Page 1

CATALOG

NO.

Main

characteristics

and

RE5E8

SERIES

E5

E8

instructions

for

technicians

Finest

Quality

Straight

and

Safety

needle

Stitch

Overedge

machines

Industrial

Sewing

Eouipment

Page 2

E-5

SERIES

1-

or

2-needle

reliable

followedisrectilinear

automatic

eccentric-cam

the

while

machine is running.

paralleltothatofthe

needle

Work

sizeischanged.

plate

Pressure lubrication by

ensures

sumpisair-cooledbymeans

Deviceonrequest

The

devices

constant

machines

for

"OVERLOCK"

needle-control

using

type

stitch

needles

designed for easy operating.

means

oil

pressure

for

lubricating

are

rationally

increasing

output.

OVERLOCK

series

straight

regulator

The

and

canbeadjustedtokeep

of

inside all

of a

fan.

the

designed

MACHINES

overedge

mechanism

needles.

and

Fitted

with

differential feed

needle guards

pump

needle

incorporated

the

moving

threads.

for

fitting

stitch

which

operate

and

with

machines.

ensures

with

pushbutton-controlled

that

adjustable

on a

plane

them

parallel

in

the

machine

fixed

components.

the

most

Absolutely

the

path

also

perfectly

when

the

which

The

oil

sophisticated

E-8

SERIES

2- or 3-needle

automatic

rectilinear

eccentric-cam

while

the

the

type

401

mechanisms

incorporated

moving

The

Work

The

devices

and

oil

sump

plate

machines are rationally designed for fitting with

for

"OVERLOCK"

needle-control

using

type

stitch

machine

is running.

chainstitch

are

inside

in

the

fixed

components.

is air-cooled by

designed

increasing

for

mechanism

straight

regulator

looperinordertofacilitate threading. All

the

machine

easy

output.

OVERLOCK

series safety stitch machines. Absolutely reliable

which

needles.

and

Fitted

with

Pushbutton-controlled

casing

which

and

ensures

meansofa fan.

operating.

MACHINES

ensures

with

differential

lubricated

constant

that

the

path

pushbutton-controlled

feed

adjustable

mechanism

for

the

by

oil

the

means

pressure

most sophisticated

of

inside all

followed

also

uncoupling

automatic

a

pump

the

is

Page 3

NEEDLE CONTROL MECHANISM (fig. 1)

The

needle control mechanism is characterized by

the

new

method

done

with

is

setatright

This fixing

needle

The

—

—

clamp

new

mechanism has been designed in

reduce

clamp;

make

wear

assembling

controllable

—increase

fine

ones;

—

limit

wearonthe

INSTRUCTIONS

JUSTING

THE

of fixing

eccentric

anglestothe

method

slider

on

needle

the

life

NEEDLE

the

pin A (fig. 1),

directionoffeed.

permits

C in its

the

moving

easier,

run.

with

positioning;

of

the

needles, especially

looper

tips.

FOR

SETTING

CONTROL

needle bartothe

the

axisofwhich

needle

barBto

order

sliderofthe

more

accurate

ON

AND

MECHANISM

(fig. 2)

—

Arrange

(fig. 2)

a)

b)

—

Set

machine

hand

hole

(fig. 2), lubricator wick A (fig. 3)

from

end

spring B (fig. 3)

the

needle

with

pins A

bar

support

turned

towards

positioning

the

pin

towards

quent

insertion of screw C (fig. 3) which, keep

ing

the

orientation

of

the

pintoa useful bar-positioning

calibrator

support

spondingtoscrew

pinsAand

head,

control

in lever F.

the

end

is

embedded

control

andBpositioned

eccentric

the

front

pin A

of

servestoorient

the

top

and

correct,

pin B

D (fig. 2).

B in

their

respective holes on

taking

caretoinsert

E (fig. 2)atthe

When

inserting

inside

the

machine

in

the

and

thus

permitting

mechanism

with

the

the

will

will

with

same

calibrator

so

spot-facing,

assembly

as follows:

milled

machine.

eccentricity

permit

limit

rotation

sector.

plane C

the

button

timeinthe

must

be pulled

that

the

pressing

said pin

pass. Releasing wick A (fig. 3) spring B (fig. 3)

extends,

tween

giving reliable

wicksAandCinside

lubrication

the

pin.

contact

bed,

follow

to:

needle

and

very

AD

part

This

of

subse

corre

the

of

pin B

other

to

be

Center locking screws R - G (fig. 2) of

the

two

pins and insert roller retainer H, taking care to

choose

be

colour

R-red

B-blue

G-grey

the

correct tolerance value, which should

that

indicated on washer L (fig. 2).

