Page 1

•

Finest Quality

2-3

NEEDLE

FLAT

BED

COVERSEAM

MACHINE

FS300

SERIES

2-3

NEEDLE

CYLINDER

BED

COVERSEAM

MACHINE

CS100

SERIES

ENGINEER'S

MANUAL

EN9424

REV. 03/19/99

Page 2

•

PREFACE

This Engineer's Manual

is

written

tor

the technical personnel

who

are responsible

for

the service and maintenance

of

the machine.

This manual describes

"Standard Adjustment", "Adjustment Proceduresft,

~Results

of

lmproperAdjustment~,

and other

important information which are

not

covered

by

the

Instruction Manual.

It

is

advisable to use the relevant Instruction Manual and Parts List together with this Engineer's Manual when carrying

out

the

maintenance

oi

these

machines.

This manual gives the

"Standard adjustment" on the former page under which the most basic adjustment value and on

the latter page

the

"Results

of

improper adjustment" under which errors and troubles arise .

Page 3

CONTENTS

1.

SPECIFICATIONS

...•.............•••......•....•.•.•••..........•..........•...••.•••......••••.•••••••••••••••••••••.•••••••••••.••••.•••••••••••••••..•••••.

4

2.

MOTOR

PULLEY

AND

BELT

.••••••••.••...•.•••••.•••..........•..•.••.......•

; .............................................................................. 5

3.

MODEL

NUMBERING

SYSTEM

............................................................................................................................ 6

4.

STANDARD

ADJUSTMENT

.•••••••...••••••.....••..•••••••••••••.••••...••.•••....•.•••....•.........••..•..........•.•....••••••......•.•...•....•......•

10

{l)FS300 ...................................................................................................................................................................................................

10

1)

NEEDlE

FEED

TIMING

.......................................................................................................................................................................

10

2)ADJUSTING

THE

TIMING

RELATION

BETWEEN

tHE

NEEDLE

BAR

AND

LOOPER

(SYNCHRONIZATION)

.................•.••.................••....

10

2)'SVNCHRONIZATJON

.........................................................................................................................................................................

12

3)

RETURNING

AMOUNT

OF

THE

LOOPER

............................................................................................................................................

14

4)HEIGHTOFTHENEEDLEBAR

............................................................................................................................................................

14

S)

Cl£ARANCE

BETWEEN

THE

LOOPER

AND

NEEDLE

..........................................................................................................................

16

6)ADJUSTINGAMOUNTOFTHELOOPER-AVOID ...............................................................................................................................

16

7)

POSmONOFTHENEEDLEGUARD

...................................................................................................................................................

16

8)

POSITION

OF

THE

FEED

DOG ...........................................................................................................................................................

18

9)

SPREADER

......................................................................................................................................................................................... 20

10)

LOOPER

THREAD

CAM .................................................................................................................................................................... 22

II)

POSITION

OF

THE

PRESSER

BAR

....................................................................................................................................................... 22

12)

POStnON

OFTHENEEDLETHREAD

TENSION

RELEASE

(WITHOUT

THREAD

TRIMMER)

.....................................................................

24

13)

POSlJION

AND

HEIGHT

OF

THE

PRESSER

FOOT

............................................................................................................................... 24

14)

POSinONOFTHETHREADGUIDE

....................................................................................................................................................

24

<2>CS100 .................................................................................................................................................................................................. 28

1)

NEEDLE

FEED

TIMING

.......................................................................................................................................................................

28

2)

ADJUSTING

THE

TIMING

OF

THE

NEEDLE

BAR

AND

LOOPER(SYNCHRONIZATION)

....................................................................... 28

2)

'SNYCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

....................................................................................................................... 30

3)

RETURNING

AMOUNT OF

THE

LOOPER

................................................................................................................................................ 32

4)

HBGHT

OF

THE

NEEDLE

BAR

............................................................................................................................................................

34

5)

POSmON

OF

THE

NEEDLE

GUARD

................................................................................................................................................... 34

6)

CLEARANCE

BETWEEN

THE

LOOPER

AND

NEEDLE

..........................................................................................................................

36

7)

ADJUSDNG

AMOUNT

OF

THE

LOOPER-AVOID

............................................................................................................ : .................. 36

8)

POSmON

OF

THE

FEED

DOG ...........................................................................................................................................................

38

9)

SPREADER

......................................................................................................................................................................................... 40

10)

LOOPERTHREADCAM

....................................................................................................................................................................

42

11)

LOOPER

THREAD

WRAP-UP

PREVENTING

CAM .............................................................................................................................. 42

12)

POSITION

OF

THE

PRESSER

BAR

....................................................................................................................................................... 44

13)

POSITION

OF

THE

NEEDLE

THREAD

TENSION

RELEASE

(WITHOUT

THREAD

TRIMMER)

..................................................................... 44

14)

POSITION

AND

HEIGHT

OF

THE

PRESSER

FOOT

...............................................................................................................................

44

15)

POSITION

OF

THE

THREAD

GUIDE

....................................................................................................................................................

46

4.

OlHER

PRECAUTIONS

...................................................................................................................................... 47

(1)

POINTS

TO

WHICH

LOCKTTTE

IS

APPLIED

.............................................................................................................................................

47

5.

TROUBLES

AND

CORRECTIVE

MEASURES

....................................................................................................... 49

•

3

Page 4

1.

SPECIFICATIONS

FS300 Series

FS322

I

FS322

I

FS332

I

FS332

Sewing

speed

~

With Puller

6000

R.P

.M.

6,500 S.P.M.

(Max) left

or

right hand undertrimmer 5500

Stitch length

1.6to

2.8 mm

No.

of

needle

2

3 2

I

3

Needle gauge

3.2,

4.0 5.6, 6.4, 4.8 3.2, 4.0

I

4.8, 5.6, 6.4

Top covering

Without

With

Oiff.

feed

ratio Gathering stitch 1

:1.5

Stretching stitch 1

:0.6

Needle

UY128GBS

#65/025 to 90/036

Presserfoot lift

B.Omm

Lubricating oil UNION SPECIAL Designated oil (Part No. 28604R)

CS1

00

Series

CS122

I

CS122

I

CS132

I

CS132

Sewing

speed

~

With Puller 6000 R.P.M. 6,500 S.P.M. {Max) Undertrimmer 5500 R.P.M.

Stitch

lenQth

1.6to3.2mm

No.

of needle 2 3

2

3

Needle gauge 3.2,

4.0, 4.8 5.6, 6.4 3.2, 4.0, 4.8 5.6, 6.4

Top

covering

Without With

Diff.

feed

ratio

Gathering stitch 1

:1.5

Stretching stitch 1 :0.6

Needle UY12t GJS #55/022 to #90/036

Presserfoot lift

B.Omm

Lubricatina

oil

UNION SPECIAL Designated

oii(PM

No. 28604R)

'*

Depending

on

Devices

•

4

Page 5

•

2. MOTOR PULLEY AND

BELT

FS300 Series

50

Hz

.

so

Hz

Motor pulley

V belt (inch)

Motor

pulley

V belt (inch)

Sewing speed {s.p.m.)

Fully-

Semi-

Fully-

Semi-

outer dia. (mm)

s!bmerged

submerged

outer dia. (mm) submerged

submerged

type type type

type

6,500

140 35

120 35

6,000

125

I

35

105

35

5,500 110 35 90

34

5,000

100

34 85 34

4,500 90 34 75 34

4,000

80

34 70 34

3,500 70 34 60 33

1) Use a UNION SPECIAL clutch

motor

{400W).

