Page 1

INDUSTRIAL

SEWING

riNEST

STYLES

63400

63400

63400

QUALI

®

TY

LB

LC

LV

MACHINES

-

'

u

CATALOG

No.

121

LB

CL

ASS

STREAMLINED

HIGH

SPEED

LOCKSTITCH

WITH

PNEUMATIC

"K

LIPP

UNION SPECIAL

CHICAGO

63400

MACHINES

-

IT~

THREAD

TRIMMER

CORPORATION

Page 2

C a t a 1 o g N

o.

121 L B

( S u p p 1 e m e n t t o C a t a 1 o g N

I N S T R U C T I 0 N S

F 0 R

o.

1 2 1 M )

e

am

T I N G

L I

S T 0 F

L A S s

C

1 i

n e d L o c k s

s

AND

t y 1

A D J U S

t r

S

6 3 4 0 0 L B 6 3 4 0 0

6 3 4 0 0

S e c o n d E d i t i o n

0 P E R A T

PART

6 3 4 0 0

e s

L y

S

t i

I N G

t c h

L C

C o p y r i g h t 1 9 7 8

by

U n i o n S p e c i a 1 C o r p o r a t i o n

R i g h t s R e s e r v e d i n A 1 1 C o u n t r i e s

UNION SPECIAL CORPORATION

INDUSTRIAL

P r i n t e d i n

SEWING

CHICAGO

2

MACHINES

U.

S.

A.

March,

1980

Page 3

Each

on

the

or

more

numbers

fixed

UNION

machine.

letters

contain

to

the

SPECIAL

Style

suffixed,

the

standard

machine

numbers

letter

Style

IDENTIFICATION

is

identified

are

but

"Z".

classified

never

contain

When

number. Example:

only

by a Style

as

the

minor

"Style

OF

standard

letter

changes

63400 LBZ".

MACHINES

number

and

special.

"Z".

Example:

are

made

which

is

stamped

Standard

"Style

in a standard

into

Style

63400 LB".

numbers have

machine a "Z"

the

name

Special

is

plate

one

Style

suf-

Styles

the

style

This

Only

those

illustrated

phantom

Opposite

and

amount

NOTE:

Catalog

that

Styles

also

direction,

at

High

Thread

Rotary

Reservoir,

Automatic

and

Bar

When

Adjusting

are

63400

This

be

the

machine.

speed

Wiper.

Hook,

Needle

11

1/8

of

number,

catalog

parts

and

to

help

required.

ordering

No.

121 M for

different

LB,

catalog

applied

such

Streamlined

Prepared

Horizontal

Enclosed

Head

Bar

inches

machines

in

that

is a supplement

which

listed

locate

the

and

with

as

Operating

Oiling,

Driving

are

at

the

illustration

repair

operating

Style

from

LC

and

applies

discretion

right,

Long

for

Automatic

Needle

Link,

(282.58

similar

Style

LY.

left,

direction

Hook

mm).

in

it

used

the

63400

parts

63400 B. The

specifically

Arm

Needle

Shaft,

Feed Timing on Lower

construction

contains

to

Catalog

on

Styles

back

of

LB,

LC

page,

parts

always

instructions

63400 B

to

some

front

of

Lockstitch

Positioner,

Push

Lubricating

Bearing

no

letters.

APPLICATION

No.

63400

this

book.

and

LY.

are

identiified

use

the

for

Styles

only

or

to

back,

handwheel

Adjustable

instructions

are

additional

the

Standard

Special

etc.,

STYLES

Machines,

One

Button

System, Head

are

grouped

Example:

OF

CATALOG

121

M and

LB,

LC

For

clarity,

part

number

63400

Styles

are

given

is

toward

OF

MACHINES

with

Needle,

Stitch

Feed

Eccentric,

Mainshaft,

under a class

"Class

should

and

LY,

certain

by

detail

listed

LB,

included

instructions

Styles

of

Regulator,

Oil

of

machines

from

the

Air

Operated

Light,

Siphon,

Maximum

63400".

be

used

but

not

number,

in

LC

and

in

that

machines

in

the

operator's

operator.

Medium

Stitch

Adjustable

Needle

Work

number which

in

used

on

63400 B

the

second

LY

are

this

catalog

pertain

as

this

class.

Thread

and Heavy

Length

Bearings

Space

differs

conjunction

Style

parts

part

similar

listed

Undertrtmmer

Hook

63400

are

number

column.

to

are

specifically

herein.

Reference

positon

Duty,

Indicator,

Oil

Control,

for

Take-up

to

Right

from

therewith.

Bare

shown

in

description,

those

in

the

ones

to

It

can

to

while

Drop

of

seated

and

Feed,

One

Lever

Needle

Air

63400

LB

heavy

Specify

size,

63400

LC

work, 1 1/2

foot,

and

63400

LY

work,

Specify

attachments

Each

kind

of

needle

eye.

Collectively,

Needle

use

needle

following

Medium

weight

attachments

High

throat

guides.

Medium

reverse

UNION

shank,

shank,

Type 180

Type 185

page.

throw

work, 1 13/64

presser

throw

inch

plate,

Maximum

throw

feed, 1 13/64

presser

and

SPECIAL

point,

denotes

the

machine,

foot,

and

machine,

(38.10

feed

recommended

machine,

foot,

guides.

needle

length,

largest

type

GXS

or

GAS

and 185

throat

guides.

for

mm)

dog,

throat

Maximum

has

groove,

diameter

number

180

GYS

GBS.

for

miscellaneous

inch

(30.56

plate,

Maximum

miscellaneous

needle

for

inch

plate,

bar

stitches

speed

miscellaneous

(30.56

feed

recommended

both a type

finish

of

and

the

is

recommended

Their

mm)

feed

needle

dog,

recommended

plain

travel.

per

inch,

5000 R.P.M. -

mm)

needle

dog,

speed

NEEDLES

number and

and

the

other

blade

size

number

description

plain

bar

stitches

speed

seaming

Type 180

thread

plain

seaming

bar

stitches

5500 R.P.M. -

details.

measured

represent

for

Styles

and

seaming

travel.

per

5500 R.P.M -

operations

GXS

size,

depending

travel.

per

size

number. The

in

63400

the

sizes

operations

Type 180

inch,

operations

inch,

The

thousandths

or

needle

on

Type 180

depending

size

the

complete

LB,

available

thread

180

operation.

thread

LC

on medium and medium

GXS

or

180

size,

depending

on medium and

GYS

needle.

type

and

on

light

GXS

size,

on

type

of

and

number

an

symbol.

LY.

are

number, stamped on

GYS

needle

on

operation.

heavy

Specify

size,

to

medium

or

180

needle

operation.

denotes

inch

across

For

heavy

listed

attachments

GYS

needle.

type

weight

presser

needle.

type

the

duty,

on

the

and

weight

and

the

the

size,

3

Page 4

NEEDLES

(Continued)

Type No.

180

GXS

180

GYS

185

GAS

185

GBS

To

needle,

A

complete

Selection

used.

stitch

Round

groove,

mium

125/049,

Round

groove,

sizes -075/029,

150/060.

Round

ball

ball

110/044, 125/049,

Round

ball

chromium

125/049,

have

needle

or

the

type

order

of

Thread

formation.

should

shank,

wide

plated -sizes

140/054,

shank,

wide

shank,

eye,

single

point,chromium

shank,

eye,

single

plated -sizes

140/054,

orders

and

size

would

proper

pass

read:

needle

freely

Description

round

angle

round

angle

round

round

promptly

SELECTING

point,

groove,

075/029, 080/032,

150/060.

point,

groove,

080/032,090/036,

point,

groove,

plated -sizes

140/054,

point,

groove,

150/060.

and

number

"1000

should

Needles,

size

through

lockstitch,

lockstitch,

lockstitch,

wide

lockstitch,

wide

075/029,

accurately

should

the

THE

SIZE

and

Sizes

struck

struck

angle

150/060.

angle

080/032,

be

forwarded.

Type 180

be

determined

needle

OF

short

groove,

090/036,

short

groove,

100/040,

short

groove,

075/029, 080/032,

short

groove,

filled,an

GYS,

eye

THE

NEEDLE

length,

deep

length,

deep

110/044,

length,

struck

length,

struck

090/036,

empty

Use

Size

by

the

in

order

spot,ball

100/040,

spot,

description

090/036".

ball

eye,

single

point,

110/044

ball

eye,

chromium

125/049, 140/054,

reinforced

groove,

090/036,100/040,

reinforced

groove,

100/040,

package, a sample

size

of

thread

to

produce

chro-

single

plated

blade,

deep

spot,

blade,

deep

spot,

110/044,

on

label.

a good

The

size

of

upon

the

The

kind

of

to

above,

er

than

Cotton

CAUTION!

on

handwheel.

strength

the

thread

size

following

thread.

which

the

size

Thread

Size

0

30

36 A

40

50

60

70

80 0000

90

100

requirement

employed. The

of

the

table

The

may

dictate

specified.

