Page 1

Please read the manual and “Safety Information”

and Warnings carefully before using the meter.

Warning

UT204A is a 4000-count AC/DC digital clamp meter

with stable performance, high degree of safety and

reliability. It is designed with large-scale integrated

circuits and dual integral A/D converter as its core,

overload protection for all ranges and novel structure,

which make it a superb tool for electricians. The

meter can measure AC/DC voltage, AC/DC current,

resistance, diode, continuity, capacitance, frequency

and temperature, etc.

I.Overview

II. Unpacking Inspection

III. Safety Information

Please open the package box and take instrument

out. Please check if following items are deficient or

damaged or not.

1 pc

1 pair

1 pc

1.

2. Test Probes

3. Temperature probe

4. Guarantee certificate 1 pc

Please contact your supplier instantly if any

item is deficient or damaged.

The instrument is designed and manufactured in

compliance with GB4793, IEC61010-1 and IEC

1010-2-032: Double Insulation, Overvoltage CAT

Ⅱ600V & CATⅢ 300V and Pollution Degree 2.

A Warning identifies conditions and actions that

may pose hazards to the user, or cause damage

to the Meter or equipment under test. Please pay

attention to warnings and use the meter as

specified as follows, otherwise the protection offered

by the clamp meter would be impaired.

1. Please inspect clamp meter and test leads before

use to avoid damage or abnormal use. Please

do not use the clamp meter again if test leads or

shell insulation is damaged obviously with LCD

display failure or clamp meter cannot operate

normally.

2. It is strictly prohibited to use clamp meter before

covering rear cover and battery cell to avoid

electric shock.

3

. Fingers cannot exceed the finger guard of probe

during measurement. Do not touch nude electric

wires, connector, unused input end or circuits

during measurement to avoid electric shock.

4. Function switch must be in correct position

before measurement. It is strictly prohibited to

change ranges during measurement to avoid

damage of clamp meter.

5. Do not exert more than 600V between terminal

of clamp meter and grounding to avoid electric

Shock or damage of clamp meter.

6. To operate the instrument carefully under DC 60V

or AC 30V to avoid electric shock.

7. Do not measure voltage or current which is more

than permissible input value. Be sure to place

function range switch to the maximum range

position if scope of measured value cannot be

determined. Be sure to cut off circuit power and

discharge all capacitors before measuring

of online resistance, diode or circuit. Disconnect

probe and measured circuit then remove probe

from input end of clamp meter and cut off power

after measurement.

8. Replace the battery when“ ” shows on the

LCD to ensure the measuring accuracy.To

take battery out if clamp meter has not been

used for a long time.

9. Please do not alter internal wiring of clamp meter

randomly to avoid instrument damage and safety

danger.

10.Do not store or use clamp meter in environment

of high-temperature, high-humidity, flammables,

explosives and strong current magnetic Field.

11.Please clean the instrument shell by soft cloth

and neutral detergent during maintenance. Do

not use abrasive or solvent to avoid shell

corrosion which may cause any damage to the

clamp meter or personal injury.

IV.Electrical Symbols

Double Insulated

AC

Diode

Warning prompt

AC or DC

To meet European Union standard.

