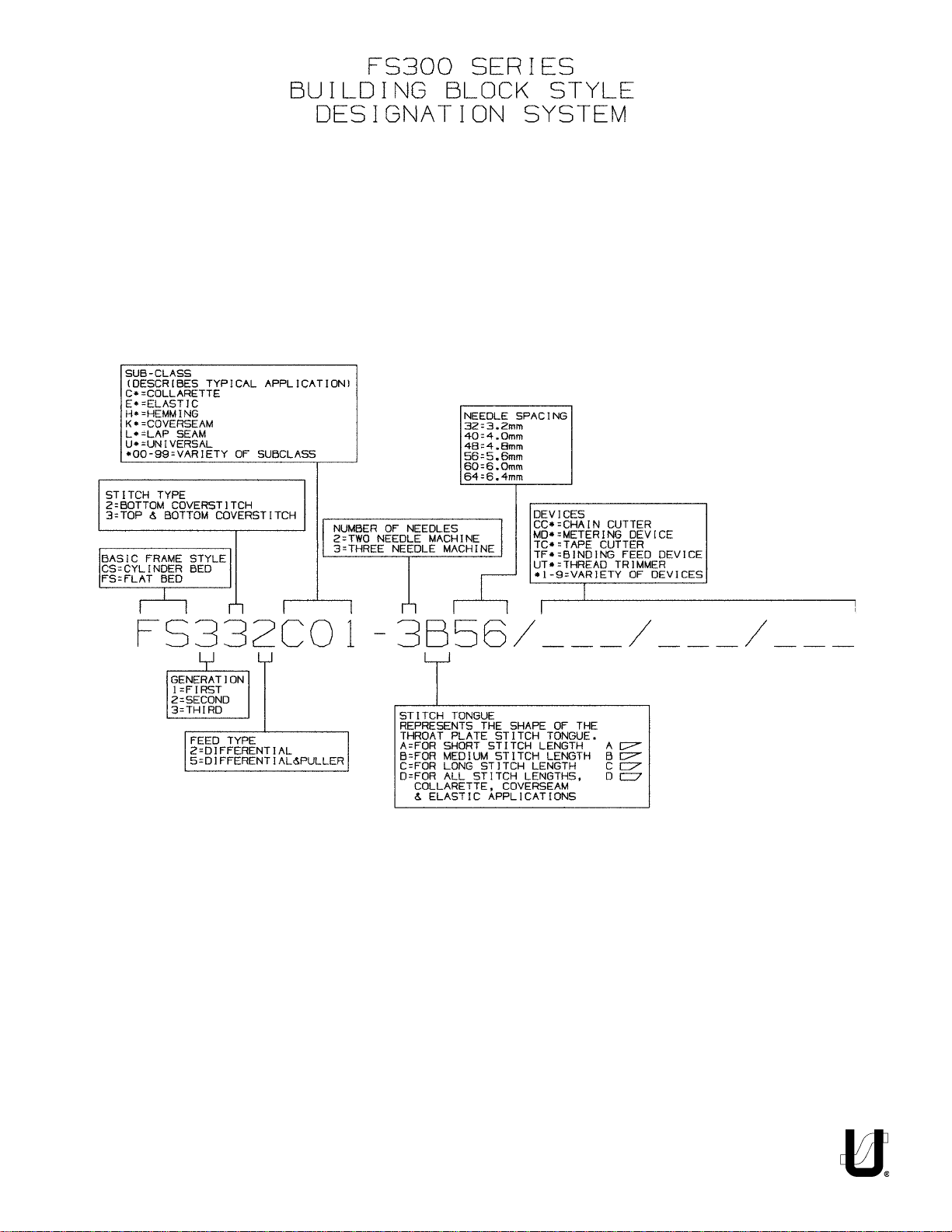

Page 1

ILLUSTRATED PARTS MANUAL

REV 5-9-00

FS300 SERIES, PLAIN AND DIFFERENTIAL FEED,

HIGH SPEED FLAT BED MACHINES

MANUAL NO. PT9800

FOR STYLES

FS322C01

FS332C01

FS322E12

FS332E12

FS335E41

USE IN CONJUNCTION WITH MACHINE SERIAL NUMBER PREFIX (BG) AND LATER

FS335E42

FS322H01

FS332H01

FS322L01

FS332L21

Page 2

Manual No. PT9800 llustrated Parts List for FS300 Series Machines

First Edition Copyright 2000

By

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. May 2000

PREFACE

This parts manual has been prepared to assist you in locating individual parts or assemblies on FS300 Series machines. It

can be used in conjunction with Union Special Operator's Manual OP9614 and Engineer's Manual EN9424.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are

designed specifically for your machine and are manufactured with utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on FS300 Series machines.

Please include part number, name and style of machine for which the part was ordered.

For optimum performance use only genuine Union Special replacement parts.

2

Page 3

CONTENTS

PREFACE .......................................................................................................................................................................................2

IDENTIFICATION OF MACHINES ..................................................................................................................................................4

STYLE OF MACHINES....................................................................................................................................................................4

ILLUSTRATIONS .............................................................................................................................................................................5

IDENTIFYING PARTS ......................................................................................................................................................................5

NEEDLES ........................................................................................................................................................................................5

SAFETY RULES ...............................................................................................................................................................................6

BUSHINGS .....................................................................................................................................................................................9

NEEDLE BAR ...............................................................................................................................................................................11

UPPER MAIN SHAFT ....................................................................................................................................................................13

SPREADER ...................................................................................................................................................................................15

THREAD GUIDE ...........................................................................................................................................................................17

TENSION RELEASE & THREAD TENSION .....................................................................................................................................19

PRESSER FOOT LIFT .....................................................................................................................................................................21

COVERS, UPPER ARM...............................................................................................................................................................23

LOWER MAIN SHAFT ..................................................................................................................................................................25

LUBRICATION, OIL TUBING & OIL PUMP ...................................................................................................................................27

LOOPER DRIVE ...........................................................................................................................................................................29

NEEDLE GUARD .........................................................................................................................................................................31

LOOPER THREAD TAKE-UP.........................................................................................................................................................33

FEED DRIVE MECHANISM

FOR FS322C01, FS332CO1,FS322H01, FS332H01, FS332L01, FS332L21 ....................................................35

FEED DRIVE MECHANISM

FOR FS322E12 & FS332E12 ...........................................................................................................................37

FEED DRIVE MECHANISM ..........................................................................................................................................................39

COVERS, LOWER BED................................................................................................................................................................41

COVERS, LOWER BED................................................................................................................................................................43

FRONT COVER ASSEMBLY

FOR FS322C01, FS332C01 ...........................................................................................................................45

SEWING PARTS

FOR FS322C01 & FS332C01 .........................................................................................................................47

SEWING PARTS

FOR FS322E12 & FS332E12 ..........................................................................................................................51

SEWING PARTS

FOR FS335E41 & FS335E42 ...........................................................................................................................53

SEWING PARTS

FOR FS322H01, FS332H01, FS332L01, FS332L21...........................................................................................57

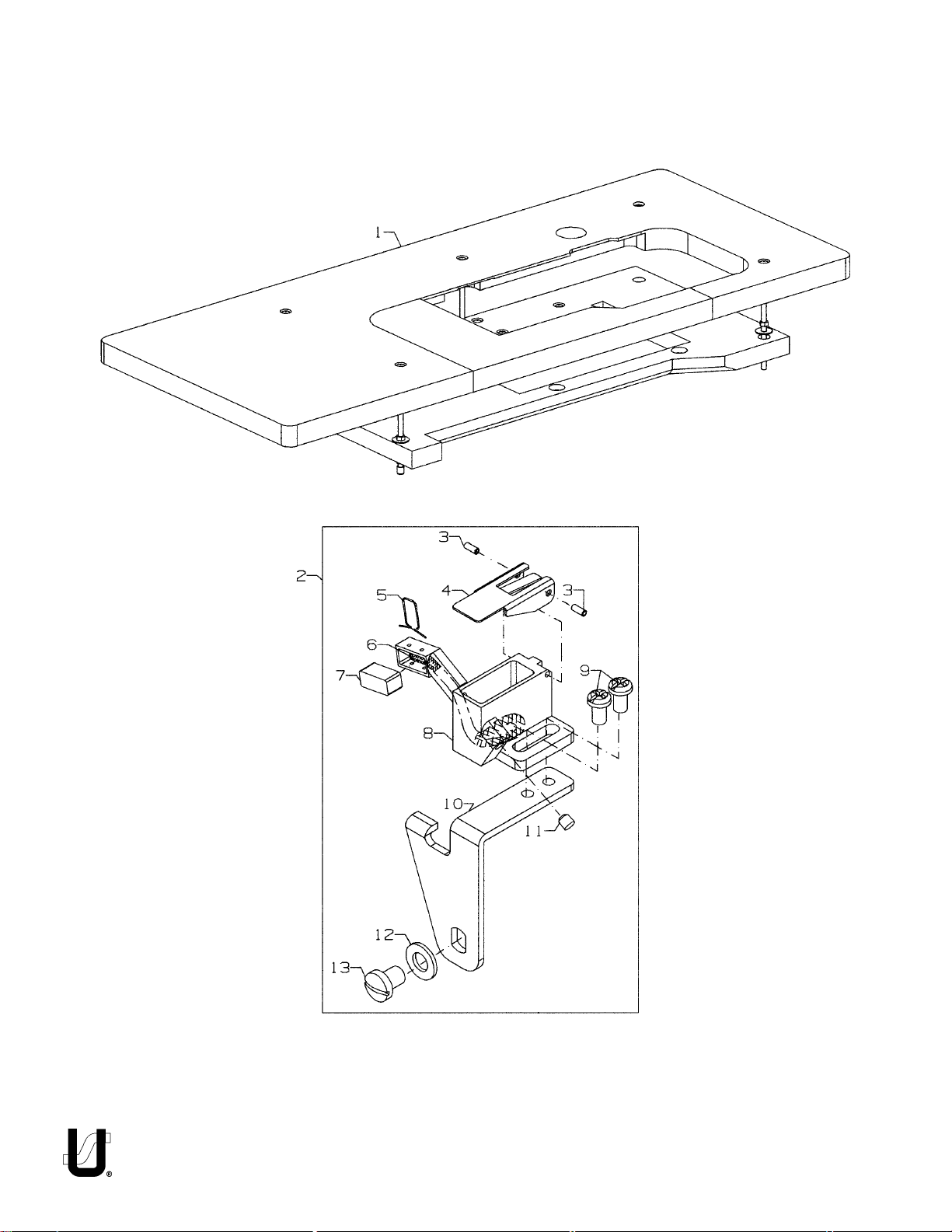

TABLING ANDNEEDLE DIPPER ASSEMBLY (EXTRA SEND CHARGE)

