Page 1

INDUSTRIAL

SEWING

®

EST

QUALITY

STYLES

63400X

63400Y

63400KX

63400KY

C 0 L U M B I

A®

MACHINES

ATALOG

No.

121KX

Second

Edition

CL

ASS

S

TREAMLINED

HIGH SPEED

LOCKSTIT

WITH

INTERMITTENT

UNION SPECIAL

63400

CH

REVERS

MACHINES

FEED

CORPORATION

C H

ICAGO

Page 2

(Supplement

Catalog

to

No.

Catalog

INSTRUCTIONS

FOR

121

KX

No.

121

M)

ADJUSTING

LIST

Streamlined

63400

634

00

Second

AND

OF

CLASS

Styles

X

KX

OPERATING

PARTS

63400

Lockstitch

63400

63400

Edition

Y

KY

Copyright

1969

by

Union

Rights

Specia

Reserved

1

Corporation

in

All

Countries

UNION SPECIAL CORPORATION

INDUSTRIAL

Print

SEWING

CHIC

e d

in

2

A

MACHINES

GO

U.

S.

A .

July.

1977

Page 3

IDENTIFICATION

OF

MACHINES

Each

on

the

machine.

Style

numbers

Example:

minor

Style

changes

number.

Styles

which

63400

differs

11

•

This

junction

KY,

book.

the

therewith.

but

not

For

63400 X and

Opposite

number,

NOTE:

description,

When

column.

Adjusting

similarto

instructions

and

B,

or

KX, Y

and

UNION

have

"Style

are

Example:

of

machines

from

catalog

used

clarity,

the

ordering

and

those

included

are

additional

KY.

SPECIAL

Style

one

63400

made

machine

numbers

or

more

X".

Special

in

a

"Style

similar

the

style

number,

APPLICATION

is a supplement

Only

on

certain

KX, Y

Styles

and

those

63400 A or B are

63400 A or B parts

KY

illustration

and

amount

repair

operating

inCatalog

in

this

instructions

No.

catalog

instructions

is

are

letters

Style

standard

63400

in

construction

to

parts

which

parts.

page,

required.

parts

always

121M

are

identified

classified

suffixed,

numbers

machine,

XZ

".

by a Style

as

but

contain

a"

are

in

that

it

contains

OF

CATALOG

Catalog

are

No.

used

121 M

illustrated

are

parts

use

for

are

the

Styles

identified

forStyles63400A

the

ones

that

that

pertain

specifically

number

standard

never

and

contain

the

Z"

is

suffixed

grouped

no

letters.

and

should

on

Styles

and

shown

63400 X and

listed

in

phantom

by

part

number

63400 X and

and

Brespectively.

are

different

on a name

special.

the

letter

letter

"Z

to

".

the

When

under a class

Example:

be

used

KX, Y

at

the

back

to

help

detail

listed

from

to

Styles

number,

in

KX, Y

Styles

the

and

63400 X and

plat

Standard

"Z

".

only

Standard

number

"Class

in

con-

and

of

this

locate

part

second

KY

are

The

only

63400 A

e

The

catalog

herein.

in

this

given

of

handwheel

High

and

Hook,

System,

Needle

Needle

to

Right

It

class.

from

Speed

Plain

Horizontal

Head

Bearing

Bar

of

can

Feed,

Needle

63400 X For

medium

1

9/64

needle.

size,

speed

needle

5500

63400 Y For

to

medium

tacking.

or

180

GYS

inch,

thread

recommended

applies

also

be

Reference

the

operator's

is

toward

Streamlined

One

Hook

Oil

Siphon,

Adjustable

Driving

Link,

Bar

attaching

weight

inch

Specify

material,

needle

presser

type

R.

P.

M. -

attaching

heavy

113/64

inch

needle.

size,

speed

specifically

applied

to

position

the

operator.

Long

Needle,

Shaft,

Adjustable

Feed

Feed

11

1/8

pockets

bar

travel.

and

size,

depending

pockets

weight

needle

Specify

needle

5500 R.

with

direction,

while

STYLES

Arm

Lockstitch

Light,

One

Eccentric,

Timing

inches.

to

shirt

where

Seam

foot,

throat

attachment

to

shirt

material,

bar

presser

type

P.

M. -

to

the

discretion

such

seated

OF

MACHINES

Medium

Reservoir

Hook

Needle

on

Lower

fronts

reverse

Spec.

plate,

on

operation.

fronts

where

travel.

foot,

and

size,

depending

Standard

to

some

as

right,

at

the

Machines,

and

Heavy

Enclosed

Oil

Control,

Beari~gs

Main

and

feed

can

301-SSa-1.

feed

and

guide.

and

similar

reverse

Seam

Spec.

throat

attachment

on

Styles

Special

left,

machine.

with

Duty,

Automatic

Shaft,

similar

be

Type

dog,

stitches

Maximum

feed

301-SSa-1.

plate,

operation.

of

machines

Styles

front,

back,

Operating

Intermittent

Drop

Automatic

for

Take-up

Maximum

operations

used

for

183

GXSor

per

operations

can

be

used

feed

and

dog,

guide.

as

listed

of

machines

etc. , are

direction

Reverse

Feed,

Rotary

Lubricating

Head

Lever

Work

on

light

Oiling,

and

Space

back-tacking.

183 GYS

inch,

thread

recommended

on

medium

for

back-

Type

180 GXS

stitches

per

Maximum

to

3

Page 4

STYLES

OF

MACinNES

(Continued)

63400

KX

trimmer)

63400

KY

trimmer)

NOTE:

Styles

able

this

63400 A and

for

catalog.

Each

type

tails.

the

number

The

blade

number

Needle

Needle

Their

Type

180

180

description

No.

GXS

GYS

183 GXS

183

GYS

Same

Same

The

as

and

as

and

same

Style

Thread

Style

Thread

sewing

B,

use

on

Styles

UNION

SPECIAL

denotes

size

number,

measured

and

the

Type

Type

183

in

size

180

GXS

and

Round

groove,

ium

shank,

wide

plated -sizes

125/049, 140/054,

Round

shank,

groove,

-sizes

075/029,080/032,090/036,100/040,

150/060.

Round

single

shank,

groove,

chromium

110/044.

Round

single

plated-

shank,

groove,

sizes

63400

Wiper.

63400

Wiper.

parts

can

be

63400

the

kind

stamped

thousandths

number

GXS

or

or

183

the

sizes

round

angle

round

wide

angle

round

wide

plated-

round

wide

075/029,

X,

except

Prepared

Y,

except

Prepared

(presser

used

KX

needle

and

of

on

has

shank,

on

of

represent

180

GYS

GYS

available

Description

point,

groove,

075/029,

150/060.

point,

groove,

point,

angle

sizes

point,

angle

equipped

for

Needle

equipped

for

Needle

foot,

Styles

KY

63400 X andY.

are

illustrated

NEEDLES

both a type

point,

the

needle

an

inch

the

are

recommended

are

recommended

are

length,

shank,

across

complete

listed

and

Sizes

lockstitch,

struck

groove,

080/032,

lockstitch,

struck

groove,

lockstitch,

groove,

struck

065/025,075/029,

lockstitch,

groove,

080/032,

struck

090/036,

with

with

throat

number

below.

short

short

"KLIPP-

Positioner.

"KLIPP-IT"

Positioner.

plate

The

and

described

and a size

groove,

denotes

the

eye.

symbol.

for

Styles

for

Styles

length,

deep

spot,

090/036,

length,

deep

spot,

110/044,

extra

short

groove,

080/032,

extra

short

groove,

100/040,

IT"

(Thread

(Thread

and

feed

dog)

sewing

at

number.

finish

and

largest

Collectively,

63400 Y and

63400 X

ball

ball

point,

100/040,

ball

chromium

125/049,

length,

deep

spot,

090/036,

length,

deep

spot,

110/044.

Under-

Under

used

parts

the

avail

back

other

diameter

the

and

eye,

single

chrom-

110/044

eye,

single

plated

140/054,

ball

ball

point,

100/040,

ball

chromium

-

on

-

of

The

de-

of

type

KY.

