Page 1

User Guide

www.ulsinc.com

Page 2

©2008 Universal Systems, Inc. All Rights Reserved. The Universal Laser Systems logo and name, and VersaLASER are registered trade-

marks, and High Power Density Focusing Optics, Quick Change, Rapid Reconguration, SuperSpeed are trademarks of Universal

Laser Systems, Inc. All other company and product names are trademarks or registered trademarks of their respective companies.

Universal’s laser systems are protected under one or more of U.S. Patents: 5,051,558; 5,661,746; 5,754,575; 5,867,517; 5,881,087; 5,894,493; 5,901,167;

5,982,803; 6,181,719; 6,313,433; 6,342,687; 6,423,925; 6,424,670; 6,983,001; 7,060,934. Other U.S. and international patents pending.

The VersaLASER system has been awarded U.S. Design Patent No. D517,474 for the unique design of its external cabinet, which also functions as a

Class 1 laser safety enclosure.

2

Page 3

Thank you for choosing Universal Laser Systems®. We appreciate innovative customers like you who

have made Universal Laser Systems an integral part of their business.

Universal Laser Systems is committed to providing the highest level of customer satisfaction and

support. To ensure your satisfaction, we urge you to read the documentation contained within the

Reference Guide and User Guide CD.

Since 1988, Universal Laser Systems has been committed to continually improving our technology

and customer-driven laser solutions. Your satisfaction is very important to us and we welcome your

feedback. Tell us about your experience with Universal Laser Systems and our systems at

moreinfo@ulsinc.com

Should you have any questions during your installation, please contact your local representative or

Universal Laser Systems’ Customer Service Team at 480-609-0297 (USA), +43 1 402 22 50 (Austria),

+81 (45) 224-2270 (Japan) or e-mail us at support@ulsinc.com.

Again, thank you for choosing Universal Laser Systems.

Your Universal Laser Systems Team

3

Page 4

USER GUIDE CD

Chapter 1 - Laser System Specications

VersaLASER VLS2.30, VLS3.50…………………………………………………………………………………………………………………………7

VersaLASER VLS3.60, VLS4.60 and VLS6.60…………………………………………………………………………………………………………9

Professional Laser System PLS3.75, PLS4.75, PLS6.75 and PLS6.150D……………………………………………………………………………11

Industrial Laser System ILS9.75, ILS9.150D, ILS12.75 and ILS12.150D………………………….…………………………………………………13

Table of Contents

Chapter 2 - Glossary of Terms

Chapter 3 - User Manual

Laser System Operation

The Universal Control Panel (UCP)……………………………………………………………………………………………………………24

VLS2.30, VLS3.50, VLS3.60, VLS4.60 and VLS6.60 System Tab…………………………………………………………………………29

PLS3.75, PLS4.75, PLS6.75 and PLS6.150D System Tab…………………………………………………………………………………31

ILS9.75, ILS9.150D, ILS12.75 and ILS12.150D System Tab………………………………………………………………………………33

Material Database Printer Driver………………………………………………………………………………………………………………39

The VersaLASER Keypad………………………………………………………………………………………………………………………42

The PLS Keypad..………………………………………………………………………………………………………………………………43

The ILS Keypad..………………………………………………………………………………………………………………………………45

Advanced Laser System Operation

Manual Control Printer Driver…………………………………………………………………………………………………………………48

Raster Sub-Tab…………………………………………………………………………………………………………………………51

Vector Sub-Tab…………………………………………………………………………………………………………………………59

Engraving Field Sub-Tab…………………………………………………………………………………………………………………60

Third-Party Graphic Software Conguration

Adobe Illustrator CS or CS2……………………………………………………………………………………………………………………62

Adobe Illustrator CS3…………………………………………………………………………………………………………………………63

AutoCAD 2000i, 2002, and 2004………………………………………………………………………………………………………………65

AutoCAD LT 2007 and 2008……………………………………………………………………………………………………………………66

CorelDRAW X3 or X4……………………………………………………………………………………………………………………………68

Graphic Page Conguration for Rotary (CorelDRAW)………………………………………………………………………………………70

General Software Set-up………………………………………………………………………………………………………………………72

…………………………………………………………………………………………………………………………16

Chapter 4 - Accessories - Installing and Operating

VersaLASER VLS2.30, VLS3.50

Air Assist Back Sweep…………………………………………………………………………………………………………………………77

Air Assist Cone……………………………………………………………………………………………………………………………79

Computer Controlled Air Cleaner Cart……………………………………………………………………………………………………80

Computer Controlled Compressed Air Unit………………………………………………………………………………………………83

Cutting Table…………………………………………………………………………………………………………………………………85

Rotary Fixture…………………………………………………………………………………………………………………………………88

VersaLASER VLS3.60, VLS4.60 and VLS6.60

Air Assist Back Sweep………………………………………………………………………………………………………………………95

Air Assist Compressor………………………………………………………………………………………………………………………97

Air Assist Cone………………………………………………………………………………………………………………………………99

Cutting Table…………………………………………………………………………………………………………………………………100

High Power Density Focusing Optic (HPDFO)……………………………………………………………………………………………103

Lens Kits………………………………………………………………………………………………………………………………………103

4

Page 5

Manual Air Assist……………………………………………………………………………………………………………………………104

Rotary Fixture…………………………………………………………………………………………………………………………………106

Professional Laser System PLS3.75, PLS4.75, PLS6.75 and PLS6.150D

Air Assist Back Sweep………………………………………………………………………………………………………………………111

Air Assist Compressor………………………………………………………………………………………………………………………113

Air Assist Cone………………………………………………………………………………………………………………………………115

Computer Controlled Air Assist……………………………………………………………………………………………………………116

Cutting Table…………………………………………………………………………………………………………………………………118

Dual Head……………………………………………………………………………………………………………………………………121

High Power Density Focusing Optic (HPDFO)……………………………………………………………………………………………126

Lens Kits………………………………………………………………………………………………………………………………………126

Manual Air Assist……………………………………………………………………………………………………………………………127

Rotary Fixture…………………………………………………………………………………………………………………………………129

Industrial Laser System ILS9.150D and ILS12.150D

Air Assist Back Sweep………………………………………………………………………………………………………………………134

Air Assist Compressor………………………………………………………………………………………………………………………137

Air Assist Cone………………………………………………………………………………………………………………………………139

Automation Kit………………………………………………………………………………………………………………………………140

Class 4 Module………………………………………………………………………………………………………………………………143

Computer Controlled Air Assist……………………………………………………………………………………………………………148

Cutting Table…………………………………………………………………………………………………………………………………152

Heavy-Duty Use Air Kit……………………………………………………………………………………………………………………155

High Power Density Focusing Optic (HPDFO)……………………………………………………………………………………………156

Lens Kits………………………………………………………………………………………………………………………………………156

Manual Air Assist……………………………………………………………………………………………………………………………157

Rotary Fixture…………………………………………………………………………………………………………………………………159

Traveling Exhaust……………………………………………………………………………………………………………………………165

Chapter 5 - Basic Maintenance

VersaLASER VLS2.30 and VLS3.50………………………………………………………………………………………………………………………170

VersaLASER VLS3.60, VLS4.60 and VLS6.60……………………………………………………………………………………………………………177

Professional Laser System PLS3.75, PLS4.75, PLS6.75 and PLS6.150D…………………………………………………………………………………184

Industrial Laser System ILS9.150D and ILS12.150D……………………………………………………………………………………………………191

ULS REFERENCE GUIDE BOOKLET

Your Universal Laser Systems Reference Guide Booklet contains the following documentation:

Software Installation CD

Your Reference Guide contains the Software Installation CD. Please follow the instructions for proper installation.

Installation & Set-up Guide

VersaLASER VLS2.30, VLS3.50……………………………………………………………………………………………………………………199

VersaLASER VLS3.60, VLS4.60 and VLS6.60………………………………………………………………………………………………………216

Professional Laser System PLS3.75, PLS4.75, PLS6.75 and PLS6.150D………………………………………………………………………240

Industrial Laser System ILS9.150D and ILS12.150D……………………………………………………………………………………………266

Safety

ULS Safety Guide……………………………………………………………………………………………………………………………………291

Warranty

Your Reference Guide contains Warranty documents pertaining to your purchase. Should you require a copy of the warranty please contact

ULS at 1-800-859-7033 or email support@ulsinc.com.

5

Page 6

User Guide

Laser System Specifications

Chapter 1 - Laser System Specications

Link to Table of Contents

6

Page 7

User Guide

VersaLASER VLS3.60, VLS4.60 and VLS6.60

System Operating Environment Requirements (User Provided)

VLS3.60 VLS4.60 VLS6.60

Operating

Environment

Well-ventilated oce (recommended) or clean, light-duty manufacturing

Laser System Specifications

Operating

Temperature

Storage Temperature 50ºF (10ºC) to 95ºF (35º C)

Operating Humidity Non-condensing

Power Consumption

up to:

Particulate/Odor

Outside Ventilated

Exhaust System

Computer

Requirements

(See the Installation & Set-up

Guide for more information)

Software

Requirement

250 CFM (cubic feet per minute) @ 6 inches static pressure

Grounded (earthed) and stable (surge and spike protected)

(425m3/hr at 1.5kPa)

Windows XP or Windows Vista (32-bit versions only)

Graphics or CAD based (See page 61 for recommendations)

50ºF (10ºC) to 95ºF (35º C) capable

73ºF (22ºC) to 77ºF (25º C) for best performance

Single Phase 110/240V AC, 10/5 Amp, 50/60 Hz

High-pressure vacuum blower capable of:

2.0 GHz Processor (minimum)

1 GB of RAM (minimum)

40 GB Hard Drive (minimum)

500 CFM (cubic feet per

minute) @ 6 inches

static pressure (850m3/hr at

1.5kPa)

Link to Table of Contents

9

Page 8

User Guide

Model System Specications

VLS3.60 VLS4.60 VLS6.60

Laser Safety

Work Area*

Table

Maximum Part

(WxHxD)

24 x 12 in

(609.6 x 304.8 mm)

29 x 17 in

(737 x 432 mm)

29 x 17 x 9 in

(737 x 432 x 229 mm)

CO2 Laser, Interlocked Safety Enclosure = Class 1

Red Diode Pointer = Class 3R

24 x 18 in

(609.6 x 457.2 mm)

29 x 23 in

(737 x 584 mm)

29 x 23 x 9 in

(737 x 584 x 229 mm)

Resolutions 1000, 500, 333, 250, 200, 83 dpi/lpi

Laser System Specifications

32 x 18 in

(812.8 x 457.2 mm)

37 x 23 in

(940 x 584 mm)

37 x 23 x 9 in

(940 x 584 x 229 mm)

Control

Requires a dedicated PC to operate; requires Windows XP or Windows Vista

(32-bit versions only)

Interconnection USB 2.0 High Speed port only

Cabinet Style Floor Standing

Laser Options 10, 25, 30, 35, 40, 45, 50 and 60 watts

Power Consumption

up to:

Overall Dimensions

(WxHxD)

36 x 38 x 30 in

(914 x 965 x 762 mm)

110V/10A

230V/5A

36 x 39 x 36.5 in

(914 x 991 x 927 mm)

44 x 39 x 37.5 in

(1118 x 991 x 953 mm)

Weight (uncrated) 235 lbs (107 kg) 270 lbs (122 kg) 325 lbs (147 kg)

Exhaust Hookup One 4-inch (10.16 cm) port Two 4-inch (10.16 cm) ports

10 Watt = 13 lbs (6kg)

Laser Cartridge

Weight

25/30 Watt = 20 lbs (9 kg)

35/40 Watt = 23 lbs (10 kg)

45/50/60 Watt = 26 lbs (12 kg)

Available Options

Standard Air Assist, Air Assist Cone, Air Assist Back Sweep, Air Compressor (desiccant or

refrigerated dryer options), Honeycomb Cutting Table, Rotary Fixture, Lens Kits

Specications subject to change without notice

Link to Table of Contents

*Work area various by speeds and thruput.

10

Page 9

User Guide

Glossary of Terms

Chapter 2 - Glossary of Terms

Link to Table of Contents

15

Page 10

User Guide

Glossary of Terms

#2 Mirror – A mirror located at the far left side of the X-Axis Arm (within the #2 mirror cover) used to direct the

horizontal laser beam from the Beam Window into the Focus Carriage.

