Page 1

INDUSTRIAL

SEWING

I

NEST

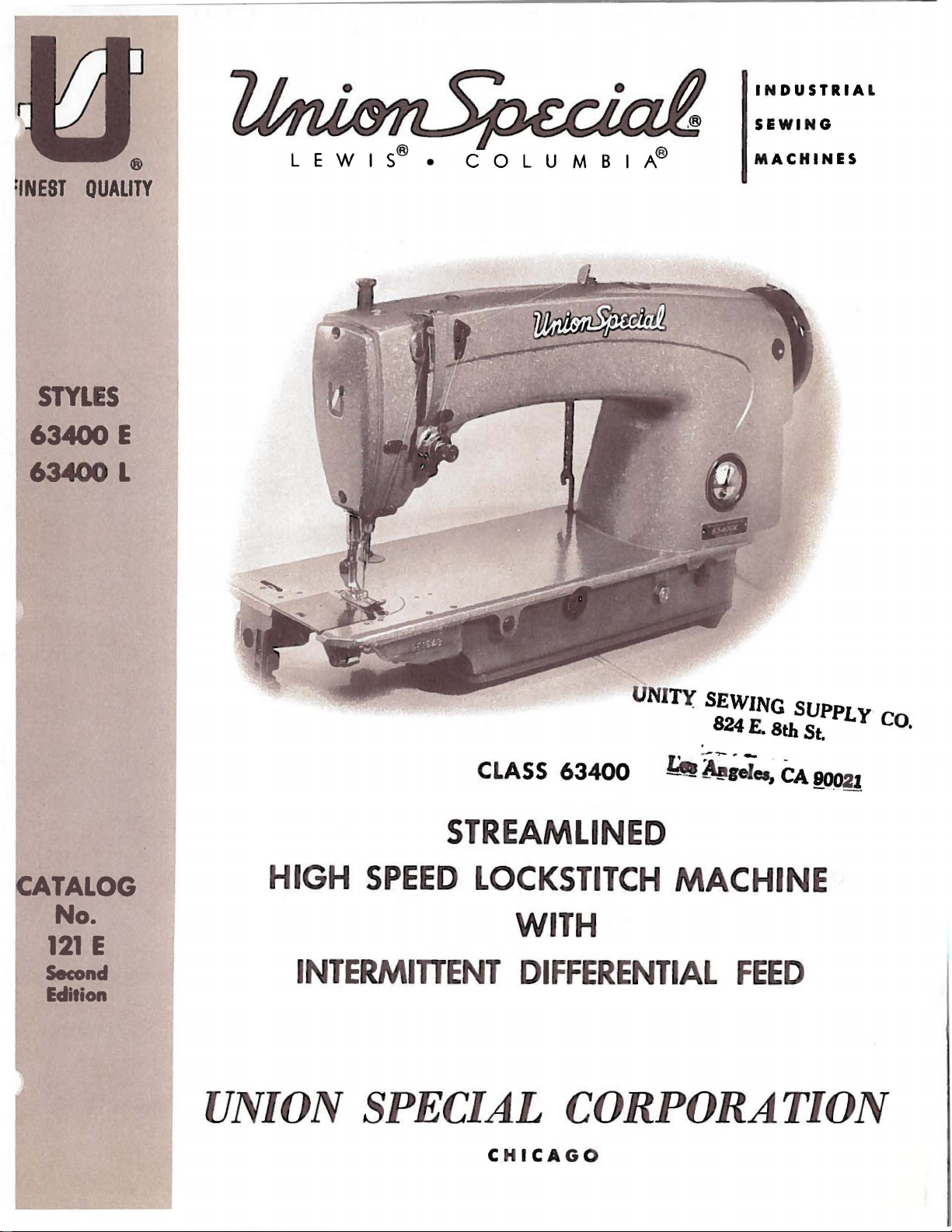

STYLES

63400 E

63400 L

C 0 L U M B I A®

MACHINES

ATALOG

No.

121

E

Second

Edition

CL

ASS

S

TREAMLINED

H

IGH

SPEED

LOCKSTITCH

WITH

INTERMITTENT DIFFEREN

UNION SPECIAL

UNJ

Tr SEWING SUP

824

E.

63400

YJ~

~elea,

8th St.

CA9002l

-

PLy

--

MACHINE

TI

AL FEE

D

CORPORATION

CO.

C H

ICA

GO

Page 2

Catalog

INSTRUCTIONS

No.

FOR

121

E

ADJUSTING

LIST

CLASS

Streamlined

63400

First

E

AND

OF

Styles

Edition

OPERATING

PARTS

63400

Lockstitch

63400

L

Union

Rights

UNION

INDUSTRIAL

Copyright

Special

Reserved

1967

by

Corporation

in

All

Countries

SPECIAL CORPORATION

Printed

SEWING

CH

ICAGO

in

2

MACHINES

U.S.A.

June,1976

Page 3

IDENTIFICATION

OF

MACHINES

Each

into

the

name

special.

tain

the

letter

letter

suffixed

"Z

to

Styles

which

11

63400

differs

11

•

This

herein.

in

this

given

of

the

High

It

class.

from

handwheel

Speed

Differential

and

Heavy

Stitch

Regulator,

Lubricating

Adjustable

Driving

Needle

Link,

Bar

UNION

SPECIAL

plate

Standard

•

When

the

Standard

of

machines

"Z

11

from

catalog

can

also

Reference

the

operator's

Streamlined

Feed

Duty,

System,

Feed

Feed

111/8

on

the

Style

11

•

only

numbers

Example:

minor

Style

similar

the

style

applied

be

applied

is

toward

Long

for

Reverse

Drop

Feed,

Stitch

Head

Eccentric,

Timing

Inches.

machine

machine.

is

Style

have

"Style

changes

number.

in

construction

number,

APPLICATION

specifically

with

to

direction,

position

the

opera

discretion

while

tor.

STYLES

Arm

Lockstitch

and

Plain

Rotary

Length

Oil

Needle

on

Indicator,

Siphon,

Bearings

Lower

identified

numbers

one

or

more

63400

are

E ".

made

Example:

in

that

OF

CATALOG

to

the

Standard

such

as

seated

OF

MACHINES

Machines,

Differential,

Hook,

One

Adjustable

Main

Shaft,

by a Style

are

letters

Special

in a standard

"Style

and

grouped

it

contains

Styles

to

some

right,

at

the

machine.

Horizontal

Reservoir

Hook

for

Oil

Take-up

Maximum

number

classified

suffixed;

Style

63400

under a class

no

of

Special

left,

One

with

front,

Adjustable

Needle,

Hook

Control,

Lever

Work

which

as

numbers

machine,

EZ

".

letters.

machines

Styles

back,

Operating

Shaft,

Enclosed

Needle

and

Space

is

stamped

standard

but

never

contain

a

Example:

as

of

machines

etc.,

direction

Intermittent

Light,

Push

Automatic

Needle

to

and

con-

the

11

"Z

is

number

listed

are

Medium

Button

Bearing

Bar

Right

of

-

63400 E For

knit

dress

length. 1 13/64

R.P.M.

63400 L Same

stretching

length.

Each

type

number

tails.

the

blade

number

Needle

Their

Type

180

No.

GXS

The

description

Maximum

UNION

size

measured

and

the

Type

simultaneously

material

requiring

inch

as

Style

material

63400

and

recommended

SPECIAL

denotes

number,

size

Round

groove,

180

and

the

stamped

in

thousandths

number

GXS

the

shank,

wide

chromium

110/044,

125/049,

seaming

needle

.

with

needle

kind

represent

or

180

sizes

round

angle

plated

up

bar

E,

except

only

has

of

shank,

on

of

GYS

available

point,

groove,

-

sizes

140/054,

and

intermittently

to

a 5

to 1 gathering

travel.

equipped

a 3

to 1 gathering

speed

5500

NEEDLES

both a type

point,

the

needle

an

inch

the

complete

is

recommended

are

Description

lockstitch,

struck

075/029, 080/032, 090/036,

150/060.

Maximum

R.

P.M.

number

length,

shank,

across

listed

and

groove,

gathering

to

give

groove,

denotes

the

eye.

symbol.

for

below.

Sizes

short

woven

ratio

depending

recommended

more

ratio

reverse

depending

and a size

finish

largest

Collectively,

Styles

length,

deep

63400 E and

ball

spot,

cotton

on

speed

feed

on

number.

and

other

diameter

the

eye,

ball

100/040,

and

stitch

5500

for

stitch

The

de-

of

type

L.

single

point,

180

GYS

I

Round

groove,

plated

125/049,

shank,

wide

-

sizes

140/054,

round

angle

075/029,

point,

groove,

150/060.

