Page 1

unïvex

INSTRUCTION MANUAL

PIZZA XPRESS

COMBINATION DOUGH DIVIDER/ROUNDER

DOUGH ROUNDER DR42

DOUGH DIVIDER DD23

PATENTED

CE

MAKES DOUGH PORTIONS AND

-

NSF -

UL APPROVED

ROUNDS THEM

CDR23 & CDR1 i

Persons under age 18 are not permitted

equipment per (J. S. Dept. of Labor Employment

ESA91-3.

3 OId Rockingham Rd.

Salem, NH 03079

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

to operate or have accessibility to operate this

Standards Administration Fact Sheet No.

Tel. 603-893-6191

Fax 603-893-1249

Page 2

CAUTION:

DOUGH DIVIDER/ROUNDER CDR 25

DOUGH ROUNDER DR42

This machine is basically the

same as the CDR1 i which handles dough

portions from 2 oz. to i i oz.

Only the following modifications

the adjustable head is replaced by

e the motor is two-speed: speed i is for small portions;

speed 2 is for bigger portions.

* a dough support is added.

. the small dough rounder is replaced by the large dough rounder

DR42.

are applied:

a fixed opening head.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE OF CONTENTS

A)

B)

i .

EMPLOYMENT OF THE MACHINE........................................PAGE 3

WORKING PLACES...................................................................PAGE 3

STARTING UP.............................................................................PAGE 3

USE AND REGULATION...........................................................PAGE 4

5

TRANSPORTATION...................................................................PAGE 4

6. INSTALLATION..........................................PAGE 4

7

ASSEMBLING.............................................................................PAGE 4

8. DISASSEMBLING AND CLEANTNG........PAGE 5

9.1 MAINTENANCE.......................................................................PAGE 6

92 REPAIRS.................................................................................PAGE 6

ELECTRICAL SCHEME................................................... ...............PAGES 18, 19,20

2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

A)

EMPLOYMENT OF TITE MACHTNE

The Dough Divider/Rounder CDR25 has been designed and

and to round them (at room temperature).

Warning: Do not introduce into the machine frozen,

which are not foreseen in these instructions.

WORKING PLACES

The machine has to be placed

be used by a single person.

on a honzontal working plane as indicated on Drawing 1,

3, STARTING UP

3 i The machine is provided with three

Before connecting the machine, be

indicated on the machine data plate, and that

overloading.

3.2 Once the machine is installed, be

( Drawing i, Page 7) are correctly placed and

33 Be sure that the rounder is correctly

cannot start.

single-phase motors and a NEMA plug.

sure that the voltage and the frequency correspond to those

the intake is grounded and properly

sure that the Cover A (Drawing 1, Page 7), and the Side Chute

are working properly.

placed under the dough divider, otherwise the

manufactured to make dough portions

half-frozen dough, or other products

page 7, and

protected from

R

machine

3.4 Furthermore, be sure that the Moveable

machine cannot start.

3 5

Before working with the dough,

everything is in order.

start the machine without dough in order to check

16 To start the dough divider:

3.6.1 Turn on Switch D (Drawing

3.6.2 Push on the Button F (Drawing

3.6.3 Once the machine has finished

Switch D (Drawing 3, Page 9)

3.6.4 The Red Alarm Push Button

blocked; to unlock it youjust need

3.7 To start the dough rounder:

3, Page 9) to give current to the electrical circuits.

3, Page 9), and the machine will start working.

to work, or once you have finished trying it, turn the

on position O.

U (Drawing 2, Page 8) stops the machine.

to turn it counterclockwise.

3.7.1 Start the machine with the Switch

3.7.2 Once the machine has finished

the Switch T on position O (Drawing

3.7.3 The Red Alarm Push Button

then remain blocked; to unblock

to work, or once you have finished trying it, place

2, Page 8).

G (Drawing 3, Page 9) stops the machine.

it you just need to turn it counterclockwise.

Doors BC (Drawing 1) are also closed, othenvise

It will then remain

T on position 1 (Drawing 2, Page 8).

It will

the

that

3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

4. USE AND REGULATION

4 i

For portions weights, hourly production, volume of the

brochure.

Attention: The data regarding PORTIONS

purely indicative since the doughs

water contained, ofyeast, type ofdough, etc.).

dough èontainer, see back of the

WEIGHTS-CAPACITyHojjpjy PRODUCTION

are

vary from each other according to the ingredients (quantity of

4.2 The dough has to be prepared first in

4.3

Once the dough is ready,

divider.