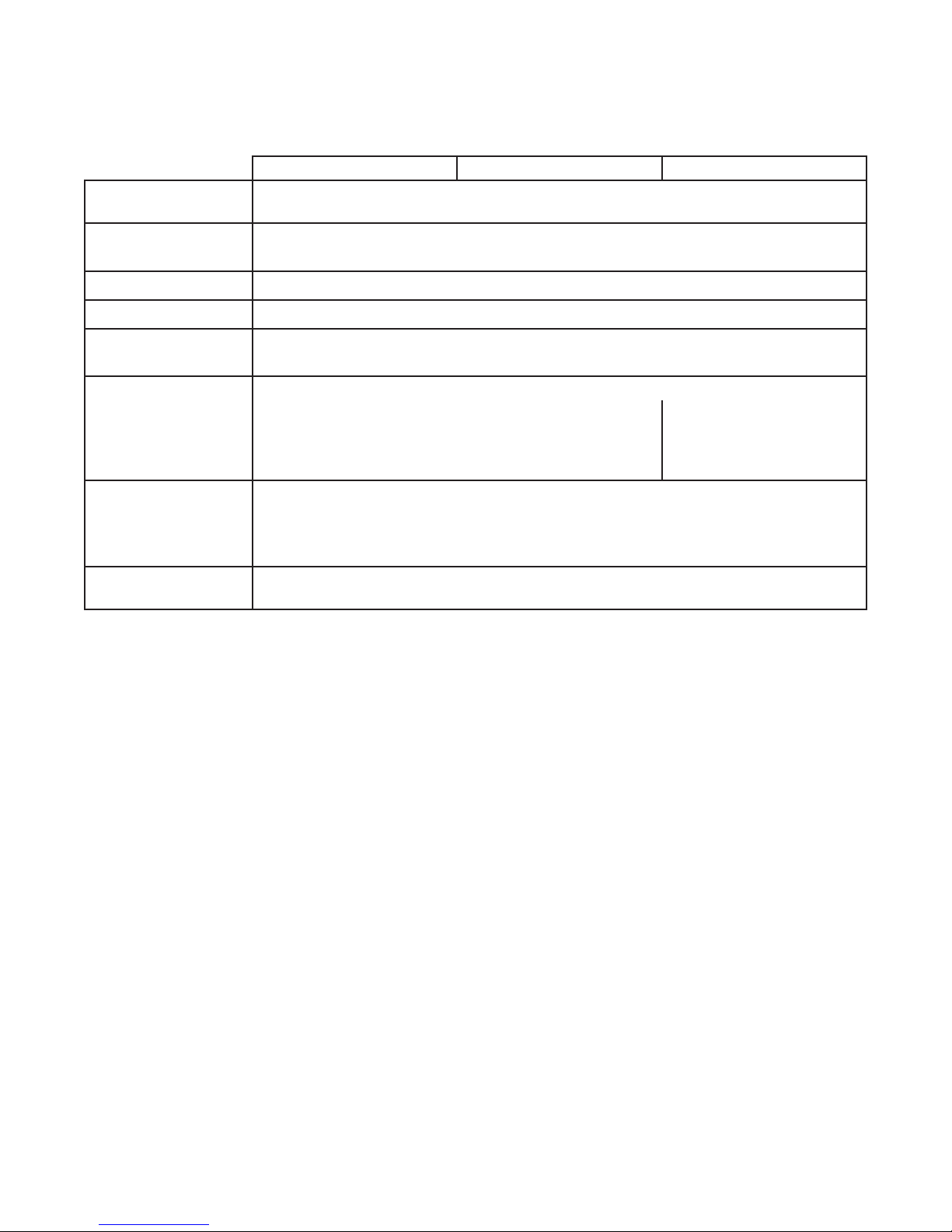

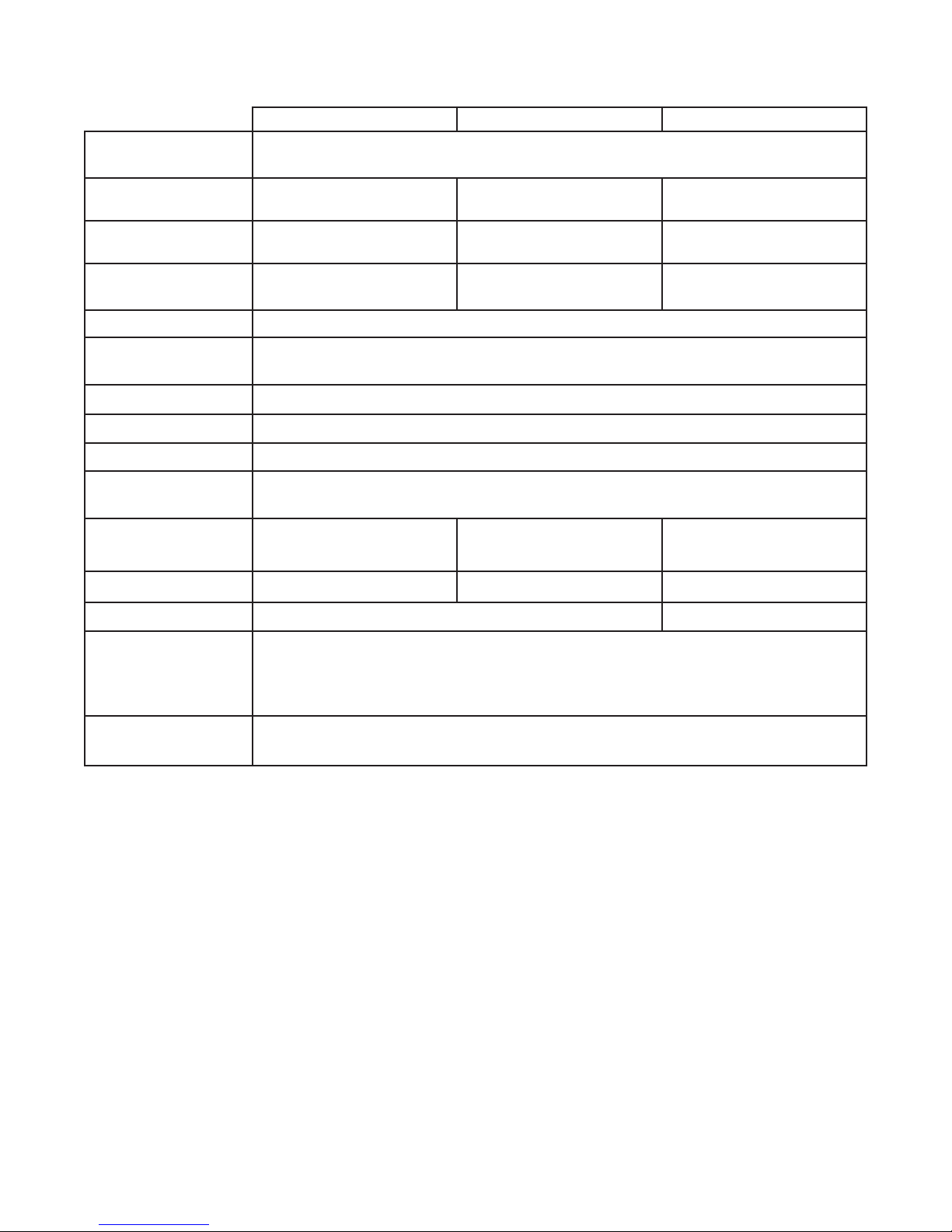

#3 Mirror – A mirror (part of the focus lens assembly) (1) located in the Focus Carriage used to direct the horizontal

laser beam downward onto the work piece.

Air Assist Cone (Coaxial Air Assist) – An accessory that attaches to the Focus Carriage to direct compressed air vertically

downward, in line with the laser beam, onto the surface of the work piece. On some materials, air assist can be used to

reduce the burning eects of the material from the laser beam’s intense heat. It also can help disperse smoke and gasses

created by processing some materials.

Air Dryer – A refrigerated device or a desiccant moisture trap that reduces the moisture content of air going to the

laser system for air assist. Air assist requires oil-free, clean, dry air with no water droplets. Water on optics can damage

them. The refrigerated dryer uses a Freon cooler to chill the air and remove moisture. The desiccant type uses replaceable

desiccant crystals that must be changed when they become lled with moisture.

Back Sweep – An accessory that attaches to the Focus Carriage to aim a jet of compressed air onto the surface of the

work piece at an adjustable angle. On some materials it can be used to reduce the burning eects of the material from the

laser beam’s intense heat. It also can help disperse smoke and gasses created by processing some materials.

Beam Alignment – A procedure that is performed on the laser system by adjusting the #2 Mirror to produce optimal

laser engraving/cutting.

Link to Table of Contents

16

Page 11

User Guide

Glossary of Terms

Beam Window – An optic (1) mounted in the left hand rear of the enclosure through which the laser beam enters the

enclosure.

Belt – A toothed belt with high-strength, stretch-free Kevlar construction, driven by a motion system motor. Belts included: X belt for left-right movement of the lens carriage; two Y belts that move the Arm forward and backward; and a Z

belt that moves the engraving table up and down.

Class 1, Class 3R, Class 4 (Laser Classication) – Denitions created by the laser industry council to indicate degrees of

laser emission and safety requirements.

Class 1• laser has a beam that is fully contained in an interlocked enclosure. A Class 1 laser is designed for safe use

in oce and production environments without the need for special eyewear or other protective measures. Universal Laser Sysetms builds systems with Class 1 enclosures for their CO

lasers.

2

Class 3R• laser requires caution (must not stare into the beam) and is the rating for the red diode pointer used in

Universal’s laser systems.

Class 4• laser has a beam that is not fully contained and that can result in direct or reected beam exposure to the

user or others. Class 4 laser users must utilize laser safety eyewear and must take other precautions to ensure safe

operation. Universal oers a Class 4 compliant option for its ILS Series models and requires a signed agreement

of understanding from the prospective Class 4 user.

For further information, please refer to the Universal Laser Systems’ Safety Manual.

Computer Controlled Air Cleaner/Cart – An accessory for VersaLASER models VLS2.30 and VLS3.50 that provides a

self-contained, computer-controlled exhaust ltration system when used with the Materials Database driver only.

Computer Controlled Compressed Air Unit – An accessory that provides dry, oil-free compressed air for use with

the Air Assist Cone and Back Sweep Accessories. With Computer Controlled air assist, the laser system turns the

compressor on and o automatically.

CPU – A Circuit Board in the laser system that communicates with the PC to drive the Motion System, pulse the Laser

Cartridge, monitor interlocks and sensors, etc.

Cutting Table – An accessory with a honeycomb insert used to support the work piece when

vector cutting. Also provides downdraft to pull smoke and debris away from the bottom of materials being cut. The

cutting table can be used as a vacuum base for holding thin sheet stock at while cutting.

Engraving Table – The solid, at metal plate that supports the work piece.

Link to Table of Contents

17

Page 12

User Guide

Glossary of Terms

Engraving Field – The horizontal work area (24” x 12” or 610 x 305mm) that is accessible by the laser beam for engraving and cutting – equal to the maximum “page” size for your laser system. Engraving area may vary based on speeds and

thruput.

Exhaust Port – Round spigot located on the back of the enclosure that allows connection of a fume extraction hose.

Fill – A color, bitmap, fountain or pattern applied to the interior area of a vector graphic.