lockstitch,

struck

080/032,

3

short

groove,

090/036,

length,

deep

100/040,

ball

spot,

eye,

single

chromium

110/044,

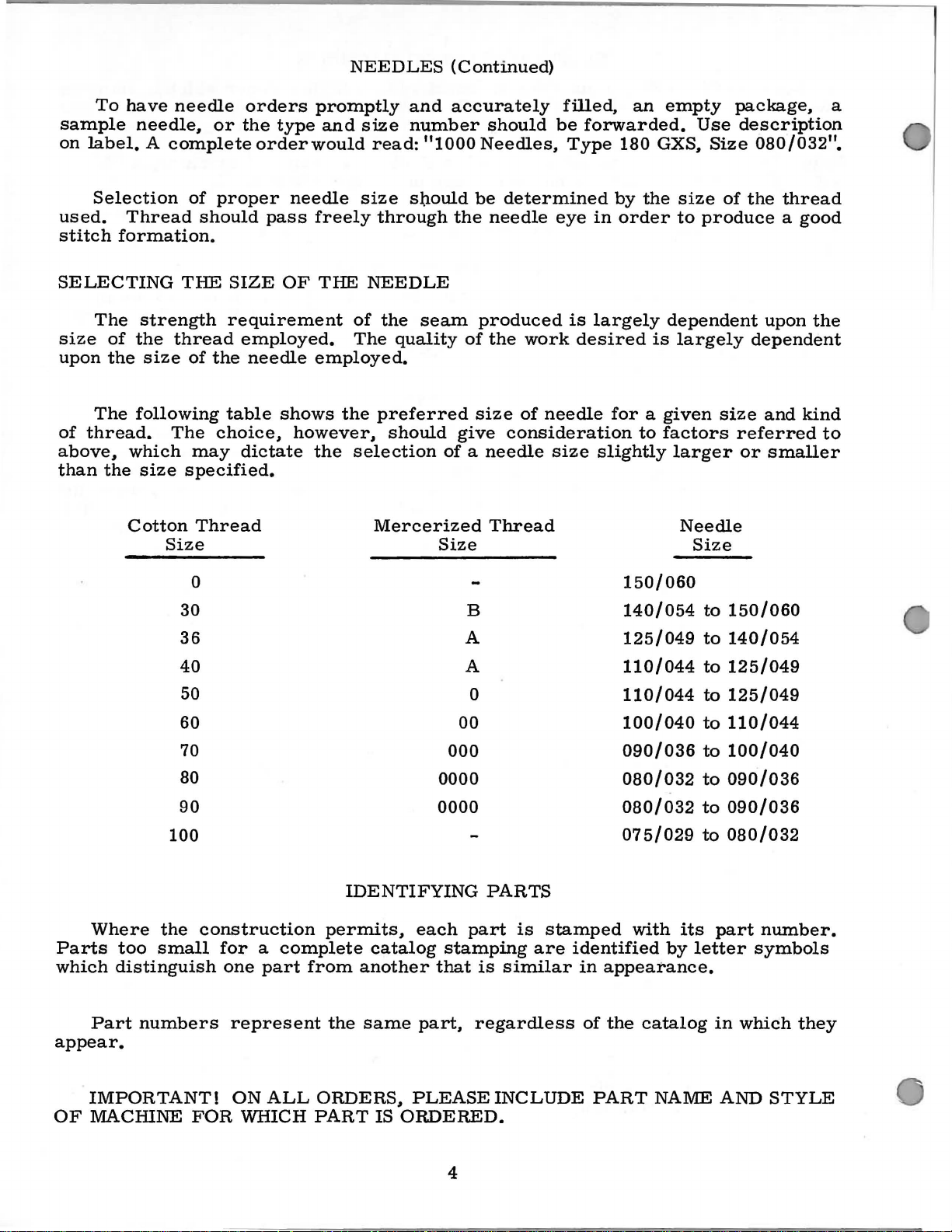

Page 4

To

have

sample

on

label. A complete

needle

needle,

or

orders

the

type

order

NEEDLES

promptly

and

size

would

read:

(Continued)

and

accurately

number

"1000

should

Needles,

filled,

be

forwarded.

Type

an

180

empty

GXS,

package,

Use

Size

a

description

080/032".

Selection

used.

stitch

Thread

formation.

SELECTING

The

strength

size

upon

of

above,

than

of

the

the

The

following

thread.

which

the

size

size

Cotton

of

proper

should

THE

thread

of

the

The

choice,

may

specified.

Thread

Size

0

30

36

needle

pass

SIZE

freely

OF

requirement

employed.

needle

table

employed.

shows

however,

dictate

the

THE

the

size

sl;lould

through

NEEDLE

of

the

The

quality

preferred

should

selection

Mercerized

be

the

seam

produced

of

size

give

of a needle

Size

B

A

determined

needle

eye

is

the

work

of

needle

consideration

size

Thread

by

in

order

largely

desired

for a given

slightly

150/060

140/054

125/049

the

size

to

dependent

is

largely

to

factors

larger

Needle

of

the

thread

produce a good

upon

the

dependent

size

and

kind

referred

or

smaller

Size

to

150/060

to

140/054

to

Where

Parts

which

too

distinguish

Part

appear.

IMPORTANT!

OF

MACHINE

40

50

60

70

80

90

100

the

construction

small

numbers

FOR

IDENTIFYING

permits,

for a complete

one

part

from

represent

ON

ALL

WHICH

the

ORDERS,

PART

catalog

another

same

PLEASE

IS

ORDERED.

000

0000

0000

each

stamping

that

part,

A

0

00

PARTS

part

is

similar

is

regardless

INCLUDE

stamped

are

identified

in

110/044

110/044

100/040

090/036

080/032

080/032

075/029

with

appearance.

of

the

catalog

PART

to

to

to

to

to

to

to

its

by

letter

NAME

125/049

125/049

110/044

100/040

090/036

090/036

080/032

part

number.

symbols

in

which

AND

they

STYLE

4

Page 5

ILLUSTRATIONS

The

arrangement

Class

plate

position.

being

will

number

63400

Six

replacement

exploded

presents

Small

discussed

be

found a listing

of

pieces

a

view

sector

keyline

fit

in

required

ORDERING

of

this

parts.

plates

of

the

views

the

assembled

of

the

in

catalog

cover

machine,

show

parts

the

particular

OF

REPAIR

is

to

facilitate

the

Standard

parts

by a blackened

machine.

with

their

On

part

view

PARTS

Styles

being

the

being

easy

and

listed

aligned

area

exactly

page

numbers,

shown.

accurate

in

this

as

in

opposite

descriptions

catalog.

their

where

the

ordering

Each

assembled

the

parts

illustration

and

the

of

Numbers

the

position

in

ordering

exploded

view

Sub-assemblies,

bracket

lies,.

tions

30

31

32

33

34

catalog,.

parts

tioned

or a solid

which

under

29126

61437

61438

660-225

88

In

those

no

for

the

in

illustration.

At

the

in

this

book.

the

part

number

in

of

the

parts.

plate

can

the

description

DD

K

B

cases

specific

various

the

description,

back

This

the

first

part

Always

carries

line

be

furnished

Feed

where a part

usage

machines

of

the

will

is

known.

column

in

the

use

a

which

box

on

of

Driving

Feed

Feed

Needle

SetScrew-------------------------------------

will

and,

book

will

facilitate

are

reference

illustration.

the

part

reference

are

sold

the

picture

for

repairs,

the

main

Eccentric

Drive

Drive

Eccentric------------------------------

Eccentric

Bearing

is

common

be

mentioned

are

not

if

necessary,

be

found a numerical

locating

numbers

Reference

number

number

complete,

plate.

are

indicated

numbers

listed

for

each

or

Component

sub-assembly.

and

Connecting

Connecting

--------------------------------

to

all

of

in

the

description.

the

same,

the

illustration

the

the

difference

only,

in

the

part

by

separate

by

indenting

Example:

Rod

Rod

the

machines

specific

index

and

and

merely

should

second

for

never

column.

sale.

part,

parts

of

sub-assemb-

their

Assembly------

----------------

covered

However,

will

of

usage

all

be

the

will

shown

description

are

descrip-

when

be

parts

when

indicate

be

used

Each

in

by

this

the

men-

in

the

shown

only

a

1

1

1

1

1

USE

Success

UNION

ration,

to

the

SPECIAL

its

most

Maximum

Genuine

pair

parts

trademark

in

the

Needles

subsidiaries

approved

efficiency

needles

are

stamped

is

your

GENUINE

operation

and

and

scientific

and

durability

are

packaged

with

guarantee

NEEDLES

of

these

Repair

Parts

authorized

principles,

are

with

the

Union

of

the

highest

AND

machines

as

furnished

distributors.

and

assured.

labels

marked

Special

quality

REPAIR

can

are

trademark,

in

TERMS

ments

unless

Prices

are

otherwise

are

strictly

forwarded

directed.

f.

o.

net

b.

A

cash

and

shipping

charge

subject

point.

is

made

5

to

change

Parcel

to

cover

PARTS

be

secured

by

the

They

made

are

with

~.

materials

without

Post

shipments

the

postage

only

Union

designed

utmost

U S

and

notice.

with

genuine

Special

Corpo-

according

precision.

Genuine

Emblem.

Each

workmanship.

All

ship-

are

insured

and

insurance.

re-

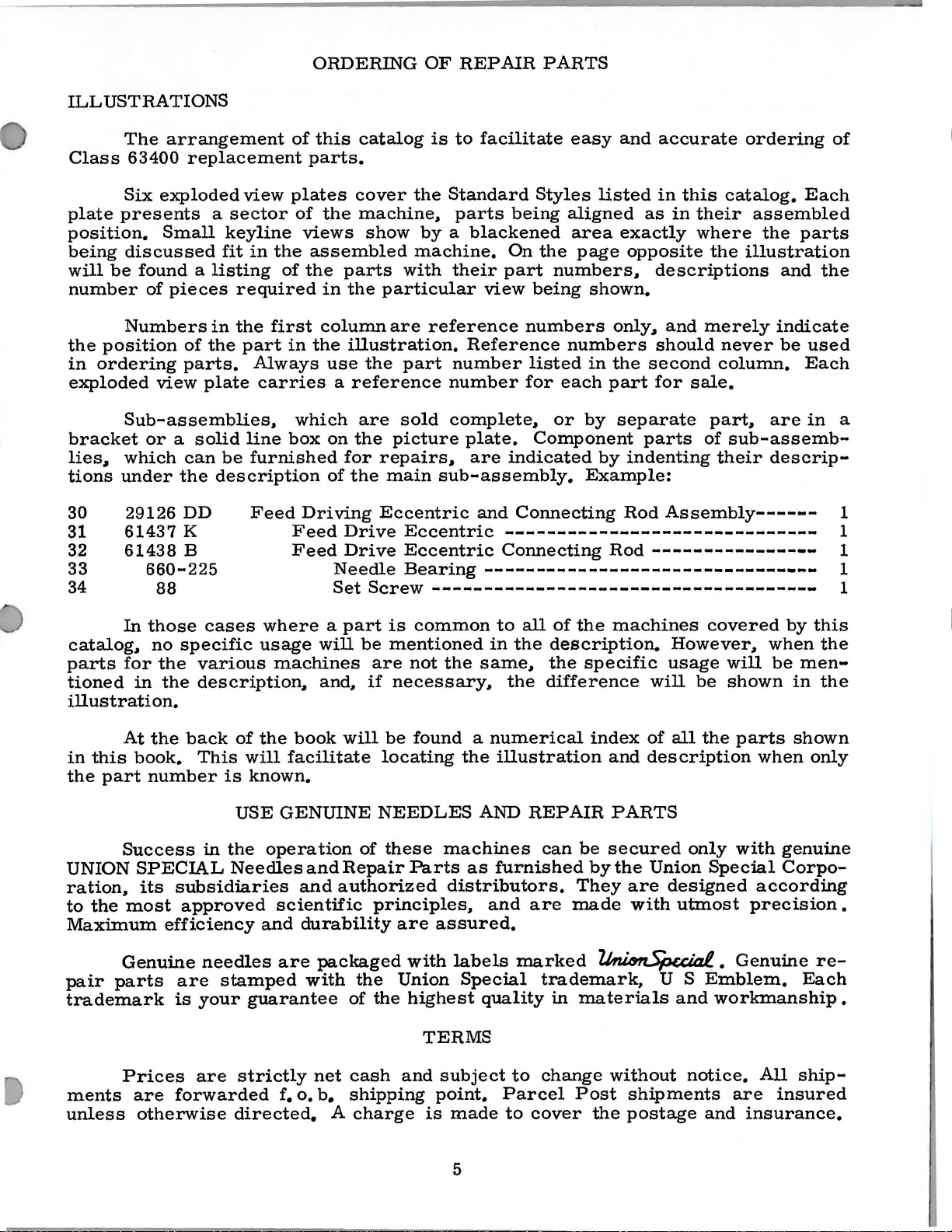

Page 6

CAUTION!

