Page 1

1-800-547-5740 • Fax: (503) 643-6322

www.ueiautomotive.com • email: info@ueitest.com

ADM4201

INSTRUCTION MANUAL

Page 2

• Disconnect the test leads from the test points before changing

functions to avoid damaging the meter when testing above 350V AC

• Choose the proper range and function for the measurement Always set the meter to the highest range and work downward for

an unknown value if you are using manual ranging mode

• Do not try voltage or current measurements that may exceed the

ratings marked on the input limit for switch or terminal

• Use current probes to measure circuits exceeding 10A

• Disconnect the “LIVE” test lead before disconnecting the

“COMMON” test lead

• Do not test a recently recharged lead-acid battery

• Disconnect the power and discharge all high-voltage capacitors

before testing in the resistance, continuity, and diode functions

• If the engine has been running, do not place the meter and its

accessories near the engine or the exhaust manifold which might

be hot and can damage the meter

• If any of the following indications occur during testing, turn

off the power source to the circuit under test:

• Arcing

• Flame

• Smoke

• Extreme Heat

• Smell of Burning Materials

• Discoloration or Melting of Components

• Read the safety precautions associated with the equipment being

tested and seek assistance or advice when performing

unfamiliar tasks.

• Keep your fingers away from the test lead metal probe contacts

and bus-bars when making measurements. Always grip the

instrument and test-leads behind the hand guards (molded into

the probes).

• In the event of electrical shock, ALWAYS bring the victim to

the emergency room for evaluation, regardless of the victim’s

apparent recovery. Electrical shock can cause an unstable heart

rhythm that may need medical attention.

International Symbols

Introduction

The ADM5201 is a handheld battery operated professional automotive

multimeter designed to provide trouble shooting solutions to the most

difficult problems encountered in today’s sophisticated automotive

electronic systems. The ADM4201 has a bright LED backlight. A battery

access door allows users to replace the battery and fuse without breaking

ca l i b r ation seals! High impact over-molded case absorbs shock over more

of the case than a conventional rubber boot design.

Features include

• Accurate RPM measurement for 2 and 4 stroke automotive

engines with 1 to 8 cylinders using the inductive pickup

• ms-pulse Width function to test on-time of both PFI type and

TBI type fuel injectors

• Duty Cycle and direct DWELL reading

• 4 step adjustable triggers on 1 to 8 cylinders

• Temperature measurement up to 2,498˚F or 1,370˚C

• 3-3/4 digit, 4,000 count display with bar-graph

(Frequency range: 99,999 counts)

• Backlit display

• Auto power off

• High impact over-molded case

• CE-mark

• IEC 1010.1-92, CAT II 1000 V rating

Safety Notes

Before using this meter, read all safety information carefully. In

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

WARNING!

Exceeding the specified limits of this meter is dangerous and can

expose the user to serious or possibly fatal injury.

• DO NOT attempt to measure any voltage that exceeds 600 volts

with this meter - UEi offers numerous alternatives for measuring

high voltage and current

• Voltages above 600 volts DC or 25 volts AC may constitute a

serious shock hazard

• DO NOT attempt to use this meter if either the meter or the test

leads have been damaged. Send unit in for repair by a qualified

repair facility

• Test leads must be fully inserted prior to taking measurements

• Never attempt a voltage measurement with the test leads inserted

into the “A” terminal and the “C O M” terminal - The “A” terminal is

protected by a fuse. You might be injured or damage the meter

• Always disconnect the live test lead before disconnecting the

common test lead from a circuit

• Turn the engine off before connecting or disconnecting inductive

pickup to avoid a shock.

