Page 1

TT':--

Instructions

UNION

BRANCHES

IJostoii.

Muss.

T^iin,

Mass.

Havcrhili.

New

Utiea.

Rochester,

Newark,

Ualtiniuro,

Detroit,

Union

Union

Union

Union

Union

Union

Compagnic

Cotnpagnie

Mass.

York.

N.

N.

Y.

X.

SERVICE

N.

J.

Md.

Mich.

Special

Special

Special

Special

Special

Special

des

dcs

for

SPECIAL

General

AND

Y.

Y.

REPRESENTATIVES,

Machine

Corporation

Machine

Company

Machine

Company

Machine

Corporation

Machine

Corporation

Macliine

Coi^oration

Machines U nion

Machines

CATALOG

Installing,

with

List

Picoetta

Class

MACHINE

Olllce

and

Factory:

CHICAGO.

SERVICE

.Johnson

Buffalo,

Troy.

N.

Philadelphia,

Reading,

Cincinnati,

Cleveland,

Knoxville,

-Atlanta,

Milwaukee,

BRANCHES—FOREIGN

of

America.

of

Canada,

Catiada,

of

America.

of

America.

of

America.

do

France.

de

France.

Ltd.

Ltd.

Union

of

Special

Special

No.

Operating

of

Parts

Machines

G79000

400

North

ILLINOIS

STATIONS,

City.

N.

Y.

N.

Y.

Y.

Pa.

Pa.

Ohio

Ohio

Tenn.

Ga.

Wis.

60

COMPANY

Franklin

Street

UNITED

UNITED

and

Adjusting

STATES

Toledo,

Ohio

Minneapolis,

St.

Louis,

Kansas

City,

I,OS

Angeles,

San

Francisco.

STATES

Dallas.

Texas

New

Orleans,

Seattle,

Wash.

Belgium,

Brussels

Canada,

Toronto

Canada,

Montreal

Denmark.

England

Leicester

England.

France,

Paris

France,

Lyons

Miun.

Mo.

Mo.

Cal.

Cal.

La.

Copenhagen

London

'

A • ■ ,jl

a!

t

"i

UNION

Berlin

Chemnitz

Foreign

Argentine

Buenos

Austria

Vienna

Australia

Melbourne

Sydney

Brazil

Rio

Santos

Sao

China

Hong

Shanghai

Cuba

Havana

Santiago

Dutch

Soerabaya,

Ecuador

Guayaquil

SPECIAL

BRANCHES

Distributors

Republic

Aires

de

Janeiro

Paulo

Kong

East

Indies

Java

Copyright.

Genera!

AND

MASCHINENFABRIK,

Office

and

102S,

Factory:

SERVICE

Koln

Ebingcn

and

England

French

Hawaiian

India

Ireland

Italy

Japan

Mauritius

Mexico

Union

STUTTGART.

Service

Leeds

Manchester

Norwich

Indo

China

Saigon

Islands

Honolulu

Bombay

Calcutta

Belfast

Milan

Osaka

Tokyo

Port

Louis

Mexico

City

Special

Machine

STATIONS,

Stations

Co..

GERMANY

are

Printed

G.

GERMANY

Erfurt

Franhfurt

Found

New

Zealand

Aurklniid

Christchurch

Wellington

Pbillpaine

Manila

Portugal

Oporto

Scotland

Glasgow

Dundee

Slam

Bangkok

South

Africa

Jolianncsburg

Durban

Capetown

Port

Spain

Barcelona

Uruguay

Montevideo

in

U.

S.

A.

m.

am

Islanda

Elizabeth

b.

Main

in:

H.

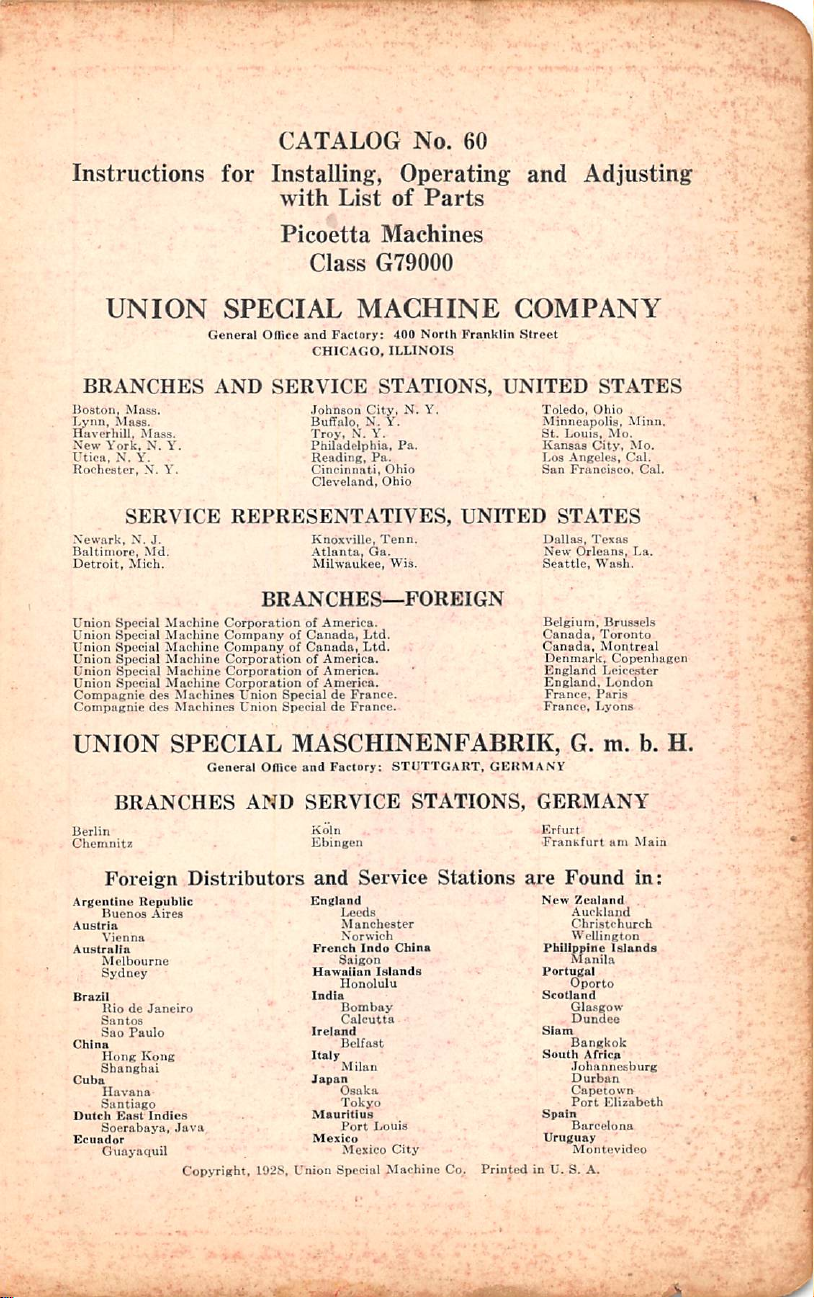

Page 2

Installation

of

Picoetta

Machine

Page 3

Style

CLASS

G79000

G79000—PICOETTA

A

For

joining

effect,

left

needle.

makes 3 stitches

and

two

pieces

repeats,

MACHINES

to

plain

of

fabric;

fagotting

right, 3 stitches

feed

both

sides

to

of

Style

Style

Style

Style

G79000B

G79000

G79000

G79000

When

and

similar

lineal

stitching

per

hour

For

C

For

D

For

E

For

picoetta

edging

articles,

per

is

easily

edging

dresses,

lace

effect,

to

left

and

edging

dresses,

lace

effect,

to

left

and

edging

arched

lace

stitches

left

of

needle.

edging

pointed

3

stitches

to

left

of

woven

lingerie

and

makes 3 stitches

repeats,

woven

lingerie

and

makes 4 stitches

repeats,

knitted

effect,

to

left

makes 4 stitches

and

knitted

lace

effect,

to

left

and

needle.

PRODUCTIONS

ladies'

the

machines

collars,

will

hour. A production

obtained.

fabrics;

similar

plain

feed

fabrics;

similar

plain

feed

and

other

handkerchiefs,

articles,

to

right, 3 stitches

to

left

of

handkerchiefs,

articles,

to

right, 4 stitches

to

left

of

elastic

to

repeats,

and

makes 3 stitches

cuffs,

complete

differential

other

repeats,

elastic

differential

brassieres,

50

of 3 dozen

to

to

55

handkerchiefs

pointed

needle.

arched

needle.

fabrics;

right,

feed

A

to

fabrics;

right,

feed

lingerie

yards

of

INSTALLING

READY

thoroughly

inspected.

machine.

tion

The

tion.

TO

OPERATE

run

This

Packed

ready

for

service.

illustration

in,

accurately

is

evidenced

by

skilled

on

page 2 shows

Before

adjusted,

by

hands,

shipment,

tested

the

test

sample

they

arrive

the

general

each

and

at

plan

machine

carefully

left

their

destina

of

installa

in

is

the

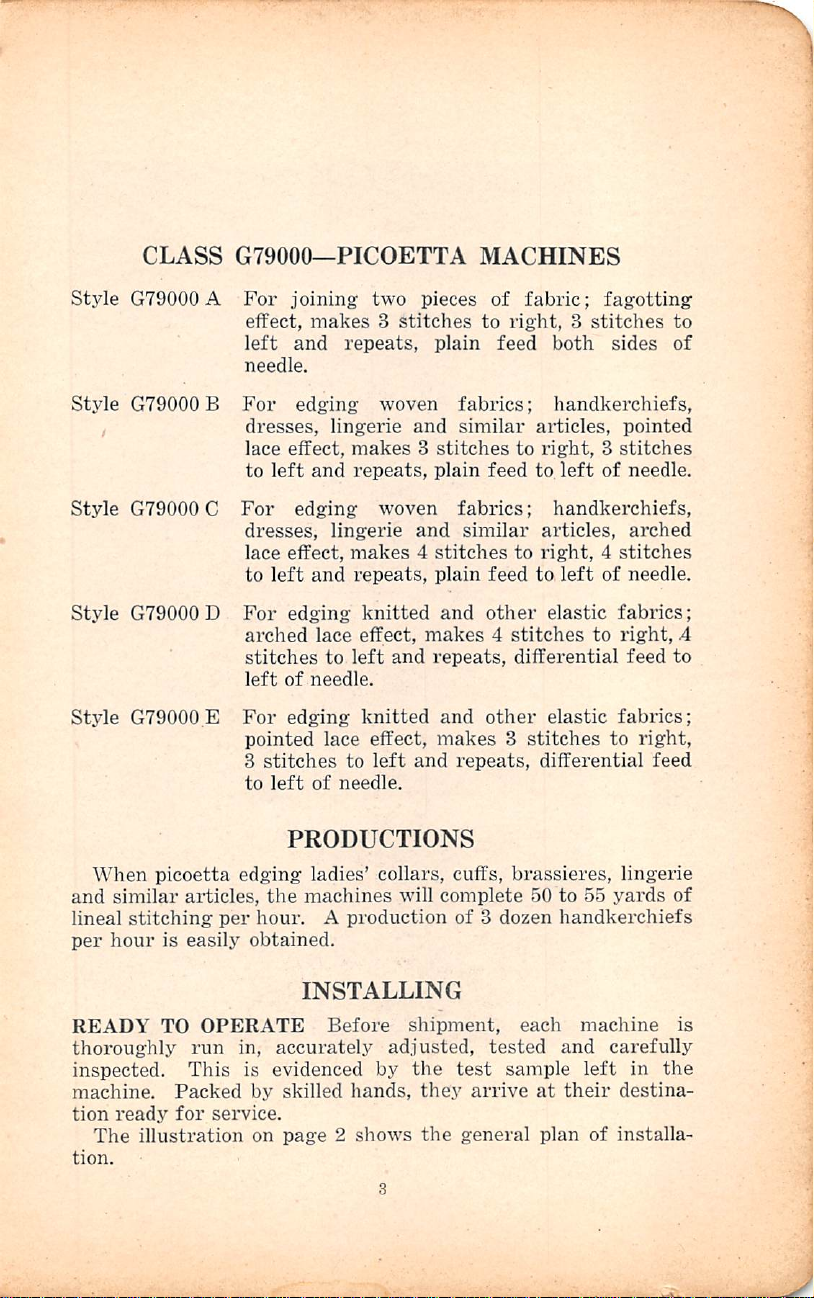

Page 4

Style

G79000

Style

G79000

A

B

Style

G79000

Style

G79000

Style

G79000

E

C

D

Photographic

U'