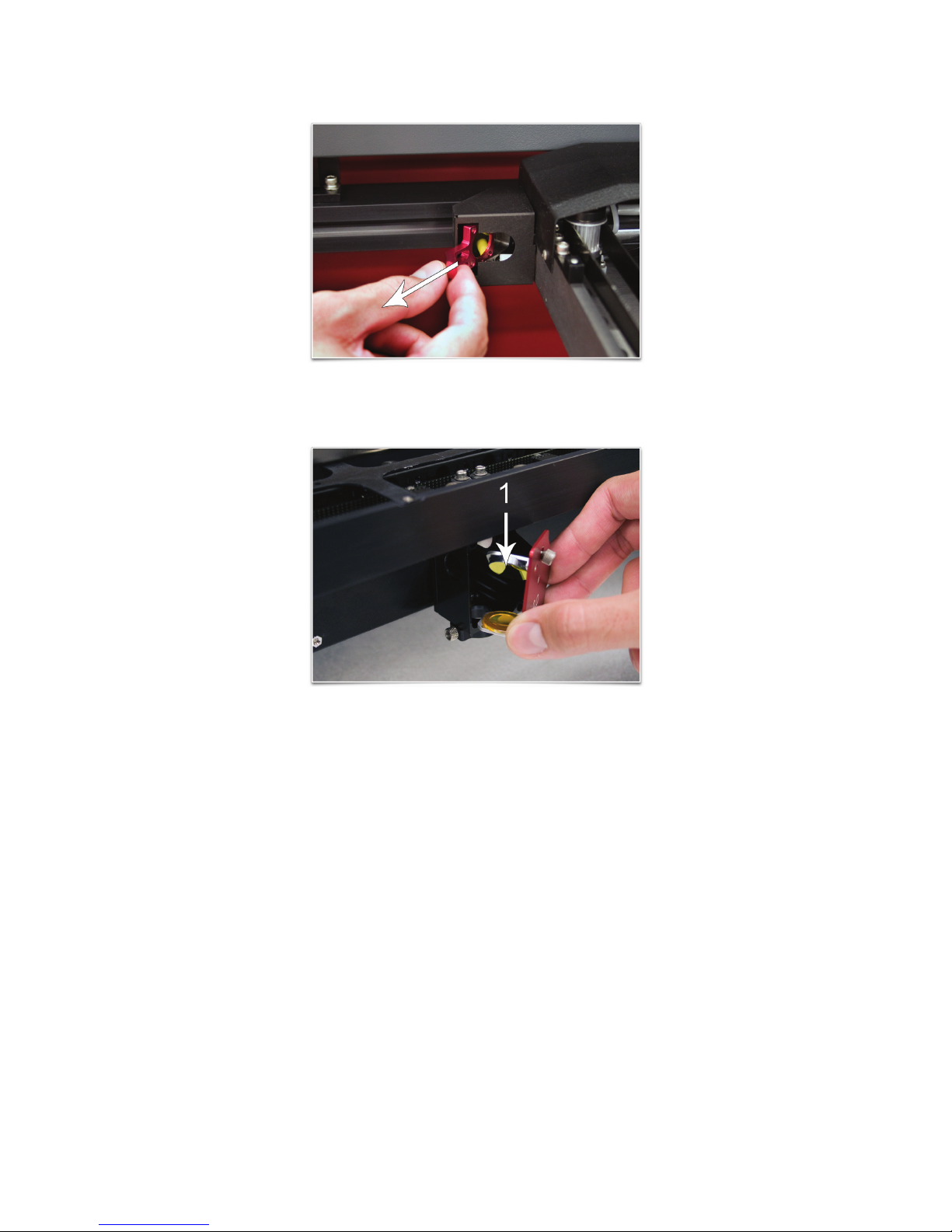

Focus Carriage – The red or black aluminum housing which houses the Focus Lens and #3 Mirror. The Focus Carriage

moves back and forth along the X-Axis arm when rastering or vectoring.

Focus Lens – An optic (part of the focus lens assembly) located in the Focus Carriage that concentrates the laser beam

into a very small, highly intense spot for cutting and engraving.

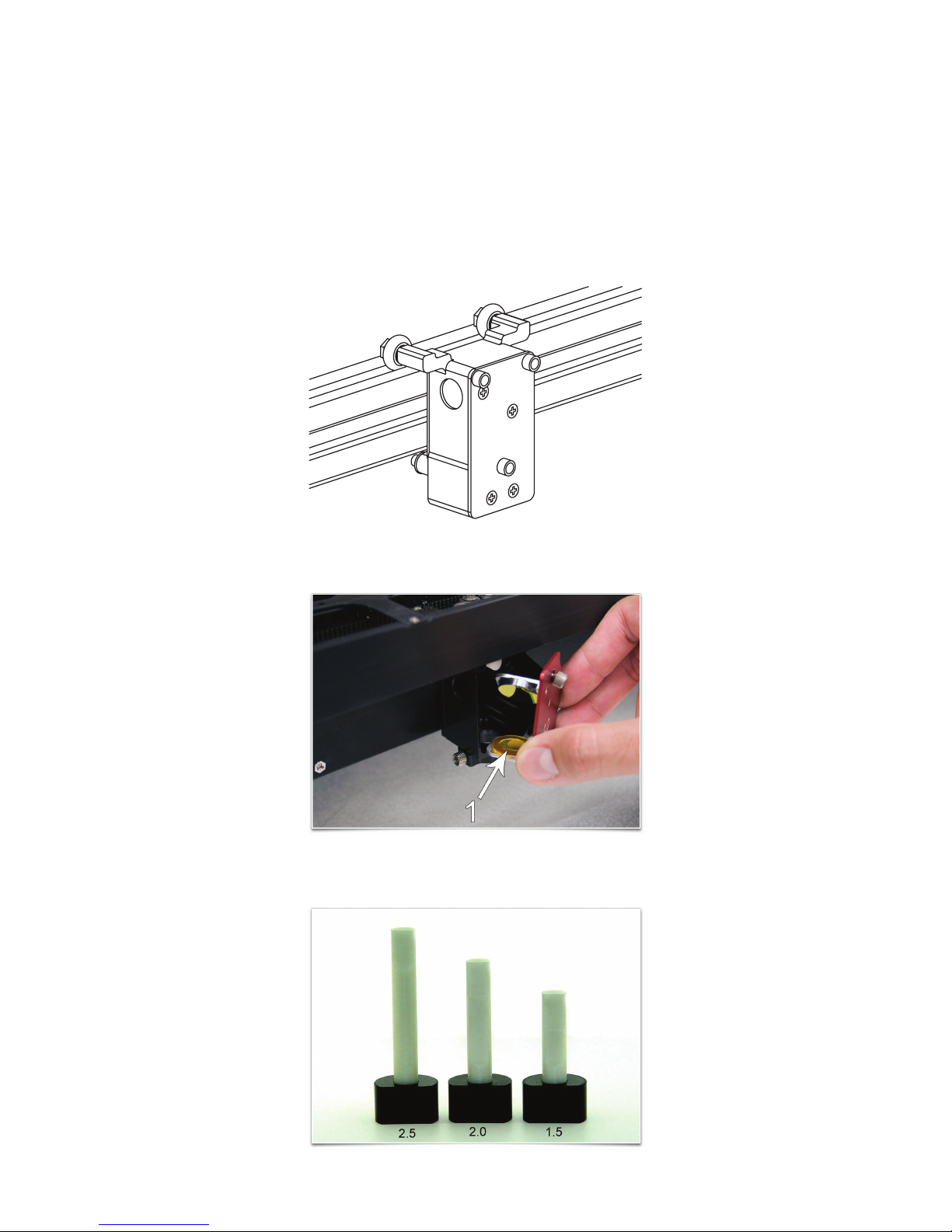

Focus Tool – An essential tool supplied with every laser system that acts as a gauge to accurately set the distance

from the Focus Lens to the work piece.

Link to Table of Contents

18

Page 13

User Guide

Glossary of Terms

Fume Extraction (Exhaust) Blower – A radial-vane motorized blower that generates high vacuum to pull exhaust air

through the enclosure. Must be properly installed and connected with ducting.

Gear – A toothed pulley that is secured to the motor drive shaft. The gear drives a belt.

Graphics Program – The software used to create bitmap and vector artwork executed by the laser system. CorelDRAW

and Adobe Illustrator are examples of graphics programs. Engineering software packages, such as AutoCAD, SolidWorks

and DesignCad, and engraving software programs, such as LaserType and EngraveLab, can also be used to drive a laser

system. A ULS laser system can also be driven as a printer from virtually any Windows software (word processing programs,

for example).

Home – The initial reference position of the lens carriage at one corner of the engraving eld. When the system is

powered on, the motion system “homes” the lens carriage to the upper right hand corner by moving it to engage

sensors in the X and Y directions. The home location is a reference point for the motion system to know the location

of the beam precisely. The user can “home” the system at any time from the print driver control screen. The system can

also “home” the Z-Axis.

Interlock – The safety mechanism that prevents the laser beam from being emitted when any enclosure door is opened.

Laser (Cartridge or Tube) – The CO

laser device that generates the beam used to cut and engrave the work piece.

2

Leveling – A procedure in which the feet of the laser system are adjusted in order to have the engraving table parallel to

the focus carriage for optimal engraving. This procedure is performed with a Focus Tool or calipers to accurately gauge the

distance from the lens carriage to the engraving table at all four corners. The distance should be the same.

Main Enclosure – The “box” in which the X-Y-Z motion system moves and the work piece is engraved or cut. The enclosure

has interlocks and viewing window designed for laser safety, as well as air inlet and exhaust ports for fume extraction.

Motion System – The mechanical/electrical system that receives commands from the CPU and moves the lens carriage

in X – Y raster or vector fashion. The motion system also controls the Z-Axis vertical location and turns the Rotary Fixture

when it is in use.

Operating System – The software that runs your computer. ULS laser systems are compatible only with a 32-bit Windows

operating system such as XP or Vista.

Optic – Any optical element such as a beam window, mirror or lens.

Link to Table of Contents

19

Page 14

User Guide

Glossary of Terms

Outline – The line that denes the shape of a vector graphic. In order for an outline to be recognized as a vector, it

must be of minimum thickness – a “hairline” – less than 0.003 inches or 0.076 mm.

PC – Personal Computer. The laser system requires a Windows-based operating systems as an integral part of its operation.

Power Supply – An electrical component that converts wall-plug electricity into voltages required for electronics and

laser operation.

CO

2

Pulley – A mechanisim composed of a wheel with groves that a belt runs across to change the direction of the focus

carriage.

Print Driver – Software that is the link between a computer and the laser system. The Print Driver for a ULS laser system

is proprietary software written by Universal Laser Systems. It has screens to allow selection of laser settings and to show

system status and conguration. When the user prints a job, the Print Driver issues software commands to the laser

system.

Raster Engraving – A method of engraving whereby the laser beam is scanned back and forth,

engraving horizontal lines in the work piece as it steps down the work piece vertically. At each pass

a series of laser pulses are applied to create the engraved image—similar in action to an inkjet or

laser printer.

Red Diode Pointer – The red beam used to indicate the path and position of the laser beam and focused spot. It is very

eective for correctly positioning work pieces and is also a beam alignment aid for maintenance. The red diode pointer

turns on whenever an interlock is open and turns o when all interlocks are closed.

Rotary Fixture – An accessory used to engrave or cut cylindrical objects.

Link to Table of Contents

20

Page 15

User Guide

Glossary of Terms

Universal Control Panel (UCP) – The software supplied by Universal Laser Systems used to operate the laser system.

This software program allows the user to view, store and execute jobs. Accessed by clicking the diamond-shaped

Icon in the System Tray.

USB 2.0 – Universal Serial Bus version 2.0 for high speed two-way communication. A standardized cable connection and

communications protocol used to connect external devices (such as the laser system) to a computer. USB connections are

very ecient and transmit information even faster than a network connection.

USB Port – A connector on the laser system into which the USB cable is connected.

Vector Cutting / Marking – A method whereby the laser beam is made to follow a path to cut or

engrave a desired outline—similar in action to a pen plotter or hand tracing lines and curves.

X-Arm or X-Axis – The black metal rail that moves front to back in the Main Enclosure during rastering or vectoring. The

Focus Carriage moves right and left along this rail. The rail has precision-honed V-shaped tracks that are pathways for the

bearings of the Focus Carriage. These tracks are designed to keep bearings properly centered and also allow debris to

move away from the bearing contact surfaces.

X-Axis Bearings – The three/four bearings on the X-Axis Arm which guide the Focus Carriage along the arm.

Link to Table of Contents

21

Page 16

User Guide

Glossary of Terms

Y-Axis – The front to back direction in the Main Enclosure. Also, the mechanical system used to move the X-Axis Arm front

to back in the enclosure.

Y-Axis Bearings – The bearings on the ends of the X-Axis Arm that guide it along the Y-rails.

Y-Rails – The two parallel rails that guide the X-Arm front and back inside the Main Enclosure.

Z-Axis – The up and down direction in the Main Enclosure. Also, the mechanical system used to raise and lower the

table on which the work piece is placed.

Link to Table of Contents

22

Page 17

User Guide

User Manual

Chapter 3 - User Manual

Link to Table of Contents

23

Page 18

User Guide

LET’S GET STARTED!

The User Guide is designed to provide you with information on how to operate your Universal laser system. The Users

Guide section will walk you through System Operation, Accessories, and Basic Maintenance.

User Manual

Laser System Operation

From the Universal Control Panel menus and buttons to the laser system keypad and basic printer driver features, this

section describes many of the features of the laser system. If you have not done so already, power ON your computer

and let it boot up completely. You do not need to turn on your exhaust system at this time.