4.4

Before beginning to regulate the dough weight,

you can introduce it immediately into the container of the dough

a dough mixer.

Drawing 6) is correctly placed in front of the

Opening Hole Control Lever (Item 5, Drawing

6)

45 With the fixed cone, you just have

with the adjustable cone

you begin to regulate the dough weight with the Cut Control

(Drawing 3, Page 9) in a middle position,

Handle M (Drawing 3, Page 9).

Remember that the more you

open the exit dough hole the heavier the portion gets, and the

to regulate the distance between the

and then open and close slowly the exit dough

push away the Cut Control Lever L (Drawing

portion gets,

4.6 For a better use of the machine, the

Lever (Item 1

cone.

,

Drawing 6) should be equal to the diameter of the

4.7 The dough rounder does not need

2.5 oz, up to 23 oz. without

any change of accessories.

distance between the exit dough hole and the

any peculiar regulation, Indeed, it can work with portions from

be sure that the Cut Control Lever (Item

hole from which the dough

6) is properly placed in the Flange (Item

comes out, and that the

6, Drawing

cone and the feeler, while

Lever L

hole with

more you

3, Page 9) from the exit dough hole the heavier

Cut Control

exit dough hole with the adjustable

i,

the

5. TRANSPORTATION

The machine is packed into

a cardboard box and put on a wooden pallet. Each cardboard box

a complete machine. Due to its weight, the machine

down taking care not to damage the

see the attached spec sheet.

cover and movable parts. For weights and sizes of the package,

6. INSTALLATION

6. 1

Place the machine far from

be higherthan 13 1°F,

6.2

Take care of leaving sufficient

function properly.

any heat sources. The temperature around the machine should

space near the motor ventilation openings

7. ASSEMBLING

7. 1 The dough rounder/dough divider

is packed ready to be used.

Warning: Check the fixing of the Chute

contains

can be extracted out of its packing tearing this

never

so that they might

R.

4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

8. DISASSEMBLING AND CLEANING

All removable parts can be washed with water and liquid detergent for dishes.

is concerned, we remind you not to clean it with neither sodium hypochlorite-based

abrasive detergents since they could damage the external

parts ofthe machine.

As far as the housing

solutions nor with

DOUGH DIVIDER:

8. 1 Stop the machine and turn off the Switch D (Drawing 3, Page 9)

and unplug the machine.

8.2 Anterior cleaning:

8 .2. 1 Open the Front Door C (Drawing i

, Page 7).

8.22 Slip off upwards the Cut Control Lever A.

8.2.3 Turn towards the hopper the Lever (Item 5, Drawing 6).

8.2A Unscrew the two Knobs (Item 4, Drawing 6) to free the removable adjustable

Cone (Item 1, Drawing 7).

825 Turn slowly (counterclockwise) the removable adjustable

its place.

83 Cleaning of the removable adjustable or Fixed Cone (Item i

8.3.

i Unscrew the two Knobs (Item 2, Drawing 7) and

open the whole device.

8.12 Before reassembling everything, remove possible dough remains from the slot

8.3.3 Reassemble everything proceeding in the opposite

way from the disassembling one.

or Fixed Cone and take it out of

,

Drawing 7):

areas.

8.4 Cleaning ofthe spiral:

8.4. 1 Remove the Cover A (Item 7, Drawing 4).

8.4.2 Unscrew the Handle (Item 2, Drawing 4) which is place at the back ofthe machine.

8.4.3 Take out the Central Section Bar (Item i 5, Drawing 4).

8.4.4 Take out the Spiral A (Drawing 4).

8.4.5 Clean everything and before reassembling, remove possible dough remains from the slot

areas. Reassemble the Spiral A (Drawing 4) fitting it at the two pins; replace the Central Bar

(Item 15, Drawing 4) and be sure that it is correctly fitted in the suitable

groove of the

Reducer Bridge (Drawing 4), and fix with the Back Knob (Item 2, Drawing 4),

or Fixed

8.5 Cleaning of the dough container:

8 .5

.

i Clean and remove all possible remains of dough or flour.

