Page 1

®

INDUSTRIAL

5

EWING

F

INE

S

63

634

ST

QUALITY

TYLES

400K

00

KL

E

LEWIS

•

COLUMBIA

MACHI

N ES

CATALOG

No.

121KE

CLASS

STREAMLINED

HIGH

SPEED

LOCKSTITCH

WITH

INTERMITTENT

"KLIPP-IT"

CHICAGO

AND

63400

MACHINES

DIFFERENTIAL

THREAD

WIPER

FEED

Page 2

Catalog

(Supplement

INS

to

TR

No.

Catalog

UC

TIONS

FOR

121

KE

No.

121

E)

ADJUSTING

LIST

Streamlined

63400

First

AND

OF

CLASS

Styles

KE

OPERATING

PARTS

63400

Lockstitch

63400

Edition

KL

Union

Rights

Copyright

by

Special

Reserved

1970

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.

Co.

Countries

A.

July 1 1970

Page 3

IDENTIFICATION

OF

MACHINES

Each

the

name

Standard

"Z".

only

Style

which

63400".

junction

not

clarity,

and

number,

NOTE:

Example:

minor

number.

Styles

differs

This

used

KL

Opposite

Union

plate

Style

therewith.

on

certain

parts.

description

When

column.

on

numbers

changes

Example:

of

machines

from

catalog

Styles

the

ordering

Special

the

"Style

is a supplement

63400 E or L are

63400 E or L parts

illustration

machine

machine.

have

63400

are

made

similar

the

style

Only

those

and

repair

Style

one

KE".

in a standard

"Style

number,

APPLICATION

parts

pages,

amount

parts

is

identified

numbers

or

more

Special

63400

in

KEZ".

construction

in

to

Catalog

which

illustrated

are

required.

always

by a Style

are

letters

Style

machine, a "Z"

that

OF

are

shown

parts

suffixed,

numbers

are

it

contains

CATALOG

No.

used

and

in

phantom

are

use

the

number

classified

contain

grouped

no

121 E

listed

identified

part

on

and

Styles

at

number

which

as

standard

but

never

the

is

suffixed

under a class

letters.

should

63400

the

back

to

help

locate

by

detail

listed

is

stamped

and

contain

letter

to

Example:

be

KE

of

this

the

"Z".

the

used

and

book.

the

63400

number,

in

the

into

special.

letter

When

Standard

number

"Class

in

con-

KL,

but

For

KE

part

second

Adjusting

those

included

are

herein.

in

given

of

High

Differential

trimmer),

Medium

Button

Lubricating

Adjustable

Driving

Needle

63400

in

Catalog

in

additional

The

It

this

handwheel

class.

from

Speed

Stitch

Link,

Bar

KE

knit

dress

length.

recommended

and

No.

this

catalog

instructions

catalog

can

also

Reference

the

operator's

is

toward

Streamlined

Feed

Thread

and

Heavy

Regulator,

System,

Feed

Feed

11

1/8

For

simultaneously

material

1

13/64

operating

121 E

are

applies

be

applied

the

Long

for

Reverse

Wiper

Duty,

Stitch

Head

Eccentric,

Timing

Inches.

requiring

inch

speed

instructions

for

Styles

the

ones

that

pertain

specifically

with

to

direction,

position

operator.

STYLES

Arm

and

and

Prepared

Drop

Oil

on

needle

5500

Feed,

Length

Siphon,

Needle

Lower

seaming

R.

P.

for

Styles

63400 E and L respectively.

that

are

different

specifically

to

the

Standard

discretion

such

while

Lockstitch

Plain

up

bar

M.

seated

OF

Differential

for

Rotary

Indicator,

Adjustable

Bearings

Main

and

to

a 5

travel.

to

as

MACHINES

Machines,

Needle

Shaft,

intermittently

to 1 gathering

63400

to

some

right,

at

the

with

Positioner,

Hook,

One

Hook

for

Take-up

Maximum

Seam

from

Styles

Styles

Special

left,

machine.

with

Horizontal

Reservoir

Oil

gathering

Spec.

KE

and

Styles

63400

of

front,

Adjustable

"Klipp-

Control,

Lever

Work

ratio,

301-SSa-1.

KL

are

The

only

instructions

63400 E and

KE

and

machines

Styles

Operating

It"

One

Hook

Enclosed

depending

of

back,

Intermittent

(Thread

Needle,

Needle

and

Space

woven

similar

L,

KL.

as

listed

machines

etc. , are

direction

Under-

Light,

Shaft,

Automatic

Needle

to

cotton

Push

Bearing

Right

on

stitch

Maximum

to

or

Bar

of

and

63400

KL

Same

stretching

length.

as

Style

material

63400

and

KE,

with

except

only

equipped

a 3

to 1 gathering

3

to

give

ratio,

more

depending

reverse

feed

on

for

stitch

Page 4

NEEDLES

Each

denotes

number,

sured

the

size

needles

Needle

Their

Type

180

180

No.

GXS

GYS

To

sample

on

label.