FOR FS322C01, FS332CO1, FS335E41, FS335E42, FS322H01, FS332H01, FS332L01, FS332L21 .................59

TABLING (EXTRA SEND CHARGE)

FOR FS322E12 & FS332E12 ...........................................................................................................................61

ACCESSORIES ............................................................................................................................................................................63

VACUUM TUBE ASSEMBLY AND PNEUMATIC CONTROL (EXTRA SEND CHARGE)

FOR FS322E12 & FS332E12 ...........................................................................................................................65

UNDER BED THREAD TRIMMER

FOR FS322E12 & FS332E12 ...........................................................................................................................67

LOWER ROLLER ASSEMBLY

FOR FS335E41 & FS335E42 ...........................................................................................................................69

UPPER ROLLER ASSEMBLY

FOR FS335E41 & FS335E42 ...........................................................................................................................71

PULLER LIFTER ASSEMBLY

FOR FS335E41 & FS335E42 ...........................................................................................................................73

PULLER DRIVE ASSEMBLY

FOR FS335E41 & FS335E42 ...........................................................................................................................75

NUMERICAL INDEX OF PARTS ...................................................................................................................................................76

NUMERICAL INDEX OF PARTS ...................................................................................................................................................77

NUMERICAL INDEX OF PARTS ...................................................................................................................................................78

NUMERICAL INDEX OF PARTS ...................................................................................................................................................79

3

Page 4

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine is identified by a style number, which is stamped into the style plate affixed to the middle

of the machine under the tension assembly. The serial number is stamped into the serial number plate affixed to the right

rear base of the machine.

STYLE OF MACHINES

FS322C01- COLLARETTE - Two or three needle, bottom coverstitch. Typical application - For attaching

flat of ribbed knit split tube borders to knit garments. Seam specification fir two needle

406BSb-1, three needle 407BSb-1. Standard gauges for two needle 32, (1/8", 3.2mm), 40,

(5/32", 4.0mm), 48, (3/16", 4.8mm), for three needle 48, (3/16", 4.8mm), 56, (7/32" 5.6mm),

64, (1/4", 6.4mm). Maximum recommended speed, depending on application is up to

6500 R.P.M.

FS332C01- COLLARETTE - Same as style FS322C01 except top and bottom coverstitch. Seam

specification for two needle 602BSb-1, for three needle 605BSb-1.

FS322E12- ELASTIC - Two or three needle, bottom coverstitch with fabric trimmer. Typical

application - For attaching elastic to briefs or lace to lingerie. Seam specification for two

needle 406LSa-1, for three needle 407LSa-1. Standard gauges for two needle 32,

(1/8", 3.2mm), 40, (5/32", 4.0mm), 48, (3/16", 4.8mm), for three needle 48, (3/16", 4.8mm),

56, (7/32", 5.6mm), 64, (1/4", 6.4mm). Maximum recommended speed, depending on

application is up to 6500 R.P.M.

FS332E12- ELASTIC - Same as Style FS322E12 except top and bottom coverstitch with fabric trimmer.

Seam specification for two needle 602LSa-1, for three needle 605LSa-1.

FS335E41- ELASTIC - Three needle, top and bottom coverstitch, differential feed and rear puller with

tooth roller. Typical application - for attaching tunnel elastic to briefs or lace to lingerie.

Seam specification 605EFg-1. Standard gauges 56, (7/32", 5.6mm), 64, (1/4", 6.4mm).

Maximum recommended speed, depending on application is up to 6000 R.P.M.

FS335E42- ELASTIC - Same as style FS335E41 except puller with smooth roller.

FS322H01- HEMMING - Two of three needle, bottom coverstitch. Typical application - for hemming

on light to medium weight knit fabrics. Seam specifications for two needle 406EFa-1 (inv.),

for three needle 407EFa-1 (inv.). Standard gauge for two needle 40, (5/32" 4.0mm), 48,

(3/16", 4.8mm), for three needle 48, (3/16", 4.8mm), 56, (7/32", 5.6mm), 64, (1/4", 6.4mm).

Maximum recommended speed, depending on application is up to 6500 R.P.M.

FS332H01- HEMMING - Same as style FS322H01 except top and bottom coverstitch. Seam

specification for two needle 602EFa-1 (inv.), for three needle 605EFa-1 (inv.).

FS332L01- LAP SEAMING - Two or three needle, top and bottom coverstitch, tandem differential

feed. Typical application - for general seaming on fleece and knit garments. Seam

specification for two needle 602LSa-1, for three needle 605LSa-1. Standard gauges for

two needle 32, (1/8", 3.2mm), 40, (5/32", 4.0mm), for three needle 48, (3/16" 4.8mm),

56, (7/32", 5.6mm), 64, (1/4", 6.4mm). Maximum recommended speed, depending on

application is up to 6500 R.P.M.

FS332L21- LAP SEAMING - Same as style FS332L01 except three needle, off set differential feeds.

Standard gauges 56, (7/32", 5.6mm), 64, (1/4"6.4mm).

4

Page 5

ILLUSTRATIONS

This manual has been arranged to simplify ordering repair parts. Exploded views of various sections of the

mechanism are shown so that the parts may be seen in their actual position in the machine. On the page

opposite the illustration will be found a listing of the parts with their part numbers, description and the number

of pieces required in the particular view being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of the part in the

illustration. The reference number should never be used in ordering parts. Always use the part number listed

in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their

descriptions under the description of the main sub-assembly. As an example refer to the following text.

5. 50366B Needle Thread Strike-Off Assembly ............................................................................... 1

6. 50358V Needle Thread Strike-Off .................................................................................. 1

7. 50370F Thread Strike-Off Component .......................................................................... 1

8. SS7060310SP Screw, for plate strike-off .................................................................................. 1

When a part is common to all machines covered in this manual, no specific usage will be mentioned in the

description. However, when the parts for the various machines are not the same, the specific usage will be

mentioned in the description and, if necessary, the difference will be shown in the illustration.

*Ref. No. showing no Part No. is for location only. Part is not for sale separately.

A numerical index of all the parts shown in this manual is located at the back. This will facilitate locating the

illustration and description when only a part number is known.

IDENTIFYING PARTS

Where construction permits, each part is stamped with its part number. On some of the smaller parts and on those

where construction does not permit, an identification letter is stamped in to distinguish the part from similar ones.

PLEASE NOTE: Part numbers represent the same part, regardless of which manual they appear. On all

orders

NEEDLES

Each needle has both a type and size number. The type number denotes the kind of shank, point, length, groove,

finish and other details. The size number, stamped on the needle shank, denotes the largest diameter of the blade

measured between the shank and the eye. Collectively, the type number and size number represent the

complete symbol which is given on the label of all needles packed and sold by Union Special.

TYPE DESCRIPTION

128 GBS Short, double groove, struck groove, ball eye, spotted, ball point, chromium plated-

Sizes available 065/025, 070/027, 075/029, 080/032, 090/036.

When changing the needle, make sure it is fully inserted in the needle holder before the screw is tightened.

When ordering needles, please use the complete type and size numbers as printed on the package to ensure

prompt and accurate processing of your order. A complete order should read as follows: "100 needles, type 128

GBS, size 075/029".

5

Page 6

SAFETY RULES

1. Before putting the machines described in this manual into service, carefully read the instructions. The

starting of each machine is only permitted after taking notice of the instructions and by qualified

operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and instructions from the

motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction manual are prohibited from being put into service until

it has been ascertained that the sewing units which these sewing machines will be built into, have

conformed with the EC Council Directives (89/392/EEC, Annex II B).

Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is

described in paragraph “STYLES OF MACHINES” of this instruction manual. Another use, going beyond

the description, is not as foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation

of the machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and changes all valid safety rules must be considered. Conversions

and changes are made at your own risk.

7. The warning hints in the instructions are marked with one of these two symbols:

8. When doing the following the machine has to be disconnected from the power supply by turning off

the main switch or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader, feed dog,

needle guard, folder, fabric guide etc.

8.3 When leaving the workplace and when the workplace is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or

special skilled personnel under consideration of the instructions.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision

of special skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are

described in the applicable sections of standard sheet DIN VDE 0105.

12. Before doing maintenance and repair work on the pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In case of existing residual air pressure, after disconnecting from compressed air supply (i.e. pneumatic equipment with air tank), the pressure has to be

removed by bleeding.