8.6 Cleaning of the funnel:

8.6.1 Unscrew the knobs counterclockwise, so that you might unblock the Funnel B (Drawing 6).

DOUGH ROUNDER

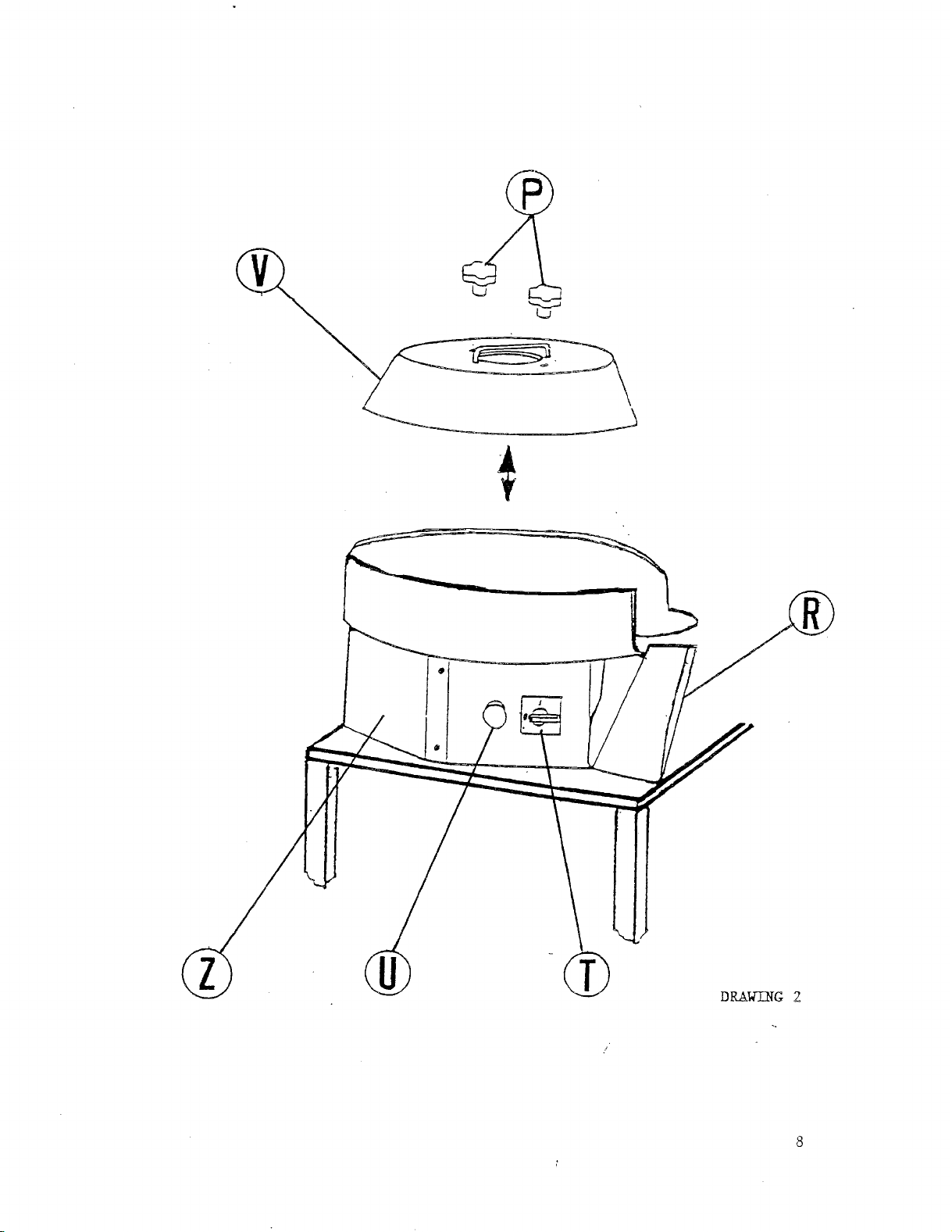

8.7 Stop the machine with the Switch T (Drawing 2) on position O and unplug the machine.

8.8 Pull the machine towards the operator in the direction indicated by the arrow in order to take out

the Cone Trunk V (Drawing 2, Page 8)

8.9 Unscrew the Knobs P (Drawing 2, Page 8) and take out the movable Cone Trunk V by its handle.

8. 10 The part V and the container Z may be cleaned with a wet cloth with water and food sanitizer.

8.1 1 Always remember to reassemble everything in the opposite way ofdisassembling one.

Always remember to try the machine without dough after each cleaning.

5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

9. MAINTENANCE AND REPAIR

9. 1 Maintenance:

To keep the machine well functioning, you just need to clean daily all dough and flour

For the disassembling, see Point 8, Page 5.

The machine does not need any peculiar lubrications.

remainings.

Warning: Do not wash the machine with water jets for safe working.

9.2 Repairs:

For repairs, controls, or replacement of damaged parts, we suggest

you apply to the retailer or directly

to the manufacturer, or to replace the damaged parts with equivalent materials especially

safety is concerned:

e electrical cable with plug (2 phases and ground)

. switch (Push Buttons)

Before any mechanical or electrical maintenance, it is compulsory to switch the machine off

pull out the plug.