symbol

206517-0-00

206518-0-00

208150-0-00

tolerance

0.000

-0.002

-0.002

-0.004

-0.004

-0.006

Tighten screw M (fig. 2) until it is right down on

needle

bar

eccentric

Set

the

needle clamp slider to

When

the

slider is

there

must

be a

between

of

is

madebyturning

This

and

ing

the

axisofpin Q (fig. 2)

plate RC908920-0-03 (fig.

settingisthe

must

not

and

timing

Gauge RC908914-0-02

are

used as

obtaining

Center

easy

the

shown

needle in

operationismade

(fig. 2) which, being right up against

fers

the

possibility of moving it

support

broughttoits

distanceof35.8

screw

same

pin A (fig. 2)

the

2-inset).

R (fig.

for

all

correct height.

lowest

mm.

(1.13/32")

and

the

Adjustment

2).

typesofmachines

be altered during subsequent

operations.

and

plate

RC908920-0-03

in fig. 2 —inset, are a help in

and

accurate

accurate

the

adjustment.

needle

plate

and

easy by screw M

hole.

the

just

by screwing.

position

surface

adjust

The

pin, of

Block screw M by fully tightening grub screw N

(fig. 2)

Center

the

needle

clamp

slider 0 (fig. 2) in

the

fork of lever P (fig. 2), dividing play equally, by

moving pin B (fig. 2).

Tighten

locking screws D —R (fig.

2).

Page 4

ABC

5

RC908914-0-02

RC908920-0-03

fig.2

Page 5

NEEDLE BAR ALIGNMENT (Fig. 4)

For aligning needle

ment

trajectory

A(fig.4)to

T.I. (fig.4)

the

needle

special

bar

(RC908920-0-03/RC979550-1-00) with dial

parator

positioned on

to

When

tom

or

A (fig.5) is

the

bottomofthe

the

needle

dead

center

viceversa,

the

there

used,

special

needle

clamp

point to

should

point B (fig.5) of which is

extension C (fig.5)

bar

(see

illustration).

slider

the

moves

top

be

dead

the

from

center

least

move

gauge

com

screwed

the

bot

point

possible

vibration of

to

the

a

short

stroke

stroke

Adjusting

tric pin C (fig.4) in

making

(fig.2), lock

needle

stroke

of 25

of

26

and

sure

the

bar.

bar

of

mm.

mm.

checkingisdone

that

the

The

amount

willvary

according

stroke: from approx. 0.02 mm. for

24

mm.to0.04

(2-needle

one

directionorthe

C is right up

pin with its

mm.

machine)

by turning

against

screw

B (fig.4).

forashort

and

medium

eccen

other.

screw

After

M

fig.4

I

Page 6

Page 7

LUBRICATION SYSTEM (Fig. 6)

A needle valve A (fig. 6) has been introduced in

the

lubrication system of the new machines for adjust

ing oil flow to the exact amount necessary for

each single subclass to suit operating conditions,

speed,

work

intensity, etc.

The

valve

has

been

setinthe

plate in which

ated.

This

trol

window

transparent

cap

serves

and

oil

both

input

Instructions for adjusting

The

valve can be

sembled

and

adjusted,

working,byremoving

tension-holder cover. Adjustment is carried

unscrewing

screw D (fig. 6) is

it is broughttothe

tion.

From

ter-clockwise

be

checked

under

this

the

nut

position

to

through

work

C (fig. 6)

turnedinthe

end

the

screw

increase

the

plate.

of its run in

oil

distributor

cap B (fig. 6) is incorpor

as an oil

circulation

plug.

the

regulator valve

with

the

machine as

the

screw on

out

that

locks

the

screw. When

clockwise

mustbeturned

the

oil

flow.

oil

window

the

closed posi

The

on

direction

flow

the

cover

con

the

by

coun

can

cover

Even when the valve is in the fully closed position,

enough

FRONT

Front

been

Their

changed,

further

their

Further,

on

the

These

tainedinany

for

the

oiltoprevent

seizing

continuestocirculate

AND REAR NEEDLE GUARDS (fig. 7)

and

rear needle guardsofnew design have

introduced

main

they

away

planes

they

2-needle

shank

fixing

features

the

needles and consequently limiting wear on

looper

tips.

on

the

new

E-5

Class

featureisthat,

can be

from

the

paralleltothe

when

the

needle

brought

closertoor

needles while maintaining

needles.

can also be adjusted in height and,

machines,

permit

case,

they

themtothe

correct

thus

ensuring

can

turn

on

supporting

collar.

positioningtobe

perfect

machines.

size is

moved

the

axis

protection

ob

Instructions for adjusting and positioning th^

needle

guards

The rear needle guard supporting block A (fig.7) is

fixed to the bed with two screws B (fig.7). There is

pin C (fig. 7) on the block where brackets or clamps

of the front and rear needle guards D (fig. 7) willbe

fixed.This support method offers the possibility of

moving

gether or further

positioning

the

front

and rear needle guards closer

apart

of

their

without

surfaces

changing the parallel

with

the

adjust them one only hastoslacken the clamp col

lar screws E (fig. 7) and move the two clamp collars

on

the

supporting

shaft.