6

Page 7

7

Page 8

8

Page 9

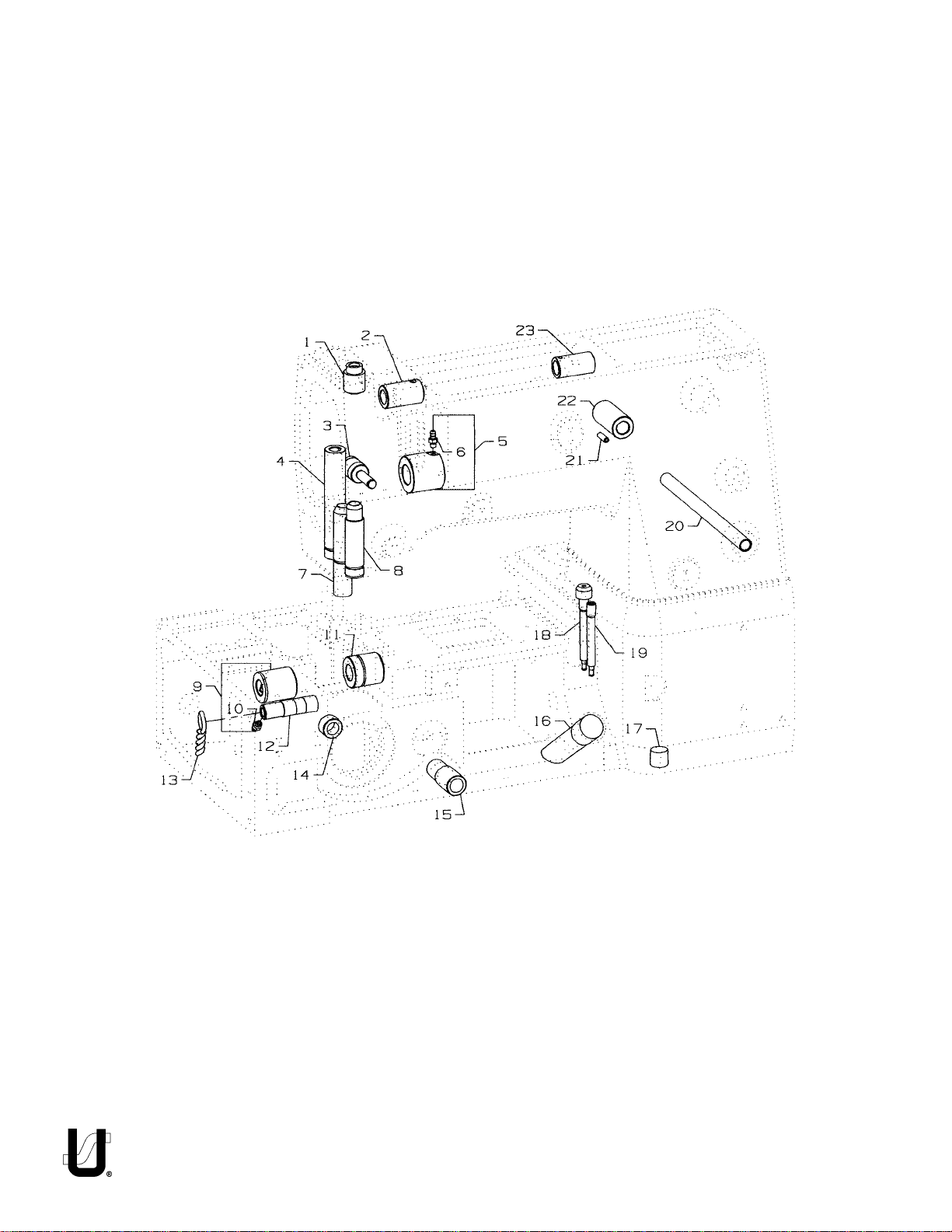

BUSHINGS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

.

Part No.

50354J

50347F

50332U

50347L

50344BU

SQ1110401MZ

50330CZ

50354H

50344BE

SQ1110401MZ

50344BF

50344BC

CL21A

50344E

35036AB

50393GE

22571L

50393EY

50393FU

50392AB

PS0400142KH

50381E

50347E

Description

Bushing, for needle bar, upper ....................................................................

Bushing, for spreader, front .........................................................................

Pin, for front lifter lever .................................................................................

Bushing, for spreader drive .........................................................................

Bushing, front ..............................................................................................

Fitting ....................................................................................................

Bushing, for presser bar ...............................................................................

Bushing, for needle bar, lower .....................................................................

Bushing, for lower mainshaft, left ................................................................

Fitting ....................................................................................................

Bushing, for lower mainshaft, right ..............................................................

Bushing, for needle lever .............................................................................

Oil Wick .................................................................................................

Bushing .......................................................................................................

Stitch Regulator Bushing .............................................................................

Oil Sight Gauge ...........................................................................................

Screw, for drain plug ...................................................................................

Fitting, filter .................................................................................................

Fitting, oil tube .............................................................................................

Bushing, for tension release.........................................................................

Pin ...............................................................................................................

Bushing, for lifter lever, back .......................................................................

Bushing, for spreader, rear ..........................................................................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

9

Page 10

10

Page 11

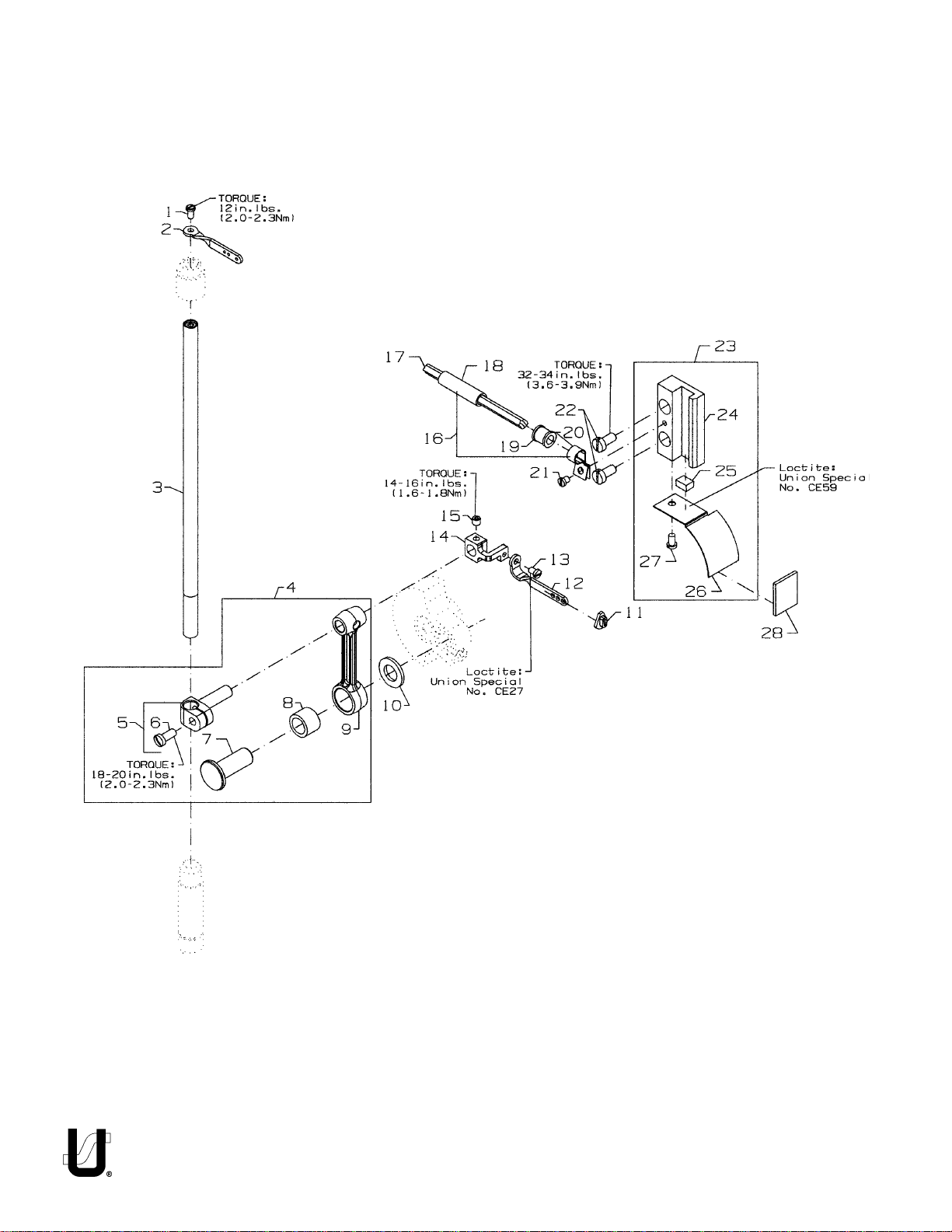

NEEDLE BAR

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

.

Part No.

SS4080620TP

50323P

50317B

50345W

50355AM

SS7111120TP

50352

661-259B

50355AN

50351A

50393JP

50358X

SS7080520SP

-

CE27

50354F

-

CE63

SS8110422TP

29476TC

CQ25220000

50393JY

50393JZ

50393JW

SS6090440SP

SS6121010SP

50354G

50393HS

-

CE59

50394AF

SS6090620SP

Description

Screw ..........................................................................................................

Needle Bar Eyelet .......................................................................................

Needle Bar ..................................................................................................

Connecting Rod Assembly .........................................................................

Needle Bar Clamp ................................................................................

Screw .............................................................................................

Pivot Pin ................................................................................................

Needle Bearing Cage ...........................................................................

Connecting Rod ...................................................................................

Washer ........................................................................................................

Eyelet Seal ...................................................................................................

Needle Thread Eyelet .................................................................................

Screw ..........................................................................................................

Loctite Adhesive, (not shown), for screw ....................................................

Slide Block ...................................................................................................

Three Bond Adhesive, (not shown), for slide block ......................................

Screw ..........................................................................................................

Oil Tube Assembly .......................................................................................

Cable ...................................................................................................

