Page 1

OPERATION MANUAL

ULS-25 LASER SYSTEM

Universal Laser Systems, Inc.

16008 North 81st Street

Scottsdale, AZ 85260

Phone: 602-483-1214

Fax: 602-483-5620

Volume I, Rev. 6

April 1995

Page 2

TABLE OF CONTENTS

NOTICE.......................................................................................................................................4

INTRODUCTION........................................................................................................................5

SECTION 1 - SAFETY

1.1 LASER SAFETY............................................................................................................6

1.2 SAFETY LABELS..........................................................................................................7

1.3 THE SAFETY INTERLOCK SYSTEM .........................................................................8

SECTION 2 - INSTALLATION

2.1 UNPACKING AND ASSEMBLING THE SYSTEM ....................................................9

2.2 OPERATING ENVIRONMENT....................................................................................11

2.3 EXHAUST SYSTEM REQUIREMENTS.......................................................................12

2.4 COMPUTER RECOMMENDATIONS AND SETUP...................................................13

2.5 LASER SYSTEM INSTALLATION..............................................................................13

2.6 HOW TO INSTALL THE ULS WINDOWS PRINTER DRIVER .................................14

SECTION 3 - SOFTWARE SETUP AND OPERATION

3.1 USING WINDOWS GRAPHICS SOFTWARE ............................................................16

3.2 THE ULS WINDOWS PRINTER DRIVER...................................................................21

3.3 USING DOS BASED PROGRAMS ..............................................................................26

SECTION 4 - LASER SYSTEM OPERATION

4.1 GENERAL SYSTEM OVERVIEW................................................................................27

4.2 THE MAIN CONTROL PANEL ...................................................................................28

4.3 MOTION SYSTEM CONTROLS .................................................................................38

4.4 LOADING AND FOCUSING THE LASER SYSTEM..................................................39

4.5 RUNNING A SAMPLE.................................................................................................41

4.6 USING THE OPTIONAL ROTARY FIXTURE.............................................................42

4.7 THE RUBBER STAMP OPTION ..................................................................................48

4.8 START UP PARAMETERS FOR VARIOUS MATERIALS .........................................51

SECTION 5 - BASIC MAINTENANCE

5.1 GENERAL CLEANING OF THE SYSTEM..................................................................77

5.2 OPTICS CLEANING.....................................................................................................72

SECTION 6 - APPENDICES

APPENDIX A - WARRANTY..............................................................................................A

APPENDIX B - LASER SYSTEM SPECIFICATIONS .......................................................B

APPENDIX C - SERIAL PORT CABLE REQUIREMENTS ...............................................C

APPENDIX D - LASER.INI MODIFICATIONS.................................................................D

2

Page 3

APPENDIX E - SOFTWARE ANOMALIES .......................................................................E

3

Page 4

This publication and its contents are proprietary to Universal Laser Systems, Inc., and are intended

solely for the contractual use of Universal Laser Systems, Inc. customers.

This publication and its contents may not be reproduced or distributed for any other purpose without the

written permission of Universal Laser Systems, Inc.

© UNIVERSAL LASER SYSTEMS INC., 1994

ALL RIGHTS RESERVED

NOTICE

Universal Laser Systems, Inc. does not assume any liability arising out of the application or use of any

products, circuits or software described herein. Neither does it convey a license under its patent rights

nor the patent rights of others. Universal Laser Systems, Inc. further reserves the right to make any

changes in any products described herein without notice. This document is subject to change without

notice.

4

Page 5

INTRODUCTION

The ULS-25 Laser System is designed to combine flexibility and full featured performance with

simplicity and ease of use. Using advanced engineering and design, the ULS -25 offers finer control,

higher precision, more versatility, better resolution, and overall greater quality than any other laser

system in its class. It combines the performance of high speed engraving and cutting capabilities with the

ease of a user friendly, specially designed, Windows printer driver interface. Actually, the ULS -25 is

such a breakthrough in technology that it is more than just a laser system, it is a precision engraving and

cutting device used as a tool for the imagination.

To begin with, we highly recommend that this entire manual be read before attempting to use the laser

system. The manual includes important information about the safety, assembly, use, and maintenance

of the laser system. We cannot overemphasize the importance of reading the owner's manual

completely.

Where to get HELP:

If it is necessary to call for technical assistance, please call our technical support services at (602)483-

1214. Please be prepared to answer our questions by following the procedures below, as this will

allow us to provide assistance in a prompt and efficient manner:

m Take a moment to write down all of the pertinent information about the computer

being used with the laser cutting and engraving system such as software, operating

system and computer type.

m Try to recreate the problem and write down the circumstances in which the problem

occurred. This will help our technical staff tremendously.

m If possible call from a phone that is close to the laser engraving system so that the

system can be operated while talking with our technical support staff.

5

Page 6

SECTION 1 - SAFETY

1.1 LASER SAFETY

This laser engraving system contains a sealed carbon dioxide laser produces intense and invisible laser

radiation (at a wavelength of 10.6 microns in the infrared spectrum). The ULS laser engraving system is

designed as a CLASS I device, meaning that the system is equipped with a protective housing and

safety devices to completely contain the laser under normal use. Do not at any time attempt to modify

or disassemble any part of the system and do not attempt to operate a system that has been modified or

disassembled. Improper use of controls and adjustments or performance of procedures other than

those specified in this manual may invalidate the Class I rating and result in exposure to the laser beam.

Please remember the following safety precautions when operating this laser cutting and engraving

system:

1. Exposure to laser radiation may produce physical burns and can cause severe eye damage.

Proper use and care of this system is very important to the safety of all people in the surrounding

area.

2. Exposure to the laser beam may cause ignition of combustible materials so a properly maintained

fire extinguisher should be kept on hand at all times.

3. Operation and care of this laser cutting and engraving system must be performed in accordance

with this manual.

4. Dangerous voltages are present within the electronics and laser enclosures of this system.

Although access to these areas is not necessary during normal use, if it becomes necessary to

open one of these enclosures for service reasons please remember to UNPLUG THE

MACHINE FIRST.

5. Never operate the laser system without properly exhausting the fumes generated by the cutting

and engraving process.

6. Please contact ULS with any questions concerning laser safety before operating this system.

Note: ULS systems are specifically designed to comply with CDRH performance requirements

under 21CFR 1040.10 and 1040.11. No guarantees of suitability or safety are provided for

any use other than those specified by Universal Laser Systems, Inc.

6

Page 7

1.2 SAFETY LABELS

According to CDRH standards, all interlocked and non-interlocked covers that allow access to a laser

beam must have appropriate laser safety labels attached to them. These labels must be visible to

personnel prior to the removal of the covers. Additional labels must be installed inside the machine and

be visible if the covers are removed from the machine. Labels that provide the manufacturer's name,

date of manufacture, description of product, model number, serial number and compliance statement

must also be visible on the outside of the machine.

All CDRH required labels are properly affixed to the machine in the appropriate locations at the time of

manufacture. These labels are not to be removed. If they become damaged or removed for any

reason, please request additional labels from Universal Laser Systems (they will be provided free of

charge). Below is a list of all the labels and their locations on the system.

Laser Processing System Manufactured By:

Scottsdale, Arizona

Model No:

Serial No:

Date of Manufacture:

Made in USA

Manufacturer's Label

Location: On the back of the machine in the lower left corner.

CDRH Compliance Label

Location: On the back of the machine below the Manufacturer's Label.

Warning Label for Interlocked Panels and Doors

Location: On the outside of the top door, on the inside of the top door

(visible when door is open), on the outside of the front door, on the

inside of the front door (visible when door is open) and next to the

defeat interlock tool receptacle.

7

Page 8

Exposure Warning Label

Location: Near the beam window inside the system where the laser

beam enters the work area and next to the beam aperture inside the

second mirror housing.

Warning Label for Non-interlocked Panels

Location: On the second mirror cover (visible when the electronics cover

is open or removed) and on the floor of the second mirror housing (visible

when the second mirror cover is removed).

1.3 THE SAFETY INTERLOCK SYSTEM

The laser cutting and engraving system incorporates a safety interlock circuit that automatically shuts off

the power supplied to the laser whenever the front or top door is opened. This interlock system is

connected in series with a switch and a red indicator light on the control panel of the system. The switch

allows the power to the laser to be manually turned on and off. The red indicator light will light up when

power is being supplied to the laser. If at any time the red indicator light remains on when the front or

top door is open, immediately unplug the system and call Universal Laser Systems for service

instructions.

WARNING:

Do not attempt to modify or defeat the safety interlock system for any reason as this could

result in exposure to hazardous laser radiation.

WARNING:

When using the interlock defeat tool, wear appropriate laser safety goggles. Failure to wear

appropriate goggles can result in severe eye damage.

