Page 1

®

INDUSTRIAL

SEWING

FINEST QUALITY

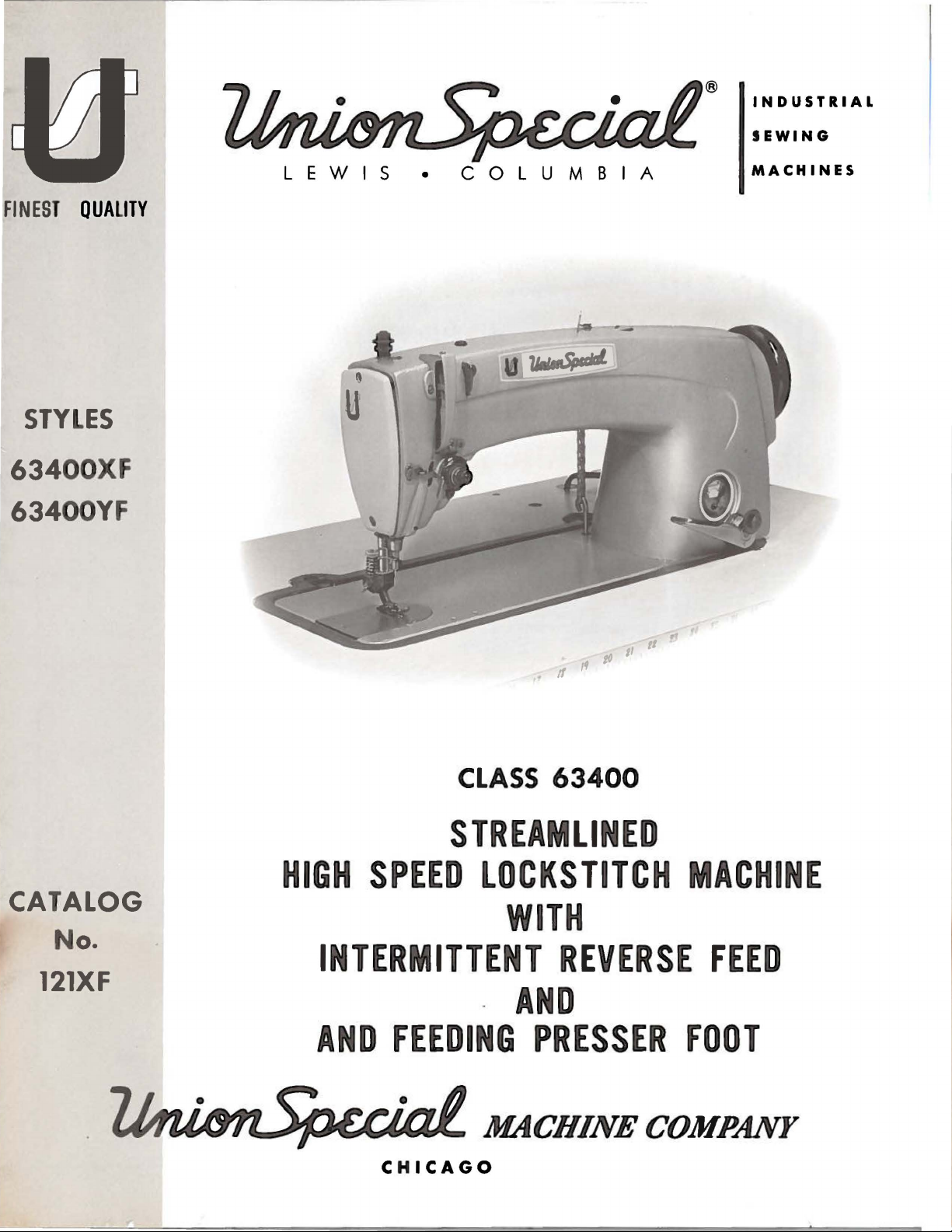

STYLES

63400XF

63400YF

LEWIS

•

COLUMBIA

MACHINES

CATALOG

No.

121XF

CLASS

STREAMLINED

HIGH

SPEED

LOCKSTITCH

INTERMITTENT

-

AND

FEEDING

II

to

d

If

63400

WITH

REVERSE

AND

PRESSER

II

MACHINE

FEED

FOOT

CHICAGO

Page 2

Here

are

Oil

for

Specifications

Union

Sewing

roleum

mended

machine

roleum

white

1.

mount.

roleum

high

mitters.

3.

used.

UN

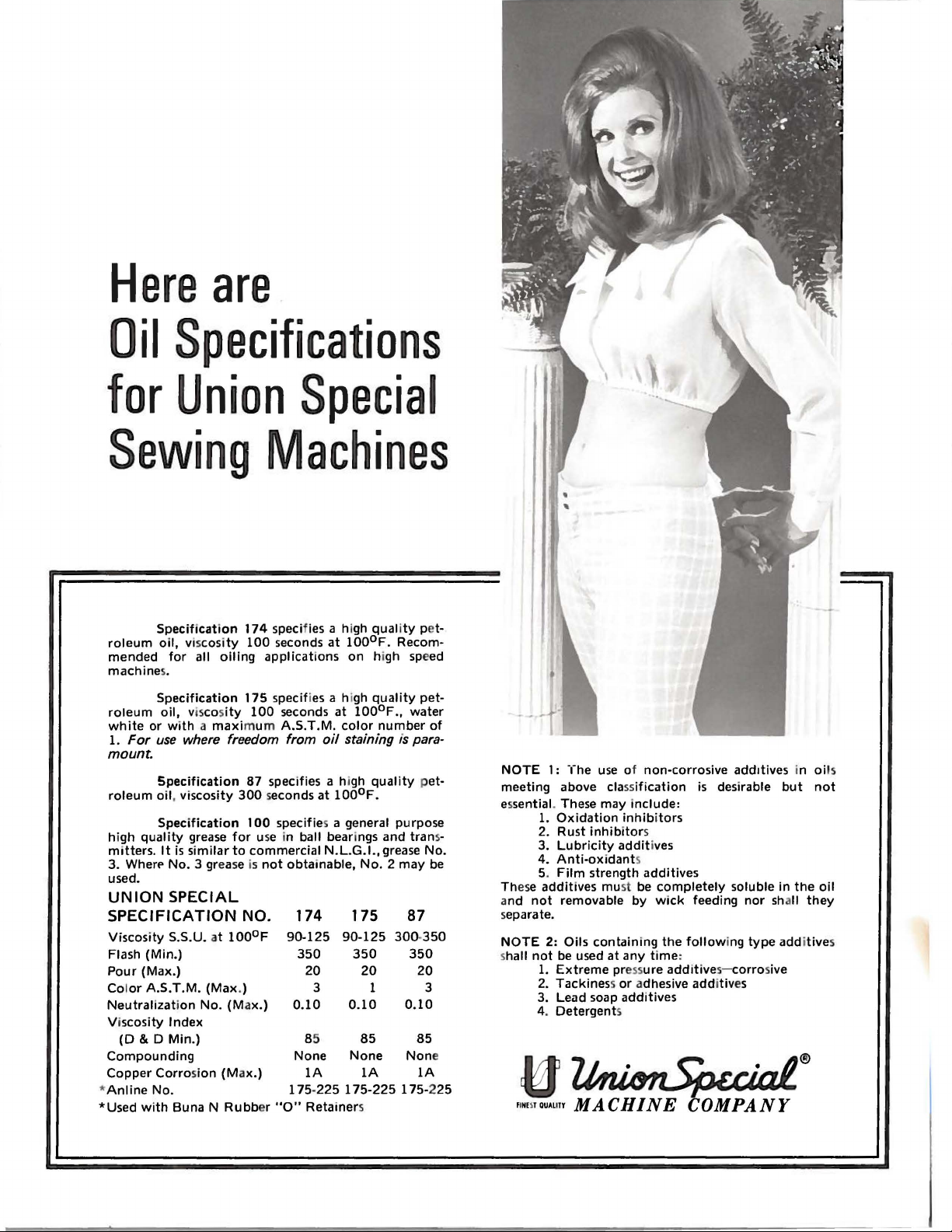

Specification

oil, vis

s.

