Universal Laser Systems VersaLaser VL-200, VersaLaser VL-300 Safety, Installation, Operation, And Basic Maintenance Manual

Models VL-200 & VL-300

Safety, Installation, Operation,

and Basic Maintenance Manual

Web Based Email Support:

Universal Laser Systems, Inc.

16008 North 81st Street

Scottsdale, AZ 85260 USA

Customer Support Department

Phone: 480-609-0297

Fax: 480-609-1203

www.VersaLASER.com

August 2005

Notice

This publication and its contents are proprietary to Universal Laser Systems, Inc. (ULS), and are intended

solely for the contractual use of ULS, Inc. customers.

While reasonable efforts have been made to assure the accuracy of this manual, ULS shall not be liable

for errors contained herein or for incidental or consequential damage in connection with the furnishing,

performance, or use of this material. ULS reserves the right to revise this manual and make changes

from time to time without obligation by ULS to notify any person of such revision or changes.

ULS does not assume any liability arising out of the application or use of any products, circuits, or

software described herein. Neither does it convey a license under its patent rights nor the patent rights of

others.

This publication and its contents may not be reproduced, copied, transmitted, or distributed in any form,

or by any means, radio, electronic, mechanical, photocopying, scanning, facsimile, or otherwise, or for

any other purpose, without the prior written permission of ULS.

ULS provides no warranties whatsoever on any software used in connection with a ULS Laser Engraving

System, express or implied. Neither does it guarantee software compatibility with any off-the-shelf

software package or any software program that has not been written by ULS.

Intended use of this system must be followed within the guidelines of this manual. In no event will ULS

be liable for any damages caused, in whole or in part, by customer, or for any economic loss, physical

injury, lost revenue, lost profits, lost savings or other indirect, incidental, special or consequential

damages incurred by any person, even if ULS has been advised of the possibility of such damages or

claims.

WARNING: UNIVERSAL LASER SYSTEMS PRODUCTS ARE NOT DESIGNED, TESTED, INTENDED OR

AUTHORIZED FOR USE IN ANY MEDICAL APPLICATIONS, SURGICAL APPLICATIONS, MEDICAL DEVICE

MANUFACTURING, OR ANY SIMILAR PROCEDURE OR PROCESS REQUIRING APPROVAL, TESTING, OR

CERTIFICATION BY THE UNITED STATES FOOD AND DRUG ADMINISTRATION OR OTHER SIMILAR

GOVERNMENTAL ENTITIES. SHOULD THE BUYER USE UNIVERSAL LASER SYSTEMS PRODUCTS FOR ANY

SUCH UNINTENDED OR UNAUTHORIZED APPLICATION, ALL WARRANTIES REGARDING THE UNIVERSAL

LASER SYSTEMS PRODUCTS SHALL BE NULL AND VOID. FURTHER, THE BUYER SHALL HAVE NO REMEDY

AGAINST UNIVERSAL LASER SYSTEMS AND ITS OFFICERS, EMPLOYEES, SUBSIDIARIES, AFFILIATES AND

DISTRIBUTORS FOR, AND THE BUYER SHALL INDEMNIFY AND HOLD THOSE PARTIES HARMLESS

AGAINST, ANY AND ALL CLAIMS, COSTS, DAMAGES, EXPENSES AND REASONABLE ATTORNEY FEES

ARISING OUT OF, DIRECTLY OR INDIRECTLY, ANY CLAIM ASSOCIATED WITH SUCH UNINTENDED OR

UNAUTHORIZED USE, INCLUDING BUT NOT LIMITED TO ANY CLAIM BASED ON WARRANTY (EXPRESS OR

IMPLIED), CONTRACT, TORT (INCLUDING ACTIVE, PASSIVE, OR IMPUTED NEGLIGENCE), STRICT LIABILITY,

PATENT OR COPYRIGHT INFRINGEMENT OR MISAPPROPRIATION OF INTELLECTUAL PROPERTY.

HP is a registered trademark of Hewlett-Packard Corporation.

Windows is a registered trademark of Microsoft Corporation.