Oil Tube .................................................................................................

Oil Tube .................................................................................................

Hose Clamp ..........................................................................................

Screw, for support bracket ..........................................................................

Screw ..........................................................................................................

Slide Block Guide ........................................................................................

Sponge .......................................................................................................

Loctite Adhesive, (not shown), for sponge ..................................................

Slide Block Guide Cover ..............................................................................

Screw ..........................................................................................................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

-

1

1

1

1

1

1

1

1

2

1

1

1

1

11

Page 12

12

Page 13

UPPER MAIN SHAFT

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

.

Part No.

50391

SS7111120TP

SS8681412TP

SS7681410TP

50322AF

50335BD

SS8660612TP

661-262

50342BE

SS8661012TP

50321M

SS8681412TP

660-1043

661-261

SS7660520SP

Description

Counter Weight ..........................................................................................

Screw, for counter weight ....................................................................

Screw, for counter weight ....................................................................

Screw, for counter weight ....................................................................

Upper Main Shaft ........................................................................................

Bearing Adapter Assembly .........................................................................

Screw, for bearing adapter ..................................................................

Retaining Ring .............................................................................................

Sprocket, for upper main shaft ....................................................................

Set Screw, for sprocket .........................................................................

Handwheel .................................................................................................

Set Screw, for handwheel .....................................................................

Tack Pin, for handwheel .......................................................................

Load Ring, for lower main shaft ...................................................................

Screw, for handwheel preload ...................................................................

Amt.

Req.

1

1

1

1

1

1

2

1

1

2

1

2

1

2

1

13

Page 14

14

Page 15

SPREADER

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

.

Part No.

50335AW

SS8660512TP

96162B

50360B

50347J

50347C

SS8110422TP

61351C

660-739

50347G

50346A

SS7080510TP

SS7110910TP

53678N

SS9090640SP

50360H

29126FW

50360G

SS7121410TP

NS6680410SP

50360F

WP0742016SP

SD1000801SH

50360

SS8660612TP

Description

Collar, for spreader shaft ............................................................................

Set Screw ..............................................................................................

Washer ........................................................................................................

Crankshaft, for spreader assembly .............................................................

Pin, for spreader rocker ...............................................................................

Lever, for spreader holder shaft ..................................................................

Screw ....................................................................................................

Washer ........................................................................................................

Oil Seal ........................................................................................................

Shaft, for spreader, vertical ........................................................................

Spreader Holder ..........................................................................................

Screw ....................................................................................................

Screw ....................................................................................................

Washer ........................................................................................................

Hex Screw, for vertical shaft ........................................................................

Spreader .....................................................................................................

Spreader Crank Rod Assembly ....................................................................

Spreader Shaft Driving Arm ...................................................................

Screw .............................................................................................

Hex Nut, for spreader drive ...................................................................

Connecting Rod, for spreader drive .....................................................

Collar, for spreader driving arm ............................................................

Stud ......................................................................................................

Eccentric, for spreader drive ......................................................................

Screw ....................................................................................................

Amt.

Req.

1

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

2

15

Page 16

16

Page 17

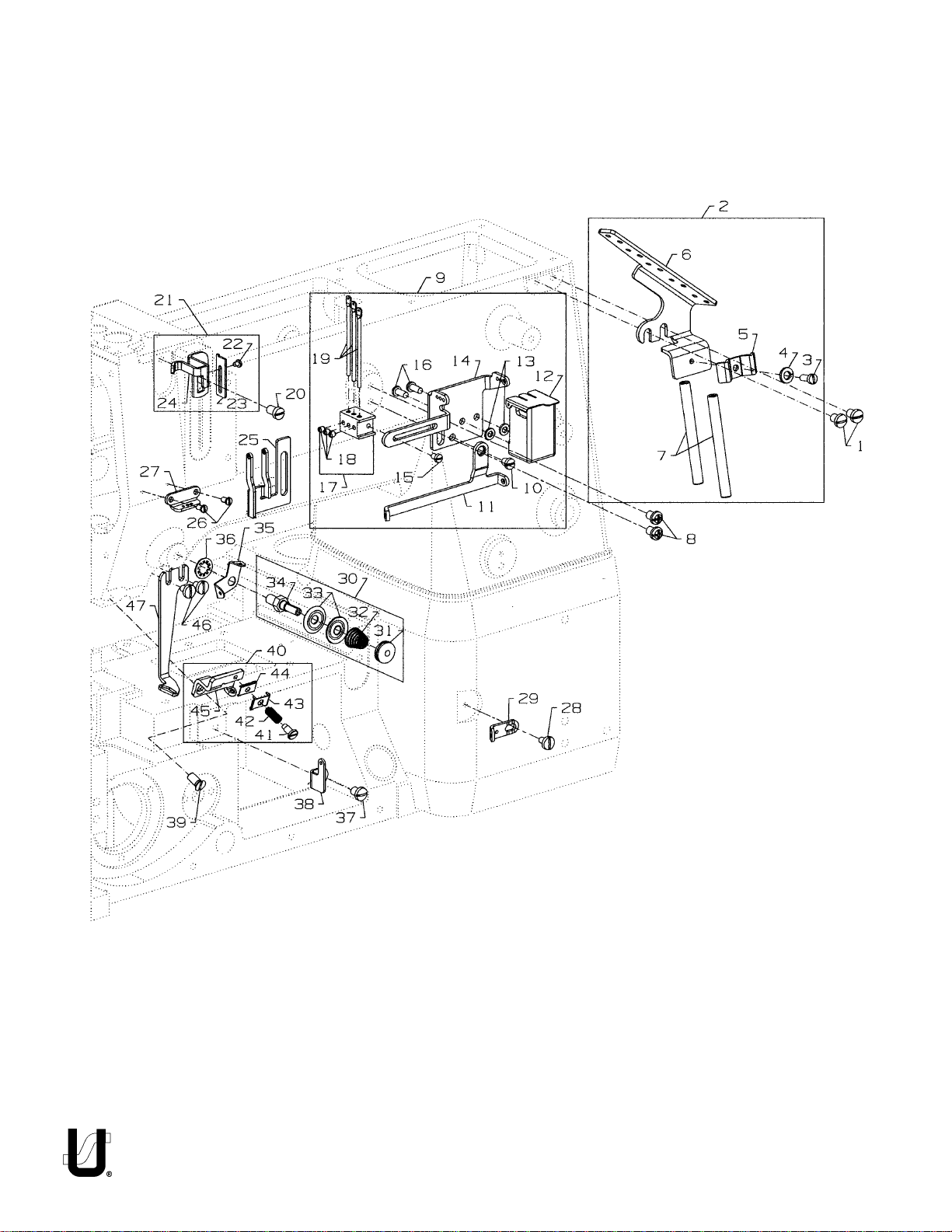

THREAD GUIDE

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

.

Part No.

SS7120640SP

50392AU

SS7090910TP

WS0510002KP

50366A

50392S

50366

SS4120615SP

50363CK

SS7110410SP

50358U

50393HH

WP0371026SD

50366J

SS7080510TP

SS4090815SP

50358W

SS8080410TP

36271A

SS7120710SP

50366B

SS7060310SP

50370F

50358V

50392T

605A

C50044E

SS7090610SP

12124202

29475CG

50392AZ

50392AY

50392AX

50392AW

57844

652C16

SS7120640SP

50392AE

SS1121010SP

50357AR

SD0380551SL

50357AS

50357Y

50357V

50366G

SS7090610SP

50346

Description

Screw, for lead-in eylet ...............................................................................

Thread Eyelet Assembly ..............................................................................

Screw ....................................................................................................

Split Washer ..........................................................................................

Thread Eyelet Tube Bracket ..................................................................

Lead-In Tension Eyelet ..........................................................................

Thread Eyelet Tube ...............................................................................

Screw, for needle thread guide ..................................................................

Needle Thread Guide and Lubricator Assembly .........................................

Screw, for spreader thread guide .........................................................

Thread Guide, for spreader ..................................................................

Silicone Thread Lubricator ....................................................................

Washer .................................................................................................

Needle Thread Guide ...........................................................................

Screw, for holder eyelet ........................................................................

Screw, for silicone tank .........................................................................

Holder, for needle thread eyelet ..........................................................

Screw .............................................................................................

Adjusting Needle Thread Eyelet ............................................................

Screw, for strike-off .....................................................................................

Needle Thread Strike-Off Assembly .............................................................

Screw, for plate strike-off ......................................................................

Thread Strike-Off Component ..............................................................

Needle Thread Strike-Off ......................................................................

Eyelet ..........................................................................................................

Screw, for needle thread guide ..................................................................

Needle Thread Guide .................................................................................

Screw ..........................................................................................................

Looper Frame Eyelet ...................................................................................

Spreader Thread Tension Assembly .............................................................

Tension Nut ...........................................................................................

Tension Spring .......................................................................................

Tension Disc ..........................................................................................

Tension Post ..........................................................................................

Eyelet ..........................................................................................................

Star Washer .................................................................................................

Screw ..........................................................................................................

Looper Frame Eyelet ...................................................................................

Screw, for thread guide ..............................................................................

Nipper Plate Assembly ................................................................................

Screw ....................................................................................................

Nipper Spring ........................................................................................

Nipper Spring Plate ...............................................................................

Nipper Plate ..........................................................................................

Thread Guide ........................................................................................

Screw, for spreader thread guide ...............................................................

Thread Guide Spreader ..............................................................................

Amt.

Req.