ADM4201-MAN P. 1

Page 3

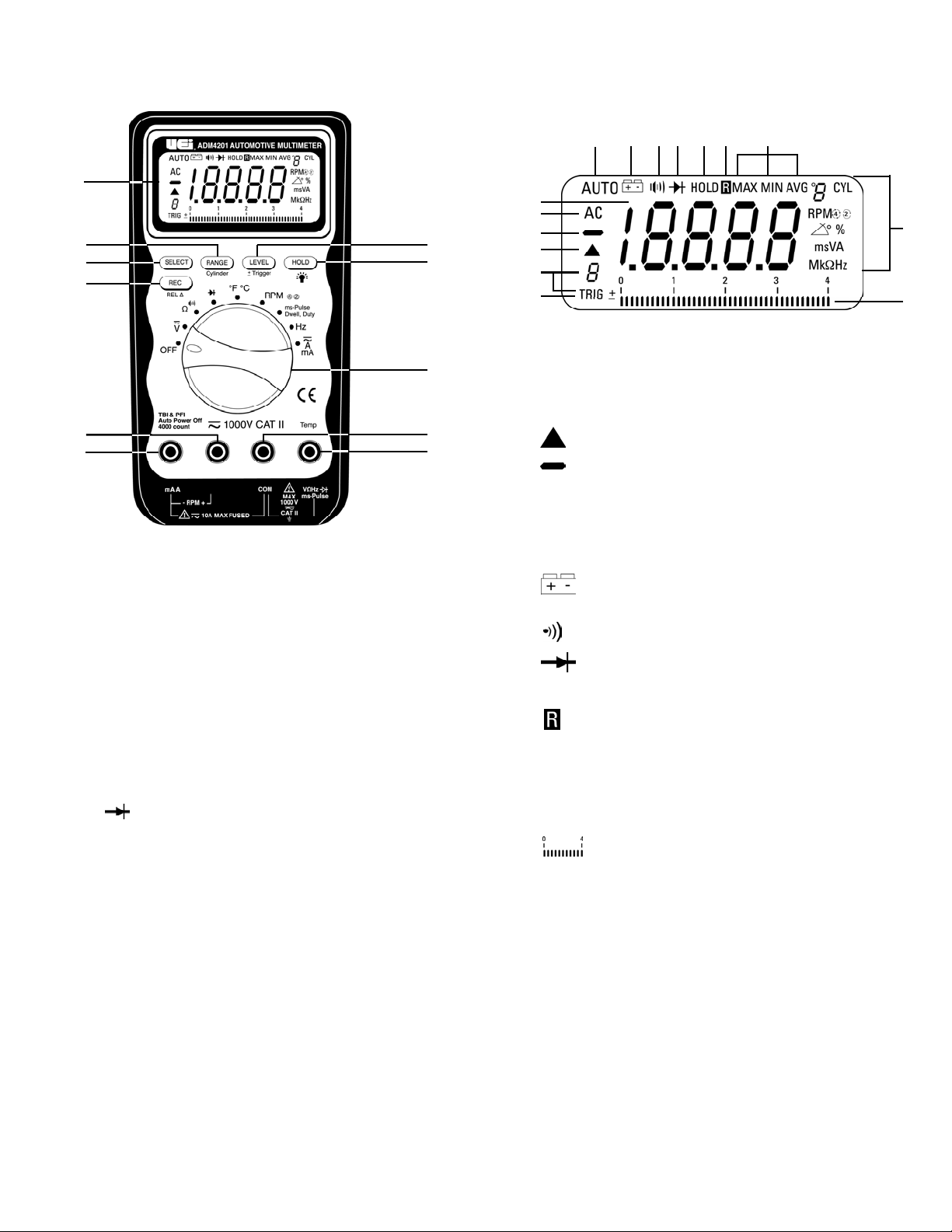

LCD Display Functional Description

12. TRIG ±: These annunciators indicate that positive (+) or negative

(-) “Trigger Slope” is selected.

13. 8 TRIG: These annunciators indicate trigger level status.

14. : This symbol indicates the “Re l a t i ve” function is activated.

15. : This symbol indicates “N e g a t i ve Po l a r i t y” .

16. AC: AC annunciator indicates alternating current is selected.

17. DATA: Digital readings of data being measured.

18. AUTO: This annunciator indicates “A u t o ra n g i n g” .

19. : Low battery alert. Replace the battery as soon as possible

to ensure accura cy.

20. : This symbol indicates the “Continuity Te s t ” function is selected.

21. : This symbol indicates the “Diode Te s t ” function is selected.

22 . HOL D : This annunciator indicates the “H o l d ” function is activated.

23 . : This annunciator indicates the “Re c o rd” function is activated.

24. MIN/MAX/AVG: These annunciators indicate Minimum,

M a ximum and Average reading is being displayed.

25. ˚8 CYL...: These annunciators indicate the function being selected

and/or the appropriate measurement units.

26. : Analog bar-graph with sca l e .

