Finest Quality

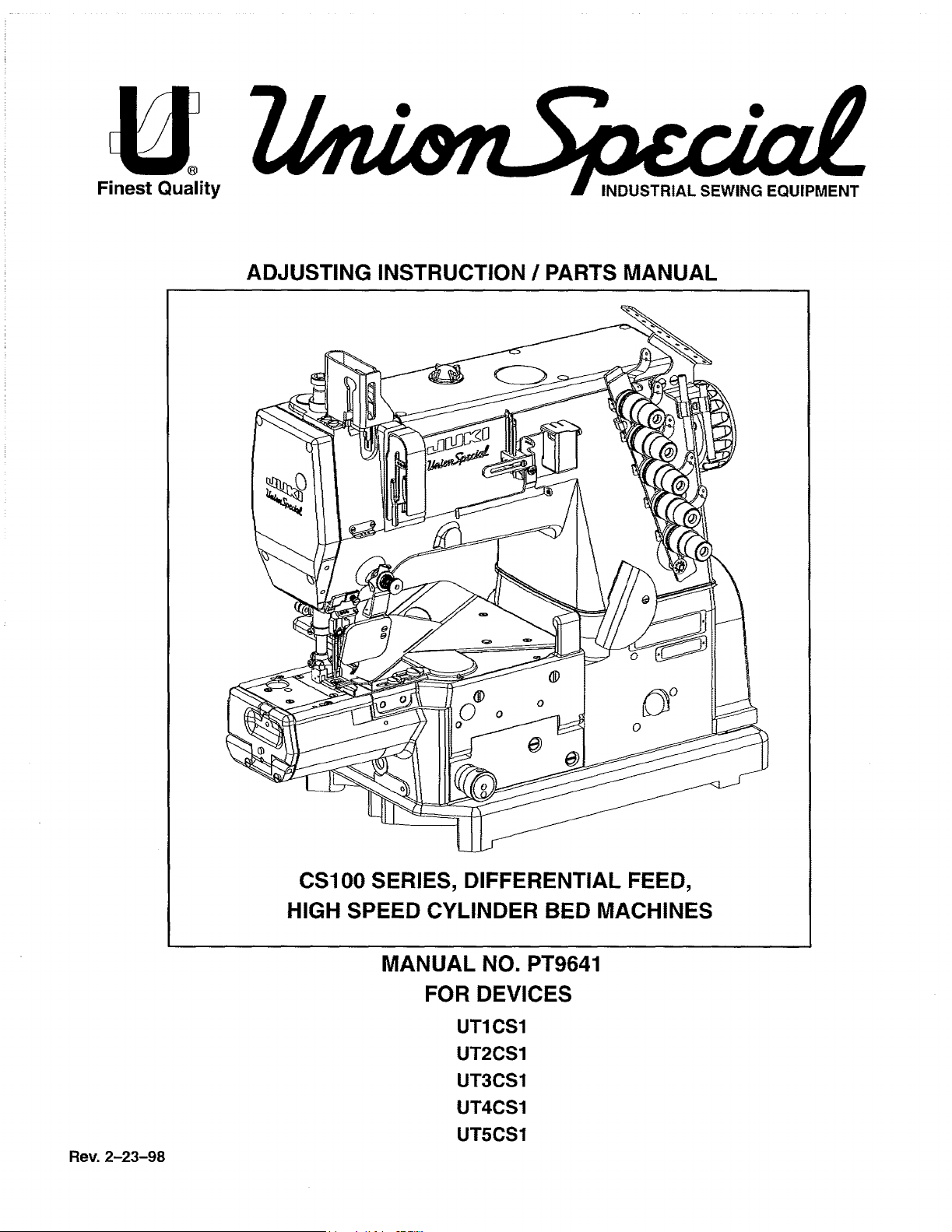

ADJUSTING INSTRUCTION I PARTS

MANUAL

CS1

00 SERIES, DIFFERENTIAL FEED,

HIGH SPEED CYLINDER

MANUAL

NO. PT9641

BED

FOR DEVICES

UT1CS1

UT2CS1

UT3CS1

UT4CS1

UT5CS1

Rev.2-23-98

MACHINES

for

Devices

Adjusting Instructions/Parts

UTlCSl

..

UT2CS1, UT3CS1,

Manual

UT4CSL

PT9641

UT5CS1

Second

Rights Reserved In All

This

parts

manual

machines. It

style) & Operator•s

It

is

the

desire

designed specifically for your

This

manual

may

incorporate

has

can

be

Manual

of

Union Special

has

been

a slight

been

prepared

used

in

conjunction

OP9637.

comprised

modification

Edition

to

that

each

machine

on

the

Copyright

1997

Countries

by

Union

Printed

Special

in

U.S.A

PREFACE

assist

you in

locating

with Union Special Parts Manuals

machine

and

are

basis

of

configuration in illustrations

run

manufactured

of

available

NEW

at

its

optimum

information.

individual parts

with utmost precision

Corporation

February

PT9512

performance.

Changes

or

part

1998

or

or

PT9425

in design

numbers.

assemblies

Parts listed in this

to

assure long lasting seNice.

on

the

(depending

and/or

improvements

CS l 00

on

manual

Series

machine

are

2

CONTENTS

•SAFETY

•

TENSION

•THREAD

•THREADING

•UNDERBED

•UNDERBED

•UNDERBED

•UNDERBED

•UPPER

•TENSION

•UNDERBED

•LOWER

•STOP

•GUIDE

•UNDERBED

•ELECTROPNEUMATIC

•SEITING

•ADJUSTING

. •SOLENOID/PNEUMATIC

•PNEUMATIC/ELECTRIC

•SETIING

•NEEDLE

•AIR

•THREAD

•UNDERBED

•ELECTRIC

•ELECTRIC

•

ELECTRIC

•ELECTRIC

•PNEUMATIC

•PNEUMATIC

•PNEUMATIC

•PRESSER

•NEEDLE

•PNEUMATIC

•NUMERICAL

•NUMERICAL

RULES

RELEASE

PULL-OFF

THREAD

KNIFE

SPRING

KNIFE

DISTANCE

DISTANCE

PROXIMITY

THREAD

THREAD

FLOW

..............................................................................................................................................................

TENSION

PRESSER

THREAD

DRIVE

SPREADER

FOOT

THREAD

......................................................................................................................................................... 4

(UNDERBED

.................................................................................................................................................. 6

DIAGRAM .......................................................................................................................................... 7

TRIMMER

THREAD

THREAD

THREAD

AND CLAMPING

THREAD

THREAD

THREAD

THREAD

CONTROL

DRIVE

THREAD

COVER

INDEX

INDEX

TRIMMER

TRIMMER

TRIMMER

..................................................................................................................................................

TRIMMER

FRONT

TO

....................................................................................................................................................

.................................................................................................................................................

TRIMMER

DRIVE

SWITCH

WIPER

CATCH

BLOWER

.................................................................................................................................................

TRIMMER

FOOT

WIPER

DOUBLE

THREAD

DOUBLE

WIPER

LIFTER

...........................................................................................................................................

BLOWER

THREAD

OF

OF

THREAD

(ELECTRIC)

ASSEMBLY

ASSEMBLY

ASSEMBLY

SPRING

ASSEMBLY

BACK

...........................................................................................................................

.............................................................................................................................

...............................................................................................................................

................................................................................................................................

.................................................................................................................................

THREAD

COVER

........................................................................................................................................

PARTS

PARTS

THREAD

KNIFE

STROKE

ASSEMBLY

ASSEMBLY

LIFTER

ASSEMBLY

ASSEMBLY

ACTION

TRIMMER

ACTION

ASSEMBLY

ASSEMBLY

TRIMMER

.............................................................................................................................

.............................................................................................................................

TRIMMER)

........................................................................................................... 8

............................................................................................................ 9

..........................................................................................................

..........................................................................................................

..............................................................................................................

..........................................................................................................

WIPER

............................................................................................................

TRIMMER

............................................................................................................

.................................................................................................................

..........................................................................................................

.......................................................................................................

..................................................................................................................

ASSEMBLY

ASSEMBLY

ASSEMBLY

.............................................................................................................

.................................................................................................................

ASSEMBLY

............................................................................................. 5

...........................................................................................

...................................................................................................

..........................................................................................

