Page 1

INSTRUCTIONS ANDINSTRUCTIONS AND

INSTRUCTIONS AND

INSTRUCTIONS ANDINSTRUCTIONS AND

ILLUSTRAILLUSTRA

ILLUSTRA

ILLUSTRAILLUSTRA

BETRIEBSANLEITUNG UNDBETRIEBSANLEITUNG UND

BETRIEBSANLEITUNG UND

BETRIEBSANLEITUNG UNDBETRIEBSANLEITUNG UND

ILLUSTRIERTES TEILEVERZEICHNISILLUSTRIERTES TEILEVERZEICHNIS

ILLUSTRIERTES TEILEVERZEICHNIS

ILLUSTRIERTES TEILEVERZEICHNISILLUSTRIERTES TEILEVERZEICHNIS

TED PTED P

TED P

TED PTED P

ARAR

AR

ARAR

TS LISTTS LIST

TS LIST

TS LISTTS LIST

TWO NEEDLE CYLINDER BED DOUBLE LOCKED STITCHTWO NEEDLE CYLINDER BED DOUBLE LOCKED STITCH

TWO NEEDLE CYLINDER BED DOUBLE LOCKED STITCH

TWO NEEDLE CYLINDER BED DOUBLE LOCKED STITCHTWO NEEDLE CYLINDER BED DOUBLE LOCKED STITCH

MACHINE FOR AMACHINE FOR A

MACHINE FOR A

MACHINE FOR AMACHINE FOR A

ZWEINADEL-ZYLINDER-DOPPELKETTENSTICH-ZWEINADEL-ZYLINDER-DOPPELKETTENSTICH-

ZWEINADEL-ZYLINDER-DOPPELKETTENSTICH-

ZWEINADEL-ZYLINDER-DOPPELKETTENSTICH-ZWEINADEL-ZYLINDER-DOPPELKETTENSTICHMASCHINE ZUM ANNÄHEN VON HOSENSTOSSBANDMASCHINE ZUM ANNÄHEN VON HOSENSTOSSBAND

MASCHINE ZUM ANNÄHEN VON HOSENSTOSSBAND

MASCHINE ZUM ANNÄHEN VON HOSENSTOSSBANDMASCHINE ZUM ANNÄHEN VON HOSENSTOSSBAND

SUPPLEMENT TO CASUPPLEMENT TO CA

SUPPLEMENT TO CA

SUPPLEMENT TO CASUPPLEMENT TO CA

ZUSAZUSA

ZUSA

ZUSAZUSA

STYLE / TYP CS112T02-2M111UTSTYLE / TYP CS112T02-2M111UT

STYLE / TYP CS112T02-2M111UT

STYLE / TYP CS112T02-2M111UTSTYLE / TYP CS112T02-2M111UT

TTTT

ACHING CUFF AND HEEL TACHING CUFF AND HEEL T

TT

ACHING CUFF AND HEEL T

TTTT

ACHING CUFF AND HEEL TACHING CUFF AND HEEL T

CACA

TT

CA

CACA

KAKA

KA

KAKA

TZ ZUM KATZ ZUM KA

TZ ZUM KA

TZ ZUM KATZ ZUM KA

ALOG NO. 307ALOG NO. 307

T

ALOG NO. 307

TT

ALOG NO. 307ALOG NO. 307

TT

ALOG NR. 307ALOG NR. 307

T

ALOG NR. 307

TT

ALOG NR. 307ALOG NR. 307

TT

ALOG NO. PT9425ALOG NO. PT9425

T

ALOG NO. PT9425

TT

ALOG NO. PT9425ALOG NO. PT9425

TT

ALOG NR. PT9425ALOG NR. PT9425

T

ALOG NR. PT9425

TT

ALOG NR. PT9425ALOG NR. PT9425

SECOND EDITIONSECOND EDITION

SECOND EDITION

SECOND EDITIONSECOND EDITION

ZWEITE AUFLAGEZWEITE AUFLAGE

ZWEITE AUFLAGE

ZWEITE AUFLAGEZWEITE AUFLAGE

APEAPE

APE

APEAPE

Page 2

Second edition / Zweite Auflage

© Union Special GmbH

09,.2007

2

Page 3

FORFOR

FOR

FORFOR

KLIPP-ITKLIPP-IT

KLIPP-IT

KLIPP-ITKLIPP-IT

MOTORMOTOR

MOTOR

MOTORMOTOR

METERINGMETERING

METERING

METERINGMETERING

THREAD GUIDESTHREAD GUIDES

THREAD GUIDES

THREAD GUIDESTHREAD GUIDES

FÜRFÜR

FÜR

FÜRFÜR

KLIPPKLIPP

KLIPP

KLIPPKLIPP

MOTORMOTOR

MOTOR

MOTORMOTOR

BANDZUMESSEINRICHUNGBANDZUMESSEINRICHUNG

BANDZUMESSEINRICHUNG

BANDZUMESSEINRICHUNGBANDZUMESSEINRICHUNG

FF

ADENFÜHRUNGADENFÜHRUNG

F

ADENFÜHRUNG

FF

ADENFÜHRUNGADENFÜHRUNG

ABAB

AB

ABAB

3

Page 4

SAFETY RULESSAFETY RULES

SAFETY RULES

SAFETY RULESSAFETY RULES

SICHERHEITSHINWEISESICHERHEITSHINWEISE

SICHERHEITSHINWEISE

SICHERHEITSHINWEISESICHERHEITSHINWEISE

1. Before putting the machines described in this manual

into service, carefully read the instructions. The starting

of each machine is only permitted after taking notice

of the instructions and by qualified operators.

IMPORTANT! IMPORTANT!

IMPORTANT! Before putting the machine into service,

IMPORTANT! IMPORTANT!

also read the safety rules and instructions from the

motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction

manual are prohibited from being put into service

until it has been ascertained that the sewing units

which these sewing machines will be built into, have

conformed with the provisions of EC Machinery

Directive 98/37/EC, Annex II B.

Each machine is only allowed to be used as foreseen.

The foreseen use of the particular machine is

described in paragraph "STYLES OF MACHINES" of this

instruction manual. Another use, going beyond the

description, is not as foreseen.

4. All safety devices must be in position when the

machine is ready for work or in operation. Operation

of the machine without the appertaining safety

devices is prohibited.

5. Wear safety glasses.

1. Lesen Sie vor Inbetriebnahme der in diesem Katalog

beschriebenen Maschinen die Betriebsanleitung

sorgfältig. Jede Maschine darf erst nach Kenntnisnahme der Betriebsanleitung und nur durch

entsprechend unterwiesene Bedienungspersonen

betätigt werden.

WICHTIG:WICHTIG:

WICHTIG: Lesen Sie vor Inbetriebnahme auch die

WICHTIG:WICHTIG:

Sicherheitshinweise und die Betreibsanleitung des

Motorherstellers.

2. Beachten Sie die für Ihr Land geltenden nationalen

Unfallverhütungsvorschriften.

3. Die Inbetriebnahme der in dieser Betriebsanleitung

beschriebenen Nähmaschinen ist solange untersagt,

bis festgestellt wurde daß die Näheinheiten bzw.

Nähanlagen, in die diese Nähmaschinen eingebaut

werden sollen, den Bestimmungen der EG-Richtlinie

Maschinen 98/37/EG, Anhang II B entsprechen.

Jede Maschine darf nur ihrer Bestimmung gemäß

verwendet werden. Der bestimmungsgemäße Gebrauch der einzelnen Maschine ist im Abschnitt

"MASCHINENTYPEN" der Betriebsanleitung beschrieben. Eine andere, darüber hinausgehende

Benutzung ist nicht bestimmungsgemäß.

4. Bei betriebsbereiter oder in Betrieb befindlicher

Maschine müssen alle Schutzeinrichtungen montiert

sein. Ohne zugehörige Schutzeinrichtungen ist der

Betrieb nicht erlaubt.

6. In case of machine conversions and changes all valid

safety rules must be considered. Conversions and

changes are made at your own risk.

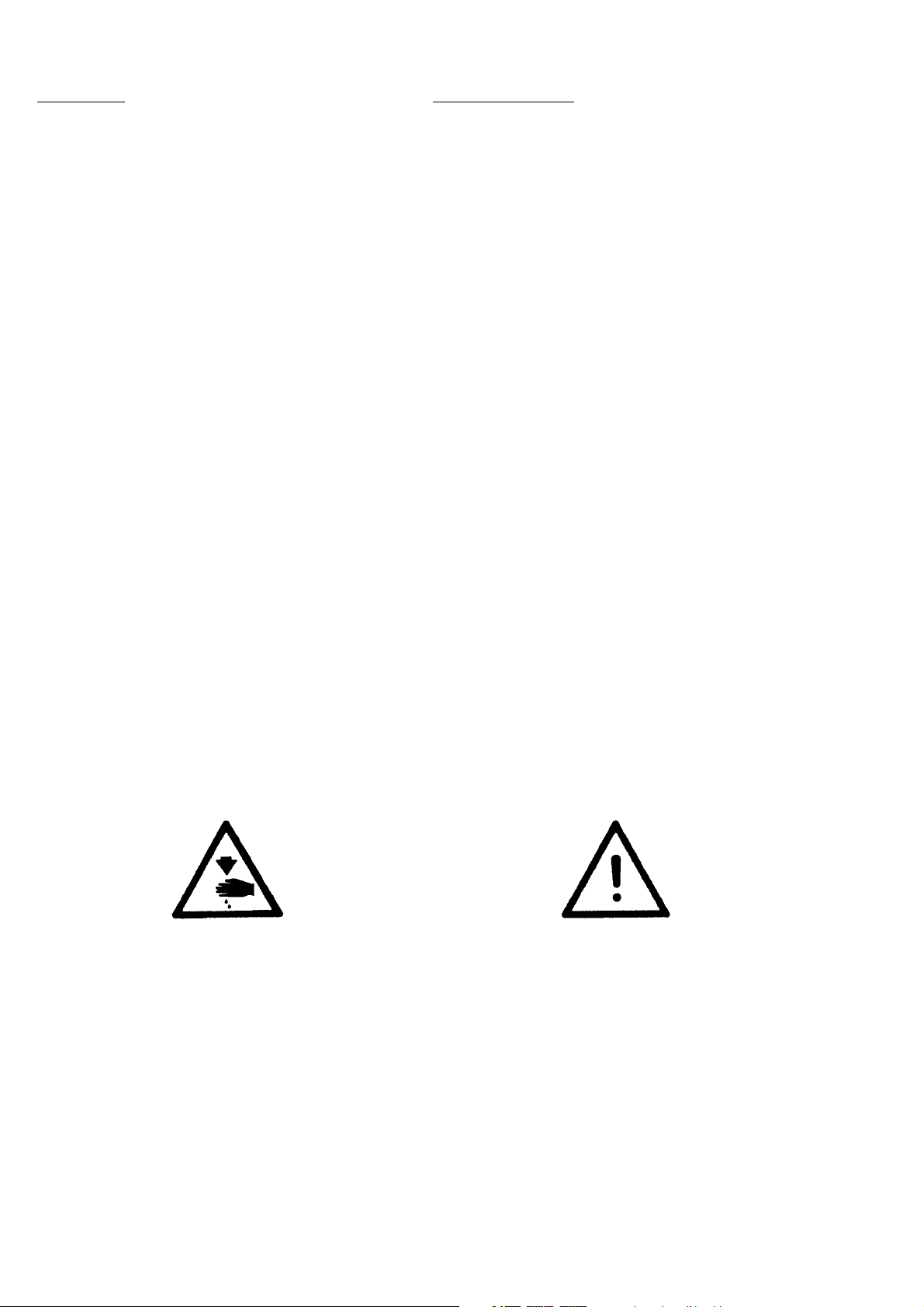

7. The warning hints in the instructions are marked

with one of these two symbols.

