USER'S MANUAL 990-057

Revision K, May 2004

Use with Firmware Release V1.19 or higher

MODEL HF2

2 kHz HIGH FREQUENCY

RESISTANCE WELDING POWER SUPPLY

MODEL NUMBER STOCK NUMBER

HF2/230 1-264-03

HF2/380 1-264-03-01

HF2/460 1-264-03-02

HF2/208 1-264-03-03

HF2S/230 1-265-03

HF2S/380 1-265-03-01

HF2S/460 1-265-03-02

HF2S/208 1-265-03-03

Units with the built-in Weld Sentry Option also require User's Manual No. 990-291

Please be sure to read all personnel and equipment

safety precautions noted in this manual.

WARNING

1998, 2002 Unitek Miyachi Corporation

The engineering designs, drawings and data contained herein are the proprietary work of

UNITEK MIYACHI CORPORATION and may not be reproduced, copied, exhibited or

otherwise used without the written authorization of UNITEK MIYACHI

CORPORATION.

Printed in the United States of America.

REVISION RECORD

Revision EO Date Basis of Revision

A ENRG-RLSE 3/95 Released original manual.

B None 9/95 Reorganize manual into chapters.

C None 1/96 Amend to Firmware V1.17 or higher.

D None 2/96 Update cover stock numbers

E None 4/97 Amend to Firmware V1.19 or higher.

F 17472 6/98 1. Remove existing calibration procedure and reference User Calibration

Procedure 994-001.

2. Miscellaneous corrections.

3. Remove SAVE error.

G

H 19012 9/01 1. Include EO# 118951 in manual.

J 19146 1/02 1. Include EO# 19012.

K 20016 5/04 Updated wire data.

18951 8/01

1. Include EO# 17693 in manual.

2. Add latest version of Operator Guide.

2. Add latest version of Operator Guide.

2. Miscellaneous Corrections.

3. Add Appendix F, Quality Resistance Welding Solutions, and Appendix

G, Replacement of Programmed Integrated Circuits.

MODEL HF2 2kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

ii 990-057

FOREWORD

The purpose of this manual is to supply operating, maintenance and service personnel with the

information needed to properly and safely operate, maintain and service the Unitek Peco Model HF2 2

kHz High Frequency Resistance Welding Power Supply.

Should questions arise, or if you have suggestions for improving this manual, please contact:

Unitek Miyachi Corporation

1820 South Myrtle Avenue

P.O. Box 5033

Monrovia, CA 91017-7133

Telephone:(626) 303-5676

FAX:(626) 358-8048

E-mail: info@unitekmiyachi.com

NOTICE

Unitek Miyachi Corporation may be released from all warranty obligations if repairs or modifications

are made by persons other than its own service personnel, or authorized representatives' personnel,

unless such repairs or modifications are specifically authorized in writing by the Unitek Miyachi

Corporation.

WARNING

Contact with voltages present in this power supply may cause serious or fatal injuries. Please read the

manual completely and note all cautions and warnings before attempting to install, operate or maintain

the power supply.

MODEL HF2 2kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 iii

CONTENTS

Page

CHAPTER 1: DESCRIPTION............................................................................................................ 1-1

HF2 description........................................................................................................................................ 1-1

CHAPTER 2: GENERAL SET-UP..................................................................................................... 2-1

Required Connections.............................................................................................................................. 2-1

Physical Space Requirements ........................................................................................................... 2-1

HF2 Weld Control Dimensions ........................................................................................................ 2-1

HF2 Weld Transformer Dimensions ................................................................................................2-1

Power Line Voltage, Current, And Wire Size Requirements........................................................... 2-2

Insulation Requirements .................................................................................................................. 2-2

Power Line Fuse Requirements ........................................................................................................ 2-2

HF2 Weld Transformer Electrical Specifications............................................................................. 2-3

HF2 Welding System Maximum Secondary Loop Resistance......................................................... 2-4

HF2 Maximum Secondary Loop Resistance Measurement ............................................................. 2-4

HF2 Weld Control To HF2 Weld Transformer Connections ........................................................... 2-4

HF2 Weld Transformer To Weld Head Connections....................................................................... 2-5

Weld Sentry Option .......................................................................................................................... 2-5

Help Screen Languages .................................................................................................................... 2-5

CHAPTER 3: WELDING SYSTEM SET-UP ................................................................................... 3-1

Welding System Set-Up Guide................................................................................................................ 3-1

General Programming Instructions.......................................................................................................... 3-1

Unitek Peco Force Fired, Foot Actuated Weld Head System.................................................................. 3-2

Weld Head Set-Up............................................................................................................................ 3-2

Firing Switch Cable Connection....................................................................................................... 3-2

Quick Start Programming Guide ..................................................................................................... 3-2

Unitek Peco Force Fired, Single Air Actuated Weld Head System ........................................................ 3-4

Weld Head Set-Up............................................................................................................................ 3-4

Firing Switch Cable Connection....................................................................................................... 3-4

Weld Head Valve Driver No. 1 Connection ............................................................................................ 3-4

Foot Switch Connection ................................................................................................................... 3-4

Single Air Regulator Adjustment (Model 80 Series) ....................................................................... 3-5

Dual Air Regulator Adjustments (Model 180 And Model 90 Series).............................................. 3-6

Quick Start Programming Guide ...................................................................................................... 3-6

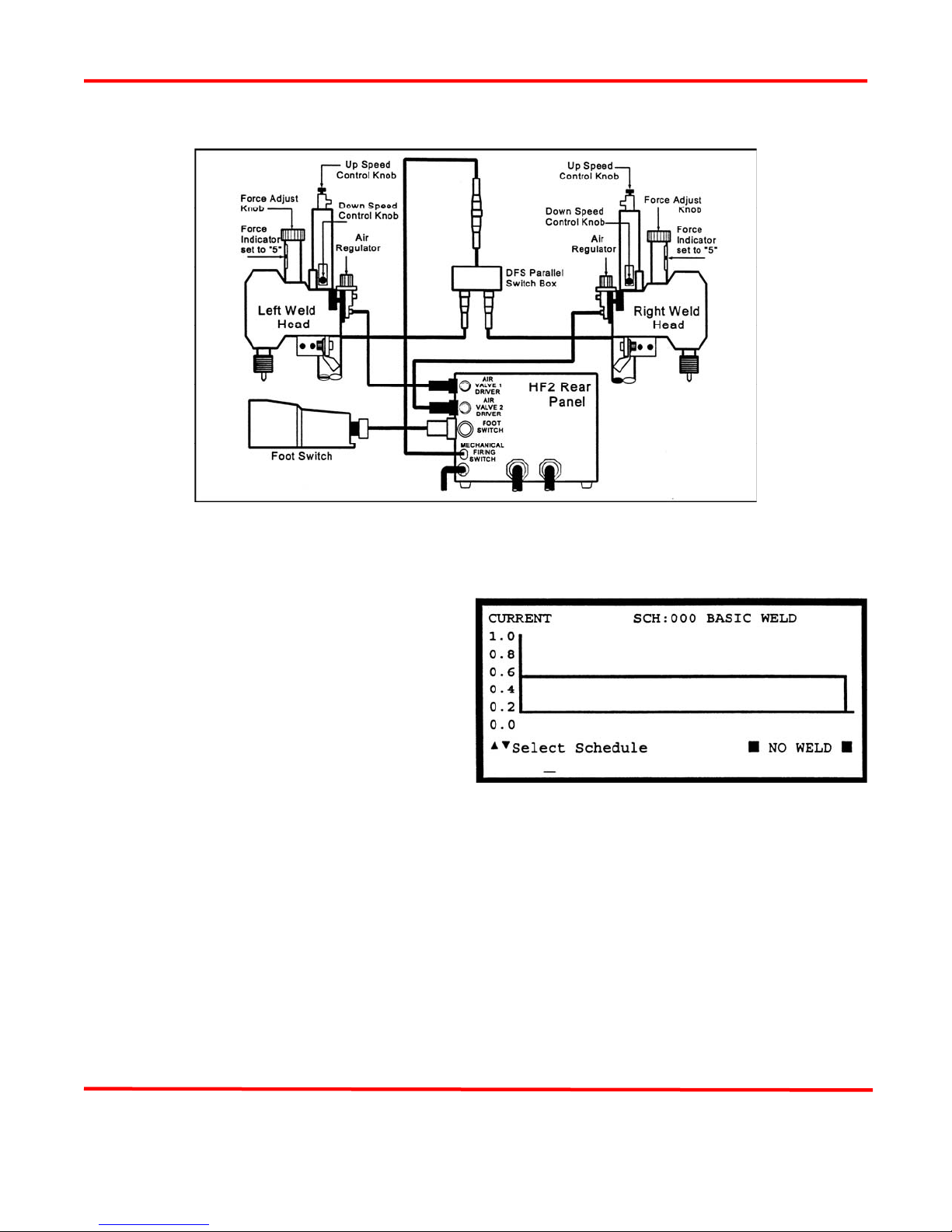

Unitek Peco Force Fired, Dual Air Actuated Weld Head System........................................................... 3-8

General Information.......................................................................................................................... 3-8

HF2 Control, Jumper Modifications................................................................................................. 3-8

Weld Head Set-Up............................................................................................................................ 3-8

Firing Switch Cable Connection....................................................................................................... 3-9

MODEL HF2 2kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

iv 990-057

CONTENTS (Continued)

Page

CHAPTER 3: WELDING SYSTEM SET-UP (Continued)

Weld Head Valve Driver Connections .......................................................................................... 3-10

Foot Switch Connection ................................................................................................................. 3-10

Dual Air Regulator Adjustments .................................................................................................... 3-11

Quick Start Programming Guide .................................................................................................... 3-15

Non-Force Fired, Single Air or Cam Actuated Weld Head System............................................... 3-17

LC To HF2 Control Electrical Connections .................................................................................. 3-17

PLC Timing Diagram ..................................................................................................................... 3-18

Quick Start Programming Guide .................................................................................................... 3-18

Non-Force Fired, Multiple Air Actuated Weld Head System ........................................................ 3-20

CHAPTER 4: CONTROLS ................................................................................................................. 4-1

HF2 Weld Control - Front Panel ............................................................................................................ 4-1

HF2 Weld Control - Rear Panel Inputs and Outputs ............................................................................... 4-3

Power ................................................................................................................................................ 4-3

Fuses F1 and F2 ............................................................................................................................... 4-3

Sensing Port ..................................................................................................................................... 4-3

Sensing Port - Connector Pin Assignments .................................................................................... 4-4

Output .............................................................................................................................................. 4-4

Foot Switch Connector .................................................................................................................... 4-5

Single-Level Foot Switch ......................................................................................................... 4-5

Two-Level Foot Switch ............................................................................................................4-5

Firing Switch Operation .......................................................................................................................... 4-6

Mechanical Firing Switch Cable ..................................................................................................... 4-6

Optical Firing Switch Connector ..................................................................................................... 4-6

Mechanical Firing Switch - 3-Wire Connection .............................................................................. 4-6

Opto Coupler Firing Switch - 3-Wire Connection .......................................................................... 4-6

Control Signals Connector ............................................................................................................... 4-7

Control Signals - Pin Assignments .................................................................................................. 4-8

Control Signals - Remote Weld Schedule Selection Input .............................................................. 4-9

Control Signals - Emergency Stop Input ......................................................................................... 4-9

Control Signals - Process Inhibit Input .......................................................................................... 4-10

Control Signals - Output Relays .................................................................................................... 4-10

Relay K1 ........................................................................................................................................ 4-10

Relay K2 ........................................................................................................................................ 4-10

Accessory Port ............................................................................................................................... 4-10

Air Valve 1 and Air Valve 2 Driver Connectors ..................................................................................4-11

Air Valve 1 Driver ......................................................................................................................... 4-11

Air Valve 2 Driver ......................................................................................................................... 4-11

MODEL HF2 2kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 v

CONTENTS (Continued)

Page

CHAPTER 5: PROGRAMMING MODES........................................................................................ 5-1

Help Screens ..........................................................................................................................................5-1

Machine States ........................................................................................................................................ 5-1

Weld Graph Run State ............................................................................................................................. 5-1

Basic Weld Monitor Run State ................................................................................................................ 5-2

Alphanumeric Run State.......................................................................................................................... 5-2

No Weld State ......................................................................................................................................... 5-2

Standby State .......................................................................................................................................... 5-2

Alarm State ............................................................................................................................................. 5-3

Fire State ................................................................................................................................................. 5-3

Menu State .............................................................................................................................................. 5-3

Program State .......................................................................................................................................... 5-4

Weld Graph Program State ..................................................................................................................... 5-4

Alphanumeric Program State .................................................................................................................. 5-5

Output Relays .......................................................................................................................................... 5-6

Relay 1 - Dual Air Head Operation ........................................................................................................ 5-7

CHAPTER 6: ADVANCED WELDING FUNCTIONS ................................................................... 6-1

Weld Functions ....................................................................................................................................... 6-1

Basic Weld ............................................................................................................................................. 6-2

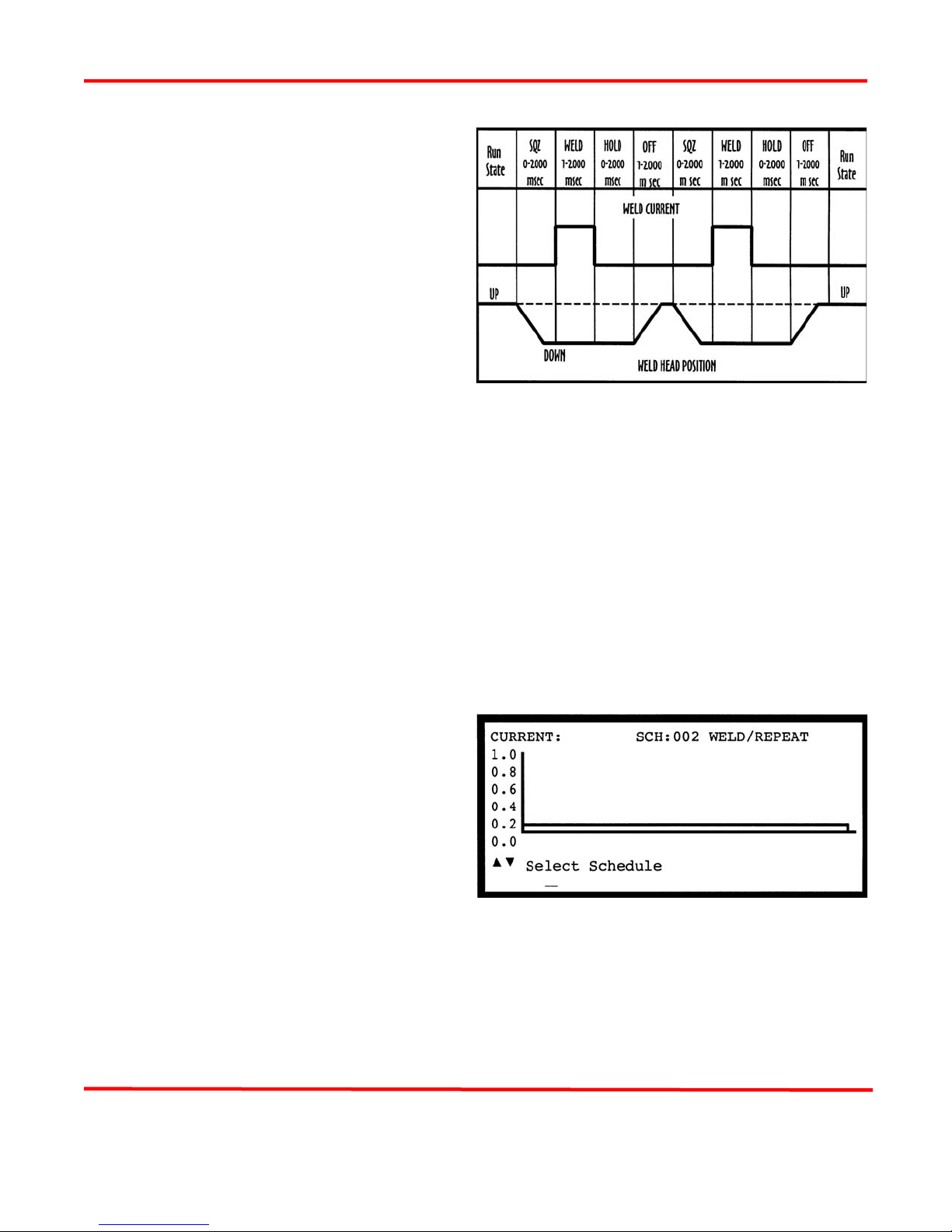

Weld / Repeat .......................................................................................................................................... 6-3