..............................................................................................

..........................................................................................

10

11

11

11

12

12

12

12

13

13

14

15

16

17

18

19

19

21

23

25

27

29

31

33

35

37

39

41

43

50

51

3

1 .

Before

starting

operators.

putting

of

each

the

machines

machine

described

is

only

in this

permitted

SAFETY

manual

after

RULES

into

taking

service,

notice

carefully

of

the

read

instructions

the

instructions. The

and

by

qualified

IMPORTANT!

2.

Observe

3. The

4.

5.

6.

7.

sewing

until

conformed

Each

described

the

description,

All

safety

of

the

Wear

In

case

and

The

warning

the

it

has

been

machine

in

devices

machine

safety

of

machine

changes

Before

the

motor

national

machines

ascertained

with

the

is

only

paragraph

is

not

must

without

glasses.

are

made

hints in

putting

safety

EC

allowed

conversions

the

the

supplier.

rules

described

that

Council

"STYLES

as

foreseen.

be

in

position

the

appertaining

at

your

instructions

to

machine

valid

in

this

the

Directives

be

OF MACHINES"

and

own

into

for

instruction

sewing

used

when

changes

risk.

are

marked

your

units

(89/392/EEC,

as

foreseen.

the

safety

service,

country.

manual

which

of

this

machine

devices

all

valid

with

also

read

are

these

sewing

Annex

The

foreseen

instruction

is

ready

is

prohibited.

safety

one

of

these

the

safety

prohibited

machines

II

B).

use

manual.

for

work

rules

must

two

rules

from

of

the

Another

or

in

be

considered.

symbols:

and

instructions

being

operation.

put

will

be

built

particular

use,

going

from

into

service

into,

have

machine

beyond

Operation

Conversions

is

8.

When

the

main

8.1

8.2

8.3

8.4

8.5

9.

Maintenance,

special

10.

Any

supervision

11. Work

described

12.

Before

disconnected

necting

removed

doing

switch

When

When

dog,

When

When

When

skilled

work

on

doing

from

the

threading

replacing

needle

leaving

doing

using

repair

personnel

on

the

of

special

parts

and

in

the

maintenance

from

compressed

by

bleeding.

following

or

by

pulling

needle(s),

any

guard,

the

workplace

maintenance

clutch

applicable

motors

and

electrical

skilled

equipment

the

compressed

the

machine

out

the

parts

such

folder.

conversion

under

air

fabric

work.

without

consideration

equipment

personnel.

under

sections

and

repair

supply

main

looper,

as

and

work

electrical

of

air

(i.e.

has

to

be

plug:

spreader

needle(s),

guide

when

actuation

work

etc.

the

(see

of

must

standard

on

supply.

pneumatic

disconnected

etc.

presser

workplace

lock,

wait

item

8)

must

the

instructions.

be

done

power

the

In

is

sheet

pneumatic

case

equipment

from

foot

throat

is

unattended.

until

the

be

done

by

an

electrician

not

permitted.

DIN VDE 0105.

equipment

of

existing

with

residual

air

the

plate,

motor

only

tank),

power

supply

looper,

is

stopped

by

trained

or

under

Permissible

the

machine

air

pressure

the

pressure has

by

turning

spreader,

totally.

technicians

direction

exceptions

has

after

discon-

feed

and

are

to

to

off

or

be

be

4

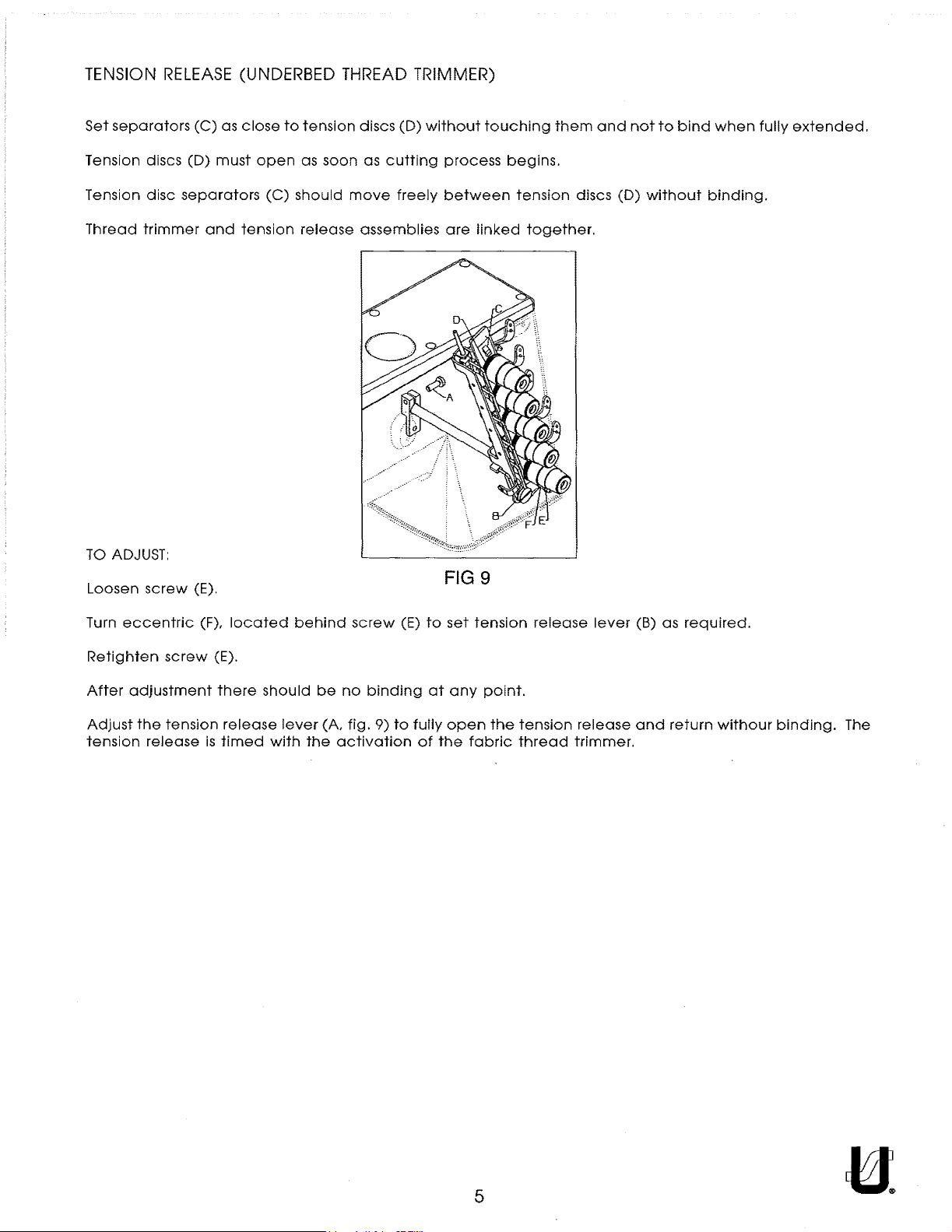

TENSION

Set

separators

RELEASE

(C)

as

(UNDERBED

close

to

tension

THREAD

discs

(D)

TRIMMER)

without

touching

them

and

not

to

bind

when

fully

extended.

Tension discs

Tension

Thread

TO

Loosen

disc

trimmer

ADJUST:

screw

(D)

must

separators

and

tension

(E).

open

(C)

as soon as

should

release

move

assemblies

cutting

freely

process

between

are

linked

FIG9

begins.

tension

together.

discs

(D)

without

binding.

Turn

eccentric

Retighten

After

adjustment

Adjust

tension

the

screw

tension

release

(F),

(E).

there

release

is

timed

located

should

with

behind

lever

the

screw

be

no

(A,

fig.

activation

(E)

binding

9)

to

to

at

fully

of

set

any

open

the

tension

point.

the

fabric

release

tension

thread

lever

release

trimmer.

(B) as

and

return

required.

withour

binding.