CAUTION: Please refer to the Safety Manual before operating the laser system.

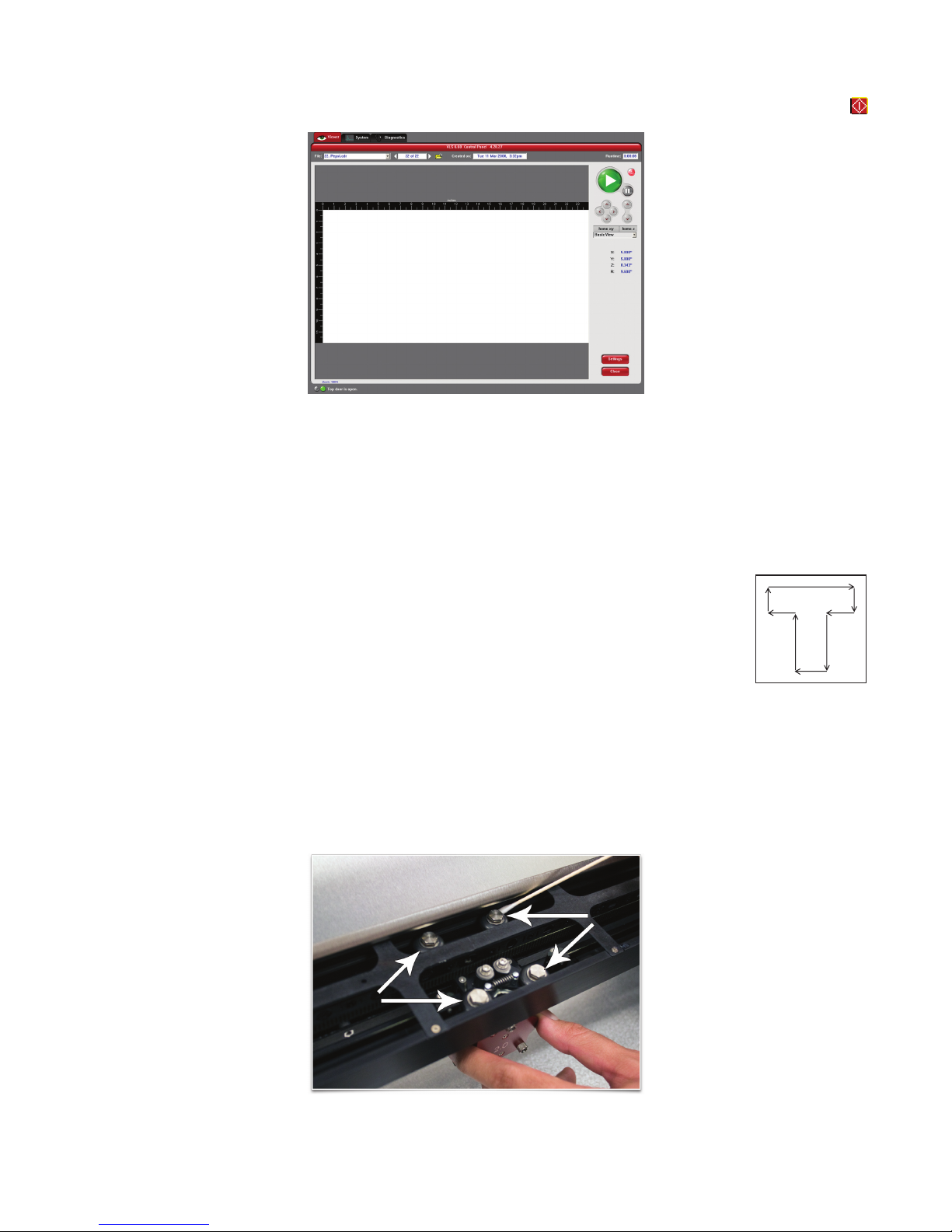

The Universal Control Panel (UCP)

The Universal Control Panel (UCP) on the computer provides a convenient interface for

interacting with and controlling your laser system. Once you have installed the UCP using the

installation disk, a red diamond-shaped icon (Figure 1) will appear in the lower right corner of

your Windows taskbar. If for any reason the UCP is deactivated, you can reactivate it by

double-clicking on the shortcut (Figure 2) found on your computer’s desktop screen. The UCP is

organized into three convenient tabs: Viewer, System and Diagnostics. The following describes the

features of each tab of the UCP.

Figure 1

Figure 2

Viewer Tab

You send jobs to your laser system by printing to it. Anytime you print to the laser system, a job is created and inserted

into the laser systems job queue. Selecting the viewer tab allows you to navigate through and manage the jobs in

the laser system job queue. The viewer tab also allows you to operate your laser system right from your computer.

(page 25)

System Tab (page 29)

The System Tab allows you to congure certain features of the laser system. If your laser system needs to be calibrated,

you will need to do so from this tab.

Diagnostics Tab (page 35)

The Diagnostics Tab gives you important information about your laser system for troubleshooting purposes. When

calling the Customer Service Department, please have the laser system serial number available.

Link to Table of Contents

24

Page 19

User Guide

Viewer Tab

User Manual

System Controls

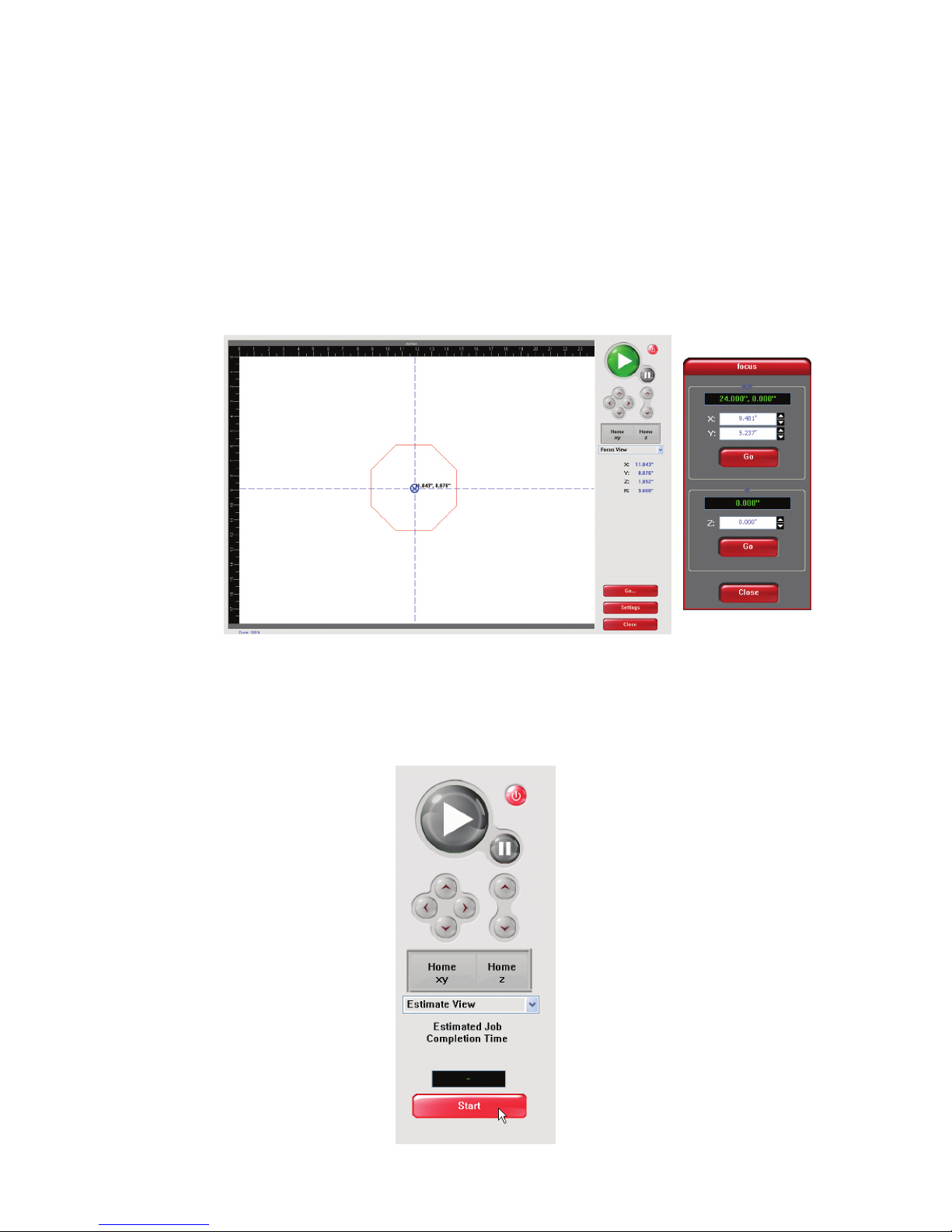

The green START button begins the engraving process.•

Clicking the PAUSE button stops the engraving process and clicking the PAUSE button again resumes the •

engraving process where it was last stopped.

The four Navigation buttons move the focus carriage back and forth or left and right.•

The two up and down buttons move the Z-Axis engraving table up or down.•

The Home XY button re-homes/moves the focus carriage to the upper right hand corner.•

The Home Z button re-homes/moves the Z-Axis table towards the bottom of the laser system.•

Basic View (drop down list)

The Basic View shows a preview window of the job currently selected.•

The cursor becomes a magnifying glass (Zoom Tool) if you pass it over the preview window. Left-clicking the •

mouse zooms in and right-clicking zooms out.

Clicking the Settings button takes you back to the printer driver. If mistakes were made or you would like •

to make additional changes, clicking this button allows for those changes. Further information about the

printer driver can be found on page 39 of this guide.

Link to Table of Contents

25

Page 20

User Guide

User Manual

Focus View (drop down list)

The Focus View allows you to move the focus carriage to a desired position on the laser system table.

To have a full range of motion of the X-Axis arm, verify that you are zoomed out in the preview window by •

right-clicking on the mouse before entering the manual focus window.

Moving the cursor over the preview window once the focus button has been clicked changes your cursor •

to a blue target with dashed vertical and horizontal lines. Clicking once on the preview window moves the

focus carriage to that position. Selecting another feature from the drop down list terminates the focus

feature and moves the focus carriage to the home position.

To move the focus carriage to a specic location, click the GO button. Type in the X and Y coordinates. Once •

you have nished typing in the coordinates, press the GO button within the Focus window and the focus

carriage will move to the specied location. You can also move the engraving table to a specic Z-height by

entering the height in the Z box.

Focus window

Estimate View (drop down list)

The “estimate” feature approximately calculates the amount of time it will take the laser system to nish

the engraving or vector cutting job. The more complex the engraving job is, the longer it will take to nish.

The less complex the engraving job is, the less time it will take to nish.

Link to Table of Contents

26

Page 21

User Guide

User Manual

Relocate View (drop down list)

The Relocate feature gives you the opportunity to move the image on the UCP into another area of the

engraving eld. This feature does not modify your original le’s image location.

When this feature is activated, the image is surrounded by nine small white squares (anchor points) allowing

you to move it around the basic view screen. The current anchor point selected, in blue, is the axis of movement.

If you would like to move the graphic back to its original location, click on the Undo button under the X and Y

cordinates until the grahic is in the desired location.

Relocation Types

You can click on any anchor point available to move the graphic within the basic view area.1.

If you would like to move the graphic to the upper left hand corner, select the top left hand anchor 2.

point and type in your desired X Y coordinates into the boxes that appear on the right hand side. This

process can be done with any available anchor point.

Using your Navigation buttons, move the focus carriage to the desired location where you would 3.

like the image to be placed. Use the red LED as a reference point. Click on the TO CARRIAGE button.

According to the anchor point you have selected, the image on the Relocate View will move to

the location of the focus carriage’s red LED.

