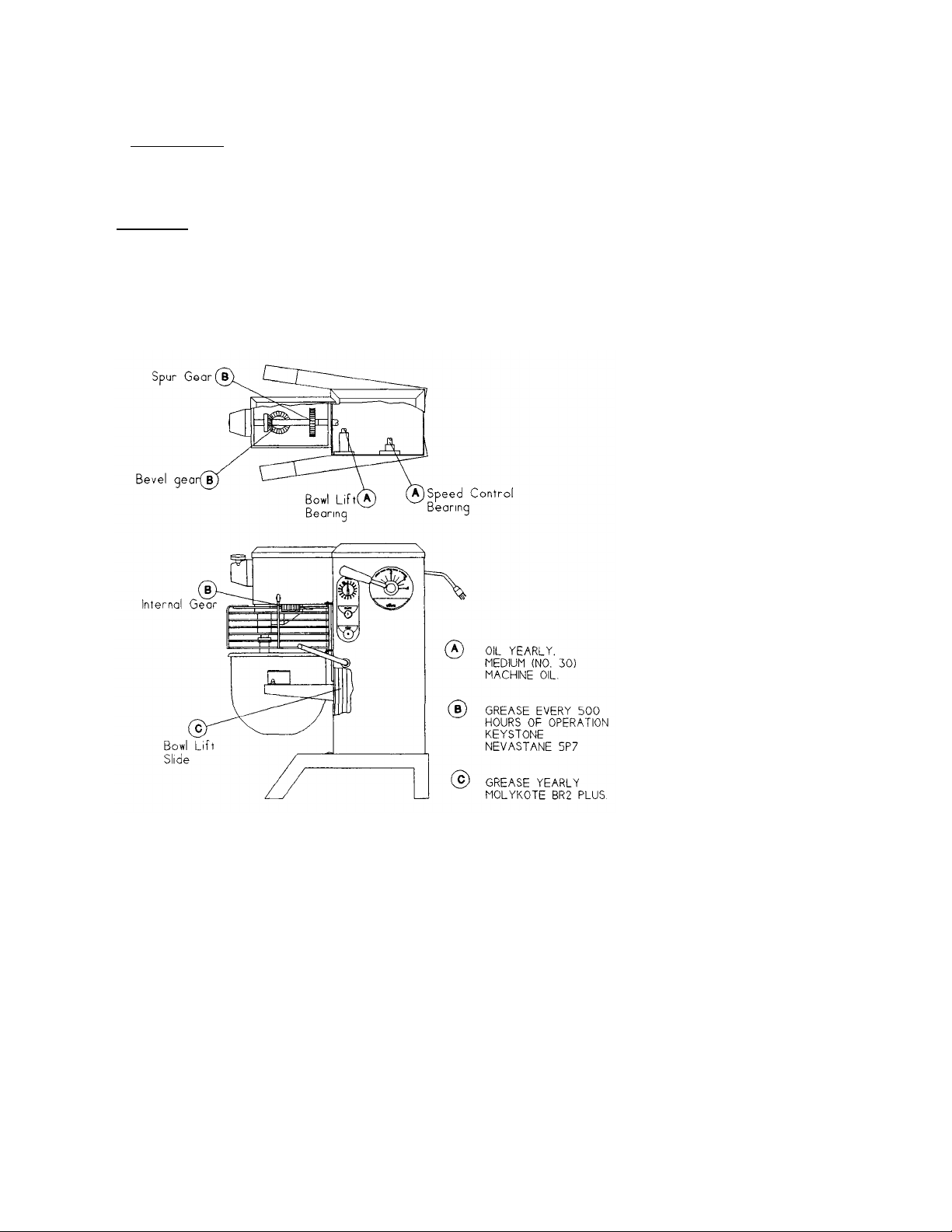

OVERALL VIEW OF FOOD MIXER

Figure 1

SRM20 - SRMF20

1. BEATER SHAFT 12. START BUTTON

2. CHUTE 13. STOP BUTTON

3. SAFETY RING ASSEMBLY 14. BOWL LIFT HANDLE

4. MAGNET 15. REAR ACCESS PANEL

5. NO. 12 HUB 16. CAP (COVERS SHIPPING BOLT HOLE)

6. THUMB SCREW 17. BOWL SUPPORT

7. UPPER MOUNTING BRACKET 18. BOWL

8. TIMER (OPTIONAL) 19. BOWL SUPPORT PIN

9. SPEED CONTROL LEVER 20. BOWL MOUNTING BRACKET

10. SPEED INDICATOR LABEL 21. LOWER MOUNTING BRACKET

11. CORD

Page 2

Page 4

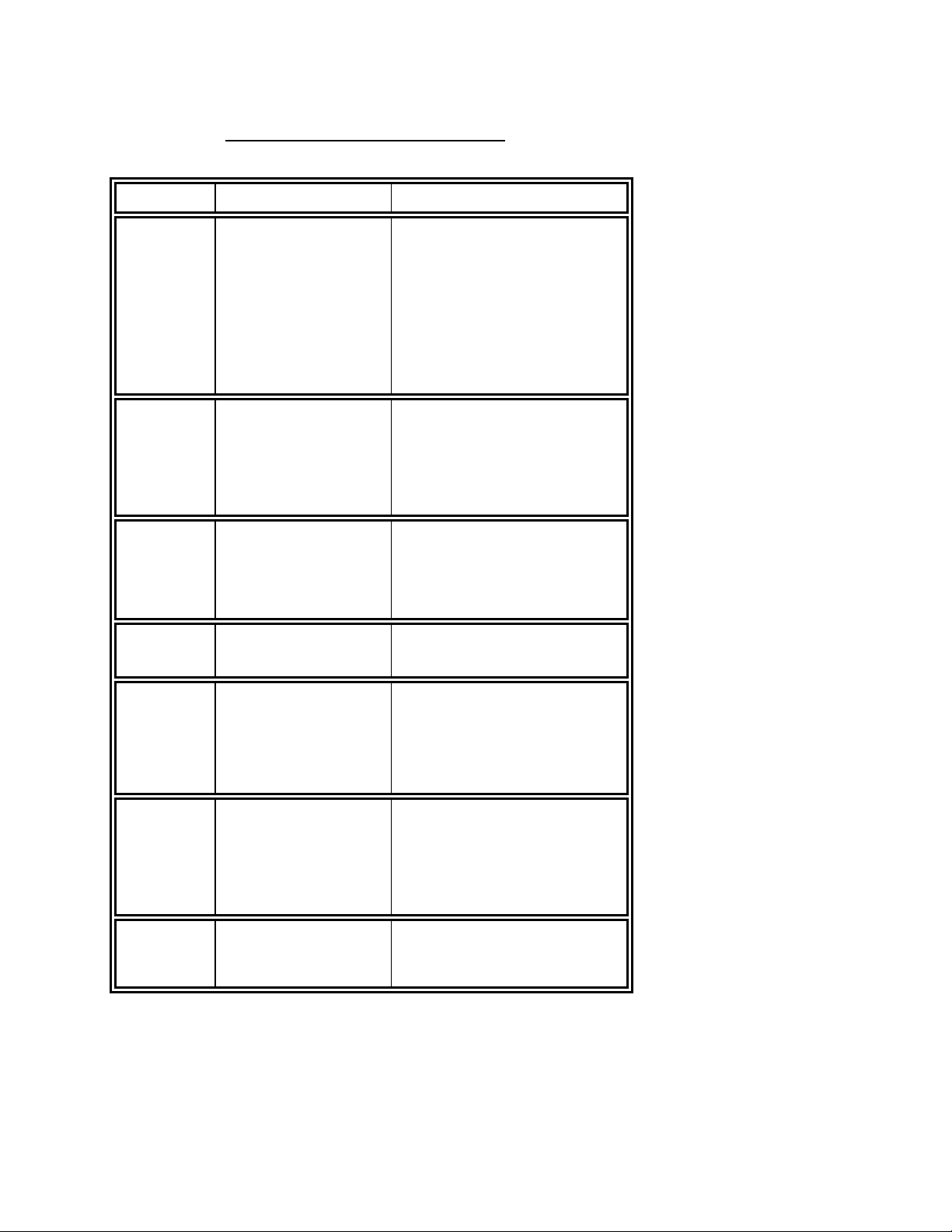

SRM20/SRMF20 TROUBLESHOOTING GUIDE

NG not mounted

Mixer runs but

While mixer running, move speed control

Speeds will not

contact bottom

between bottom of bowl and

Misalignment of transmission

Lack of adequate lubricant on

TROUBLE POSSIBLE CAUSE REMEDY

SRM20 - SRMF20

1. Mixer will not

operate.

2.

beater will not

turn.

3. Slippage of

agitator during

mixing.

4.

change.

1.1 Electrical service down

1.2 Burned switch contacts

1.3 Timer not turned on

1.4 Motor capacitor defective

1.5 Burned out motor

1.6 SAFETY RI

and closed.

1.7 Bowl not raised

2.1 Speed changed while

mixer not running

2.2 Broken or slipping belt

2.3 Key or Pin sheared on

input shaft input gear,

bevel pinion, vertical

shaft or beater shaft.

3.1 Loose belts

3.2 Mixer bowl is over-loaded

3.3 Speed is set too high for

the mix

4.1 Loose belts

4.2 Vari-speed pulley inoperable.

1.1 Check electrical service. Replace

fuse or reset circuit breaker as

necessary.

1.2 Replace.

1.3 Turn timer on.

1.4 Replace

1.5 Remove, test, repair or replace.

1.6 Install SAFETY RING ASSY

1.7 Raise bowl completely

2.1

lever slowly forward then back

2.2 Broken or slipping belt

2.3 Locate by step inspection and replace

defective part.

3.1 Tighten belt.

3.2 Readjust contents of bowl per table of

contents.

3.3 Shift speed lower till action rotates

smoothly.

4.1 Tighten or replace

4.2 Remove, clean and lubricate or replace.

5. Attachments

of bowl.

6. Excessive noise. 6.1 Gears need to be repacked