Grounding

DC

Low battery Indication

Buzzing ON/OFF

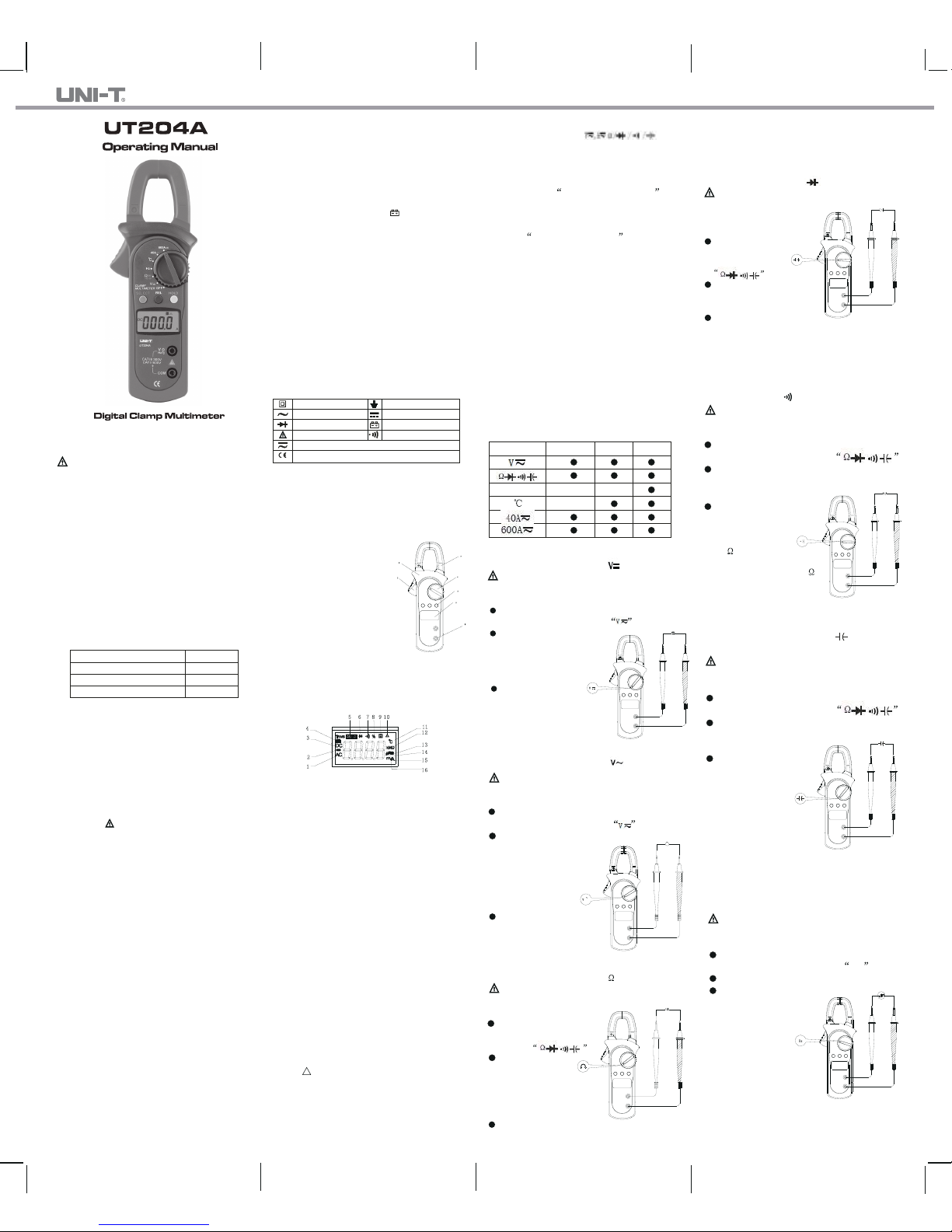

V.The Meter Structure (See Figure 1)

1. Input end;

2. LCD digit display;

3. Function key: To select basic functions;

4. Measurement function knob: White mark is

initially set value; Blue mark is validated after

selecting blue key;

5. Clamp head trigger: To press

the trigger to loosen clamp

head.

Clamp head will be

again

trigger;

6. Hand protection: It prevents

users from touching any

dangerous area.

7. Clamp head: It is a device to

convert current to voltage. Single

conductor of measured current must pass through

center of clamp head perpendicularly;

1

2

5

7

6

4

3

Figure 1

tightened

if loosening the

measure AC/DC current to

VI.Display Symbols(See Figure 2)

3

4

6

10

11

13

12

5

8 9

15

1

2

16

7

14

Figure 2

1. Indicator for AC Measurement;

2. Indicates negative polarity;

3. Indicator for DC Measurement;

4. Low Battery Indication;

5. under Auto-Ranging Mode;

6. Indicator for Diode Test;

7. Indicator for Continuity Test;

8. Indicator for Duty Cycle Test;

9. Data Hold is Active;

10. Indicator for Relative Measurement;

11. Temperature Unit (℃);

12. Resistance Unit (Ω, KΩ and MΩ);

13. Frequency Unit (Hz);

14. Capacitance Unit (nF and µF);

15. Current Unit (A);

16. Voltage Unit (mV and V)

VII. Key Functions and Automatic

Shutdown

1.HOLD

It is to maintain displayed reading by triggering.