• •- 'J

5*^, i r f I'i--'jif

reproductions

Picoetta

Class

of

Machines

G79000

'

slEti

stitching

accomplished

4

if

]

i

on

Page 5

TREADLES

ter

is

directly

The

treadle

of

the

transmitter

Installing

The

transmitter

under

for

the

needle.

lifting

treadle.

the

(Cont'd)

treadle

presser

is

foot

so

located

is

located

that

its

to

the

cen

right

PULLEYS

line

shaft,

11, 12,

BELTS

means

shaft

The

from

SPEED

stitches

STARTING

machine

direction

turns

OILING

quently

will

systematic

should

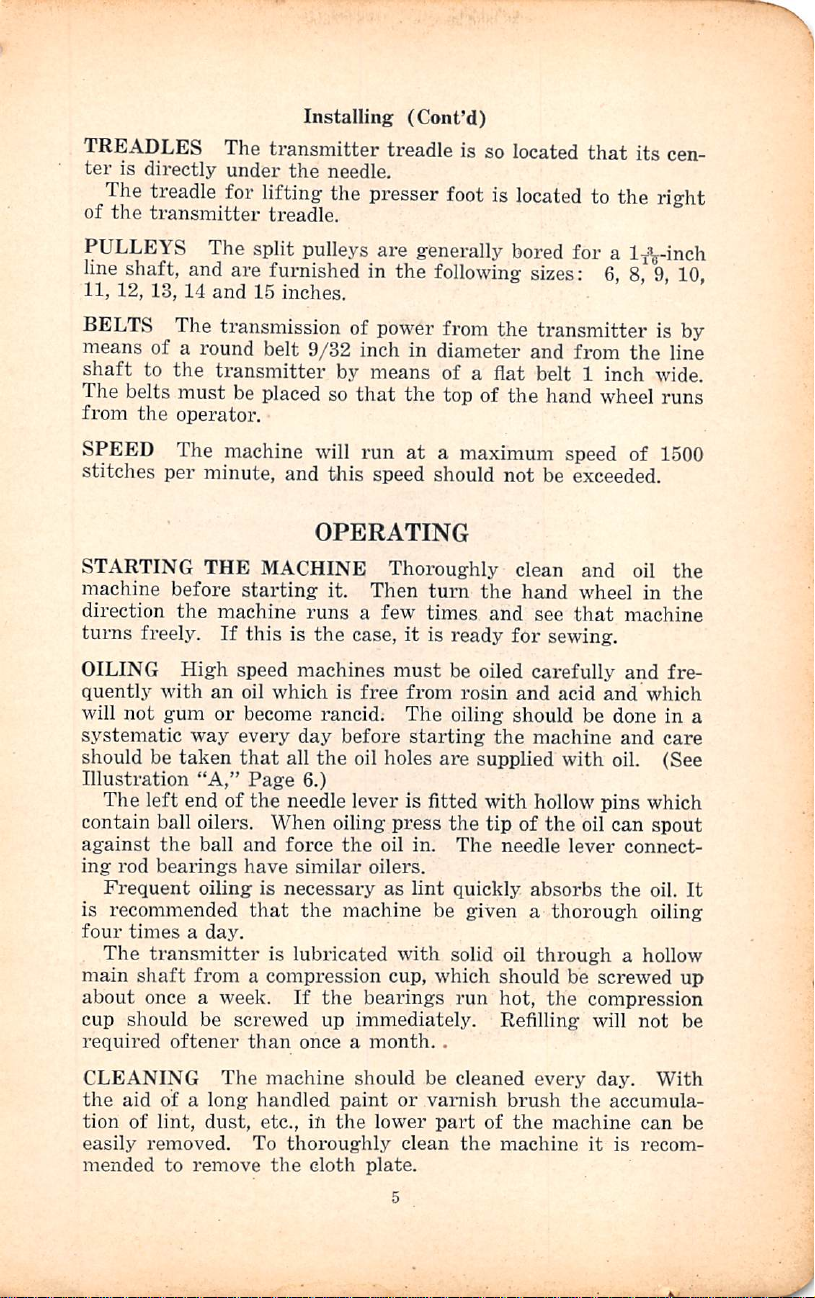

Illustration

contain

against

ing

is

four

main

about

cup

required

to

belts

the

freely.

not

The

left

rod

Frequent

recommended

times a day.

The

shaft

once a week.

should

The

and

13,

14

The

of a round

the

must

operator.

The

per

minute,

THE

before

the

High

with

gum

way

be

taken

"A,"

end

ball

oilers.

the

ball

bearings

oiling

transmitter

from a compression

be

oftener

split

are

and

pulleys

furnished

15

inches.

transmission of

belt

9/32

inch

transmitter

be

placed

machine

MACHINE

starting

machine

If

this

speed

an

oil

which

or

become

every

that

Page

of

the

When

and

have

is

that

is

screwed

than

by

so

that

will

run

and

this

OPERATING

it.

runs a few

is

the

case,

machines

is

free

rancid.

day

before

all

the

oil

6.)

needle

lever

oiling

force

the

similar

necessary

the

machine

lubricated

If

the

up

immediately.

once a month.

are

generally

in

the

following

power

means

from

in

diameter

of a fl

the

top

at a maximum

speed

Then

oilers.

bearings

should

Thoroughly

turn

times

it

is

ready

must

be

from

rosin

The

oiling

starting

holes

are

supplied

is fitted

press

the

oil

in.

The

as

lint

quickly

be

given a thorough

with

solid

cup,

which

run

.

bored

for a ItVinch

sizes:

the

transmitter

and

from

at

belt 1 inch

of

the

hand

speed

not

be

exceeded.

clean

the

and

for

oiled

and

should

the

with

tip

of

needle

oil

should

hot,

Refilling

and

hand

wheel

see

that

sewing.

carefully

acid

be

machine

with

hollow

the

oil

lever

absorbs

through a hollow

be

the

compression

6,

8,

9,

is

the

line

wide.

wheel

pins

screwed

will

of

oil

in

machine

and

and

which

done

and

oil.

which

can

connect

the

not

runs

1500

fre

in

care

(See

spout

oil.

oiling

10.

by

the

the

a

It

up

be

CLEANING

the

aid

of a long

tion

of

lint,

easily

mended

removed.

to

remove

The

dust,

To

machine

handled

etc.,

in

thoroughly

the

cloth

should

paint

the

lower

plate.

be

or

vaniish

part

clean

cleaned

brush

of

the

the

machine

every

the

machine

day.

accumula

it

is

With

can

recom

be

Page 6

SETTING

are

designated

groove

needle

of

the

itself

is

into

the

The

of

the

eye

of

will

cause

THE

of

which

must

be

needle

size

thread,

the

is

in

line

needle

of

the

needle.

frequent

NEEDLE

Type

No.

the

longer

set

so

that

directly

with

the

bar

as

it

needle

that

is,

If

breakage.

Operating

The

needles

8021.

one

enters

the

long

in

front

stitching.

will

go,

and

must

be

the

thread

the

needle

(Cont'd)

for

They

are

the

groove,

of

the

Insert

tighten

in

proportion

must

pass

is

too

this

class

made

eye

of

the

which

operator,

the

needle

the

needle

to

freely

small

for

of

machine

with a double

needle.

enters

and

clamp

the

through

the

The

the

eye

the

eye

as

far

nut.

diameter

the

thread

up

it

f7

is

15 ' 15 a „

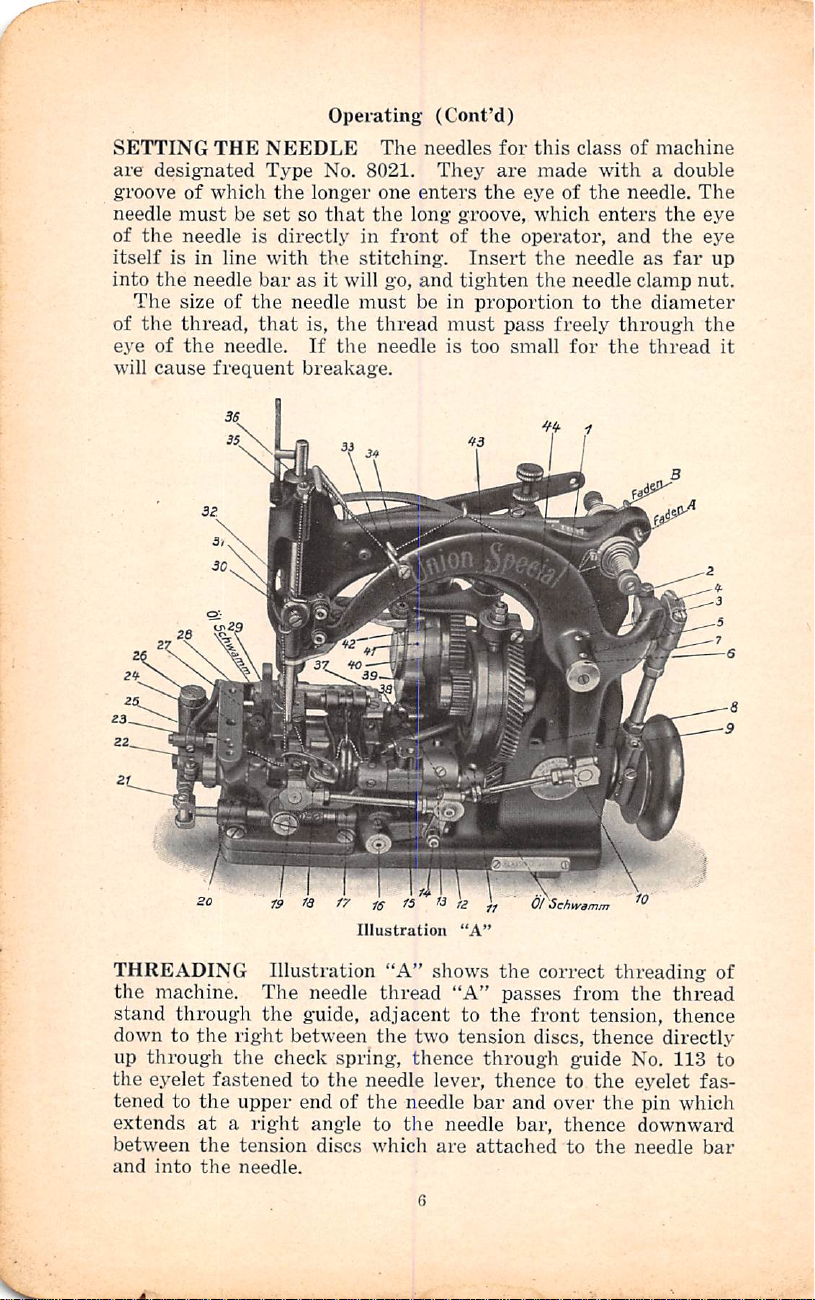

Illustration

"A"

shows

thread

adjacent

the

two

thence

needle

the

to

which

lever,

needle

the

are

"A"

the

"A"

passes

to

the

tension

through

thence

bar

and

needle

attached

01

Sehtyamm

correct

from

front

discs,

guide

to

over

bar,

thence

to

threading

tension,

thence

the

the

the

THREADING

the

machine.