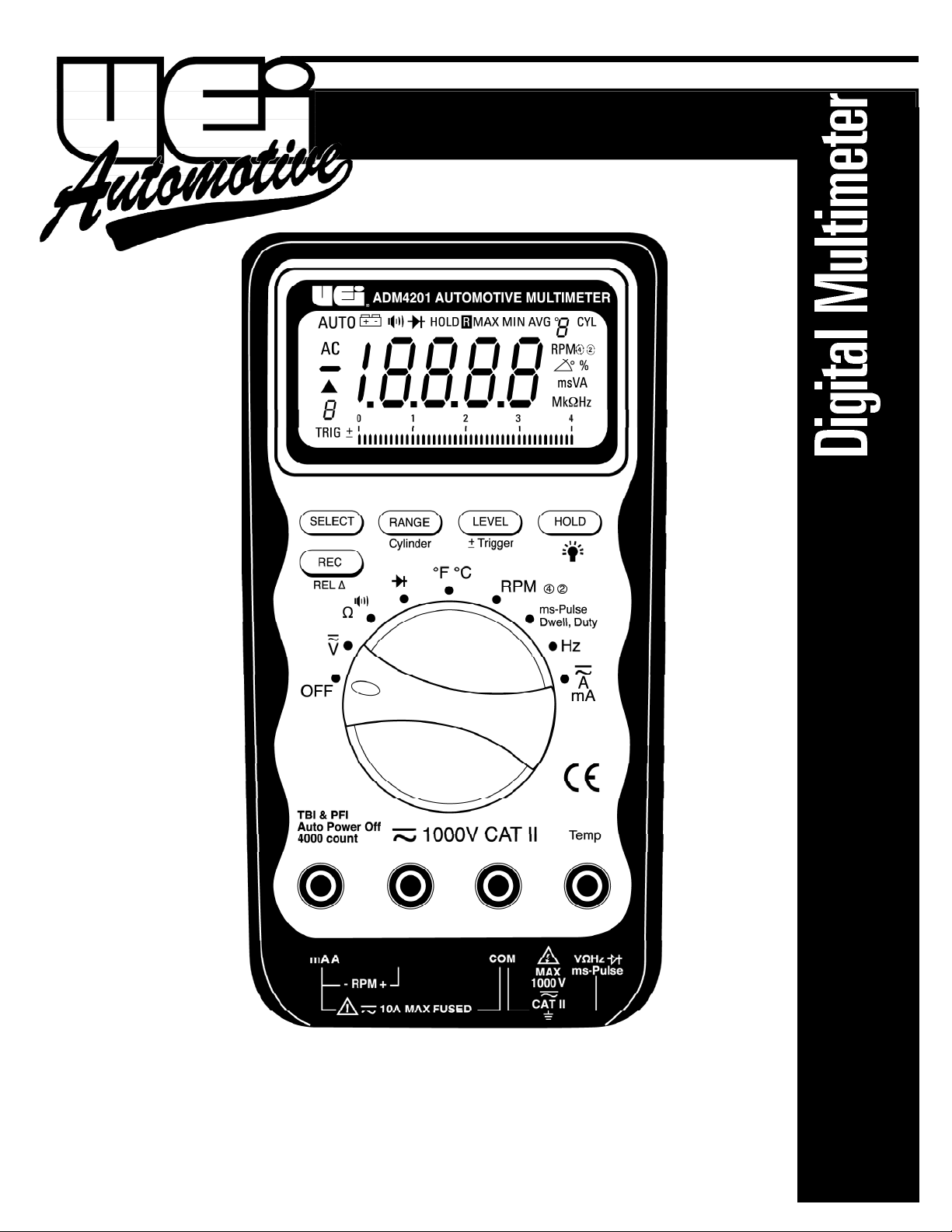

C o n t r ols and Indicators

1. LCD Display: 3 - 3 /4 digit, 4000 count display with bar-gra p h .

2. LEVEL Push-button: Press this push-button momentarily to select

trigger levels. Press this push-button for more than 1 second to toggle

b e tween positive and negative trigger slopes.

3. HOLD Push-button: Press this push-button momentarily to

activate “HOL D” for simply freezing a reading. Press this

push-button for more than 1 second to turn the LCD backlight on.

4. SELECTOR: Turn the power ON/OFF and select a function.

5. COM: Common (ground reference) input terminal for all functions

except RPM functions.

6. VΩHz , ms-Pulse & Temp: Input terminal for all functions

except current and RPM functions.

7. RPM +: Input terminal (+) for RPM function.

8. mA A/RPM-: Input terminal (+) for mA A functions. Ground

reference (-) input terminal for RPM function.

9. REC Push-button: Press this push-button momentarily to activate

“Re co r d” function. Press this push-button for more than 1 second

to select “Re l a t i v e Zero” .

10. SELECT Push-button: Press this push-button momentarily to

select (blue colored around selector) secondary functions.

11. RANGE Push-button: Press this push-button momentarily to

select ranges in the manual ranging mode of most functions or

number of cylinders on “D w e l l” function. Press this push-button

momentarily to toggle between the “PFI” mode and the “TBI”

mode when measuring on-time of fuel injectors. Press this

push-button for more than 1 second to toggle “A u t o / M a n u a l”

ranging in most functions.