Link to Table of Contents

27

Page 22

User Guide

User Manual

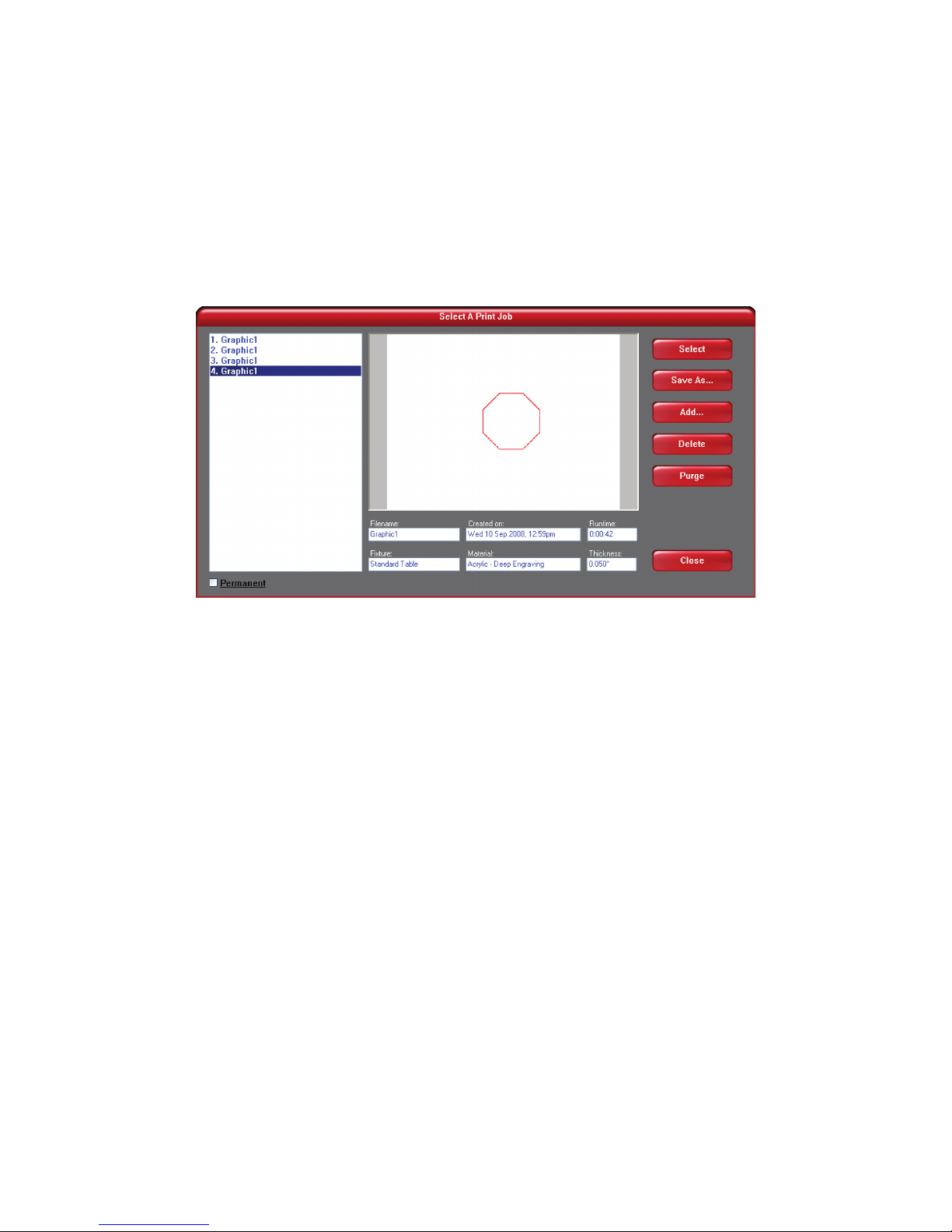

File Management

File Management displays the name of the current job, the number of jobs stored, the date and time the job

was stored on your hard drive and the run time near the top of the window. Once the Print Cache reaches the

maximum number of jobs, the printer driver deletes the oldest jobs as newest jobs enter the cache.

The print job navigation buttons allow you to preview the print jobs stored on your hard drive.•

The “open folder” button displays and allows you to select your print jobs in a le management style. It also •

allows you to delete print jobs stored from your hard drive and save print jobs as .efm les.

The PURGE button deletes ALL cached print jobs stored on your hard drive.•

If the Permanent box is marked, this indicates that the selected le will not be deleted from your hard •

drive even after clicking the PURGE button.

Link to Table of Contents

28

Page 23

User Guide

User Manual

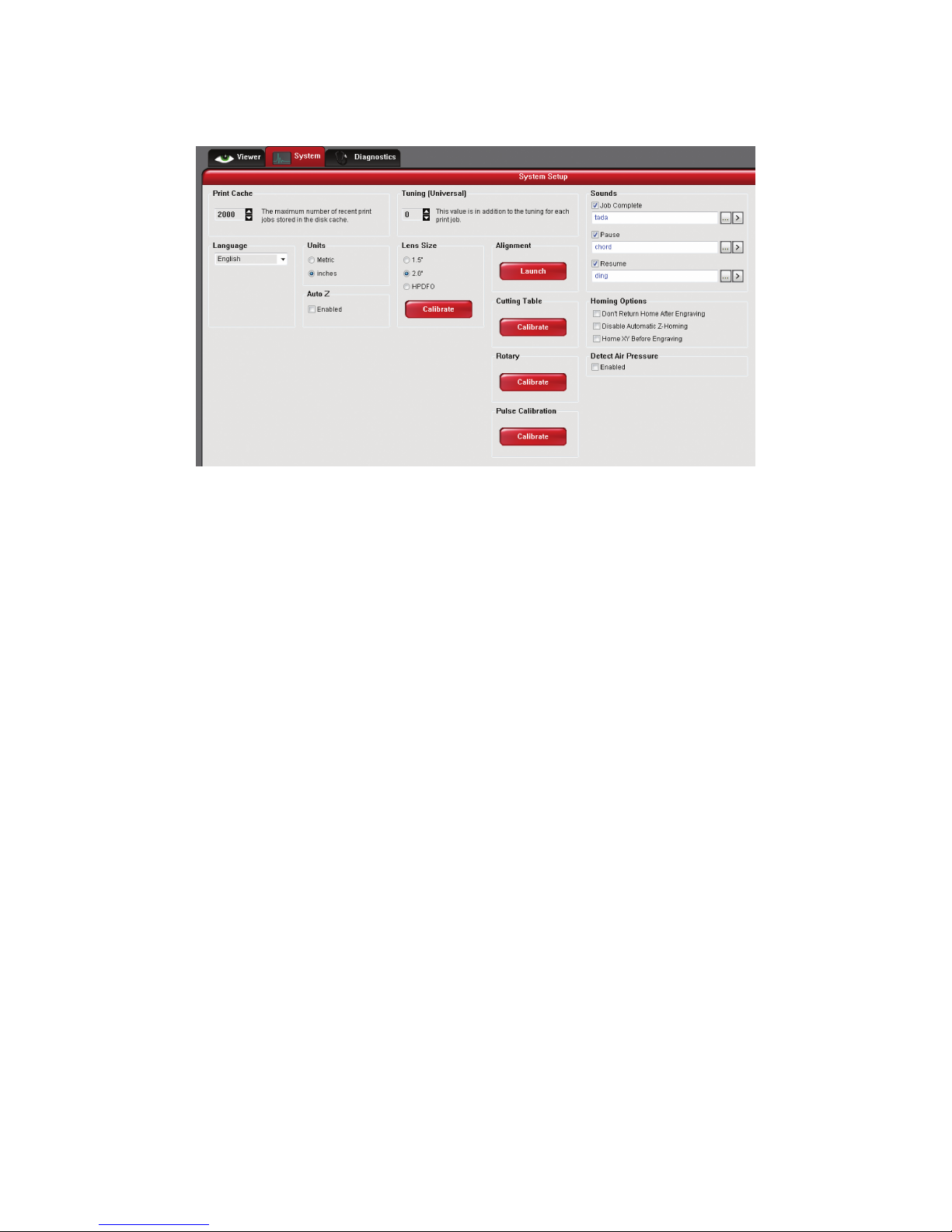

VLS2.30, VLS3.50, VLS3.60, VLS4.60 and VLS6.60 SYSTEM TAB

The System Tab allows you to congure certain features of the laser system. Not all features will appear on the System

Tab.

The PRINT CACHE number is adjustable. It indicates the maximum number of print jobs that you would like to •

be stored on your hard drive. If you exceed the number shown, the software will automatically begin deleting

the oldest jobs as newest jobs enter the cache, unless “Permanent” is checked in the File Managment window.

LANGUAGE allows you to switch between available languages according to your preference.•

UNITS allow you to choose between Metric or Inches.•

AUTO Z should be enabled if you would like the device to focus the laser beam by automatically adjusting •

the height of the Z-Axis table. This operating principle is based on the material thickness that you specify in the

laser system printer driver. If it is disabled, you will need to set focus manually by using the included Focus Tool.

The TUNING (UNIVERSAL) number is a value set by the ULS factory for your particular machine. In the fu-•

ture, as your laser system is used, it may be necessary to change this value to sharpen the resulting

image. Do not change this number unless instructed to do so by our Customer Service Department.

The LENS SIZE selected from the list should be the same as the number printed on the lens assembly on the front •

of your Focus Carriage. If you change lens (available accessory) and use something other than the standard 2.0

lens, then you MUST select the value that matches your installed lens. You will need to calibrate the focus lens

to the top surface of the table by clicking the red CALIBRATE button, otherwise the system will not focus

the laser beam properly. Contact the Customer Service Department if you have any question about lens

calibration.

The ALIGNMENT Launch button opens the Alignment Mode window. The Alignment feature should only be •

used if instructed by our Customer Service Department at ULS.

CUTTING TABLE allows you to calibrate a new Z-height to the top surface of Cutting •

Table. You need to have the Cutting Table installed in the system to activate the

CALIBRATE button.

ROTARY is activated once the rotary accessory is installed. Rotary calibration should be done once when the •

rotary is installed for proper engraving. For more information about the rotary, read the Accessories section of

this manual.

PULSE CALIBRATION manipulates the laser beam to be tuned for ner pulsing. • Do not use this feature unless you

have been ULS factory trained or with factory approval.

If the SOUNDS box is checked, the computer will play the sound shown indicated once the le has nished •

engraving. Be sure that your computer speakers are on and at an appropriate volume.

HOMING OPTIONS disable or enable certain homing features from the laser system.•

Normally after the engraving job is complete it will return home after engraving. If you would like to keep •

the focus carriage from going home, check the ‘Don’t Return Home After Engraving’ box.

Link to Table of Contents

29

Page 24

User Guide

User Manual

If the laser machine was improperly shut down, the engraving table will home at start up. To have this •

feature turned o, check the ‘Disable Automatic Z-Homing.’ Disabling this feature can also be helpful when

troubleshooting Z-Axis problems.

If you would like the laser system to re-home before it engraves a job, select ‘Home XY Before Engraving.’•

Universal laser systems contains an Air Pressure detection switch. This feature is only present when you use Manual •

Air Assist. To enable this feature, check the DETECT AIR PRESSURE box. If sucient air pressure (1.5 psi) is not

present, then an error message is displayed. If you use Computer Controlled Air Assist, this feature is not present

because our laser system automatically detects if sucient air pressure is present.

Link to Table of Contents

30

Page 25

User Guide

User Manual

VLS3.60, VLS4.60 and VLS6.60 DIAGNOSTICS TAB

The Diagnostics Tab displays important information about your laser system and personal computer. This information

can be used for troubleshooting purposes.

ENGRAVER shows the current Firmware and FPGA version being used. It also displays the Serial Number of •

your laser system. The Serial Number is needed when calling the Customer Service Department at ULS.

SOFTWARE displays the current Materials Database, Language Database and Printer Settings Library versions •

being used.

OTHER DEVICES displays the current rmware version for the devices listed.•

LASER displays the watts being produced by the laser cartridge. It also displays the current version rmware •

being used. If a red ‘x’ appears, this indicates that the laser tube is not functioning properly or a door is opened

on the laser system.

If you press the Test button under USB LATENCY, it displays the time it takes for information to travel on the •

USB cable. Avg USB should be below 10 msec and Max USB should be below 100 msec.

SYSTEM displays information about your personal computer.•

ALARMS alerts you if the inside of the laser system is above the recommended temperature or if the Thermal •

Sensor battery is low in power. If the Thermal Sensor inside the laser system is triggered, an alarm will sound

and shut down your laser system.

FIXTURES indicates if a Engraving Table, Cutting Table or Rotary is installed and properly communicating.•

INTERLOCKS shows you if the Top, Front or Rear Doors are opened or closed.•

COMPRESSOR displays the current device being used, shown by a green check mark, to supply compressed air to •

the laser system. If a ULS compressor is connected, it will show the current rmware version.

