Page 1

Table of Contents

Title Page

Overview

Unpacking Inspection

Safety Information

Rules For Safe Operation

International Electrical Symbols

The Meter Structure

Functional Buttons

Display Symbols

Measurement Operation

A. DC & AC Voltage Measurement

B. AC Current Measurement

C. Measuring Resistance

D. Frequency and Duty Cycle Measurement

E. Operation of Hold Mode

General Specifications

Accuracy Specifications

A. DC Voltage

3

4

5

7

9

10

10

11

13

13

15

16

18

18

20

22

22

Model UT211: OPERATING MANUAL

1

Page 2

Title Page

B. AC Voltage

C. AC Current

D. Resistance

E. Frequency

F. Duty Cycle

Maintenance

A. General Service

B. Replacing the Battery

23

23

24

25

25

26

26

26

Model UT211: OPERATING MANUAL

2

Page 3

Overview

Warning

This Operating Manual covers information on safety and cautions. Please read the

relevant information carefully and observe all the Warnings and Notes strictly.

To avoid electric shock or personal injury, read the “Safety Information” and “Rules

for Safety Operation” carefully before using the Meter.

The Model UT211 (hereafter referred to as “the Meter”) are a 3999 counts 3 3/4 digits

auto clamp multimeter, they auto sense on AC & DC voltage, AC current and resistance

measurement. They have full range overload protection and special outlook design.

They are such a smart electrical testing clamp meter.

It equips also with frequency, duty cycle, low battery display and data hold features.