Specification

oil,

or

For

use

Specification

oil

Specification

quality

It

WherE>

ION

for

all

viscos

with a maxi

where freedom

, viscosity

grease

is

similar

No.

3 gr ease is

SPECIAL

SPECIFICATION

Viscosity

Flash

Pour

Col

Neutralization

Viscosity

(0

Compounding

Copper

"

Anline

*Used

S.S.U. at

(Min.)

(Max.)

or

A.S.T.M.

Index

& D

Min.)

Corrosion (Ma

No.

with

Buna N

174

cosi

ty

100

oiling

175 specifi

ity

100

mum

87 specifies a hi

300

100

for

to

commercial

NO. 174 175

l00°F

(Max

.) 3 1 3

No. (Ma

x.)

x.)

Rubb

Special

Machines

specif

ies

es

from

obta

inable,

90-125

350

20

0.10

85

None

1A

1 75-

225

Retainers

a high qual i

at

100°F.

on

a hi

gh

100°F

color

oil

staining is para-

gh

100°F.

N.L.G.I.,

90-125

350 350

0.10 0.10

None

175-225

seconds

applications

seconds at

A.S.T.M.

seconds at

specifies a general purpose

use in ball bearings and

not

er

"0"

ty

Recom-

high speed

quality

••

water

number

quality

tran

grease

No. 2 may

87

300-350

20

85

Non

1A

1 75-225

pet-

pet-

of

pet-

s-

No.

be

20

85

e

1A

..

NOTE

meeting above classification

essential. These

These additives mu

a

separate.

NOTE

shall

1: "fhe

1.

2. Rust

3.

4.

5.

nd

not

2: Oils

not

1.

2.

3. Lead soap additives

4.

use

may

Oxidation

inhibitor

Lubricity

Anti-oxidant

Film

strength

removable

containing

be

used at

Extreme press

Tackiness

Detergent

of non-corrosive additives in

include:

inhibitors

s

additives

s

additives

st

be

completely

by

wick

the

any

time

ure

or

s

additives-corro

adhesive addi

is

desirable

feeding

following

:

soluble in

nor sha

type

tiv

es

sive

but

ll

addi

the

®

oil

not

oil

they

tive

s

s

Page 3

(S

u p p l e m e n t

atalo

C

g N

to

o.

Catalo

121

g N

XF

o.

121

M )

INSTRUCTIO

ADJUSTING

LIST

Streamlin

63400

XF

AND

CLASS

Styl

FOR

OF

e d

OPERA

PARTS

63400

Locksti

e s

6 3

NS

400

T I

t c h

YF

NG

Copyri

Union

Rights

Special

R e

served

MACHINE

INDUSTRIAL

P r

Fir

s t

g

ht

by

COMPANY

SEWING

CHICAGO

int

d i n U

Ed

i t i

@

Ma

i n

on

19

7 2

chin

All

MACHINES

.S.

e

Countr

A .

Co.

i

es

October.

197

2

3

Page 4

IDENTIFICATION

OF

MACHINES

Each

the

machine.

numbers

Example:

only

minor

Style

number.

Styles

which

differs

"Class

This

junction

not

used

Opposite

number,

NOTE:

Adjusting

those

ions

B,

inCatalog

included

or

are

Union

Sty

have

one or

"Style 63400

changes

Example:

of

machines

from

63400

11

•

catalog

therewith.

on

Styles

the

description

When

ordering

column.

and

in

additional

Spe

cial

machine

le

numbers

more

XF".

are

made

are

letters

Special

in a standard

"Style

similar

lhe

style

APPLICATION

is a supplement

Only

those

parts

63400 A and B are

illustration

and

amount

operating

No.

121M

this

catalog

repair

parts

instructions

for

Styles63400

are

instructions

is

identified

classified

63400

in

construction

number,

to

Catalog

which

page,

required.

always

the

ones

that

pertain

by a Style

as

standard

suffixed,

Style

numbers

machine, a "Z"

XFZ".

in

that

OF

CATALOG

No.

are

used

illustrated

parts

are

use

for

Styles

A

and

that

are

specifically

number

and

but

never

contain

are

grouped

it

contains

121 M

and

on

Styles

listed

and

identified

the

part

number listed

63400

Brespectively.

different

to

on a name plate on

special.

contain

the

is

suffixed

under a class

no

should

63400

at

the

by

detail

XF

and

from

Styles

Styles

Standard

the

letter

to

letters.

be

XF

oack

number,

in

YF

are

The

onlyinstruct-

63400

Styl

lett

er " Z

"Z".

the

used

and

of

Wh

Standard

numb

Examp

in

con-

YF,

this

book.

en

er

l :

bu

par

the

second

similar

to

63400 A and

XF

and

YF.

e

".

t

t

This

herein.

this

class.

from

It

the

catalog

operator's

handwheel

Streamlined,

Feed,

justable

Thread

63400

Automatic

Hook

Tension.

XF

on

light

necessary.

bar

travel.

range 7 to

size,

pending

63400

YF

on

medium

tacking

inchneedle

Stitch

type

and

-

depending

applies

can

also

be

Reference

position

is

toward

Flat

the

Bed,

Lubrication,

Oil

Supply,

For

attaching

to

medium

The

reverse

Se

am

18

per

attachment

on

operation.

For

attaching

to

medium

are

necessary.

bar

travel.

range 7 to

size, attachment

on

operation.

specifically

applied

to

direction,

operator.

Lockstitch

Equipped

pockets

weight

Spec.

inch.

and

guide.

pockets

heavy

Seam

18

per

with

while

STYLES

Gauged

to

material,

feed

can

301-SSa-1.

Specify

Maximum

to

weight

The

reverse

Spec.

inch.

and

guide.

to

the

Standard

discretion

such

as

seated

OF

Machine,

Oil

to

right,

at

MACHINES

with

Supply,

with a Feeding

shirt

fronts

where

be

used

for

Type

stitches

per

recommended

shirt

fronts

and

material,

feed

can

301-SSa-1.

Specify

stitches

Maximum

Styles

some

the

Special

left,

machine.

Intermittent

Adjustable

Presser

and

similar

matching

back-tacking.