The

5

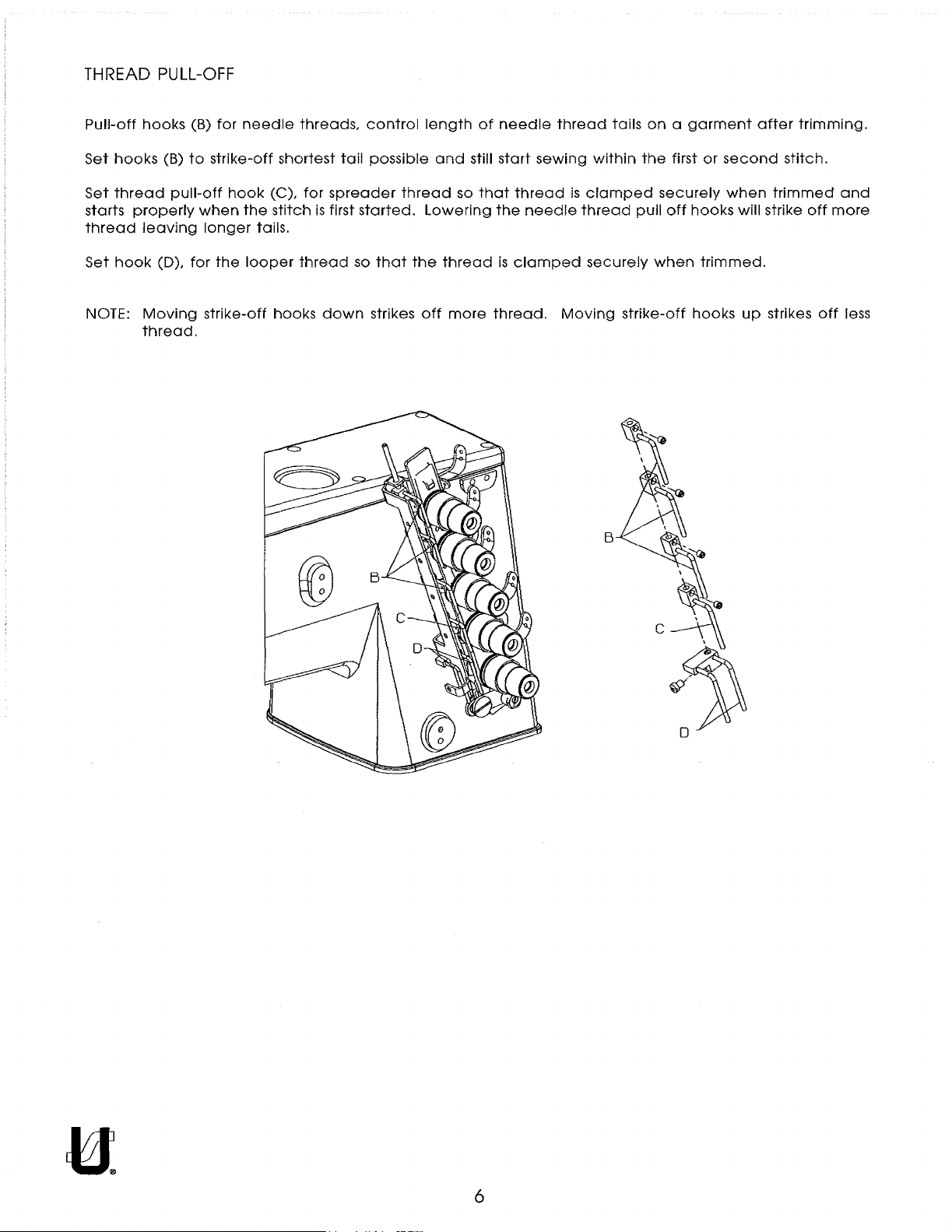

THREAD

PULL-OFF

Pull-off

Set

hooks

Set

thread

starts

thread

Set

hook

NOTE:

hooks

(B)

pull-off

properly

leaving

(D),

Moving

thread.

(B)

for

to

strike-off

hook

when

longer

for

the

strike-off

needle

shortest

(C),

the

stitch

tails.

looper

hooks

threads,

tail

for

spreader

is

first

thread

down

control

possible

started.

so

that

strikes

length

and

thread

lowering

the

off

of

still

so

that

thread

more

needle

start

thread

the

needle

is

clamped

thread.

thread

sewing

is

Moving

tails

within

clamped

thread

securely

strike-off

B

on a garment

the

first

or

securely

pull

off

hooks

when

trimmed.

hooks

after

second

when

will strike

up

trimming.

stitch.

trimmed

off

strikes

off

and

more

less

6

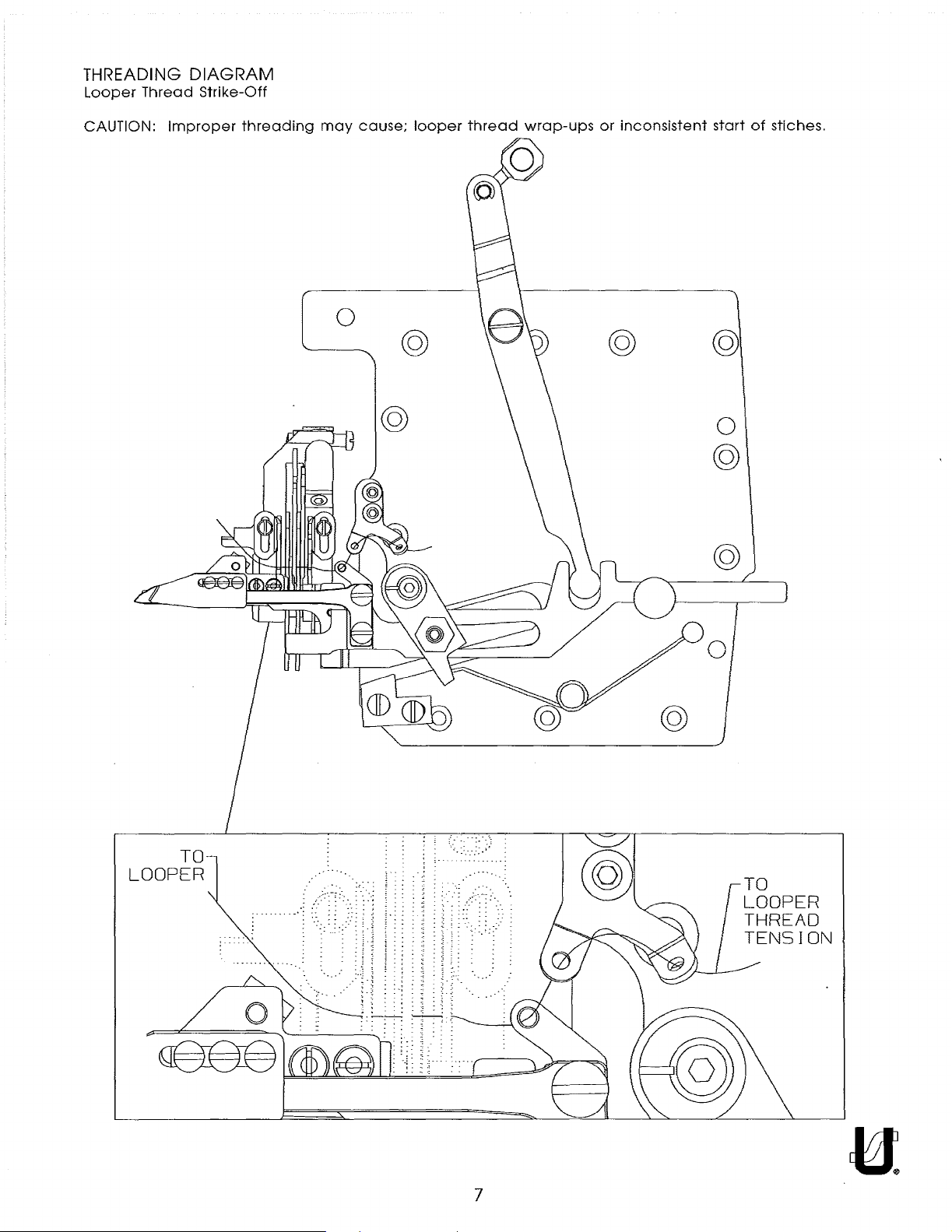

THREADING

Looper

Thread

DIAGRAM

Strike-Off

CAUTION:

Improper

threading

may

0

cause;

@

looper

@

thread

wrap-ups

or

inconsistent

@

start

@

0

@

of

stiches.

TO

LOOPER

:"

/::·--:::. - .