1

ADM4201-MAN P. 2

2

3

4

5

6

11

10

9

7

8

18 19 20 21 22 23 24

25

26

17

16

15

14

13

12

Page 4

Operating Instructions

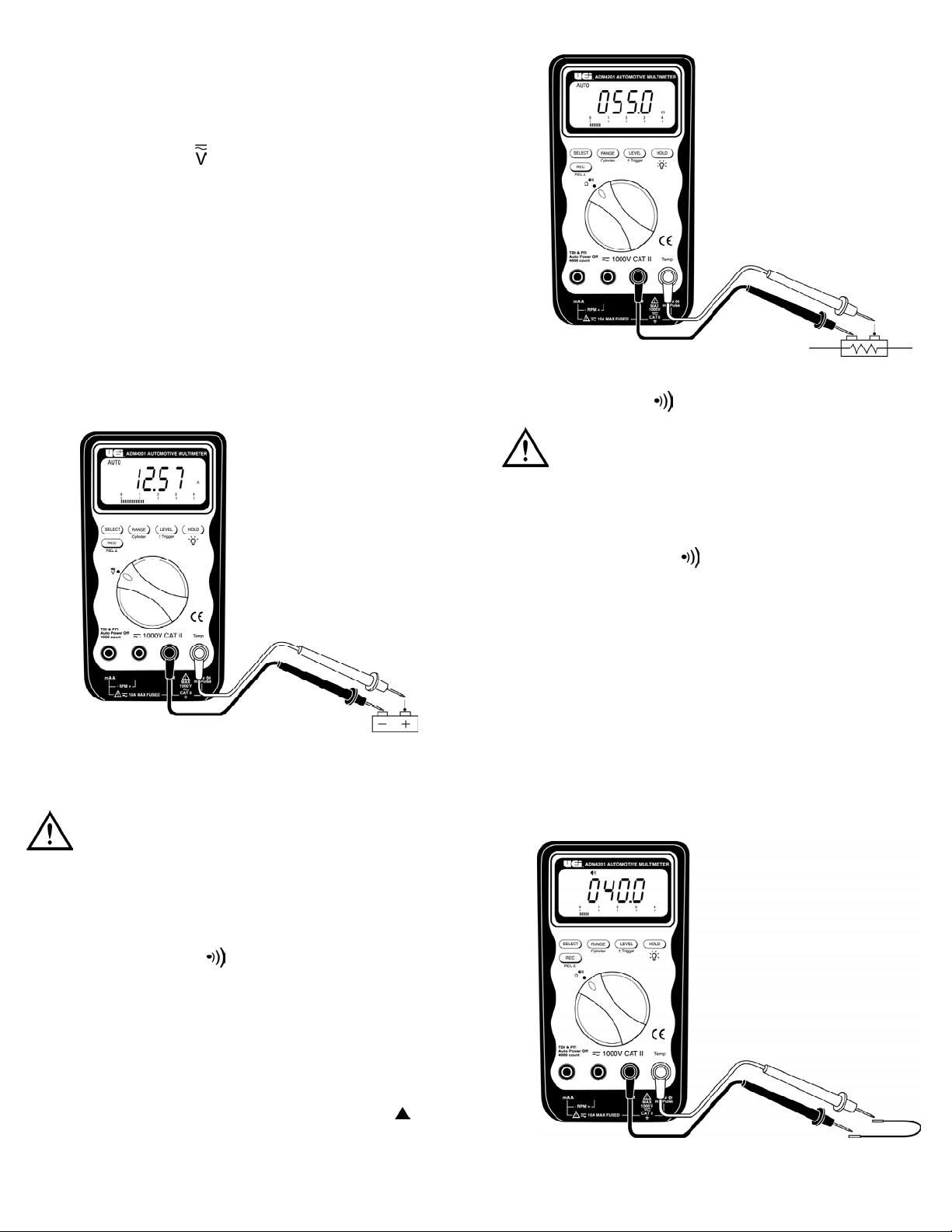

Measuring Voltage (V)

To measure DC or AC volts:

1. Set rotary selector to “ “ position. The meter defaults at DC.

2. Press the “SELECT” push-button momentarily to select AC,

if required.

3. Insert red lead into “V” terminal and black lead into “C OM” terminal.

4. Touch black probe to ground or negative side of the circuit and

touch red probe to positive side of the circuit coming from the

power source (Fig 1).

NOTE: Voltage must be measured in parallel (red probe

measuring circuit from power source).

The analog bar graph is easier to read when the data causes the

digital display to rapidly change. It is also useful for trend setting or

directional data.

Measuring Resistance (Ω)

CAUTION!

Turn off power and discharge all capacitors on circuit to be tested

before attempting in circuit resistance measurements. Accurate

measurement is not possible if external or residual voltage is present.

To measure Resistance:

1. Set rotary selector to “Ω “ position. The meter defaults at Ω

function. “

OFL

” is displayed.

2. Insert black lead into “COM” terminal and red lead into

“Ω” terminal.

3. Touch the test lead probes across the resistance or circuit

to be tested (Fig 2).

NOTE: The resistance in the test leads can affect accuracy in the

400Ω range. Short the leads together and press the “REL “

push-button to automatically subtract the test lead resistance

from the measured resistance.

Measuring Continuity ( )

CAUTION!

Turn off power off on the test circuit. A beeper tone does not necessarily

mean zero resistance.

To measure Continuity :

1. Set rotary selector to “Ω “ position.

2. Press the “SELECT” push-button to select “Continuity” function.

“

OFL

” is displayed.

3. Insert black lead into “COM” terminal and red lead into

“Ω” terminal.

4. Touch the test lead probes across the device being tested (Fig 3).

If the resistance of the device is more than 50Ω, there is a continuous

beep tone.

If the resistance of the device is more than 50Ω, there is no beep tone.

This is useful for checking wiring connections and operation of switches.

ADM4201-MAN P. 3

(Fig 1)

(Fig 2)

(Fig 3)

Parallel Connection

Parallel Connection

Page 5

Measuring Diode Test ( )

CAUTION!

Turn off power off on the test circuit.

To perform Diode test:

1. Set rotary selector to “ “ position. “

OFL

” is displayed.

2. Connect the test leads as shown and observe the digital display.

Normal forward voltage drop (forward biased) for a good silicon

diode is between 0.4V to 0.9V. A reading higher than that indicates

a leaky diode (defective). A zero reading indicates a shorted diode

(defective). An “

OFL

” indicates an open diode (defective) (Fig 4).

3. Reverse the test leads connections (reverse biased) across

the diode.