Quench/Temper ....................................................................................................................................... 6-4

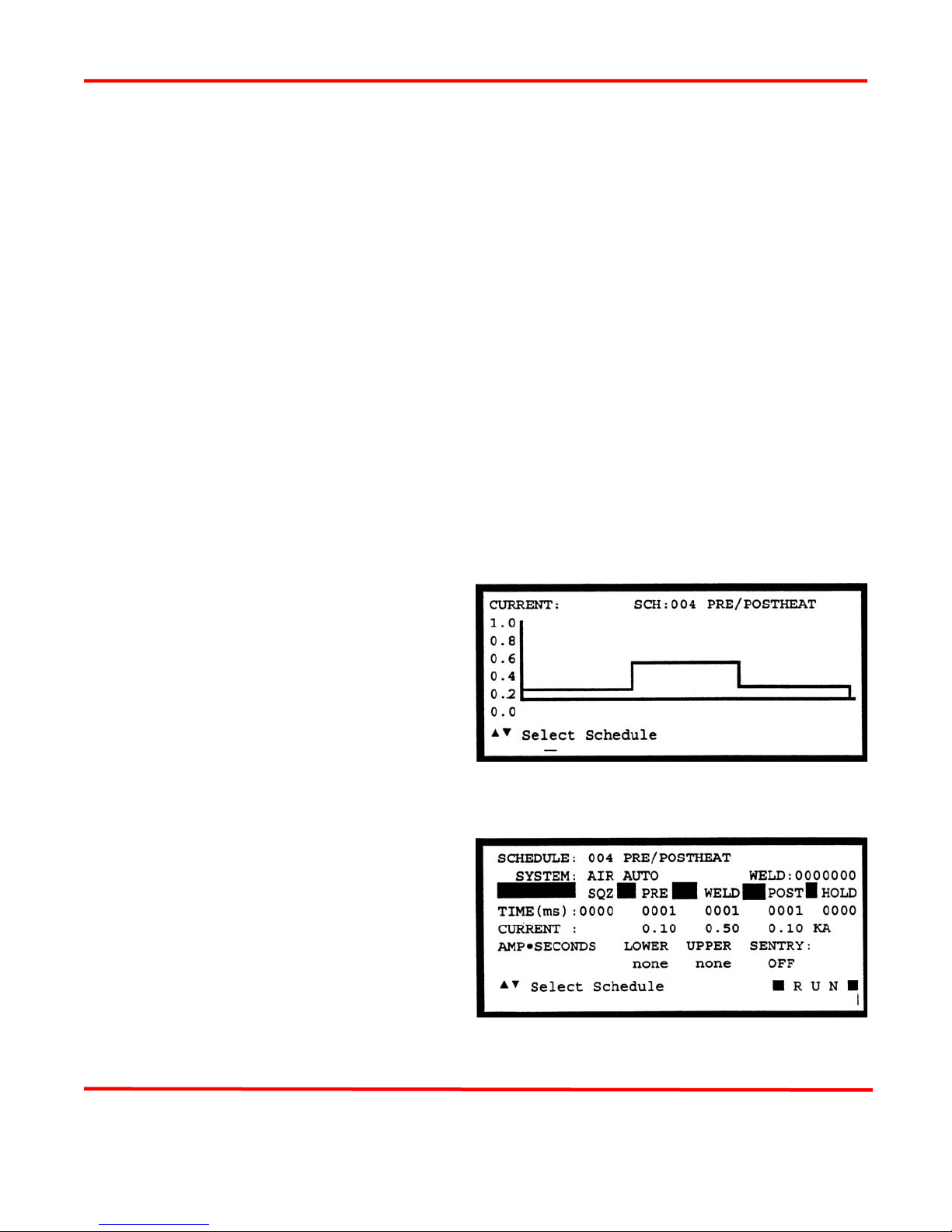

Pre/Postheat ............................................................................................................................................ 6-5

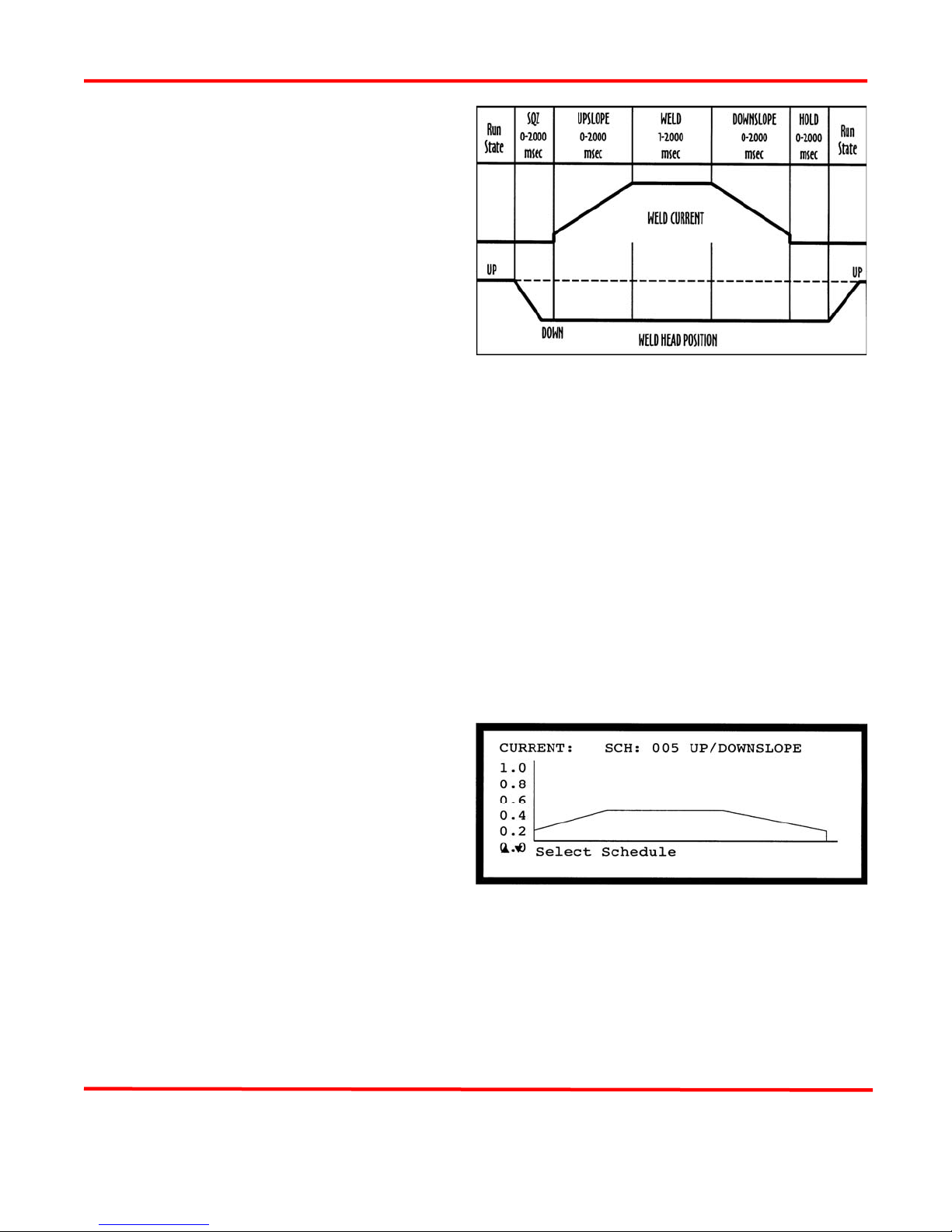

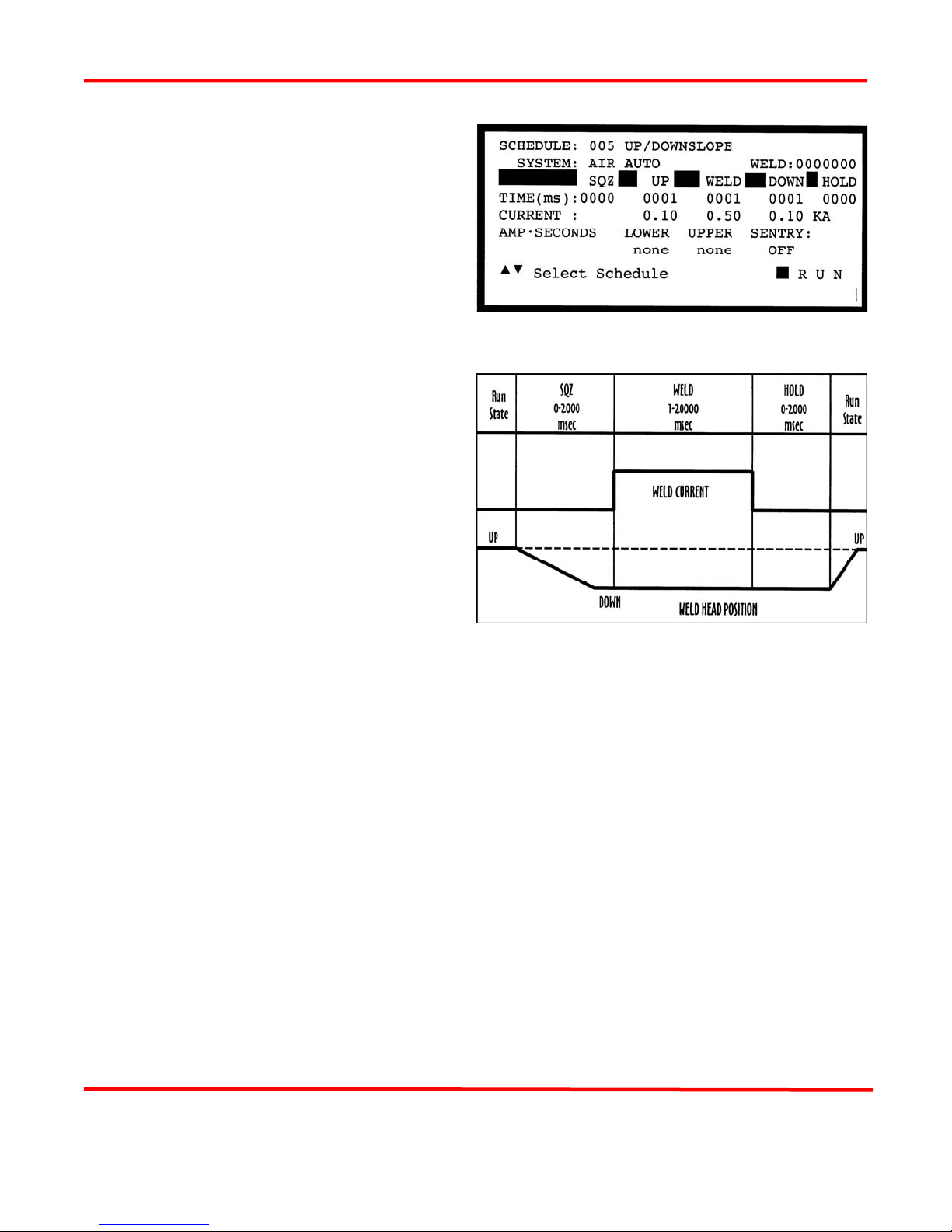

Up/Down Slope ....................................................................................................................................... 6-7

Braze .................................................................................................................................................. 6-8

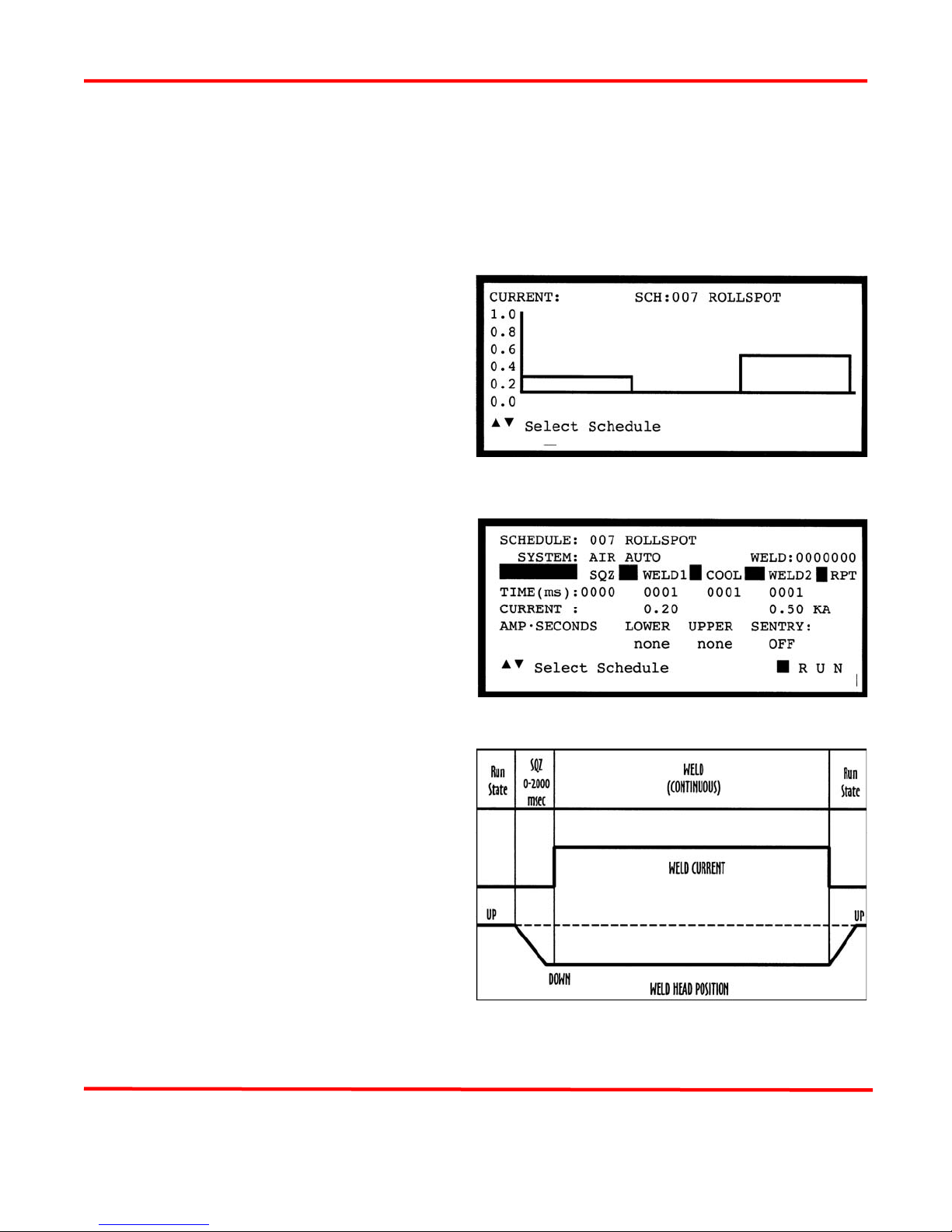

Rollspot .................................................................................................................................................. 6-9