180

GXS

inch,

similar

where

be

used

Type

per

recommended

front,

Foot

plain

plies

or

thread

speed

plain

matching

for

180GXS

inch,

of

machines

Styles

back,

Operating

Reverse

Feed

and

seaming

and

back-tacking

1

9/64

180

GYS

size,

5500

seaming

back-tackin

or180

thread

speed

as

of

machines

etc.,

are

di

rection

and

Eccentric,

Rotary

operations

inch

needle.

needle

R.

type

P.M.

operations

plies

and

g. 1

GYS

size,

5500

R.

listed

in

given

of

Plain

Ad-

Needle

are

needle

Stitch

and

-

de-

back-

13/64

needle.

needle

P.M.

4

Page 5

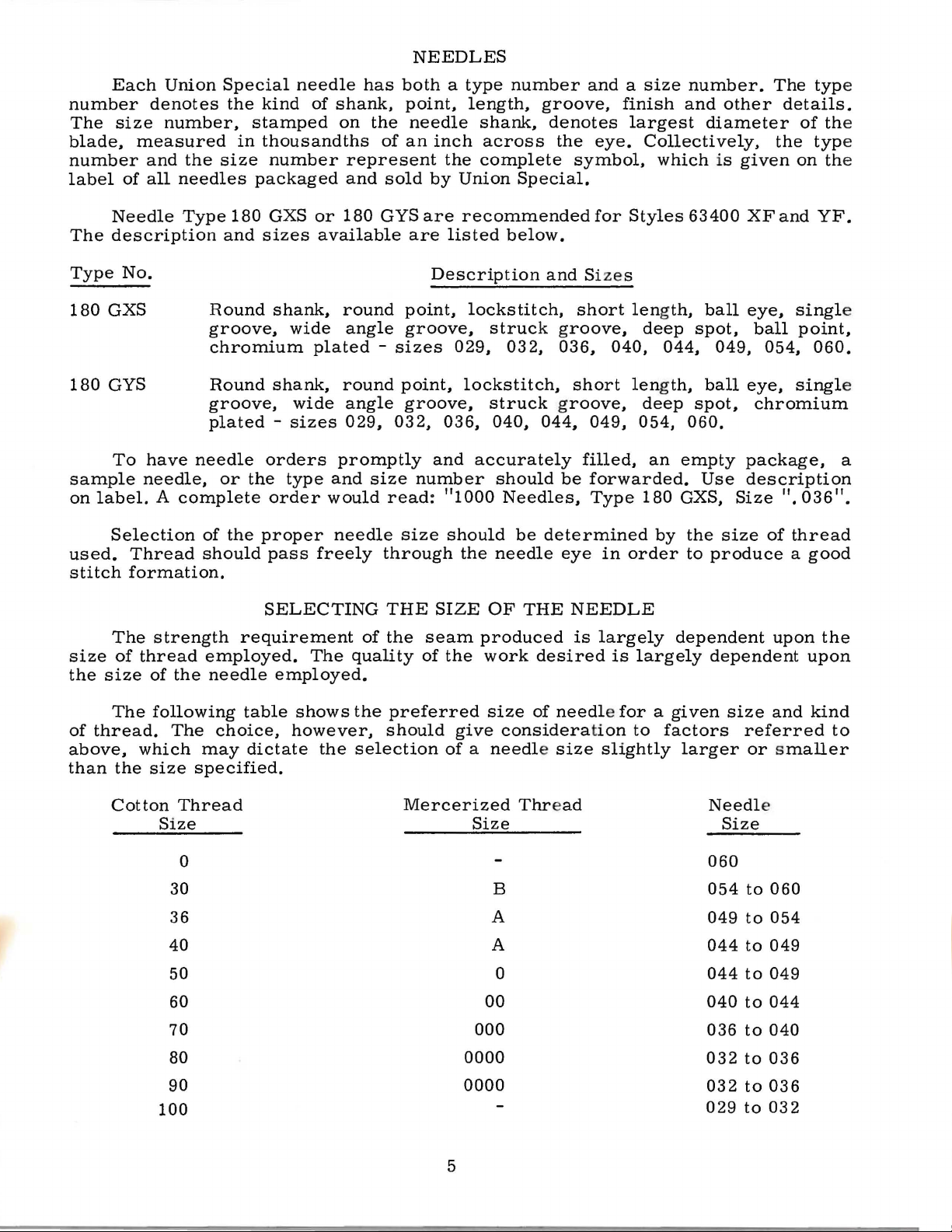

NEEDLES

Each

number

The

size

blade,

number

label

Needle

The

description

Type

180

GXS

180

GYS

To

sample

on

label.

Selection

used.

stitch

Union

denotes

number,

measured

and

the

of

all

needles

Type

No.

have

needle,

A

complete

Thread

formation.

Special

the

kind

stamped

in

thousandths

size

number

packaged

180

GXS

and

sizes

Round

groove,

shank,

wide

chromium

Round

groove,

shank,

wide

plated -sizes

needle

or

orders

the

type

order

of

the

proper

should

pass

needle

of

has

shank,

on

the

of

represent

and

sold

or

180

GYS

available

round

angle

plated -sizes

round

angle

029,

032,

promptly

and

size

would

read:

needle

freely

through

both a type

point,

needle

an

are

length,

shank,

inch

by

are

across

the

complete

Union

recommended

listed

Description

point,

groove,

lockstitch,

struck groove,

029, 032, 036, 040, 044,

point,

groove,

lockstitch,

struck

036,

and

accurately

number

"1000

size

should

the

number

groove,

Special.

below.

040,

044,

should

Needles,

be

determined

needle

and a size

denotes

the

eye.

symbol,

for

and Siz

short

short

groove,

049,

filled,

be

forwarded.

Type

eye

finish

largest

Collectively,

which

Styles

es

length,

deep

length,

deep

054,

an

180

by

in

order

number.

and

other

The

diameter

the

is

given

63400

spot,

ball

XF

eye,

ball

and

049, 054,

ball

eye,

spot,

chromium

060.

empty

GXS,

the

to

package,

Use

description

Size

size

of

produce a good

typ

details.

of the

typ

on the

YF.

singl

point,

060.

singl

".

036".

thread

e

e

e

e

a

The

size

the

size

The

of

thread.

above,

than

Cotton

of

the

thread

which

strength

employed.

of

the

needle

following

The

choice,

may

size

specified.

Thread

Size

0

30

36

40

50

60

70

80

SELECTING

requirement

The

employed.

table

shows

however,

dictate

the

THE

of

the

quality

the

preferred

should

selection

Mercerized

SIZE

seam

of

the

give

OF

THE

produced

work

size

of

consideration

of a needle size

Thread

Size

B

A

A

0

00

000

0000

NEEDLE

is

largely

desired

is

largely

needle for a given

to

factors

slightly

dependent

dependent

size

referred

larger

or smaller

Needl

Size

060

054

to

049

to

044

to

044

to

040

to

036

to

032

to

upon

and

e

060

054

049

049

044

040

036

the

upon

kind

to

90

0000

100

5

032

029

to

to

036

032

Page 6

IDENTIFYING

PARTS

Where the

Parts

which

too

dist

Part

appear.

IMPORTANT!