8. When doing the following the machine has to be

disconnected from the power supply by turning

off the main switch or by pulling out the main plug.

8.1 When threading needle(s), looper,

spreader etc.

8.2 When replacing any parts such as

needle(s), presser foot, throat plate,

looper, spreader, feed dog, needle guard,

folder, fabric guide etc.

8.3 When leaving the workplace and when

the work place is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without

actuation lock, wait until motor is stopped

totally.

5. Tragen Sie eine Schutzbrille.

6. Umbauten und Veränderungen der Maschinen dürfen

nur unter Beachtung der gültigen

Sicherheitsvorschriften vorgenommen werden.

Umbauten und Veränderungen erfolgen auf eigene

Verantwortung.

7. Überall da, wo die Betriebsanleitung Warnhinweise

enthält, sind diese durch eines der beiden Symbole

gekennzeichnet.

8. Bei folgendem ist die Maschine durch Ausschalten am

Hauptschalter oder durch Herausziehen des

Netzsteckers vom Netz zu trennen:

8.1 Zum Einfädeln von Nadel(n), Greifer, Leger

usw.

8.2 Zum Auswechseln von Nähwerkzeugen, wie

Nadel, Drückerfuß, Stichplatte, Greifer, Leger,

Transporteur, Nadelanschlag, Apparat, Nähgutführung usw.

8.3 Beim Verlassen des Arbeitsplatzes und bei

unbeaufsichtigtem Arbeitsplatz.

8.4 Für Wartungsarbeiten.

8.5 Bei mechanisch betätigten Kupplungsmo-

toren ohne Betätigungssperre ist der Stillstand

des Motors abzuwarten.

4

Page 5

9. Maintenance, repair and conversion work (see

item 8) must be done only by trained technicians

or special skilled personnel under condsideration

of the instructions.

9. Wartungs-, Reparatur- und Umbauarbeiten (siehe

Punkt 8) dürfen nur von Fachkräften oder entsprechend unterwiesenen Personen unter Beachtung der Betriebsanleitung durchgeführt werden.

Only genuine spare parts approved by UNION

SPECIAL have to be used for repairs.

10. Any work on the electrical equipment must be

done by an electrician or under direction and

supervision of special skilled personnel.

11. Work on parts and equipment under electrical

power is not permitted. Permissible exceptions

are described in the applicable section of standard

sheet EN 50 110 / VDE 0105.

12. Before doing maintenance and repair work on the

pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In

case of existing residual air pressure after

disconnecting from compressed air supply (e.g.

pneumatic equipment with air tank), the pressure

has to be removed by bleeding. Exceptions are

only allowed for adjusting work and function checks

done by special skilled personnel.

Für Reparaturen sind nur die von UNION

SPECIAL freigegebenen Original-Ersatzteile zu

verwenden.

10. Arbeiten an der elekrischen Ausrüstung dürfen nur

von Elektrofachkräften oder unter Leitung und

Aufsicht von entsprechend unterwiesenen Personen durchgeführt werden.

11. Arbeiten an unter Spannung stehenden Teilen und

Einrichtungen sind nicht erlaubt. Ausnahmen regeln

die zutreffenden Teile der EN 50 110 / VDE 0105.

12. Vor Wartungs- und Reparaturarbeiten an pneumatischen Einrichtungen ist die Maschine vom

pneumatischen Versorgungsnetz zu trennen.

Wenn nach der Trennung vom pneumatischen

Versorgungsnetz noch Restenergie ansteht (z. B.

bei pneumatischen Einrichtungen mit Windkessel),

ist diese durch Entlüften abzubauen. Ausnahmen

sind nur bei Einstellarbeiten und Funktionsprüfungen

durch entsprechend unterwiesene Fachkräfte

zulässig.

