Universal Enterprise ADL7103 Installation Manual

ADL 7103

Automotive

Scope / GMM / OBD II Code Reader

Copyright © 2005 UEi

T

o receive a FREE catalog of

our complete line of diagnostic equipment,

call our UEi sales of

1-800-547-5740

Find more test instrument

information on the

internet at

or

email info@ueitest.com.

www.ueitest.com

fice at

ADL7103-MAN 1/05

User’

s Man

ual

Menu Overview

DANGER

When measuring signals greater than

150V Peak on inputs CH A and/or CH

B, make certain that both the OBD II

and USB cab les are not connected to

the instrument. Activating inputs CH

A and/or CH B with the USB or OBD II

t o gether on high vo l t age could result

in instrument damage, serious injury

or death.

CAUTION

W hen ha nding any ex t r e m e ly high

vo l t age si gna ls , e. g. the s ig na ls

g e ne ra t e d f r om t he s pa rk p lug s,

NEVER PUT ANY TEST LEADS (Either

the Red or Ye l l ow test leads Or the

S e c o n d a ry i gni tion pr obe l ead Or

Power Cable from Cigarett e Lighte r)

CONNECTED TO THE SCOPE IN THE

AR EAS NEA R THOSE STRO N G

SI GN AL S . I f so , the sco pe c an be

damaged or worked improperly.

MAIN MENU

COMPONENT TESTS

SCOPE

GRAPHING MULTIMETER

OBD II CODE READER

VEHICLE DATA

INSTRUMENT SETUP

GRAPHING MULTIMETER MENU

VOLT DC, AC

OHM/DIODE/CONTINUITY

RPM

FREQUENCY

DUTY CYCLE

PULSE WIDTH

DWELL

IGNITION PEAK VOLTS

IGNITION BURN VOLTS

IGNITION BURN TIME

INJECTOR PEAK VOLTS

INJECTOR ON TIME

AMP DC, AC

TEMPERATURE C F

LIVE

INSTRUMENT SETUP MENU

FILTER MENU

INPUT A : OFF

INPUT B : OFF

LANGUAGE MENU

LANGUAGE : ENGLISH

DISPLAY OPTIONS

FILTER

AUTO POWER OFF

LANGUAGE

VERSION INFORMATION

SCOPE CALIBRATION

COMPONENT TESTS MENU

SENSORS

ACTUATORS

ELECTRICAL

IGNITION

(or DIESEL)

VEHICLE DATA MENU

CYLINDERS

CYCLES : 4

BATTERY : 12 V

IGNITION : CONV

IGNITION MENU

CONV (default)

DIS

DIESEL

DISPLAY OPTIONS MENU

AUTO POWER OFF MENU

AUTO POWER OFF : ON

AUTO POWER OFF TIME : 30 min

: 4

USER LAST SETUP : OFF

CONTRAST : 4

GRATICULE : ON

HORIZ TRIG POS : 10 %

ACQUIRE MODE : PEAK DETECT

SENSOR TESTS MENU

ABS Sensor (Mag)

O2S Sensor (Zirc)

Dual O2Sensor

ECT Sensor

Fuel Temp Sensor

IAT Sensor

Knock Sensor

TPS Sensor

CKP Magnetic

CKP Hall

CKP Optical

CMP Magnetic

CMP Hall

CMP Optical

VSS Magnetic

VSS Optical

MAP Analog

MAP Digital

MAF Analog

MAF Digi Slow

MAF Digi Fast

MAF Karman-Vrtx

EGR (DPFE)

ACTUATOR TESTS MENU

Injector PFI/MFI

Injector TBI

Injector PNP

Injector Bosch

Mixture Cntl Sol

EGR Cntl Sol

IAC Motor

IAC Solenoid

Trans Shift Sol

Turbo Boost Sol

Diesel Glow Plug

ELECTRICAL TESTS MENU

Power Circuit

V Ref Circuit

Ground Circuit

Alternator Output

Alternator Field VR

Alternator Diode

Audio System

DC Switch Circuits

DIESEL MENU

DIESEL INJECTOR

ADVANCE

IGNITION TESTS MENU

PIP/ SPOUT

DI Primary

DI Secondary

DIS Primary

DIS Secondary

Contents

Menu Overview

1. Introduction

1.1 Comparing Scan Tools, DSO’s and DMM’s 1- 1

1.2 Vehicle Service Manuals 1- 2

2. Safety Information

3. Automotive Electronic Signals

3.1 Primary Signal Types Found in Modern Vehicles 3- 1

3.2 Critical Characteristics of Automotive Electronic Signals 3- 2

3.3 The Golden Rule of Electronic System Diagnosis 3- 2

3.4 Signal Probing with an Oscilloscope 3- 2

4. Getting Started

4.1 Product Description 4- 1

4.2 Quick Tour 4- 2

4.3 Front Panel Controls 4- 6

4.4 Measurement Connections 4- 7

4.5 Grounding Guidelines 4- 8

4.6 Display 4- 9

4.7 SCOPE Mode 4-15

4.8 GMM (GRAPHING MULTIMETER) Mode 4-16

4.9 OBD II Code Reader Mode 4-17

5. Instrument Operation

5.1 Instrument Test Modes 5- 1

5.2

SCOPE Displays

5.3 GMM Displays 5- 7

5.4 Dual Input Scope Operation 5-13

5.5 Changing the Vehicle Data and Instrument Setup 5-13

5.6 Freezing, Saving, and Recalling Screens 5-17

5.7 Glitch Snare Operation 5-18

5.8 Tips for Noise Management 5-19

5.9 OBD II Code Reader Mode 5-20

Appendix: About OBD II System

6. Automotive Diagnostics & Applications

6.1 Component Tests 6- 1

6.2 Sensor Tests 6- 1

6.3 Actuator Tests 6-32

6.4 Electrical Tests 6-48

6.5 Ignition Tests 6-57

6.6 Diesel Tests 6-68

7. Maintenance

8. Specifications

Glossary

Menu Overview

5- 1

5-24

1. INTRODUCTION

Vehicle manufacturers have helped you locate drivability problems by designing Electronic Control Units with trouble

code generating capabilities. ECU ’s aren’t perfect and occasionally don ’t detect every event (most transients and

intermittent events). On-board diagnostic systems are engineered with fairly wide set limits for sensors, actuators,

connectors and terminals. When a component exceeds its limit consistently a trouble code is generated. To keep

warranty costs in line tolerances are not set to catch all transients even though they can cause some of your worst

drivability problems.

Therefore repair technicians are finding more and more uses for a Digital Storage Oscilloscope (DSO) and Digital

Multi Meters (DMM). A DSO can capture a live “signature” of a circuit and store it for later analysis or comparison

against known-good waveforms – an invaluable resource for detecting marginal components. A GMM (Graphing

Multi Meter) give s you advanced multimeter capabilities coupled with the visual power of tren d g raphin g a nd

waveform display.

This meter – a combination DSO, GMM and OBD II code reader – represent the most powerful and versatile tool

available for troubleshooting automotive electronics since we can track down elusive no-code drivability problems as

well as diagnose OBD II sensors and components.

1.1 COMPARING SCAN TOOLS, DSO’s AND DMM’s

All of these tools have unique capabilities, and today ’s vehicles demand that automotive technicians are able to use

all three tools to correctly diagnose various drivability problems. DSO ’s alone cannot replace DMM ’s or scan tools,

yet DMM’s and scan tools cannot replace DSO’s.

For example, when anti-lock brakes on a car are sometimes erratic, you might first perform a road test to verify that

the ABS light does not come on. When you get back to the shop, you plug in your scan tool and find no trouble

codes.

Because you still have your DMM, you follow the manufacturer ’s instructions and look at the output voltage from

each whe el speed sensor. They all appear to b e in tole rance, a nd the manuf acture fault tree recommends you

replace the ABS computer. Unfortunately, the ABS computer on the vehicle in embedded in the master cylinder, so

you must replace everything. The worst thing is the problem still exists even after you complete all of the work.

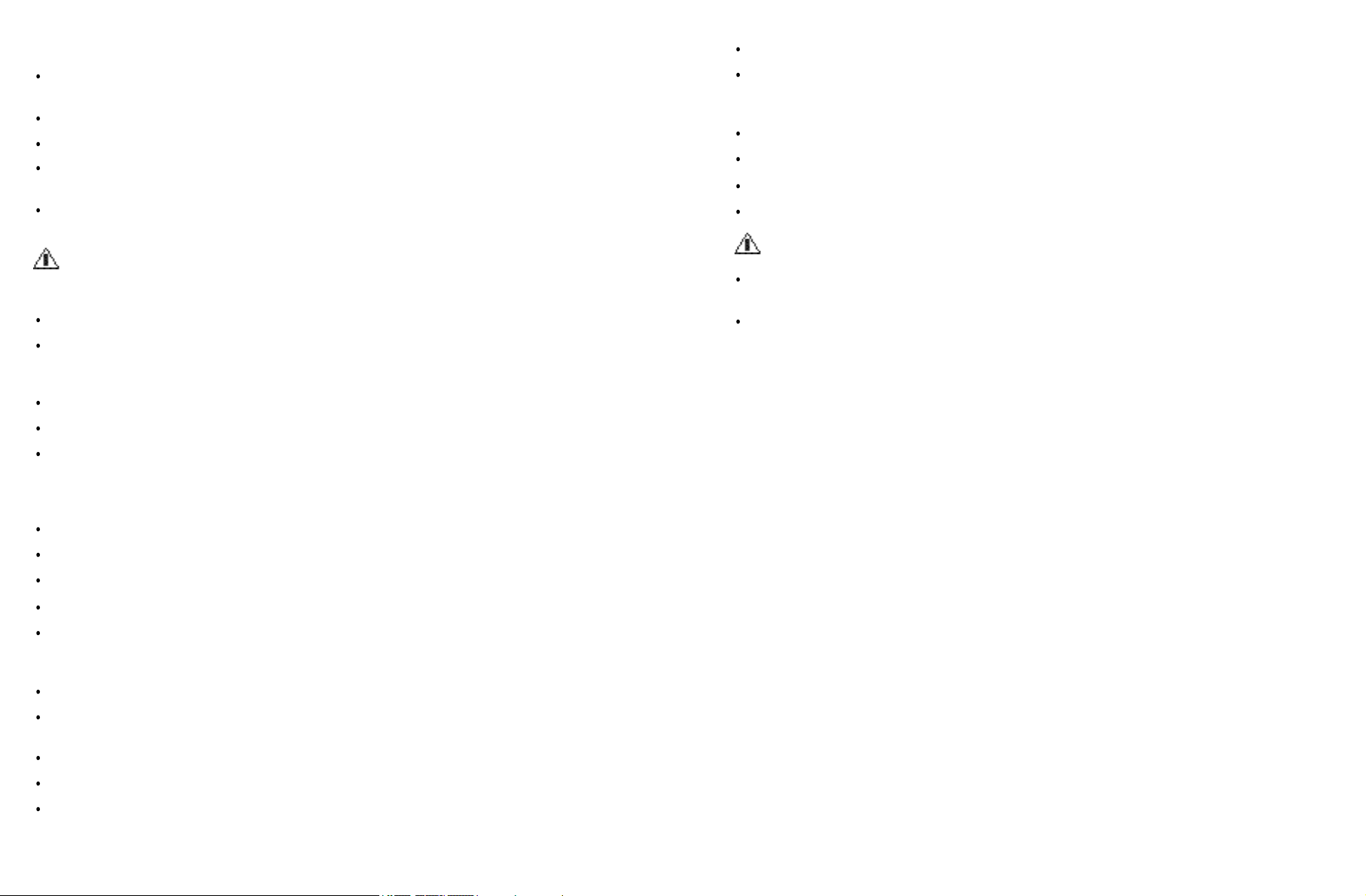

Normal ABS Signal

Most of the signal shown above is visible to scan tools, DSO’s and DMM’s.

Faulty ABS Signal

However, the faults shown above are not visible to scan tools and DMM’s. They are only visible to DSO’s.

1-1

If you had a DSO, you could look at the output signal from each of the wheel speed sensors. From this you would

have discovered that the left rear wheel speed sensor had some very fast aberrations that caused the ABS computer

t

o act strange. You replace the left r ear wheel speed sensor and cure the problem. The scan tool missed this

problem becau se no trouble co des w ere set, and the co mpu ter comm unication bus w as to o slow to pick up the

spike s. Th e DMM misse d this problem because it avera ge d the sensor sig nals an d could not see the fast

aberrations.

Scan tools and DMM ’s sample very slow when compared to a DSO. DSO ’s are typically more that a few hundred

thousand times faster than scan tools and more than 1,000 times faster than DMM’s.

There are many examples of vehicle signals that DMM ’s and scan tools are unable to see. There are many vehicle

problems that can occur that require a DSO, or combination of a DSO, DMM and OBD II code reader to diagnose

accurately.

1.2 VEHICLE SERVICE MANUALS

Th is in st rument tells how to hook up it to th e selecte d vehicle components to be tested. However, it is stron gly

recommended that you con sult the manufacturer’s service manual for your vehicle before a ny t est or repair

procedures are performed in order to get the color of the wire or the PCM’s pin number from a wiring diagram.

Fo r availability of these service man uals, co nta ct your local ca r dealership, auto parts store, o r bookst ore, The

following companies publish valuable repair manuals:

Mitchell International

14145 Danielson Street

Poway, CA 92064

Tel : 888-724-6742

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Tel : 1-800-442-9637

Motor Publications

5600 Crooks Road, Suite 200

Troy, MI 48098

Tel : 1-800-426-6867

Helm Inc.

14310 Hamilton Avenue

Highland Park, MI 48203

Tel : 1-800-782-4356

1-2

2. SAFETY INFORMATION

WARNING

READ “SAFETY INFORMATION” BEFORE USING THIS MANUAL.

This instrument is designed to be used by properly trained, skilled professional automotive technicians.

It is assumed that the user has a thorough understanding of vehicle systems before using this instrument.

To use this instrument safely, it is essential that operating and servicing personnel follow both generally accepted

safety procedures and the safety precautions specified in this manual.

A DANGER identifies an imminently hazardous situation which, if not avoided, will result in death or serious injury to

the user or the bystanders.

A WARNING identifies conditions and actions that pose hazard(s) to the user or the bystanders.

A CAUTION identifies conditions and actions that may damage the instrument or the vehicle.

Th e term “Isolated (or Electrically flo ating)” is u sed in this manual to indica te a measurement in which the COM

terminal of this instrument is connected to a voltage different from earth ground. The term “Grounded” is used when

the COM terminal is connected to an earth ground potential. The COM terminal of this instrument is rated up to 300

V rms above earth ground for the safety of isolated measurements.

Using Your Instrument Safely

Follow safe servicing practices as described in your vehicle service manual. To use this instrument safely, follow the

safety guidelines below :

DANGER

Use this instrument only in WELL VENTILATED service areas that provide at least four changes of air per hour.

Engines produce carbon monoxide, an odorless, colorless and poisonous gas that causes lower reaction time and

can result in death or serious injury. Route the engine exhaust outside with an approved extraction system while

performing tests with the engine running.

Set the parking brake and block the wheels, especially the wheels on front-wheel drive vehicles, before testing or

repairing the vehicle because the parking brake does not hold the drive wheels.

Be sure there is adequate clearance between any moving components when testing. Moving components and

belts ca n CATCH lo ose clothing , parts of your body or the instrument and cause serious damage or personal

injury.

Always wear approved sa fety eye protection when t esting or repairing ve hicles. Objects can be propelle d by

whirling engine components can cause serious injury.

When handling any signals higher than 150 V peak, don’t electrically activate BOTH CH A and/or CH B terminal(s)

AND USB and/or OBD II terminal(s) together at a time. If they are electrically activated simultaneously, a death or

a serious personal injury could be resulted in.

2-1

Avoid Fires:

Do not position head directly over carburetor or throttle body. Do not pour gasoline down carburetor or throttle

body when cranking or running engine. Engine backfire can occur when air cleaner is out of normal position.

Do not use fuel injector cleaning solvents or carburetor sprays when performing diagnostic testing.

The instrument has internal arcing or sparking parts. Do not expose the instrument to flammable vapors.

Do not smoke, strike a match, place metal tools on battery, or cause a spark in the vicinity of the battery. Battery

gases can ignite.

Keep a fire extinguisher rated for gasoline, chemical, and electrical fires in work area. Fires can lead to serious

injury or death.

WARNING

Avoid Electrical Shock:

Make sure that the vehicle to be tested is at a safe potential before making any measurement connections.