7. Difficulty in

raising or

lowering bowl.

5.1 Dented bowl

5.2 Insufficient clearance

beater.

5.3

in relation to bowl support.

with grease.

6.2 Badly worn or frayed drive

belts.

6.3 Attachments hitting bowl

6.4 Overloaded mixing bowl.

7.1

bowl lift slide assembly and

housing.

Page 3

5.1 Remove dent or replace bowl.

5.2 Readjust bowl lift

5.3 Realign transmission.

6.1 Locate source by inspection and

repack with grease.

6.2 Replace belts.

6.3 Inspect for cause Ref: 5.1 and 5.2.

6.4 Readjust contents of bowl per table of

mixing capacities.

7.1 Lubricate with grease per Figure 2.

Page 5

SRM20

- SRMF20

REMOVAL OF TOP COVER

maintenance operations. It is secured by a spring clip at its front end and a screw

lift rear of cover, push

Every six months a mechanic should perform the following inspection and maintenance as

raise or lower

for overheating, noise and excessive end play of shaft.

qt. batter beater on

a. The top cover (Fig. 12 [16]) must be removed in order to perform the

at its rearward end. First, DISCONNECT THE ELECTRICAL POWER FOR

SAFETY. Then, remove the screw in the rear (Fig. 12 [20]),

forward about 3 inches and lift cover off.

b. Re-install in reverse procedure using care to insure that the cover sits squarely

and uniformly on the mixer housing.

MECHANICS MAINTENANCE

required:

1. BELTS

a. WARNING: Start mixer and adjust speed control (Fig. 1 [9]) to speed 4. Stop

mixer. FOR SAFETY, DISCONNECT POWER.

b. Remove top cover (Fig. 12 [16]) and rear access panel (Fig. 12 [23]).

c. Check belts (Fig. 11 [11 & 21]). If broken, glazed or worn, replace.

d . Check belt (Fig. 11 [11]) for proper tension. The outer edge of the belt

should be flush with the outer diameter of the variable speed pulley

(Fig. 11 [10]). If not, adjust by loosening the Jam Nut (Fig. 10 [15]) and

turning the connecting rod (Fig. 10 [14]) until the outer edge of belt is

flush with the outer diameter of the pulley. Retighten Jam Nut.

e. WARNING: Plug machine in, start mixer, and adjust speed control to speed 1.