Warning: The repairs are to be carried out by qualified peop1e

Periodically check the good

conditions ofthe machine, ofthe cover and doors, ofthe emergency button, and ofthe cable and

plug.

B) ELECTRICAL SCHEME (See Drawing 9, Page 14; Drawing 10, Page 15; Drawing i 1, Page

as far as

and to

16).

6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

DRAWING 3

9

Page 11

DOUGH DIVIDER

DRAWING 4

Illus.

i

2

3

4

5

6

7

8

9

10

11

12

13

14

15

i 6

17

i 8

19

20

21

22

23

24

25

26

27

28

29

Part No.

3 1 1 0302

6509153

3110304

3110306

3110308

3110310

3 1 103 12

3110314

3 1 103 16

3110318

3110320

3110322

31 10324

3110326

31 10328

3 1 1 0330

3110332

3 1 10334

3110336

3110338

3 1 10340

3110342

3110344

3110346

3110348

3110350

3 1 10352

3110354

3110356

Description

Flanged Bushing

Knob

Reducer

Motor

Circuit Board with Box

Door9Front

Door, Dough Container

Cover

Magnetic Detector

Microswitch

Pulley, Knife

Shaped Knife

Bushing, Knife

Knife Reducer

Central Shaft Assembly

Collar, Bronze

Feeler

Microswitch, Feeler

Moveable Lever

Hole Regulator

Pin, Regulation Lever

Knob

Knob, Feeler

Guide Bushing

Gear

Feeler Support

Micro Start Shaft

Rack Support

Rod

o

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

DOUGH ROUNDER

DRAWING 5

Illus. Fart No.

i

3110018

2

3 1 1 00 1 6

3

3110358

4

106450 1

5

3110532

6

3110537

7

3110360

8

6509153

9

1012167

lo

3110508

11

3110362

12

3110364

13

3110366

Description

Switch

Emergency Pushbutton

Belt

Bearing (6206LL)

Gear

Gear

Bearing

Knob

Beanng(6203LL)