Connect the COM input of the instrument to vehicle ground before clamping the standard SECONDARY PICKUP

(supplied) on the ignition wires. This ground connection is required IN ADDITION TO the normal measurement

ground connections.

Do not touch ignition coils, coil terminals, and spark plugs while operating. They emit high voltages.

Do not puncture an ignition wire to connect the instrument, unless specifically instructed by vehicle manufacturer.

Be sure the ignition is in the OFF position, headlights and other accessories are off, and doors are closed before

disconnecting the battery cables. This also prevents damage to on-board computer systems.

Disconnect the live test lead before disconnecting the common test lead.

Do not perform internal service or adjustment of this instrument unless you are qualified to do so.

Avoid Burns:

Do not touch hot exhaust systems, manifolds, engines, radiators, sample probe, etc.

Do not remove radiator cap unless engine is cold. Pressurized engine coolant may be hot.

Wear gloves when handling hot engine components.

Use a suitable battery carrier when transporting batteries.

CAUTION

Disconnect circuit p ower and discharge all high voltage capacitors before connecting the inst rum ent to make

resistance, continuity, or diodes measurements.

Do n ot rely on questionable, erratic, or obviously erroneo us te st inf ormations or result s. Make su re that all

connections and data entry information are correct and that the test procedure was taken correctly. Do not use

suspicious test information or results for diagnostics.

IF the ground of the instrument is connected to a voltage higher than 42 V peak (30 V rms);

Use only the standard test leads set supplied with the instrument.

Do not use conventional exposed metal BNC or BANANA PLUG connectors.

Use only one ground connection to the instrument (GROUND LEAD of the CH A’s shielded test lead).

Remove all probes and test leads that are not in use.

Connect the power adapter to the AC outlet before connecting it to the instrument.

Follow the general safety guidelines below;

Avoid working alone.

Inspect the test leads for damaged insulation or exposed metal. Che ck test lead continuity. Replace damaged

leads before use.

Do not use the instrument if it looks damaged.

Select the proper function and range for your measurement.

When using the probes, keep your fingers away from probe contacts.

Keep your fingers behind the finger guards on the probes.

2-2

2-3

3. AUTOMOTIVE ELECTRONIC SIGNALS

3.1 PRIMARY SIGNAL TYPES FOUND IN MODERN VEHICLES

Once you become familiar with basic vehicle waveforms it will not matter how new or old the vehicle is, or even who

manufactured the vehicle. You will be able to recognize signals that do not look right.

Direct Current (DC) Signals

The types of sensors or devices in a vehicle that produce DC signals are:

Power Supplies - Battery voltage or sensor reference voltages created by the PCM.

Analog senso r signals - engine coolant tempe rat ure, fuel temperature, intake air temp erature, throt tle position,

EGR pressure and valve position, oxygen, vane and hot wire mass airflow sensors, vacuum and throttle switches

and GM, Chrysler and Asian manifold absolute pressure (MAP) sensors.

Alternating Current (AC) Signals

The types of sensors or devices in a vehicle that produce AC signals are:

Vehicle speed sensors (VSS)

Antilock brake system wheel speed sensors (ABS wheel speed sensors)

Magnetic camshaft (CMP) and crankshaft (CKP) position sensors

Engine vacuum balance viewed from an analog MAP sensor signal

Knock sensors (KS)

Frequency Modulated Signals

The types of sensors or devices in a vehicle that produce Frequency Modulated signals are:

Digital mass airflow (MAF) sensors

Ford’s digital MAP sensors

Optical vehicle speed sensors (VSS)

Hall Effect vehicle speed sensors (VSS)

Optical camshaft (CMP) and crankshaft (CKP) position sensors

Hall Effect camshaft (CMP) and crankshaft (CKP) position sensors

Pulse Width Modulated Signals

The types of circuits of devices in a vehicle that produce Pulse Width Modulated signals are:

Ignition coil primary

Electronic spark timing circuits

EGR, purge, turbo boost, and other control solenoids

Fuel injectors

Idle air control motors and solenoids

Serial Data (Multiplexed) Signals

The types of circuits or devices in a vehicle that produce Serial Data signals are:

Powertrain control modules (PCM)

Body control modules (BCM)

ABS control modules

Other control modules with self diagnostics or other serial data / communications capability

3-1

3.2 CRITICAL CHARACTERISTICS OF AUTOMOTIVE ELECTRONIC SIGNALS

O

nly 5 critical chara cteristics (or information types) given from the Automotive electronic signals a re important

because the vehicle’s PCM considers them important.

Amplitude - The voltage of the electronic signal at a certain point in time.

Frequency - The time between events, or cycles, of th e electronic sign al, usually given in cycles per second

(Hertz).

Shape - The signature of the electronic signal, with its unique curves, contours, and corners.

Duty Cycle - The on-time, or relative pulse width of the electronic signal.

Pattern - The repeated patterns within the signal that make up specific messages, like synchronous pulses that

t

ell the PCM that cylinder # 1 is at TDC (Top Dead Center), o r a repeated pattern in the serial data

stream that tells the scan tool the coolant temperature is 212 F (or 100 C), etc.

3.3 THE GOLDEN RULE OF ELECTRONIC SYSTEM DIAGNOSIS

For t he ve hic le’s comp ut er sy stem to functio n properly, it mus t se nd and re ceiv e s ignals wi th the critical

characteristics it was designed to communicate with.

Each of the primary types of electronic signals use the critical characteristics to establish electronic communication.

Th ey each use different combinations of the critical characteristics to communicate. Here’s a list o f which critical

characteristics each of the primary signal types uses to communicate:

Direct Current signals use Amplitude only.

Alternating Current signals use Amplitude, Frequency, and Shape.

Frequency Modulated signals use Amplitude, Frequency, and Shape.

Pulse Width Modulated signals use Amplitude, Frequency, Shape, and Duty Cycle.

Serial Data signals use Amplitude, Frequency, Shape, Duty Cycle, and Pattern.

To minimize this possible interference with the oscilloscope, keep these tips and suggestions in mind:

Most interference will be picked up by the oscilloscope test leads.

Route the test leads away from all ignition wires and components whenever possible.

Use the shortest test leads possible, since other test leads may act as an antenna and increase the potential for

in terference, especially at higher freq uency leve ls that are found when probing near the vehicle’s on-board

computer.

With the potential for RF interference in the engine compartment, if possible, use the vehicle chassis as ground

when connecting the oscilloscope test leads. In some cases the engine block can actually act as an antenna for

the RF signals.

Th e t est le ads are a very importa nt part of any oscillosco pe . Substituting other lea ds in bo th le ng th and

capability may alter the signals on your display.

The oscilloscope can also pick up interference like the test leads.

Because the oscilloscope circuits are so sensitive, and therefore powerful, do not place the oscilloscope directly

on ignition wires or near high energy ignition components, like coil packs.

If you are using the AC or DC charger/adaptor to power the oscilloscope, keep the external power leads far

away from the engine and ignition if possible.

The list will help to give you a better understanding of which signal types use which critical characteristics to do their

electronic communication. The above rules work very well and hold up in most cases, but there are exceptions to its

rules. Not many, but a few.

It may come as no surprise to some that serial data signals are the most complex signals in the vehicle. They use all

5 critical characteristics to communicate with. Thus, they take a special analyzer to decode them - one very familiar

to most technicians - the scan tool.

3.4 SIGNAL PROBING WITH AN OSCILLOSCOPE

Th e e ngine compartment of a ru nning vehicle is a very unfriend ly environment for a utomotive sig nals to live.

Temperature extremes, dirt and corrosion, and electrical leaks, or noises from the high voltage pulses generated

from a t ypical ignition system can produce interference that can co ntribute significa ntly to the cause of many

driveability problems.

When you are probing components, sensors and circuits, be aware that the electrical noises from today’s high output

ignition systems can produce an RF energy that is similar to a radio station. Since oscilloscopes are so sensitive,

this interference can actually override the signals you are trying t o capture and give yo u a false reading on the

display.

3-2

3-3

4. GETTING STARTED

4.1 PRODUCT DESCRIPTION

This instrument is a battery-operated 2-channel lab scope, advanced true rms graphing multimeter (GMM), and OBD

II Code Reader designed expressly for use in the automotive service market. The main purpose of this instrument is

to provide advanced troubleshooting capabilities for automotive service technicians in an easy-to-operate format.

This instrument offers the following features:

A 25 Mega-sample/Second (one channel minimum) sample rate for rapid data updates.

Lab scope signal patterns.

True RMS Graphing Multimeter (GMM) measurements and graphs.

OBD II Code Reader function.

A unique “ Glitch Snare” m ode which captures, d isplays and optionally save s abnormal signal patterns in the

Scope mode of the COMPONENT TESTS only when they occur.

Preset tests that enable the user to check the majority of automotive sensors, actuators and systems easily and

quickly.

P

owerful built-in reference information for each preset test which includes a test procedure sh owing h ow to

connect to the circuit, a normal reference signal pattern, theory of operation and troubleshooting tips.

Menu-driven interf ace has automa tic co nfigu rations f or most of non-pre set tests, s o you will fin d that the

instrument is easy-to-use.

The Secondary Ignition Single function displays the waveform along with the spark voltage, RPM, burn time and

burn voltage.

The Diesel function allows you to set injection pump timing and RPM using the optional Diesel accessories.

USB interface supports updates for code and data.

Even though this instrument is designed to configure itself to almost any test, it is very important that you continue

through this manual and carefully read and understand the capabilities of this instrument before attempting actual

measurements.

4-1

4.2 QUICK TOUR

Powering the Instrument

Press the POWER key to turn the instrument on. The instrument beeps once and turns on.

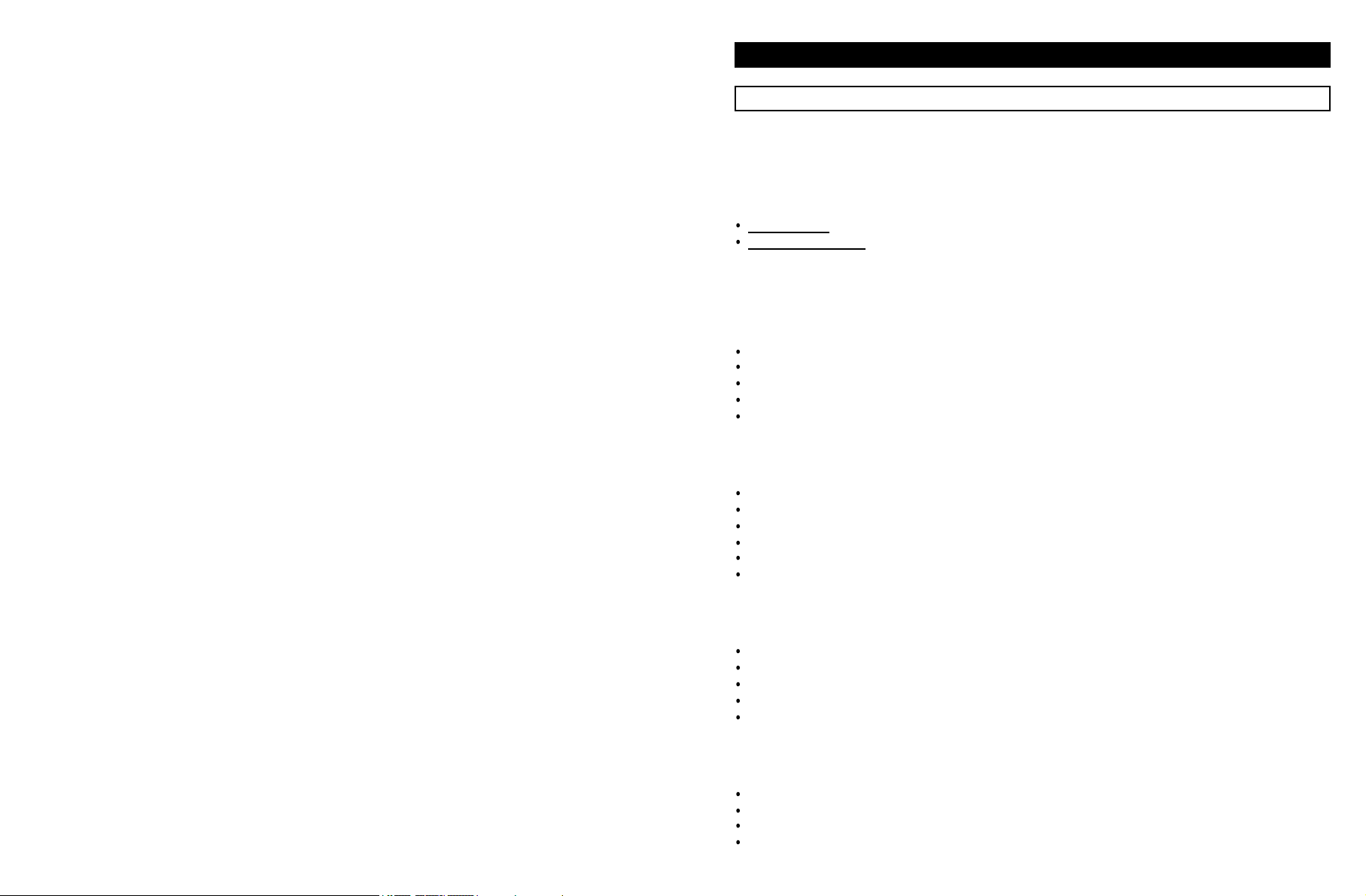

At power on, the instrument displays the VEHICLE DATA menu as shown in Figure 1.

The fastest way to set up the instrument to test most automotive devices (sensors, actuators...)

and circuits

is

to choose from one of the built in COMPONENT TESTS. Each test places the instrument in a configuration best

suited to display signals for the chosen device or circuit.

Press a Four Way arrow ke y to position the HIGHLIGHT B AR o ver the C OMPONENT TESTS menu choice and

press to select.

VEHICLE DATA MENU

Press the F1 key to

accept the displayed

settings.

CYLINDERS : 4

CYCLES

: 4

BATTERY : 12 V

IGNITION : CONV

OK SELECT

Figure 1. Vehicle Data Menu at Power-On

Default settings:

You can change the

settings to match with

the vehicle under test.

Press the F5 key to

change the highlighted

selection.

Changing the Power-On Display

Use “Instrument Setup” menu option to change the Power-On display from VEHICLE DATA MENU(default) to the

user’s last display.

Resetting the Instrument

If you want to restore the instrument settings as delivered from the factory, do the following:

1.

Turn the instrument off by pressing the POWER key.

2. Keep depressed while you turn the instrument on by pressing the POWER key. Release . You will

hear a double beep to indicate that the Master Reset has been executed.