Displayed value will be locked for constant display

by pressing the key once. It can be pressed again

to release locking status and return to common

measurement status.

2.REL

3.SELECT

To switch over between

Note: Automatic shutdown function will be

cancelled if pressing SELECT key to wake up

the meter from the sleep mode.

4.Automatic Shutdown

Clamp meter will power off automatically

(under sleeping status) to save electric energy if

function key and knob switch fail to operate

within 15 minutes during measurement.

Clamp

meter will start up automatically (under

working status) by rotating function key under

automatic shutdown status. (Please refer to Item

6 for effective key operation.)

Press down the key to use current reading as the

reference value and reset the display to "0". This

reference value is subtracted every time from

measuring results until you press the key again

to exit the mode.

Note: Automatic shutdown function will be

cancelled by pressing SELECT key for wake-up

under sleeping status.

5.Buzzer

Buzzer will beep if pressing any effective function

key under any measurement range. It will not ring

if the key is invalid. Buzzer will issue 5 warning

voices continuously about 1 minute before

automatic shutdown. It also will issue a long-term

voice before power off.

6.Key validity

Not all keys are valid under any range. As indicated

below, corresponding functions or to wake up the

meter can be achieved only when the keys are valid.

Key

Hz

SELECT

N/A N/A

N/A

REL HOLD

VIII. Measurement Instructions

1. DC voltage measurement ( ) (See Figure 3)

Warning: Clamp meter cannot be used for

conductive object of which voltage exceeds

AC/DC 600V.

To set knob.

Please place function knob to

To select key functions.

The clamp meter defaults at

DC Voltage and auto-ranging

mode. Press REL △ to

access relative mode.

To connect load.

V

T o disconnect probe

and measured circuit then

remove probe from input

end after all measurement

operations.

Figure 3

2. AC voltage measurement ( ) (See Figure 4)

Warning: Clamp meter cannot be used for

conductive article of which voltage exceeds

AC/DC 600V

.

To set knob.

Please place function knob to

To select key functions.

Press SELECT button to

select AC voltage mode,

it defaults at auto

-ranging.Press

REL△ to access

relative mode.

To connect load.

V

~

~

Figure 4

To disconnect probe and

measured circuit then

remove probe from

input end after all measurement operations.

3. Resistance measurement ( ) (See

Figure 5)

Warning: Be sure to cut off circuit power and

discharge residual charge of all capacitors

before load connection.

To set knob.

Please place function

knob to

To select key

functions.

It defaults at Ω

mode and in auto

-ranging.Press REL

△ to access relative mode.

To connect load.

Figure 5

To gain excellent measured result by separating

element from circuit.

To disconnect probe and measured circuit then

remove probe from input end after all

measurement operations.

4. Diode measurement ( ) (See Figure 6)

Warning: Be sure to cut off circuit power and

discharge residual charge

of all capacitors before

load connection.

To set knob.

Please place

function knob to

To select functions.

To select diode detection

by pressing SELECT key;

To connect load.

.

Figure 6

To gain excellent measured result by separating

element from circuit.

To disconnect probe and measured circuit then

remove probe from input end after all

measurement operations.

5. Continuity Test ( )

(See Figure 7)

Warning: Be sure to cut off circuit power and

discharge residual charge of all capacitors

before load connection.

To set knob.

Please place function knob to

To select functions.

To select conductance detection by pressing

SELECT key;

To connect load.

.

Figure 7

Buzzer will ring if

measured resistance

is less than

10

. It can ring or

not ring if measured

resistance exceeds 10

.

To disconnect probe and

measured circuit then

remove probe from input

end after all measurement operations.

6. Capacitance measurement ( ) (See

Figure 8)

Warning: Be sure to cut off circuit power and

discharge residual charge of all capacitors

before load connection.

To set knob.

Please place function knob to

To select functions.

To select capacitance detection by pressing

SELECT key;

To connect load.

Figure 8

Measurement notice:

1)Be sure to reset by

pressing REL key

before measurement.

2)Instrument reading will

delay for about 30

seconds normally when

measuring large capacitance.