Using

After

be

PREPARATION

extra

is

eyelet

STANDARD

winder

assembly

machine

TABLE

FLUSH

MACHINE MOUNTING

hinge

securely.

and

and

between

to

of

both

Before

the

machine

followed:

A

bag

bobbin,

packed

Insert

(A,

Included

assembly,

rest

TOPS

Lockstitch

with

On a suitable

lugs

tighten

snug

up

Place

the

insure a good

Tip

machine

the

cross

When

hands

leaving

of

with

hinge

Fig.

and

to

Assemble

securely.

sewing

on

factory,

and

OF

MACHINE

assembly

two

hinge

each

machine.

studs

2).

ACCESSORIES

also

with

the

its

rubber

pin.

These

machines

the

top

of

tableboard,

the

rear

bed

nuts

lightly.

head

cloth

plate

grip

back

shaft

should

unpacking,

bed

casting,

each

accessories

parts,

studs,

in

holes

each

machine

the

FRAME

(Fig.

Assemblethe

in

edge

on

against

machine

pad,

parts

are

machine

1).

positioning

the

frame

and

the

underside

be

taken

DO

NOT

lift

gently.

Union

FOR

consisting

and

provided

mounting

bed

are

installed

INSTALLATION

place

Insert

the

rest

Special

have

been

INSTALLATION

of

two

screws

for

is a box

frame,

positioning

essential

in

mounting

machine

the

spring

retaining

mounting,

frame

up

pin,

by

sides,

of

and

the

the

INSTALLING

lift

machine

machine

removed

one

for

them

spring

when

table

frame.

mounting

countersunk

(63474A)

plate

and

rap

board

assemblethe

cone

from

frame

holding

in

rear

of

STANDARD

one

oil

and

setting

tops,

frame

over

(21293

after

the

and

bearings,

out

of

is

sewed

the

packing

thread

drain

prepared

retaining

tighten

eyelet,

miscellaneous

of

cloth

ACCESSORIES--

jar

screw,

up

the

(21393

wood

screw

r i

ght

R)

to

being

sure

locking

knee

press

but

box

by

placing

off,

inspected

box,

one

plate.

and

its

four

isolator

machine.

with

cut-out,

N)

in

through

hingepad;insertround

outside

plate

must

front

there

smartly

nuts

assembly

not

one

and

the

following

eyelet

attachments

clamp

the

is

bind.

attaching

Assemble

containing

spring,

pads

so

machine

left

hinge

of

pan

about

upward

securely.

as

hand

on

carefully

to

the

the

one

and

clips,

that

the

cut-out

pad

head

section,

1/16

inch

with a hammer

shown.

handwheel.

packed.

steps

should

screw,

bed

plate,

upper

All

frame

one

bobbin

knee

and

bed

plate

with

and

tighten

wood

as

shown,

clearance

end

lifter

screw

one

one

is

the

play

TABLE

BOARD

22846Q-16

63476

21393N

J

660

I

21663D

-168

63474

A

6

Page 7

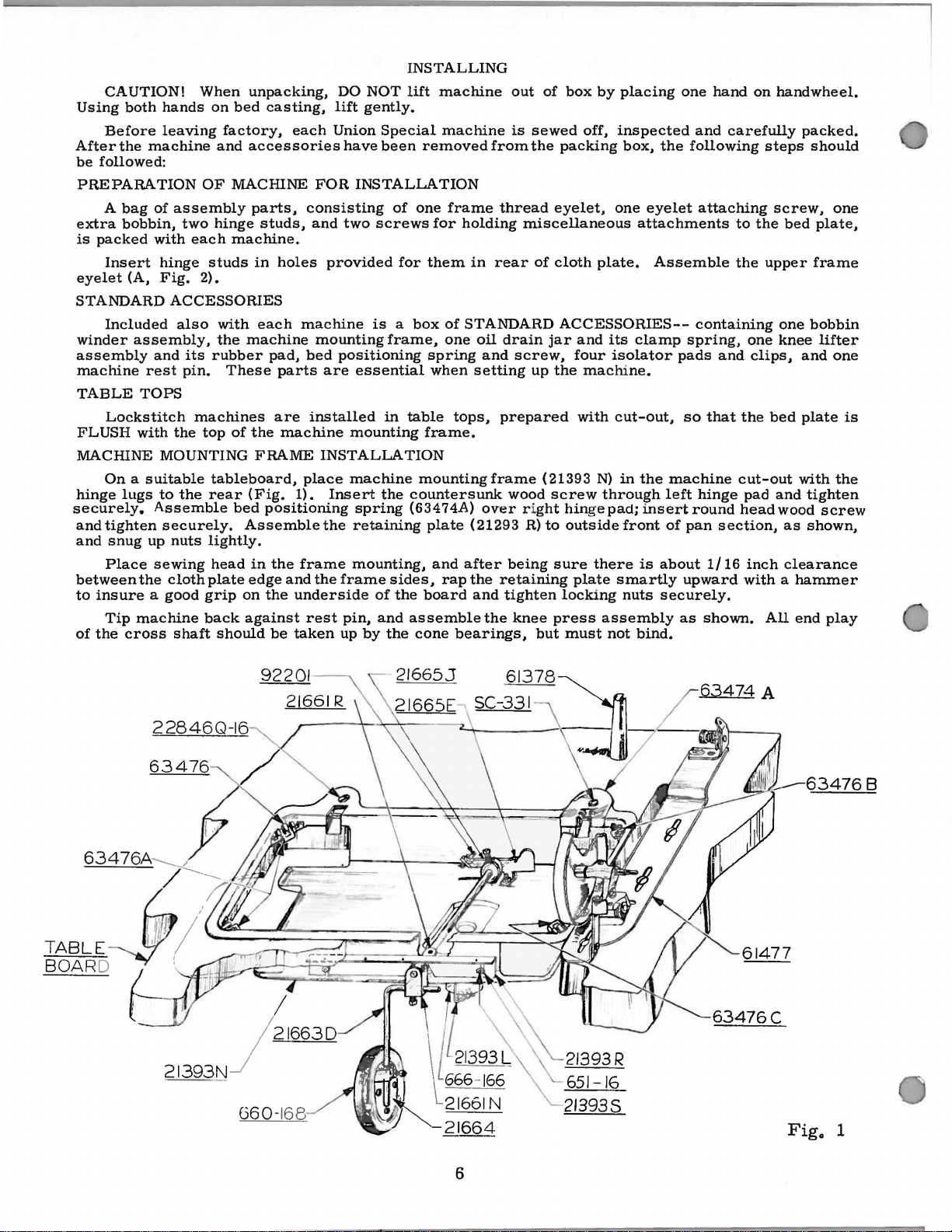

INSTALLING

(Continued)

MACHINE

Before

adjusted.

its

parts

so

that

the

BOBBIN

The

bobbin

front

of

winder

away

pressure

under

BELTS

the

has

from

"Winding

These

MOUNTING

the

machine

The

do

WINDER

left

not

interfere

presser

winder

sewing

two

elongated

belt

against

machines

as

the

the

FRAME

is

stop

bar

Bobbin",

put

screw

with

raises

should

machine

attaching

needed.

belt

to

are

equipped

INSTALLATION

into

production,

22597 F should

moving

be

belt

The

wind

under

parts

approximately

secured

and

holes,

pulley

the

bobbin.

OPERATOR1S

to

use

will

of

either

(Continued)

the

be

within

the

5/16

to

the

table

bear

which

allow

the

winder,

Regulation

#1

bell

crank

set

so

head.

inch.

top

against

the

INSTRUCTIONS.

"Vee"

that

This

so

the

mechanism

when

and

operation

or

round

(21665

the

that

belt

J)

maximum

may

its

when

in

operation,

of

belts.

of

the

be

pulley

lift

done

in

operation.

to

be

moved

the

bobbin winder

knee

of

by

will

should

lifter

the

setting

be

located

closer

exert

rod

presser

the

The

to

only

is

should

bar

stop

screw

directly

base

of

or

farther

enough

described

be

and

in

the

7

Fig.