When

unpacking,

Using

both

needle

shows

choice,

hands

of

the

quality

employed.

the

preferred

however,

the

selection

Mercerized

INSTALLING

DO

NOT

on bed

seam

should

Size

000

0000 080/032

lift

casting,

produced

of

the

size

give

of a needle

Thread

B 140/054

A 110/044

0

00

machine

is

largely

work

desired

of

needle

consideration

size

out

lift

gently.

of

dependent

is

largely

for a given

to

slightly

150/060

125/049

110/044

100/040

090/036

080/032

075/029

box by

placing

factors

larger

upon

the

dependent

size

and

referred

or

Needle

Size

to

150/160

to

140/054

to

125/049

to

125/049

to

110/044

to

100/040

to

090/036

to

090/036

to

080/032

one hand

small-

Before

carefully

ing

box,

leaving

packed.

the

following

factory,

After

the

machine and

steps

each

should

UNION

be

SPECIAL

accessories

followed:

4

machine

have

is

been

sewed

off,

removed from

inspected

the

and

pack-

Page 5

CLIIIIP

Foe

fA:>tt

':IOI..Et.aOI D vlti..VES

"'2E

3 ·

WAY

£ 4 'I¥Al

LEADS

<071F·I3

t;71 F·S

717

<;71

F· ll

Ee

R

lf()tJNf/116

SOlEIJOIO

RX>T

j

-10

<103

t

1111<;.

1'\.~EA!'>\

OF

ELECTeiCAL

PII.ET"'

01.1

EQUII'PE.O

Po'>ITIOIJt£!..

1\.I':>TI'\.\.Al\ON

1)

MO

U'-IT

""'

"'>\CWU.

Z)

MOUIJl

liiiDteS\tlE

SC·3Z~

A SCREWS

~)

MOOI.IT

REGUlA10R

LEF 1 R£-'11 ll<BI..E LE.(; .

IIJST.•lL

'I)

To

1"E

MA.C>III.I

t . P.

S)

PLI<Cii:

YOW

T

')

;3~

35 P

IF

....

-

FE

=~'!»\~[)

7)

C

OO<IJ

EC.T

8)

TO

DI

~COtJ~

L\

f:'T

, RO"'rtti

ll<t 3 •

IT W•TH

PLUEi

AS t•TI!A.

.-

lr!II(H

!IRC

JIIHE TO

•

/

RS

SHOWN

<;.\lOWS

11\E 1\.1';11<ll1<110\.l

A.IJ[) I'IJE\l"""11C

~Melo~\\.~t\.'(

WIT)\

BOo'fP-~2

eoo.,-P-~Z

SOLE.IJOIO

OF

'liE

MAC\III.IE

IIJ<;.H~UCT

EH.R

MA.C""'E

S

YIJC~IJI

fOOL

wr.; 1HE I>EFLtC10e PlATE

AOV:,

ALL

EC.T AI

"'"' •.;cu

(1\ • <071 F·c;.

sceew.

~[)

~ttliJ~E.

\JEEOLE

B~~ET

TABLE 130AeD

81!/loCKE.T

~"3470l.

A.CCESS

•

O"<;,

FU21o11'>\\tD

TO

Pl.·

~12.

o1.1

1\<

E ,\,jSo

ZE~

A>lD

TA.PE

-">JUST.

,.,_

RlE

~li~~~~~:I!\KIIOIJ"'

,.

~·1

\JS

E.,_

A~

~

10

l~E ~~S

"~C2' Ftlt'

\.l~

•

"'O

D V

,O.lVE

A!>t.I'Re

'"~"

,.

..

.,~

A.IJO

c...ec,• tlO<::O.

t;7HO

C#71C·I

~

t;71

F-9

.a.'>'>EK!ILY

1/Ai.l/€

11\I?EAD

~-375

1<.71

· 17

,a.';<;.El'ISLY

SOlEWOIO

"''"~''"'"..__

22~05

SECTIQI..l

A-A

L

~EGULA.TOR

~T

F..

,0.\ll.ILA.Bl.E.

·~~~

_:

'MlH

REGULA.Toe•c;7, o -7.

4WA.'f

---------------~

~E.T

.0.'>'1>E.I-I8LY

RtG~LA.TOI!

•

C.71

0 · 7

I~

CF

"Z'!l"BO!<L

A<;.

~~E&'T~~~~~c

1W

IJOT

I<JT,

EXT~

BUT

1

t~l=-::.-------=-=

.::::.-::,.

.

cr'

,..

...

7, f ·

!l

,-

"'I!·

Gi11 F·l'!.

/

FllTEI?

-1<.71F

1<.710

STIIJl

~

· 7 1

· 5

IYRSJI(RS

--

- l\JBII-IGt FRo>\ Tei.I

RELSASE

"t\o\E

-

"'

·

"'~

-GROOND

! '

SOLWOID

or

FOE

PRES'>U~

'HIPE'e. •

OF

"-~'f

~llJ..\1€

KU\f'€

.

WIRE

•J.'

f-----..,

!all!&

f.'

<;11!01"\l'IE. T TO

BE

SUI'f'I.IED

\IEEt".E I'OSii tOIJ

'OI0

\.1

SY

NOIRON!ZE

BRI/CKET.

?.·wA.Y

FOR

WITh

t;ROUND WJR£7fit:Jif

110

701<

fERJivrRL

.

~01'\PoutiJT

~~1.'\

IJ~EOLE

Po.,_I\IO

~U:

~"?.470'1'

TO

~\..C.

("\

TO

02 1

E.,_

A.~Cat!DIIJ(;

..,ITH

l~E

A.L<A.TIO>J

A.IJ[)

QlE<:I<I\l{:o

To

SEE

'i»>IWII

~Ee

,1\

Plt)O

F'

8 1

Qot'\

AIJD

IIEPUCE

,..., Vl.lZS71F

""'•

A.""'LA.Bl.-

ll'\

T

GI!EE\.1

<03"70Z

~to

WHITE.

E.\JLA.EGEO

>ne

T~E

?. ·

Te\6\0\.1

Ri.I.EASE.. SO...EIJOI[).

llJ..L

ELE<:lltiCAL. WIRE'!\

BE.

FA.'>lE.»ED

TI.BLE 80A.Rtl

VIEW

WA'f

OF

i " ·

5U:UI<!E.L'<

WIT\\

c...aLE

l\4£

WAY

ELEC.ll11c...L

50LE\JOIO

-""0

l'lO"Il:>R

10

~E

CLI<11P'!\

OlolNtC.

V,.LVE

"-110

CA.6l£.<;. MU'ST

INI:i£R·'!oiOE

I'I!OVIOEO.

Fig.

,,

TICIJS

eF

TilE

~

1KE:

1

IITTIICH

FOR

~sz

u-1+-

18j

,

<0'2.7

ZIC.57E

MOJ.ITI\.IG.

OF

RE.GU~"TO'e

~I<.E.T

lAI!U.

-oo

IIETII!N/NG

SrlfCHIIOII'IZ£R PLUG.

WJIIE

'60Af.'0

I.IEEDLE I'OSI"t\0\.IE'il ~~~E

S~O

ee.

"'ET

iO

UIJE.

TO

!tOll

"-\.l<i.LE

BE

WILL !lot PULLED

iO

ALI.DW

lO

'ltES l 1'0"'1"110\..l

l..OCJI.TE.

\JEEDLE f'O!.ITI0\1;1'!

SO

TI<E.

K.TUI\n\lc;.

I~

A

s"I'R,o."-111

ROD

Mot\oC~I'-IE

Bl!o\C:.l<ET

"""""'

liLTEO

OVE12

TeE.A.t>LE

\.!