Macintosh is a registered trademark of Apple Computer Corporation.

PostScript, Photoshop, and Streamline are registered trademarks of Adobe Systems Inc.

CorelDRAW is a registered trademark of Corel Corporation.

AutoCAD is a registered trademark of AutoDesk Inc.

ULS Platforms are protected under one or more of U.S.

patents 5,661,746; 5,754,575; 5,867,517; 5,881,087;

5,894,493; 5,901,167; 5,982,803; 6,181,719; 6,313,433;

6,342,687;

patents pending.

6,424,670; 6,423,925. Other U.S. and International

© Universal Laser Systems Inc., 2005

All Rights Reserved

Introduction

All of us at Universal Laser Systems, Inc. (ULS) would like to thank you for your purchase. Since 1988,

the staff at ULS has been dedicated to total customer satisfaction. When you buy Universal you get more

than a money making product, you get a team of talented, experienced, and enthusiastic people who are

focused on your satisfaction. Our commitment is to help you be successful right now and in the future.

To begin with, we highly recommend that this entire manual be read before attempting to use the device.

The manual includes important information about safety, assembly, use, troubleshooting, and basic

maintenance.

How To Get Help

Before contacting our Technical Support Department, make sure that you have read this entire manual as

well as any other accompanying manuals included with your laser system.

Step 1:

Try to recreate the problem and write down the circumstances in which the problem occurred. Try to

recall if the problem began all of a sudden, worsened over time, or began after you performed any recent

maintenance. Also be prepared to describe all pertinent information about the computer being used such

as graphics software, VersaLASER Controller software version, computer operating system and computer

type, configuration, and accessories.

Step 2:

Make sure that you have the serial number available. The serial number tag is located on the back of the

machine, next to the exhaust port. It can also be found located in the ABOUT tab of the VersaLASER

Controller software. We may not be able to assist you without this number.

Step 3:

Contact your local VersaLASER reseller. If possible, call from a phone that is close to the VersaLASER

so that it can be operated while speaking on the telephone.

Step 4:

If your local VersaLASER reseller cannot assist you and you would like to use our FREE, email based

support system, log on to our website:

then click on the “Technical Support Request Form” and follow the instructions.

Step 5:

If you are unable to obtain Internet access, you may contact our Technical Support Department at:

Universal Laser Systems, Inc.

www.VersaLASER.com. Click on the “Technical Support” link,

Technical Support Department

16008 North 81

st

Street

Scottsdale, AZ 85260

Phone: 480-609-0297

Fax: 480-609-1203

M-F 8am – 5pm Arizona Time

Specifications

System Operating Environment Requirements (user provided)

Model VL-200 VL-300

Operating Environment Well-ventilated office (recommended)

or clean, light-duty manufacturing area

Operating Temperature 50ºF (10ºC) to 95ºF (35º C) capable

73ºF (22ºC) to 77ºF (25º C) for best performance

Storage Temperature 50ºF (10ºC) to 95ºF (35º C)

Operating Humidity Non-condensing

Electrical Power 110/220 VAC, 10/5A, Grounded 110/220 VAC, 10/5A, Grounded

Particulate/Odor Outside

Ventilated Exhaust System

Computer Requirement Windows XP Home or Professional Editions

Software Requirement Any Windows based Graphics or CAD application

150 CFM (cubic feet per minute) @ 6 inches static pressure

High-pressure vacuum blower capable of

(255m3/hr at 1.5kPa)

Available USB 1.1 port or higher

System Specifications

Laser Safety CO2 Laser, Interlocked Safety Enclosure = Class I

Red Diode Pointer = Class IIIa

Laser Source 25 or 30 watt CO2 Laser 30,40, or 50 watt CO2 Laser

Cooling Air Cooled

Work Area 16” x 12” (406.4 x 304.8 mm) 24” x 12” (609.6 x 304.8 mm)

Printer Driver Windows XP

Hardware Interface USB 1.1

Dimensions 26”Wide x 25” Deep x 14”Height

(660.4mm x 635mm x 355.6)