2

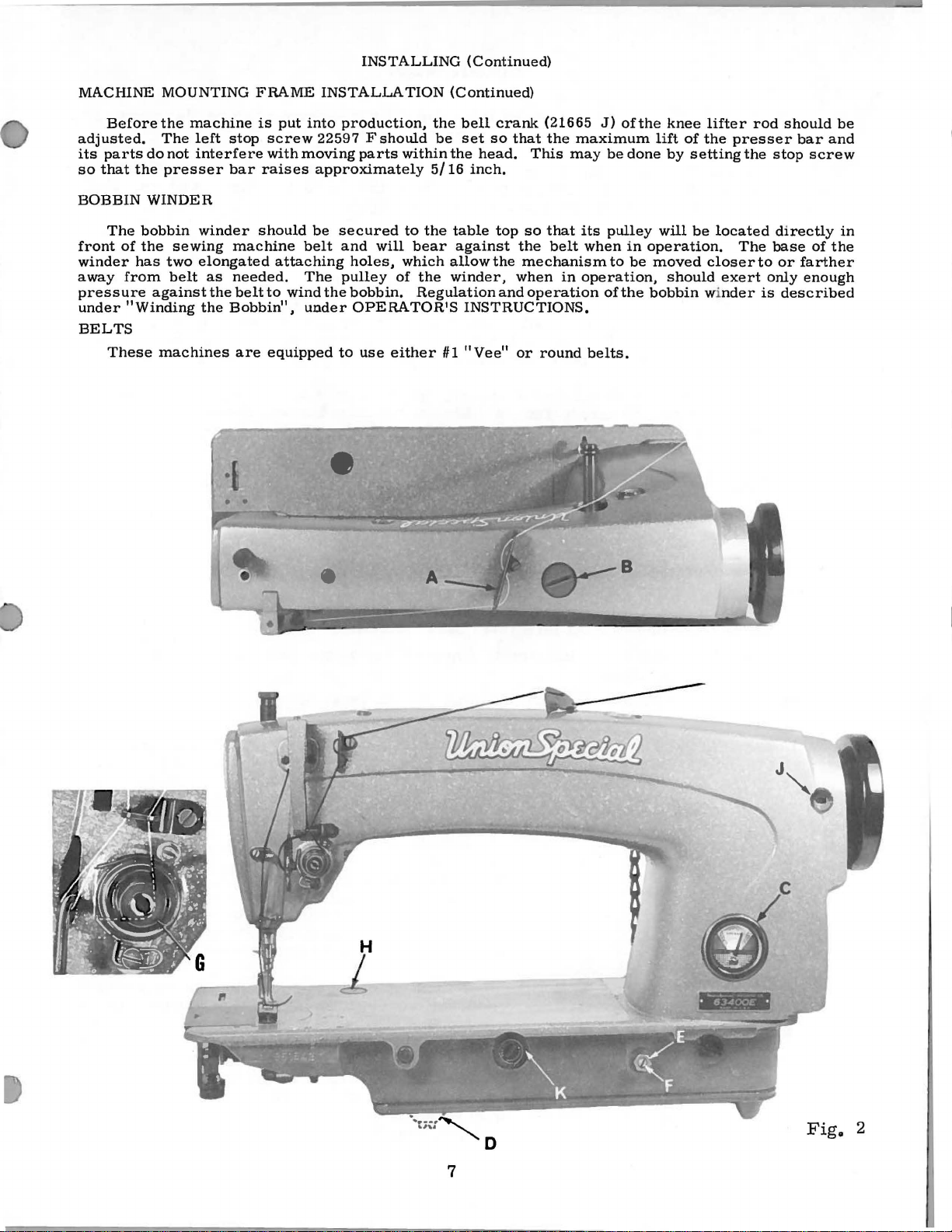

Page 8

LUBRICATION

CAUTION 1

the

reservoir

and

run

speed

Lubricate

slowly

operation

must

machine

for

RECOMMENDED

Use a stainless

to

125

Special

check

marked

It

an

extended

oil

the

place

Oil

OIL

GAUGE

The

Should

seconds

specification

oil

level

"full".

is

recommended

bearings

end

may

oil

an

at

at

period,

cover

be

gauge

adjustment

Oil

has

been

be

filled

thoroughly,

can

several

then

minutes

be

OIL

~ater-white

100

Fahrenheit

No.175.

gauge

Oil

(C);

should

be

that a new

be

lubricated

of

the

needle

as

no

further

drained

is

set

from

at

the

become

drained

before

starting

in

to

expected

straight

in

Fill

main

oil

is a maximum

added

machine,

as

bar

link,

hand

main

oiling

reservoir

factory

necessary,

from

the

to

accordance

distribute

without

mineral

the

main

reservoir

when

needle

follows:

take-up

will

to

show

the

main

operate.

the

damage.

reservoir.

level

is

or

one

Remove

and

be

required.

by

removing

the

proper

following

reservoir

with

instructions

oil

to

oil

of a Saybolt

at

plug

when

in

yellow

that

has

the

its

lever

oil

steps

before

the

This

screw

needle

band

been

end

and

plug

level

shipment

which

various

parts.

viscosity

equivalent

(B,

Fig.

is

in

yellow

marked

out

of

service

cover

and

needle

screw

should

in

(D,

the

be

and

follow,

Full

of

to

Union

2)

and

band

"low".

for

directly

bar.

Fig.

Re-

2).

reservoir.

followed:

90

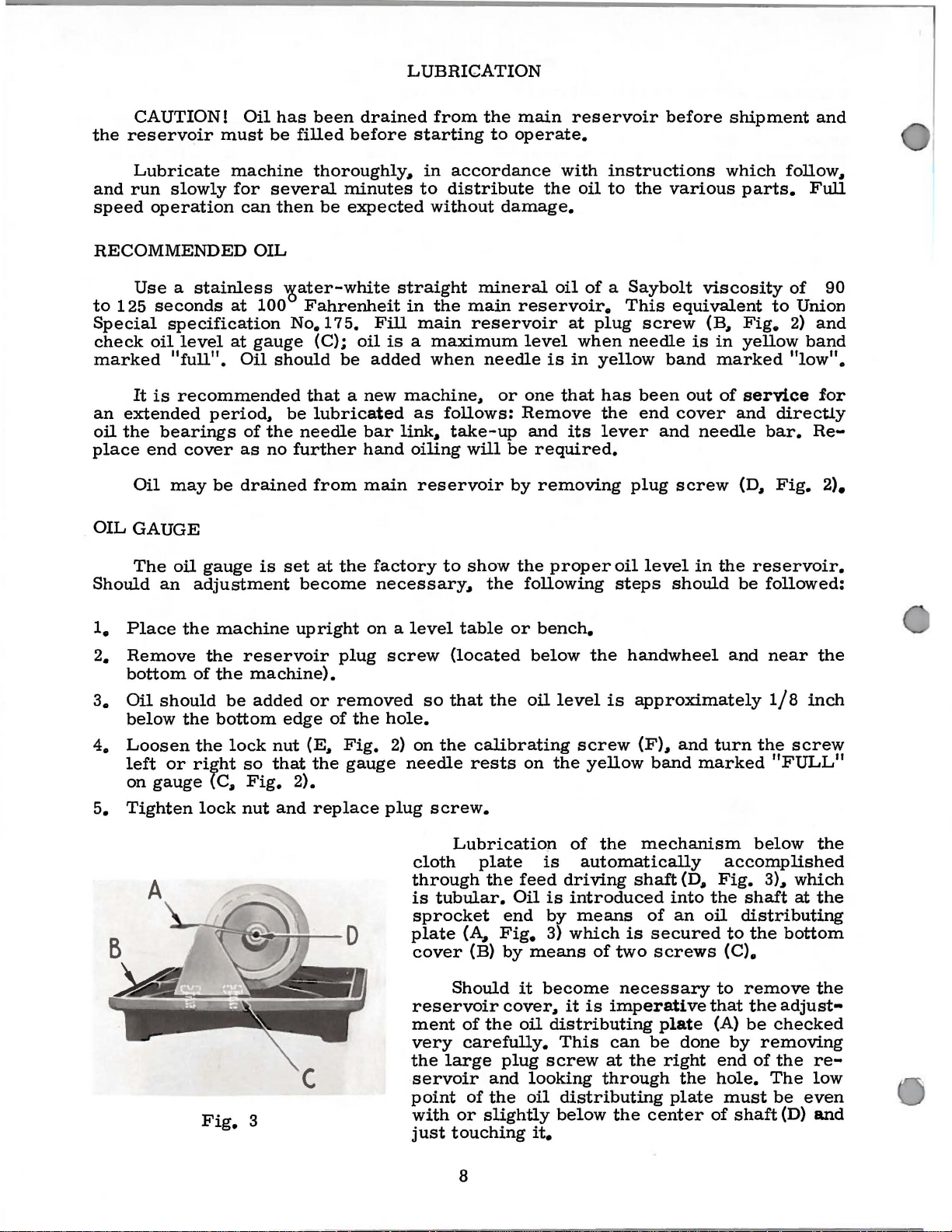

1.

2.

3.

4.

5.

Place

the

Remove

bottom

Oil

should

below

the

Loosen

left

or

on

gauge

Tighten

machine

the

of

the

be

bottom

the

lock

right

(C

..

lock

Fig.

upright

reservoir

machine).

added

edge

nut

(E,

so

that

Fig.

nut

2).

and

3

plug

or

removed

of

the

Fig.

the

gauge

replace

on a level

screw

so

hole.

2)

on

the

needle

plug

screw.

cloth

through

is

tubular.

sprocket

plate

cover

reservoir

ment

very

the

servoir

point

with

just

table

or

(located

that

the

calibrating

rests

Lubricatiop

plate

the

feed

Oil

end

(A,

Fig.

(B)

by

Should

it

cover,

of

the

oil

carefully.

large

plug

and

of

the

or

slightly

touching

bench.

below

oil

level

screw

on

the

of

is

automatically

driving

is

introduced

by

means

3)

which

means

become

it

distributing

This

screw

looking

oil

distributing

below

it.

the

handwheel

is

approximately

(F),

yellow

the

shaft

is

of

two

necessary

is

imperative

can

at

the

through

the

and

turn

band

marked

mechanism

(D,

Fig.

into

the

of

an

oil

secured

screws

to

that

plate

be

right

center

done

the

plate

(A)

end

hole.

must

of

and

near

1/8

the

the

inch

screw

"FULL"

below

the

accomplished

3),

which

shaft

at

the

distributing

to

the

bottom

(C).

remove

the

be

by

removing

of

shaft

The

the

adjust-

checked

the

re-

low

be

even

(D)

