Page 1

OPERATOR / ILLUSTRATED PARTS MANUAL

08-20-08

FS300 SERIES, PLAIN AND DIFFERENTIAL FEED,

HIGH SPEED FLAT BED MACHINES

MANUAL NO. PT9914

FOR STYLES

FS315L63

FS316L61

FS316L62

FS316L63

Page 2

Manual No. PT9914 llustrated Parts List for FS300 Series Machines

First Edition Copyright 2000

By

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. Jan. 2000

PREFACE

This parts manual has been prepared to assist you in locating individual parts or assemblies on FS300 Series machines.

It can be used in conjunction with Union Special Engineer's Manual EN9424.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are

designed specifically for your machine and are manufactured with utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on FS300 Series machines.

CONTENTS

PREFACE .................................................................................................................................................................... 2

IDENTIFICATION OF MACHINES ............................................................................................................................... 4

CLASS DESCRIPTION ................................................................................................................................................. 4

STYLE OF MACHINES ................................................................................................................................................. 4

STYLE OF MACHINES CONT. .................................................................................................................................... 5

ILLUSTRATIONS........................................................................................................................................................... 5

IDENTIFYING PARTS ................................................................................................................................................... 5

NEEDLES ..................................................................................................................................................................... 5

SAFETY RULES ............................................................................................................................................................ 6

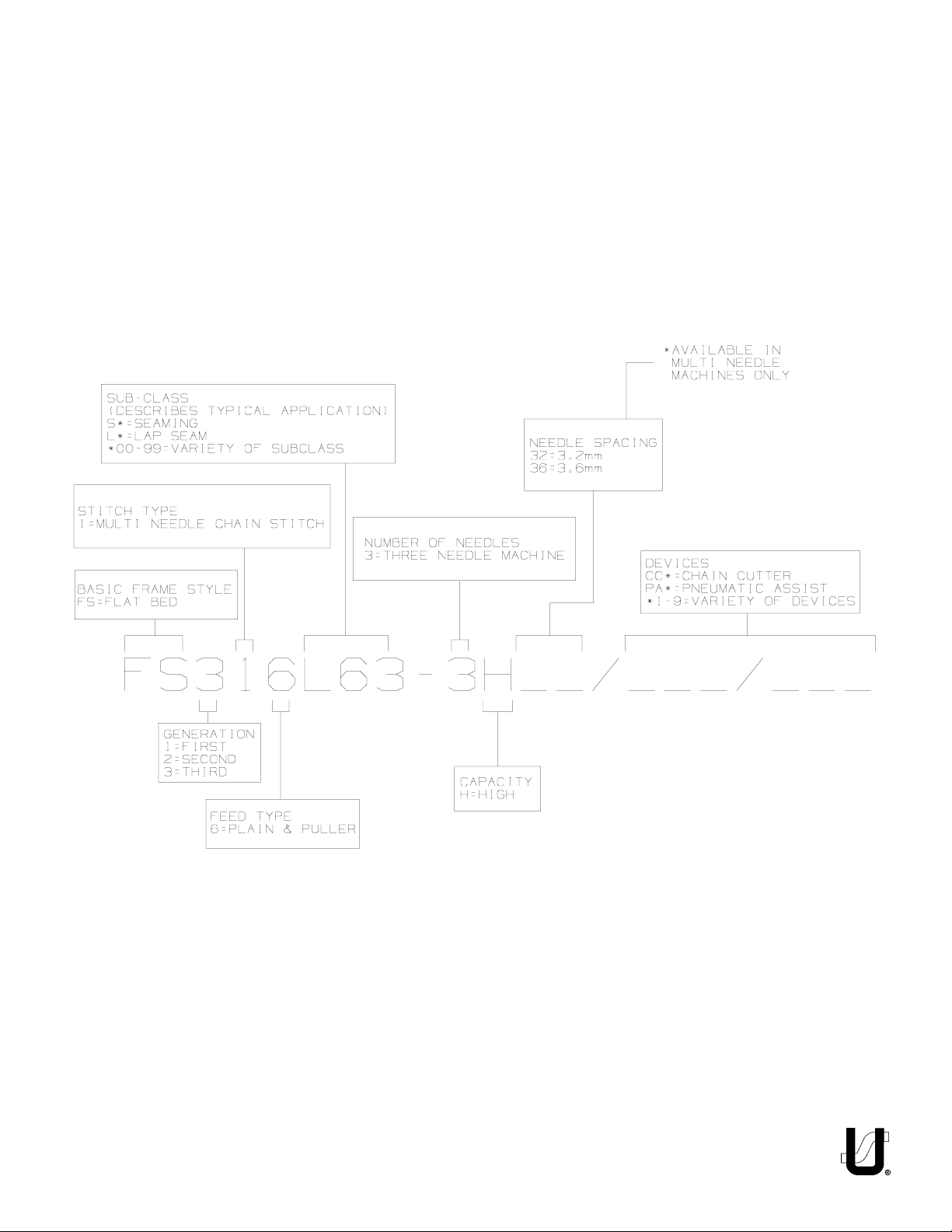

FS300 SERIES BUILDING BLOCK STYLE DESIGNATION SYSTEM................................................................................ 7

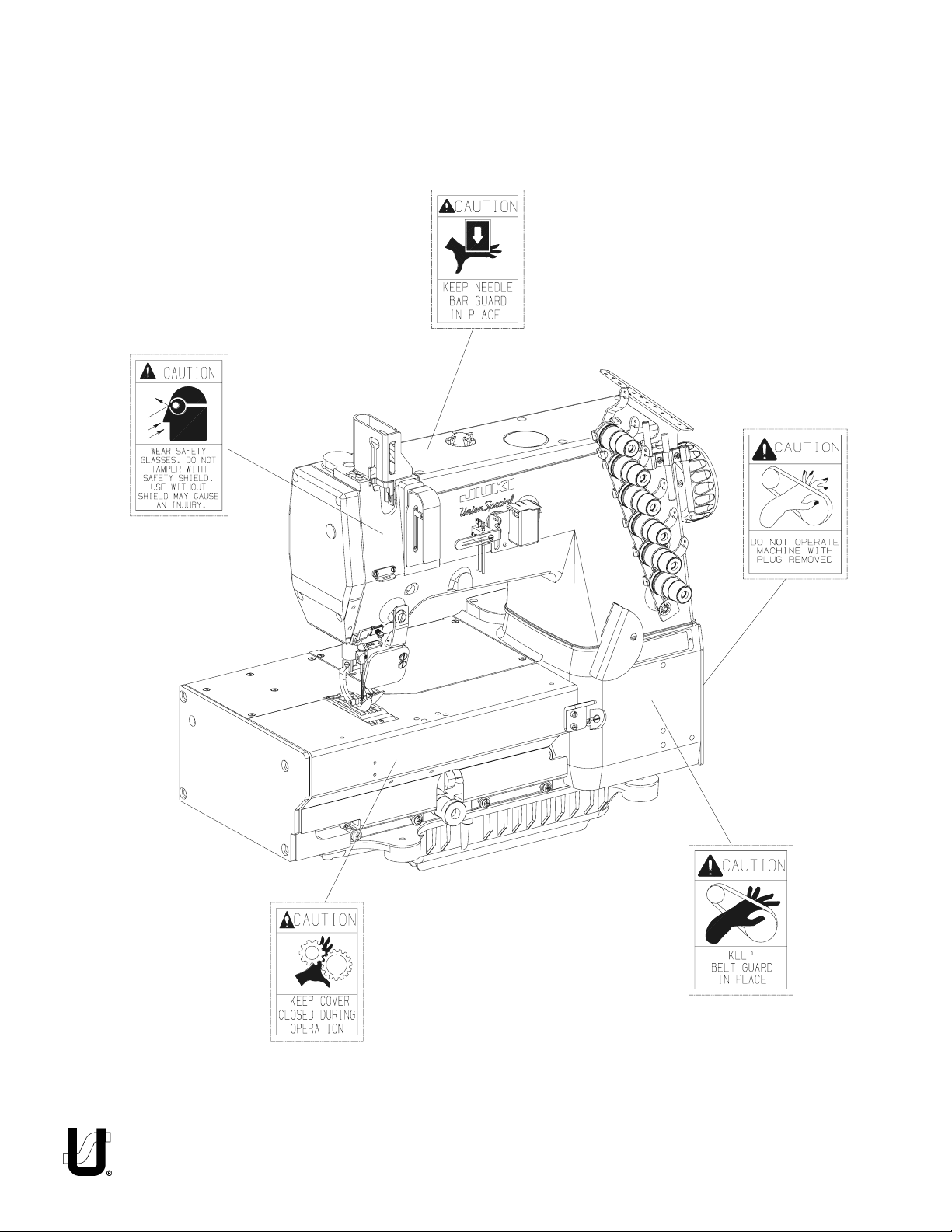

CAUTION AREAS: ...................................................................................................................................................... 8

OPERATOR'S DAILY CHECK LIST:.............................................................................................................................. 9

OPERATING CAUTIONS: ........................................................................................................................................... 9

OPERATING CAUTIONS (CONT.): .......................................................................................................................... 10

OPERATING THE PEDALS: ....................................................................................................................................... 10

LUBRICATION: ......................................................................................................................................................... 11

THREADING THE MACHINE: ................................................................................................................................... 12

THREADING THE MACHINE (CONT.): .................................................................................................................... 13

THREADING METHODS ........................................................................................................................................... 14

ADJUSTING THE STITCH LENGTH: ........................................................................................................................... 15

PRESSER FOOT PRESSURE AND LIFTER: .................................................................................................................. 15

FEED, NEEDLE LOOPER TIMING:............................................................................................................................. 16

NEEDLE ALIGNMENT: .............................................................................................................................................. 16

LOOPER SETTING:.................................................................................................................................................... 17

NEEDLE BAR SETTING: ............................................................................................................................................. 17

2

Page 3

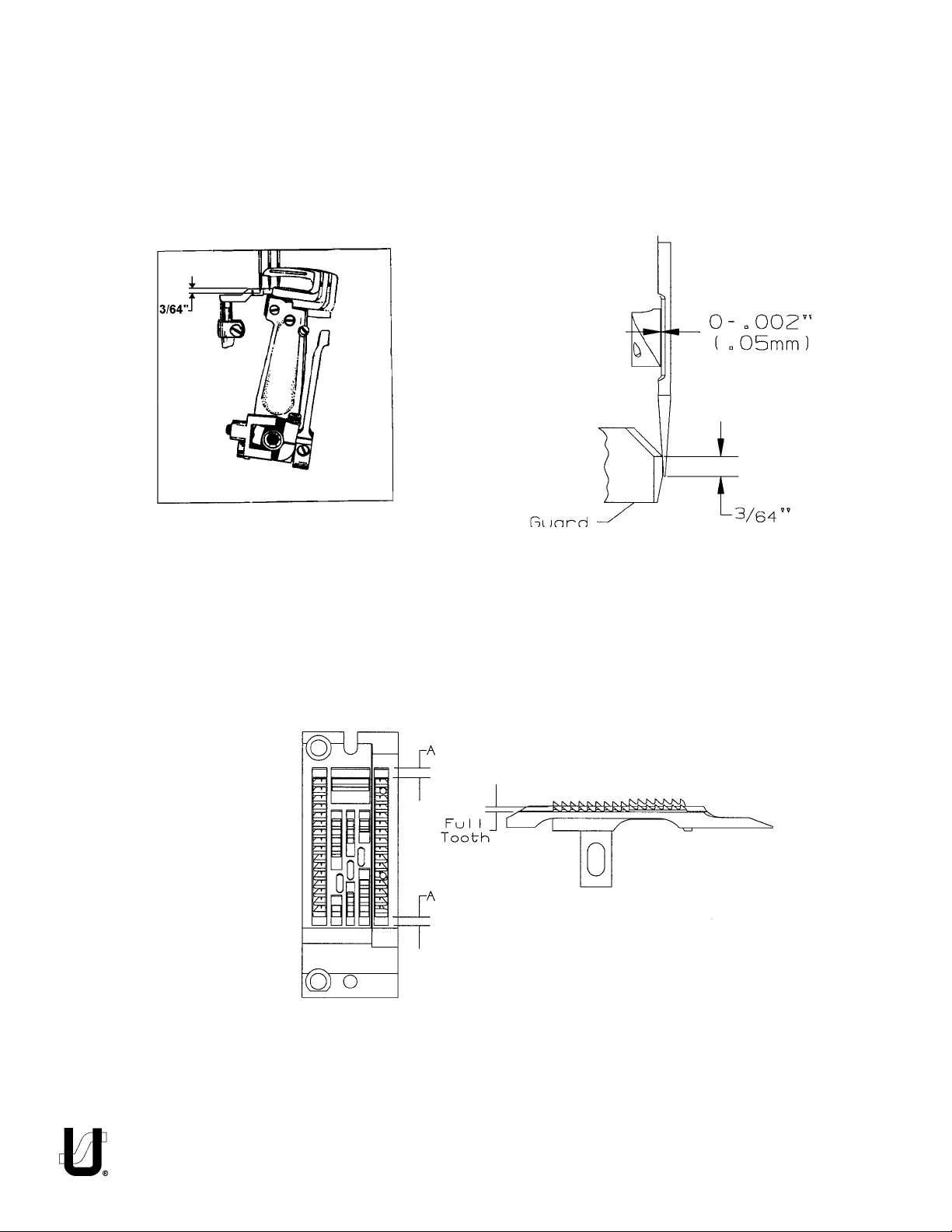

REAR NEEDLE GUARD: ........................................................................................................................................... 18