2) Use

an

M type V belt.

3)

The table shows the sewing speeds obtained

by

the use

of

motor

pulleys with different diameters and V belts

with different lengths.

4) Note that the effective diameter

of

the pulley

of

the machine head

i~

54mn

CS100

Series

50

Hz

60Hz

Motor pulley v belt (inch)

Motor pulley V bell

(inch)

Sewing speed (s.p.m.)

Fully- Semi-

. Fully- Semi-

outer dia. (mm)

submerged

submerged

outer dia. (mm)

subrre'lJE'f

submerged

type type type

type

6,500 145 43

40

120

41

38

6,000

135

I

43 40 110

41

38

5,500

120

I

41

38 100

41

38

5,000

110

I

41

38

90

39

37

4,500

95

I

41

38 80

39 37

I

4.000

85

39

37 70

39 37

3,500

75

39

37

60

38

35

1)

Use a

UNION

SPECIAL clutch

motor

(400W).

2)

Use

an

M type V belt.

3)

The table shows the sewing speeds obtained

by

the use of

motor

pulleys with different diameters and V belts

with different lengths.

4) Note that the effective diameter of the pulley

of

the machine head is 57.5 mm.

5

Page 6

•

3. MODEL NUMBERING SYSTEM

CS100 SERIES ORDERING INFORMATION

Stitch type Sub-class

Number

of

needles Needle

spacing

Devices

2 = Bot!om coverslitch

(describes typical application)

2

"'

Two

needle machine

32"'

3.2

mm

CC'

= Chain cutter

3 =Top & bottom coverstitch

c· = Col!arette

3 "' Three needle machine

40=4.0mm

MD'

= Metering device

E'

=Elastic 48 = 4.8

mm

TC'

"'Tape

culler

Basic

frame style

H":

Hemming

56"'

5.6

mm

TF'

= Binding feed device

CS

= Cylinder

bed

K'

= Coverseam

60=6.0mm

UT" = Thread trimmer

FS

=Flat

bed

L •

=lap

seam

64

= 6.4

mm

'1-9

= Variety

or

devices

U'

= Universal

'00·99

" Variety

ol

sub-class

~

l

I

I I

I

FS332C01-3D56/TC4/

I

l

Generation Feed type

Stllch tongue

1 =First 2 = Dlflerential

Represents

the

shape

of

the

throat plate

2 =Second 5 = Differential & puller

stitc-h

tongue.

3

=Third

A = For short stitch length

A

c;:=-

B =

For

medium

stitc-h

length

Bt:='"

C =

For

long stitch length

c c::::7'"

0

=

For

all

stitch lengths, collaretle,

D='"

coverseam & elastic applications

Page 7

•

CS100 SERIES ORDERING INFORMATION

SUtch

type

Sob-class

Number

of

needles

Needle

spacing

Devices

2 = Bottom coverstitch (describes typical application) 2

=Two

needle machine

32"'

3.2

mm

cc·

"' Chain culler

3

=Top

& boHom coverstitch

C' = Co1larette

3 = Three needle machine

40=

4.0 mm

MD'=

Metering device

E'

=Elastic

48·,

4.8 mm

TC'

=Tape

culler

Basic

frame style

H'

=Hemming

56=

5.6 mm

TF'

= Binding feed device

CS

= Cylinder bed

K'

= Coverseam

60=6.0mm

UT"

= Thread trimmer

FS

=Flat

bed

L'

=Lap

seam 64 = 6.4 mm

'1·9

= Variety of devices

U'

=Universal

'00-99

=Variety

or

sub-class

.

~I

I

I

I

I

I

l

I

CS132H01-2C32/UT2/

I

Generation Feed type

Stitch

tongue

1

=First

2 = Differential

Represents the shape

of

the throat plate

2

=Second

5 = Differential & puller stitch tongue.

3

=Third

A

"'

For short slilch length

A~

8

"'

For medium stitch length

Be?"

C

""

For long stitch length

c

=""

D = For all stitch lengths, collarelle,

D

t:::7

coverseam & elastic applications

Page 8

FS300

Series

Code

Specification

Description of Sub-Class

C01

For Cellarette Basic style

E12 For elastic tape attaching Right hand fabric under trimmer and metering device (Upper side)

E41

For

elastic taoe attaching Elastic tape attaching with puller

and

metering device (Lower side) (with endless rubber)

H01

For

hemming Basic style with hem guide

L01

For

lap seam Basic style

L21

For

l_ap_

seam For the top sleeve of

knit

fabric

C$100

Series

Code Soecification Description of Sub-Class

E11

For Elastic tape attaching Right hand fabric

under

trimmer, (Preclosed Elastic)

E12 For elastic tape attaching Fabric under trimmer,

and

metering device (Upper side)

H01

For Hemming Basic style with hem guide

-

H11

For Hemming With cloth puller

H21

For

Hemming Lett hand fabric under trimmer

K01

Covering With standard fixed seam guide, light weight fabric

K02 Covering With adjustable seam guide for medium to heavy-weight fabrics

K11

Coverseaming With special fold over seam guide

•

8

Page 9

Under-bed thread

trimming

device

Electromagnetic type

Pneumatic

type

Top

Needle Needle

Top

Thread

Needle

covering

Thread

•~o

•~o

Code

For

use on model

thread

Auto-lifter

_,

wiper

covering

•

Auto-lifter

trimmer

wiper

thread

trimmer

(Mecha- (Pneu-

thread

trimmer

nieal) matie)

trimmer

UT1

CS122

0 0

0

UT2

C$132

0

0

0

UT3 CS122

0 0

0

UT4 CS122

0 0

0

UTS

C$132

0

0 0

UT10 FS322

0

0

0

UT11 FS332

0 0 0

UT12

FS322

0 0

UT13

F$332

0

0

0

Elastic tape metering

device

Code

Description

For

use on model

MD1

Metering device (upper side) Electric single stage

FS322, FS332, CS122,

C$132

MD2 Metering device (upper side)

Electric

two

stage

F$322,

F$332,

CS122,

CS13~

MD3

Metering device

(lower side) Electric single stage FS322, FS332, C$122, CS132

MD4

Metering device (lower side) Electric

two

stage

FS322, FS332, C$122,

C$132

Automatic tape feeding

device

Code

I

Description

For

use on model

TF1

Automatic

tape feeding device (upper side)

For

MD1,

MD2

TF2

Automatic tape feeding device (lower side)

ForMD3,

M04

Under-bed thread

trimming

device

•

Code

Description

For

use on model

CC1

Pneumatic

type

chain-off

thread

cutter l Mounted

horizontal

venturi

suction

FS322,FS332

Cloth

puller

Code

Description

For

use on model

PL1

Cloth puller

FS322, FS332, CS122, CS132

>

9

Page 10

•

4. STANDARD ADJUSTMENT

(1) FS300

Standard Adjustment

1) Needle feed timing

.

First screw

(A)

in

operating direction on double eccentric

(B)

of feed drive assembly must

be

straight

up,

when the needle bar is at bottom of stroke.

r--

I~

i\

B

1--B

'

/

A-

il

~

f--A

-

1---

0

2)

Adjusting the timing relation between the needle bar and looper

(synchronization): Without gauges

When the blade point

of

the looper moves

to

the left

in

the rear of the needle

and

to

th_e

right

in

front of

the

needle, align the upper end of the eyelet of the left needle with the lower

face

of the

looper

so

that the distance between A and

B.

the side of the left needle to the blade point of the

looper,

should

be

equal.