and

8

Page 9

THREAD

INSTRUCTIONS

FOR

OPERA

TORS

While

ofthe

the

of

unwind,

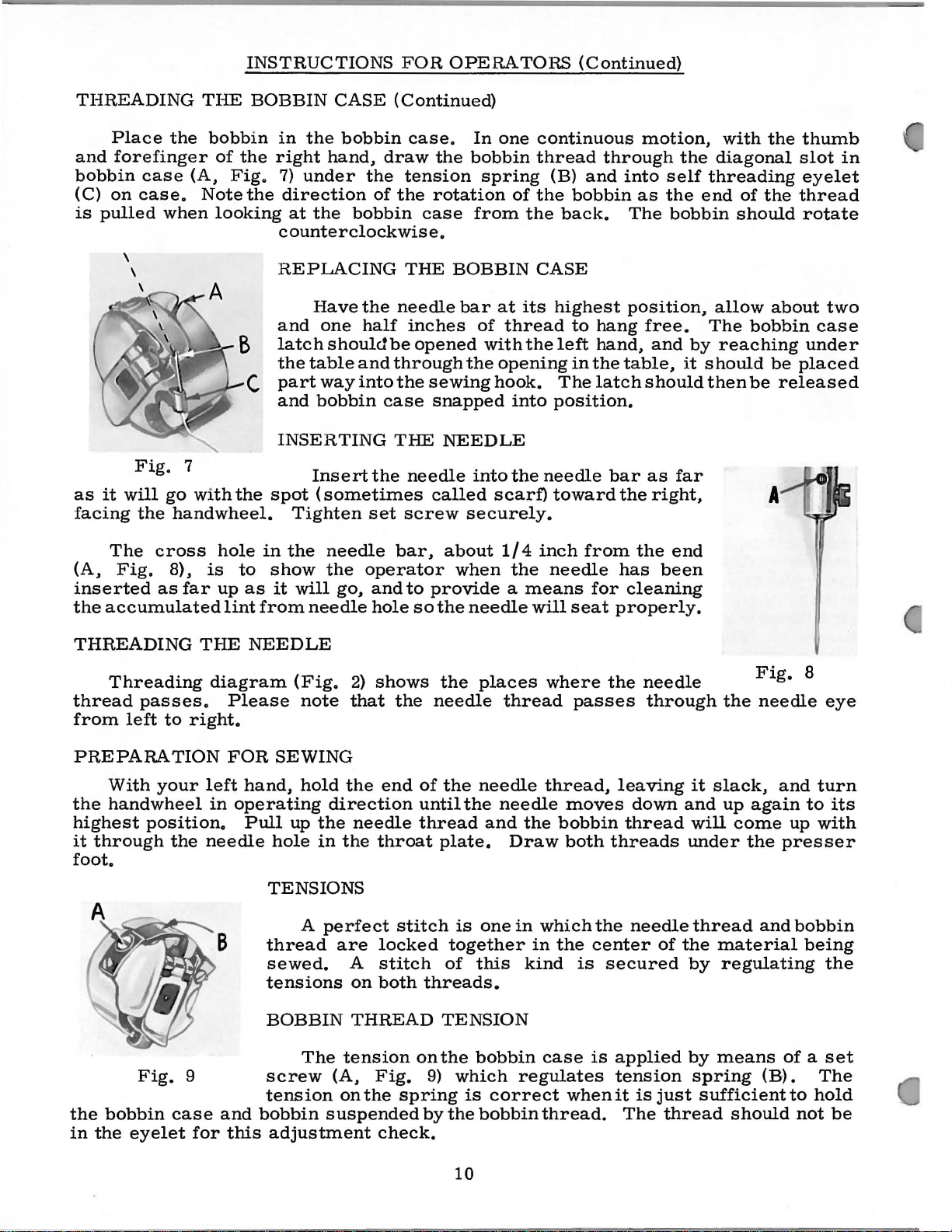

WINDING

from

down

post.

up

a

wardly

contact

position.

will

automatic

pulley.

varied

direction

each

Thread

the

between

to

the

few

turns

be

hook

hand.

Fig.

Press

on

rotated

by

the

direction

rotation

of

twist,

Turn

it

is a left

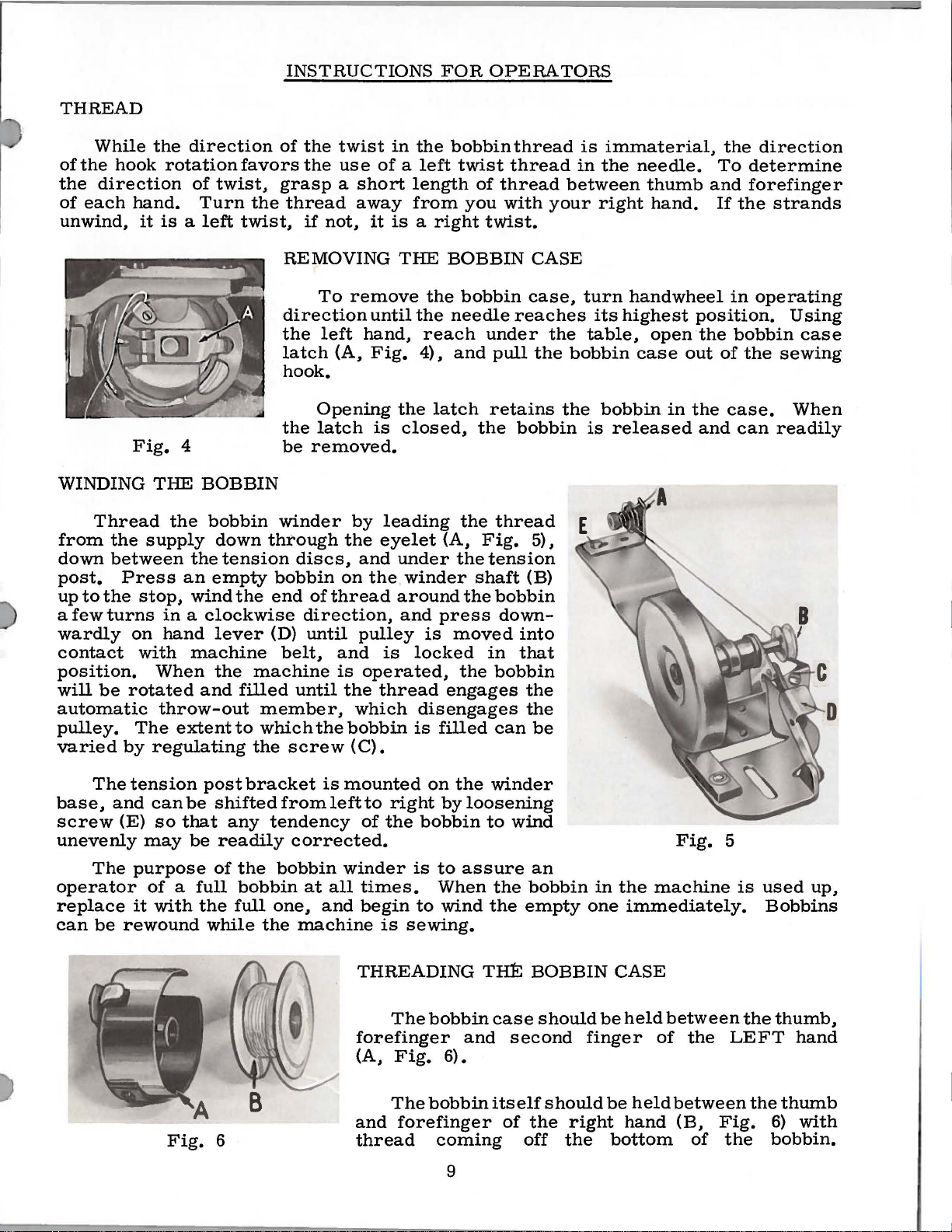

4

THE

supply

stop,

with

The

regulating

BOBBIN

the

bobbin

down

the

tension

an

empty

wind

in a clockwise

hand

When

throw-out

lever

machine

the

and

extent

of

favors

grasp a short

the

thread

twist,

REMOVING

direction

the

latch

hook.

the

be

winder

through

discs,

bobbin

the

end

(D)

belt,

machine

filled

to

until

member,

which

the

screw

the

twist

the

use

away

if

not,

it

To

remove

until

left

hand,

(A,

Fig.

Opening

latch

removed.

of

direction,

until

the

is

by

the

and

on

the. winder

thread

pulley

and

is

operated,

the

which

bobbin

(C).

in

the

of a left

length

from

is a right

THE

the

the

reach

4),

the

latch

closed,

leading

eyelet

under

around

and

press

is

is

locked

thread

disengages

is

filled

bobbin

twist

of

thread

you

tWist.

BOBBIN

bobbin

needle

under

and

pull

retains

the

the

thread

(A,

Fig.

the

tension

shaft

the

bobbin

down-

moved

in

the

bobbin

engages

can

thread

thread

with

CASE

case,

reaches

the

bobbin

5),

(B)

into

that

the

the

be

is

in

between

your

turn

the

table,

bobbin

the

is

immaterial,

the

needle.

thumb

right

its

bobbin

hand.

handwheel

highest

open

case

released

position.

the

out

in

the

and

the

To

and

If

in

bobbin

of

case.

the

the

can

direction

determine

forefinger

strands

operating

Using

case

sewing

When

readily

The

base,

screw

unevenly

operator

replace

can

and

(E)

The

be

rewound

tension

can

so

may

purpose

of a full

it

with

be

that

be

Fig.

post

shifted

any

readily

of

the

while

6

bracket

from

tendency

the

bobbin

bobbin

full

one,

the

is

mounted

leftto

of

corrected.

winder

at

all

times.

and

begin

machine

THREADING

forefinger

(A,

and

thread

on

right

the

bobbin

is

to

When

to

is

sewing.

The

bobbin

Fig.

The

bobbin

forefinger

coming

the

by

loosening

assure

wind

Tim

and

6).

9

winder

to

wind

the

bobbin

the

empty

BOBBIN

case

second

itself

of

the

off

an

should

should

in

one

finger

right

the

the

machine

immediately.

CASE

be

held

between

of

be

held

between

hand

botto:r:p.

Fig.

the

(B,

of

5

is

the

LEFT

Fig.

the

used

Bobbins

thumb,

hand

the

thumb

6)

bobbin.

up,

with

Page 10

INSTRUCTIONS

FOR

OPERA

TORS

(Continued)