KX.

,

eye,

eye,

To

sample

onlabel.

Selection

Thread

have

needle,

should

needle

or

Acomplete

of

proper

pass

orders

the

type

orderwould

needle

freely

promptly

and

size

read:

size

through

and

number

"1000

should

the

needle

accurately

should

Needles,

be

determined

eye

in

formation.

The

size

of

upon

the

The

size

and

referred

smaller

strength

the

thread

size

table

kind

to

above,

than

requirement

of

the

on

the

of

thread.

the

size

SELECTING

employed.

needle

employed.

following

The

which

may

specified.

THE

of

the

The

page

choice,

dictate

SIZE

seam

quality

shows

however,

the

OF

produced

of

the

the

preferred

should

selection

4

THE

work

of a needle

filled,

be

forwarded.

an

Type180GXS,

by

the

order

to

produce a good

NEEDLE

is

largely

desired

give

is

siz

~

consideration

size

empty

Use

Size080/032

size

of th_

dependent

largely

of

needle

slightly

package,

description

...

ead

11

used.

stitch

upon

the

dependent

for a given

to

factors

larger

or

a

Page 5

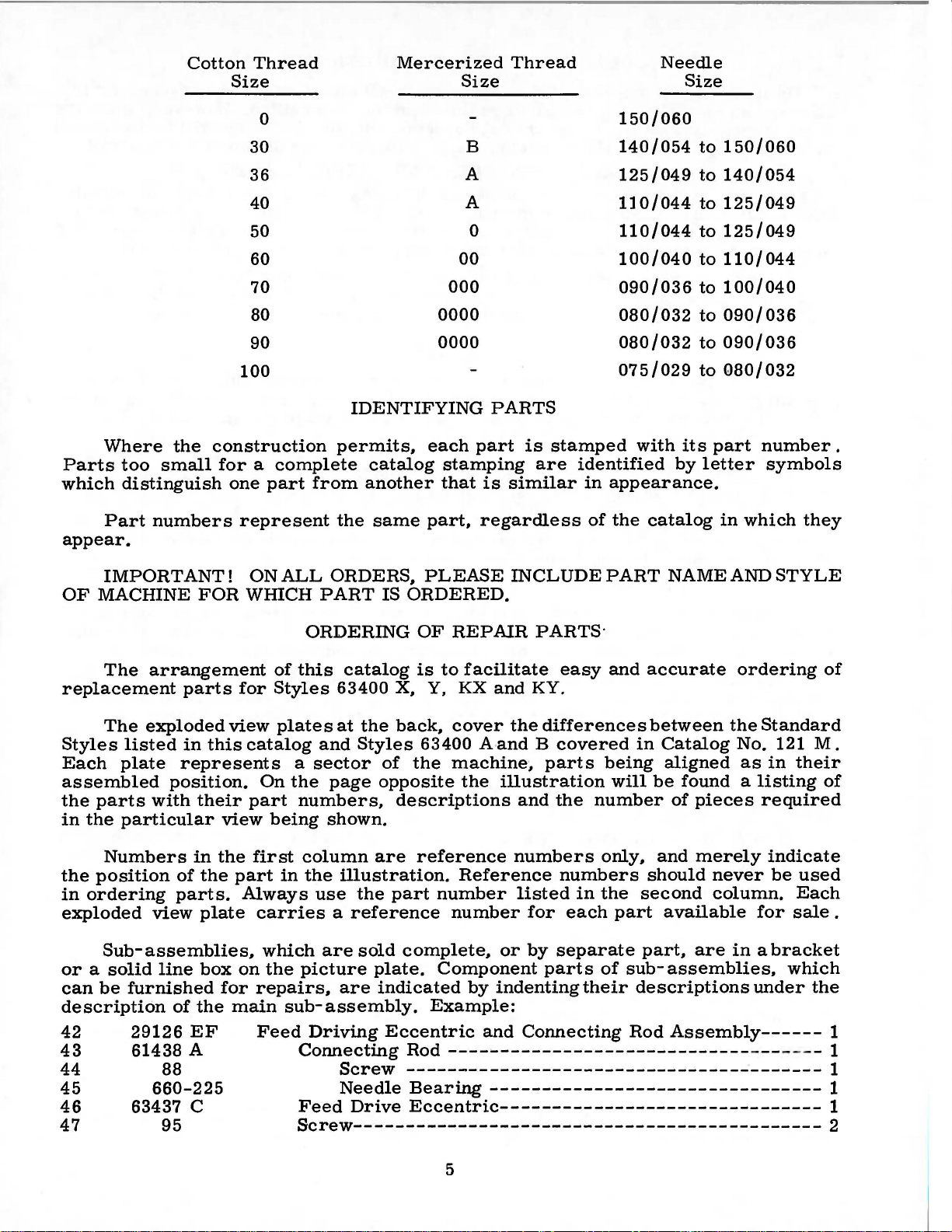

Cotton

Size

Thread

Mercerized

Size

Thread

Needle

Size

Where

Parts

which

Part

appear.

the

too

small

distinguish

numbers

0

30

36

40

50

60

70

80

90

100

construction

for a complete

one

part

from

represent

0000

0000

IDENTIFYING

permits,

catalog

another

the

same

each

stamping

that

part,

B

A

A

0

00

000

PARTS

part

is

regardless

is

stamped

are

similar

150/060

140/054

125/049

110/044

110/044

100/040

090/036

080/032

080/032

075/029

with

identified

in

appearance.

of

the

catalog

its

by

to

150/060

to

140/054

to

125/049

to

125/049

to

110/044

to

100/040

to

090/036

to

090/036

to

Q80/032

part

letter

in

number.

symbols

which

they

IMPORTANT!

OF

MACHINE

The

arrangement

replacement

The

exploded

Styles

Each

listed

plate

assembled

the

in

parts

the

with

particular

Numbers

the

position

in

ordering

exploded

view

Sub-assemblies,

or a solid

can

be

furnished

description

42

43

29126

61438 A

44

45

46

660-225

63437 C

47

FOR

parts

in

this

represents

position.

their

in

of

the

parts.

plate

line

box

of

the

EF

88

95

WIDCH

for

view

catalog

part

view

the

part

Always

on

for

main

ONALL

of

Styles

plates

On

being

first

in

carries

which

the

repairs,

Feed

ORDERS,

PART

IS

ORDERING

this

catalog

63400

at

and

a

sector

the

page

numbers,

X, Y, KX

the

back,

Styles

of

opposite

descriptions

shown.

column

the

use

are

picture

are

illustration.

the

part

a

reference

sold

plate.

are

indicated

sub-assembly.

Driving

Eccentric

Connecting

Screw

Needle

Feed

Drive

PLEASE

INCLUDEPART

ORDERED.

OF

REPAIR

is

to

facilitate

cover

63400 A-and B

the

machine,

the

reference

Reference

number

number

complete,

Component

by

PARTS·

easy

and

KY.

the

differences

covered

parts

illustration

and

the

numbers

numbers

listed

for

or

by

separate

parts

indenting

Example:

and

Connecting

Rod

-----------------------------

---------------------------------------Bearing

--------------------------------

Eccentric-------------------------------

Screw---------------------------------------------

number

in

each

their

and

accurate

between

in

being

will

be

only,

and

should

the

second

part

part,

of

sub-

descriptions

Rod

NAMEANDSTYLE

ordering

the

Standard

Catalog

aligned

No. 121

as

in

their

found a listing

of

pieces

merely

never

column.

available

are

assemblies,

required

indicate

be

used

Each

for

sale

in a bracket

which

under

the

Assembly------

---- - - - 1

of

M.

of

.

1

1

1

1

2

5

Page 6

In

catalog,

PC\,rts

in

for

the

Success

UNION

ration,

to

the

those

cases

no

specific

the.

v~rious

descr1pt1on,

in

the

SPECIAL

its

subsidiaries

most

approved

ORDERING

where a part

usage

ma?hines

and,

1f

necessary,

USE

GENUINE

operation

Needles

and

and

scientific

OF

will

be

are

of

Repair

authorized

principles,

REP

AIR

is

common

mentioned

not

the

the

d1fference

NEEDLES

these

machines

Parts

distributors.