2

1

1

1

1

1

2

2

1

1

1

1

2

1

1

2

1

3

3

1

1

1

1

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

17

Page 18

18

Page 19

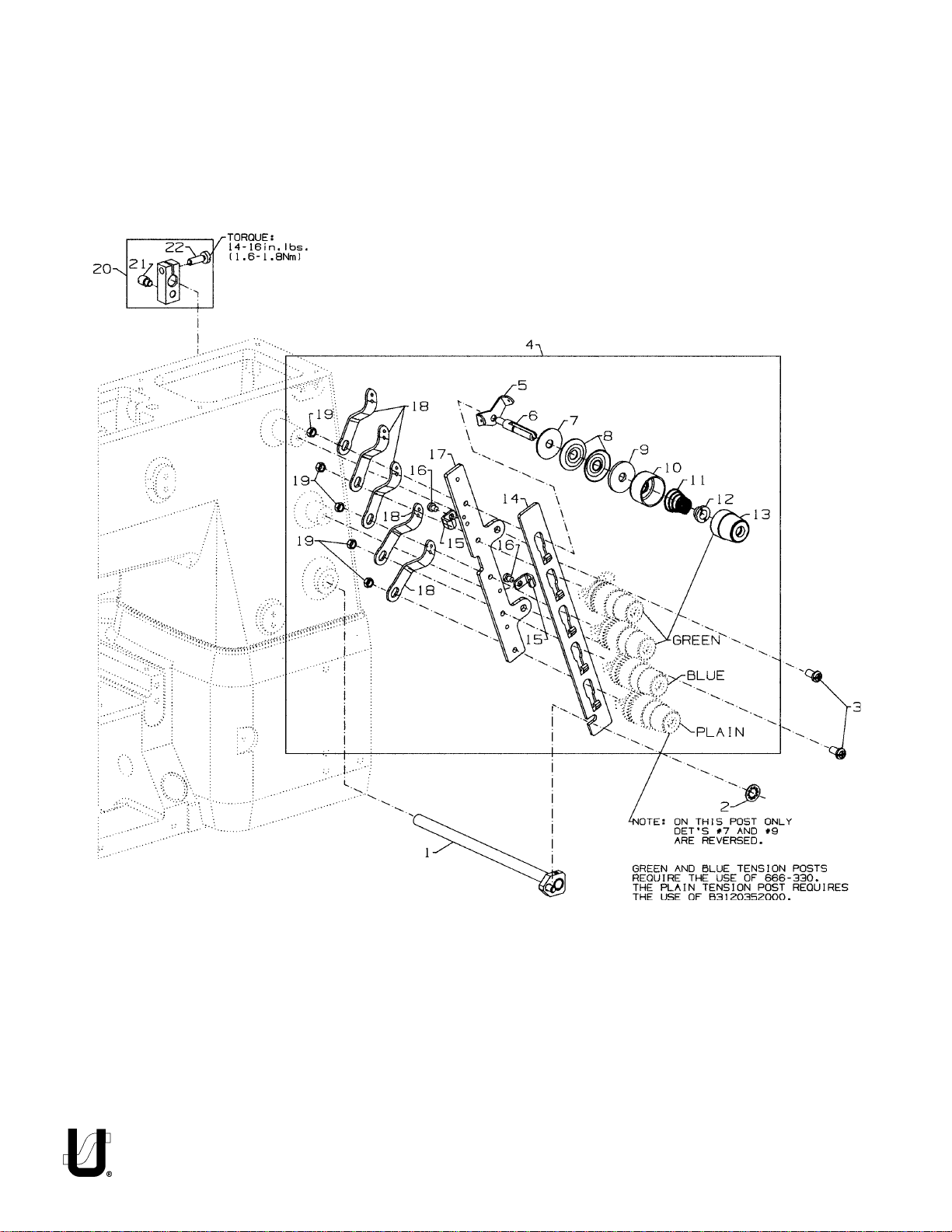

TENSION RELEASE & THREAD TENSION

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

.

Part No.

50392Z

660-283A

SS4120915SP

50392Y

57892K

56392G

B3120352000

-

666-330

B3126012000

B3120704000

56392H

11550209

-

B3103804000

-

B3121804000

B3112704000

50692G

-

56392M

-

56392R

50392W

50392AV

SS7090520SP

50392X

57865

NS6110420SP

50392BC

22875N

SS7121410TP

Description

Tension Needle Lever Assembly ..................................................................

Retainer Washer .........................................................................................

Screw, for tension assembly ........................................................................

5 Thread Tension Assembly ..........................................................................

Thread Tension Eyelet ...........................................................................

Tension Post ..........................................................................................

Tension Disc Felt ....................................................................................

Disc Felt ................................................................................................

Tension Disc ..........................................................................................

Tension Disc Felt ....................................................................................

Spring Shield .........................................................................................

Spring, needle (green) .........................................................................

Spring, spreader (blue) .........................................................................

Spring, looper (plain) ............................................................................

Ferrule, tension spring ...........................................................................

Knob, needle (green) ...........................................................................

Knob, spreader (blue) ..........................................................................

Knob, looper (plain) ..............................................................................

Tension Disc Separator .........................................................................

Guide, for tension disc separator ..........................................................

Screw, for guide ....................................................................................

Tension Bracket ....................................................................................

Lead-In Thread Guide ...........................................................................

Nut ........................................................................................................

Tension Release Lever Shaft Connection ....................................................

Base Spring Screw .................................................................................

Binder Screw .........................................................................................

Amt.

Req.

1

1

2

1

5

5

1

4

10

5

5

3

1

1

5

3

1

1

1

2

2

1

5

5

1

1

1

19

Page 20

20

Page 21

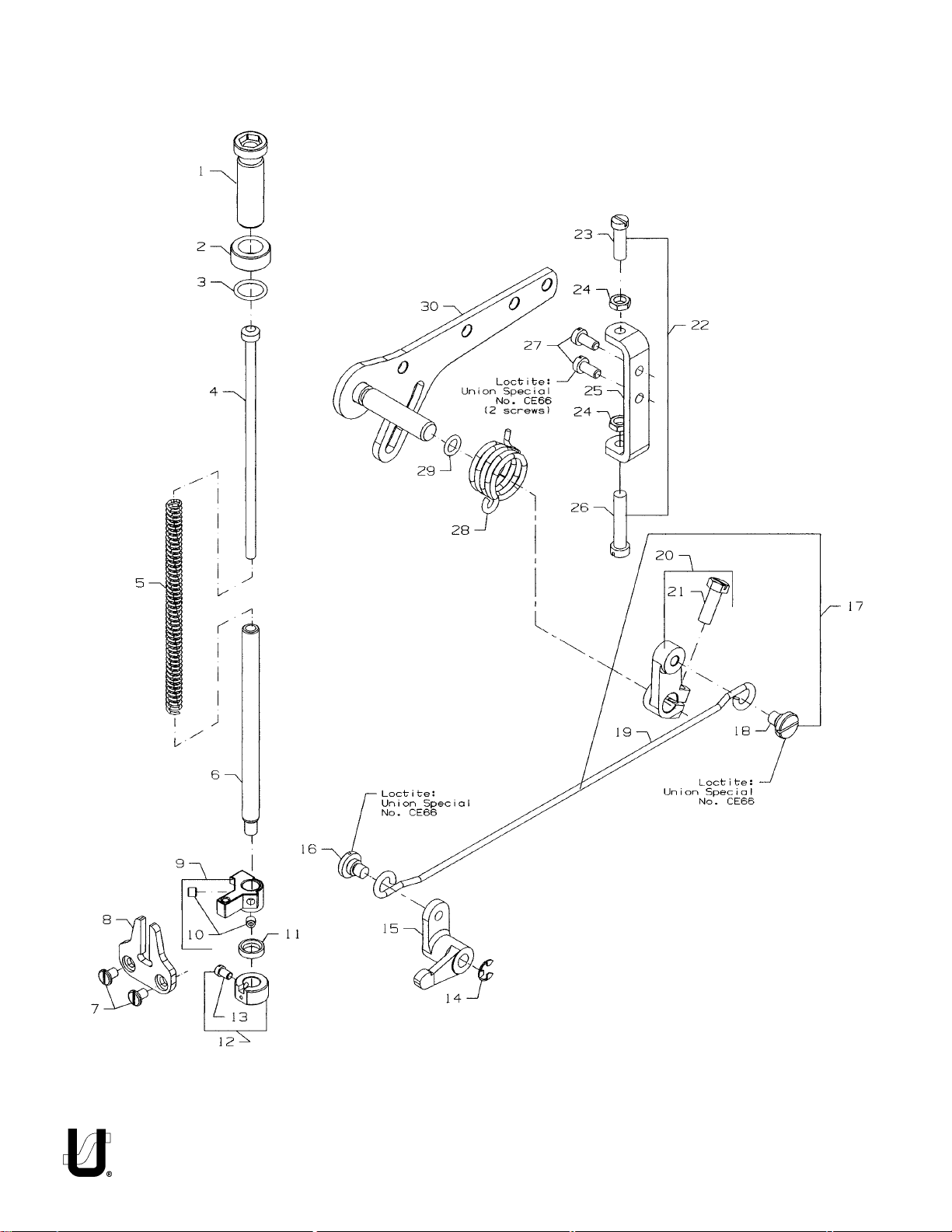

PRESSER FOOT LIFT

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

.

Part No.

11071602

11071701

660-1014

C50056B

50357AP

50335AF

SS6110610TP

50335AG

50335AH

SS8110422TP

660-739

50333P

22562

RE0500000K0

50381F

SD0790303SP

-

CE66

29476TK

SD0790303SP

50355AR

50381G

SS9151740CP

29476TT

SS6121010SP

NS6150310SP

50332V

SS6153040SP

SS6151920SP

-

CE66

50381

RO068190100

50381B

Description

Adjusting Screw, for spring ..........................................................................

Locking Nut .................................................................................................

"O" Ring .......................................................................................................

Spring Rod ..................................................................................................