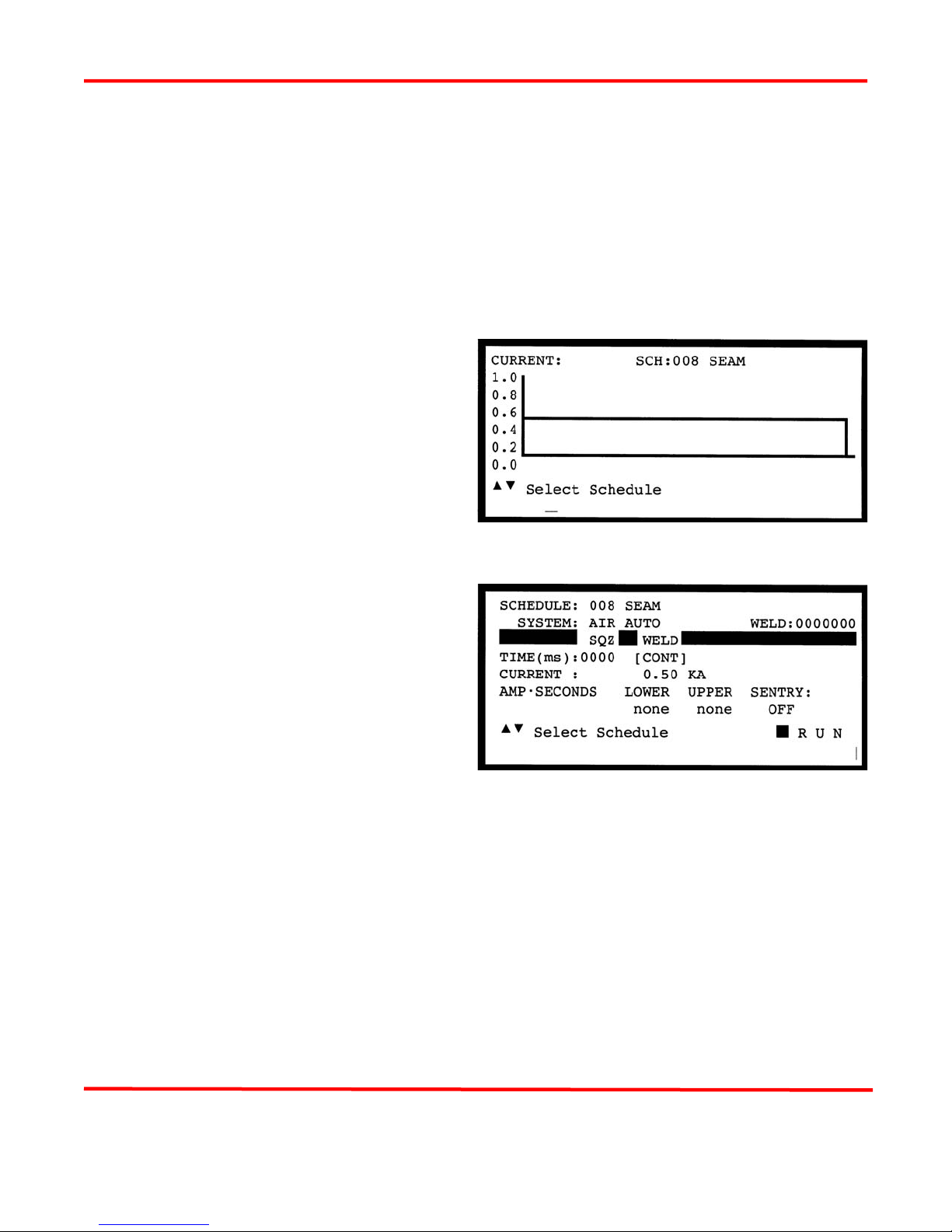

Seam ................................................................................................................................................ 6-10

Dual Pulse ............................................................................................................................................. 6-11

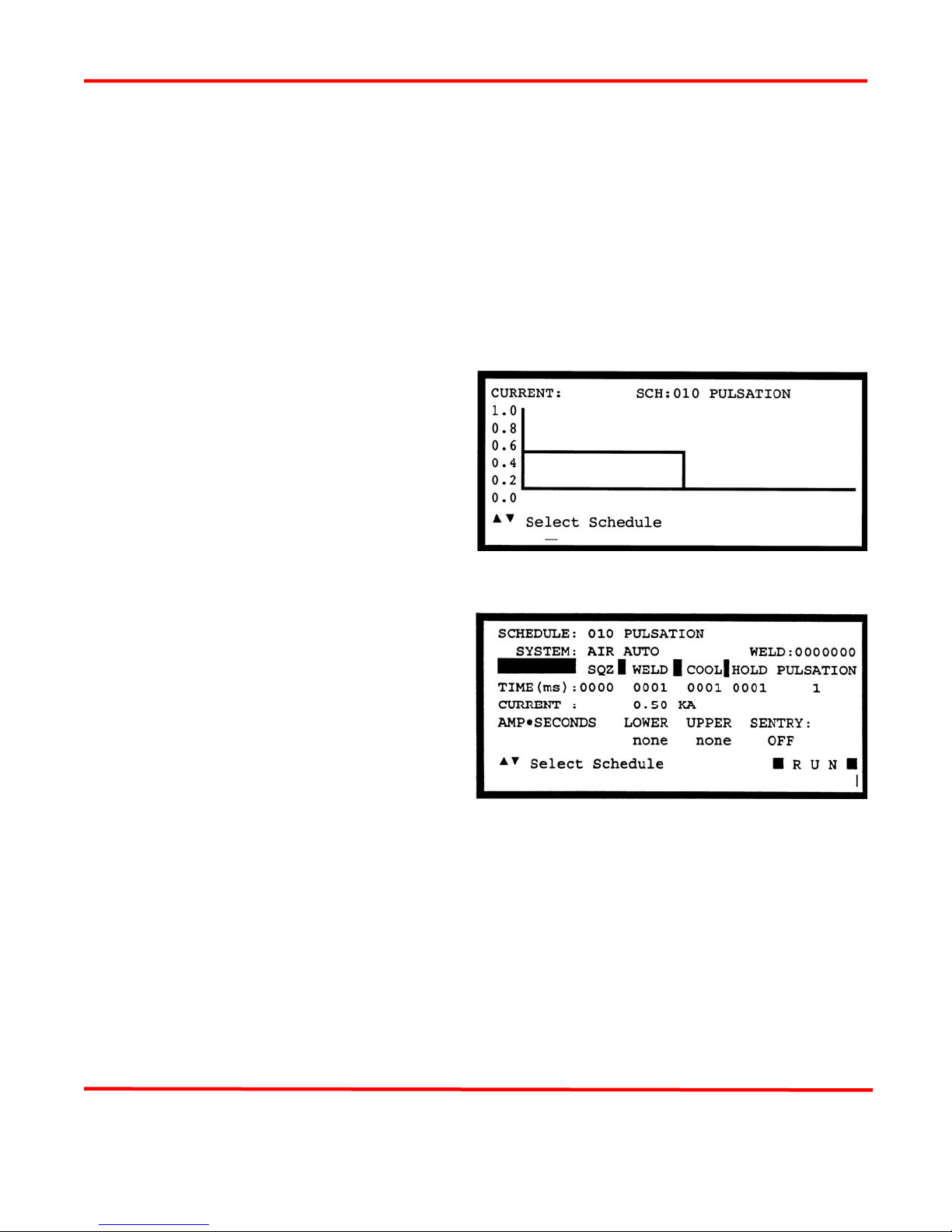

Pulsation ................................................................................................................................................ 6-13

CHAPTER 7: SPECIAL FEATURES ............................................................................................... 7-1

System Options ....................................................................................................................................... 7-1

Weld Counter .......................................................................................................................................... 7-8

Copy a Schedule ..................................................................................................................................... 7-9

System Security ...................................................................................................................................... 7-9

System Help ......................................................................................................................................... 7-11

Weld Sentry .......................................................................................................................................... 7-11

Calibrate HF2 ........................................................................................................................................ 7-11

Reset to Defaults ................................................................................................................................... 7-11

Installation ............................................................................................................................................. 7-13

Transformer Model ............................................................................................................................... 7-13

MODEL HF2 2kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

vi 990-057

CONTENTS (Continued)

Page

CHAPTER 8: WELD MONITORING .............................................................................................. 8-1

Basic Weld Monitor General Description................................................................................................ 8-1

Weld Current and Weld Voltage Measurements .................................................................................... 8-2

Data Output Capabilities ......................................................................................................................... 8-2

Weld Monitoring Suggestions ................................................................................................................. 8-2

Basic Weld Monitor Programming.......................................................................................................... 8-3

Energy Limit Monitor General Description............................................................................................. 8-4

Energy Limit Monitor Programming....................................................................................................... 8-5

CHAPTER 9: RS-485 DATACOM .................................................................................................... 9-1

Description ............................................................................................................................................. 9-1

RS485 Serial Port Connections ............................................................................................................... 9-2

Datacom Software Installation................................................................................................................. 9-2

F1:Setup .................................................................................................................................................. 9-4

F2:Collect Data ....................................................................................................................................... 9-5

F3:Erase Data .......................................................................................................................................... 9-5

F4:Exit` ................................................................................................................................................... 9-5

APPENDIX A: TECHNICAL SPECIFICATIONS ........................................................................ A-1

APPENDIX B: RECOMMENDED SPARE PARTS ........................................................................B-1

APPENDIX C: ALARM MESSAGES.................................................................................................C-1

APPENDIX D: HELP SCREEN LANGUAGES ............................................................................. D-1

APPENDIX E: THE BASICS OF RESISTANCE WELDING .........................................................E-1

APPENDIX F: QUALITY RESISTANCE WELDING SOLUTIONS:

DEFINING THE OPTIMUM PROCESS ................................................................................... F-1

APPENDIX G: REPLACEMENT OF PROGRAMMED INTEGRATED CIRCUITS .............. G-1

INDEX ............................................................................................................................................ Index-1

MODEL HF2 2kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 vii

CHAPTER 1

DESCRIPTION

The Unitek Peco High Frequency Inverter (HF2) is a 2 KHz, three-phase, state-of-the-art inverter

welding control for joining precision small parts at high speed with controllable rise times using 2 KHz

output pulses superimposed on pure DC welding energy. High speed (250 micro-second) digital

feedback automatically controls weld current, voltage, or power, providing more welding consistency

compared to traditional direct energy (AC) or stored energy (CD) technologies. Microprocessor

technology automatically compensates for changes in workpiece resistance, load inductance, weld

transformer saturation, and ñ 13% changes in line voltage. The HF2 uses IGBT power device

technology for precisely controlling the weld energy at both high and low energy levels.

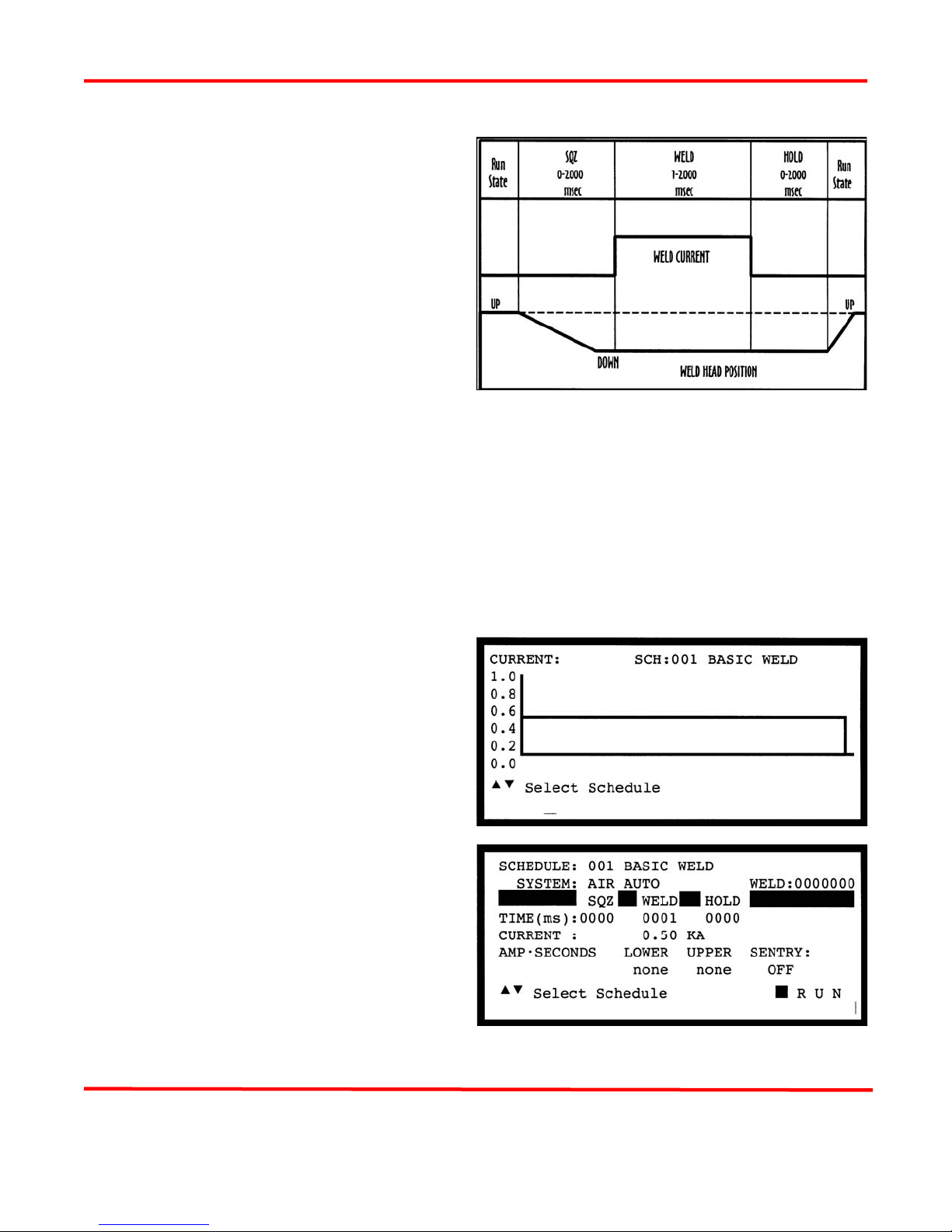

Easy to use constant weld current, voltage or power feedback ensures repeatable welding and has proven

to extend electrode life in many applications by a factor of five or more. A selectable weld energy

limiting feature also contributes to repeatable welds and high nugget quality. The user can program the

HF2 using a graphical or numerical interface. The Weld Graph Program Mode (Figure 1-1) emulates

many of the popular word processing programs by using the front panel cursor keys to easily modify any

time period, current, voltage, or power value. The Weld Graph Run Mode (Figure 1-2) gives the user

instant visual feedback on the actual current, voltage or power used to make each weld.

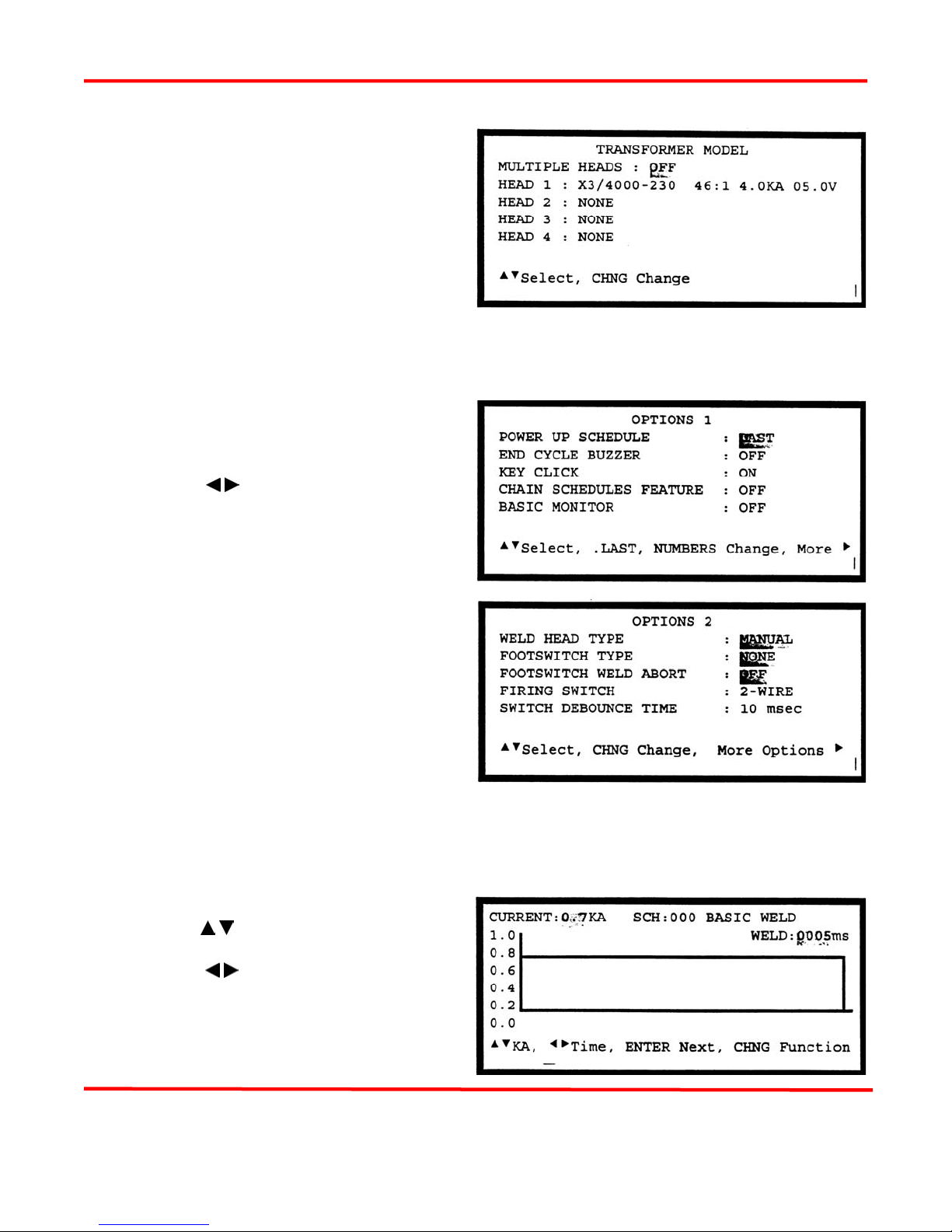

Figure 1-1. Program Mode Figure 1-2. Actual Weld Current

The HF2's exclusive, context sensitive, User Help Screens quickly guide the user through even the most

complex program. Each weld schedule can use any one of 10 different Weld Functions, thus matching

the appropriate weld energy profile to the application.