4J'

A=B

A

B

Vca=

/ca:::

'¢:J

Mov:e

to the left

¢Move

to

the

right

I

Looper

v

Looper

tl--

Left needle

.

Allgn~L

Left

needle

.0.

10

.

Page 11

•

Adjustment Procedures

Remove

top

cover,

oil

reservoir cover, gasket

and

cloth plate.

Loosen screws (C) of sprocket (D).

• Rotate lower

main

shaft

in

operating direction clockwise, until

the

first screw (A) on double eccentric (B) is straight up.

•

Holding

pulley

to

prevent

it

from turning,

rotate

handwheel

of

upper

main

shaft

until

needles

are

at

top of their

stroke.

•

Torque

screw

(C)

to

45-46

in.

lbs. (5.2-5.4Nm).

•

Replace

top

cover,

oil

resevoir

cover,

gasket

and

cloth

plate.

Note:

Earlier machines

have

(4)

screws.

• Turn handwheel in operating direction until bottom

of

looper is

even with tap of needle eye. Note dimension (A)

Continue

turning

handwheel

in

operating direction until bottom

of

looper

is

even

w~h

top of needle

sye

when

looper

is

in

front

of

needle.

Note dimension (8)

•

If

(A)

is

greater than (8)

-loosen

(C)

on sprocket

(D).

-Turn sprocket

(D)

in

operating direction

-Tighten

screws

(C)

-Repeat

above

two steps until (A)"' (8)

•

If

(A)

less than

(B)

-loosen

screws

(C)

on

sprocket

(D)

-Turn sprocket

(D)

in

reverse direction

-Tighten screws

(C)

-Repeat sbove

two

s1eps

until (A)"'

(B)

Results

of

Improper Adjustment

• Needle breakage

• Looper missing needle thread

•

If

the timing

is

not correct, skip

st~ching

may

occur.

11

Page 12

FS300

Standard Adjustment

2)' Synchronization

• Rotate handwheel

in

operating direction until

pin

in

looper holder contacts gauge plate.

• Reposition needle bar as required to set pointer

of

indicator

gauge

at

"0~.

• Rotate handwheel in reverse direction until

pin

in looper holder again makes contact with gauge plate.

• A variation

of

(1) graduation

on

scale is permissible .

•

12

Page 13

•

Adjustment Procedures

o Rotate handwheel in operating direction until pin (9 contacts

gauge plate

e .

o Loosen screw (!) in needle bar connection & position needle

bar

8 as required

to

set pointer 0 of indicator gauge 0 at

~a~

tighten screw (!)lightly.

o Rotate handwheel

in

reverse direction until pin 8 makes

contact with gauge plate

0 .

Note reading on gauge. A variation of

(1)

graduation

on

scale

is permissible.

To adjust:

o Loosen screws

0

on

looper drive sprocket

€t

.

o If reading is above

~a"

tum sprocket towards operator.

o

If reading is below "0" tum sprocket away from operator.

o snug screws

0 .

o

Continue

to

check

& adjust in both operating & reverse·

directions until pointer 0 of indicator gauge

4D

comes within

(1) graduation

on

scale when turning handwheel

in

either

direction.

o Tighten screws

0.

o Torque needle bar screw

(9

to 20 inllbs.

CD

Results of Improper Adjustment

o Skipped stitches

o

Improper chaining

13

Page 14

•

FS300

Standard

Adjustment

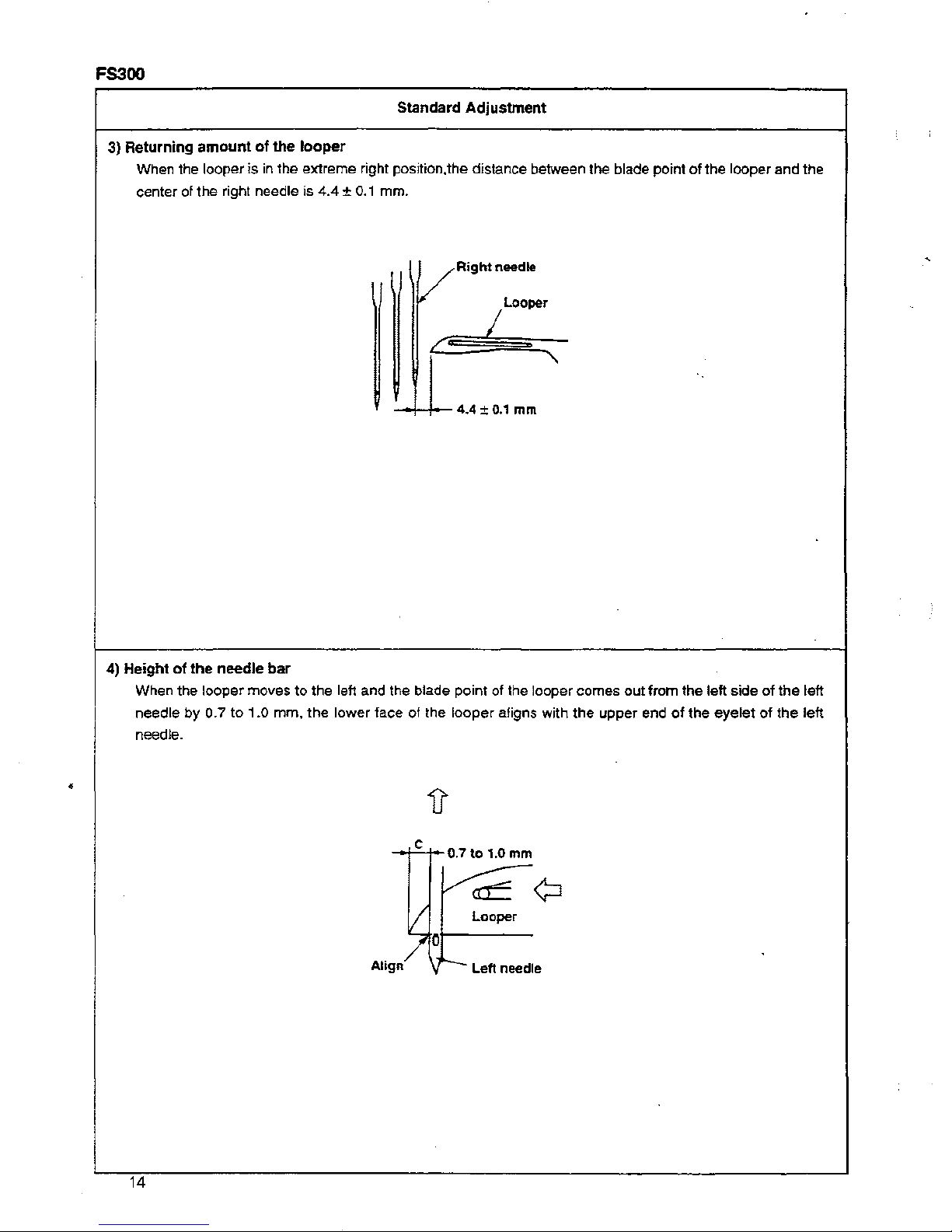

3) Returning

amount

of

the

looper

When the looper is

in

the extreme right position,

the

distance between the blade point

of

the looper and the

center of the right needle is 4.4 ±

0.1

mm.