..

~

. . .:-~ .

@

-·

TO

LOOPER

THREAD

TENSION

7

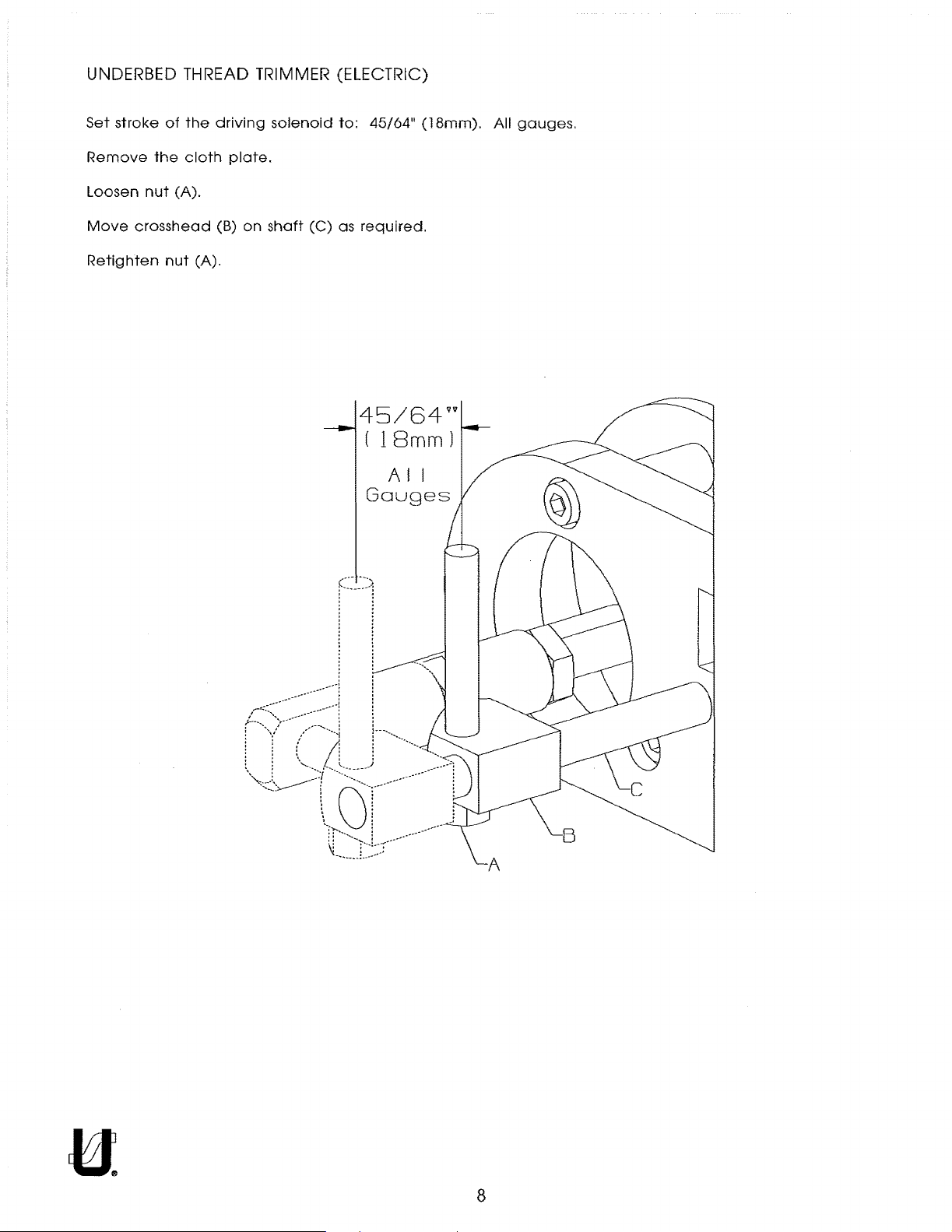

UNDERBED THREAD TRIMMER (ELECTRIC)

Set

stroke

Remove

Loosen

Move

Retighten

crosshead

the

nut

of

(A).

nut

the

cloth

(A).

driving

plate.

(B)

on

solenoid

shaft

(C)

to:

45/64

as

required.

45/64vv

(

18mm)

AI

Gouges

11

(18mm).

I

All

gauges.

8

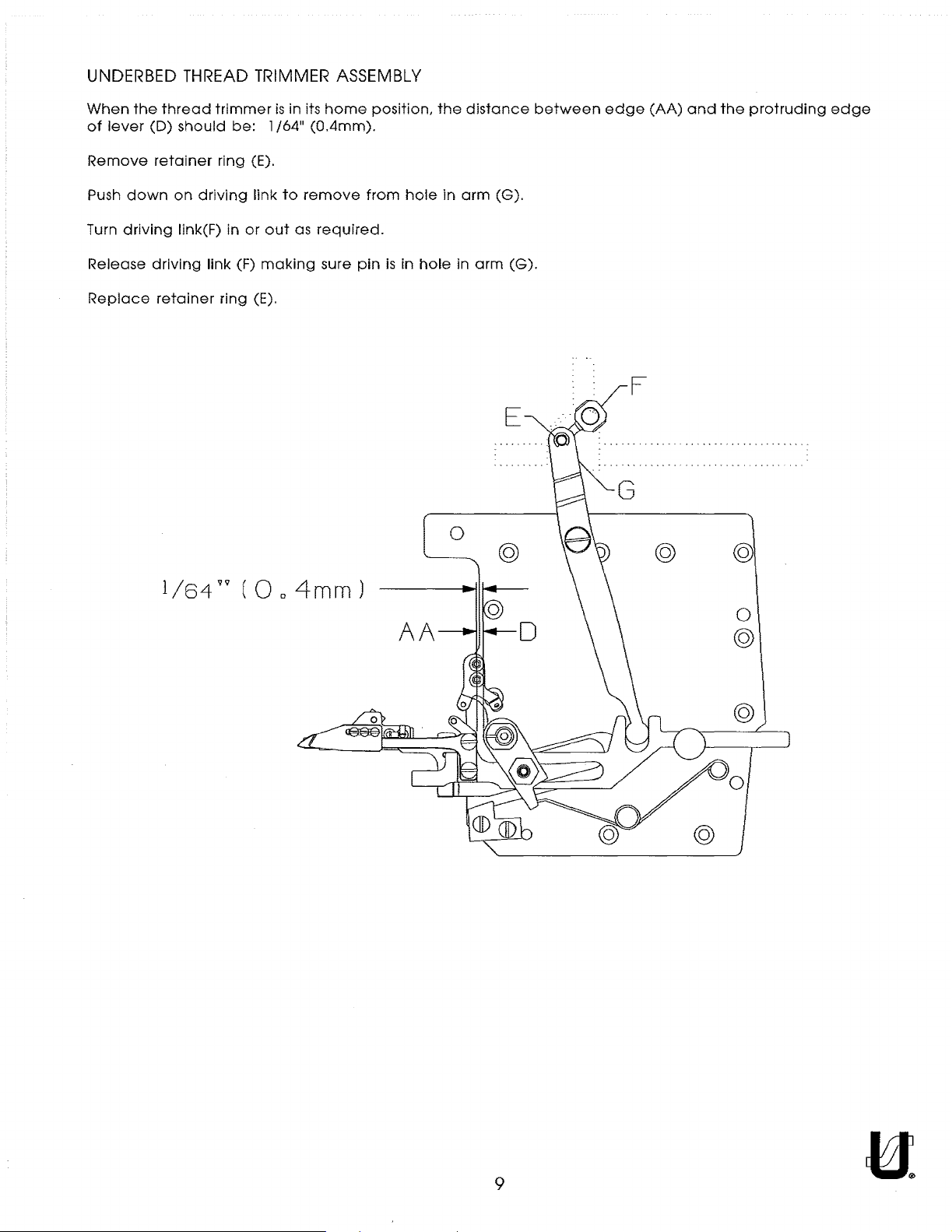

UNDERBED

THREAD

TRIMMER

ASSEMBLY

When

of

Remove

Push

Turn

Release

Replace

the

lever

down

driving

thread

(D)

should

retainer

on

link(F) in

driving

retainer

trimmer

be:

ring (E).

driving

link (F)

ring (E).