Simple automated welding control is easily accomplished using the BCD Remote Schedule Select

feature. For more complex automation processes, a host computer can use the HF2 Bi-Directional

RS422/RS485 Communications Port to select HF2 Weld Schedules and receive average weld current

and weld voltage data for each weld. Refer to the separate RS-485 Datacom Manual, P/N: 990-058, for

Advanced RS-485 Datacom operation. The 2 KHz operating frequency ensures that the HF2 Weld

Transformers are light weight and compact, providing a significant advantage when they are built into

robotics or automatic machines.

MODEL HF2 2 KHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 1-1

CHAPTER 2

GENERAL SET-UP

REQUIRED CONNECTIONS

Physical Space Requirements

Unitek Peco recommends that the HF2 Weld Control and HF2 Weld Transformer be installed in a well

ventilated area that is free from excessive dust, acids, corrosive gases, salt and moisture. Allow

sufficient clearance around both sides and back of the HF2 Weld Control and HF2 Weld Transformer so

that cooling air may flow properly. Figure 2-1 shows the cooling airflow pattern for the HF2 Weld

Control. Figure 2-2 shows the cooling airflow pattern for the HF2 Weld Transformer.

Figure 2-1. HF2 Weld Control

Air Flow Pattern

HF2 Weld Control Dimensions

Width (in/cm) Height (in/cm) Depth (in/cm) Weight (lbs/Kg)

10.5 / 26.7 8.5 / 21.5 15.0 / 38.1 42 / 19

HF2 Weld Transformer Dimensions

Model Height (in/cm) Width (in/cm) Depth (in/cm) Weight (lbs/Kg)

X2/2000A 7.0 / 17.6 5.4 / 13.8 11.0 / 28.0 14.3 / 6.5

X3/4000A 7.2 / 18.3 7.2 / 18.3 13.4 / 34.0 28.6 / 13

X5/3000A 7.5 / 18.9 7.2 / 18.3 14.2 / 36.0 31 / 14

X11/4000A 7.5 / 18.9 7.2 / 18.3 17.9 / 45.5 46 / 21

X11/4/460A 7.4 / 18.8 7.2 / 18.3 18.9 / 48.5 55 / 25

X3/4/380A 7.2 / 18.3 7.2 / 18.3 13.4 / 34.0 28.6 / 13

X3/4/460A 7.2 / 18.3 7.2 / 18.3 13.4 / 34.0 28.6 / 13

Figure 2-2. HF2 Weld Transformer

Air Flow Pattern

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 2-1

CHAPTER 2: GENERAL SETUP

Power Line Voltage, Current, and Wire Size Requirements

WARNING: The HF2 Weld Control and HF2 Weld Transformer are assembled at the factory for

operation at a specific input power line voltage. Serious damage can result if these units are used on

different voltage other than the voltage for which they are wired. The HF2 weld transformer input

voltage must match the HF2 weld control power line voltage.

Use the following table to select the correct power line circuit breaker and wire gauge size. To

minimize peak power losses, use single unbroken wire lines. Note: To minimize peak power losses,

Unitek Peco recommended wire gauge sizes exceed the USA National Electrical Code

recommendations.

3-Phase Service

Voltage (RMS)

208V to 230V 50A AWG 8 @ 133 strands

380V to 460V 30A AWG 10 @ 105 strands

Insulation Requirement

Oil-resistant synthetic rubber rated at 90°C and 600V.

Power Line Fuse Requirements

Service Voltage Fuse Size: F1, F2 Unitek Peco P/N

3-Phase Service Breaker

Current (RMS)

Copper Wire Gauge Size

(AWG)

208, 230, 380 3AG, 440 V, 2 A 330-071

460 3AG, 500 V, 2 A 330-100

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

2-2 990-057

CHAPTER 2: GENERAL SETUP

HF2 Weld Transformer Electrical Specifications

Model Input Volts

(Rms)

X3/4/380A 380 9 6 6.5 4,000 500

X3/4/460A 460 9 6 6.5 4,000 500

X3/4000A 230 9 6 6.5 4,000 500

X9/6000A 230 19 6 9.3 (32:1 TR) 4,900 500

Input kva

(Rms)

Duty Cycle ( %) Peak Open Ckt

Output Voltage

Peak Output

Max. (Amps)

Max Sec

Resist. (μΩ)

X11/4/460A 380 4 5 11.8 (44:1 TR)

10.0 (52:1 TR)

8.6 (60:1 TR)

7.5 (68:1 TR)

X11/4000A 230 15 5 10.7

460 4 5 14.3 (44:1 TR)

12.1 (52:1 TR)

10.5 (60:1 TR)

9.2 (68:1 TR)

10.0 (52:1 TR)

8.6 (60:1 TR)

8.7

8.8

8.9

TRANSFORMER SPECIFICATION NOTES:

1 For the Model X11/4/460A, turns ratios

(TR) are selectable by a switch on the

transformer rear panel.

2 HF2 Weld Control Input voltage selection

must be jumpered at E12 on the HF2 Weld

PCB as shown in Figure 2-3. E12 is

located at the center of the PCB left edge.

4,000

4,000

4,000

4,000

4,000

4,000

4,000

4,000

4,000

4,000

4,000

1,300

1,100

950

825

1,300

1,100

950

825

1,300

1,100

3 Maximum weld time at Maximum Short

Circuit Current is 50 milliseconds.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 2-3

Figure 2-3. Voltage Jumpers

CHAPTER 2: GENERAL SETUP

HF2 Welding System Maximum Secondary Loop Resistance

To use the HF2 Weld Control and HF2 Weld Transformer system to its maximum capability, the

Maximum Secondary Loop Resistance must not exceed the values listed in the preceding table.

Exceeding these maximums will produce a "FEEDBACK RANGE EXCEEDED" alarm.

HF2 Maximum Secondary Loop Resistance Measurement (Figure 2-4)

1 Connect a four terminal micro-ohmmeter

as shown in Figure 2-4.

2 Put the parts to be welded between the

electrodes.

3 Measure the total loop resistance which

includes both Weld Cables, Weld Head,

Electrodes, and parts.

4 If the total loop resistance exceeds the

table value, use:

A) Larger diameter Weld Cables

Figure 2-4. Secondary

Resistance Measurement

B) Shorter length Weld Cables, or

C) Copper Bus Bars to connect the HF2 Weld Transformer to the Weld Head. If these

suggestions do not work, then a different Weld Transformer Model may be required.

CAUTION: For product safety, the system power cable and all inter-unit cabling should be as short as

possible, and be dressed so that all cables stay separated.

HF2 Weld Control to HF2 Weld Transformer Connections (Figure 2-5)

The HF2 Weld Control must always be connected

to the HF2 Weld Transformer as shown in Figure 25, regardless of what Weld Head System is used.

1 Connect the HF2 Weld Control POWER

Cable to the line voltage source as

specified in Chapter 2, Power Line

Voltage, Current, and Wire Size

Requirements.

2 Connect the HF2 Weld Control OUTPUT

Cable to the matching connector on the

HF2 Weld Transformer.

3 Connect the HF2 Weld Control SENSING

PORT Cable to the matching connector on

the HF2 Weld Transformer.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

2-4 990-057

CHAPTER 2: GENERAL SETUP

HF2 Weld Transformer to Weld Head Connections (Figure 2-6)

1 Connect the Upper Weld Cable to the

Positive Terminal on the HF2 Weld

Transformer.

2 Connect the Lower Weld Cable to the

Negative Terminal on the HF2 Weld

Transformer.

3 Attach the Voltage Sensing Cable

connector to the HF2 Weld Transformer

INPUT connector.

4 Attach each lead at the opposite end of

the Voltage Sensing Cable to each

Electrode Holder. Note: Polarity is not

important.

5 Strain relief each Voltage Sensing lead to its corresponding Electrode Holder so that the lead

will not break or move under heavy production operating conditions.

Figure 2-6. HF2 Weld Transformer to

Weld Head Connections

6 Do not attach the Firing Switch Cable at this time. This procedure is covered in Chapter 3.

Weld Sentry Option

A small tag displaying the message WELD SENTRY INSTALLED will be attached to the front panel of

the HF2 Weld Control if the optional Weld Sentry Module has been installed. Refer to the separate

Weld Sentry User's Manual, 990-291 for Weld Sentry operation.

The Built-in Weld Sentry Module can be added to the HF2 Weld Control after purchase by ordering the

HF2 Weld Sentry Module, P/N 3-130-01-01.

Help Screen Languages

Integrated circuit chip U2 on the Main printed circuit board varies in memory capacity according to the

help screen languages available. Refer to Appendix D for special jumpering instructions relative to the

installation of IC chip U2.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 2-5

CHAPTER 3

WELDING SYSTEM SET-UP

Welding System Set-Up Guide

To complete the welding system installation, select the welding system that best matches your Weld

Head configuration using the Welding System Set-Up Guide listed below:

Welding System Set-Up Guide Page

Unitek Equipment Force Fired, Foot Actuated Weld Head 3-2

Unitek Equipment Force Fired, Single Air Actuated Weld Head 3-4

Unitek Equipment Force Fired, Dual Air Actuated Weld Head 3-9

Non-Force Fired, Single Air or Cam Actuated Weld Head 3-17

Non-Force Fired, Multiple Air Actuated Weld Heads Not Released

General Programming Instructions

The following nomenclature and symbols will be used for programming the HF2 Weld Control:

1 Press and release HF2 Weld Control front panel keys that are enclosed by [ ] symbols.

2 Use the vertical cursor keys [ ] in conjunction with the horizontal cursor keys [ ] to

select or highlight a requested Menu Option, followed by the [ENTER] key.

3 Words shown in UPPER CASE ITALIC letters indicate flashing Menu Options on the HF2

Weld Control LCD Display.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-1

CHAPTER 3: WELDING SYSTEM SET-UP

UNITEK EQUIPMENT FORCE FIRED,

FOOT ACTUATED WELD HEAD SYSTEM

Weld Head Set-up

1 Adjust the Weld Head Force Adjust

Knob to produce 5 units of force as

displayed on the Force Indicator. For a

complete description of force control

and its effect on the welding process,

please refer to your Weld Head manual.

2 Install electrodes in Weld Head

Electrode Holders.

Firing Switch Cable Connection

Connect the Weld Head Firing Switch Cable

Connector to the matching cable connector

on the rear of the HF2 Weld Control.

Quick Start Programming Guide

1 Set the HF2 Weld Control front panel

WELD/NO WELD switch to NO

WELD.

Figure 3-1. Firing Switch Cable Connection

2 Turn the circuit breaker switch located

on the HF2 Weld Control rear panel to

ON. After a series of power up screens,

the last RUN screen displayed will

appear. Press the [CHNG] key to access

the Weld Graph RUN screen for the

BASIC WELD Function.

3 Press [MENU]. The MAIN MENU

screen will appear.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-2 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

4 Select TRANSFORMER MODEL.

The TRANSFORMER MODEL screen

appears.

5 Select MULTIPLE HEADS: OFF. If

the display reads ON, then press

[CHNG] until OFF is displayed.

6 Select HEAD 1 : X3/4000-230.

X3/4000-230 is the default Transformer

Model number. Press [CHNG] until

the correct Transformer Model that you

have purchased appears.

7 Press [RUN] to return to the Graphical RUN screen.

8 Set the HF2 Weld Control front panel WELD/NO WELD switch to WELD.

9 Make a test weld by pressing on the Weld Head foot actuator until the HF2 Weld Control fires.

The default WELD time of 1 ms and the default CURRENT of 0.5 kA may not be sufficient to

make a good weld.

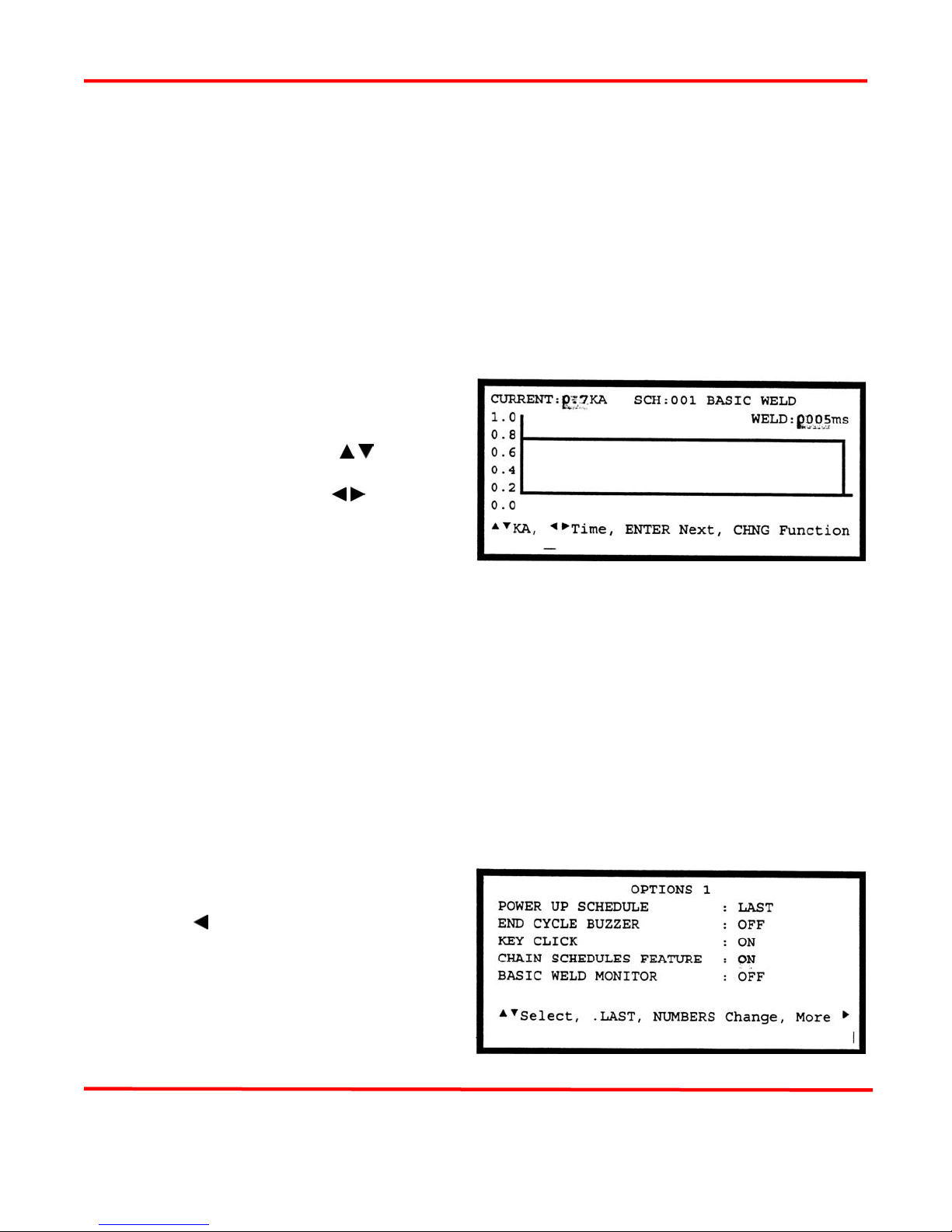

10 Press [PROG]. Use the vertical cursor

keys [VW] to increase the weld

CURRENT. Use the horizontal cursor

keys [ ] to increase or decrease the

WELD time. In this example, weld

CURRENT has been increased to 0.7

kA and WELD time has been increased

to 5ms.

