Page 1

STENCILING & MARKING SYSTEMS

OWNER’S MANUAL

NON-POROUS

CONVEYOR LINE PRINTERS

ALL MODELS

INSTALLATION - OPERATION - MAINTENANCE

UNIVERSAL STENCILING & MARKING SYSTEMS, INC.

P.O. BOX 871 - ST. PETERSBURG, FLORIDA 33731 USA

PH: (727) 894-3027 FAX: (727) 821-7944

E-Mail: sales@universal-marking.com Website: www.universal-marking.com

NPCLP-07002

1

Page 2

IMPORTANT NOTE

UNIVERSAL products are manufactured to exacting standards and every available step has been taken to assure your

complete satisfaction. It is most important, however, that the instructions contained in this manual are read and carefully

followed for best results. Failure to do so may result in unsatisfactory performance, damage to the equipment and personal

injury.

PREFACE

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

SPECIFICATIONS

CLP-100 Series

CLP-200 Series

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Indexing and Non-Indexing Models

Mounting Configurations

Printing Dies

Ink Rolls

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

QUICK START

Installing the Inking System Assembly

Installing the Pre-Inked Roll

Installing the Printing Dies

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Adjusting the Ink Roll Eccentric

BASIC PRINCIPLES OF OPERATION

Inking System

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Using the 4 Oz. Reservoir Ink Cartridges

Selecting an Appropriate Ink

Ink Drying Time Considerations

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3

4

5

6

6

7

8

9

10

14

15

16

16

17

18

WEB PRINTING

Mounting the Coder

Special Web Printing Applications

Printing on Narrow Web Materials

Printing directly on Master Rolls

Gang Mounting

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

CARTON PRINTING

Carton Alignment

Die Positioning for Indexing Applications

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

MAINTENANCE

Pre-Inking a New Ink roll

Cleaning the Transfer Roll

Cleaning the Coder

Cleaning the Printing Dies

Mounting Configuration Conversion

Inking System Assembly

P ARTS DIAGRAMS & P A RTS LISTS

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

- LIMITED WARRANTY -

UNIVERSAL Non-Porous Conveyor Line Printers are guaranteed to be free from defects in materials and workmanship

for a period of 90 days from the date of purchase. Components found to be defective during this time will be repaired

free of charge if returned to the factory . Damage resulting from use of improper inks, improper installation, or operation

is not covered under the scope of this warranty . For warranty service please contact our Customer Service Department.

20

21

21

21

22

23

25

27

28

28

29

30

37

39

2

Page 3

PREFACE

Printing on non-porous materials has always been a major problem in industrial applications. The high degree of

maintenance required to keep conventional coders operating with solvent based inks has made many companies opt for manual marking as a cost effective alternative. With UNIVERSAL Non-Porous Coders, printing on

non-porous materials can be accomplished with the same relative ease as printing on porous materials. This

breakthrough in Non-Porous coder design opens up in-plant printing opportunities which previously were regarded as too costly to consider.

Inks used to print on porous materials dry through absorption into the material being printed. Inks used to print on

non-porous materials dry through the rapid evaporation of the ink solvents after the print is applied. Since the ink

solvents must evaporate very rapidly on the printed material, they also evaporate very rapidly from the ink rolls

and ink wells of conventional coders therefore requiring constant maintenance.

The proprietary design of the UNIVERSAL Non-Porous Inking System effectively eliminates the rapid evaporation

of the ink solvents from the ink roll and additionally provides for convenient automatic re-inking of the roll without

interrupting the printing process. After many months of design engineering and field testing, the Non-porous

Conveyor Line Printer is both simplistic in design and extremely effective in operation. The relatively low cost of

this system makes in-plant printing of all types of non-porous materials a practical reality . The following pages of

this manual explain the installation, operation and maintenance of Non-Porous Conveyor Line Printer and are the

key to trouble free non-porous printing.

QUICK START

PAGES 9 THRU 15

This manual was written with a full understanding that very few people like to read manuals or have the

time to do so. To accommodate those who have little time to spare, we have included a Quick S tart section

which will get your coder operating in just a few minutes.

T o keep your coder operating properly , it is important to read and underst and the Basic Principles of Operation section which explains the basic operation of the Non-Porous Inking System.

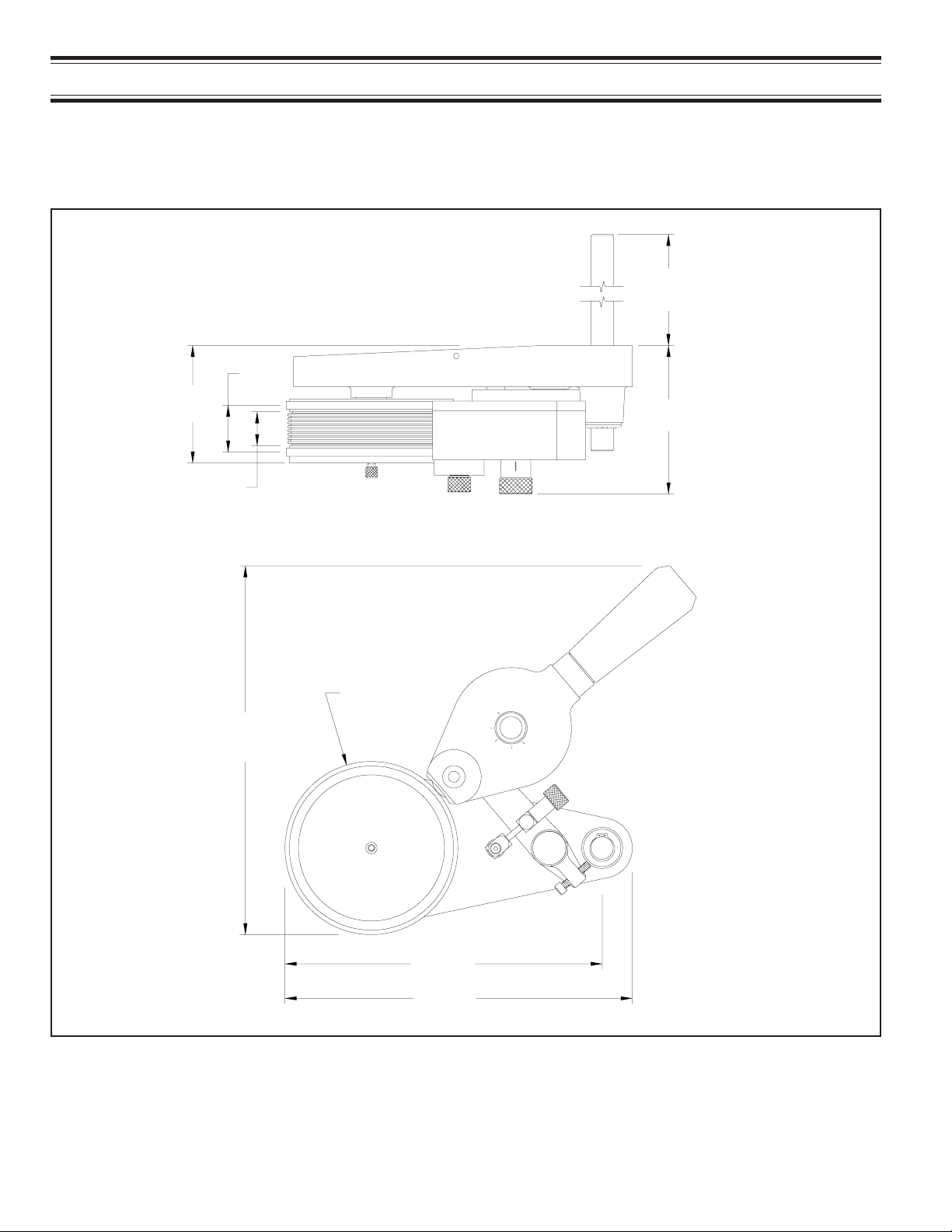

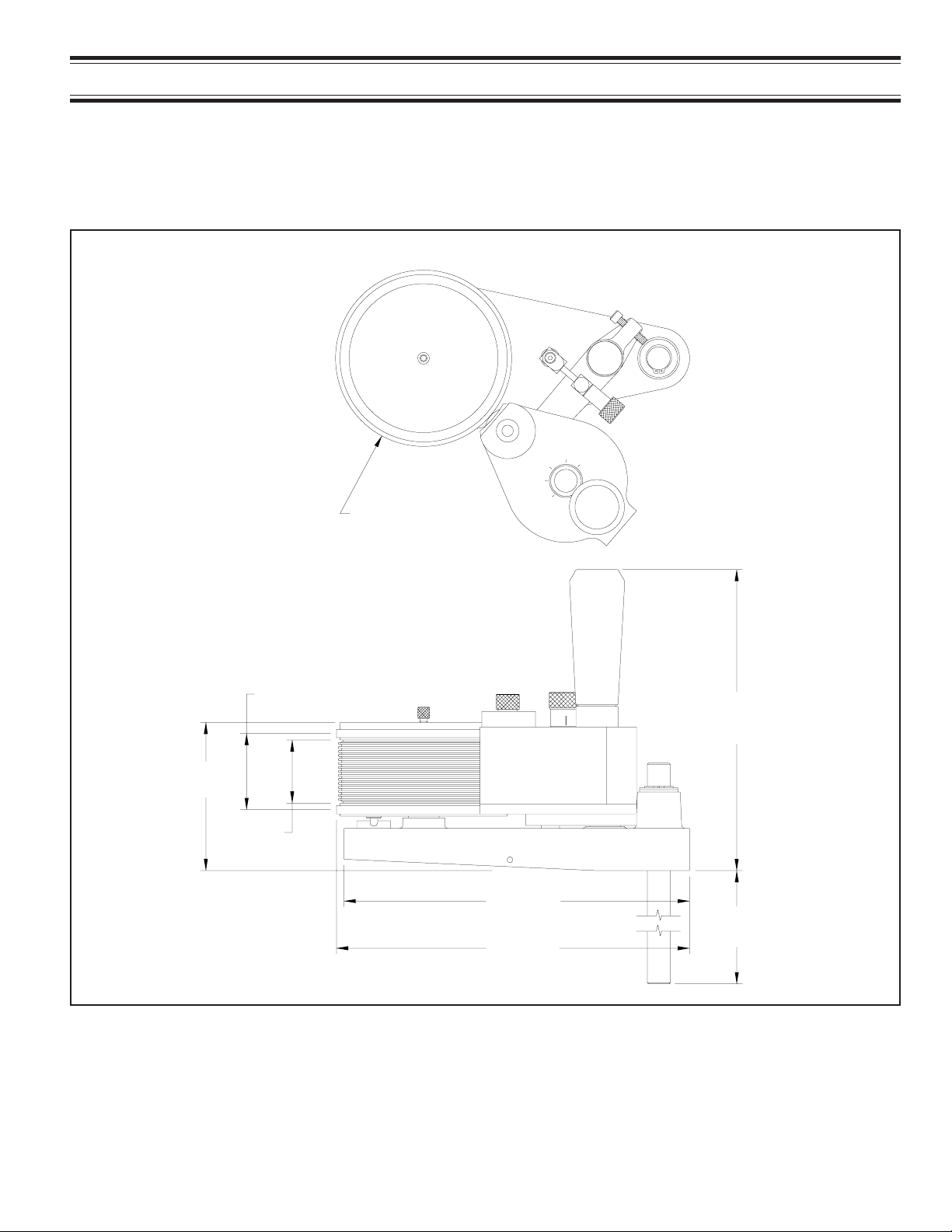

CODER SPECIFICATIONS

The specification section includes drawings with the basic dimensions of the coders, the net weights, maximum

die capacities, maximum print width and print drum circumferences. This section also lists the specifications for

the printing dies and an explanation of the Indexing and Non-Indexing models and the various mounting configurations.

3

Page 4

3.90

(99.06 MM)

(28.70 MM)

SPECIFICATIONS

CONVEYOR LINE PRINTER SPECIFICATIONS

TOP MOUNT SERIES

Model Shown: CLP-100NI-NPRT

8.25

(209.55 MM)

1.56

(39.62 MM)

4.93

(125.22 MM)

1.13

5.75

11.89

(302.01 MM)

(146.05 MM)

MAX

3

2

MIN

1

10.51

(266.95 MM)

11.50

(292.10 MM)

NET WEIGHT : 10 LBS. - 12 OZS. (4.88 KG.)

MAXIMUM DIE SIZE: 7 RIBS WIDE X 16-15/16" LENGTH (7 RIBS WIDE X 430 MM LENGTH)

MAXIMUM PRINT WIDTH: 1" (25.4 MM)

PRINT DRUM CIRCUMFERENCE: APPROXIMA TEL Y 18" (457 MM) MEASURED A T THE DIE F ACE

4

Page 5

SPECIFICATIONS

CONVEYOR LINE PRINTER SPECIFICATIONS

SIDE MOUNT SERIES

Model Shown: CLP-200NI-NPLS

3

MAX

2

1

5.75

(146.05 MM)

MIN

2.49

4.80

(121.92 MM)

(63.25 MM)

9.80

(248.92 MM)

2.00

(50.80 MM)

11.25

(285.75 MM)

8.25

(209.55 MM)

11.50

(292.10 MM)

NET WEIGHT: 11 LBS. -5 OZS. (5.13 KG.)