MAIN MENU

COMPONENT TESTS

SCOPE

GRAPHING MULTIMETER

OBD II CODE READER

VEHICLE DATA

INSTRUMENT SETUP

BACK SELECT

Figure 2. Main Menu

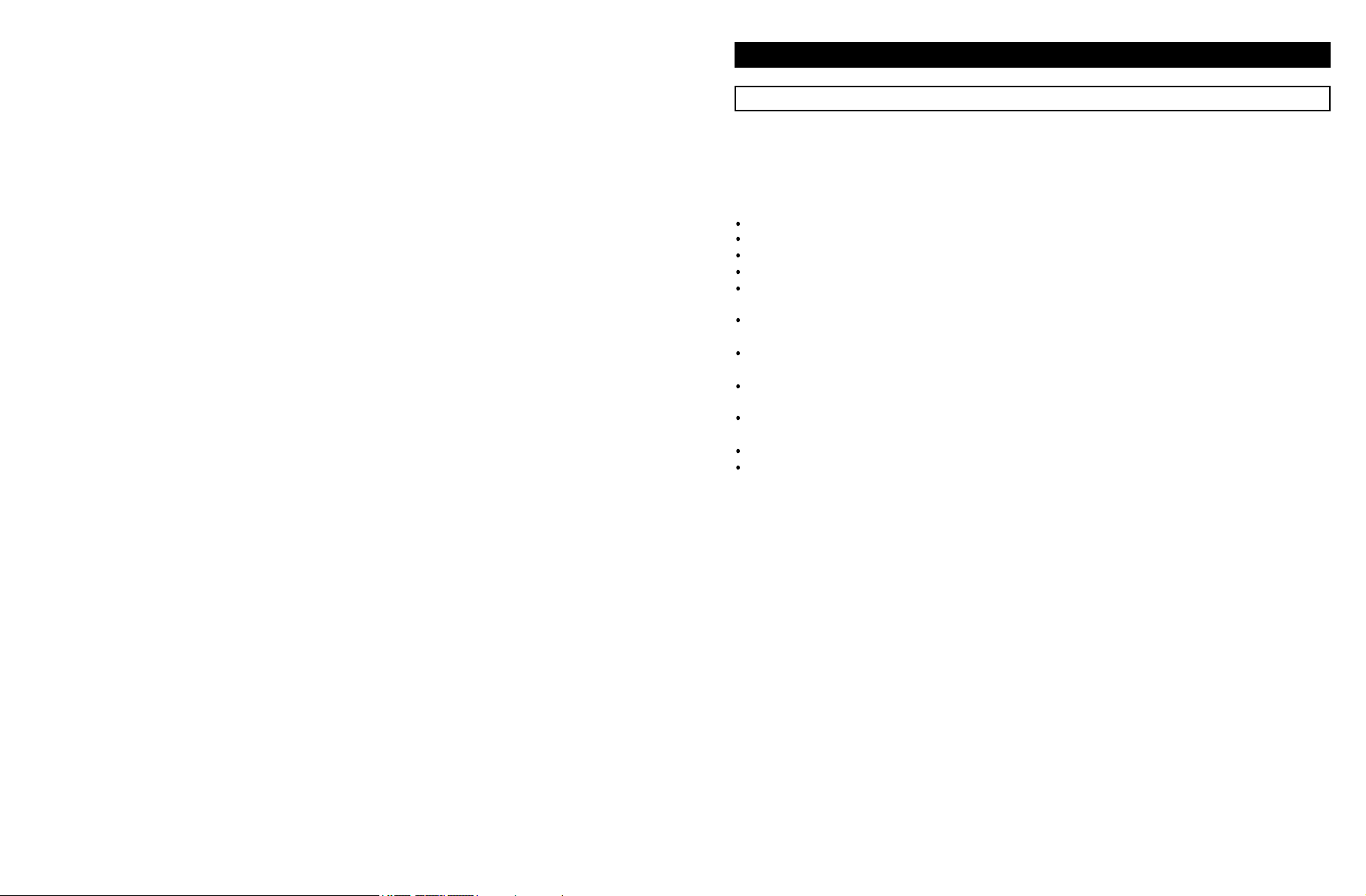

From the resulting COMPONENT TESTS menu, select IGNITION from the test group. Then, press to select.

COMPONENT TESTS MENU

SENSORS

ACTUATORS

ELECTRICAL

IGNITION

NOTE

The Master Reset clears all memory data.

Performing a Navigation Exercise

To display the MAIN MENU while a measurement display is active, press the MENU key to display the MAIN MENU

as shown in Figure 2. This menu lists all of the tests, displays and setups available:

COMPONENT TESTS

SCOPE

GRAPHING MULTIMETER

OBD II CODE READER

VEHICLE DATA

INSTRUMENT SETUP

4-2

BACK SELECT

Figure 2. Selecting IGNITION Menu

4-3

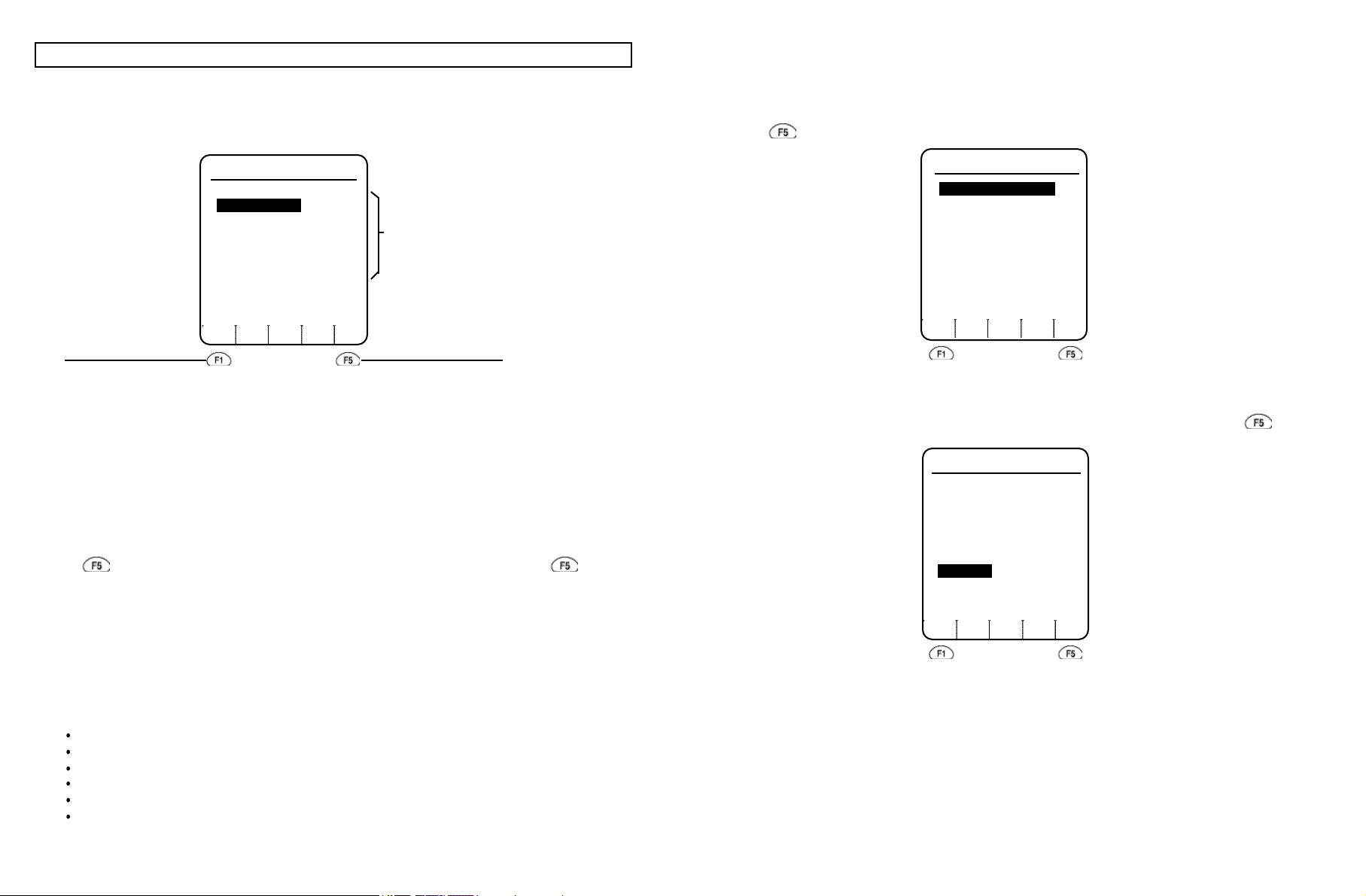

Next, press the Four Way arrow keys to highlight PIP/SPOUT. Press to select. Now, the instrument is ready

to test the input signal(s).

Figure 3. Example of Result Display

Press to remove the Reference Waveform(s).

Press to enter t he scope into t he test mode and continue t o d isplay t he Refere nce Wave form (s) f or

comparison to a live waveform(s).

For this demonstration, view the following reference information specific to the test selected. Reference information

is available at any time by pressing the HELP key. Press when finished viewing each area under the HELP

menu.

Test Procedure - Tells how to hook up the scope, and what accessories to use. Describes how to stimulate the

sensor or operate the circuit to obtain a diagnostic waveform.

Reference Waveform (REF WFM)

- Shows a typical good or normal signal pattern. Describes significant waveform

features or variations.

Theory of Operation - Explains what the sensor or circuit does and the important signals involved.

Troubleshooting Tips - Tells the symptoms caused by the defective component and how to fix up the problems.

Function Information - Explains about the particular function keys that can be used for the selected test for certain

COMPONENTS.

Pressing moves back through the previous displays to return to active tests or to test selected menus.

After you choose a preset test, you may change most instrument settings to get a better look at the signal. You can

even change to different display modes, moving between Scope mode and GMM mode as needed, by pressing the

GMM MODE function key in the Scope display or the SCOPE MODE function key in the GMM display.

You can hold the information in memo ry at a ny time b y pressing th e HOLD key to freeze the display. N otice that

SAVE, RECALL, and CLEAR function key labe l is displayed above the Function key on the bottom display after

is pressed.

Press the SAVE key to save the present screen in the next memory location.

Press the RECALL key to recall the screen last saved in memory.

Press the CLEAR key to clear all the memory locations.

Press the BACK key to resume measuring or to return to the previous display.

Power Sources and Charging the Battery

The instrument can be powered from any of the following sources:

Internal Battery Pack

This is a rechargeable Ni-MH Battery Pack already installed.

Power Adapter

The Power Adapter / Battery Charger powers the instrument from a standard AC outlet and charges the installed

Ni-MH Battery Pack.

The instrument can be used during battery charging. Verify that your local line voltage is appropriate before using

the Power Adapter to power the instrument.

Charging Adapter (Optional)

This adapter charges the instrument’s Ni-MH Battery Pack from a standard 12 V DC cigarette lighter outlet

WARNING

TO AVOID ELECTRICAL SHOCK, USE A BATTERY CHARGER THAT IS

AUTHORIZED FOR USE WITH THE AUTOMOTIVE SCOPE.

USE the following procedure to charge the battery pack and to power the instrument:

1. Connect the Power Adapter / Battery Charger to line voltage.

2. Insert the Power Adapter’s low voltage plug into the Power Adapter connector of the instrument. You can now use

the instrument while the Ni-MH batteries are being charged slowly. If the instrument is turned off, the batteries are

charged more quickly.

During operation, when the batteries are low, a battery symbol appears on the top right of the display. When

this occurs, replace or recharge the internal battery pack immediately.

3. The Power Adapter uses a trickle charging method for the batteries, so no damage can occur even if you leave it

charging for long periods.

Typically a 8 hour recharge during instrument working and a 4 hour recharge during instrument off provides the

instrument with the maximum use of 4 hours.

Auto-Power-Off

When o pe rated on batteries (no adapter co nnec ted), the inst rum ent c onserve s powe r by turnin g itse lf off

automatically, if you have not pressed a key for 30 minutes or if the battery level is too low. The instrument turns

back on if the POWER key is pressed.

The Auto Power-off feature is disabled automatically in the GMM mode.

You can adjust the Auto-Power-Off time between 5 minutes and 120 minutes to use “Instrument Setup” menu option.

4-4

4-5

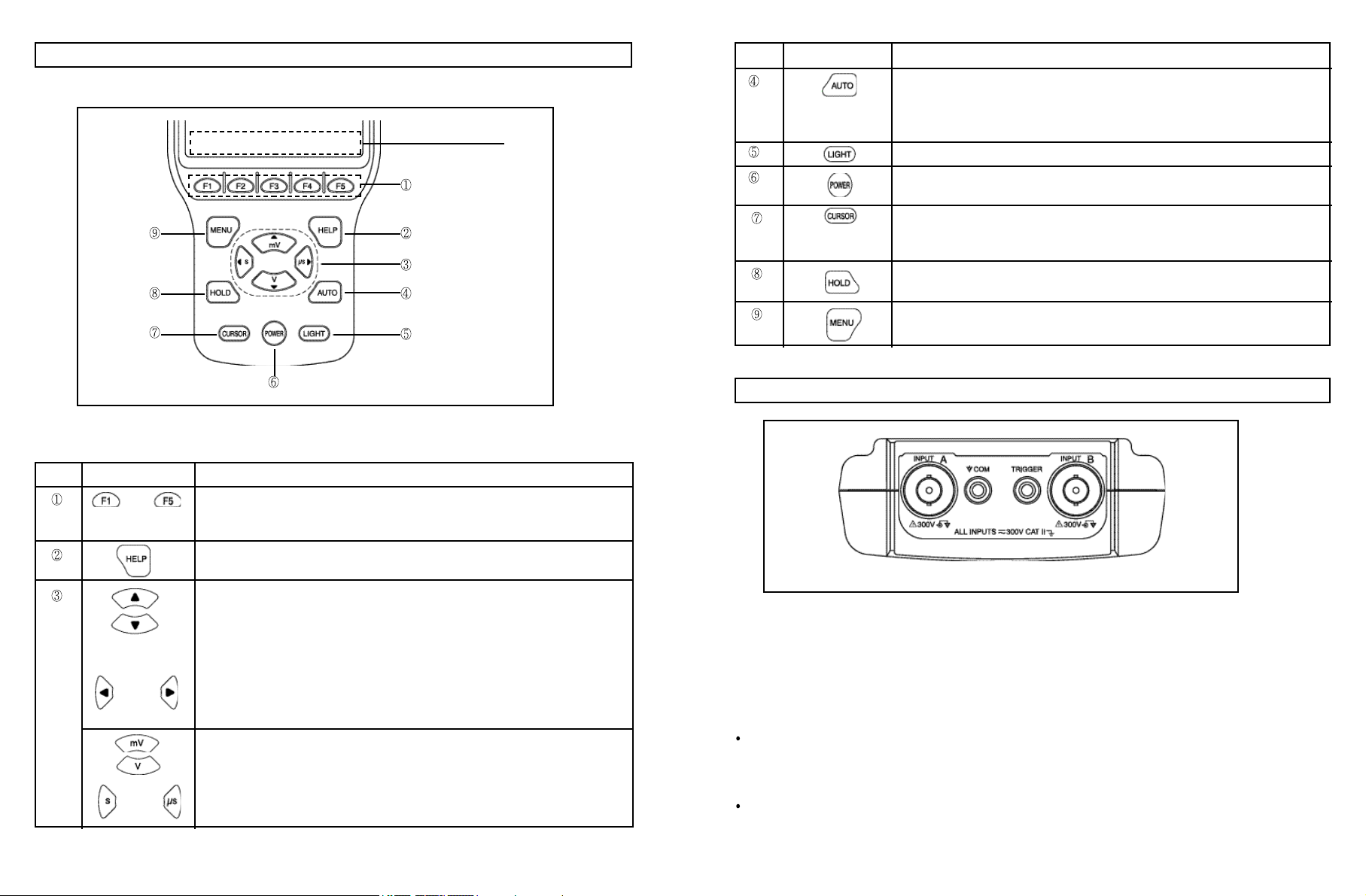

4.3 FRONT PANEL CONTROLS

Key Control Overview

Display area for the

Function Key Labels

ITEM KEYS DESCRIPTION

Sets automatic ranging on and off (toggle).

When on , t he top righ t d isplay shows A UTO. Whe n t his f unction is se t on, it

searches for the best range and time ba se settings and once f ound it t racks the

signal. When this function is off, you should manually control ranging.

Turns the LCD Backlight on and off.

Turns the power on and off (toggle). When you turn the power on, previous settings

are activated.

Allows you to use cursors for measurements on waveforms. A cursor is a vertical

line or a horizontal line that you can move over the waveform like a ruler to measure

values at specific points.

Freezes the display (HOLD is displayed at the top right). Also displays a menu to

save or recall screens or to clear the memory.

Takes you back to the main navigation menu.

Figure 4. Key Control Overview

Key Descriptions

ITEM KEYS DESCRIPTION

to These are the Function keys.

The function assigned to each key is indicated by the Function Key Label displayed

above the key on the bottom display.

Displays information about the highlighted menu choice during menu selection.

Displays information about the function keys when a selected test is running.

Performs one of the following actions:

• Moves up and down through menu choices.

• Moves a waveform up and down.

• Moves a voltage cursor up and down.

• Adjusts the trigger level when you are in the SCOPE mode.

Performs one of the following actions:

• Moves a waveform right and left.

• Moves a time cursor left and right.

Ranges amplitude up and down for both channels (CH A & CH B).

Ranges Time Bass up and down for both channels (CH A & CH B).