5

Page 6

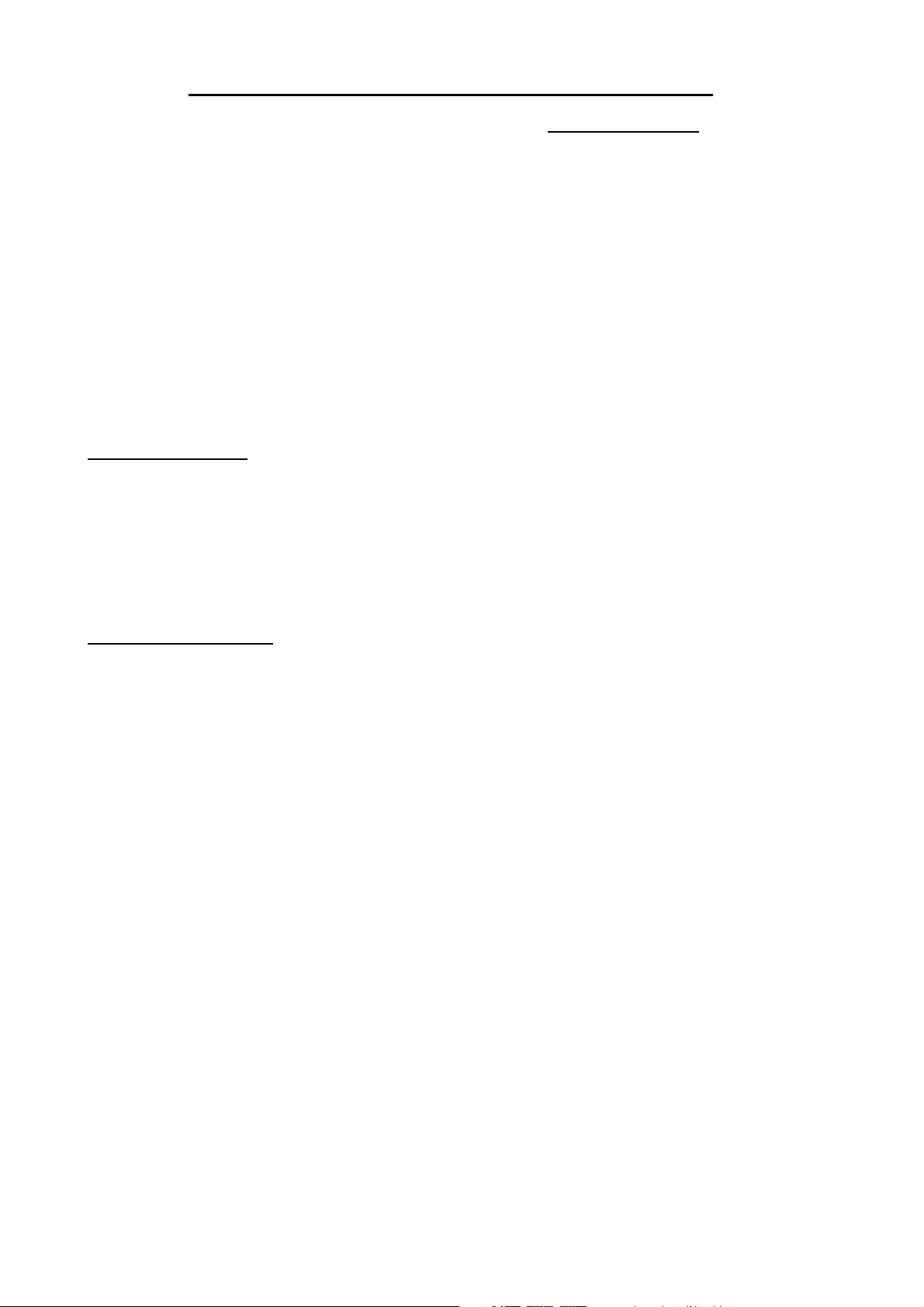

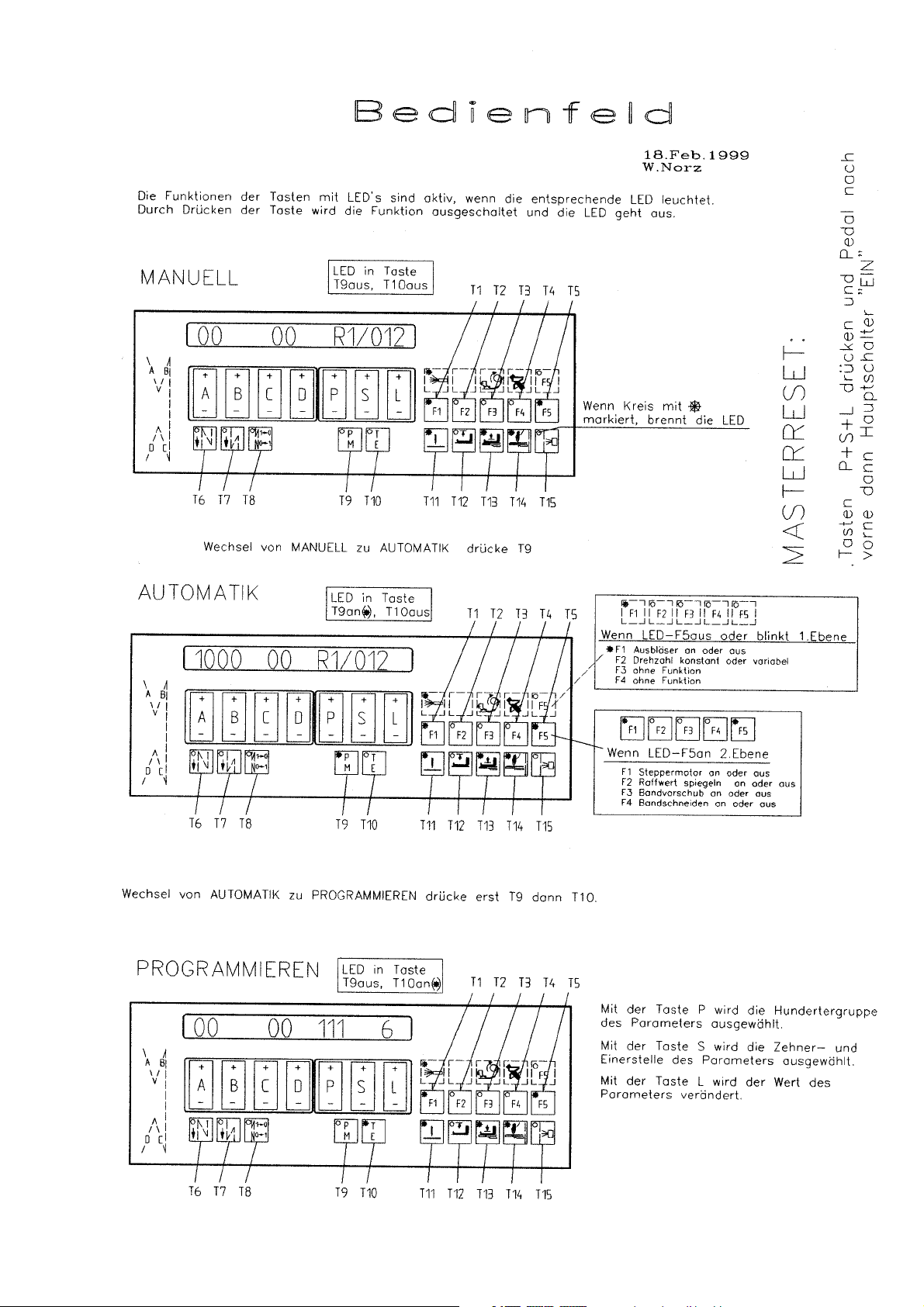

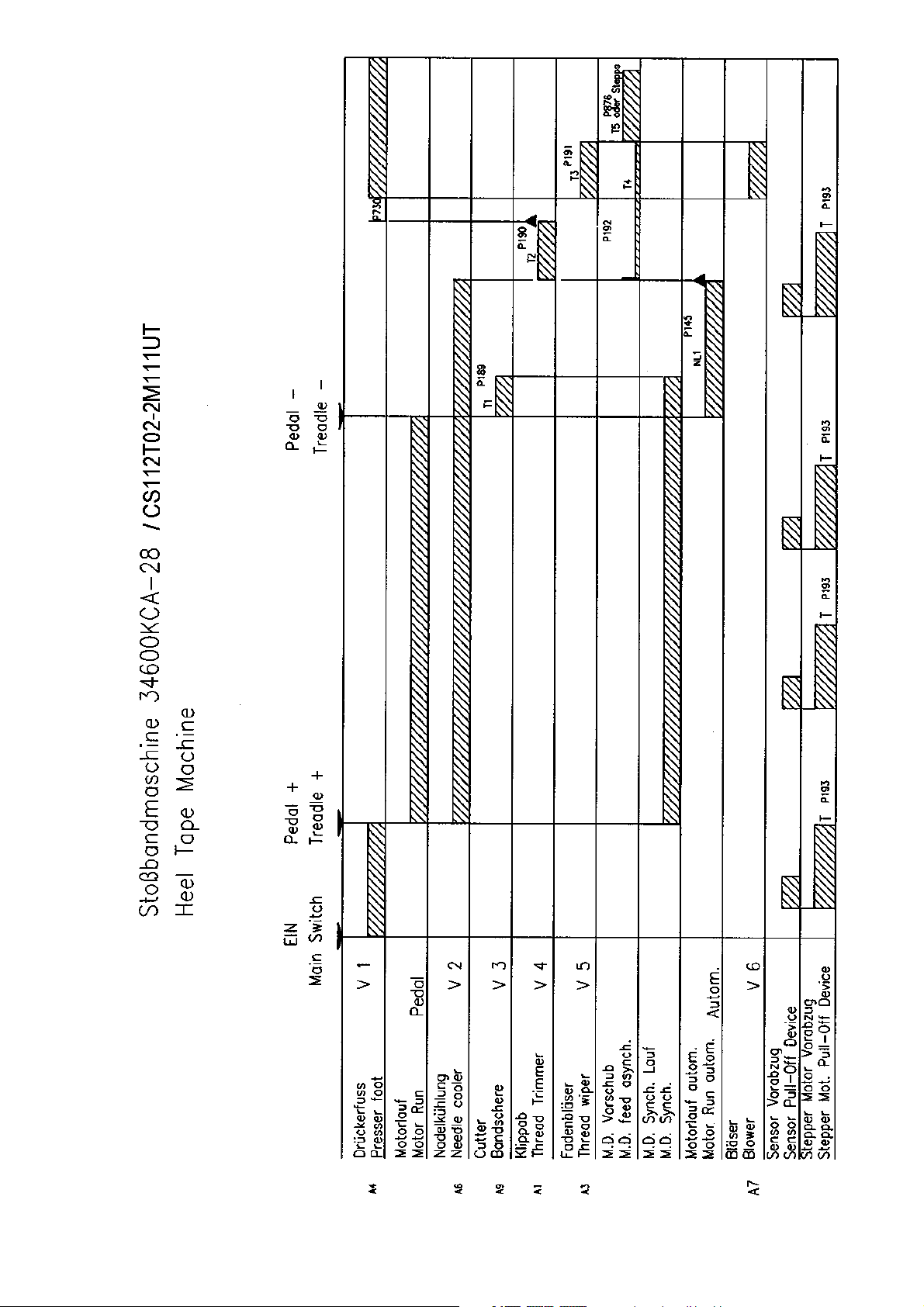

Instructions for Heel Tape Machine with Quick Motor 997A736

As shown on page “Operating Panel” the following LED’s have to be lit in the MANUAL – MODE (press the

appertaining key to switch LED “ON” or “OFF”).

T11 – means Needle up at machine stop

T13 – means Presser foot up at end of seam

T14 – means KLIPP-IT works in “Manual-Mode”

F5 off or flashing: 1

rst

level for F1 to F4 keys active

F1 flashing, metering device running.

F5 on 2

nd

level for F1 to F4 keys active.

F1 flashing, thread blower active behind KLIPP-IT .

LED’s of keys T6, T7, T8, T12 and T15 are included in all modes MANUAL, AUTOMA TIC and PROGRAMMING

“OFF”.

Within this mode you can handle the sewing-in of the machine, while the metering device is not running.

AUTOMA TIC MODE

Apart from all LED’S flashing as in the MANUAL MODE, now switch on T9 to achieve AUTOMATIC-MODE

“ON”.

When actuating the foot pedal forward while in this mode the metering device runs synchronously with the

sewing machine. Moving the foot pedal back activates cutting of the tape, end – beginning automatically sewn

with chainstitch, threads cut, presser foot up, the needle threads are blown over the presser foot and the tape

is inserted.

PROGRAMMING MODE

A-Level

Apart from all LED’s flashing as in the MANUAL MODE, now switch on T10 to achieve PROGRAMMING

MODE, level A “ON”.

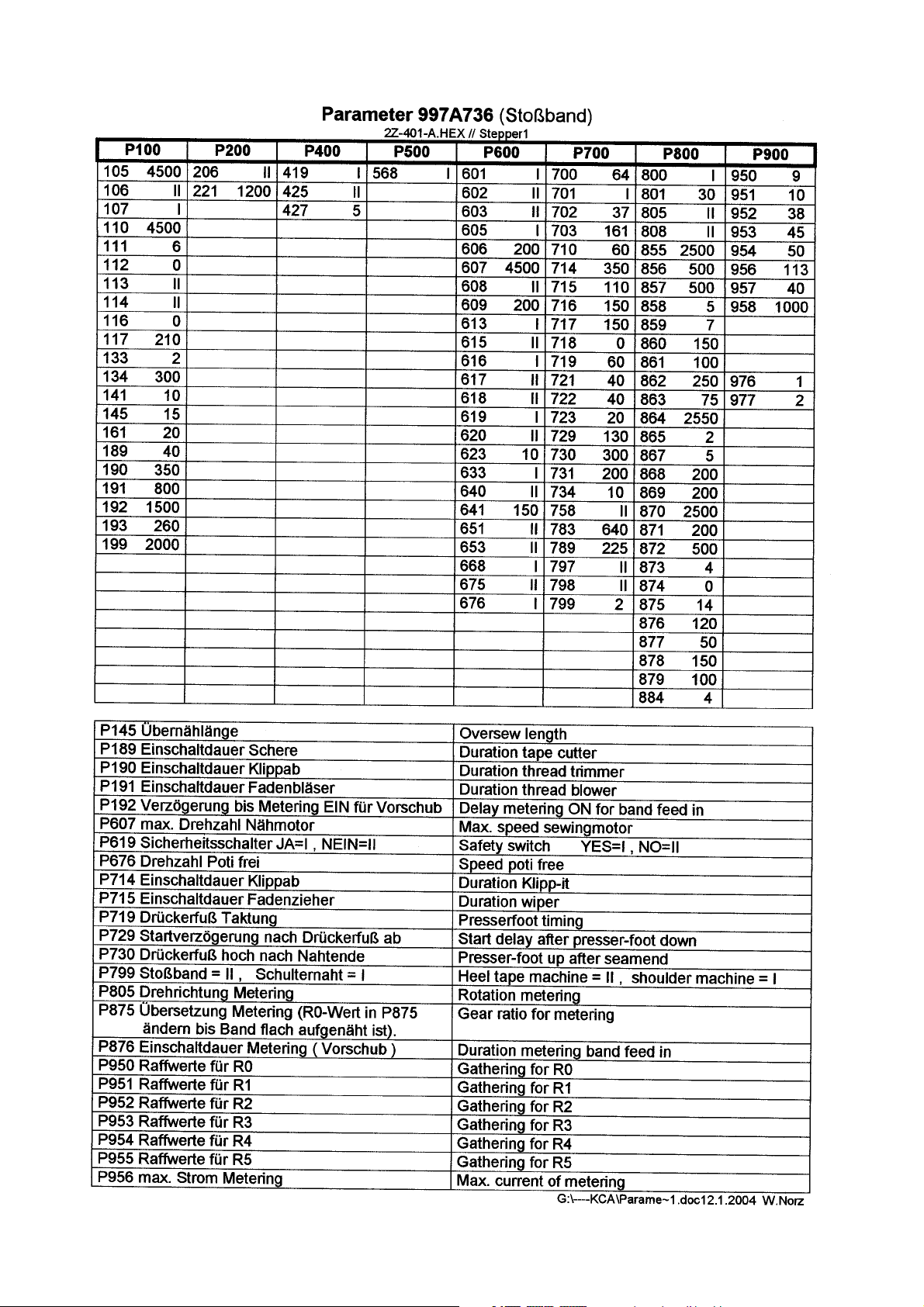

Important parameters in the A-level:

P145 excess seam length

P872 speed, insert tape

P875 transmission ratio Metering Devise to main motor

P876 length, insert tape

P959 (RO) gathering factor 1

P951 (R1) gathering factor 2

P952 (R2) gathering factor 3

P953 (R3) gathering factor 4

P954 (R4) gathering factor 5

B-Level

Master switch “OFF”

Press keys T9 and T10 simultaneously and turn master switch “ON”.