OF

MACHINE

The

arrangement

replacement

The

exploded

Styles

Each

position.

their

view

listed

plate

On

part

being

Numbers

the

position

in

ordering

exploded

view

construction

small

inguish

numbers

for a complete

one

part

r e

present

ON

ALL

FOR

WHICH

of

parts

in

for

view

this

catalog and

Styles

plates

presents a sector

the

page

numbers,

opposite the

descriptions

shown.

in

the

first

of

the part

parts.

plate

in

Always

carries

permits,

catalog

from

the

another

same

ORDERS,

PART

IS

ORDERING

this

catalo

63400

at

the

Styles

of

the

machine,

illustration

and

column are

the

illustration.

use

the

a

reference

each

stamp

that

part, rega

PLEASE

ORDERED.

OF

REPAIR

g i s

XF

back,

to facilitate easy and

and

cov

63400

the

number

reference

Reference

part

number

number

part

is

stamp

ing

are identified

is

simil

ar

rdless

in appearance.

of

INCLUDEPARTNAME

PARTS

YF.

er

the

differenc

A a

nd B cover

parts

being aligned

will

be

found a listing

of

piec

numbers

es r e

only,

numbers should

listed

for

in the

each

ed

with

its

by letter

the

catalo

accurate

es

between the Sta

ed in

Catalog No.

as

in

quired

and

second

part

available

par t

g i n

which

AND

or de

numb

sy

mbol

they

STYLE

ring

e r .

ndard

121

M.

their assembled

of

the

par

ts

with

in

the

particular

merely indicate

never

b u

sed

column. Each

for s

ale.

s

of

Sub-assemblies,

or a solid

can

be

description

In

catalo

parts

in

the

Success in

Uni

on

Company,

to

the

line

box

furnished

of

the

those

g,

for the

cases

no spe

various

description,

Special

Ne

its subsidiaries

most approv

cific

the

Maximum efficiency

Genuine needl

parts are sta

g

uarantee

Prices

are

forwarded

of

are

mped

the hig

strictly

f.

which

on

the

for

repairs,

main

sub-assembly.

where a part

usage

machines

and,

if

U

SE

GENUINE

operation

edl

es

and

ed

scientific

and

es a

re

packaged

with

hest

quality

net

o.

b.

shipping

picture pla

will

necessary,

Repair

and

durability

the

cash

otherwise directed. A charge

are

sold

complete,

te.

are indicated

is

common

be

me

ntioned

are

not

NEEDLES

of these

Parts

authoriz

principles,

ar

with labels

Union

Speci

in

materials and wor

and

subject

point.

is

made

Component

by

to

in

the sam

e,

the diffe r e

AND

machin

as

furnished

ed distri

a

e assure

d.

mar

al trade

TERMS

to

Parc

el

to

cov

er the

or

by

separa

parts

indenting

all

of

the

description.

the

specific

nce

will

REPAIR

es

can

butors.

nd

are

ked

~

mark.

km

chan

ge wit

Po

st

shipment

post

te

the

of s

their

ma

part,

ub-assemblies,

descriptions

chines

are

covered

However,

be

usage

shown

will

in

the

PARTS

be

secured

by

the

They are

made

with

Union

designed

utmost

only

Special

. Ge

Each

ans

hout notice.

hip.

s ar e i

trade

All

nsured

age and i nsurance.

in a brack

which

unde r

by

wh

en the

be

mentioned

illustratio

with genuin

Machin

according

precision.

nuine

mark

rep

is

shipmen

unless

et

the

thi

n.

ai r

your

ts

s

e

e

6

Page 7

INSTALLING

CAUTION!

on

handwheel.

Before

carefully

packing

A

attaching

miscellaneous

Insert

the

upp

Includ

ing one bobbin

its clamp spring, one

a

nd

scr

e

ssenti

packed.

box,

bag

of

screw,

hinge

er

frame eyelet

ed also with each

ew,

four

al whe n s etting

When

Using

leaving factory,

After

the

following

PREPARATION

assembly

one

attachments

studs

wind

er

isolator

unpacking,

both

hands

each

the

machine

steps

parts,

extra

to

in

holes

(A,

Fig.

STANDARD

machine,

assembly,

knee

up

lifter

pads

the

DO

on

bed

Union

should

OF

MACHINE

consisting

bobbin,

the

bed

provided

2A).

the

assembly

and

clips,

machine.

NOT

is a box

machine

lift

castin

Special

and

be

two

plate,

ACCESSORIES

g,

accessories

follow

of one

hinge

is

for

them

of

and

and

one

machine

lift

machine

ed:

FOR

studs

packed

STANDARD

mounting frame,

its

rubber

machine

out

of

gently

INSTALLATION

frame

in

.

is

sewed

have

and

with

rear

been

thread

two

each

of

ACCESSORIES-

pad,

rest

box

by

placing

off,

inspected

removed

eyelet,

screws

machine.

cloth

bed

plate.

one

oil

drain

positioning spring

pin.

These

one

from

one

eyelet

for

holding

Assemble

-containjar

parts

hand

and

the

and

are

Lockstitch

t

he

be d

plate

On

a s

cu

t-out

throu

over right

th

e r

nuts lig

1/16

tai

ning pl

of the

as

show

mu

st

with

gh

left

eta

ining plate (21393

htly.

Pl

a ce sewing head

inch clea

board

Tip

ma chine ba ck

n.

not bind.

i s

uitabl

the

hin

ge pad a

hin

ge

r ance

ate s m a

and tighten

All

end play

ma

chin

es

FL

USH

MACHINE

e t

ableboard,

hin

ge lugs

nd tighten

pa d;

insert

between

rtly

upward

against the rest pin, a

of the

TABLE

are

install

with

the

MOUNTING

place

to

the rear (Fi

round head

R)

to

in

the

frame mountin

the

with a hamm

locking nuts secu

cross

ed

top

of

machine mounting

securely. Ass

outside

cloth

shaft should

TOPS

in

tabl

the

FRAME INSTALLATION

g.

wood

front of

pla

te edge and the

er

rely.

m a

1).

scr

g, a

to

nd ass

tops,

chine

Insert

emble

ew

pa n

nd

ins

be

prepared

mounting

frame

the

bed

positioning

and

tighten

section,

after

ure

a g

mble the kn

taken

up

(21393

countersunk

being

frame

ood

by the

with

frame.

N)

spring

securely.

as

shown, and

sure

sides,

grip

on

ee

cone

cut

-out,

in

the

wood

there

rap

the

press

bearings,

so that

machine

scr

ew

(63474

Assembl

snug up

is a

the

underside

assembly

A)

e

bout

r e -

but

7

Page 8

MACHINE

MOUNTING

FRAME

INSTALLATION

(Continued)

Before

lifter

maximum

within

raises

located

in

the

pulley

the

under

121M.

al

"THREAD

rod

the

approximately

The

directly

operation.

mechanism

of

belt

to

"Winding

These

Thread

requirements,

the

machine

should

lift

head.

bobbin

the

wind

machines

machine

CONTROL".

be

of

the

This

winder

in

The

to

winder,

the

the

adjusted.

presser

may

5/16

front

base

be

moved

when

bobbin.

Bobbin",

are

as

has

been

is

put

The

bar

be

done

inch.

should

of

the

sewing

of

the

winder

closer

in

operation,

Regulation

under

equipped

indicated

enlarged

Needle

into

production, the

left

stop

and

its

by

setting

BOBBIN

be

secured

machine

has

to

or

and

OPERA

BELTS

to

use

THREADING

in

Fig.

for

is

threaded

screw

parts

the

WINDER

to

the

belt

two

elongated

farther

should

operation

TOR'S

eith

er # 1

2A.