}

/Right

needle

V Looper

c=

I

-+-+---

4.4 ± 0.1

mm

4) Height

of

the

needle

bar

When the looper moves

to

the left and the blade point of the looper comes out from the left side of the left

needle

by 0.7 to 1.0 mm, the lower face of the looper aligns with the upper end

of

the eyelet

of

the left

needle .

c

-I"'-J-0.7to

1.0

mm

I/

Looper

~of---

Align/

Lett

needle

14

Page 15

•

Adjustment

Procedures

o Loosen the looper base setscrew

0 and adjust the returning

amount of the

lOoper.

(Use

a 5/32

inch

hexagonal wrench.)

o Loosen the needle bar holder screw 0

and

adjust the height

of

the needle bar.

(Caution)

After

the adjustment,

check

that

the

direction

of

the

needle

clamp

is

correct

and

the

respective

needles enter the center

of

the

holes

of

the

throat

plate.

@

0

\\

0

0

mill

0

0

0 0

Results

of

Improper

Adjustment

o If the returning amount is large,

skipping stitch and

tangling stitch

may occur and the range of the

thickness of the cloth to be sewn is

reduced.

o If the returning amount is small,

skipping stitch and tangling stitch

may

occur.

o If the distance of C is large, skip

stitching and tangling stitch may

occur.

o If the distance of C is small, skip

stitching and tangling stitch may

occur.

o

If

defective stitch occurs with the

wooly

nylon thread,

make

the

distance C as small as possible.

15

Page 16

•

FS300

Standard

Adjustment

5) Clearance between

the

looper

and

needle

Clearance between the

blade

point

of

the looper

and

the grooves

of

the rightlleft needles is 0 to 0.05 mm.

(Clearance

of

the

middle needle becomes larger a liHie.)

Otoo.os

mm

VRight

needle

Looper

j

j

===;~/~::::-;;::::~;.

;;;;

Oto0.05mm4

0

Needle

Top end

of

looper

6)

Adjusting

amount

of

the looper-avoid

When the needle descends, the top point

of

the needle touches the

back

of

the looper

at

the position of

213

from the

upper

side

of

the looper.

Needle

desce:tlr

~

i

>13

Back

of

looper

t

113

7) Position

of

the needle

guard

<D

Rear

needle

guard

o

The

height

of

the rear needle guard is in the position

that

the rear needle guard is 1.2

mm

above the top

of

the

needle

when

the

looper

moves

to the left as shown in the figure.

o The longitudinal position

and

inclination

of

the rear needle guard are in the position that

when

the right

side of the respective

needles comes to the blade top

of

the looper, the top

of

the

needle slightly touches

the rear

needle

guard.

<?

~

~

!.:.;

==~t.2mm

guard Slightly

touch

® Moving needle guard

16

o When

the

looper

advances, the clearance between the needle

and

the moving needle

guard

is

0.05 to

0.13mm.

==J~;;:~=t

0.05to0.13mm

Page 17

•

Adjustment

Procedures

o Loosen the looper base setscrew 0 and adjust by moving

the looper base back and forth.

o Loosen the two screws G and

adjust by rotating the eccentric pin

8.

0 Amount of the avoid increases in

the direction

of+.

o Amount

of

the avoid reduces

in

the

direction

of-.

(Caution)

After

the

adjustment,

check

again

the

clearance

between

the

blade

point

and

the

groove

of

the needle.

o Loosen the

screwO

and adjust the-

height and inclination of the

r~ar

needle guard

0.

Loosen the screw

G'!>

and

adjust

the

longitudinal

position

of

the rear needle guard

0.

(Caution)

Check

that

the

rear

needle

guard

does

not

break

the

loop

of

the

needle

thread

by

touching

the

groove

of

the needle.

o Loosen the screw

Gt

and

adjust the

clearance between the moving

needle guard

fD

and the needle.

(Caution)

Check

that

the needle

is

never

caught

between

the

moving

needle guard

and rear needle

guard

in

any case.

Results

of

Improper

Adjustment

o

If

the clearance is too large, the loop

of the needle thread is not scooped

and the

back

of

the

looper

hits

strongly the top point of the needle

which causes the damage

of

the

needle

point

o

If

the

clearance

is

too

small,

skipping stitch will· occur due to the

damage

otthe

tip

of

the looper, the

needle breakage, and the large

clearance between the back

ot

the

.

looper and the needle.

o If the amount

of

the avoid is large,

the clearance

of

the

back

of

the

looper and the needle becomes

large,

and

skipping

stitch

and

tangling stitch

will occur.

o If the amount of the avoid is small,

the needle hits strongly the back of

the looper. This causes the damage

of the

needle

point,

the needle

breakage and the damage on the

back

of

the looper.

o

If

the returning

amount

is large,

skipping stitch and tangling stitch

occur,

and

the

range

of

the

thickness

of

the cloth to be sewn is

reduced .

o If the returning

amount

is small,

skipping stitch and tangling stitch

occur.

17

Page 18

FS300

Standard Adjustment

8} Position

of

the

feed

dog

o

The

clearance of the left/right sides of the feed

dog

should

be

equal

in

the slots

of

the throat plate.

o

At

the maximum travel, the clearance of the main feed dog and differential feed

dog

is equal to

A=

A', 8

:8'.

o The height of the teed dog is 1.0 mm at the top of their stroke.

o The

tilt of the feed dog is parallel

to

the throat plate when the needle bar is at the highest position.

1.0mm

•

18

Page 19

•

Adjustment

Procedures

Open the cover located at the rear side of the needle entry.

o Adjust

the

longitudinal position of the main feed dog after

loosening the

nut@) and rotating the eccentric nut

ID.

o Adjust the longitudinal position of the differential feed dog

after loosening the nut

Q)

and rotating the eccentric nut

0.

o Adjust the inclination of the feed dog after loosening the screw

4D

and rotating the eccentric shaft inside with a slit-screwdriver

through the hole

~.

o Loosen the screw

G>

and adjust the height of the main feed

dog@).

o Loosen the screw

§)

and adjust the height of the differentia!

feed dog

@1.

Results

of

Improper

Adjustment

o If the letvright positions of the feed

dog are

incorrect,

the left/right sides

and the throat plate

will wear out.

o Heating and abnormal noise will

be

produced.

o The feed components

wiH

wear out

early. And,

the looseness, bending

and

abnormal

noise

will

be

produced.

o If the inclination

of

the feed dog

is

raised toward you, starting

of

the

workpiece

will

be

affected.

o If the inclination of the feed dog is

towered toward you,

it

may

cause

the

irregular

stitching

and

puckering .

o

If

the position of the feed dog

is

high,

it

causes

the

return

feed,

skip

stitching and defective chain-off.

o If the main feed dog, differential

feed

dog and throat plate come

in

contact

each

other,

it

will

cause

the

breakage.

o

If the position

of

the

fe:ed

dog is low,

the

stitch

length

becomes

short

when the sewing is finished.

19

Page 20

•

FS300

Standard

Adjustment

9)

Spreader

(!)Timing

Descend.[!,

Highest

point

2.5 ±

0.1

mm

c~~~~~g~~~~

.:::0

Return

Just

when

the

needle descends 2.5

mm

from

the

highest point of the needle bar, the spreader

begins to return from its extreme left position.