FEED DOG CENTERING AND HEIGHT ABOVE THROAT PLATE: ............................................................................ 18

PRESSER FOOT: ........................................................................................................................................................ 18

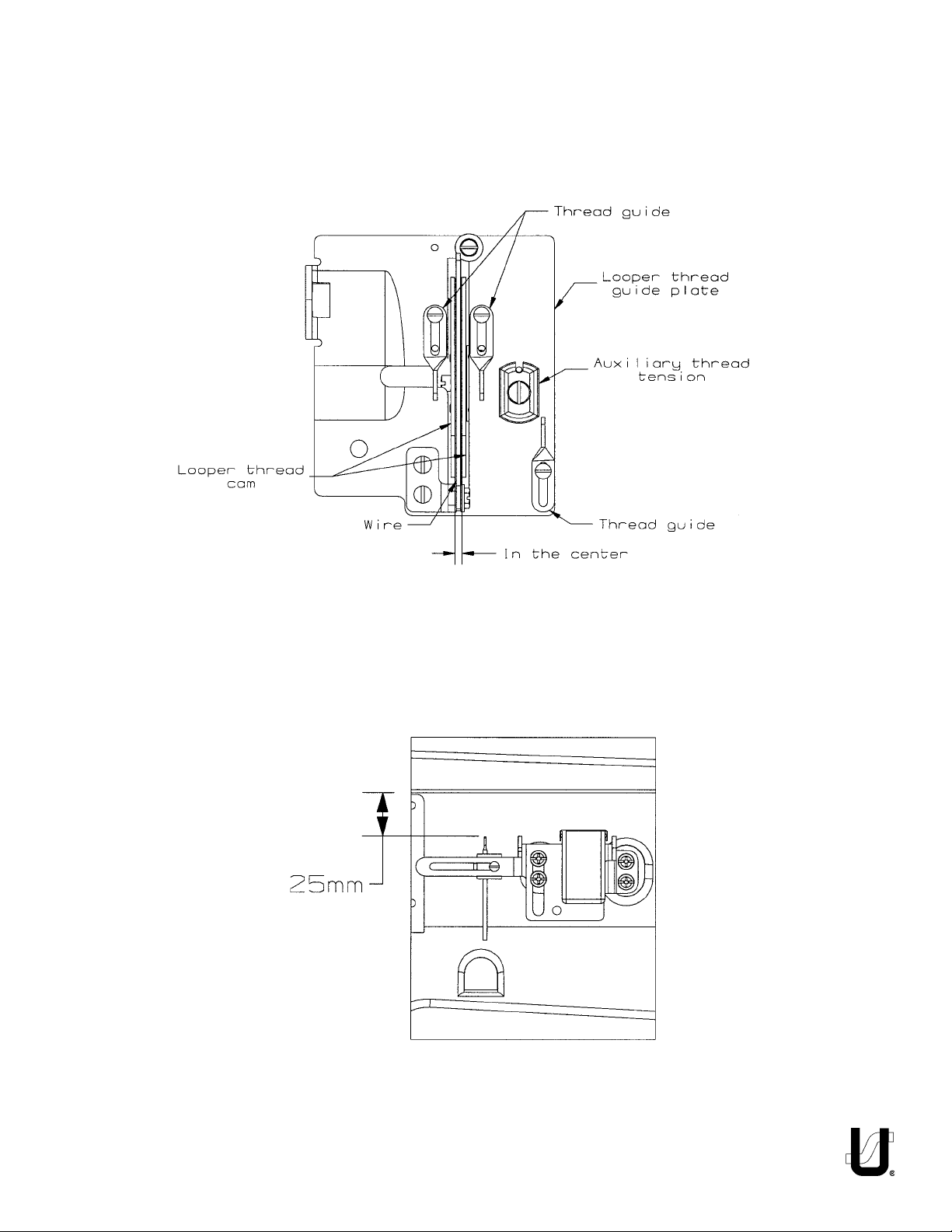

LOOPER THREAD TAKE-UP CAM SETTING: ............................................................................................................ 19

THREAD CONTROL: ................................................................................................................................................ 19

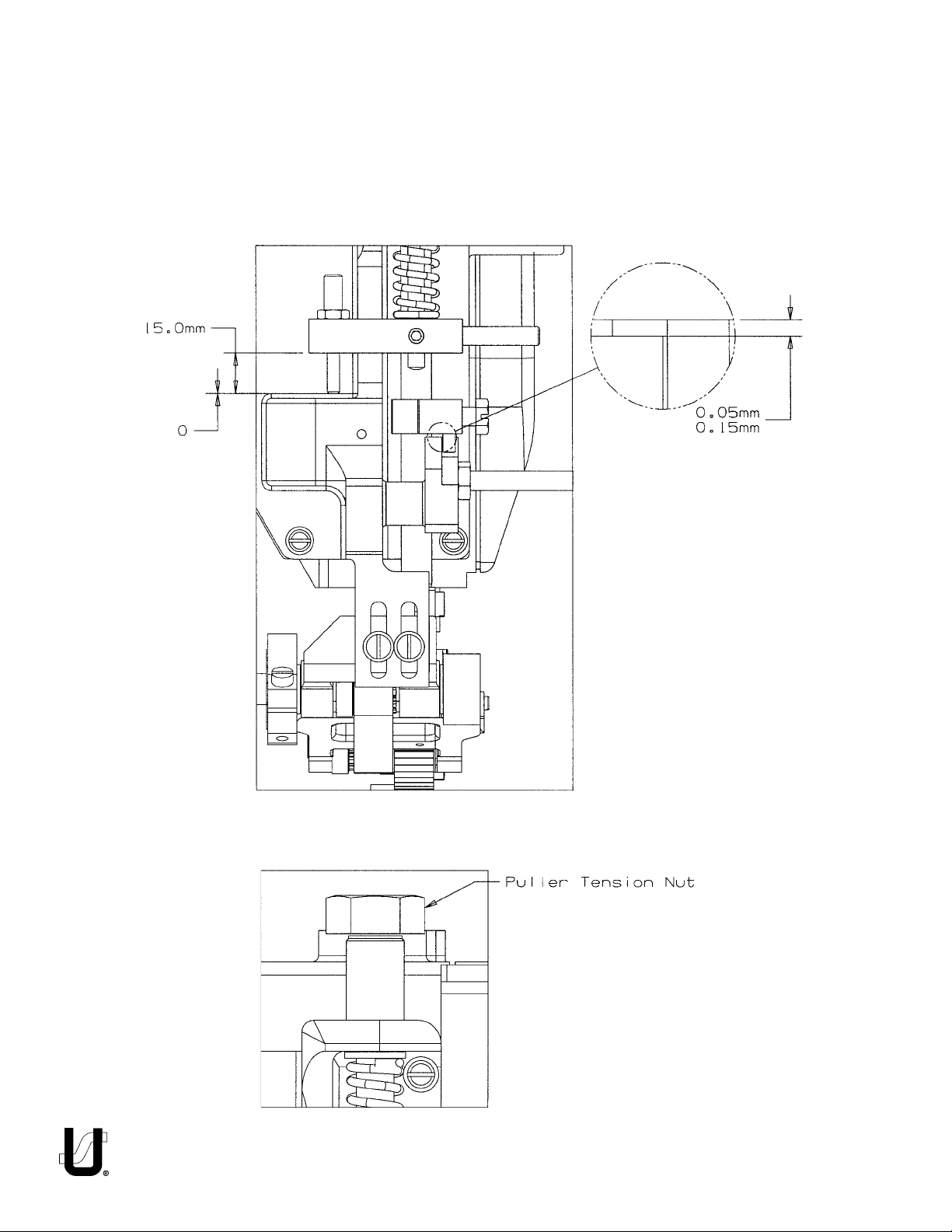

PULLER ADJUSTMENTS: ........................................................................................................................................... 20

PULLER ADJUSTMENTS CONT.: ............................................................................................................................... 21

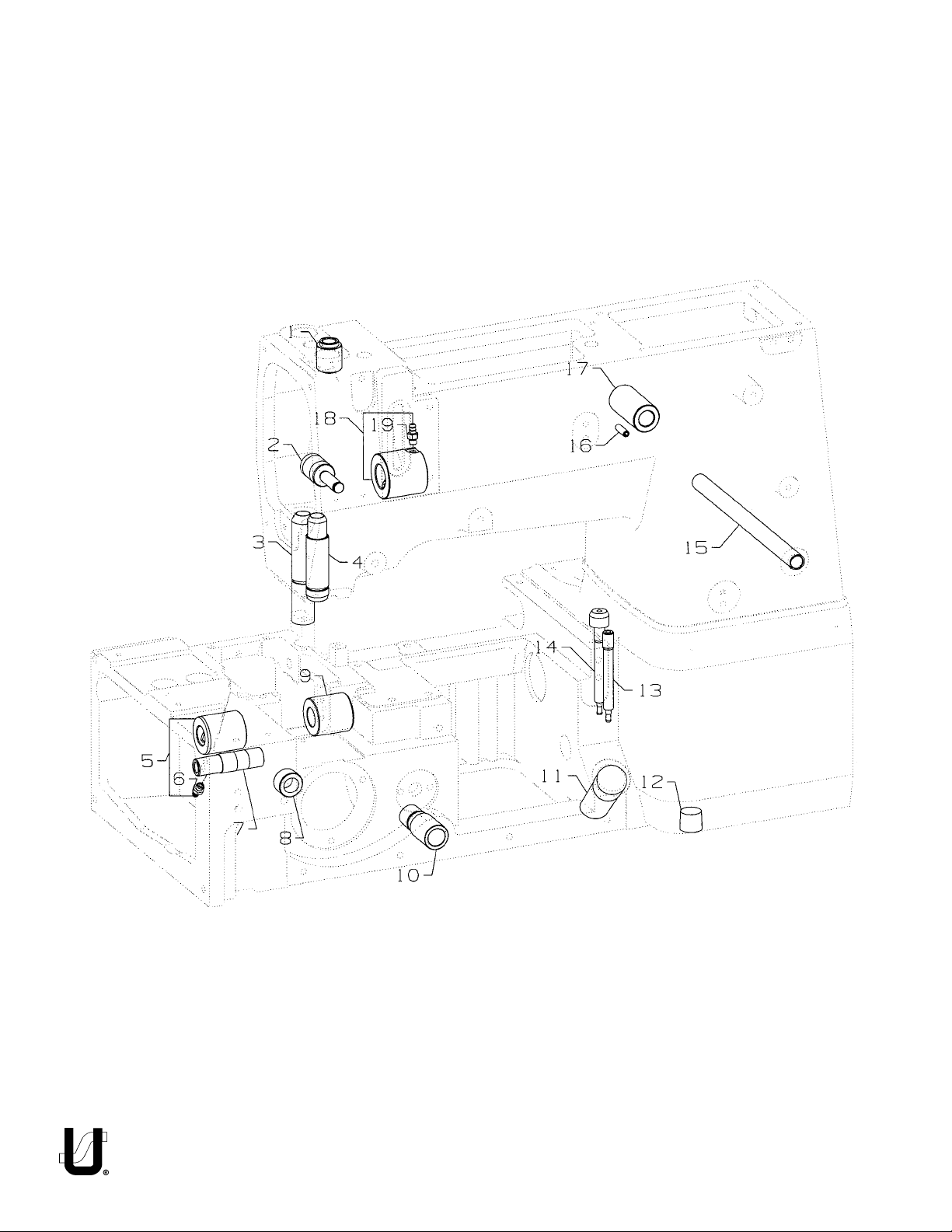

BUSHINGS ................................................................................................................................................................ 23

NEEDLE BAR ............................................................................................................................................................ 25

UPPER MAIN SHAFT ................................................................................................................................................. 27

THREAD GUIDE ........................................................................................................................................................ 29

TENSION RELEASE & THREAD TENSION .................................................................................................................. 31

PRESSER FOOT LIFT .................................................................................................................................................. 33

COVERS, UPPER ARM ............................................................................................................................................ 35

LOWER MAIN SHAFT ............................................................................................................................................... 37

LUBRICATION, OIL TUBING & OIL PUMP ................................................................................................................ 39

LOOPER DRIVE ........................................................................................................................................................ 41

NEEDLE GUARD ...................................................................................................................................................... 43

LOOPER THREAD TAKE-UP ..................................................................................................................................... 45

FEED DRIVE MECHANISM FOR PLAIN FEED .......................................................................................................... 47

FEED DRIVE MECHANISM FOR DIFFERENTIAL FEED .............................................................................................. 49

FEED DRIVE MECHANISM FOR PLAIN FEED .......................................................................................................... 51

FEED DRIVE MECHANISM FOR DIFFERENTIAL FEED .............................................................................................. 53

COVERS, LOWER BED............................................................................................................................................. 55

COVERS, LOWER BED............................................................................................................................................. 57

SEWING PARTS ........................................................................................................................................................ 59

FOLDERS .................................................................................................................................................................. 61

PULLER DRIVE ASSEMBLY ........................................................................................................................................ 63

PULLER ASSEMBLY ................................................................................................................................................... 65

PULLER ASSEMBLY ................................................................................................................................................... 67

MISCELLANEOUS PARTS PA1 (USE WITH CC2 CHAIN CUTTER) ........................................................................... 69

MISCELLANEOUS PARTS PA1A (USE WITHOUT CC2 CHAIN CUTTER) .................................................................. 71

TUBING PA1 WITH CHAIN CUTTER ......................................................................................................................... 72

TUBING PA1A WITHOUT CHAIN CUTTER ................................................................................................................ 73

TABLING (EXTRA SEND CHARGE) .......................................................................................................................... 75

PRESSER FOOT LIFTER .............................................................................................................................................. 77

ACCESSORIES ......................................................................................................................................................... 79

NUMERICAL INDEX OF PARTS ................................................................................................................................ 80

NUMERICAL INDEX OF PARTS ................................................................................................................................ 81

3

Page 4

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine is identified by a style number, which is stamped into the style plate affixed to the

middle of the machine under the tension assembly. The serial number is stamped into the serial number plate affixed

to the right rear base of the machine.