Check

clarity

from

do

bell

(22597

not

stop

table

and

away

exert

of

INSTRUCTIONS,

"Vee"

spring

and

left

crank

F)

interfere

screw

top

so

will

bear

attaching

from

only

enough

the

bobbin

or

threading

described

to

right.

should

(21665

with the

so

that

that

against

holes,

belt

winder

round

under

J)

be

set

moving

the

presser

its

pull

the

which

as

needed.

pressure

is

in

belts.

with

paragraph

of

the

knee

so

that

parts

bar

ey

will

belt

when

allow

The

agains

described

Catalog

dimension-

No.

Lhe

be

t

on

- 21664

Fig.

1

8

/

,/

6

3476C

Page 9

OILING

CAUTION!

the

reservoir

Fill

oil

is

be

added

straight

in

the

Oil

left

in

The

of

the

arrow

the

flow

It

long

period,

parts.

Run

machine

speed

Oil

has

main

at

maximum

when

mineral

main

may

the

oil

quantity

machine

must

reservoir

reservoir.

be

reservoir

level

needle

oil

drained

of

just

be

of a Saybolt

oil

below

(counterclockwise)

of

oil.

is

recommended

be

lubricated

After

operation

oiling,

slowly

can

replace

for

then

been

filled

at

plug

when

is

in

yellow

This

from

cover.

supplied

the

increases

that a new

by

several

be

expected

drained

before

screw

needle

is

equivalent

main

to

cloth

removing

head

minutes

from

starting

(B,

is

in

band

marked

viscosity

reservoir

the

hook

plate.

the

oil

machine,

cover

without

the

to

Fig.

yellow

of

to

is

Turning

flow

or

the

as

no

to

distribute

main

operate.

2A)

and

band

"LOW".

90

to

125

Union

by

removing

controlled

and

in a clockwise

one

that

head

cover

further

damage.

reservoir

check

oil

marked

Use a stainless

seconds

Special

specification

plug

by

dial

the

dial

in

has

been

and

hand

oil

to

oiling

the

before

level

"FULL".

at

100°

screw

located

the

direction

direction

out

of

oiling

will

various

shipment

at

gauge

Oil

water-white

Fahrenheit

No.

located

on

the

decreases

service

all

the

be

required.

parts.

and

(C);

should

175.

on

the

front

of

the

for

moving

Full

a

WRAP

ROTARY

2

THEN

POST

1/2

THREAD

TENSION

TURNS

THREAD

EYELET

AROUND

DISC

CLOCKWISE

TENSION

Fig.

2A

9

Page 10

The

adjusting

instructions

63400 A and B covered

INSTRUCTIONS

for

Styles

in

Catalog

No.

FOR

63400

121 M,

MECHANICS

XF

and

YF

with

the

additions

are

the

same

as

follows:

as

for

Styl

es

FEED

both

DOG

The

feed

directions,

approximately

CHANGING

To

change

adjusting

sulting

reverse.

NOTE:

at

screw

in

more

Tighten

After

the

front

Fig.

it

may

require

feed,

feed

feed,

check

will

refer

affect

SETTING

dog

must

across

3/64

THE

STITCH

the

stitch

(B).

stitches

locknut

setting

and

28

adjustments

the

stitches

the

to

paragraph

be

the

inch

above

length,

Turning

per

the

back

per

travel

centered

line

of

the

in

the

feed

throat

as

LENGTH

inch)

(A)

stitch

in

both

loosen

the

screw

after

length,

the

SETTING

NOTE:

knurled

and

turning

obtaining

make

forward

THE

The

on

the

the

reverse

as

the

Set the

both

the

forwa

edusingheavypaperorv

12

stitches

of

both

mechanisms.

inch

in

both

of

the

on

"CHANGING

other.

To

feed

slots

well

as

plate

at

locknut

clockwise

the

the

sure

and

REVERSE

reverse

reverse

feed

control

stitch

r d

and

per

inch

directions,

chan

THE

STITCH LENGTH".

ofthe

in

the

the

top

decreases

screw

desired

the

reverse

feed

feed

control

will

lev

er is

length

r eve

e

on the

Aft

er

be

ge the

(A,

throat

line

of

Fig

of

its

plate

feed.

stroke.

. 28)

the

counterclockwise

stitch

feed

FEED

is

length.

dog

has

feed

direction.

MECHANISM

actuated

lever

continue

held

at 12

rse feed.

ry lig

ht

forward

making an

cause

stitch

to

down.

stitches

This

cardboard.

and

adjustm

an

adju

length

and

leveled

It

should

and

turn

stitch

by

length

equal

clearance

pushing down

(C, F

ig

op erate

per

can

be

To

revers

ent

stme

nt

of the

rise

the

feed

(re-

acts

the

. 28)

as

and

long

inch,

check-

obtain

e

feed,

to

one

to

one

forward

in

on

The

reverse

adjusting

This

back

screw

move

the

can

be

against

(B).

the

control

reverse

decrease

after

length

NOTE:

making an adjustment

in

both dire

Once

been

in

stitch

under

reverse fe

s

hould get

of s

titches in

CAUTION!

control

move

ag

ain

feed

the stit

ch

accomplished

the

rest

When

the

lever (A)

fe

ed

the

travel.

ctions.

the

forward

set

at 12

length

"Cha

ngi

ed

will

approx

bot

On

machin

r e

vers

this

lev

er before tippi ng mach

s t

the

rest pin.

travel

control

pin

machine

travel

Retighten

stitches

can

ng

The

not have

imate

h d

ire

es

e fe

ed

can

be chang

by

and

towa

or

lever

tipping

away

(A,

F ig.

the machine

loosening clamp

is

in

this pos

r d

you

to

incr ea

from

clamp scre

and

check the

and

be

revers

per

ma

de

Stitch

to

be a

inch,

e feed

a

chan

as

described

Length", the

dju

sted, y

ly the sam e number

ctions.

equipped

lev

er

wit

h a

(A,

F ig. 30) r e -

treadle

ine

ed

29).

ition

you

w (B)

stitch

has

back

by

se

to

ge

ou

Fig. 29

10

Page 11

SETTING

If

equal

titch

s

ns

i

as

length

ide

the

follows:

THE

REVERSE

stitch length,

control

machine.

lever,

The

FEED

forward

adjustment

feed

linkage

MECHANISM

and

reverse

should

is

pre-set

(Continued)

cannot

be

at

made

the

be

factory

obtained

to

the

feed

and

by

adjusting

linkage

may

be

the

located

check

ed

Fig.

verse

and

screw

adjusting screw.

ADJUSTING

feed

adjust

(B)

lever

the

stop screw

in

this

THE

30

(A,

po

wh en

FE

Fig.

sit

EDING

30)

(B.

ion

with

reverse feed

PRESSER

remove

cover.

stitches

ing

move

plunger

er

above

Retighten

and

voir

can

feed

scribed

hold

Fig.

locknut

Drain

screw

of

replace

cover.

be

On

down

30)

is

FOOT

machine

the

bottom

Set

the

machine

per

inch.

(A,

the

lever

screw

the

made

control

earlier.

machines equipped wit

the

to

(C).

actuated

stitch

(B).