In T9 LED has to be “OFF”, if not press key T9. In T10 LED has to be “ON”, otherwise press key T10.

Use key P to select the hundred group.

Use key S to select the tens and the units.

Use key L to change parameter value.

The most important parameters have been listed on a separate sheet titled “parameter”.

6

Page 7

As the gathering factors of tapes or trouser cloths are likely to vary , we can select 5 different gathering factors.

T o adjust transmission ratio of the metering device to the main motor we recommend to proceed as follows:

Set parameter 875 to 15

Set parameter 950 to 0

Now sew tape desired onto the respective trouser cloth. If the heel tape is too short use key “L” in

programming mode (level B) to select a lower value of P875. Factor in parameter P875 has been

selected correctly , if the tape has been attached smooth and evenly without any loops between presser

foot and metering device.

Now you are ready to insert the factors in parameters 951, 952 and 954. The higher the factor the shorter the

heel tape length.

Press key “P” to select a gathering factor R0 to R4 in the AUT OMA TIC MODE.

7

Page 8

Anleitung für Stoßband mit Quick-Motor 997A736

G:\—KCA \ Anleitung für Stoßband

Wie im Blatt „Bedienfeld“ gezeigt, müssen folgende LED`s im MANUELL - Modus brennen (drükken auf die entsprechende Taste schaltet die LED „AN“ oder „AUS“):

T11 Bedeutung: Nadel oben wenn Maschine anhält

T13 Bedeutung: Drückerfuß oben wenn Nähoperation beendet.

T14 Bedeutung: Klippab arbeitet im Manuell - Modus.

F5 aus oder blinkt: 1. Ebene für die F1 bis F4 Taste ist aktiv.

F1 brennt, Metering arbeitet.

F5 an : 2. Ebene für die F1 bis F4 Taste ist aktiv.

F1 brennt, Fadenbläser ist nach dem Klippab aktiv.

Die LEDs der Tasten T6, T7, T8, T12 und T15 sind in den Modi Manuell, Automatik und Programmieren „AUS“.

In diesem Modus kann die Maschine eingenäht werden, das Metering arbeitet nicht.

Automatik – Modus:

Alle LED‘s wie im Manuell – Modus, jedoch T9 nun einschalten, dadurch Automatik – Modus EIN.

In diesem Modus arbeitet das Metering beim V orwärtstreten des Pedals synchron mit der Nähma-

schine. Wird das Pedal nach hinten getreten wird das Band geschnitten, Ende - Anfang automatisch übernäht, die Fäden geschnitten, der Drückerfuß geht hoch, die Nadelfäden werden über den

Drückerfuß geblasen und das Band vorgelegt.

Programmier – Modus:

A-Ebene

Alle LED‘s wie im Manuell – Modus, jedoch T10 nun einschalten, dadurch Programmier – Modus, Ebene A, EIN.

Wichtige Parameter in der A-Ebene:P145 Übernählänge

P872 Geschwindigkeit, Band einschießen

P875 Übersetzung Metering zu Hauptmotor

P876 Länge, Band einschießen

P950 (R0) Raffwert 1

P951 (R1) Raffwert 2

P952 (R2) Raffwert 3

P953 (R3) Raffwert 4

P954 (R4) Raffwert 5

B-Ebene

Hauptschalter „AUS“

Taste T9 und T10 gleichzeitig drücken und Haupt schalter „EIN“.

In T9 muss die LED AUS sein, ist dies nicht der Fall, Taste T9 drücken. In T10 muss die LED AN

sein, eventuell Taste T10 drücken.

Mit der P-Taste wird die Hundertergruppe ausgewählt.

Mit der S-Taste wird die Zehner- und Einerstelle angewählt.

Mit der L-Taste wird der Wert des Parameter geändert.

Die wichtigsten Parameter sind auf dem Blatt „Parameter“ aufgeführt.

8

Page 9

Die wichtigsten Parameter sind auf dem Blatt „Parameter“ aufgeführt.

Da der Raffwert je nach Band oder Hosenstoff unterschiedlich ist kann man 5 verschiedene

Raffwerte wählen.

Die Übersetzung vom Metering zum Hauptmotor wird wie folgt eingestellt:

Parameter 875 auf 15 stellen.

Parameter 950 auf 0 stellen.

Nun wird das gewünschte Stoßband auf den entsprechenden Hosenstof f genäht. Ist das

Band zu kurz muss der Wert von P875 im Programmier Modus (B Ebene) mit der Taste „ L “niedriger gewählt werden.

Wird das Band glatt aufgenäht und zwischen Drückerfuß und Metering bildet sich keine

Schlaufe ist der Wert in P875 richtig gewählt.

Jetzt können die Werte in Parameter 951, 952, 953 und 954 eingegeben werden. Je höher der

Wert desto kürzer wird das Stoßband.

Durch drücken der „P“ Taste kann der Raf fwert von R0 bis R4 im AUTOMATIK MODUS ausgewählt werden.

9

Page 10

101112

Page 11

Page 12

Page 13

13

Page 14

11.4 List of Parameters (2A_401_2.EN2)

No. Function(Meaning) Level Range of Standard

Values Value

105 (AR/DRZ/STVD) Speed for front B,C 100 - 6400 3500

backtack/stitch condensation

(00000011)

106 (AR/DRZ/STVD) Speed for front B,C 0

backtack/stitch condensation

I variable (treadle-controlled)

II constant (corresponding to <105>)

107 (AR/RIE/DRZ/STVD) Speed for front B,C 0

backtack/stitch condensation when <106> = I

I limited by <105>

II limited by <607>

110 (ER/RIE/DRZ/STVD) Speed for end B,C 100 - 6400 5000

backtack/stitch condensation

11 1 (LS) Photocell compensation stitches 1 A,B,C 1 - 255 6

(stitches from photocell clear to seam end)

112 (LS) Number of stitches for photocell fade-out A,B,C 0 - 255 0

on knit fabrics (according to stitch size)

113 (LS/ST ART) S tart with photocell B,C 0

I when photocell is dark only

II also when photocell is clear

114 (PR/STOP/NE) Stop before seam end after B,C 0

stitch count (last seam section)

I yes

II no

116 (SANL) Soft start stitches A,B,C 0 - 255 0

(00000111)

117 (SANL/DRZ) Speed for soft start stitches B,C 30 - 640 400

133 (PR) Stitches for seam section 6 A,B,C 1 - 255 2

134 (PR) Stitches for seam section 7 A,B,C 0 - 2550 300

141 (FW) Number of stitches until bobbin thread B,C 0 - 255 10

monitor signal becomes active

(signal suppression on bobbin thread monitor)

145 (NE) Number of stitches for seam end A,B,C 0 - 255 15

(00001001)

161 (LS/ST AR T) Start delay for st art of photocell B,C 0 - 2550 70

189 (VERZ) Delay t1 B,C 0 - 2550 50

190 (VERZ) Delay t2 B,C 0 - 2550 180

191 (VERZ) Delay t3 B,C 0 - 2550 600

192 (VERZ) Delay t4 B,C 0 - 2550 1000

199 (DRZ/LS) Speed for photocell compensation B,C 300 - 6400 2000

stitches

206 (NE/PR/STOP) Interrupt/discontinue seam B,C 0

sections at speed = constant (<203> = II)

I with treadle -2

II with treadle 0

14

Page 15

11.4 Parameterliste (2A_401_2.DE2)

Nr. Funktion(Bedeutung) Ebene Einstell- Standard-

bereich wert

105 (AR/DRZ/STVD) Drehzahl für Anfangsriegel/ B,C 100 - 6400 3500

-stichverdichtung

(00000011)

106 (AR/DRZ/STVD) Drehzahl für Anfangsriegel/ B,C 0

-stichverdichtung

I variabel (pedalabhängig)

II konstant (entspr . <105>)

107 (AR/DRZ/STVD) Drehzahl für Anfangsriegel/ B,C 0

-stichverdichtung bei <106> = I

I begrenzt durch <105>

II begrenzt durch <607>

110 (ER/RIE/DRZ/STVD) Drehzahl für Endriegel/ B,C 100 - 6400 5000

-stichverdichtung

11 1 (LS) Lichtschrankenausgleichsstiche 1 A,B,C 1 - 255 6

(Stichzahl von Lichtschranke hell bis

Nahtende)

112 (LS) Stichzahl zur Lichtschrankenausblendung A,B,C 0 - 255 0

bei Maschenware(entsprechend der

Maschenweite)

113 (LS/ST ART) S tart mit Lichtschranke B,C 0

I nur wenn Lichtschranke dunkel

II auch wenn Lichtschranke hell

114 (PR/STOP/NE) Stopp vor Nahtende nach B,C 0

Stich zählung (letzte Nahtstrecke)

I ja

II nein

116 (SANL) Sanftanlaufstiche (Soft start) A,B,C 0 - 255 0

(00000111)

117 (SANL/DRZ) Drehzahl für Sanftanlaufstiche B,C 30 - 640 400

133 (PR) Stiche für Nahtstrecke 6 A,B,C 1 - 255 2

134 (PR) Stiche für Nahtstrecke 7 A,B,C 0 - 2550 300

141 (FW) Stichzahl bis Spulenfadenwächter-SignalB,C 0 - 255 10

wirksam ist

(Signalunterdrückung des Spulenfadenwächters)