The operation isfacilitated by a rear block F (fig. 7)

fhat acts as a

screws can be

Adjusting

The

adjusting

needle

a)

machines.

1-needle

The

rear needle guard

hasaflat

to oriented correctly. For making

in height,

tom

rear needle guard bevel

formerisadjustedinheighttoobtain

of

the

ensure

needle and check

through

dead

b)

2-needle

stop

to the clamp collars, so

turned

the

rear needle guard

procedure

machines

surface

the

needle must be brought to

dead

center

eye in line with

that

it is

the

eye

center

position.

machines

easily.

differs

for

on

the

position

correctly

that

when

for

1-needle

single-needle machines

shank

which

the

and,

referringtothe

and

the

needle eye,

the

bevel (see fig. X). To

adjusted,

the

thread passes freely

the

needle is

For 2-needle machines the height adjustment is

made as for single-needle machines. The only dif

ference is

planeonthe

that

there is no orienting and fixing

shank.

This offers the possibility of orienting the rear

that

needle guard so

positioned in relationtothe

(see

Fig.

2) Tighten the locking screw,takingcare

nottoalter

Adjusting

the

front

height setting.

needle guard

the needles are correctly

two

internal planes,

For making the height adjustment the front needle

guard is positioned according to

the

needle

of

- 3 mm. thick needle plate: plane Y (fig.W)must

plate,

as follows:

the

be positioned close against clamp collar B

—4.25 mm. thick needle plate: plane Y

must be positioned at 1.3 mm. from plane B.

For

adjusting

needle guard.

direction,

proceed

as

needles.

that

their

and

enables

adjustment

the

bot

the

bottom

thread

the

bottom

thickness of

(fig.

for

the

rear

to

To

2-

it

the

the

W)

Page 8

fig.

6

r

fig. 7

Page 9

OIL

SEAL

SYSTEM

In

ordertoimprove

ON

FEED

the

oil seal on feed

DOG

SLIDERS

dog

sliders

E (fig. 8) a new oil seal system has been designed,

which

of a special rubber

andanew

section has been modified by rounding

cornerssothat

With

gaskets. All

needle

and

bracket

semble

consistsoftwo

this

plate,

the

(fig. 8) in

them.

new

gaskets A (fig.

guide

compound,

system

B (fig.

with oil scraper lip

8).

Further,

the

the

the

gaskets last longer.

new

system

that

feed dogs,

has

it is also

to

easiertoreplace

be

doneisdisassemble

loopers,

rear

needle

feed mechanism cover plate C (fig. 8)

for

E-8

and

remove

ordertoreach

the

two

the

gaskets

slider

and

8),

outside

guard

looper

guide

made

slider

the

the

disas

D

NEEDLE

BAR

(Fig. 9)

The

new

needle

corporates

top

tension-holder

be removed

unscrewedtoreach

cleaningofthe

maintenance

bar

the

presser

and

the

needle

operations

Also, an L-shaped

around

the

the

bottom

bed,toensureaperfect

leakage ontothe

along.

OIL

SUMP (Fig. 10)

MECHANISM

mechanism

foot

cover

two

locking screws B (fig. 9)

the

needle

bar

are very

gasket

C (fig. 9) has been

edgeofthe

work

plate

COVER

cover

assembly.

plate

A (fig. 9) has

bar

mechanism

much

cover

oil seal

where

PLATE

plate

also

So

only

mechanism,

and

relative

easier.

fitted

plate,

touching

andsoprevent

the

fabric moyes

in

the

to

thus

The

new

sump

tical

channel

any

oil

special

any

oil

Another

ting

bed

screws,

plate

has

ed.