Stop mixer. FOR SAFETY, DISCONNECT POWER.

f. Check belt (Fig. 11 [21]) for proper tension. The outer edge of the belt should be

flush with the outer diameter of the variable speed pulley (Fig. 11 [10]). If not,

adjust by loosening nuts (Fig. 11 [13 ]), holding motor (Fig. 11 [30]),

the motor until the outer edge of belt is flush with the outer diameter of pulley.

Retighten Nuts.

2. MOTOR

Check motor (Fig. 11 [30])

Replace if defective.

3. BOWL LIFT ADJUSTMENT (Fig. 8 and 9)

a. Place 20 qt. mixing bowl (Fig. 1 [18]) on bowl support and 20

beater shaft (Fig. I [1]).

b. Raise bowl support to the high position.

c. Check clearance between bottom of bowl and lowest point of batter beater.

Clearance should be 3/16 inch, plus or minus 1/16 inch.

d. If adjustment is required, disconnect power, loosen lock nut (Fig. 8 [10]) and turn

linkage rod (Fig. 8 [9]) until desired clearance is obtained. Retighten lock nut.

Page 4

Page 6

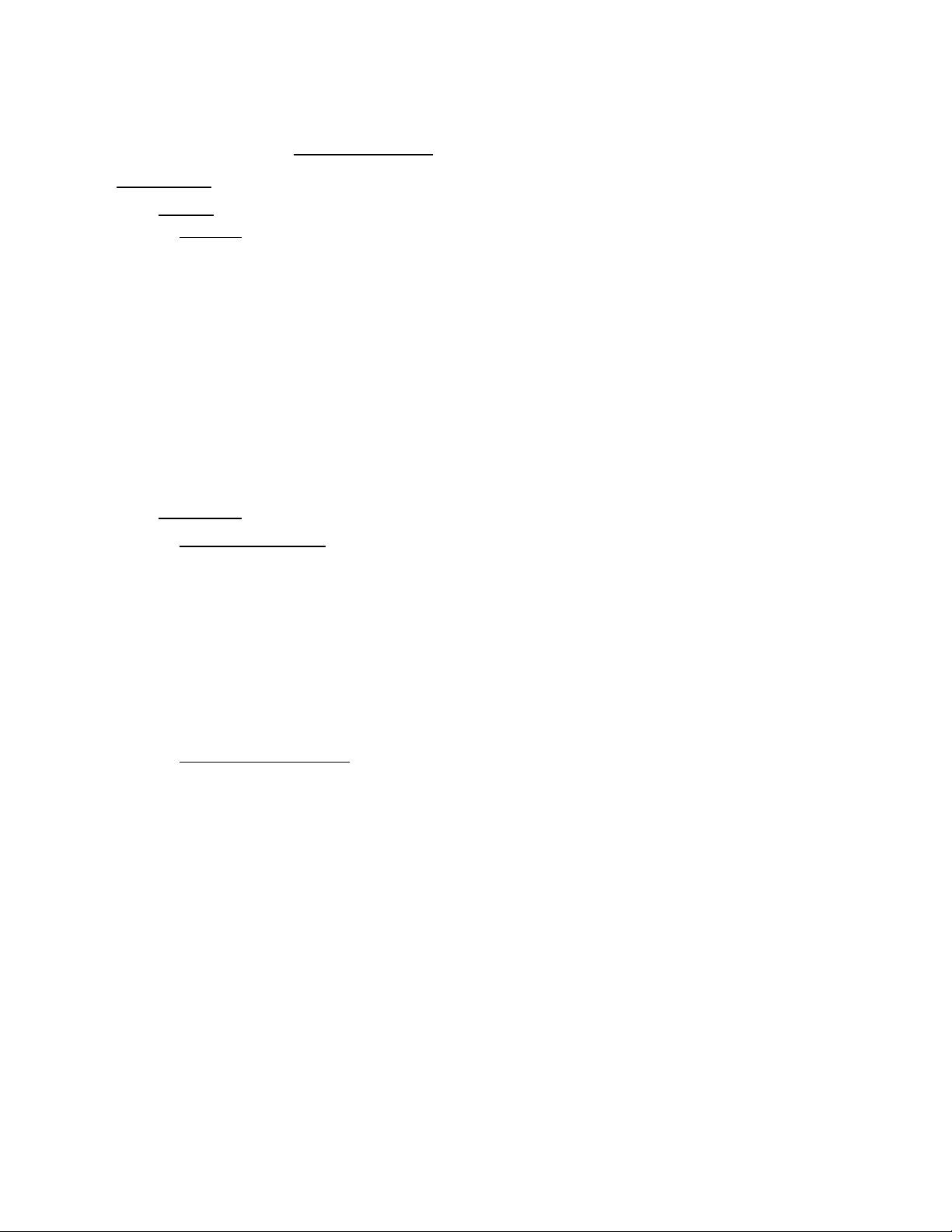

4. LUBRICATION

lubricated bearings with a service interval

often years. The transmission and beater head gearing are packed with Nevastane 5p7 grease. They

NEVER WORK ON THE TRANSMISSION WITH THE MIXER RUNNING. IT IS

RECOMMENDED THAT THE ELECTRICAL SERVICE BE DISCONNECTED TO PREVENT

The lubrication instructions are in Fig. 2. Motors have pre-

must be repacked every 500 hours of operation.

WARNING:

ACCIDENTAL START UP.

LUBRICATION INSTRUCTIONS

FIGURE 2

SRM20 - SRMF20

Page 5

Page 7

REPAIR INSTRUCTIONS

(Including disassembly, replacement and reassemble)

securing transmission housing to

in by hand and inspect for worn or chipped gears, bent shafts, worn

1.

and remove beater head

2.