8

Page 9

SECTION 2 - INSTALLATION

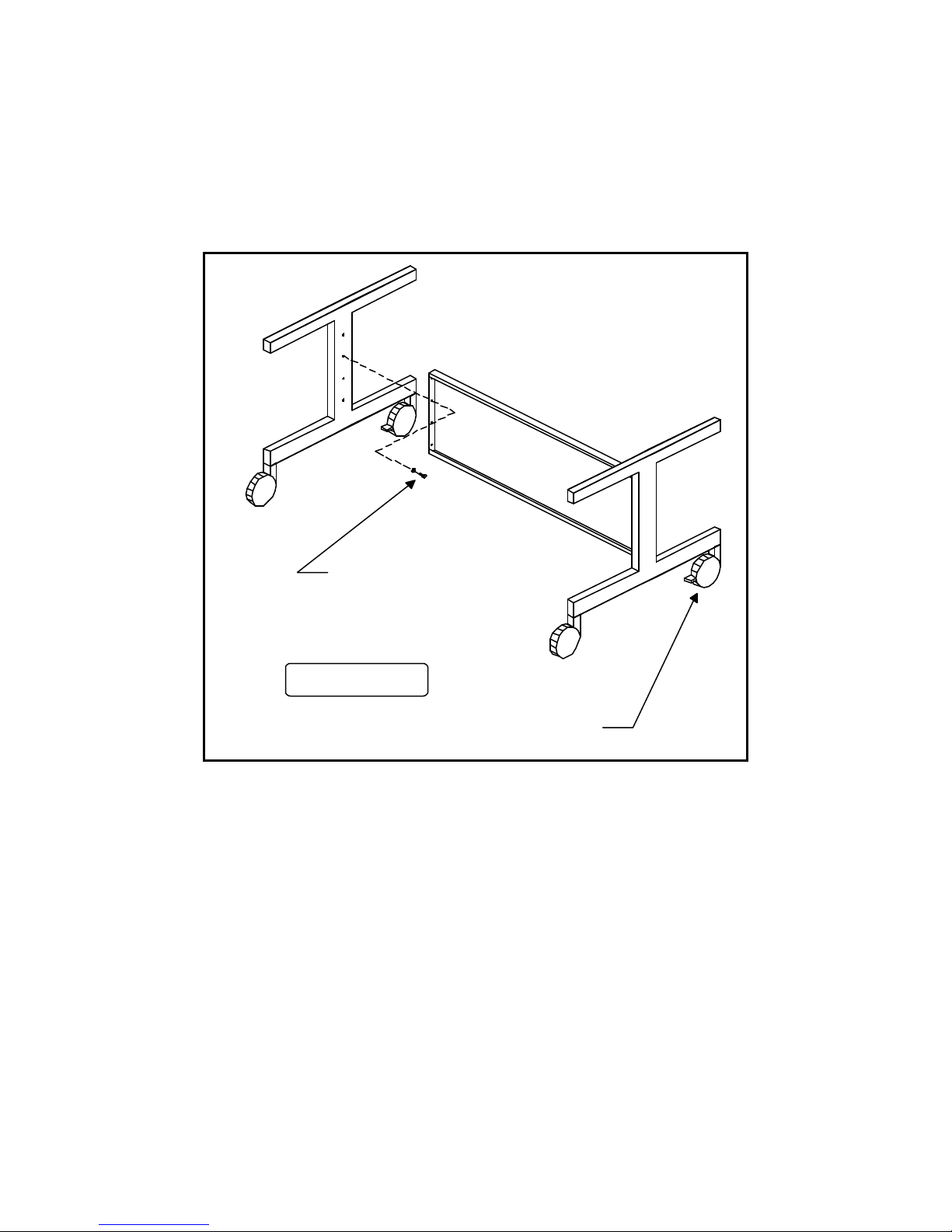

2.1 UNPACKING AND ASSEMBLING THE SYSTEM

The laser engraving machine is shipped in one crate that contains the system, a cart with casters and

various accessories. The following steps outline the unpacking and assembly of the system. Please

follow these steps carefully.

IMPORTANT

Save the shipping crate. If the system must be returned for

service, it will have to be packed in its original shipping crate.

1. Remove the top and four sides from the wooden shipping crate. Remember, after the laser

engraving system is assembled, store the flattened crate in a dry place.

2. Remove the cart panel and accessories box from the crate. The cart panel is shipped between two

pieces of foam in front of the laser engraving system and the accessories box is shipped behind the

system underneath the enclosure with the four fans mounted on it.

3. Carefully remove the foam which protects the viewing window on the top of the system and remove

the tape which holds the top door in place.

4. Remove the box containing the two cart legs. This box is shipped inside the laser engraving system.

To remove the box, open the top lid of the system and raise the engraving table by turning the

engraving table adjusting knob clockwise until the table is raised high enough to free the box

underneath it. Then open the front door of the system and slide the box out through the front

opening.

5. Open the accessories box and remove the four black casters and the bag of hardware. The

hardware bag should contain the following:

(8) 10-32 Allen head screws

(8) #10 lock washers

(4) 1/4-20 Allen head screws

(4) 1/4 " ID flat washers

(1) 5/32 inch Allen wrench

(1) 3/16 inch Allen wrench

A 3/4 inch wrench provided in the accessories box is needed to complete the stand assembly.

6. Using the smaller Allen wrench, attach the two legs to the center panel with the eight 10-32 Allen

head screws and #10 lock washers as shown in the figure below.

9

Page 10

7. Attach the four black casters to the cart by threading the casters into the nuts that are welded onto

the bottom of each leg. Tighten each caster in place with the 3/4 inch wrench. There are two

locking and two non-locking casters provided. Make sure when attaching the casters that the

locking casters are installed on the front of the cart. To identify the front of the cart look at the

center panel. The finished side of the center panel should face forward (see figure below).

Use 10-32 screws and

lock washers

View is from the

back side of the cart

Assemble cart with

lockable casters in front

Cart Assembly

8. When the cart is assembled, position it so that the finished side of the center panel is facing

forward.

9. Lift the laser engraving system from the crate and place it on the cart. This will require two people

as the machine weighs approximately 170 lbs.

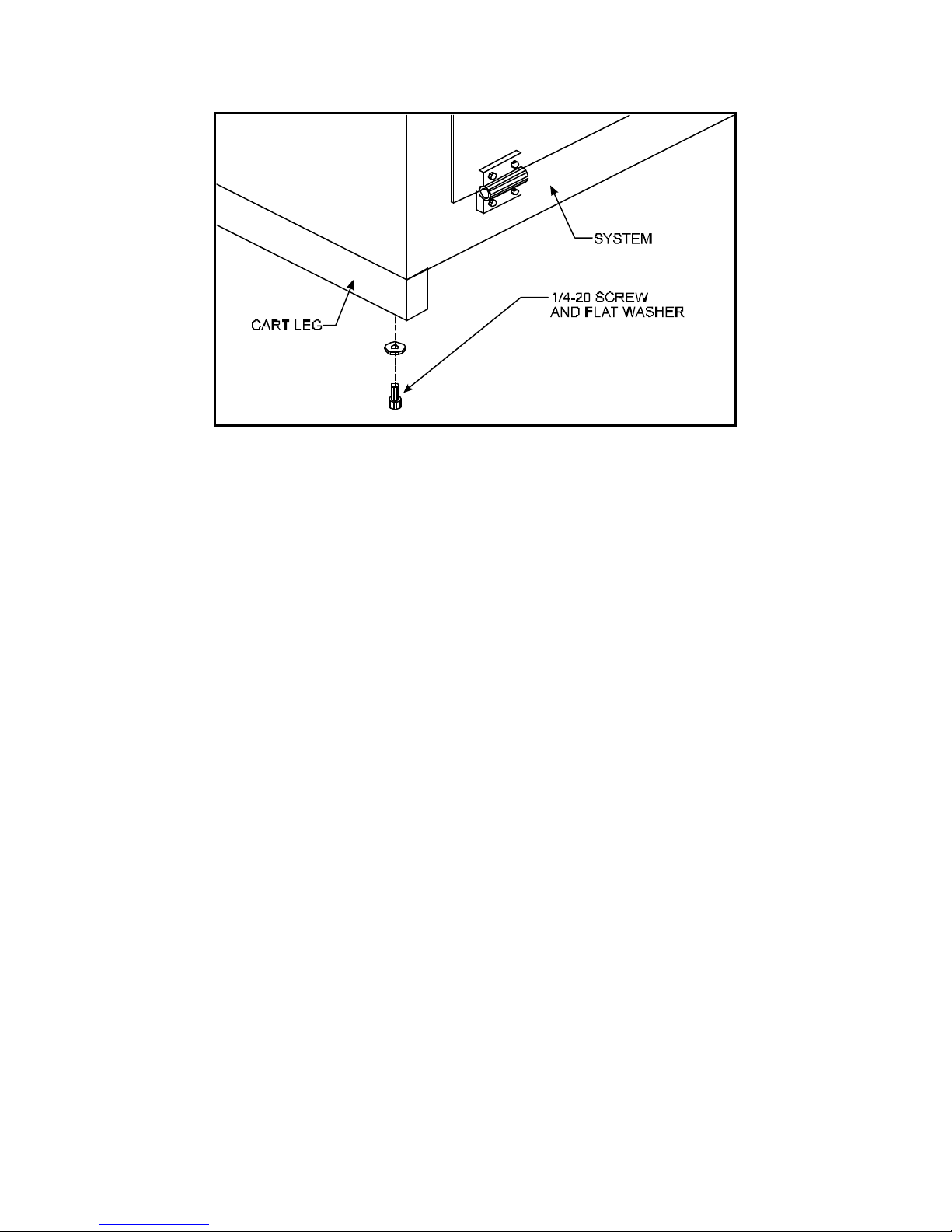

10. Using the larger Allen wrench, attach the system to the cart using the four 1/4-20 Allen head

screws and flat washers. The screws pass through the cart legs and into the bottom of the system

as shown in the drawing below.

10

Page 11

Attaching Cart to Laser System

2.2 OPERATING ENVIRONMENT

Before the system is installed, choose a suitable location. Follow the guidelines below:

m Avoid places where the system may be exposed to high temperatures,

dust, or high humidity (humidity exceeding 70% or where the

temperatu re is near the dewpoint). The laser system should be installed in

an office type environment.

m Avoid places where the system may be exposed to high levels of vibration

or electrical noise. We recommend using a high quality surge protector

(15 Amp capability) to protect the laser engraving system's electronics.

m Avoid small enclosed areas where ventilation is poor.

m Choose a place where the ambient operating temperature will remain

between 60 and 75 degrees Fahrenheit.

m Choose a place which provides a short and direct path to the exhaust

duct work (not provided).

m If planning to connect the laser engraving system to a computer through

the parallel port, choose a location where the computer can be placed

within 10 feet of the machine since this is the recommended maximum

distance for a parallel cable.