B":"-

Page 6

PREPARATION

OF

MACHINE

AND

TABLING

Included

bobbin

spring,

screw,

kit

for

sisting

two

hinge

one

synchronizer

er

lead

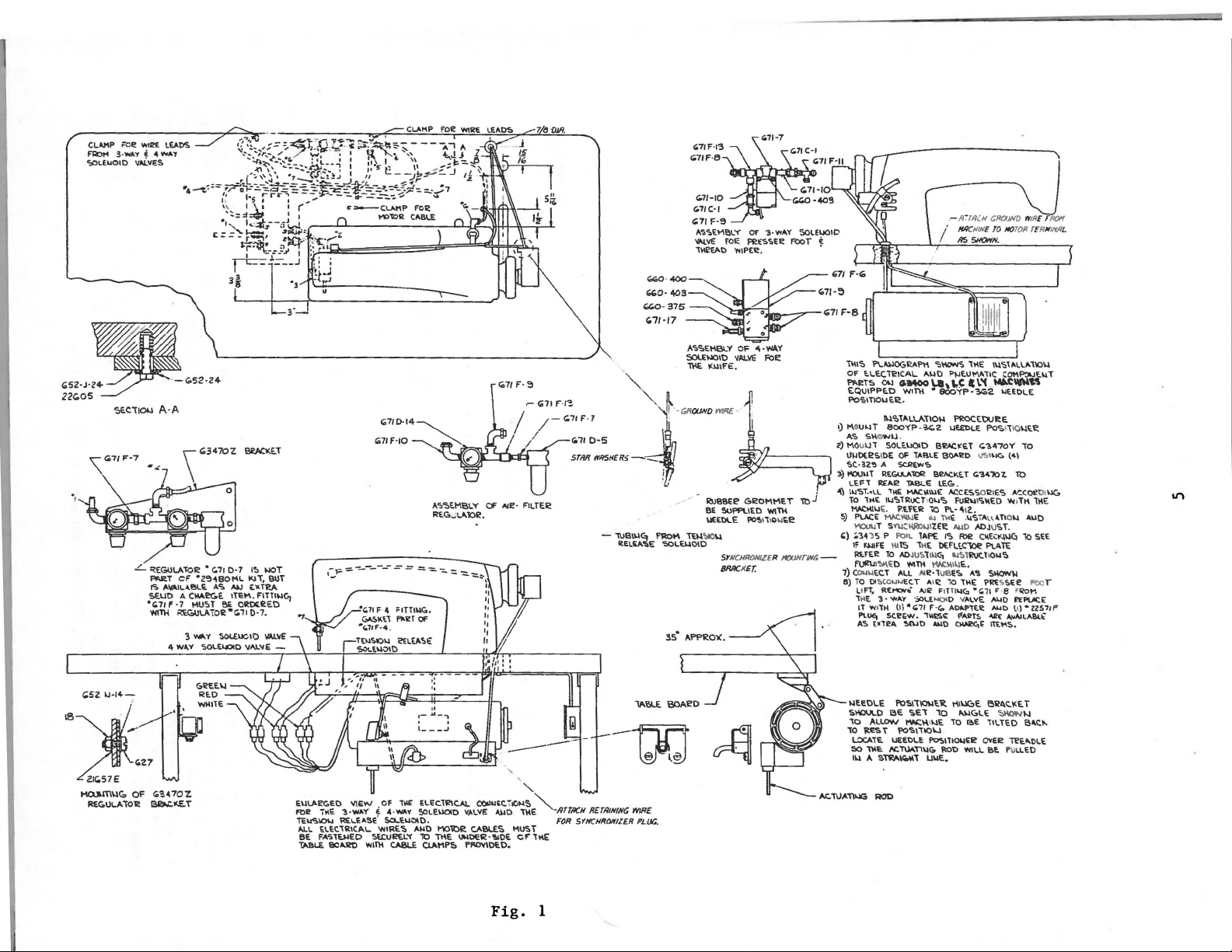

1.

Preparation

ing,

(a)

(b)

winder

one

four

"KLIPP-IT"

of

wire

Fasten

per

Cut

with

assembly,

knee

lifter

isolator

one

frame

studs,

two

bracket,one

clamp and clamp

of

turn

up

side

the

(Fig.

length

cylinders

(c)

Wire

(d)

Attach

(e)

Attach

(f)

2.

Machine Mounting Frame

leads

front

tions

Secure

frame

leg

electro

wire

that

electrical

using

each

machine

the

assembly

pads

and

thread

thread

screws

Electro

down

solenoid

1).

of

air

tubing

as

per

(Fig.

with

of

stripped

table

drive

coming from

come

with

cable

clamps and

is

machine

and

clips,

trimmer,

eyelet,

for

holding

synchronizer

for

tension

Drive

and

and

install

valves

desired

1).

ends

frame.

to

underside

switch

electro

and

screws

Installation.

a box

of

mounting

its

rubber

one

machine

also

one

included

eyelet

miscellaneous

release

Pneumatic

the

and

filter

and

to

switch

box

drive.

leads

provided.

STANDARD

frame,

pad,

rest

attaching

lead

wire

Accessories

following.

regulator

connect

box and mount

of

table.

to

electric

to

underside

Insert

ACCESSORIES-containing one

one

oil

bed

pin

is a bag

attachment

clamp,

solenoid

assemblies

all

drive

of

all

drain

positioning

and

of

screw,

one

lead

Kit

solenoid

as

tableboard

plugs

jar

and

spring

pneumatic

assembly

one

screw

to

parts,

extra

the

for

wire.

with a suitable

to

the

valves

switch

box

outlined

and

(Fig.

its

clamp

and

accessories

con-

bobbin,

bed

plate,

synchroniz-

table

and

air

to

right

in

instruc-

to

table

1).

tabl-

as

NOTE:

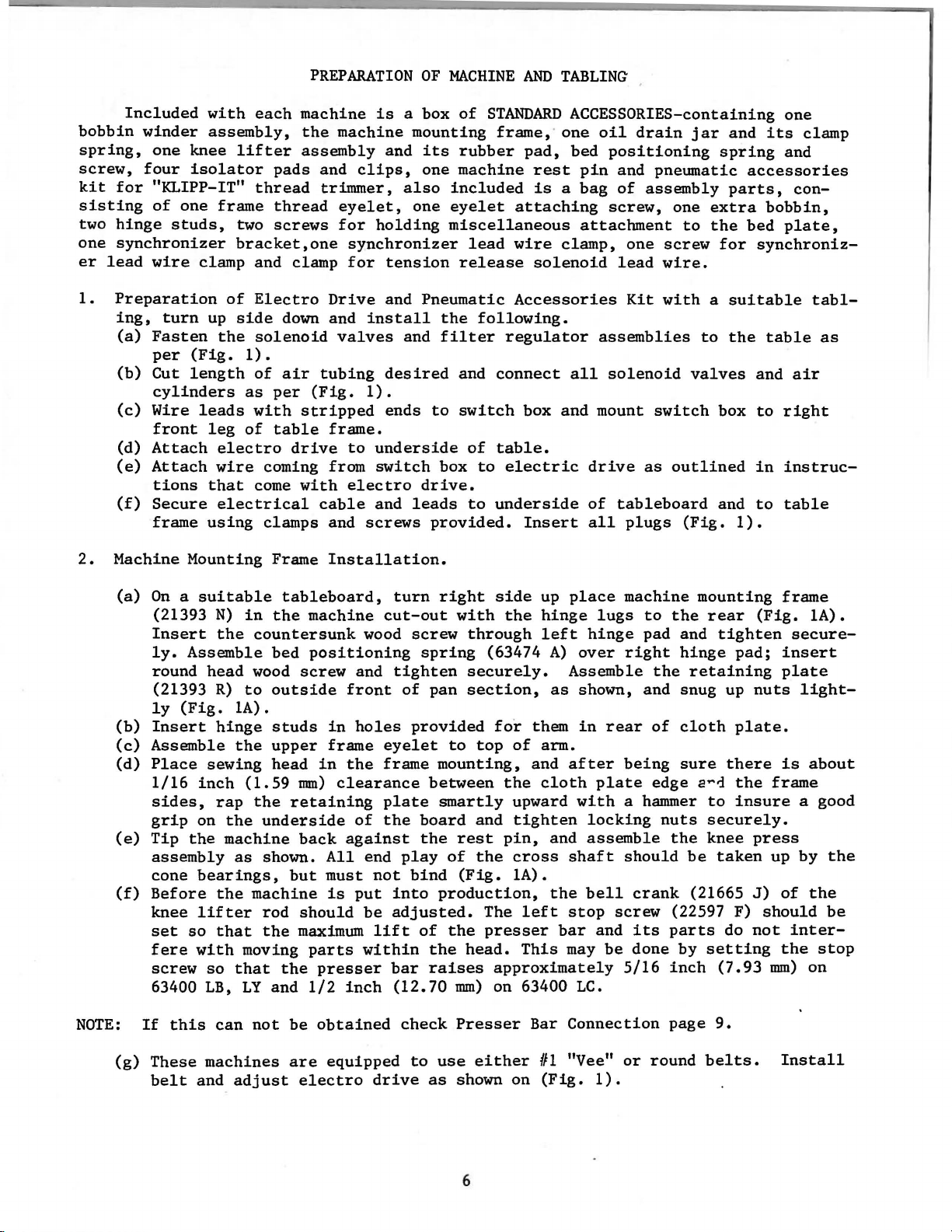

(a)

On a suitable

(21393

Insert

ly.

round

(21393

ly

(Fig.

(b)

Insert

(c)

Assemble

(d)

Place

1/16

sides,

grip

(e)

Tip

assembly

cone

(f)

Before

knee

set

fere

screw

63400

If

this

tableboard,

N)

in

the

the

countersunk

Assemble bed

head

wood

R)

to

outside

1A)

•

hinge

sewing

inch

rap

on

the

machine

bearings,

the

lifter

so

that

with

so

LB,

can

the

(1.59

the

the

underside

as

shown.

machine

rod

the

moving

that

LY

not

studs

upper

head

retaining

but

the

and

be

machine

wood

positioning

screw

and

front

in

holes

frame

in

the

mm)

clearance

of

back

against

All

end

must

is

put

should

be

maximum

parts

within

presser

1/2

inch

obtained

turn

cut-out

screw

tighten

of

provided

eyelet

frame

plate

the

play

not

bind

into

adjusted.

lift

bar

(12.70

check

right

with

through

spring

securely.

pan

section,

to

top

mounting,

between

smartly

board

the

rest

of

and

the

(Fig.

production,

The

of

the

presser

the

head.

raises

mm)

Presser

side

up

place

the

hinge

left

hinge

(63474

A)

over

Assemble

as

shown, and snug up

for

them

in

of

arm.

and

after

the

cloth

upward

tighten

pin,

cross

with

and

shaft

locking

assemble

1A).

the

bell

left

stop

bar

This

may

approximately

on 63400

Bar

Connection

LC.

machine

lugs

right

rear

being

plate

a hammer

should

screw

and

be

5/16

to

the

pad and

the

of

edge

nuts

the

crank

(22597 F)

its

parts

done

inch

page

mounting

rear

tighten

hinge

retaining

cloth

sure

there

a~1

to

securely.

knee

be

taken

(21665

do

by

setting

(7.93

9.