4. The primary display shows “

OFL

” if the diode is good. Any other

readings indicate the diode is resistive or shorted (defective).

Use the table to determine if the diode is good or bad.

Measuring Temperature (˚F/˚C)

To measure Te m p e r a t u r e :

1. Set rotary selector to “˚F/˚C” position.

The meter defaults at “˚F”. “OFL” is displayed with LCD

annunciators ˚F turned on. If required, press the “SELECT”

push-button to select “˚C” function.

2. Insert banana plug K-type temperature bead probe with

correct +/- polarities. You can also use a thermocouple probe

adapter (optional accessory) to adapt other standard K-type

temperature probes (Fig 5).

3. Touch the end of the thermocouple probe to the measurement

point and read the digital display with ˚F or ˚C.

NOTE: The measured temperature is displayed with 0.1˚F (0.1˚C)

resolution up to 400˚F (400˚C) and with 1˚F (1˚C) resolution up to

2,498˚F (1,370˚C) from 401˚F (401˚C).

ADM4201-MAN P. 4

(Fig 4)

Diode Forward Bias ( ) Reverse Bias ( )

Good 0.4V to 0.9V OFL

OFL 0.4V to 0.9V

Bad OFL 1.0V to 3.0V

1.0V to 3.0V OFL

0.4V to 0.9V 0.4V to 0.9V

OFL OFL

0.000V 0.000V

(Fig 5)

Collects under test

Banana plug

K-type temperature probe

Forward Bias

Reverse Bias

Page 6

ADM4201-MAN P. 5

RPM

WARNING!

Be sure the inductive pickup is in the terminals marked “- RPM +”

when measuring RPM’s. If the pickup is in the wrong terminal, personal

injury or meter damage may occur.

The ignition system can generate a potential shock hazard. Ensure that

the engine is off before connecting or removing the inductive pickup.

To perform Diode test:

1. Set rotary selector to “RPM “ position.

The meter defaults at (trigger) level.

2. Press the “SELECT” push-button to toggle between “RPM “

for 4-stroke engine and “RPM “ for 2-stroke and DIS engine.

3. Insert the dual banana connector into the “RPM -” and the

“RPM +” input terminals. Ensure the plug with the ground tab

goes into the “RPM -” terminal (Fig 6).

4. Clamp the inductive pickup to a spark plug wire with the arrow

sign facing the spark plug as shown. Ensure the pickup jaws are

completely closed.

5. Read RPM in the primary display.

Fuel Injection On Time

This function applies to both Port Fuel Injectors (PFI) which operate with a

single On Time pulse and Throttle Body Injectors (TBI) which operate with

twin pulses.

1. Set rotary selector to “ms-Pulse, Dwell, Duty“ position.

The meter defaults at ms-Pulse with -TRIG 1 2 3 level in the “PFI”

mode (“P” appears in the display).

Press the “RANGE” push-button to toggle between the “PFI” and

the “TBI” mode (“E” appears in the display).

4 trigger levels (-TRIG 1 2 3 -TRIG 1 2 -TRIG 1

-TRIG 1 2 3 4) are selectable by pressing “LEVEL” push-button

momentarily in this function.

2. Insert black lead into “COM” terminal and red lead into

“ms(-Pulse)” terminal.

3. Connect the test leads as shown and read “On Time” in the

primary display (Fig 7).

3

TRIG

(Fig 6)

(Fig 7)

ON TIME

Port Fuel Injection Wa v e f o r m

ON TIME

Port Body Injection Wa v e f o r m

S i g n a l

Jumper Wires

12V Supply ORB +

PFI or TBI

Injector

Ground Tab

Distributor

Cap

Spark Plug

Conventional

Ignition Coil

Inductive

Pickup

Page 7

ADM4201-MAN P. 6

Dwell

1. Set rotary selector to “ms-Pulse, Dwell, Duty“ position.

2. Press the “SELECT” push-button to select “DWELL” function. The

meter defaults at 4 cylinders (4 CYL). Press the “RANGE”

(Cylinder) button momentarily and repeatedly to select the

required number of cylinder and display the cylinder setting at the

upper right corner.

3. Insert black lead into “COM” terminal and red lead into

“ms(-Pulse)” terminal.

4. Connect the test leads as shown and read Dwell angle. Adjust

trigger levels by pressing the “LEVEL” push-button momentarily,

if necessary (Fig 8).

5. Press the “SELECT” push-button momentarily to display Dwell

reading in terms of percentage if required.

6. Adjust the Dwell angle according to the procedures outlined in

your vehicle service manual.

NOTE: Recheck the timing whenever the Dwell angle has

been adjusted.

Duty Cycle

1. Set rotary selector to “ms-Pulse, Dwell, Duty“ position.

2. Press the “SELECT” push-button twice to select “DUTY” function.

3. Insert black lead into “COM” terminal and red lead into

“ms(-Pulse)” terminal.

4. Connect the test leads as shown and read the Duty Cycle

percentage. Adjust trigger levels by pressing the “LEVEL”

push-button momentarily, if necessary (Fig 9).

5. Press the “SELECT” push-button or 3 momentarily to display

“Duty Cycle” reading in terms of ms (Pulse Width) or (Dwell)

angle if required.