Connected

the

internal

removing

ing

maintenance

10

all

sweating

screw

B (fig.10) is provided for draining off

that

may

important

and

sump,

accessible

been

components

the

oil-filled

containing

round

that

accumulate.

featureisthe

whichisdonebymeans

removed

in this way,

and

its

may

from

above

and

sump

conversion

lubricating oil

perimeter

occur

the

for

on

methodofconnec

once

the

work

thereiseasy

of

the

machine

from

the

unit

operations.

hasaver

collecting

the

walls. A

top

plate

access

without

stand

of five

cover

open

to

dur

Page 10

WORK PLATE (fig. 11)

A

new

pivotal

work

plate (fig. .11). Connected

bed

and

anchoredtoit, is a new device

system

has

been

lever A (fig. 11) situated on

mits

the

work

platetobe uncoupled.

pads B (fig. 11) on

are

for

damping plate vibrations,

reducing noise when

this purpose

C

and

cover M (fig. 11)ofthe

been increased by

ADJUSTING

the

feed mechanism cover plate

the

machine is working. For

the

distance between

0.5

mm.

INSTRUCTIONS

For adjusting plate rotation

(fig. 11) must be set so

tiontoa

rect setting

the

greaterorlesser

turn

nut

springs are compressed

that

extent.Toobtain

E (fig. 11) on

introduced

with

the

machine, per

thus

the

on

the

machine

that,

through

The

rubber

considerably

work plate

feed mechanisms has

the

two cup springs D

they brake the rota

the

pivotsothat

to

a greaterorlesser

the

cor

degree,

completely,

The

that

work

so

the

To

fixedtothe

set

to

Block H (fig. 11)

must

has

Lever L (fig. 11)

that

lesser

pads

the

making

uncoupling

thereisalways

plate

that

there

needle

adjust

then

and

plate

this

sure

lock

device

the

is no

and

position,

that

counter-nut

about

edgeofthe

'step'

thatofthe

machine head by

in a

slot,

which

permitsittobebrought

the

edgeofthe

needle

acts

be resting

been

closed

on

and

the

adjusted.

actsonthe

closingitforcesitdownwards

extent,

and

needle

thus

accurate

plate.

ensuring

adjustmentinheightinrelation

they

must

between

the

plate.

as a

latter

contact

are

F (fig. 11).

be

positioned

0.2

mm.

needle

the

work

plate.

uncoupling

two

screws G (fig. 11)

stoptothe

after

the

top

partofthe

toagreater

with

not

flattened

between

plate

surface

hook,

work

the

block

closer

hook

rubber

so

the

and

of

is

so it

plate

so

or

to

11

Page 11

SETTING

ON

AND

ADJUSTING

(Fig. 12)

—

Insert

the

needle

down

fasten it with screw A (fig. 12)

—

Set

the

clamponslider

position

on

—Position

ting

To

make

lows:

the

table.

the

machine

the

the

adjustment

needle

needle

with

height

—Slacken screw B (fig. 12)

—

Turn

adjusting

stoptothe

to

increase

decrease

—

Bearinmind

the

correspondstoa

In

additiontosimplifying

system offers

clamp

for

any

and

for

better

to

loopers

several

needles.

screw

clampinthe

the

needle

height.

that

one

height

the

possibility of disassembling

maintenanceorconversion

orientation

and

needle guards in machines

NEEDLE

inside

B (fig.

the

12),

scarf

the

taking

facing

as specified in

in

height,

and

C (fig. 12)

slider

height

full

take

turn

proceed

off

which

seat,

and

of

the

tightening it

slackening

the

differenceof0.45

the

of

setting

the

operation,

needlesinrelation

CLAMP

clamp

and

care

inwards

the

set

as fol

clamp

acts

screw

mm.

this

operations

with

to

as

to

C

the

12

Page 12

E-S

CLASS

E-8

Class

characteristicsasthose

for

the

are

not

moistening

The

element

is

the

with

the

derived

The new mechanism

Improve

parts

and

fluff,

sequently

Facilitate

MACHINES

safety

stitch

machines

describedsofar,

front

and

rear

designed

the

that

needie

for being fitted with

needie points

most

guards.

characterizes

new chainstitch looper control

chainstitch looper elliptical

directiy from

lubrication

and, at the

thus

the

the

making

looper

inside

has

the

been

of the moving mechanical

same

time, protect

the

mechanism—and

movement—more

timing

operation,

chainstitch looper movement is

overedge

surface

looper

small

stitch

on

the

slant,

correction.

bottom

looper

looper

shank

to which it is

possibletomake

have

Further

containers

and

eyes.

this

mechanism

movement

base.

designed in

them

since

separate

movement.

determines

the

same

except

they

Class

order

from

dust

con

reliable.

from

A flat

for

to:

the

the

the

Facilitate

needstobe

bottom

which, turning

permits

dead

quick

the

threading

pressed,

center

towards

and

operation.

when

the

needles

position, to uncouple the looper

the

outsideofthe

easy

threadingofthe

in the looper. Recoupling is automatic when

looper is

Ensure

troduction of a new

suring

chainstitch (entering

triangle formed by

dle

larger profile for continuous control of

thread.