TRANSMISSION (Fig. 3)

Removal

1. WARNING: DISCONNECT POWER FOR SAFETY.

2. Remove housing top cover (Fig. 12 [16]).

3. Adjust speed control to low speed, then back to high speed, remove upper

retainer bracket (FIG. 11 [15]), and upper V-belt (Fig. 11 [11]) from transmission

driven pulley (Fig. 11 [12]). Remove driven pulley.

4. CAUTION: Transmission assembly is heavy and must be supported prior to

removing. Remove four cap screws (Fig. 3 [10])

mixer housing. Remove transmission assembly and place on work bench.

5. Remove transmission cover (Fig. 3 [2]) by sliding toward the rear and lifting up,

6. Rotate gear tra

bearings and excessive backlash. Backlash measured at gear teeth exceeding

1/32" is considered excessive. After trouble has been isolated, proceed to

disassemble.

Disassembly

Beater Head Assembly (Fig. 4)

NOTE: If a gear requires replacement, always replace it's mating gear.

SRM20 - SRMF20

a. Remove cap screw, left hand thread, (Fig. 4 [12])

assembly using jacking screws (Fig. 4 [9[) if necessary.

b. Remove drive pin (Fig. 4 [1]), top retaining ring (5), gear (6), key (3),

bottom retaining ring (5), retaining ring (7) and press shaft (2) and bearing

(4) from housing (10).

c. Press bearings (4) along with spacer (8) from shaft (2).

Power-Take-Off Assembly (Fig. 5)

a. Remove three cap screws (Fig. 5 [8]), washers (6 & 7), deflector (5),

retaining ring (3), gear (12), and withdraw assembly from housing (4).

b. Remove adapter (2), retaining ring (10) and press shaft (13) bearings (9)

and gear (11) assembly from housing (4).

c. Remove pin (17), gear (11), remaining retaining rings (3), key (14) and

press bearings (9) from shaft (13).

Page 6

Page 8

3.

from transmission

procedures stated above. Successful reassembly is very dependent on

surface of shafts. It is well to recheck

SRM20 - SRMF20

Input Assembly (Fig. 6)

a. Remove two cap screws (Fig. 6 [10]) and withdraw assembly from

transmission.

b. Remove retaining ring (1), gear (2), keys (5, 7), retaining rings (1) and

press shaft (6) and bearing (4) from housing (8).

c. Remove retaining rings (3) and press bearing (5) from housing (6).

d. Remove retaining ring (1) and press shaft (6) from bearing (4).

4. Vertical Shaft Assembly (Fig. 7)

a. Remove key (4).

b. Invert housing on suitable support and press shaft (2)

housing (Fig. 3 [1]).

c. Remove lower bearing (8) with puller and remove spacer (7).

d. Remove retaining ring (6) and pull or press upper bearing (5) from

transmission housing (Fig. 3 [1]).

e. Remove pin (3) and press shaft (2) from gear (1).

REASSEMBLE

a. Clean all components except bearings with safety approved cleaning

c. Reassembly should be carried out in the reverse of the disassembly

d. Transmission should be progressively checked for smooth operation

solvent. Inspect components for defects and replace those found to be

defective.

NOTE: All gears should be replaced as sets.

b. If shafts have become slightly scored during the disassembly process,

polish the shafts with fine machinist's crocus cloth. Use care to avoid

excessive removal of shaft surface or proper fit of components will be

lost.

the cleanliness of all surfaces particularly the bores of housings, gears

and bearings as well as the outer

each component for cleanliness as it is picked up for reassembly. New

keys and roll pins should be used on reassembly.

while on the workbench by hand turning each assembly as it is installed.

Page 7

Page 9

SRM20 - SRMF20

the mixer. Apply Keystone Nevastane 5P7 grease to the spur gear and bevel

support must be held while screws are being removed in order to

BOWL SUPPORT ASSEMBLY (Fig. 9)

SLIDE ASSEMBLY (See Fie. 9)

e. Lubrication of the transmission should be done following its installation on

gear meshes. This may be simplified by feeding the grease into the rotating

gear meshes. Caution should be exercised to avoid entrapment of the

application implement in the gear teeth. Insure the deflector (Fig. 5 [5]) is

positioned to dynamically guide the lubrication into the bevel gear mesh.

1. WARNIN G: Disconnect electrical power for safety.

2. Remove housing top cover (Fig. 12 [16]), and rear access panel (Fig. 12 [23]).

3. Remove four cap screws (Fig. 9 [15]) and remove bowl support (Fig. 9 [1]) and

slide cover (Fig. 9 [3]).

CAUTION: Bowl

prevent it from falling.

4. Reassembly is the reverse procedure.

1. Carry out above disassembly procedure for removing bowl support.

2. Remove fixed slide cover (Fig. 12 [6]) by removing two nuts. (Fig. 12 [5])

3. Remove retaining ring (Fig. 9 [8]) from rod end pin (6). Withdraw pin (6) from rod

end (7).

4. Remove four kep nuts (Fig. 9 [13]) and withdraw slide frame (5) from housing

studs.

5. Remove four cap screws (Fig. 9 [14]) and lift off gibbs (11). Remove slide (10).

6. Clean and inspect sliding surfaces for excessive wear

7. Replace parts showing excessive wear.

8. Lubricate sliding surfaces with grease.

9. Reassemble and reinstall in the reverse of the above procedure.

10. Check clearance between batter beater and bowl per Mechanics Maintenance

paragraph 3 a - d and readjust as necessary.

Page 8

Page 10

SRM20 - SRMF20

to

(11)

SPEED CONTROL ASSY. (Fig. 10)

Disassembly

1. Remove housing cover (Fig. 12 [16]) and rear access panel (Fig. 12 [23]).

2. Loosen screw on collar (Fig. 10 [17]). Remove collar rod end (16) and o'ring

(Fig 11 [8]) from cam assembly (11). Loosen set screws (10) in cam assembly

(11).

3. Drive roll pin (4) from hub (3) and pull hub (3), lever (2), and handle (1) from

cam assembly shaft (11). Remove washer (5) from cam assembly (11).

4. Unscrew hub (3) and handle (1) from lever (2).

5. Remove nut (8) and washer (7) from studs holding speed control bearing (6)

housing (Fig. 12 [3]).