11 Press [SAVE] to save your program. You are now back in the Weld Graph RUN State.

12 Make additional test welds and then reprogram WELD time and weld CURRENT as necessary

to make a good weld. Try to use the minimum time and current necessary to make a good weld

so that the weld joint heat affected zone will be minimized.

13 Up to 128 different weld schedules can be created and saved. To recall any specific weld

schedule, press the up or down vertical arrow keys [VW] until the desired schedule number

appears on the display screen. A faster technique for recalling a specific schedule is to input

the Schedule number using the number keys.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-3

CHAPTER 3: WELDING SYSTEM SET-UP

UNITEK EQUIPMENT FORCE FIRED,

SINGLE AIR ACTUATED WELD HEAD SYSTEM

Weld Head Set-up (Figure 3-2)

1 Adjust the Weld Head Force Adjust

Knob to produce 5 units of force as

displayed on the Force Indicator. For a

complete description of force control

and its effect on the welding process,

please refer to your Weld Head manual.

2 Install electrodes in Weld Head

Electrode Holders.

3 Connect a properly filtered air line to

the Inlet Air Line on the Weld Head Air

Valve Driver Solenoid assembly which

is located on the back of the Weld

Head. Use 0.25 inch O.D. by 0.17 inch

I.D. plastic hose with a rated burst

pressure of 250 psi. A lubricator should

only be used with automated

installations. Turn on the air system and check for leaks.

Firing Switch Cable Connection (Figure 3-2)

Figure 3-2. Single Air Actuated

Weld Head Connections

Connect the Weld Head Firing Switch Cable Connector to the matching cable connector on the rear of

the HF2 Weld Control.

Weld Head Valve Driver No. 1 Connection (Figure 3-2)

A single air actuated Weld Head has one Solenoid Valve Driver Cable for automatic actuation and

timing control by the HF2 Weld Control. The HF2 Weld Control will automatically recognize the

solenoid voltage of the Weld Head. Connect the 4 pin black plastic connector on the cable to the

matching Air Valve 1 Driver connector located on the HF2 Weld Control rear panel.

Foot Switch Connection (Figure 3-2)

1 Connect a Model FS1L, 1-Level, or a Model FS2L, 2-Level Foot Switch to the FOOT

SWITCH connector located on the HF2 rear panel. The HF2 will automatically recognize

which model of Unitek Equipment Foot Switch has been connected.

2 1-Level Foot Switch - The l-Level Foot Switch must be fully depressed by the operator. When

the Foot Switch closes, the HF2 energizes the Air Actuated Weld Head, causing the Upper

Electrode to descend and apply force to the parts. If the Foot Switch is released before the

Weld Head applies the Preset Firing Force, the HF2 will automatically return the Upper

Electrode to its up position.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-4 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

3 2-Level Foot Switch - When a 2-Level Foot Switch is pressed to the first level, the HF2

energizes the Air Actuated Weld Head, causing the Upper Electrode to descend and apply force

to the parts. If the Foot Switch is released before the operator presses the Foot Switch to the

second level, the HF2 will automatically return the Upper Electrode to its up position so that

the parts can be repositioned. Once the second level has been reached and the Force Firing

Switch in the Weld Head has closed, Weld Current will flow and the HF2 will automatically

return the Upper Electrode to its up position.

Single Air Regulator Adjustment (Model 80 Series Weld Heads - Figure 3-2)

1 Set the HF2 Weld Control front panel

WELD/NO WELD switch to NO WELD.

2 Turn the Power Switch located on the

HF2 Weld Control rear panel to ON.

After a series of power up screens, the

last RUN screen displayed will appear.

Press the [CHNG] key to access the Weld

Graph RUN screen for the BASIC

WELD function.

3 Turn the Air Regulator Clockwise (CW)

to produce 10 psi on the Pressure Gauge.

4 Press and hold the Foot Switch

completely down to close all switch

levels. The lower right hand corner of

the display should show the status

message STANDBY .

5 Continuing turning the Air Regulator

Clockwise (CW) until the HF2

automatically returns the Upper Electrode

to its "up position". The lower right hand

corner of the display should now show

the status message END if you have

not released the Foot Switch. Release the

Foot Switch.

6 Note: You have 10 seconds to make the

Air Regulator adjustment or a buzzer

alarm will sound and the HF2 will

automatically return the Upper Electrode

to its up position. The status message

changes from STANDBY to

ALARM FIRING SWITCH . Press

[RUN] to clear the alarm and then repeat

steps 4 and 5.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-5

CHAPTER 3: WELDING SYSTEM SET-UP

7 Adjust the Down Speed Control Knob so the Upper Electrode descends smoothly onto the

parts.

8 Adjust the Up Speed Control Knob so that the Upper Electrode Holder does not impact upon

returning to in "up position".

Dual Air Regulator Adjustments (Model 180 Series and Model 90 Series Weld Heads Figure 3-2)

1 Turn the Air Regulator located on the right-hand side of the Weld Head Clockwise (CW) to

produce 10 psi on the Pressure Gauge.

2 Adjust the left-hand side Air Regulator following steps 4, 5, and 6 for the Single Air Regulator

Adjustment.

3 Re-adjust the right-hand side Air Regulator to produce the same air pressure as finally used on

the left-hand side Air Regulator.

4 Repeat steps 7 and 8 for the Single Air Regulator Adjustment.

Quick Start Programming Guide

1 Press [MENU]. The MAIN MENU screen will appear.

2 Select TRANSFORMER MODEL.

The TRANSFORMER MODEL screen

appears.

3 Select MULTIPLE HEADS: OFF. If

the display reads ON, then press

[CHNG] until OFF is displayed.

4 Select HEAD 1 : X3/4000-230.

X3/4000-230 is the default Transformer

Model number. Press [CHNG] until

the correct Transformer Model that you have purchased appears.

5 Press [RUN] to return to the Weld Graph RUN State.

6 Set the HF2 Weld Control front panel WELD/NO WELD switch to WELD.

7 Make a test weld by pressing on the Weld Head foot actuator until the HF2 Weld Control fires.

The default WELD time of 1 ms and the default CURRENT of 0.5 KA may not be sufficient to

make a good weld.

8 Press [PROG]. Press [ENTER] to

change SQUEEZE to WELD, as

displayed in the upper right corner. Use

the vertical cursor keys [] to

increase the weld CURRENT. Use the

horizontal cursor keys [ ] to

increase or decrease the WELD time.

In this example, weld CURRENT has

been increased to 0.7 KA and WELD

time has been increased to 0.5 ms.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-6 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

9 Press [SAVE] to save your program. You are now back in the Weld Graph RUN State.

10 Make additional test welds and then re-program WELD time and weld CURRENT as necessary

to make a good weld. Strive to use minimum time and current necessary to make a good weld

so that the weld joint heat affected zone will be minimized.

11 Up to 128 different weld schedules can be created and saved. To recall any specific weld

schedule, press the up or down vertical arrow keys [ ] until the desired schedule number

appears on the display screen. A faster technique for recalling a specific schedule is to input

the Schedule number using the number keys.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-7

CHAPTER 3: WELDING SYSTEM SET-UP

UNITEK EQUIPMENT FORCE FIRED,

DUAL AIR ACTUATED WELD HEAD SYSTEM

General Information

Dual Air Actuated Weld Head System operation uses sequential action to activate one Weld Head and

then a second weld head using a single HF2 Weld Control and HF2 Weld Transformer. The operator

must close and release the Foot Switch to initiate each sequential weld. Sequential Weld Head

activation ensures that only one weld current path exists at a single point in time. To use multiple Weld

Heads simultaneously, refer to Chapter 3, Non-Force Fired, Multiple Air Actuated Weld Head System.

HF2 Weld Control, Jumper Modifications (Figure 3-3)

Warning: Before modifying jumpers, disconnect the 3-phase input power to the HF2 to prevent

serious injury.

1 Remove the HF2 Weld Control cover.

2 The HF2 Weld Control PCB is located

on the right-hand side of the HF2 Weld

Control. Locate Jumpers E10 and E11

by looking in the lower right-hand

corner of the HF2 Weld Control PCB.

3 Using a needle nose pliers, move

Jumpers E10 and E11 from the RELAY

position to the HEAD2 position.

4 Replace the HF2 Weld Control cover.

5 Connect 3 phase input power to the

HF2.

Figure 3-3. HF2 Jumper Modifications

Weld Head Set-up (Figure 3-4)

1 Connect the Upper Weld Cable from each Weld Head to the Positive Terminal on the HF2

Weld Transformer.

2 Connect the Lower Weld Cable from each Weld Head to the Negative Terminal on the HF2

Weld transformer.

3 Adjust each Weld Head Force Adjust Knob to produce 5 units of force as displayed on the

Force Indicator. For a complete description of force control and its effect on the welding

process, please refer to your Weld Head manual.

4 Install electrodes in each Weld Head Electrode Holder.

5 Parallel two sets of twisted wire cables to the clip end of the standard Voltage Sensing Cable

that is connected to the Weld Transformer front panel. Connect one twisted wire cable to the

Left Weld Head electrodes and the other twisted wire cable to the Right Weld Head electrodes.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-8 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

Figure 3-4. Weld Cable and Air Line Connections for Dual Air Actuated Weld Heads

6 Connect a properly filtered air line to the Inlet Air Line on the Weld Head Air Valve Driver

Solenoid assembly which is located on the back of the Weld Head. Use 0.25 inch O.D. by 0.17

inch I.D. plastic hose with a rated burst pressure of 250 psi. Run separate air lines to each Inlet

Air Line. Do not split a single 0.25 O.D. line into two lines or the Weld Heads will not have

sufficient air flow to work properly. A lubricator should only be used with automated

installations. Turn on the air system and check for leaks.

Firing Switch Cable Connection (Figure 3-5)

Connect the Weld Head Firing Switch Cable Connector on each Weld Head to the matching connectors

on the Model DFS Parallel Switch Box. Connect the Model DFS Firing Switch Cable to the matching

cable connector on the rear of the HF2 Weld Control.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-9

CHAPTER 3: WELDING SYSTEM SET-UP

Weld Head Valve Driver Connections (Figure 3-5)

1 Each air actuated Weld Head has one Solenoid Valve Driver Cable for automatic actuation and

timing control by the HF2 Weld Control. The HF2 Weld Control will automatically recognize

the solenoid voltage of your Weld Head. Connect the 4 pin black plastic connector on the Left

Weld Head Solenoid Valve Driver Cable to the matching Air Valve 1 Driver connector located

on the HF2 Weld Control rear panel.

2 Connect the 4 pin black plastic connector on the Right Weld Head Solenoid Valve Driver

Cable to the matching Air Valve 2 Driver connector located on the HF2 Weld Control rear

panel.

Foot Switch Connection (Figure 3-5)

1 Connect a Model FS1L, 1-Level, or a Model FS2L, 2-Level Foot Switch to the FOOT

SWITCH connector located on the HF2 rear panel. The HF2 will automatically recognize

which model of Unitek Equipment Foot Switch has been connected.

2 1-Level Foot Switch -- The l-Level Foot Switch must be fully depressed by the operator.

When the Foot Switch closes, the HF2 energizes the Air Actuated Weld Head, causing the

Upper Electrode to descend and apply force to the parts. If the Foot Switch is released before

the Weld Head applies the Preset Firing Force, the HF2 will automatically return the Upper

Electrode to its up position.

3 2-Level Foot Switch -- When a 2-Level Foot Switch is pressed to the first level, the HF2

energizes the Air Actuated Weld Head, causing the Upper Electrode to descend and apply force

to the parts. If the Foot Switch is released before the operator presses the Foot Switch to the

second level, the HF2 will automatically return the Upper Electrode to its up position so that

the parts can be repositioned. Once the second level has been reached and the Force Firing

Switch in the Weld Head has closed, Weld Current will flow and the HF2 will automatically

return the Upper Electrode to its up position.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-10 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

Dual Air Regulator Adjustment (Model 188 - Figure 3-5)

Figure 3-5. Dual Air Actuated Weld Heads Electrical Connections

1 Set the HF2 Weld Control front panel WELD/NO WELD switch to NO WELD.

2 Turn the Power Switch located on the

HF2 Weld Control rear panel to ON.

After a series of power up screens, the

last RUN screen displayed will appear.

Press the [CHNG] key to access the

Weld Graph RUN screen for the BASIC

WELD Function.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-11

CHAPTER 3: WELDING SYSTEM SET-UP

3 Press [MENU]. The MAIN MENU

screen will appear.

4 Select TRANSFORMER MODEL. The

TRANSFORMER MODEL screen

appears.

5 Select MULTIPLE HEADS: OFF. If

the display reads ON, press [CHNG]

until OFF is displayed.

6 Select HEAD 1 : X3/4000-230.

X3/4000-230 is the default Transformer

Model number. Press [CHNG] until

the correct Transformer Model that you

have purchased appears.

7 Press [MENU] to return to the MAIN

MENU screen.

8 Select OPTIONS. The OPTIONS 1 screen

appears.

9 Press [ ] to select the OPTIONS 2

screen.

10 Select WELD HEAD TYPE: AUTO.

Press [CHNG] until the DUAL AIR

option appears.

11 Press [MENU] to return to the MAIN

MENU.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-12 990-057

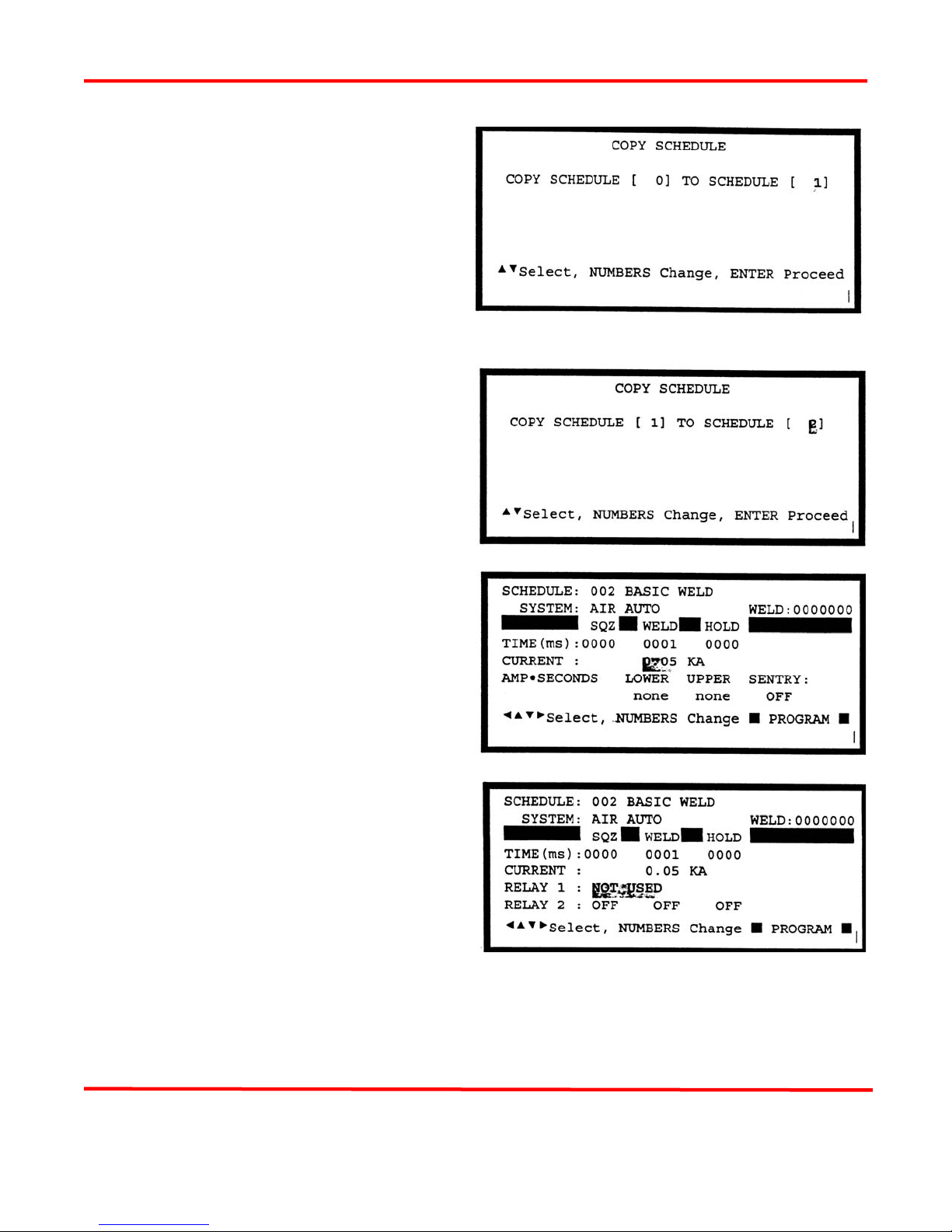

12 Select COPY A SCHEDULE. The

COPY SCHEDULE screen will appear.

