Page 1

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

MA1

INSTRUCTION MANUAL

Page 2

Introduction

The MA1 is a high sensitivity direct reading AC ammeter. It is designed

to simplify the setting of oil and gas thermostat heat anticipator and for

measuring the performance of AC relays, solenoids and other low current AC devices.

Features include

• Ranges: 0 - 1.2 AC Amps

• A c c u r a cy: ±3% of full sca l e

Safety Notes

Before using this meter, read all safety information carefully. In

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

Operating Instructions

WARNING!

Like all direct reading ammeters, the MA1 must be connected IN

SERIES with the circuit under test. The maximum value of current

that can be measured with the MA1 is 1.2 AC amperes (1,200 AC

milliamps). Do not exceed this value or the MA1 may be damaged.

Testing Heat anticipator

For the most efficient operation, the heat anticipator in the thermostat

must be set to correspond to the value of the control circuit current.

Thermostats are of two types: preset or adjustable. Many cooling

thermostats and some heating thermostats are preset. these require

no adjustment.

Adjustable thermostats should be set to the value of current noted on

the furnace rating label. If this information is not available then the

control current must be measured and the heat anticipator set to the

measured value of current as follows:

1. Remove the thermostat cover from the sub base.

2. Set the furnace controls to the ON position

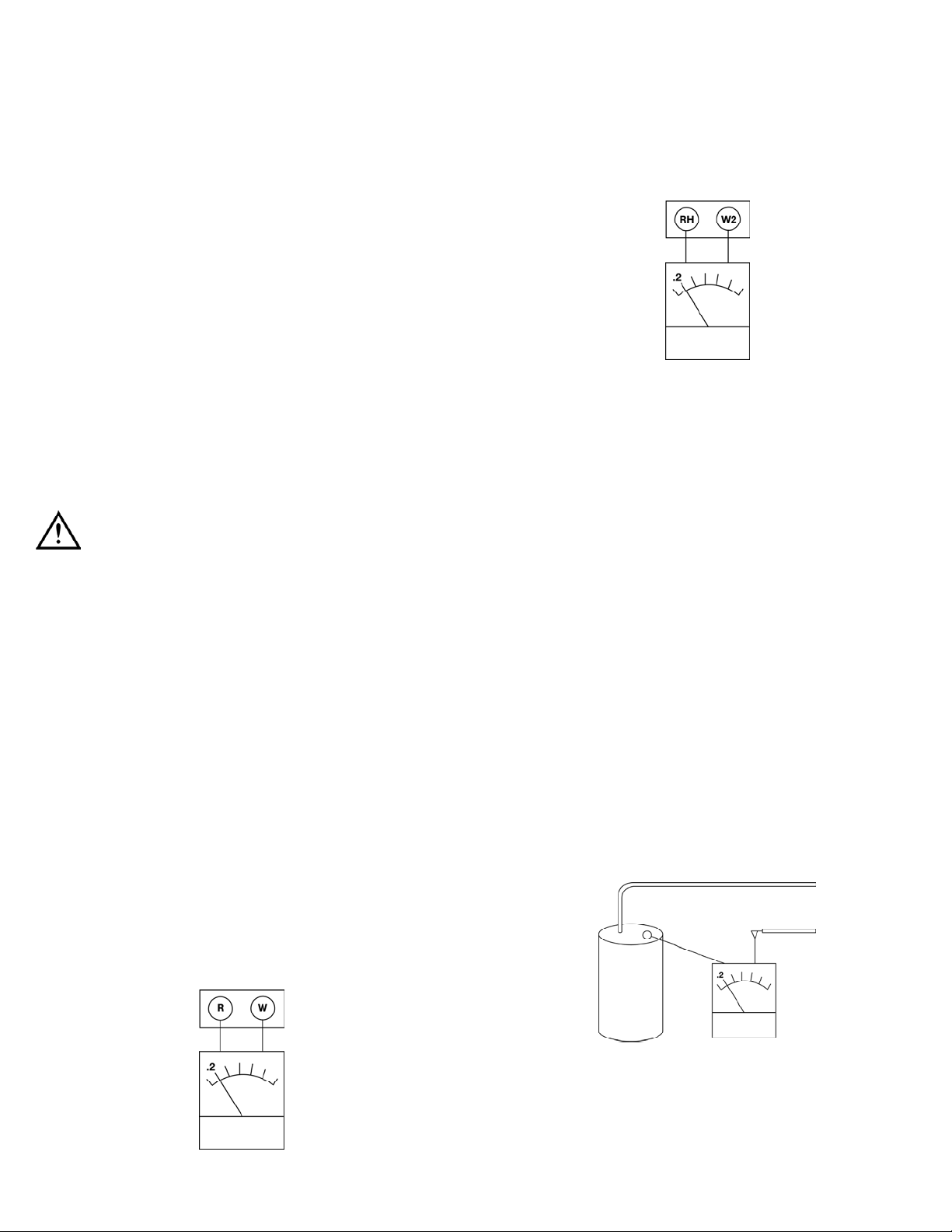

3. For thermostats with a single stage heat control connect one lead

of the MA1 to the “R” terminal on the sub base and the other

lead of the MA1 to the “W” terminal (Fig 1).

4. Note the magnitude of the current on the meter scale of the MA.

Set the heat anticipator to this value of current.

5. For thermostats with a two stage heat control repeat steps 1 thru

4 for stage 1. The second stage heat control current is measured

by connecting one lead of the MA1 to the “RH” terminal and the

other lead to the “W2” terminal (Fig 2).

6. Replace the thermostat cover and check the system for

proper operation.

NOTE: If a fan limit control is used this can affect the length of

the heating cycle. Check the ON and OFF fan control set points.

NOTE: If a longer heating cycle is desired, the pointer on the sub base

can be adjusted to a slightly higher setting. If a shorter cycle is desired

the pointer can be adjusted to a slightly lower setting.

Typical Values of Control Circuit Current:

1. 0.2 amperes for gas furnace without spark igniter.

2. 0.4 thru 0.8 amperes for gas furnace with spark igniter.

3. 1.0 amperes for oil furnace.

Other Uses For MA1