6, Withdraw bearing (6) and remaining assembly from housing (Fig. 12 [3]).

7. Pull cam assembly (11) from bearing (6).

8. Remove screws (20), lock washers (21), strap (22), and spring (19) from

bearing (6).

9. Remove screws (13) and detent disk (12).

Reassemble

10 Reassemble in reverse of above procedure. Grease cam assembly shaft

and detent disk (12) during assembly with MolyKote BR2 Plus or general

purpose bearing grease. Adjust belt as described in Mechanics Maintenance 1

paragraph a,d-f.

11 If speed control handle (1) moves while the mixer is running, tighten set screws

(10) against spring washer (9) until movement stops.

VARI-SPEED ASSEMBLY Fig. 11)

Disassembly

1. Remove housing cover (Fig. 12 [16]) and rear access panel (Fig. 12 [23]) as

described in the cover removal section.

2. Shift handle (Fig. 10 [1]) from fourth speed to first speed and back to fourth

speed with the mixer OFF. (Squeezing the belts (Fig. 11 [11 & 21]) together at

midspan will help.)

3. Unscrew nut (13) and remove washer (14) and belt retainer (15).

4. Unwrap belt (11) from pulley (12) and withdraw from vari-speed pulley (10).

5. Shift handle (Fig. 10 [1]) to first speed.

6. Unscrew nuts (13). Remove washers (14) and belt retainer (22) from mixer.

Page 9

Page 11

SRM20

- SRMF20

which secure motor cord power

ground lead. Pull

Unscrew

11

speed pulley assy. from

and remove from

(20).

7. Unwrap belt (21) from pulley (27). Withdraw belt (21) from vari-speed pulley

8. Loosen screws on contactor (Fig. 12 [32])

9. Remove nuts securing motor (30) and lift motor from mixer. Loosen set

10. Remove two screws securing connection box plate on rear end of motor.

11. Loosen jam nut (Fig. 10 [15]). Loosen set screw on collar (Fig. 10 [17]).

12. Remove nuts (13) and washers (14). Withdraw vari-

13. Loosen the two set screws on each vari-speed pulley (10)

14. Remove retaining rings (6) from rod end pin (5) and bracket swivel pin

Reassemble

15. Reassemble in reverse of above procedure. Adjust belts as described in

16. Adjust upper and lower belt retainers (15 & 22) 1/8" from outer belt surface.

(10).

leads (34). Remove nut (38), lock washer (37) and motor cord ground lead

from weld stud. Remove nuts (38), washers (36) and cord clamps (35).

screw (28) and slide pulley (27) and key (29) off motor shaft.

Remove green grounding screw securing motor cord (33)

cord leads from motor terminals.

Slide collar and rod end (Fig. 10 [16]) off cam assy. (Fig. 10 [11]).

rod end (Fig. 10 [16]) and jam nut (Fig. 10 [15]) from connecting rod (Fig.

[17]). Unscrew connecting rod from rod end (Fig. 11 [7]).

mixer housing.

shaft (9). Remove woodruff keys (16) and retaining rings (1) from shaft.

Drive shaft (9) from pulley swivel bracket (4). Press remaining ball bearings

(2) from shaft (9) and from swivel bracket (4). Remove retaining rings (3)

from swivel bracket.

Drive pins (20 & 5) from swivel bracket (4) and swivel bracket base (18).

Mechanics Maintenance 1 paragraph a,d-f.

HOUSING (Fig 12)

For the remaining parts which have not been discussed pertain to electrical

components and the housing. Figures 12, 13A, 13B, and 13C should provide

adequate guidance for the disassembling and reassembling of these parts.

Page 10

Page 12

SRM20 - SRMF20

TRANSMISSION

FIGURE 3

ILLUS. PART NO. DESCRIPTION QTY.

1. 1024434 Transmission Housing 1

2. 1024117 Transmission Cover 1

3. 1200012 Phillips Hd. Screw 10-32 x 1/2 6

4. 1024041 Spring Clip 1

5. 1200076 Steel Flat Washer #10 2

6. 4400065 Split Lock Washer #10 6

7. 8800022 Foam Strip 1

8. 1200084 Steel Flat Washer 1/2 4

9. 1200085 Split Lock Washer 1/2 4

10. 1200057 Socket. Hd. Cap Screw 1/2-20 x 1 4

11. 4400194 Dowel Pin 1/4" O.D. x 1/2" LG 2

12. 1200440 Hex Hd. Cap Screw 10-32 x 1 4

13. 1020011 Internal Gear 1

14. 4400342 Label, Univex SRM20) 1

4400343 Label, Univex (SRMF20) 1

15. 1012438 Holder, Magnet 2

16. 1012439 Magnet 2

Page 11

Page 13

SRM20 - SRMF20

BEATER HEAD ASSEMBLY

FIGURE 4

ILLUS. PART NO. DESCRIPTION QTY.

1023075 Beater Head Assembly 1

1 1200381 Drive Pin 3/8" x 1-1/4" 1

2 1023014 Beater Head Shaft 1

3 1200113 Woodruff Key #9 1

4 1030019 Ball Bearing 6204LL 2

5 1200119 Retaining Ring, External 3

6 1012003 Beater Head Gear 1

7 1200117 Retaining Ring, Internal 1

8 1012012 Beater Head Spacer 1

9 8900038 Set Screw 2

10 1020106 Beater Head Casting 1

11 4400499 Washer 7/16" x 1-1/8" x 5/64" 1

12 1200051 Hex. Hd. Cap Screw 3/8-24 x 1-1/4" L.H. 1

13 1020002 Splash Ring 1

14 4400269 Label, Rotation 1

Page 12

Page 14

SRM20 - SRMF20

1

1

1

1

1

1

1

1

1

1

*

Not available

–

Part of P.T.O. Shaft Illus NO.