The RUNTIME DIAGNOSTICS box is for ULS Engineering use only.•

The PRINT button gathers the information displayed on the Diagnostics Tab into a PDF le. This PDF le can be •

emailed to the Customer Service Department for troubleshooting.

Link to Table of Contents

36

Page 26

User Guide

User Manual

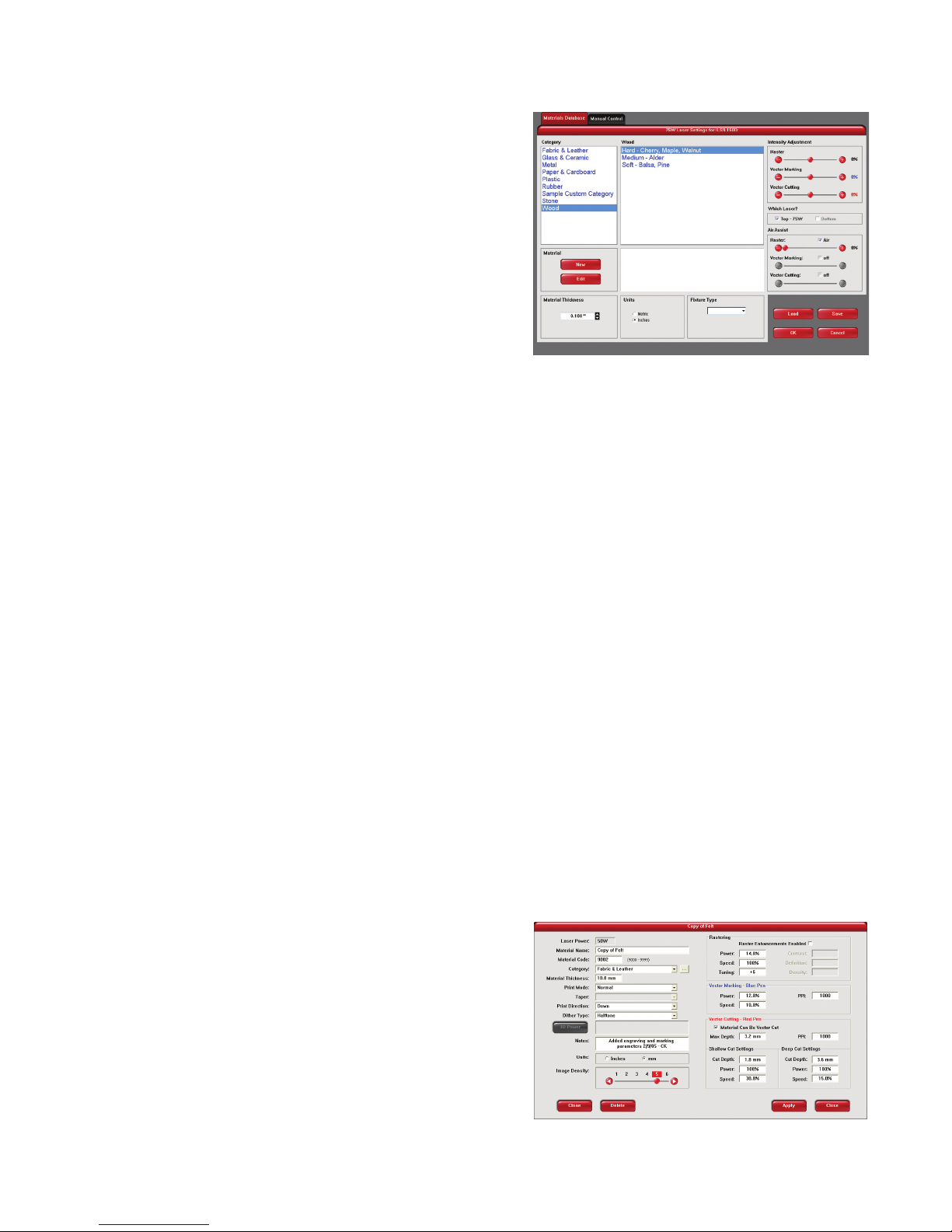

Materials Database Printer Driver

This tab of the printer driver is for the beginning user and

automatically calculates the appropriate power and speed

settings according the material selected.

Category List

This section allows you to choose from eight original types

of material categories.

Material List

Once you select a category, a variety of material types will

appear to the right of the category section.

Intensity Adjustments

Intensity Adjustments allows you to change the intensity of your Raster Engraving, Vector Marking and Vector

Cutting. The default settings are set to 0%, but they can be changed from -50% to +50%. Increasing the settings

increases the intensity of the engraving process, giving you deeper results. Decreasing the setting decreases the

intensity of the engraving and gives you shallower results. Always start at 0% on a scrap piece of material and

make any appropriate changes accordingly. There is no need to make changes to these controls unless undesired

results are produced.

Which Laser? (Dual laser systems only)

If you would like to only use the top or bottom laser tube to engrave or vector cut, select from TOP or BOTTOM. If

you only purchased one laser tube, select the appropriate laser tube according to the set-up of your laser system. If

you would like to use both laser tubes for your project, select both boxes.

Air Assist (Computer Controlled Air Assist systems only)

If you have the Air Assist accessory on the laser system, you can activate it through this option. You are able to turn

on Air Assist for Raster Engraving, Vector Marking and Vector Cutting. If you activate this feature, adjust the air ow

according to the desired results. If the laser system does not come equipped with Air Assist, turn the feature OFF.

Material (Only available when Manual Control Tab is activated)

The NEW button allows you to add a custom Category and Material to the printer driver. The EDIT button gives you

the opportunity to modify the selected Material by creating a copy of the original.

Note: This part of the Materials Database requires knowledge of the Manual Control features. Learn more

about the Manual Control Tab in the Manual Control section of the User Guide.

Material Editing

This feature gives you further control over the

Materials Database and has similar features to the

Manual Control Tab in the printer driver. Custom

categories and materials can be added and deleted.

They can also be modied to your specic requirements.

Once you have added the new material, the printer

driver will add the new material to the list. This new

material will be available for you to use in future jobs.

To access this window, you will need to select a current

category or material and click the NEW or EDIT button.

The Materials Editing window and the Manual Control

Tab have similar features. You can refer to the Manual Control section for further explanation of these features.

Link to Table of Contents

39

Page 27

User Guide

User Manual

Material Code

The Material Code box will automatically display a new material code number when making a new

material and category. You can add a custom Material Code from 9000-9999 if desired.

Taper

This drop down menu is activated when Print Mode is set to Rubber Stamp. This feature is similar to the one

in the Raster sub-tab for Rubber Stamping.

3D Power

This button can be activated by setting the Print Mode to 3D. This feature can be modied similarly to the

Raster sub-tab for 3D.

Vector Marking - Blue Pen

These settings are similar to the settings on the Raster Sub-Tab under the Manual Control Tab.

Vector Cutting - Red Pen

This section of the Material Editor window allows the user to input preliminary numbers for the Material

Editor to properly calculate future power and speed settings. To properly congure the Vector Cutting - Red

Pen section, you will need to vector cut two materials in the laser system so the Material Editor can calculate

the appropriate percentage amounts for dierent thicknesses.

If the material being added to the Material Editor can be vector-cut, check the empty box called “Material

Can Be Vector Cut” and input the percentages.

The Shallow Cut Settings and Deep Cut Settings sections are similar to one another. First measure two

identical material types, but with dierent thicknesses. For example, test a 1/8” piece of acrylic and a ½” of

acrylic. Input the thinnest material measurement in the Cut Depth box of the Shallow Cut Settings. Next,

type in the thickest material measurement in the Cut Depth box of the Deep Cut Settings section. The

Power and Speed in both settings refer to the least amount of percentage power required to cut through

the material without causing undesired results. You may have to experiment with this section several times

to get the exact results you desire.

Max Depth

The number input in this box refers to the maximum material thickness that the laser system is able to

cut.

PPI

Available settings are 1 to 1000. For further explanation about this setting, read the Manual Control

section of the User Guide.

Shallow Cut Settings

These parameters set the starting point for the Printer Driver’s Material Editor.

Deep Cut Settings

These parameters set the ending point for the Printer Driver’s Material Editor.

Link to Table of Contents

40

Page 28

User Guide

User Manual

How to create a new Category and Material

Select one of the existing Categories on the left and click on the NEW button.1.

From the Category drop down menu list on the left, select ‘**New Category.’2.

The Material Category window appears allowing you to type a name of the new category in the blank 3.

space. A Category ID (900-999) will automatically be assigned once a new category is made.

Click the OK button.4.

Once a category is made, you can add a material name to the new category by typing in a name in the 5.

Material Name blank area.

Once that is done you can make your necessary modications to each area in the Material Editing 6.

window.

To save your new category and material, you must click the APPLY button, then click the CLOSE button. 7.

If you click the CLOSE button, without rst clicking APPLY, your changes will not be saved in the

Materials Database Tab.

Material Thickness

In order for the laser system to properly vector cut and/or engrave on the material, the printer driver needs to know

the thickness of the material before it starts engraving. Using a caliper or similar measuring device, measure the

thickness of your material and enter it into the Material Thickness box.

Units

This section allows you to switch between Metric and Inches.

Fixture Type

None

If you are not using any type of xture, set the drop down menu to NONE.

Rotary

If you have purchased this accessory, read how to install and operate this xture in the Accessories section of

the User Guide.

Custom

If you use a prop (other piece of material) to adjust the height of the material you want to process, you need

to compensate for that additional height by using the Custom Height eld.

Link to Table of Contents

41

Page 29

User Guide

User Manual

The VersaLASER Keypad

The Keypad on the laser system provides limited access to controls necessary for cutting and engraving operations. When

the laser system has nished initializing and homing, and if all the doors are closed, the red light on the keypad will be

illuminated and ready to run a le.

The Green or Red LED (Light Emitting Diode) will display dierently depending on the current state of the laser system.

Please refer to the chart below.

CONDITION RED LED GREEN LED

O The doors are closed The VersaLASER is o

On The front, top or back door is open The VersaLASER is on

VLS2.30

and

VLS3.50

VLS3.60,

VLS4.60 and

VLS6.60

POWER: This button turns the VersaLASER on, only if the computer is powered on,

booted into Windows, the Universal Control Panel is running and the USB cable is

connected from the computer to the VersaLASER. Holding the key down for about ve

seconds will power the VersaLASER o.

START: Begins laser processing of the current le displayed on the UCP. If any of the doors

are opened when you press this button, the motion system will start to move as if it is

processing the le, however, the CO

laser beam is disabled and the red diode pointer will

2

be enabled to simulate the laser process.

PAUSE: If a le is running, the PAUSE button halts the engraving or cutting process and

the focus carriage will move to its home position in the upper right corner of the

engraving area. If the PAUSE button is pressed again after the initial pause it will resume

cutting or engraving again at the location where the motion system was paused. Please

wait for the motion system to stop and move to the home position before opening any

door otherwise the laser beam will not resume from the position it stopped at.

UP and DOWN: These buttons allow you to move the table up and down.