The MA1 can also be used to check the operating current of AC relays,

solenoids, motors and other devices rated at 1.2 AC amperes or less.

1. Turn OFF the power to the device to be tested.

2. Disconnect one of the power input leads at the device to be tested.

3. Connect one lead of the MA1 to the device and the other lead to

the power input wire previously disconnected (Fig 3).

MA1-MAN P. 1

(Fig 1)

(Fig 2)

(Fig 3)

MA1

Typical

sub base

MA1

Power input lead

MA1

Typical

sub base

Motor

Page 3

4. Check to make sure that the lead connections are not shorting to

each other or the frame.

5. Turn ON the power and read the current on the MA1.

6. Readings higher than normal can indicate: shorted turns in the

winding, high supply voltage, or restricted rotation in motors.

7. Readings lower than normal can indicate low supply voltage or

dirty or corroded electrical connections.

8. Turn OFF the power and disconnect the MA1. Reconnect, repair or

replace the device, as required.

M a i n t e n a n c e

Periodic Service

WARNING!

Repair and service of this instrument is to be performed by qualified

personnel only. Improper repair or service could result in physical

degradation of the meter. This could alter the protection from

electrical shock and personal injury this meter provides to the

operator. Perform only those maintenance tasks that you are

qualified to do.

These guidelines will help you attain long and reliable service from

your meter:

• Calibrate your meter annually to ensure it meets original

performance specifications

• Keep your meter dry. If it gets wet, wipe dry immediately.

Liquids can degrade electronic circuits

• Whenever practical, keep the meter away from dust and

dirt that can cause premature wear

• Although your meter is built to withstand the rigors of daily

use, it can be damaged by severe impacts. Use reasonable

caution when using and storing the meter

Cleaning

Periodically clean your meter’s case using a damp cloth. DO NOT use

abrasive, flammable liquids, cleaning solvents, or strong detergents as

they may damage the finish, impair safety, or affect the reliability of the

structural components.

MA1-MAN P. 2

Page 4

Limited Warranty

The MA1 is warranted to be free from defects in materials and workmanship for a period of

one years from the date of purchase. If within the warra n ty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warra n ty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not

covered by warra n ty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired (when

r e p a i r able) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

MA1

AC Ammeter

Copyright © 2007 UEi MA1-MAN 1/07

PLEASE

RECYCLE

Loading...

Loading...