Gear

GearSupport

Knob

Motor

12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

DRAWING 5

13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

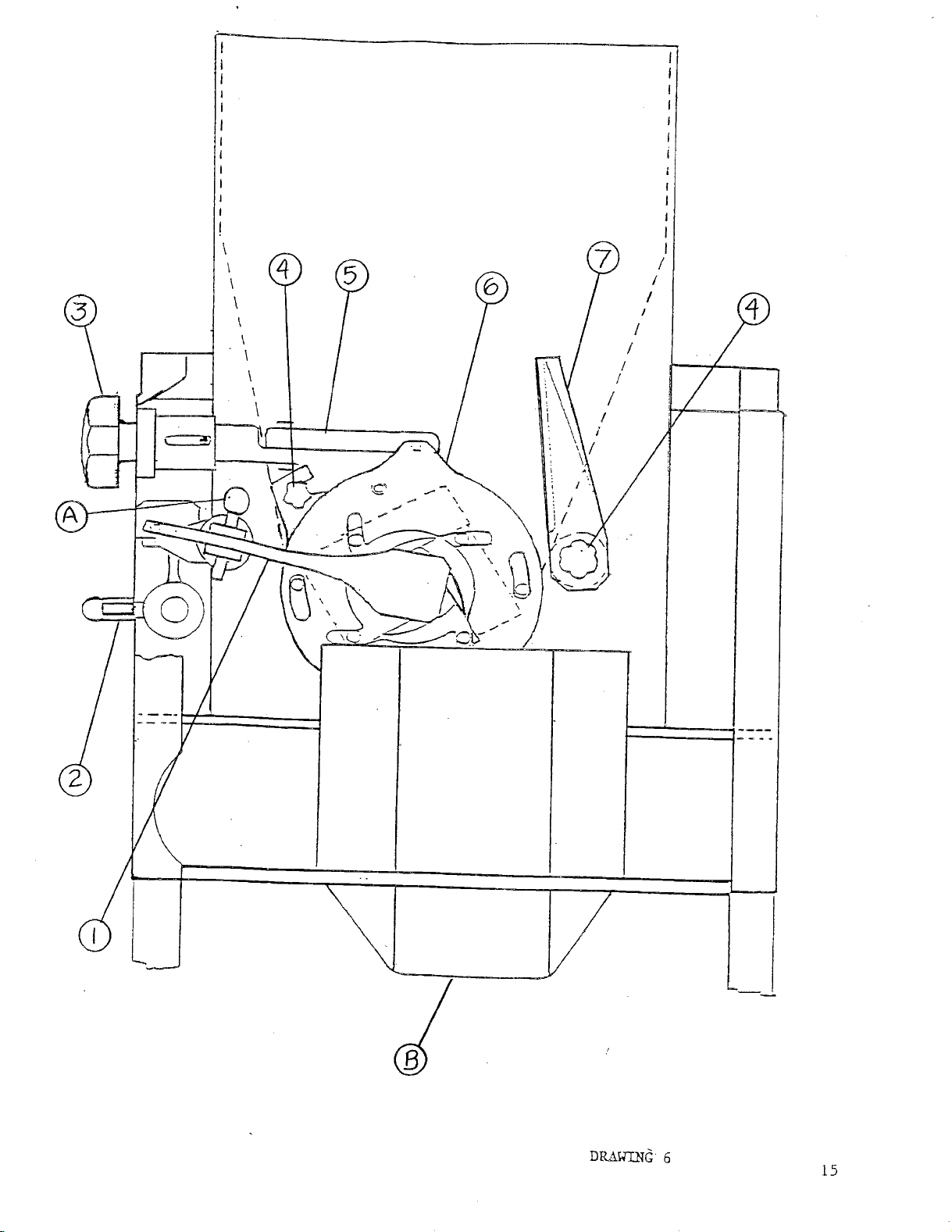

DOUGH DIVIDER

DRAWING 6

Illus. Part No.