PARTS

to

in

s.ame,

AND

as

furnished

and

(Continued)

all

of

the

description.

the

specific

w1ll

REPAIR

can

are

made

the

be

be

by

They

machines

usag~

shown

PARTS

secured

the

Union

are

with

utmost

covered

However,

will

~e

1n

the

lllustratlon.

only

with

Special

designed

precision.

by

this

when

men

the

ti~ned

genuine

Corpo-

according

Genuine

pair

parts

mark

is

are

your

Prices

are

forwarded

otherwise

directed.

CAUTION!

on

handwheel.

Before

carefully

packing

A

attaching

packed.

box,

bag

of

screw,

miscellaneous

The

bag

chronizer

lead

wire

bracket,

clamp

needles

are

stamped

guarantee

are

strictly

f. o.

b.

A

When

Using

leaving

both

factory,

After

the

following

PREPARATION

assembly

one

attachment

of

assembly

one

and

three

packaged

with

the

of

the

highest

net

cash

shipping

charge

is

unpacking,

hands

each

the

machine

steps

parts,

extra

bobbin,

to

the

parts

synchronizer

clamps

with

Union

Special

quality

TERMS

and

subject

point.

made

Parcel

to

INSTALLING

DO

NOT

on

bed

casting,

Union

Special

and

should

OF

be

MACHINE

consisting

two

bed

plate,

for

Styles

lead

for

tension

labels

marked~.

trademark,

in

materials

to

change

Post

cover

lift

the

machine

lift

machine

accessories

followed:

FOR

of

one

hinge

are

studs,

packed

63400

wire

clamp,

release

U S

and

without

notice.

shipments

postage

out

of

and

box

gently.

is

sewed

have

been

INSTALLATION

frame

KX

and

with

and

thread

KY

one

two

each

also

screw

solenoid

Genuine

Emblem.

Each

workmanship.

All

are

insured

insurance.

by

placing

off,

inspected

removed

eyelet,

screws

for

machine.

include

for

synchronizer

lead

wire.

re-

trade-

shipments

unless

one

hand

and

from

one

the

eyelet

holding

one

syn-

Insert

the

(4)

1.

2.

3.

4.

upper

For

steps:

Attach

(376

Attach

Slide

Attach

frame

Styles

A)

clamp

STANDARD

Included

ing

one

bobbin

its

clamp

and

screw,

essential

TABLE

spring,

when

TOPS

Lockstitch

the

bed

plate

hinge

the

studs

eyelet

63400

synchronizer

screws.

in

to

KX

The

synchronizer

(660-356)

clamp

to

synchronizer

ACCESSORIES

also

with

each

four

winder

isolator

setting

one

assembly,

knee

up

machines

is

FLUSH

with

holes

top

and

upper

to

adaptor

over

machine

lifter

pads

the

are

the

provided

of

arm

(A,

KY,

use

bracket

screw

of

synchronizer

bracket

is a box

the

machine

assembly

and

clips,

machine.

installed

top

of

for

them

Fig.

Fig.

(63495

also

2A).

lA

D)

to

handwheel

lead

using

of

mounting

and

its

and

one

in

table

the

machine

6

in

rear

as a guide

to

the

back

hold

clamp

assembly

wire.

(J87

J)

screw.

STANDARD

frame,

rubber

machine

tops,

pad,

rest

prepared

mounting

of

cloth

to

complete

of

plate.

machine,

(660-352)

using

the

two

ACCESSORIES-

one

oil

drain

bed

positioning

pin.

These

with

cut-out,

frame.

Assemble

the

following

using

in

position.

set

screws.

contain-

parts

jar

and

spring

are

so

that

two

Page 7

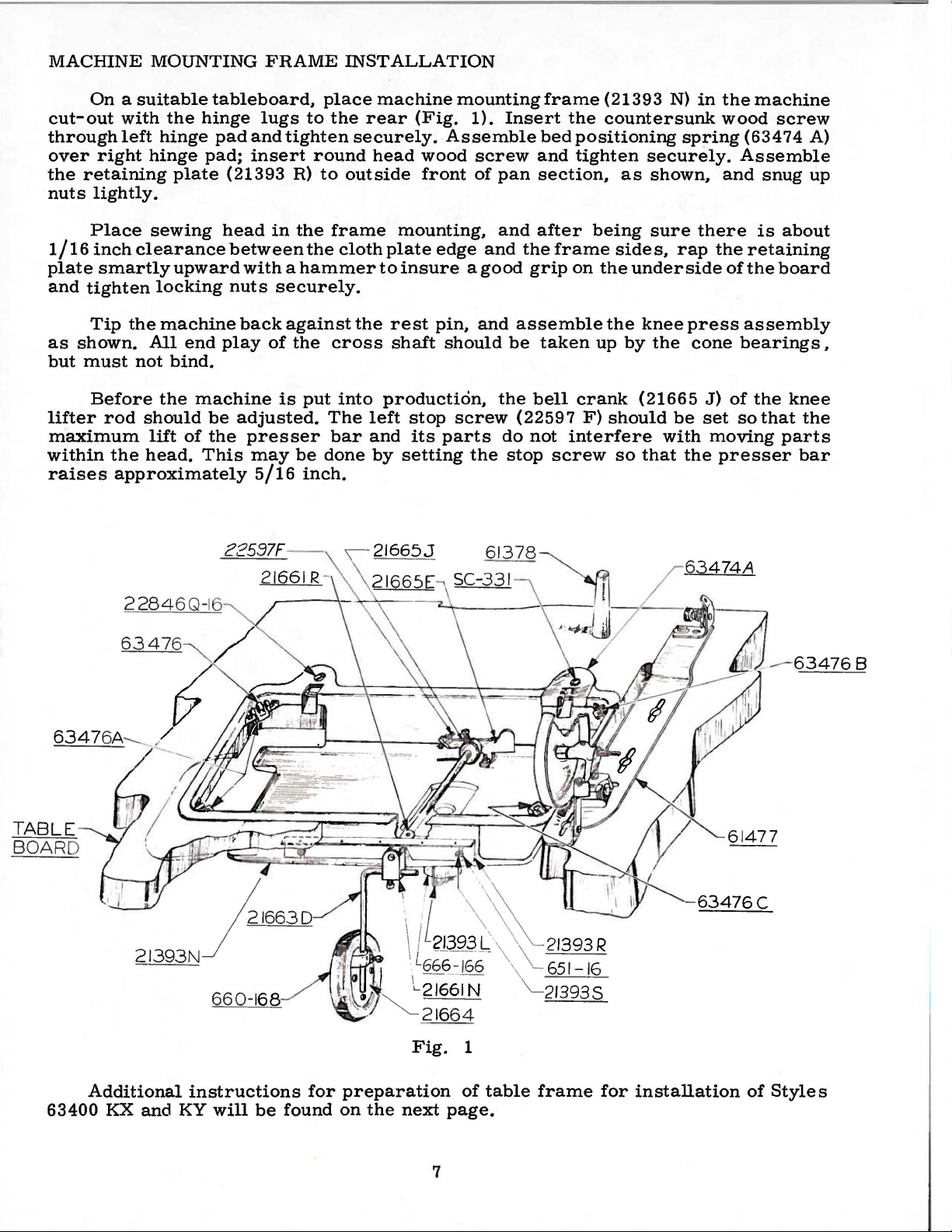

MACHINE

MOUNTING

FRAME

INSTALLATION

On a suitable

cut-out

through

over

the

nuts

with

left

right

retaining

lightly.

Place

1/16

inch

plate

and

smartly

tighten

Tip

as

shown.

but

must

Before

lifter

rod

maximum

within

raises

the

approximately

the

hinge

hinge

plate

sewing

clearance

upward

locking

the

machine

All

end

not

bind.

the

should

lift

of

head.

tableboard,

hinge

pad;

pad

lugs

and

insert

(21393

head

between

with a hammer

nuts

back

play

machine

be

adjusted.

the

presser

This

may

5/16

place

to

tighten

round

R)

to

in

the

the

securely.

against

of

the

is

put

The

be

done

inch.

the

rear

securely.

head

outside

frame

cloth

the

cross

into

left

bar

and

by

machine

mounting

(Fig.