Spring, for presser bar .................................................................................

Presser Bar ..................................................................................................

Screw, for guide plate ................................................................................

Guide Plate, for presser bar ........................................................................

Presser Bar Guide ........................................................................................

Set Screw ..............................................................................................

Oil Seal ........................................................................................................

Collar ..........................................................................................................

Screw ...................................................................................................

E Ring, for pin ..............................................................................................

Lever, for lifter, front ....................................................................................

Screw, for wire connector ..........................................................................

Loctite Adhesive, (not shown), for screw ....................................................

Rear Lifter Lever Assembly ..........................................................................

Screw ...................................................................................................

Wire Connector ..........................................................................................

Lifter Lever, rear ..........................................................................................

Hex Screw .............................................................................................

Stop Assembly ............................................................................................

Screw, for stopper ................................................................................

Hex Nut .................................................................................................

Stopper, for lifter lever ..........................................................................

Screw, for adjusting stopper .................................................................

Screw, for adjusting stopper .................................................................

Loctite Adhesive, (not shown), for screw ....................................................

Spring, for lifter lever ...................................................................................

"O" Ring .......................................................................................................

Lifter Lever Assembly ..................................................................................

Amt.

Req.

1

1

1

1

1

1

2

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

21

Page 22

22

Page 23

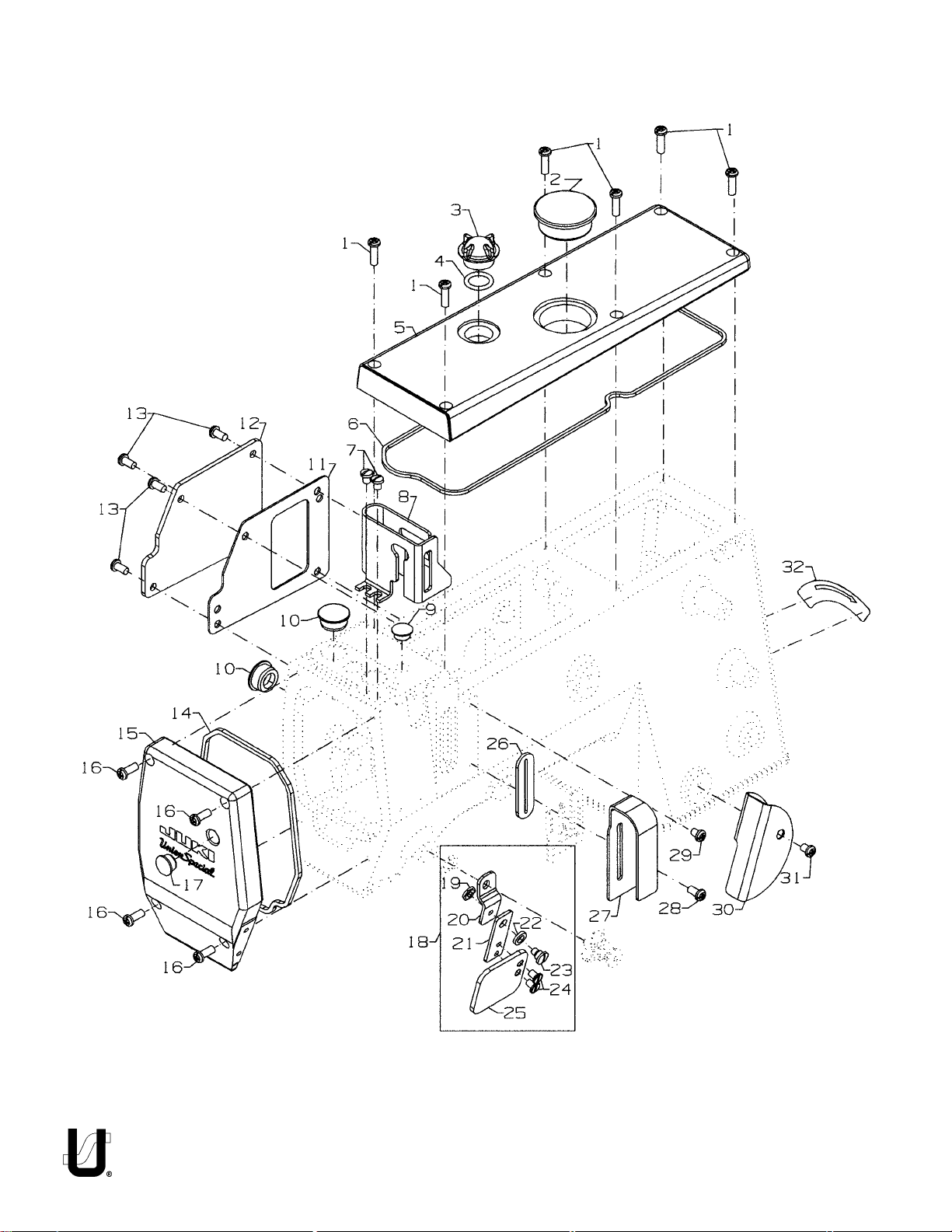

COVERS, UPPER ARM

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

.

Part No.

SS4121615SP

50393EU

B3530555000

660-212

50382FW

50382FZ

SS7120640SP

50317C

TA1050504R0

50393HB

50384L

50382GB

SS4120915SP

50382FY

50382FX

SS4121215SP

TA1100604R0

99682XCB

NS6620320SP

50383AE

50383AD

WZ0641510KP

SD0640323TP

SS6110610SL

99682XC3

50393EW

50382GA

SS4120915SP

SS4120615SP

50382GM

SS4120615SP

LA452

Description

Screw, for top cover ....................................................................................

Plug, for top cover .......................................................................................

Oil Sight Gauge, top ....................................................................................

"O" Ring, for oil sight gauge .........................................................................

Top Cover ...................................................................................................

Quad Ring, for top cover ............................................................................

Screw, for needle bar guard .......................................................................

Needle Bar Guard .......................................................................................

Plug, for bed ................................................................................................

Plug, for bed ................................................................................................

Gasket, for puller drive cover ......................................................................

Puller Drive Cover .......................................................................................

Screw, for puller drive cover .......................................................................

Quad Ring, for head cover .........................................................................

Head Cover ................................................................................................

Screw, for head cover .................................................................................

Plug, for head cover ...................................................................................

Protection Shield Assembly, for all styles except FS322E12 & FS332E12 ....

Nut ........................................................................................................

Bracket Holder ......................................................................................

Bracket .................................................................................................

Spring Washer .......................................................................................

Shoulder Screw .....................................................................................

Counter Sunk Head Screw ....................................................................

Protection Shield ..................................................................................

Rubber Gasket, for needle lever ................................................................

Cover, for thread take-up ...........................................................................

Screw, for thread take-up cover .................................................................

Screw, for thread cover ..............................................................................

Thread Cover ..............................................................................................

Screw, for thread take-up cover .................................................................

Label, direction of rotation .........................................................................

Amt.

Req.

6

1

1

1

1

1

2

1

1

2

1

1

4

1

1

4

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

23

Page 24

24

Page 25

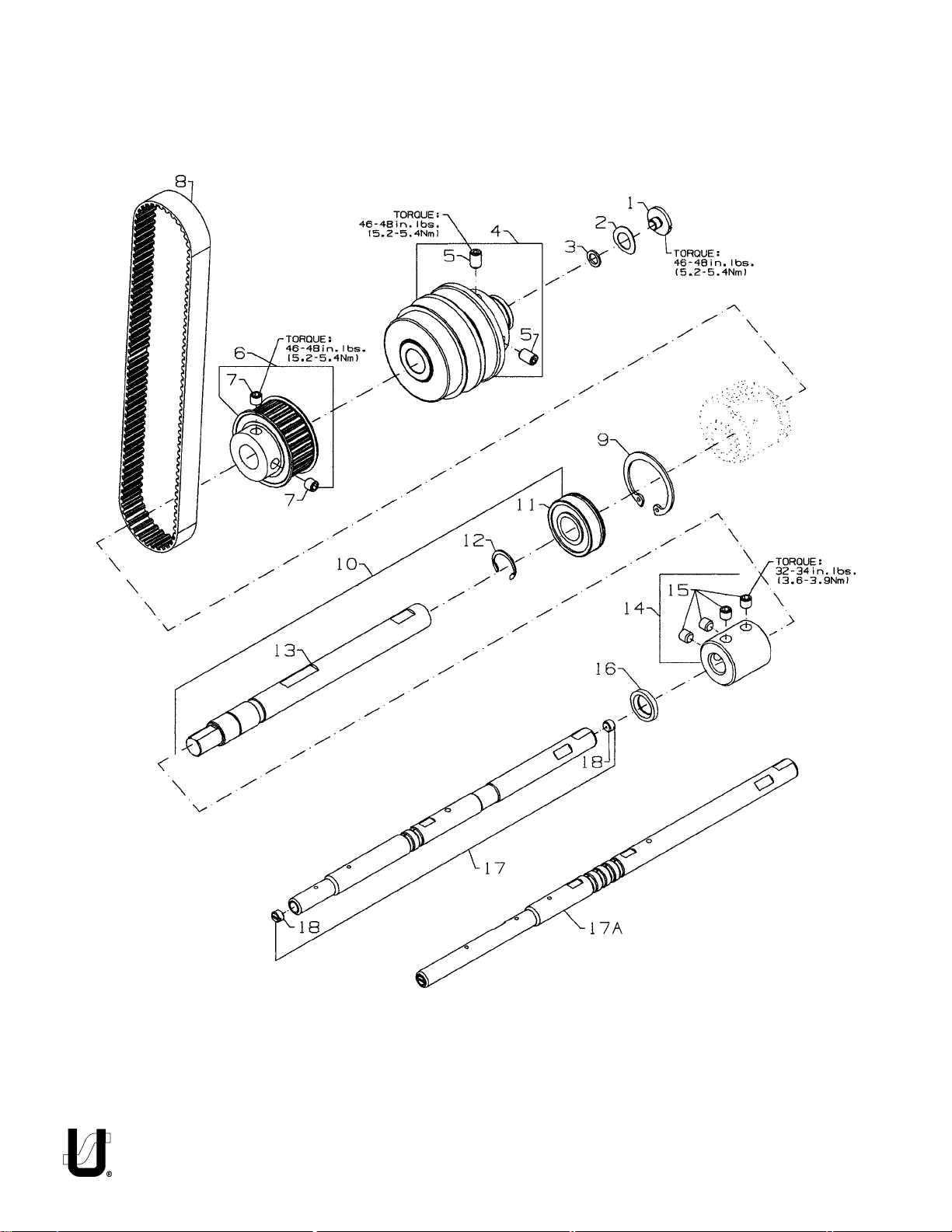

LOWER MAIN SHAFT

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

17A.