Model UT211: OPERATING MANUAL

3

Page 4

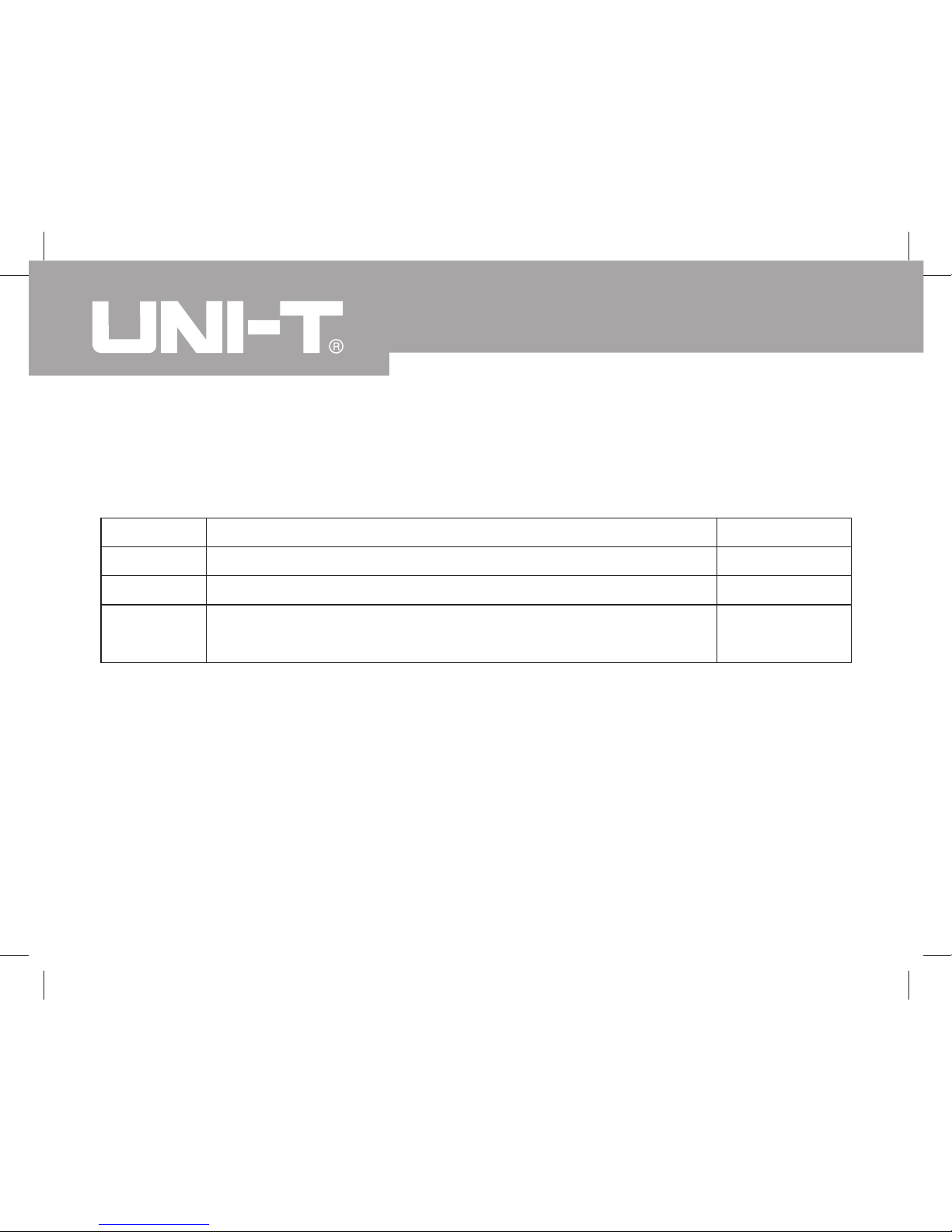

Unpacking Inspection

Open the package case and take out the Meter. Check the following items carefully

to see any missing or damaged part:

Item Description Qty

1

2

Operating Manual

Test Lead

1 piece

1 pair

In the event you find any missing or damage, please contact your dealer immediately .

9V Battery (NEDA 1604, 6F22 or 0006P)

(installed inside the Meter)

1 piece3

Model UT211: OPERATING MANUAL

4

Page 5

Safety Information

This Meter complies with the standards IEC61010: in pollution degree 2, overvoltage

category (CAT. II 600V / CAT III 300V) and double insulation.

CAT II: Local level, appliance, PORTABLE EQUIPMENT etc., with smaller transient

voltage overvoltages than CAT. III

CAT. III: Distribution level, fixed installation, with smaller transient overvoltages than

CAT. IV.

Under the influence of Radiated, Radio-Frequency Electromagnetic Field phenomenon,

the UT211 may malfunction and can self-recover after the test.

Use the Meter only as specified in this operating manual, otherwise the protection

provided by the Meter may be impaired.

In this manual, a Warning identifies conditions and actions that pose hazards to the

user, or may damage the Meter or the equipment under test.

Model UT211: OPERATING MANUAL

5

Page 6

A Note identifies the information that user should pay attention on.

International electrical symbols used on the Meter and in this Operating Manual are

explained on page 9.

Model UT211: OPERATING MANUAL

6

Page 7

Warning

Rules For Safe Operation

To avoid possible electric shock or personal injury, and to avoid possible

damage to the Meter or to the equipment under test, adhere to the following

rules:

Check for the lever is in good condition when measuring AC current.

Must center the wire (conductor) within the transformer jaw.

Before using the Meter inspect the case. Do not use the Meter if it is damaged

or the case (or part of the case) is removed. Look for cracks or missing

plastic. Pay attention to the insulation around the connectors.

Inspect the test leads for damaged insulation or exposed metal. Check the

test leads for continuity. Replace damaged test leads with identical model

number or electrical specifications before using the Meter.

Do not apply more than the rated voltage 600V, between the terminals or

between any terminal and grounding.

When the Meter working at an effective voltage over 60V in DC or 30V in AC,

special care should be taken for there is danger of electric shock.

When using the test leads, keep your fingers behind the finger guards.

Model UT211: OPERATING MANUAL

7

Page 8

Disconnect circuit power and discharge all high-voltage capacitors before

testing resistance.

Replace the battery as soon as the battery indicator appears or no display

when turning on the Meter. With a low battery, the Meter might produce

false readings that can lead to electric shock and personal injury.

Before carrying out any measurement, make sure the Meter is in good

condition after turning it on.

When servicing the Meter, use only the same model number or identical

electrical specifications replacement parts.

The internal circuit of the Meter shall not be altered at will to avoid damage

of the Meter and any accident.

Soft cloth and mild detergent should be used to clean the surface of the

Meter when servicing. No abrasive and solvent should be used to prevent

the surface of the Meter from corrosion, damage and accident.