Assemble

wood

front

mounting,

plate

to

edge

insure a good

rest

pin,

shaft

should

production,

stop

screw

its

parts

setting

1).

screw

of

pan

and

and

and

the

do

the

frame

Insert

bed

and

section,

after

the

frame

grip

assemble

be

taken

bell

(22597

not

stop

screw

(21393

the

countersunk

positioning

tighten

as

being

sides,

on

the

underside

the

knee

up

by

crank

F)

(21665

should

interfere

so

that

N)

in

spring

securely.

shown,

sure

there

rap

press

the

cone

J)

be

set

with

moving

the

the

machine

wood

(63474

Assemble

and

snug

is

the

retaining

of

the

assembly

bearings,

of

the

so

that

presser

screw

A)

up

about

board

knee

the

parts

bar

TABLE

BOARD

2284

6347

6Q-16

6

Fig.

1

-

63476C

Additional

63400

KX

and

instructions

KY

will

be

for

found

preparation

on

the

next

page.

7

of

table

frame

for

installation

of

Styles

Page 8

CLAMP

'-~-i

00

-

5YNCHR

ON

IZER

*c;;3"1-~5'D

6RAC.I<Er

*Jsu

SC

REW

2_

FRO

M TENSION-

J RELEASE

)_

FROM CUTTIN

J

SOLENOI

.SOLENO

D

*sc-a

92

SC

REW

}~~--:rl,

~=

't::,i.C-:t:J

ID

G.

-tr

,

..

(APPROX.)-----1

SCRcW.S

= = =

=::__

==

, ,

( DIA. DR

(BRACKET

EE

DETAIL

S

*

"SYNCHRONI

)

...

ILL

ZE.~

NU

TS

TO

SECUR£

BOX

UNDE

RTR

IMMER ELECTR

F

OR

63-400

IONS

ICATES

TilE

KN

362

EE

&.

ES

SHOWN

~BDIII

BUT

SWITCH

* INDICAT

DIMENS

NOT EQUIPPED WI

**IND

BOOXT-

1

if

63900

PA

SERIES MACHI

RT

INCLU

FOR DRIL

TH

STANCARD HOLES.

'PART INC

IS 0.

L..U0£0

·KN£

\IP.

ELIM

••

DIA.

ONI

C. EQUIPM

DED

E

SWITCHj

ILABLE (EXTRA

INATES

IN

PACKING.

LED

IN

29480

ENT

NE

HOLES ARE

WHICH

TREADU

PART

HP

5£ND

NE 5WI

NCI

S OX

IS

**TRIMM

NO

TE:

800XT-3~2

FOR

NOT

&.

CHARGE).

TC.I-I

£~

CI

BOARO WI

REMO

FROM

PRIIV

CIRCU IT

W

ITH

INSTALLATIONS

PART

RCU

TH

RELA

VE POWE.R PACI<

BOlt

AND

T~O

TR

IMH

BOARD

SCR£11$.

OF

Fig.

IT I I"=":

YS

I

NS~T

£R

(£SE

CURE

lA

aJ.IN

ECTEt

l

t-I

SIDE OF

SWITCH

80>

Page 9

1.

2.

3.

4.

5.

6.

Once

Wire

of

Attach

Drill

Attach

Secure

using

clutch

Connect

release

green.

Assemble

again

leads

table

power

holes

electro

electrical

clamps

arm

using

with

frame.

pack

in

table

drive

and

switch

leads

solenoid

relays

Fig.

striped

to

leg

cable

screws

and

from

(green

as

1A

ends

left

rear

if

to

underside

and

provided.

treadline

power

leads).

shown

as a guide

to

switch

leg

required.

of

leads

pack

in

to

or

to

Be

Fig.

proceed

box

of

table

table

underside

Connect

knee

42,

switch.

cutting

sure

page

and

frame

board.

cable

solenoid

to

connect

17.

as

follows:

attach

using

of

tableboard

to

switch

nuts

power

(white

white

box

and

and

pack,

leads)

to

white

to

right

bolts

to

table

auxiliary

and

and

front

provided.

green

leg

frame

drive,

tension

to

Fig.

2A

9

Page 10

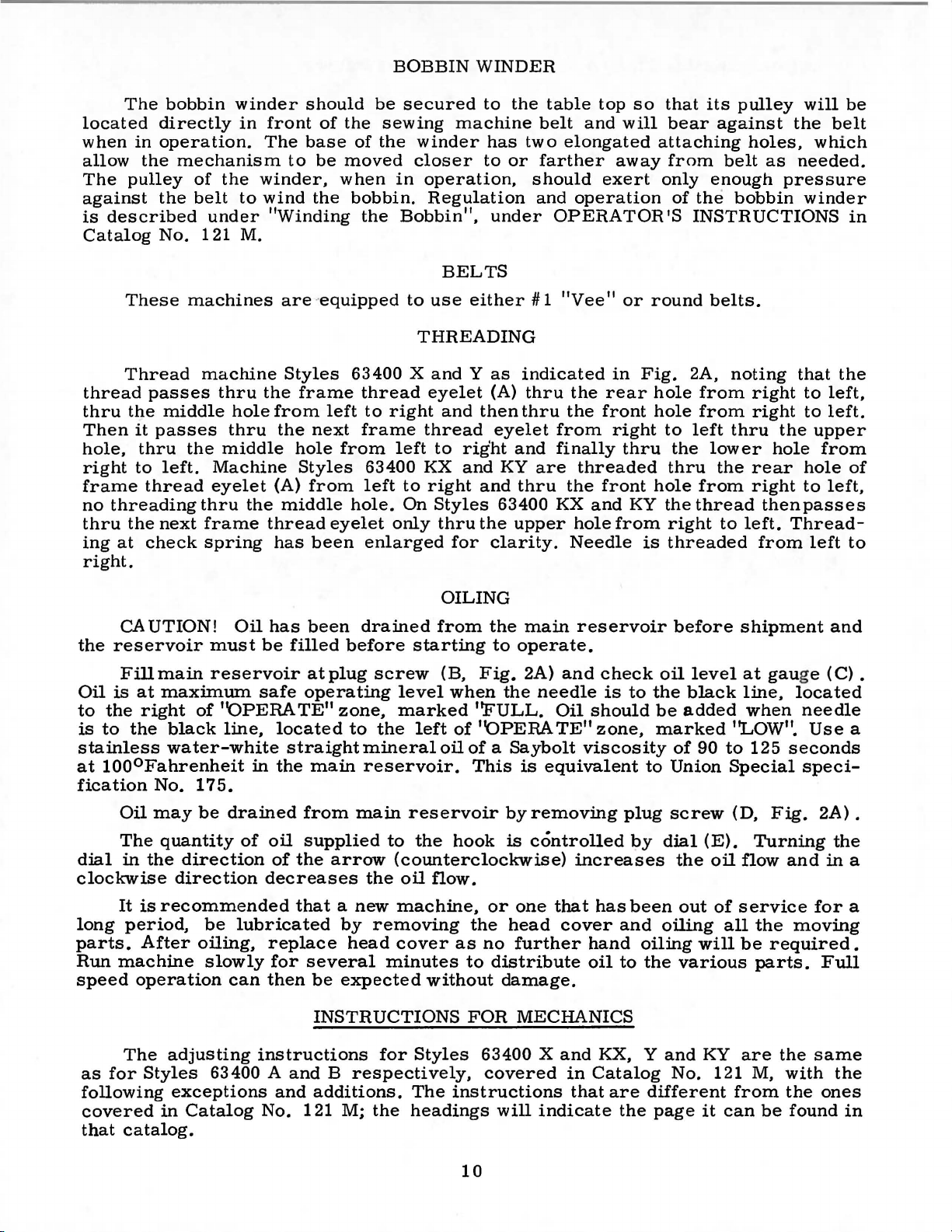

The

located

when

in

allow

The

pulley

against

is

described

Catalog

bobbin

directly

operation.