In most applications, the negative trigger slope is assigned to display

the percentage of time that the plunger is in the closed position (low

duty cycle) during one duty cycle. The positive slop is assigned to

display the percentage of time that the plunger is in the open position.

Refer to the car’s service manual to verify slope assigned to position for

each component. Press the “LEVEL” (±Trigger) push-button for more

than 1 second to toggle between the negative (-) slope and the positive

(+) slope, if required.

(Fig 8)

(Fig 9)

Chassis

Ground

To

Distributor

Distributor

Coil

To DCM

Page 8

ADM4201-MAN P. 7

Frequency (Hz)

1. Set rotary selector to “Hz“ position.

2. Insert black lead into “COM” terminal and red lead into

“ms(-Pulse)” terminal.

3. Touch black probe to ground and touch red probe to the

“Signal out” wire on the sensor (Fig 10).

Adjust trigger levels by pressing the “LEVEL” push-button

momentarily, if necessary.

AC or DC Current ( )

WARNING!

Do not measure any circuit that draws more than the current rating

of the installed fuse. Replace the defective fuse with a proper fuse

only. Failure to do this may result in injury or damage to the meter.

Do not attempt current measurements where the open circuit voltage is

above 600V.

For measuring circuits of more than 10A, use voltage output current

clamp adapters compatible with the meter voltage functions.

1. Set rotary selector to “ “ position. The meter defaults

at DC current.

2. Press the “LEVEL” push-button to select AC.

3. Insert black lead into “COM” terminal and red lead into

“mA A” terminal.

4. Connect red lead probe to the side of the circuit closest to

the power source (Fig 11).

5. Connect black lead probe to the side of the circuit closest

to ground.

6. Turn the power ON and test. DO NOT crank the engine.

(Fig 10)

(Fig 11)

Ground

Signal Out

Electronic Voltage

AC Terminal

Page 9

ADM4201-MAN P. 8

Manual and Auto Ranging

Press the “RANGE” push-button momentarily to select manual ranging,

and the meter will remain in the range it was with LCD annunciator

“AUTO” turned off. Press this button momentarily again to step through

the ranges. Press this button for more than 1 second to resume

autoranging.

In Dwell “ “ function, press the “RANGE” (Cylinder) push-button

momentarily to display the cylinder setting at the upper right corner of

the LCD. Defaults is “4 CYL” (4 Cylinder). Press this button momentarily

again to select the number of cylinders from 1 through 8 (1, 2, 3, 4, 5, 6

and 8 cylinders) to match the engine under test.

Record Mode ( R )

Press the “REC” push-button momentarily to activate record mode with

LCD annunciators “ R MIN MAX AVG” turned on. The meter beeps

when new maximum or minimum reading is updated. Press this button

momentarily to read throughout the Minimum (MIN), Maximum (MAX)

and Average (AVG) readings. Press this button for more than 1 second

to exit the “Record” mode.

Relative Mode (∆)

Press the “REC” (REL∆) push-button for more than 1 second to select

the “Relative Zero” (∆) mode with annunciator ∆ turned on.

This feature allows the user to offset the measured value with a relative

reference value. Press the “REC” (REL∆) push-button for more than 1

second to exit the “Relative” mode and resume normal measurements.

RPM Selection

In the “RPM” function, the meter defaults to RPM for conventional

4-stroke engine. Press the “SELECT” push-button momentarily to toggle

to “RPM “ for DIS or 2-stroke engine.

Trigger Level and ± Trigger Slop Selection

This feature is available for Hz, RPM, Dwell, ms-Pulse, or Duty function.

The meter is set at selected trigger level as power up default in

individual function as follows:

However, car signal levels under test may vary due to aging of

components, abnormal conditions, and each car manufacturer’s

different design. Therefore, positive and/or negative 4 selectable trigger

levels, which are carefully designed and tested to cover all the extreme

conditions, are available in these functions to provide more flexibility to

cope with your applications.

If your reading is unstable, select lower sensitivities (high trigger level

number) by pressing the “LEVEL” push-button momentarily.

If your reading shows zero, select higher sensitivities (lower trigger

level number).

The 4 selectable trigger levels are cycled through as follows:

• Hz, RPM:

+(= +TRIG 1 2 3) +(= +TRIG 1 2) +(= +TRIG 1) +(= +TRIG 1 2 3 4)

• Dwell, ms-Pulse, Duty:

-(= -T RIG 1 2 3) -(= -T R IG 1 2) -(= -T RIG 1) -(= -T RIG 1 2 3 4)

In some cases, positive trigger levels may be required for measuring

Dwell, ms-Pulse, or Duty. Press the “LEVEL” (±Trigger) push-button for

more than 1 second to toggle between positive (+) and negative (-)

trigger level for the selected trigger level.

NOTE: Positive (+) trigger or negative (-) trigger is to identify whether

the On or Off portion of the signal under test is of measuring interest.

For example, if you get a reading of 10% Duty Cycle in the Positive (+)

Trigger (On portion), you then will get a reading of 90% Duty Cycle in

the Negative (-) Trigger (Off portion).