®Position

of spreader

II

5.5 ±

0.1

mm

..,.-JIHI

~

11.5

:±

0.2

mm

(10.8 ±

0.2

mm

throat

plate for 4.8 mm

or

more

needle gauge)

Left needle

0.3

to

~j=ii::;:f~i,~o~o'::;:;/

0.5

mm

f

@Fixing

spreader thread guide

Spreader

Extreme

right

~Return

0.4to

\

o.a

mm

Top

blade

should

be

between left

side

and

middle

of

the

groove.

Show

spreader at

extreme

right

position

when

setting

height

®Needle

clamp spreader thread guide

Fixing

spreader

thread

guide

Needle

clamp

spreader

thread

guide

20

@Stroke

•..

Direction

o1

cloth feeding

fl..

~ l';"'''

,

,,

~~--.--..~

,,

19±

0.1

mm

o The height is 11.5 ±

0.2

mm

(4.0 + 3.2

gauge).

(10.8 ± 0.2

mm

for4.8

mm,

5.6

mm.

and

6.4

mm

gauges.

o When the spreader is in the extreme left position,

the distance between the center of the

left needle

and the top blade of the spreader is

5.5

± 0.1

mm.

o When the

spreader

returns

to

the

right,

the

clearance between the spreader and the left needle

is

0.3

to

0.5 mm.

o When the spreader

is in

~he

extreme right position,

the top

blade of the spreader

__

should be between

left side and middle

of·

the spreader thread guide

groove.

o The height

is

0.4 to 0.8 mm from the surface

of

the

spreader.

o When the needle bar is in the lowest position, the

clearance between the needle

clamp spreader

thread guide and the

upper

face

of

the fixing '

spreader thread guide is 4.0 ± 0.5 mm.

o The center of the

hole of the thread guide aligns

with the left side of the fixing spreader thread guide

groove.

Page 21

•

Adjustment

Procedures

o Adjust

the

timing

by

loosening

screw

€!)

of

the

spreader

eccentric cam

@)

and rotate the spreader eccentric cam

~.

o Adjust the stroke by loosening the nut G

and

move back and

forth.

If it

is

moved toward you,

the

stroke becomes small,

and to the back

it

becomes large.

o Adjust the height of the spreader by loosening the screw@)

and moving the spreader 0 up and down.

o Adjust the clearance between

the

spreader and left needle

by loosening the

screw@)

and

move the

spreader 0 back

and forth.

o Adjust

the

extreme left position

by

loosening the screw G

and move the spreader G

to

the left and right.

0 <

o Adjust the fixing spreader thread

guide~

by loosening the

screw~.

o

Adjust

the

needle

clamp

spreader

thread

guide G by

loosening the screw @).

Results

of

Improper

Adjustment

o If the timing is too advanced,

the

needle does not catch the covering

thread when it descends. This

is

likely to cause the skipping stitch.

On

the

contrary, if the timing

is

too

retarded,

the

right needle is likely

to break

as the resistance when the

covering thread is

pulled from

the

spreader becpmes

large~

o If

the

movement

amount

of

the

spreader

is

not set right, it will cause

skip stitching

of

the top

covering

thread.

o If

the

height

of the spreader is no!

set right,

it will cause skip stitching

of the top covering thread.

; o

If

the

clearance

between

the

spreader and needle is small, it will

cause

the

needle breakage. If it is

large,

it will cause skip stitching of

the top covering thread.

o If

the

protruding

amount

of

the

spreader

is

large,

it

will

cause

uneven stitching of the top c9vering

thread.

If

it

is

small, it will cause skip

stitching of the top covering thread.

o If the height

of

the

fixed spreader

thread guide

is

set as high as

0.

8 ,

the top covering

perlonnance by the

spun

thread

is

improved.

But,

defective looping

may

occur when

other threads are used.

o

If

1he

position of the fixed spreader

thread

guide

is

not

correct, it will

cause

skip

stitching

of

the

top

covering thread.

o If the position of the needle clamp

spreader thread guide

is

not correct,

it

will cause skip stitching of the top

covering thread.

21

Page 22

•

FS300

Standard

Adjustment

10)

Looper

thread

cam

CD

Timing

Needle

descends

,(\

l];aackof

~

looper

Align

with

lower

face

of

looper

Looper

vthread

Looper

thread cam

o When the looper thread is pulled from the highest

point of the looper thread cam, the top point

of

the

left needle aligns with the lower face

of

the looper.

ell

Position of looper thread guide plate and looper thread cam pawl wire

1.6mm

Looper

thread cam

Wire

Tou~a--;::l;===·

====:0~tj

9.6

mm

Looper thread

guide plate

@

looper

thread

cam

pawl

®Position

of thread guide and auxiliary thread tension

guide

plate

Auxiliary thread

11)

Position

of

the

presser

bar

22

o The height

of

the looper thread guide plate is 1.6

mm from the lowest part

of

the looper cam

to

the •

upper part

of

the looper thread guide plate.

o

The

rear

side of the looper thread

cam

pawl

touches

the wire, and its front side is 9.6 mm above the

upper face

of

the wire at the highest place

of

the

inside.

o The looper thread cam pawl and wire are to

be

positioned in the

center

of

the

looper thread cam

plate.

o The. position of the

thrE!ad

guide is to

be

set

at

the

position that the looper thread

just

becomes tight

when

the

looper is in the extreme left.

o Adjust

the

tension of

the

auxiliary thread tension

to make as

low as the thread is

just

stabilized .

The

clearance between the presser bar. bracket and

the presser bar bushing

is

0.8

mm

when the feed dog

is

under

the

throat plate and the bottom face

of

the

presser foot touches the upper face of the throat plate

at the

time

that

the needle

bar

is

in

the lowest point.

Page 23

•

Adjustment

Procedures

o Adjust the timing of the looper thread cam

by

loosening the

two screws

@I.

o Adjust the height of the looper thread guide plate by loosening

the screw

E1i)

and move the looper thread guide

plate®

up

and down.

Adjust the looper thread cam pawl by loosening the

screwS

and move the looper thread cam pawl

61

up and down.

Adjust the lateral relation of the looper thread guide plate by

loosening the screw

ED

and move the looper thread guide

plate

®to

the left and

right

(Caution)

Use a 3132" hexagonal

wrench

for

the

screw

t!>.

o Adjust the position of the thread guide by loosening the two

screws$

and move the thread guide

E@

(2 pes.)

up

and down.

o Adjust

by

loosening the two

screws~

and move the presser

bar bracket

€i)

up and down.

Results

of

Improper

Adjustment

o If

the

timing

of

the looper thread

cam

is

too

advanced,

the

skip

stitching on the back of the looper

will occur.

If

it is too retarded, the

tightening

of

the

thread

will

be

inferior.

o If the clearance ·between the looper

thread

cam

pawl and

the

wire

is

large, the looper thread suddenly

slackens and

_skip

stitching on the

back side will occur.

o If

the

looper thread cam is not

il'

the

center,

the

cam

will

be

damaged.

o If

the

thread guide is raised, the

looper thread after sewing

will be

slack.

o It the thread guide is lowered, the

looper thread

after

sewing will be

tight.

o

If

the

clearance

between

the

presser bar bracket and the presser

bar bushing is

small, the bottom

face

of

the

presser

toot

can

not

contact tightly to the throat plate.

o

If the clearance is large, the lifting

amount of the presser foot

will be

reduced.