34”Wide x 25” Deep x 14”Height

(863.6mm x 635mm x 355.6)

System Weight System = 85 lbs. (38 kg) System = 100–106 lbs. (45-48 kg)

Laser Cartridge Weight 25/30 Watt = 20 lbs (9 kg)

Available Options Cart, Integrated Air Cleaner, Rotary Fixture, Air Assist, Compressed Air,

Specifications subject to change without notice

40 Watt = 23 lbs (10 kg)

50 Watt = 26 lbs (12 kg)

Cutting Table, Focus Lens Kits

Table of Contents

Section 1 - Safety

Description of Appropriate Use........................................................................................1-1

General Safety.................................................................................................................1-1

Laser Safety.....................................................................................................................1-2

Safety Labels ...................................................................................................................1-2

EU Compliance (CE)........................................................................................................1-4

FCC Compliance..............................................................................................................1-5

Recycling..........................................................................................................................1-5

Section 2 – Step-By-Step Installation

Establishing a Proper Operating Environment.................................................................2-1

Providing a Suitable Electrical Power Source..................................................................2-1

Extracting Fumes and Particulates..................................................................................2-1

Computer and Operating System ....................................................................................2-2

Recommended Software Programs ................................................................................2-3

Unpacking and Assembling the VersaLASER.................................................................2-3

The VersaLASER Software Installation CD-ROM...........................................................2-4

Configuring Your Graphics Software ...............................................................................2-5

Section 3 –Operation

How it Works....................................................................................................................3-1

The VersaLASER Keypad ...............................................................................................3-1

The VersaLASER On-screen Control Panel (VCP).........................................................3-2

Running Your First Job, Step-By-Step.............................................................................3-3

Step 1 - Creating Your Artwork..................................................................................3-3

Step 2 – Printing Your Artwork..................................................................................3-3

Step 3 – Powering On the VersaLASER...................................................................3-4

Step 4 – Loading and Positioning Your Material.......................................................3-4

Step 5 – Focusing the Laser Beam...........................................................................3-4

Step 6 – Running Your Job .......................................................................................3-4

Section 4 – Basic System Maintenance

Safety...............................................................................................................................4-1

Cleaning and Maintenance Supplies ...............................................................................4-1

Optics...............................................................................................................................4-2

The Motion System..........................................................................................................4-4

The Main Enclosure.........................................................................................................4-5

Adjustments and Lubrication............................................................................................4-5

Interlock Safety Check.....................................................................................................4-5

Fuse Replacement...........................................................................................................4-5

Cooling Fan Filters...........................................................................................................4-6

Maintenance Schedule.....................................................................................................4-6

Section 5 – Accessories

Rotary Fixture...................................................................................................................5-1

Cutting Table....................................................................................................................5-4

Integrated Cart.................................................................................................................5-6

Computer Controlled Air Cleaner / Cart...........................................................................5-6

Computer Controlled Compressed Air Unit......................................................................5-9

Air Assist Cone...............................................................................................................5-10

Back Sweep...................................................................................................................5-12

Step 7 – Powering Off the VersaLASER...................................................................3-4

Optics Handling Guidelines.......................................................................................4-2

Optics Cleaning Procedure........................................................................................4-2

Accessing the Optics.................................................................................................4-2

#2 Mirror ....................................................................................................................4-3

#3 Mirror and Focus Lens..........................................................................................4-3

Beam Window............................................................................................................4-4

Section 1

Safety

Description of Appropriate Use

This device is designed for laser cutting and etching of the materials listed in the VersaLASER printer driver.

Materials to be processed must fit completely inside the system for proper operation. Use of the equipment in a

manner other than that described in this manual may r esult in injury to yourself and others and may cause sever e

damage to the equipment and your facility.

Notice: This device is not designed, tested, intended or authorized for use in any medical applications,

surgical applications, medical device manufacturing , or any similar p rocedu re or pro cess requ iring ap pro val,

testing, or certification by the United States Food and Drug Administration or other similar governmental

entities. Please see the Notice herein for further information regarding such uses.