(Fig.

pad;

nuts

plate.

the

frame

insure

press

up

J)

should

not

mm)

frame

1A).

secureinsert

plate

light-

is

about

a good

by

of

the

interthe

stop

on

the

be

(g)

These

belt

machines

and

adjust

are

equipped

electro

drive

to

as

use

either

shown on

6

Ill

(Fig.

"Vee"

1).

or

round

belts.

Install

Page 7

(h)

Connect

tension

leads),

hose

and

shown

PREPARATION

trimmer

release

connect

wires

(Fig.

1) .

22597F---

harness

solenoid

air

hoses

to

underside

OF

MACHINE

leads

(green

to

air

of

AND

to

cutting

leads)

wiper

tabling

TABLING

solenoid

and

foot

and

presser

with

clamps and

(Continued)

valve

lifting

foot

screws

(white

solenoid

lift

and

provided

leads),

valve

secure

(red

air

as

TABLE

BOARD

---

3.

22846Q-1

6347

BOBBIN

6

6

" }

213931\J

660-168

WINDER

216630

Fig.

61477

1A

The

located

when

allow

pulley

scribed

4.

wise

in

the

of

the

belt

121

M.

PRELIMINARY

PRESSER

Turn

(closed)

bobbin

directly

operation.

mechanism

the

winder,

to

wind

under

FOOT

both

"Winding

needle

until

winder

in

the

SOLENOID

ASSIST

should

front

The

to

be

when

bobbin.

the

valves

further

of

the

base

of

moved

in

Regulation

Bobbin",

VALVE

(A, B,

instructions.

be

secured

sewing

the

closer

operation,

ADJUSTMENT

machine

winder

to

under

Fig.

to

the

has

two

or

farther

should

and

operation

OPERATOR'S

FOR

2)

clock-

7

table

belt

exert

top

and

elongated

away from

only

of

INSTRUCTIONS

so

will

enough

the

that

its

bear

attaching

bobbin

belt

pressure

in

Fig.

against

as

winder

pulley

holes,

needed.

Catalog

2

will

the

belt

which

The

against

is

de-

No.

be

Page 8

5.

PRELIMINARY

PREPARATION

TRIMMER

VALVE

OF

MACHINES

ADJUSTMENT

AND

TABLING

(Continued).

Turn

wise

6.

(B)

ponent

7.

(out)

REGULATOR

After

to

OILING

flow

until

Fig.

the

12-18

parts.

control

it

stops.

3

ADJUSTMENT

air

line

P.S.I.

Do

valve

has

not

exceed 20.

adjusting

Place

been

connected

screw

a mark on

P.S.I.

(A,

the

to

since

air

Fig.

head

filter

this

3)

completely

for

future

(A,

will

adjustment.

Fig.

Fig.

result

counter

4

4)adjust

in

damage

clock-

regulator

to

com-

CAUTION:

reservoir

Fill

Oil

is

at

located

needle

a

stainless

seconds

specification

dial

a

clockwise

long

After

machine

operation

to

is

at

Oil

May

The

quantity

in

the

It

is

period,

oiling,

slowly

Oil

has

must

main

maximum

can

be

filled

reservoir

safe

the

right

to

the

black

water-white

100°Fahrenheit

No.

175.

be

drained

of

direction

direction

recommended

be

lubricated

replace

for

several

then

be

been

before

at

operating

of

"OPERATE"

line,

straight

in

from

oil

supplied

of

the

decreases

that

by

head

expected

cover

minutes

drained

starting

plug

a new

screw

level

located

mineral

the

main

main

arrow

the

removing

as

without

from

zone,

reservoir

to

(counterclockwise)

flow

machine,

no

to

the

main

to

operate.

(A,

Fig.

when

to

reservoir.

the

the

further

distribute

damage.

THREADING

needle

marked "FULL".

the

left

oil

of a Saybolt

by

removing

hook

of

oil.

or

head

is

one

hand

cover

reservoir

5)

and

of

oil

of

"OPERATE"

This

oil

is

controlled

increases

that

has

and

oiling

to

before

check

Oil

plug

the

oil

gauge

should

viscosity

equivalent

screw

by

been

oiling

will

various

level

is

zone,

dial

the

out

the

be

shipment

at

to

the

be

added

marked "LOW".Use

of

90

to

UNION

(C,

Fig.

(D).

oil

of

service

moving

required.

parts.Full

and

gauge

black

when

to

5).

Turning

flow

parts.

the

(B).

line,

125

SPECIAL

the

and

in

for

Run

speed

a

Thread

larged

for

machine

clarity.

as

indicated

Needle

is

threaded

in

Fig.

5.

from

8

Threading

left

to

at

right.

check

spring

has

been

en-

Page 9

Fig.

5

The

adjusting

63400 B,

The

PRESSER

The

inch

by

tipping

and

relocating

stop

accomplished.

covered

instructions

BAR

presser

(11.11

the

screw

to

instructions

in

Catalog

that

are

CONNECTION

bar

connection

mm)

above

machine

the

the

Tighten

the

stop

right

the

different

lower

back

screw

or

lock

INSTRUCTIONS

for

Styles

No. 121

against

(B)

left,

(A,

Fig.

presser

on

the

nut

(A)

M,

with

from

the

the

proper

to

FOR

63400

the

6)

bar

rest

lifter

lock

the

should

bushing

setting

MECHANICS

LB,

LC

following

ones

pin,

covered

be

loosening

lever

the

stop

(Fig.

bell

of

9

and

exceptions

in

set

so

6).

the

screw

LY

are

Catalog

that

This

the

lock

crank

presser

in

the

same

and

No. 121

it

is

is

accomplished

nut

(C).

By

bar

place.

as

for

additions.

M.

about

connection

7/16

(A,

Fig.

turning

Style

7)

the

is

Page 10

PRESSER

BAR

GUIDE

When

presser

with

set

between

foot

the

properly

guide

To

obtain

presser

presser

plate.

sion,

enters

guide.

ing

that

above

the

Set

the

the

Set

center

the

Now,

regulator

the

ADJUSTING

1.

Insert

with

the

right.

locating

must

feed

dog

when

(B)

this

spring

foot

the

to

guide

the

middle

apply

needle

underside

throat

THE

NEEDLE

a

new

the

needle

the

presser

rest

directly

in

its

there

and

presser

setting,

(C) and

insure

to

foot

by

of

its

pressure

(J,

Fig.

thread

of

the

plate.

AND

needle

eye

bar

lowest

is

a

bar

remove

loosen

its

being

the

1/16

turning

slot

and

to

6)

clockwise.

take-up

wire

HOOK

is 4 3/4

Type 180

at

90

degrees

guide

against

position.

1/16

inch

connection

the

set

down

inch

it

so

retighten

the

presser

wire

GXS,

180

to

(B,

Fig.

the

throat

The

guide

(1.59

(A,

mm)

Fig.

pressure

screw

(1.59

that

(D).

on

the

mm)

the

screw

foot

by

(A,

Fig.

inches(121.00

GYS,

the

185

line

6),

plate

space

from

Tap

throat

dimenneedle

(D)

turn-

8)

GAS

of

the

is

6).

the

on

in

so

mm)

or

feed

185

and

GBS

the

Moli-----

Fig.

of

spot

the

6

proper

or

J

scarf

size

to

2.

The

presser

3.

The

with

stroke.

63400

machines).

4.

To

the

as

rection

until

lower

needle

needle

the

LB,

set

two

to

prevent

the

edge

foot.

lower

The

the

set

until

must

be

Fig.

bar

height

edge

lower

LC

pair

and LY(upper

hook,tip

screws

interference

needle

needle

of

the

bar

needle

in

of

the

and

bar

is

the

center

7

is

correct

the

needle

of

lines

pair

machine

hold

with

is

ascending

bar

of

when

are

are

back

the

hook and

the

at

its

bushing.

the

bar

used

used

so

needle.

lowest

and

needle

the

upper

bushing

with

with

that

bobbin

position.

its

lower

hole

with

needle

needle

it

Turn

in

timing

the

Type 183

rests

case

the

Continue

timing

throat

mark

bar

on

at

Type 180

for

on

the

support

holder

in

handwheel

to

mark

is

plate

the

the

or

Fig.

bar

bottom

185

low

and

8

is

for

throw

pin,

slot

even

of

Styles

loosen

such a position

in

operating

turn

handwheel

even

with

the

in

its

di-

10

Page 11

ADJUSTING

4.

Continued.

THE

NEEDLE

AND

HOOK

(Continued)

5.

6.