CLASS DESCRIPTION

Precision high speed, single needle, plain or differential feed flat bed machines. Totally enclosed feed and looper

drive mechanism, automatic forced feed lubrication system with easily replaceable filter. Main feed has thumbscrew

adjustment and differential feed has lever adjustment and independently driven rear needle guard.

STYLE OF MACHINES

FS316L61-3H36CC2PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, flat sewing parts, close-

coupled toothed roller puller, pneumatic power "AIR-KLIPP" Chain cutter, pneu

matic assisted presser foot and roller lift, and double lap seam folder with 1/8"

(3.2mm) capacity. For attaching the risers to jeans, seat seaming operations on

jeans, bibs to overalls and piecing sleeves on denim jackets. Seam Specifications

401LSc-3. Recommended needle 128 GAS sizes 140/054 - Stitch range 7-10 S.P.I..

Maximum recommended speed 6000 R.P.M.

FS316L61-3H36PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, flat sewing parts, close-

coupled toothed roller puller, pneumatic assisted presser foot and roller lift, and

double lap seam folder with 1/8" (3.2mm) capacity. For attaching the risers to jeans,

seat seaming operations on jeans, bibs to overalls and piecing sleeves on denim

jackets. Seam Specifications 401LSc-3. Recommended needle 128 GAS sizes 140/

054 - Stitch range 7-10 S.P.I.. Maximum recommended speed 6000 R.P.M..

FS316L62-3H36CC2PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .040" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic power "AIR-KLIPP"

Chain cutter, pneumatic assisted presser foot and roller lift, and double lap seam

folder with 1/8" (3.2mm) capacity. For attaching the risers to jeans, seat seaming

operations on jeans, bibs to overalls and piecing sleeves on denim jackets. Seam

Specifications 401LSc-3. Recommended needle 128 GAS sizes 140/054 - Stitch

range 7-10 S.P.I.. Maximum recommended speed 6000 R.P.M..

FS316L62-3H36PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .040" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic assisted presser foot

and roller lift, and double lap seam folder with 1/8" (3.2mm) capacity. For attaching

the risers to jeans, seat seaming operations on jeans, bibs to overalls and piecing

sleeves on denim jackets. Seam Specifications 401LSc-3. Recommended needle

128 GAS sizes 140/054 - Stitch range 7-10 S.P.I.. Maximum recommended speed

6000 R.P.M..

FS316L63-3H32CC2PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .070" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic power "AIR-KLIPP"

Chain cutter, pneumatic assisted presser foot and roller lift, and double lap seam

folder with 1/8" (3.2mm) capacity. For attaching the risers to jeans, seat seaming

operations on jeans, bibs to overalls and piecing sleeves on denim jackets. Seam

Specifications 401LSc-3. Recommended needle 128 GAS sizes 140/054 - Stitch

range 7-10 S.P.I.. Maximum recommended speed 6000 R.P.M..

FS316L63-3H32PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .070" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic assisted presser foot

and roller lift, and double lap seam folder with 1/8" (3.2mm) capacity. For attaching

the risers to jeans, seat seaming operations on jeans, bibs to overalls and piecing

sleeves on denim jackets. Seam Specifications 401LSc-3. Recommended needle

128 GAS sizes 140/054 - Stitch range 7-10 S.P.I.. Maximum recommended speed

6000 R.P.M..

4

Page 5

STYLE OF MACHINES CONT.

FS315L63-3H32CC2PA1 Same as FS316L63-3H32CC2PA1 except differential feed.

FS315L63-3H32PA1 Same as FS316L63-3H32PA1 except differential feed.

ILLUSTRATIONS

This manual has been arranged to simplify ordering repair parts. Exploded views of various sections of the mechanism are

shown so that the parts may be seen in their actual position in the machine. On the page opposite the illustration will be

found a listing of the parts with their part numbers, description and the number of pieces required in the particular view

being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of the part in the illustration. The

reference number should never be used in ordering parts. Always use the part number listed in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their descriptions under

the description of the main sub-assembly. As an example refer to the following text.

5. 50366B Needle Thread Strike-Off Assembly ................................................................................ 1

6. 50358V Needle Thread Strike-Off .................................................................................. 1

7. 50370F Thread Strike-Off Component ......................................................................... 1

8. SS7060310SP Screw, for plate strike-off .................................................................................. 1

When a part is common to all machines covered in this manual, no specific usage will be mentioned in the description.

However, when the parts for the various machines are not the same, the specific usage will be mentioned in the description

and, if necessary, the difference will be shown in the illustration.

*Ref. No. showing no Part No. is for location only. Part is not for sale separately.

A numerical index of all the parts shown in this manual is located at the back. This will facilitate locating the illustration and

description when only a part number is known.

IDENTIFYING PARTS

Where construction permits, each part is stamped with its part number. On some of the smaller parts and on those where

construction does not permit, an identification letter is stamped in to distinguish the part from similar ones.

PLEASE NOTE: Part numbers represent the same part, regardless of which manual they appear. On all orders please include

part number, name and style of machine for which the part was ordered.

For optimum performance use only genuine Union Special replacement parts.

NEEDLES

Each needle has both a type and size number. The type number denotes the kind of shank, point, length, groove, finish

and other details. The size number, stamped on the needle shank, denotes the largest diameter of the blade measured

between the shank and the eye. Collectively, the type number and size number represent the complete symbol which

is given on the label of all needles packed and sold by Union Special.

TYPE DESCRIPTION

128 GAS Short, double groove, struck groove, ball eye, spotted, round point, chromium plated- Sizes available 080/032,

090/036, 100/040, 110/044, 125/049, 150/060.

When changing the needle, make sure it is fully inserted in the needle holder before the screw is tightened.

When ordering needles, please use the complete type and size numbers as printed on the package to ensure prompt and

accurate processing of your order. A complete order should read as follows: "100 needles, type 128 GAS, size 150/060".

5

Page 6

SAFETY RULES

1. Before putting the machines described in this manual into service, carefully read the instructions. The

starting of each machine is only permitted after taking notice of the instructions and by qualified

operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and instructions from the

motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction manual are prohibited from being put into service until

it has been ascertained that the sewing units which these sewing machines will be built into, have

conformed with the EC Council Directives (89/392/EEC, Annex II B).

Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is

described in paragraph “STYLES OF MACHINES” of this instruction manual. Another use, going beyond

the description, is not as foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation

of the machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and changes all valid safety rules must be considered. Conversions

and changes are made at your own risk.

7. The warning hints in the instructions are marked with one of these two symbols:

8. When doing the following the machine has to be disconnected from the power supply by turning off

the main switch or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader, feed

dog, needle guard, folder, fabric guide etc.

8.3 When leaving the workplace and when the workplace is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or

special skilled personnel under consideration of the instructions.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision

of special skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are

described in the applicable sections of standard sheet DIN VDE 0105.

12. Before doing maintenance and repair work on the pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In case of existing residual air pressure, after disconnecting from compressed air supply (i.e. pneumatic equipment with air tank), the pressure has to be

removed by bleeding.

6

Page 7

FS300 SERIES BUILDING BLOCK STYLE DESIGNATION SYSTEM

7

Page 8

CAUTION AREAS:

8

Page 9

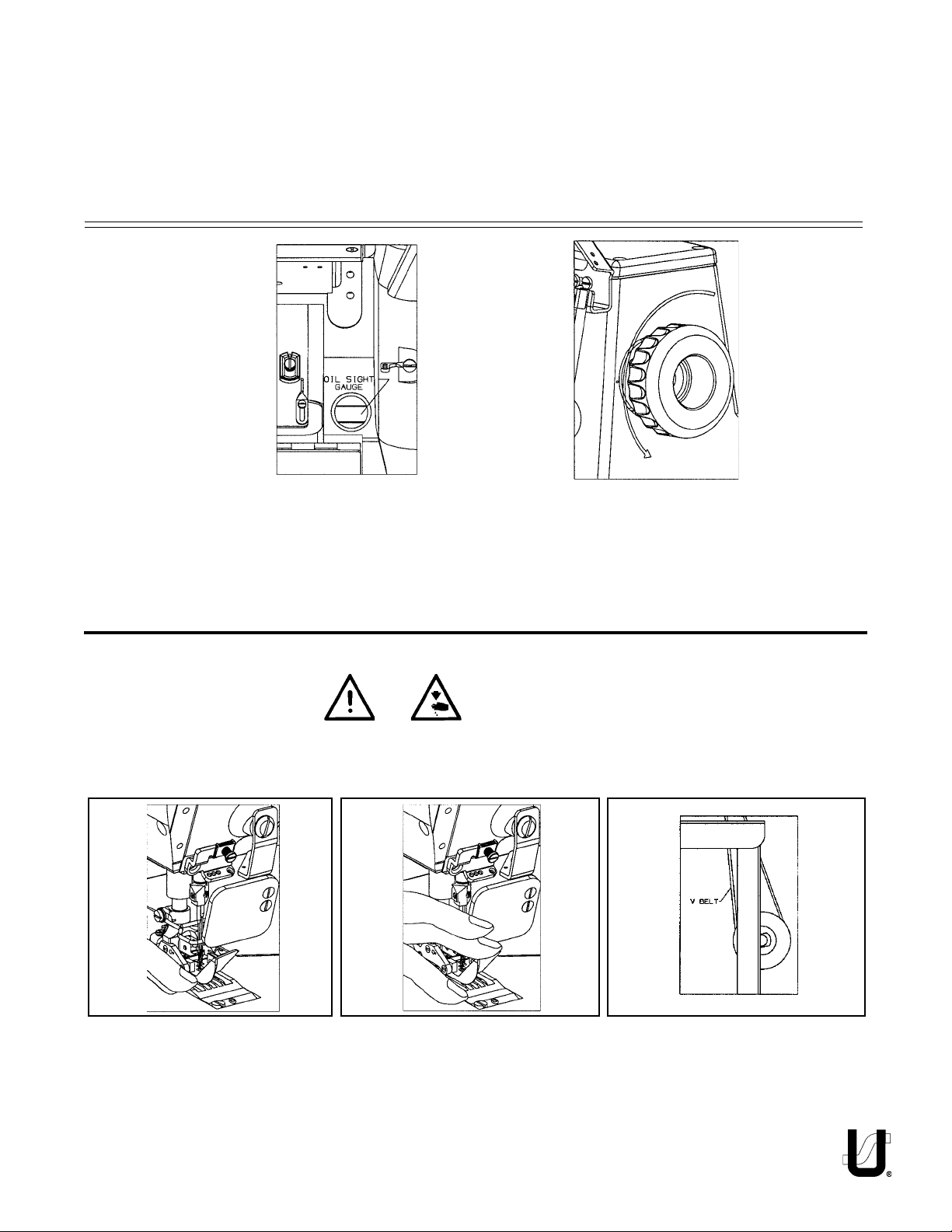

OPERATOR'S DAILY CHECK LIST:

The following should be checked daily and cleaned as required when it applies to your Union Special

machine:

••Lint area (clean with compressed air or brush)

••Needle bar bushings

••Under feed dogs & throat plates

••In knives

••In thread control eyelets

1. The oil level in the sight gauge

should be between the two red

lines when the machine is at rest.