Backlight

Press the “HOLD” ( ) push-button for more than 1 second to toggle

the backlight On and Off. The backlight will also automatically be Off 30

seconds after each activation to extend the battery life.

Auto-Power Off

The meter automatically turns off after approximately 30 minutes of no

activities to extend the battery life. However, if there is any activity

within 100 counts from the last activity, the Auto-Power Off time will

always be counted from the new last activity.

M a i n t e n a n c e

Periodic service

WARNING!

Repair and service of this instrument is to be performed by qualified

personnel only. Improper repair or service could result in physical

degradation of the meter. This could alter the protection from

electrical shock and personal injury this meter provides to the

operator. Perform only those maintenance tasks that you are

qualified to do.

These guidelines will help you attain long and reliable service from

your meter:

1. Calibrate your meter annually to ensure it meets original

performance specifications.

2. Keep your meter dry. If it gets wet, wipe it dry immediately. Liquids

damage electronic circuits.

3. Whenever pra c t i cal, keep the meter away from dust and dirt, which

can cause premature wear.

4. Although your meter is built to withstand the rigors of daily use, it

can be damaged by severe impacts. Use reasonable caution when

using and storing the meter.

NOTE: When servicing the meter, use only the replacement parts specified.

Battery: 9V, NEDA 1604 or IEC 6F 22

Fuse: 600V / 15 A IR 100 kA fast acting fuse for A input

Cleaning and Decontamination

Periodically clean your meter’s case using a damp cloth. DO NOT use

abrasives, cleaning solvents or strong detergents, as they may damage

the finish or affect the reliability of the structural components.

Functions Default Trigger Level

Hz, RPM + (= + TRIG 1 2 3)

Dwell, ms-Pulse, Duty - (= - TRIG 1 2 3)

3

TRIG

3

TRIG

3

TRIG

2

TRIG

1

TRIG

4

TRIG

3

TRIG

2

TRIG

1

TRIG

4

TRIG

➞➞➞➞

➞ ➞ ➞ ➞

Page 10

ADM4201-MAN P. 9

Battery Replacement

Always use a fresh replacement battery of the specified size and type.

Immediately remove the old or weak battery from the meter and dispose of it in accordance with your local disposal regulations. Old or

defective batteries can leak chemicals that corrode electronic circuits.

WARNING!

To avoid electric shock, be sure to turn off the meter’s power and

disconnect both test leads from any equipment before you remove

or install batteries.

To install a new battery, follow these procedures:

1. Remove the screw from the battery compartment cover on the

back (lower half) of the meter and lift the cover.

2. Remove and discard the old battery. Always dispose of old batteries

promptly in a manner consistent with local disposal regulations.

WARNING!

Under NO circumstance should you expose batteries to extreme heat or

fire as they may explode and cause injury.

3. Place a fresh 9V battery in the compartment.

NOTE: If you do not plan to use the meter for a month or more,

remove the battery and store it in an area that won’t be damaged by a

leaking battery.

4. Reattach the battery compartment cover to the meter and

reinstall the screw.

S p e c i f i c a t i o n s

Safety & Compliance

Physical Specifications

Feature Summary

Electrical Specifications

DC Voltage

NMRR: > 50 dB @ 50/60 Hz

CMRR: > 100 dB @ DC 50/60 Hz, RS = 1 KΩ

Input Impedance: 10 MΩ, 30 pF nominal

(16 MΩ nominal for 400.0 mV range)

Maximum voltage between 600V DC/AC (but, 1000V DC/AC peak for

any terminal and and functions)

earth ground

Compliance Complies with UL&cUL standard UL 3111-1,

CSA C22.2 No. 1010.1-92, ANSI/ISA-S82,

01-94 to 1000V Overvoltage Category II

Certifications CE-marking certificated

Surge Protection 6.5 kV peak per IEC 1010.1-92

Fuse Protection for 600V / 15 A IR 100 kA fast fuse

A input

Display (LCD) Digital - 4000 counts display updates

3/sec nominal

Analog - 41 segments, updates 3/sec

Operating Temperature 32˚ to 122˚F (0˚ to 50˚C)

Storage Temperature -4˚ to 140˚F (-20˚ to 60˚C)

Temperature Coefficient nominal 0.15 x (specified accuracy) /˚C

@ (0˚ to 18˚C or 28˚ to 50˚C) or

otherwise specified

Relative Humidity 0% to 80% @ (32˚ to 95˚F)

0% to 70% @ (94˚ to 122˚F)

Altitude Operating - up to 2000 m

Storage - 10000 m

Battery Type Single 9V battery - NEDA 1604, JIS 006P or

IEC 6F 22

Battery Life 180 hrs. typical (with backlight off)

Shock Vibration Per MIL-T-P RF 28800 for a Style D,

Class III Instrument

Pollution Degree 2

E.M.C Meets EN 61326 : 1997 + A

1

Size (H x W x D) 6.77 x 3.62 x 1.59” (172 x 92 x 40.5mm)

without mounted accessory

Weight Approx. 386g (0.86 lbs.)