the

mechanism

of

the

belt

No.

winder

in

the

to

under

121 M.

should

front

The

to

of

base

be

winder,

wind

the

"Winding

be

the

sewing

of

the

moved

when

bobbin.

the

BOBBIN

secured

machine

winder

closer

in

operation,

Regulation

Bobbin",

BELTS

WINDER

to

the

belt

has

two

to

or

farther

should

and

under

table

top

and

so

will

elongated

away

exert

operation

OPERATOR'S

that

its

pulley

bear

attaching

from

only

of

against

belt

enough

the

holes,

bobbin

INSTRUCTIONS

will

the

as

needed.

pressure

winder

be

belt

which

in

These

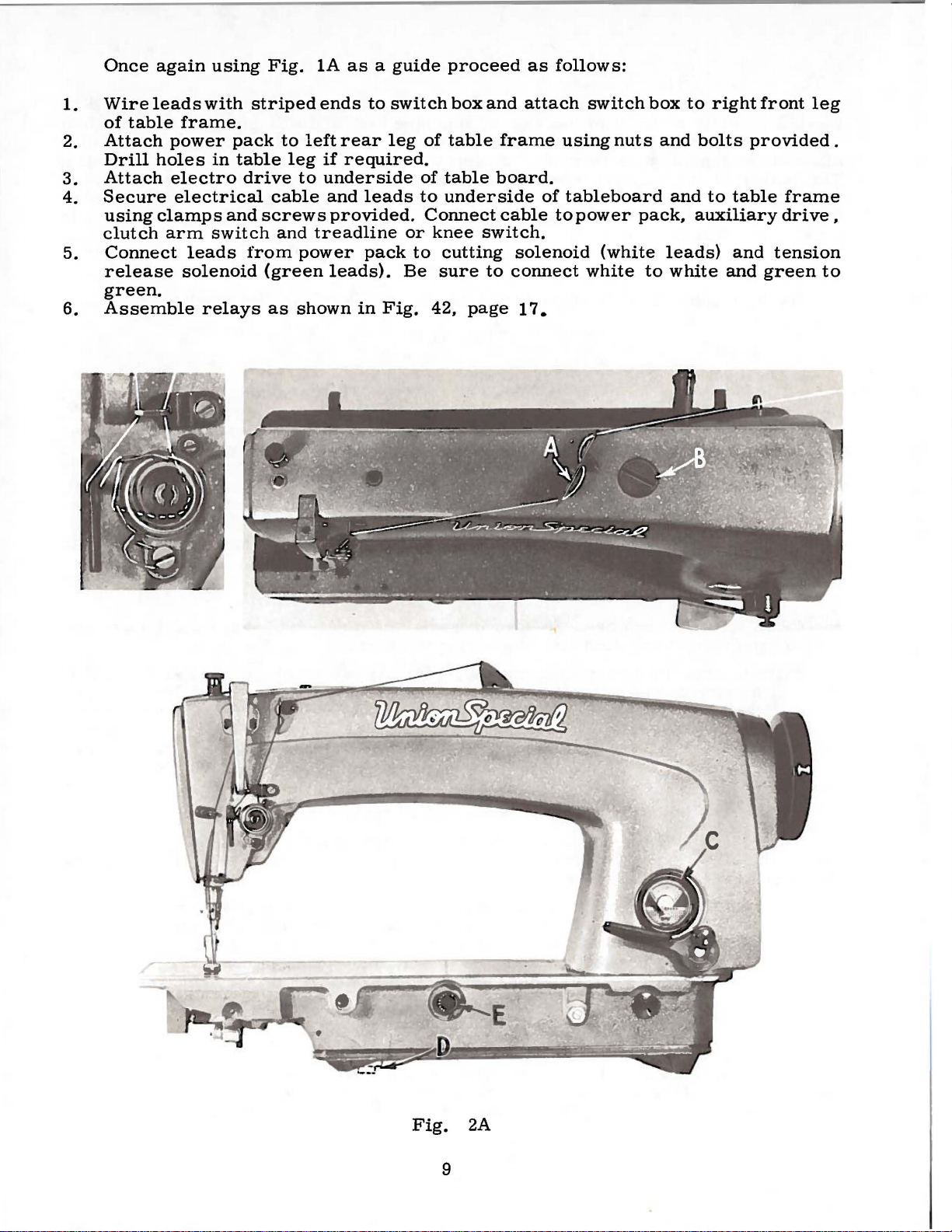

Thread

thread

thru

Then

hole,

right

frame

no

thru

ing

passes

the

middle

it

passes

thru

to

left.

thread

threading

the

next

at

check

right.

CAUTION!

the

reservoir

Fillmain

Oil

is

at

maximum

to

the

right

is

to

the

black

stainless

at

1000Fahrenheit

fication

water-white

No.

machines

machine

thru

hole

thru

the

middle

Machine

eyelet

thru

the

frame

spring

Oil

must

reservoir

of

''OPERATE"

line,

in

175.

are 'equipped

Styles

the

frame

from

the

left

next

hole

Styles

(A)

from

middle

thread

has

has

be

eyelet

been

been

filled

atplug

safe

operating

zone,

located

straight

the

main

to

use

either# 1 "Vee"

THREADING

63400 X and Y as

thread

to

frame

from

63400

left

hole.

enlarged

right

left

to

On

only

eyelet

and

thread

to

right

KX

and

right

Styles

thru

for

then

and

the

OILING

drained

before

screw

to

the

mineral

reservoir.

from

starting

(B,

level

when

marked

left

oil

Fig.

't.FULL.

of

''OPERATE"

of a Saybolt

This

indicated

(A)

thru

thru

eyelet

and

KY

are

thru

63400

upper

clarity.

the

main

to

operate.

2A)

the

needle

is

in

the

rear

the

front

from

right

finally

threaded

the

front

KX

and

hole

from

Needle

reservoir

and

check

is

Oil

should

zone,

viscosity

equivalent

or

Fig.

thru

KY

is

to

to

round

2A,

hole

hole

to

left

the

thru

hole

the

thread

right

threaded

before

oil

level

the

black

be

added

marked

of

90

Union

belts.

noting

from

from

thru

lower

the

from

to

to

Special

right

right

the

hole

rear

right

then

left.

Thread-

from

shipment

at

gau

line,

when

"LOW".

125

seconds

that

the

to

left,

to

left.

upper

from

hole

to

left,

passes

left

and

ge

(C).

located

needle

Use

speci-

of

to

a

Oil

may

be

The

dial

in

the

clockwise

It

is

long

parts.

Run

speed

period,

After

machine

operation

The

as

for

Styles

following

covered

that

catalog.

drained

quantity

of

direction

direction

recommended

be

lubricated

oiling,

slowly

can

adjusting

63400 A

exceptions

in

Catalog

from

oil

supplied

of

the

decreases

main

arrow

the

that a new

by

removing

replace

for

then

head

several

be

expected

INSTRUCTIONS

instructions

for

and B respectively,

and

additions.

No. 121 M;

the

reservoir

to

the

hook

by

is

(counterclockwise)

oil

flow.

machine,

cover

minutes

without

Styles

or

one

the

head

as

no

further

to

distribute

damage.

FOR

MECHANICS

63400 X and

covered

The

instructions

headings

will

removing

controlled

that

cover

indicate

10

plug

increases

has

and

hand

oil

to

KX,

in

Catalog

that

are

the

screw

by

dial

been

oiling

oiling

the

Y

and

No.

different

page

(E).

the

oil

out

of

all

will

various

KY

121 M,

it

can

(D,

Fig.

Turning

flow

service

the

be

required.

parts.

are

from

be

and

for

moving

the

same

with

the

found

2A).

the

in

Full

the

ones

in

a

a

Page 11

CHANGING

To

change th

locknut

(B).

stitch

turning

locknut

NOTE:

(A,

Turning

length

the

(A)

Mter

feed

dog

verse

THE STITCH

e l e

Fig.