11

Page 12

2.3 EXHAUST SYSTEM REQUIREMENTS

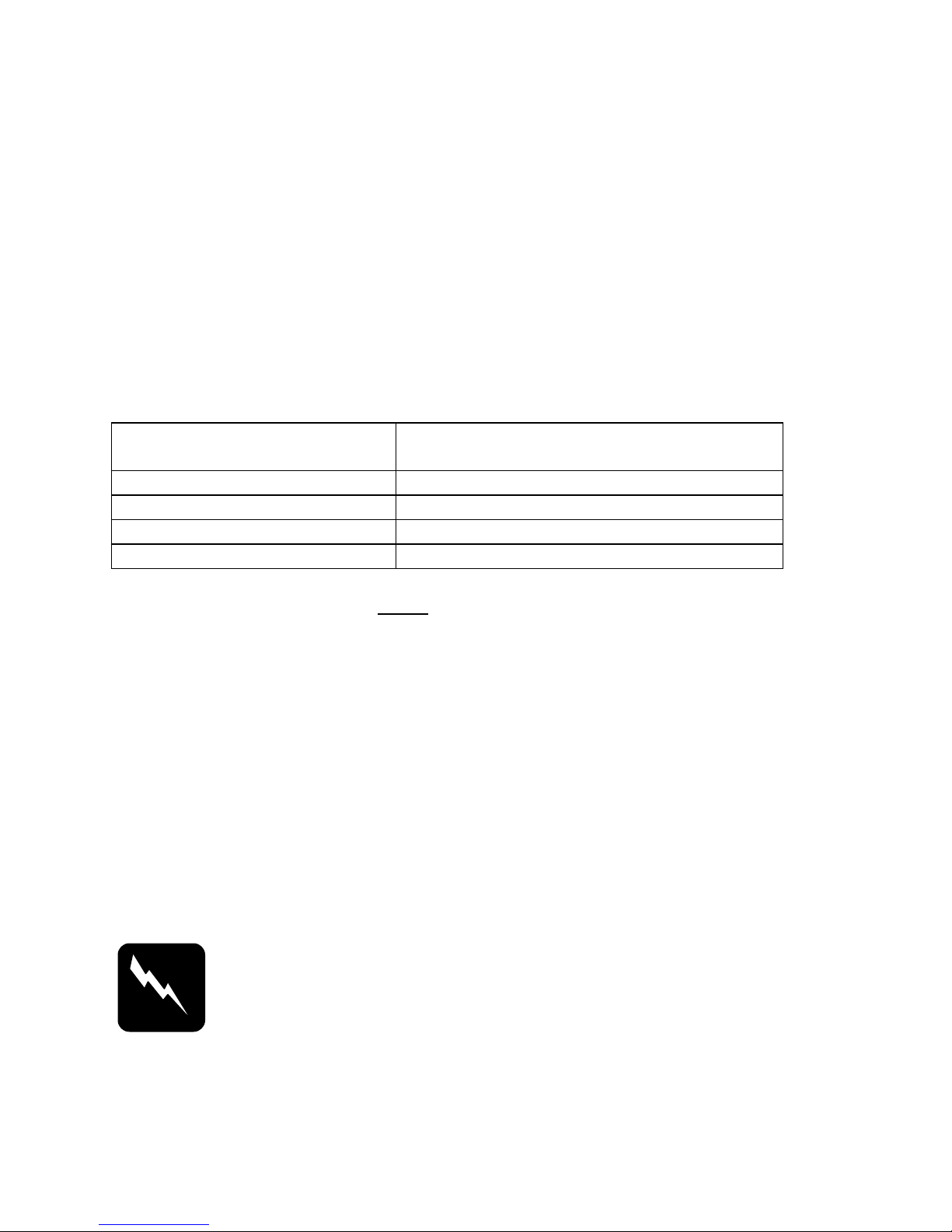

To properly exhaust fumes and smoke from the laser engraving system during operation, it is necessary

to provide an exhaust unit moving a minimum of 235 CFM at 6 inches of static pressure. Many

industrial supply companies carry blowers that should meet these requirements.

THROUGH OUR RESEARCH WE HAVE ESTABLISHED GUIDELINES ON THE PROPER CFM

RATINGS REQUIRED FOR THE EXHAUST SYSTEM. THESE RATINGS ARE BASED ON THE

MEASURED DISTANCE BETWEEN THE EXHAUST OUTLET ON THE LASER SYSTEM AND

THE INLET OF THE EXHAUST BLOWER. WE HAVE FOUND A SUITABLE SUPPLIER FOR

THIS TYPE OF EQUIPMENT IF YOU CHOOSE NOT TO USE THIS SUPPLIER, PLEASE

ENSURE THAT THE BLOWER THAT YOU PURCHASE MEETS OR EXCEEDS THE

FOLLOWING SPECIFICATIONS.

DISTANCE BETWEEN

BLOWER AND LASER

6 INCHES STATIC PRESSURE

CFM RATING AT

UP TO 7 FEET 235 @ 6 INCHES STATIC PRESSURE

8 - 14 FEET 410 @ 6 INCHES STATIC PRESSURE

15 - 22 FEET 535 @ 6 INCHES STATIC PRESSURE

23 - 30 FEET 625 @ 6 INCHES STATIC PRESSURE

The blower must be mounted on the outside of the building either on the roof or on a cement pad next

to the building. Rigid duct work should be used between the blower unit and the laser system. The

exhaust tubing should be smooth walled and have as few bends as possible. Use duct work with a

diameter that matches the blower unit and reduce the duct work to four inches just before the point

where it attaches to the laser system. Also consider installing a gate to control air flow and to close off

the exhaust from the outside environment when the laser is not in use. This is especially useful in colder

climates where it is not good to have cold air coming into the laser from the outside. Do not connect the

rigid duct work directly to the laser system. Use a short piece of industrial grade, wire reinforced

rubber tubing to connect the end of the gate, or tubing, to the laser system. This will provide mobility

and will dampen blower vibrations. Do not use a very long piece because it’s spiral construction

reduces air flow. Install a hose clamp on both ends of the hose to prevent leaks and to prevent the hose

from slipping off.

Having the blower wired to a wall switch in the same room will make it easy to turn it off and on.

WARNING

Do not attempt to operate the laser engraving system without a properly installed and

operating exhaust system. Some materials when cut or engraved can produce fumes

that are hazardous in concentrated amounts.

12

Page 13

We recommend installation of the exhaust system by a licensed contractor to meet safety and local code

requirements. Please contact a local air quality control specialist. Again, if there are any questions,

please contact our technical support.

13

Page 14

Sample Exhaust System Layouts

14

Page 15

2.4 COMPUTER RECOMMENDATIONS AND SETUP

The following computer configuration is the minimum requirement necessary to operate in the Windows

environment. Using a computer with more speed, memory, and storage capacity will enable the

graphic images to be produced faster. A faster computer will perform calculations quicker and will

shorten download time to the laser system. Remember, the following is the minimum requirement:

m 386 or higher PC compatible computer

m 4 MB of RAM

m 100 MB hard drive

m One floppy disk drive

m Color VGA monitor

m Mouse

m Microsoft Windows version 3.1

m Windows compatible graphics program

The same configuration can be used for CAD systems except Windows 3.1 and a Windows graphics

program would not be necessary.

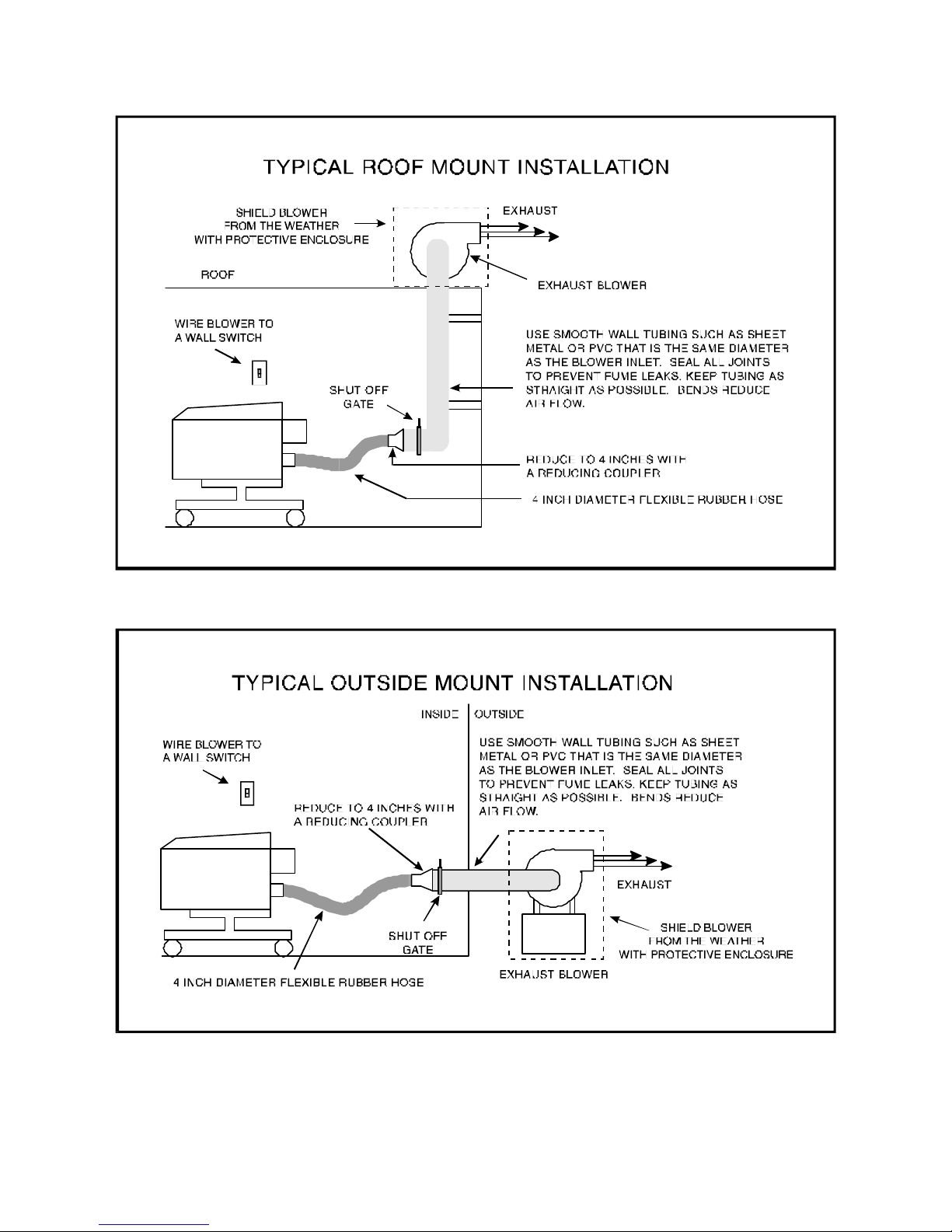

2.5 LASER SYSTEM INSTALLATION

CAUTION: Please make the following connections in the exact order described otherwise

static electricity can damage the computer and/or the laser system’s electronics.

1. Connect one end of the AC power cord into the receptacle on the right side of the laser system

next to the on/off switch. Then connect the other end of the power cord to a 110 volt 60 Hz AC

outlet through a good quality surge suppresser. Do the same for the computer system.

2. Make sure both the computer and laser engraving system are plugged in and turned OFF, then

connect the laser engraving system to the computer using either a serial or parallel connection..

We recommend the use of a Parallel port connection because it normally provides the best

performance. Refer to the following diagram.

15

Page 16

Cabling Connections

2.6 HOW TO INSTALL THE ULS WINDOWS PRINTER DRIVER

Installation of the ULS Windows Driver will allow Microsoft Windows version 3.1 to interface with the

laser engraving system. This driver is installed the same way as most other Windows printer drivers,

and a simple step-by-step installation procedure is outlined below. Complete understanding of how

Microsoft Windows works is essential to the operation of the laser system. Please consult the

Windows owner's manual on its installation, use, and operation before continuing.

Installation Procedure for the ULS Windows Driver:

1. Start Microsoft Windows, open the Main group in the Program Manager and choose the

Control Panel icon. The Control Panel window should open up.

2. Choose the Printers icon from inside the Control Panel window. The printers dialog box should

appear.