chainstitch

GS needles which have the

to

ensure

a

stitches.

loop)

pushed

the

the

and

The

that

lightly forward.

best

best

conditions

with a

needles

and

the

the

loop is

stitch

shaped

the

the

looper

looper

used

formation

looper, designed for en

for

loop

thread

are

the

overedge

scarf

takenupperfectly

formation

and

thread

same

stitch;

designed specially

Only a button

areinthe

machine,

two

with

entering

and

control

cam

the

for

they

holes

the

of

the

looper

both

are

3029

on both

the

in

the

the

nee

with

the

13

Page 13

INSTRUCTIONS

ASSEMBLING

STITCH

Disassembly

—

— Remove

Take

LOOPER

off

the

the

feed dogs, rear

—Disassemble looper

FOR

AND

CONTROL

cover

sewing

and

ADJUSTING

plates

front

brack;et

ing screw 2 (fig. 1)

— Disassemble

thread

guide assembly 1 (fig. 2)

slackening screws 2 (fig. 2),

3 (fig. 2)

— Disassemble

1)

—

Slacken

and

supporting flange 4 (fig. 2)

the

big-endofconnecting-rod

Allen

screw4and

6(fig.1)

—

Take

off

shaft

7 (fig. 1)

— Disassemble big-end

— Disassemble

counter

of

DISASSEMBLING,

THE

MECHANISM

and

the

work

parts:

needle

needle

guards

1 (fig. 1) by unscrew

thread

screws5,remove

con-rod

feed

shaft

8 (fig. 1)

5 (fig. 2)

plate

plate,

take-up

RE

CHAIN-

cutters,

cam

3 (fig.

screw

after

screwing

handle9,differential

sector

— Disassemble

bly

moving

Take

—

— Remove spring 16

—

Take

screws6,7

11 (fig. 2)

stitch

regulator

12 (fig. 2) bringing

screw13and

off

con-rod

screws14(fig. 2)

15 (fig. 2)

and

off

cam

18 (fig. 2)

and8,then

handle

10

eccentric-cam assem

the

pointto"0"

take

off

cam

after

unscrewing relative

and

screws 19 (fig. 2)

— Unscrew ring screws 9 (fig. 1)

by

—Slacken screwsofretainer 10 (fig. 1)

baseatthe

— Remove

endofpin 11 (fig. 1)

snap

ring 12 (fig. 1) and

take

—Disassemble lever 13 (fig. 1) removing screw 14

and

taking

out

pin

15

—

Take

off

un

chine

wards;

con-rod.

con-rod

handwheel

thisisthe

16 (fig. 1) leveringonthe

and

springing

only

waytodisassemble

remove

differential

17 (fig. 2)

setinthe

out

the

shaft

arm

and

pin 11

ma

out

said

of

re

9

16

fig.