13

POWER TAKE OFF ASSEMBLY

FIGURE 5

ILLUS. PART NO. DESCRIPTION QTY

1. 8800033 Cover, P.T.O. (With PTO ) 1

2. 8800012 Adapter, Attachment (With PTO ) 1

3. 1200119 Retaining Ring, External 5

4. 4400025 Housing, P.T.O. (With PTO ) 1

1012428 Housing, (Without PTO ) 1

5. 1024417 Deflector, Lubrication 1

6. 4400005 Washer, Lock 1/4 3

7. 1200075 Washer, Flat 1/4 1

8. 1200025H Screw, Hex Hd. Cap 1/4-20 x 3/4 3

9. 1030019 Ball Bearing 6204 LL 2

10. 1200117 Retaining Ring, Internal

11. 1030031 Bevel Gear, Pinion Only

12. 1020004 Spur Gear

13. 1021016 Shaft, P.T.O. ( With PTO )

1024420 Shaft, ( Without PTO )

14. 1200113 Woodruff Key #9

15.* 4400006 Spring, P.T.O. Shaft ( With PTO )

16.* 4400016 Ball, P.T.O. Shaft ( With PTO )

17. 1200103 Roll Pin 5/16" x 1-1/4"

18. 4400229 Knob Assy, P.T.O. ( With PTO )

19. 4400210 Washer, P.T.O. 1

20. 8900019 Screw SFHD 6-32 x 3/8 2

Page 13

Page 15

SRM20 - SRMF20

INPUT ASSEMBLY

FIGURE 6

ILLUS. PART NO. DESCRIPTION QTY.

1021036 Input Assembly 1

1. 1200119 Retaining Ring, External 6

2. 1020010 Spur Gear, Input Pinion Only 1

3. 1200117 Retaining Ring, Internal 2

4. 1030019 Ball Bearing 6204LL 2

5. 1200113 Woodruff Key #9 1

6 1024186 Input Shaft 1

7. 4400230 Key 3/16" sq. x 1-1/2" Ig. 1

8. 1030017 Input Housing 1

9. 4400003 Steel Flat Washer 1/4 I.D. 2

10. 1200022H Hex. Hd. Cap Screw 1/4-20 x 1 2

11. 4400005 Lock Washer, 1/4 2

Page 14

Page 16

SRM20 - SRMF20

VERTICAL SHAFT ASSEMBLY

FIGURE 7

ILLUS. PART NO. DESCRIPTION QTY.

1 1020215 Bevel Gear 1

2 1012434 Vertical Shaft 1

3 4400022 Roll Pin 5/16" x 1-1/2" 1

4 1200113 Woodruff Key #9 1

5 1030035 Ball Bearing 63204 ZZ 1

6 1200117 Retaining Ring, Internal 1

7 1020009 Vertical Spacer 1

8 1030019 Ball Bearing 6204 LL 1

Page 15

Page 17

SRM20 - SRMF20

1

1

1

1

1

**

Includes items

14

and

15.

BOWL LIFT ASSEMBLY

FIGURE 8

ILLUS. PART NO. DESCRIPTION QTY.

1 1024004 Lever, Bowl Lift (SRMF20 ONLY) 1

1025004 Lever, Bowl Lift (SRM20 ONLY) 1

2 1024406 Collar, Bowl Lift 1

3 4400118 Roll Pin 1 x 3/16" 2

4 1200301 Nylon Washer 5/8 1

5 1012133 Bowl Lift Bearing 1

6 4400127 Steel Flat Washer 3/8 3

7 1200063 Kep Nut 5/16-18 3

8 ** 1024012 Cam Assembly (includes items 14 & 15) 1

9 * 1023053 Connecting Rod 1

10 1200155 Hex Nut 3/8-24

11 1012201 Rod End, 3/8-24 R.H.

12 1020441 Collar & Set Screw

13 1030318 Spacer, Nylon 3/8

14 1200435 Reversible Locknut 5/16-24

15 1200434 Set Screw 5/16-24 x 1 1/8 1

* Part No. 1023053 is broken in half in Figure 10. It is actually one piece and only one is

needed for bowl lift.

Page 16

Page 18

SRM20 - SRMF20

BOWL SUPPORT ASSEMBLY

FIGURE 9

ILLUS. PART NO. DESCRIPTION QTY.

1 1021028 Bowl Support 1

2 4400219 Pin, Bowl Support 2

3 1021019 Slide Cover, Movable 1

4 4400278 Gasket Strip 2

5 1012190 Frame, B.L. 1

6 1012181 Pin, Rod End 1

7 1012202 Rod End 3/8-24 L.H. 1

8 1200311 Retaining Ring, External 2

9 * 1023053 Connecting Rod, B.L. 1

10 1012189 Slide, B.L. 1

11 1012191 Gibb, B.L. 2

12 4400127 Steel Flat Washer 3/8 4

13 1200063 Kep Nut 5/16-18 4

14 1200039 Hex Hd. Cap Screw 5/16-18 x 3/4 4

15 4400178 Hex Hd. Cap Screw 5/16-18 x 1-1/2 4

16 1200077 Lock Washer 5/16 4

* Same part as ILLUS. NO. 9 in Figure 9.

Page 17

Page 19

SRM20 - SRMF20

needed for speed control, vari

-

speed assembly.

SPEED CONTROL ASSEMBLY

FIGURE 10

ILLUS. PART NO. DESCRIPTION QTY.

1 4400202 Handle 1

2 1020066 Lever, S.C. 1

3 1012137 Hub, S.C. 1

4 1200300 Roll Pin 3/16" x 2" 1

5 1200301 Nylon Washer 5/8 1

6 1020068 Speed Control Bearing 1

7 4400127 Steel Flat Washer 3/8 2

8 1200063 Kep Nut 5/16-18 2

9 1200156 Spring Washer 5/8 2

10 1200304 Set Screw 10-32 x 3/4 2

11 1020069 Cam Assy, S.C. 1

12 1023222 Detent Disk 1

13 1200012 Phillips Hd. Screw 10-32 x 1/2 2

14 * 1030223 Connecting Rod, S.C. 1

15. 1200155 Hex Nut 3/8-24 1

16 1012201 Rod End 3/8-24 R.H. 1

17 1020441 Collar & Set Screw 1

18 1030318 Spacer, Nylon 3/8" ID 1

19 1023223 Spring, S.C. 1

20 4400208 Phillips Pan Hd. Screw 1/4-20 x 1/2 2

21 4400005 Lock Washer 1/4 2

22 1023225 Strap, S.C. 1

* Part No. 1030223 is also shown in Figure 12. It is actually one piece and only one is

Page 18

Page 20

SRM20 - SRMF20

VARI-SPEED ASSEMBLY

FIGURE 11

ILLUS. PART NO. DESCRIPTION QTY.