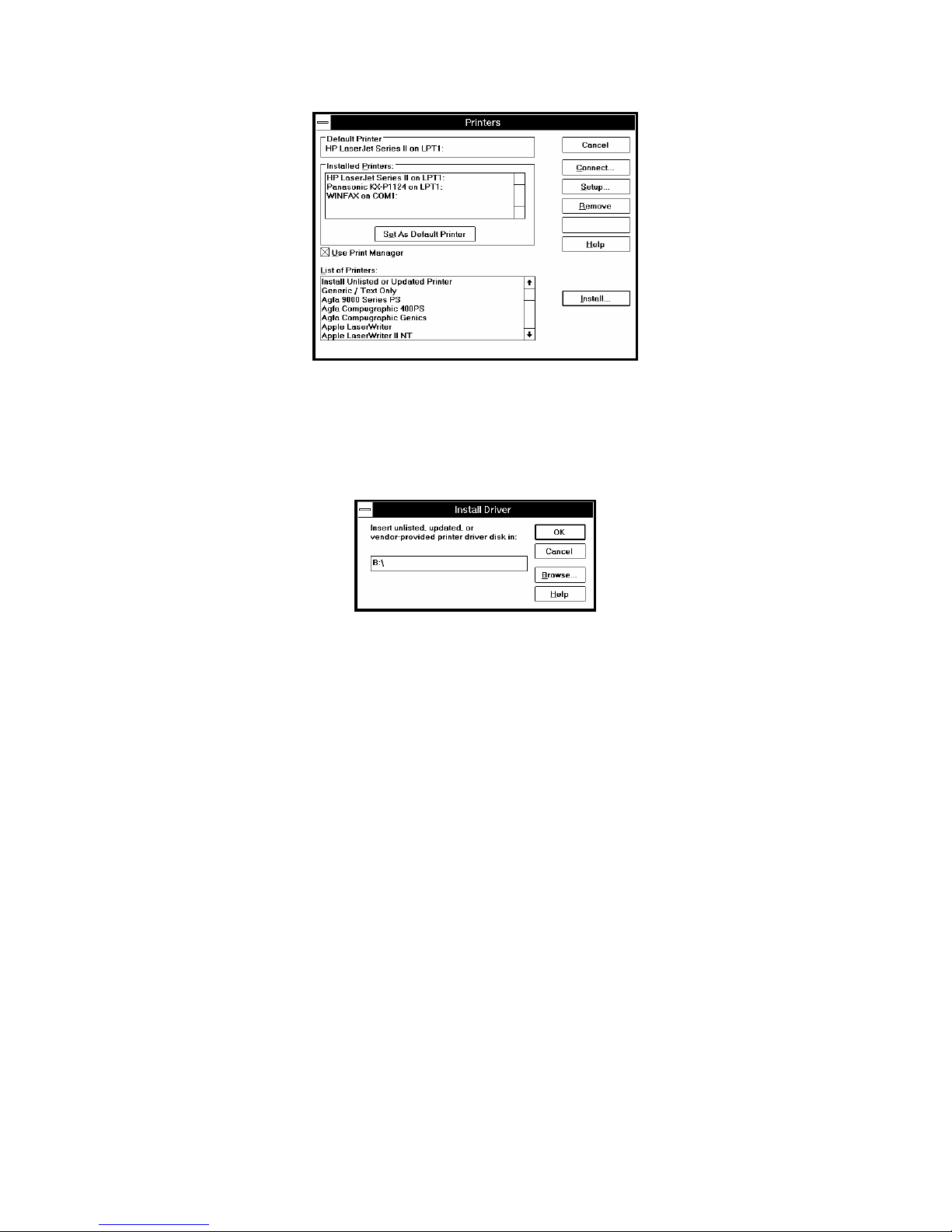

3. Press the Add button. The dialog box should expand to include a list of printer drivers as shown

in the figure below.

16

Page 17

Printers Dialogue Box

4. Select "Install Unlisted or Updated Printer" and press the Install button. The Install Driver

dialogue box should appear as in the figure below asking for the location of the new driver.

Add Unlisted Printers Dialog Box

5. Insert the floppy disk containing the Universal Laser Systems Windows Driver into the

appropriate disk drive and type the letter of that drive in the Install Driver box.

6. Press the OK button. A new dialogue box called "Add Unlisted or Updated Printer" should

appear. Choose the appropriate laser system from the list and press the OK button. The driver

should now install itself and the laser system should appear in the “Installed Printer” dialog box.

7. Highlight the laser system and click on “Connect”. Select the port the laser system is attached to.

NOTE: A check box named “Fast Printing Direct to Port” located on the bottom of the dialog

box should NOT be checked, otherwise file transmission errors can occur. Select OK.

8. Now you MUST click on SETUP to initiate the installation of the driver. The driver settings

screen will now appear. Select OK in the lower right hand corner.

9. Setting the laser system as the default printer and using Print Manager are of personal preference.

At this point, exit the Printers dialogue box and the Control Panel window. Printer driver

installation is now complete. Store the driver disk in a safe place.

17

Page 18

SECTION 3 - SOFTWARE SETUP AND OPERATION

3.1 USING WINDOWS GRAPHICS SOFTWARE

Page Setup

To properly generate and position artwork, most graphics software will permit the customization of the

page size and orientation. Set the page orientation, in the graphics software to Landscape, and the

page size to a horizontal length of 17 inches and vertical length of 11.5 inches. The ULS driver’s

orientation and page size MUST then be set to match these specifications, otherwise the artwork may

not print correctly. When setting page orientation and driver orient ation to Landscape mode, the laser

system will operate in the horizontal direction, left to right. If page orientation and driver orientation is

set to Portrait mode, the laser system will operate in the vertical direction, forwards and backwards.

The laser system is designed to operate best in the Landscape mode and this orientation is highly

recommended. The page size may also be reduced to match the size of the engraving material, but

remember to adjust the page size in the ULS Windows printer driver to correspond to the graphics

software’s page size. Note that in production situations it is often more efficient to leave the page size at

its maximum of 17 x 11.5 inches and engrave or cut more than one object at a time. This is

accomplished by duplicating the image on screen as many times as necessary to fill up the entire page.

Ruler Setup

Usually the graphics software will provide on-screen rulers which can be configured to match the rulers

in the laser system. Using rulers in the software and matching them with the ones provided in the laser

system gives the ability to correctly align the graphic on the screen with the material in the laser system.

The laser system’s origin is fixed in the upper left corner of the engraving area and cannot be altered. It

is necessary to change the ruler position on screen to match the laser system with the origin (0,0) in the

upper left corner.

It is also possible to use a page size smaller than the maximum engraving area. For example, if an 8 x

10 inch page size is desired, set this page size in the graphics software as well as the ULS Windows

printer driver. The laser system will automatically move the engraving area to the origin so place the 8 x

10 inch object all the way up into the left hand corner against the rulers in the laser system.

Power Control Through Color Selection

The laser system allows the use of 8 different colors to access 8 different power settings when cutting

and engraving. This feature is controlled by the ULS Windows printer driver if using Microsoft

Windows. When using this power change feature with the ULS Windows printer

18

Page 19

driver, the colors that are used MUST exactly match the colors listed in the driver. The colors are

black, red, green, yellow, blue, magenta, cyan, and orange. Some programs will provide these

basic colors pre-defined and other programs may require the creation of each of the colors by defining

them in CMYK percentages. If the eight driver colors are not automatically provided in the software,

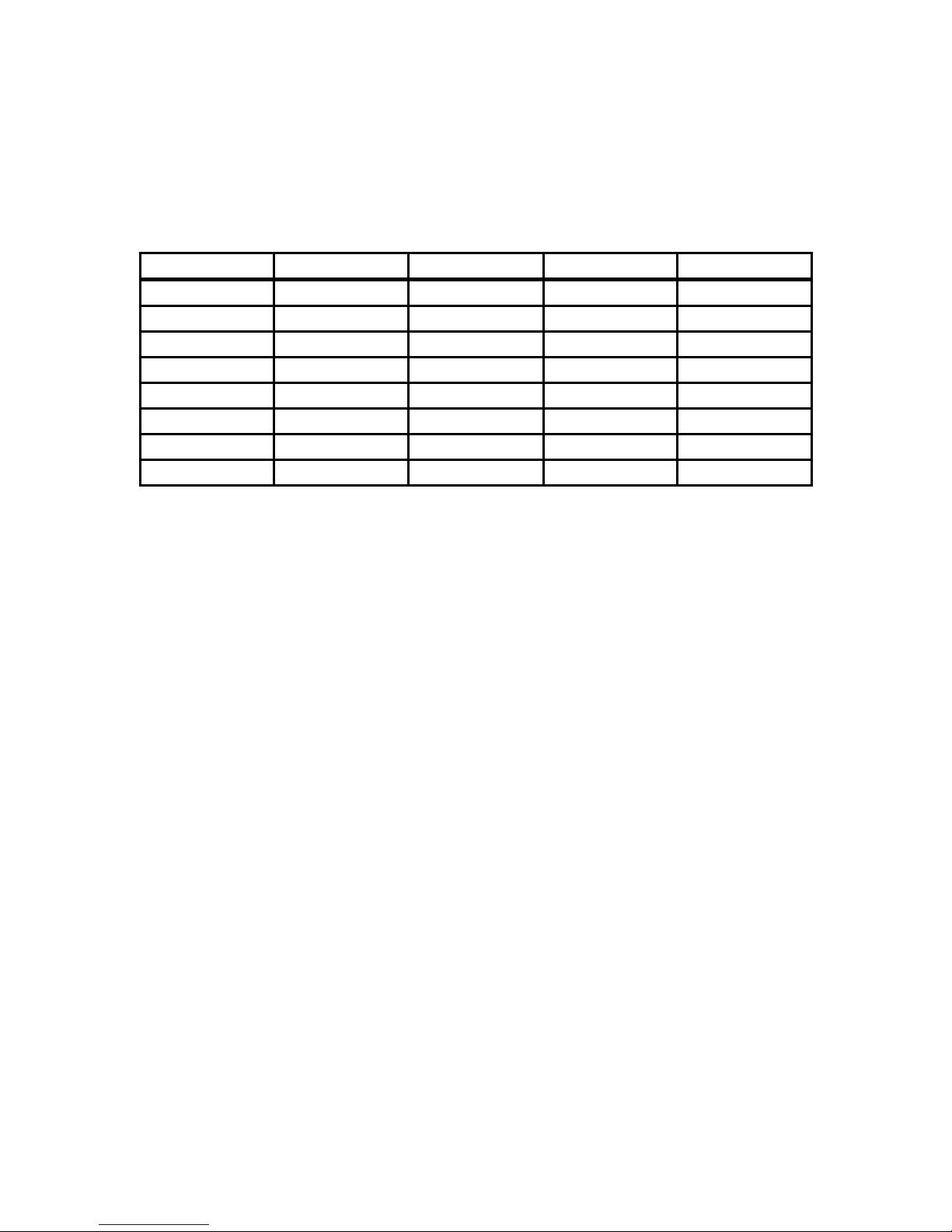

use the chart below to create the eight driver colors by specifying the appropriate CMYK values:

COLOR CYAN MAGENTA YELLOW BLACK

BLACK 0 % 0 % 0 % 100 %

RED 0 % 100 % 100 % 0 %

GREEN 100 % 0 % 100 % 0 %

YELLOW 0 % 0 % 100 % 0 %

BLUE 100 % 100 % 0 % 0 %

MAGENTA 0 % 100 % 0 % 0 %

CYAN 100 % 0 % 0 % 0 %

ORANGE 0 % 60 % 100 % 0 %

If using a color other than the exact colors listed above, the driver will attempt to match it to a color in

the driver that it most closely resembles. The driver will then use that color’s power setting and apply a

halftone pattern to represent the original color’s shade. For example, if using a color like pink to fill a

rectangle, the driver takes a reading of the percentage of different colors used to create that color and

will use the power setting assigned to one of the eight colors of the driver that it most closely resembles.