If not, fill with Union Special

Specification 175 oil, (Union Special Part No. 28604R).

2. The correct rotating direction of

••Cooling airways

••In the machine

••In the motor

••In the cooling package

(package is an extra send charge)

the handwheel is counterclockwise, as viewed from the

handwheel's side. NEVER run the

machine in reverse direction.

OPERATING CAUTIONS:

1. Do not put your hand under

the needles when turning on

the power switch or at any

time.

2. Do not put your hand into the

sewing area while the machine

is running.

3. Turn off the power switch and

make sure the clutch motor is

at rest before removing the V

belt.

9

Page 10

OPERATING CAUTIONS (CONT.):

4. During operation, do not allow head, hands or any instrument, tool etc. near handwheel, V belt and

motor.

5. Do not operate your machine without the proper belt guard, sewing guards or any other protectors that

have been provided. Doing so is very dangerous.

6. Before inspecting, adjusting, cleaning, threading the head or replacing needles, turn OFF the power

switch. Make sure the flywheel on the motor has stopped, it will be kept running by inertia after turning

OFF the power switch. DO NOT depress the foot pedal while the machine is running or it will cause the

machine to rotate abruptly.

7. Turn OFF the power switch when you leave your machine or in case of a power failure.

8. Do not wipe the machine surface with lacquer thinner.

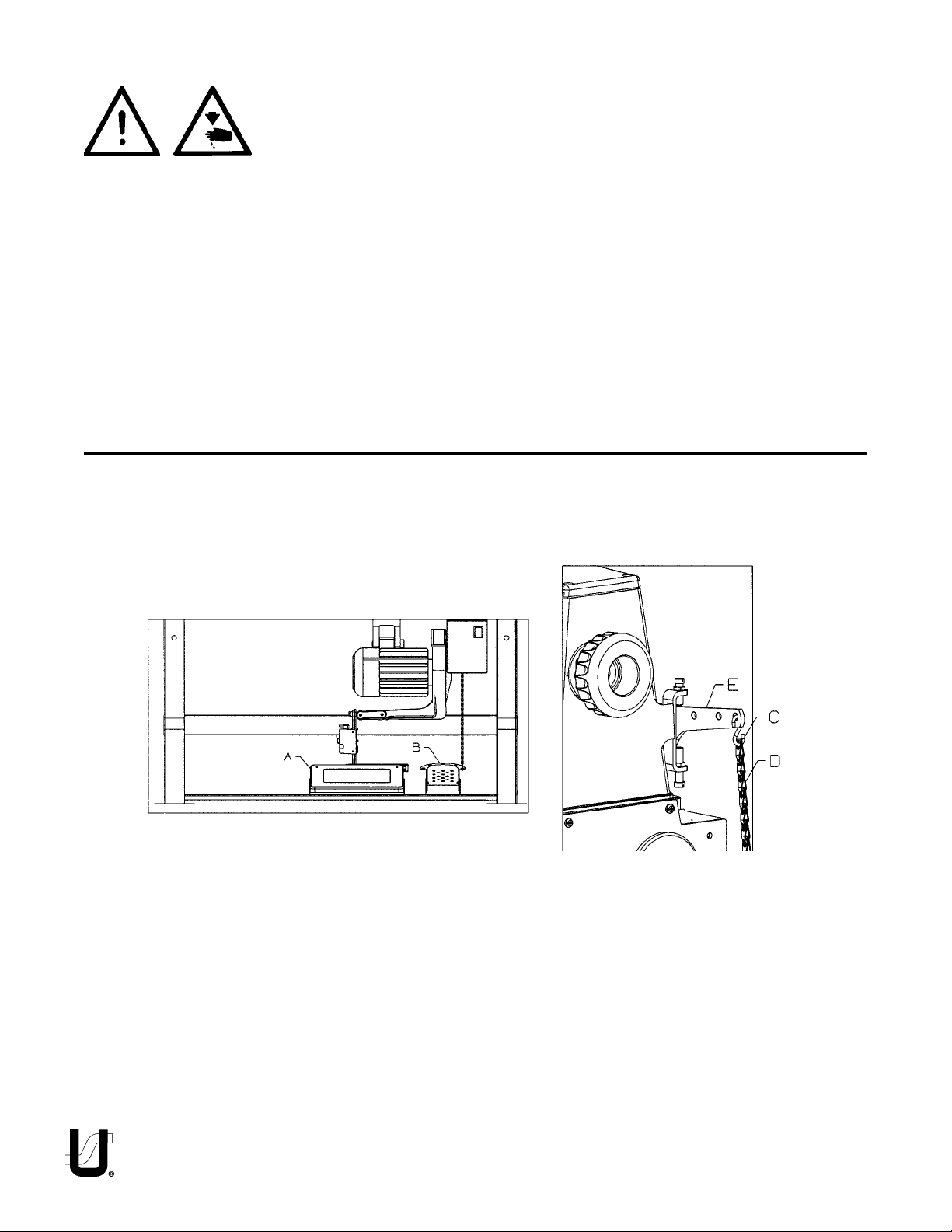

OPERATING THE PEDALS:

1. Locate the center of drive treadle (A) to be in line with the

needles.

2. Locate presser lifter pedal (B) for operator comfort.

3. Use S-shaped hook (C) to connect presser lifter pedal chain (D) to

presser lifting lever (E).

10

Page 11

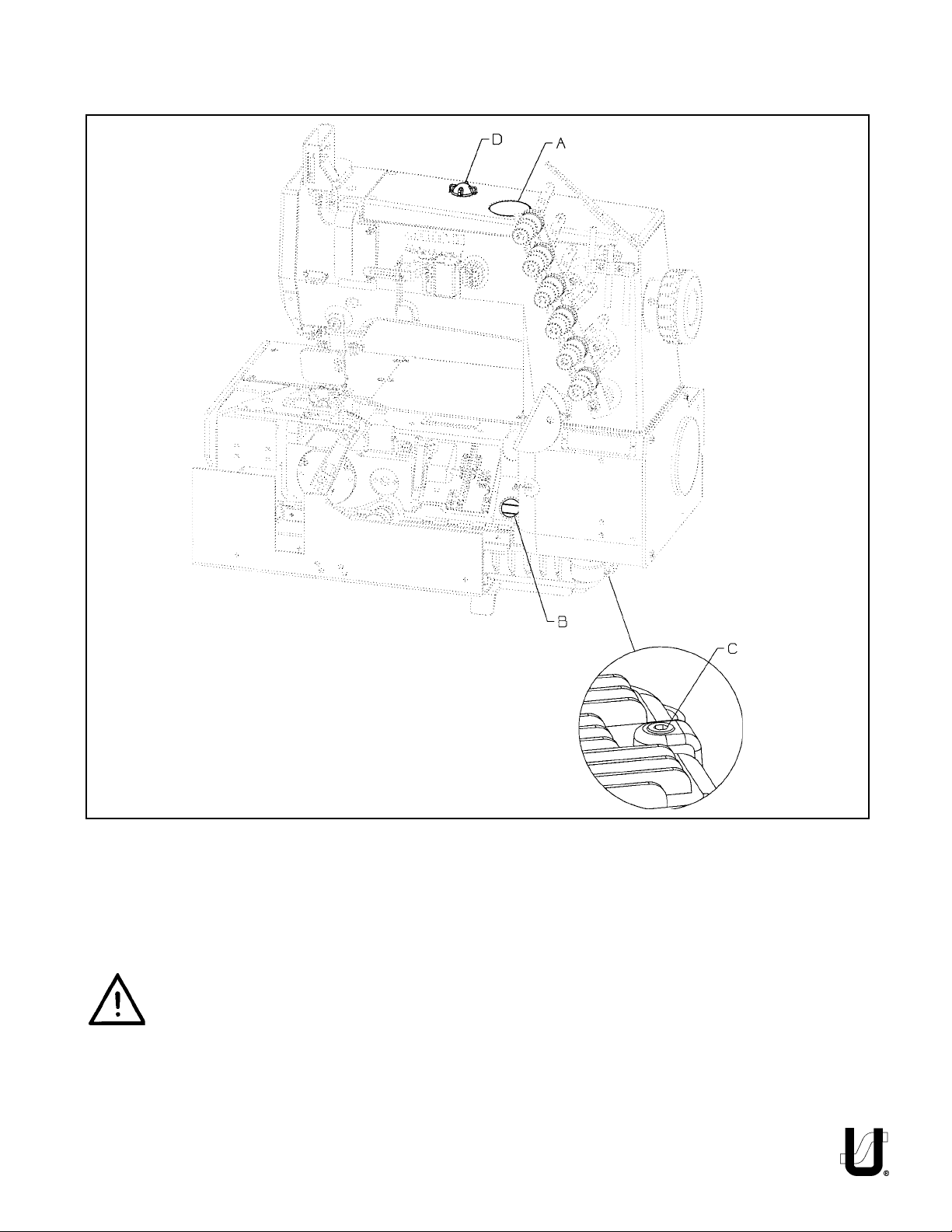

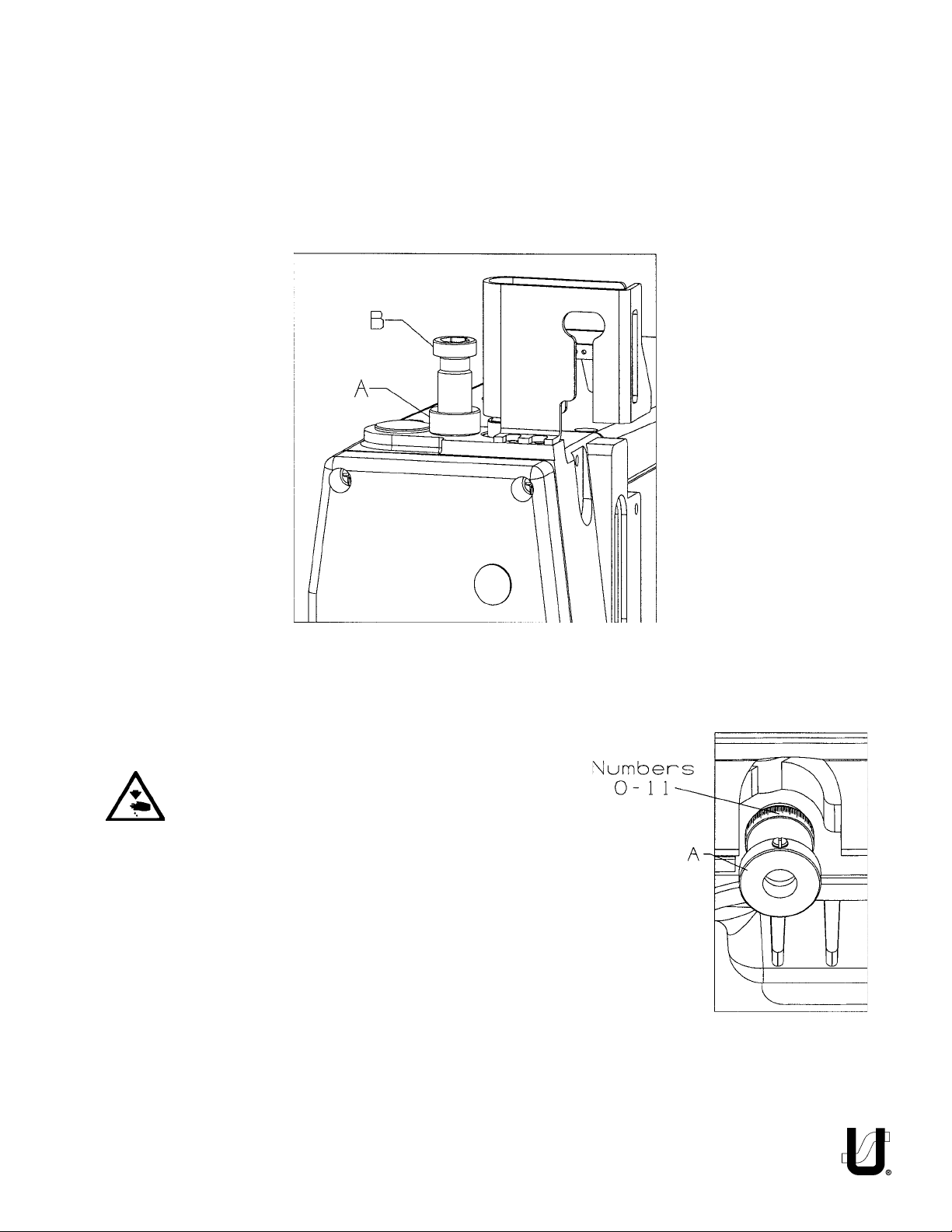

LUBRICATION:

The oil should be between the two red lines in sight gauge (B) when the machine is at rest.

1. If oil is required remove oil cap (A).

2. Fill between lines (B) with Union Special Specification 175 oil (Union Special Part No. 28604R).

CAUTION! Do not exceed the upper red marker line. Excessive oil in the machine will result in

oil leakage and possible overheating.