MAXIMUM DIE SIZE: 14 RIBS WIDE X 16-15/16" LENGTH (14 RIBS WIDE X 430 MM LENGTH)

MAXIMUM PRINT WIDTH: 1.875" ( 47.6 MM)

PRINT DRUM CIRCUMFERENCE: APPROXIMA TEL Y 18" (457 MM) MEASURED A T THE DIE F ACE

5

Page 6

SPECIFICATIONS

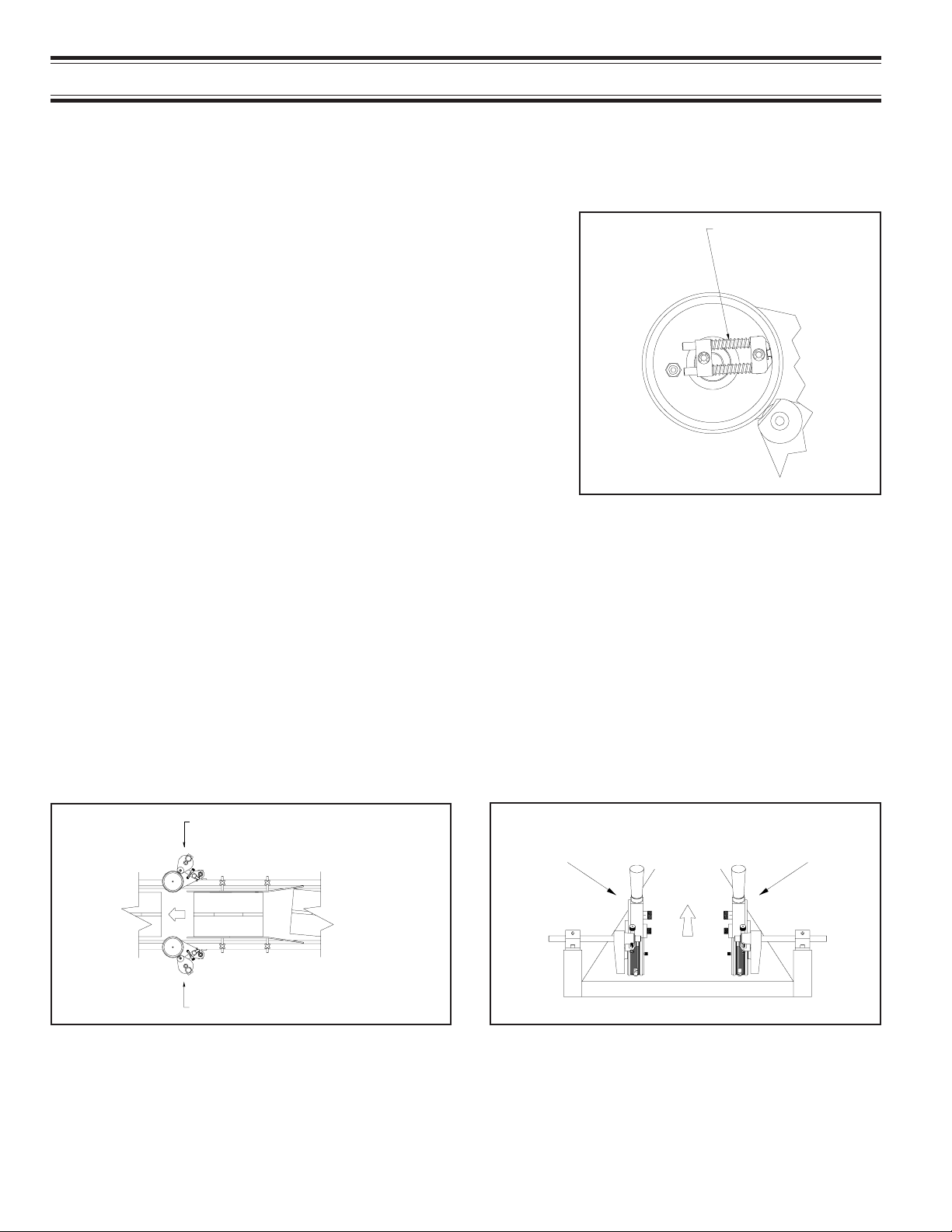

INDEXING AND NON-INDEXING MODELS

Universal Non-Porous Conveyor Line Printers are available in both indexing and non-indexing models.

Indexing coders contain a print drum spring return mechanism

which provides print registration capabilities when carton printing

(see Figure 1). As the trailing edge of a carton passes the coder,

the print drum automatically rotates back to the same starting or

“home” position. There must be adequate space between cartons

at any given line speed for this mechanism to work properly . Printing with an indexing coder will allow the imprint on each carton to

be registered in the same position relative to the leading edge of the

carton. The code will repeat every 18" down the length of the carton.

Non-indexing coders have print drums which simply rotate on

bearings with no spring return mechanism. These coders are normally used for web printing applications where the print drum stays

in contact with the web at all times. If used in carton printing applications, when the trailing edge of a carton passes the coder, the

print drum rotation stops at a random position. When the next carton engages the print drum, the code will begin printing at a random

position relative to the leading edge of the carton and repeat the

code every 18" down the length of the carton.

SPRING RETURN

MECHANISM

FIGURE 1

MOUNTING CONFIGURATION

The mounting configuration of a coder is determined by how the machine is designed to be mounted in relation to

the product and its movement. All references to mounting configuration are made as though you are viewing the

production line with the product moving away from you. Universal Conveyor Line Printers are available from the

factory in 4 different mounting configurations as shown in Figures 2 and 3.

RIGHT HAND

SIDE MOUNT

LEFT HAND

SIDE MOUNT

FIGURE 2

LEFT HAND

TOP MOUNT

FIGURE 3

Note: Due to the symmetrical design of the Inking System on the Non-Porous Conveyor Line Printer, the Right

Hand and Left Hand mounting configurations are field convertible. Due to the location of the ports for the 4 Oz.

Reservoir Ink Cartridges, T op Mount and Side Mount orient ations cannot be field converted and must be properly

specified when ordering.

RIGHT HAND

TOP MOUNT

6

Page 7

SPECIFICATIONS

RIBtype PRINTING DIES

®

Universal Non-Porous Coders are designed to use Universal RIBtype

rubber type, printing dies which have a molded rib backing. The ribs

on the back of the die snap into mating ribs in the RIBtype Drum

®

Cover on the print drum as shown in Figure 4.

Universal RIBtype dies are available in many standard character styles

®

and sizes. Dies are available in sets containing a combination of

individual alphabetic and numeric characters or in sets containing

numeric characters only. These character sets or “sorts” can be

used to make up text messages and code numbers as necessary.

RIBtype dies are also available in “logo” form in which a complete

®

text message is produced on a single piece of rib backed rubber.

Logo dies are much faster to change and normally produce better

print quality than individual characters due to their unitized construction.

FRICTION

BEARER

Universal RIBtype dies are manufactured to precision

thickness tolerances which are very critical to the performance of these coders. When installed, the face of the

printing die should extend only .007" - .008" beyond the

.007” - .008”

radius of the Friction Bearers as shown in Figure 5. Using dies that do not meet the design specifications will

result in poor print quality and possible damage to the transfer roll.

PRINTING DIE

Although there are several competitive rib backed die sys-

DRUM COVER

tems available, it is very important to note that they are not

all made to the same rib spacing or thickness specifications and they are not interchangeable.

®

FIGURE 4

®

FIGURE 5

®

CODER MODELS DESIGNED FOR METRIC RIBtype PRINTING DIES

Universal also offers Metric RIBtype die systems for use in countries where metric character sizes are the

standard. The Metric dies are thicker and the rib spacing differs slightly from the standard RIBtype printing dies

therefore the two versions are not compatible. To accommodate the differences, the print drums for Metric dies

are machined to a slightly different diameter from the U.S. versions.

The coder model numbers on Metric coders will have a “-T” suffix and the Metric RIBtype Drum Covers have a

distinct pink color.

®

®

®

7

Page 8

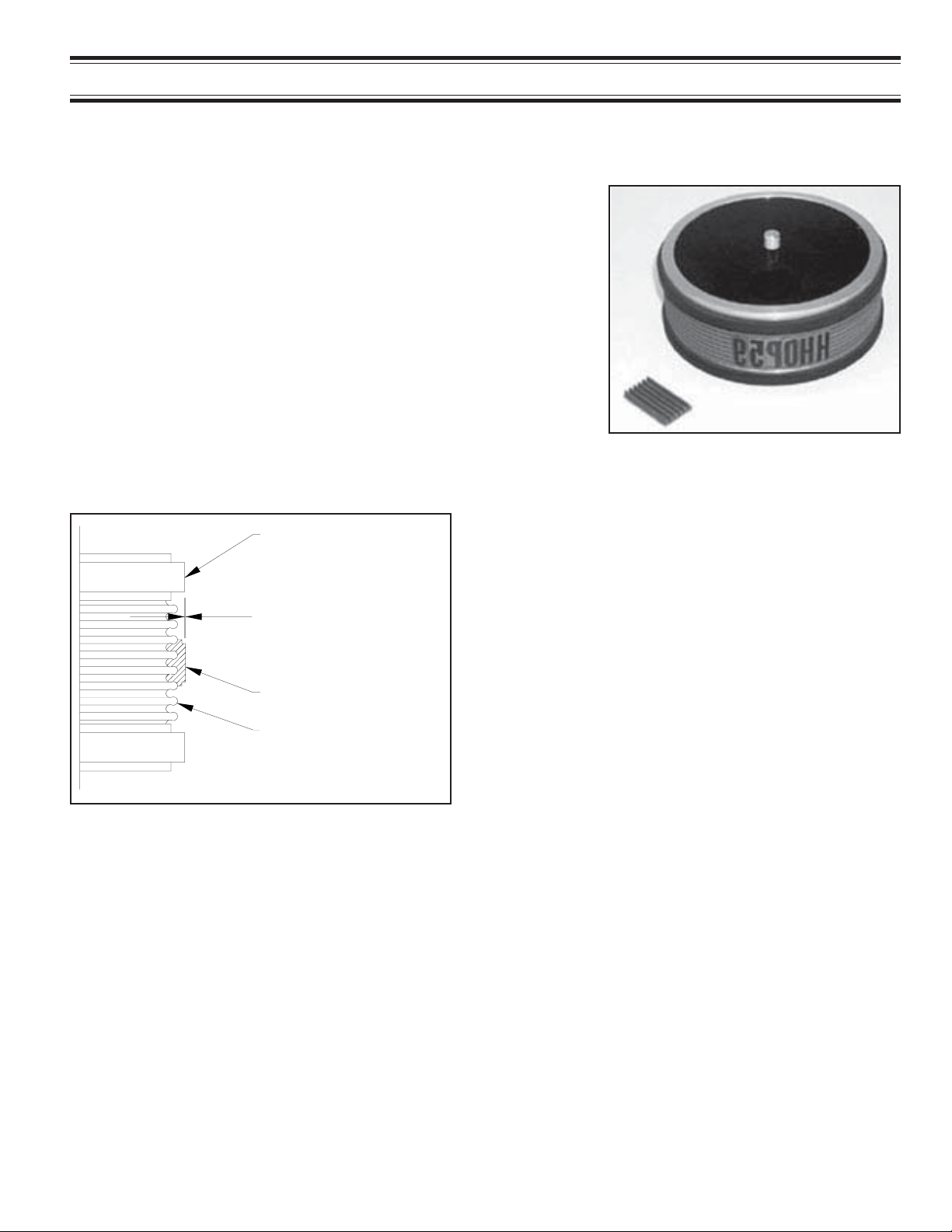

SPECIFICATIONS

INK ROLLS

Universal offers two ink roll options for the Non-Porous Conveyor Line Printers each with unique characteristics

which will help determine the suitability for a specific printing application. The coders are designed to accommodate both types of ink rolls without modification. A detailed review of your printing requirements will determine the

best choice of ink rolls for your particular application.

XF NEOPRENE INK ROLLS

Universal’s XF Neoprene Ink Rolls are a re-inkable roll which

can be used with a variety of alcohol or glycol base inks. These

rolls are normally supplied in a dry condition with the coder and

require pre-inking prior to installation. Pre-inked rolls are available from the factory and are recommended for first time users.

During production printing, when the ink capacity of the roll is

depleted, installing a 4 Oz. Reservoir Ink Cartridge in the coder’s

reservoir Bottle Port will re-ink the roll automatically as production continues.

FIGURE 6

In high speed web printing applications, Universal’s #100 Inks

provide drying times of approximately 2 seconds at 75 Degree

F . (24 Deg. C) ambient temperature. Many other inks, both dye

and pigment based, can be used in these ink rolls to meet the

specific application requirements. Refer to the Basic Principles

of Operation section on Page 16 for more information on selecting an appropriate ink.

TYPE MT INK ROLLS

Universal’s T ype MT Ink Rolls are disposable pre-inked rolls which

are available in a variety of fast drying colors. The MT Ink Rolls

provide excellent color density and adhesion on most materials

and an average yield of just under 500,000 impressions before

replacement is necessary . Since these rolls are not re-inkable,

all references in the manual regarding the use of 4 Oz. reservoir

Ink Cartridges should be disregarded when using these rolls on

your coder. The ability to operate the coder without a Reservoir

Ink Cartridge makes the MT Rolls particularly well suited for applications requiring printing on the bottom of web materials.