Turn the Meter off when it is not in use and take out the battery when not

using for a long time.

Constantly check the battery as it may leak when it has been using for some

time, replace the battery as soon as leaking appears. A leaking battery will

damage the Meter.

Model UT211: OPERATING MANUAL

8

Page 9

International Electrical Symbols

Do not use or store the Meter in an environment of high temperature, humidity ,

explosive, inflammable and strong magnetic field. The performance of the

Meter may deteriorate after dampened.

Deficiency of Built-In Battery

AC or DC

Grounding

The allowed removable dangerous voltages existed between the leads.

Conforms to Standards of European Union

Warning. Refer to the Operating Manual

Double Insulated

Model UT211: OPERATING MANUAL

9

Page 10

The Meter Structure (see figure 1)

(figure 1)

1. Transformer Jaws designed to pick up the AC

current flowing through the conductor.

2. LCD Display.

3. Function Buttons

4. Input Terminals

Functional Buttons

Button Operation Performed

Hz/%

HOLD

Press to select Frequency or Duty Cycle measurement mode.

Press HOLD to enter the Hold mode in any mode

Press to turn the Meter on and off.

(POWER)

2

3

1

4

Below table indicated for information about the functional

button operations.

Model UT211: OPERATING MANUAL

10

Page 11

Display Symbols (see figure 2)

(figure 2)

Number Symbol Meaning

Hz / %

HOLD

“ “

AC

DC

1

2

3

4

5

Frequency and duty cycle measurement

Data hold is active.

Indicator for negative reading

Indicator for AC Voltage.

Indicator for DC Voltage

Model UT211: OPERATING MANUAL

11

Page 12

Number Symbol Meaning

OL

Auto

,k ,M

6

7

8

9

Indicator for overloading

The Meter is in the auto range mode in which the

Meter automatically selects the range with the best

resolution.

Ohm. The unit of resistance.

Kilohm. 1 x 103 or 1000 ohms.

Mega ohm. 1 x 106 or 1,000,000 ohms.

The battery is low.

Warning: To avoid false readings, which could lead

to possible electric shock or personal injury, replace

the battery as soon as the battery indicator appears.

V

A

Hz

%

Volts. The unit of voltage.

Indicator for AC current

Hertz. The unit of frequency.

Percent: Used for duty cycle measurements.

Model UT211: OPERATING MANUAL

12

Page 13

Measurement Operation

The LCD displays full icon while turning on the Meter, then the Meter will enter to

resistance testing mode, the LCD display “OL”.

A. DC and AC Voltage Measurement (See figure 3)

figure 3

Warning

To avoid harms to you or damages to the Meter

from electric shock, please do not attempt to

measure voltages higher than 600V although

readings may be obtained.

When measure high voltages, take extra care

to avoid electric shock.

red black

Model UT211: OPERATING MANUAL

13

Page 14

To measure DC and AC voltage, connect the Meter as follows:

1. Insert the red test lead into the V terminal and the black test lead into the COM

terminal.

2.Connect the test leads across with the object being measured. When the AC

voltage is higher than AC1.4V or DC voltage is higher than ±1.4V, the Meter will

automatically enter the voltages measurement mode.

The measured value shows on the display.

Input Impedance is around 10M .

When DC and AC voltage measurement has been completed, disconnect the

connection between the testing leads and the circuit under test, and remove the

testing leads away from the input terminals of the Meter.

Note

Model UT211: OPERATING MANUAL

14

Page 15

B. AC Current Measurement (See figure 4)

L

N

a b

figure 4

correct incorrect

To measure current, do the following:

1.Check the lever is in good condition.

2. Press the lever to open the transformer jaws.

3. Center the conductor within the transformer jaw

like figure 5

4. When the tested current is greater than AC0.4A,

the Meter will automatically enter current testing

mode.

The measured value shows on the display, it is a

effective value of sine wave (mean value response).

When current measurement has been

completed, disconnect the connection between

the conductor under test and the jaw, and

remove the conductor away from the

transformer jaw of the Meter.