145 (NE) Stichzahl für Nahtende A,B,C 0 - 255 15

(00001001)

161 (LS/ST ART) S tartverzögerung für B,C 0 - 2550 70

Lichtschrankenstart

189 (VERZ) V erzögerungszeit t1 B,C 0 - 2550 50

190 (VERZ) V erzögerungszeit t2 B,C 0 - 2550 180

191 (VERZ) V erzögerungszeit t3 B,C 0 - 2550 600

192 (VERZ) V erzögerungszeit t4 B,C 0 - 2550 1000

199 (DRZ/LS) Drehzahl für B,C 300 - 6400 2000

Lichtschrankenausgleichs stiche

206 (NE/PR/STOP) Unterbrechen/Abbrechen B,C 0

der Nahtstrecken bei Drehzahl = konstant (<203> = II)

I mit Pedal -2

II mit Pedal 0

15

Page 16

221 (PR/DB/DRZ) Speed limitation for sewing B,C 300 - 6400 1200

programs (or sewing program 1)

419 (RIV/RIUNT/STVD) Function of external key B,C 0

I backtack/stitch condensation inversion

II backtack/stitch condensation suppression

(flip-flop function)

425 (ENTKET) Unlocking of chain at seam end A,B,C 0

I yes

II no

427 (PF/HV/PULL/STOP/MESSER) Selection of B,C 1 - 5 5

the function available with input E4

1 = presser foot

2 = stroke adjustment

3 = control of puller@4 = stop

5 = chopper

6-9 without function

568 (TUM/STVD/BSN) output A4 is at B,C 0

I Feed reverse / stitch condensation

II T ape cutter

601 (SN) T rimming B,C 0

I yes

II no

602 (NE) Seam end at treadle position B,C 0

I slightly heeled (-1)

II fully heeled (-2)

603 (ST AR T) St art after seam end B,C 0

I after treadle 0 only

II immediate start of operation

605 (DRZ) Actual speed in display B,C 0

I yes

II no

606 (DRZ) Speed: level 1 (min.) B,C 30 - 640 200

(00010001)

607 (DRZ) Speed: level 12 (max.) B,C 100 - 10000 4000

608 (DRZ) Speed level curve (treadle B,C 0

characteristic)

I linear

II not linear

609 (SN/DRZ) T rimming speed 1 B,C 30 - 300 200

(00010011)

613 (ANLSP/STOP) Input „Ex“ induces block/stop B,C 0

at

I potential „zero“

II potential „plus“

615 (LS) End recognition when photocell goes B,C 0

I from light to dark

II from dark to light

616 (NPW/NHOS) Function of external key (input B,C 0

E2)

I needle position change-over (NPW)

II needle up without trimming (NHOS)

16

Page 17

221 (PR/DB/DRZ) Drehzahlbegrenzung für Näh- B,C 300 - 6400 1200

programme (bzw. Nähprogramm 1)

419 (RIV/RIUNT/STVD) Funktion des externen B,C 0

Tasters

I Riegelinvertierung/

Stichverdichtungsinvertierung

II Riegelunterdrückung/Stichverdichtungsunterdrückung (Flip-Flop-Funktion)

425 (ENTKET) Entketteln am Nahtende A,B,C 0

I ja

II nein

427 (PF/HV/PULL/STOP/MESSER) Auswahl der B,C 1 - 5 5

Funktion des Eingangs E4

1 = Presserfuß

2 = Hubverstellung

3 = Pullersteuerung

4 = Stopp

5 = Abhacker

6 - 9 z. Z. keine Funktion

568 (TUM/STVD/BSN) Ausgang A5 ist bei B,C 0

I T ransportumstellung / Stichverdichtung

II Bandschneider

601 (SN) Schneiden B,C 0

I ja

II nein

602 (NE) Nahtende bei Pedalstellung B,C 0

I leicht rückwärts (-1)

II voll rückwärts (-2)

603 (ST ART) S tart nach Nahtende B,C 0

I nur nach Pedal 0

II sofortiger Nähbeginn

605 (DRZ) Istwert in der Anzeige(<725>) B,C 0

I ja

II nein

606 (DRZ) Drehzahl: Stufe 1 (min.) B,C 30 - 640 200

(00010001)

607 (DRZ) Drehzahl: Stufe 12 (max.) B,C 100 - 10000 4000

608 (DRZ) Drehzahlstufenkurve B,C 0

(Pedalcharakteristik)

I linear

II nicht linear

609 (SN/DRZ) Schneiddrehzahl 1 B,C 30 - 300 200

(00010011)

613 (ANLSP/STOP) Eingang“Ex“ führt zu B,C 0

Laufsperre/Stopp

I bei Potential „null“

II bei Potential „plus“

615 (LS) Enderkennung durch Lichtschranke B,C 0

I von hell nach dunkel

II von dunkel nach hell

616 (NPW/NHOS) Funktion des externen Tasters B,C 0

(Eingang E2)

I Nadelpositionswechsel (NPW)

II Nadel hoch ohne Schneiden (NHOS)

17

Page 18

617 (EST/RIV/STVD) Function of external key B,C 0

(input E3)

I single stitch (EST)

II backtack/stitch condensation inverted (RI

V)

618 (RDR) Inverse rotation after seam end B,C 0

I yes

II no

619 (SN/ANLSP/STOP) Control of thread trimming B,C 0

(safety switch no run)

I yes

II no

620 (FW) Thread monitor function B,C 0

I yes

II no

623 (RDR/VERZ) Delay in start-up time (ms) for B,C 0 - 2550 10

inverse rotation

633 (SN/PF) Trimming and presser foot B,C 0

I with treadle „-2“ only (<602> = II)

II corresponding to <602>

640 (LS/START) S tart possible by obscuring the B,C 0

photo- cell (if existing, note parameter 1 13!)

I yes

II no

641 (LS/START/VERZ) Delay before start (ms) B,C 0 - 2550 150

after photocell (at <640> = I)

651 (PF) Presser foot with automatic descent on B,C 0

machine stop

I yes

II no

653 (PEIPO) T arget stitch before sewing B,C 0

I yes

II no

668 (BLA/WI) Thread wiper/thread clearer B,C 0

I yes

II no

(00010101)

675 (NAPO) Automatic needle change-over into B,C 0

position@2 (up) after enabling

I yes

II no

676 (DRZ) Speed adjustment via potentiometer B,C 0

possible

I yes

II no

700 (NAPO) Needle position 0 B,C 0 - 239 0

(reference position of the needle)

701 (NAPO) Angular adjustment B,C 0

I with handwheel (teach-in)

II by keys (+/-)

18

Page 19

617 (EST/RIV/STVD) Funktion des externen B,C 0

T asters (Eingang E3)

I Einzelstich (EST)

II Riegel/Stichverdichtung invertiert (RIV)

618 (RDR) Rückdrehen nach Nahtende B,C 0

I ja

II nein

619 (SN/ANLSP/STOP) Überwachung des B,C 0

Fadenschneiders (Anlaufsperre)

I ja

II nein

620 (FW) Fadenwächterfunktion B,C 0

I ja

II nein

623 (RDR/VERZ) Einschaltverzögerung (ms) für B,C 0 - 2550 10

Rückdrehen

633 (SN/PF) Schneiden und Presserfuß B,C 0

I nur mit Pedal „-2“ (<602> = II)

II entsprechend <602>

640 (LS/ST ART) S tart durch Lichtschranke B,C 0

abdunkeln möglich (wenn vorhanden,

Parameter 1 13 beachten!)

I ja

II nein

641 (LS/ST ART/VERZ) S tartverzögerung (ms) B,C 0 - 2550 150

nach Lichtschranke (bei <640> = I)

651 (PF) Presserfuß mit automatischer AbsenkungB,C 0

bei Stillstand der Maschine

I ja

II nein

653 (PEIPO) Peilposition vor dem Nähen B,C 0

I ja

II nein

668 (BLA/WI) Fadenwischer/Fadenausbläser B,C 0

I ja

II nein

(00010101)

675 (NAPO) Nadel automatisch nach Einschalten B,C 0

in Position 2 (oben)

I ja

II nein

676 (DRZ) Drehzahleinstellung über B,C 0

Potentiometer möglich

I ja

II nein

700 (NAPO) Nadelposition 0 B,C 0 - 239 0

(Referenzposition der Nadel)

701 (NAPO) Winkeleinstellungen B,C 0

I am Handrad (teach-in)

II mit T astern (+/-)

19

Page 20

702 (NAPO) Needle position 1 (needle down) B,C 0 - 239 210

(0001011 1)

703 (NAPO) Needle position 2 (thread take-up B,C 0 - 239 60

lever up)

710 (NAPO/NHOS) Needle position 3 (needle up) B,C 0 - 239 60

(00011011)

714 (EINZ/SN/RDR) Duration (ms) for chainstitch B,C 0 - 2550 350

trimming or inverse rotation

715 (EINZ/WI) Duration (ms) of thread wiper B,C 0 - 2550 110

716 (VERZ/WI) Delay in start-up time (ms) for B,C 0 - 2550 150

thread wiper

717 (SN/VERZ) Delay in start-up time (ms) for B,C 0 - 2550 150

trimming method when the machine is not

activated by the treadle

718 (STBR) Timing of residual brake B,C 0 - 100 0

(0 = brake off)

719 (PF/TA) Timing output A4 B,C 0 - 100 60

(0 = 100% switching on)

721 (TUM/TA) Timing output A5 B,C 0 - 100 40

(0 = 100% switching on)

722 (DRZAN) Acceleration ramp B,C 1 - 50 40

1 gradual

50 steep

723 (DRZAB) Brake ramp B,C 1 - 50 20

1 gradual

50 steep

729 (STVERZ/PF) Start delay after lowering B,C 0 - 2550 350

presser foot

730 (PF/VERZ) Lift delay for presser foot after B,C 0 - 2550 300

seam end

731 (ER/WRIE/VERZ) Delay before stitch counting B,C 0 - 2550 200

for end backtack (ERV)

734 (SN/TA) Timing output A2 B,C 0 - 90 10

783 (BLA/EINZ) Time needed to switch on (ms) B,C 0 - 2550 640

for thread blower

758 (REG/DRZAB) Deceleration ramp B,C 0

I braking as per <723>

II braking with maximal moment

789 (PEIPO) Needle position 10 B,C 0 - 239 225

(target stitch)