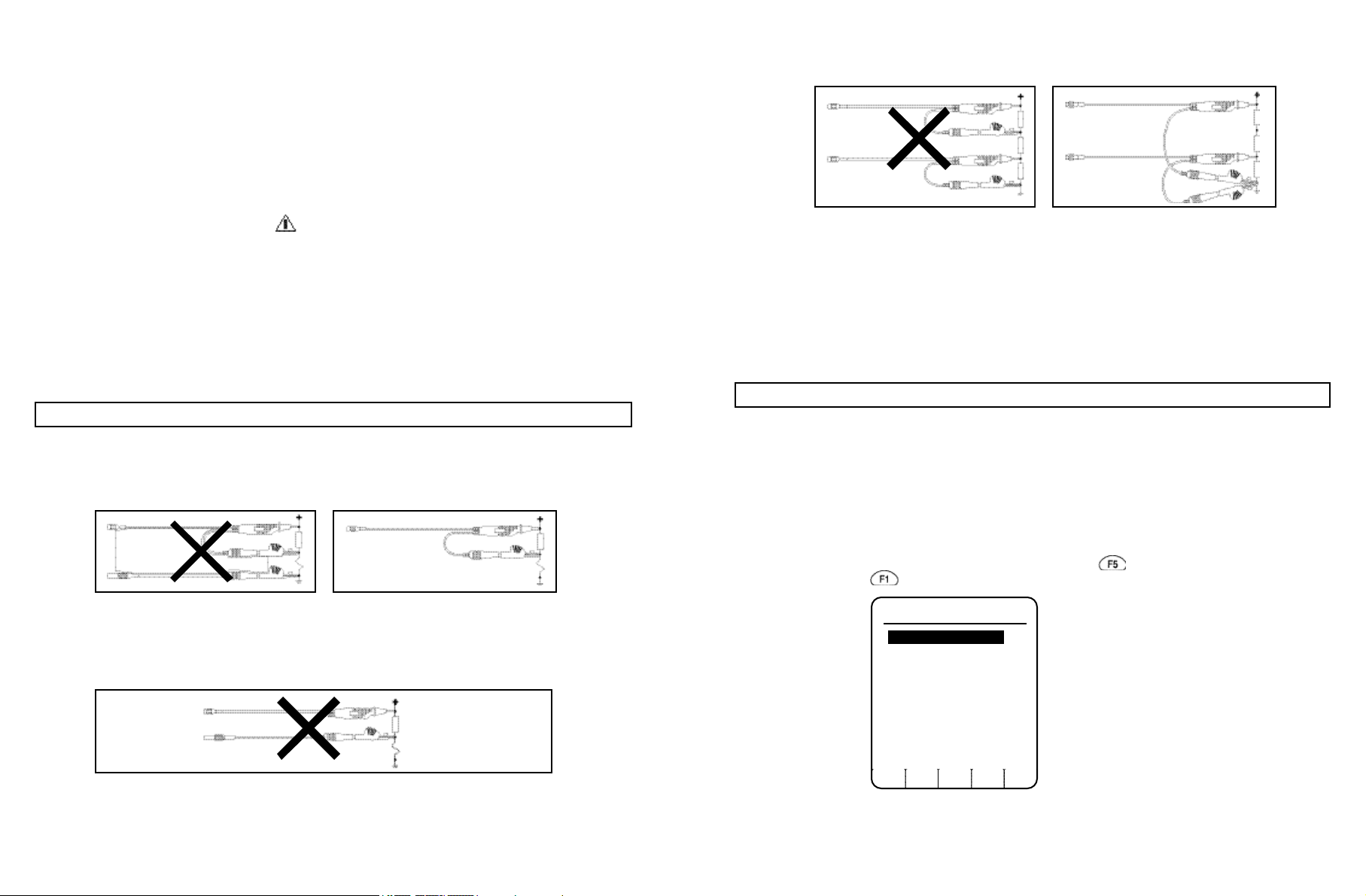

4.4 MEASUREMENT CONNECTIONS

Figure 5. Measurement Connections

INPUT A (Red)

INPUT A is used for all single channel measurements, sometimes combined with use of the other inputs, Various

test leads and adapters are required depending on the type of measurement selected.

INPUT B (Yellow)

INPUT B is used in conjunction with INPUT A.

In COMPONENT TEST mode,

for DUAL O2 SENSOR measurements.

for PIP/SPOUT measurements.

for ADVANCE measurements.

In SCOPE mode you can use the instrument as a dual trace oscilloscope with INPUT A and INPUT B connected.

4-6

4-7

COM, TRIGGER

Used as external trigger for probes with dual banana plugs, such as the RPM Inductive Pickup.

TRIGGER (as single input)

Used in SCOPE mode to trigger (or start) acquisitions from an external source.

COM (as single input)

Used for safety grounding when the Capacitive Secondary Pickup is connected to the ignition system.

WARNING

T O A VO ID ELE CTR ICAL SHO CK , CO NNECT THE C OM I N PUT OF THE

INSTRUMENT TO VEHICLE GROUND BEFORE CLAMPING THE CAPACITIVE

SECONDARY PICKUP(SUPPLIED) ON THE IGNITION WIRES.

THIS GROUND CONNECTION IS REQUIRED IN ADDITION TO THE NORMAL

MEASUREMENT GROUND CONNECTIONS.

For other tests, the COM input should not be connected to engine ground when the probes have their own ground

connection at the probe end. See the GROUNDING GUIDELINES.

4.5 GROUNDING GUIDELINES

Incorrect grounding can cause various problems:

1. A ground loop can be created when you use two ground leads connected to different ground potentials. This can

cause excessive current through the grounding leads.

INPUT A

COM

(Incorrect Grounding)

Ground Loop b y Double Gr o unding on

Different Grounds

2. Excessive noise shown on the measured signal.

INPUT A

COM

INPUT A

(Correct Grounding)

Shield of Test Lead Connected to Ground

3. Measurement faults or short circuit with the DUAL INPUT SCOPE mode. This occurs when you perform floating

measurements with grounding at different points.

INPUT A

INPUT B

(Incorrect Grounding)

S hort Circuit by Grounding on Dif feren t

INPUT A

INPUT B

(Correct Grounding)

Grounding at One Point

Potentials

Instrument Grounding for Measurements on the Ignition System

Fo r the in strume nt sa fety, connect the COM input to engine ground b efore you perform measurements on the

ignition system with the Capacitive Secondary Pickup.

To prevent ground loops, connect all ground leads to the SAME engine ground.

4.6 DISPLAY

The instrument presents “live” measurement data in the form of Scope and GMM displays. Temporary displays are

used to display frozen and saved measurement data.

Menus are provided as a means of choosing instrument ’s measurement configuration. To display the MAIN MENU

while a measurement display is active, press the MENU key at any time.

Menu Display

When you press MENU key, the instrument displays the MAIN MENU. To select a menu option, use the Four Way

arrow keys to move the highlight bar to the desired item. Then press . To exit the MAIN MENU and return to

the previous setup, press . During menu selection, the bottom part of the screen is used to display the function

key menu.

MAIN MENU

COMPONENT TESTS

SCOPE

GRAPHING MULTIMETER

OBD II CODE READER

VEHICLE DATA

INSTRUMENT SETUP

4-8

(Incorrect Grounding)

Noise Pickup on Unshielded Ground Lead

BACK SELECT

4-9

COMPONENT TESTS

Leads to a series of predefined setups to test most common sensors and circuits.

SCOPE

Use Single Input Scope mode if you want to measure a single signal, INPUT B is turned off. Use Dual Input Scope

mode if you want to simultaneously measure two waveforms - one on INPUT A and the other on INPUT B.

GRAPHING MULTIMETER

INPUT A is used for all GMM(Graphing Multimeter) tests. The probes and test leads to be used depend upon the

type of test performed.

OBD II CODE READER

The OBD II cable input is located on the right side of the housing. Connect the standard OBD II cable supplied to

the vehicle’s sixteen-pin DLC (Data Link Connector).

VEHICLE DATA

Set the vehicle data to match the vehicle under test. If they do not match, you could get incorrect test results and

may not be able to select all available tests for this vehicle. This menu appears at power-on as the start-up display

due to its importance.

INSTRUMENT SETUP

Use this menu option to set the following:

Optimal settings for display.

Filter function enabled and disabled.

Auto-Power-Off enabled and disabled and adjusting the Auto-Power-Off time.

Language for menus and HELP text.

Version Information of current software.

Scope Calibration when using the scope in abnormal operating environments.

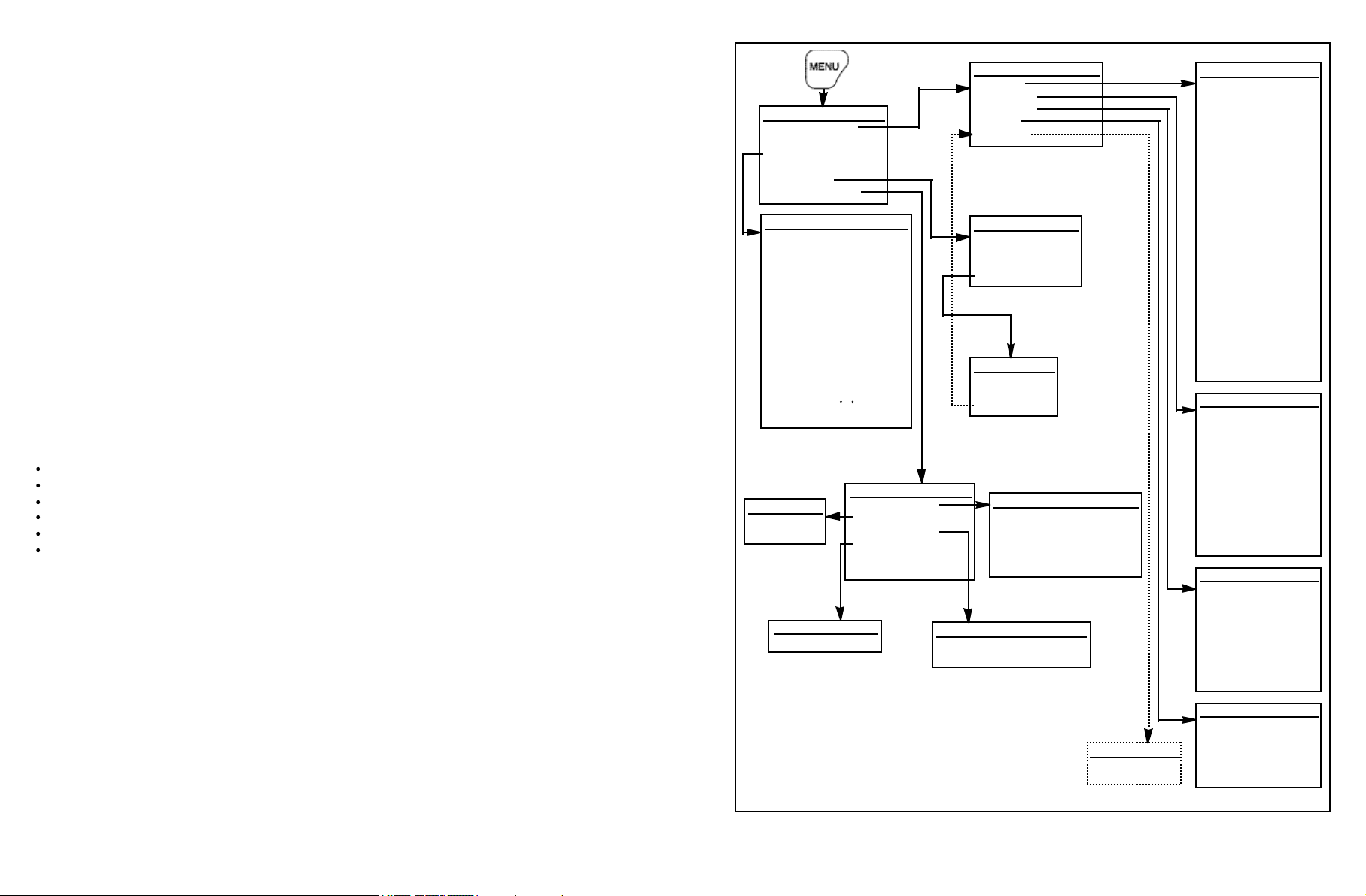

Menu Overview

Figure 6. shows an overview of available test functions, displays and setups from the MENU key. The MAIN MENU

choices represent categories of applications that are listed in sub-menus as shown in the following figure.

MAIN MENU

COMPONENT TESTS

SCOPE

GRAPHING MULTIMETER

OBD II CODE READER

VEHICLE DATA

INSTRUMENT SETUP

GRAPHING MULTIMETER MENU

VOLT DC, AC

OHM/DIODE/CONTINUITY

RPM

FREQUENCY

DUTY CYCLE

PULSE WIDTH

DWELL

IGNITION PEAK VOLTS

IGNITION BURN VOLTS

IGNITION BURN TIME

INJECTOR PEAK VOLTS

INJECTOR ON TIME

AMP DC, AC

TEMPERATURE C F

LIVE

IN STR UMENT SETUP MENU

FILTER MENU

INPUT A : OFF

INPUT B : OFF

LANGUAGE MENU

LANGUAGE : ENGLISH

DISPLAY OPTIONS

FILTER

AUTO POWER OFF

LANGUAGE

VERSION INFORMATION

SCOPE CALIBRATION

COMPONENT TESTS MENU

SENSORS

ACTUATORS

ELECTRICAL

IGNITION

(or DIESEL)

VEHICLE DATA MENU

CYLINDERS

CYCLES : 4

BATTERY : 12 V

IGNITION : CONV

IGNITION MENU

CONV (default)

DIS

DIESEL

DISPLAY OPTIONS MENU

AUTO POWER OFF MENU

AUTO POWER OFF : ON

AUTO POWER OFF TIME : 30 min

: 4

USER LAST SETUP : OFF

CONTRAST : 4

GRATICULE : ON

HORIZ TRIG POS : 10 %

ACQUIRE MODE : PEAK DETECT

SENSOR TESTS MENU

ABS Sensor (Mag)

O2S Sensor (Zirc)

Dual O2Sensor

ECT Sensor

Fuel Temp Sensor

IAT Sensor

Knock Sensor

TPS Sensor

CKP Magnetic

CKP Hall

CKP Optical

CMP Magnetic

CMP Hall

CMP Optical

VSS Magnetic

VSS Optical

MAP Analog

MAP Digital

MAF Analog

MAF Digi Slow

MAF Digi Fast

MAF Karman-Vrtx

EGR (DPFE)

ACTUATOR TESTS MENU

Injector PFI/MFI

Injector TBI

Injector PNP

Injector Bosch

Mixture Cntl Sol

EGR Cntl Sol

IAC Motor

IAC Solenoid

Trans Shift Sol

Turbo Boost Sol

Diesel Glow Plug

ELECTRICAL TESTS MENU

Power Circuit

V Ref Circuit

Ground Circuit

Alternator Output

Alternator Field VR

Alternator Diode

Audio System

DC Switch Circuits

4-10

DIESEL MENU

DIESEL INJECTOR

ADVANCE

Figure 6. Automotive Test Functions & Setups Overview

IGNITION TESTS MENU

PIP/ SPOUT

DI Primary

DI Secondary

DIS Primary

DIS Secondary

4-11

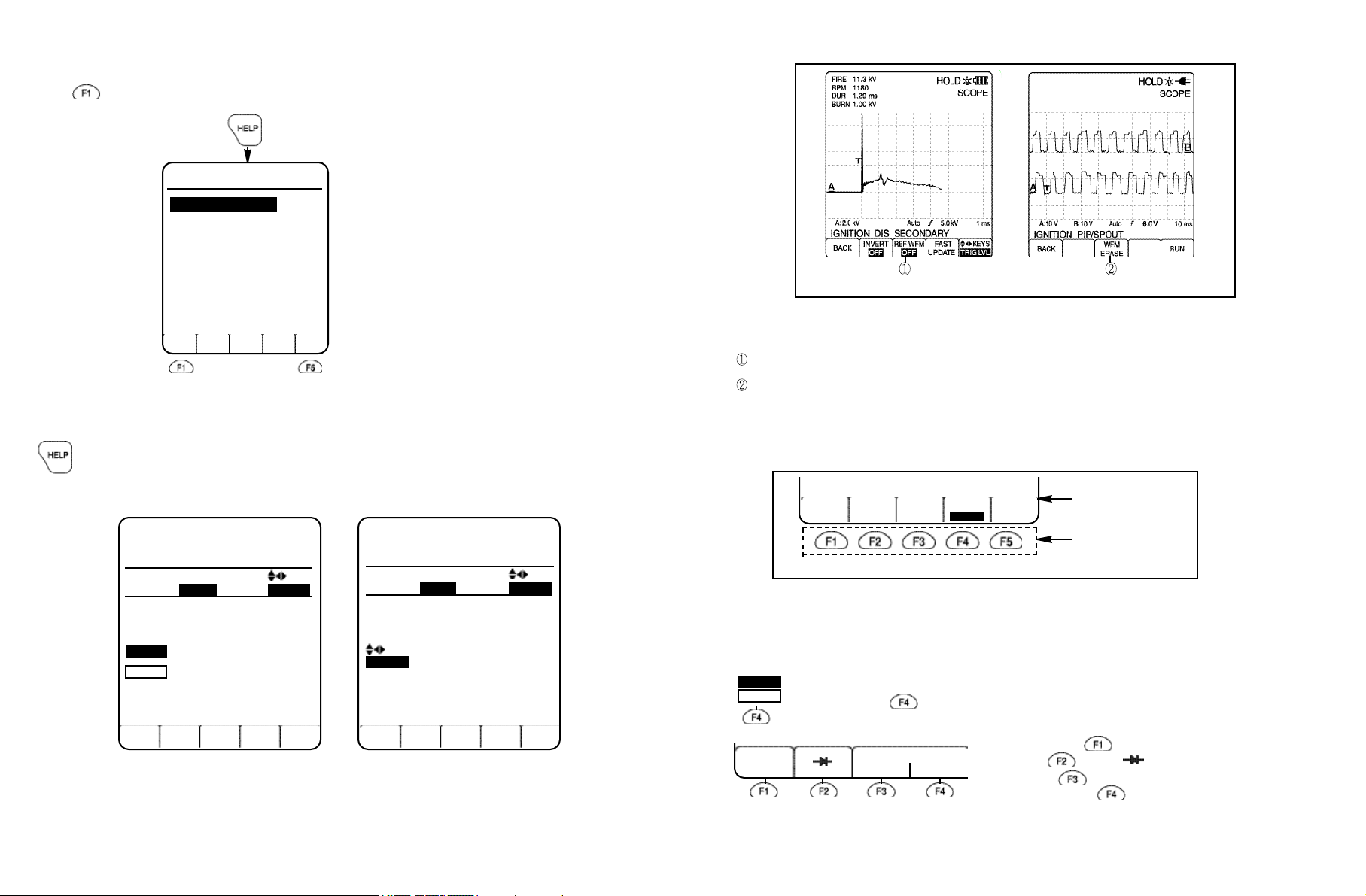

Getting Reference Information for the Selected Test

Reference information is available at any time by pressing the HELP key.