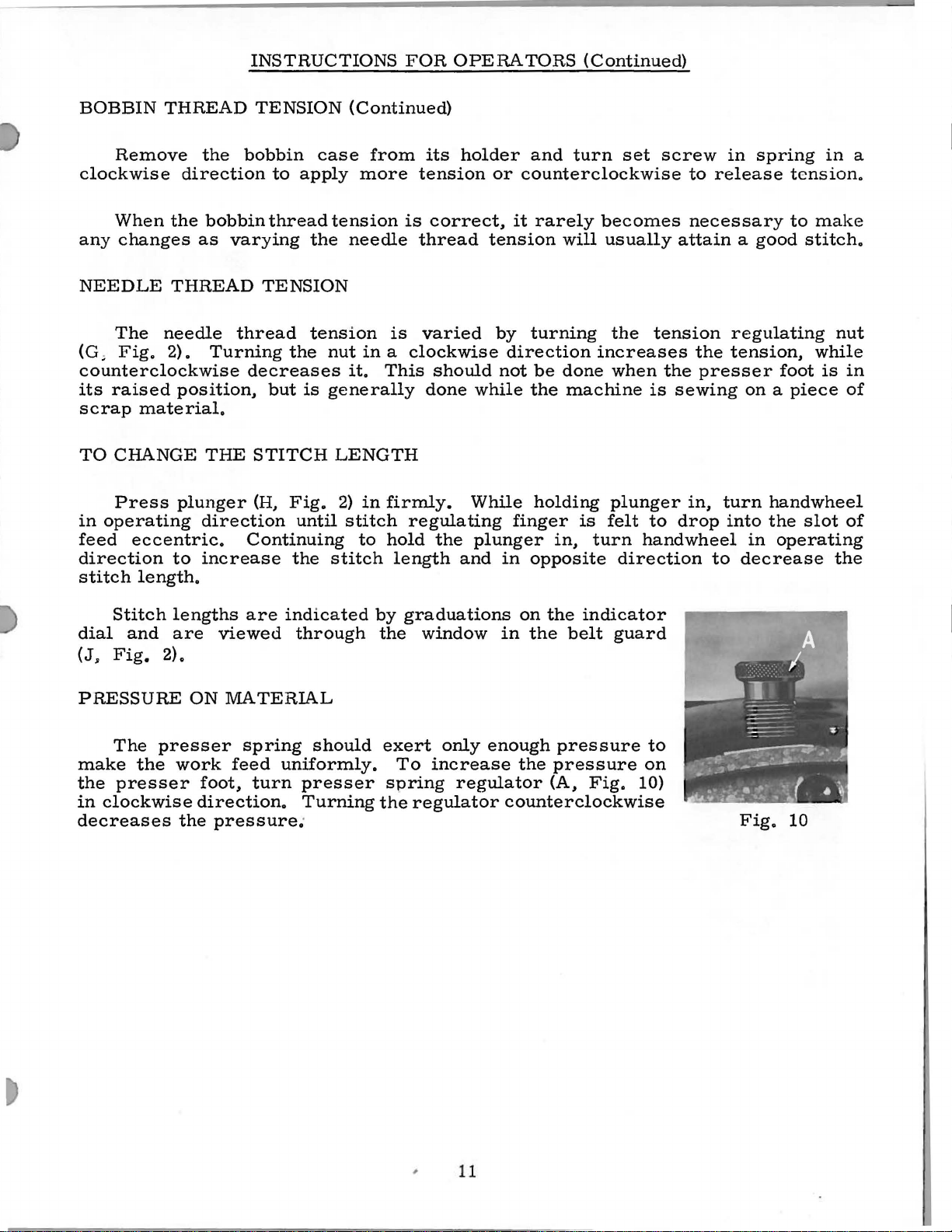

THREADING

Place

and

forefinger

bobbin

(C)

on

is

pulled

as

it

facing

The

(A,

Fig.

inserted

the

accumulated

case

case.

Fig.

will

the

the

when

go

handwheel.

cross

8),

as

THE

(A,

Note

7

with

far

BOBBIN

bobbin

of

the

Fig.

the

looking

C

the

hole

is

to

up

as

lint

CASE

in

the

bobbin

right

7)

counterclockwise.

REPLACING

and

latch

the

part

and

INSERTING

spot

in

show

it

from

hand,

under

direction

at

the

Have

one

should

table

way

bobbin

Insert

(sometimes

Tighten

the

needle

the

will

go,

needle

the

of

bobbin

the

half

and

into

the

set

operator

and

hole

(Continued)

case.

draw

tension

the

case

THE

needle

inches

be

opened

through

the

case

THE

needle

screw

bar,

to

so

In

the

bobbin

rotation

from

BOBBIN

bar

the

sewing

snapped

NEEDLE

into

called

securely.

about

when

provide a means

the

needle

one

spring

of

at

of

thread

with

opening

hook.

into

the

scarf)

1/4

the

continuous

thread

(B)

and

the

bobbin

the

back.

CASE

its

highest

to

the

left

in

The

position.

needle

toward

inch

from

needle

for

will

seat

through

into

as

The

position,

hang

hand,

the

table,

latch

bar

the

the

has

cleaning

properly.

motion,

the

self

the

bobbin

free.

and

by

it

should

as

far

right,

end

been

with

diagonal

threading

end

of

should

allow

The

bobbin

reaching

should

then

be

the

thumb

slot

eyelet

the

thread

rotate

about

under

be

placed

released

A

in

two

case

THREADING

Threading

thread

from

PREPARATION

the

highest

it

through

foot.

the

in

passes.

left

With

handwheel

bobbin

the

your

position.

Fig.

eyelet

to

the

case

right.

9

for

THE

diagram

Please

FOR

left

hand,

in

operating

Pull

needle

B

and

this

NEEDLE

(Fig.

note

SEWING

hold

up

the

hole

TENSIONS

thread

sewed.

tensions

BOBBIN

screw

tension

bobbin

adjustment

in

A

The

2)

shows

that

the

the

end

direction

needle

the

throat

perfect

are

tension

(A,

on

suspended

stitch

locked

A

stitch

on

both

THREAD

Fig.

the

check.

the

needle

of

until

thread

plate.

threads.

TENSION

on

the

9)

spring

by

places

the

needle

the

and

is

one

together

of

this

bobbin

which

is

correct

the

bobbin

where

thread

thread,

needle

the

Draw

in

which

in

kind

case

regulates

thread.

passes

moves

bobbin

both

the

the

center

is

is

when

the

needle

through

leaving

down

thread

threads

needle

of

secured

applied

tension

it

is

just

The

it

and

will

under

thread

the

by

by

spring

sufficient

thread

Fig.

the

needle

slack,

up

material

regulating

means

should

and

again

come

the

and

(B).

8

eye

turn

to

its

up

with

presser

bobbin

being

the

of a set

The

to

hold

not

be

10

Page 11

INSTRUCTIONS

FOR

OPERA

TORS

(Continued)

BOBBIN

Remove

clockwise

When

any

NEEDLE

The

(G,

THREAD

the

changes

THREAD

needle

Fig.

2).

the

direction

bobbin

as

Turning

counterclockwise

its

raised

scrap

TO

CHANGE

Press

in

operating

feed

direction

stitch

position,

material.

THE

plunger

direction

eccentric.

to

increase

length.

TENSION

bobbin

to

thread

varying

TENSION

thread

the

decreases

but

STITCH

(H,

Fig.

until

Continuing

the

case

apply

tension

the

tension

nut

is

generally

LENGTH

2)

stitch

(Continued)

from

more

needle

is

is

its

tension

correct,

thread

varied

in a clockwise

it.

This

should

done

in

firmly.

stitch

to

regulating

hold

the

length

holder

or

tension

by

not

while

While

plunger

and

in

and

turn

set

counterclockwise

it

rarely

turning

direction

be

the

holding

finger

in,

opposite

becomes

will

usually

the

increases

done

when

machine

plunger

is

felt

turn

direction

screw

to

release

necessary

attain a good

tension

the

the

presser

is

sewing

in,

to

drop

handwheel

to

in

spring

regulating

tension,

foot

on a piece

turn

handwheel

into

the

in

operating

decrease

in

tension.

to

make

stitch.

nut

while

is

in

of

slot

of

the

a

Stitch

dial

(J~

and

Fig.

2).

PRESSURE

The

presser

make

the

in

the

presser

clockwise

decreases

lengths

are

viewed

ON

work

foot,

direction.

the

pressure.

are

indicated

through

MATERIAL

spring

feed

turn

should

uniformly.

presser

Turning

·

by

graduations

the

window

exert

To

increase

spring

the

regulator

only

enough

regulator

on

the

indicator

in

the

belt

guard

pressure

the

pressure

(A,

Fig.

counterclockwise

to

on

10)

Fig.

10

11

;

Page 12

INSTRUCTIONS

FOR

MECHANICS

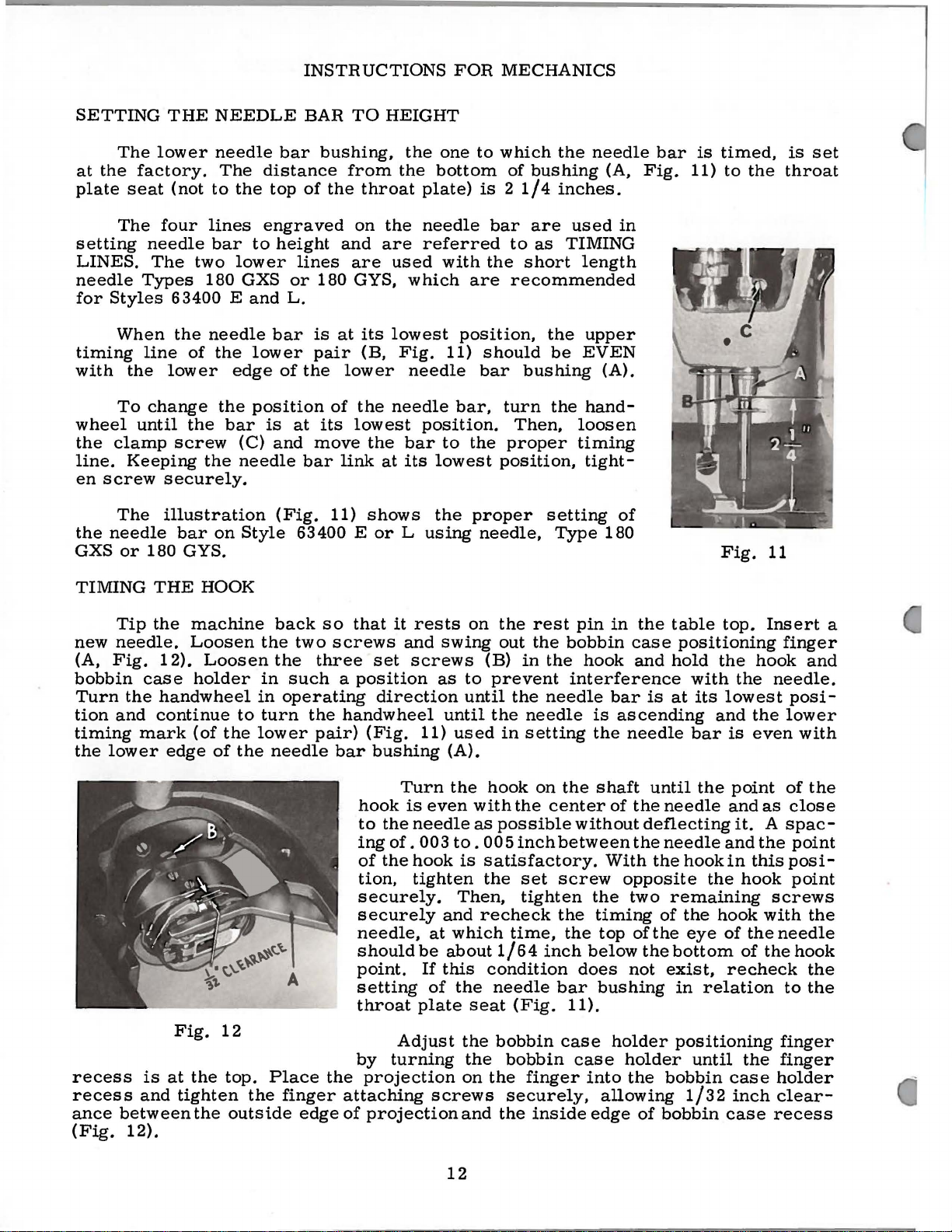

SETTING

The

at

the

factory.

plate

setting

LINES.

needle

for

timing

with

wheel

the

line.

en

the

GXS

seat

The

Types

Styles

When

the

To

until

clamp

Keeping

screw

The

needle

or

line

180

THE

lower

four

needle

The

lower

change

securely.

illustration

NEEDLE

needle

The

(not

to

lines

bar

two

180 GXS

63400 E and

the

needle

of

the

the

the

screw

the

bar

on

GYS.

the

to

lower

lower

edge

position

bar

(C)

needle

Style

BAR

bar

bushing,

distance

top

of

the

engraved

height

lines

or

180 GYS,

L.

bar

is

pair

of

the

is

at

its

and

move

bar

(Fig.