23

Page 24

•

FS300

Standard Adjustment

12)

Position

of

the

needle

thread

tension

release

(without

thread

trimmer)

When the presser foot is raised by 3 mm, the thread tension opening

pawlet

touches the thread tension

6)

and when the presser foot is in the highest position, the thread tension disc opens and there is no tension

on

the thread.

=~=---'

3mm

Throat plate

13) Position and height

of

the presser

foot

CD

Adjust the position of the presser foot so that the needles enter the center

of

the needle entry holes in the

presser foot

on

condition that the presser toot is set correct to the presser bar.

CV

Adjust the height of the presser foot so that when the needle bar is

in

its highest point, the needle point

does not come out from the lower face of the presser toot.

Lower

bushing

Spreader

Needles

"'"'-'""'lf"'-'""""'"f

Max.

8.0

mm

Throat

plate

Note:

On

elastic

machines

height

is

7.0

nm.

14) Position

ofthe

thread

guide

<D

Middle thread guide and thread guide holder

Spun thread

Cotton thread

Wooly nylon thread

Tetoron thread

( Fix at the

extreme

right

position

of

the

slot. )

24

Left needle

thread

27mm

27mm

27mm

27mm

£

Middle needle Right needle

thread thread

25mm

23mm

25mm 23mm

25mm 23mm

25mm 23mm

Page 25

Adjustment Procedures

o Adjust

by

loosening the

screw@.;!

and move the bracket

4».

E>

e

o Adjust the position by loosening the screw

€il

and move

th~

presser foot

ii>

to the left and right.

o Adjust the height by loosening the

nut®

and rotate the screw

~

and hit it to the lever<$ so that the needle top comes 0.3

mm

over from the lower part of the presser foot when the

needle is in its highest point. At this time, loosen the two

screws

® and

fix

the collar i> so that the clearance between

the

collar and the lower bushing is 0.2 mm.

Adjust

by

loosening the nut

€!1

and rotate the

screw~

so

that

the

clearance between the top end

of

the screw ~ and the

lever~

becomes 0.5 mm on condition that the presser toot

descends and rests tightly on the throat plate.

l!ll

IIL.--i!ll

@:J;:--'--.li""""~""~

0.5

mm

o Loosen the

screw~

and fix the thread guide attaching base

(i)

to the extreme right. Loosen the

screw~

and adjust the

respective heights

.2

referring to the left table. Make the fine

adjustment watching the actual stitching.

Results of Improper Adjustment

o If the position

of

the presser toot is

not correct,

it

will cause defective

and non-straight sewing.

o

If the height of the presser

loot

is

not correct,

it will cause breakage

of

the spreader, the needle scratch

on

workpiece, defective sewing and

the lack of feeding force.

o

If

it is raised, the needle thread

is

tightened.

o

If

it is lowered, the needle thread

slackens.

o The tightened stitches of the right

needle

and

left

needle

can

be

simply slackened

if

the thread guide

holder is moved to the left.

25

Page 26

•

FS300

Standard Adjusbnent

® Needle

bar

needle thread release

o When

the

loop

of

the needle thread is not

easily

formed, raise the needle thread release as shown in the

figure

at

the time

of

the lowest point of the

needle

bar.

Lowest

point

of

needle bar

ohN~dle

ba• eyelet

/

~Needle

thread release

o

If

the needle thread is a cotton thread, raise the right needle thread release so that the right needle

thread

only

touches

at

the

time

of

the lowest point

of

the needle bar.

Lowest

point

of

needle

bar

_,

_ _;)\

Right needle thread release

o

If

the needle thread is a spun thread, lower

the

needle thread release

so

that the needle thread does not

touch it.

Lowest

point

of

needle bar

-!],

Needle

bar

balance

Needle thread release

® Spreader balance thread guide

h should be positioned that

the

top covering thread does not slacken and the spreader does not pull

out

the thread,

when

the spreader has moved

to

the extreme left position.

@ Needle thread nipper

26

'

0

/Not

slacken

r

-K-~

Thread

guide

All

the

needle

threads

are

to

be

threaded

through

the

needle thread

nipper,

except

the

cotton

and teteron

type

threads.

Page 27

•

Adjustment Procedures

o Loosen

screw®

and adjust by moving the needle thread

release

f)

up and down.

o Loosen

screw®

and

adjust by moving the right needle thread

release

~

up and down.

o Loosen

screw~

and adjust by moving the thread guide

1!9

up

and

down.

Resuhs

of

Improper

Adjustment

o If it is raised, the loop of the needle

thread becomes

larger~

o

If

it is lowered,

the

loop of the needle

thread becomes

smalfei::".

o

If

the loop is not formed (the loop is

too small) and skip stitching occurs,

raise the needle thread release.

o

If

the loop is excessively formed

(the loop

is

too large) and the skip

stit(fhing

occ~;~rs,

lower the needle

thread release.

o

lf it is raised, the thread slackens .

o

If

it is lowered, the thread tightens.

o Use of the nipper

depenling

on

the

threads

to

be

used

..

Not

used

for

cotton thread and

tetoron thread.

Used for wooly nylon thread and

spun thread (stretching thread).

27

Page 28

•

(2) CS100

Standard Adjustment

1) Needle feed

timing

FiJSt

screw 0

in

operating direction

on

double eccentric

49

of

feed

drive

assembly

must

be

straight

up,

when

the

needle

bar

is

at

top

of

stroke.

0 0

0

2} Adjusting the timing

of

the needle bar

and

looper

(Synchronimtion) :

Withcut

Gauges

28

When

the

blade

point

of

the

looper

moves

to

the

left

in

the

rear

of

the needle

and

to

the

right in

the

front

of

the

needle,

and

the

top

end

of

the

hole of

the

left needle aligns with the

lower

part of

the

looper,

the

distance

between

the

left side

of

the

left needle

and

the

blade point

of

the

looper should

be

equal

to

the

distance

A

and

B .

A=B

A

~

Move

to

the

left

¢ Move to the right

Looper

Left

needle

Left needle

Page 29

•

Adjustment Procedures

Remove

top

cover, oil reservoir cover, gasket and cloth plate.

• Loosen screws (C) of sprocket {D).

• Rotate lower main shaft in operating direction clockwise, until the

first screw {A) on double eccentric (B)

is straight up.

• Holding pulley to prevent

i1

from turning, rotate handwheel of upper

main shaft

until needles are at top

of

their stroke.

• Torque screw {C) to

45-46

in. lbs. {5.2-5.4Nm).

Replace top cover, oil resevoir cover, gasket and

cloth plate.

Note: Earlier machines have (4) screws.

• Turn handwheel

in

operating direction until bottom of looper is

even

wrth top of needle eye. Note dimension {A)

• Continue turning handwheel in operating direction until bottom

of

looper is even with

top

of

needle sye when looper

is

in front of

needle. Note dimension (B)

•

If

(A) is greater than {B)

--Loosen (C)

in

connector (D).

-Move

connector {D) away from connector (E)

-Tighten

(C)

-Repeat

above

two

steps until

{A)

= (B)

• If

(A)

less than {B)

-Loosen

screw {C) in connector (D)

-Move

connector (D) toward

(E)

-Tighten

(C)

-Repeat

sbove two steps until

(A)=

(B)

)

)

Results of Improper Adjustment

• Needle breakage

• Looper missing needle thread

•

If

the timing is not set right, it is likely

to

occur skipping and tangling stitches.