3. To drain oil reservoir, remove oil drain cap (C) on the underside of the machine.

4. To ensure oil flow through machine, check oil flow window (D).

11

Page 12

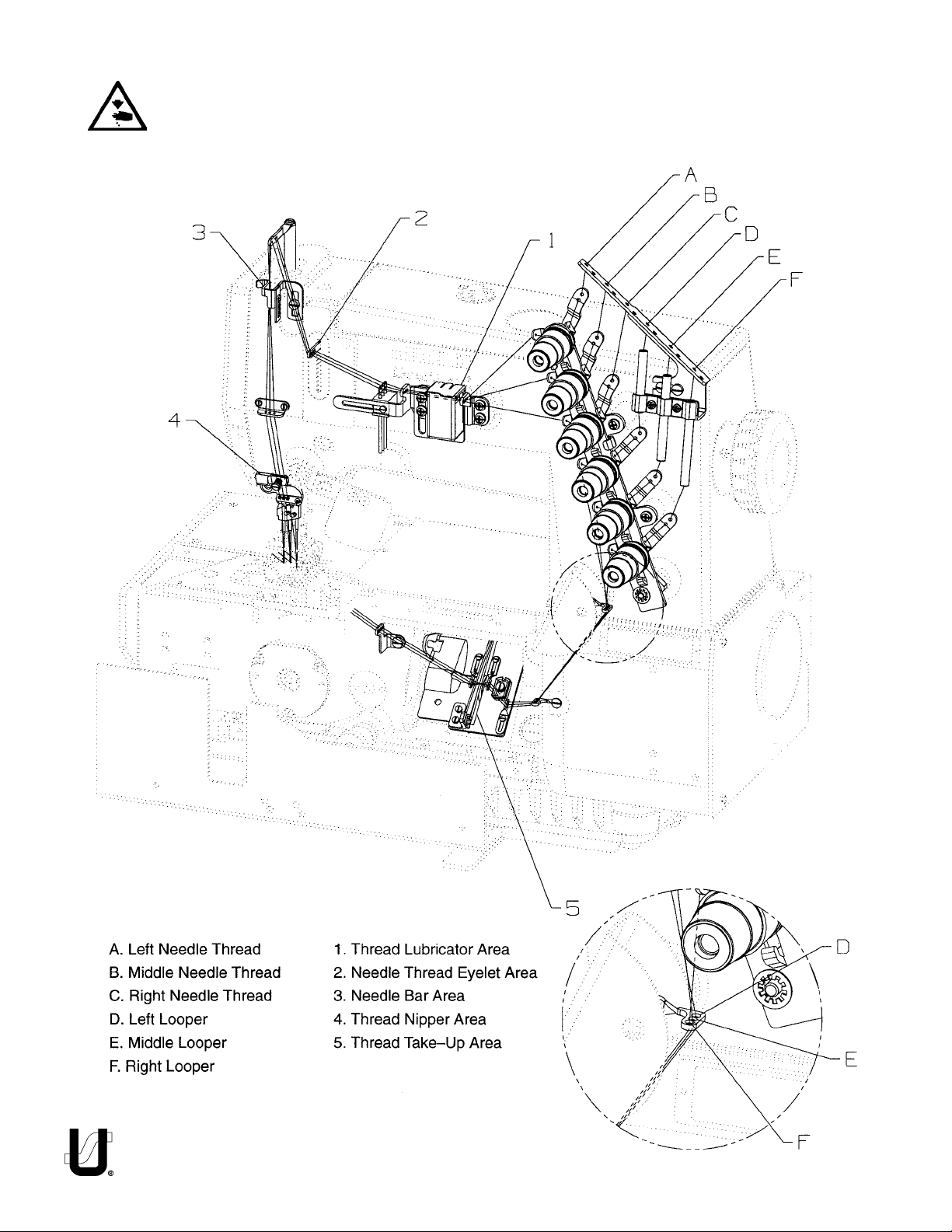

THREADING THE MACHINE:

Turn off main power switch before threading! When using clutch motors without actuation lock

wait until the motor has completely stopped.

Thread the machine according to the following threading illustrations.

12

Page 13

THREADING THE MACHINE (CONT.):

13

Page 14

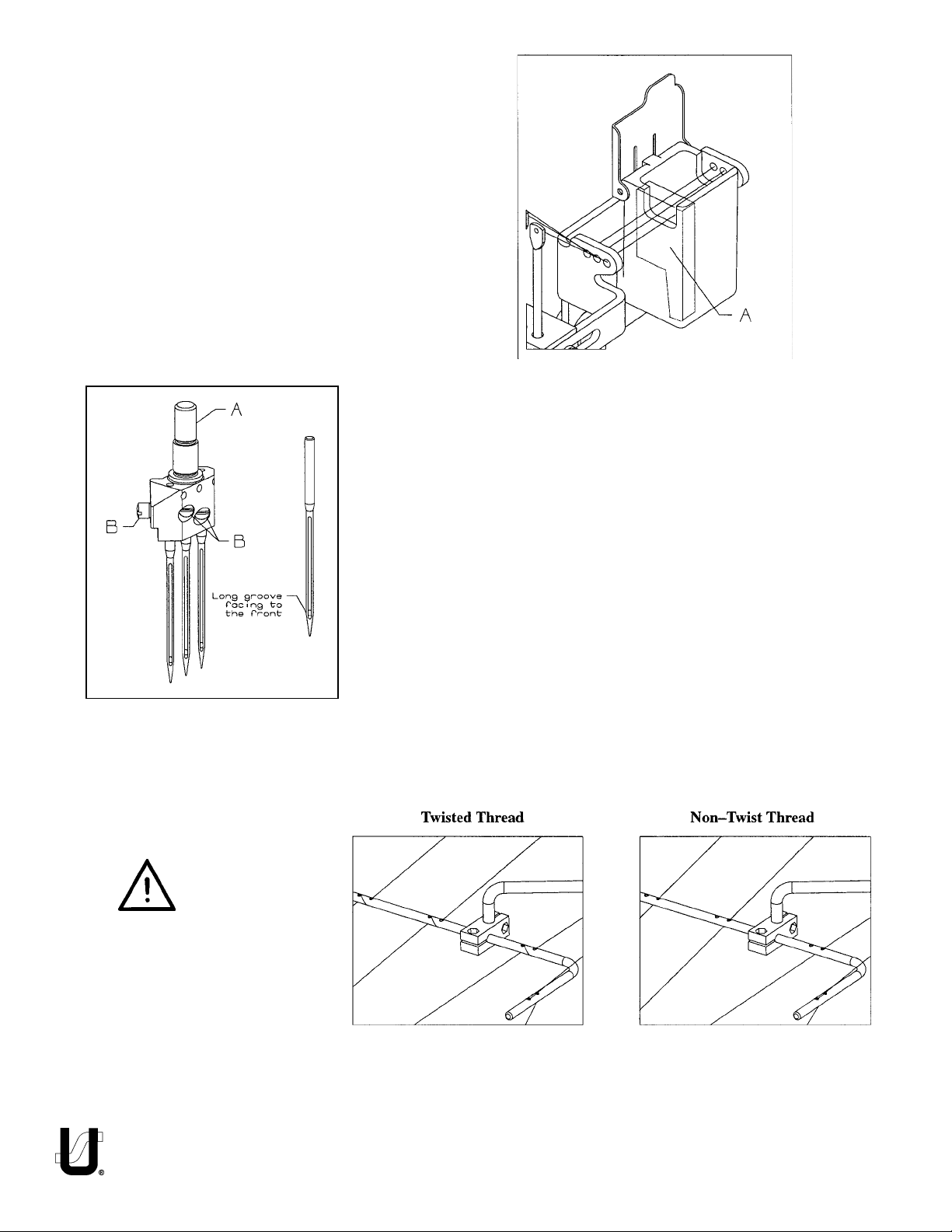

threading the machine (cont.):

When the needle thread lubricator is used:

1. Saturate felt (A).

2. Pass thread over felt.

When the needle thread lubricator is not used:

1. Remove felt (A).

The standard needle is 128 GAS, needle range sizes "090/036 150/060."

Insert needle according to the following procedure:

1. Bring needle head (A) to the highest position.

2. Loosen screw (B), insert needle into holes. The needle scarf

should face rearwards as viewed from the operator's side.

THREADING METHODS

CAUTION!

When using an untwisted thread

such as wooly nylon or weak

thread, do not wind it around the

intermediate thread guide.

3. Retighten screw (B).

14

Page 15

PRESSER FOOT PRESSURE AND LIFTER:

1. Adjust presser foot pressure by loosening nut (A) and turning presser foot adjust screw (B) clockwise to

increase the pressure, counterclockwise to decrease the pressure.

2. Retighten nut (A).

ADJUSTING THE STITCH LENGTH:

Turn off main power switch before setting the

stitch length! When using clutch motors without

actuation lock wait until the motor has completely stopped.

1. To change stitch length turn stitch regulating screw (A).

Clockwise to increase the stitches per inch/shorten the

length of one stitch.

Counterclockwise to decrease stitches per inch/increase

the length of one stitch.

2. Numbers 0-11 on stitch regulating screw are for operator's

reference only.

15

Page 16

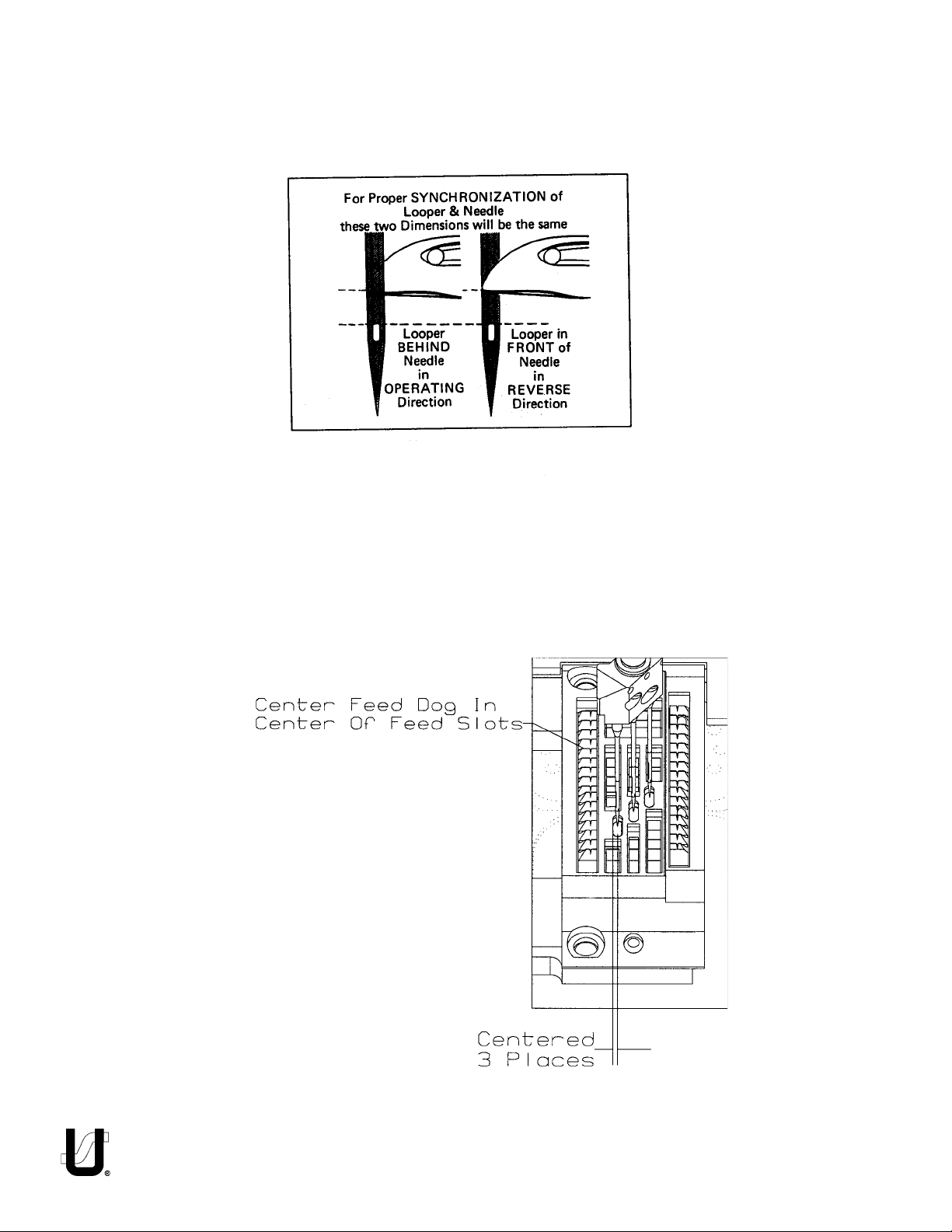

FEED, NEEDLE LOOPER TIMING:

Set the first screw in operating direction of the feed drive eccentrics to be straight up, then, holding this

position, set the needle bar at B.D.C.. Set the looper timing to the needles to be synchronized. Adjust the

looper timing with the looper avoid drive sprocket.