63400 E

TO

from

and

are

at

lower

of

lowest

link

11)

throat

on

its

(B,

the

the

shows

HEIGHT

the

one

the

bottom

plate)

the

needle

are

referred

used

lowest

needle

at

or L using

which

Fig.

needle

position.

bar

its

lowest

the

with

position,

11)

bar,

to

to

which

of

bushing

is 2 1/4

bar

are

to

the

short

are

recommended

should

bar

bushing

turn

Then,

the

proper

position,

proper

needle,

the

inches.

as

TIMING

the

be

the

setting

Type

needle

(A,

used

length

upper

EVEN

(A).

handloosen

timing

tight-

180

in

of

bar

Fig.

is

11)

timed,

to

the

Fig.

is

throat

11

set

TIMING

Tip

new

needle.

(A,

Fig.

bobbin

Turn

tion

timing

the

recess

recess

ance

(Fig.

the

and

lower

between

12).

THE

the

machine

Loosen

12).

case

mark

is

and

holder

handwheel

continue

(of

edge

Fig.

at

the

tighten

the

HOOK

Loosen

to

the

of

the

12

top.

outside

back

the

the

in

in

turn

lower

needle

Place

the

so

two

three

such a position

operating

the

pair)

the

finger

edge

that

it

screws

set

direction

handwheel

(Fig.

bar

bushing

Turn

hook

to

the

ing

of.

of

the

tion,

securely.

securely

needle,

should

point.

setting

throat

Adjust

by

turning

projection

attaching

of

projection

rests

and

swing

screws

as

until

11)

is

even

needle

003

hook

tighten

and

at

be

If

this

of

plate

screws

on

the

out

(B)

to

prevent

until

the

used

(A).

the

hook

with

as

possible

to.

005

is

satisfactory.

the

Then,

recheck

which

about

condition

the

seat

the

the

on

the

and

1/64

needle

bobbin

the

rest

the

in

the

the

needle

needle

in

setting

on

the

center

inch

between

set

screw

tighten

the

time,

inch

bar

(Fig.

case

bobbin

finger

securely,

inside

pin

in

the

bobbin

hook

interference

the

without

the

does

11).

case

case

and

bar

is

ascending

the

needle

shaft

of

the

the

With

opposite

the

two

timing

top

of

below

not

bushing

holder

holder

into

the

allowing

edge

deflecting

the

of

table

positioning

hold

with

is

at

its

bar

until

the

needle

needle

the

hook

remaining

of

the

the

eye

bottom

exist,

in

positioning

until

bobbin

1/32

bobbin

top.

the

hook

the

lowest

and

the

is

even

point

and

it. A spac-

and

in

this

the

hook

hook

of

the

of

recheck

relation

the

case

inch

case

Insert

finger

needle.

posi-

lower

of

as

close

the

point

posi-

point

screws

with

needle

the

to

finger

finger

holder

clear-

recess

a

and

with

the

the

hook

the

the

12

Page 13

INSTRUCTIONS

FOR

MECHANICS

(Continued)

In

(B,

Fig.

The

in

contact

toward

is

at

bottom

time,

there

For

of

size • 048

guarding

Before

related

1.

See

2.

Check

3.

Rotate

Check

cited

the

hook,

13)

is

purpose

with

the

hook

of

should

additional

and

su~face

metal

settings

that

the

for

handwheel

for

above

NEEDLE

at

GUARD

the

found a needle

of

this

guarding

the

needle

point.

its

The

vertical

be

little

needle

larger

may

needles,

be

necessary.

removal

should

be

needle

proper

hook

in

excessive

needle

as a desirable

INSTRUCTIONS

right

side

guarding

surface

(D)

at

needle

travel.

or

clearance,

removal

from

the

checked

bar

is

timing.

operating

deflection

condition.

of

the

surface

is

to

loop-taking

guard

no

will

if

the

deflection

especially

of

guarding

as

follows:

set

to

correct

direction

beyond

needle

prevent

time,

deflect

hook

some

surface.

by

FOR

(A,

is

properly

of

with

needle

height.

hand.

what

hole

Fig.

the

should

the

needle

use

all

is

NO.

in

13).

hook

needle

29474

the

bobbin

point

the

needle

slightly.

timed.

by

the

P

(C)

(At

needle

Fig.

case

from

be

when

holder

coming

deflected

needle

loop-taking

guard.)

13

4.

If

needle

(

1)

Remove

(

2)

Remove

using a 1/8

bench

is

the

needle

CAUTION!

needle

hook

guarding

The

base.

bobbin

When

REMOVED

Bobbin

pulling

on

slightly.

HOOK

LUBRICATION

CAUTION!

damage

may

deflection

bobbin

excess

and

removed.

bobbin

guarding

Damage

surface.

case

altering

or

disturbed

case

holder

bobbin

Do

result.

inch

rubbing

When

case

holder

holder

needle

case

not

is

excessive,

case

metal

strip

the

metal

is

obtained.

to

hook

guarding

from

only

stem

run

the

holder

from

offine

guarding

should

point

should

its

may

be

as

machine

follow

from

needle

emery

is

being

be

may

be

surface.

timed

removed

the

handwheel

steps 1 and 2 below.

hook.

guarding

cloth

surface

removed

re-inserted

result

thoroughly

position.

by

without

surface.

(#320),

back

and

from

frequently

if

too

cleaned

it

is

suggested

removing

is

rocked

the

bobbin

with

forth

needle

much

gib

This

one

end

until

guarding

and

tested

metal

before

is

re-assembly

the

screws

backwards

case

in

the

may

be

done

secured

sufficient

surface,

until

proper

removedfrom

hook

and

gib

and

hook

NOT

forwards

as

to

metal

into

and

hook

by

the

BE

by

With

piece

about

should

of

white

five

be

the

bobbin

paper

seconds,

observed.

case

directly

remove

in

under

the

the

hook,

the

paper

run

the

machine

hook

and

continue

and a definite

and

13

for a full

running

distinct

minute.

the

machine.

pattern

of

Place

oil

a

After

spots

Page 14

INSTRUCTIONS

FOR

MECHANICS

(Continu

ed)

Should

required,

adjusting

cated

chine

on

just

surface,

change

in

should

before

oil

the

flow.

required.

hook

be

checking

SETTING

The

14

should

depth

throat

of

slots

ximum

lower

of a full

plate

travel

of

feed

the

Tighten

backward

more

turn

shaft

the

below

in

the

oil

run

THE

main

be

at

and

the

throat

travel.

main

screw.

settings

or

less

the

oil

(K,

Fig.

front

the

of

the

cloth

direction

After a change

flow,

about

MAIN

feed

the

center

for

set

tooth

the

machine

one

the

FEED

dog

(A,

to

rise

above

highest

in

plate

To

raise

feed

dog,

The

feed

of

the

HOOK

oil

control

2),

lo-

ma-

plate

of

the

minute

desired

DOG

Fi

the

the

point

the

feed

at

rnaloosen

bar

main

LUBRICATION

be

g.

or

screw

has

been

feed

dog

set

are

(Continued)

(B)

and

at

the

factory

established.

set

Fig.

feed

so

14

dog

the

to

specified

lateral.,

height.,

forward

or

plate

Fig.

across

15

the

SETTING

line

of

set

at

of

this

the

screw

at

dog

The

with

ential

(F)

elongated

machine

screws

forward

properly.

the

can

feed.

THE

the

the

DIFFERENTIAL

The

differential

to

rise

highest

throat

the

teeth

top

surface

To

raise

(D)

specified

Loosen

forward,

sides

the

main

feed

and

move

back

(A,

or

differential

be

aligned

Tighten

the

depth

point

plate

of

of

or

and

adjust

height.

feed

backward

of

the

feed

dog

is

feed

slots

against

Fig.

backward

The

loosening

parallel

screws

feed

of a full

of

travel

at

maximum

the

differential

the

throat

lower

feed

Tighten

dog

holding

differential

dog.

required,

dog

of

feed

the

15)

and

as

feed

bar

securely.

FEED

dog

the

dog

or

If

more

so

that

dog.

rest

move

required

of

to

with

sideways

DOG

(C.,

Fig.

tooth

and

plate

center

feed

feed

across

above

travel.

should

differential

holder

screw.

screws

(F)

in

feed

dog

adjustment

first

loosen

screws

Tighten

pin.

Loosen

differential

to

screws

be

the

top

(A)

rotated

surface

14)

should

the

in

the

the

feed

(E)

to

to

space

the

should

holding

are

screws.

position

will

so

throat

feed

In

addition

be

parallel

line

dog

set

feed

the

thr0at

be

of

the

centered

Now

the

fe

ed

feed

also

the

feed

of

the

also

plate

slots

of

feed.

loosen

dog

feed

plate.

in

line

differ-

screws

two

set

bar

(B)

dog

allow

dog

throat

be

to

to

in

tip

14

Page 15

INSTRUCTIONS

FOR

MECHANICS (Continued)

Set

the

rear

(G,

Fig.

clockwise

wise

front

(J)

by

more

lesser

gathering

located

NOTE:

stops

engage

dogs

feed

contact

vel.

63400 E and 3 to 1 on

main

14)

by

for

for

less

intermittent

turning

gather

gathering

ratio

in

the

After

(G

and

the

differential

have

slot

The

feed

clearance

and

each

gathering

dog.

and

bed

J)

other

differential

turning

more

differential.

differential

screw

counterclockwise

ratio.

can

plate.

setting

turn

that

the

at

ratio

DIFFERENTIAL

feed

screw

differential

(K)

be

read

the

machine

to

at

two

the

is 5 to 1 on

Style

(H)

counter-

or

Then

feed

clockwise

The

be

the

back

differential

on

differential

by

hand

sure

front

feeds

end

63400

clock-

set

dial

the

end

do

of

L,

stop

stop

for

feed

feed

tra-

Style

FEED

the

for

a

(L)

and

of

not

depending

ADJUSTMENT

on

the

length

Fig.

of

16

stitch

set

at

the

The

presser

set

so

that

it

guide

back

16),

bell

left,

accomplished.

screw

(B).

against

and

relocating

crank

the

proper

in

place.