The Type MT Ink Rolls provide drying times between 4 - 7 seconds at 75 Degree F. (24 Deg. C) ambient temperature. The

added convenience and simplicity of using the T ype MT Ink Rolls

makes them an ideal choice when production operators have little

time to monitor the inking system.

FIGURE 7

8

Page 9

QUICK START

INSTALLING THE INKING SYSTEM ASSEMBLY

Y our new Non-Porous Conveyor Line Printer was fully assembled and adjusted at the factory before final inspection. In order to minimize the size of the shipping cartons used to package these machines, the Non-Porous

Inking System Assembly was removed from the Pivot Arm and must be reinstalled before operation.

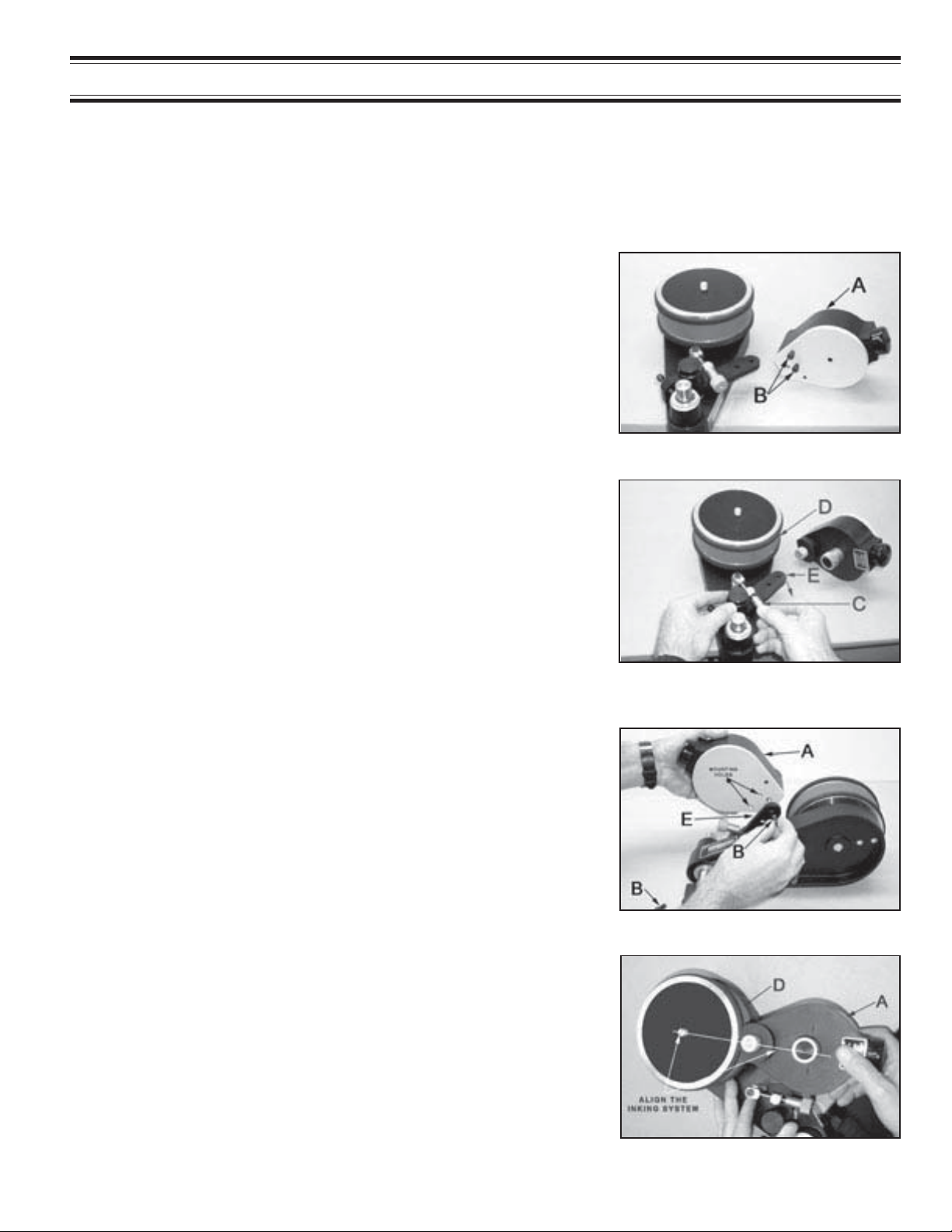

1 -To install the Inking System Assembly “A” remove the (2)

Mounting Screws “B” from the bottom of the assembly.

FIGURE 8

2 -Loosen the Pivot Arm Adjusting Knob “C” and rotate the

Pivot Arm “E” away from the Print Drum “D” slightly.

This will allow the Inking System to be installed without

contact interference with the print drum.

3 -Position the Inking System Assembly “A” on top of the Pivot

Arm “E” and align the two holes in the Inking System with

the matching holes in the Pivot Arm. Reinst all the two Mounting Screws “B”.

Thread the screws in all the way but do not tighten.

4 -Rotate the Pivot Arm until the Inking System Assembly “A”

contacts the Print Drum “D”. There is a small amount of clearance in the mounting holes in the Pivot Arm. While holding

the Inking System against the Print Drum, align the Inking

System so that it points directly at the center of the Print

Drum and tighten the two mounting screws securely.

FIGURE 9

FIGURE 10

FIGURE 11

9

Page 10

QUICK ST ART

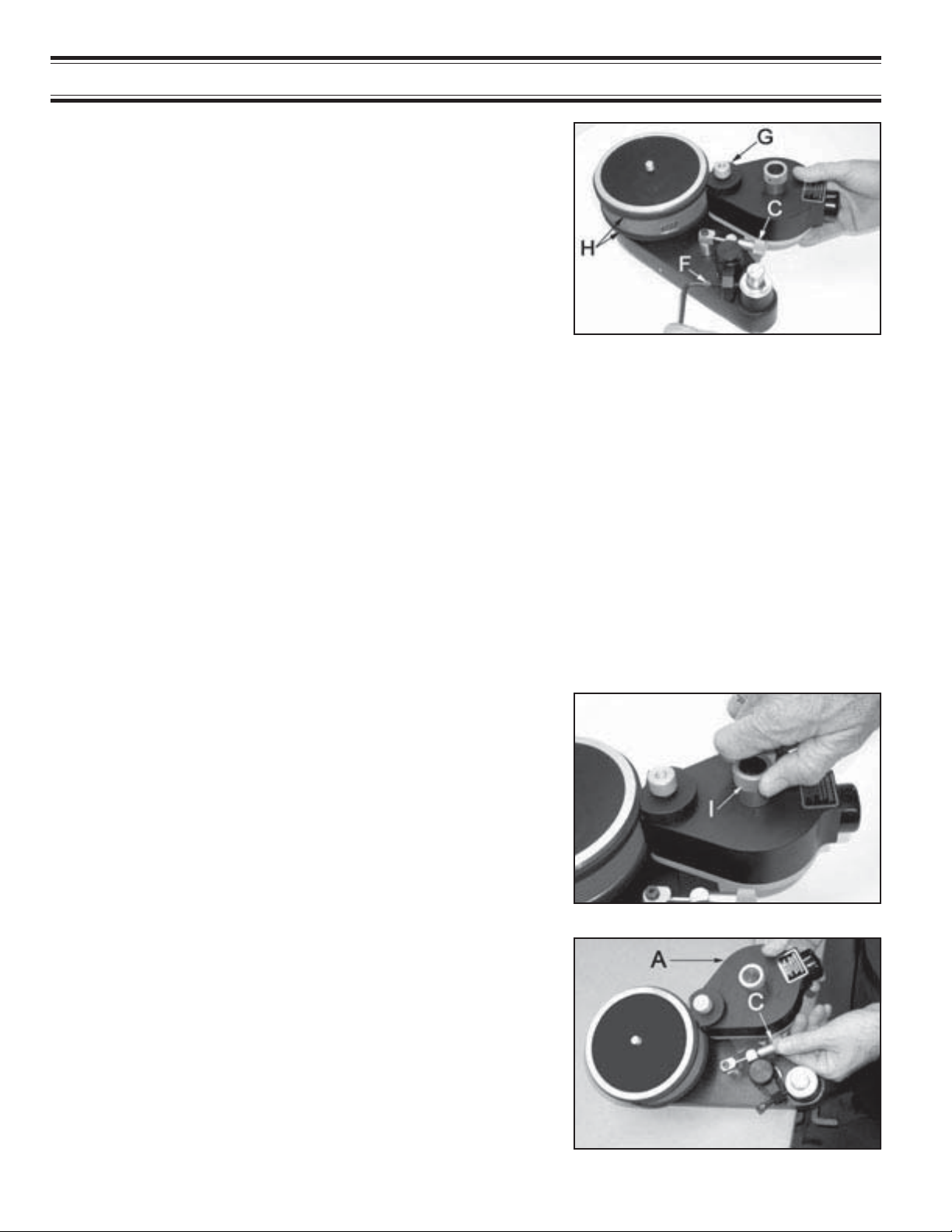

5 - Press the Inking System Assembly towards the Print Drum

and adjust the Position Adjusting Screw “F” until the

Knurled Drive Wheel “G” makes positive contact with the

Friction Bearer “H” on the Print Drum. When the Pivot

Arm Adjustment Knob “C” is tightened, the Knurled Drive

Wheel should only contact the Friction Bearer Ring with

enough pressure to drive positively when the print drum

is rotated.

This adjustment procedure also controls the Transfer Roll contact with the printing dies. Excessive engagement pressure

should be avoided as this will cause unnecessary drag on the

print drum and result in smudged impressions.

INSTALLING THE PRE-INKED ROLL

Warning: Non-Porous inks contain flammable solvents. Do not smoke or handle these rolls in the

presence of sparks or open flames. Inks will also stain clothing, furniture, carpeting and your hands.

Rubber gloves should be worn during the following procedures.

The ink roll you install on the coder must be properly pre-inked. If your coder was supplied with a dry XF

Neoprene ink roll, refer to the Maintenance Section page 27 for inking instructions.

FIGURE 12

Rollers that have been pre-inked at the factory are normally slightly oversaturated with ink to compensate for

potential solvent loss during shipping and storage. If you received a pre-inked ink roll with your coder, it is

important to examine the roll prior to installation. The ink roll should be thoroughly saturated with ink but not

dripping wet. Excess ink can be easily removed by lightly rolling the ink roll across a clean piece of absorbent

paper.

1 - To install the pre-inked roll, first turn the Ink Roll Eccen-

tric Adjusting Knob “I” to the “MIN” position.

This moves the ink roller axle away from the Transfer Roll

and enables the ink roll to be installed without interference

with the Transfer Roll during reassembly of the inking system.

FIGURE 13

2 - Loosen the Knurled Pivot Arm Knob “C” & swing the

Inking System Assembly “A” away from Print Drum.