To disconnect probe and measured circuit then

remove probe from input end after all

measurement operations.

7.Frequency measurement (Hz) (See Figure 9)

Warning: Clamp meter cannot be used for

conductive objecte of which voltage exceeds

AC/DC 600V.

To set knob.

Please place function knob to Hz

To select key functions.

To connect load.

Hz

Figure 9

To disconnect probe and

measured circuit then

remove probe from

input end after all

measurement

operations.

Operating Manual

Page 2

P/N:110401104251X

8.Temperature measurement ( ) (See

Figure 10)

To set knob.

To place function knob to

Figure 10

To select functions.

To connect load.

1) LCD will display OL if failing to insert

temperature sensor. Clamp meter will display

current indoor temperature after user inserting

temperature sensor.

2) The protection for the temperature range is

1KΩ resistor(R59). any conductor with voltage

present cannot be inserted into input jack to

avoid.

A

9. DC current measurement ( ) (See

Figure 11)

To set knob.

To place function knob to 40A or 600A

To select functions.

The meter defaults at DC Current Mode.

To connect load.

Figure 11

Please do not loosen trigger suddenly. As a

sensitive device, Hall element will be sensitive to

heat and mechanical stress to different extents

in addition to magnetic sensitivity. Collision will

cause short-term reading variation. Please open

the clamp head by pressing trigger then fetch

measured conductor by clamp head and loosen

trigger slowly until it is closed completely. Please

check if measured conductor is in the middle of

clamp head or not. Additional error may be caused

if failing to place it in the middle of clamp head.

Clamp meter can measure a current conductor

once and measurement reading error may be

caused if measuring two or more current

conductors at the same time.

10. AC current measurement ( ) (See

Figure 12)

To set knob.

To place function knob to 40A

or 600A

To select functions.

To press SELECT key for AC current

measurement;

To connect load.

Figure 12

Please do not loosen trigger suddenly. As a

sensitive device, Hall element will be sensitive to

heat and mechanical stress to different extents

except magnetic sensitivity. Collision will cause

short-term reading variation.Please open the

clamp head by pressing trigger then fetch meas

-ured conductor by clamp head and loosen trigger

slowly until it is closed completely. Please check

if measured conductor is in the middle of clamp

head or not. Additional error may be caused if

failing to place it in the

middle of clamp head.

Clamp meter can measure

a current conductor

IX. Technical Indicators

1.General specification

LCD display: 4000 counts;

Polarity display: Automatic display;

Overload display: To display OL or -OL ,

Low Battery Indication: shows as battery

voltage is less than required working voltage.

Sampling rate: 3 times/second;

Sensor category: Hall affect sensor for DC/AC

measurement;

Error of testing position: 1.0% of additional

reading error may be caused if failing to place

measured source to center of clamp head during

current measurement;

Shock-resistant: pass 1m drop test;

Max.clamp Opening : 28mm diameter;

Max. Tested Conductor: 26mm diameter;

Influence of electromagnetic field: Device used

near electromagnetic field may display unstable

or incorrect reading;

2.Environment limitation

Indoor use

The

altitude height: 2,000m

Safety rules: ICE 1010-1 CAT.II 600V

CAT.III300V

Pollution degree: 2

Operation temperature & humidity: 0 to 30

(not more than 80%R.H.)

30 to 40 (not more than 75%R.H.)

40 to 50 (not more than 45%R.H.)

Storage temperature & humidity: -20 to +60

(not more than 80%R.H.)

3.Electrical specification

Accuracy:

Calibration period for 1 year

Ambient temperature: 23 5

Ambient humidity: Not more than 80% R.H.

Temperature coefficient: 0.1*precision/1

(1)DC voltage ( )

Range

400.0mV

4.000V

40.00V

400.0V

600V

Resolution

0.1mV

1mV

10mV

100mV

1V

Accuracy

(0.8%+3)

(0.8%+1)

(1%+3)

Overload protection

600V DC/AC

Input impedance: 10M Ω

(2)AC voltage ( )

Range

Resolution

Accuracy

Overload protection

4.000V

40.00V

400.0V

600V

1mV

10mV

100mV

1V

(1%+5)

(1.2%+5)

600V DC/AC

Input impedance: 10M //not less than 100pF

Frequency response: 40Hz~400Hz

AC conversion type:

AVG response, RMS value for sinewave input.