1 1200119 Retaining Ring, External 2

2 1030019 Ball Bearing 6204LL 2

3 1200117 Retaining Ring, Internal 2

4 1030167 Pulley Swivel Bracket 1

5 1012181 Rod End Pin 1

6 1200311 Retaining Ring, External 4

7 1012202 Rod End 3/8-24 L.H. 1

8 4400009 Rubber "0" Ring 3/16" x 4" 1

9 1021022 Vari-Speed Shaft 1

10 1020061 Vari-Speed Pulley (Comes with (2) 1/4-20x3/8 set screws) 2

11 1020501 Cog Belt 1

12 1020500 Pulley, Driven (Comes with 5/16-18x3/8 set srew) 1

13 1200063 Kep Nut 5/16-18 11

14

15 1023240 Belt Retainer, Upper 1

16 1200113 Woodruff Key #9 2

17 * 1030223 Connecting Rod, S.C. 1

18 1030216 Swivel Bracket Base 1

19 1200083 Steel Flat Washer 3/8 4

20 1030191 Bracket Swivel Pin 1

21 1020502 Cog Belt 1

22 1023220 Bracket, Belt Retainer 1

23 4400127 Steel Flat Washer 3/8 10

24 4400178 Hex Hd. Cap Screw 5/16-18 X 1-1/2 1

25 1023221 Bushing, Belt Retaining Bearing 1

26 1012166 Ball Bearing 6203ZZ 1

27 1021030 Pulley, Drive (Comes with 5/16-18x1/4 set screw) 1

28

29 4400230 Key, 3/16" sq. x 1-1/2" 1

30 1020024 Motor, 1/2HP, 115V/230V, 60HZ, 1PH (Includes item 29) 1

1020024A Motor, 1/2HP, 220V-240V, 50HZ, 1PH, ( Includes item 29)

1020026 Motor, 1/2HP, 380V,50HZ,3PH (For Europe Only) (Includes

31 1020218 Motor Mount SRM20 Only 1

32 7100107 Strain Relief 1

33 8800200 Cord, Electric 115V, 60HZ, 1PH

8800201 Cord, Electric 230V, 60HZ, 1PH

8800102 Cord, Electric 230V, 50HZ, 1PH (CE) 1

7100100 Cord, Electric 220/380V, 50HZ, 3PH

8800101 Cord, Electric 230V, 50HZ, 1PH, (British) 1

34 8800203 Cord, Motor 1PH 1

8800226 Cord, Motor 3PH 1

35 4400101 Clamp, Cord 3

36 1200076 Washer, Flat #10 2

37 4400065 Lock Washer #10 2

38 1200060 Hex Nut, 10-32 6

39 4400398 Tie Wrap (Not Shown) 1

* Same part as ILLUS. NO. 4 in Figure 11.

Reserved

Reserved

100V, 50/60HZ, 1PH 1

item 29) 1

100V, 50/60HZ, 1PH 1

220-240V, 50HZ, 1PH 1

400V, 60HZ, 3PH, 400V, 50HZ, 3PH, (British & CE) 1

Page 19

Page 21

SRM20 - SRMF20

VARI-SPEED ASSEMBLY

FIGURE 11

Page 20

Page 22

SRM20 - SRMF20

1

1

1

1

1

1

HOUSING ASSEMBLY, FIGURE 12

ILLUS. PART NO. DESCRIPTION QTY.