i

3110332

2

3110344

3

3110342

4

6509153

5

3110336

6

3 1 1 0368

7

3110322

Description

Feeler

Knob, Feeler

Knob

Knob

Moveable Lever

Regulation Flange

Shaped Knife

14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

DRAWTN

6

15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

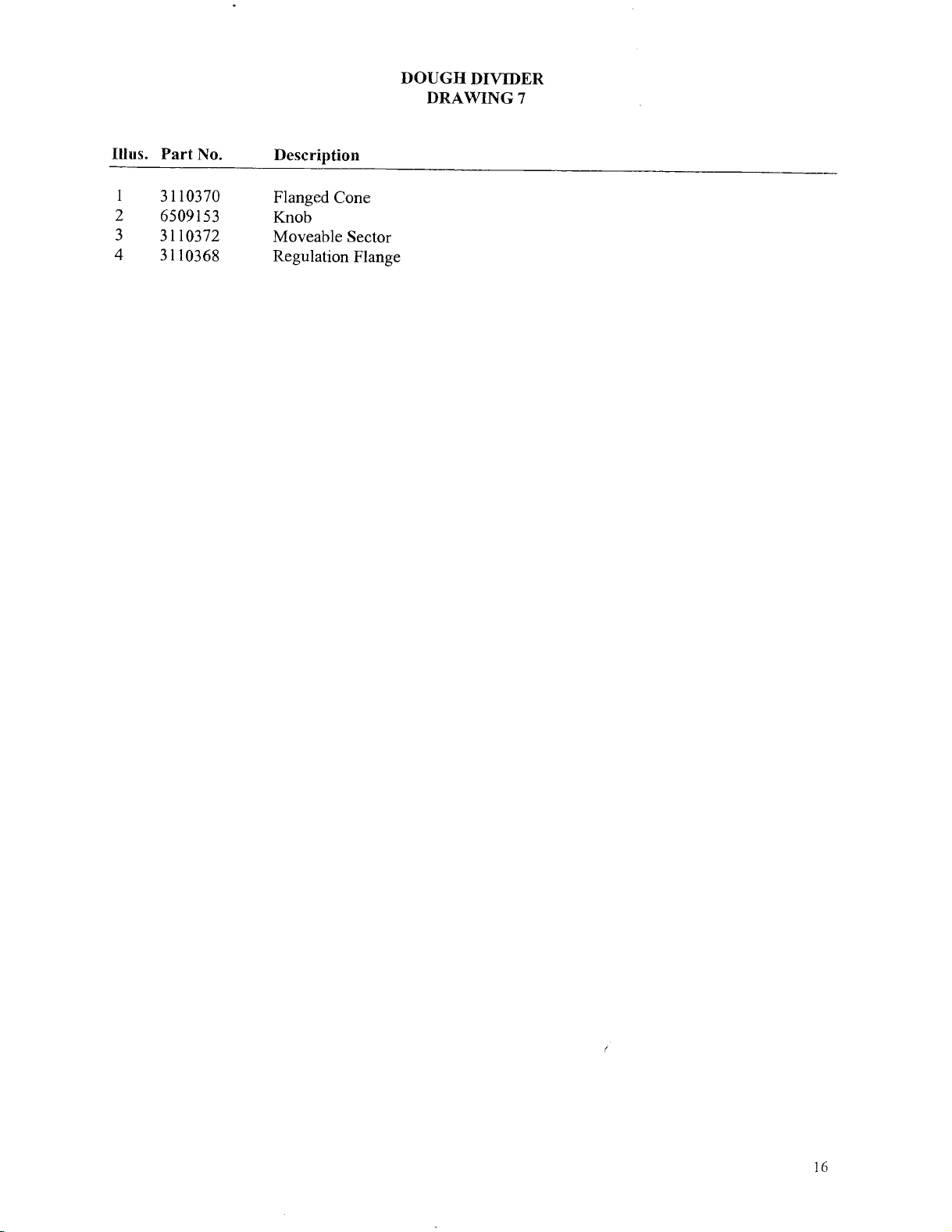

Page 17

DOUGH DIVIDER

DRAWING 7

Illus. Part No.