Press when finished viewing each area under the HELP menu.

HELP MENU

TEST PROCEDURE

REFERENCE WAVEFORM

THEORY OF OPERATION

TROUBLESHOOTING TIPS

FUNCTION INFORMATION

BACK SELECT

Screen Displays

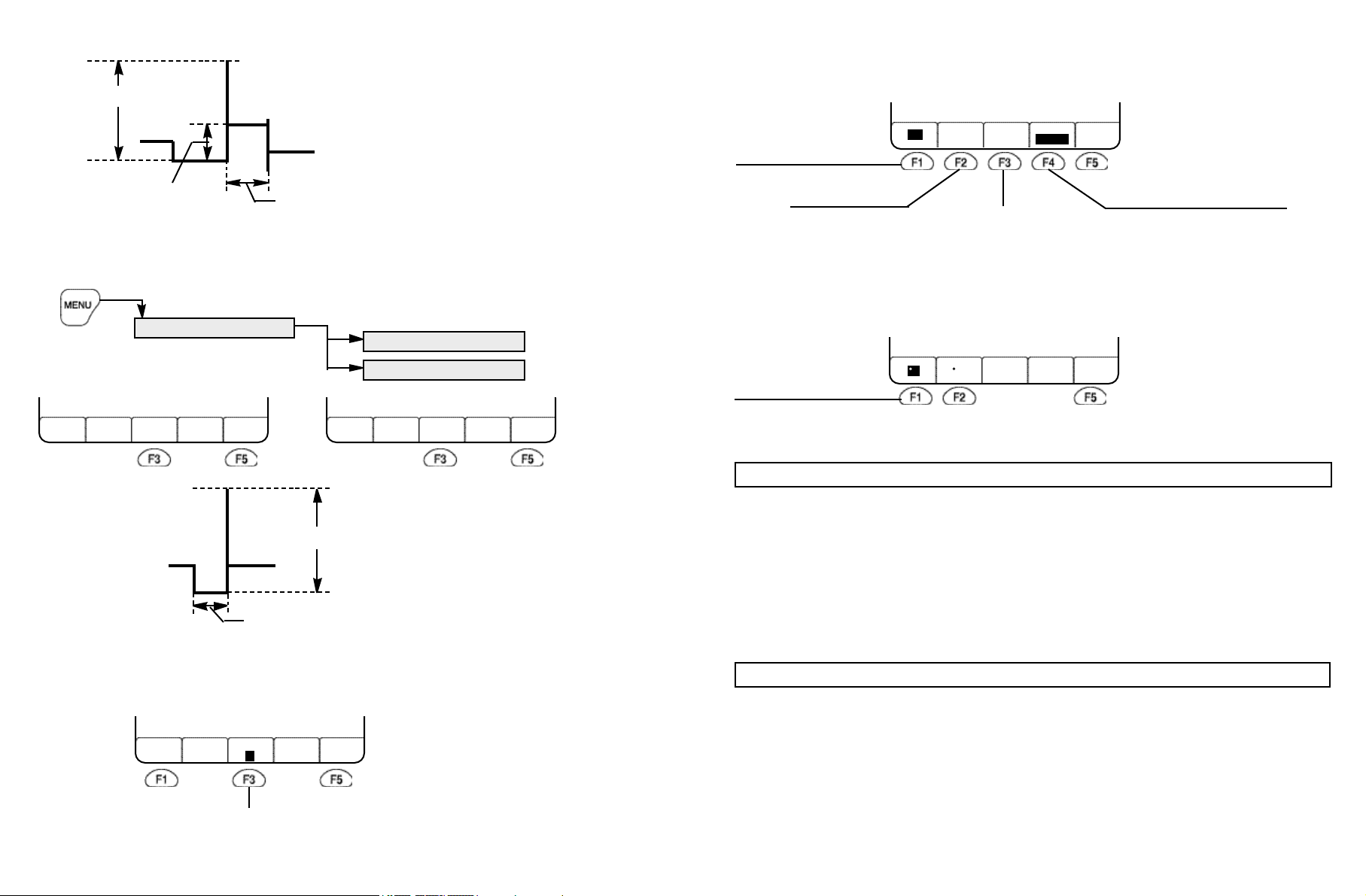

Figure 8. Single and Dual Input scope in COMPONENT TESTS

Use Dual Input Scope mode if you want to sim ultaneously measure two waveforms - one on INPUT A and the other

on INPUT B.

Use SINGLE INPUT SCOPE mode if you want to measure a single signal, INPUT B is turned off.

Use DUAL INPUT SCOPE mode if you want to simultaneously measure two signals.

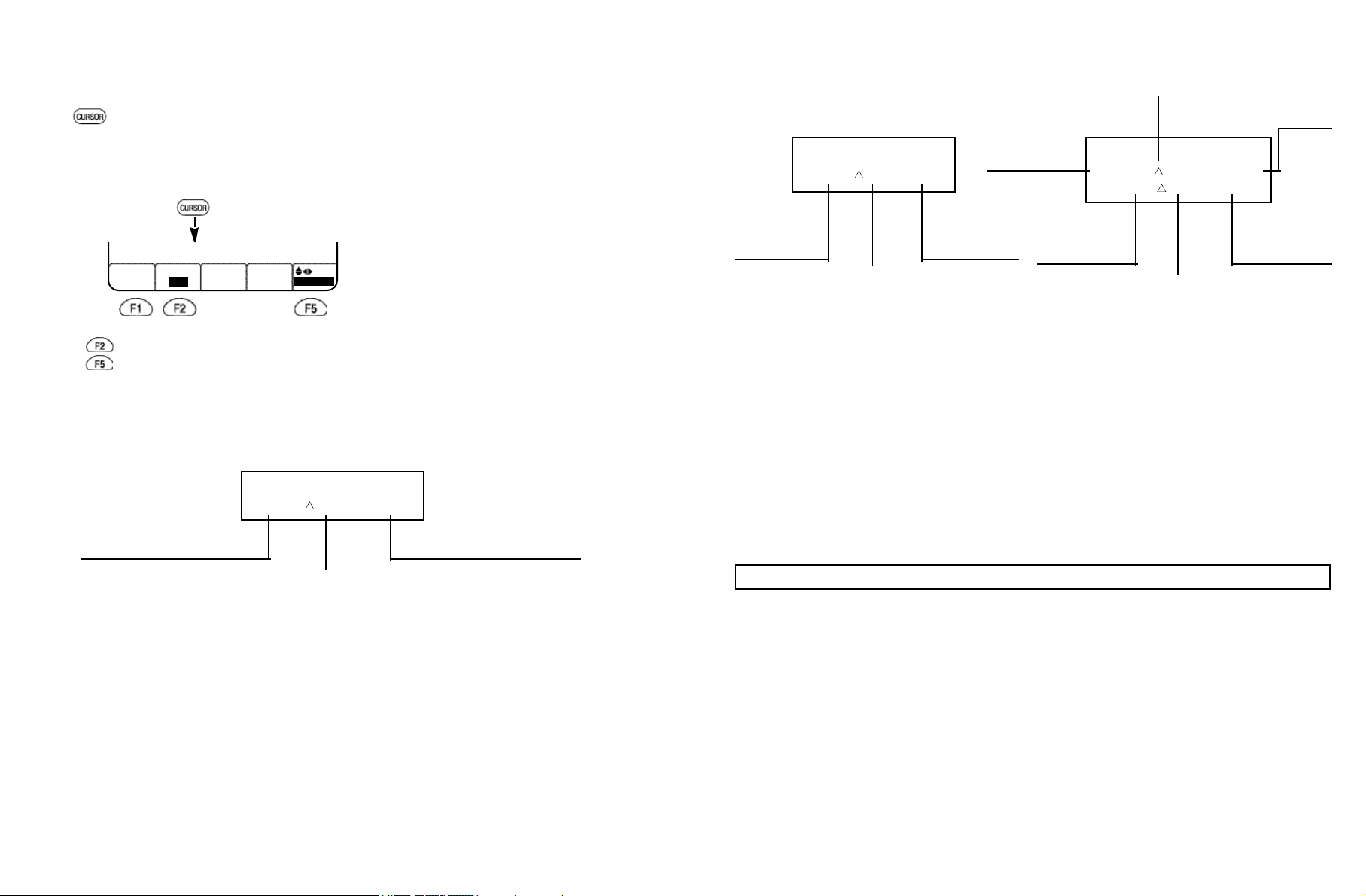

Getting Information About the Function Keys During a Running Test

When you press this key during a running test, you get information about the function keys that can be used

for the test.

For example,

DI Primary

Function Info

VEHICLE

DATA

VEHICLE

DATA

CYLINDER

SINGLE

PARADE

BACK

CYLINDER

SINGLE TRIG LVL

Giv es a list of options to d efin e

the type of vehicle under test.

S INGLE -d i sp l a ys th e i gniti o n

pattern of one single cylinder.

P AR AD E-di sp lays t h e ig n iti o n

patte rn of al l cyl in ders in fi rin g

order.

FAST

UPDATE

Page 1 of 2

Function Info

KEYS

PAGE

DOWN

VEHICLE

DATA

FAST

UPDATE

TRIG LVL

BACK

Figure 7. Information About the Function keys

DI Primary

CYLINDER

SINGLE TRIG LVL

Turns all readings off to make the

me a sur em ent f a ste r and m ore

reliable.

You can adjust trigger level for a

KEYS

stab le d ispla y b y using the fou r

way arrow keys.

FAST

UPDATE

PAGE

UP

Page 2 of 2

KEYS

4-12

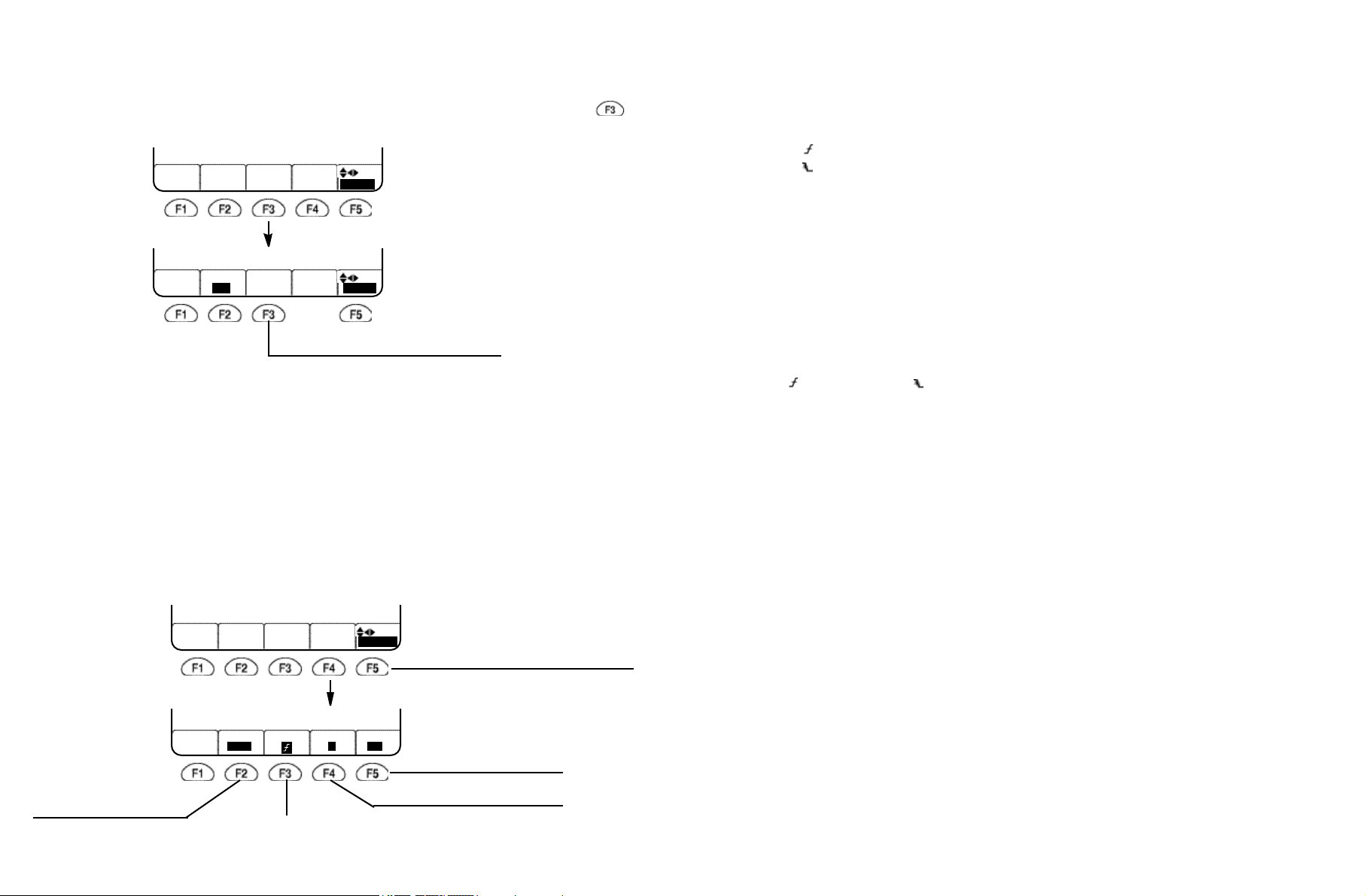

Using the Function keys

Fo r each test, one or more Function Key Labels are displaye d, depending on the sub-select ions po ssible. The

Labels indicate what the keys do when you press them. (See the following example.)

IGNITION DI SECONDARY

VEHICLE WFM CYLINDER

BACK RUN

DATA ERASE PARADE

Function Key Labels

Function keys

Figure 8. Function Key Labels for SECONDARY IGNITION

Pressing a function key that has no label has no effect.

The same Function Key Label can appear in several tests and it performs a similar function.

Examples of Function Key Labels

CYLINDER

PARADE

SINGLE

OHM

Two separate functions can be allowed to the same function key.

You can use the function key to toggle between the functions.

When you press , you can select between PARADE and SINGLE cylinder test.

CONTINUTY

OPEN

CLOSE

When you press , OHM becomes the active function. When

you press , Diode ( ) becomes the active function. When

you press , OP EN CO NTINU ITY b ecomes th e active

function. P ressing , CLOSE CONTINUITY be comes t he

active function.

4-13

KEYS

RANGE A

MOVE A

TRIG LVL

KEYS

CURSOR 1

CURSOR 2

REPEAT

TEST

INVERT

OFF

ON

The KEYS icon indicates that you can use the Four Way arrow keys to change Volt & Time

ranges, to move the waveform position, and to adjust the trigger level for either INPUT A or INPUT B.