stand

down

up

the

tened

extends

between

and

through

to

the

through

eyelet

fastened

to

the

at a right

the

into

the

»

fa

Illustration

The

needle

the

guide,

right

between

the

check

upper

tension

needle.

spring,

to

the

end

of

angle

discs

the

thread

thence

directly

No.

113

eyelet

needle

fas

pin

which

downward

of

to

bar

Page 7

The

looper

the

guide

sion

discs,

located

the

58,

No.

hang

in

guiding

thence

103

and

loosely

thread

adjacent

thence

the

through

rear

tube,

into

the

from

downward

of

thence

the

the

Operating

"B"

passes

to

the

rear

the

frame

between

two

looper.

end

(Cont'd)

from

tension,

through

at

the right

the

openings

Leave

of

the

about

looper.

the

the

of

two

the

thread

thence

guide

side,

springs

take-up

three

stand

between

No.

40

thence

Nos.

thread

inches

of

through

the

ten

which

is

through

57

and

eyelet

thread

IMPORTANT

properly,

lowing

Should

that

CAUTION

machine

a

few

machine

may

NEEDLE

then

its

bar

the

(use

When

needle

ment

eccentric

to

the

Again

reaches

yet

reasons

(1)

See

the

may

(2)

Examine

position

(3)

See

perfect.

(4)

If

(5)

See

needle.

(6)

Clean

the

some

always

times

until

result.

turn

farthest

to

its

lowest

point

looper

the

with a distance

is

accomplished

fork

desired

tura

its

HINTS

seems

may

if

the

different

have

the

and

if

the

the

needle

if

the

and

machine

part

of

the

Whenever

tuiii

to

make

this

AND

LOOPER

hand

wheel

position

point

of

looper

adjusting

looper

No.

position.

the

machine

lowest

Should

to

be

in

good

be

the

cause:

machine

tension

accumulated

needle

properly

needle

is

thread

oil

the

still

is

devices

and

is

perfectly

damaged

passes

machine

fail

to

machine

ADJUSTING

any

changes

the

hand

sure

there

test

has

been

Insert a new

in

operative

to

the

right

of

travel.

to

the

center

gauge

moves

79090,

point

to

of

.005

by

loosening

after

in

of

No.

the

inch

operative

travel

the

machine

condition,

threaded

and

between

see

if

seated

needs

in

straight

or

bent

freely

carefully.

operate

adjusting.

have

wheel

in

is

no

made,

direction

which

At

this

of

needle

21225-'i4)-

left,

its

between

the

which

the

direction

and

farthest

fail

any

one

correctly,

remove

the

it

is

the

install a new

through

properly,

the

bind.

as

needle

also

time

all

tension

set

in

needle

and

if

the

it

been

made

operative

Do

otherwise,

in

until

looper

brings

the

distance

should

point

should

them.

set

screws

looper

can

until

position

to

function

of

the

fol

especially

lint

discs.

the

bar.

the

eye

is

probable

direction

not

needle

the

be

pass

This

in

be

the

at

which

correct

point

needle.

of

the

in

the

run

the

damage

bar,

reaches

needle

from

inch

the

adjust

looper

moved

needle

to

the

is

Page 8

left.

As

moves

the

upper

the

to

left,

edge

needle

the

point

of

eye

moves

Adjusting

upwardly

of

the

looper

in

needle.

(Cont'd)

from

should

this

point,

pass

and

1/64

inch

looper

above

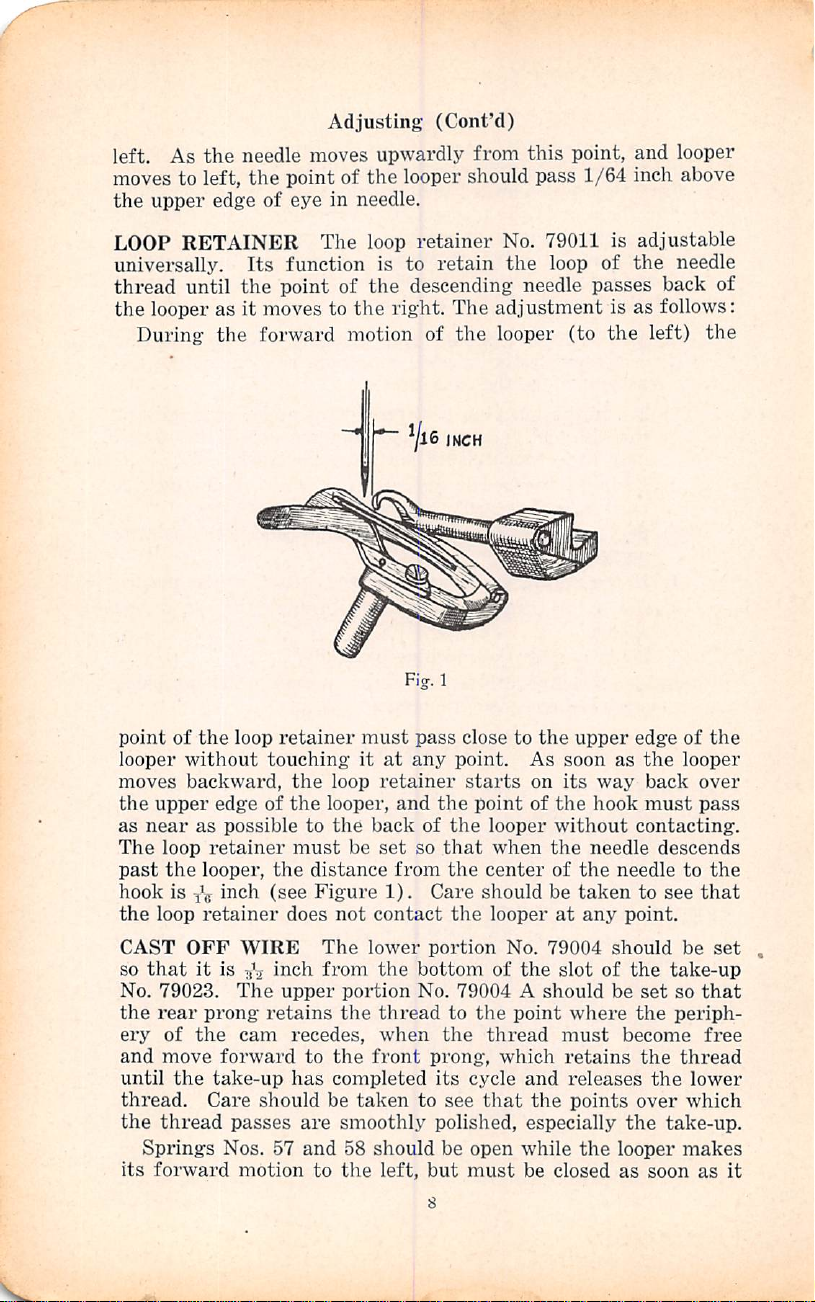

LOOP

universally.

thread

the

point

looper

moves

the

as

The

past

hook

the

CAST

so

No.

the

ery

and

until

thread.

the

its

RETAINER

until

looper

During

of

the

without

backward,

upper

near

as

loop

retainer

the

looper,

is

loop

retainer

OFF

that

it

79023.

rear

prong

of

the

move

the

take-up

Care

thread

Springs

forward

Its

the

as

it

moves

the

forward

loop

touching

edge

of

possible

inch

(see

WIRE

is

The

retains

cam

forward

should

passes

Nos.

motion

The

function

point

of

to

the

motion

retainer

it

the

loop

the

looper,

to

the

must

be

the

distance

Figure

does

not

The

inch

from

upper

57

portion

the

recedes,

to

the

has

completed

be

taken

are

smoothly

and

58

to

the

loop

retainer

is

to

retain

the

descending

right.

of

Fig.

1

must

pass

at

any

retainer

and

the

back

of

set

so

that

from

the

1).

Care

contact

lower

portion

the

bottom

No.

thread

when

front

prong,

to

should

left,

but

the

its

see

polished,

be

No.

79011

the

loop

needle

The

adjustment

the

looper

close

to

point.

starts

the

the

79004 A should

to

cycle

must

point

looper

when

center

should

looper

No.

of

the

the

point

thread

which

that

open

while

be

As

on

of

and

the

especially

passes

(to

the

upper

soon

its

the

without

the

needle

of

the

be

taken

at

any

79004

slot

where

must

retains

releases

points

the

closed

is

adjustable

of

the

back

is

as

follows:

the

left)

edge

as

the

way

back

hook

must

contacting.

descends

needle

to

see

point.

should

of

the

be

set

the

become

the

the

over

the

take-up.