1 1021102 Mixer Base 1

2 4400038 Feet 4

3 1024432 Mixer Housing, SRM20 I

1024433 Mixer Housing, SRMF20 1

4 1200076 Steel Flat Washer #10 6

5 1200060 Hex Nut 10-32 6

6 1024435 Fixed Slide Cover 1

7 7100123 Switch, Guard 2

8 4400413 Bolt, Carr 1/4-20 X 3/4 SS 4

9 4400003 Spacer 4

10 1012441 Bracket, Upper 2

11 4400141 Nut, Kep 1/2-20 4

12 4400001 Nut, Tinnerman 1

13 1200092 Washer, Flat #8 2

14 4400183 Washer, Lock #8 2

15 1200008 Screw, 8-32 x 3/8" PPHD 2

16 1024126 Housing Cover 1

17 4400114 Label, To Lift Cover (NOT FOR EUROPE) 1

18 4400113 Label, Stop Unplug (NOT FOR EUROPE) 1

19 1024042 Spring, Top Cover 1

20 1200422 Screw Sheet Metal #12 PPHD 1" LG. 1

1200451 Screw (Security Option) 1

21 1200433 Nut, Elastic Stop 4-40 2

22 4400065 Lockwasher #10 4

23 1024024 Rear Access Panel, SRM20 1

1024111 Rear Access Panel, SRMF20

24 8800022 Rubber Strip 6 ft

25 1200012 Phillips Hd. Screw 10-32 x 1/2 7

1200452 Screw (security Option) 7

26 7100023 Insulation Barrier 1

27 1200432 Screw, Hex HD 4-40 x 3/4 2

28 7100103 Switch, Guard 1

29 1024411 Bracket, Bowl Switch 1

30 4400349 Label, Speed Control 1

31 7100010 Mount, Contactor 1

32 7100011 Contactor 115V/60HZ/1PH 1

7100012 Contactor 208-230V/60HZ/1PH, 220V/50HZ/1PH 1

7100013 Contactor 240V/50HZ/1PH 1

7100015 Contactor 100V/50-60HZ/1PH 1

7100040 Starter 115V, 60HZ, 1PH (Canadian use only)

1033327 Starter 380-400V,50HZ, 3PH (For Europe Only)

7100108 Starter 220-240V,50HZ,1PH (For Europe Only)

33 7100101 Push Button, Start

34 7100102 Push Button, Stop

35 4400015 Kep Nut 3/8-16 4

36 1200083 Steel Flat Washer 3/8 4

37 1200084 Steel Flat Washer 1/2 4

38 4400310 Decal. Start/Stop 2

4400311 Decal, Start/Stop/Timer (optional) 1

39 1012442 Bracket, Lower 1

40 4400081 Screw, Drive 4

41 4402017 Screening 1

42 1200125 Cap 4

43 7100027 Timer, 15 min. 1

Page 21

Page 23

SRM20 - SRMF20

44 4400079 Screw CHZ HD M4-.7mm x 6mm LG 2

45 7100028 Knob, Timer 1

46 7100106 Transformer, Control, 380V Primery / 21V Secondary

( For Europe Only) (Not Shown) 1

47 4400171 Bushing, (Not Shown) 3

48 1200022H Screw 1/4-20 X 1 (For Europe Only) ( Not Shown) 1

49 4400057 Nut 1/4-20 ( For Europe Only) (Not Shown) 2

50 4400005 Lockwasher 1/4 (For Europe Only) (Not Shown) 1

51 1200450 Tool Kit (Security Option) 1

HOUSING ASSEMBLY

FIGURE 12

Page 22

Page 24

SRM20 - SRMF20

INCHES

WIRING DIAGRAM 115/208-230V, 60HZ, 1PH

220-240V, 50HZ, 1PH

100V, 50/60HZ, 1PH

FIGURE 13A

WIRE TABLE

PART

NUMBER

8800221

8800203 W11

WIRE

NO.

W1 16 3

W2 16 3

W1 W/0

TIMER

W3 16 3 4 2 2 BLACK

W4 16 3 7 2 2 WHITE

W5 16 3 4 1 2 RED

W6 16 3 2 1/2 1 1 RED

W7 16 3 26 1 11 1 1 BLACK

W8 16 3 30 1 1 RED

W9 16 3 2 1/2 1 1 RED

W10 16 3 2 1 11 1 1 RED

GA

16 3 21 1 2 WHITE

SEE

NOTE

LENGTH

IN

END A

SEE NOTE

END B

SEE NOTE

COLOR

NOTES: 1. ATTACH DOUBLE CRIMP FERRULE.

2. ATTACH DOUBLE CRIMP 1/4" FEMALE QUICK DISCONNECT

FULLY INSULATED.

3. MATERIAL: 1015 TEW CSA AND UL APPROVED.

IMPORTANT: Before making electrical connections, check the specifications on the data plate

(located on the rear access panel) to assure they agree with those of your electrical service.

WARNING: Whenever maintenance is being performed or whenever the top cover or rear access

panel have been removed, DISCONNECT electrical cord and place a tag on it indicating the mixer is

being wo rked on.

Page 23

Page 25

SRM20 - SRMF20

WIRING DIAGRAM 115V, 60HZ, 1PH

FOR CANADIAN ONLY

220-240, 50HZ, 1PH FOR EUROPE ONLY

FIGURE 13B

WIRE TABLE

PART

NUMBER

8800221

NOTES: 1. ATTACH DOUBLE CRIMP FERRULE.

2. ATTACH DOUBLE CRIMP 1/4- FEMALE QUICK DISCONNECT FULLY INSULATED).

3. MATERIAL: 1015 TEW CSA AND UL APPROVED.

8800203 W13

WIRE NO. GA

W1 16 3

W2 16 3

W1 W / 0

TIMER

1 6 3 21 1 2 WHITE

W3 16 3 4 2 2 BLACK

W4 16 3 7 2 2 WHITE

W5 16 3 4 1

W6 16 3 2 1/2 1 1 RED

W7 16 3 26 1 /2 1

W8 16 3 30

W9 16 3 2 1/2 1

W10 16 3 2 1/2 1 1 RED

W11 16 3 10 1

W12 16 3 10

SEE

NOTE

LENGTH

INCHES

END A

IN

NOTE

SEE

1

1

END B

SEE

NOTE

2 RED

1

1

1

1

1

COLOR

BLACK

RED

RED

RED

BLACK

IMPORTANT: Before making electrical connections, check the specifications on the data plate (located

on the rear access panel) to assure they agree with those of your electrical service.

WARNING: Whenever maintenance is being performed or whenever the top cover or rear access panel

have been removed, DISC ONNECT electrical cord and place a tag on it indicating the mixer is being

worked on.

Page 24

Page 26

WIRING DIAGRAM

INCHES

NOTE

NOTE

380-400V, 50HZ, 3PH

FIGURE 13C (For Europe Only)

POWER IN

w13

SRM20 - SRMF20

WIRE TABLE

PART

NUMBER

8800221

8800226 W14 CORD

NOTES: I. ATTACH DOUBLE CRIMP FERRULE.

2 ATTACH DOUBLE CRIMP 1/4- FEMALE QUICK DISCONNECT FULLY INSULATED

3. MATERIAL: 1015 TEW CSA AND UL APPROVED

WIRE NO. GA

W1 16 3

W2 16 3

W1 W / 0

TIMER

16 3 21 1 2 WHITE

W3 16 3 4 2 2 BLACK

W4 16 3 7 2 2 WHITE

W5 16 3 4 1

W6 16 3 2 1 /2 1

W7 16 3 26 1/2 1 1 BLACK

W8 16 3 30 1

W9 16 3 2 1/2 1

W10 16 3 2 1 /2 1 1 RED

W11

W12

W13

SEE

NOTE

LENGTH

END A

IN

SEE

END B

SEE

2 RED

1 RED

1 RED

1 RED

COLOR

IMPORTANT: Before making electrical connections, check the specifications on the data plate

(located on the rear access panel) to assure they agree with those of your electrical service.

WARNING: Whenever maintenance is being performed or whenever the top cover or rear

access panel have been removed, DISCONNECT electrical cord and place a tag on it indicating

the mixer is being worked on.

Page 25

Loading...

Loading...