And also you can use the Four Way arrow keys to adjust the sensitivity level in the COMPONENT

TEST (IGNITION mode).

Press to toggle among RANGE A,MOVE A , and TRIG LVL for INPUT A, or among

RANGE B , MOVE B , and TRIG LVL for INPUT B.

The icon indicates that you can use the Four Way arrow keys to move CURSOR 1 (if

CURSOR 1

is highlighted) or move CURSOR 2 (if CURSOR 2 is highlighted). Press the function key to toggle

between CURSOR 1 and CURSOR 2.

This Label is displayed for SINGLE DISPLAY tests, for example the knock sensor test. To repeat the

test, press the function key, then perform the required action. The knock sensor test is a single shot

measurement, which means that the signal from the knock sensor is displayed only once. To get a new

test result, you have to press the key and then tap the engine block or the sensor again. You

may have to readjust the vertical RANGE to get an optimal waveform.

To change to the opposite polarity. Puts the waveform display upside down.

4.7 SCOPE MODE

SCOPE mode provides a display of signal patterns from

either CH A or CH B over times ranging from 1 µs to 50

seconds per division, and for voltage ranges from 50 mV

to 300 V full scale.

The display m ay be triggered at all tim e se tt ings, and

trigg er slop e and level m ay be adjusted as needed. The

scope display is defaulted in Glitch Detect mode to display

even the narrowest glitches.

The SINGLE INPUT SCOPE mode (Com ponent Test s

onl y) pro vi des fo r th e d i spla y o f up to f o u r m e t e r

measurements above the waveform viewing area.

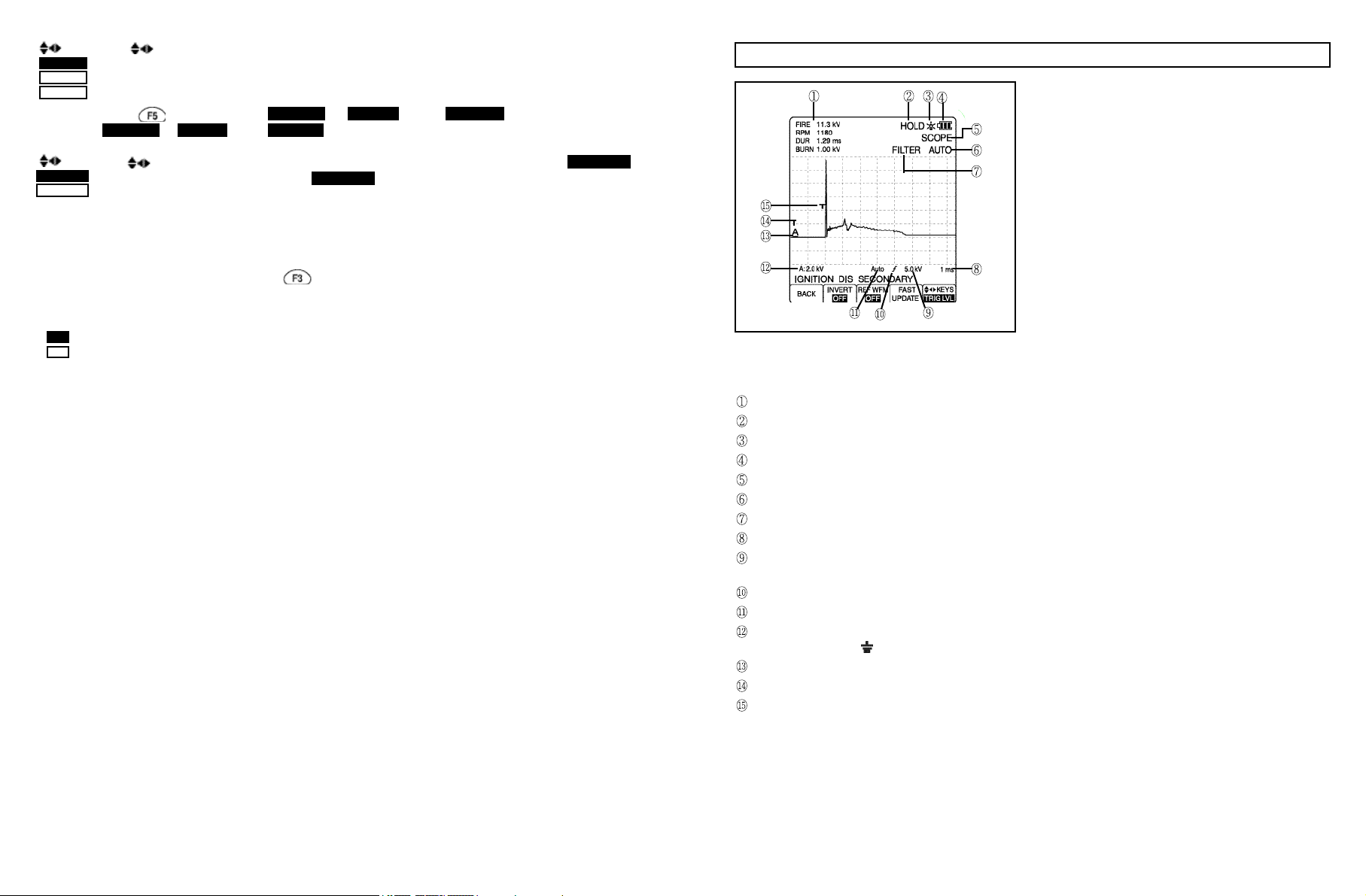

Figure 9. Scope Mode Indicators

GMM

MODE

SCOPE

MODE

GLITCH

SNARE

This Label is displayed in the Scope test mode of the COMPONENT TESTS only.

To change from Scope test mode to GMM test mode, press the function key.

This Label is displayed in the GMM test mode of the COMPONENT TESTS only.

To change from GMM test mode to Scope test mode, press the function key.

This Label is displayed in the Scope test of the COMPONENT TESTS only.

To capture, display, and optionally save abnormal signal patterns when they occur, press the function

key.

Indicate meter measurement function.

Indicate HOLD function enabled.

Backlit indicator.

Low battery indicator.

Indicate SCOPE mode.

Indicate AUTORANGING mode.

Indicate FILTER function enabled.

Indicate time base per division.

Indicate trigger level voltage.

Blank if DC, ~ if AC.

Indicate trigger slope (rising or falling).

Indicate AUTO triggered.

Indicate voltage per division and coupling.

Blank if DC, ~ if AC, if GND.

Indicate signal source channel.

Indicate INPUT A zero level.

Indicate trigger location.

4-14

4-15

4.8 GMM (GRAPHING MULTIMETER) MODE

4.9 OBD II CODE READER MODE

GMM mode plots the results of signal measurements such

as freq uency as t he values change with time. The time

range in GMM mode may be set manually from 5 seconds

to 24 hours per display.

Ranges for the vertica l sca le may also be set m anually

,

and the available range depends upon the measurement

being displayed.

Where possible, measurements plotted in GMM mode are

performed on a cycle-by-cycle basis, resulting in extremely

fast response.

This mode is very suitable to find faults in slowly changing

processes.

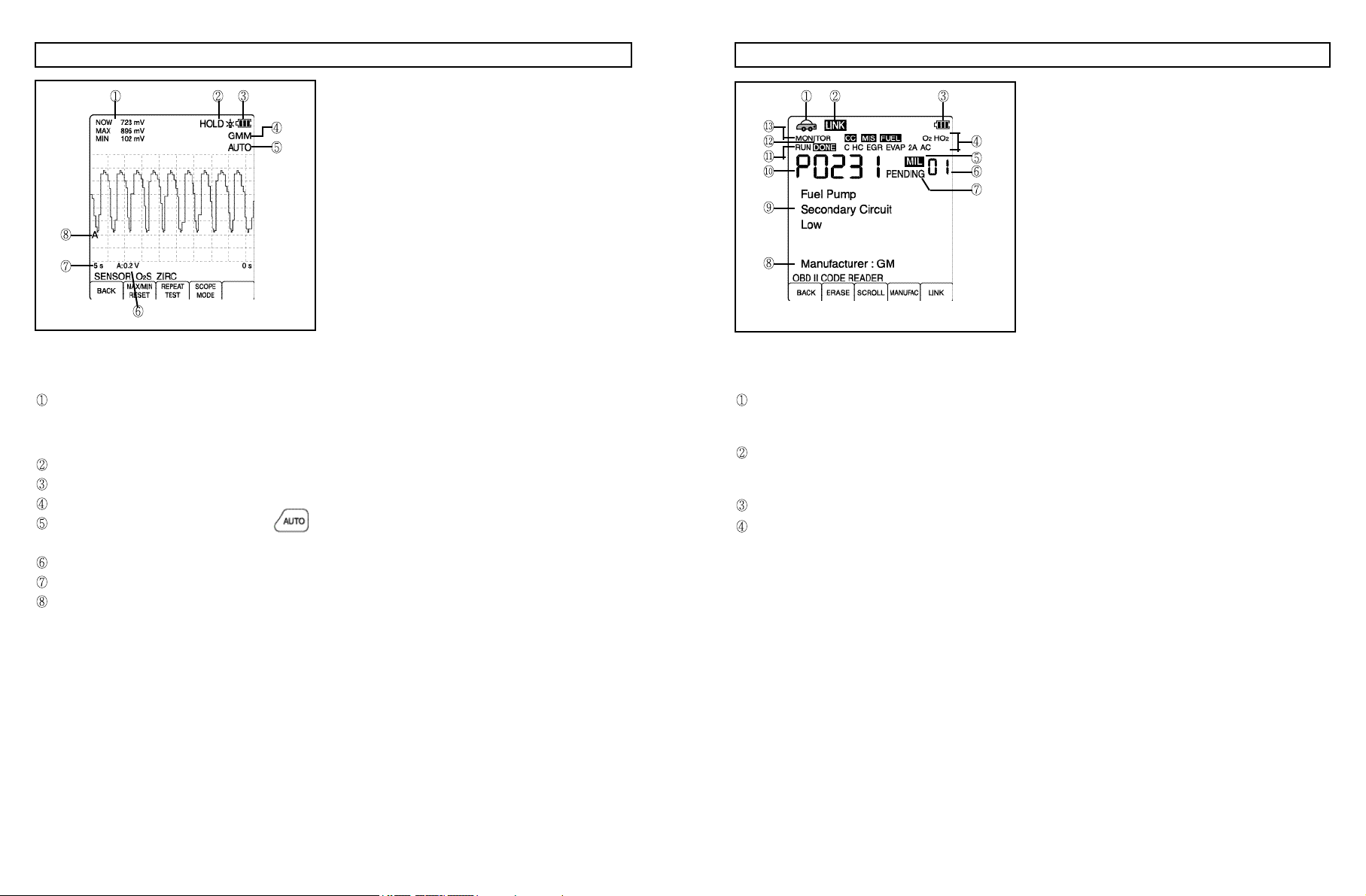

Figure 10. GMM Mode Indicators

Indicate meter measurement functions.

NOW: Most recent meter reading.

MAX: Maximum value since last reset.

MIN: Minimum value since last reset.

Indicate HOLD function enabled.

Low battery indicator.

Indicate GMM mode.

Indicate AUTORANGING mode. Pressing sets automatic ranging on. Using the Four Way arrow keys for

ranging turns automatic ranging off and extinguishes AUTO.

Indicate voltage per division.

Indicate time per display.

Indicate signal source channel.

4-16

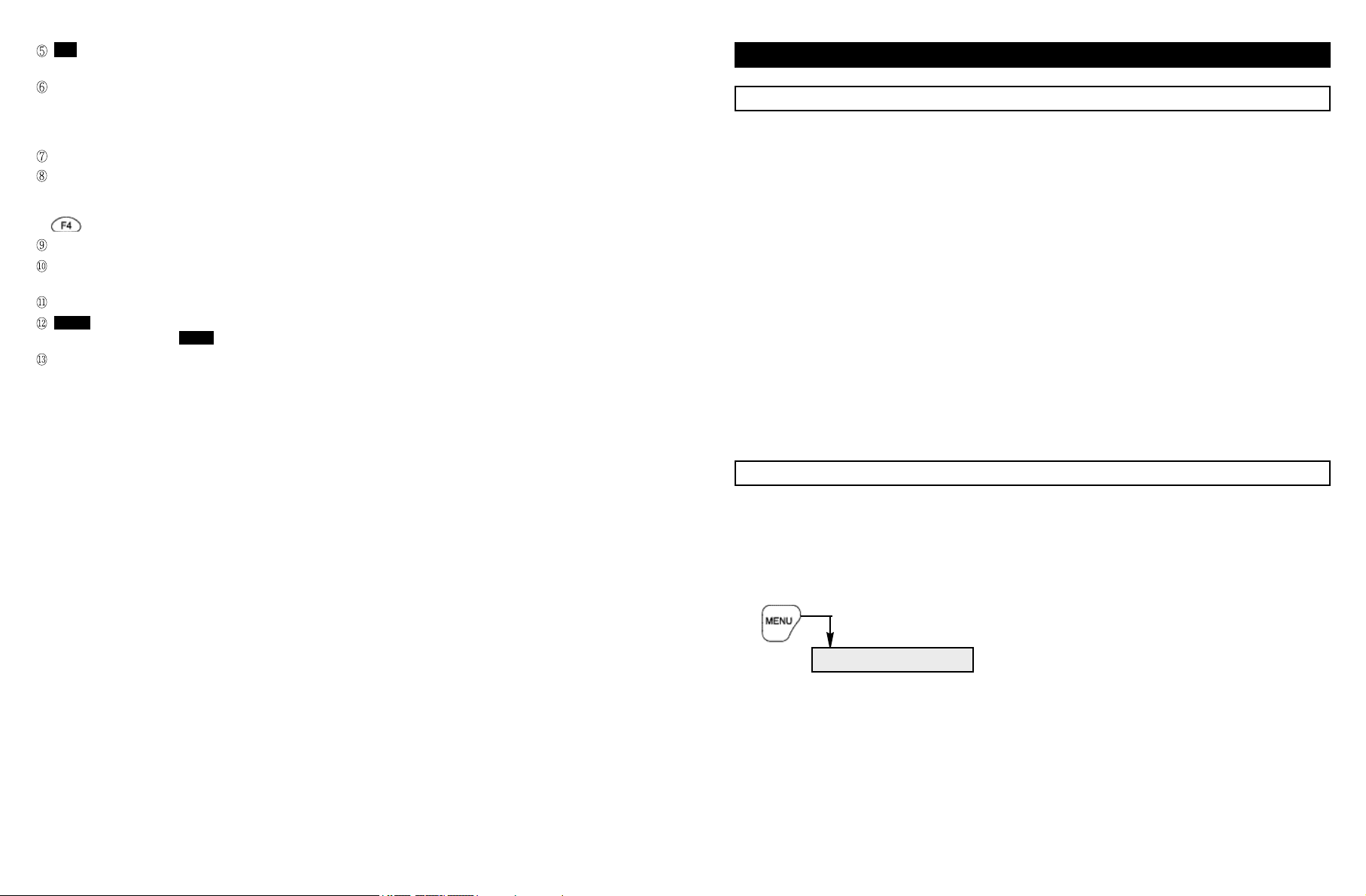

OBD II Code Reader mode is designed t o ret rieve the

Diagnost ic Tro u b le Code s (DTC’ s) f rom the ve h icle

Powertrain Co nt rol Mod ule (PC M) and t o provid e an

indication of I/M Readiness Monitor status.

This mode is useful to check what code may be causing

the malfunction indicator lamp (MIL) to light, or to verif y

that test results from the scope or GMM are reflecting the

same problem.

This als o wil l dis play t he re a diness status o f certa in

emissions test monitors.

Figure 11. OBD II Code Reader Mode Indicators

Vehicle icon - Indicates whether or not the instrument ( in the Code Reader mode) is being properly powered

through the vehicle ’s Data Link Connector (DLC). A visible icon indicates that the instrument is being powered

through the vehicle’s DLC connector.

Link icon - Indicates whether or not the instrument (in the Code Reader mode) is communicating (linked) with the

vehicle’s on-board computer. When visible, the instrument is communicating (linked) with the PCM. If the Link

icon is not visible, the instrument is not linked to the PCM.

Battery icon - Low battery indicator of the instrument.

Monitor icons - Indicates which Monitors a re sup ported by t he vehicle under t est, and whe ther or n ot t he

associated Monitor has run its diagnostic testing. When a Monitor icon is

Solid, it indicates that the associated

Monitor has completed it’s diagnostic te sting. When a Monitor icon is F l a s h i n g, it indicates that th e veh icle

supports the associated Monitor, but the Monitor has not yet run its diagnostic testing. On OBD II systems, a

maximum of eleven Monitors are utilized. Not all Monitors are supported by all vehicles.