looper

as

soon

needle

of

the

of

the

looper

over

pass

to

the

that

be

set

take-up

so

that

periph

free

thread

lower

which

makes

as

it

Page 9

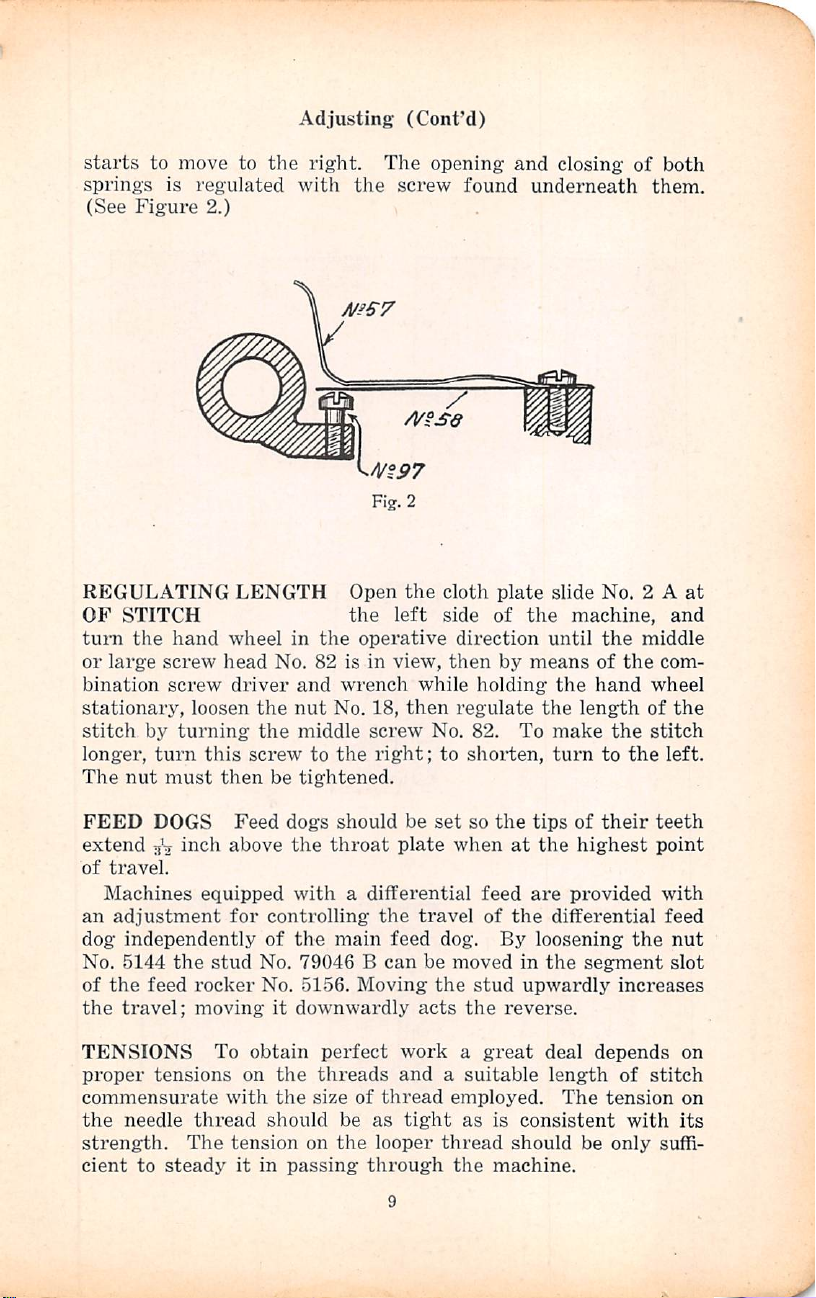

Adjusting

(Cont'd)

starts

springs

(See

to

move

is

regulated

Figure

REGULATING

OF

STITCH

turn

the

hand

or

large

screw

bination

stationary,

stitch

longer,

The

by

nut

screw

loosen

turning

turn

must

to

2.)

LENGTH

wheel

head

driver

this

then

the

with

in

No.

and

the

nut

the

middle

screw

be

tightened.

right.

the

A/iS7

m97

Open

the

the

operative

82

is

in

wrench

No.

18,

screw

to

the

right;

The

screw

A/^sa

the

left

view,

while

then

opening

found

clotli

plate

side

of

direction

then

by

holding

regulate

No.

82.

to

shorten,

and

closing

underneath

slide

No. 2 A

the

machine,

until

the

means

To

the

the

make

turn

of

hand

length

to

of

the

the

the

both

them.

at

and

middle

com

wheel

of

the

stitch

left.

FEED

extend

of

an

dog

No.

of

the

TENSIONS

proper

commensurate

the

strength.

cient

DOGS

i^ch

travel.

Machines

adjustment

equipped

independently

5144

the

stud

the

feed

rocker

travel;

moving

To

tensions

needle

thread

The

to

steady

Feed

dogs

above

the

with a differential

for

controlling

of

the

No.

79046 B can

No.

it

downwardly

obtain

on

the

with

the

should

tension

it

in

passing

should

throat

main

5156.

Moving

perfect

threads

size

of

be

on

the

be

set

so

plate

when

feed

the

travel

feed

be

acts

dog.

moved

the

the

of

stud

work a great

and a suitable

thread

as

looper

through

employed.

tight

thread

the

as

the

tips

of

at

the

are

provided

the

differential

By

loosening

in

the

upwardly

reverse.

deal

length

The

is

consistent

should

machine.