Turn

needle

of

will

between

Adjust

finger

holder

of

A

bobbin

The

contact

ward

needle

time,

It

for

larger

.003

the

the

(.79

the

needle

will

the

be

hook

hook and

mm)

purpose

the

there

additional

hook on

and

as

close

to

.005

satisfactory.

point

hook

the

recess

recess

clearance

recess.

guarding

case

with

hook.

slightly

be

needles

securely,

point

tighten

hook

is

and

holder,

of

this

the

should

necessary

needle

are

the

hook

shaft

to

the

needle

inch

positioning

With a properly

when

(.076

and

in

at

the

tighten

between

surface,

has

guarding

needle

the

be

in

used.

to

With

the

then

needle.

place.

finger

top.

the

the

located

been

provided

surface

at

loop-taking

needle

little

clearance.

some

or

cases

until

as

.127

hook

tighten

Set

Place

finger

outside

timed

is

no

This

its

point

possible

mm)

between

in

this

the

other

the

hook

by

turning

the

projection

attaching

edge

on

the

right

in

this

is

to

time

hook,

at

the

bottom

deflection

to

remove some

is

especially

is

without

the

position,

screw

positioning

the

screws,

of

the

side

hook.

prevent

should

the

needle

of

of

the

even

with

deflecting

point

tighten

and

bobbin

on

the

allowing

projection

of

the

the

hook

the

needle

guard

its

travel.

needle

of

the

true

the

of

hook

recheck

collar

case

finger

needle

point

will

by

needle

when

center

it.

and

the

screw

the

(63432)

holder

into

1/32

and

the

from

be

deflected

deflect

At

the

guarding

size

of

A

spacing

the

needle

opposite

clearance

against

until

the

case

inch

inside

hole

needle

in

coming

the

loop-taking

guard.

surface

125/049

the

the

edge

the

in

to-

and

Before

checked

a)

See

b)

Check

c)

Turn

ive

d)

If

towards

excess

inch

bench

is

as

point

The

bobbin

hook.

It

is

suggested

its

timed

holder

the

bobbin

slightly.

inserted

guarding

removing

as

follows:

that

needle

needle

removed.

this

only

the

for

the

handwheel

the

material

(3.17

and

will

may

case

position

may

case

As

metal

and

tested

surface

any

material

needle

proper

deflection.

deflection

mm)

rubbing

result.

hook

needle,

from

strip

CAUTION!

reduce

holder

that

the

if

be

removed

holder

is

frequently

from

bar

timing.

in

the

is

remove

needle

of

the

guard

Care

the

should

hook

altering

by

stem

removed

being

from

the

is

set

to

operating

judged

fine

effectiveness

be

not

removing

while

removed.

excessive,

the

bobbin

guard

emery

surface

must

thoroughly

be

of

the

rocking

from

the

with

the

be

removed

guard,

the

correct

direction

case

surface.

cloth

back

taken

of

needle

the

gib

the

guard,

needle

all

related

height

by

with

holder

This

(#320)

and

forth

so

as

the

guard

cleaned

from

guard

the

screws

handwheel

the

as

a means

hand

the

bobbin

from

may

with

until

not

and damage

before

machine

is

required.

and

bobbin

settings

..

and

check

case

the

be

done

one

end

sufficient

to

remove

reassembling

or

gib

and

backward

case

holder

of

preventing

should

holder

hook

and

by

using a 1/8

secured

too

to

disturbed

The

by

and

for

excess-

remove

material

much

the

in

bobbin

pulling

foward

may

too

be

pulled

to

the

metal

hook

the

from

case

be

much

on

re-

11

Page 12

ADJUSTING

THE

NEEDLE

AND

HOOK

(Continued)

HOOK

ADJUSTING

1.

Check

CAUTION!

2.

3.

1.

OILING

damage

With

inch

tinue

definite

Should

front

the

change

be

run

Check

rise

teen

throat

oil

flow

Do

may

the

bobbin

(50.80 x 101.60

running

and

more

of

the

for

FEED

height

.040

or

less

plate.

to

hook.

not

run

result,

case

the

machine.

distinct

or

less

machine

required.

about

MECHANISM,

to

of

feed

.045

teeth

one

inch

the

machine

and

needle

in

the

hook,

mm)

piece

After

pattern

oil

be

required

just

below

After a change

minute

For

dog.

to

the

Styles

(1.02

inch

before

Feed

to

without

positioner

run

of

white

about

of

oil

spots

turn

the

cloth

in

checking

63400

dogs

1.14

should

having

mm)

the

paper

five

the

LB

rise

the

bobbin

adjusted

machine

directly

seconds,

should

the

hook

plate

hook

for

and

LC

twenty

above

the

throat

depth

case

for

one

be

observed.

oil

surface,

oil

flow,

desired

two

of

in

proper

full

minute.

under

remove

control,

in

the

oil

teeth

plate.

the

the

top

the

the

located

the

machine

flow.

per

Those

teeth

hook

as

speed.

Place

hook and

paper

direction

inch

should

having

above

hook

a 2 x 4

con-

and a

on

the

of

should

six-

the

.

At

their

the

line

2.

Adjust

3.

Set

stitch

a)

Press

b)

Holding

the

eccentric.

c)

Lengthening

operating

d)

Shortening

opposite

e)

Release

ADJUSTING

1.

The

reverse

and

the

long

2.

Set

the

both

checked

To

attain

reverse

mechanisms

presser

THE

reverse

as

stitch

the

using

feed,

maximum

of

feed

to

plunger

the

teeth

direction.

plunger.

REVERSE

feed

the

control

forward

12

stitches

height,

as

well

foot

required

regulating

direction

the

length

heavy

it

pressure

all

plunger

the

stitch

stitch

FEED

is

actuated

feed

will

lever

and

reverse

paper

may

require

feed

as

length.

the

down,

finger

with

MECHANISM,

at

12

per

dogs

in

for

way

in

turn

is

accomplished

the

is

accomplished

by

continue

is

held

stitches

feed.

or

very

inch

on

adjustments

should

the

line

good

To

change

until

the

is

felt

plunger

FOR

pushing

to

down.

This

light

the

be

of

feeding

stitch

it

stops.

handwheel

to

by

held

by

STYLE

down

operate

per

inch,

can

cardboard.

forward

of

level

feed.

action.

snap

turning

down.

turning

63400

on

as

be

and

both

length:

in

into

the

on

in

both

operating

the

the

the

LY

feed

directions,

direction

slot

in

handwheel

handwheel

control

lever

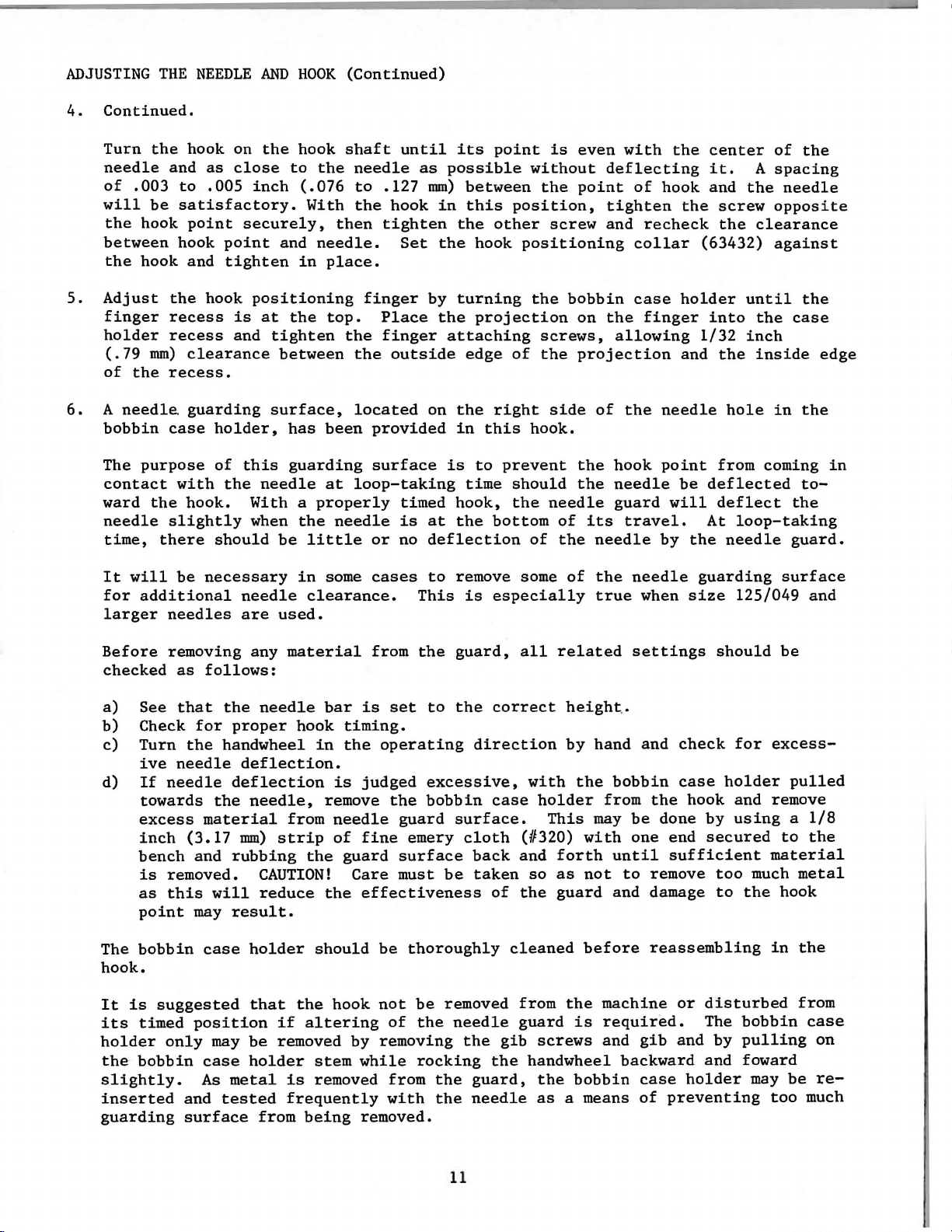

Fig.

the

adjustable

in

in

9

across

until

the

the

(C,

12

Page 13

ADJUSTING

2.