General Safety

• Exposure to the laser beam may cause physical burns and can cause severe eye damage.

Proper use and care of this system are essential to safe operation.

• Never operate the laser system without constant supervision of the cutting and etching

process. Exposure to the laser beam may cause ignition of combustible materials and start a fire. A

properly maintained fire extinguisher should be kept on hand at all times.

• A properly configured, installed, maintained, and operating particulate/fume exhaust system is

mandatory when operating the laser system. Fumes and smoke from the etching process must

be extracted from the laser system and either filtered through the Integrated Exhaust Filtration

Module (an optional accessory) or exhausted outside through a user supplied exhaust system.

Some materials, during and after laser processing, may produce toxic fumes. We suggest that

•

you obtain the Material Safety Data Sheet (MSDS) from the materials manufacturer. The MSDS

discloses all of the hazards when handling or processing that material. Some materials continue

emitting fumes for several minutes after laser processing and may pose a health hazard. Avoid using

this device in small, enclosed, or non-ventilated areas.

• Some materials, during and after laser processing, may produce corrosive fumes.

DISCONTINUE processing any material that produces signs of chemical deterioration in the laser

system such as rust, metal etching or pitting, peeling paint, etc. Damage to the laser system from

corrosive materials is NOT covered under warranty.

• Care should be taken when moving or lifting this device. Obtain assistance from 1 or 2 additional

people when lifting or carrying (secure motion system and access door). Severe bodily injury may

occur if improper lifting techniques are applied or the system is dropped.

• Dangerous voltages are present within the electronics and laser enclosures of this system.

Although access to these areas is not necessary during normal use, if it becomes necessary to open

one of these enclosures for service reasons, please remember to disconnect the power cord from

your electrical supply.

• This device is specifically designed to comply with CDRH performance requirements under 21

CFR 1040.10 and 1040.11. CDRH is the Center for the Devices of Radiological Health division of the

Food and Drug Administration (FDA) in the USA. It also complies with CE (European Community)

safety regulations. No guarantees of suitability or safety are provided for any use other than those

specified by Universal Laser Systems, Inc.

SAFETY

Laser Safety

The device contains a sealed carbon dioxide (CO2) laser in a Class I enclosure that produces intense

invisible and visible laser radiation at a wavelength of 10.6 microns in the infrared spectrum. For your

protection, this enclosure is designed to completely contain the CO2 laser beam.

CAUTION – Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

• The intense light that appears during the etching or cutting process is the product of material combustion or

vaporization. DO NOT STARE AT THIS LIGHT FOR EXTENDED PERIODS OR ATTEMPT TO VIEW IT WITH

OPTICAL INSTRUMENTS.

• This device contains a visible Red Dot Pointer (Class IIIa, 5mw maximum output, 630-680 nm). DO NOT

STARE AT THIS RED LIGHT FOR EXTENDED PERIODS OR ATTEMPT TO VIEW IT WITH OPTICAL

INSTRUMENTS.

• The user access door of this device is safety interlocked and will disable the CO2 laser beam when the access

door is opened. The Red Dot Pointer is NOT safety interlocked a nd is activated when the user access door is

open.

• DO NOT OPERATE THE LASER SYSTEM IF ITS SAFETY FEATURES HAVE BEEN MODIFIED, DISABLED

OR REMOVED. This may lead to exposure to invisible and visible CO2 laser radiation which may cause

permanent blindness and/or severe burns to the skin.