NEEDLE ALIGNMENT:

Torque needle head to 14 to 16 in-lbs (1.6 to 1.8Nm).

Install the feed dog, needles and throat plate. Use the adjustable ferrules to align the needles in the throat

plate and align the feed dog so it is centered side to side. tighten the throat plate support and ferrules in

place.

16

Page 17

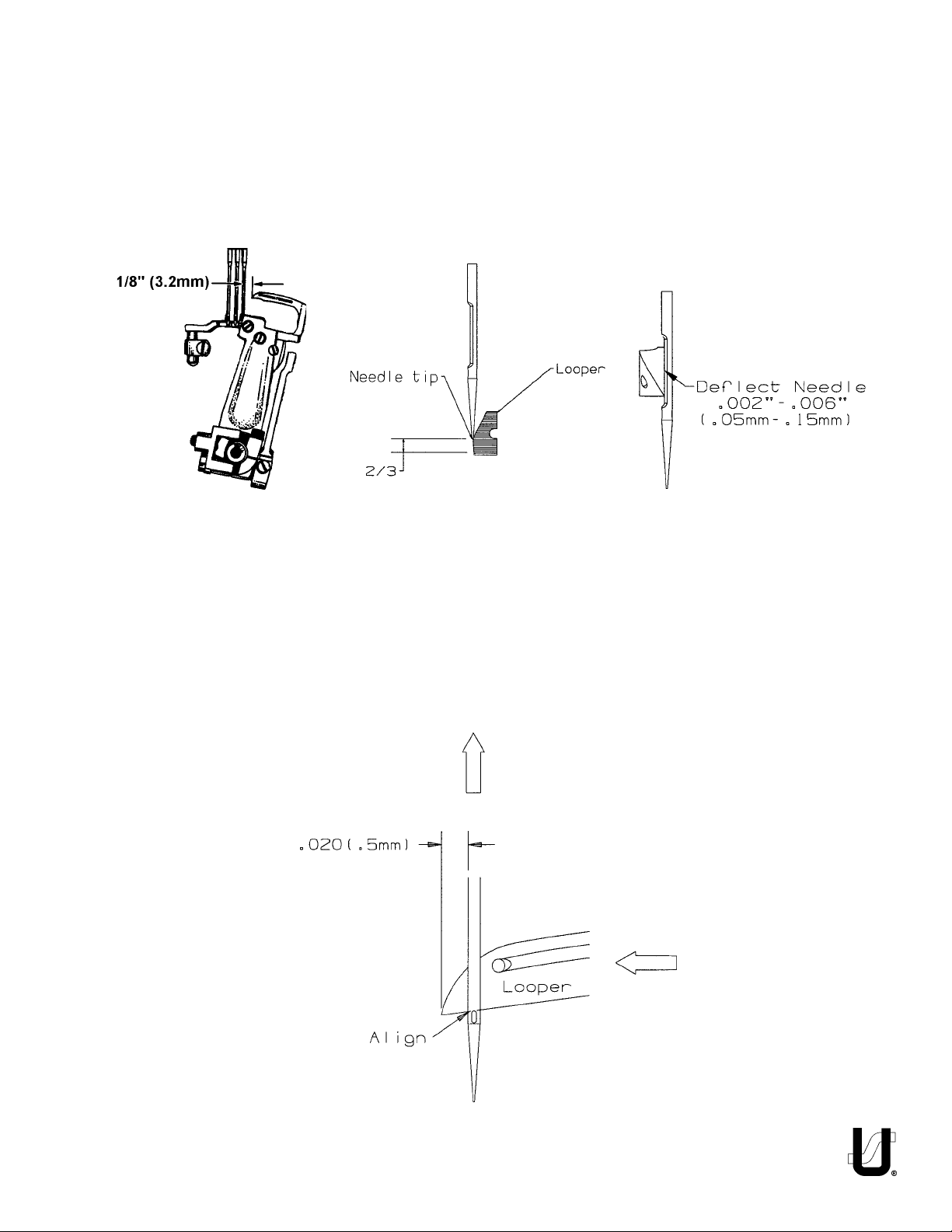

LOOPER SETTING:

Use the right needle and looper to set the looper gauge. Set the looper gauge to 1/8" (3.2mm)when loopers

at extreem right. Set the loopers front to back to deflect the needles forward .002" to .006" (.05mm to

.10mm). set the looper avoid so the needle touches the back of the looper 2/3 down back as needles

decend.

NEEDLE BAR SETTING:

Set the needle height so when the top of the needle eye is even with the bottom of the looper (on it's travel

to the left) the looper tip is .020" (.5mm) past the needle. Use the left needle. Recheck looper setting.

Torque needle bar clamp screw to the following specifications:

Torque needle bar@

18 to 20 in.-lbs. (2.0 to 2.3Nm)

17

Page 18

REAR NEEDLE GUARD:

Set the timing of the rear needle guard so the guard reaches it's furthest travel forward as the loopers enter

the scarfs on the travel to the left.

Bring the looper tips to the center of the needles in the scarf. The tip of the needles should be 3/64"

+/-1/64" (1.2mm +/-.4mm) below the top guarding surface. The guard should just touch the needles up to

.002 (.05mm) deflection. The loopers when traveling to the left should just touch the needles to .002"

(.05mm) clearance when entering the scarf area.

FEED DOG CENTERING AND HEIGHT ABOVE THROAT PLATE:

Set the machine to its longest stitch length. Center feed dog, front to back, so as to obtain equal clearance

on the front side and back side of feed dog in the throat plate slots. Set the feed dogs to come out of the

throat plate level. Set feed dog height to be full tooth at the rear when the feed dog is at the top of its

stroke.

PRESSER FOOT:

Center the needles in the presser foot needle slots. The presser foot lifter lever stop should be set to when

the foot is lifted it does not interfere with the needle head when the needle bar is down.

18

Page 19

LOOPER THREAD TAKE-UP CAM SETTING:

The looper thread cam should be set so that the looper threads cast off the high lobe of the cam as the point

of the needles are just even with the under side of the looper. Set the cast-off plate eyelets so that when

the looper reaches its left end of travel, all of the looper thread is used and no thread is drawn from the

cone. Move down for less. Set the retaining finger so that the finger is even with the bottom edge of its

holder and the tip on the right side is touching the cast-off plate.

THREAD CONTROL:

Set the individual needle thread eyelets so they are 25mm below the top casting and to the extreme right

when using the mount adapter.

19

Page 20

PULLER ADJUSTMENTS:

With the roller resting on the top of the throat plate, the stop collar should be set about 15mm above the

ledge of the puller casting where the stop screw rests. Set the stop screw to rest on the casting and lock

in place. Set the lifter lever block to have 0.05mm to 0.15mm clearance above the lifter lever in the neutral

position.

Note: When changing sprockets, if the total number of teeth on both sprockets is differentthan what was

on the puller, check and readjust these settings.

Use the puller tension nut to add or remove pressure frm the roller.

20

Page 21

PULLER ADJUSTMENTS CONT.:

When assembeling the puller to the

machine, make sure that a minimum of

.05 clearence is maintained between

the roller and the throat plate step.

Also the roller must sit flat on the throat

plate.

Time the puller so the roller feeds at

the same time the feed dog is feeding.

When setting, both should be feeding

at the same S.P.I.. Adjust the timing by

using the sprocket on the upper main

shaft in the arm.

SNOITANIBMOCTEKCORPSRELLUP

EVIRDRELLUP

TEKCORPS

RELLUP

TEKCORPS

2/1±.I.P.S

HCTITS

41518

41412/17

51417

51312/16

31512/18

316

19

61316

21612/19

116101

21

Page 22

22

Page 23

BUSHINGS

Ref.

No.

Part No.

1.

50654

2.

50332U

3.

50330CZ

4.

50654A

5.

50344BE

6.

SQ1110401MZ

7.

50344BC

8.

50344E

9.

50344BF

10.

35036BS

11.

50393GE

12.

22571L

13.

50393FU

14.

50393EY

15.

50392AB

16.

PS0400142KH

17.

50381E

18.

50344BU

19.

SQ1110401MZ

Description

Bushing, for needle bar, upper .....................................................................

Pin, for front lifter lever ..................................................................................

Bushing, for presser bar ................................................................................

Bushing, for needle bar, lower ......................................................................

Bushing, for lower mainshaft, left .................................................................

Fitting .....................................................................................................

Bushing, for needle lever ..............................................................................

Bushing ........................................................................................................

Bushing, for lower mainshaft, right ...............................................................

Stitch Regulator Bushing ..............................................................................

Oil Sight Gauge ............................................................................................

Screw, for drain plug ....................................................................................

Fitting, oil tube ..............................................................................................

Fitting, filter ..................................................................................................

Bushing, for tension release..........................................................................

Pin ................................................................................................................

Bushing, for lifter lever, back ........................................................................

Bushing, front ...............................................................................................

Fitting .....................................................................................................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

23

Page 24

24

Page 25

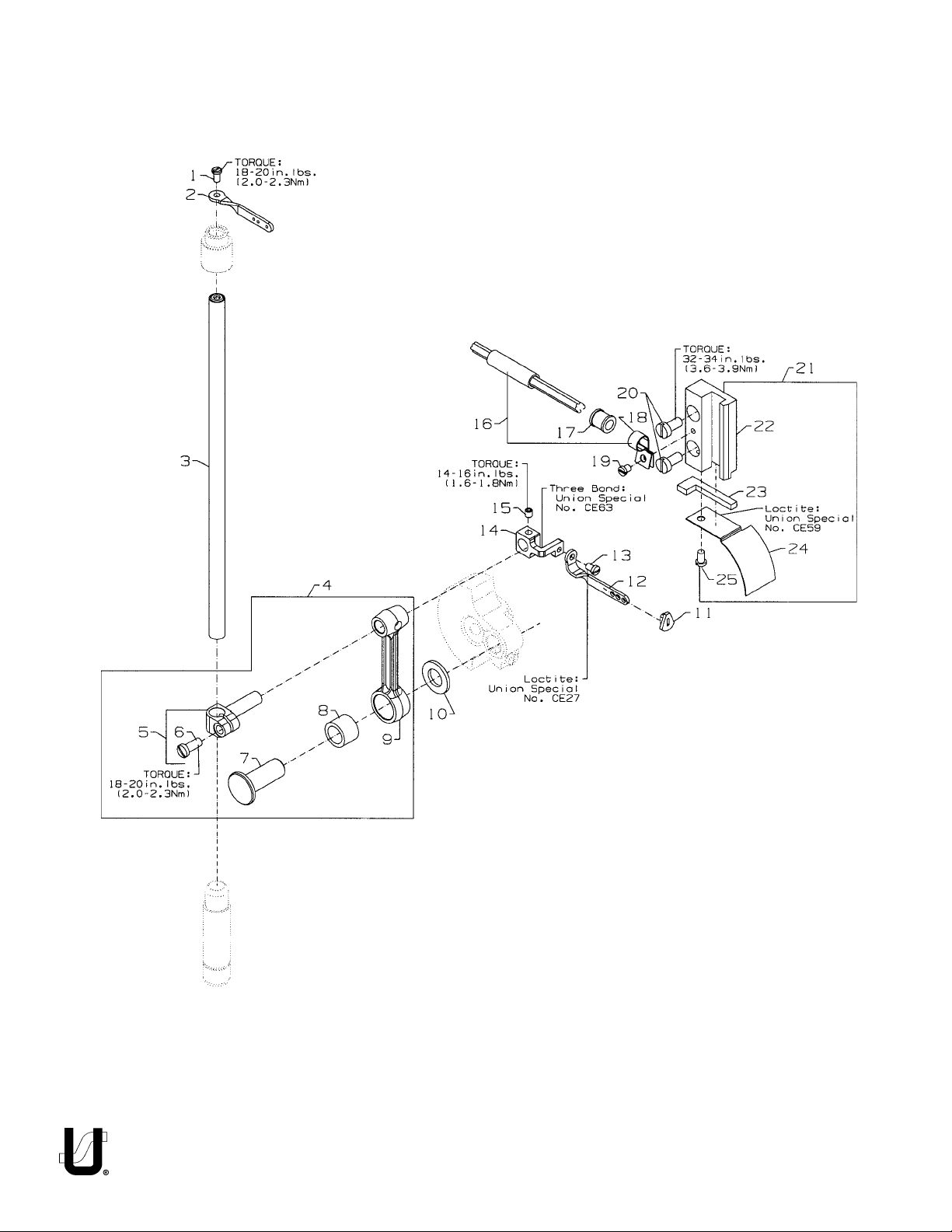

NEEDLE BAR

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

-

14.

-

15.

16.

17.

18.

19.

20.

21.

22.

23.

-

24.

25.

Part No.