It might be expected that the driver will use the power setting assigned to the color red but instead the

driver may choose the magenta setting and halftone the rectangle as a representation of the pink color’s

lighter shade. To prevent the incorrect assignment of laser power, be sure to use the right colors. If

using graphics with colors other than the eight listed above or to simplify the assignment of power

settings, try using the B/W Raster feature in the driver. This feature will cause the system to only use

the power setting assigned to the color black and halftone all of the other colors.

Outlines and Fills

The ULS Windows drive r distinguishes between raster mode (engraving) and vector mode (cutting) by

the type of graphic artwork being used. Basically all graphics other than outlines of very thin line widths

will be interpreted as engraved images and the raster mode will be used for output. If laser cutting is

desired, set the line thickness of the lines that are drawn in the graphics software to .001 inches or the

smallest possible line thickness that is available. The printer driver will interpret these objects as vectors

and will cut them out. The use of color fills or bitmaps will cause the laser system to engrave. The

combination of engraving and cutting is available in most Windows graphics software. We suggest that

when combining engraving and cutting objects, use different colors for the fills and outlines since

engraving requires different power settings than cutting objects. One thing to keep in mind when

creating cutting objects is that if the outline thickness is set too thick, the driver might interpret the

outline as a filled object and will engrave the outline instead of cutting. At times this might be desirable if

19

Page 20

engraving thick outlines is desired. The outline thickness at which the driver will interpret cut lines as

filled objects is dependent on the software used. Usually, any line thickness .008 inches or greater will

engrave. The only way to determine the cross over point for line thickness is to experiment with

different line widths. Software programs that do not have outline capabilities will not have the ability to

cut.

Image Processing Order

When cutting or engraving a graphic image, the laser system will perform all engraving first, then

proceed to cutting. Engraving will proceed in the exact order of the colors listed in the driver. For

example, all black filled objects will engrave first, then all red filled objects, then all green filled objects

and so on. When all engraved objects have been completed, the laser system will proceed to cut any

outlines present in the artwork. Unlike engraving, cutting will proceed in the order from which the

outlines are drawn regardless of color. There are several different ways to control the order in which

the outlines are cut. One way is to draw them in the exact order in which they need to be cut, but this

is not always practical. Another way is to select the outline in the graphics software and “send it to the

back," behind the other objects, to cause the outline to be cut first. Bringing the outline “to the front”

will cause that outline to cut last. A final way is to cut and paste each outline in the cutting order

desired. This effectively works the same way as the two previous suggestions.

Overlapping Fills

If the artwork created has overlapping filled areas, the driver will automatically filter these fills to

prevent the overlapped area from being engraved twice. This is similar to color separation in the

printing industry. The entire filled area of the object on top will be engraved and only the visible part of

the underlying filled area will be engraved. The final result is a what-you -see-is-what-you-get output.

In this way the color white can be used as an effective drawing tool. Since the laser system will not

engrave the color white (this is the background color), it can be used to block out the undesired

engraving areas of filled regions and/or bitmaps.

Overlapping Outlines

The ULS Windows printer driver does not filter outlines that overlap each other. If placing one outline

one on top of another, both outlines will be cut by the laser system. This is a useful feature that will

allow deeper cutting by passing the laser over a single outline path twice or more. To take advantage of

this feature, duplicate the outline on top of itself.

20

Page 21

Hidden Vector Lines in Artwork

The ULS Windows printer driver does not automatically filter out outlines that are overlapped by

engraved objects such as fills. If there are filled objects with some hidden outlines underneath the filled

area, the laser system will then engrave out the fill and cut the hidden outline on top of the fill. This is a

common occurrence when using pre-drawn ClipArt designed for laser printers. To prevent this from

happening, turn on the B/W raster feature in the ULS Windows printer driver. This feature disables the

cutting mode and converts all visible outlines to engraved objects and ignores all hidden outlines.

Optimizing Speed

It is advantageous to engrave an object in its longest direction because total engraving time will be

reduced when the motion system has to make fewer stops and starts. If the engraving object is longer

than it is tall, a greater engraving speed can be achieved by rotating the graphic 90 degrees and placing

the material in the laser system sideways. Be aware that some graphics programs do not allow the

rotation of bitmaps. In this case, it may be necessary to use bitmap image processing software to first

rotate the bitmap before importing the bitmap into the graphics program.

If the artwork contains engraved objects of the same color with a great deal of space between them in

the engraving direction, processing time can be longer since the laser must make long strokes to

engrave both objects at the same time. To reduce engraving time in cases like these, use different

colors for each of the objects but assign the same power setting to both colors. This will cause the laser

to engrave one object at a time, skipping over all blank space, which in many cases will reduce

engraving time.

Bitmaps

A Bitmap is a pattern of dots blended to form pictures much like the pictures in a newspaper. Most

bitmaps are created by scanning artwork into a computer through a scanner. Others are created by

drawing them in a bitmap image processing program. There are essentially two types of bitmaps that

the laser system can utilize, monochrome and grayscale bitmaps. Monochrome bitmaps are one bit

black and white images and grayscale bitmaps are 8 bit images. There is no advantage to scanning in or

using color bitmaps because the ULS Windows Printer Driver converts color bitmaps into grayscale

halftone patterns when printing. Color bitmaps consume a large amount of memory and are therefore

NOT recommended. Monochrome bitmaps are used when scanning and engraving line art or camera

ready black and white images. Grayscale bitmaps are used for scanning and engraving photographs.

21

Page 22

When scanning black and white images, scan at the highest DPI that the scanner allows. The higher the

DPI, the smoother the image will be. Scanning in at 300 DPI is the minimum recommended resolution

for scanning line art (monochrome bitmaps), but 600 DPI provides a significant improvement in the

image quality. Grayscale bitmaps usually should be scanned in at no more than 300 DPI. Scanning

them in at a higher DPI does not effectively improve image quality and consumes large amounts of

memory. As a rule of thumb, scan photographs at 300 DPI and line art images at 600 DPI. Feel free

to experiment with different scanning resolutions and note the results.

There are several different bitmap formats available: TIF, BMP, PCX, and others. The format

makes no difference to the laser system. The difference in formats involves how they are stored on the

computer’s hard disk. Bitmaps cannot be edited in most graphics software. Some basic functions such

as cropping, scaling, or mirroring might be possible but it is usually necessary to use an image

processing software to perform a dot by dot editing or rotation of the bitmap.

Bitmap images cannot be cut by the laser system only engraved. The only way to have the laser system

cut out a bitmap is to first convert it to a vector file format such as an EPS. Raster to vector conversion

programs are available that trace the bitmap (this only works well with monochrome bitmaps) and

creates a separate EPS vector file. These EPS files can then be imported into the graphics program and

printed out from there. Since tracing programs have many adjustments, some practice with them is

necessary to produce desirable results.

Postscript Files

The laser system does not support Encapsulated Post Script (EPS) printing directly. EPS files can only

be edited and printed if they are first imported into a graphics program. However, since EPS files do

support engraving and cutting objects, they are therefore useful for transferring artwork from one

graphics program to another. Once an EPS file has been imported into a graphics program, the objects

can be outlined, stretched, rotated, mirrored, filled with different colors, or anything else desired. Be

careful when using EPS files in layout software as opposed to true graphics software. Layout software

may allow the placement of EPS files in the artwork but may not actually import and convert the EPS

file to a useful format for the ULS Windows printer driver. The ULS laser system is not a postscript

device. This means that postscript fills, postscript textures, and postscript fonts will not be able to print

to the laser system.