their

highest

segment

increases

depends

of

tension

be

only

teeth

point

with

feed

the

stitch

with

suffi

nut

slot

on

on

its

Page 10

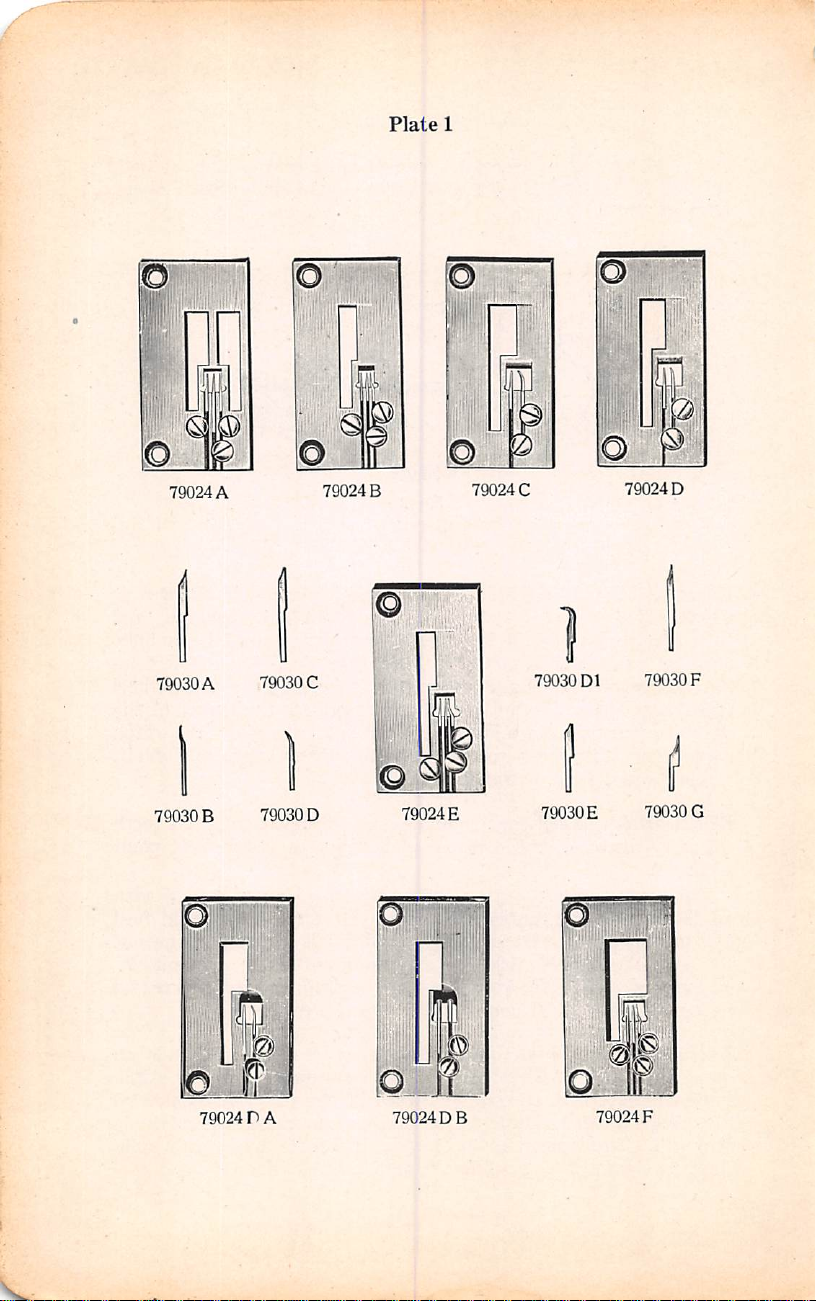

Plate

1

79024

79030A

79030B

D1

©

79024D

79030F

79030G

©

A

79030C

79030D

79024B

79024E

79024C

79030

79030E

iJL

79024 r A

79024 D B

79024F

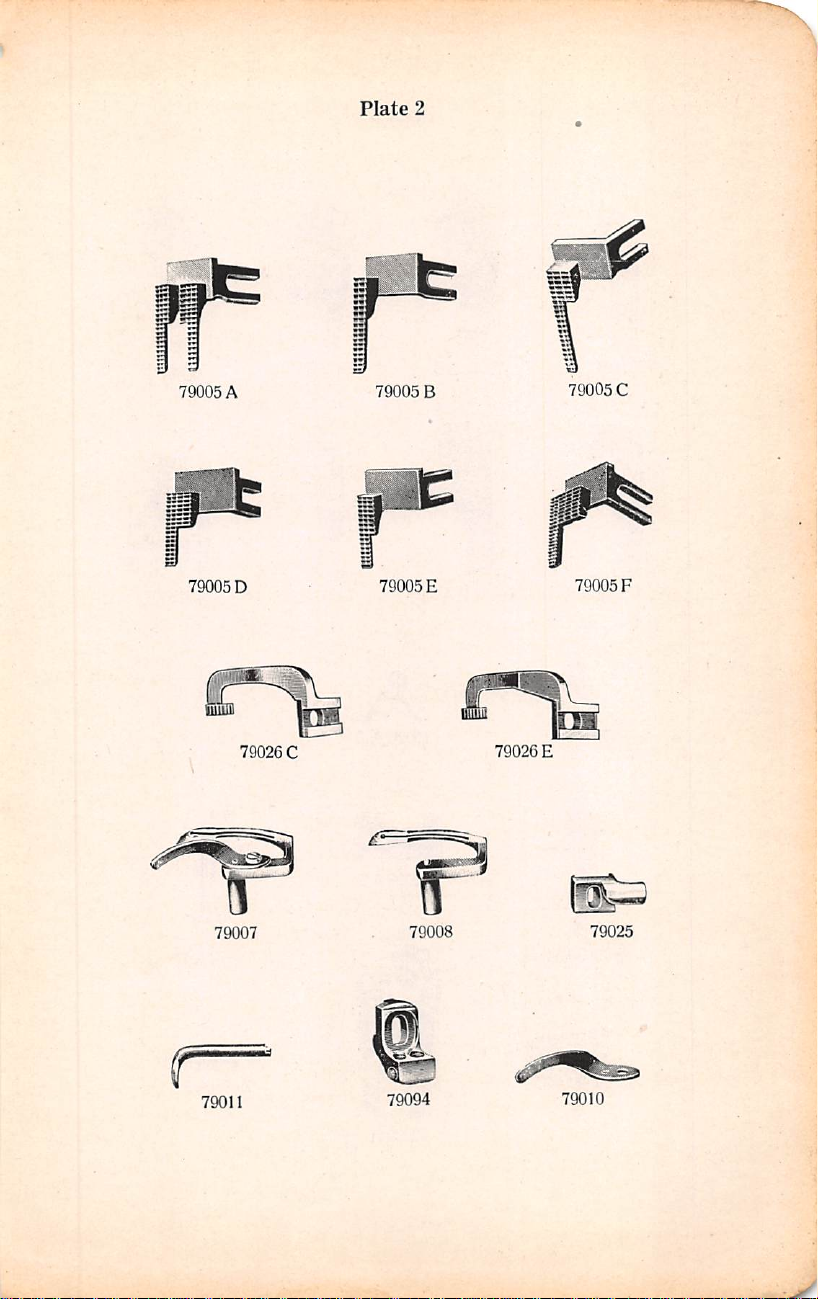

Page 11

Plate

2

79005

79005D

A

79007

79026C

79005

79005E

79008

B

79026E

79005C

79005F

79025

79011

79094

79010

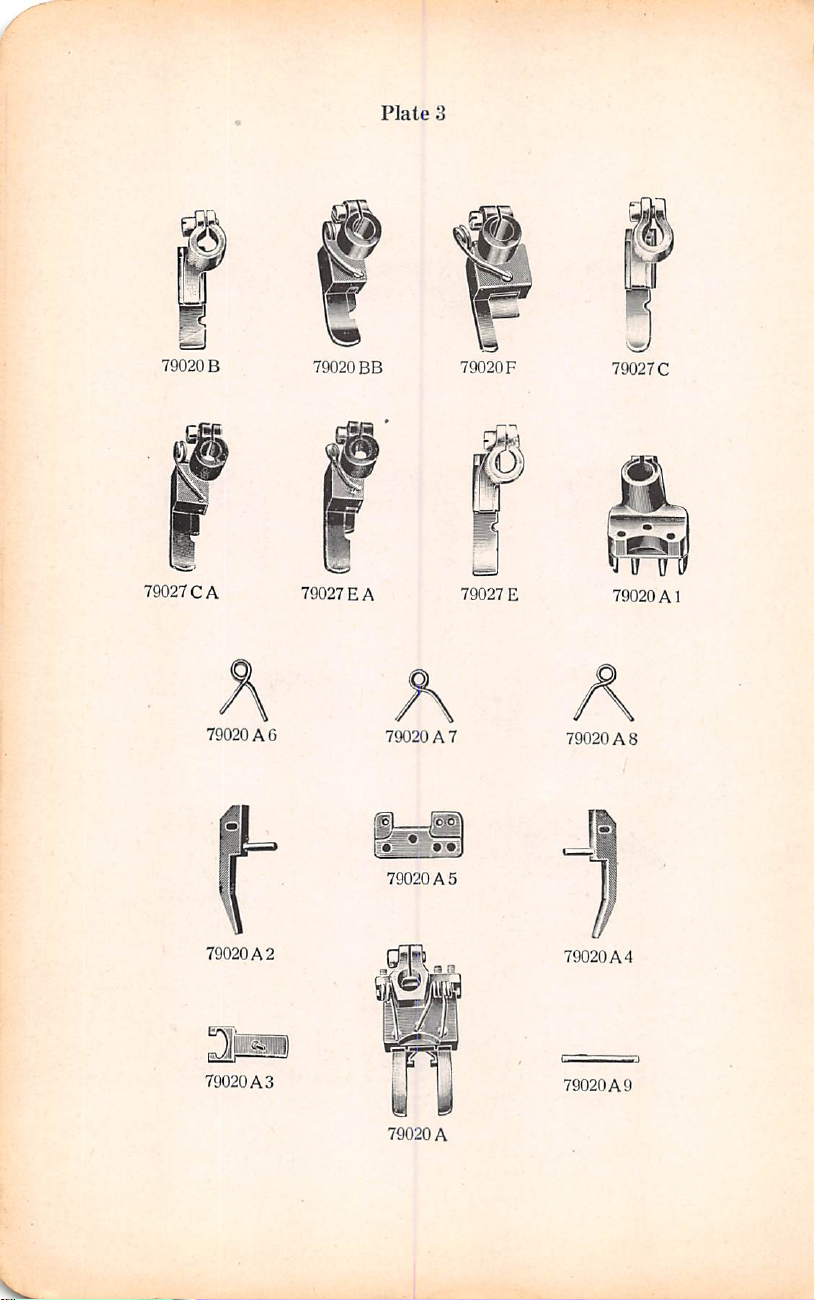

Page 12

79020B

79020

BB

Plate

3

79020F

V®/

79027C

79027CA

79020 A 6

79020A

79020A3

2

79027EA

79020 A 7

00

79020A

79020

A

79027

5

E

79020

79020

A8

A1

I

79020A4

79020A9

Page 13

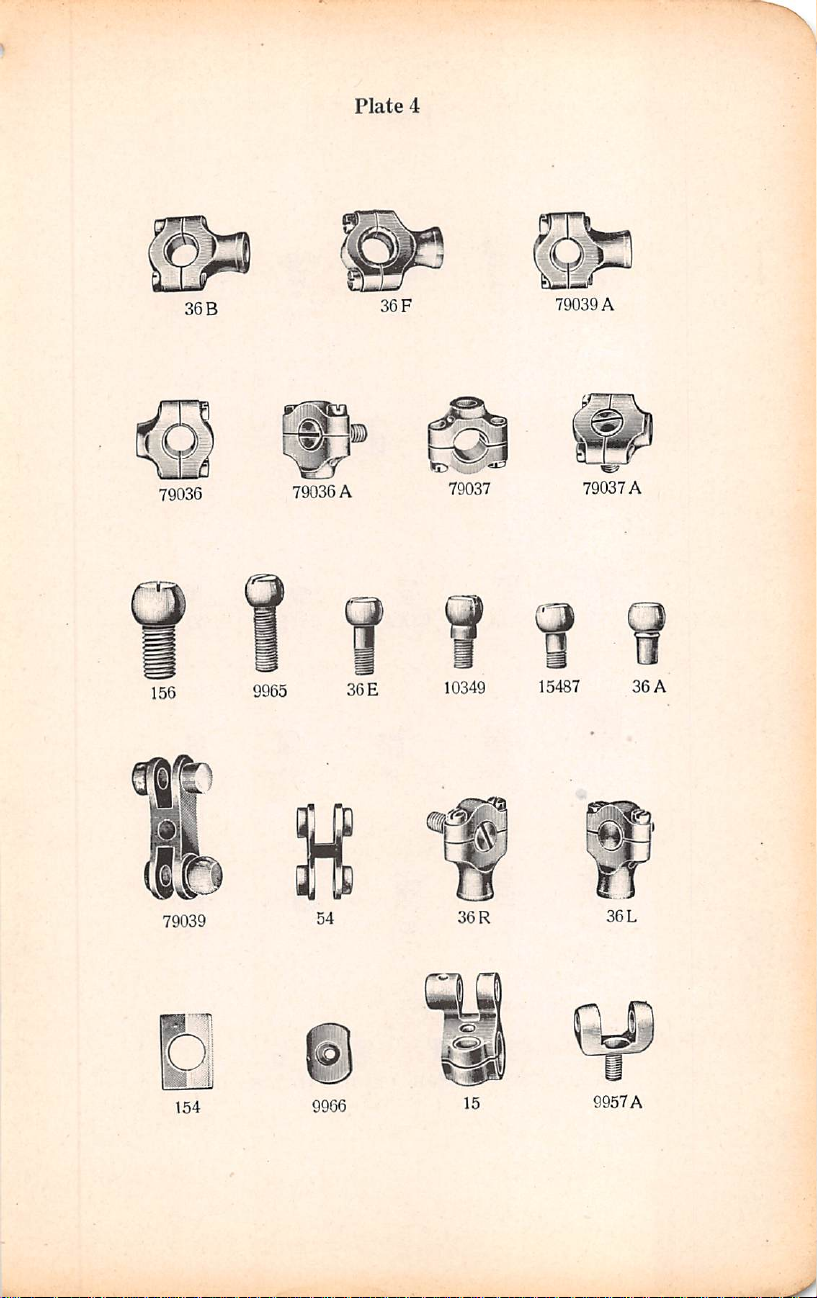

36

B

79036 79036

A

Plate

36

4

79039

F

79037

A

79037

A

Q

156

9^

79039

D

154

9965

54

9966

36E

10349

36

R

15

15487

36

9957A

36

L

A

Page 14

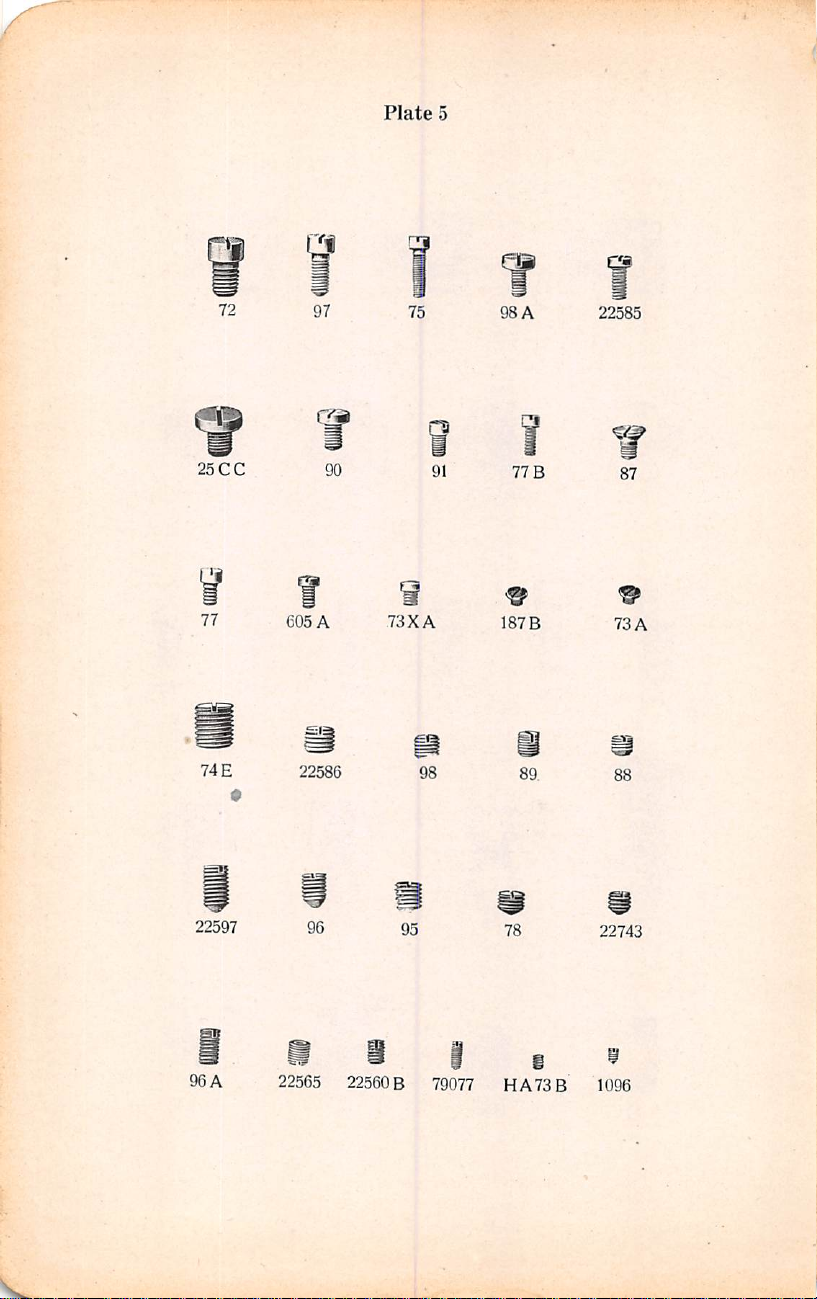

Plate

5

25

77

74

72

CC

E

97

cm

e05A

22586

90

75

73XA

98

91

98

A

77

B

1873

89

22585

87

73A

88

22597

96A

96

22565

95

22560 B 79077

78

HA73B

22743

1096

Page 15

Plate

6

tMWttWU

64A

22587

92124

17

85

A

a

6042

75A

135

22814

5!