Continued

THE

REVERSE

FEED

MECHANISIM,

FOR

STYLE

63400

LY

(Cpntinued)

After

directions,

other.

"Adjusting

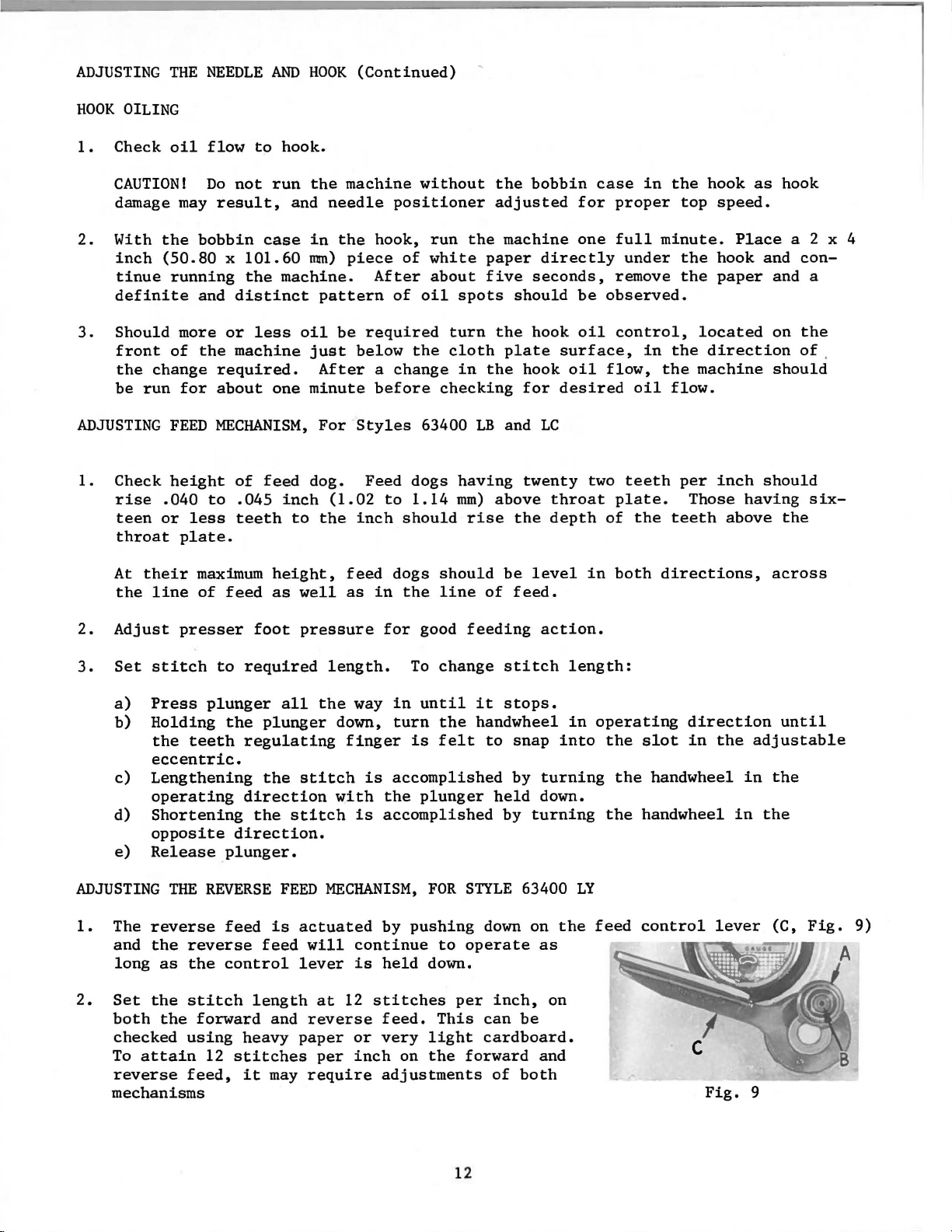

3.

The

adjusting

10).

the

loosening

is

(A)

travel

travel.

making

length

4.

Once

set

stitch

"Adjusting

reverse

You

ber

making

To

reverse

This

machine

in

this

toward

or

Retighten

an

in

the

at

12

length

feed

should

of

stitches

an

adjustment

because

change

Feed Mechanism"

feed

the

stitch

can

be

back

clamp

position

you

away from you

adjustment

both

directions.

forward

stitches

can

Feed Mechanism"

will

get

an

the

stitch

travel

control

accomplished

against

screw

move

to

increase

clamp

and

and

reverse

per

be

made

not

approximately

in

both

to

one

feed,

adjustment

length

part

can

the

(B).

When

the

to

screw

check

inch, a change

as

have

direction.

3.

be

changed

lever

by

tipping

rest

the

control

the

reverse

decrease

(B)

the

feed

described

part

3,

to

be

adjusted.

the

same num-

to

one

of

the

(A,

pin

and

machine

lever

the

after

stitch

has

been

in

the

check

feed

forward

by

Fig.

feed

under

the

will

stitches

affect

feed

refer

per

the

inch

travel

to

paragraph

in

of

both

the

on

5.

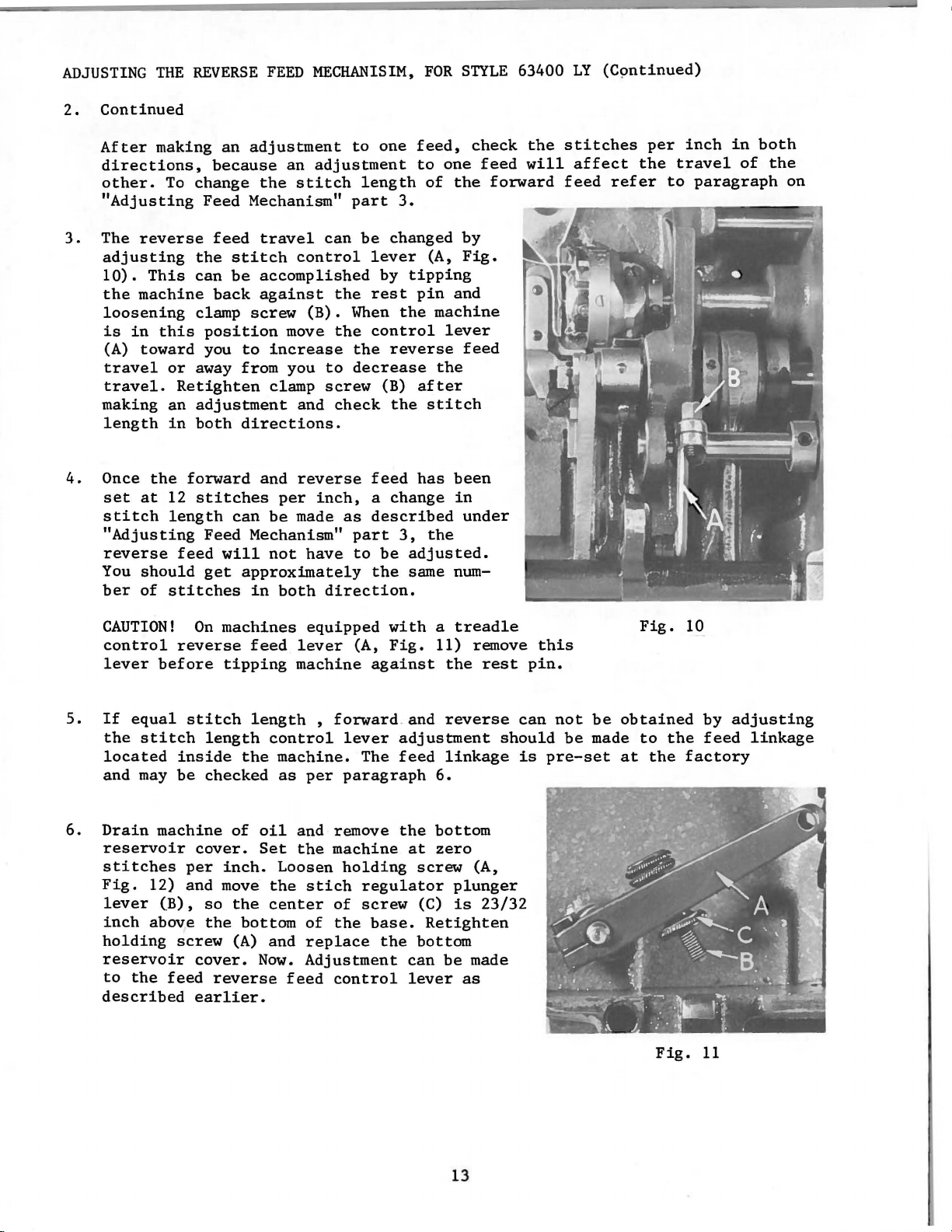

6.