Warranty 3 years

Calibration Interval 1 year

Backlight For clear readings in poorly lighted areas

Fast Autoranging Meter automatically selects the best range

momentarily

HOLD Holds readings on display for later view

Continuity/Open test Beeper sounds

Bar Graph 41 segments for peaking an nulling

Record Mode Record maximum, minimum, and

average values

Relative Relative zero

Level 4 selectable trigger levels

±Trigger Selectable positive and negative trigger slope

Cylinder 7 selectable number of cylinders in Dwell

RPM 4 For 4-stroke engine application

RPM 2 For DIS and 2-stroke engine application

ms-Pulse/Duty Cycle Measures the time signal is On or Off in

milliseconds or in %

Battery/Fuse Access Door Battery or fuse replaceable without voiding

calibration

High-impact Over molded Protective holster features

Case

Accuracy is given as ±([% of reading] + [number of digits]), or otherwise

specified, at 23˚C ±5˚C and less than 80% RH for a period of one year

after calibration.

Range Resolution Accuracy

400.0 mV 0.1 mV

4.000 V 0.001 V

40.00 V 0.01 V 0.5% + 2 d

400.0 V 0.1 V

1000 V 1 V

Page 11

ADM4201-MAN P. 10

AC Voltage (50 - 400 Hz)

CMRR: > 60 dB @ DC to 60 Hz, RS = 1 KΩ

Input Impedance: 10 MΩ, 30 pF nominal

DC Current

AC Current (50 - 400 Hz)

Burden Voltage: 0.03 V/A

Ohms

Open Circuit Voltage: Typical 1.3V DC (2.7V DC @ 400.0ΩRange)

Diode Tester

Temperature

Sensor: K-type Thermocouple, sensor accuracy

not included

Audible Continuity Tester

Frequency

Minimum frequency 0.5 Hz, sensitivity 250 mV

4 Selectable trigger levels

RPM

4 Selectable trigger levels

Dwell

*Selectable trigger levels and ± trigger slopes

*Selectable cylinders 1, 2, 3, 4, 5, 6, 8

*Specified ranges depend on ± trigger slopes, engine RPM

ms-Pulse and Duty Cycle

Fuel Injection Detector (Both TBI & PFI)

*Selectable trigger levels and ± trigger slopes

*Specified ranges depend on ± trigger slopes, engine RPM and

number of cylinders

Range Resolution Accuracy

4.000 V 0.001 V

40.00 V 0.01 V 0.75% + 3 d

400.0 V 0.1 V

1000 V 1 V 1.2% + 5 d

Range Resolution Accuracy

4000 mA 1 mA 0.75% + 3 d

10.00 A 0.01 A 1.0% + 10 d

Range Resolution Accuracy

4000 mA 1 mA 1.5% + 3 d

10.00 A 0.01 A 1.5% + 10 d

Range Resolution Accuracy

400.0 Ω 0.1 Ω 0.75% + 10 d

4.000 kΩ 0.001 kΩ 0.75% + 3 d

40.00 kΩ 0.01 kΩ 0.75% + 3 d

400.0 kΩ 0.1 kΩ 0.75% + 3 d

4.000 MΩ 0.001 MΩ .075% + 5 d

40.00 MΩ 0.01 MΩ 1.5% + 10 d

Range Resolution Accuracy

2.00 V 3.0 mA <3.0V DC

Range Resolution Accuracy

-40˚ to 68˚F 0.1˚F ±(5.4˚F)

(-40˚ to 20˚C) (0.1˚C) ±(3.0˚C)

68˚ to 400˚F 0.1˚F ±1.0% + 3.6˚F

(20˚ to 400˚C) (0.1˚C) (±1.0% + 2.0˚C)

400˚ to 2,498˚F 1˚F ±3% of reading

(400˚ to 1,370˚C) (1˚C) (±3% of reading)

Audible Threshold Approx < 50Ω

Open circuit voltage < 1.2V

Range Resolution Accuracy

199.99 Hz 0.01 Hz

199.9 Hz 0.1 Hz 0.02% + 3 d

19.999 kHz 1 Hz

199.99 kHz 0.01 kHz

Range Resolution Accuracy

4-stroke 120 - 19999 RPM ±2 RPM

2-stroke 60 - 10000 RPM

Range* Resolution Accuracy

0.0 - 356.4 0.1 1.2/krpm + 2 d

Mode Resolution* Accuracy

Multi-Point-Injection 0.5 ms - 1999.9 ms 0.5 ms + 1 d

0.0% - 100.0% 0.2%/krpm + 2 d

Single-Point-Injection 0.5 ms - 1999.9 ms 0.5 ms + 1 d

0.0% - 100.0% 0.2%/krpm/cyl + 2 d

Page 12

Limited Warranty

The ADM4201 is warranted to be free from defects in materials and workmanship for a period

of three years from the date of purchase. If within the warra n ty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warra n ty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not

covered by warra n ty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired (when

r e p a i r able) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueiautomotive.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

ADM4201

Digital Multimeter

Copyright © 2007 UEi Automotive ADM4201-MAN 1/07

PLEASE

RECYCLE

Loading...

Loading...