1

14

Page 14

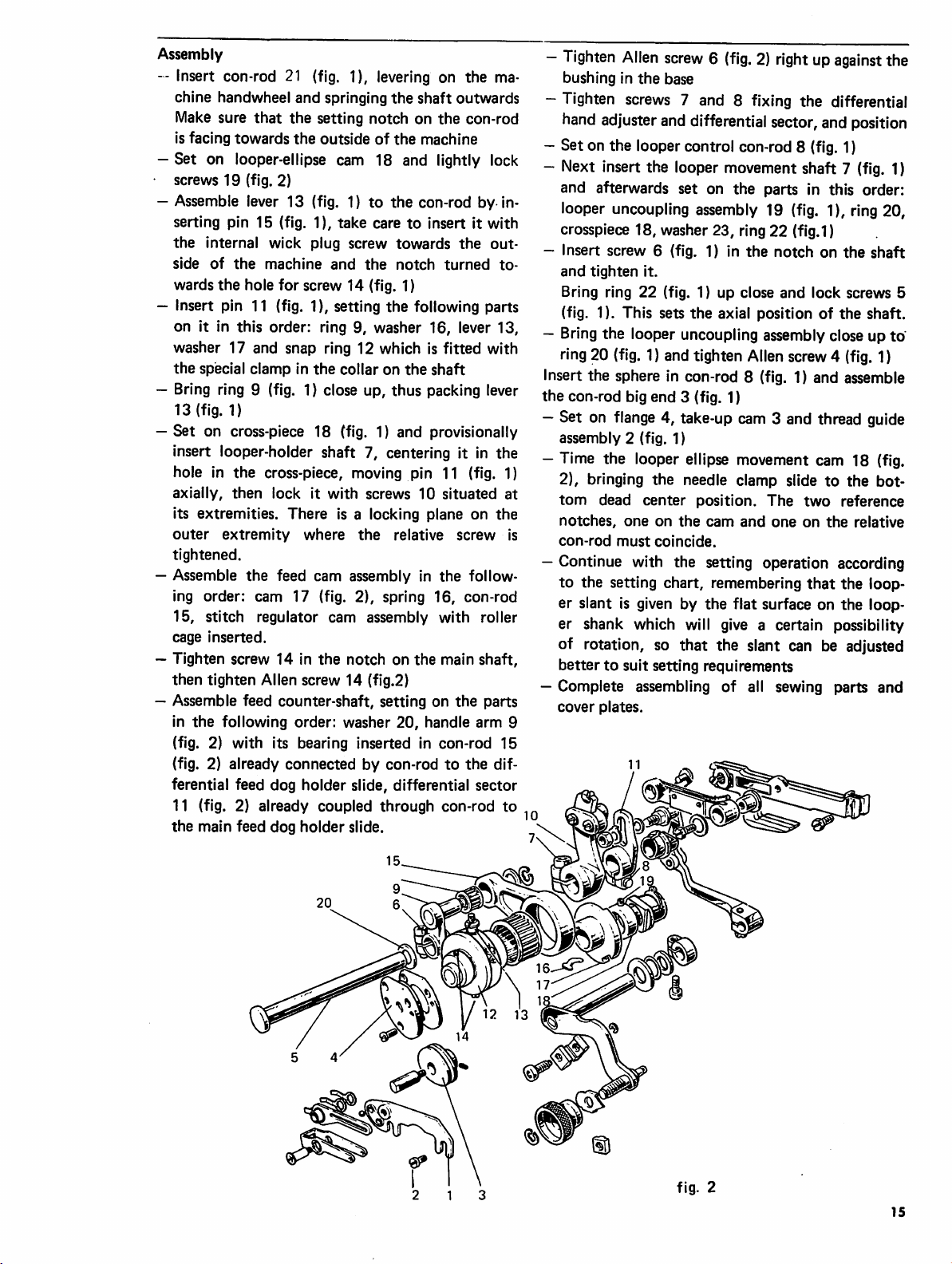

Assembly

-- Insert con-rod 21 (fig. 1), levering on the ma

chine handwheel

Make sure

is facing

towards

that

and

springing

the

setting

the

outsideofthe

the

shaft

notchonthe

machine

outwards

con-rod

—Set on looper-ellipse cam 18 and lightly lock

screws 19 (fig. 2)

—Assemble lever 13 (fig. 1) to

serting pin 15 (fig. 1),

the

internal wick plug

side

of

the

machine

wards

the

hole

for

take

and

screw 14 (fig. 1)

— Insert pin 11 (fig. 1), setting

the

con-rod by in

caretoinsert it

screw

towards

the

notch

the

following parts

the

turned

with

out

to

on it In this order: ring 9, washer 16, lever 13,

washer 17 and snap ring 12 which is fitted with

the

special clamp in

—Bring ring 9 (fig. 1) close up,

13 (fig. 1)

—

Set

on cross-piece 18 (fig. 1) and provisionally

the

collar on

the

shaft

thus

packing lever

insert looper-holder shaft 7, centering it in the

hole in

axially,

its extremities.

outer

tightened.

—Assemble

the

cross-piece, moving pin 11 (fig. 1)

then

lockitwith

extremity

the

There

where

feed cam assembly in

screws

is a locking plane on

the

10

relative

situated

screw

the

follow

the

ing order: cam 17 (fig. 2), spring 16, con-rod

15, stitch regulator cam assembly with roller

cage

inserted.

—Tighten screw 14 in

then

tighten Allen screw 14 (fig.2)

—Assemble feed

in

the

following

the

notchonthe

counter-shaft,

order:

washer

main

settingonthe

20,

handle arm 9

shaft,

parts

(fig. 2) with its bearing inserted in con-rod 15

(fig. 2) already connected by con-rod to the dif

ferential feed dog holder slide, differential sector

11 (fig. 2) already coupled through con-rod to

the

main feed dog

holder

slide.

—

Tighten

bushing in

—Tighten

hand

Allen

screw6(fig.2)rightupagainst

the

base

screws

adjuster and

7 and 8 fixing the differential

differential

sector, and

—Set on the looper control con-rod 8 (fig. 1)

—Next insert the looper movement shaft 7

and afterwards set on the parts in this order:

looper uncoupling assembly 19

(fig.

crosspiece 18, washer 23, ring 22 (fig.1)

— Insert screw 6 (fig. 1) in

and

tighten

Bring ring

(fig. 1). This sets

it.