CAUTION!

control

lever

If

the

located

and

Drain

reservoir

stitches

Fig.

lever

inch

holding

reservoir

to

described

before

equal

stitch

may

machine

12) and move

(B),

above

the

feed

On

machines

reverse

tipping

stitch

length

inside

be

checked

cover.

per

inch.

so

the

screw

cover.

reverse

earlier.

equipped

feed

lever

machine

length , forward

control

the

of

oil

Set

the

center

bottom

(A)

and

Now.

machine.

as

Loosen

the

feed

lever

per

paragraph

and remove

the

machine

holding

stich

of

of

the

replace

Adjustment

control

with a treadle

(A,

Fig.

against

and

adjustment

The

feed

the

at

screw

regulator

screw

base.

the

(C)

Retighten

bottom

can

lever

11) remove

the

rest

reverse

should

linkage

6.

bottom

zero

(A,

plunger

is

23/32

be

made

as

this

pin.

can

is

not

be

be

made

pre-set

Fig.

obtained

to

the

at

the

Fig.

10

by

adjusting

feed

factory

11

linkage

13

Page 14

ADJUSTING

7.

On

machines

lever

lever

to

stop

this

to

the

actuated

is

THE

REVERSE

(A,

Fig.

(B,

Fig.

against

position

feed

FEED

equipped

11),

9) and

the

with

adjusting

by

stepping

MECHANISIM,

with a treadle

hold

down

bed

lock

adjust

casting.

nut

screw,

on

the

(C).

when

the

the

reverse

stop

Lock

This

reverse

treadle.

FOR

STYLE

control

screw

stop

is

feed

screw

to

feed

63400

reverse

control

(B,

Fig.

(B)

prevent

is

LY

(Continued)

feed

11)

in

damage

THREAD

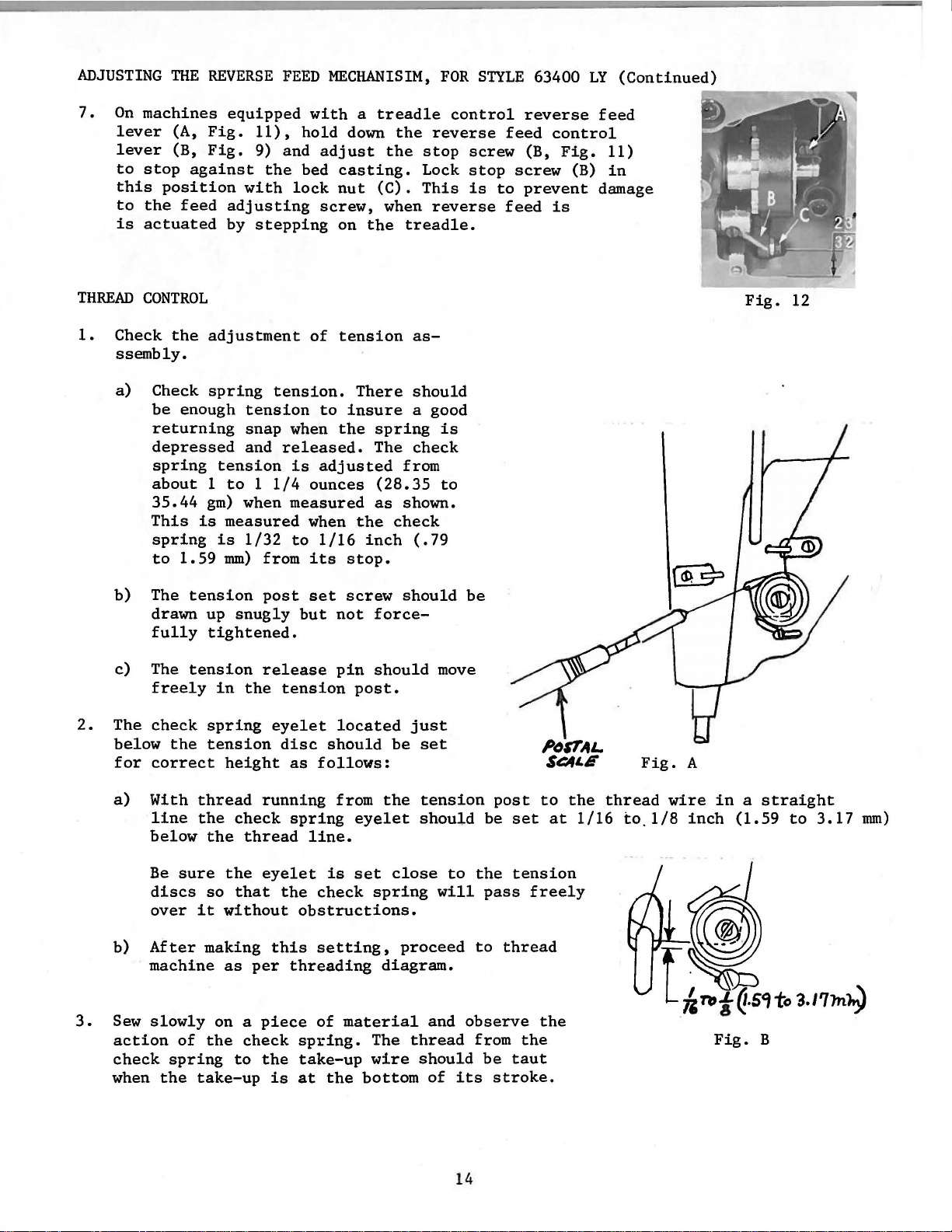

1.

Check

ssembly.

a)

b)

c)

2.

The

below

for

CONTROL

the

adjustment

Check

be

returning

depressed

spring

spring

enough

tension

tension.

tension

snap

and

about 1 to 1 1/4

35.44

This

spring

to

The

drawn up

fully

The

freely

check

correct

is

1.59

tension

tension

the

gm)

when

measured

is

1/32

mm)

from

post

snugly

tightened.

release

in

the

spring

eyelet

tension

height

of

tension

to

when

the

released.

is

adjusted

ounces

measured

when

to

1/16

its

set

but

not

pin

tension

located

disc

as

follows:

should

There

insure

spring

The

(28.35

as

the

inch

stop.

screw

force-

should

post.

as-

should

a good

check

from

shown.

check

(.79

should

just

be

set

is

to

move

be

Fig.

A

Fig.

12

a)

3.

With

below

Be

discs

over

b)

After

machine

Sew

slowly

action

check

when

line

spring

the

thread

the

the

sure

so

it

making

of

the

take-up

check

thread

the

that

without

as

per

on a

check

to

running

spring

line.

eyelet

the

check

obstructions.

this

setting,

threading

piece

of

spring.

the

take-up

is

at

from

eyelet

is

set

material

the

bottom

the

tension

should

close

spring

proceed

diagram.

The

thread

wire

should

to

will

and

of

post

be

the

pass

to

observe

from

be

its

stroke.

to

set

tension

freely

thread

the

the

taut

at

14

the

1/16

thread

to.1/8

wire

inch

in a straight

(1.59

Fig.

to

B

3.17

mm)

Page 15

THREAD

3.

Continued

CONTROL

(Continued)

Slight

reasonable

The

tension

tension.

men~,

tension

changes

machines

on

but

can

tension

are

70-2

The

check

this

be

in

needle

should

sewn

cord

is a required

reduced.

off

or

similar

spring

thread

be

at 3 to 4 ounces

CB'I

used

will

setting

tension

to

thread.

feel

may

be

maintain a uniform

(85.05

Depress

heavy

for

I I

to

the

I

necessary

to

check

you when compared

63400 and

at

this

and

consistent

113.40

gm)

spring

as a result,

~

needle

when

to

point

checking

61400

the

but

a

stitch.

thread

adjust-

disc

the

PRESSURE

The

formly.

(61457 B

wise

TENSION

3.

1.

2.

Tension

decreases

Set

centered

Solenoid

lease

a minimum

(1.59

sembly

ine

screw

(.127

tension

ON

MATERIAL

presser

To

or

RELEASE

the

pin

mm).

in

arm and moving

release

in

mm)

disc.

spring

increase

63457

tension

N)

the

on

the

plunger

and

the

of

1/32

If

or

out

bracket.

clearance

pressure.

assembly

check

pin

adjustment

by

solenoid

should

the

pressure

in a clockwise

(E,

end

inch· (.79

loosening

stop

Solenoid

between

so

spring

Fig.

of

solenoid

is

screw

is

exert

that

eyelet

mm)

required

secured

plunger

it

Fig.

only

on

direction.

14) must

to a maximum

set

(B,

and

the

presser

the

tension

(A,

plunger

move

screw

Fig.

to

pin

the

C

enough

flat

Turning

Fig.

touch

pin

tension

located

13)

as

of

(E)

is

tension

pressure

foot,

discs

13).

tension

must

of

required.

turn

are

protrude

1/16

post

under

bushing

to

have

release

to

make

the

spring

the

regulator

reinch

as-

mach-

(F,

Fig.

approximately

pin

without

the

work

regulator

counterclock-

Fig.

14)

with a set

thread

feed

.005

13

inch

in

uni-

the

15

Page 16

TENSION

3.

Continued

RELEASE

(Continued)

This

spacer

end

should

it

taken

tension

4.

The manual

so

presser

The

and

ions.

to

the

NOTE:

oil

wick

The

wick

gauge

can

between

of

tension

then

contacts

not

that

tension

then

The

5/16

throat

Head

in

must

to

be

be

accomplished

be

the

to

exert

disc.

tension

it

will

foot

is

cam

raising

average

inch

(6.35

plate.

oiler

the

bracket

center

contact

sure

it

the

head

release

slipped

solenoid

too

After

release

not

release

raised

can

be

or

lowering

tension

to

Tighten

of

the

reads

by

placing

of

solenoid

pin.