10

FIGURE 14

Page 11

QUICK START

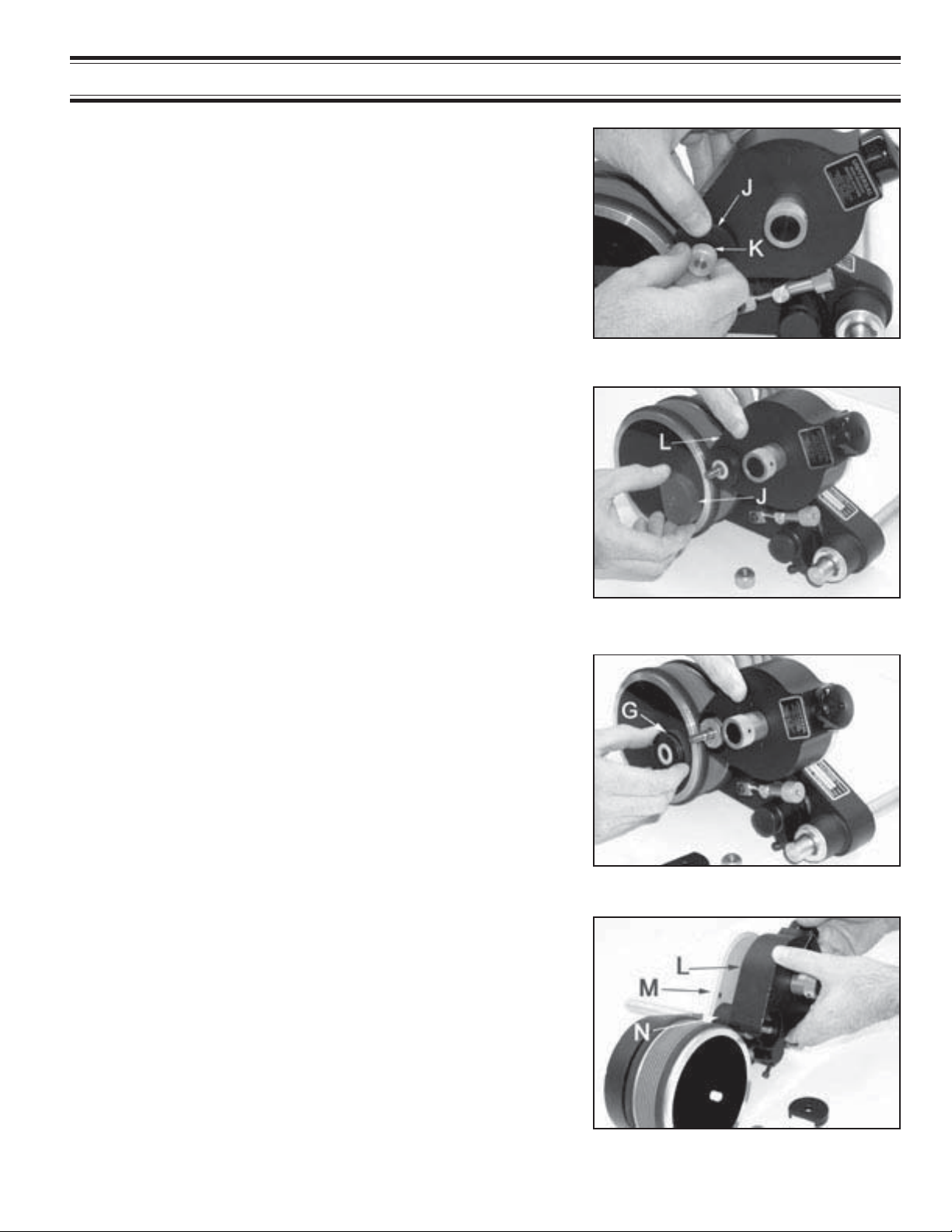

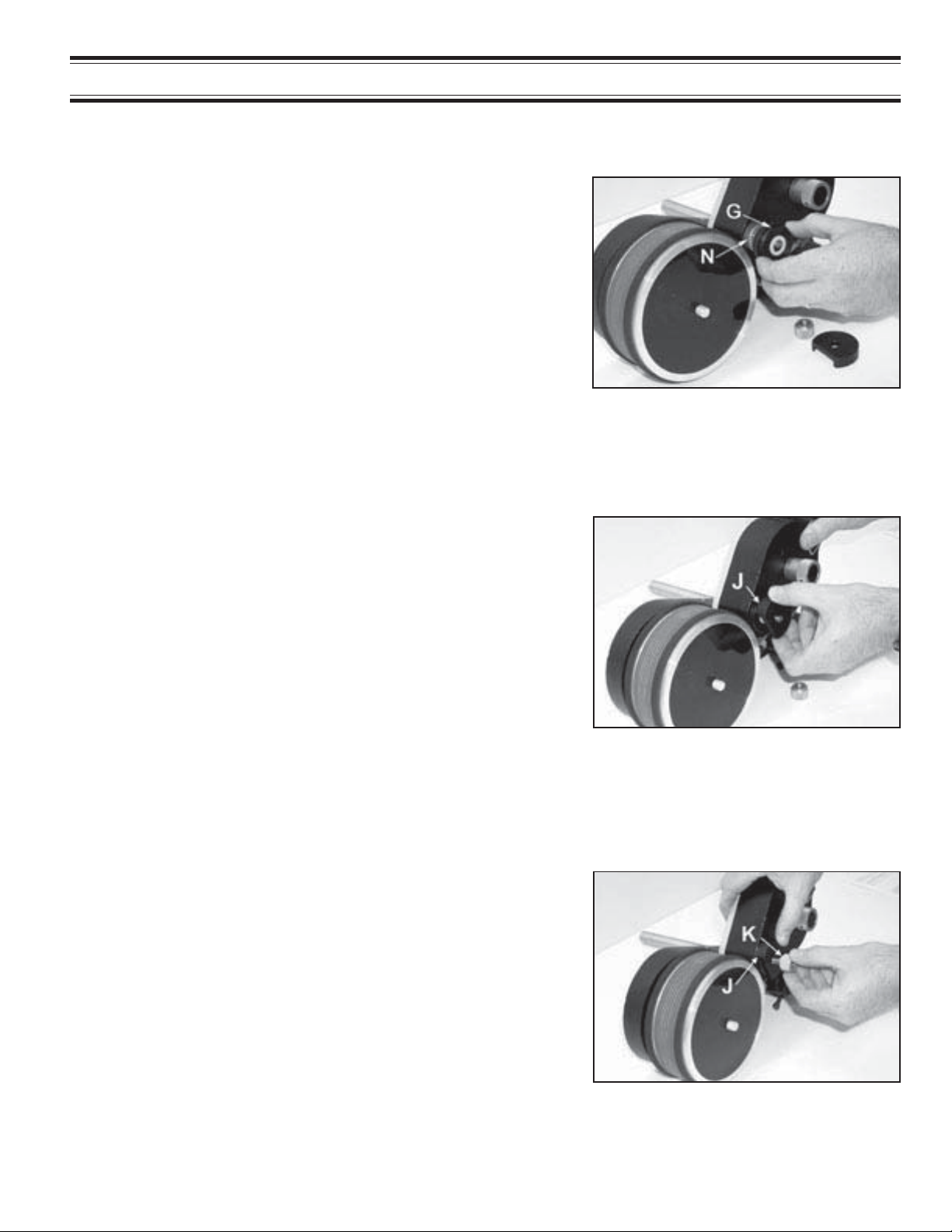

3 -While holding the Knurled Drive Wheel Cover “J” in place,

remove the Knurled Cover Retaining Knob “K” by turning

it counter-clockwise.

The Cover Retaining Knob holds the entire inking system

together and other parts may fall free from the coder if not

held securely when this knob is removed.

4 -Hold the Inking System Cover “L” in place and remove the

Knurled Drive Wheel Cover “J”.

The Knurled Drive Wheel Cover is very loose fitting.

Note: The flat on the side of the Drive Wheel Cover is

aligned towards the print drum. During reassembly, this

must be replaced in the same position.

FIGURE 15

5 -Continue to hold the Inking System Cover and Remove

the Knurled Drive Wheel “G”.

The Knurled Drive Wheel rests on top of the Transfer Roller

and is installed over 3 stainless steel drive pins which protrude through 3 mating holes in the Drive Wheel.

6 -Carefully pull the Inking System Cover “L” directly away

from the Inking System Baseplate “M”. Do not let the cover

drag across the surface of the Transfer Roller “N”.

The Transfer Roll Surface is a finely engraved Delrin plastic

material which can be easily scratched. When assembled,

the Transfer Roll resides in a very close fitting cavity in the

Inking System Cover.

FIGURE 16

FIGURE 17

11

FIGURE 18

Page 12

QUICK ST ART

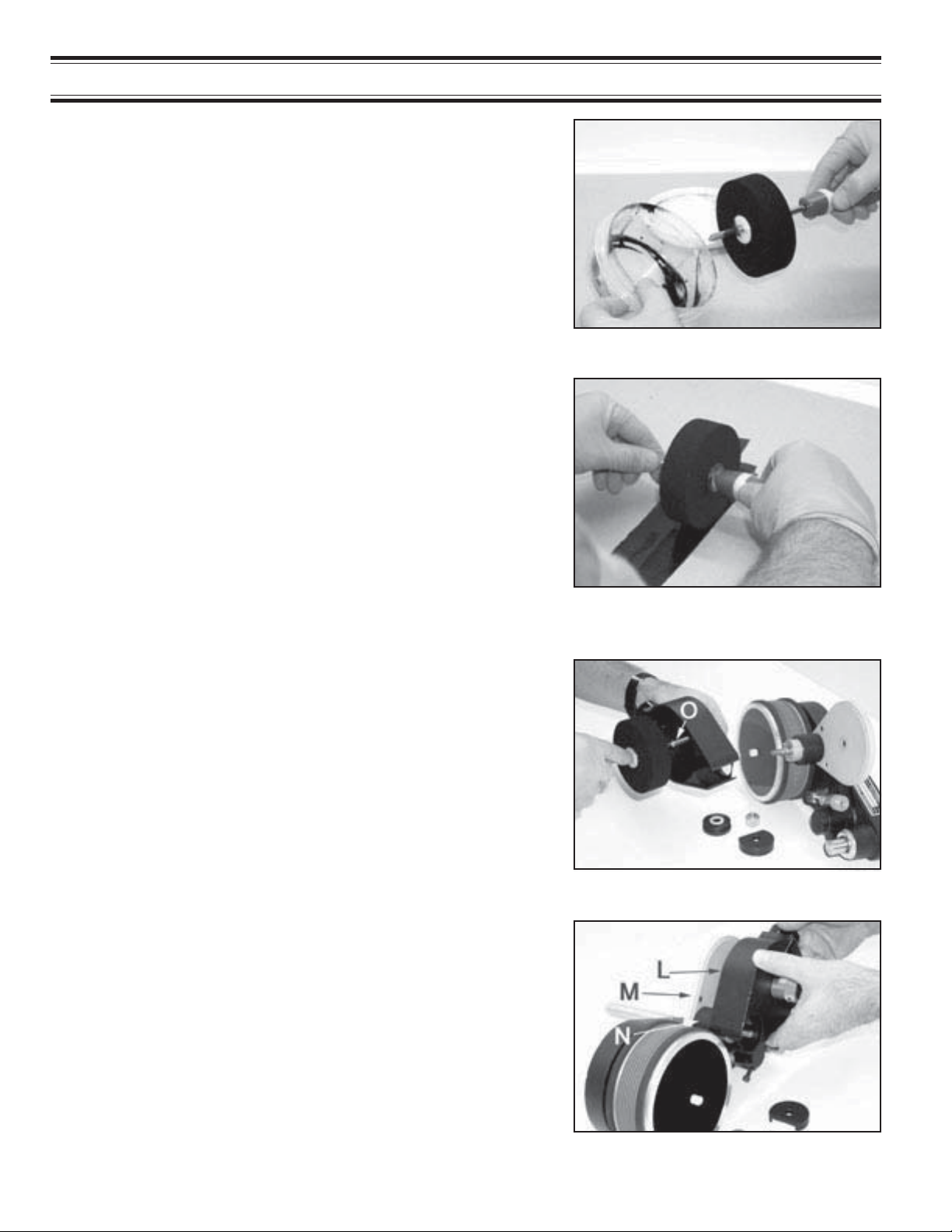

7 -Put on a pair of rubber gloves and remove the pre-inked

ink roller from the storage container by inserting a small

rod (a pencil works nicely) in the center of the core.

Keeping ink off your gloves at this stage will prevent contamination of the external parts of the coder during roll installation.

8 -Inspect the roll for excess surface wetness. Remove

any excess ink by rolling the roll lightly over a piece of

absorbent paper.

Rolls which have been pre-inked at the factory are typically over

saturated with ink to compensate for potential solvent loss during shipping and storage. Installing an over saturated roll on the

coder will result in ink leakage from the Inking System and in

extreme cases may damage the ball bearings in the Transfer

Roll. When the roller is installed, it must be thoroughly saturated with ink but you should not be able to see any liquid ink on

the surface of the roll. If necessary, blot excess ink from the

sides of the roll with a dry paper towel before installation.

FIGURE 19

FIGURE 20

9 -Install the ink roll on the Ink Roll Axle “O” by aligning

the end of the rod or pencil with the end of the axle

and pushing the roll onto the axle.

When this step is complete, remove the rubber gloves to prevent ink contamination with the external parts of the coder .

10 - Immediately replace the Inking System Cover “L” by

carefully guiding the cover over the Transfer Roll “N”.

Try not to let the cover contact the surface of the Transfer Roll to prevent scratching. Make sure the Cover is

seated properly against Baseplate “M”.

While handling the ink rolls, solvents will evaporate from the rolls

very rapidly at normal room temperatures. The Inking System

Cover must be replaced quickly to prevent solvent loss.

FIGURE 21

12

FIGURE 22

Page 13

QUICK START

11 -Replace the Knurled Drive Wheel “G” by aligning the 3

small holes with the 3 stainless drive pins on the top of the

Transfer Roll “N” and pressing the Drive Wheel onto the

Transfer Roll.

The tops of the stainless pins will be flush with the top of the

Drive Wheel when seated properly .

FIGURE 23

12 - Replace the Knurled Drive Wheel Cover “J” and rotate

it into position with the flat edge directly facing the Print

Drum.

Hold the Drive Wheel Cover and Inking System Cover in

place.

13 - Replace the Knurled Cover Retaining Knob “K” and

lightly tighten. Do not over tighten this knob or you may

bend the top of the Knurled Drive Wheel Cover “J” and

cause it to bind against the Knurled Drive Wheel. Now

retighten the Pivot Arm Knurled Knob.

FIGURE 24

The Cover Retaining Knob should be just tight enough to keep

the Inking System Assembly together and prevent the Drive

Wheel Cover from rotating out of position.