28)

and

the

screw

resulting

screw

after

feed

to

obtaining

setting

has

equal

direction.

the

the

LENGTH

ngth

of

turn

to

in

more

left

acts

the

stitch

clearance

stil.ch,

the

the

desired

(Page

feed

right

stitches

the

reverse.

length

at

12)

loosen

adjusting

decreases

per

stitch

make

the

front

knurled

screw

inch

and

Tighten

length.

sure

and

the

the

back

in

both

Fig.

the

28

forward

and

re-

NOTE:

lever

control

Set

feed.

stitches

both

inch

the

"Changing

This

mechanisms.

in

both

other.

The

(C,

the

can

per

To

The

SETTING

reverse

Fig.

lever

stitch

inch

directions,

28)

is

length

be

checked

on

After

change

Stitch

feed

is

and

held

down.

at

using

the

forward

making

because

the

Length".

THE

actuated

the

12

stitch

REVERSE

reverse

stitches

heavy

and

an

adjustment

an

adjustment

length

adjusting

This

back

(B).

control

verse

the

ing

both

by

pushing

feed

per

inch,

paper

reverse

of

the

The

reverse

the

can

be

against

When

travel.

an

directions.

the

lever

feed

adjustment

FEED

will

or

feed,

accomplished

the

travel

Retighten

MECHANISM

down

continue

on

both

very

it

to

one

to

one

forward

feed

stitch

rest

machine

(A)

toward

or

and

light

pin

on

the

to

the

may

feed,

feed

feed

travel

control

and

is

in

you

away

clamp

check

reverse

operate

forward

cardboard.

require

check

will

affect

refer

lever

by

tipping

loosening

thispositionmove

to

from

screw

the

as

adjustments

the

to

paragraph

can

be

(A,

increase

you

(B)

stitch

the

clamp

feed

and

To

stitches

the

to

control

long

reverse

attain

travel

changed

Fig.

machine

the

decrease

after

length

as

the

12

per

on

by

29) .

screw

the

re-

mak-

in

of

of

can

made

the

factory

not

to

be

obtained

the

Fig.

feed

and

29

by

linkage

may

adjusting

located

be

checked

NOTE:

CAUTION:

the

stitch

inside

as

outlined

Once

been

stitch

"Changing

feed

get

in

control

move

against

If

set

length

will

approximately

both

directions.

On

this

the

equal

length

the

machine.

on

the

11

the

at

12

can

The

not

have

machines

reverse

lever

rest

stitch

control

next

forward

stitches

The

be

made

Stitch

to

be

the

feed

before

pin.

length,

lever,

feed

page.

and

reverse

per

inch, a change

as

Length",

adjusted,

same

equipped

number

lever

tipping

forward

adjustment

linkage

feed

described

the

reverse

you

of stitches

with a treadle

(A,

Fig.

machine

and

reverse

should

is

pre-

has

under

should

30)

re-

back

set

in

be

at

Page 12

SETTING

THE

REVERSE

FEED

MECHANISM

(Continued)

verse

and

screw

adjusting

NOTE:

feed

adjust

(B)

APPLY

lever

the

in

screw,

THE

Fig.

TO

30

(A,

Fig.

stop

this

REMAINDER

screw

position

when

MACHINE

reverse

30),

hold

(B,

Fig.

with

OF

THE

STYLES

Drain

remove

cover.

stitches

ing

screw

the

stitch

ver

(B),

(C)

is

bottom

holding

the

bottom

Now

to

ver

locknut

feed

adjustment

the

as

On

down

30)

is

actuated

ADJUSTINGINSTRUCTIONS

63400

PRESSER

machine

the

bottom

Set

the

per

inch.

(A,

regulator

so

the

23/32

of

the

screw

reservoir

reverse

described

machines

the

reverse

to

stop

(C).

This

KX

AND

machine

Loosen

Fig.

31)

center

inch

base.

(A)

can

feed

earlier.

equipped

against

is

by

stepping

KY

BAR

plunger

and

control

feed

to

of

oil

and

reservoir

at

zero

hold-

and

move

le-

of

screw

above

Retighten

be

prevent

ONLY.

CONNECTION

the

replace

cover.

made

le-

with a treadle

control

the

bed

casting.

damage

on

the

IN

Fig.

lever

treadle.

THIS

(Page

31

control

(C,

Fig.

Lock

to

CATALOG

the

15)

stop

feed

re-

28)

When

directly

is

set

properly

connection

To

obtain

loosen

Set

needle

pressure

direction.

the

set

guide

enters

locating

against

(A,

screw

to

to

the

Fig.

the

when

Fig.

this

(D).

the

the

presser

12A

the

presser

throat

there

16A).

setting,

Tap

1/16

middle

plate

is a 1/16

remove

on

presser

inch

of

its

foot

by

should

the

This

back

nut

(B)

ing

setting

complished.

stop

bar

guide

with

the

inch

the

foot

dimension,

slot

and

turning

The

be

lower

is

against

(A,

Fig.

on

the

the

stop

of

screw

PRESSER

(B,

Fig.

feed

space

pressure

to

insure

center

retighten

the

presser

presser

set

presser

accomplished

lifter

screw

the

in

dog

between

the

bar

so

that

the

rest

15)

and

lever

to

presser

Tighten

place.

BAR

16A),

in

its

from

its

the

being

foot

screw

spring

the

the

lowest

connection

it

is

about

bar

bushing

by

tipping

pin,

relocating

bell

crank

right

bar

the

lock

GUIDE

presser

position.

guide

(B)

presser

down

by

turning

(D)

in

regulator

(A,

7/16

(Fig.

the

loosening

the

(C).

or

left,

connection

nut

(A)

(Page

foot

and

presser

spring

on

the

throat

it

so

guide.

Now,

in a clockwise

Fig.

inch

machine

the

stop

By

the

proper

to

lock

16)

must

The

(C)

that

16A)

above

16A).

lock

screw

turn-

is

ac-

the

rest

guide

bar

and

plate.

the

apply

Set

the

wire

is 4 3/4

needle

inches

thread

above

take-

the

up

wire

throat

(A,

plate.

12

Fig.

16B)

so

that

the

underside

of

the

Page 13

out

Fig.

thread

16A

in

the

TENSION

1.

2.

3.

tension

RELEASE

Set

the

tension

that

centered

eyelet

Solenoid

16A)

lease

noid

trude a minimum

to a maximum

If

move

in

screw

arm

(B,

Tension

(F,

plunger

clearance

the

(A,

must

pin

plunger

adjustment

tension

or

out

located

and

Fig.

Fig.

disc.

tension

on

the

Fig.

plunger

touch

and

the

pin

post

by

moving

18A)

release

16A)

pin

(E)

between

(Page 1 7)

assembly

discs

check

18A)

pin

(E.

tension

end

of

must

of

1/3 2 inch

of

1/16

is

required

assembly

loosening

under

with

stop

as

required.

solenoid

is

it

machine

a

to

ar

spring

Fig.

re-

sole-

pro-

inch.

set

screw

set

have

and

the

so

e

is

secured

screw

in

approximately

tension

Fig.

to

flat

bracket.

release

16B

of

bushin

Solenoid

.

005

pin

4-

inch

with

3"

4

g

-

4.

This

solenoid

noid

should

plunger

the

tension

The

manual

release

The

raising

point

screw

NOTE:

as

is

of

Check

Fig.

the

can

be

plunger

then

pin.

Care

disc.

tension

thread

tension

or

lowering

between

securely.

Head

the

18A

case

oiler

slot

the

may

accomplished

pin

and

be

slipped

should

After

tension

release

1/

4to

in

the

oil

gauge

TRIMMER

ger

chine

1.

There

shake

carrier

adjustment

loosening

pivot

taking

be.

tightening

release

when

to

suit

5/16

bracket

connecting

Remove

and

knife

and

the

end

onto

be

taken

cam

the

cam

can

the

inch

must

to

be

ADJUSTMENTS

the

assembly

proceed

should

in

lower

(A,

screw

release

up

the

by

placing

of

tension

bushing

not

to

set

(G,

presser

be

positioned

sewing

of

presser

locate

rod.