Link to Table of Contents

42

Page 30

User Guide

User Manual

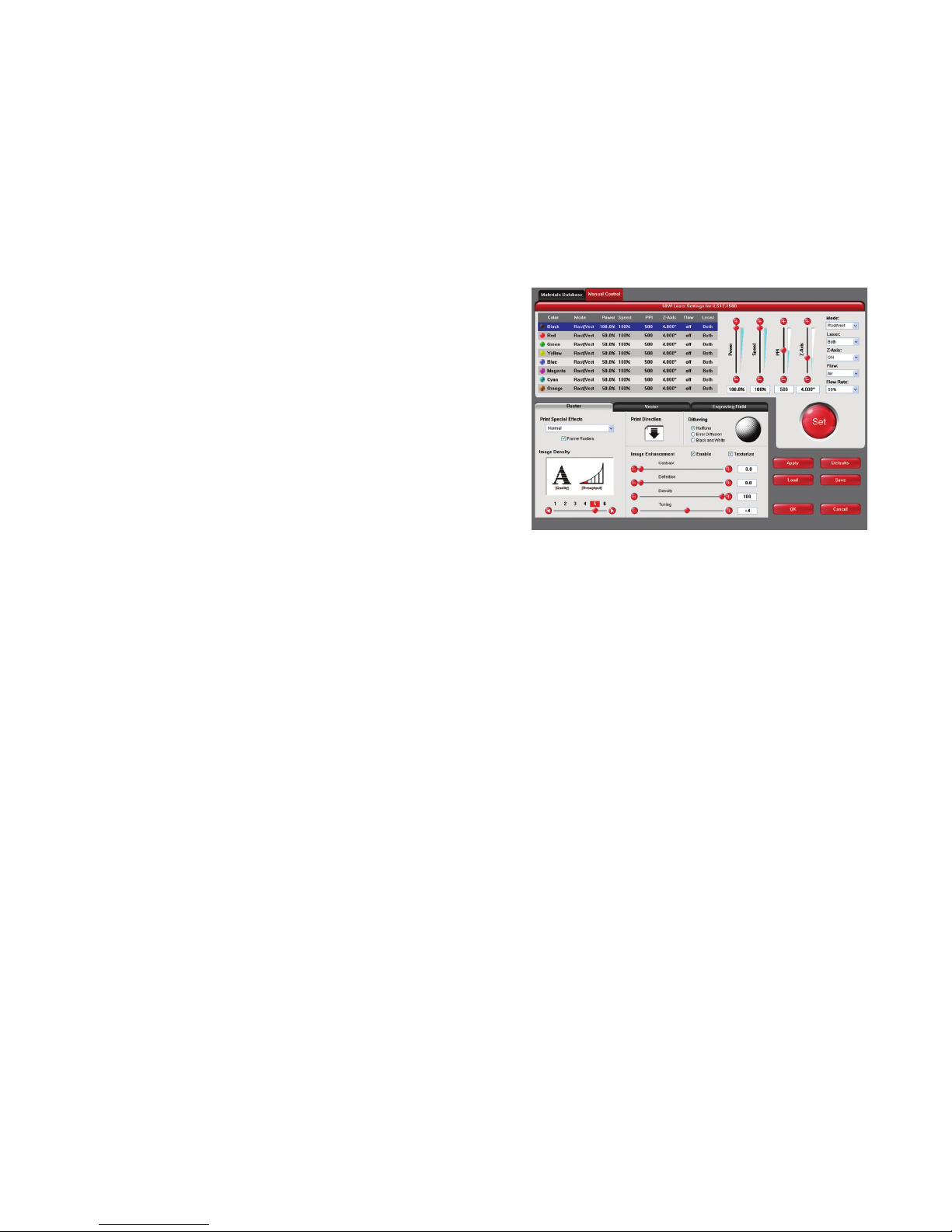

Advanced Laser System Operation

From the PPI and speed settings to Rubber Stamp and Image Enhancement settings, this section covers how each

feature of the Manual Control Printer Driver funtions for the advanced user.

Note: When adjusting the printer driver settings in the Manual Control Tab, it is highly recommended that you

practice engraving or cutting on a scrap portion of that material in case the settings need to be re-adjusted to

obtain the desired results.

Manual Control Printer Driver

The Manual Control Tab in the printer driver gives you full control

of the engraving and vector settings. This tab of the printer driver

is meant for the advanced user.

Color, Power, Speed, and PPI

To change the % Power, % Speed and/or PPI of a color, position

the mouse arrow on the color name and click once. This will

highlight the color’s parameters and will allow you to change

the settings by using the scroll bars, plus (+) or minus (-)

buttons or by typing in each setting in the appropriate

control box. It is possible to click on more than one color to

set them to the same setting at the same time.

% Power

Available settings are from 0 to 100%. This setting is directly related to how deep the engraving will be. The higher

the setting, the deeper it engraves, marks or cuts, and vice-versa.

% Speed

Available settings are from 0 to 100%. This setting determines the maximum rate of travel of the motion system.

Actual engraving time (throughput) is not only dependent on the % Speed setting, but is also dependent on

the size and the placement of the graphic in the engraving eld. The motion system will accelerate/decelerate

as fast as it can up to the chosen speed. If the motion system cannot achieve the chosen speed based on the

size of the graphic or graphical placement in the eld, it will automatically adjust its speed internally to the

maximum speed it can achieve. This is evident when you see the motion system automatically slow down while

cutting curves or circles as opposed to straight lines. Automatic proportional pulsing (see PPI) of the laser beam

will ensure that there is no dierence in the depth of cut from straight lines to curves. We will discuss how to

optimize the throughput of the system later in this manual.

% Power and % Speed work together in determining how deep the engraving or cutting will be. Higher power and

slower speeds produce deeper results. Lower power and higher speeds produce shallower results.

Note: 100% raster speed is dierent than 100% vector speed. Due to the inertia of the X-Axis arm, movements

in the Y-direction, and also depending on which model you have, vector speeds will range from one-third

to one-half the maximum raster speed.

Link to Table of Contents

48

Page 31

User Guide

User Manual

PPI

Available settings are 1 to 1000. The laser beam is always pulsing and never “on” continuously even though it

may appear that way. The PPI setting indicates how many laser pulses, per linear inch, the laser cartridge

will emit. The pulsing of the laser beam is electronically linked to the motion system. These pulses will always

re, equally spaced, from one to the next, regardless of changes in speed.

In raster mode, dot positioning is determined by the driver based on image dark areas. The

print driver has the ability to place dots at any resolution up to 1000 PPI according to the

image composition. For solid lled areas (solid black for example) the machine places dots

at 1000 PPI because all pixels are completely lled with color. For halftones, the print driver

determines laser pulse location based on whether image pixels are black or white (and edge

threshold decisions). For grayscale, the print driver determines laser pulse location and

power based on image pixel color value (and edge threshold decisions).

In vector mode, laser pulsing follows the path of the outline of the object. Imagine the

laser system working like a sewing machine where the stitching always remains

consistent whether you sew fast, slow or around curves. The setting you use will be

application material dependent. Using less than 150 PPI may result in the pulses being

spread so far apart that they may or may not touch one another. Perforated paper has this

characteristic. Higher PPI settings may cause more of a melting or burning eect on the

edges whereas lower PPI settings may reduce the burning, melting or charring, but may result in a serrated

or perforated-looking edge. Increasing or decreasing the PPI setting does not aect engraving speed, only the

frequency of the pulses.

Mode (Drop Down Menu)

The driver uses the word “MODE” because the laser system works similarly to the operation of a pen plotter

output device. A pen plotter physically selects a colored pen that matches the same colored objects in your

graphic, called “color mapping,” and draws the graphic, on paper, in that color. The laser system, however, applies

a Mode, % Power, % Speed and PPI setting, to the individually colored objects in your graphic. Up to eight (8) sets

of user-adjustable parameters, which control laser beam delivery to your application material, can be “mapped” to

the respectively color lled or outlined objects in your graphic.

Note: Black and white, grayscale and color bitmaps are all mapped to the black color’s settings.

Selecting the appropriate color and clicking the drop down menu button toggles through the following laser beam

delivery modes for the each of the eight respective pen colors.

RAST/VECT (default) raster lls and vector marks or cuts proper outlines.•

RAST rasters all lls AND outlines regardless of outline thickness.•

VECT only vector marks or cuts proper outlines. It will skip all lls and will skip all outlines with line weights •

thicker than a hairline.

SKIP ignores all lls and outlines.•

Laser (Dual laser cartridge system only)

If your laser system comes equipped with more than one laser cartridge, you are given the choice of using either

both laser cartridges or a single laser cartridge (Top or Bottom.) If your laser system has one laser tube, select the

appropriate laser cartridge according to your laser system set-up.

Z-Axis

This control on the Printer Driver lets you oset the Z-Axis table from the current focal point. When the feature is

turned on and a height is set, the table lowers to the height entered and starts engraving. This feature can be used as

a Material Thickness focusing method.

Link to Table of Contents

49

Page 32

User Guide

User Manual

Flow (Computer Controlled Air Assist only)

This feature will not appear if you do not have the Computer Controlled Air Assist option. If you do have Computer

Controlled Air Assist, but are not using it, you MUST leave the setting to OFF, otherwise your system will hesitate

up to 10 seconds after you press the start button on the machine. If you purchased the Computer Controlled Air

Assist option, please refer to the Accessories Guide for detailed instructions on how to use the printer driver controls

properly.

Flow Rate

To control the Flow Rate of the Computer Controlled Air Assist accessory, select from the percentage rates available.

(Computer Controlled Air Assist only)

Set Button

After making % Power, % Speed, PPI and any other adjustments for the Pen parameters, you must click the SET button

to register the changes. The changes will not be saved until the OK or APPLY buttons are clicked.

Save Button

By clicking Save, the “Save Engraving Setup” dialog box will appear and will allow you to enter in a le name. All

settings will be stored in this le that has a “.LAS” extension. These les can be stored in any directory on your hard

drive and you can have as many setting les as your disk can hold. Verify that you have clicked the SET button before

you save any .LAS les to ensure you have properly saved your settings.

Load Button

To recall printer driver settings that have been previously saved, click on the “Load” button and choose the desired

.LAS settings le. The settings that are currently on screen will be replaced by the settings from the .LAS le. You may

abort this change by clicking Cancel; clicking OK will approve the change.

Default Button

The Default button will reset the driver settings to the original manufacturer values.

Cancel Button

The Cancel button closes the printer driver window and takes you back to the previous window. If the SET, OK or

APPLY buttons were not clicked, the changes will not be saved by the Printer Driver.

Apply Button

The APPLY button saves all changes made to the Manual Control Tab. These changes include any modications made

to the Raster, Vector or Engraving Field sub-tabs.

Link to Table of Contents

50

Page 33

User Guide

User Manual

Raster Sub-Tab

Print Special Eects

In this dropdown list, you can choose from four

dierent printing modes, Normal (default), Clip art,

3D and Rubber Stamp.

Clip Art

This control simulates laser printer output and

is very useful if using a drawing with many

colors, shades of gray or many outlines. It is

recommended to turn this control ON when

using DRAWN clip art because there may be

some underlying cutting lines hiding behind lled areas. Having this control ON gives a what-you-seeis-what-you-get output very similar to laser printer output. The entire drawing will be raster engraved,

including all outlines, and only the Black color setting is used. The driver automatically turns OFF its

color-mapping feature and all colors are engraved as dierent shades of gray, represented by a halftone

pattern. The type of halftone pattern is based upon the “Quality” setting of the driver the same way

grayscale bitmaps are interpreted. Since clip art images use a wide variety of colors, shades and outlines,

the only eective way to engrave these images is to have this control turned ON. Clip art mode also

provides greater compatibility with Windows software that does not work well with vector devices such

as the laser system. Do not activate this control when printing photographs or bitmapped images; use it

only with DRAWN clip art.

3D

There are two ways to use the 3D feature. The rst method is used to produce an engraving that has a

contoured depth, giving it a three dimensional feel. It is used in combination with grayscale bitmaps

by automatically assigning laser power levels to the shades of gray of the bitmap without converting

the image to a halftone. These power settings are based on the setting you entered for the color black

in the printer driver. The darkest shades of gray (black) will be assigned the value of the setting for the

black color. The lightest shade of gray (white) will automatically be assigned a 0% power. All other

shades of gray that fall between black and white will automatically be assigned an appropriate power

level that matches the darkness of the color. The engraving will appear “3D” because the depth of the

engraving will vary according to the image. Sometimes it takes several passes to create enough relief in the

engraving to get the desired results.

Special 3D software is required to produce the type of grayscale images that are compatible with

this mode. You cannot simply use ANY grayscale bitmap to produce a “3D” eect. Please contact our

Applications Department for the latest 3D software recommendations.

The second way to use the 3D feature is to engrave any photograph lightly onto the surface of hard

materials, such as black marble, anodized aluminum, painted brass, micro-surface engravers plastic, etc.,

to produce exceptional photographic quality. Using the appropriate materials and settings, the end

result is an engraving that looks more like a photograph than a halftoned or diusion dithered image

does. To use the 3D feature in this method you must rst follow the steps below.

Choose Your Material

The best material to use is one that has the highest contrast, such as black anodized aluminum, black

marble or black cored engravers plastic with a white micro surfaced coating. While other materials

may work okay, they may not produce the highest quality.

Establishing Nominal Power

Choose your % Speed and your Image Density settings. Set the PPI to 1000, but don’t set the %

Power setting just yet. The objective is to use the LOWEST % Power setting that produces the

most contrast such as the whitest (as in black anodized aluminum) or the darkest (as in black cored

engravers plastic with a white micro surfaced coating) results.

Link to Table of Contents

51

Page 34

User Guide

00 01 02

03

04 05 06 07 08 09 10 11 12 13 14 15

User Manual

This is what we call the “nominal” power setting. Over-powering the material will produce poor

results.