82

22574

85

22596

25

TB

r

97

93

94

A

A

79

303

25CD

80

86

134

22548

15438

22730

D

93

79048

22539

Page 16

Plate

7

79049

258

15430C

1346

47

18

15430D

5144

T1

34

1280

nr

1347

15037

A

37

107

7947

L

5G

37

2)212

108

7948

R

79031

48

i{0«

15488

36

G

129

20

22586 A 22702

64

B

Page 17

113

79004

57

.2)

J

Plates

103

79004A

58

F

w

79059

16

52

A

sdtrqM

15438J

m

79059B

40

109

12534

19

W

15438B

104

'

41

A

79057

Page 18

Plate

9

111

2U

EZZG

I

HA

42D

1362

1286

A

1362

79041-1

15437A

79074

!

9957

1286

1230D

15438H

B

79046 B HS65P-4

426A

41046G

79051-1

84

a

79086

A

1361A

21

12964C

1349

Spfcirr

OF

A

DiAMtWR

NNtRe

79085

1230B

42C

15438C

15452

Page 19

Plate

79093

10

79003D

79079

A

, . 5 si

X.

70

Jl-*

A

79092

6B

lOA

M

61B

70

79003E

9962

79002

B

B

79003C

79003F

Page 20

Plate

11

fjwiwj

79081

7907&

9961

B

7904G

79079

75240

O

79046A

HA66K

43

79055

79013

HS

10314

33

K

I

128D

79068

_

79043

1

79023

Page 21

@3

79045

Plate

12

5156

79072

79041

79047

79060

5'

79073

79075B

A

79071A

79054

79012

Page 22

Plate

13

32

14544

4973

B

79040

1275

79058A

79056

31

79076

A

79035

C

122

s

A

62

B

79035B

a

10356

79060 A 4517

60

3

79022

Page 23

79062

79063

A

Plate

14

A

79063C

^0

79062C

9943

B

79064

79061

A

79064

79061C

A

Page 24

1.

Plate

15

B

79042

79051

1221

79002

79091

79042

A

A

79090

63B

79052

79002

Page 25

1216C

1230

Plate

16

79001

1230

G

C

79015

79044

1230

A

Page 26

Plate

17

2138SB

21681

116

21388

"

f/

118B

79050

21206

6

529

NT8A

NTS

I

G

105

A

69AP

413

99163

Page 27

21662

Plate

18

21665

21687

69FD

99162

99163

21677B

21679

Page 28

Plate

19

79084

79080

79na3

Page 29

LIST

OF

PARTS

Symbol

to

NTS

NTS

Order

A1

2

2

6

6

8

8-408

8-410

8^13

8-416

8-419

8-422

10

15

16

17

18

19

20

21

25

25

25

31

31-40S

31-410

31-413

31-416

31-419

31^22

32

32^08

32-410

C

A

U

A

CC

CD

The figures

by

parts

Main

Cloth

Cloth

Looper

Feed

Feed

Feed

Feed

Feed

Feed

Feed

Screw

A

Screw

Feed

Feed

Feed

Feed

Feed

Feed

Feed

Feed

Screw,

Screw,

TB

Thumbscrew,

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

in

and

are

Shaft

Plate

Plate

Eccentric

No.

94)

Rocker

standard

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Driver,

Driver,

Bar

Prong

Crank

long,

No.

No.

79,

Crank

Crank

Crank

Crank

Crank

Crank

No.

77)

for

for

G79000

Rock

standard

Rock

Rock

Rock

Rock

Rock

Rock

Rock

standard

Rock

Rock

the

last

column

not

to

be

used

Renewable

Slide,

left

Hinged

Cover

Fork

Shaft,

S-fg

diameter

Link,

22569,

obsolete)

Link

Stud

Stud

Stud

Stud

cloth

cloth

A

diameter

diameter

.407

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

standard

large

small

Sponge

hardened

lock

Ferrule,

Nut;

Cap

Washer

Link

Pin,

plate

plate

for

cloth

Shaft,

3j

.407

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

standard

Shaft,

ij

.407

Shaft,

standard

Shaft,

.standard

guides

refer

only

in

ordering,

Bearing,

Shoe,

inches

right,

Latch

hardened

long,

inch

(screw

diameter

diameter

diameter

diameter

diameter

diameter

(shim

nut

No.

7947,

hardened

also

for

Nos.

(screws

No.

hardened

hinged

cover

Nos.

plate

slide

inches

long,

inch

diameter

diameter

diameter

diameter

diameter

diameter

inches

long,

inch

diameter

diameter

to

the

plates

Refer

to

pint-

2y|

inches

No.

and

ground

hardened

plus

.001

plus

.003

plus

.006

plus

.009

plus

.012

plus

.015

No.

1248,

screw

screw ^ inch

and

ground

36

E,

128

77)

and

ground

79003

C,

79003

No.

79002,

hardened

plus

.001

plus

.003

plus

.006

plus

.009

plus

.012

plus

.015

hardened

plus

.001

plus

.003

illustrating

insert

for

the

prices.

long....

134)

(screw

and

ground,

inch.

...

inch. ...

inch. ..

.

inch.

...

inch. ..

.

inch....

inch

long,

D,

128

D-1

(set

screw

!

F

on

Style

and

ground,

inch....

inch....

inch.

...

inch.

...

inch.

...

inch...

and

ground,

inch....

inch....

Plate

No.

15

9

10

13

—

—

—

—

—

—

17

17

10

4

8

6

7

8

7

9

5

6

6

13

—

—

—

—

—

—

.

13

—

29

Page 30

LIST

OF

PARTS

Symbol

to

Order

32-413

32-416

32-419

32-422

33

HS33

34

36

36

36

36

36

36

36

37

37

40

41

41

42

42

43

47

48

52

54

56

57

58

60

60

60

60

60

60

61

by

K

A

B

E

F

G

L

R

L

R

A

F

C

D

A

B

B-322

B-325

B-328

B-331

B-334

B

The figures

parts

and

arc

Looper

Rock

Looper

Rock

Looper

Rock

Looper

Rock

Looper

Rocker

Woodruff

Looper

Rocker

Looper

Connecting

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Frame

Hand

Lifter

Lifter

Lifter

Feed

Needle

Needle

Needle

Needle

Needle

Looper

Looper

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Connecting

No.

97

Connecting

Connecting

No.

97

Connecting

Connecting

No.

97

Connecting

No.

97

Connecting

Connecting

Looper

Lifter,

Lever

Lever

Lever

Lift

No.

96)

Lever

Lever

Lever

Lever

Clamp

Thread

Thread

ating

screw

Bar,

.319

inch

Bar,

Bar,

Bar,

Bar,

Bar,

Bar

No.

97)

in

the

last

column

not

to

be

used

Shaft,

Shaft,

Shaft,

Shaft,

Stud,

Key,

for

looper

Stud

A)

A)

A)

Rod

A)

Thread

hardened

(stud

No.

Spring

Spring

Eccentric,

Stud

Stud

Thread

Link,

Nut,

Nipper

Nipper

No.

97)

hardened

standard

standard

standard

.standard

standard

Connection

refer

only

in

ordering.

standard

standard

standard

standard

-jV

diameter

diameter

diameter

diameter

inch

diameter

compensating

Nut

Rod

Ball

Stud,

Rod

Ball

Rod

Ball

Ball

Ball

Ball

Ball

Joint

Nut,

Nut,

Stud,

Joint

Joint

left

right

Rod

Rod

Rod

Rod

Rod

Guide,

(stud

No.

92124)

Pin

ground,

Nut,

hardened

Washer

Eyelet

(screw

hardened;

also

hardened

Spring,

Spring,

and

ground,

diameter

diameter

diameter

diameter

diameter

(screw,

to

the

Refer

left

Joint

right

Joint

Shell,

Wa.sher

Assembly,

Assembly,

thread

thread

lower,

right

86)

throw

No.

for

upper

(screw

lower

(screw

plus

.003

plus

.006

plus

.009

plus

.012

plus

.015

front,

plates

illustrating

to

pink

insert

plus

.006

plus

.009

plus

.012

plus

.015

horizontal

Shell,

left

(nut

No.

right

left

right

.062

inch

98

A)

Nos.

79052,

No.

No.

standard

inch

inch

inch

inch

inch

No.

89,

screw,

the

for

prices.

inch.

...

inch....

inch.

...

inch....

shaft..

(screws

18)...

.

(screws

(screws

(screws

(screw

79054.

.

90)

90,

oper

diameter

rear,

Plate

No.

11

16

11

13

10

6

7

4

4

4

4

7

9

9

7

7

8

4

7

30

Page 31

LIST

OF

PARTS

^mbol

to

HS65

HA66

72

73

73

HA73

74

75

75

77

77

78

79

80

82

84

85

85

86

86

87

88

Order

62

B

62

B-322

62

B-325

62

B-328

62

B-33I

62

B-334

63

B

64

A

64

B

P-4

K

68

B

69

AP

69

AW

69

ES

69

FD

70

70

A

A

XA

B

E

A

B

A

A

A

The figures

by

parts

Presser

eter

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Pre.sser

Needle

Woodruff

Main

Thread

Spool

Thread

Set

thread.s

for

Looper

No.

Looper

Set

Screw,

Set

Set

Set

Screw,

Screw,

crank

Screw,

HA1286,

Screw,

Set

79073,

Screw, ^ inch

Screw,

Screw,

Stitch

Clamp

Clamp

Hand

Hand

Screw,

Set

79046,

in

the

and

are

not

Guide

.319

inch

Guirle

Guide

Guide

Guide

Guide

Spring

Spring

Spring

Thread

Key,

Shaft

Sleeve,

Stand

Support

Stand

Screw,

square

to

Nos.

21665,

Eccentric

93

A)

Eccentric

Screw,

for

for

looper

Screw,

for

Screw,

for

Screw,

for

for

looper

front,

connection

for

feed

1286

for

presser

Screw,

for

79073

inch

for

regulating

Regulating

Screw,

Screw,

Lifter

Stud

Lifter

Stud,

for

throat

Screw,

for

79047,

last

column

to

be

Bar,

Bar.