797 (HWT) Hardware test B,C 0

I yes

II no

798 (EBC) Programming level C B,C 0

I yes

II no

20

Page 21

702 (NAPO) Nadelposition 1 (Nadel unten) B,C 0 - 239 210

(00010111)

703 (NAPO) Nadelposition 2 (Fadenhebel oben) B,C 0 - 239 60

710 (NAPO/NHOS) Nadelposition 3 (Nadel oben) B,C 0 - 239 60

(00011011)

714 (EINZ/SN/RDR) Einschaltzeit (ms) für B,C 0 - 2550 350

Kettenstich schneiden oder Rückdrehen

715 (EINZ/WI) Einschaltzeit (ms) für Fadenwischer B,C 0 - 2550 110

716 (VERZ/WI) Einschaltverzögerungszeit (ms) B,C 0 - 2550 150

für Fadenwischer

717 (VERZ/SN) Einschaltverzögerungszeit (ms) B,C 0 - 2550 150

für Schneidsystem in Ruhelage

718 (STBR) Stillstandsbremse-Taktung B,C 0 - 100 0

(0 = Bremse aus)

719 (PF/TA) T aktung Ausgang A4 B,C 0 - 100 60

(0 = 100% Einschaltung)

721 (TUM/T A) T aktung Ausgang A5 B,C 0 - 100 40

(0 = 100% Einschaltung)

722 (DRZAN) Beschleunigungsrampe B,C 1 - 50 40

1 flach

50 steil

723 (DRZAB) Bremsrampe B,C 1 - 50 20

1 flach

50 steil

729 (STVERZ/PF) Startverzögerung nach B,C 0 - 2550 350

Absenkung des Presserfußes

730 (PF/VERZ) Anhebeverzögerung für PresserfußB,C 0 - 2550 300

nach Nahtende

731 (ER/WRIE/VERZ) Stichzählverzögerung für B,C 0 - 2550 200

Endriegel (ERV)

734 (SN/TA) T aktung Ausgang A2 B,C 0 - 90 10

783 (BLA/EINZ) Einschaltzeit (ms) für B,C 0 - 2550 640

Fadenausbläser

758 (REG/DRZAB) Bremsrampe B,C 0

I Bremsen entsprechend <723>

II Bremsen mit maximalem Moment

789 (PEIPO) Nadelposition 10 (Peilposition) B,C 0 - 239 225

797 (HWT) Hardware-T est B,C 0

I ja

II nein

798 (EBC) Programmierebene C B,C 0

I ja

II nein

21

Page 22

799 (MAKL) Machine class which has been B,C 1 - 3 2

selected

(00011101)

800 (DRR) Direction of motor rotation viewed from B,C 0

belt pulley

I left-hand rotation

II right-hand rotation

801 (RDR) Reverse rotation angle after seam B,C 5 - 200 30

end

805 (DRR/ZUSAN/SMOT) Rotational direction of B,C 0

auxiliary drive

I lefthand rotation

II righthand rotation

808 (DRR/ZUSAN/SMOT) Rotating direction of B,C 0

auxiliary drive 2

I lefthand rotation

II righthand rotation

850 (DRZ) Maximum motor speed C 4500

851 (PR/DRZAB) Brake ramp for stitch-count C 0

seams

I steep

II gradual

855 (SMOT) maximum speed of stepping motor 2 B,C 10 - 2550 2500

856 (SMOT) Start-/stopping speed of stepping B,C 10 - 1000 500

motor 2

857 (SMOT) band engagement speed of stepping A,B,C 10 - 1000 100

motor 2

858 (SMOT) acceleration of stepping motor 2 B,C 1 - 20 5

859 (SMOT) reduction ratio of main motor/steppingB,C 1 - 255 20

motor 2

860 (SMOT) acceleration increments of stepping B,C 0 - 255 150

motor 2

861 (SMOT) braking increments of stepping motor B,C 0 - 255 100

2

862 (SMOT) maximum current of stepping motor 2 B,C 1 - 255 255

(255 = 3.6 A)

863 (SMOT) stationary current of stepping motor 2 B,C 0 - 255 128

(255 = 3.6 A)

864 (SMOT/VERZ) delay time from stop until B,C 0 - 2550 2550

switch-on of stationary current of stepping

motor 2 (ms)

865 (SMOT) Stepping motor 2 activated A,B,C 0

I yes

II no

22

Page 23

799 (MAKL) Ausgewählte Maschinenklasse B,C 1 - 3 2

(00011101)

800 (DRR) Motordrehrichtung mit Blick auf B,C 0

Keilriemen- scheibe

I Linkslauf

II Rechtslauf

801 (RDR) Rückdrehwinkel nach Nahtende B,C 5 - 200 30

805 (DRR/ZUSAN/SMOT) Drehrichtung B,C 0

Zusatzantrieb

I Linkslauf

II Rechtslauf

808 (DRR/ZUSAN/SMOT) Drehrichtung B,C 0

Zusatzantrieb 2

I Linkslauf

II Rechtslauf

850 (DRZ) Maximale Motordrehzahl C 4500

851 (PR/DRZAB) Bremsrampe für gezählte Nähte C 0

I steil

II flach

855 (SMOT) Maximaldrehzahl des Schrittmotors 2 B,C 10 - 2550 2500

856 (SMOT) Start-/Stopdrehzahl des Schrittmotors B,C 10 - 1000 500

2

857 (SMOT) Band-Vorlagegeschwindigkeit des A,B,C 10 - 1000 100

Schrittmotors 2

858 (SMOT) Beschleunigung des Schrittmotors 2 B,C 1 - 20 5

859 (SMOT) Untersetzungsverhältniss B,C 1 - 255 20

Hauptmotor/ Schrittmotor 2

860 (SMOT) Beschleunigungsschritte des B,C 0 - 255 150

Schrittmotors 2

861 (SMOT) Bremsschritte des Schrittmotors 2 B,C 0 - 255 100

862 (SMOT) Maximalstrom des Schrittmotors 2 B,C 1 - 255 255

(255 = 3,6A)

863 (SMOT) Stillstandsstrom des Schrittmotors 2 B,C 0 - 255 128

(255 = 3,6A)

864 (SMOT/VERZ) V erzögerungszeit (ms) von B,C 0 - 2550 2550

Stillstand bis Einschaltung

Stillstandsstrom des Schrittmotors 2

865 (SMOT) Schrittmotor 2 aktiv A,B,C 0

I ja

II nein

23

Page 24

867 (REG) integral amplification, band regulation B,C 0 - 40 5

868 (SMOT) band forward movement 2 of A,B,C 0 - 2550 200

stepping motor 1

869 (SMOT) band reverse movement 2 of A,B,C 0 - 2550 200

stepping motor 1

870 (SMOT) maximum speed of stepping motor B,C 10 - 2550 2500

1

871 (SMOT) Start-/stopping speed of stepping B,C 10 - 1000 200

motor 1

872 (SMOT) band engagement speed of stepping A,B,C 10 - 1000 500

motor 1

873 (SMOT) acceleration of stepping motor 1 B,C 1 - 20 5

874 (SMOT/REG) proportional amplification of B,C 0 - 50 0

band tension regulation

875 (SMOT) reduction ratio of main B,C 0 - 255 22

motor/stepping motor 1

876 (SMOT) band forward movement of stepping A,B,C 0 - 2550 200

motor 1

877 (SMOT) band reverse movement 2 of A,B,C 0 - 2550 50

stepping motor 1

878 (SMOT) acceleration increments of stepping B,C 0 - 255 150

motor 1

879 (SMOT) braking increments of stepping motor B,C 0 - 255 100

1

884 (REG) Proportional amplification of the speed B,C 4 - 50 20

control (in general)

885 (REG) Integral amplification of the speed C 0 - 100 30

control

886 (REG) Proportional amplification of the order C 1 - 50 20

controllers

887 (REG) Differential amplification of the order C 1 - 100 30

controllers

889 (EINZ/REG) T ime required for order C 0 - 1000 400

controlling (0 = always)

890 (REG) Proportional amplification of the C 1 - 50 25

superior order controllers for the residual

brake

891 (REG) Proportional amplification of the lower C 1 - 50 20

speed controllers for the residual brake

894 (REG) Rotational direction of motor and C 0

synchronizer

I different

II same

24

Page 25

867 (REG) Integralverstärkung B,C 0 - 40 5

Bandspannungsregler

868 (SMOT) Bandtransportstrecke 2 vorwärts A,B,C 0 - 2550 200

des Schrittmotors 1

869 (SMOT) Bandtransportstrecke 2 rückwärts A,B,C 0 - 2550 200

des Schrittmotors 1

870 (SMOT) Maximaldrehzahl des Schrittmotors 1 B,C 10 - 2550 2500

871 (SMOT) Start-/Stopdrehzahl des Schrittmotors B,C 10 - 1000 200

1

872 (SMOT) Band-Vorlagegeschwindigkeit des A,B,C 10 - 1000 500

Schrittmotors 1

873 (SMOT) Beschleunigung des Schrittmotors 1 B,C 1 - 20 5

874 (SMOT/REG) Proportional-Verstärkung B,C 0 - 50 0

Bandspannungsregelung

875 (SMOT) Untersetzungsverhältniss B,C 0 - 255 22

Hauptmotor/ Schrittmotor 1

876 (SMOT) Bandtransportstrecke 1 vorwärts A,B,C 0 - 2550 200

des Schrittmotors 1

877 (SMOT) Bandtransportstrecke 1 rückwärts A,B,C 0 - 2550 50

des Schrittmotors 1

878 (SMOT) Beschleunigungsschritte B,C 0 - 255 150

des Schrittmotors 1

879 (SMOT) Bremsschritte des Schrittmotors 1 B,C 0 - 255 100

884 (REG) Proportional-Verstärkung der B,C 4 - 50 20

Drehzahl- regelung (allgemein)

885 (REG) Integral-Verstärkung der C 0 - 100 30

Drehzahlregelung

886 (REG) Proportional-Verstärkung des C 1 - 50 20

Lagereglers

887 (REG) Dif ferential-Verstärkung des C 1 - 100 30

Lagereglers

889 (EINZ/REG) Zeit für Lageregelung C 0 - 1000 400

(0 = immer)