(3) Resistance ( )

Range

400.0

4.000K

40.00K

400.0K

4.000M

40.00M

Resolution

100m

1

10

100

1K

10K

Accuracy

(1.2%+2)

(1%+2)

(1.2%+2)

(1.5%+2)

Overload protection

600Vp

(4) Diode test ( )

Range

Resolution

Accuracy

Overload protection

1mV

To display

positive pressure

drop. (Open circuit

voltage is about

600Vp

(5) Continuity test ( )

Range

Resolution

Accuracy

Overload protection

600Vp

Buzzer will ring if

equal to

10 .

(Open circuit

voltage is about

0.1

Note: Buzzer will ring or not ring if measured

resistance exceeds 10

approximate

1.48V.)

it is less than or

0.45V.)

(6) Capacitance ( )

Range

Resolution

Accuracy

Overload protection

600Vp

4nF

40nF

400nF

4µF

40µF

µ

F

0.001nF

0.01nF

0.1nF

0.001µF

0.01µF

0.1µF

(4.0%+3)

(5.0%+10)

To measure under RELATIVE measurement mode;

(7) Frequency (Hz)

Range

10Hz

100Hz

1kHz

10kHz

100kHz

1MHz

10MHz

Resolution

0.001Hz

0.01Hz

0.1Hz

1Hz

10Hz

100Hz

1kHz

(Reading is only for reference.)

Accuracy

Overload protection

(0.5%+3)

600Vp

Sensitivity: 300mV rms if 100kHz;

600mV rms if 100kHz;

800mV rms if 1MHz;

(8) Temperature ( )

Range

-40 ~

1,000

Accuracy

Overload protection

-40 ~0

0 ~400

400 ~1,000

(8%+5)

(2.5%+3)

(3.0%+3)

Plug-in resistance

of 1K

Note:

1) There is no voltage protection for temperature

ranges. It is not allowed to insert electrified

conductor into jack to avoid burnout of 1K

resistance;

100

2) K type thermocouple (Ni-Cr~Ni-Si) is only

suitable to temperature measurement of less

than 230 . Rod type temperature sensor shall

be used for temperature measurement of more

than 230

.

(9) DC current ( )

Range

40.00A

600A

0.01A

1A

Accuracy

(2%+5)

Overload protection

600A DC/AC

Note:

Current measurement function must be operated

between

0 and 40 . Current direction is

from bottom to top for positive reading during

DC current measurement. (As shown in Figure

11, panel is on the top and bottom cover is on the

bottom.) Please do not loosen the trigger

suddenly after pressing. As a sensitive device,

Hall element will be sensitive to heat and

mechanical stress to different extents addition to

magnetic sensitivity. Collision will cause short

-term reading variation.

More correct

by following operation methods:

Press the trigger and open clamp head to

fetch measured conductor by clamp head then

loosen trigger slowly until clamp head is closed

completely. Please check if measured conductor

is in the middle of clamp head or not. Additional

reading error of 1.0% may be caused if failing

to place it in the middle of clamp head;

To remove clamp head away from the current

conductor;

To press REL key for display resetting;

To repeat step

;

To gain more correct reading by above

measurement steps;

Resolution

measurement can be guaranteed

(10) AC current ( )

Range

40.00A

600A

0.01A

1A

Accuracy

Overload

protection

600A DC/AC

Resolution

(2.5%+8)

(2.5%+5)

Frequency

response

50Hz~60Hz

Note:

Current measurement function must be fulfilled

between 0 and 40 . Frequency response:

50Hz~60Hz;

Instable or incorrect inductive reading with less

than 10 words may be displayed in AC current

gear and it will not influence measurement result.

Please do not loosen trigger suddenly. As a

sensitive device, Hall element will be sensitive to

heat and mechanical stress to different extents

in addition to magnetic sensitivity. Collision will

cause short-term reading variation.

AC conversion type:

AVG response; RMS value for sinewave input.