22

Page 23

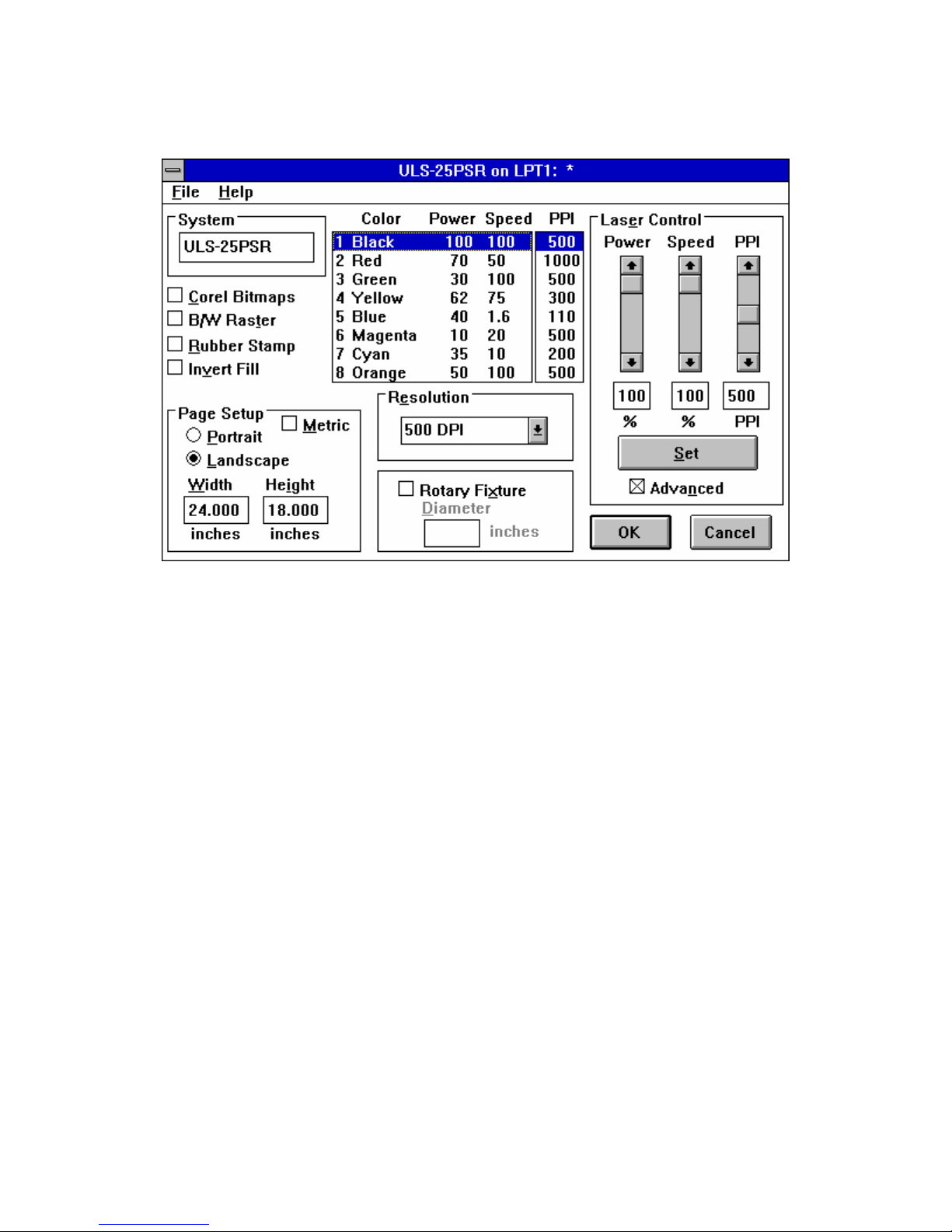

3.2 THE ULS WINDOWS PRINTER DRIVER

The ULS Windows Printer Driver

NOTE: When the following sections refer to turning a switch ON, this means putting an "X" in the

box next to the driver selection desired. Turning a switch OFF signifies removing the "X" from the box.

To change the POWER, SPEED, and PPI of a color, position the mouse arrow on the color and

click once with the left mouse button. This will highlight the color and allow changing of the settings by

using the scroll bars or highlighting out and typing in each setting. It is possible to set one color at a time

or click on additional colors to set more than one at a time.

POWER SETTING

Laser power is controlled by assigning the percentage of power from 0 - 100% to each color used in

the graphic drawing. Since the laser is proportionally pulsed, this percentage represents how long the

laser remains on for each laser pulse fired. Basically, the power setting is directly related to how deep

the engraving will be.

23

Page 24

SPEED SETTING

This setting controls how fast the motion system moves in a percentage of the maximum speed of the

system. For example, 100% SPEED is equivalent to 16.5 inches per second straight line velocity.

Therefore, 10% SPEED is equal to 1.65 inches per second. When engraving, this is the rate in which

the motion system moves back and forth. When cutting, this is the speed of the straight lines. If cutting

curves or circles, the motion system automatically slows down. For example, there is no speed

difference when cutting a circle at 50% or 100% SPEED because curves will run slower than straight

lines even if it is set to 100%. Proportional pulsing of the laser will ensure that there is no difference in

the depth of cut from straight lines to curves. Power and speed work together in determining how deep

the engraving will be. Higher power settings and slower speeds will produce deeper engraving.

PPI

PPI stands for laser pulses per inch. This setting determines how many laser pulses, per linear inch,

the laser system will fire. Again, since the laser system is proportionally pulsed, all pulses will fire

equally spaced from one to the next regardless of changes in SPEED, POWER, acceleration,

deceleration, or the cutting of curves. For example, when setting the PPI to 500 and using a standard

lens that has a laser spot size of seven thousandths of an inch, significant pulse overlap will occur. The

laser system fires a laser pulse and moves over two thousandths of an inch (that is 1 inch divided by

500). It then fires the next pulse and so on, overlapping the pulses significantly. Lines are formed by

pulsing the laser pulses so close together and slightly overlapping each other that it appears to be a

continuous line. Dot matrix printers work the same way except the laser system uses laser pulses

instead of ink dots. When engraving, it is advisable to use a PPI setting of 500 or higher. If using less,

the image resolution of the engraving is reduced. For cutting, a PPI of 150 and above can be used.

Using less than 150 will result in the pulses being spread so far apart that they will not touch one

another. This is a good example on how to perforate paper. Increasing or decreasing the PPI setting

has absolutely no effect on engraving speed. The laser must either fire more quickly or slowly.

Experiment with using different PPI settings on some scrap material when cutting or engraving and note

the results.

SET

This button must be pressed after adjusting the POWER, SPEED, and PPI settings in order for these

changes to take effect. If forgetting to click on SET, and clicking on the OK button instead, the

settings will go back to the previous ones and will engrave the object with the incorrect settings.

24

Page 25

ADVANCED

Turning this switch ON will permit the changing of the PPI settings. If the switch is turned OFF, the

word AUTO will appear in the PPI column and will be colored gray. Since 500 PPI is the setting that

is used most often, AUTO sets the PPI to 500 automatically and does not allow change unless the

ADVANCED switch is turned back ON.

RESOLUTION

This setting is the image resolution of the engraving in DPI or dots per inch. There are six DPI settings

to choose from: 500, 250, 250 x 166, and DRAFT. The resolution can also be referred to as

horizontal lines per inch or fill spacing. This is how many raster strokes per vertical inch of travel that

the motion system steps down to produce an engraving. Higher resolutions will produce cleaner and

deeper engraving but take longer to engrave. Lower resolutions produce a coarser and shallower image

but are quicker to engrave. Experiment with the different settings and note the results.

COREL BITMAPS

This switch is for CorelDraw! users ONLY. Turn this switch ON only when there is an imported

monochrome or grayscale bitmap in CorelDraw!. If printing any drawing that has a bitmap in it and

forgetting to turn this switch ON, everything else except the bitmap will print. If the bitmap does not

engrave, go back and turn the switch ON, select the bit map only, and print Selected Objects Only in

the software. Make sure to leave this switch OFF if there is no bitmap present. This switch should

remain OFF if using software other than CorelDraw!.

B/W RASTER

This switch simulates laser printer output and is very useful if using a drawing with many colors, shades

of gray, or many outlines. It is recommended to turn this switch ON when using ClipArt because there

may be some underlying cutting lines hiding behind some filled areas. Having this switch ON gives a

what-you -see-is-what-you-get output very similar to laser printer output. The entire drawing will be

engraved, including all outlines, and only one power level will be used which is black. The color

change ability of the driver is essentially turned off and all colors are engraved as different shades of

gray. The laser system represents different shades of gray by producing a halftone pattern when

engraving. Since ClipArt images use a wide variety of colors, shades, and outlines, the only effective

way of engraving these images is to have this switch turned ON. B/W raster mode also provides

greater compatibility with Windows software that do not work well with vector devices such as the

ULS laser system. Call or fax our technical support if there seems to be a compatibility problem with a

particular software program.

25

Page 26

In order to engrave photographs and ClipArt that use colors and greyscales for shading, a halftone

pattern must be created. A halftone is a series of dots arranged in a specific pattern. By varying the

size and intensity of these dots, shading can be simulated in a process that is similar to that used to

generate newspaper photographs. This same process is also used by black and white laser printers.

There are two ways in which a halftone pattern can be generated. If printing directly from an image

processing software, the halftone pattern can be assigned to the photograph or greyscaled scanned

image before printing to the laser system. Sometimes this is referred to as setting the screen for printing.

The other way is to let the ULS printer driver apply the halftone screen. The ULS printer driver

automatically uses a 90 line per inch, 45 degree, round shaped halftone pattern if the RESOLUTION

is set to 500. A 45 line per inch, 45 degree, round shaped halftone pattern is automatically used if the

RESOLUTION is set to 250. If the imaging software being used is capable of producing its own

halftone patterns, the characteristics of the pattern will need to be specified. Refer to the imaging

software for more details about the direct printing of halftone patterns.

SOFTWARE OVERRIDE

Leave this switch turned ON at all times if planning to control the power through the Windows driver. If

the switch is turned OFF, the power settings must then be manually input at the laser system.

PAGE SETUP AND ORIENTATION

Input here lets the ULS Windows printer driver know what page size and orientation is being used in the

graphics software. These settings MUST match the gr aphics software settings EXACTLY otherwise

no output, partial output, or misalignment of the graphic will occur. It is up to the operator to enter in

the correct settings. Not only must the page size be EXACT, but the orientation must be the same

also. Maximum page size is 17 inch width by 11.5 inch height in the Landscape mode. Select the

Metric box if metric units are desired.

ROTARY FIXTURE

It is only necessary to use this selection if the optional Rotary Fixture has been purchased. For full

details on how to use this option, please refer to section 4.6. Do not skip over to that section until the

rest of this manual, up to that section, has been read. There is important information about the

operation of the laser system that must be read before being able to fully understand and operate the

Rotary Fixture.

26

Page 27

RUBBER STAMP and INVERT FILL

These two selections will only appear in the driver if the Rubber Stamp option has been purchased. For

a full explanation on how to use this option, refer to section 4.7. Again, please read the rest of this

manual up to that point before attempting to use this option. A full understanding of how the laser

system works is essential to producing correct results.

FILE

A unique feature of the driver is being able to store the power settings that are currently on screen. By

selecting FILE and then SAVE SETUP FILE, all settings will be stored in a file that can be named as

desired. The file extension, however, must remain as .LAS for the driver to recognize this file as a

setup file. These files can be stored in any directory and may be retrieved by selecting FILE and then

LOAD SETUP FILE.

The LASER.INI file can be thought of as being a file that stores the current power settings when the

OK button is pressed. This gives the driver the ability to restore these settings every time the driver is

accessed. Without this file, The power settings would have to be entered in every time the graphic is

sent to print. Selecting FILE then LOAD LASER.INI SETTINGS will restore the settings that were

saved the last time the OK button in the driver was pressed. Once the OK button is selected, the

current power settings will be stored in the LASER.INI file and the original ones will be erased.

HELP

Select this option to access HELP on the use of the ULS Windows printer driver. Selecting HELP

and then ABOUT will display the current driver version number and our copyright notice.

27

Page 28

3.3 USING DOS BASED PROGRAMS

When using DOS based programs, there are a few things to keep in mind. DOS software is not

standardized and each application will work differently. When using DOS applications, it is not

possible to print through the ULS Windows printer driver and for this situation, the system has been

designed to automatically emulate a Hewlett Packard plotter. Plotters use a special language called

HPGL which the laser system has been designed to accept. When configuring the DOS based

program, select the HP7475 plotter as the printing device. Set the maximum paper size to 17 inches

wide by 11.5 inches tall (refer to the DOS software manual for how to configure the printing device).