13

FIGURE 25

Page 14

QUICK ST ART

INSTALLING THE PRINTING DIES

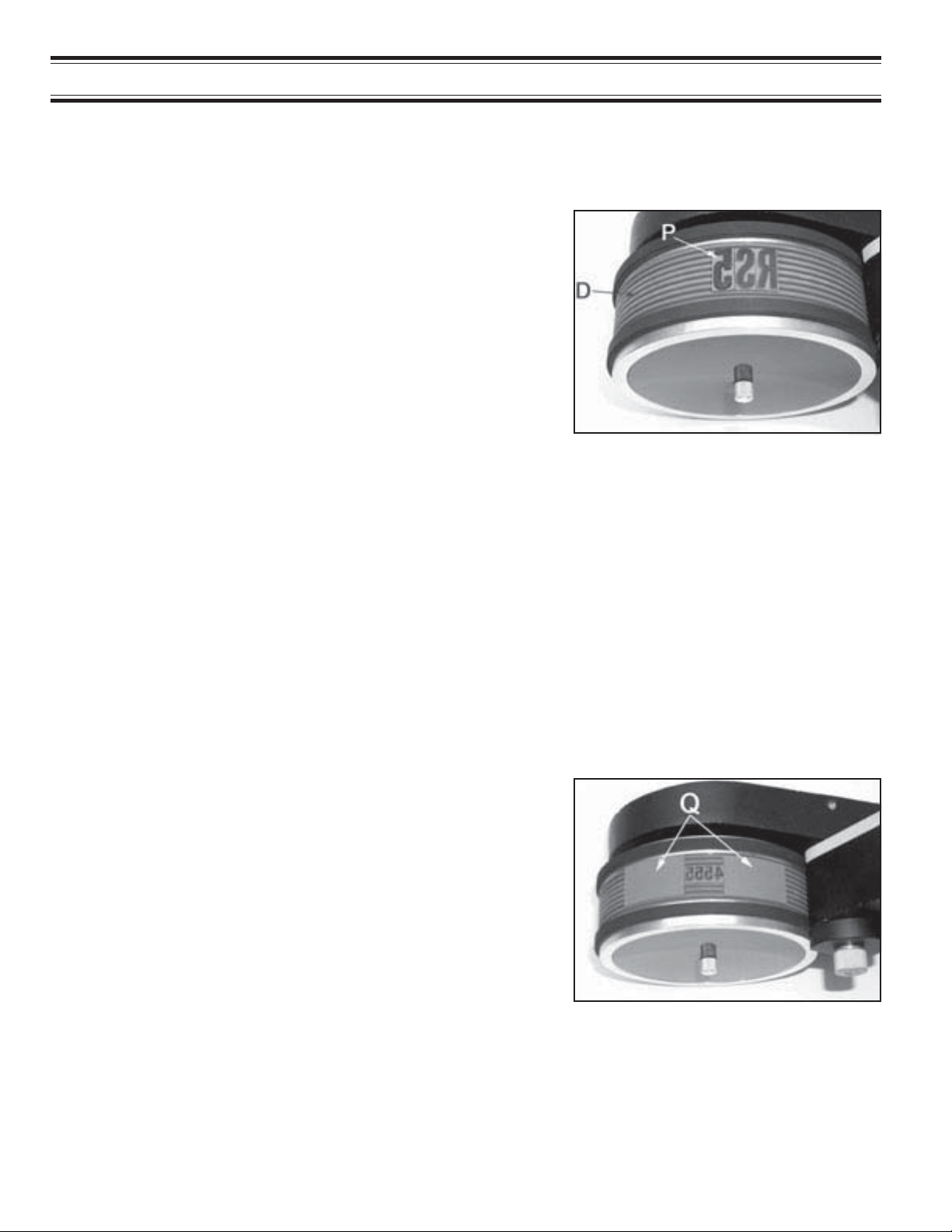

1 - Align the ribbed backing on the Printing Dies “P” with the

mating Drum covering on the Print Drum “D” and press

firmly until they are completely engaged. It is best to install

the dies as close to the middle of the print area on the

Print Drum as possible.

Individual character codes or text messages are installed in a

mirror image of normal written text. In other words install in a right

to left direction as shown. When printed, codes or text installed

in this orientation will print in normal left to right order .

FIGURE 26

Tip: To make die installation easier, moisten a sponge with water containing a small amount of liquid

detergent. Lightly moisten the back of the printing die and then immediately press the die into the

drum cover. Do not apply too much liquid or the dies will slip during printing.

Note: Do not apply silicone, oil or any other lubricating agent to the rib backing or the dies will not hold

properly during printing.

2 - When using the smaller individual characters to make

up a code message, use the Type Blocking Kit “Q” included with your coder to support the leading and trailing ends of the type as shown.

Characters with only a 2 or 3 rib backing do not have the stability of the larger sizes when snapped into the drum cover. Adding the rib backed type blocks on either size of the code will

provide added stability . The T ype Blocks are not as thick as the

Type and will not pick up ink from the Transfer Roll.

FIGURE 27

14

Page 15

QUICK START

ADJUSTING THE INK ROLL ECCENTRIC

1 - After the printing dies are inst alled on the print drum, manu-

ally rotate the print drum continuously in one direction while

slowly rotating the Ink Roll Eccentric Adjusting Knob “I” from

the “MIN” position towards the “MAX” position. Turn the

Eccentric Knob in small increments and observe the face

of the Printing Dies “P” for signs of ink between each adjustment.

As soon as you can see complete ink coverage on the die faces,

stop rotating the eccentric. Proper adjustment will normally be

reached when the reference line on the Eccentric is somewhere

between the 2 and 3 dial position.

FIGURE 28

Note: This adjustment procedure brings the Ink Roller into contact with the surface of the Transfer Roller which

in turn applies the ink to the face of the printing dies. Do not rotate the Ink Roll Eccentric Knob further than

necessary towards the “MAX” position or the excess contact pressure will squeeze ink out of the ink roll and may

cause dripping inside the cover.

FOR MOUNTING INSTRUCTIONS

REFER TO THE APPROPRIATE SECTION

FOR YOUR APPLICATION

WEB PRINTING - PAGE 19

CARTON PRINTING - PAGE 23

15

Page 16

BASIC PRINCIPLES OF OPERATION

NON-POROUS INKING SYSTEM

Inks designed for printing on non-porous surfaces contain very fast drying alcohol solvents, a component to

impart color which can be either a liquid “dye” or a finely ground solid or “pigment”, and a resin material which

binds the color medium to the material surface. When the printed marks are applied by the coder, the solvent s

rapidly evaporate from the surface of the material leaving only the dried resin and color.

Preventing rapid solvent loss from the inking system, which would cause the coder to stop printing, has traditionally been a very difficult task. Universal’s patented Non-Porous Inking System design has overcome this problem

by enclosing all of the inking system components in a tightly sealed housing. This unique design offers the

capabilities of a flexographic printer without the limitations associated with having an open well of ink. The

advantages of this design include minimal maintenance requirements, unrestricted mounting configurations and

the ability to rapidly change ink colors.

The inking system is comprised of two main components as shown in Figure 29. The ink roll serves

as a reservoir for the ink, and a transfer or “anilox”

roll transfers the ink from the ink roll to the face of

the printing dies. T o prevent the loss of ink solvent

through evaporation, these rolls are mounted in

separate precision machined cavities in a sealed

aluminum housing. The integrity of the housing is

such that the system can be left idle for days without risk of the ink roll drying out.

INK ROLL

4 OZ. RESERVOIR

INK CARTRIDGE

PLASTIC BALL

The ink roll is installed on an eccentric mounted

axle which enables the roll to be adjusted into contact with the transfer roll. The surface of the transfer

or “anilox” roll is finely engraved with thousands of

ECCENTRIC

TRANSFER

ROLL

microscopic cavities which picks up ink from the

ink roll and transfers it to the surface of the printing

dies. Since the transfer roll applies a very thin film

of ink to the die face, the printed marks dry very

rapidly .

FIGURE 29

USING THE 4 OZ. RESERVOIR INK CARTRIDGES

It is important to note that the Reservoir Ink Cartridge shown in Figure 29 is not considered to be an integral part

of the inking system but is used only to re-ink the XF neoprene ink roll when needed. The 4 Oz. Reservoir Ink

Cartridges should be installed only after the ink supply in the XF neoprene ink roll has been depleted

and the printed marks indicate a need for more ink. Depending on the amount and size of the text being

printed and number of imprints being applied per hour, the ink capacity of the XF neoprene ink roll may last

anywhere from 1 hour to several days of continuous operation. Installing a 4 ounce Reservoir Ink Cartridge

prematurely may result in over saturation of the XF neoprene ink roll and flooding of the inking system. 4 Oz.

Reservoirs Ink Cartridges are not compatible with ketone or petroleum based inks and cannot be refilled after

use.

Note: The MT Ink Roll is disposable by design and is not to be used with the 4 oz. ink cartridge. When the ink is

depleted from the MT Ink rolls they are to be discarded.

16

Page 17

BASIC PRINCIPLES OF OPERATION

When a Reservoir Ink Cartridge is threaded into the bottle port, the plastic ball in the cartridge comes into contact

with the surface of the neoprene ink roll. When the ink roll rotates during the printing operation, a thin film of ink

is transferred from the reservoir cartridge onto the surface of the ink roll. The printed impressions will improve

within a few seconds after installation of the cartridge. When the printing operation is stopped, the Reservoir Ink

Cartridge automatically stops feeding ink to the roller to prevent over saturation during idle periods.

The knurled drive wheel shown in Figure 30 sits on top of

the transfer roll and is engaged by three stainless steel

drive pins. The knurled face of the drive wheel runs in

contact with a friction bearer on the print drum. When the

print drum starts to turn, the knurled drive wheel rotates

FRICTION

BEARER

KNURLED DRIVE

WHEEL

INK ROLL

the transfer roll at the exact surface speed of the die face.

TRANSFER

ROLL

Keeping these two surfaces running at a synchronous

speed ensures a uniform coating of ink on the die face

and extends die life.

PRINTING DIE

FIGURE 30

SELECTING AN APPROPRIATE INK

Universal’s Non-Porous Inking System is compatible with a wide range of alcohol base marking inks. Although

we offer a variety of inks for specific applications, you are not restricted to using only Universal brand inks. When

selecting inks from other manufacturers however, it is your responsibility to make sure the inks are compatible

with the coder.

Dye base inks contain liquid color which is translucent and will provide good color contrast only on light colored

materials. These inks are generally faster drying than pigmented inks and normally produce less residue buildup

on the transfer roll and printing dies, thus requiring less frequent cleaning of the coder. Although dye base inks

are normally the easiest to use, they will fade more rapidly than pigmented inks when exposed to direct sunlight.

Pigmented inks contain finely ground solids which are opaque, providing much greater color contrast when

marking on dark colored surfaces. These inks also resist fading when exposed to direct sunlight. Pigmented

inks have a tendency to build up on the surface of the transfer roll and the die face more rapidly than dye base

inks and will generally require more frequent cleaning of these parts.

The first step in selecting an appropriate ink, is to determine if the ink will bond to the surface of the material being

printed and provide acceptable color contrast. It is normally recommended that inks be test printed on the

material being marked with a rubber stamp to determine if the resulting marks are acceptable. Please note that

when testing inks with a rubber stamp, the drying times will generally be much slower than when the inks are

applied with the Non-Porous Conveyor Line Printer.

It is also extremely important to test the affect of other manufacturer’s ink on the XF Neoprene ink roll.

Since the ink roll must fit into a precision machined cavity in the inking system housing with little clearance,

swelling of the roll, in reaction to non-compatible solvents in the ink, could cause serious problems with the

performance of your coder. The dry XF neoprene ink roll measures 3.425" (86.99 mm) OD. After thoroughly

saturating the ink roll with ink, the roll should not exceed 3.500" (88.90 mm) OD.

17

Page 18

BASIC PRINCIPLES OF OPERATION

INK DRYING TIME CONSIDERATIONS

Depending on the specific characteristics of the printing application, some consideration needs to be given to the

drying time of the ink and its suitability for the application. Printing on a plastic film in an intermittent motion Form

and Fill Machine may require a slower drying ink formulation than that recommended for high speed continuous

web printing applications. Although extremely fast drying inks are normally specified by customers in all applications, the ink must be suitable for the specific application or it will not perform properly in the coder .

Universal #100 ink is an extremely fast drying formulation and is normally recommended for continuous motion web printing applications. In these applications, the

ink must dry very rapidly on the material

to prevent downstream transfer to idler

rolls. When the print drum is rotating at

high speeds, the dies rotate past the

Transfer Roll where ink is applied and

within milliseconds the die face contacts

the surface of the material being printed

and the impression is transferred. (See

Figure 31)

WEB MATERIAL

TRANSFER

DIE FACE

ROLL

MAX

3

2

MIN

1

FIGURE 31

When printing on very slow moving web materials, the print drum rotates at much slower speeds. As a result,

when the dies rotate past the Transfer Roll and the ink is applied, it may take several seconds for the dies to

contact the web. Since the solvents in the #100 Inks evaporate very rapidly at normal room temperatures (even

from the die faces), the die faces may be dry before contact with the web material. In these applications, a

slightly slower drying ink formulation would be necessary to ensure that the ink remains wet on the die faces until

they contact the web material.

When the coder is installed on a Form and Fill machine, the plastic film may move at fairly high speed when

pulled from the supply roll but it stops for a period of time during the product fill cycle. In these applications, if the

die face has already rotated passed the Transfer Roll and picked up ink and the web motion stops for several

seconds, a very fast drying ink like the #100 will flash off the die face before the web motion resumes. It is

therefore necessary to take into consideration the cycle rate of the particular machine when selecting an ink.