13 Select the last flashing 0 of TO

SCHEDULE [ 0] and use the number

keys to change the flashing 0 TO

SCHEDULE [ 1].

14 Press [ENTER] to complete the

schedule copy process and to

automatically return to the Weld Graph

RUN State.

15 Press [MENU] to return to the MAIN

MENU.

16 Select COPY A SCHEDULE. The

COPY SCHEDULE screen will appear.

17 Select the last flashing 1 of TO

SCHEDULE [ 1] and use the number

keys to change the flashing 1 TO

SCHEDULE [ 2].

CHAPTER 3: WELDING SYSTEM SET-UP

18 Press [ENTER] to complete the

schedule copy process and to

automatically return to the Weld Graph

RUN State.

19 Press [PROGRAM] twice to select the

Alphanumeric PROGRAM screen.

20 Press the down vertical cursor key [W]

until the RELAY 1: NOT USED and

RELAY 2: OFF option items appear.

21 Select RELAY 1: NOT USED. Press [CHNG] to select the AIR HEAD 2 option.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-13

CHAPTER 3: WELDING SYSTEM SET-UP

22 Press [SAVE] to update Schedule 2,

then press [CHNG] to automatically

return to the Weld Graph RUN State.

You are now ready to adjust the Right

Weld Head Air Regulators.

23 Turn both Air Regulators located on the

right-hand side of the Right Weld Head

Clockwise (CW) to produce 10 psi on

the Pressure Gauge.

24 Press and hold the Foot Switch

completely down to close all switch

levels. The lower right hand corner of

the display should show the status

message STANDBY .

25 Turn the Air Regulator that feeds the

Top Right Air Cylinder on the Right

Weld Head Clockwise (CW) until the

HF2 automatic-ally returns the Upper

Electrode to its up position. The lower

right hand corner of the display should

now show the status message END if

you have not released the Foot Switch.

Release the Foot Switch.

26 NOTE: You have 10 seconds to make

the Air Regulator adjustment or a

buzzer alarm will sound and the HF2

will automatically return the Upper

Electrode to its up position. The status

message changes from STANDBY to

ALARM FIRING SWITCH . Press

[RUN] to clear the alarm, then repeat

steps 24 and 25.

27 Re-adjust the Air Regulator that feeds the Bottom Right Air Cylinder on the Right Weld

Head to produce the same air pressure as finally used on the Top Air Regulator on the Right

Weld Head.

28 Adjust the Right Weld Head Down Speed Control Knob so the Right Weld Head Upper

Electrode descends smoothly onto the parts.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-14 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

29 Adjust the Right Weld Head Up Speed Control Knob so that the Right Weld Head Upper

Electrode Holder does not impact upon returning to in up position.

30 Press [ W ] to select SCH:001 BASIC WELD. You are now ready to adjust the Left Weld

Head Air Regulators.

31 Repeat steps 24 through 29 for the Dual Air Weld Head System, All Regulator Adjustments

for the Left Weld Head.

Quick Start Programming Guide

1 Make a test weld using Schedule 1 by pressing on the Weld Head foot actuator until the HF2

Weld Control fires. The default WELD time of 1 ms and the default CURRENT of 0.5 KA

may not be sufficient to make a good weld.

2 Press [PROG]. Press [ENTER] to

change SQUEEZE to WELD, as

displayed in the upper right corner. Use

the vertical cursor keys [

increase the weld CURRENT. Use the

horizontal cursor keys [ ] to

increase or decrease the WELD time.

In this example, weld CURRENT has

been increased to 0.7 KA and WELD

time has been increased to 0.5 ms.

] to

3 Make additional test welds and then re-program WELD time and weld CURRENT as necessary

to make a good weld. Try to use the minimum time and current necessary to make a good weld

so that the weld joint heat affected zone will be minimized.

4 Press [SAVE] to save the updated Schedule 1. You are now back in the Weld Graph RUN

State.

5 Press [>] to select SCH:002 BASIC WELD. You are now ready to make test welds using the

Right Weld Head.

6 Repeat steps 1 through 3 using the Right Weld Head.

7 Press [SAVE] to save the updated Schedule 2. You are now back in the Weld Graph RUN

State and ready to turn on the Chaining Feature, which will enable Schedule 1 to automatically

sequence to Schedule 2, then back to Schedule 1.

8 Press [MENU] and then select

OPTIONS. Use the horizontal cursor

key [

] to select the OPTIONS 1

screen.

9 Select CHAIN SCHEDULES

FEATURE: OFF. Press [CHNG] to

change to ON.

10 Press [RUN] to return to the Weld

Graph RUN State.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-15

CHAPTER 3: WELDING SYSTEM SET-UP

11 Press [PROGRAM] twice to select the

Alphanumeric PROGRAM screen for

Schedule 2.

12 Verify that NEXT: 001 is correctly

displayed so that Schedule 2 will

automatically advance to Schedule 1

after one weld has been completed. If

you want to make more than one weld

using Schedule 2 before advancing to

Schedule 1, change STEP : 00001 to the

desired number of welds.

13 Press [SAVE] to save the updated Schedule 2.

14 Press [ W ] to select SCH:001 BASIC WELD.

15 Press [PROGRAM] once to select the Alphanumeric PROGRAM screen for Schedule 1.

16 Select NEXT: 001. Change 001 to 002

so that Schedule 1 will automatically

advance to Schedule 2 after one weld

has been completed. If you want to

make more than one weld using

Schedule 1 before advancing to

Schedule 2, change STEP : 00001 to the

desired number of welds.

17 Press [SAVE] to save the updated Schedule 1. Press [CHNG] to return to the Weld Graph

RUN State. You are now ready to make alternating welds, beginning with Schedule 1, by just

pressing on the Foot Switch to activate each weld.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-16 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

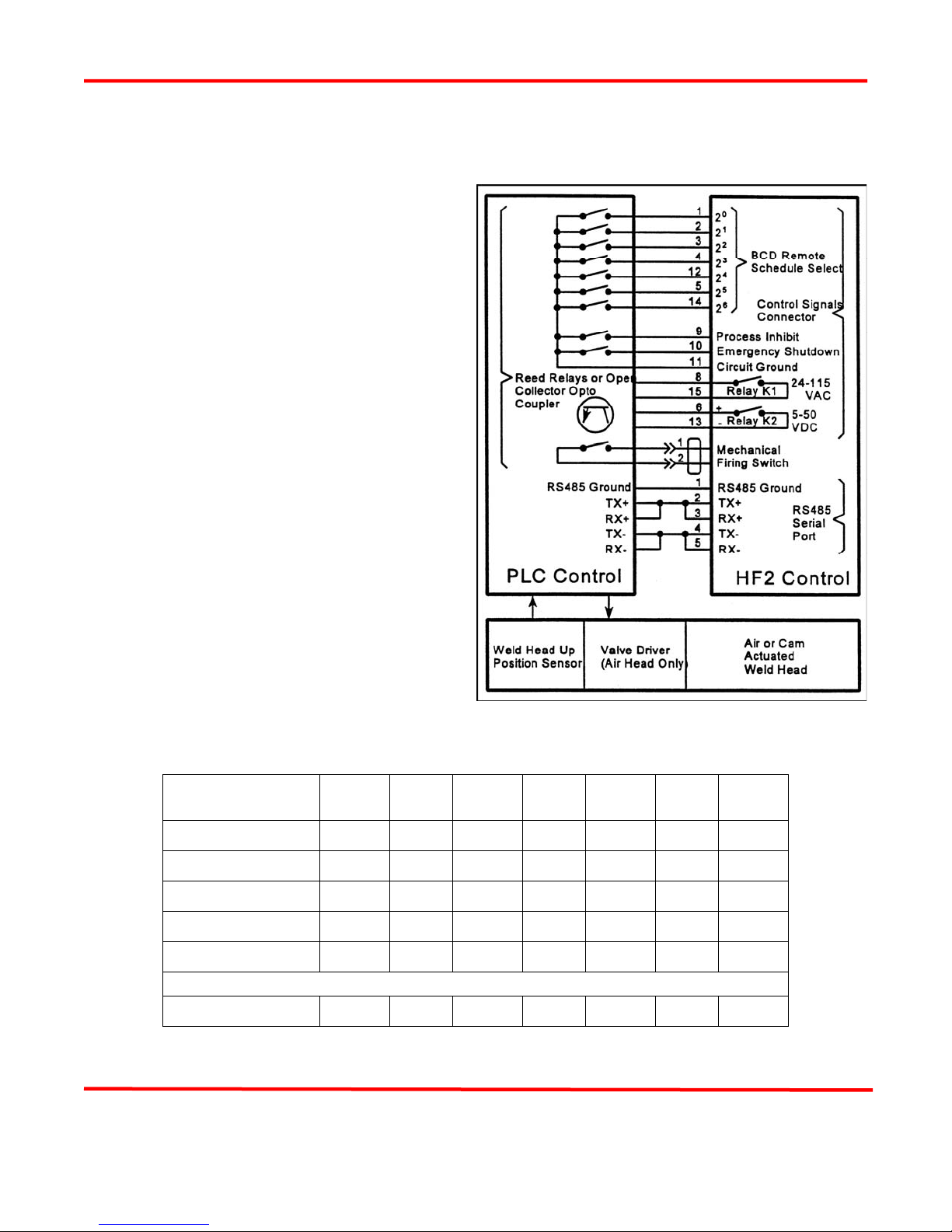

NON-FORCE FIRED, AIR OR CAM ACTUATED WELD HEAD SYSTEM

PLC to HF2 Weld Control Electrical Connections (Figure 3-6)

1 Connect your Programmable Logic

Control (PLC) or Host Computer output

control signals to the HF2 Weld Control

inputs using reed relays or the open

collector of an opto coupler. The

emitter of each opto coupler must be

connected to The HF2 Weld Control

Rear Panel Control Signals connector,

Pin 11.

2 For a complete description of how to

program Relay 1 and Relay 2, reference

Chapter 5, Programming Modes,

Output Relays.

3 For a complete description on how to use

the RS-485 Datacom feature, reference

Chapter 9, RS-485 Datacom.

4 All weld schedules must be entered and

saved using the HF2 Weld Control

Front Panel keys. After saving the

desired weld schedules, each schedule

can be recalled prior to initiating the

welding process cycle by closing the

binary Remote Schedule Select lines

according to the following table:

WELD

SCHEDULE

0 0 0 0 0 0 0 0

1 1 0 0 0 0 0 0

2 0 1 0 0 0 0 0

3 1 1 0 0 0 0 0

4 0 0 1 0 0 0 0

Binary progression from 5 to 126

127 1 1 1 1 1 1 1

20

Pin 1

21

Pin 2

Figure 3-6. PLC to HF2 Weld Control

Electrical Connections

22

Pin 3

23

Pin 4

24

Pin 12

25

Pin 5

Pin 14

26

NOTE: 0 = Open; 1 = Closed

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-17

CHAPTER 3: WELDING SYSTEM SET-UP

PLC Timing Diagram (Figure 3-7)

Figure 3-7. PLC Timing Diagram.

Quick Start Programming Guide

1 Set the HF2 Weld Control front panel

WELD/NO WELD switch to NO

WELD.

2 Turn the Power Switch located on the

HF2 Weld Control rear panel to ON.

After a series of power up screens, the

last RUN screen displayed will appear.

Press the [CHNG] key to access the

Weld Graph RUN screen for the BASIC

WELD Function.

3 Press [MENU]. The MAIN MENU

screen will appear.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-18 990-057

CHAPTER 3: WELDING SYSTEM SET-UP

4 Select TRANSFORMER MODEL.

The TRANSFORMER MODEL screen

appears.

5 Select MULTIPLE HEADS: OFF. If

the display reads ON, press [CHNG]

until OFF is displayed.

6 Select HEAD 1 : X3/4000-230.

X3/4000-230 is the default Transformer

Model number. Press [CHNG] until

the correct Transformer Model that you have purchased appears.

7 Press [MENU] to return to the MAIN MENU screen.

8 Select OPTIONS. The OPTIONS 1 or

OPTIONS 2 screen appears. This

example shows the OPTION 1 screen.

9 Press [ ] to select the OPTIONS 2

screen.

10 Select WELD HEAD TYPE: AUTO.

Press [CHNG] until the MANUAL

option appears. Note: FOOTSWITCH

TYPE: AUTO will automatically

change to NONE.

11 Select FOOTSWITCH WELD ABORT:

ON. Press [CHNG] until the OFF

option appears.

12 12.Press [RUN] to return to the Weld

Graph RUN State.

13 Set the HF2 Weld Control front panel WELD/NO WELD switch to WELD.

14 Make a test weld by pressing on the Weld Head foot actuator until the HF2 Weld Control fires.

The default WELD time of 1 ms and the default CURRENT of 0.5 KA may not be sufficient to

make a good weld.

15 Press [PROG]. Use the vertical cursor

keys [

] to increase the weld

CURRENT. Use the horizontal cursor

keys [ ] to increase or decrease

the WELD time. In this example, weld

CURRENT has been increased to 0.7

KA and WELD time has been increased

to 0.5 ms.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 3-19

CHAPTER 3: WELDING SYSTEM SET-UP

16 Press [SAVE] to save your program. You are now back in the Weld Graph RUN State.

17 Make additional test welds and then re-program WELD time and weld CURRENT as necessary

to make a good weld. Try to use the minimum time and current necessary to make a good weld

so that the weld joint heat affected zone will be minimized.

18 Up to 128 different weld schedules can be created and saved. To manually recall any specific

weld schedule, press the up or down vertical arrow keys [ ] until the desired schedule

number appears on the display screen. A faster technique for recalling a specific schedule is to

input the Schedule number using the number keys.

19 To recall any weld schedule automatically, use the binary Remote Schedule Select Control

Lines as discussed under the step 4 of the PLC to HF2 Weld Control Electrical Connections

section.

NON-FORCE FIRED, MULTIPLE AIR ACTUATED WELD HEAD SYSTEM

This system configuration is not released.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

3-20 990-057

CHAPTER 4

CONTROLS

HF2 Weld Control - Front Panel (Figure 4-1)

Figure 4-1. HF2 Weld Control Front Panel

KEY DESCRIPTION

[KEYPAD] Use the numeric keys to enter numeric information. Use the [ . ] to enter decimal

values.

[KEYPAD] Use the numeric keys to change weld schedules without the need to use the

[ ] keys. For example, pressing [1] [0] will recall weld schedule 10.

[ ] In the RUN State, press [ ] to select a higher number weld schedule or press

] to select a lower number weld schedule.

[

[ ] In PROGRAM and MENU States, use both [ ] to move up and down on the

LCD Display to select user options.

[

] In the PROGRAM and MENU States, use [ ] to select user options.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 4-1

CHAPTER 4: CONTROLS

[PROG] In the RUN State, press [PROG] to enter the Graphical PROGRAM State to make

changes to the selected weld schedule fields. Press [PROG] a second time to

make changes using the Alphanumeric PROGRAM State. Press [PROG] a third

time to make changes to the Weld Sentry programs related to the selected weld

schedule. Press [PROG] a fourth time to return to the HF2 Graphical Program

screen.

[RUN] In the PROGRAM State, press [RUN] to exit the PROGRAM State without

saving the changed weld schedule. The changed weld schedule will become

Weld Schedule 0 and will not be written to permanent memory. Welding parts is

done in the RUN State.

[RUN] In the MENU State, press [RUN] to exit the MENU State and begin welding

parts.

[SAVE] In the PROGRAM State, press [SAVE] to save the selected weld schedule and its

related Weld Sentry programs to permanent memory. The HF2 Weld Control will

then automatically exit the PROGRAM State and return to the RUN State.

[SAVE] has no function in the RUN State.

[MENU] In either the RUN or PROGRAM States, press [MENU] to provide a menu list of

user options which are common to all weld schedules.

[HELP] Press this key whenever you need HELP or additional information on any user

menu option or flashing user programmable field. The HF2 contains a built-in

operating manual. Press [HELP] a second time to return to the original State.