1/64

link

or

out

making

is

to

in its

as

home

11

(0.4mm).

remove

required.

sure

position,

from

pin

is

hole

in

hole

the

in

in

0

distance

arm

(G).

arm

E

@

between

(G).

edge

(AA)

and

the

protruding

edge

l/64v'l

(0o4mm)

0

@

@

9

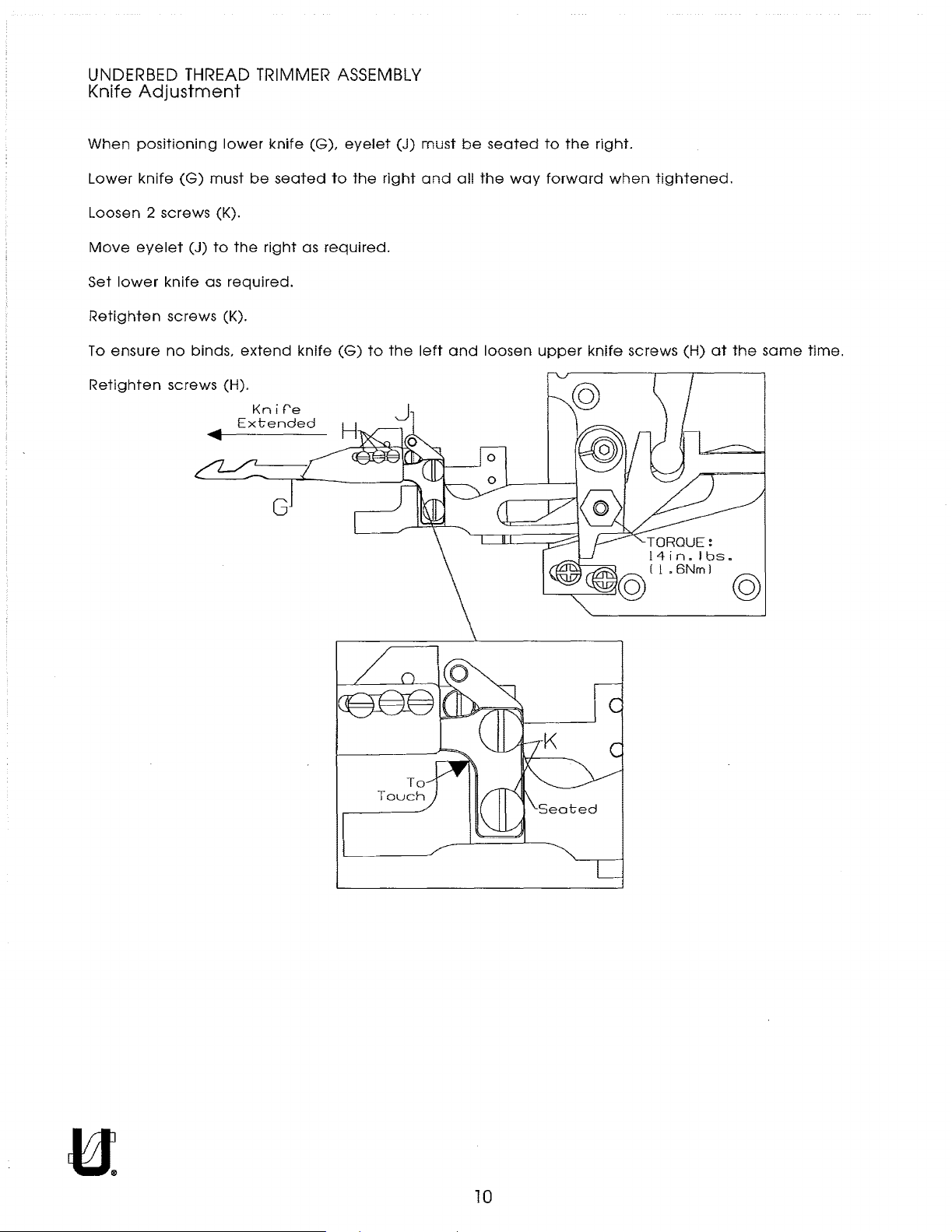

UNDERBED

Knife

Adjustment

THREAD

TRIMMER

ASSEMBLY

When

Lower

Loosen 2 screws (K).

Move

Set

Retighten

To

Retighten

positioning

knife

eyelet

lower

ensure

lower

(G)

must

(J)

to

knife

as

required.

screws (K).

no

binds,

screws (H).

knife

be

seated

the

right

extend

Knif'e

Extended

(G),

as

required.

knife

eyelet

to

the

(G)

to

(J)

right

the

must

and

left

be

all

and

seated

the

way

loosen

to

the

right.

forward

upper

when

knife

tightened.

screws

(H)

at

TORQUE:

14

in. I bs

._______,.,.--------.:=..1@

I l • 6Nm I @

the

•

same

time.

10

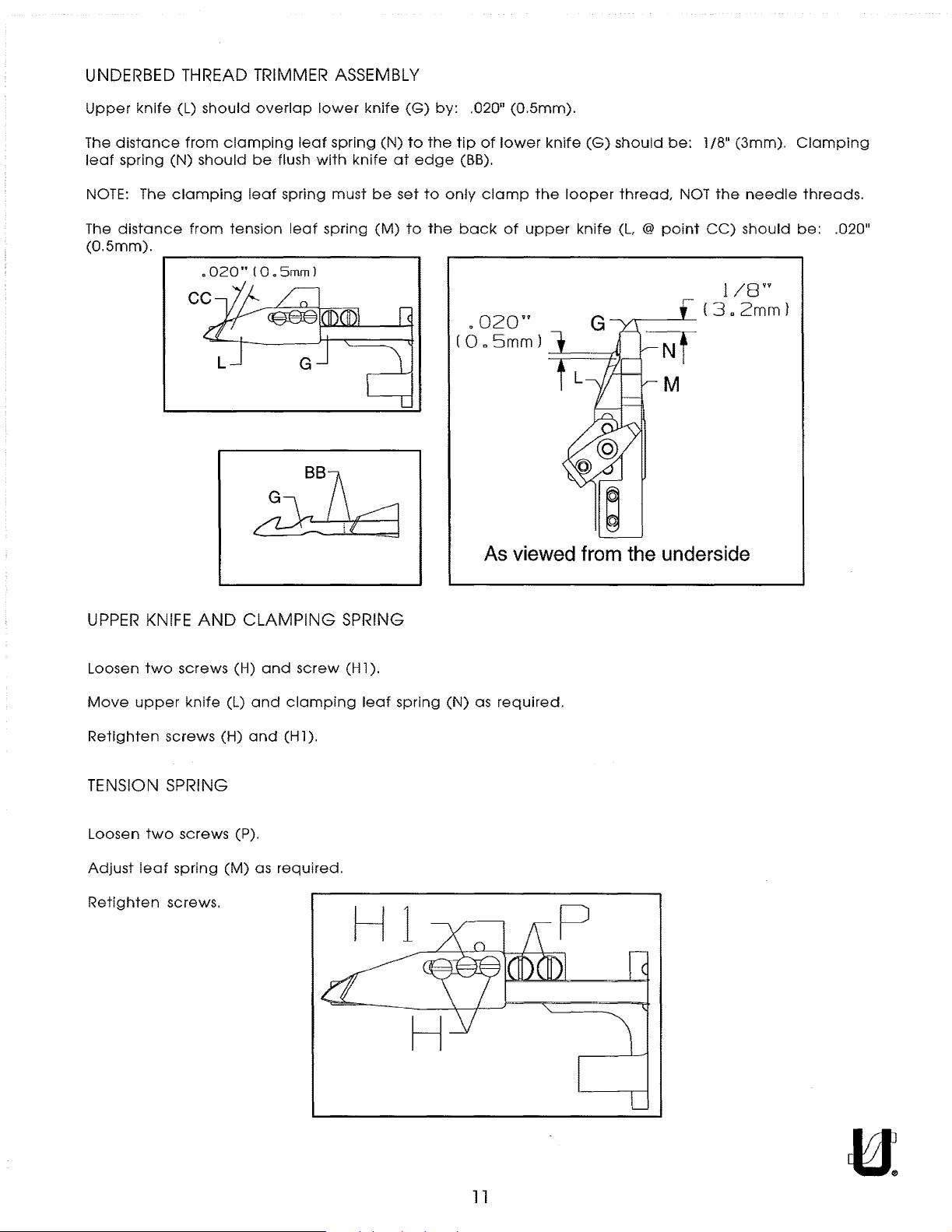

UNDERBED THREAD TRIMMER ASSEMBLY

Upper

The

leaf

knife

distance

spring (N)

(L)

from

should

clamping

should

overlap

be

flush

leaf

with

lower

spring

knife

knife

(N)

at

(G)

to

by:

the

edge

.020

tip

(BB).

of

11

lower

(0.5mm).

knife

(G)

should

be:

l/8"

(3mm).