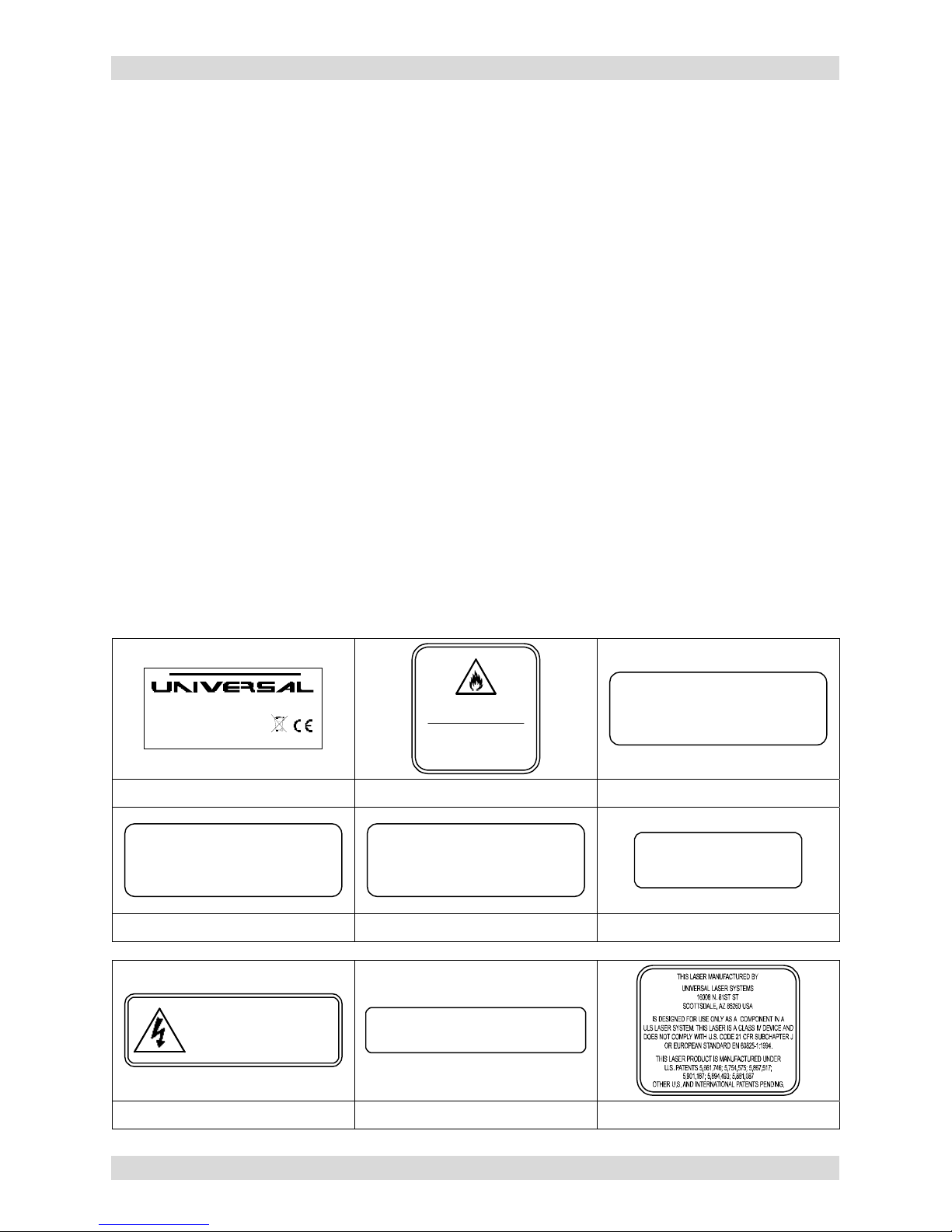

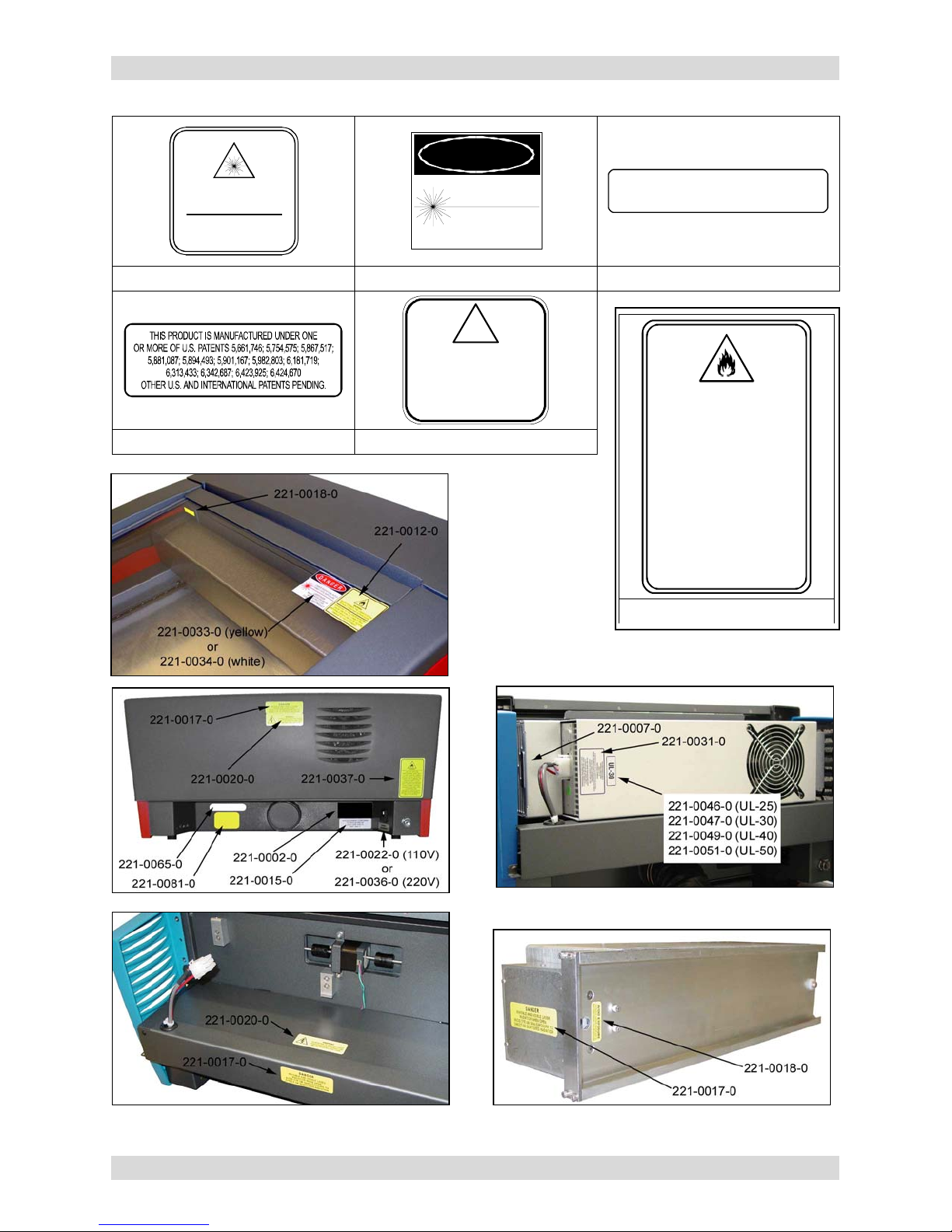

Safety Labels

CDRH and CE regulations require that all laser manufacturers affix warning labels in specific locations

throughout the equipment. The following warning labels are placed on the laser system for your safety.

DO NOT remove them for any reason. If the labels become damaged or are removed for any reason, DO

NOT OPERATE the laser system and immediately contact Universal Laser Systems, Inc. for free

replacements. Labels are NOT to scale.

LASER SYSTEMS INC.

Model N o:

Manufactured:

Serial No: Made in USA

Scottsdale, Arizona

XXXXX

XXXXX

XXXXX

221-0002-0 221-0012-0 221-0015-0

INVISIBLE AND VISIBLE LASER RADIATION

WHEN OPEN

DEFEATED

DIRECT OR SCA TTERED RADIA TION

TO

DANGER

AND INTERLOCK F AILED OR

AVOID EYE OR SKIN EXPOSURE

221-0016-0 221-0017-0 221-0018-0

WARNING

NEVER OPER ATE THE LA SER SYSTEM

WITHOUT CONSTANT SUPERVISION

EXPOSURE TO THE LASER BEAM M AY

CAUSE IGNITION OF COMBUSTIBLE

MATERIALS WHICH CAN CAUSE SEVERE

DAMAG E TO TH E EQ UIPMENT

DANGER

INVISIBLE AND VISIBLE LASER

RADIATION WHEN OPEN

AVOID EYE OR SKIN EXPOSURE TO

DIREC T O R SC ATTE RE D RA DIATION

THIS EQUI PME NT CONFORMS

TO PROVISIONS OF

US 21 CFR 1040.10

AND 1040.11

A V OID EXPOSURE

INVISIBLE LASER RADIATION IS

EMITTED FROM THIS APERTURE

WARNING

TO AVOID RISK OF ELECTRIC SHOCK

ALWAYS DISCONNECT POWER CORD

BEFORE REMOVING THIS CO VER

221-0020-0 221-0022-0 221-0031-0

INPUT POWER:

110 VAC; 50/60 Hz; 10 A

Section 1-2

SAFETY

DANGER

CAUTION LASER RADIATION

DO NOT STARE INTO BEAM OR VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 3R LASER PRODUCT

LASER DIODE

WA VE LENGTH: 630-680 nm

MAX. OUTPUT: 5 mW

LASER RADIATION - AVOID

DIRECT EYE EXPOSURE

LAS ER DI O DE

WA V E LE NGT H: 630-680 nm

MAX. OUTPUT: 5 mW

CLAS S 3R LA SE R PRODUCT

221-0033-0 221-0034-0 221-0036-0

INPUT POWER:

220 VAC; 50/60 Hz; 5 A

!

WARNING

Do use in medical or surgical

NOT

applications or to manufacture

medical devices. See the Safety,

Installation, Operation, an d Basic

Maintenance Manual, or the OEM

Laser Integration Manual for

further information.

THIS SYSTEM IS DESIGNED FOR

221-0065-0 221-0081-0

WARNING

USE WITH INERT AND

NON-OXIDIZING GASES ONL Y

(i.e. DR Y CL EAN AIR, CARBO N

DIOXI DE, HELI UM, NITRO G EN).

CONNECTING FLAMMABLE OR

OXIDIZING GASES TO THIS

SYSTEM CRE ATES A SERIO U S

SAFETY AND/OR FIRE HAZARD.

DO NOT CONNE CT ANY GAS

SOURCES EXCEEDING 75 PSI

(5 ATM) PRESSURE.

UNIVERSAL LASER SYSTEMS

ASSUMES NO RESPONSIBILITY

ARISING FROM THE IMPROPER

USE OF THIS SYSTEM.

221-0037-0

Section 1-3

EU Compliance (CE)

LASER SYSTEMS INC.

Product Identification: VersaLASER VL-200 and VL-300

Manufacturer: Universal Laser Systems, Inc.

This equipment Is manufactured in conformity with the following directives:

89/336/EEC (EMC Directive)

73/23/EEC (Low Voltage Directive)

98/37/EEC (Machinery Directive)

based on the standards listed.

Standards Used:

Safety:

EN 60950: 2002

EN 60825: 2001 (Class 3R)

EMC:

EN 55022: 2003 (Class A)

EN 50082-1: 1998

EN 61000-3-2: 2001 (class A)

EN 61000-3-3: 2002

EN 61000-4-2: 2001 (6kV CD, 8kV AD)

EN 61000-4-3: 2003 (3 V/m)

EN 61000-4-4: 2002 (2 kV power line, 0.5 kV signal line)

EN 61000-4-5: 2001 (class 2)

Note: This is not a declaration of conformity. The importer of this equipment

supplies the declaration of conformity.

Warning -

may cause radio interference in which case the user may be required to take

adequate measures.

This is a Class A product. In a domestic environment, this product

SAFETY

st

16008 N. 81

Scottsdale, AZ 85260

Phone: (480) 483-1214 Fax: (480) 483-5620

USA

St.

Section 1-4

SAFETY

FCC Compliance

This ULS laser system has been tested and found to comply with Federal Communication Commission

(FCC) directives regarding Electromagnetic Compatibility (EMC). In accordance with these directives ULS

is required to provide the following information to its customers.