22

(fig. 1) up close

the

the

notchonthe

and

lock

axial position of

—Bring the looper uncoupling assemblyclose up to

ring20

(fig.

1) and tighten

Allen

screw4

Insert the sphere in con-rod 8 (fig. 1) and assemble

the

con-rod big end 3 (fig. 1)

—Set on flange 4, take-up cam 3 and thread guide

assembly

2 (fig. 1)

—Time the looper ellipse movement cam 18 (fig.

2), bringing the needle clamp slide to the bot

at

is

tom

notches,

con-rod

dead

must

one

center

on

coincide.

position.

the

cam

and

The

two

oneonthe

—Continue with the setting operation according

to the setting chart, remembering

that

er slant is given by the flat surface on the loop

er shank which will give a certain possibility

of rotation, so that the slant can be adjusted

bettertosuit setting requirements

—Complete assembling of all sewing parts

cover

plates.

the

position

(fig.

1)

1), ring 20,

shaft

screws 5

the

shaft.

(fig.

1)

reference

relative

the loop

and

I®

15

Page 15

o

CO CO

LU LU LU LU

00

00

tu

CO

LU LU LU

00

CO CO

00

UJ

UJ UJ

CO CO

00

til

11?

00

00

til

\ii

CO

00

'M

CO

<

ooooo

ooooo

OOOT-t-

T^<6i«!.(ico

1-t-CM

ooo

ooo

ficneo

ooo

ooo

ooo

CO

d)

000000

000000

O O O

lA

CO

CM

in

T-

CM

CM

o

I

ooooo

999

9 9 9

OOO

909999

o o o o o o

o

(/}

O)

(/)

m

CM CM CM CM CM CM CM CM

111 lU UJ

op 9

o o o o ^

1-

O O O O CM

o o o o o

CO

00 00

CM C\J CM CM CM

2 S S 2 S

CM CO

£D

O

CO

tu

op Q

CO m

r>-

UJ

•«•

O D

CVJ CM

OOO

9 9 9

CM CM CM

CM CM CM CM CM CM

00

O CM CO

O CM CM

UJ

UJ

00

oo

UJ

00

UJ UJ UJ UJ UJ UJ

00 CO CO

CM CM CM

1-

•A

CM CM

O O

9

O O O

g g S o o o

g g g

O O O O O O

CM CM CM CM CM CM

2 H S

oT

CO

CO

CM

v:

Q 9 9

CM

CO

00

CM

CM CM

CO

CO

CO

UJ

O

u

Page 16

S.l

555-00

O)

O)

★

E50007-DC1/203-97

★

E50001-DC1/203-97

★

E50002-DC1/203-97

•

E50030-DC1/203-97

★

E50031-DC1/203-97

Needle

plate

surface

Ensure that the needle touches the front and rear needle guards when the point

of

the

primary

looper

enters

the

needle

groove.

Please Note;By pushing the needle at its lowest point against the needle guard,

the

thread

should

run

free.