SS4080620TP

50323P

50317B

50345W

50355AM

SS7111120TP

50352

661-259B

50355AN

50351A

50393JP

50358X

SS7080520SP

CE27

50354F

CE63

SS8110422TP

29476TC

50393JZ

50393JW

SS6090440SP

SS6121010SP

29476VN

50338

666-328

CE59

50338A

SS6090620SP

Description

Screw ...........................................................................................................

Needle Bar Eyelet .........................................................................................

Needle Bar ...................................................................................................

Connecting Rod Assembly ...........................................................................

Needle Bar Clamp .................................................................................

Screw ...............................................................................................

Pivot Pin .................................................................................................

Needle Bearing Cage ............................................................................

Connecting Rod ....................................................................................

Washer .........................................................................................................

Eyelet Seal ....................................................................................................

Needle Thread Eyelet ...................................................................................

Screw ...........................................................................................................

Loctite Adhesive, (not shown), for screw .....................................................

Slide Block ....................................................................................................

Three Bond Adhesive, (not shown), for slide block .......................................

Screw ...........................................................................................................

Oil Tube Assembly ........................................................................................

Oil Tube ........................................................................................................

Hose Clamp .................................................................................................

Screw, for oil tube assembly .........................................................................

Screw ...........................................................................................................

Slide Block Guide and Cover Assembly ........................................................

Guide, for slide block .............................................................................

Felt, for slide block ..................................................................................

Loctite Adhesive, (not shown), for felt ...................................................

Cover, for guide .....................................................................................

Screw .....................................................................................................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

-

1

1

1

1

1

1

2

1

1

1

1

1

25

Page 26

26

Page 27

UPPER MAIN SHAFT

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

Part No.

50322BC

50691

SS7111120TP

SS7681410TP

SS8681412TP

50322AF

50642A

22894T

50335BD

SS8660612TP

661-262

50342BE

SS8661012TP

660-1087

50321F

SS8681412TP

660-1043

661-261

SS7660520SP

Description

Upper Main Shaft Assembly ..........................................................................

Counter Weight .....................................................................................

Screw, for counter weight ...............................................................

Screw, for counter weight ......................................................................

Screw, for counter weight ......................................................................

Upper Main Shaft ...................................................................................

Sprocket, Main Drive ....................................................................................

Screw .....................................................................................................

Bearing Adapter Assembly ..........................................................................

Screw, for bearing adapter ...................................................................

Retaining Ring ..............................................................................................

Sprocket, for upper main shaft .....................................................................

Set Screw, for sprocket ...........................................................................

"O" Ring.........................................................................................................

Handwheel ..................................................................................................

Set Screw, for handwheel ......................................................................

Tack Pin, for handwheel ...............................................................................

Load Ring, for lower main shaft ....................................................................

Screw, for handwheel preload ....................................................................

Amt.

Req.

1

1

1

1

1

1

1

4

1

2

1

1

2

1

1

2

1

2

1

27

Page 28

28

Page 29

THREAD GUIDE

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

Part No.

SS7120640SP

50666A

SS4090815SP

50666

50692E

50666C

50366

SS4120915SP

50663A

50393HH

50392V

SS4090815SP

36271A

50358W

SS8080410TP

SS7080510TP

50683

50658B

SS7090610SP

SS7120640SP

50658A

SS1121010SP

50357AE

SD0380551SL

50357AS

50357Y

50392BA

50357V

605A

C50044E

SS7120710SP

50366B

SS7060310SP

50370F

50358V

Description

Screw, for lead-in eylet ................................................................................

Thread Eyelet Assembly ...............................................................................

Screw .....................................................................................................

Tube Bracket ..........................................................................................

Lead-In Tension Eyelet ...........................................................................

Thread Tube ...........................................................................................

Thread Eyelet Tube ................................................................................

Screw, for spreader thread guide ................................................................

Thread Ratio Control Assembly ....................................................................

Silicone Thread Lubricator .....................................................................

Needle Thread Guide ............................................................................

Screw, for silicone tank ..........................................................................

Adjusting Needle Thread Eyelet .............................................................

Holder, For Needle Thread Eyelet ...........................................................

Screw ...............................................................................................

Screw .....................................................................................................

Mounting Bracket ........................................................................................

Looper Frame Eyelet ....................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Looper Frame Eyelet ....................................................................................

Screw, for thread guide ................................................................................

Nipper Plate Assembly .................................................................................

Screw .....................................................................................................

Nipper Spring .........................................................................................

Nipper Spring Plate ................................................................................

Thread Guide .........................................................................................

Nipper Plate ...........................................................................................

Screw, for needle thread guide ...................................................................

Needle Thread Guide ..................................................................................

Screw, for strike-off .......................................................................................

Needle Thread Strike-Off Assembly ..............................................................

Screw .....................................................................................................

Thread Strike-off Component ................................................................

Needle Thread Strike-off ........................................................................

Amt.

Req.

2

1

2

2

1

1

2

2

1

1

1

2

3

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

29

Page 30

30

Page 31

TENSION RELEASE & THREAD TENSION

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

-

12.

13.

-

14.

15.

16.

17.

18.

19.

20.

21.

22.

Part No.

50392Z

660-283A

SS4120915SP

50692D

57892K

56392G

B3120352000

B3126012000

B3120704000

56392H

11550100

B3103800400

B3112704000

50692J

56392M

50692

50392AV

SS7090520SP

50692A

57865

NS6110420SP

50392BC

22875N

SS7121410TP

Description

Tension Needle Lever Assembly ...................................................................

Retainer Washer ...........................................................................................

Screw, for tension assembly .........................................................................

Six Thread Tension Assembly .........................................................................

Thread Tension Eyelet ............................................................................

Tension Post ...........................................................................................

Tension Disc Felt .....................................................................................

Tension Disc ...........................................................................................

Tension Disc Felt .....................................................................................

Spring Shield ..........................................................................................

Spring, needle (Purple) ..........................................................................

Spring, looper (Blue) ..............................................................................

Ferrule, tension spring ............................................................................

Knob, needle (Purple) ............................................................................

Knob, looper (Blue) ................................................................................

Tension Disc Separator ...........................................................................

Guide, for tension disc separator ...........................................................

Screw, for guide .....................................................................................

Tension Bracket ......................................................................................

Lead-In Thread Guide ............................................................................

Nut .........................................................................................................

Tension Release Lever Shaft Connection .....................................................

Stop Screw .............................................................................................

Binder Screw ..........................................................................................

Amt.

Req.

1

1

2

1

6

6

6

12

6

6

3

3

6

3

3

1

2

2

1

6

6

1

1

1

31

Page 32

32

Page 33

PRESSER FOOT LIFT

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

-

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

-

26.

27.

28.

Part No.

11071602

11071701

660-1014

C50056B

50632A

50643C

SS6110610TP

50335AG

50335AH

SS8110422TP

660-739

RE0500000K0

50381F

SD0790303SP

CE49

29476YD

SD0790303SP

50355AR

50381G

SS9151740CP

29476TT

SS6151920SP

NS6150310SP

50332V

SS6153040SP

SS4121215SP

CE49

50381

RO068190100

50381B

Description

Adjusting Screw, for spring ...........................................................................

Locking Nut ..................................................................................................

"O" Ring ........................................................................................................

Spring Rod ....................................................................................................

Spring, for presser bar ...................................................................................

Presser Bar ....................................................................................................

Screw, for guide plate ..................................................................................

Guide Plate, for presser bar ..........................................................................

Presser Bar Guide .........................................................................................

Set Screw ...............................................................................................

Oil Seal .........................................................................................................

E Ring, for pin ................................................................................................

Lever, for lifter, front .....................................................................................

Screw, for wire connector ............................................................................

Loctite Adhesive, (not shown), for screw .....................................................

Rear Lifter Lever Assembly ............................................................................

Screw, for lifter lever assembly ...............................................................

Wire Connector .....................................................................................

Lifter Lever, rear .....................................................................................

Hex Screw ........................................................................................

Stop Assembly ..............................................................................................

Screw, for adjusting stopper ..................................................................

Hex Nut ..................................................................................................

Stopper, for lifter lever ............................................................................

Screw, for adjusting stopper ..................................................................

Screw, for stopper ........................................................................................

Loctite Adhesive, (not shown), for screw .....................................................

Spring, for lifter lever .....................................................................................

"O" Ring ........................................................................................................

Lifter Lever Assembly ....................................................................................

Amt.

Req.

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

33

Page 34

34

Page 35

COVERS, UPPER ARM

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

*21.

*22.

*23.

*24.

*25.

*26.

*27.

*28.

*29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

Part No.

SS4121615SP

50393EU

B3530555000

660-212

50382FW

50382FZ

SS7120640SP

50317C

TA1050504RO

50393HB

50684C

50662A

SS6121050SP

50684B

WP0480856SP

22569B

50382FY

50382FX

SS4121215SP

TA1100604RO

21237EV

21237DR

22784N

21237ET

660-886

21237EU

51170D

671-102A

SS7090610SP

99682XCA

NS6620320SP

99682XC1

99682XC2

WZ0641510KP

SD0640323TP

99682XC

SS1110640SL

22517B

652C16

50393EW

50382GA

SS4120915SP

SS4120615SP

50382GM

SS4120615SP

50658B

LA452

Description

Screw, for top cover .....................................................................................

Plug, for top cover ........................................................................................

Oil Sight Gauge, top .....................................................................................

"O" Ring, for oil sight gauge ...........................................................................

Top Cover .....................................................................................................

Quad Ring, for top cover ..............................................................................

Screw, for needle bar guard ........................................................................

Needle Bar Guard ........................................................................................

Plug, for bed .................................................................................................

Plug, for bed .................................................................................................

Gasket, for puller drive Adapter ...................................................................

Puller Drive Adapter .....................................................................................

Screw, for puller drive adapter .....................................................................

Gasket, for Puller Drive Housing ....................................................................

Washer .........................................................................................................

Screw ...........................................................................................................

Quad Ring, for head cover ...........................................................................

Head Cover .................................................................................................

Screw, for head cover ..................................................................................

Plug, for head cover .....................................................................................

Needle Cooler Assembly ..............................................................................

Cooler Tube ...........................................................................................

Screw .....................................................................................................

Cooler Housing ......................................................................................

O-Ring ....................................................................................................

Bracket ..................................................................................................

Nut .........................................................................................................

Flow Control ...........................................................................................

Screw ...........................................................................................................

Protection Shield Assembly ..........................................................................

Nut .........................................................................................................

Bracket Holder .......................................................................................

Bracket ..................................................................................................

Spring Washer ........................................................................................

Shoulder Screw ......................................................................................

Protection Shield ...................................................................................

Counter Sunk Head Screw .....................................................................

Screw ...........................................................................................................

Washer .........................................................................................................

Rubber Gasket, for needle lever ..................................................................

Cover, for thread take-up ............................................................................

Screw, for thread take-up cover ..................................................................

Screw, for thread cover ...............................................................................

Thread Cover ...............................................................................................

Screw, for thread take-up cover ..................................................................

Eyelet ...........................................................................................................

Label, direction of rotation ..........................................................................

Amt.

Req.