When the instrument is linked to a vehicle, only the icons for Monitors that are supported by the vehicle under

test are visible on the display.

Following is a list of Monitor icons and their associated Monitors:

CC - Comprehensive Component Monitor

MIS - Misfire Monitor

FUEL -

Fuel System Monitor

O

2 - Oxygen Sensor Monitor

HO2 - Oxygen Sensor Heater Monitor

C - Catalyst Monitor

HC - Heated Catalyst Monitor

EGR - Exhaust Gas Recirculation (EGR) Monitor

EVAP - Evaporative System Monitor

2A - Secondary Air System Monitor

AC - Air Conditioning System Refrigerant (R-12) Monitor

4-17

MIL - Indicates the status of the Malfunction Indicator Lamp (MIL).

This icon is visible only when a DTC has commanded the MIL to illuminate on the vehicle’s dash.

Code Number Sequence - The instrument assigns a sequence number to each DTC that is present in the PCM ’s

memory, in a scending order, starting with “ 01”. This h elps keep track of the number of D TC’s present in the

PCM’s memory. C ode number “01” will always be the h ig hest priority code, and the code for which “Freeze

Frame” data has been stored.

Pending icon - Indicates if the currently displayed DTC is a Pending Code.

Vehicle M anufacturer Displa y Area - Displays the name of the vehicle manufa cturer, whose Manuf actu rer

Specific DTC Definition or Generic DTC Definition will be displayed along with the associated DTC, if a fault will

be detected. “Generic” or a manufacturer among GM, Ford, Chrysler, Toyota, and Honda can be selected by the

key.

DTC Definition Display Area - Displays the DTC Definition per the currently displayed DTC.

DTC Display Area - Displays the Diagnostic Trouble Code (DTC) number.

Each particular fault is assigned a Code Number that is specific to that fault.

RUN - Indicates the Monitor RUN status of all the Monitors that apply to the vehicle under test.

DONE - When visible, indicates that all the Monitors that apply to the vehicle under test have run and completed

their Diagnostic Testing, DONE is visible only when all supported Monitors have completed their testing.

MONITOR - Identifies the Monitor icon area.

NOTE: Items 11 t hrough 13 are associated with I/M Readiness Monitor Status. Some state s req uire that all

vehicle monitors have run and completed their diagnostic testing before a vehicles emissions test (smog check)

can be performed.

5. INSTRUMENT OPERATION

5.1 INSTRUMENT TEST MODES

From the MAIN MENU, you can choose 4 independent instrument test modes:

• COMPONENT TESTS

• SCOPE

• GRAPHING MULTIMETER

• OBD II CODE READER

The fastest way to set up the instrument to test most devices and circuits is to choose from one of the built in

COMPO NENT TESTS. These tests p rese t th e inst rument to eit he r Sin gle or Dual In put S cop e mode. Most

instrument settings may be adjusted manually once you have chosen a Component Test, enabling you to fine tune

settings to get a better look at the sig nal. Cha nges yo u make t o settin gs specif ic to a Compon ent Test are

temporary, and are restored to their preset values each time another test is chosen. When configured for a specific

Component Test, the instrument displays the reference waveform and data as well as the name of the test on the

bottom display along with the Function Key Labels specific to the test chosen.

If you prefer total control over your instrument configuration , choose SCOPE test mode from the MAIN MENU.

Settings for SCOPE are separately preserved and restored each time you choose SCOPE from the MAIN MENU.

Th es e settings are not affected when yo u choose a Compon ent Test. This is also true f or t he G

MULTIMETER test mode, so in effect they are “custom” setups.

RAP HING

5.2 SCOPE DISPLAYS

4-18

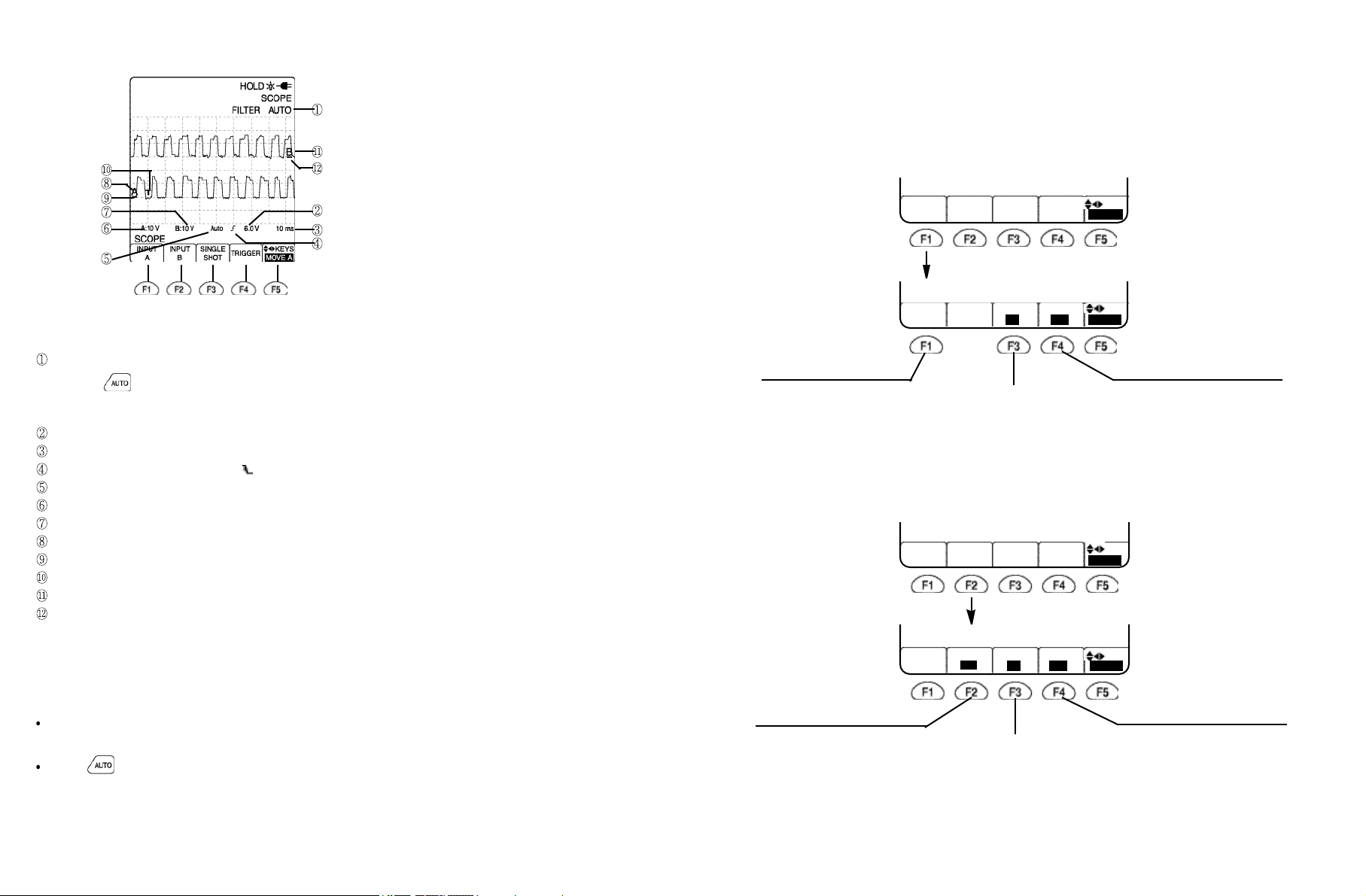

Using Single and Dual Input Scope Mode

The instrument can be configured to show scope displays for either CH A or CH B signals: In DUAL INPUT SCOPE

mode, both CH A and CH B may be displayed at the same time.

Use SINGLE INPUT SCOPE mode if you want to measure a single signal, INPUT B is turned off.

Use DUAL INPUT SCOPE mode if you want to simultaneously measure two signals.

SCOPE

5-1

Function keys and Result Screen

Figure 12. Scope Display

SCOPE displays are defaulted in “Glitch Detection” mode. This means that all signals are sampled at the full sample

rat e of the inst rument and the minimum and maximum excu rsions are always shown on the d isplay, even if the

horizontal time setting is too slow to show each individual sample interval. In this mode, every noise spike of 40 ns

and wider will be displayed.

INPUT A Control Functions

When you are in SCOPE, you can control the INPUT A functions as follows:

SCOPE

INPUT INPUT SINGLE KEYS

A B SHOT

TRIGGER

MOVE A

SCOPE INPUT A

BACK

COUPLING

INVERT KEYS

D C OFF MOVE A

Automatic ranging and signal tracking is on.

Pressing sets automatic ranging and signal tracking on and off.

AUTO is displayed when auto ranging is active. Manually selecting the range will cause the AUTO indication to

turn off.

Trigger level voltage of INPUT A.

Time base range.

Trigger icon. Indicates trigger slope ( indicated negative slope).

Auto triggered.

INPUT A range setting.

INPUT B range setting.

Indicates signal source channel A.

INPUT A zero level.

Indicates trigger location.

Indicates signal source channel B.

INPUT B zero level.

Making an Easy Setup

When you enter th e scope mode, the instrument automatically optimizes vertical r ange, time base, and t rigger

settings to create a stable display. (Autoranging is default)

When you press one of the Voltage and Time control keys, the instrument switches to manual control of range

and trigger settings.

Press to toggle between automatic and manual control of range and trigger settings. Use this key if you

cannot get a stable display using manual control.

Press t o return to the

previous menu.

Press to invert the INPUT A

signal waveform.

Press to select DC, AC or GROUND coupling.

DC Coupling allows you to measure and display both the DC and AC components of a signal. AC Coupling blocks

the DC component and passes the AC component only. GND grounds the input of the instrument internally.

INPUT B Control Functions

When you are in SCOPE, you can control the INPUT B functions as follows:

SCOPE

INPUT INPUT SINGLE KEYS

A B SHOT MOVE A

TRIGGER

SCOPE INPUT B

DISPLAY COUPLING INVERT KEYS

BACK

OFF D C OFF MOVE B

Press to invert the INPUT B

Press to turn INPUT B on or off.

signal waveform.

Press to select DC, AC, or GROUND coupling.

When you entered SINGLE DISPLAY, INPUT B is turned off by default, but you can turn it on by pressing F2.

5-2

5-3

Single-Shot Function

Normally the sco pe m od e automa tically repeats t he measure ments t o a cquire wave form s by th e recu rrent

acquisition mode.

SINGLE-SHOT allows you to perform single acquisition to snap events that occur only once. REPEAT TEST ( )

is used to start a next single acquisition.

SCOPE

INPUT INPUT SINGLE KEYS

A B SHOT MOVE A

TRIGGER

SCOPE SINGLE SHOT

BACK

SINGLE REPEAT KEYS

OFF TEST MOVE A

Press to repeat a single-shot acquisition.

AUTO versus NORMAL acquisitions

If you select AUTO, the instrument always performs acquisitions, i.e., it always displays the signals on the input. If

NORMAL is selected, a trigger is always needed to start an acquisition.

TRIGGER SLOPE

If you select , trigger occurs at a rising(positive) edge of the signal.

If you select , trigger occurs at a falling(negative) edge of the signal.

TRIGGER SOURCE

If you select TRIGGE R SOURCE A (default), a cq uisitio ns start when the signal on INPUT A fulf ills the selected

trigger conditions.

If you select TRIGGER SOURCE TRIG, the previous rule is valid for the signal on the TRIGGER input.

TRIGGER LEVEL

This function allows you to set the level that the signal must cross to trigger acquisitions.

Normally, after you enter SINGLE or DUAL INPUT SCOPE mode, the AUTO RANGE function automatically sets

and maintains an optimal trigger level as the signal changes.

Trigger Control Functions

TRIGGER is a set of conditions that determine whether and when acquisitions start. The following will determine the

trigger conditions:

• Select INPUT A or TRIGGER as the TRIGGER SOURCE input.

• Use AUTO or NORMAL acquisitions.

• Select trigger to occur on a positive or negative SLOPE of the signal.

• SET the trigger LEVEL.

If you change the trigger level, the AUTO RANGE function is turned off.

When you are in SCOPE, you can control the trigger functions as follows:

SCOPE

INPUT INPUT SINGLE KEYS

A B SHOT TRIG LVL

TRIGGER

Press to select the trigger level adjustment.

SCOPE TRIGGER

MODE SLOPE SOURCE COUPLING

BACK

AUTO A DC

Press to select DC or AC.

Press to select AUTO or

NORMAL acquisitions.

Press to select the trigger source.

Press to select the trigger slope.

5-4

Move the trigger level icon (or icon) to the desired level by using

¡ã and ¡å keys.

HORIZONTAL TRIGGER POSITION (HORIZ TRIG POS)

Y

ou can use the INSTRUMENT S ETUP menu to se t the H orizontal Tr igge r Position (Horiz Tr ig Po s) to t hree

different horizontal locations on the display, depending on whether you want to see conditions that led up to the

trigger event, or those following it.

• 10 % Trigger located close to left edge of display.

• 50 % Trigger located at center display.

• 90 % Trigger located close to right edge of display.

Use 10 % Trigger to show events which happen after the trigger.

Use 90 % Trigger to show events leading up to the trigger.

Noise Filter Function

There are cases where you may want to filter out noises in order to see a better signal. This can be especially true

when ignition noise is present. The instrument provide s a noise filter for e ach input ch annel which reduces the

bandwidth from it s norm al 5 MHz t o 2 KHz. Y ou can enable or d isable CH A Filter o r CH B Filter usin g t he

INSTRUMENT SETUP menu. When enabled, the FILTER indicator appears on the screen.

5-5

Cursor Key Function

A cursor is a vertical line or a horizontal line placed over the displayed waveform to measure values at certain points.

The instrument can measure signal details by using Cursors. This function is not possible for all tests.

Press to display the Function key Menu for cursor operation.

If cursor operation is not possible for the actual measurement, the instrument beeps to alert you.

Two cursors (vertical lines) appear on the display.

The left cursor is named CURSOR 1, the right CURSOR 2.

CURSORS

CURSOR KEYS

BACK

TIME CURSOR 1

For VOLTS CURSORS,

VOLTS 1 DELTA VOLTS 2

2.4 V 7.2 V 9.8 V

Sa mple v alu e a t

VOLTS CURSOR 1

p osi ti on on t he

waveform.

Volts difference between CURSOR 1

and CURSOR 2 positions.

Vo lts d if fe r en ce b etw een C URSO R 1 a nd

CURSOR 2 positions on the INPUT A waveform.

Sa mp l e v a lue at

CURSOR 1 position

on th e I NPUT A

waveform.

Sa mple va lue a t

VOLTS CURS O R

2 posit io n o n t he

waveform.

VOLTS 1 DELTA VOLTS 2

A: 130 mV 520 mV 650 mV

B: 24.0 mV 74 mV 98.0 mV

Sa mple value at

CURSOR 1 position

o n t he I NPUT B

waveform.

Volts difference between CURSOR 1

an d CUR SOR 2 pos it i on on t he

INPUT B waveform.

Sa mp l e v a lue at

CURSOR 2 position

on th e I NPUT A

waveform.

Sa mp l e v a lue at

CURSOR 2 position

on th e I NPUT B

waveform.

•

Press to set TIME cursor or VOLTS cursor or cursor OFF.

• Press to select the cursor you want to move (1 or 2).

• Use the Four Way arrow keys to move the cursors.

The top display shows readings related to values at the cursor positions.

For TIME cursors,

TIME 1 DELTA TIME 2

20.4 ms 48.1 ms 68.5 ms

Sample va lue at TIME CURSOR

1 position on the waveform(s).

Sample value at TIME CURSOR 2

position on the waveform(s).

Time difference between TIME CURSOR 1

and TIME CURSOR 2 positions.

Reading Test Results on the SCOPE (Component Tests only) Display

Mea surement results can be displayed as numeric values (referred to as readings) and w aveform. The t ypes of

readings depend on the test taking place.

For example, during a O 2S SENSOR (Zirc) test, MAXIMUM and MINIMUM values are displayed as readings and

during a DUAL O2 SENSOR test MAXIMUM and MINIMUM values of the signals from the oxygen sensor before and

after the catalytic converter are displayed as readings. During a DI SECONDARY test, SPARK VOLTAGE, RPM,

BURN TIME, and BURN VOLTAGE are displayed as readings.