Selection

used.

stitch

Union

the

kind

stamped

in

thousandths

number

packaged

Type

description

have

needle

needle,

A

complete

of

Thread

should

formation.

Special

of

on

represent

and

180

and

Round

groove,

chromium

Round

groove,

needle

shank,

the

of

an

sold

GXS

the

shank,

shank,

point,

needle

inch

the

by

or

sizes

wide

plated -sizes

wide

plated -sizes

orders

or

the

type

order

proper

needle

pass

freely

has

length,

shank,

across

complete

Union

180

GYS

available

round

angle

round

angle

028, 03 2,

promptly

and

size

would

size

through

both a type

groove,

denotes

the

eye.

symbol,

Special.

is

recommended

are

Description

point,

lockstitch,

groove,

028,

point,

lockstitch,

groove,

03

6,

and

accurately

number

read:

"1000

should

be

the

and a size

finish

largest

Collectively,

which

listed

below.

and

struck

032,

struck

040,

should

groove,

036,

groove,

044,

be

Needles,

determined

needle

eye

number.

and

other

diameter

is

given

for

Styles

Sizes

short

length,

deep

040,

short

length,

deep

048,

filled,

forwarded.

Type

by

in

order

the

044,

054,

an

180

the

The

type

details.

of

the

type

on

the

63400

ball

-spot,

The

blade,

number

label

KE

and

eye,

ball

048, 054,

ball

eye,

spot,

chromium

060

empty

GXS,

size

to

package,

Use

description

Size

of

the

produce a good

number

size

mea-

and

of

all

KL.

single

point,

060

single

036".

thread

a

size

upon

of

thread.

above,

than

The

of

the

The

which

the

Cotton

strength

the

thread

size

of

following

The

may

size

specified.

Size

30

36

40

50

60

70

80

requirement

employed.

the

needle

table

choice,

dictate

Thread

0

SELECTING

of

The

employed.

shows

the

however,

the

selection

THE

the

preferred

should

SIZE

seam

quality

OF

produced

of

the

size

give

of a needle

~ercerized

Thread

Size

B

A

A

0

00

000 036

0000

THE

work

of

needle

NEEDLE

is

largely

desired

consideration

size

slightly

dependent

is

largely

for a given

to

factors

larger

Needle

Size

060

054

to

048

to

044

to

044

to

040

to

to

032

to

upon

dependent

size

referred

or

060

054

048

048

044

040

036

and

kind

smaller

the

to

90

0000

100

4

032

028

to

to

036

032

Page 5

IDENTIFYING

PARTS

Where

Parts

which

appear.

OF

replacement

listed

plate

position.

their

view

the

in

exploded

or a solid

can

description

too

distinguish

Part

IMPORTANT!

MACHINE

The

Two

Numbers

position

ordering

Sub-

be

numbers

arrangement

exploded

in

this

presents

On

part

being

view

assemblies,

furnished

the

construction

small

numbers,

shown.

line

of

for a complete

FOR

parts

catalog

a

the

page

in

the

of

the

parts.

plate

box

for

the

one

part

represent

ON

ALL

WHICH

of

for

Styles

view

and

sector

opposite

descriptions

first

part

main

in

Always

carries

which

on

the

repairs,

sub-assembly.

permits,

catalog

from

ORDERING

this

plates

Styles

of

column

the

picture

another

the

same

ORDERS,

PART

catalog

63400

cover

63400 E

the

machine,

the

and

illustration.

use

the

a

reference

are

sold

plate.

are

each

stamping

that

part,

PLEASE

IS

ORDERED.

OF

REPAIR

is

to

KE

and

the

and L covered

parts

illustration

the

number

are

reference

part

number

number

complete,

Component

indicated

Example:

part

is

are

is

similar

regardless

INCLUDE

PARTS

facilitate

63400

differences

Reference

by

KL.

being

will

be

of

numbers

listed

for

or

by

indenting

stamped

identified

in

easy

between

in

aligned

found a listing

pieces

numbers

in

each

separate

parts

their

with

appearance.

of

the

catalog

PARTNAME

and

accurate

Catalog

as

required

only,

should

the

second

part

part,

of

sub-

descriptions

its

part

by

letter

in

AND

the

Standard

No.

121

in

their

of

the

in

the

and

merely

never

column.

available

are

in a bracket

assemblies,

number

symbols

which

STYLE

ordering

Styles

E.

Each

assembled

parts

particular

under

with

indicate

be

used

Each

for

sale.

which

.

they

of

the

37

38

39

40

41 670

42

catalog,

the

mentioned

illustration.