[CHNG] In the PROGRAM State, press [CHNG] to restore the previous contents of a user

programmable field.

[CHNG] In the MENU State, press [CHNG] to select different menu options.

[CHNG] In the RUN State, press [CHNG] to change the Graphical RUN State screen to the

Alphanumeric RUN State screen.

[ENTER] Press [ENTER] after keying in numeric program data.

WELD/NO WELD Weld current will not flow when this switch is in the NO WELD position.

SWITCH However, operation in the NO WELD switch position permits the HF2 to initiate

and execute a complete welding sequence without weld current flowing.

Operating the HF2 in the NO WELD position is required to adjust Unitek Peco

Weld Heads. This switch must be in the WELD position in order to make a weld.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

4-2 990-057

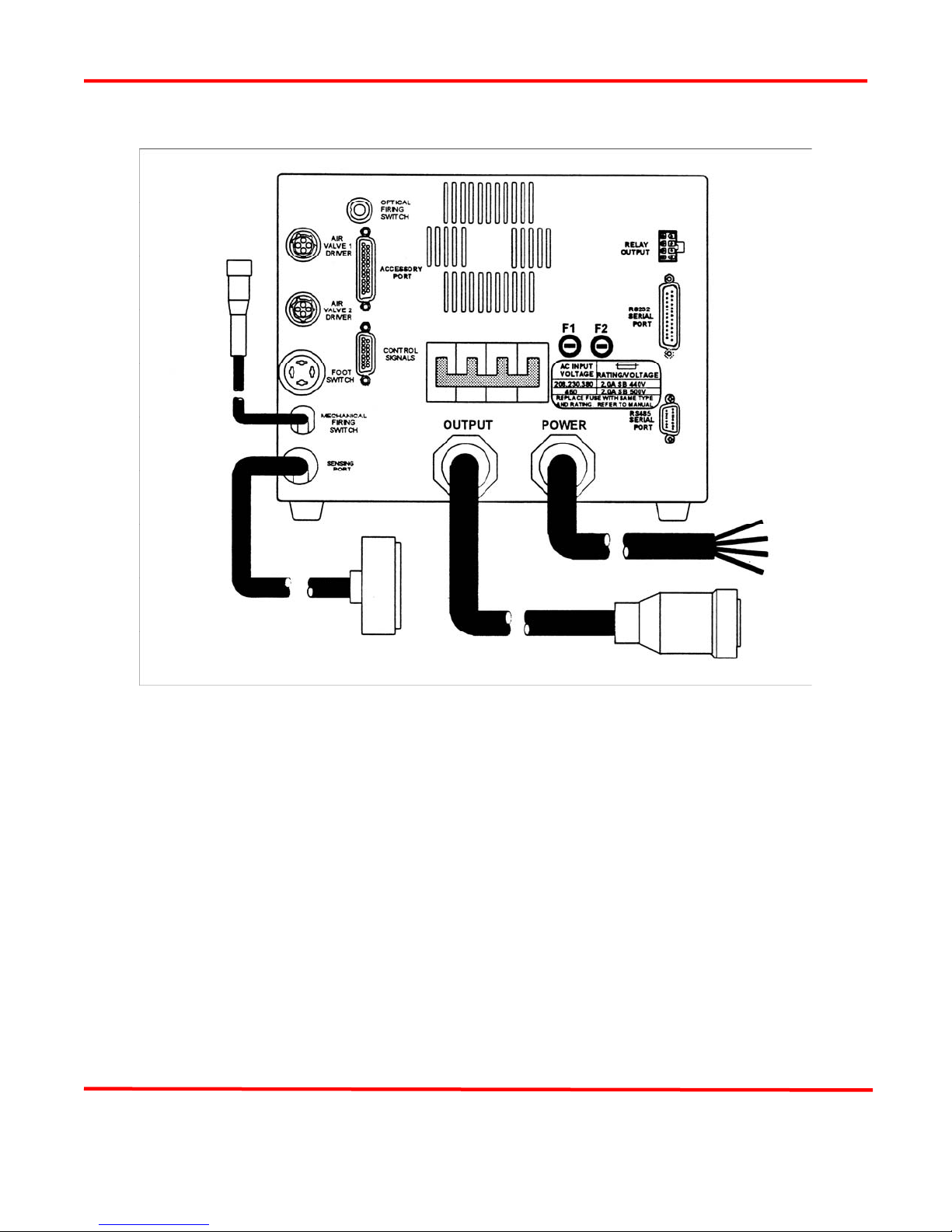

HF2 Weld Control - Rear Panel Inputs and Outputs

CHAPTER 4: CONTROLS

Figure 4-2. HF2 Weld Control Rear Panel

• POWER - Refer to Chapter 2, Power Line Voltage, Current, and Wire Size Requirements, for

complete instructions on how to properly apply power to the HF2 Weld Control.

• FUSES F1, F2 - Refer to Chapter 2, Power Line Fuse Requirements for complete

specifications for Power Line Fuse sizes.

• SENSING PORT

The Sensing Port contains both input and output lines for communicating to the HF2 Weld

Transformer and the MA-600 Multiple Weld Head Selection Box. The connector attached to

the end of the Sensing Port Cable is a 16 pin Honda, P/N: MC16LSF, (Unitek P/N: 250-235).

This connector mates with the connector on the HF2 Weld Transformer.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 4-3

CHAPTER 4: CONTROLS

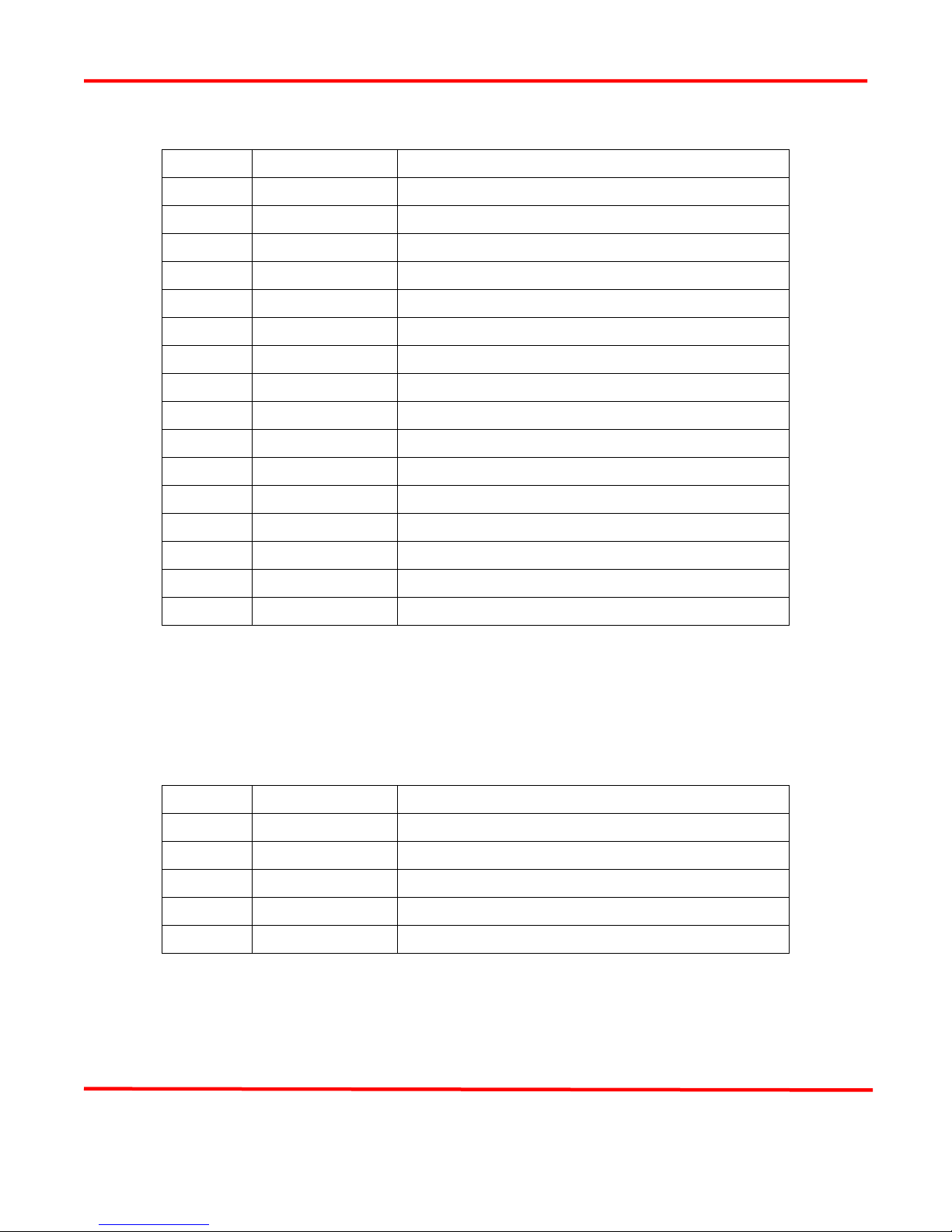

Sensing Port - Connector Pin Assignments

Pin No. Wire Color Description

1 Red Secondary Weld Current Measurement

2 Red +12 VDC

3 Red Secondary Weld Voltage Measurement

4 Red Weld Transformer Select Line 2 (For MA-600)

5 Red Weld Transformer Thermo Switch

6 Red Weld Transformer Select Line 4 (For MA-600)

7 Red Digital Signal Ground

8 Black 230 VAC Weld Transformer Fan

9 Black Secondary Weld Current Measurement Return

10 Black Weld Transformer Select Line 1 (For MA-600)

11 Black Secondary Weld Voltage Measurement Return

12 Black Weld Transformer Select Line 3 (For MA-600)

13 Black Weld Transformer Thermo Switch Return

14 Black Future Expansion

15 Red Future Expansion

16 Red 230 VAC Weld Transformer Fan Return

OUTPUT

The Output Cable feeds high voltage, pulse width modulated, primary weld current to the primary

winding of the HF2 Weld Transformer. The connector attached to the end of the Output Cable is an

AMP 206136-1 (Unitek P/N: 520-115). The mating connector on the HF2 Weld Transformer is an

AMP 206137-1 (Unitek P/N: 550-071).

Pin No. Wire Color Description

1 Black Primary HF2 Weld Transformer

2 Red Primary HF2 Weld Transformer

4 Green Chassis Ground

6 White Primary HF2 Weld Transformer Return

7 Orange Primary HF2 Weld Transformer Return

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

4-4 990-057

CHAPTER 4: CONTROLS

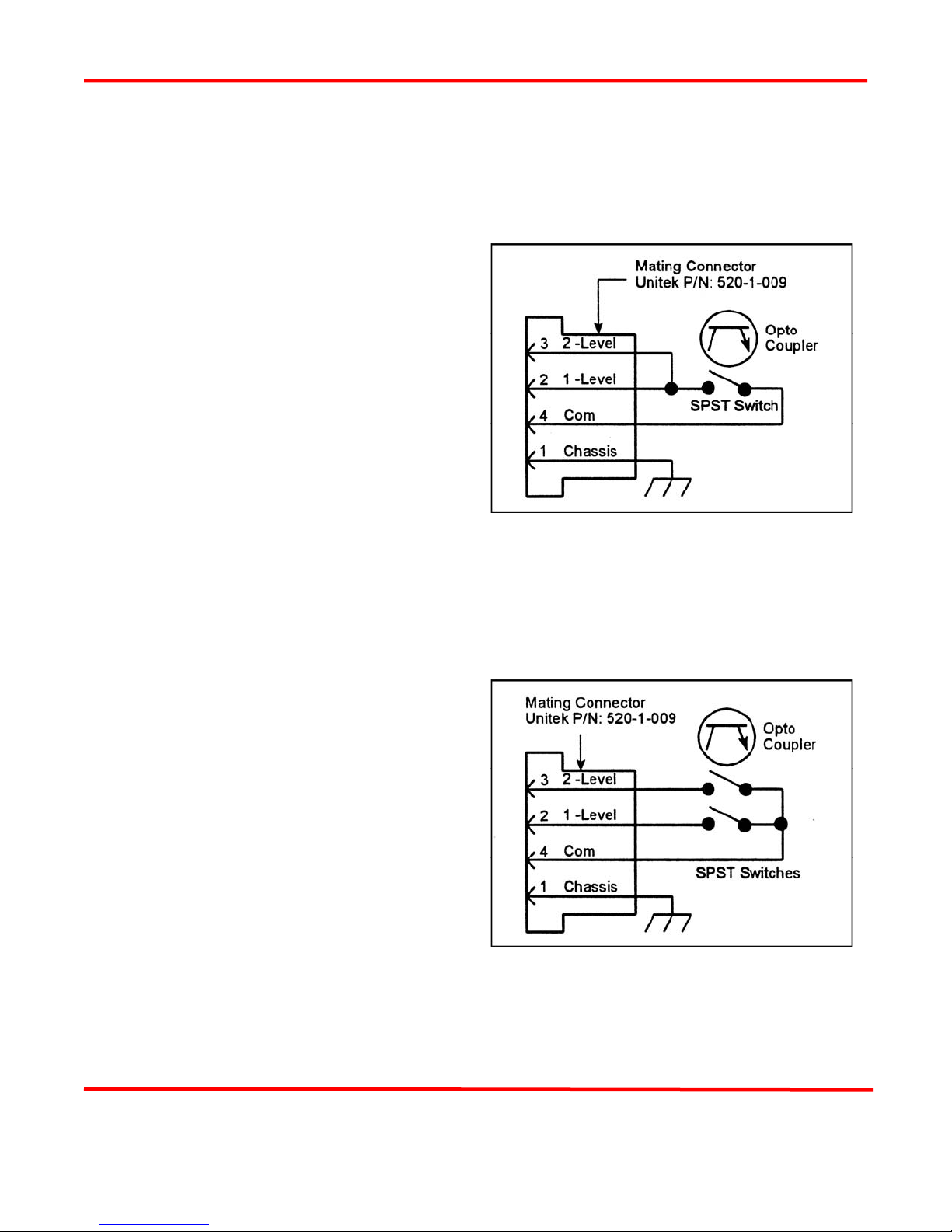

FOOT SWITCH Connector

HF2 Weld Control FOOT SWITCH connector uses a 4-pin Amphenol 91-PC4F (Unitek P/N: 550-1-

006) bulkhead connector that mates with an Amphenol 91-MC4M (Unitek P/N: 520-1-009).

Single-Level Foot Switch (Figure 4-3)

1 A Single-Level Foot Switch must be

fully depressed by the operator. When

the Foot Switch closes, the HF2 Weld

Control energizes the Air Actuated

Weld Head, causing the Upper

Electrode to descend and apply force to

the parts. If the Foot Switch is released

before the Weld Head applies the Preset

Firing Force, the HF2 Weld Control

will automatically return the Upper

Electrode to its up position.

2

Connect a Unitek Model FS1L Foot

Switch, reed relay, or the open collector

of an opto coupler to the Foot Switch

connector to initiate the welding process. The emitter of the opto coupler must be connected to

Pin 4.

Figure 4-3. Single-Level Foot Switch

3 When using a non-Unitek Peco Foot Switch, connect Pin 2 to Pin 3.

Two-Level Foot Switch (Figure 4-4)

1 When a Two -Level Foot Switch is

pressed to the first level, the HF2 Weld

Control energizes the Air Actuated

Weld Head, causing the Upper

Electrode to descend and apply force to

the parts. If the Foot Switch is released

before the operator presses the Foot

Switch to the second level, the HF2

Weld Control will automatically return

the Upper Electrode to its up position so

that the parts can be re-positioned.

Once the second level has been reached

and the Force Firing Switch in the Weld

Head has closed, Weld Current will

Figure 4-4. Two-Level Foot Switch

flow and the HF2 Weld Control will automatically return the Upper Electrode to its up position.

2 Connect a Unitek Model FS2L Foot Switch, reed relay, or the open collector of an opto

coupler to the Foot Switch connector to initiate the welding process. The emitter of the opto

coupler must be connected to Pin 4.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 4-5

CHAPTER 4: CONTROLS

Firing Switch Operation

The HF2 Weld Control can use: (a) a Single Pole, Single Throw Switch (SPST); (b) a Single Pole,

Double Throw (SPDT 3-wire) Switch; or (c) an Optical Switch as an input signal to indicate when the

Weld Head has applied the proper force to the parts. Weld Heads with single pole Firing Switches

should be connected to the Mechanical Firing Switch Connector. A 3-Wire Switch or Optical Firing

Switch, either of which should be connected to the Optical Firing Switch Connector, eliminate switch

bounce, which causes false triggering, and should be used when the welding speed exceeds 1.5 welds

per second.