(C)

bottom

holding

the

bottom

Now

to

lev

reverse feed control

stop against

This

by

of

oil

reservoir

at

Loosen

Fig.

is

31)

regulator

so

the

23/32

of

the

screw

reser-

adjustment

the

revers

er as de -

the bed castin

is

to prevent

s tepping

hold-

cent-

base.

and

zero

and

inch

(A)

e

h a treadle contr

l e v

er

dam

age

on

the tr

eadle

F ig . 31

(C,

Fig

g. L ock

to

the feed

.

ol

. 28)

stop

re-

Adjust

(3)

threads

Ba ck o

r esting fla t on

jus

ting li

Tighten

Loosen s crew (E, F

pr

ess

er b

li

fte r lever.

S

et

above the thro

machine

screw in

or

left,

tighten the

spring

i

nch

space between

is

in alignment with the nee

the p

are

ff stop screw

nes

on

loc

k nut (D).

ar

(G) dep

the p

resser

a t

back

the lift

the

as requir

ag

prop

locknut

resser spring

visible

the

thr

the

presser

ress

bar

plate

ainst the

er

lev

er s

to

ed

to reset the

the guide

above

(B,

oat

plat and

ig.

presser

connection

seat (See

rest

er b e

ll

ett

ing

for

lock the

dle

regulato

the

bed casti

Fig.

16A)

foot

bottom, line

16A)

in presser bar guid

foot

Fig.

pin,

crank

and

(61468

the

stop

presser

press

before

r (A, F ig .

ng.

in fee

feed

lift

(A, Fig.

loosening the

presser

scr

er

tightening screw

din

g p

dog

down, adjust stop

up

er le ver and r

16B)

16B).

ew in pla

bar guide

11

F).

bar

Th

By

bar

connection,

16A)

resser foo

with

s o its t

is

turning the s

connection

ce.

s o tha t a

the

e (F ),

etight

op sur face i s 5

is

accomplished

locknut

Relea

(F ,

Fig.

(E).

cen

s e

be sure th

pproximately three

t.

With the presser foot

nut

(C) unt

terline

whil

e h

oldi

n screw (E

and reloca

top

s crew

is

accompli

pressur

16A)

allow

il

of

the nee

ng

down

). Release

1/8 inch

by

tippin

ting the stop

to the

she

e

on pres

ing a 1/16

e p

resser foo

the a

g the

rig

d.

d-

dle.

on

es

ht

Re

s e r

-

t

Page 12

ADJUSTING

THE

FEEDING

PRESSER

FOOT

(Continu

ed)

presser

between

stop

screw

mum

of

spring

the

{F)

1/64

Fig.

top

in

inch

(B)

and

of

the

feeding

on

16A

adjusting nut

yoke

throat

(E)

foot

plate

and

so

top

that

when

er

and

presser

of

Lock

(A)

on

of

spring

presser

foot

Remove

spring

adjust

the

in

presser

foot

is

lifted

(B)

foot

needle

position

(B)

bottom

with

12

nut

stop

is

slot

foot

with

(A,

of

the

nut

pushed

will

with

and

the

slides

feed

Fig.

feeding

(C)

forward,

not

locknut

adjust

feed

rearward

dog

Fi

g.

18C)

so

that

touch

to

dog

down.

16B

and

presser

when

the

(D).

45/64

down.

press-

foot

the

the

rear

needle.

Replace

inch

Adjust

a

maxi-

Page 13

ADJUSTING

Lift

feeding

Should

loosen

18C)

adjustment

screw

as

required

THE

in

FEEDING

presser

be

necessary,

bottom

to

obtain

foot

of

presser

proper

PRESSER

and

check

remove

foot

position.

FOOT

to

see

shank

(Continued)

if

bottom

the

presser

to

reposition

Retighten

is

foot

screw.

parallel

from

leveling

to

the

spring

throat

machine

(G,

plat

Fi

e .

and

g.

THREAD

Set

(underside)

(See

Set

1

I 64

thread

the

thread

spring

check

thread

Thread

thread 2 1/2

tary

tension

Set

spring

bottom

is

at

CONTROL

needle

Fig.

16A).

tension

inch

running from the

pull-up

not

spring

pull-up

machine

check

overthrows

of

check

speed.

Fig.

of

clearance

threaded

times

disc.

18C

thread

bracket

post

bracket.

1/2

inch

bracket

as

shown.

clockwise

spring tension

threadline

spring

pull-up

to

top

eyelet

between

rotary

(See

above

(See

motion

of

so

with

Fig.

Wind

so

when

bracket

cloth

there

it

and

tension

the

18D).

bottom

Fig.

around

that

slightly

machine

(H,

plate

is

the

to

check

Set

of

18E).

needle

ro-

check

at

Fi

g. 16A) 4 19 I 3 2

a

Fig.

inches

18D

from

bottom

Set

light

being

may

to

feed

needle

as

possible to

sure

When

have

the

and

bottom

produce

check

sewing various

to

bottom

be

changed

spring

ply

faster

thread

a

is

acting

materials,

to

get

and

tension

good

properly.

good

ply

vice-versa.

as

stitch

the

pressure

matching.

13

of

the

Increasing

Fig.

feeding

the

18E

foot

presser

pressure

spring

will

tend

Page 14

14

Page 15

T

he

p a r

ts illu

pr

esent the p arts that a r e used o

U

se Catal

strated

og No. 1

21 M (Styl

on the oppo

nStyles 6:34

es 634

site page and

00

XF

00

A or B) f

on page

and YF,

or all parts

16 and des

but

not

used on

not illu

cr ib

ed

Styles 6:34

strate

on this page an

d or

00

A or

described

d page 1

Brespectiv

in this c a

7, re-

ely .

talo

g.

Hefere nc e n

indicate they are

P a

R

No.

10

11

12

13

14

15

16

17

l B

19

20

21

22

23

24

2

26

27

28

29

30

31

32

33

34

34

35

36

37

38

39

40

4

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

f.

1

2

3

4

5

6

7

8

9

A

0A

rt

N

o.