890 (REG) Proportional-Verstärkung des C 1 - 50 25

übergeordneten Lagereglers für

Stillstandsbremse

891 (REG) Proportional-Verstärkung des C 1 - 50 20

untergeordneten Drehzahlreglers für

Stillstandsbremse

894 (REG) Laufrichtung von Motor und C 0

Istwertgeber

I verschieden

II gleich

25

Page 26

897 (SONST) Commutation transmitter C 0

I ABB

II QR

898 (SONST) Number of motor poles C 0

I 4 poles

II 6 poles

950 (SMOT/RAFF) gathering value 1 of stepping A,B,C 0 - 200 10

motor axis 1

951 (SMOT/RAFF) gathering value 2 of stepping A,B,C 0 - 200 14

motor axis 1

952 (SMOT/RAFF) gathering value 3 of stepping A,B,C 0 - 200 18

motor axis 1

953 (SMOT/RAFF) gathering value 4 of stepping A,B,C 0 - 200 22

motor axis 1

954 (SMOT/RAFF) gathering value 5 of stepping A,B,C 0 - 200 26

motor axis 1

956 (SMOT) maximum current of stepping motor 1 B,C 1 - 255 140

(255 = 3.6 A)

957 (SMOT) stationary current of stepping motor B,C 0 - 255 70

1 (255 = 3.6 A)

958 (SMOT/VERZ) delay time from stop until B,C 0 - 2550 1000

switch-on of stationary current of stepping

motor 1 (ms)

990 (REG) Distance to position at switch over C 1 - 255 32

from speed control to position control

26

Page 27

897 (SONST) Kommutierungsgeber C 0

I ABB

II QR

898 (SONST) Polzahl des Motors C 0

I 4 Pole

II 6 Pole

950 (RAFF/SMOT) Raffwert 1 der A,B,C 0 - 200 10

Schrittmotorachse 1

951 (RAFF/SMOT) Raffwert 2 der A,B,C 0 - 200 14

Schrittmotorachse 1

952 (RAFF/SMOT) Raffwert 3 der A,B,C 0 - 200 18

Schrittmotorachse 1

953 (RAFF/SMOT) Raffwert 4 der A,B,C 0 - 200 22

Schrittmotorachse 1

954 (RAFF/SMOT) Raffwert 5 der A,B,C 0 - 200 26

Schrittmotorachse 1

956 (SMOT) Maximalstrom des Schrittmotors 1 B,C 1 - 255 140

(255 = 3,6A)

957 (SMOT) Stillstandsstrom des Schrittmotors 1 B,C 0 - 255 70

(255 = 3,6A)

958 (SMOT/VERZ) V erzögerungszeit (ms) von B,C 0 - 2550 1000

Stillstand bis Einschaltung

Stillstandsstrom des Schrittmotors 1

990 (REG) Entfernung von Sollposition bei C 1 - 255 32

Umschaltung von Drehzahl- auf Lageregelung

27

Page 28

28

Page 29

29

Page 30

grau 6

Weiss 2

Grün 3

Gelb 5

Stecker X 4

Luftnetz

Air supply

Weiss 2

Gelb 3

+24V Braun 1

+ 24 V Braun 1

Stecker X 6

Filter Regulator

Filterdruckminderer

999-196

998-82EA

998-82E

998-82EB

998-82E1-10

C:‘----KCA‘buschpneu.vsd

1

2

34567

671-104 A

999-196 F

8

1

9

10

1

+ 24 V

12

+ 24 V

Presserfoot

Drückerfuss

Nadelkühlung

V1

V2

Needlecooler

+ 24 V

+ 24 V

Tape cutter

Bandschere

V3

Klippab

V4

+ 24 V

Klipp - it

Fadenbläser

Thread blower

V5

998-82EC

90233LE178

+ 24 V

Blower

Ausbläser

V6

+ 24 V

Suction

Absaugung

V8

999-179

999-401G1/8-6

6

999- 411G1/4-

999-140 C

671-103 A

Stossbandmaschine

CS 112 T 02 - 2 M 111 / UT

WS72800 GHP 1 A

999 - 151

zum Klippab / to Klipp - it

999- 460 G1/8 - 4

999 - 153 A

999 - 165

A4

A

A

B

B

999 - 196

A9

A1

A

B

A6

A

B

999 - 411 G1/8 - 4

A3

A3

AB

A

B

999 - 196

999 - 411 G1/8 - 6

A6

999 - 287

A

B

zur Nadelkühlung / Fadenbläser

999 - 411 G 1/8 - 4

999 - 411 G 1/8 - 4

to Needle cooler / Thread wiper

A 10361 BA MONTIERT

AUF MONTAGEPLATTE

30

Page 31

31

Page 32

32

Page 33

DESCRIPTION OF PDESCRIPTION OF P

DESCRIPTION OF P

DESCRIPTION OF PDESCRIPTION OF P

TEILEBESCHREIBUNGTEILEBESCHREIBUNG

TEILEBESCHREIBUNG

TEILEBESCHREIBUNGTEILEBESCHREIBUNG

ARAR

AR

ARAR

TSTS

TS

TSTS

33

Page 34

34

Page 35

353637

Page 36

Page 37

Page 38

Hints for adjusting the thread chain cutter of this sewing machineHints for adjusting the thread chain cutter of this sewing machine

Hints for adjusting the thread chain cutter of this sewing machine

Hints for adjusting the thread chain cutter of this sewing machineHints for adjusting the thread chain cutter of this sewing machine

Problems with uneven beginning of the threadProblems with uneven beginning of the thread

Problems with uneven beginning of the thread

Problems with uneven beginning of the threadProblems with uneven beginning of the thread

34600KCA/ CS112T02-2M111UT34600KCA/ CS112T02-2M111UT

34600KCA/ CS112T02-2M111UT

34600KCA/ CS112T02-2M111UT34600KCA/ CS112T02-2M111UT

(also see Adjusting Instruction in Catalog 282CA, Page 20 to 25)(also see Adjusting Instruction in Catalog 282CA, Page 20 to 25)

(also see Adjusting Instruction in Catalog 282CA, Page 20 to 25)

(also see Adjusting Instruction in Catalog 282CA, Page 20 to 25)(also see Adjusting Instruction in Catalog 282CA, Page 20 to 25)

1.1.

Make sure that the catching knife - support M (page 40) neither in its right nor in itsMake sure that the catching knife - support M (page 40) neither in its right nor in its

1.

Make sure that the catching knife - support M (page 40) neither in its right nor in its

1.1.

Make sure that the catching knife - support M (page 40) neither in its right nor in itsMake sure that the catching knife - support M (page 40) neither in its right nor in its

left final position hits against the screw (page 40).left final position hits against the screw (page 40).

left final position hits against the screw (page 40).

left final position hits against the screw (page 40).left final position hits against the screw (page 40).

In both positions 1 mm of the radius at the end of the guiding slot N (page 38) hasIn both positions 1 mm of the radius at the end of the guiding slot N (page 38) has

In both positions 1 mm of the radius at the end of the guiding slot N (page 38) has

In both positions 1 mm of the radius at the end of the guiding slot N (page 38) hasIn both positions 1 mm of the radius at the end of the guiding slot N (page 38) has

to be visible next to the head of the screw S (page 40) (see also catalog 282CA,to be visible next to the head of the screw S (page 40) (see also catalog 282CA,

to be visible next to the head of the screw S (page 40) (see also catalog 282CA,

to be visible next to the head of the screw S (page 40) (see also catalog 282CA,to be visible next to the head of the screw S (page 40) (see also catalog 282CA,

page 22, Fig. 36).page 22, Fig. 36).

page 22, Fig. 36).

page 22, Fig. 36).page 22, Fig. 36).

The distance in resting position of the knife carrier M (page 40) can be adjustedThe distance in resting position of the knife carrier M (page 40) can be adjusted

The distance in resting position of the knife carrier M (page 40) can be adjusted

The distance in resting position of the knife carrier M (page 40) can be adjustedThe distance in resting position of the knife carrier M (page 40) can be adjusted

by turning the bolt B (page 40) on the thread of the driving collar L (page 40) asby turning the bolt B (page 40) on the thread of the driving collar L (page 40) as

by turning the bolt B (page 40) on the thread of the driving collar L (page 40) as

by turning the bolt B (page 40) on the thread of the driving collar L (page 40) asby turning the bolt B (page 40) on the thread of the driving collar L (page 40) as

described above to at least 1 mm. Movement to the left can be limited with thedescribed above to at least 1 mm. Movement to the left can be limited with the

described above to at least 1 mm. Movement to the left can be limited with the

described above to at least 1 mm. Movement to the left can be limited with thedescribed above to at least 1 mm. Movement to the left can be limited with the

set collar K (page 36) with the same distance. Tighten screw in set collar K securely.set collar K (page 36) with the same distance. Tighten screw in set collar K securely.

set collar K (page 36) with the same distance. Tighten screw in set collar K securely.

set collar K (page 36) with the same distance. Tighten screw in set collar K securely.set collar K (page 36) with the same distance. Tighten screw in set collar K securely.

2.2.

Make sure enough thread is pulled to ensure clean cutting and clamping of theMake sure enough thread is pulled to ensure clean cutting and clamping of the

2.

Make sure enough thread is pulled to ensure clean cutting and clamping of the

2.2.

Make sure enough thread is pulled to ensure clean cutting and clamping of theMake sure enough thread is pulled to ensure clean cutting and clamping of the

sewing thrsewing thr

sewing thr

sewing thrsewing thr

in its highest position (upper dead center).in its highest position (upper dead center).

in its highest position (upper dead center).

in its highest position (upper dead center).in its highest position (upper dead center).

Swing in the catching knife completely by pushing against the clevis C (page 36)Swing in the catching knife completely by pushing against the clevis C (page 36)

Swing in the catching knife completely by pushing against the clevis C (page 36)

Swing in the catching knife completely by pushing against the clevis C (page 36)Swing in the catching knife completely by pushing against the clevis C (page 36)

of the air cylinder.of the air cylinder.

of the air cylinder.

of the air cylinder.of the air cylinder.

Release the clevis again slowly and watch the thread in the area of the take upRelease the clevis again slowly and watch the thread in the area of the take up

Release the clevis again slowly and watch the thread in the area of the take up

Release the clevis again slowly and watch the thread in the area of the take upRelease the clevis again slowly and watch the thread in the area of the take up

hooks H1 to H4 (page 38). Excess thread built up while turning in the catching knifehooks H1 to H4 (page 38). Excess thread built up while turning in the catching knife

hooks H1 to H4 (page 38). Excess thread built up while turning in the catching knife

hooks H1 to H4 (page 38). Excess thread built up while turning in the catching knifehooks H1 to H4 (page 38). Excess thread built up while turning in the catching knife

should be just used up when the catching knife reaches its resting position.should be just used up when the catching knife reaches its resting position.

should be just used up when the catching knife reaches its resting position.

should be just used up when the catching knife reaches its resting position.should be just used up when the catching knife reaches its resting position.