The

onto

bushing

plunger

much

pressure

tightening

cam

thread

for

back

positioned

released

7.94

mm)of

screw

must

the

needle

full

locate

slot

bearings.

and

tension

pin.

set

(G,

tacking.

to

suit

presser

securely.

in

operates

a

.005

plunger

and moved

Care

thereby

screw

Fig.

tension

by

loosening

the

point

the

needle

the

connecting

inch(.127

pin

release

should

remove

14)

should

when

sewing

is

between

foot

Check

freely.

and

solenoid

in

until

opening

spacer.

the

screw

condit-

lift

bar

link

rod.

the

oil

TRIMMER

mm)

the

be

the

be

set

(H)

1/4

above

ADJUSTMENTS

Mil-----

Fig.

J

14

2.

knife

to

raise

Position

ing

finger.

If

this

(F)

until

pin

hole

side

of

Adjust

turn

it.

Fig.

upper

is

not

the

in

the

lower

flange

15

knife

Check

so,

knives

the

arm

knife

screw

(D)

to

see

loosen

are

eccentric

of

the

until

(G,

bly

1.

c

parallel

that

the

parallel.

bushing

positioning

it

Fig.

the

finger

just

15)

Remove

from

machine

There

knife

ment

the

can

pivot

excessive

the

case

with

the

lower

set

A good

(F)

located

finger

contacts

clockwise

the

positioning

should

pivot

be

release

end

may

left

knife

screw

starting

(Fig.

the

to

and

proceed

be

no

bind

carrier

made by

(A,

loosening

lever

play

or

be.

side

of

the

is

parallel

(E) and

turn

point

approximately

17).

upper

lower

knife.

knife

finger

or

Fig.

as

follows:

shake

and

15).

screw

(C)

and

relieving

arm

of

with

would

and

the

the

eccentric

be

90°

to

To

adjust

counterclockwise

knife

in

lower

This

(B) on

taking

the

bind

the

position-

upper

to

have

the

right

the

assem-

adjustup

the

as

knife.

bushing

the

lower

16

Page 17

TRIMMER

2.

Continued

ADJUSTMENTS

(Continued)

CAUTION!

justment

Fig.

finger

and

as

position

Be

sure

will

have

16

indicated

knife.

bushing

to

D

at

is

not

be

checked.

The

should

sitioning

adjustment

after

#5).

cutting

point

not

the

As

edge

(D).To make

turned

lower

extend

finger

will

trUnmer

the

lower

(C)

while

Fig.

knife

beyond

(B).

need

has

must

17

(A,

If

to

been

knife

coincide

these

making

Fig.

lower

be

moves

16)

the

left

made

assembled

adjustments

this

adjustment

in

its

side

of

knife

to

at a point

to

the

the

extends

trUnmer and

to

right,

loosen

extreme

the

beyond

the

machine

of

or

Fig.

left

arm

the

run

the

positioning

screws

parallel

18

position

of

the

this

air

cylinder

(See

out

(A,

po-

point

Item

of

Fig.

ad-

the

17)

3.

Assemble

case

a)

b)

c)

d)

e)

positioning

holder

Fig.

With

air

Tip

machine

Loosen

Adjust

(.127

This

out.

Position

with

holding

mm)

is

the

positioning

19

to

the

back.

screw

piston

done by

Retighten

in

(B,

mimimum

lower

left

place

finger

finger

machine

Fig.

rod

(C,

between

loosening

nut

knife

side

of

tighten

19.)

Fig.

after

(A,

the

and

knife

and

holder

the

finger

tighten

screw

ance

the

4.

5.

on and

20)

nut

nut

.005

Fig.

arm

screw

assembly

knife

projection

securely,

between

inside

Locate

as

line

If

the

finger,

be

electrical

to

(C,

(C) and

16)

of

until

into

the

far

of

the

left

made

stop

Fig.

(.127

in

the

(B,

assembly

edge

the

back

lower

Fig.

into

by

the

finger

(A,

Fig.

the

bobbin

finger

the

feed.

side

the

to

19)

turning

mm)

its

positioning

and

allowing

outside

of

bobbin

knife

as

possible

knife

of

following

the

tr~er

power

internally

and

space

extreme

19).

machine.

turning

recess

18) on

case

knife

1/32

edge

case

cylinder

(A,

the

arm

adjustment

off.

by

air

cylinder

the

piston

has

been

left

finger

Adjust

the

is

the

holder

assembly

inch

of

recess

bracket

and

parallel

Fig.

16)

of

the

and

air

leaving

rod

obtained.

position

(B)

the

bobbin

at

the

positioning

recess

attaching

(.79

mm)

projection

(Fig.

(A,

extends

positioning

will

cylinder.

.005

(D).

in

or

to

While

bobbin

case

top.

(B) and

clearand

18).

Fig.

with

beyond

need

inch

line

Place

19)

the

to

up

17

Page 18

TRIMMER

6.

Adjust

extreme

left

does

7.

Be

sure

out

wire

8.

The

has

from

off).

er

Foot

not

ADJUSTMENTS

the

lower

right

side

not

the

when

does

knife

become

opening

To

Assist

the

same

of

the

hit

the

spring

the

lower

not

return

critical.

up and

adjust

as

hand

make

Adjustment.

{Continued)

knife

needle

hook

spring

for

used

stop

position,

slot

point.

retainer

knife

contact,

is

(A,

The

interfering

the

slowest

on 63400

screw

the

in

wire

in

bend

Fig.

spring

NOTE:

KA,

(B,

left

the

(B,

its

extreme

retainer

20)

itself

with

knife

Knife

KB

Fig.

corner

bobbin

Fig.

may

be

is a safety

the

hook

return,

return

and

KC.

20)

so

when

(E,

Fig.

case

holder.

17)

enters

right

wire

removed when

hand

to

suit.

(if

the

see

Final

spring

the

16)

CAUTION!

the

bobbin

position.

bobbin

device

air

Trimmer

on 63400

lower

is

to

compressor

knife

in

line

Be

case

If

over-spinning

prevent

Valve

LB,

LC

with

sure

holder

the

the

should

and

and

is

in

the

knife

spring

knife

Press-

LY

its

cut-

be

are

Fig.

20

18

Page 19

800 YP-362

NEEDLE

POSITIONER

SETTINGS

TRANSFORMER

1.

Measure

2.

Disconnect

3.

Remove

CAUTION!

CONNECTIONS

line

bottom

Transformer

when removing

NOTE:

4.

Dummy

not

being

Connector

sponding

be

connected

tween .175-199

voltage

unit

from power

cover

taps

or 'replacing

connector

used,

and

lead

to

line

voltage.

to

the

VAC,

with

volbmeter.

source.

from

control

(A,

Fig.

connectors

(B)

MUST

to

prevent

(C) must

Examples:

tap

marked 215-229

remove

dummy

box.

21)

remain

any

be

connected

connector

are

very

(B

or

C).

on

the

possible

If

line

as

flexible

transformer

damage

to

the

proper

voltage

shown.

(B)

and

and

tap

to

unit.

measured

Should

connect

care

should

be

marked 175-199 when

transformer

219

line

voltage

(C)

to

tap

VAC,

tap.

(C)

measure

taken

corre-

should

be-

1.

Attach

ing

Place

synchronizer

bearing

the

bracket,

from

rubber

two

the

synchronizer

tension

grommet

onto

plate

set

screws

securely.

over

INSTALLATION

mounting

release

over

the

adaptor

grommet on

in

synchronizer.

(Position

solenoid

the

end

of

synchronizer

of

Fig.

bracket

handwheel

the

21

OF

THE

to

the

back

of

synchronizer

Tighten

synchronizer

SYNCHRONIZER

(63495

R),

of

machine,

assembly,

bracket

screws

importance).

2.

Pneumatic

NOTE:

NOTE:

Synchronizer

Remove

with

These

"KLIPP-IT"

the

trim

trim

disc

settings

Thread

comes from

disc

marked

marked

are

"air".

made

Trimmer

factory

Adjustment

set

"electric"

lo~king

from

for

the

electric

from

right

Of

the

19

ground

as

mounting

aligning

to

stabilize

holding

on

handwheel

Discs

"Klipp-It"

synchronizer

end

of

machine.

wire,

shown

bracket.

the

same and

the

synchronizer

adaptor

thread

and

clamp and

in

Figure

Assemble

slot

of

tighten

is

trimmer.

replace

tub-

1

front

of

no

it

Page 20

NEEDLE-DOWN

a)

With power

taking

until

POSITION

its

time,

opening

off,

with

turn

needle

is

the

handwheel

on

centered

in

upstroke.

in

the

operating

Rotate

synchronizer

the

direction

needle-down

head.

until

disc

hook

(A,

is

Fig.

at

loop

22)

NOTE:

NEEDLE-UP

b)

With power

is

1/8

(A,

finger

its

All

printed

should

the

handwheel.

POSITION

inch

Fig.

23)

(C)

smaller

face

off,

(3.18

in

with

opening

words

away from

turn

mm)

the

needle

on

the

before

hook

in

is

centered

discs

Fig.

handwheel

top

dead

deflector

the

up

position.

in

22

in