6

1

1

1

1

1

2

1

1

2

1

1

5

1

4

4

1

1

4

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

* PA1 KIT ONLY

35

Page 36

36

Page 37

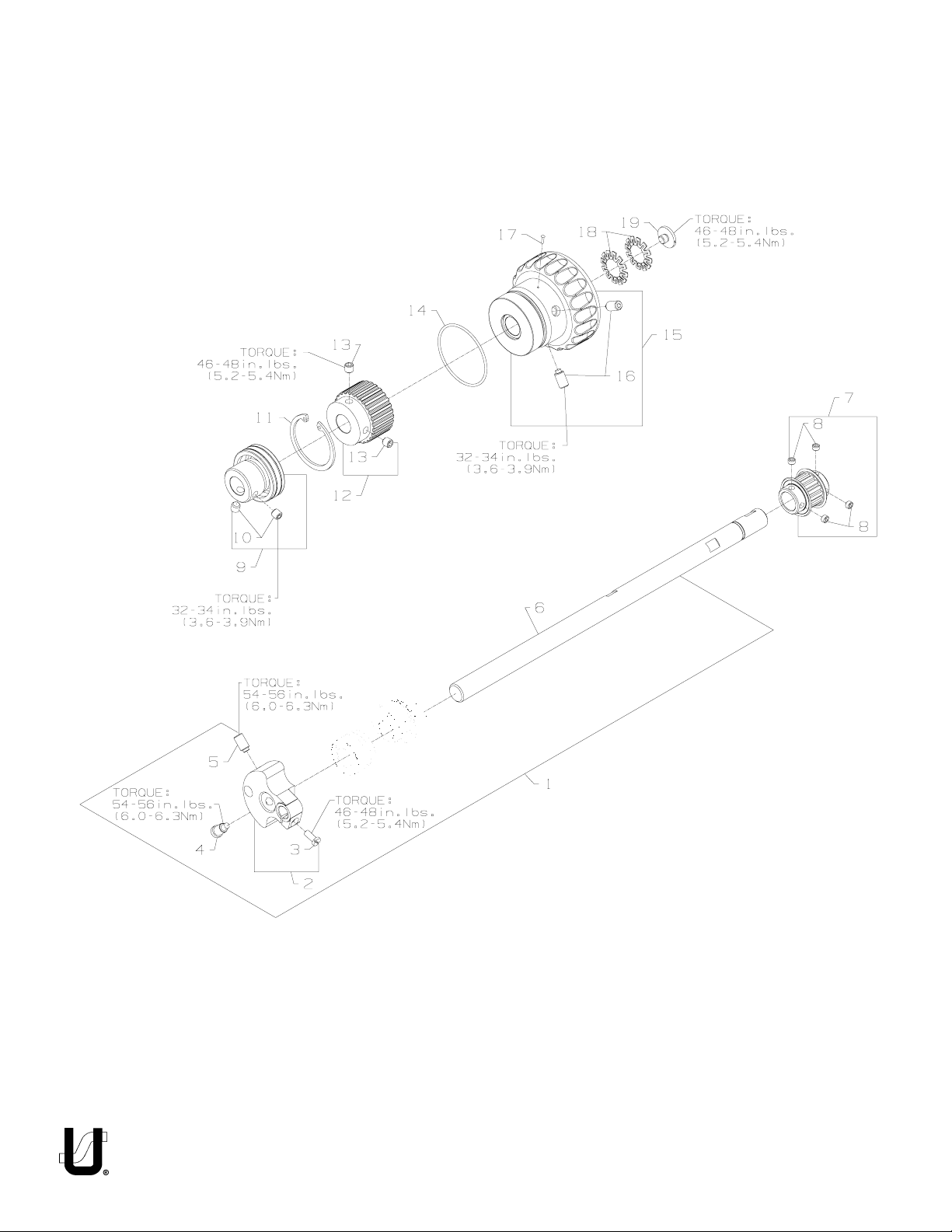

LOWER MAIN SHAFT

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

17A.

18.

Part No.

SS7660520SP

660-1062

50374

50321G

SS8661012TP

50342AX

SS8660612TP

50342BS

50335AK

29476UH

50322AL

50335BB

50322AG

50333A

SS8660612TP

660-934

50622D

50622E

SS8660410SP

Description

Shoulder Screw, for lower main shaft, right ..................................................

Spring Washer ..............................................................................................

Spacer, for pulley assembly .........................................................................

Pulley Assembly ...........................................................................................

Set Screw ...............................................................................................

Sprocket, for lower main shaft .....................................................................

Screw ....................................................................................................

Timing Belt ....................................................................................................

Retaining Ring, for ball bearing ...................................................................

Mainshaft Assembly, lower, right .................................................................

Ball Bearing, for lower main shaft ...........................................................

Retaining Ring .......................................................................................

Lower Main Shaft, right ..........................................................................

Coupling, for lower main shafts ....................................................................

Screw ....................................................................................................

Oil Seal .........................................................................................................

Lower Main Shaft, left for plain feed.............................................................

Lower Main Shaft, left for differential feed ...................................................

Screw ....................................................................................................

Amt.

Req.

1

1

1

1

2

1

2

1

1

1

1

1

1

1

4

1

1

1

2

37

Page 38

38

Page 39

LUBRICATION, OIL TUBING & OIL PUMP

Ref.

No.

Part No.

1.

50393HN

2.

SS8660612TP

3.

50332S

4.

34393D

5.

50393EX

6.

SS8660612TP

7.

50393GB

8.

50393GD

9.

SS4091015SP

10.

50393FR

11.

50384

12.

11843208

13.

50393FV

14.

29476XV

15.

SS7120710SP

16.

NS6110310SP

17.

SQ1110402MZ

18.

50393KH

19.

50393-27

20.

50393KM

21.

50393-407

22.

13765607

23.

50393-47

24.

50393-51

25.

50393-89

26.

29476UT

27.

50393KH

28.

50393-70

29.

50393KM

30.

13765607

31.

50393-140

32.

50393-40

33.

50393-170

34.

50393KF

35.

50393KM

36.

50393HR

37.

50393HL

38.

50393FS

39.

998-358F

40.

SS4090815SP

41.

50393HK

42.

SS6151812TP

43.

WS0631510KP

44.

22571E

45.

RM2871B

46.

50393EB

47.

50384A

48.

50393FT

49.

50393HJ

Description

Oil Pump Assembly, 2-stage .........................................................................

Screw .....................................................................................................

Spring, for plunger..................................................................................

Plunger ..................................................................................................

Collar, for oil pump .................................................................................

Screw ...............................................................................................

Oil Pump Housing, 2 Stage......................................................................

Oil Pump Housing, 2 Stage......................................................................

Screw, for oil filter cover................................................................................

Cover, for oil filter..........................................................................................

"O" Ring, for oil filter cover.............................................................................

Oil Filter.........................................................................................................

Oil Tube, for supply (1) ..................................................................................

Oil Supply Assembly, upper ..........................................................................

Screw, for front upper tube ....................................................................

Nut .........................................................................................................

Fitting .....................................................................................................

Tube Retaining, spring ...........................................................................

Oil Tube ..................................................................................................

Tube Retaining, spring ...........................................................................

Oil Tube ..................................................................................................

"T" Connector .........................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Supply Assembly, lower ...........................................................................

Tube Retaining, spring ...........................................................................

Oil Tube ..................................................................................................

Tube Retaining, spring ...........................................................................

"T" Connector .........................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Oil Tube ..................................................................................................

Tube Retaining, spring ...........................................................................

Plug, for feed chamber ..........................................................................

Oil Tube, for suction ................................................................................

Oil Tube Holder .............................................................................................

Plastic Clip ....................................................................................................

Screw, for oil tube holder ..............................................................................

Felt ...............................................................................................................

Screw, for oil pan ..........................................................................................

Spring Washer ..............................................................................................

Screw, for oil drain plug ................................................................................

Cable Tie ......................................................................................................

Oil Pan ..........................................................................................................

"O" Ring ........................................................................................................

Oil Tube, for suction ......................................................................................

Oil Tube, for suction ......................................................................................

Amt.

Req.

1

2

2

2

1

2

1

1

3

1

1

1

1

1

2

1

1

1

1

7

1

2

1

1

1

1

2

1

5

2

1

1

1

1

3

1

1

1

1

1

1

6

6

1

2

1

1

1

1

39

Page 40

40

Page 41

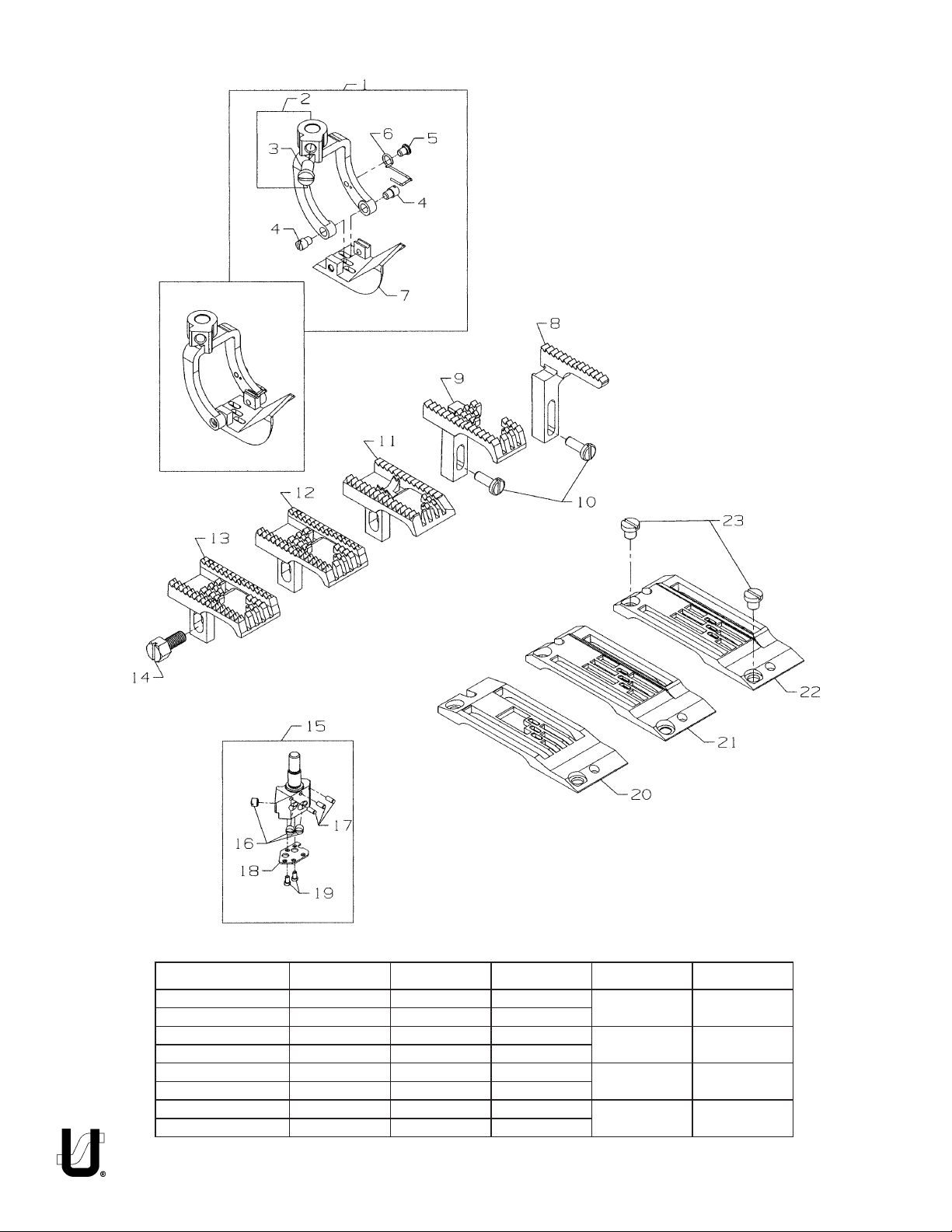

LOOPER DRIVE

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

-

15.

-

16.

-

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Part No.

50313C

22652B10

22565

C50041D

538A

C50041H

22652J10

C50041E

53634C

22881C

C50041G

C50041F

51909C

51909D8

51909D9

51908B8

51908B9

SS7120910SP

CE63

660-893

50344AM

660-455

50313J

SS7120910SP

50314F

50314E

50642

22653J8

667J33

660-979

50342BJ

SS8660612TP

50342BK

SS8660612TP

50342BP

Description

Looper Holder ..............................................................................................

Screw, for looper holder ........................................................................

Screw, for looper holder ........................................................................

Looper Throwout Lever ................................................................................

Screw ....................................................................................................

Collar, Stop ..................................................................................................

Screw ....................................................................................................

Lock, Looper Holder .....................................................................................

Washer .........................................................................................................

Screw ...........................................................................................................

Stop .............................................................................................................

Spring, Plunger ......................................................................................

Looper, Middle (all gauges) .........................................................................

Looper, Rear (32 gauge) ..............................................................................

Looper, Rear (36 gauge) ..............................................................................

Looper, Front (32 gauge) .............................................................................

Looper, Front (36 gauge) .............................................................................

Screw, for bearing housing ..........................................................................

Three Bond Adhesive, (not shown), for screw ..............................................

Oil Seal, looper .............................................................................................

Bearing Housing Assembly, for looper drive .................................................

"O" Ring, for bearing housing assembly ........................................................

Looper Rocker Assembly .............................................................................

Screw, for retaining plate ............................................................................

Eccentric Retaining Plate ............................................................................

Looper Avoid Adjusting Eccentric ...............................................................

Looper Drive Assembly ................................................................................

Screw ....................................................................................................

Crank Pin ...............................................................................................

"O" Ring ..................................................................................................

Sprocket, for looper driven ..........................................................................

Screw ....................................................................................................

Sprocket, for looper drive ............................................................................

Screw ....................................................................................................

Looper Drive Belt ..........................................................................................

Amt.

Req.

1

1

2/3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

2

1

1

1

1

1

2

1

2

1

2

1

41

Page 42

42

Page 43

NEEDLE GUARD

Ref.

No.

Part No.

1.

50373DA

2.

SS8110422TP

3.

50368W

4.

50668

5.

SS8110422TP

6.

50368E

7.

50368A

8.

50622C

9.

RC0560711KP

10.

50625

11.

SS6090620SP

12.

C50025E

Description

Needle Guard Eccentric .............................................................................

Screw, for needle guard eccentric .......................................................

Connecting Rod Assembly, for needle guard ..............................................

Pivot Link ......................................................................................................

Screw .....................................................................................................

Washer .........................................................................................................

Pivot Pin ........................................................................................................

Shaft, for needle guard ................................................................................

Retaining Ring .......................................................................................