Note

Model UT211: OPERATING MANUAL

15

Page 16

C. Measuring Resistance (see figure 5)

red black

figure 5

Warning

To avoid damages to the Meter or to the devices

under test, disconnect circuit power and discharge

all the high-voltage capacitors before measuring

resistance.

When the Meter working at an effective voltage

over 60V in DC or 30V in AC, special care should

be taken for there is danger of electric shock.

To measure resistance, connect the Meter as

follows:

1. Insert the red test lead into the terminal and

the black test lead into the COM terminal.

2. Connect the test leads across with the object

being measured.

The measured value shows on the display.

Model UT211: OPERATING MANUAL

16

Page 17

Note

The test leads can add 0.1 to 0.2 of error to resistance measurement. To obtain

precision readings in low-resistance measurement, it is necessary to subtract the

value measured when the testing leads are short circuited from the reading.

If reading with shorted test leads is not less than 0.5 , check for loose test leads,

incorrect function selection, or any other reasons.

The LCD displays OL indicating open-circuit or the tested resistor or the resistor

value is higher than the maximum range of the Meter.

For high-resistance measurement (>1M ), it is normal to take several seconds

to obtain a stable reading.. In order to obtain stable reading, try to use as short

as test lead possible.

When resistance measurement has been completed, disconnect the connection

between the testing leads and the circuit under test, and remove the testing leads

away from the input terminals of the Meter.

Model UT211: OPERATING MANUAL

17

Page 18

D. Frequency and Duty Cycle Measurement

Frequency Measurement

Press Hz% one time when measuring AC voltage, the LCD display will switch to

frequency measurement mode from voltage measurement mode.

Duty Cycle Measurement

Press Hz% two times when measuring AC voltage or square wave voltage, the LCD

display will switch to duty cycle measurement mode from voltage measurement mode.

E. Operation of Hold Mode

During current measurement

Press HOLD when the Meter is under current measurement mode, the measured

data will be hold. When the measuring signal is removed, the hold data remains

unchanged. Press HOLD again, the hold data will be disappeared and the Meter

automatically enters the resistance measurement mode.

Model UT211: OPERATING MANUAL

18

Page 19

During voltage, frequency and duty cycle measurement

Press HOLD when the Meter is under voltage, frequency and duty cycle measurement

mode, the measured data will be hold. When the measuring signal is removed, the

hold data will be disappeared. The Meter automatically enters resistance measurement

mode.

Resistance measurement

Press HOLD when the Meter is under resistance measurement mode, the measured

data will be hold. When the measuring signal is removed, the hold data remains

unchanged. Press HOLD again, the hold data will be disappeared.

Model UT211: OPERATING MANUAL

19

Page 20

Maximum Voltage between

any Terminals and Grounding: Refer to different range input protection

voltage.

Maximum Current Measurement: 400A.

of Transformer Jaw:

Auto Function: Auto detect

Maximum Display: Digital: 3999, 3 3/4 digits

Overload Display: OL

Range: Auto

Polarity Display: Auto

Measurement Speed: Updates 2-3 times/second.

Below 1V/m electrostatic discharge: Accuracy = specified accuracy + 5% of the

range.

Over 1V/m electrostatic discharge: Without specified accuracy.

Temperature: Operating: 0 to +40 (32 to +104 ).

Storage: -10

to +50 (14 to +122 ).

Relative Humidity: 5% @ 0 to 30 ; 50% @ 30 to 40 .

Model UT211: OPERATING MANUAL

20

General Specifications

Page 21

Altitude: Operating: 2000 m.

Storage: 10000 m.

Battery Type: One piece of 9V (NEDA1604 or 6F22 or 006P).

Battery Deficiency: Display

Dimensions (HxWxL): 210mm x 75.6mm x 30mm

Weight: Approximate 300g (battery included).

Safety/Compliances: IEC61010 CAT. II 600V / CAT III 300V overvoltage

and double insulation standard.

Certifications:

Model UT211: OPERATING MANUAL

21

Page 22

Accuracy Specifications

A. DC Voltage

Range Resolution Accuracy RemarksOverload

Protection

4V

40V

400V

1mV

10mV

100mV

(0.8%+1)

(1%+3)60V 1V

600V

Input impedance: Around 10M

Testing sensitivity: DC 1.4V

Accuracy: (a% reading + b digits) , guarantee for 1 year.