The

sure

can

it

reads

positioning

as

follows:

be

no

knife

Fig.

be

(B)

lever

excessive

a .

005

release

and

moved

exert

screw

Fig.

conditions.

the

from

bind

32).

made

(C)

16A)

foot

foot

needle

wick

full

fin-

ma-

pivot

This

on

and

too

remove

by

the

end

is

by

lift

must

or

inch

spacer

pin.

in

until

much

spacer.

should

raised

loosening

The

above

bar

contact

and

operates

play

The

tension

it

contacts

pressure

be

set

for

back

average

the

throat

link

oil

the

or

relieving

between

release

thereby

so

that

tacking.

screw

tension

plate.

wick

in

needle

freely.

Fig.

32

the

head

the

solenoid

opening

it

will not

(H)

and

release

Tighten

the

bearings

the

of

sole-

then

center

.

bind

13

Page 14

THIMMER

ADJUSTMENTS

(Continued)

Fig.

33

adjustment

The

beyond

moves

of

loosen

the

to

the

positioning

screws

or

lower

left

the

Position

the

tioning

lower

knife.

finger

centric

are

would

eccentric

mately

arm

Adjust

adjust

to

CAUTION:

parallel

knife

side

right.

(A.

left

parallel.

of

lower

(A.

of

the

finger

Fig.

upper

side

finger.

knife

set

If

is

this

screw

bushing

be

to

have

bushing

90°

to

the

positioning

lower

the

lower

knife

Be

adjustment

Fig.

the

33)

arm

run out

as

indicated

34)

and

knife

of

the

Check

parallel

is

not

(E)

(F)

A

good

the

(F)

the

knife

knife

and

counterclockwise

sure

will

in

its

of

the

of

the

position

(D)

parallel

arm

to

with

so.

and

until

of

the

see

the

loosen

turn

the

starting

pin

hole

located

right

finger

until

turn

side

(Fig.

it

just

flange

approxi-

bushing

have

to

extreme

positioning

cutting

at

point

edge

(D).

knife.

posi-

that

upper

the

knives

point

in

of

contacts

screw

is

not

be

checked.

left

finger

with

the

the

ec-

the

the

34) .

to

turned

position

(C)

must

To

make

(G.

raise

(B).

Fig.

the

upper

Fig.

it.

while

should

As

the

coincide

these

34

knife.

32)

clockwise

making

not

extend

lower

at a point

adjustments

To

this

knife

4.

5.

Locate

far

forward

of

feed.

tacting

the

pivot

inch

clearance

spring

Adjust

when

the

position.

with

the

case

holder.

the

With

the

release

(A.

the

lower

the

left

Fig.

cutting

as

possible

the

cutting

to

Fig.

lower

knife

left

side

35

solenoid

cutting

solenoid

lever

be

maintained

36)

is

knife

corner

of

the

is

(D),

in

stop

in

bracket

and

parallel

solenoid

plunger

so

position.

screw

its

(E.

needle

Assemble

3.

assembly

case

assembly

until

the

ing

cess

assembly

ing

edge

bobbin

(A.

lever

that

there

when

(B.

extreme

Fig.

slot

33)

in

holder

the

projection

finger

(B)

1/32

of

Fig. 3 5)

with

the

(B)

(C).

is a 1/32

knife

return

Fig. 3 6)

right

is

in

the

bobbin

positioning

into

by

finger

into

and

attaching

inch

projection

case

recess

as

line

con-

adjust

so

hand

line

machine.

positioning

turning

the

recess

(A.

Fig.

the

bobbin

tighten

screws

clearance

and

(Fig.

finger

Adjust

finger

bobbin

is

at

12A)

the

finger

between

the

12A).

Fig.

and

the

and

case

the

top.

on

the

case

holder

and

securely.

the

inside

36

knife

bobbin

knife

holder

Place:

position-

re-

knife

allow-

outside

edge

of

CAUTION:

making

Be

this

adjustment.

sure

cutting

Also

solenoid

be

sure

lever

knife

contacts

does

14

not

the

hit

lower

the

hook

knife

point.

stop

when

Page 15

TRIMMER

6.

Be

when

not

sure

the

make

ADJUSTMENTS

the

spring

lower

contact,

retainer

knife

bend

is

in

its

retainer

(Continued)

wire

extreme

(B,

right

wire

Fig.

to

34)

hand

suit.

contacts

position.

the

If

bobbin

the

spring

case

hold

wire does

er

NOTE:

7.

from

Knife

machine

return

tension

(D)

to

the

SYNCHRONIZER

(a)

Rotate

the

plate

assembly

stroke

(b)

At

band

front

this

flectorplate

set

required.

(c)

The

at

rotate

loosen

rotate

the

If

positioning

spring

of

knife

right

handwheel

needle

(C,

of

this

time

(A,

edge

adjustment

screws

needle

bottom

handwheel

screw

third

middle

or

position

(A,

r e

turn

to

increase

ADJUST

clearance

Fig.

is

in

line

the

needle

the

Fig.

of

3 7)

the

position

as

described

(C)

in

positioner

of

stroke.

(D)

band

of

the

finger

assembly

changed,

Fig.

36)

spring

loosen

tension

lVIENT

in

operating

cut

12A)

on

with

the

the

bar.

brass

contact

should

brush

holder

needle

above,

synchronizer

should

If

not,

until

at

from

black

end

it

is

of

left

plastic

or

check

to

have

proper

screw

or

to

the

direction

in

the

deflector

rotating

needle

be

flush

(B).

bar

on

of

the

with

To

and

then

and

move

position

with

power

at

bottom.

synchronizer

(E)

in

operating

band.

cutting

step

(C)

left

until

hook

the

up

left

the

make

de-

loosen

as

needle

off

Then

and

solenoid

5.

tension

and

move

to

decrease

direction

to

cut

tension

bracket

threads.

the

Fig.

until

are

To

spring

tension.

37

its

brush

removed

adjust

bracket

is

in

(d)

The

needle

Fig.

38

needle

or

If

in

top

end

band

the

Turn

positions

CLUTCH

1.

Set

2.

Adjust

so

nut

inch

thread

1/8

inch

not,

with

operating

of

its

of

synchronizer

from

middle

on

power

ARM

needle

clutch

that

treadle

washer

from

stroke.

of

end

15

positioner should

take-up

from

power

direction

the

top

off

Then

at

top

of

rotate

until

loosen

and

left

(F)

of

the

and

the

SWITCH

in

work.

arm

will

(B)

is

of

until

black

check

needle

spring

retur.n

to

be

stud).

its

the

bar.

ADJUSTMENT

approximately

position

of

its

strok

its

up

stroke.

handwheel

it

is

at

the

screw

rotate

brush

plastic

up

and

at

fourth

is

in

band

down

I

(A, Fig. 38)

to

stop

(win

1/2

e

.

g

Page 16

CLUTCH

3.

Close

switch

it

needle

this

and

setting.

ARM

treadline

screw

the

micro

positions

SWITCH

switch

(C).

until

switch.

up.

ADJUSTMENT

and

loosen

there

Tighten

is

Then

no

tighten

nut

(Continued)

clutch

contact

screw

(D)

to

lever

between

until

maintain

CAUTION!

lever

ning;

engaged.

THREAD

1.

Rotate

adjust

hook

is

catches

at

the

Fig.

switch

one

click

WIPER

thread

thread

top

39

Clutch

is

wiper

wiper

the

of

its

~..,...--

8

3 1.

2.

must

closed

must

not

or

auxiliary

be

heard

ADJUSTMENTS

mounting

guide

needle

(63470

thread

stroke.

ADJUSTING

Depress

indicates

Adjust

1/16

Loosen

Lock

treadle

switch

clutch

to

1/8

lock

Motor)

approximately

the

top

on

the

engages

engage

as

described

when

motor

before

collar

P),

when

(63470

so

the

CLUTCH

unit

is

so

that

inch

travel

screw

just

one

turn.

right

clutch

is

run-

clutch

t~at

H)

is

and

the

take-up

until

open.

clutch

before

(E.

enough

end

above.

one

arm

Fig.

to

Adjust

of

the

Tighten

click

has

clutch

38)

unlock

screw

motor

is

heard,

which

approximately

is

engaged.