6

:345

7 M

3457

6

612

57 G

51257 G

6:3957

21

390 BE

57 WD

57

57 WB

225

64 B

634 71

634

71

634

70 s

90

2935A

1

639

92 A

HS

24

22513

639 70 A

29475 BE

660-

6

3992

225

60

349

2

6

349

2 B

6

634 53 N

614

92 T

49

2 s

61

92

61 4

6

349

2 C

612

92 c

61405 AA

61424 AA-063

63420

420

63

63430 u

227

85

22560 B

63430 T

56330

634

30

63430 s

99

227

73 A

56

33

0 AS

56330 AJ

56330

56330

604

529

30 AC

5 1430 F

56330

4

107

1 G

56330 AD

343

0 v

6

61

405 AB

61

424 AB-063

63459 B

22570

73 c

umbers tha

com po

nen

L

A

we

A

C

269 A

G

H

-4

J

H

AP

w

AB

AG

AF

AU

t ar e

insi

t pa r

de a bracket or box on the pi

ts

of a

com

Lock N

Stop Nut

P r esser Spri

Presser

P r

Ni

L ow

Sc

Scr

T

Screw

Screw, fo r t

Th r

Rotary

Fee

T

Presser Foo

Presser Foot,

Feed Do

T

Pres se r Ba r Guide

ut-------------------------------------

--------------------------------------------------------

Bar ----------------------------------------------------

esser Bar

pp

er Sp ring A

Scr

ew, f

Ni

ppe

per Sp

Nip

Screw

Nip

pe

Ni

pper Sp

er

Need

r ew, f

or nipper spr

ew, fo r

ensi

on P o

----------------

ea

d P

ull-up

Needle

Quad

Te

nsi

Set Scr

Te

ns i

Tensi

Ta

ke

-up Spr ing---

Felt Washer

R

otary

Tensi

Te

ns i

Tensi

d Dog, 22

hroat

P l

ate

Yo

ke

Sc

Screw

Presse

Bu

Presser

63420

Presse

6

34

20 H

Hinge Pin

Sc

r ew,

Hinge Spr ing

Hinge Pin-------

Regula

Li

nk Hin

Scre

w, f

Chain Cutt

Nu

t---------------------

as

her

W

L

oc

k N

Compression

Re

gula ting NuL

hr

g,

oa t Pla te , . 063 inch need

Scr e w

Scr

ew

cture

plete part

ng Regulator a

Bushi

or

r Spring

rin

------------------------------------------------------

r Ba se--

r ing Mounti

le Thread Ey

tension assembly------------------------

st Socket

hre

ad pull-up

Tension

Ring-------------------------------------on

P os t

on

P os t -

on

Release

Tensi

on

Release Washer

on

Spr

on Nut

tee

, . 063 inch n

t, for w

for

-----------------------r e \v

--------------------------------------------------

--------------------------------------------------

r F

oot Link

shing------------------------

F.oot B

3-------------

r F

ool Bot

--------------------------------------------------Screw----------------------------------

for

hin

ting Scre

ge Screw -------------------------------------------or cha

ing Kn

-----------------------------------------------------

ut---------------

22

Leeth per i n

-----------------

---------------------------------------------------

or

assembly

Descripti

nd

Bu h ing

ng,

ssembly--------------nippe r spring

Br acket

ew --- - -

ing

lower--------------------------------------

------------------------------------------------

g P la te - -

-----------------------------------------------

ing asse

Eyelet ---

Soc

ket

----------------------------------------------P in

---------------------on Disc

----------------------------------------------

----------------------------------------------

th per inc h, f

ide

narr

, m

otto

tom, m

ge spring

---------------------------------------------

----

w------------------------------

in

cut

ife, marke

Spr

ing

-----------------------------------------------

-----------------

--------------------------------------

----------------------------------------

ng Brack

elet --------------------------------------

mbly

------------------------------------

-

----------------------------------------br a c

ket

--------------------ssembly

----------------------------------------

------------------------------------------

-----

-----------------------------------

feed combination---------------------------

ow

m ,

- - -

----------------------------------------

- -

-----------------------------------

or

eedle hol

feed comb

ark

ed

marked "BV",

-

-------------------------------------arked "B

- -

------------------------------------

-------------------

ti ng

knife

d "

-

-----------------

-

----------------------------------------

-------------

ch,

for nar r

le hol

-

---------------------------

plate and ha ve indent

.

on

-----------------------------

-

--------------------------

et-------------------------------

---------------------------------

--------------

----------------------------------

----------------------------------

-

--------------------------

wid

e feed comb

e,

for wid e

ination---------------------

-

---------

"C"

-------------------------------

U", for

------------------

D"

------------------------------

ow

e, f

or narrow

-

-----------------------------

fee

-

-----------------------

for

pr e

pre

-

----------------------

fe ed

comb

-

------------------

-

--------------

-

---------

-

--------------------

-

------------

ina

tion--------------

d c

omb

ination

-

--------------------

sser fool

s ser fool No.

-

--------------------

-

-----------------

ination

feed co

No.

-

-

--------------

-

--------------

------------

mbi nation

ed descrip

-

--------

-

-------

-------

-

---------

-----

-

--------

---1

tions

Am

Rc

- - 1

- 1

- 1

---1

---

- 1

- 1

---1

- - 1

,

t.

q,

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

15

Page 16

16

Page 17

REVERSE

FEED

MECHANISM

PARTS

Ref.

No.

*1

*2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

:33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58 97

59

60

61

62 6

63

Part

No.

421

660-264

63444

64 B

64 A

22517

63444

22894

660-206

63444

93

22539

86

63444

63444

22570

39552

63432

22894

G61447

G6144

531

6343

22

586

G61436

6343

G61

4:3

G614:

36

22830

63433 B

99284

96

505

634

34

88

88 D

G6

1439

2277 5 A

12934 A

G61436

99285

63436

22519

29126

61438

88

660-22

63437

95

63432

2289

660-207

99282

99283

63444

22894

22894

12 4 6 L -

63

44

660-206

6

3444

343

22651

D-28

A

c

w

D

M

E

F

A

c

H

w

8

2 F

5

6 A

C

B

A

B

u

II

E F

A

c

H

4 w

G

p

u

9

B

2 G

CD

5

-5

1/

-

----

------

-

----

-----

-

-----

------

- - -

-

----

-----

-

----

---

Amt.

Req.

1

2

1

1

1

1

1

2

1

1

1

1

2

1

1

l

2

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

2

1

1

1

1

2

Description

Treadle

"S"

Reverse

C

ollar,

"0"

Re

Plug

Screw,

Reverse

Reverse

Thrust

Collar,

Reverse

Collar,

Feed

Feed

Feed

Reverse

Screw,

Reverse

Screw,

Link

Feed

Screw,

Feed Dog H

Screw,

Nut,

Reverse

Reverse

Reverse

Feed

Thrust

"O"

Adjusting Screw, for adjus

Lock

Reverse

2

Screw,

Reverse Feed

"0"