Operating temperature: 23 5 .

Relative humidity: 75%.

Model UT211: OPERATING MANUAL

22

Page 23

B. AC Voltage

Range Resolution Accuracy RemarksOverload

Protection

4V

40V

400V

1mV

10mV

100mV

(1.2%+5)

(1.5%+5)600V 1V

600V

Input impedance: Around 10M

Displays effective value of sine

wave (mean value response).

Frequency response:

50Hz~400Hz.

Testing sensitivity: AC1.4V

C. AC Current

Range Resolution Accuracy Remarks

40A

400A

10mA

100mA

>20A: (2.0%+8)

200A: (1.5%+5)

>200A: (1.5%+50)

0.4A input current

20A: (3.0%+8)

Frequency response

50Hz~60Hz.

Display effective value of sine

wave (mean value response).

Testing sensitivity: AC0.4A

Model UT211: OPERATING MANUAL

23

Page 24

Range Resolution Accuracy Overload Protection

4k

40k

400k

4M

40M

600Vp

400

1

10

100

1k

10k

0.1

(1.2%+2) + test lead short

circuit resistance value

(1.0%+2)

(1.2%+2)

(1.5%+2)

D. Resistance

Model UT211: OPERATING MANUAL

24

Page 25

E. Frequency

Range Resolution Accuracy Overload Protection

1kHz 1Hz (1%+3) 600Vp

F. Duty Cycle

Range Resolution Accuracy Overload Protection

99.9% 0.1% For reference only 600Vp

Model UT211: OPERATING MANUAL

25

Page 26

Maintenance

This section provides basic maintenance information including battery replacement

instruction.

Warning

Do not attempt to repair or service your Meter unless you are qualified to do

so and have the relevant calibration, performance test, and service information.

To avoid electrical shock or damage to the Meter, do not get water inside the case.

A. General Service

Periodically wipe the case with a damp cloth and mild detergent. Do not use

abrasives or solvents.

To clean the terminals with cotton bar with detergent, as dirt or moisture in the

terminals can affect readings.

Turn the Meter off when it is not in use.

Take out the battery when it is not using for a long time.

Do not use or store the Meter in a place of humidity, high temperature, explosive,

inflammable and strong magnetic field.

Model UT211: OPERATING MANUAL

26

Page 27

B. Replacing the Battery (See figure 6)

Warning

To avoid false readings, which could

lead to possible electric shock or

personal injury, replace the battery as

soon as the battery indicator “ ”

appears or no display when turning on

the Meter.

Make sure the transformer jaw

and the test leads are disconnected

from the circuit being tested before

opening the case bottom.

Make sure the test leads are

removed from the input terminals.

serew

battery

figure 6

Model UT211: OPERATING MANUAL

27

Page 28

** END **

This operating manual is subject to change without notice.

To replace the battery:

1. Turn the meter power off and remove all the connections from the terminals.

2. Remove the screw from the battery compartment, and separate the battery compartment

from the case bottom.

3. Remove the battery from the battery compartment.

4. Replace the battery with a new 9V battery (NEDA1604, 6F22 or 006P).

Rejoin the case bottom and battery compartment, and reinstall the screw.

Model UT211: OPERATING MANUAL

28

Page 29

Model UT211: OPERATING MANUAL

29

Page 30

Copyright 2005 Uni-Trend Group Limited.

All rights reserved.

Manufacturer:

Uni-Trend Technology (Dongguan) Limited

Dong Fang Da Dao

Bei Shan Dong Fang Industrial Development District

Hu Men Town, Dongguan City

Guang Dong Province

China

Postal Code: 523 925

Headquarters:

Uni-Trend Group Limited

Rm901, 9/F, Nanyang Plaza

57 Hung To Road

Kwun Tong

Kowloon, Hong Kong

Tel: (852) 2950 9168

Fax: (852) 2950 9303

Email: info@uni-trend.com

http://www.uni-trend.com

Model UT211: OPERATING MANUAL

30

Loading...

Loading...