FCC Compliance Statement and Warnings

This device complied with FCC Rules Part 15. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device as set

forth in Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with

manufacturer’s instructions, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his or her own expense.

Users should be aware that changes or modifications to this equipment not expressly approved by the

manufacturer could void the user’s authority to operate the equipment.

This equipment has been type tested and found to comply with the limits for a Computing Device per FCC

part 15, using shielded cables. Shielded cables must be used in order to insure compliance with FCC

regulations.

Recycling

By placing the above symbol on our products and accessories Universal Laser Systems is indicating that

we are committed to helping reduce the amount of waste electronics ending up in municipal landfills.

Therefore Universal Laser Systems urges consumers to recycle this product and its accessories.

Universal Laser Systems is equipped to recycle any of its electronic products and accessories and will

assist our customers with their recycling options. To arrange for recycling of your ULS product or

accessory, please contact Universal Laser Systems for more information.

Section 1-5

Section 2

Step-By-Step Installation

In this section we will step you through site preparation, computer and software setup, and unpacking and

assembling the VersaLASER. Please follow the instructions in the order shown.

Establishing a Proper Operating Environment

• The device MUST be installed in an office-type or light duty manufacturing environment. Airborne

pollutants can damage the device. Keep the device isolated from any sandblasting, sanding or

machining equipment or any other machinery that produces airborne particles. Also, do not

operate or store this device near sources of water, saltwater, or oil vapor.

• For best results, we recommend operating this air-cooled device in the ambient temperature

range of 73ºF (22ºC) to 77ºF (25º C). However, it can operate in the ambient temperature range

of 50ºF (10ºC) to 95ºF (35º C).

• Avoid storing the device outside the temperature range of 50ºF (10ºC) to 95ºF (35º C) as

excessively cold or hot temperatures can damage the laser cartridge or reduce its lifetime.

• Ambient humidity levels must be non-condensing.

Providing a Suitable Electrical Power Source

• The electrical power requirements can be found either in the “Specifications” table in the

beginning of this manual or printed on the sticker next to the power inlet of the VersaLASER.

• The VersaLASER and VersaLASER accessories are equipped with standard IEC 60320

“computer style” power cord receptacles. A power cord may or may not be included with the

device. If the power cord is not present, please refer to the “Additional Requirements”

supplement for more information.

• Never remove the ground (earth) lead to the electrical cord and plug the system into a nongrounded (non-earthed) outlet. Operating the device without the ground connection is very

dangerous and can lead to a severe, if not fatal, electrical shock. It may also cause the device to

exhibit unpredictable behavior.

• Noisy or unstable electricity as well as voltage spikes may cause interference and possible

damage to the device’s electronics. If electrical power fluctuations, brown outs, or constant

power outages are a problem in your area, an electrical power stabilizer, UPS (Uninterruptible

Power Supply), or backup generator may be required.

• To prevent the overload of your electrical power circuit or to control an unstable or noisy electrical

power source, it may be necessary to connect the device to a dedicated electrical circuit.

• The device is designed as a Class I, Group A, pluggable device. It is also designed for connection

to IT power systems.

Extracting Fumes and Particulates

Fumes, smoke, and particulates are a byproduct of the cutting and marking of materials in the

VersaLASER and MUST be extracted (vacuumed) from the VersaLASER. You may choose to either

exhaust them to the outside environment or filter them.

External Exhaust (most common): We recommend that you contact a local contractor to design and

install an exhaust system that not only meets the minimum requirements of this device but also complies

with local environmental laws.

• The exhaust system MUST be capable of supplying a minimum of 150 CFM (cubic feet per

minute) of airflow while under a load of 6 inches of static pressure (254 m3/hr at 1.5kPa). DO

NOT install forward incline, backward incline, in-line, or ventilator fans because these types of air

handlers are inadequate and inappropriate for this type of installation. A high-pressure blower

MUST be used to meet minimum airflow requirements.

Loading...

Loading...