18

Page 19

WEB PRINTING

This section applies to the installation of the Non-Porous Conveyor Line Printers for printing on continuous web

materials such as plastic films, rubber sheeting, metals and other extruded materials.

Careful consideration should be given to selecting an appropriate area in the production line for installation of the

coder. Since the coders are friction driven by the moving web of material, a primary factor is to select an area

where the position of the web material is accurately controlled and preferably supported by an idler or guide roller

on the underneath side as shown in Figure 32.

The only real consideration with respect to the

attitude of the coder frame is that the 4 oz. reservoir ink cartridge (when installed) should be

kept as near to a vertical position as possible

with the plastic ball pointing down. This will ensure proper ink feed from the 4 oz. cartridge to

the ink roll. When disposable T ype MT Ink Rolls

are used on the coder, 4 oz. Reservoir Ink Cartridges are

not used and therefore the coder can

be mounted in any convenient attitude. When

installing the coder, the print drum axle of the

coder should be in parallel alignment with the

idler roll and the print drum should contact the

web at the point where the web is tangent to the

idler roll and solidly supported. It is also important that the distance “C” between idler roller “A”

and idler roller “B” should be adequate so that at

the maximum web speed, the ink will dry before

the printed marks contact idler roller “B”. If distance “C” is not adequate for the drying time of

the ink used, a ghost image transfer of the marks

may be overprinted on the web by idler roller “B”.

MOUNTING

COLUMN

o

15

WEB TRAVEL

4 OZ RESERVOIR

INK CARTRIDGE

PRINT DRUM

IDLER ROLL B

C

IDLER ROLL A

FIGURE 32

To eliminate this problem, if idler roller positions are

not adjustable, a slight undercut in the face of idler

roller “B” where the printed marks pass under the roll,

will prevent the wet marks from touching the face of

the idler. Generally the undercut in the idler roller

needs to be only .020" - .030" deep and slightly wider

than the printed marks as shown in Figure 33.

UNDERCUT

.020” - .030”

IDLER ROLL

WET IMPRINT

FIGURE 33

19

Page 20

WEB PRINTING

In high speed web applications, the distance the web travels at a given speed in 2-3 seconds can be substantial.

It is important to note that when the printed web is tightly rewound, the additional pressure applied to the printed

marks can increase the possibility of a ghost image transfer of the ink to the back of the web.

If this situation occurs and the web speed cannot be slowed down to allow more drying time, air blowers can be

used to direct heated air on the printed marks to accelerate drying. Preheating the web material slightly with hot

air before printing can also be an effective method to decrease the drying time. If either of these techniques are

used, it is recommended that the hot air blowers be electrically tied into the web feed motor energizing circuit.

This will ensure that the blowers are turned off automatically if the web is stopped.

MOUNTING THE CODER

1 - After determining the best location

to mount the coder, install the supplied mounting bracket (Figure 34) on

a rigid surface using two 3/8" diameter

bolts, nuts, washers and lock washers (not supplied). Be sure that the

mounting column of the coder is parallel to the idler roll.

2 - Insert the mounting column into the

mounting bracket and allow the print

drum to pivot into contact with the

idler roll. Do not tighten the bracket

clamping screw at this time.

PRINT DRUM

AL

MOUNTING

COLUMN

MOUNTING BRACKET

CLAMPING SCREW

MOUNTING

BRACKET

3/8” BOLTS

SPRING TENSION ARM

TENSION SPRING

FIGURE 35

PRESS DOWNWARD

IDLER ROLL

IDLER ROLL

FIGURE 34

3 -Press down lightly on the spring tension arm

to compress the tension spring slightly . (Figure 35) While holding a light pressure on the

arm, tighten the mounting bracket clamping

screw.

Note: This procedure is used to adjust the contact

pressure which the print drum exerts against the

web. Only enough pressure should be applied to

ensure positive friction drive of the print drum. Excessive contact pressure will impose unnecessary

drag on the web and may result in poor print quality .

20

Page 21

WEB PRINTING

DO NOT INST ALL A 4 oz. RESERVOIR INK CARTRIDGE A T THIS TIME. The coder is designed to print using

the ink contained in the pre-inked ink roll. Since a freshly saturated Ink Roll was just installed on the coder, the

system will have plenty of ink. Installing a 4 oz. Reservoir Ink Cartridge immediately will result in over saturation

of the ink roll and flooding of the Inking System. The 4 oz. Reservoir Ink Cartridge should not be installed until

most of the ink is consumed from the ink roll and the print quality shows signs that more ink is needed.

SPECIAL WEB PRINTING APPLICATIONS

In applications where the web material is too narrow for both friction drive bearers to contact the surface of the

web, contact with one friction bearer is acceptable. When the web is too narrow for even one friction bearer to

contact the web and still position the print as necessary, a custom made guide roller can often be utilized.

PRINTING ON NARROW WEB MA TERIALS

Using this approach, the guide roll must be machined with

a groove which will not only accurately guide the web material and drive the guide roll but it must also keep the surface

of the web material flush with the surface of the guide roll

PRINT

DRUM

FRICTION

BEARER

NARROW

WEB MA TERIAL

GROOVE

AL

MODIFIED

GUIDE

ROLLER

where the friction bearers make contact. (See Figure 36.)

This method of mounting is generally more appropriate when

the web material is extruded rubber or some similar material which has a high coefficient of friction since it must drive

both the guide roll and the print drum. Using a custom guide

roller which is driven by an external power source is certainly acceptable but it is generally rather costly since the

surface speed of the guide roller must precisely match the

speed of the web or smeared prints will result.

FIGURE 36

PRINTING DIRECTL Y ON MASTER ROLLS

Universal Non-Porous Conveyor Line Printers can also be

mounted on custom designed extension arms which will

enable them to print directly on the surface of a master roll

of web material as it is unwound. This technique is frequently used when conveniently positioned idler rolls are

not available. In these applications, as the master roll of

web material decreases in size, the mounting arm pivots

and keeps the print drum in constant contact with the surface of the roll as shown in Figure 37. In these installations, the weight of the coder is used to supply printing

pressure and typically the standard spring tension mechanism and mounting column are removed. Custom mounting brackets and extension arms should be carefully designed to keep the coder in an acceptable attitude when

printing on a full roll of film all the way down to the smaller

diameter of the core. For more details on custom mounting systems, contact our engineering department.

21

PIVOT

POST

CODER

TRAVEL

EXTENSION ARM

CODER

WEB TRAVEL

MASTER

ROLL

FIGURE 37

Page 22

WEB PRINTING

GANG MOUNTING

In web printing applications where multiple coders are required to be mounted across the web, Universal offers

special mounting hardware which facilitates gang mounting the coders as indicated in Figure 38. In these installations, special CLP-SBA Saddle Mount Bracket Assemblies are used in conjunction with an extruded structural

aluminum mounting bridge. The 1.5" x 3.0" extruded aluminum bridge is ordered in an appropriate length to span

across the web line and custom mounting plates are designed to support the bridge. The coders are installed

using the Saddle Mounts which provide quick lateral positioning adjustment capabilities for the coder . T o position

the coder, a ratchet handle is loosened and the Saddle Mount can be moved laterally to the desired position and

retightened.

For additional information on this mounting option, please contact our Engineering Department.

PRODUCT

TRAVEL

PRODUCT TRA VEL

SADDLE MOUNT

BRACKET ASSEMBL Y

EXTRUDED ALUMINUM BRIDGE

FIGURE 38

22

Page 23

CARTON PRINTING

Printing on non-porous surfaces, such as waxed or varnished cartons, can be accomplished easily with Universal Non-Porous Conveyor Line Printers. The selection of an appropriate place for installation on your conveyor

line or other packaging equipment is a very important consideration in the performance of your coder . The most

important factor to consider is carton alignment.

CARTON ALIGNMENT

T o ensure print reliability and prevent damage to your coders, the cartons must be accurately guided through the

printing station by guide rails as shown in Figure 39. If your conveyor is not equipped with guide rails - they must

be installed before proceeding with coder installation.

station is imperative. Improper alignment will produce poor print quality, poor print registration, and in extreme

cases, could damage the machine.

Proper alignment of the cartons as they pass the printing

GUIDE RAILS

IMPROPER ALIGNMENT PROPER ALIGNMENT

FIGURE 39

Universal Non-Porous Conveyor Line Printers are spring loaded so that the print drums will press against the

carton surface on contact. This pressure is necessary to accomplish the friction drive rotation of the print drum

and ensure enough printing pressure to give you a sharp impression. The spring tension mechanism on the

coder will also compensate for slight variations in the width of the cartons without jamming the conveyor line.

Excessive pressure, caused by improperly guided cartons, will result in smudged impressions and could cause

damage to the spring tension mechanism.

23

Page 24

CARTON PRINTING

Universal Non-Porous Conveyor Line Printers are designed so the frame of the machine will pivot on the mounting column. This allows the print drum to deflect, or swing, on contact with the leading edge of the carton a

maximum of 2". It is recommended that cartons be aligned between guide rails with no more than 1/4" clearance

on each side as shown in Figure 40. This should allow ample clearance for cartons and protect your printer from

damage.

CLEARANCE 1/4”

PRINTERS MOUNTED IN

CLOSE PROXIMITY TO

END OF GUIDE RAILS

CLEARANCE 1/4”

FIGURE 40

GUIDE RAILS

In most applications, installation of the printer can be accomplished by attaching the mounting bracket to the side

rails of the powered conveyor using two 3/8" machine bolts. The printers should be mounted as close as

possible to the end of the guide rails to ensure that proper carton alignment is maintained at the printing station.

Before tightening the mounting bolts, check alignment of the print drum. It is very important for proper tracking

that the top of the print drum is parallel to the top of the conveyor (Figure 41) and the side of the print drum is

parallel to the side of the carton (Figure 42). Once this alignment has been achieved, tighten the mounting bolts.

IMPROPER

TOP ALIGNMENT

PROPER

TOP ALIGNMENT

FIGURE 41 FIGURE 42

IMPROPER

SIDE ALIGNMENT

24

PROPER

SIDE ALIGNMENT

Page 25

CARTON PRINTING

Loosen the mounting column clamping bolt (Figure 43) and position the printer to the required height for printing.

Swing the printer into position so that the print drum will lightly contact the side of the cartons as they emerge

from between the guide rails. Check the print drum contact with the cartons while the conveyor is under power

and adjust the print drum position to obtain approximately 1/4" - 3/8" deflection (Figure 44).

PIVOT POINT

ADJUST FOR

1/4” TO 3/8”

DEFLECTION

PIVOT POINT

MOUNTING COLUMN

CLAMPING SCREW

FIGURE 43 FIGURE 44

DIE POSITIONING FOR INDEXING APPLICATIONS

Non-Indexing models of the coder do not

offer print registration capabilities, therefore mounting the printing dies at a specific location on the print drum is not important. On Indexing machines, however,

the position of the die on the print drum

determines the registration of the print on

the carton. Since non-porous marking

inks are normally extremely fast drying, die

positioning will also have an affect on the

ability of the coder to reliably transfer ink

to the carton surface. Production cycle

rates, ambient temperature and ink selection are also factors which have to be considered to ensure proper performance of

the system.

TRANSFER ROLL

LEADING EDGE

OF DIE

LEADING EDGE

OF CARTON

FIGURE 45

Figure 45 illustrates the best die position for carton printing when using extremely fast drying inks. Note that the

leading edge of the printing die should be positioned rotationally upstream of the transfer roll. When the leading

edge of the carton contacts the print drum, the drum begins to rotate in a clockwise direction. The die travels a

short distance and then contacts the transfer roll where ink is applied to the die face. When the die contacts the

carton the mark is applied. The print drum will continue to rotate until the trailing edge of the carton passes the

coder, then the print drum will automatically return to the same st arting position.

25

Page 26

CARTON PRINTING

Although installing the printing dies in this position restricts how close to the leading edge of the carton you can

register the print, it is one of the only ways to ensure a good imprint on every carton. Since the fastest drying nonporous inks will dry in approximately 2 seconds at 75 Degree F. ambient temperature, the ink will also dry on the

die face within 2 seconds after it is applied by the transfer roll. If the dies have not contacted the carton surface

before then, no imprint will be transferred to the carton.

If the cycle rate of the production line is very fast and the ambient temperature is relatively low, the printing dies

could be positioned rotationally downstream of the transfer roll so they print much closer to the leading edge of

the carton. When the coder completes one printing cycle, a portion of the die or all of the die may have already

passed the transfer roll and picked up ink in preparation for printing the next carton. The machine can remain idle

like this for only a second or so before the next carton must contact the print drum or the ink will dry on the die

face and not be transferred to the carton.

If your production cycle rate is not fast enough but you still need to print close to the leading edge of the carton, the

only alternative is to use a slower drying non-porous ink. When making the ink selection, be sure to consider

ambient temperature, it can have a dramatic affect on ink drying times. Hot temperatures make inks dry faster ,

cold temperatures retard drying.