The values you see on the display most often depend on the vehicle under test. Refer to the Service Manual of the

vehicle manufacturer.

In Chapter 6 “Automotive Diagnostics & Applications” you can find typical results of certain applications.

5.3 GMM DISPLAYS

The instrument performs cycle by cycle measurements of a variety of signal characteristics in Real Time and plots

them as t hey cha nge with tim e as a graph. The instru ment also performs certain o ther measu remen ts o n a

continuous basis, delivering the results for graphing 20 times per second. You can also plot the input signal directly

(as in SCOPE mode) by choosing LIVE.

The GMM display includes a meter reading showing the current value of the graphed parameter. This reading is an

average over many result values. In some cases, measurements are the maximum or minimum of a series of signal

values over the most recent 1 second interval.

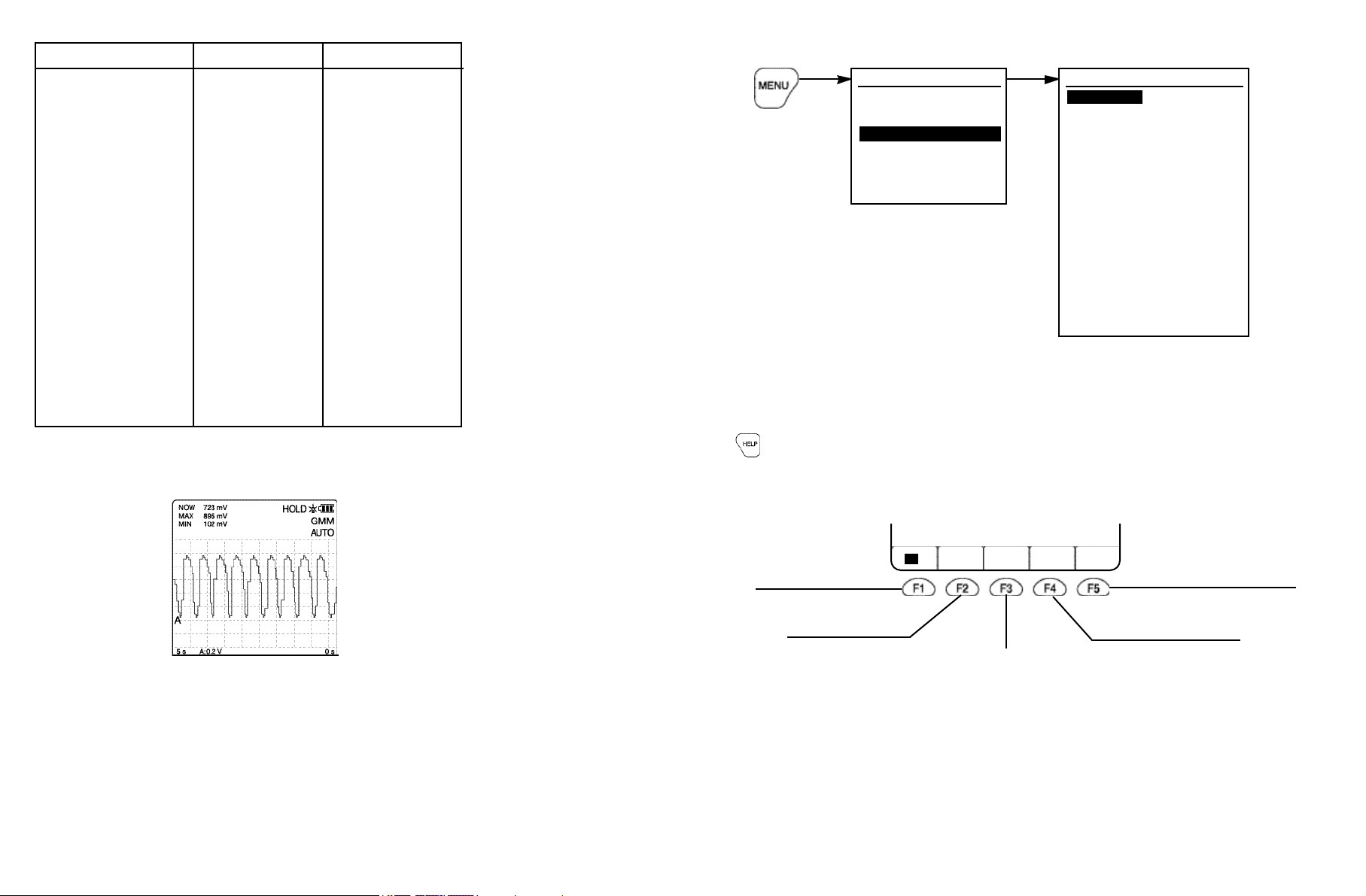

Th e following tab le shows m easurements which can be plotted in GMM displays and the type o f graphing a nd

readout.

5-6

5-7

Code

DC VOLT

AC VOLT

AC+DC VOLT

OHM

DIODE

CONTINUITY

RPM

FREQUENCY

DUTY CYCLE

PULSE WIDTH

DWELL

IGNITION PEAK VOLTS

IGNITION BURN VOLTS

IGNITION BURN TIME

INJECTOR PEAK VOLTS

INJECTOR ON TIME

TEMPERATURE

LIVE

Measurement

DC Average

AC Average

AC+DC Average

Ohms

Diode drop

Continuity

RPM

Frequency

Duty Cycle

Pulse Width

Dwell

Ignition Peak Volts

Ignition Burn Volts

Ignition Burn Time

Injector Peak Volts

Injector On Time

Temperature °C, °F

Live

Graphing Type

Continuous

Continuous

Continuous

Continuous

Continuous

Continuous

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Cycle by Cycle

Continuous

Direct input samples

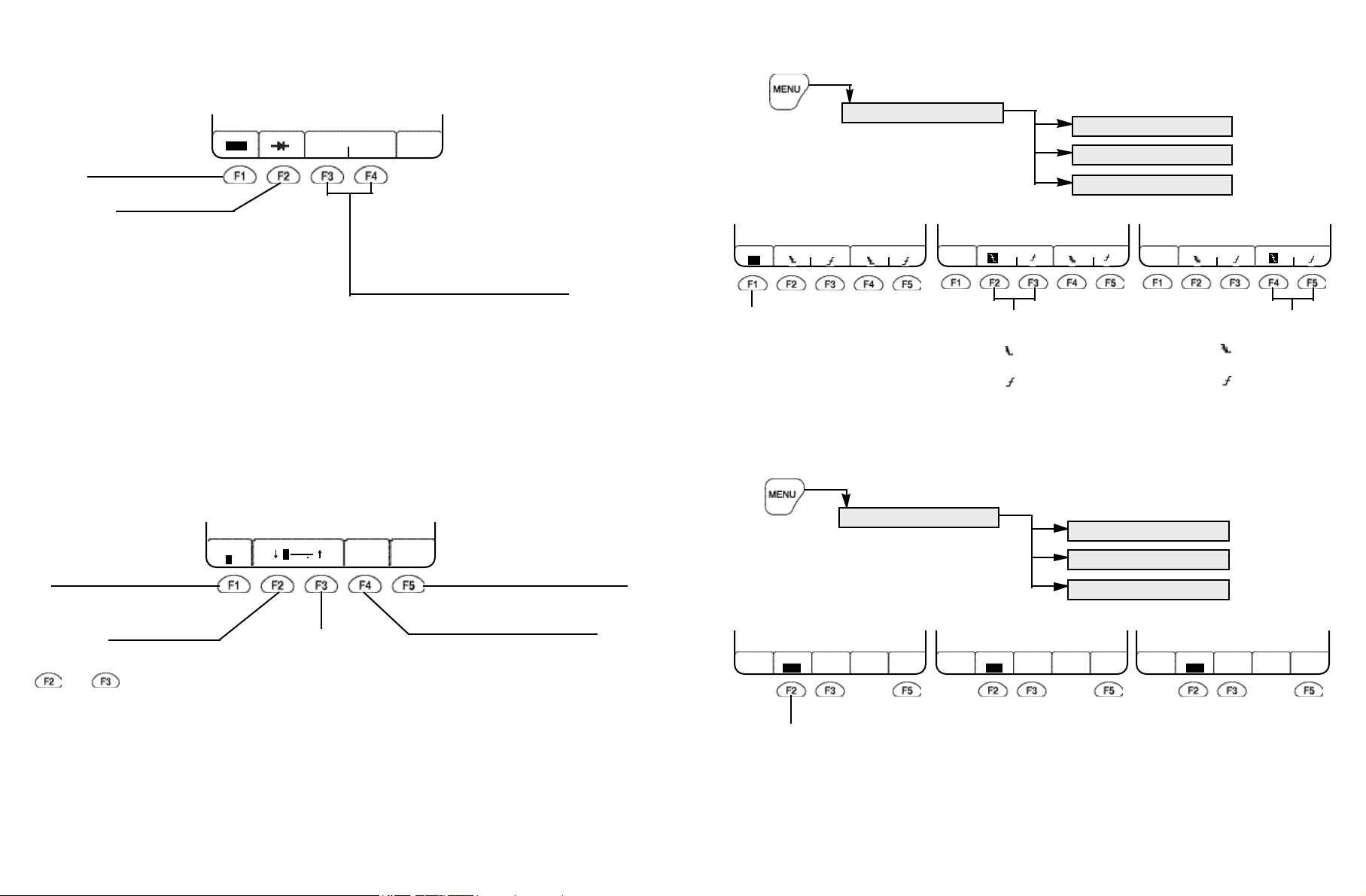

Using Graphing Multimeter (GMM)

MAIN MENU

COMPONENT TESTS

SCOPE

GRAPHING MULTIMETER

OBD II CODE READER

VEHICLE DATA

INSTRUMENT SETUP

GRAPHING MULTIMETER MENU

VOLT DC, AC

OHM / DIODE / CONTINUITY

RPM

FREQUENCY

DUTY CYCLE

PULSE WIDTH

DWELL

IGNITION PEAK VOLTS

IGNITION BURN VOLTS

IGNITION BURN TIME

INJECTOR PEAK VOLTS

INJECTOR ON TIME

AMP DC, AC

TEMPERATURE °C, °F

LIVE

Making Connections

INPUT A is used for all GMM tests except the RPM measurement. The probes and test leads to be used depend on

the type of test performed. When you select certain GMM tests, a connection help screen will guide you by pressing

. This tells you which probe or test lead to use and where to connect it.

Vertical and Horizontal Scaling

Figure 13. Changing Vertical and Horizontal Ranges

The vertical and horizontal ranges in GMM displays are manually adjustable by using the Four Way arrow keys.

The vertical ranges available in GMM displays vary with the measurement being graphed, and generally cover the

possible output range of the measurement.

The time ranges available for GMM displays range from 5 sec. to 24 hrs. per display.

Auto-Power-Off will not occur du ring the GMM mode, b ut t o graph for periods of 5 min a nd longer, operate the

instrument from external power because operating endurance on internal power is limited to about 4 hours with fresh

batteries.

5-8

Function Key Labels for Each Test

Testing Volt DC, AC

GMM VOLT

Press to measure DC

DC AC AC+DC

MAX/MIN REPEAT

RESET TEST

voltage.

Press to measure AC

true rms voltage.

Press to reset maximum

and minimum.

Press to measure AC+DC true rms voltage.

You can stop graphing by pressing HOLD key on the instrument.

Press to start plotting a new

graph as new samples are

acquired.

5-9

Testing Resistance, Diode, and Continuity

Use this menu option to test resistance, diode forward voltage, and the continuity of wiring and connections. Connect

the test lead tip and test lead ground across the object to be tested.

GMM OHM

Press to measure

OHM

CONTINUTY

OPEN CLOSE

resistance.

Press to test diodes.

Press to test continuity of wiring and

connections.

If you select OPEN, the instrument beeps

when the tested connection is open.

If you select CLOSE, it beeps when the

tested connection is closed.

Testing Frequency, Duty Cycle, or Pulse Width

GRAPHING MULTIMETER

GMM FREQUENCY

Hz

% ms

GMM DUTY CYCLE

Hz

% ms

FREQUENCY

DUTY CYCLE

PULSE WIDTH

GMM PULSE WIDTH

Hz

% ms

OFL is displayed when the resistance is outside the instrument ’s maximum range. This occurs when the resistance

of the sensor is too high or the connection to the sensor is interrupted or open.

To test a diode, the instrument sends a small current through the diode to test the voltage across it. Depending on

the type of diode, this voltage should be in the range from 300 to 600 mV. A diode that has an internal short will

display about 0 V. OFL

is displayed when the diode is defective or when it is connected in reverse. If you are not

certain about the polarity of the diode, try the reverse connection. If this also displays OFL , the diode is defective. A

good diode must display OFL when connected in reverse.

Measuring RPM

The instrument automatically scales and displays the waveform on the screen. Connect the Inductive Pickup to the

COM/TRIGGER input terminals and clamp the pickup probe on the spark plug wire close to the spark plug.

GMM RPM

Press to adjust the built-in

4 step trigger levels.

Default is Level 2.

RPM TRIG n DEFAULT REPEAT

2 720 SETUP TEST

1

Press to start plotting a new graph

as new samples are acquired.

Press to restore the d efault value

Press to decrease.

Press to increase.

settings stored in VEHICLE DATA.

and keys are used to set the number of Spark Signal Pulses to the instrument per 720 (two crank shaft

revolutions). n = 1, 2, 3, 4, 5, 6, 8, 10, or 12

Press to test the signal

frequency in Hz.

P ress t o test the dut y cycle of the

signal.

If you select , the duty cycle of the

negative-going pulse is displayed.

If you select , the duty cycle of the

positive-going pulse is displayed.

Testing Secondary Ignition Peak Volts, Burn Volts, and Burn Time

GRAPHING MULTIMETER

IGNITION PEAK VOLTS

IGNITION BURN VOLTS

IGNITION BURN TIME

GMM IGNITION PEAK VOLTS

INVERT REPEAT MAX/MIN

OFF TEST RESET

GMM IGNITION BURN VOLTS

INVERT REPEAT MAX/MIN

OFF TEST RESET

P ress t o inver t th e displaye d ignition

waveform.

Press to test the pulse width of the

signal.

If you select , th e w idth o f th e

negative-going pulse is displayed.

If you select , th e w idth o f th e

positive-going pulse is displayed.

GMM IGNITION BURN TIME

INVERT REPEAT MAX/MIN

OFF TEST RESET

5-10

5-11

SINGLE cylinder waveform

SPARK VOLTAGE

BURN VOLTAGE

BURN TIME

Testing Current

Use this menu option to test current with a current probe. (optional accessory)

GMM AMPERES

DC AC AC+DC

RANGE REPEAT

10 mV/A TEST

Press to measure DC current.

P re ss to m e a su re

AC true rms current.

Press to select between

10 mV/A, and 100 mV/A.

Press to measure AC+DC

true rms current.

Testing Injector Peak Volts and On Time

GRAPHING MULTIMETER

INJECTOR PEAK VOLTS

INJECTOR ON TIME

GMM INJECTOR PEAK VOLTS

REPEAT MAX/MIN

TEST RESET

GMM INJECTOR ON TIME

REPEAT MAX/MIN

TEST RESET

PEAK VOLTS

INJECTION PULSE WIDTH (ON TIME)

Testing Dwell

The test is done with the shielded test lead on INPUT A connected to the primary side of the ignition coil.

GMM DWELL

VEHICLE DWELL MAX/MIN

DATA % RESET

Don’t forget to set the Current Probe to zero before using it for measurements.

Testing Temperature

Use this menu option to test temperature with a temperature probe. (optional accessory)

P ress to se lec t b et w ee n

measuring degrees Celsius

GMM TEMPERATURE

C F

REPEAT

TEST

and degrees Fahrenheit.

5.4 DUAL INPUT SCOPE OPERATION

Dual Input Scope

Use the scope function if you want to simultaneously m easure two w aveforms - one on INPUT A and th e other on

INPUT B.

Using Single and Dual Input Scope

Use SINGLE INPUT SCOPE if you want to use a single signal, INPUT B is turned off.

Use DUAL INPUT SCOPE if you want to simultaneously measure two signals.

5.5 CHANGING THE VEHICLE DATA & INSTRUMENT SETUP

There are two groups of setups in the Main Menu.

VEHICLE DATA : Use this menu option to enter the correct vehicle data, such as the number of cylinders or cycles

on the vehicle under test.

5-12

Press to select b etween rea dings in % ,

degrees ( ) crankshaft rotation, or in ms.

5-13

Loading...

Loading...