i

3110370

2

6509153

3

3 1 10372

4

3110368

Description

Flanged Cone

Knob

Moveable Sector

Regulation Flange

16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

DRAWING 7

17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

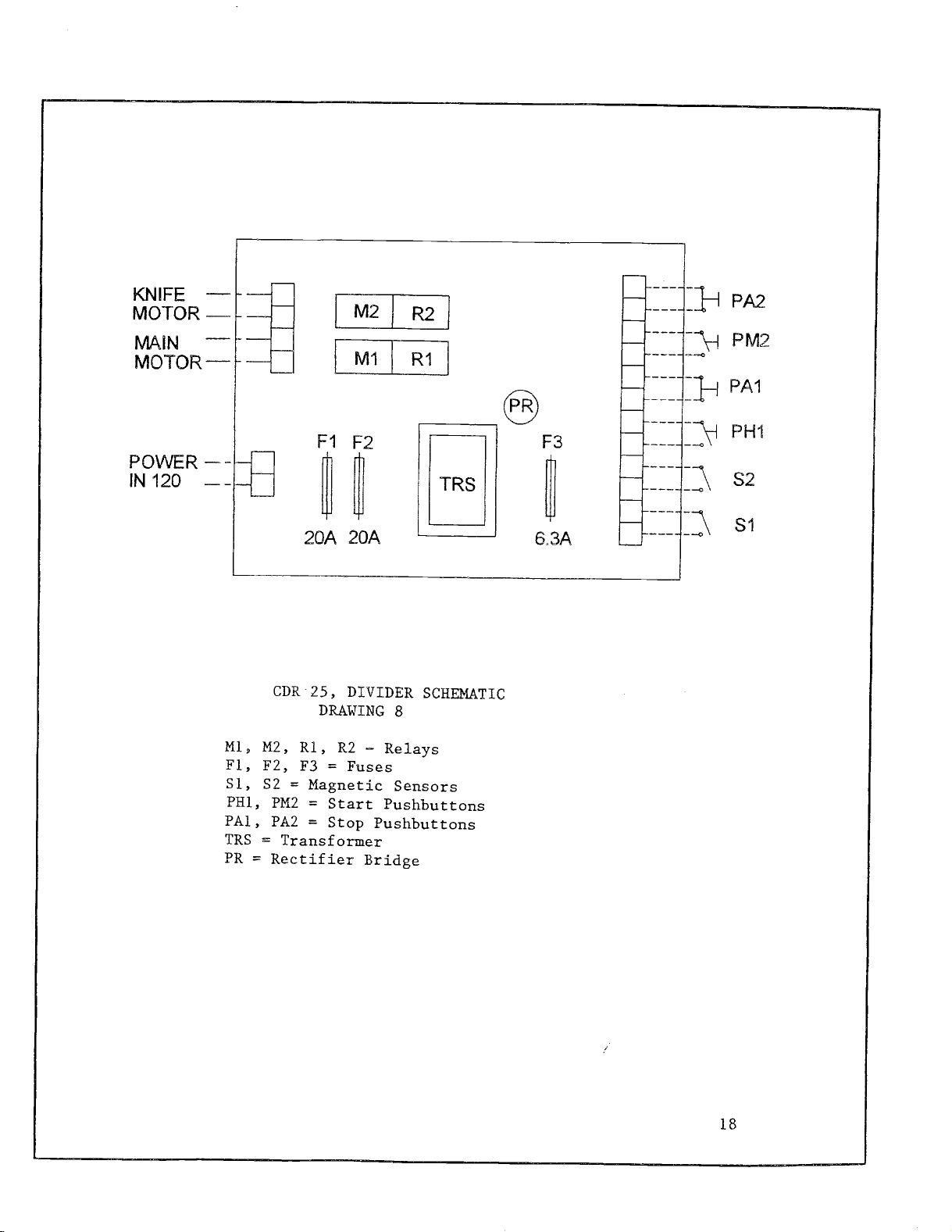

Page 19

KNIFE -

MOTOR

-

M2

R2

11H

PA2

MAIN

MOTOR -

POWER

IN 120

FI

2DA 2DA

CDR25, DIVIDER SCHEMATIC

DRAWING 8

Ml, M2, Rl, R2

Ml

F2

Rl

TRS

Relays

Fi, F2, F3 = Fuses

Si, S2 = Magnetic Sensors

PHi, PM2 = Start Pushbuttons

PAl, PA2 = Stop Pushbuttons

TRS = Transformer