18.

.

Part No.

SS7660520SP

660-1062

50374

50321G

SS8661012TP

50342AX

SS8660612TP

50342BS

50335AK

29476UH

50322AL

50335BB

50322AG

50333A

SS8660612TP

660-934

50322AU

50322AT

SS8660410SP

Description

Shoulder Screw, for lower main shaft, right .................................................

Spring Washer .............................................................................................

Spacer, for pulley assembly ........................................................................

Pulley Assembly ..........................................................................................

Set Screw ..............................................................................................

Sprocket, for lower main shaft .....................................................................

Screw ....................................................................................................

Timing Belt ...................................................................................................

Retaining Ring, for ball bearing ...................................................................

Mainshaft Assembly, lower right ..................................................................

Ball Bearing, for lower main shaft ..........................................................

Retaining Ring ......................................................................................

Lower Main Shaft, right .........................................................................

Coupling, for lower main shafts ...................................................................

Screw ....................................................................................................

Oil Seal ........................................................................................................

Lower Main Shaft, left ..................................................................................

Lower Main Shaft, left, for FS322E12, FS332E12 ............................................

Screw ....................................................................................................

Amt.

Req.

1

1

1

1

2

1

2

1

1

1

1

1

1

1

4

1

1

1

2

25

Page 26

26

Page 27

LUBRICATION, OIL TUBING & OIL PUMP

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

.

Part No.

50393HN

18-1470

50332S

34393D

50393EX

SS8660612TP

50393GB

50393GD

SS4091015SP

50393FR

50384

11843208

50393FV

SS7120710SP

29476US

NS6110310SP

50393KC

SQ1110402MZ

50393-27

50393KM

50393-407

50393-140

29476UT

50393KH

50393-70

50393KM

13765607

50393-140

50393-40

50393-170

50393KF

50393KM

50393HR

50393HL

50393FS

998-358F

53678N

SS4090815SP

50393HK

SS6151812TP

WS0631510KP

22571E

RM2871B

50393EB

50384A

50393FT

50393HJ

Description

Oil Pump Assembly, 2-stage .........................................................................

Screw .....................................................................................................

Spring, for plunger..................................................................................

Plunger ..................................................................................................

Collar, for oil pump .................................................................................

Screw ...............................................................................................

Oil Pump Housing, 2 Stage......................................................................

Oil Pump Housing, 2 Stage......................................................................

Screw, for oil filter cover................................................................................

Cover, for oil filter..........................................................................................

"O" Ring, for oil filter cover.............................................................................

Oil Filter.........................................................................................................

Oil Tube, for supply (1) ..................................................................................

Screw ...........................................................................................................

Oil Supply Assembly, upper ..........................................................................

Nut .........................................................................................................

Oil Gutter ...............................................................................................

Fitting .....................................................................................................

Oil Tube ..................................................................................................

Tube Retaining, spring ...........................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Supply Assembly, lower ...........................................................................

Tube Retaining, spring ...........................................................................

Oil Tube ..................................................................................................

Tube Retaining, spring ...........................................................................

"T" Connector .........................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Tube Retaining, spring ...........................................................................

Plug, for feed chamber ..........................................................................

Oil Tube, for suction ................................................................................

Oil Tube Holder .............................................................................................

Plastic Clip ....................................................................................................

Washer .........................................................................................................

Screw, for oil tube holder ..............................................................................

Felt ...............................................................................................................

Screw, for oil pan ..........................................................................................

Spring Washer ..............................................................................................

Screw, for oil drain plug ................................................................................

Cable Tie ......................................................................................................

Oil Pan ..........................................................................................................

"O" Ring ........................................................................................................

Oil Tube, for suction ......................................................................................

Oil Tube, for suction ......................................................................................

Amt.

Req.

1

2

2

2

1

2

1

1

3

1

1

1

1

2

1

1

1

1

1

4

1

1

1

2

1

5

2

1

1

1

1

3

1

1

1

1

1

1

1

6

6

1

2

1

1

1

1

27

Page 28

28

Page 29

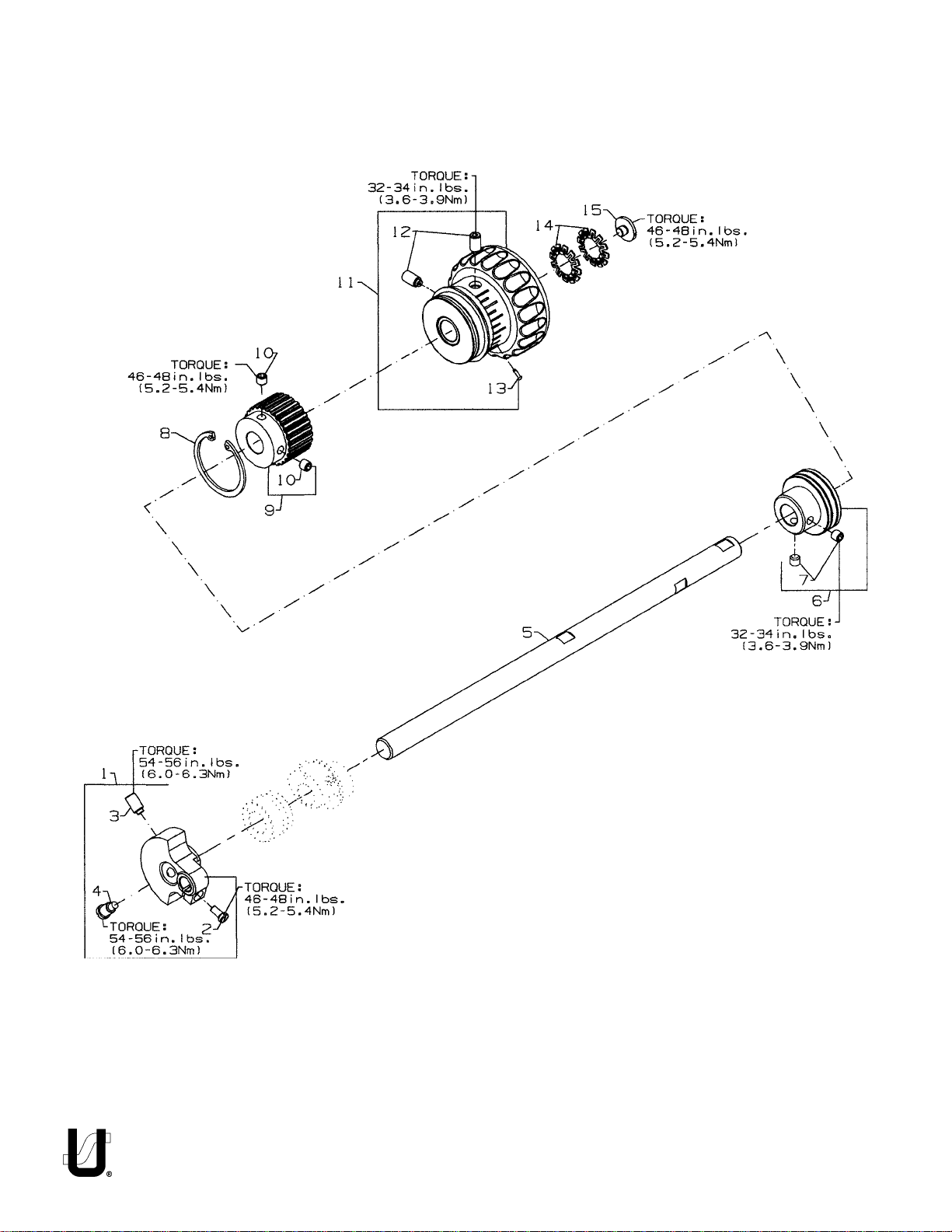

LOOPER DRIVE

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

.

-

Part No.

50313P

22652B10

22565

50309K

SS7120910SP

CE63

660-893

50344AM

660-455

50313J

SS7120910SP

50314J

50314E

50313M

22653J8

667J33

660-979

50342BJ

SS8660612TP

50342BK

SS8660612TP

50342BP

Description

Looper Holder .............................................................................................

Screw, for looper holder .......................................................................

Screw, for looper holder .......................................................................

Looper ........................................................................................................

Screw, for bearing housing .........................................................................

Three Bond Adhesive, (not shown), for screw ..............................................

Oil Seal, looper ............................................................................................

Bearing Housing Assembly, for looper drive ................................................

"O" Ring, for bearing housing assembly .......................................................

Looper Rocker Assembly .............................................................................

Screw, for retaining plate ............................................................................

Eccentric Retaining Plate ...........................................................................

Looper Avoid Adjusting Eccentric...............................................................

Looper Drive Assembly ................................................................................

Screw ....................................................................................................

Crank Pin ..............................................................................................