Reverse

Reverse

Screw, for

22653

Chain,

Hook,

Feed

Lock

Stop

Screw,

Clamp

for

Set

Screw

Ring,

verse

Feed

Screw

Screw,

for

Feed

Feed

Screw

Washer,

right,

Set

Screw

Feed

left,

Screw

Driving Shaft

Plug

Screw------------------

Rocker

Rock

F e

Sliding Block---------

for

Feed

for left

Pin, for

Bar

Set

Screw

feed

for feed dog

for

reverse

Feed

Fe d Rock

Fe d Shaft

Clamp

Driving Eccen

Connecting Rod--------------

Set

Needle

Feed

Driving Eccentric--------------

Set

Screw

Collar,

Set

Screw

Rin

g,

Nut, for

Feed

Set

Screw

Spot Screw

Dr

ive Pin-------------------------------

for

Rin

g, f

Feed

Feed Shaft

D-6)------------------

28 inches

for

treadle

Foot

Control

Nut,

for

stop

foot

Scr

ew

reverse

for

-----------------------------------------------------reverse

---------------------------------------------

---------------

er

ed

sliding

----------------------------------------------

older

Screw

for

reverse

or

feed driving s haft sprock

------------------------------------------------

---------------------------------------------------

reverse

Control

for

reverse feed

Control

Shaft

for right

for

reverse feed shaft

---------------------------------------------------

Shaft Ret

for

reverse

----------------------------------------

---------------

Shaft

-----------------------------------------

Rocker,

block (u

Lever

reverse

reverse feed roc

---------------------------------------------------

dog

holde

Support----------------------

feed

Rocker Lin

er

--------------------tr ic Asse

Screw

------------------------

Bear

---------------------left,

--------------------------

reverse fe

adjust

Hand

Control Operating Lever------------------------

---------------------------------------------------

-------------------------------------------------feed stit

Stitch

rever

se

Control Sha

long-------------------------------------

chain---------------------------------------

screw

control

feed

control

feed

Shaft

feed

control

Connecting Link-----------------------------

Lever, right

rever

urn

feed sha

with dri ve crank

Link----

feed shaft lever

r s

uppor

hold

er s upport - ----

rocker link s

k----------------------------------------

Link Stud------------------------------------

Le ve

r, left

ing

------------------------------------------

for

r eve r

ed sha

ing scre

Control Flange-------------------------

feed s

ft---------------------------------------

----------

Operatin

operating lev

control

Rocker

shaft

Spring

-

--------------------------------------

----

s ed i n pl ac e of s c r ew

- - -

t - -

mbly

se feed s ha ft

tin

g s

w-----------------

ch control flan

titch

g Le ve

-----------

shaft------------------------------

shaft

Lever--------------------------

---------------------------------

connect

----------------------------------

se

feed shaft lever

----------------------------

ft r etur n s

-

- - -

--------------------------

----------------------------

-----------------------------

ker

link-----------------------------

----------------------------------

tud

------------------------------------

---------------------------------

-

-------------------------------

ft

----------------------------------

titch

1 ng

control

- - -

--------------------------------et

----

-------------------------------

r------------------------

-

-------------------------

er

-----------------------

---------------------------

ing

link-----------

return

--------------------------

- -

(used

spring------------------

pring--------------------

- -

-------------No.

--------------------

--

---------------------------

-----------------------

-

--------------------------

-

----------------------

- - - - - - -

-

----------------------------

--------------------------

- - -

----------------------

th

-------------------------

-

-

ge

-----------------------

fl a ng

e---------

in pla

-

---------

-------------------

88

------------------

------------------

-------------------

----------

ce

of scr w

-

-

-----------

13)------

--

- - -

-

-----------

--------

-

- - -

-

- - -

-------

------

-

------

No.

'

~

Not furnished

able

for oper a

with

tin

g the r e

m a

chine,

ava

verse feed

ila

bl e

as

an

mechanism.

extra se

nd and

cha

r ge

17

item, wher e a

foot

treadle

is d

esi

r-

Page 18

BOOST

PRODUCTION

WITH

WORK

UNION

THESE

AIDS

SPECIAL

FROM

PNEUMATIC

convent

sci

ssor-action mechan is m

ve

positi

AIR

FABRIC

signed

to remove

kn

it

mater

area.

Style

ional

cui.

for

ials as

Style

Class

curls

2899

CHAIN-CUTTER

Class

2899

UNCURLER-This

39500

from

fabr

B-1

39500

and

thai

A-1

machines, uses

top and

bottom

ic passes

- for

39600

is a durable

makes a clean

...

unit, de-

plies

through

use

on

air

jets

of

flat

sewing

PNEUMATIC

operated

machines

simply by

CHAIN

small

for

36200

foot

allows

CUTTER-

pneumatic

installation

Flalseamers.

FOOT

lifter for

the

knee-touch

cha

as an accessory unot o

LIFTER-The

use

operator

ing an

The above

1n

cutter

Style 2899A-6

on Class

to raose

actuating

photo

that is available

the

swit

shows

rl

39500

Class

air-

loot

ch .

the

KNIFE

GRINDER

type knoves,

nates defective garment s caused

sharpens

is

simple and easy to operate,

straight

by

dull knives.

®

u

IIN!IT QUA

LIIY

M A

cHINE

wheel

msuring

ELECTRONIC

to

move

better

NEEDLE

the

needle

control, unif

up

or

orm

POSITIONERS

down

...

quality

AMCO

or

angle

elimi-

this

allows

and increased

HEAT

DISPELLER-Un

unit

(arrow) is an effective means

oil

temperature

qu

ires o

l.

eliminate

the

operator to keep

producllon.

where heavy duty service re-

Style

2899

E-1

the

necessity

ion Spec o

of reaching

both

hands on the

al's

lor

for

the hand-

auxiliary

reducing

work

,

Page 19

Helpful,

ci

ent

types

machine

Sales

Promotion

esting,

obligation

illustrated

authontative information

of

equi

sewed

are the

pment

article

Department.

bulletins

follow

for

is

ava

ilable

Among

that

ing:

on

the

mak

from

are

most

ing

virtually

Union

the

many inter

available without

eff

any

Special'

i-

s

-

HERE

ARE

HELPFU

L

No.

240, "Men's, Women's, C!'lildren's

No.

249,

"Rainwear"

No. 250,

No.

No.

No. 253,

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No. 1100,

No.

"Columbia

mg Mac

No

. 15

"Men's

251,

"Service

252, "Men's

"Overall

254,

"Men's Knit

256,

"Knit

259,

"Men's

260,

"Work

262,

"Cotton, Burl

263,

"Men's Clothing

264,

"Men's

265,

"Women's Wear"

266,

"Women's

26

7, "Corsets, Girdles, Brassieres"

268,

"Children's

269, "Mattresses,

Upholstery"

271, "Awnings

273,

"Curtains & Drapes"

610,

"Kiipp-it"

710,

"MCS

730, "MCS

Hemmer"

740, "MCS

750,

"Fusing

stitch,

1105,

hin

00, "Alteration

Oute

Bags"

ForMation

Automat

Automat

"Lewis

"Button

Bl i

ndstitch,

es"

Dress

Shirts"

Shirts

and

Shorts

and Pajamas"

s, Coveralls, and Dungarees"

Underwear"

rwear"

Sports Shi

Glove

s"

ap,

Jute

"

Women's,

Wear

And High

Wear"

Slip Covers,

, Canopie

ic Dual

ic Ri

Press

es"

Blindst

Machi

itch, Cha

nes"

Sewers-

Saddle

Depart

Pants"

rts"

, and

Multiwall

Children

s,

Uni

Ticket Tacker

's

Jackets"

Fashion"

Furnitur

Tents, Tarps"

t"

Underfront

b-Knit

Cuff

insti

tch,

Stitch,

ment

and Tie

Machines"

Footwear"

Pap

e

Shirt

Machine"

Lock

s"

Clo

BULLETI

TO HEL

SEWI

er

·

s-

NG P

NS

P

and

YOU

ROB

CATALOGS

SOLV

LEM

E

S

®

Page 20

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

facilities throughout the

aid

you

SPECIAL

maintains sales

and

world. These offices

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

and

and

is

a Union Special Representative to

serve you. Check with

ATLANTA,

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

ILL.

TEXAS

YORK, N.

Y.

PA.

are

efficiently. Whatever your loca-

service men

able

to serve your needs

him

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUTTGART, GERMANY

service

will

are

fac-

CANADA

ENGLAND

ENGLAND

400

Representatives

MACHI

N.

FRANKLIN

industrial

and

distributors

cities throughout

NE

COMPANY

ST.,

CHICAGO,

In

all Important

the

world.

ILL.

60610

Loading...

Loading...