17

Page 17

Needle

clampintopmost

Looper fully forward

position

MACHINE

E50001-SC1

E50003-SC1

E50001-DC1

E50002-DC1

ES0007-DC1

E50025-DC1

ES0026-CX:i

E50029-DC1

ES0031-DC1

E50101-DC1

E50102-DC1

E50104-DC1

ES0105-DC1

E51002-OC1 E53401-DC1

E51006-OC1

ES0109-OC1

E50020-DC1

ES0006-DC1

ES0030-OC1 ES2301-DC1

E50103-OC1

E52804-UC1

E50001-DC1/203-97

E50007-OC1/203-97

E50005-DC1

E50009-DC1

E50039-OC1

E50005-DC1/203-97

E50010-DC1

E50023-OC1

E50034^C1

E53007-DC1

ES0023-DM1 ES2812-DM1

E50033-OM1

ES0108-DM1

E52207-DM1

E54g01-DM1

E50050-DC1

CLASSES

E52813-DC1

E50601-DC1

E52202-DC1

ES2203-DC1

E52204-DC1

ES2302-DC1

E52802-OC1

E52809-CX:i

E52g01-DCl

E52902-DC1

E52905-DC1

E52906-DC1

E53402-DT1

E54001-SC1

E50138-DC1

E52201-DC1

E52806-UC1

E52807-DC1

E52812-DC1

E50010-SC1

ES3402-DM1

E53403-DM1

Looperatfarthest

Needle

plate

surface

B

A

X

10~

Y

9.9~

V

9.9~

X

9.4-

X

9,1-

y

9.9-

Y

9.9-

Y

9,9-

X

10.2-

Y

11.2-

X

10.7-

X

10.7-

X

10.5-

1.5-

1.5-

1.5-

1.5-

2,5-

1.5-

1.5-

1.5~

3-

1-

2.5-

2.5-

4.5-

c

2.3t2.5

2.3t2.7

2.3t2.7

2.3t2.7

2.5t2.8

1.8t2

2.3-

2.3-

2.6t3

2.3t2.5

2.5t3

2.5t3

2.6t3

3.5.74

3.5t4

3.5t4

3.7t4

3.5t4

E

D

3.5t4

5-

-

4-

8-

5t5.1

4.4-

4.2-

F

4.2-

4.2-

4.2-

4.2-

4-

4.2-

5—

5-

5-

- - - - -

- - - -

-

- - -

- - -

- -

-

- -

-

- -

- - - -

-

-

-

- - - C

rear

position

0.05

max

H

G

Do

4,

R

Fig. 1

-

-

-

-

-

-

-

-

-

-

-

Fig. 3

-

-

Fig. 3

Fig. 3

-

- Fig. 3

Fig. 3

-

Fig. 3

-

-

Fig. 3

Fig. 2

A

Fig. 3

A

Fig. 3

B

Fig. 3

Fig. 2

18

Page 18

qI]

Looper

fully

4^

forward

Needle

clampintopmosl

posillon

±z=x.A_

Fig. 1

Fig. 3

Fig. 2

Fig. 4

o

Looper at

♦

Needle

plate

surface

farthest

rear

position

MACHINE

E5002O-OM2

E50036-OM2 E50107-DM2

E50001-SM2

E5Q002-SM2

E50021-DM2

E50012-DC2

E50013-DC2

ES0018-DC2

E50041

E50001-SC2

E50014-OC2

E50015-OC2

E500164DC2

E50017-DC2 E52206-OC2

E50038-DC2

E5O044-OC2

E50t20-DC2

-002

CLASSES

E50003-SM2

E50in-DM2

E50047-DC2

E50106-DC2

E50002-SC2

E50032-DC2

E50045-DC2

E50t05-OC2

X

X

Y

X

X

X

X

X

X

A B

9,9-

9,9-

9-

9,0-

9t9,5

9.4-

9.4-

9,7-

9-

1.5-

t,5~

3.7f3.9

1,5-

1,5-

1,5-

1,5-

3-

1,5-

c

2.3t2,7

2,3^2,7

3,3t3,5

3.5-;-3.7

2,3t2,5

2.3^-2.4

2.7^2.9

1.8-I-2

6,1t6.4

2,3f2.53.If

2,2t2,4

2.5^-3

2,3^2,4

D E

a.5-

3,5

4f4,5

3-

6.5

F

-

-

-

- - -

3,5f3.7

444,5

-

- - -

- - -

- -

-

- -

3-

- - -

-

-

H

G

-

-

-

-

-

-

-

-

- - -

PD

A

B

-

8

A

-

A

A

4.

Fig. 1

Fig. 1

Pig. 2

Fig. 1

Fig. 1

Fig. 1

Fig. 3

Fig. 4

Fig. 1

Page 19

c5^

w

WORLDWIDE

Union

service

offices

sewing

Union

servicemen

serve

Whatever

Corporation

with

It is

COLUMBIA®

Special

most

machines.

Special

facilities

will

equipment

Special

your

him

today.

important

Corporation,

complete

M2lmionSp€cici£

Finest

Union

Union

Corporation

throughout

aid

you

Corporation

are

factory

needs

your

location,

representative

to

machines

line

Quality

Special

Special,

SALES

maintains

the

world.

In

the

selection

for

your

particular

representatives

trained

promptly

there

remember

are

thus

of

the

Corporation, 400 N. Franklin

GmbH,

is a

to

serve

that

also

products

offering

Finest

Schwabstrasse

and

and

Union

LEWIS®

the

Quality

of

are

you.

industry

33. D-7000

AND

sales

SERVICE

and

These

the

right

operation.

and

able

to

efficiently.

Special

Check

and

of

Union

the

sewing

K Industrial Sewing Equipment

Street,

Stuttgart

Sewing

Chicago, IL 60610, U.S.A.

1. West Germany.

Norcross,

Chicago,

Dallas,

Commerce,

New

Philadelphia,

Woburn,

Opa-Locka,

Montreal,

Toronto,

Catano,

Brussels,

Leicester,

Paris,

Stuttgart,W.Germany

Hong

other

all

partsotthe

Equipment

GA

IL

TX

CA

York,

NY

PA

MA

FL

Quebec

Ontario

Puerto

Belgium

England

France

Kong

Representatives

world

Rico

throughout

PrintedinU.S.A.

(462)

Loading...

Loading...