"O" Ring .................................................................................................

Sprocket, for looper driven .........................................................................

Screw ....................................................................................................

Sprocket, for looper drive ...........................................................................

Screw ....................................................................................................

Looper Drive Belt .........................................................................................

Amt.

Req.

1

1

1

1

3

1

1

1

1

2

1

1

1

1

1

2

1

2

1

2

1

29

Page 30

30

Page 31

NEEDLE GUARD

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

.

Part No.

29476UJ

50373DA

SS8110422TP

50368W

50368T

SS8110422TP

50368V

50368E

50368A

50374

50354L

SS8110422TP

50325AF

50325AE

SS9090420TP

SS7060310SP

50325AJ

Description

Rear Needle Guard Drive Assembly ............................................................

Needle Guard Eccentric ......................................................................

Screw, for needle guard eccentric ................................................

Connecting Rod Assembly, for needle guard ......................................

Pivot Link ...............................................................................................

Screw .............................................................................................

Shaft, for needle guard ..................................................................

Washer .................................................................................................

Pivot Pin ................................................................................................

Washer ........................................................................................................

Coupling, for needle guard ........................................................................

Screw ....................................................................................................

Holder, for needle guard ............................................................................

Needle Guard, rear .....................................................................................

Screw, for rear needle guard ......................................................................

Screw, for front needle guard .....................................................................

Needle Guard, front ....................................................................................

Amt.

Req.

1

1

2

1

1

2

1

2

1

1

1

2

1

1

1

1

1

31

Page 32

32

Page 33

LOOPER THREAD TAKE-UP

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

.

Part No.

50357AM

SD0380551SL

50332AC

50347R

51959B

SS7060310SP

52958D

50357AN

50304N

SS6080410SP

SS6110610TP

29476UK

SS9111010SP

50383F

50304K

50386J

SD0630275SP

SS9111010SP

50323R

SS8660612TP

Description

Cast-Off Plate Assembly .............................................................................

Knurled Nut ...........................................................................................

Tension Spring .......................................................................................

Roll Pin ..................................................................................................

Tension Disc ..........................................................................................

Screw ....................................................................................................

Take-up Eyelet ......................................................................................

Cast-off Plate .......................................................................................

Retaining Finger ....................................................................................

Screw ....................................................................................................

Screw, for cast-off holder ............................................................................

Cast-Off Plate Holder Assembly ..................................................................

Screw, for collar bracket ......................................................................

Take-up Collar Bracket .........................................................................

Cast-Off Plate Holder ............................................................................

Washer .................................................................................................

Shoulder Screw, for cast-off plate holder .............................................

Screw, for collar bracket .............................................................................

Take-up Assembly .......................................................................................

Set Screw ..............................................................................................

Amt.

Req.

1

1

1

1

2

4

3

1

1

2

1

1

1

1

1

1

1

1

1

2

33

Page 34

34

Page 35

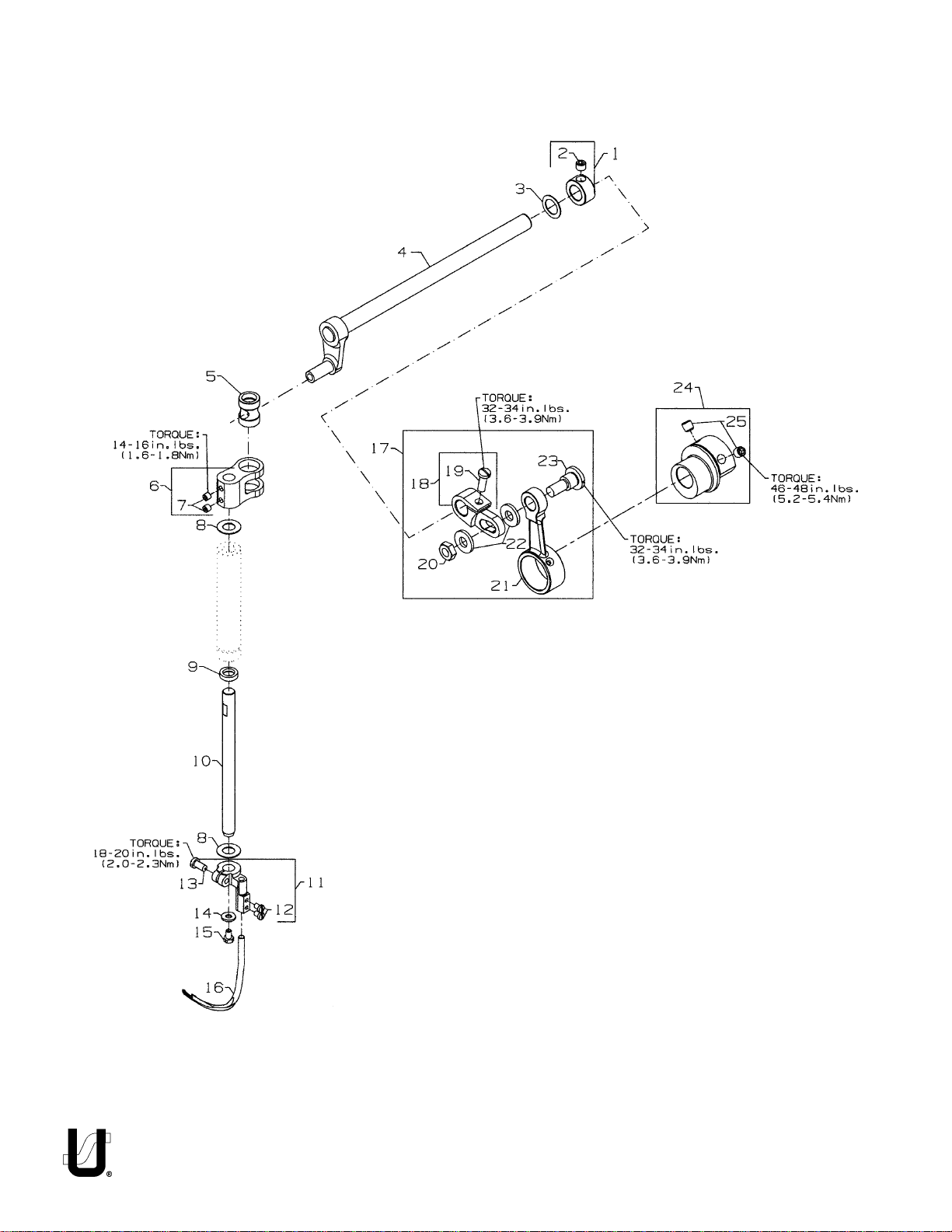

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

.

Part No.

18-1432

50334BD

50334AW

50334BE

50334AX

50340D

SS8660612TP

SS7090530SP

50334Y

50334V

50334BH

50335AM

50335BA

50334BJ

50335AN

RO0681190100

50337J

SS4121215SP

29476YH

50337H

50337U

50337BD

SS7090610SP

B1647704000A

50387

SS7090610SP

50337S

SS8110422TP

50337L

SS6110650TP

50337R

SS8090710SP

SS6091022TP

SP0550271TP

50337M

50340F

SS8660612TP

FEED DRIVE MECHANISM

FOR

FS322C01, FS332CO1, FS335E41, FS335E42

FS322H01, FS332H01, FS332L01, FS332L21

Description

Screw .....................................................................................................

Hex Eccentric Stud .................................................................................

Drive Fork Assembly ................................................................................

Feed Bar Assembly .................................................................................

Drive Fork Assembly, right .......................................................................

Feed Eccentric, main .............................................................................

Screw ...............................................................................................

Screw .....................................................................................................

Oil Shield .................................................................................................

Oil Scraper .............................................................................................

Feed Bar Seal ..........................................................................................

Guide Plate, left, rear .............................................................................

Guide Plate, right, rear ...........................................................................

Feed Bar Seal ..........................................................................................

Guide Plate, front ...................................................................................

"O" Ring ..................................................................................................

Stem, for differential feed lever ..............................................................

Screw, for stem .......................................................................................

Differential Feed Lever Assembly ...........................................................

Differential Feed Lever .....................................................................

Stop ..................................................................................................

Plate, for differential feed lever .......................................................

Screw ...............................................................................................

Knob, for differential feed lever .......................................................

Screw ...............................................................................................

Screw .....................................................................................................

Collar .....................................................................................................

Screw ...............................................................................................

Coupling, for differential feed lever .......................................................

Screw ...............................................................................................

Collar, for differential feed lever ............................................................

Screw ...............................................................................................

Screw ...............................................................................................

Screw, for spring .....................................................................................

Spring, for differential feed lever ............................................................

Feed Eccentric, differential ...................................................................

Screw ..............................................................................................

Amt.

Req.

2

2

1

1

1

1

2

10

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

2

1

2

1

2

1

1

1

1

1

1

2

35

Page 36

36

Page 37

FEED DRIVE MECHANISM

FOR

FS322E12 & FS332E12

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

.

Part No.

18-1432

50334BD

50340F

SS8660612TP

50334AW

50334BE

50334AX

50340D

SS8660612TP

SS7090530SP

50334Y

50334V

50334BH

50335AM

50335BA

50334BJ

50335AN

50337S

SS8110422TP

50337L

SS6110650TP

50335AS

SS8110422TP

50336V

50332W

18-1445

NS6110530SP

RO068190100

50337Y

SS4121215SP

29476YH

50337H

50337U

50337BD

SS7090610SP

B1647704000A

50387

SS7090610SP

Description

Screw ..........................................................................................................

Hex Eccentric Stud ......................................................................................

Feed Eccentric, differential ........................................................................

Screw, for Feed Eccentric, differential..................................................

Drive Fork Assembly, left ..............................................................................

Feed Bar Assembly ......................................................................................