(where

it.

it

which

located

until

lock

clutch

screw

says

is

near

(E).

2.

Thread

3.

snap

Form

ment

when

in

CAUTION!

solenoid

wiper

against

when

failure

to

return

INSTALLATION

When

be

sure

located

before

not

function

Should

later

date.

replaced

position

wiper

lever

(63470

released.

thread

thread

guide

plastic

adjusting

of

wiper

Thread

from

(63470

solenoid

wire

wiper

guide

wiper

returning

P)

tube.

Be

thread

will

completely.

OF

INCffiNG

installinginchingswitch.

to

remove

between

connecting

pin

the

#2

inching

properly.

the

inching

the

jumper

or

the

needle

up.

E)

(63470

(63470

hook

to

its

so

that

sure

wiper

result

jumper

and

pin

switch

switch

wire

(A,

positioning

must

F)

for

P).

must

stop.

hook

to

does

loosen

lever.

if

it

is

SWITCH

(No.

wire

#3

plug

be

removed

Fig.

return

free

not

Move

not

set

Premature

not

670

(A.

Fig.

on

socket

or

39)

must

unit

will

with

move-

prevent

thread

stop

screws

allowed

B-21)

39)

(B)

it

will

at

be

not

a

a

Fig.

40

16

Page 17

If

pressed,

treadle

out

trimming.

needle

the

pushbutton,

the

is

heeled

out

of

cutter

while

This

the

work,

which

band

the

enables

but

PUSHBUTTON

is

mounted

of

the

synchronizer

pushbutton

the

operator

without

having

on

is

depressed.

to

trimmed

FUNCTION

the

front

is

interrupted.

the

readjust

or

the

edge

needle

realign

threads.

of

the

table

Th~refore,

will

the

board,

position

garment

is

when

up

with-

with

de-

the

the

To

screws

moved

length.

If

more

can

be

compressed

ion

bushing

If

more

bushings,

should

The

switch

(E).

be

roller

actuator

adjust

in

and

the

the

(C)

or

the

back

less

up

travel

micro-switch

taken

on

the

bushing

length

three

more

or

is

so

that

switch

TREA

of

panel.

bushings

pressure

or

down.

required

actuator

only

should

(D).

DLINE

the

If

more

is

less

in

enough

This

SWITCH

pitman

adjustment

inside

the

required

accordingly

the

treadle

(D)

and

travel

not

be

allowed

is

accomplished

rod

switch

when

stop

is

ADJUSTING

(A,

Fig.

40)

is

necessary

relocated

heeling

by

moving

for

actuating

bushing

provided

to

to

ride

by

adjustment

loosen

the

the

(E).

actuate

over

the

to

obtain

treadle,

pitman

the

trim

must

the

bevel

of

the

two

cover

must

the

the

rod

spring

cycle,

be

lowered.

the

micro-switch.

on

the

the

stop

Allen

be

desired

spring

the

micro-

bushing

set

re-

(B)

tens-

two

Care

The

power

circuitbreaker.

fuses

AMP

the

located

and

the

slow

primary

under

relay

auxiliary

blow

coil

Fig.

winding

41

pack

The

fuse

the

chassis,

control

FUSING

incorporates

11/2

motor

(A,

of

AMPcircuit

as

Fig.

the

transformer.

for

circuit

well

42)

the

(24

THE

a

safety

as

the

located

thread

VDC).

POWER

feature

breaker(A.

positioner

on

top

of

The 5 AMP

wiper

17

PACK

consisting

Fig.

the

solenoid

41)located

circuit

chassis

straight

(30 VDC),

~

Fig.

42

of

two (2)

inthe

components.

fuses

blow

the

fuse

cutter

fuses

frontpanel

The 1 1/4

AC

input

(B.

Fig.

solenoid

and

for

41)

a

Page 18

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1.

FOR

Unit

Unit

Unit

Unit

Unit

Auxiliary

Unit

Auxiliary

Unit

Auxiliary

Check

does

positions

trips

trips

keeps

positions

trips

FOR

the

TYPICAL

UNITS

not

position.

up

in

circuit

the

on

motor

motor

circuit

motor

UNITS

following:

breaker.

circuit

stitching

runs

slowly.

runs

breaker

will

TYPICAL

WITH

second

breaker

at

while

very

not

WITH

NEEDLE

PRINTED

position.

every

an

inching

clutch

hot.

after

turn

NEEDLE

PRINTED

positioning

over

POSITIONER

CIRCUIT

but

does

few

hours

speed.

is

engaged

one

although

POSITIONER

CIRCUIT

you

PROBLEMS

BOARD

not

position

or

every

with

BOARD

rna

time.

know

SOLUTIONS

CONSTRUCTION

down.

few

days.

in

motor.

power

CONSTRUCTION

is

feeding

it.

Circuit

Synchronizer

Treadle

Input

Auxiliary

Loose

PrintedCircuitBoard(Check

nal

2.

The

the

3.

SCR

4.

Check

Grounded

Oil

Field

Operator

5.

Check

breaker

jack

power

motor

connection

End).

treadle

power

is

saturated

is

shorted.

the

following:

armature

deteriorated.

fluttering

the

following:

jack

switch

turned

armature.

and

brushes

(check

is

not

off

Replace

(tie

Replace.

treadle

brushes

and

soldered

opening.

and

then

board.

bolt

excessively.

armature

connections)

forlooseconnection

The

unit

will

back

touching

on

again.

field).

or

oxidation

position

down

on

the

Plug

first

in

Termi-

time

after

Synchronizer

Brush

Damaged

Synchronizer

Very

Defective

location

loose

field

V-belt.

brake

male

loose

and

on

synchronizer.

coil

in

on

SCR

female

au:x:iliary

handwheel.

circuit.

jacks.

motor.

Replace

Clean

printed

18

synchronizer.

circuit

board.

Page 19

6.

Treadle

7.

Armature

ture

8.

Check

switch

has

dressing

the

following:

is

not

poor

stone).

opening,

commutation

or

is

defective.

or

is

partially

shorted

and

dirty.

(Use

arma-

Setting

Opera

Grounded

Brake

No.

Check

two

position

of

the

9.

Check

Lead

Brush

10.

Check

Armature

The

of

treadle switch.

tor

fluttering

field

gear

9855.

operation.

units,

operation.

the

following:

rubbing

holder

the

following:

Chassis

coil

seized

Sometimes

thereby

This

in

armature.

jammed

brushes

is

Equipped

the

(tie

on

will

and

treadle.

bolt),

hub.

it

using

Replace

is

the

greatly

against

brush

armature.

holder.

Voltage

With A Dual

or

defective

possible

positioner

prolong

field

with

new

to

remove

to

life

and

Adjustment

Value

Power

coil.

gear

and

the

only

raise

minimize

Resistor

Replace

brake

down

the

maintenance.

(See

field.

assembly,

position

Needle

Figure

brush

at

the

Part

on

end

43).

As

Figure

portion

portion

is

is

43

to

be

used

shows

used

when

the

when

the

75

50

Ohm

resistor

the

supply

Ohm

over

220

has a value

line

voltage

voltage

Volt

Fig.

220

and

is

Volt

43

is

220

above

of

50

volts

220

ohm

or

volts.

and

75

lower,

ohm.

second

The

the

50

75

ohm

ohm

19

Page 20

Before

bility

at

for

suggestions

this

all

machine

times.

which

left

If,

however,

may

the

prove

factory,

the

beneficial

it

was

trimmer

adjusted

has

been

to

you,

and

inspected

readjusted

and

so

is

as

not

to

give

trimming

the

utmost

properly,

satisfaction

see

the

and

chart

dura-

be low

Both

Needle

thread

Bobbin

thread

Lower

the

way

threads

thread

cut

thread

cut

knife

Condition

not

cut

not

cut,

not