Bar,

Bar,

Bar,

Bar,

refer

used

in

ordering.

hardened

standard

standard

standard

standard

standard

Regulating

Regulating

Tension

for

Wire

for

Base

inch, | inch

Take-up

looper

compensating

1^

inches

thread

stands

head,

cup

long,

21677

B,

Sponge

Sponge

looper

eccentric

needle

guard

looper

presser

foot

looper

compensating

compensating

inch

long,

crank

stud

A,

79004,

foot

l)racket

upper

needle

A

long,

for

feed

long

for

cloth

length

Ferrule,

for

looper

for

needle

eccentric

loop

retainer

plus

size

pktes;

also

bar;

also

79092

only

to

Befer

and

ground,

diameter

diameter

diameter

diameter

diameter

Screw

Screw

Look

Spring

long...,

point,

for

thread

21679

Holder

fork

springs

cam

cam

for

loop

cap;

also

79004

A,

lever

link

crank

link,

plates

of

stitch

inch

long

fork

rocker

threads,

for

Nos.

for

Nos.

the

plates

to

pink

standard

plus

.003

jiltis

.006

plus

.009

plus

.012

plus

.015

Nut,

Stud...

vertical

inch

stand

and

Sponge

shaft

gear

pinions

retainer

for

Nos.

79011

pin;

obsolete

tap

No.

62

B,

5156,

9961B,

illustratirg

insert

for

the

prices.

diam

inch

inch

inch

inch

inch

knurled

.

shaft

diameter,

18

seat;

also

(screw

!

shaft

bell

21,

122,

also

for

Nos.

V113

129

79012,

No.

13

15

6

7

9

11

11

17

17

17

18

10

10

5

5

5

5

'

5

5

- 6

5

5

5

6

6

6

9

6

6

6

—

5

5

31

Page 32

LIST

OF

PARTS

•

to

0105

VI09

Symbol

Order

89

90

91

93

93

94

95

96

96

97

97

98

98

103

104

107

108

109

111

113

VI13

116

IIS

VI

IS

122

127

128

128

128

128

129

The figures

parts

by

Screw,

Screw,

Clamp

Screw,

A

Screw,

Screw,

Screw,

Screw,

A

Set

Screw,

A

Screw,

Screw,

A

F

Screw,

Looper

Looper

A

Stove

Tension

Ten.sion

Tension

Tap,

Tension

Frame

Tap,

Wrench, ^ inch,

U

Threa<l

Tap,

Pivot

D

D-1

D-2

D-3

and

front,

for

79059

Screw,

Nos.

113,

79079,

79054

for

79022,

79043

Screw,

Nos.

Nos.

Nos.

79037

Bolt,

m.arked

93

A')

marked

marked

Pin,

bar

.swinging

Needle

Cam

Roller

Cam

Roller

Cam

Roller,

Cam

Roller

Prcs.scr

in

the

last

not

to

for

79074

for

looper

column

be

used

presser

thread

pre.sscr

thread

are

looper

B,

for

79044, 79078,

for

looper

eccentric

79079

for

looper

eccentric

needle

79053,

feed

lift

79068

for

needle

A,

operating

B,

103

lower

B,

36

79039

tension

needle

Take-up

Take-up

for

fastening

Ferrule

bar

79063

F,

bell

F,

A,

thread

lever

79031,

for

79063

for

61

for

36

A,

for

for

Thread

Thread

Spring

Regulating

Disc,

hardened

"J2",

Thread

Eyelet,

Thread

Guide,

"Q2",

for

Tweezers

"X2",

I5

inches

frame

Bar

Oscillating

Assembly

Stud,

hardened

hardened

Stud

Guide

Holder

Bar

refer

in

ordering.

bar

connection;

nipper

feet

take-up

79079,

79079

sponge

A,

79081,

fork

oscillating

79071

eccentric;

bar

oscillating

B,

79063

looper

thread

79012,

79046

crank

eccentric

36

L,

36

79042,

79042

evelet;

thread

Eyelet

Eyelet

base

Nut,

knurled

and

for

No.

22526

with

attaches

for

No.

needle

for

No.

long,

hardened

bell

crank

Cam

fctamp

and

ground

Cap

(screw

only

to

the

Refer

to

springs;

also

eyelet

A,

79094

holder;

79083

shoe;

cam

pinions;

A

also

for

Nos.

cam

C,

79063

nipper

A,

79046

connection;

R,

79036,

A

also

for

eyelet;

also

(adjusting

Spring

plate

to

lapped

two

eyes

to

top

86

.V

clamp

nut

22521

and

(set

Wa.sher

screw

ground

No.

screw

No.

87)

Stud

and

plates,

illustrating

pink

insert

also

for

No.

for

Nos.

spring;

also

also

for

Nos.

also

10314, 79012,

shaft;

D

.springs;

B

79036

A,

Nos.

9271,

for

No.

screw

No.

(screw

No.

table

(screw

No.

of

arm

(screw

grovmd,

No.

136)

(nut

No.

for

79023

79059,

also

for

for

also

also

also

79037,

79012.

9966..

93)..

98)....

for

77)

18)....

the

pnces.

for

Nos.

132,

Nos.

for

for

for

97).

.

..

No.

needle

Plate

No.

5

5

◦

6

6

6

5

5

6

5

6

5

5

s

8

IV

V

V

8

—

9

8

—

IV

17

—

13

7

11

—

—

—

V

32

Page 33

LIST

OF

PARTS

^mbol

to

Order

132

. 134

136

154

156

187

258

303

413

426

Y502-319

Y502-322

Y502-325

Y502-328

Y502-331

Y505-407

Y505-410

Y505-413

Y505-416

Y505-419

Y506-530

Y506-533

529

605

Y800

Y801

Y802

1096

1216

1221

1230

1230

1230

1230

The figures

by

parts

Needle

Screw,

Clamp

Needle

Needle

B

Screw,

Loop

Adjusting

Oil

A

Lifter

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

Expansion

A

Thread

Screw,

Taper

Taper

Taper

Stop

C

Needle

Eccentric

A

B

C

D

Needle

Needle

Needle

Needle

(screw

and

are

Bar

for

Screw,

for

No.

Lever

Lever

for

Retainer

No.

9965

Can,

Lever

bars,

size

Hook

for

Reamer,

Reamer,

Reamer,

link

pins

Screw,

Lever

feed

oiling;

1230

D,

No.

41046

Lever

No.

22587)

Lever

Spring

Lever

left

thread

Lever

in

the

last

not

to

be

Swinging

clotli

plate

79065

Buffer,

Ball

throat

Shaft

Screw,

with

spout

Spring

Reamer,

.319

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

Reamer,

needle

bar

for

for

for

for

cloth

Connecting

one

1230

G,

G

Pulley,

Connecting

Connecting

Connecting

No.

15430

Connecting

No.

22586

column

used

in

Frame

hinged

inch

long,

wood fibre

Stud,

plate

stitch

Knuckle

for

loop

Pin

for

size

size

size

size

for

feed

size

size

size

size

for

size

thread

lever

frame

needle

plate

each

15430

throw

C,

refer

only

ordering.

Brace

cover

for

hardened

tongues.

Link

retainer

prcsser

.322

inch

.325

inch

.328

inch

.331

inch

rocker

.410

inch...

.413

inch.

.416

inch

.419

inch.

main

shafts

.533

inch

evelet

end

of

needle

end

of

lever

slide

Rod

Assembly,

No.s.

1230

C,

15430

.529

inch

Rod

Rod

Rod

Tube,

nut,

right

Rod

to

the

plates

Refer

to

(screw

latch

cam

roller

.

Lock

shaft

bars

and

shafts,

..

,

..

size

,530

lever

needle

lever

link

pins

No.

79002

A,

1230

D,

22586 A and

(screws

Upper

Upper

includes

thread,

Upper

illustratirg

pink

insert

fcr

No.

94).

assembly;

Nut;

also

knuckle

link..

presser

size

.407

inch

stud

.stud.

and

feed

wick

and

B,

1230

No.

22597).

Bearing

(screws

Bearing

felt

No.

15430

Bearing

the

prices.

. .

also

for

..

guide

inch..

crank

splash

C,

two

...

Valve

(nut

D)

Valve

No.

10

6

6

4

4

5

7

6

17

9

_

17

5

—

5

16

15

16

9

16

9

33

Page 34

LIST

OF

PARTS

to

1230

1248

1275

1275

1275

1275

1275

1280

1286

1286

1288

HA1286

1346

1347

Symbol

Order

G

A

E

.1

1349

1349

1361

by

F

H

A

B

A-2

A^

A

The figures

parts

Needle

Feed

Needle

Needle

Needle

Needle

in

the

and

arc

not

to

Lever

Connecting

splash

feed

oiling

Crank

Link

Lever

Stud,

Lover

Stud,

.002,

.003,

Example;

on

frame

.002,

1275

section

.006, .012,

1275

section

Lever

Stud,

.003,

.006

F-003

Lever

Stud,

last

represents a stud

.001, .002, .003,

ample:

each

Needle

(.001,

(.002,

(.006,

(.012,

(.018,

Specify

lever

stud

section,

on

screw

Needle

Needle

and

Needle

screw,

Needle

Looper

Tension

for

Tension

Tension

Tension

Presser

1275

section.

Lever

Stud,

.002)

.003)

.001)

.003)

.006)

plus

section

plus

.003

1275

frame

section

No.

22586,

Lever

Ball

Lever

Link

ground

Lever

lower

Lever

Link

Compensating

Assembly

Post,

use

with

Post

(set

for

Ferrule,

Spring,

Spring,

Spring

(.001,

(.002,

(.006,

(.012,

amounts,

la.st.

column

used

in

refer

ordering.

be

Rod

(screws

Shim,

standard

leather

plus

size

No.

.018

E-003

represents

plus

size

inch;

specify

plus

size

.006

H-003

inch;

represents

plus

size

.003)

(.001,

.006)

,002)

.006)

arranged

Example:

inch

enframe

J-006-003

Link

No.

represents a stud

and

.003

felt)

Stud

Clamp

Pin

.\s.sembly,

Pin

(set

77)

Pin

Spring

Horizontal

screw

No.

looper

hardened

.025

.035

Pin

77)

thread,

.steel

hardened

inch

diameter

inch

diameter

only

to

the

Refer

Lower

22587)

diameter

on

frame

inch;

specify

a

on

lever

plus

amount.

plus

equal

on

specify

a

.stud

unequal

on

.006)

(.003,

.002)

(.006,

.003)

(.018,

.001)

frame

1275

J-003-006

section

and

inch

on

Bolt

Nut

internal

screw,

Shaft

length

ferrule

wire,

wire,

plates

illustrating

to

pink

insert

for

Bearing,

section,

stud

section,

wick

viz.:

phis

amount.

plus

.003

viz.:

Example:

.003

inch

on

each

section,

plus

amount.

plus

.003

each

section,

(.002,

.001)

(.003,

.006)

(.012,

.002)

(.018,

.002)

section first

represents

.006

inch

plus

.006

lever

section

oiling,

hardened

upper

No.

Arm

Link

overall

1^

for

looper

for

needle

the

prices.

and

.001,

inch

•

•

.001,

lever

viz.:

Ex

inch

on

viz.:

and

a

on

lever

inch

(plug

78,

set

Pin

inches,

thread

thread

Plate

No.