In no way at the end of the movement - in which you have to pull at the clevis CIn no way at the end of the movement - in which you have to pull at the clevis C

In no way at the end of the movement - in which you have to pull at the clevis C

In no way at the end of the movement - in which you have to pull at the clevis CIn no way at the end of the movement - in which you have to pull at the clevis C

(page 36) - thread should be pulled from the bobbin through the thread tension.(page 36) - thread should be pulled from the bobbin through the thread tension.

(page 36) - thread should be pulled from the bobbin through the thread tension.

(page 36) - thread should be pulled from the bobbin through the thread tension.(page 36) - thread should be pulled from the bobbin through the thread tension.

Is this the case, check the position of the take up hooks H1 to H4. (page 38).Is this the case, check the position of the take up hooks H1 to H4. (page 38).

Is this the case, check the position of the take up hooks H1 to H4. (page 38).

Is this the case, check the position of the take up hooks H1 to H4. (page 38).Is this the case, check the position of the take up hooks H1 to H4. (page 38).

These must be positioned in such a way, that the belonging thread runs closelyThese must be positioned in such a way, that the belonging thread runs closely

These must be positioned in such a way, that the belonging thread runs closely

These must be positioned in such a way, that the belonging thread runs closelyThese must be positioned in such a way, that the belonging thread runs closely

underneath without being diverted.underneath without being diverted.

underneath without being diverted.

underneath without being diverted.underneath without being diverted.

TT

o get moro get mor

T

o get mor

TT

o get moro get mor

hook H1 to H4 (page 38) by loosening the screw 19 (page 36) and moving it inhook H1 to H4 (page 38) by loosening the screw 19 (page 36) and moving it in

hook H1 to H4 (page 38) by loosening the screw 19 (page 36) and moving it in

hook H1 to H4 (page 38) by loosening the screw 19 (page 36) and moving it inhook H1 to H4 (page 38) by loosening the screw 19 (page 36) and moving it in

small steps upwards until desired thread length is available. Fasten the screwssmall steps upwards until desired thread length is available. Fasten the screws

small steps upwards until desired thread length is available. Fasten the screws

small steps upwards until desired thread length is available. Fasten the screwssmall steps upwards until desired thread length is available. Fasten the screws

securely again. Check at the same time if take up hooks H1 to H4 do not hit againstsecurely again. Check at the same time if take up hooks H1 to H4 do not hit against

securely again. Check at the same time if take up hooks H1 to H4 do not hit against

securely again. Check at the same time if take up hooks H1 to H4 do not hit againstsecurely again. Check at the same time if take up hooks H1 to H4 do not hit against

anything or block in some way. Make sure that between take up hooks H2 andanything or block in some way. Make sure that between take up hooks H2 and

anything or block in some way. Make sure that between take up hooks H2 and

anything or block in some way. Make sure that between take up hooks H2 andanything or block in some way. Make sure that between take up hooks H2 and

the lower fastening clip of the thread guide strip always a distance of 1 mm remainsthe lower fastening clip of the thread guide strip always a distance of 1 mm remains

the lower fastening clip of the thread guide strip always a distance of 1 mm remains

the lower fastening clip of the thread guide strip always a distance of 1 mm remainsthe lower fastening clip of the thread guide strip always a distance of 1 mm remains

when catching knife is turned in - meaning being in its outermost left position.when catching knife is turned in - meaning being in its outermost left position.

when catching knife is turned in - meaning being in its outermost left position.

when catching knife is turned in - meaning being in its outermost left position.when catching knife is turned in - meaning being in its outermost left position.

ead. For this you make a seam, cut ofead. For this you make a seam, cut of

ead. For this you make a seam, cut of

ead. For this you make a seam, cut ofead. For this you make a seam, cut of

e thre thr

e thr

e thre thr

ead incread incr

ead incr

ead incread incr

ease the movement of the bar 21 (page 38) for the take upease the movement of the bar 21 (page 38) for the take up

ease the movement of the bar 21 (page 38) for the take up

ease the movement of the bar 21 (page 38) for the take upease the movement of the bar 21 (page 38) for the take up

f the air and put the needle barf the air and put the needle bar

f the air and put the needle bar

f the air and put the needle barf the air and put the needle bar

3.3.

Regulate the speed of the air cylinder with the flow control D (page 36) in such aRegulate the speed of the air cylinder with the flow control D (page 36) in such a

3.

Regulate the speed of the air cylinder with the flow control D (page 36) in such a

3.3.

Regulate the speed of the air cylinder with the flow control D (page 36) in such aRegulate the speed of the air cylinder with the flow control D (page 36) in such a

way that the speed of the back stroke of the catchingknife is only half the speedway that the speed of the back stroke of the catchingknife is only half the speed

way that the speed of the back stroke of the catchingknife is only half the speed

way that the speed of the back stroke of the catchingknife is only half the speedway that the speed of the back stroke of the catchingknife is only half the speed

of the forward motion.of the forward motion.

of the forward motion.

of the forward motion.of the forward motion.

4.4.

Please watch for small, approx. 10 mm long u-shaped thread residue inside of thePlease watch for small, approx. 10 mm long u-shaped thread residue inside of the

4.

Please watch for small, approx. 10 mm long u-shaped thread residue inside of the

4.4.

Please watch for small, approx. 10 mm long u-shaped thread residue inside of thePlease watch for small, approx. 10 mm long u-shaped thread residue inside of the

machine. This is a clue that one or both of the catching knifes cut ofmachine. This is a clue that one or both of the catching knifes cut of

machine. This is a clue that one or both of the catching knifes cut of

machine. This is a clue that one or both of the catching knifes cut ofmachine. This is a clue that one or both of the catching knifes cut of

thread loop instead of just cutting it open.thread loop instead of just cutting it open.

thread loop instead of just cutting it open.

thread loop instead of just cutting it open.thread loop instead of just cutting it open.

Adjust the knife in the middle of the looper as described in catalog 282CA (S. 22,Adjust the knife in the middle of the looper as described in catalog 282CA (S. 22,

Adjust the knife in the middle of the looper as described in catalog 282CA (S. 22,

Adjust the knife in the middle of the looper as described in catalog 282CA (S. 22,Adjust the knife in the middle of the looper as described in catalog 282CA (S. 22,

Fig. 35).Fig. 35).

Fig. 35).

Fig. 35).Fig. 35).

38

f the needlef the needle

f the needle

f the needlef the needle

Page 39

3940414243

Page 40

Page 41

Page 42

Page 43

THREAD TENSION

FADENSPANNUNG

Ref. No.

Pos. Nr.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Part No.

Teil Nr.

29477NL

NS6110420SP

57865

SS7090520SP

50392AP

SS7090520SP

50392AV

59392X

50392AR

57892K

56392G

B3120352000

B3126012000

B3120704000

56392H

B3103804000

B3101804000

B3021804010

B3112704000

56392M

56392L

56392S

SS4120615SP

96711

50932AS

G51358KE

28C

A9858

77A

99296

50392AN

22735

99620

22596

G51346KA

22757

77A

A9858C

99306

A10476B

A10476A

90

Description Beschreibung

Five Thread Tension Assembly

Nut

Lead-in Thread Guide

Screw

Thread Guide

Screw

Guide for tension disc separator

Tension Bracket

Tension Disc Separator

Thread Tension Eyelet

Tension Post

Tension Disc Felt

Tension Disc

Tension Disc Felt

Spring Shield

Spring for spreader (blue)

Spring for needle (red)

Spring for looper (plain)

Ferrule for tension spring

Knob for spreader (blue)

Knob for needle (red)

Knob for looper (plain)

Screw

Spring

Rod for thread puller

Thread Pull-off Hook

Screw

Thread Pull-off Hook

Screw

Shoulder Screw

Tension Release Assembly

Shoulder Screw

Tension Release Assembly

Screw

Tensions Release Eccentric

Screw

Screw

Thread Pull-off

Screw

Thread Guide Support

Thread Guide

Screw

Fünf Fadenspannung komplett

Mutter

Fadenführung

Schraube

Fadenführung

Schraube

Träger für Fadenspannung

Ablöseleiste

Fadenführung

Fadenspannungsbolzen

Filzscheibe für Fadenspannung

Fadenspannungsscheibe

Filzscheibe für Fadenspannung

Federhülse

Feder für Fadenspannung (blau)

Feder für Nadel (rot)

Feder für Greifer (einfach)

Zahnscheibe für Fadenspannung

Fadenspannungsmutter (blau)

Fadenspannungsmutter (rot)

Schraube

Feder

Stange für Fadenspannungsauslösung

Fadenabzug

Schraube

Fadenabzug

Schraube

Zylinderschraube

Auslösestange komplett

Zylinderschraube

Schraube

Exzenterring

Schraube

Schraube

Doppelfadenabzug

Gewindestift

Halter für Fadenführung

Fadenführung

Zylinderschraube

Amt. Req.

Anzahl

1

5

5

2

1

2

2

1

1

5

5

5

10

5

5

1

3

1

5

1

3

1

2

1

1

4

4

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

Page 44

444546

Page 45

Page 46

Thread G uides Faden führungen

Part No.

Teil Nr.

A10476D Thread Pull-Off Fadenabzug

A19838 Th read Guide Holder Halter für Fadenführung

A10476CV Thread Guide Fadenführ ung, vorn

A19827 Rocker Schw inghebel

A10476F Thread Pull-Off Fadenabzug

A10476E Thr ead Pull-Off Fadenabzug

A10476CH Thread Guide Fadenführung, hinten

Description Beschreibung

Page 47

Thread G uides Fadenführungen

Part No.

Teil Nr.

A10476B Thread Guide Suppo rt Halter für Fadenführung

A10476A Thread Guide Faden führung

A9858C Th r ead Pull-Off Doppelfadenabzug

Description Beschr eibung

47

Page 48

484950

Page 49

Page 50

Page 51

METERING DEVICE

BANDZUMESSEINRICHTUNG

51

Page 52

52

Page 53

METERING DEVICE

BANDZUMESSEINRICHUNG

53

Page 54

54

Page 55

KNIFE HOLDER ASSEMBLY

MESSERHALTER KOMPLETT

55

Page 56

56

Page 57

57

Page 58

Loading...

Loading...