Once configured properly, the laser system should interface with the program very nicely and act just

like a plotter. The following are a few points to remember when printing from DOS based programs.

1. Some DOS programs will not allow the page size to be set at 17 x 11.5 inches in the Landscape

mode. If this is not possible, the full engraving field cannot be utilized. If a smaller page size is

used, determine where the program will place the graphic on the engraving table by running a few

tests to see where the laser system will output.

2. Some DOS programs use the lower left corner of the engraving field as the origin so remember this

when setting up the graphic drawing.

3. When assigning power settings to the graphic, it will be necessary to assign an HPGL plotter pen to

the different colors in which the graphic was drawn. In most cases the pen numbers should match

the power setting numbers in the laser systems POWER SETTINGS display.

4. Some DOS programs may allow the setting of pen speed for the different plotter pens. These

speeds will be ignored by the laser system so do not be concerned with making those settings in the

software. The only place that the settings can be made is in the POWER SETTINGS display

section of the laser systems control panel.

5. After every file download, an END-OF-FILE marker must be inserted at the laser system so that

the buffer control will work properly.

6. Power setting for plotter pens can only be done at the laser system itself through the main control

panel display. Section 4.2 of this manual will explain how to set the POWER, SPEED, and PPI

settings for plotter pens. It will also describe how to insert an END-OF FILE marker and why it is

necessary after every file download. Please refer to that section for more explicit details. If having

trouble with using DOS based programs, please contact our technical support.

28

Page 29

SECTION 4 - LASER SYSTEM OPERATION

4.1 GENERAL SYSTEM OVERVIEW

1. Top Door 9. Front Door

2. Top Door Window 10. Interlock Defeat Tool Socket

3. Top Door Counterbalances 11 Air Intake Filter

4. Engraving Table Adjustment Knob 12. Parallel and Serial Connectors, On/Off

5. Focus Lens Holder Assembly Switch, Power Cord Inlet

6. Motion System Y-Axis Arm 13. Main Control Panel

7. Engraving Table 14. Motion System Control Panel

8. Exhaust 15. Motion System Protective Overhang

29

Page 30

4.2 THE MAIN CONTROL PANEL

The main control panel on the ULS laser engraving system provides easy access to all of the controls

necessary for cutting and engraving operations. The control panel consists of a liquid crystal display

(LCD), indicator lights, buttons, and a laser ON/OFF switch. The control panel is divided into three

sections: Menu System and Controls, Process Controls and Laser ON/OFF controls.

The four keys surrounding the liquid crystal display give complete access to the menu system. Use the

up and down arrow keys to move the cursor up or down through the items on the display and press the

SELECT key to choose an item. Some items on the display lead to other menus and some are settings

that can be adjusted. After positioning the cursor on the desired item, press the SELECT key to

access that item. The ESCAPE key allows backing up through the menu system to the main menu.

The ESCAPE and SELECT buttons also function for changing a setting. The SELECT key accepts

and stores the change and the ESCAPE key exits without changing the setting.

The green READY indicator light serves two purposes. It will illuminate to indicate when a job is

completed and the system is ready to begin a new job, and if the PAUSE key is pressed, it will blink

to indicate that the system is paused. When the laser is first powered on, the green light will blink until a

job is run for the first time.

The red BEAM indicator light will illuminate when the laser is being pulsed. This provides a visual cue

that the laser is firing. (NOTE: This indicator light actually signals that the main control board is sending

pulses to the laser, so the light will continue to blink even if the power to the laser is turned off.)

30

Page 31

The Menu system

All of the features built into the laser cutting and engraving system can be accessed and controlled

through the menu system. The menu system is divided into four general areas each of which is accessed

through the main menu. The main menu will display when the system is turned on. To access the

submenus of the menu system from the main menu, select it with the cursor (move the cursor with the

arrow keys) and press SELECT.

The OPERATION DISPLAY submenu

Then

This is the OPERATIONS DISPLAY submenu which will probably remain on most of the time during

normal operation. It has been designed to show all pertinent operating information at a glance so that

constantly jumping from menu to menu is not needed. The first line indicates that the laser system’s print

buffer is empty, but when the buffer is loaded with files, this line will display the currently selected file.

To move to the next file in the buffer press the NEXT FILE button. Page through the list of files

available in the buffer by placing the cursor on the first line of this display and pressing the SELECT

button. The up and down arrow keys can then be used to move through the list of files in the buffer.

When the desired file is found, simply press the SELECT key to make that file the current file. This

will move the cursor back to the left hand side of the display. To run the currently selected file simply

press the RUN FILE button. Changing the current file is not possible while running the laser system.

No other items in this submenu can be selected or changed.

31

Page 32

The # OF COPIES feature on the second line indicates the number of times the current file has been

used since it was loaded into the buffer (the system keeps a running count of the number of times each

file in the buffer has been processed). The second line also contains a timer to time files as they are run

(this is useful for costing jobs). The timer will pause when the PAUSE key is pressed and starts up

again when cutting or engraving has been resumed.

The last two lines show the power setting last used by the laser system. BLACK indicates the current

power setting color used for all of the portions of the computer artwork which are colored black,

SPEED indicates the speed of the motion system, POWER indicates the power output of the laser

and the PPI setting indicates the laser’s pulse rate (in this case 500 laser pulses per inch). The

OPERATIONS DISPLAY mode is the part of the menu system that is used most often. In this mode,

the file name will be displayed as well as the current power setting that the laser system is processing.

When the laser system is first powered on and this submenu is selected, there will be an initial power

setting displayed. Even after the first file is downloaded and the name of the file appears on the display,

the power setting will still be unchanged. Please ignore these settings. Only until the file is run will the

display show the correct power setting that was entered in the ULS Windows printer driver when the

file was sent to print.

The POWER SETTINGS submenu

Then

This submenu serves several purposes. The first purpose is to display the current power settings the

laser system is using while it is running a job. This is very similar to the OPERATIONS DISPLAY

submenu except that the name of the file running is not shown. Secondly, it is possible to change these

settings while the laser system is running which is very useful for testing purposes. To adjust these

settings, press the up or down arrow key until the cursor is on the desired selection. Press the

SELECT key which moves the cursor to the right and then use the arrow keys to increase or decrease

the values. Pressing the SELECT key again will accept the change and pressing the ESCAPE key will

32

Page 33

restore it to the original setting. It is possible to adjust the settings while engraving on some scrap

material until the desired POWER, SPEED, and PPI settings are obtained. Note these settings,

change them in the ULS Windows printer driver and resend the file to the laser system for the final run.

Lastly, the laser system allows eight different power settings to be saved in memory and used when

processing a DOS based file. Since a DOS based printer driver is not available, the 8 power settings

must be set manually on the laser system. Think of it as being able to assign laser POWER, SPEED,

and PPI to the pens on a flatbed plotter. This is not necessary when using Windows since all settings

can be set in the driver.

To access the power settings, press the SELECT key when the cursor is on POWER SETTINGS,

then use the up and down arrow keys to scroll through settings 1 through 8. When the desired power

setting number is found, press the SELECT key again to bring the cursor over to the left hand side of

the display, and proceed to make the adjustments as previously described. If setting the PPI higher

than 1000, the laser system will display the word “CONTINUOUS”. This mode is used for

maintenance procedures and is not used under normal operation.

NOTE: Do not use power setting #WIN because this power setting is used by the ULS Windows

printer driver to temporarily store information during operation, and any settings stored

there will be lost.

The BUFFER CONTROL submenu

The laser engraving system comes equipped with a built in 4 megabyte memory buffer which is

expandable to 16 megabytes. The buffer has built in file handling intelligence enabling each individual file

in the buffer to be run in any order. The files are stored sequentially based on the order in which they

were transferred from the computer and each one is assigned a number to help for tracking. A running

total of the free space left in the buffer is provided at the bottom of the display. A small amount of

memory is used by the system so there will never be a full 4 megabytes free. The file name displayed on

Then

33

Page 34

the screen is always the currently active file and there are two methods for looking through the list of

files and choosing another file. The first method is to press the NEXT FILE button on the control

panel. Each time the NEXT FILE button is pressed, the next file in the buffer becomes the current file.

The second method is to point the screen cursor at the file name and press the SELECT key which will

move the cursor to the right, then us e the arrow keys to move backward or forward through the list

until the file desired is displayed and then press the SELECT key again.

Eventually the buffer will fill up with files that will need to be removed from memory. It is possible to

select each individual file and delete them one at a time. To accomplish this, make the desired file for

deletion the current file in the same manner as previously described, then select the DELETE THE

FILE option from the menu. To do this, use the up or down arrow keys until the cursor is pointing to

that menu choice and then press the SELECT key. The display will then ask if you are sure and will

expect a cancel or a yes response. To completely clear out the entire buffer all at once, bring the

cursor down to the BUFFER SPACE option and press SELECT. The laser system will again ask if

you are sure so respond accordingly.

Since the laser system is equipped with a unique way of storing multiple files in memory, special

provisions are made to distinguish one file from the next. When using the ULS Windows printer driver,

an end -of -file(EOF) marker is automatically sent to the laser system after each file is downloaded. An

end-of -file marker is needed by the buffer in order for it to recognize the end of one file, the beginning

of the next file, and to calculate the remaining free buffer space. Without an EOF, the buffer will not

operate properly.

There are two ways that a downloaded file will have a missing EOF. The first is if printing through the

ULS Windows printer driver and printing is canceled, interrupted, or file size exceeds the remaining

free buffer space. When this occurs, chances are that the EOF never made it to the buffer and the

buffer will show that it is empty or that the file does not exist. If this happens, part of the file might still

remain in the buffer and that part might become mixed up with other files. This is when having an

INSERT-END-OF-FILE option becomes important. In order to delete that partial file, the buffer

must either be cleared entirely or an EOF must be manually inserted into the buffer by simply bringing

the cursor down to the appropriate menu choice and pressing SELECT. This provides an alternative to

clearing out the entire buffer by inserting the EOF marker at the end of the unwanted file fragment.

Next, press the NEXT FILE button and this fragment will then show up on the display as NONAME

and will allow its solitary deletion without having to delete the other files in the buffer.

Secondly, when using DOS based programs, a printer driver other than the ULS Windows printer

driver must be used. That driver does not know to send down to the laser system the required EOF

marker at the end of file downloading. Again, the buffer will not recognize that the file exists because it

does not see the end of it. In this case, an EOF must be manually entered into the buffer after each and

every file download from a DOS based program. Since the file name is not sent to the laser system by

a DOS based printer driver, every file will be called NONAME. To distinguish one NONAME file

from the next, the display will number the files in the order from which they were downloaded.