29

Page 30

•

CS100

Standard Adjustment

2)' Synchronizing looper

and

needle motions :

With

Gauges

30

•

Set

looper

to its extreme right position.

• Rotate handwheel clockwise until looper

has

moved

.400"

(10

mm) from right to lett.

•

Set

indicator

point

to

"OH

on

top

of

needle bar.

• Move

looper

to its extreme right position

by

turning handwheel counterclockwise.

• Continue rotating handwheel counterclockwise until looper

has

moved

.400~

(1

0 mm) in that direction.

• Indicator point should return to

"0~

in that direction.

• Synchronization is correct when looper moves .400 {10 mm)

back

and forth (clockwise and

counterclockwise

and

dial indicator

on

needle

bar

moves to zero in each direction.

(Note)

Synchronization can

only

be

obtained

after

needle/feed timing

has

been

set,

and

only

by

moving

looper

drive lever rocker

shaft

until synchronization

has

been

obtained.

Looper at extreme right

-{

.400" t end position

l..--~~~.::~

____

1 I

v---------~

Needles

Fig.1 ClockWise

(

10

mm) end position

j

.400" t Looper

at

extreme right

~

1.'------~

\!}'----------

Needles

Fig. 2 Counterclockwise

9/64allen

Fig.4

~

•

----

-

-----

Shorten if needed

F1g.S

"l=

t'

Fig.3

__:!m'f--

-"

10

0

f:J

I

0

~

lid

o.

01

I

0

~

~~

'I

0

I L.l

~

Page 31

•

Adjustment Procedures

o Drain oil.

o Remove

oil pan.

o Modify a standard

9/64" allen wrench (Fig.4).

o Flag indicator from TT146 may need to

be shorten (Fig. 5).

o Remove looper and mount modified

allen wrench in looper

holder.

o With needle bar at bottom dead center adjust

looper holder

so allen wrench is

.400" {10 mm) from throat plate (Fig. 6).

o Tum machine

in

opera1ing

direction until allen wrench contacts

throat plate, assemble indicator

to

top of machine

as

shown

in

(Fig. 3) and set indicator point to

~a~.

o

Tum

machine in opposite direction until allen wrench contacts

throat plate.

(Note)

Reading of indicator.

If distance

is

less than

~a~.

• Loosen screw 0 (Fig. 7).

• Move drive lever crank

4D

away from looper rocker lever

8.

• Retighten screw

0.

• Recheck indicator readings in both rotating directions, until

they are the same,

+1- 1 mark.

• Torque screws

0.

• If distance is more than

~o·.

• Loosen screw G (Fig. 7).

• Move drive lever crank

4D

towards looper rocker

lever@.

• Retighten screw

0.

• Recheck indicator readings

in

both rotate directions. until they

are the same,

+1-

1.

• Torque screw 0 to 130

in.

lbs. (15 Nm) .

• Replace removed parts.

• Refill with UNION SPECIAL 175 oil. (Part No. 28604A)

0

0

)

)

ResuHs

of

Improper Adjustment

o Skipped stitches

31

Page 32

•

CS100

Standard Adjustment

3)

Returning amount

of

the

looper

When the looper is

at

the extreme right position, the distance between the

blade

point of the looper and the

center

of

the right needle is 4.8 ±0.1 mm.

32

}

/Right

needle

V Looper

I

4.8±0.1

mm

Page 33

Adjustment Procedures

Results

of

Improper Adjustment

o Adjust the returning amount

by

loosening the looper holder

If

the

returning

amount

is

large,

binder screw e. skipping stitch and tangling stitch will

occur.

And

the

thickness of the material

to be sewn will be reduced.

It

the

returning

amount

is

small,

skipping stitch and tangling stitch will

occur.

4.8±0,,

mm

~

'\

16\

~

e

•

'

33

Page 34

•

CS100

Standard

Adjustment

4)

Height

of

the

needle

bar

When the looper moves

to

the left and the point

of

the looper comes out from the lett side of the left needle

by

1.0

±0.3

mm, the

lower

part of the looper aligns with the top end

of

the hole

of

the lett needle.

c

-r::-t-

1.0

±0.3 mm

V

en:=

¢:J

Move

to

the

left

II

Looper

h

Left

needle

5)

Position

of

the

needle

guard

34

Q)

The

height

of

the

rear needle guard is adjusted so that

the

poin1

of

the

right needle comes to

the

1/2

height

of

the contact surface of the rear needle guard when the blade point

of

the looper aligns with the

right side

of

the right needle.

The pushing amount is 0 to

0.1

mm

to

all needles.

(The blade point

of

the looper should not contact the respective grooves

of

the all needles.)

Align

I

J-o·~_:~::::~~~~~~:

....,,

Contact surface

of

rear needle guard

Pushing

amount

Oto0.1mm

® The height

of

the front needle guard

is

2.0 ±0.1 mm from the lower part

of

the looper.

The

face

of

the

guard position is parallel to all needles having a clearance of 0.25 ±0.1 mm.

2.0 ±0.1 mm

:f:=;:;;;=;~~

[;l:V

Looper

r--

Front needle guard

Needle

0.25±0.1

mm

1

_D

6 0

'I~

ph;

Front

needle

guard

Page 35

•

Adjustment

Procedures

o Loosen the screw 0 of the needle bar binder bracket inside

the face cover and adjust the height

of

the needle bar.

(Caution)

After

the adjustment,

check

that

the

direction

of

the needle head

is

right

and

that

the

respective

needles enter

the

center

of

the

holes

of

the throat

plate.

@

0

\\

0

0

)

0

mm

0

~

~

0

0'-::

o Adjust the height of the rear needle guard by loosening the

screw

6B

and move the rear needle guard

Q)

up and down.

Adjust the pushing amount by loosening

the

screw

it

and

move the rear needle guard back and forth.

o Adjust the height

of

the front needle guard

by

loosening the

screw

~

and move the front needle guard ~ up and down.

Adjust the inclination at the same time. Adjust the clearance

for the needle

by

loosening the screw ~ .

(Caution) Use a

3132"

hexagonal wrench

for

the

screw ® .

Check

that

there

is

no

looseness

on

the left/right

sides

of

the

rear needle

guard

when

tightening

the screw

41)

•

Results

of

Improper

Adjustment

If the measurement of C is large, skip

stitching and thread tangling occur.

If the measurement of C is small, skip

stitching and thread tangling occur.

o

If the clearance between

the

rear

needle

guard

and

the

needle is

large, it causes the skipping stitch,

the damage

of

the blade point

of

the

looper and needle breakage.

o

If the rear needle guard and

the

needle hits strongly, it will cause the

damage of the needle top.

o

If the clearance between the front

needle

guard

and

the

needle is

large, the loop becomes

small and

the skipping stitch will occur.

o If the front needle guard and the

needle

hits

strongly,

the

loop

becomes large and the skipping

stitch, the damage

of

the

needre

point and the damage

of

the blade

point of the looper

will occur.

35

Page 36

•

CS100

Standard

Adjustment

6) Clearance

between

the

looper

and

needle

Clearance between the blade point of the

looper and the grooves of the right and left needles

is 0 to

0.05

mm.