This

(C).

PRESSER

bar

is

about

is

accomplished

the

rest

the

By

turning

setting

Tighten

BAR

connection

1/16

pin,

inch

loosening

stop

screw

the

of

the

the

lock

CONNECTION

(A, Fig. 17)

below

by

(B)

stop

presser

nut

tipping

the

lock

on

screw

bar

(A)

the

the

to

to

should

presser

the

machine

nut

(A,

lifter

the

connection

lock

lever

right

the

be

bar

Fig.

or

is

stop

Fig.

17

15

Page 16

INSTRUCTIONS

FOR

MECHANICS

(Continued)

PRESSER

When

directly

set

is

t

he

top

To

l

oosen

plate.

the needle ente

pressure to

P

RESSER

The presser

press

presser

To

follows:

1.

Remove

2.

Insert

3.

Loosen

the

BAR

locating

against

properly

of the

obtain

s et

screw

Set the g

the presser

BAR

er feet.

bar

adapt

presser

the

screw

GUIDE

the

the

throat

wh n there

throat plate

this setting,

(C).

uide to

rs the mi

Howeve

is

adaptable.

the

presser

set

as a handle.

the

bar

machine

foot

foot

screw

presser

is

(Fig.

Tap

4 3 I 4

ddle

foot

No.

r,

should

to

and

screw

in

bar

plate

of

63457 J is

the

with

a 4 3 I 4

17)

remove

on

presser

inch

its

slot

by

turning

feet

receive

presser

in

the

presser

guide

the

inch

the

dimension,

and

presser

presser

(B,

feed

space

pressure

foot

to

retighten

the

regulator

designed

of a different

feet

foot

screw

bar

guide

Fig.

dog

in

between

from

insure

center

screw

primarily

of

from

bar

so

and

17),

the

presser

its

lowest

the

thread

the

presser

its

being

the

foot

(C)

(A,

Fig.

to

manufacture

other

it

rotate

manufacture,

presser

screws

presser

position.

take-up

down

by

turning

in

guide.

10)

clockwise.

receive

be

bar.

in

from

foot

must

The guide

spring

on

the

it

Now,

Union

required,

proceed

right

bar

180°

wire

(F)

throat

so

apply

Special

to

using

r e

st

and

and

that

th

as

left.

e

4.

Attach

the

5.

Check

CAUTION!

the

presser

Test

should

snap

it

located

assembly,

loosen

socket

wise

upper

tension

spring

proceed

desired

the

adjustment

the

be

when

require

tension

(C).

until

stop

post

again

tension

slotted

presser

needle.

the

guide

check

enough

spring

adjusting,

under

and

Turn

the

(E)

(D)

further

tension

post

of

end

foot

presser

When

height

spr

tension

is

arm

remove

post

the

check

and

in a clockwise

touches

in

is

set

the

check

of

bar

presser

TENSION

ing

tension

depressed

loosen

and

tension

set

tension

spring

has

the

the

obtained.

screw

the

to

the

bar

guide

feet

must

screw

no

(B)

spring

tension

be

(A,

to

assure a good

and

set

to

the

assembly.

(B)

post

moves

tension

upper

same

When

should

tension

and

align

for

correct

other

checked

ASSEMBLY

screw

(D)

direction

stop

direction

be

post

than

and

Fig.

18).

returning

released.

in

right

in

on

of

Partially

tension

counterclock-

away

drawn

from

it.

(E).

until

correct

can

be

(D)

the

needle

height

of

Union

reset

ADJUSTMENT

There

Should

the

tension

Turn

until

Then,

1

y

up

made

and

and

Special

where

head

post

the

the

the

the

set,

snugly,

by

turning

hole

or

tighten

manufacture

necessary.

yet

not

inserting

in

the

slot

of

the

set

screw

F"

lg.

18

forcefully.

a

screwdriver

required

foot

securely.

are

E

Further

direction.

with

used,

0

into

Replac.:etension

take-up

should

wire.

be

While

resting

assemblywith

the

tension

on

the

throat

the

post

plate.

check

assembly

spring

16

is

about

being

318

inch

replaced,

above

the

presser

the

thread

foot

Page 17

INSTRUCTIONS

FOR

MECHANICS

(Continued}

TENSION

The

seams

tension

insure a good

is

depressed

is

adjusted

with a postal

RELEASE

tension

or

when the

release

Fig.

19

and

from

release

cam

returning

released.

about 1 to 1 1/4

scale

whenthecheckspringis

The

tension

but

not

release

(D ~ Fig.

located

correct

post

forcefully

pin

should

18}.

just

height

The

below

as

set

tightened

follows:

should

presser

(D ~ Fig. 1 7}

are

when

(A~

the

position

screw.

positioned

raising

the

of

presser

release

THREAD

Check

snap

(C~

Fig.

1/32

screw

move

check

the

spring

tension

be

foot

required

The

in

the

tension

Fig.

flange

The

tension

or

average

cam

Check

spring

when

The

ounces

20}.

to1/16

should

(B~

Fig.

freely

discs~

set

so

that

is

raised

and

the

in

for

proper

and

out

position

discs

19}.

is

Set

the

of

the

tension

maintained.

release

by

loosening

lowering

release

foot

lift

set

screw

CONTROL

the

adjustment

tension.

spring

check

(B~

spring

when

This

is

inchfromitsstop.

be

drawn

18).

in

eyelet

the

The

tension

(A~

should

it

will

for

back

and

out

operation.

are

in

stop

Tighten

cam

set

the

cam

point

above

securely.

of

There

Fig.

tension

measured

measured

up

snugly

tension

post

Fig.

be

set

not

tacking.

position

of

the

tension

line

with

screw

assembly

(D ~ Fig. 1 7)

screw

to

suit

being

the

throat

tension

should

20)

19}

~

for

release

The

of

the

assembly

the

(B~

Fig.

rests

the

tension

(E~

the

between

plate.

assembly

be

C

when

adjustment

tension

check

19}

spring

so

against

assembly

should

Fig.

17)

sewing

1/4

to

Tighten

(A~

enough

sewing

over

of

assembly

is

correct

eyelet

that

when

it~

now

and

then

conditions.

5/16

inch

tension

Fig.

tension

the

this

set

be

20).

to

With a thread

thread

should

(Fig.

dis.cs

19).

so

without

to

thread

Class

63400,

wire

in a straight

be

set

Be

that

1/16

sure

the

obstruction.

machine

Fig.

and

running

from

line,

to

1/8

the

eyelet

check

After

as

spring

per

making

threading

21

as a result,

the

inch

is

will

the

the

tension

check

below

set

close

pass

this

setting~

spring

the

to

freely

post

thread

the

diagram

Sew

slowly

the

action

the

check

taut

when

stroke.

may

tension

Slight

be

necessary

should

consistent

with 3 to 4 ounces

cord

(A,

checking

heavy

or

Fig.

to

similar

the

adjustment,

disc

tension

17

to

eyelet

line

tension

over

proceed

(Fig.

on a piece

of

the

spring

the

take-up

changes

be

stitch.

21}.

tension.

you

when

but

can

be

the

it

2).

check

to

the

at

this

used

The

needle

thread

Depress

The

compared

this

is a required

reduced.

Fig.

of

material

spring.

The

take-up

is

at

the

in

needle

point,

to

maintain a uniform

but a reasonable

machines

thread

20

and

thread

wire

bottom

thread

are

tension

using a postal

check

check

spring

spring

to

Class

setting

observe

from

should

of

tension

sewn

on

70-2

scale

when

will

61400

for

be

its

and

off

feel

the

Page 18

BOTTOM

Before

accessible

clean

be

as

the

and

gaskets

place

1.

2.

temporarily

hard

be

position

measuring

the

needle

on a scale.

loosen

and

inch

and

bushing,

one

shaft

securely.

collar

press

pinion

and

securely.

quantity

travel

is

plate).

only

REMOVAL

1.

2.

3.

4.

5.

container.

tapped

the

gasket

CAUTION!

gasket

Before

dirt.

are

and

To

replace a damaged

Clean

The

gasket

the

cover

the

gasket

and

the

gasket

The

bolt

The

hook

steel

Should

disturbed,

hook

shaft

(G)

To

reposition

the

collar

dimension.

thrust

and

of

the

FLAT,

and

the

so

as

tighten

Hook

of

throu

controlled

The

to

feed

The

following

Remove

Remove

Apply

using Allen

to

drop

pump

Remove

Remove

COVER

removing

from

underneath.

free

with a wooden

may

When

seat

area

replacing

The

cover

used

tighten

cover

washers

can

and

set

and

washer

its

collar

oiling

finger

disc

gasket recess

in

resting

in

long

is

in

place.

sealing

cemented

shaft

the

hook

the

be

from

to

the

reading

screws

establish

after

set

screws

tighten

Liberally

washer

to

remove

both

is

oil

supplied

gh

the

by a dial

hook

oil

to

OF

OILING

hook

hook

wrench,

pivot

(F),

metering

cog

(H)

INSTRUCTIONS

the

bottom

Remove

Tipthemachineback,

block

become

of

the

gasket

to

seal

the

two

cross

the

middle

sloped

gaskets

(A,

(D)

shaft

left

determined

the

hook

point

the

of

Move

against

making

both

away

set

accomplished

metering

oil

feed

the

steps

oil

feed

oil

control

pressure to

pin

disc

from

damaged.

the

bottom

the

cover,

should

the

bolts

cover

section

as

it

does

edge

in

place

Fig.

22)

between

setting

and

end

of a new

35/64

hook

shaft,

the

pinion

the

35/64

the

pinion

the

certain

is

on

screws

coat

with

oil

from

all

end

screws

to

the

(P,

roller

unit

from

DEVICE

are

roller

loosen

located

is

free

cup

(G)

hook

machine

the

bolts

securely.

gasket,

of

is

in

of

the

inward.

may

have a tendency

by

is

held

the

right

by

of

inch

left

the

the

and

the

play

hook

feltofmetering

Fig.

(A,

the

necessary

(A,

finger

hook

set

in

the

to

along

oil

FOR

MECHANICS

cover,

or

cover

also

and

any

triangular

the

back

applying

long

by a high

is

23)

oil

(B).

oil

screw

fall.

with

control

place

this

plug

loosenandremovethetwocoverscrews.

mallet.

is

bottom.

machine

be

inspected

must

proceed