34

Page 35

The SETUP submenu

The SETUP menu choice allows laser system reconfiguration. Selecting this option will lead to other

menu choices.

Then

TICKLE is the term used for small pulses which are fed to the laser to keep the plasma inside

energized. This allows the laser to respond quickly for high speed cutting and engraving. The tickle is

preset at the factory and usually will not require adjusting. However as the laser ages it may become

necessary to change these settings to maintain peak performance.

WARNING:

Do not attempt to adjust the TICKLE setting. Consult the ULS technical staff first to

determine whether it is necessary.

35

Page 36

The CONFIGURATION selection allows the reconfiguration of certain features of the engraving

system. Selecting this option will lead to other menu choices.

AUTO POWER and BUZZER menu options can be toggled either ON or OFF by placing the cursor

on the appropriate menu choice and pressing SELECT. The AUTO POWER feature allows the laser

system to change power settings while it is cutting and engraving a file. If this feature is ON (the default

setting), the power settings will change in response to different colors used in the artwork (or in the

case of DOS applications different pen numbers assigned to the artwork) as described earlier in the

section on the power settings display. If this feature is turned OFF, the system will use the current

power setting selected in the POWER SETTINGS menu and no power changes will take place.

The BUZZER option emits a sound to indicate when a file has finished running and may be turned

OFF.

36

Page 37

Two ports are provided on the right side of the system for interface with a computer, a serial and a

parallel port. Only one port can be used at a time. To activate a port, select PORTS from this menu

and one of the following sub menus will appear:

or

The menu that appears indicates the currently active port on the laser system. To switch to the other

port press the SELECT key. In order to use the SERIAL port the communication settings MUST

match those of the computer. Refer to the computer’s hardware and software manuals for details on

setting up the computer’s serial port.

If using the SERIAL port, select the fastest possible BAUD rate for communication since this effects

how quickly the computer can send file s to the laser system. For BAUD rates of 9600 and above, set

the number of STOP BITS on the computer to a higher value than the number of STOP BITS selected

on the laser engraving machine. For example if the number of STOP BITS on the laser engraving

system is set to 1, then set the computer’s stop bits to 1.5 or 2.

PARITY of the laser system and the computer MUST match exactly and the choices are ODD,

EVEN, or NONE. Pressing the SELECT key while the cursor is on PARITY will toggle through

these choices.

37

Page 38

The LOAD DEFAULTS selection on the last line returns the system to its factory default settings.

WARNING:

Do not select the LOAD DEFAULTS menu selection without first consulting a ULS

technical support representative.

The DIAGNOSTICS selection allows the testing of certain features of the engraving system. Selecting

this option will lead to other submenus.

It may be necessary to use the diagnostic tests if instructed to do so by a member of the ULS technical

support staff. The first line on the menu display is a buffer memory test but in the process of testing

memory all files in the buffer will be erased. Once the memory test is started it will continue to run until

it is canceled. The second line displays the current position of the motion system in motion system units.

Each unit represents a single step of the motion system motors. The final two lines are a copyright

notice.

38

Page 39

By selecting RETAIN SETTINGS, any and all changes made to the display settings will be

permanently stored even if power is turned off to the laser system. Those settings will be retained in the

laser system until they are changed and RETAIN SETTINGS is selected again.

THE PROCESS CONTROLS

RUN

FILE

RUN FILE

Press the RUN FILE button to start cutting or engraving the current file in the system buffer. Do not

press the RUN FILE button while the system is cutting or engraving a file; either pause the system or

wait until it has completed the job.

and

RESUME

PAUSE

PAUSE AND RESUME

The PAUSE button can be pressed while the system is cutting or engraving a file to pause all

operations. When paused, the motion system arm will move to its home position under the protective

overhang. When ready to resume operation, press the RESUME key and the system will begin

cutting or engraving again where it left off. The READY indicator light will blink when the system is

paused.

NEXT

NEXT FILE

FILE

Pressing the NEXT FILE button brings up the next file in the system buffer and makes it the current file.

Pressing the RUN FILE button starts cutting or engraving of the file. (Do not press the NEXT FILE

button while the system is cutting or engraving a file; either pause the system or wait until it has

completed the job.)

39

Page 40

THE LASER CONTROLS

The LASER ON/OFF switch allows the laser’s power to be turned on and off

manually for emergencies. The red indicator light will light up when power is being

supplied to the laser. The indicator light is also tied in with the safety interlock

system, so the light will go on and off as the doors to the system are opened and

closed.

4.3 MOTION SYSTEM CONTROLS

The motion system control panel, accessed when the top door is open, allows the positioning of the

motion system in order to use the focusing tool. The functions of the keys are described below.

POSITIONING KEYS

Use these keys to move the motion system in the indicated direction. Pressing two adjacent keys

together moves the focus lens carriage in a diagonal direction.

FAST

FAST KEY

Pressing this key together with an arrow POSITIONING key increases the speed at which the motion

system moves.

REFERENCE POINT KEYS - P1 AND P

P

2

P

1

2

Press the P1 or P2 key to move the motion system to the lower left or upper right corners of the

engraving area, respectively.

AUX KEY

AUX

This key is currently not in use.

TEST KEY

TEST

This key turns the laser beam on and off. This key is used for maintenance procedures only and is not

operational without the use of the interlock defeat tool.

40

Page 41

4.4 LOADING AND FOCUSING THE LASER SYSTEM

Loading materials

The first step to laser engraving is loading the material and focusing the laser beam on the top surface.

Let’s use a 4 x 6 inch wooden plaque as an example. Open the top door and place the wood on the

engraving table. Rotate the wood so that the longest direction is in the horizontal direction. Slide the

wood into the upper left hand corner of the engraving table against the horizontal and vertical rulers.

Materials larger than 17 x 11.5 inches can be processed provided they fit into the machine and allow all

the doors to be closed properly. Space is provided within the system for material to hang over the right

edge of the engraving table and pieces of up to 30 inches in length can easily be processed. If you have

an application of this type, load the material through the front door of the system. However, all the

doors must be able to close before cutting and engraving. Do not attempt to defeat the interlock system

in order to process materials too large to fit into the system as this could result in exposure to laser

radiation.

To process more than one piece of material at a time, such as in a production application, a template

can be easily made to help in loading the system. To ma ke a template draw a slightly oversized outline

of the material to be processed and duplicate it as many times as will fit into the 11.5 x 17 inch field.

Place a piece of 11.5 x 17 inch material such as paper, acrylic, or cardboard on the engraving table

and cut the outlines into the material. Position the engraving objects within the template outlines. Now

position the graphics on screen so that they are aligned within the template outlines. Finally, print only

the graphics and not the outlines to the laser system. A convenient template has now been made for

quickly loading the system.

Focusing the laser beam

In order to cut and engrave with precision the laser beam in the laser engraving system is focused to a

small spot by the focus lens. This focused beam is 2.5 inches below the lens (for the standard lens

provided with the system).

1. Turn the laser system on and move the motion system using the arrow keys on the motion system

control panel until the focus lens holder assembly is positioned over the plaque.

2. Move the engraving table up or down by turning the engraving table adjustment knob until the

base of the focusing tool can be placed on the top surface of the material to be processed and the

flat of the focusing tool can be placed flat against the side of the lens holder as in the diagram

below.

41

Page 42

3. Observe the top of the focusing tool. Now raise the engraving table until the focusing tool just

starts to tilt away from the lens holder as shown in the diagram below. Back the engraving table

down again slightly so the focusing tool again sets flat against the side of the lens holder. The point

in which the focusing tool just starts to tilt away is the optimal focus distance.

NOTE: The focal length of the optional high resolution focus lens is 1.5 inches. A high resolution

focus tool must be used with this lens.

MOTION SYSTEM ARM

(FRONT VIEW)

LENS HOLDER

FOCUSING TOOL TILTED

FOCUSING TOOL

(TILT EXAGERATED)

MATERIAL SURFACE

42

Page 43

4.5 RUNNING A SAMPLE

The following outline is a step by step procedure used to produce a laser engraved object. Please

follow this procedure to understand the steps necessary for laser engraving.

STEP 1 Turn on the computer and then the laser system. Be sure to turn the equipment on in this

order.

STEP 2 Load the object that will be engraved into the laser system and position it in the desired

location in the engraving area. Usually, the object is placed up against the rulers in the

upper left hand corner of the engraving area. Use the rulers to determine the size of the

engraving object. Use either the top door or the front door for loading.

STEP 3 By using the motion system control keys, position the focus lens assembly over the

engraving material. Adjust focus by using the focusing tool and adjusting the height of the

engraving table.

STEP 4 Create a graphic using the graphics software program and position the graphic on screen so

that it matches the placement of the object in the laser system.

STEP 5 Before printing, go to the ULS Windows printer driver and assign the power settings. If

using DOS based programs, go to the laser system and enter in the power settings on the

main control panel.

STEP 6 Now send the file down to the laser system.

STEP 7 Turn on the exhaust blower.

STEP 8 Finally, when the file is in the laser system’s buffer, press the RUN FILE button to start

engraving.

STEP 9 While the laser system is running, start setting up the next job.

43

Page 44

4.6 USING THE OPTIONAL ROTARY FIXTURE

The Rotary Fixture controls in the ULS Windows printer driver are used along with the optional Rotary

Fixture to engrave onto round or cylindrical objects. In order to compensate for different diameter

objects, the image must be adjusted. This is done automatically by the ULS Windows printer driver

when selecting Rotary Fixture and entering in the diameter of the object being engraved.

The rotary fixture allows the engraving of cylindrical work pieces up to 4.75 inches in diameter (5.75

inches with the high resolution lens attached) and up to 12.5 inches long. Two attachments come with

the fixture, a cone shaped disk attached to the motorized end of the fixture and a flat disk with foam

padding attached to the adjustable end of the fixture. These attachments are designed to hold wine

glasses, mugs, cups, etc. The following is a step by step procedure in the installation and operation of

the Rotary Fixture. We are going to use a glass as an example.

Installation of the Rotary Fixture

1. Turn the laser system OFF. Open the top door of the laser engraving system and place the

Rotary Fixture on the engraving table with the black box on the Rotary Fixture to the right.

2. Attach the Rotary Fixture to the engraving table by sliding the U shaped pivot block clamps onto

the engraving plate. Before tightening the thumbscrews, slide the fixture towards the top of the

engraving area as close to the top ruler as possible. Position the fixture so that it is squarely

aligned with the rulers. Being square to the rulers will ensure that the fixture is square to the

engraving area. The rulers also provide a visual guide as to where to locate the graphic in the

graphics software. From underneath the plate tighten the thumbscrew clamps so that the fixture is

secured to the engraving table.

44

Page 45

3. Connect the Rotary Fixture control cable to the connector on the laser engraving system. To find