26

Page 27

MAINTENANCE

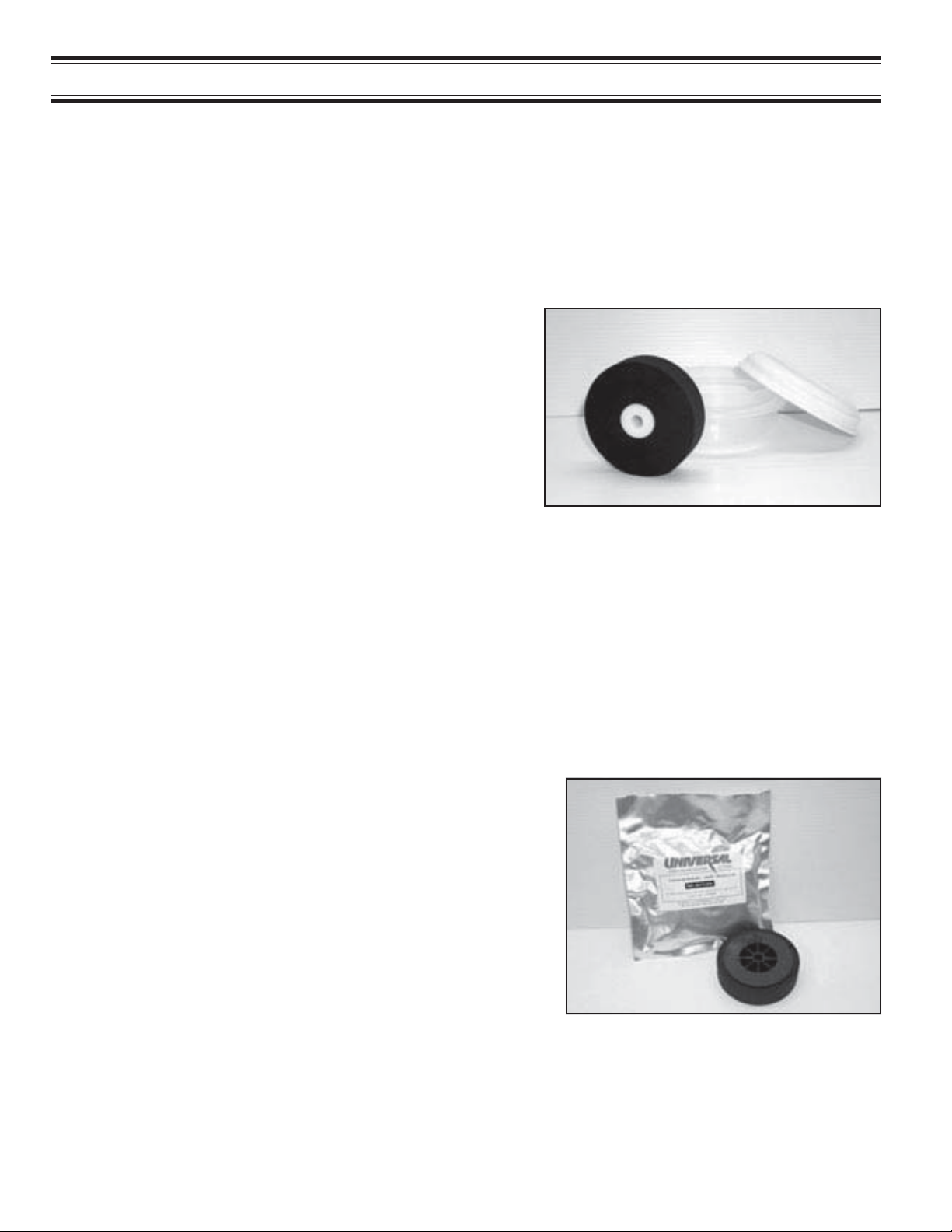

PRE-INKING A NEW INK ROLL

When you are ready to begin printing, you must first install an ink roll which has been properly pre-inked with the

appropriate non-porous ink. Unless you ordered a pre-inked roll with your machine, you will find a dry roll in a

plastic container with your coder . Note: Dry rolls cannot be inked automatically using the 4 Oz. Reservoir

Ink Cartridges.

Warning: Non-Porous Inks contain flammable solvents. Do not smoke or handle these rolls in the presence of sparks

or open flames. Inks will also stain clothing, furniture, carpeting and your hands. Rubber gloves should be worn

during the following procedures.

A dry XF Neoprene ink roll has the same characteristics as a sponge with the capacity to absorb approximately

3-4 fluid ounces of ink in 1" rolls and 6-7 fluid ounces of ink in 2" rolls. Please follow the guidelines below to

properly pre-ink your roll:

1 - Remove the dry roll from the storage container. Pour 3 to

4 oz. of ink into the container. Note: The ink level should

be just below the textured line “R” on the side of the container.

2 - Carefully place the roll into the container of ink. Using

your finger tips, firmly press down on the foam side of the

ink roll and then release the pressure. Repeat this process several times while rotating the roll in the container

and pressing on different areas. This will force the air out

of the roll and the voids will be filled with ink.

Remove the roll from the storage container and turn it over , placing the un-inked side down in the container . Repeat the process

above until all the ink in the container has been absorbed into

the roll.

3 - Inspect the roll to ensure it is completely saturated with

ink but not dripping wet. If the surface of the roll seems

excessively wet after inking, remove the excess ink by inserting a rod through the core and while pressing down

lightly, roll the roller across a clean piece of paper.

FIGURE 46

FIGURE 47

After this process is completed, the roll should immediately be

installed on the coder or it should be placed back in the storage

container and the lid tightly sealed to prevent solvent evaporation.

27

FIGURE 48

Page 28

MAINTENANCE

CLEANING THE TRANSFER ROLL

The surface of the transfer roll is made from DuPont Delrin material and the O.D. of the roll is finely engraved

which enables it to hold a uniform film of ink. This surface material is very fragile and under no circumstances

should you attempt to clean it with anything abrasive.

Warning: Most of the ink solvents used for cleaning are flammable liquids. Follow all safety precautions recommended by the manufacturer during this process.

1 - To clean dust and ink residue from the surface of the

transfer roll, first remove it from the coder. Lightly

saturate a soft cotton cloth with the appropriate ink

solvent and gently rub the surface of the roll until it is

clean.

DO NOT SUBMERGE THE TRANSFER ROLL IN SOLVENT!

If the transfer roll is submerged in solvent, the bearings will

be permanently damaged.

CLEANING THE CODER

1 - Periodically, the inking system should be disas-

sembled and inspected for ink residue and dust contamination. To remove ink contamination from the

surface of the machine, moisten a soft cotton cloth

with the appropriate ink solvent and rub it across the

contaminated area.

The frequency of required cleaning can be greatly reduced if

the inking system is kept in proper adjustment during normal operation and if the ink roll does not become over saturated with ink.

FIGURE 49

28

FIGURE 50

Page 29

MAINTENANCE

CLEANING THE PRINTING DIES

All inks which are formulated for printing on non-porous surfaces contain a resin binder which bonds the dye or

pigment in the ink to the surface of the material being printed. As the ink begins to dry, this binder becomes

“tacky” or “sticky”. While in this stage of the drying process, the tack on the printing dies will tend to pick up both

airborne dust and any dust or dirt on the surface of the material being printed. After some period of use, the

accumulation of contaminates on the printing dies will cause degradation of the print quality . When this happens,

the dies should be cleaned or replaced. Cleaning the printing dies is a very easy process and, excluding excessive wear to the die face, will restore the print quality of the coder.

The easiest method of cleaning Printing Dies requires the appropriate solvent for the ink being used, a pair of

rubber gloves, safety glasses, an apron to protect your clothing is recommended, a toothbrush, some clean

paper towels and a plastic bag to protect your workbench from staining. (Naturally, the toothbrush will never be

suitable for oral hygiene use after this process.)

1 - Place the contaminated Printing Die on top of several lay-

ers of paper towels to absorb the excess solvent. Pour

just enough solvent on the face of the die to cover the die

face.

2 - Using the toothbrush, carefully scrub the face of the die

to remove the contamination and old ink as shown in. Add

more solvent as necessary and repeat the process until

the die is clean.

Do not submerge or soak the dies in solvent as this may cause

swelling of the rubber compound.

3 - Blot the surface of the die with a clean paper towel to dry

as shown in and reinstall the clean dies on the coder.

FIGURE 51

FIGURE 52

29

FIGURE 53

Page 30

MAINTENANCE

MOUNTING CONFIGURATION CONVERSION

LEFTHAND/RIGHTHAND FIELD CONVERSION

Mounting configuration conversion involves the “mirror image” reversal of the pivot arm assembly that holds the

inking system and the tension arm assembly which provides the printing pressure. Indexing printers require the

additional reversal of the index ramp and repositioning of the index ring.

Universal Non-Porous CLP Coders are assembled at the factory for either right-hand or left-hand mounting. If

field conversion is required, the following steps will guide you through the conversion process.

PIVOT ARM & INKING SYSTEM ASSEMBLY CONVERSION

1- Loosen the Pivot Arm Adjustment Knob and rotate the Inking System away from the Print Drum slightly .

2- Remove the Inking System Assembly from the coder by removing the 2 socket head cap screws on

the underneath side of the Pivot Arm.

3- Remove the Pivot Screw and lift the tension adjustment assembly off of the coder.

4- Remove the Pivot Arm Cap and lif t the Pivot Arm assembly off it’s axle.

5- Reinstall the Pivot Arm on the axle in the opposite or “mirrored” orientation and replace the Pivot

Arm Cap.

6- Remove the Position Adjusting Screw and reinstall in the reverse position.

7- Replace the tension adjusting assembly and the Pivot Screw.

INKING SYSTEM

ASSEMBLY

PIVOT ARM

PIVOT SCREW

PIVOT ARM CAP

POSITION ADJUSTING

SCREW

PIVOT ARM

ADJUSTMENT KNOB

LEFT HAND

CONFIGURATION

FIGURE 54

TENSION

ADJUSTMENT

ASSEMBLY

RIGHT HAND

CONFIGURATION

8 - Remove the Baseplate Plug from the bottom side of the Inking System Assembly Baseplate (See

Figure 55).

9 - Reinstall the Baseplate Plug in the threaded hole on the opposite side of the Baseplate. Thread the

Plug into the Baseplate only until the flush with the Baseplate surface.

30

Page 31

MAINTENANCE

10 -Reinstall the Inking System Assembly and

adjust as explained on Page 9 - Installing the

Inking System Assembly .

SET SCREW

POSITION

FOR RIGHT

HAND MOUNT

BOTTOM VIEW OF

INKING SYSTEM BASEPLATE

FIGURE 55

SET SCREW

POSITION

FOR LEFT

HAND MOUNT

TENSION ARM ASSEMBLY CONVERSION

1- Loosen the Lock Nut and screw the Adjusting Bolt in to relieve the spring pressure (Figure 56).

2- Remove the spring by lifting the end off the Locating Button.

3- Remove the Adjusting Bolt and replace it on the opposite side of the Tension Arm.

4- Remove the Spring Cup and replace it on the opposite side of the Tension Arm.

5- Replace the Spring by inserting one end into the Spring Cup and lifting the other end over the

Locating Button.

6- Readjust the position of the Adjusting Bolt to center the Tension Arm between the sides of the coder

base plate. Snug the Lock Nut against the Tension Arm to prevent movement from conveyor vibration.

SPRING CUP

LOCATING

BUTTON

SPRING

LOCATING

BUTTON

ADJUSTING BOLT

LOCK NUT

TENSION ARM

FIGURE 56

31

Page 32

MAINTENANCE

PRINT DRUM INDEX MECHANISM CONVERSION

1- Using a 5/64” hex wrench, loosen the Nylon Tip Set Screw

located in the top rim of the Print Drum.

2- Remove the Print Drum Dust Cover.

FIGURE 57

3- To relieve the spring tension on the index mechanism, ro-

tate the Print Drum approximately 3/4 turn. The Index Compression Springs will now be in the fully extended (relaxed)

position.

4- Using a 5/32" hex wrench, remove the two Index Ramp Mount-

ing Screws which are located on the under side of the Coder

Baseplate. The Index Ramp will be reinstalled in the opposite orientation to allow the Print Drum to turn in the reverse

direction.

FIGURE 58

FIGURE 59

32

FIGURE 60

Page 33

MAINTENANCE

5- Using a 1/8" hex wrench, loosen the Brass Tipped Set Screw

located in the side of the Index Ring until the Index Ring

rotates freely.

PRINT DRUM AXLE

RECESS AREA

.04

BRASS TIP

SET SCREW

FIGURE 61

Important Note: The Print Drum Axle is machined with

thread relief as shown in Figure 40 so the tip of the set

screw will not damage the threads. To completely remove

the Index Ring from the Axle, the Brass Tip Set Screw must

be loosened at least 2 full turns to prevent damage to the

threads.

FIGURE 62

6- Rotate the Index Ring in a clockwise direction until it stops turning. Next, turn the Index Ring in the

counterclockwise direction as necessary until the Brass Tip Set Screw is pointing directly at the

Transfer Roll Axle as shown in Figure 63.

INDEX PLUNGER

INDEX RING

INDEX RING PIN

BRASS TIP SET SCREW

TRANSFER

ROLL AXLE

LEFT HAND

CONFIGURATION

FIGURE 63

RIGHT HAND

CONFIGURATION

7- Retighten the Brass Tipped Set Screw to lock the Index Ring in position. This screw must be tight to

prevent the Index Ring from rotating under spring tension.

33

Page 34

MAINTENANCE

8- Reinstall the Index Ramp in the proper orientation for your mounting configuration as shown in

Figures 64 & 65.