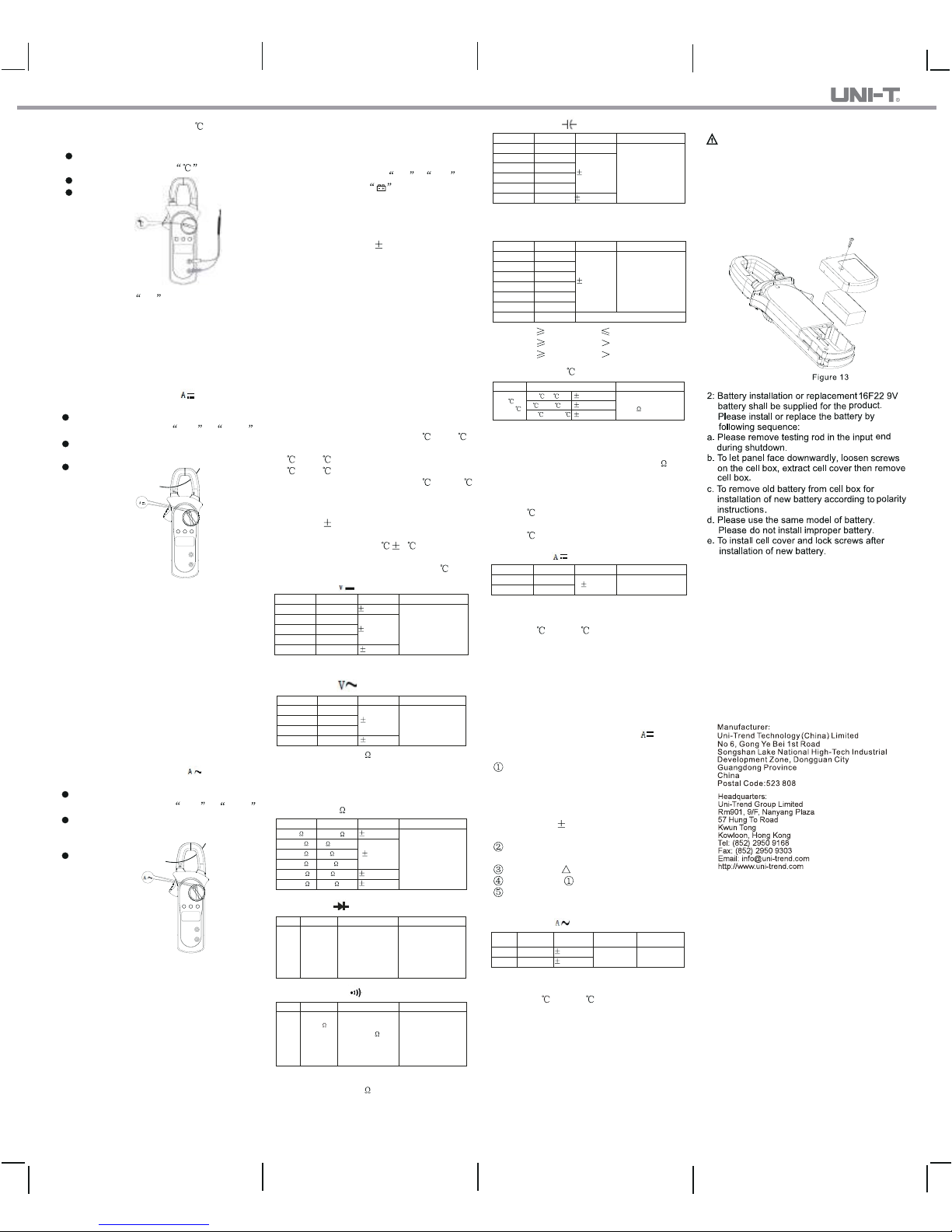

X. Maintenance(See Figure 13)

Warning: Please remove testing rod before

opening bottom cover to avoid electric shock.

1. General maintenance

A. The clamp meter must be repaired and served

by qualified professional repair personnel or

designated repair department.

B. To clean the shell periodically by dry cloth.

However, it is not allowed to use detergent

with abrasive or solvent .

once and measurement reading error may be

caused if measuring two or more current cond

-uctors at the same time.

(a% readings + b digits)

Loading...

Loading...