Clamping

NOTE:

The

The

distance

(O.Smm).

UPPER

clamping

KNIFE

leaf

from

tension

o020"10o5mml

AND

CLAMPING

spring

leaf

must

spring

SPRING

be

(M)

set

to

to

only

the

back

o02Qn

(0o5mm)

clamp

of

the

upper

looper

knife

thread,

(L

@

point

NOT

the

CC)

} /Bvv

~-_I_

(3a2mm)

As viewed from the underside

needle

should

threads.

be:

.020

11

Loosen

Move

Retighten

two

upper

screws (H)

screws

knife (L)

TENSION SPRING

Loosen

Adjust

Retighten

two

leaf

screws.

screws (P).

spring

(H)

(M)

and

and

and

as

screw

clamping

(H

l ).

required.

(H

1 ).

leaf

spring

(N)

as

required.

ll

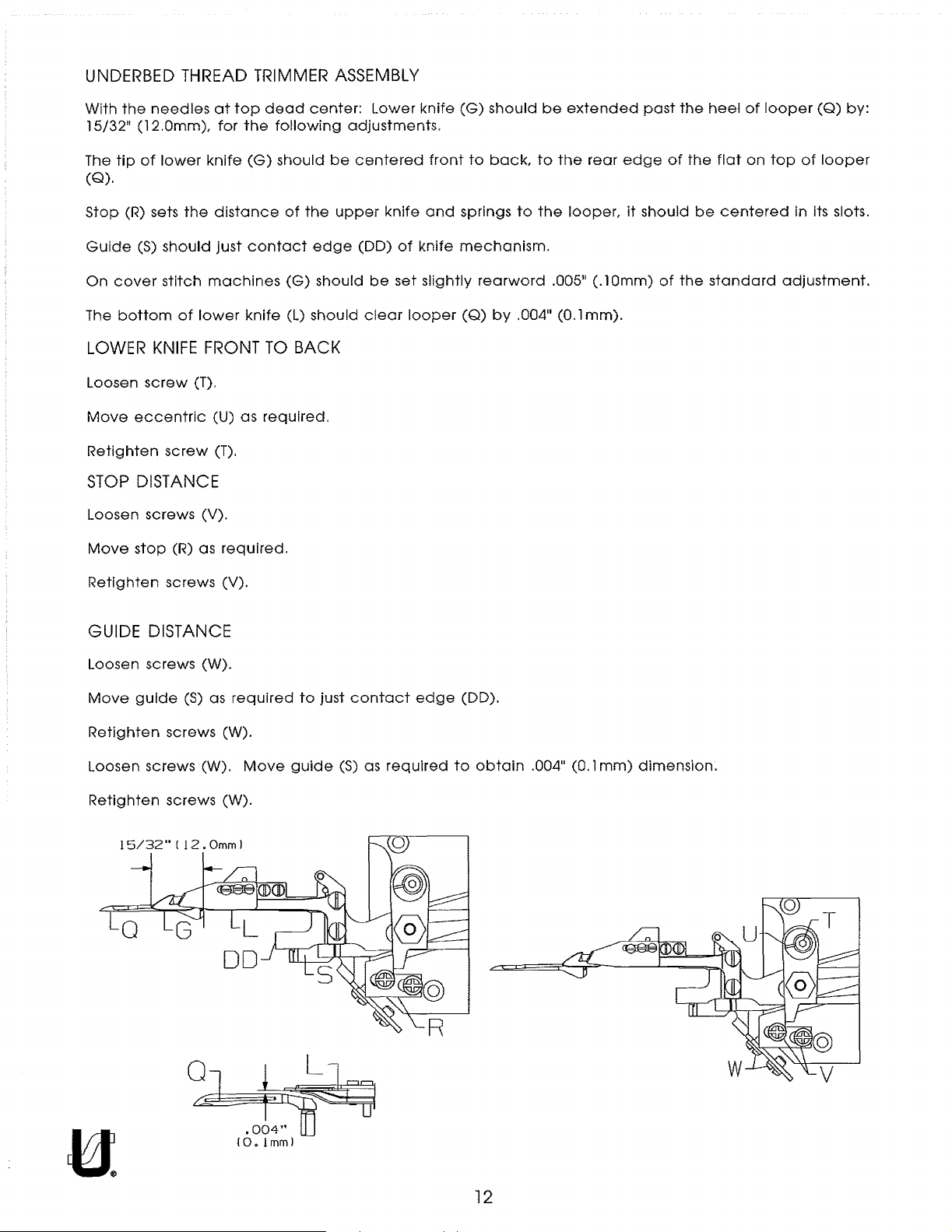

UNDERBED

With

the

needles

11

15/32

The

(Q).

Stop

(12.0mm),

tip

of

(R) sets

lower

THREAD

at

top

for

knife

the

distance

TRIMMER

dead

the

following

(G)

should

of

ASSEMBLY

center:

adjustments.

be

the

upper

Lower

centered

knife

knife

front

and

(G)

should

to

back,

springs

to

be

extended

to

the

the

rear

looper,

past

edge

it

should

of

the

the

heel

flat

be

centered

of

on

looper

top

of

in its slots.

(Q)

by:

looper

Guide

On

The

LOWER

Loosen

Move

Retighten

STOP

Loosen screws (V).

Move

Retighten

(S)

should

cover

stitch

bottom

KNIFE

screw

eccentric

screw

DISTANCE

stop

screws

of

(T).

(R)

just

machines

lower

FRONT

(U)

(T).

as

GUIDE DISTANCE

Loosen screws (W).

Move

guide

(S)

as

contact

knife

TO

as

required.

required.

(V).

required

edge

(G)

(L)

should

BACK

to

should

just

contact

(DO)

be

clear

of

set

looper

edge

knife

slightly

mechanism.

rearward

(Q)

by

.004

(DO).

.005

11

(0.1

11

(.lOmm)

mm).

of

the

standard

adjustment.

Retighten

Loosen screws (W).

Retighten

screws

screws

15/32" ( 12.

Omm

0 i

~

(W).

Move

(W).

l

10.1mml

guide

(S)

as

required

q~

to

obtain

.004

11

(0.1

mm)

dimension.