RIGHT HAND CONFIGURATION

FIGURE 64

LEFT HAND CONFIGURA TION

FIGURE 65

REPLACING PRINT DRUM INDEX SPRINGS

1- To replace Print Drum Index Springs, rotate the Print Drum approximately 3/4 turn to relieve spring

tension as shown in Figure 59, Page 32.

2- Using a small screwdriver, remove the two Snap Rings on

the Index Spring Assembly.

3- Remove the Index Spring Assembly by lif ting it straight up off

the pivot pins.

34

FIGURE 66

FIGURE 67

Page 35

MAINTENANCE

4- Holding onto the Index Assembly Block “A”, pull the Index Assembly Block “C” off the guide shaf t s

(Figure 68). Remove the Drum Index Springs (Figure 69)

FIGURE 68

FIGURE 69

5- Install new Index Springs over the stainless steel guide shafts and replace Index Block “C”.

Ensure that Block “C” is installed in the same orientation as Block “A” with the flange of the white bushing (the

large diameter end) facing in the same direction.

6- Reinstall the Index Spring Assembly in the Print Drum with the flanges of the white bushings facing

the open end of the Print Drum.

7- Reinstall the two Snap Rings.

REMOVING AND REPLACING INDEX BLOCK “B”

1- To remove Index Block “B” from the Print Drum, roll down

the RIBtype Drum Cover directly behind the Index Block to

®

expose the Index Assembly Mounting Screw. Using a screw

driver, turn the Mounting Screw in a clockwise direction until the Index Block becomes loose and can be removed.

35

FIGURE 70

Page 36

MAINTENANCE

2- Lift Index Block “B” straight up to remove.

The head of the Index Assembly Mounting Screw engages the TSlot in Index Block “B”. This mounting design facilitates height

adjustment of the Index Block during reassembly .

FIGURE 71

Before replacing Index Block “B”, ensure that the Index Ring is properly adjusted as explained in

Steps 5 - 7 on Page 33.

3- When replacing Index Block “B” it is very important to align

the top surface of the Index Block with the top surface of the

Index Ring as shown in Figure 72.

The easiest way to accomplish this is to hold a flat block of metal

or wood across the top of the Index Ring. While holding the block in

place, raise Index Block “B” up to contact the bottom of the alignment block. Ensure that Block “B” is level and vertically aligned

with the Index Ring.

4- While holding Index Block “B” in this position, tighten the

Index Assembly Mounting Screw by turning it counterclock-

wise until tight.

FIGURE 72

36

FIGURE 73

Page 37

MAINTENANCE

INKING SYSTEM ASSEMBLY

The following steps will guide you through the Ink Roll Eccentric Assembly.

1 - Install the O-Ring in the groove of the Eccentric flange,

then install one of the white delrin washers on the Eccentric.

2 - Apply a thin coating of grease to the O-Ring and the Ec-

centric to approximately 1/2” from the flange.

Automotive wheel bearing grease is recommended.

ECCENTRIC O-RING

FIGURE 74

FIGURE 75

3 - Insert the Eccentric into the Inking System Cover. Rotate

and pull the Eccentric from the opposite side until the oring slips into the bore. When fully seated, the flange of

the eccentric will be approximately 0.010” above the surface of the cover. Rot ate the Eccentric and align the dimple

on the Eccentric flange with the dimple in the cover.

4 - Install the second white delrin washer over the Eccentric.

ALIGN DIMPLES

FIGURE 76

FIGURE 77

37

Page 38

MAINTENANCE

5 - Install the Eccentric Knurled Knob and align the engraved

line on the knob with the “MAX” line on the Inking System

Cover. Set the ink roller axle on a small block of wood or

metal . The block used should be tall enough so the entire

assembly is supported by the ink roller axle (the Inking System Cover should not touch the table top).

6 - Press down firmly on the Eccentric Knurled Knob. While

holding pressure on the knob, tighten the two set screws.

When adequate pressure is applied to the Eccentric Knob during assembly , the knob should have a moderate resist ance to

turning. When assembled properly , the ink roller axle should be

feel rigid.

FIGURE 78

FIGURE 79

38

Page 39

NON-POROUS CONVEYOR LINE PRINTER CE GUARD ASSEMBLY

6

5

4

1

2

3

NON-POROUS CONVEYOR LINE PRINTER CE GUARD ASSEMBLY PARTS LIST

KEY NO.

1

2

3

4

5

6

PAR T NUMBER

CF-32

NP-23

MS-36

NP-70

NP-72

NP-73

NP-71

1

1

4

1

1

1

SCREW, 5/16-18 X 1/2” SHC

SCREW, 1/4-20 X 1/2” SHC

SCREW, 8-32 X 1/2” SHC

MOUNTING ARM, CLP CE GUARD

TOP PLA TE, #100 CLP CE GUARD

TOP PLA TE, #200 CLP CE GUARD

END PLA TE, CLP CE GUARD

DESCRIPTION QTY . REQD.

39

Page 40

NON-POROUS CONVEYOR LINE PRINTER ASSEMBLY

29

1

28

2

27

3

4

7

6

8

9

10

11

12

5

14

13

15

16

17

18

26

25

23

24

23

22

21

40

19

20

Page 41

NON-POROUS CONVEYOR LINE PRINTER PARTS LIST

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PAR T NUMBER

CM-04

CF-05

CW-03

CA-06

CA-02

NP-18

CM-27

CF-26

CLP-PAB

CM-26

NP-28

CW-04

CA-03

CM-16

CF-02

CS-06

CM-25

QTY . REQD.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

DESCRIPTION

KNURLED RETAINING RING

SET SCREW, 8-32 X 3/16” S.S. NPS

WASHER, PRINT DRUM BRASS

PRINT DRUM AXLE - 1”

PRINT DRUM AXLE - 2”

KNOB, PIVOT ARM ADJUSTMENT

BLOCK “A ’ PIVOT ARM

SHOULDER SCREW

BLOCK “B” ASSEMBL Y, PIVOT ARM

PIVOT ARM POST

PIVOT ARM ASSEMBL Y , NON-POROUS

WASHER, PIVOT ARM BRASS

AXLE, PIVOT ARM

CAP , PIVOT ARM

SCREW, 1/4-20 X 1-1/4” SHC

SPRING , TENSION ARM COMPRESSION

TENSION ARM ADJUSTING CUP

17

18

19

20

21

22

23

24

25

26

27

CF-11

CF-10

CF-09

CW-02

CM-17

CLP-MCA

CW-05

CC-01

CW-01

CF-13

CLP-100NI-NP-PDA

CLP-100NP-PDA

CLP-200NI-NP-PDA

CLP-200NP-PDA

CLP-100NI-NP-PDA-T

CLP-100NP-PDA-T

CLP-200NI-NP-PDA-T

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

HEX NUT

HEX BOLT

SCREW, 3/8-16 X 1-1/2” SHC

3/8” STEEL FLA T W ASHER

MOUNTING BRACKET

MOUNTING COLUMN ASSEMBL Y

3/4” NYLON FLAT W ASHER

BASE PLATE ASSEMBL Y

3/4” STEEL FLA T W ASHER

SNAP RING , FOR 3/4” SHAFT

1” NON-INDEXING PRINT DRUM ASSEMBLY - COMPLETE

1” INDEXING PRINT DRUM ASSEMBL Y - COMPLETE

2” NON-INDEXING PRINT DRUM ASSEMBLY - COMPLETE

2” INDEXING PRINT DRUM ASSEMBL Y - COMPLETE

1” NON-INDEXING PRINT DRUM ASSEMBLY - COMPLETE - METRIC

1” INDEXING PRINT DRUM ASSEMBL Y - COMPLETE - METRIC

2” NON-INDEXING PRINT DRUM ASSEMBLY - COMPLETE - METRIC

28

29

CLP-200NP-PDA-T 1

CF-04

CM-13

2” INDEXING PRINT DRUM ASSEMBL Y - COMPLETE - METRIC

1

1

SET SCREW, 1/4-20 X 3/8” BTS

DUST COVER

41

Page 42

NON-POROUS CONVEYOR LINE PRINTER INKING SYSTEM ASSEMBLY

1

2

3

4

5

6

7

20

19

18

17

16

15

14

8

9

10

11

42

13

12

Page 43

NON-POROUS CONVEYOR LINE PRINTER INKING SYSTEM PARTS LIST

KEY NO.

1

2

3

4

5

6

7

8

9

10

11

12

NP-17

NP-16

NP-15

NP-14

NP-01-CS

NP-01-CT

NP-02-CS

NP-02-CT

NP-TRA-1

NP-TRA-2

NP-05

NP-06

HP-04

NP-03

NP-31

NP-23

NP-24

QTY . REQD.PAR T NUMBER

1

1

1

1

1

1

1

1

1

1

2

1

COVER RET AING KNOB

DRIVE WHEEL COVER

DELRIN WASHER, DRIVE WHEEL

KNURLED DRIVE WHEEL ASSEMBL Y W/NP-15 DELRIN WASHER

INKING SYSTEM COVER ASSEMBL Y - SIDE MOUNT - CLP-100 SERIES

INKING SYSTEM COVER ASSEMBL Y - TOP MOUNT - CLP-100 SERIES

INKING SYSTEM COVER ASSEMBL Y - SIDE MOUNT - CLP-200 SERIES

INKING SYSTEM COVER ASSEMBL Y - TOP MOUNT - CLP-200 SERIES

1” TRANSFER ROLL ASSEMBL Y

2” TRANSFER ROLL ASSEMBL Y

1” CLP TRANSFER ROLL AXLE

2” CLP TRANSFER ROLL AXLE

BRASS WASHER, PRINT DRUM

CLP NON-POROUS INKING SYSTEM BASEPLA TE

SET SCREW, 1/4-20 X 3/8” FPS

SCREW, 1/4-20 X 1/2” SHC

SET SCREW, 5/16-18 X 3/8” FPS

DESCRIPTION

13

14

15

16

17

18

19

20

NP-XC1

NP-XC2

NP-21

NP-07

NP-08

NP-20C

NP-29

*NP-KRP

HP-42

NP-19

HP-06

1

1

1

1

1

2

1

2

1” CLP XF NEOPRENE INK ROLL - DRY

2” CLP XF NEOPRENE INK ROLL - DRY

O-RING , ECCENTRIC

1” CLP INK ROLL AXLE

2” CLP INK ROLL AXLE

ECCENTRIC, INK ROLL

BLACK VINYL CAP

KNURLED RESERVOIR PLUG

DELRIN WASHER

ECCENTRIC KNURLED KNOB

SET SCREW , 8-32 X 3/16” CPS

*OPTIONAL THREADED PLUG WITH O-RING SEAL FOR RESERVOIR PORT

43

Page 44

NON-POROUS CONVEYOR LINE PRINTER PRINT DRUM ASSEMBLY

1

23

4

NON-POROUS CONVEYOR LINE PRINTER PRINT DRUM ASSEMBLY PARTS LIST

KEY NO.

1

2

3

4

CO-02S

CLP-BL1

CLP-BL2

CLP-BL1T

CLP-BL2T

CLP-PD1-NP

CLP-PD1I-NP

CLP-PD2-NP

CLP-PD2I-NP

CLP-PD1-NPT

CLP-PD1I-NPT

CLP-PD2-NPT

CLP-PD2I-NPT

CB-04

QTY . REQD.PAR T NUMBER

2

1

1

2

FRICTION BEARER RING - SQUARE CUT

1” CLP RIBtype RING

2” CLP RIBtype RING

1” CLP RIBtype RING - METRIC

2” CLP RIBtype RING - METRIC

CLP-100 NON-INDEXING PRINT DRUM (W-CB-04 PRINT DRUM BEARINGS)

CLP-100 INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS)

CLP-200 NON-INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS)

CLP-200 INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS)

CLP-100 NON-INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS) - METRIC

CLP-100 INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS) - METRIC

CLP-200 NON-INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS) - METRIC

CLP-200 INDEXING PRINT DRUM (W/CB-04 PRINT DRUM BEARINGS) - METRIC

PRINT DRUM BEARING

®

®

®

®

DESCRIPTION

44

Page 45

NON-POROUS CONVEYOR LINE PRINTER INDEX ASSEMBLY

1

2

11

10

9

3

4

5

6

7

8

NON-POROUS CONVEYOR LINE PRINTER INDEX ASSEMBLY PARTS LIST

KEY NO.

1 CF-28 2 SNAP RING

2

3

4

5

6

7

8

9

10

11

CLP-IA

CLP-IB

CF-27

CS-07

CLP-IC

CM-34

CF-29

CLP-IP

CLP-IR2

CF-04

QTY . REQD.PART NUMBER

1

1

1

2

1

1

2

1

1

1

INDEX ASSEMBL Y BLOCK “A”

INDEX ASSEMBL Y BLOCK “B”

INDEX ASSEMBL Y MOUNTING SCREW

DRUM INDEX SPRING

INDEX ASSEMBL Y BLOCK “C”

INDEX RAMP

SCREW, 10-32 X 1/2” SHC

INDEX PLUNGER ASSEMBL Y

INDEX RING

SET SCREW, 1/4-20 X 3/8” BTS

DESCRIPTION

45

Loading...

Loading...