MECHANICAL FIRING SWITCH Cable

1 The Mechanical Firing Switch Cable is

5 feet long, Type 2/C, 600 volt cable

and contains 2 shielded, twisted 22

AWG conductors of high-flex stranded

wire. The Firing Switch Connector is a

2-pin Amphenol 80-MC2FI (Unitek

P/N: 520-011), with strain relief that

mates with an Amphenol 80-MC2M

(Unitek P/N: 520-001). Pin 2 is Digital

Ground.

2 Connect a Unitek Model Weld Head

Firing Switch, reed relay, or the open

collector of an opto coupler to the Foot

Switch connector to initiate weld

Figure 4-5. Mechanical Firing Switch

current. The emitter of the opto coupler must be connected to Digital Ground, Pin 2.

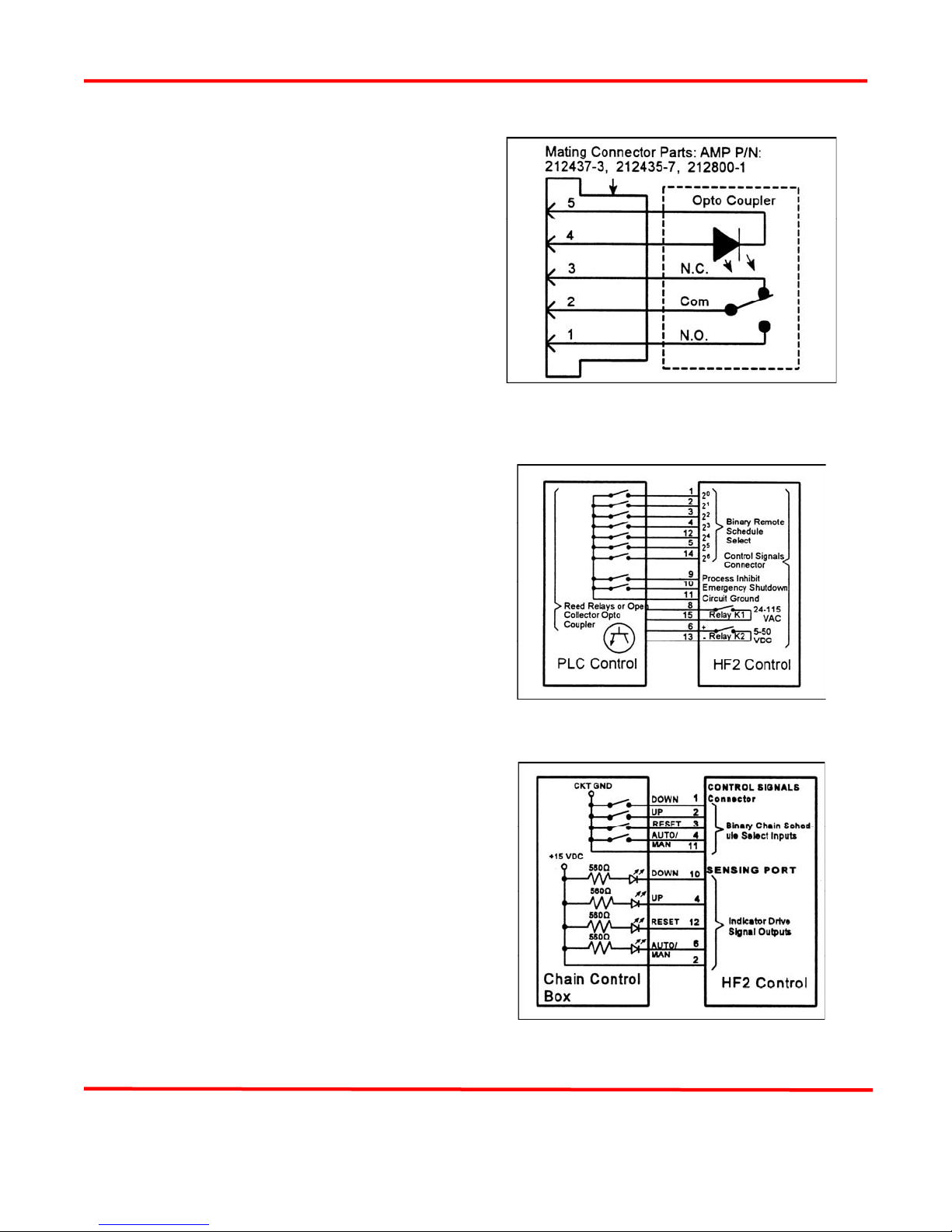

OPTICAL FIRING SWITCH Connector

The Optical Firing Switch Connector is a 5 pin

AMP 212044-1 (Unitek P/N: 550-064) bulkhead

connector and mates with an AMP Assembly

consisting of an AMP 212437-3 Plug, 212435-7

Ferrule and 212800-1 Strain Relief. The Optical

Firing Switch can be used in two configurations

for initiating a welding process: a) Single Pole

Double Throw (SPDT 3-wire); or b) Opto

Coupler.

Mechanical Firing Switch - 3-Wire

Connection

A SPDT (3-wire) mechanical switch can be

connected to the Optical Firing Switch connector

Figure 4-6. Wire Firing Switch

to eliminate the use of Switch Debounce Time when welding at rates of 1.5 welds/second.

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

4-6 990-057

Opto Coupler Firing Switch - 3-Wire Connection

A SPDT opto coupler switch can be connected to

the Optical Firing Switch connector to eliminate the

use of Switch Debounce Time when welding at

rates of greater than 1.5 welds/second.

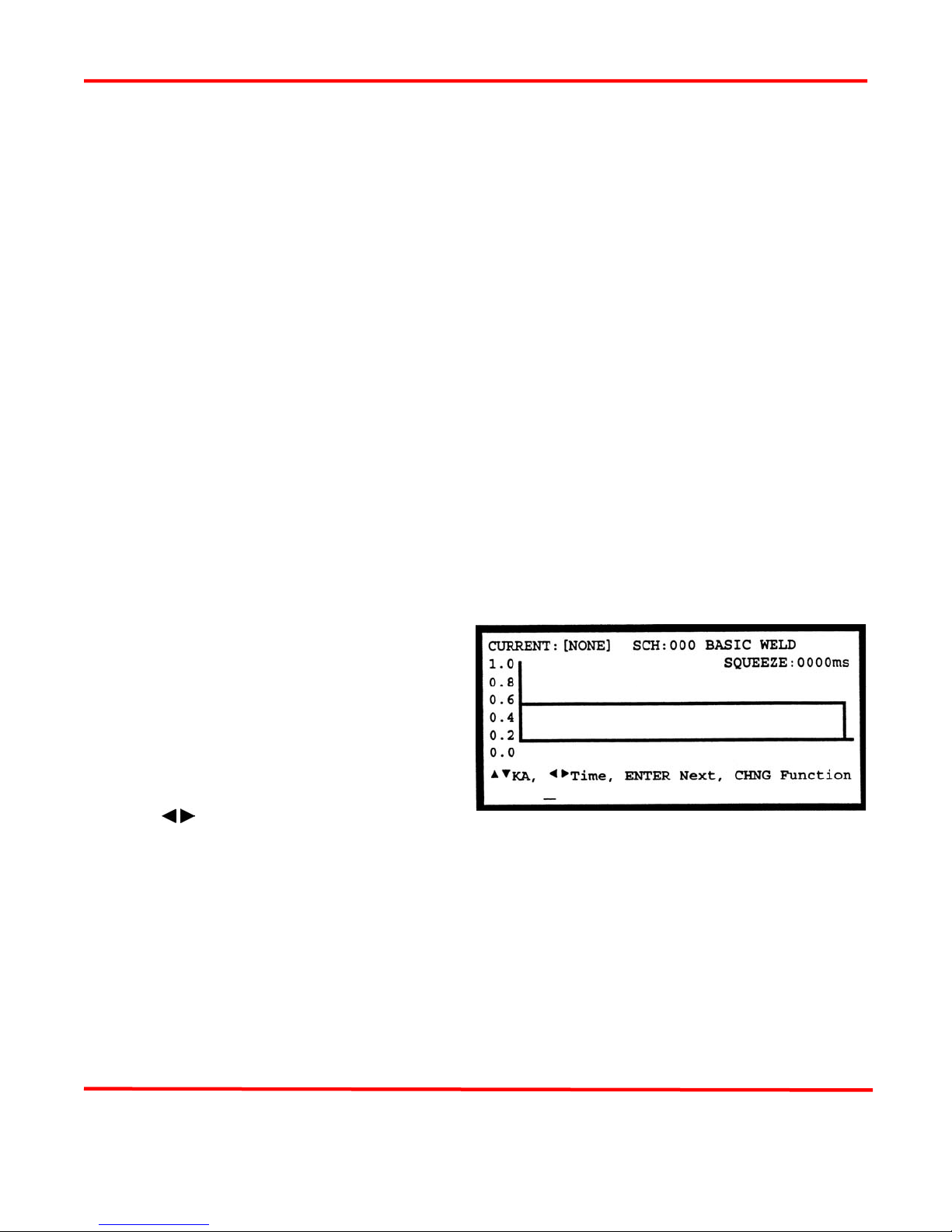

CONTROL SIGNALS Connector

1 A 15-pin, sub-miniature "D" Control

Signals Connector includes inputs for:

(a) Remotely selecting weld schedules 1

through 127; (b) Inhibiting the HF2

Weld Control from beginning a new

welding process; and (c) Invoking an

Emergency Stop Condition which

abruptly terminates the welding process.

The Control Signals inputs

and outputs are designed to be used

with a Programmable Logic Control

(PLC) (see Figure 4-8) or a Host

Computer in automated environments.

Figure 4-7. Opto Coupler Firing Switch

CHAPTER 4: CONTROLS

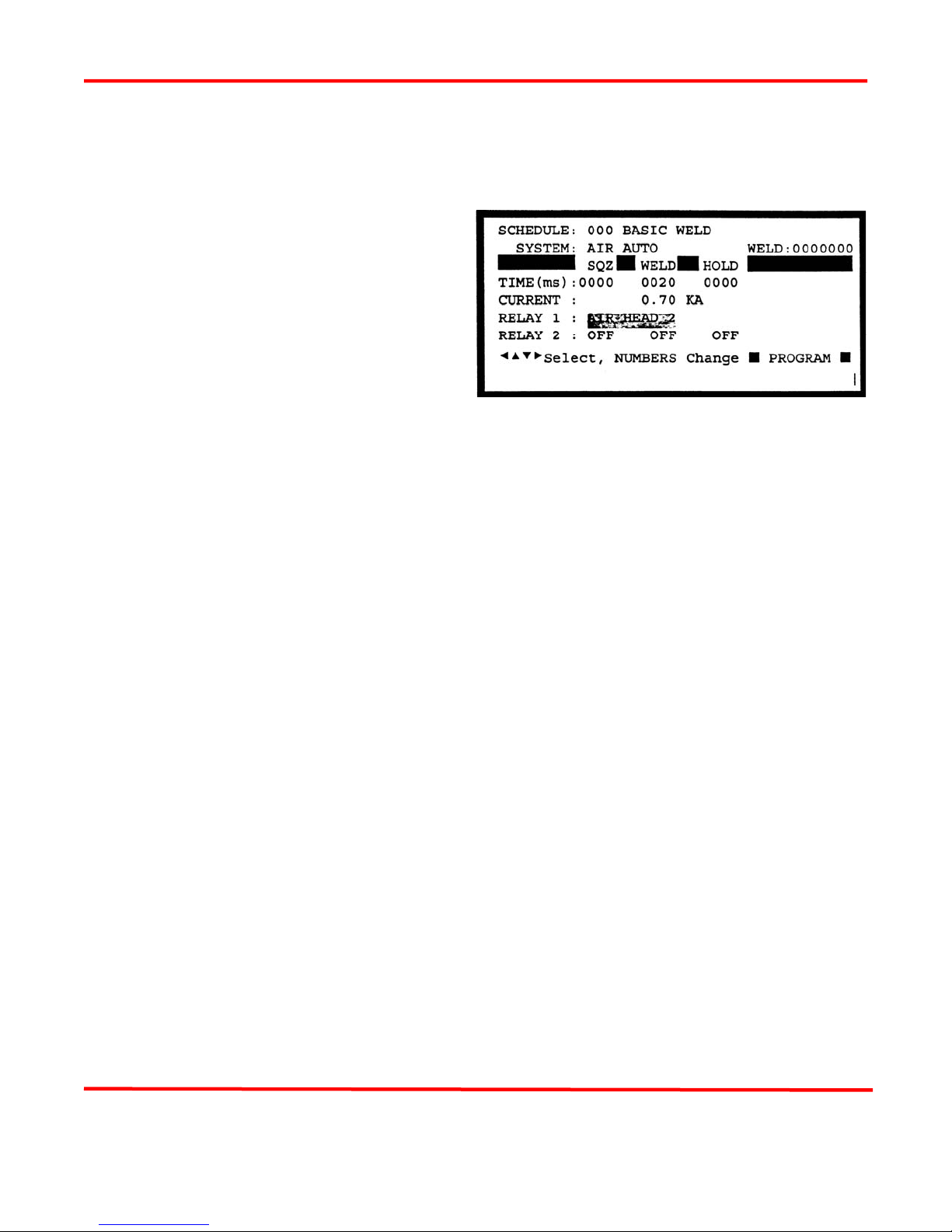

2 When an external chain control box is

connected to the Control Signals

Connector in place of a PLC, chained weld

schedules can be implemented semiautomatically with an external chain

control box (see Figure 4-9).

3

The Control Signals Connector also

includes outputs for: a) One DC Solid

State Relay; and b) One AC Solid State

Relay.

4 The 15 pin connector is a Viking

DMRST15RA05CG (Unitek P/N: 2501-195). The mating connector is a

TRW Cinch Connector comprised of a

DA-15P (Unitek P/N: 250-1-199) male

connector and a DE-51210-1 (Unitek

P/N: 250-1-200) plastic junction shell.

The mating connector is included in the

HF2 Weld Control Shipping Kit.

Figure 4-8. Control Signals Connection

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

990-057 4-7

Figure 4-9. Remote Chain Control Box

Input/Output Signals

CHAPTER 4: CONTROLS

5 Connect a reed relay, or the open collector of an opto coupler to the Control Signals connector

to initiate the selection process. The emitter of the opto coupler must be connected to Pin 11.

Keep the selected input closed to maintain the selection.

Control Signals - Pin Assignments

Pin No. I/O Description

1 Input PLC input: Remote Weld Schedule Selection, Control Line 20

Chain control box (CCB) input: Schedule Down (decrement number)

2 Input PLC input: Remote Weld Schedule Selection, Control Line 21

CCB input: Schedule Up (increment number)

3 Input PLC input: Remote Weld Schedule Selection, Control Line 22

CCB input: Reset (set schedule # to power up schedule #)

4 Input PLC input: Remote Weld Schedule Selection, Control Line 23

CCB input: Auto/Manual (enable/disable chain function)

5 Input Remote Weld Schedule Selection, Control Line 25

6 Out-put Relay K2, + 5-50 VDC (User must supply power)

7 NC

8 Out-put Relay K1, 24-115 VAC (User must supply power)

9 Input Process Inhibit

10 Input Emergency Stop

11 Input Circuit Ground

12 Input Remote Weld Schedule Selection, Control Line 24

13 Out-put Relay K2, + 5-50 VDC Return

14 Input Remote Weld Schedule Selection, Control Line 26

15 Out-put Relay K1, 24-115 VAC Return

MODEL HF2 2 kHz HIGH FREQUENCY RESISTANCE WELDING POWER SUPPLY

4-8 990-057

CHAPTER 4: CONTROLS

Control Signals - Remote Weld Schedule Selection Input

All weld schedules must be entered and saved using the HF2 Weld Control Front Panel keys. After

saving the desired weld schedules, each schedule can be recalled prior to initiating the welding process

cycle. Using the PLC (Figure 4-8), remote weld schedule selection (chain schedule feature turned off)

can be implemented by closing the binary Remote Schedule Select lines according to the following

table:

WELD

SCHED

0 0 0 0 0 0 0 0

1 1 0 0 0 0 0 0

2 0 1 0 0 0 0 0