12

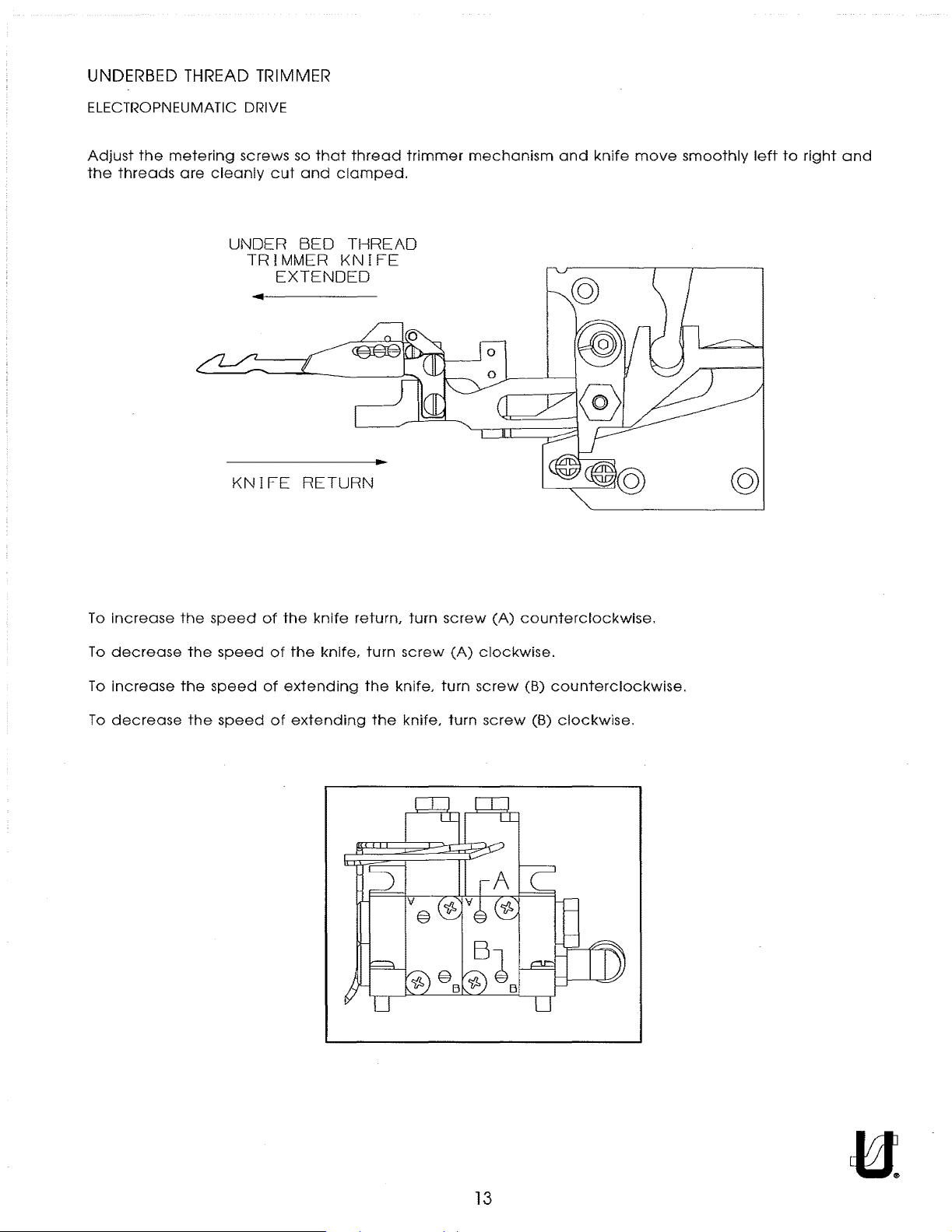

UNDERBED

ELECTROPNEUMATIC DRIVE

THREAD

TRIMMER

Adjust

the

threads

the

metering

are

cleanly

screws so

cut

UNDER

TRIMMER

EXTENDED

KNIFE

that

thread

and

clamped.

BED

THREAD

KNIFE

RETURN

trimmer

mechanism

and

knife

move

smoothly

@

left

to

right

and

To

increase

To

decrease

To

increase

To

decrease

the

the

the

the

speed

speed

speed

speed

of

the

of

the

of

extending

of

extending

knife

knife,

return,

turn

the

the

turn

screw

knife,

knife,

screw

(A)

turn

turn

(A)

counterclockwise.

clockwise.

screw

screw

(B)

(B)

counterclockwise.

clockwise.

13

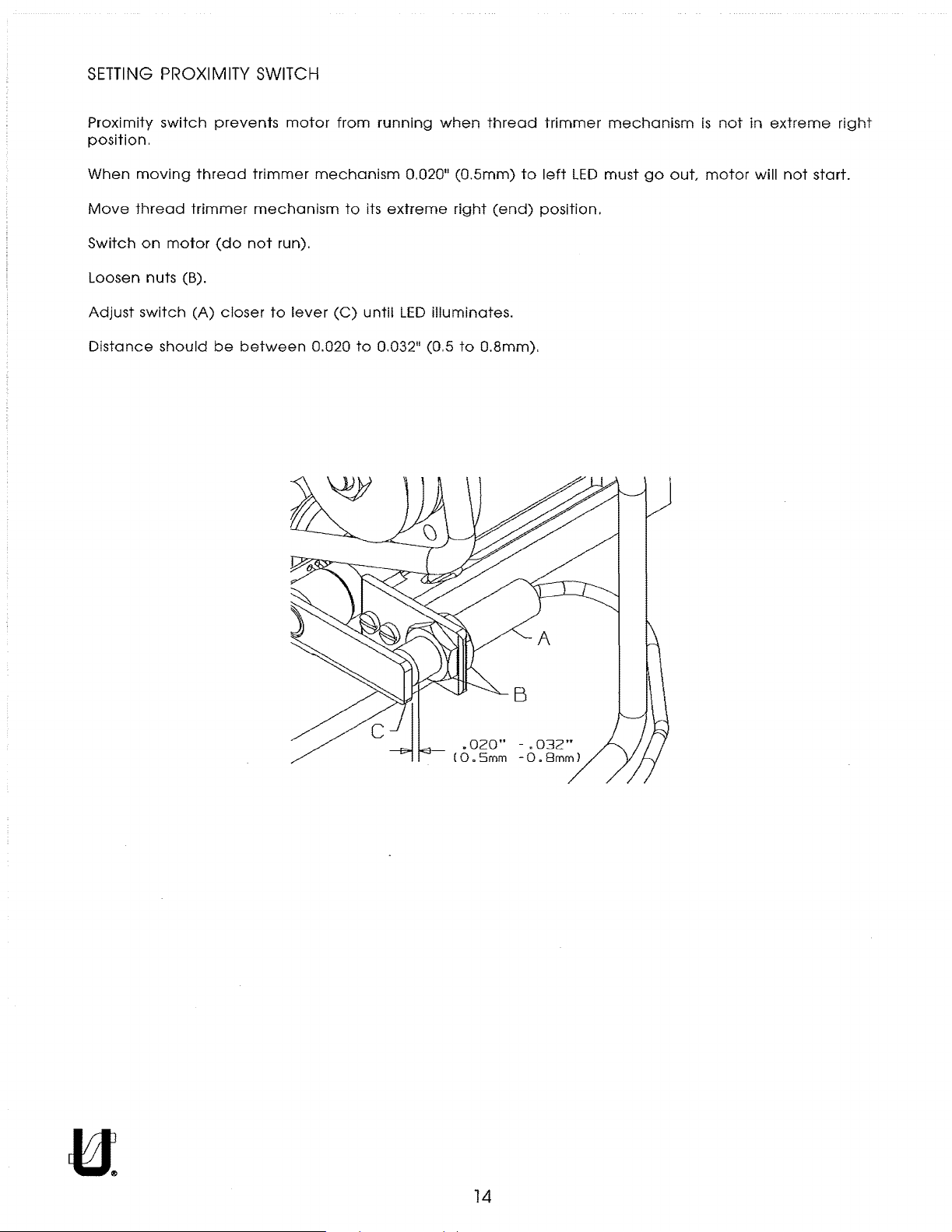

SETTING

PROXIMITY

SWITCH

Proximity

switch

position.

When

Move

Switch

moving

thread

on

motor

thread

trimmer

Loosen nuts (B).

Adjust

Distance

switch

should

(A)

prevents

trimmer

mechanism

(do

not

closer

be

between

motor

run).

to

lever

from

running

mechanism

to

its

(C)

until

0.020

to

0.032

0.020

extreme

LED

illuminates.

11

(0.5

when

11

(0.5mm)

right

to

thread

to

(end)

0.8mm)

trimmer

left

LED

position.

.

mechanism

must

go

out

is

not

motor

in

extreme

will

not

right

start.

.