In your graphics software, create a series of ve rectangles that are about ¼ inch high and 6 inches

wide as in the following diagram:

Starting with the top rectangle, set the power setting to a value that you know will be too low. For

example, engrave the rst rectangle at 5% power, increasing the power for each subsequent

rectangle in 5% increments, nishing the series o at 25% power and note the results. Choose the

rectangle that uses the lowest % Power setting to achieve the most contrast. If 25% is not enough

power, then engrave the rectangles once again, this time starting at 25% and increasing in 5%

increments as above.

In this particular example, we’ll say that 20% power looks over-burned, but 15% appears

under-burned. Since the material may be sensitive to small power changes, you may need to

narrow it down a bit further. Engrave a new series of rectangles, but this time start the top rectangle

at 15% then add 1% for the next rectangle, and so forth, until you nd the best setting between 15%

and 20%.

The setting that produces the highest contrast using the least amount of % Power is called the

“nominal power setting.”

Engraving a Calibration Scale

Now that you have established the nominal power setting, you will need to engrave a grayscale

calibration scale. You can create one of your own or use the one provided for you which can be

found on the Software Installation CD-ROM called “3D Calibration Scale.cdr.” This is a CorelDRAW 8

le so using versions 8 and higher will open the le.

The scale looks like this:

Each rectangle is 0.5 inches wide (12.7 mm) and 0.25 inches tall (6.35 mm). Each successive shade

of gray is incremental by 16 levels starting at 0 and ending at 255. The numbers below the scale

are there as a reference to the 16 levels of power control (explained later) and do not need to be

engraved if you do not want to.

Engrave the calibration scale, onto your material, using the nominal power setting you established

earlier. Compare it to the actual calibration scale that you see on screen or in this manual. If the

response of your material to the laser beam was perfectly linear, then the result should look exactly

like the calibration scale. Most likely you will nd that several rectangles appear to have the same

appearance of shading. The objective would be to engrave the calibration scale and produce a

result that would appear as if each rectangle would have its own distinguishable level of gray,

starting from white all the way to black. To help you achieve those results, the printer driver gives

you the ability to calibrate the power level of each one of the rectangles. To access the feature, click

on the “Setup” button.

Link to Table of Contents

52

Page 35

User Guide

User Manual

Setup Button

When you click this button, the ULS 3D Power Calibration screen will appear. Notice that there are

16 slider bars representing the 16 shades of gray of the calibration scale. The 00 and the 15 are not

adjustable as they represent white and black. The other 14 can be adjusted. The objective is to go

back and forth between adjusting the corresponding slider bars and re-engraving the calibration

scale until you can duplicate the appearance of the calibration scale as best as possible. As you are

progressing, make sure you keep saving your settings in an LAS le just in case your computer

crashes, etc. This is a lengthy procedure so you do not want to have to do it twice.

Once you have duplicated the 3D Calibration Scale onto your material, calibration is now complete.

You only need to do this calibration one time for each material you intend on using to produce

photographs.

Note: If you are using a type of material that becomes lighter when you engrave, such as

black marble, you will need to invert the photograph rst (make a negative image) in your

photo editing software, otherwise when you engrave the image, it will appear like a negative

image.

APPLY Button

Click Apply to enable the settings that you just set.

CLOSE Button

The Close button closes the 3D Power Calibration settings window and cancels any changes

you made to the scale if you didn’t click the APPLY button.

DEFAULTS Button

The Defaults button applies the factory default settings to the 3D Power Calibration settings.

Rubber Stamp

Rubber Stamp mode causes a “shouldering” eect when raster

engraving rubber stamp material or any other material that

requires a “shouldered” engraving. The eect looks as if the

laser beam engraved the material on an angle, but in

actuality it is the precise control of laser power that creates

This image..

...turns into this

image by the driver...

...and the engraved

image looks like this.

this appearance. This is a “raster only” feature that only works

with black colored graphics and uses the power setting of

the black color in the printer driver. Vectors are processed

normally and can be used for vector engraving or cutting by

assigning any of the seven other printer driver colors to the

outline desired.

To obtain a “raised” engraving such as a rubber stamp, simply

This image..

...turns into this

image by the driver...

...and the engraved

image looks like this.

create a “negative” graphic so that the background is black

and the text or graphic objects are white. This way, the background engraves and the text or objects

remain untouched, producing a “pyramid” eect.

To obtain a “chiseled” or “sunken” engraving, create a “positive” graphic so that the background is white

and the text or objects are black. This way, the text or graphic engraves and the background remains

untouched, producing a “chiseled” eect.

Setup Button

Selecting the Setup button opens a pop-up window so you can choose from the following

settings:

Taper Selection

Choose from various types of shoulder angles. Experiment with each setting and note the

result.

Link to Table of Contents

53

Page 36

User Guide

.002”

0

8

20

31

39

49

59

100

User Manual

Image Options

Invert Page

This converts all black objects into white and all white objects into black for the entire page.

This is very useful for engraving a full sheet of rubber stamps.

CAUTION: When using the “Invert Page” feature you may need to

reduce your page size so that the entire work area is not engraved.

Mirror Page

This mirrors the entire page from left to right (horizontally). It will not mirror individual

objects or selections. This is very useful for engraving full sheets of rubber stamps because

the graphics on screen are non-mirrored and can be proof-read easily.

Power

Notice that when you click on dierent Taper Selections that the power table changes. This is

because the laser applies power in dierent proles to produce dierent styles of taper. You

will notice that you cannot adjust the pre-dened Taper; however, if you would like to create

a custom taper of your own, rst select the Taper Selection that you would like to start with

and then click the “NEW” button. This will copy the taper as a “Custom Shoulder” that you can

rename by typing a new name in the dialog box and clicking “Rename.” You can also adjust

the prole however you desire. Each slider bar controls the laser’s power for that step. The

numbers at the bottom of that slider bar dene the width of the step in 0.001 inches (mils). The

square at the top of each slider bar is the activate/deactivate button. Always deactivate the

steps you are not using so that it will apply 100% power to that level.

Step Power %

Step Width

Normal Rubber Stamp Setting ...will give you these results

Material

The diagram on the previous page is an example of the Normal Rubber Stamp Taper Selection.

You can see that there are 8 steps used to create the shoulder. The surface of the material is

considered the rst step and the bottom of the engraving is considered the last step. You can

dene as many as 16 steps, but the rst or the last steps are not denable because they are

xed at a power setting of 0% and 100% respectively. You can only dene the parameters for

the 14 steps in between.

Note: The maximum shoulder width is 0.056 inches (1.42 mm).

Reduction

Raster Block Reduction (also known as Print Growth Management) reduces the number of pixels of a

raster image only in the X and Y directions. Raster Block Reduction does not aect vector images.

Sliding the bar to the right will remove pixels from the image that is being engraved, practically

thinning the raster image. This feature does not aect your original le, only the le that is in cache

storage. This feature is useful for bar code labels with thin lines.

Image Density

The Image Density setting determines how many raster strokes per vertical inch of travel the motion

system steps down to produce the engraving. It can also be referred to as the vertical lines per inch or ll

spacing. In the Windows XP driver it is termed Image Density and there are six Image Density choices in

all models. Higher Image Density (DPI) settings produce better quality raster images, but reduce

productivity by increasing engraving time. Lower Image Density (DPI) settings produce lower quality raster

images, but increase productivity by decreasing engraving time.

Link to Table of Contents

54

Page 37

User Guide

User Manual

Image Density (DPI) settings will also have an eect on vector quality and vector speeds when

vectoring lines other than straight horizontal or vertical lines. For example, a circle is made up of very small

straight-line segments linked together at very small angles. If you choose a high quality setting such as

6 (1000 DPI), then these segments are as small as possible and they are high in quality. The result is

the smoothest looking circle, but it will take longer to vector engrave or cut because the focus carriage

must start and stop at the ends of each line segment. Since there are many segments, it will take longer

to process, but the quality will be the highest that the machine can produce. If using a low quality

setting such as 1 (DRAFT), these segments become longer, but there are less of them, resulting in more

at-edged looking curves that will process faster.

By running samples on scrap materials and practicing with dierent settings, you can nd a compromise

between throughput and engraving quality.

Print Direction

The default direction is Down which begins engraving at the top of the eld and nishes at the bottom.

On some materials you may get better results by starting at the bottom and engraving towards the top

of the eld (Up). This is because the engraving smoke is being drawn towards the top of the eld. On

some materials engraving Down causes the smoke or debris from the engraving to be deposited onto

the previously engraved surface, possibly damaging the engraved area. Experiment with the dierent

directions using dierent materials and choose the best method for your application.

Note: The Up direction is especially useful when engraving rubber stamps and utilizing the Back

Sweep Air Assist option.

Dithering

Dithering settings are used when printing grayscale or color bitmapped images such as TIF, JPG and

BMP formatted images. Since the laser system is essentially a black and white printer (black turns the laser

ON and white turns the laser OFF), and if you choose the correct settings, the driver will automatically

convert the grayscale or color bitmap into a 1-bit “halftoned” black and white image. This process is very

similar to how newspaper photographs, as well as laser printer photographs, are printed. For a more

detailedexplanation of the terms “grayscale,” “bitmap,” “halftone” or “dither,” please refer to the “Graphic

Software Setup” section in this manual.

Halftone

This halftone pattern generator converts grayscale bitmaps into a halftoned image based on your Image

Density choice in the driver.

Image Density Angle Shape Lines Per Inch

6 45 Degrees Round 180

5 45 Degrees Round 90

4 45 Degrees Round 60

3 45 Degrees Round 45

2 45 Degrees Round 36

Error Diusion

Unlike halftone, error diusion scatters the black pixels in a random pattern to represent shading. It

uses the quantity of black dots instead of the size of the black dots to represent the dierent shades of

gray. The pattern created will be dependent on the quality setting that you choose in the driver with the

exception that there is no chart to reference. Higher quality settings, such as 5, will produce a more

densely packed, higher dot quantity pattern, whereas a lower resolution setting, such as 2, will produce

a loosely packed, lower quantity dot pattern.

Note: Do not use Error Diusion when engraving rubber stamps, otherwise dots will appear in

the background. Choose only Halftone.

Link to Table of Contents

55

Page 38

User Guide

UniversalLaser Systems, Inc.

User Manual

Black and White Mode

The Black and White mode thresholds the image at 50% black. Each pixel that is greater than 50% black

will be converted into white and each pixel that is 50% black or less will be converted into black. This

eect is very similar to trying to duplicate a photograph using a photocopier.

Helpful Tip

Engraving grayscale bitmaps using a dithering pattern requires some practice and a bit of trial and

error to achieve perfection. It also requires some knowledge of bitmap editing software. These images

will visually appear dierent on one material as opposed to another material even if you use the same

driver settings. As a rule of thumb, use an Image Density setting of 5 using halftone or diusion pattern

on harder materials, such as marble, anodized aluminum or microsurfaced engraver's plastic. Use an

Image Density setting of 3 using the halftone or diusion pattern for softer materials, such as wood or

materials that you intend to engrave very deeply.

Image Enhancement

The Image Enhancements controls allow the user to “ne tune” the image to enable the laser system to

produce the highest quality, highest detailed images at high or low speeds. Image Enhancement may be

used at any engraving speed and with any material.

Note: Image Enhancement will cause les to take longer to print. Since most materials do not require

the use of Image Enhancement, use this feature only as needed. Image Enhancement and 3D Eects

cannot be selected at the same time. The printer driver will automatically notify you if you attempt

to do so. Image Enhancements work best for low power, high speed applications such as marking

anodized aluminum, etc.

The following procedure may appear lengthy, but when you learn how to use the controls, establishing

the correct parameters is easy and quick. Once you have established those parameters you can “SAVE”

them in the ULS printer driver as .LAS settings and recall them when needed. Many users choose to name

these saved settings according to the application material’s name.

Note: The Image Enhancement settings are designed to work with the BLACK pen color in the printer

driver. However, the other seven pen colors of the printer driver will use the same Image Enhancement

settings. Keep in mind that those settings will have a dierent resulting eect on if the other colors’ %

power, % speed and PPI are dierent than the black pen color’s setting.

Texturize

The Texturize feature adds random textured laser pulse patterns to an engraving job while using

Image Enhancements. It reduces motion system marks like banding from appearing on some materials

like tile and marble.

Denitions

CONTRAST: Contrast adjusts the dierence between the unengraved and engraved areas in the high density