16

13

34

Page 35

LIST

OF

PARTS

Symbol

to

Order

1362

1362

4517

4973

5144

5156

6042

7947

7948

9271

9943

9943

9957

9957

9961

9962

9965

9966

10314

10349

10356

12534

12964

14544

15037

15430

1.5430

15430

15437

15438

15438

15438

15438

15438

15452

15487

The

figures

in

the

last

coluinn

refer

only

to

the

plates

parts

and

are

not

to

be

used

in

Pin, right

Pin,

left

No.

Cam

Bar

Link

No.

Stud

Nut;

also

Horizontal

(screw

Cam

Knuckle

Knuckle

Crank

Knuckle

258)

Crank

Crank

ground

Horizontal

Rod,

R,

nut,

Eyelet

Pin

Ball

Vertical

No.

22587)

Horizontal

Vertical

ordering.

and

Clamp

left

and

Thread

Thread

Thread

Thread

by

Main

Shaft

Sleeve

Main

Shaft

A

Needle

.200

B

Needle

Differential

Feed

Needle

Feed

Looper

Nut,

Knee

B

Needle

No.

E

A

B

B

B

Needle

Loop

Loop

Loop

Loop

303,

Loop

Loop

98

Looper

Looper

Looper

thread

Needle

C

A

C

D

M

Needle

Feed

Looper

Needle

Needle

Needle

oiling

A

B

C

D

H

J

Needle

Needle

Needle

Needle

Needle

Needle

Looper

Pin

Looper

No.

Sleeve

Bar,

hardened

inch

(set

Bar

Rocker

Lever

Crank

screws

Oscillating

Feed

(screws

Ball

Link

Compensating

left

thread

Press

Collar

Bar

O.scillating

95)...'

Bar

Oscillating

Retainer

Retainer

Retainer

Retainer

lock

Retainer

Retainer

A)

nut

Shaft

Shaft

Bell

Shaft

No.

Bell

Bell

Eccentric,

Compensating

Connecting

No.

37

Bar

Thread

Lever

Link

Bar

Shaft

Compensating

Lever

Connecting

Lever

Connecting

Lever

Connecting

(screws

Bar

Connection

Bar

Connection

Bar

Connection

Bar

Connection

Bar

Connection

Bar

Connection

Compensating

Spring

Compensating

15037

A)

ground,

88)

Shaft

Stud

88)

Bolt

for

No.

No.

98)

Cam

Pinion,

Pinion

Pin

Cone

(screws

Link

Ball

Stud

Ball

Stud

(screw

left,

3^

thread

(screw

Shaft

Rod

Nut,

Rod

Nut,

Rod

Lower

Thread

Nipper

Nipper

Nipper

Nipper

Shaft

Refer

(set

Nut

79035

Shaft

(screws

(adjusting

(lock

No.

Shaft

inches

No.

No.

left

right

Nipper

Rock

illustrating

to

pink

insert

standard

screw

No.

C

Connecting

obsolete

No.

No.

88)

nut

Washer

(screw

96)

Arm

Ball

long

(nut, right

37

L)

605

A)

Arm

Ball

thread

thread

Bearing,

Assembly

Disc

Spring

Stud

Guide

Shaft

Arm

Ball

for

diameter

96

A).

(screws

95)

screw

No.

258).

Stud..

Stud

wick

Arm

Stud

the

prices.

..

Rod

No.

.

No.

.

Nut.

feed

Link

(nut

Plate

No.

13

13

12

18

14

11

10

11

13

13

7

6

7

7

4

9

4

4

4

9

7

7

7

35

iMliii

>11

I'lll/'

inii'ii

I

Page 36

LIST

OF

PARTS

^mbol

to

Order

1.54SS

21206

21212

212252I26I

21262

21350

21351

21355

21355

21358

21371

21371

21371

21371

21371

21371

21371

21384

21388

21388

21394

21394

21394

21394

21662

21665

21677

21679

1

"4

A

B

M

T-2

T-^

T-6

T-8

T-16

A

B

G

H

K

B

The figures

parts

by

I.rf)oper

Screw

Fresser

Looper

Leather

Leather

Malleable

Wire

Chair

Chair

Main

Table

Individual

Individual

Individual

Individual

Individual

Individual

Leather

Wrench,

Wrench,

Small

Emery

Emerj'

Grinder,

Knee

Knee

Knee

Knee

in

tlic

lost

not

to

colunin

be

used

and

are

Compensating

Wa.=her

Driver

Wrench

Bar

Collar

.080

Adjusting

Belt,

malleable

Belt,

including

Belt

Leg

Leg

Shaft

Top,

thick

belting,

pulley

guard,

electric

fied

D.

C.

electric

single

phase,

single

phase,

three

pha.se,

Plug,

hardened,

hardened,

Utility

diameter, f inch

lutions

per

Gauge, 7 inch

flat, 1 inch

iron

belt

round, ^ inch

wire

l)elt

Iron

Belt

Hook,

for ^ inch

Extension, 4 inches

Extension, 6 inches

Lubricator

48

inches

Power

Table,

transmitter

Power

Table,

pitman,

motor.

Power

Table,

motor

Power

Table,

60

Power

Table,

60

Power

Table,

60

cycle,

for

cloth

Note:

cycle,

cycle,

for f inch

for h inch

Grinder,

face,

minute

Wheel, 5 inches

hole,

grade

M,

Wheel, 5 inche.s

grade

M,

including

face,

recommended

Press

Press

Press

Press

emerv

emery

60

emery

Bracket

Rod

Connection

Lever

(set

Rod

(set

refer

only

thick

to

Refer

Shaft

in

ordering.

Vertical

inch

measurement

wide,

63

fastener

No.

21350

diameter,

hook

No.

21351

Fastener,

for 1 inch flat

round

long

long

Felt

long,

I65

inches

excludes

and

electric

motor,

includes

belting, 5 H.

Style

of

machine

equipped

equipped

A.

C.

electric

with ^ H.

equipped

A.

0.

electric

equipped

A.

plate

C.

electric

screw

with ^ H.

hexagon

hexagon

including

emerj'

recommended

diameter, f inch

60

diameter, | inch

wheel, 5 inches

speed

3000

revolutions

(screws

screw

No.

No.

69

69

FD)

screw

the

plates

illustrating

to

pink

insert

Arm

Ball

inches

long,

including

44

inches

belt

belt

wide,

if

pulley

guard,

includes

transmitter,

P.

115

Volt,

must

be

with 5 H.

P.

P.

230

110

motor

with j H.

P.

220

motor

P.

220

motor

holes

nuts

nut.?

wheel, 5 inches

speed

3000

face, | inch

face, | inch

diameter, ^ inch

per

No.

69

FD)

FD)

the

for

prices.

Joint

long,

inches

pitman,

treadle

treadle,

D.

C.

.speci

Volt

Volt,

Volt,

Volt,

revo

hole,

minute.

Plate

No.

17

—

—

—

—

—

—

—

17

17

18

18

18

18

7

7

36

Page 37

LIST

OF

PARTS

Symbol

to

Order

21681

21687

22.521

22.526

22.53fl

22548

22.560

22.560

22.565

22.569

22574

2258.5

22.586

22586

22587

22596

22597

22702

22730

22743

22814

28606-f

28606-1

29066

29086

29086

29346

41046

75240

79001

79002

79002

79002

79002

The figures

by

parts

Thumbscrew,

Knee

Screw,

Screw,

Plug

Screw,

Screw,

B

Set

Set

Screw,

Screw,

Screw,

Plug

A

Screw,

Screw,

Screw,

Screw,

Screw,

Screw,

Set

Screw,

Powdered

Powdered

B

A

E

Needle

Eccentric

Eccentric

Needle

G

Spring

Main

Cloth

Cloth

A

B

C

Cloth

Cloth

Cloth

in

the

are

not

last

to

be

and

for

Press

Chain

plus

size,

plus

No.

.size,

V109

Screw, ^ inch

for

loop

for

Screw,

Screw,

ff

for

79026

Screw,

for

for

for

for

for

for

Screw,

one

1230 D and

Nos.

one

each

No.

41046

lapped

bearing

Shaft

Plate

Plate

No.

25

Plate

Plate

G79000

25

CC)

retainer

needle

for

needle

lower,

inch

long,

inch

long,

feed

bar

E

for

needle

needle

needle

looper

eccentric

cam

spring

fabric

for

differential

for

loo))er

Oil

Stone, i lb.

Oil

Stone, 1 lb.

Lever

Connecting

each

Nos.

22586

Pulley

1221

and

Pulley

Nos.

G

Lever

Assembly;

together,

Valve

Oiler,

No.

1230

Sleeve,

(screws

Slide,

TB,

stop

Hinged

Slide,

D,

G79000E

Plate

Hinged

column

refer

only

to

used

in

ordering.

fastening

for

cloth

plates,

machine

diameter ^ inch,

long,

for

.shaft,

lever

link

pin

thread

for

looper

eccentric

for

feed

for

cloth

needle

rear

lever

lever

connecting

lever

connecting

thread

ca.st-off

Refer

tap

for

right

main

frame;

spring

take-up

crank

link

plates

guard;

stud

rod

rod

wire

the

to

also

pulleys

valve

oiler

edge

guides

feed

bar

compensating

link

vertical

package

j)ackage

Bed

1230

A,

A

Assembly,

15430 M lapped

Assembly,

1221,

47

and

for

needle

Upper

156

lapped

wick

feed

together

wick

and

1230 G lapped

one

each

Nos.

22.586

lever

G

left

No.

80,

pin

for

No.

with

for

No.

Stjdc

Ci79000 A (thumbscrew

1096)

latch

Styles

G79000

without

front,

screw

Cover,

front,

Cover,

plates

illustrating

to

pink

insert

base

plate

No.

V118

throat

plates,

shaft

oil

re.scrvoir

for

No.

79045...

wire

fork

also

for

Nos.

79026

ujipor

bearing

bearings

.stand

shaft

bracket.

Bearing

As.sembly;

together,

oiling;

one

splash

feed

together

79015

and

connecting

rod

79041-1)

(screw.s

B,

latch

No.

G79000

(screws

for

prices.

tap

valve

...

1230

each

oiling;

and

two

1275

lower

25

CC).

No.

the

C,

B,

C,

Plato

No.

17

18

^

A

11

16

15

15

10

37

Page 38

LIST

OF

PARTS

Symbol

to

Order

79003

79003

79003

79003

79003

79004

79004

79QD5

79005

79005

79005

79005

79005

79007

79008

79010

79011

79012

79013

79015

79020

79020

79020

79020

79020

79020

79020

79020

79020

79020

79020

79020

79020

79022

C

D

E

F

A

A

B

C

D

E

F

A

A-1

A-2

A-3

A-4

A-5

A-6

A-7

A-8

A-9

B

F

BB

by

The figures

parts

and

arc

Fabric

Edge

Fabric

Edge

G79000

Fabric

Edge

Fabric

Edge

Fabric

Edge

Cloth

Plate

No.

25

Looper

Thread

Looper

Thread

Feed

Dog,

Feed

Dog,

Feed

Dog,

Main

Feed

Main

Feed

Feed

Dog,

Feed

Dog

Looper,

Looper,

Looper

Loop

Looper

Looper

Presaer

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Pre.sser

Presser

Presser

Presser

Presser

Presser

Presser