020"

(0.5mm

14

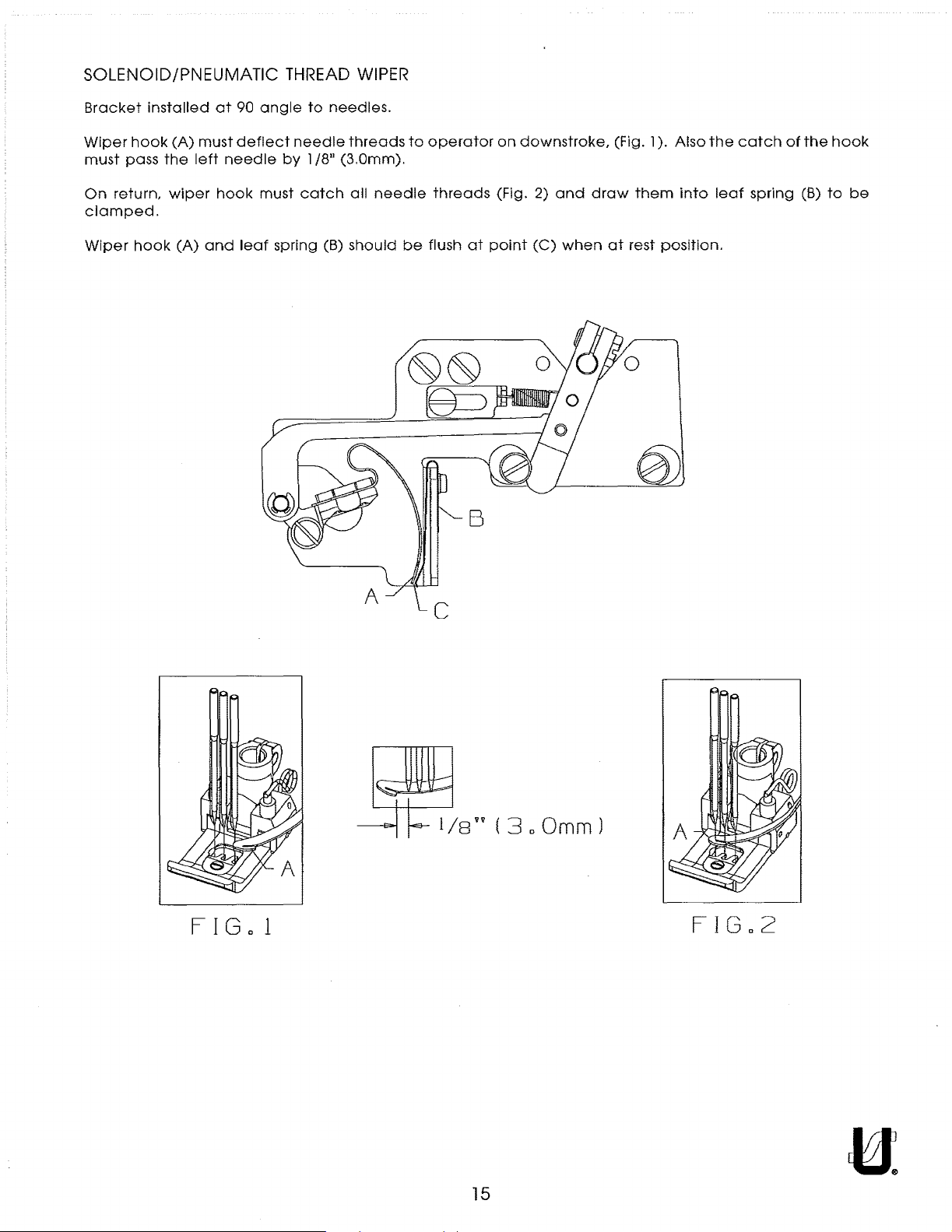

SOLENOID/PNEUMATIC

THREAD WIPER

Bracket

Wiper

hook

must

pass

On

return,

clamped.

Wiper

hook

installed

(A)

must

the

left

wiper

(A)

at

needle

hook

and

90

angle

deflect

must

leaf

spring (B)

to

needle

by l /8

catch

needles.

threads

11

(3.0mm).

all

needle

should

to

be

operator

threads

flush

at

B

on

downstroke,

(Fig. 2)

point

(C)

and

when

(Fig. l ). Also

draw

them

at

rest

the

into

position.

catch

leaf

of

the

spring (B)

hook

to

be

FIG

Jf,t

o 1

..

(

3.0mm)

15

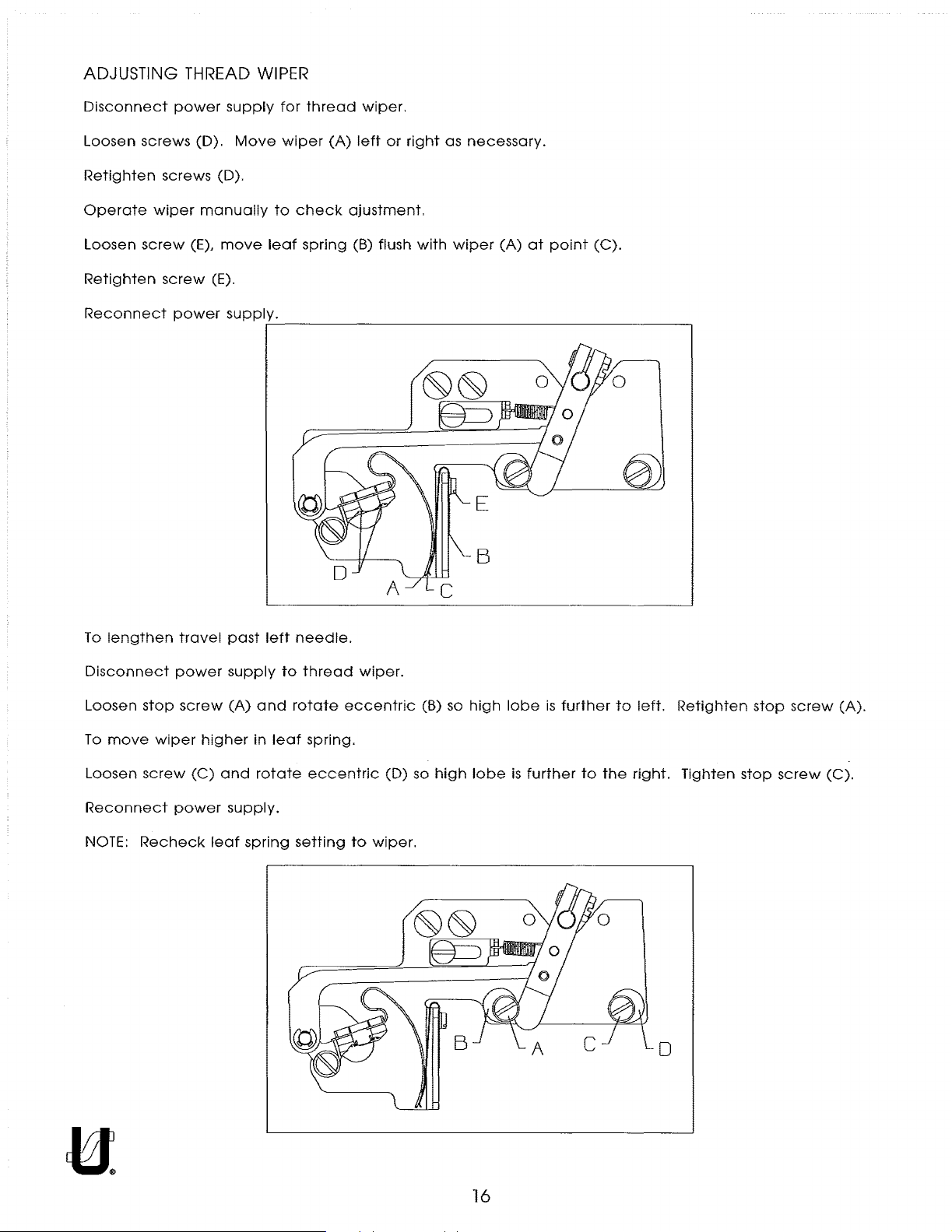

ADJUSTING THREAD WIPER

Disconnect

Loosen screws (D).

Retighten

Operate

Loosen

Retighten

Reconnect

power

screws (D).

wiper

screw

(E),

screw

power

manually

(E).

supply

move

supply.

for

thread

Move

wiper

to

check

leaf

spring

r-----------------------------------------~

wiper.

(A)

left

ajustment.

(B) flush

or

right

with

as

necessary.

wiper

(A)

at

point

(C).

To

lengthen

Disconnect

Loosen

To

Loosen

Reconnect

NOTE:

stop

move

screw

Recheck

travel

power

screw

wiper

power

higher

(C)

leaf

past

supply

(A)

in

and

supply.

spring

left

to

and

leaf

rotate

needle.

thread

rotate

spring.

eccentric

setting

wiper.

eccentric

(D)

to

wiper.

(B) so

so

high

high

lobe

lobe

is

further

is

further

to

to

the

left.

right.

0

Retighten

Tighten

stop

stop

screw

screw

(A).

(C).

16

Loading...

Loading...