PR = Rectifier Bridge

F3

63A

PAl

11H

1:c

PHI

11s2

11sl

i8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

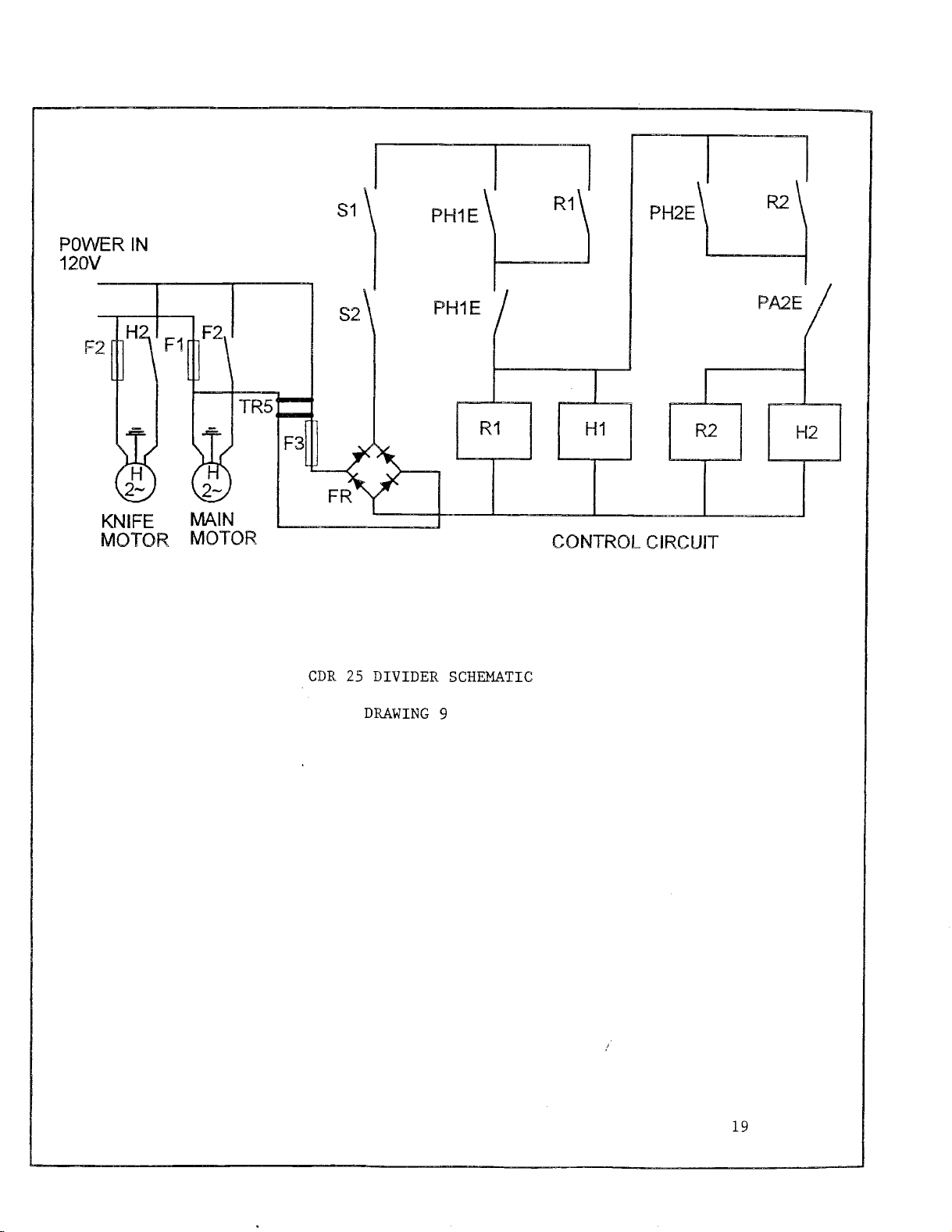

Page 20

POWER IN

I 20V

si\

PHIE

RI

PH2E

R2

PA2E/

F2

FI

T

KNIFE

MAIN

MOTOR MOTOR

TR5

CDR 25 DIVIDER SCHENATIC

DRAWING 9

HI

CONTROL CIRCUIT

H2

19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

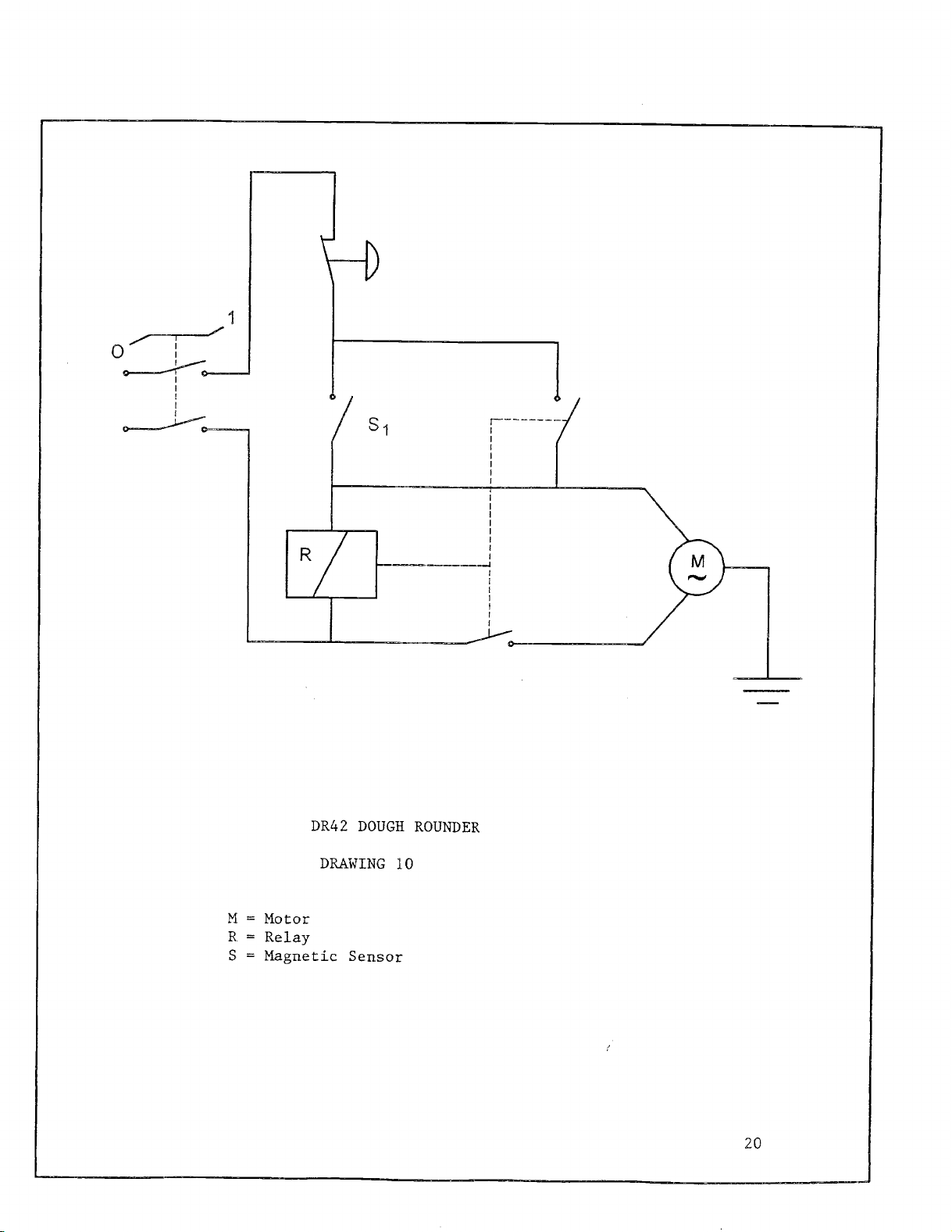

Page 21

SI

DR42 DOUGH ROUNDER

DRAWING 10

M = Motor

R = Relay

s

Magnetic Sensor

20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...