(Clearance of the middle needle is a little larger.)

v Right needle

0 toO.OS

mm

looper

lj

==;;:!/~:::<:::::;~~~

DtoD.OSmm

I'

0

Needle

Top point of looper

.

7)

Adjusting

amount

of

the

looper-avoid

36

o The clearance between the blade point

of

the looper, and the grooves

of

the left and right needles should

be

equal.

longitudinal

moving

1

amount

of

looper

{Ref. 1.54

mm)

Left

needle Right needle

~Locus

ofloope'

L.

o When the looper moves to the right, the tip

of

the left needle contacts the back

of

the looper at the

position

of

213

from

the

upper side

of

the looper.

/Left

needle

)I

Loope'

Needletipr

(Adjust when the needle is replaced with an excessively different sized needle. Check that the clearance

between

the

looper

and

the

needle

is

correct

and

the

needle

tip

contacts the back of

the

looper

at

the ,

posilion

of

213

from the

upper

side of the looper.)

Page 37

•

Adjustment

Procedures

o Adjust by loosening the looper base setscrew G and move

the looper holder back and forth.

<D

Adjustment of looper path

Loosen the setscrew

0 of the looper path shifting cam

0.

Place

the engraved line D about 3 mm from the engraved line E and

rotate the cam

8 to adjust so that the clearance between the

rightlleft

needles and the blade point of the looper should be

equaL

®Adjustment

of avoid

Amount of avoid

small t

Amount

of

avoid large

~~~

Loosen the screw 0 and nut 0

of

the looper

cam

guide

i)

.

Then move the screw 0 back and forth to adjust. {Use a 3/8"

spanner

forO.)

Needle Path of looper

•••

'

/

{Caution)

After

the

adjustment,

check

again

the

clearance

between

the

blade

point

of

the

looper

and

the

groove

of

the

needle.

Use a

1/8"

hexagonal

wrench

for

the

screw

0.

Results

of

Improper

Adjustment

o

If

the clearance is large, skipping

stitch of

the needle thread scooping

occurs. And

the

damage

of

the

needle point will occur due

to

the

strong

hit on the back of the looper.

o

If

the

clearance

is

small,

the

damage

of

the-blade point of

the

looper and the

needle

breS.kage

will

occur. And, the skipping stitch will

occur

as

the clearance between the

back of the .looper and the needle

becomes large.

Left needle Right needle

~st)~

Position

of

D-C

o Looper path between the engraved

lines

D and C is left upward.

The

clearance of the left needle is large

and skipping stitch occurs.

o If the engraved line E

is

turned more

than

3 mm from

D,

the looper path

is left downward. The

damage

of the

blade point

of

the looper and needle

breakage occur.

o

If

the amount

of

avoid is large, the

clearance between the needle and

the

back

of

the

looper

becomes

large.

In

this case, skipping stitch

and tangling stitch occur.

o

If

the amount of avoid is small, the

hitting of the needle and the

bac~

of the looper becomes strong.

In

this

case, the damage of the needle top,

needle breakage and scratch on the

back of the looper occur.

37

Page 38

•

CS100

Standard Adjustment

8) Position of

the

feed dog

38

o The clearance between the slot on the throat plate and the leftlright sides

of

the feed dog should be

equal.

o In the maximum stroke end of the main feed dog and differential feed dog, the clearance should be equal

toA=A'andB=B'.

o Height of the teed dog is 1.0 mm at the top of

their

stroke.

o Tilt of the feed dog is parallel

to

the throat plate when the needle bar

is

in its highest position.

o Adjust so that the throat plate and the main feed dog do not contact each other even

if

the main feed dog

is

in its maximum stroke end .

o Adjust so that the throat plate and the differential feed dog do not contact each other even

if

the stroke

is

maximized.

Page 39

•

Adjustment Procedures

o Loosen screw

6

to

adjust the left/right position of the main

feed dog

fj.

o Loosen

screw

@4

to

adjust

the

left/right

position

of

the

differential feed dog

8).

o Loosen screw

'I)

and move the main feed dog back and forth

to

adjust the longitudinal position of the main feed dog

ti

.

o Loosen screw

f1)

and rotate the eccentric nut

to

adjust the

longitudinal position of the differential feed dog

8)

.

o Loosen

screw@!)

to adjust the height of the main feed dog

fi

and the differential feed dog

f)

.

o To adjust the maximum stroke of the main feed dog, loosen

screw

e and rotate spacing stop

~so

that

it

contacts the pin

@I

when the main feed dog has reached its maximum stroke

and while the throat plate does not contact the

main-

feed

dog.

o To adjust the maximum stroke of

the

differential feed dog,

loosen screw

til

and enter the stopper pin

~to

the end when

the differential feed dog has reached its maximum stroke and

while the differential feed dog does not contact the throat

plate and the front end of the main feed dog.

Results

of

Improper Adjustment

o

If the lateral position of the feed dog

is

not

correct, the left/right sides of

the feed dog and

the

throat plate

will wear out. Heating

and

abnormal

noise

will be produced. Also, the

feed

components

will

wear

out

quickly and looseness and bending

of the components

will occur. Also,

abnormal

noise

from

the

components

~ill

be produced.

o If the height.of the feed dog

is

low,

the

stitch

length

at

the

finish

of

sewing becomes smaller.

o

lithe

height

o1

the feed dog

is

high,

it

will cause the return feed, skipping

stitch and defective chain-off.

o

If

the

main feed dog, differential

feed dog, and throat plate come

in

contact

With

each other, it will cause

breakage.

39

Page 40

•

40

Standard

Adjustment

9)

Spreader

CD

Timing

Descend~

Highest

point

2.5:!:

0.1

mm

C~~~~~~~~~~

.::::::>Return

Just when the needle descends 2.5 mm from

the

highest

point of the needle bar. the

spreader

begins to return from its extreme left position.

Q)

Position of spreader

II

5.5:!:

0.1

mm

--r-*'1

~

@Fixing

spreader thread guide

Spreader

Extreme

right

Top

blade

should

be

between

left

side

and

middle

of

the

groove.

Show

spreader at

extreme right

position

when setting height

® Needle clamp spreader thread guide

Fixing spreader

thread

guide

Needle

clamp

spreader

thread guide

®Stroke

.

:,

•.

_;;

'

,.

Direction

of

cloth

feeding;;

/

;-t

...

19±0.1mm

~

..

-~

''

...

o The height is 11.5 ± 0.2 mm (4.0 + 3.2

gauge).

(10.8 ±

0.2

mm for 4.8 mm,

5.6 mm,and 6.4 mm gauges.

a When the spreader is in the extreme lett position,

the distance between the center

of

the left needle

and the top blade of the spreader

is

5.5 ±

0.1

mm.

o

When

the

spreader

returns

to

the

right,

the

clearance between the spreader and the left needle

is

0.3 to 0.5 mm.

o When the spreader is in the extreme right position,

the

lop

blade

of

the spreader

..

should be between

left side

and

middle

of-

the spreader thread guide

groove.

o The height is

0.4

to

0.8 mm from the surface of the

spreader.

o When the needle

bar

is

in

the lowest position, the

clearance

between

the

needle

clamp

spreader

thread

guide

and

the

upper

face

of

the

fixing

spreader thread guide

is 4.0 ± 0.5

mm.

o

The

center

ol

the

hole of the thread guide aligns