Union

Company,

to

the

Maximum

parts

guarantee

29480

63458

660-360

660-347

670 G-23

In

those

no

parts

Success

Genuine

for

Special

its

most

efficiency

are

of

in

stamped

FM

E

G-18

cases

specific

the

the

in

Needles

subsidiaries

approved

needles

the

where a part

various

description,

USE

the

operation

and

are

with

highest

Rotary

Rotary

Rotary

Solenoid

Female

Male

usage

GENUINE

and

scientific

will

machines

Repair

and

durability

packaged

the

quality

Tension

Solenoid

Solenoid

Wire

is

common

be

mentioned

and,

Union

if

NEEDLES

of

these

Parts

authorized

principles,

are

with

Special

in

materials

Release

Lead

Connector

are

necessary,

Cover------------------------------1

Terminal------------------------------

not

machines

as

distributors.

assured.

labels

TERMS

Solenoid

Cover

----------------------------------1

to

the

AND

furnished

and

marked

trade

and

----------------------------1

Sleeve,

all

of

in

the

same,

the

REPAIR

can

are

mark.

workmanship.

Assembly--------------1

green-------------------2

the

machines

description.

the

specific

difference

PARTS

be

secured

by

the

Union

They

made

~

are

with

Each

covered

However,

will

be

only

Special

designed

utmost

•

Genuine

trade

usage

shown

with

precision

mark

by

this

when

will

be

in

the

genuine

Machine

according

repair

is

your

2

•

Prices

are

forwarded

otherwise

are

strictly

f.

directed

o.

. A

b.

charge

net

cash

shipping

is

and

point.

made

subject

Parcel

to

cover

5

to

Post

change

shipments

the

postage

without

and

notice.

are

insured

insurance.

All

shipments

unless

Page 6

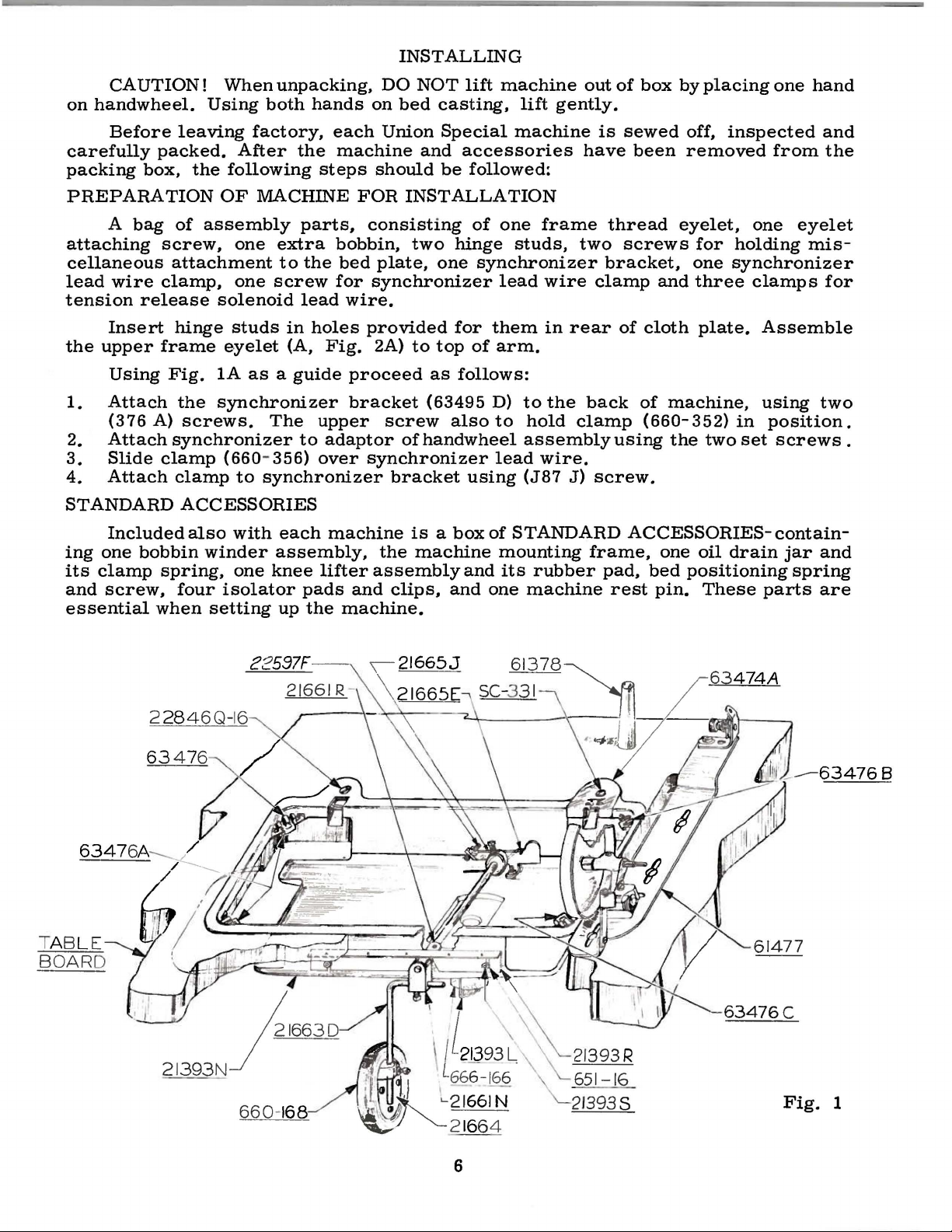

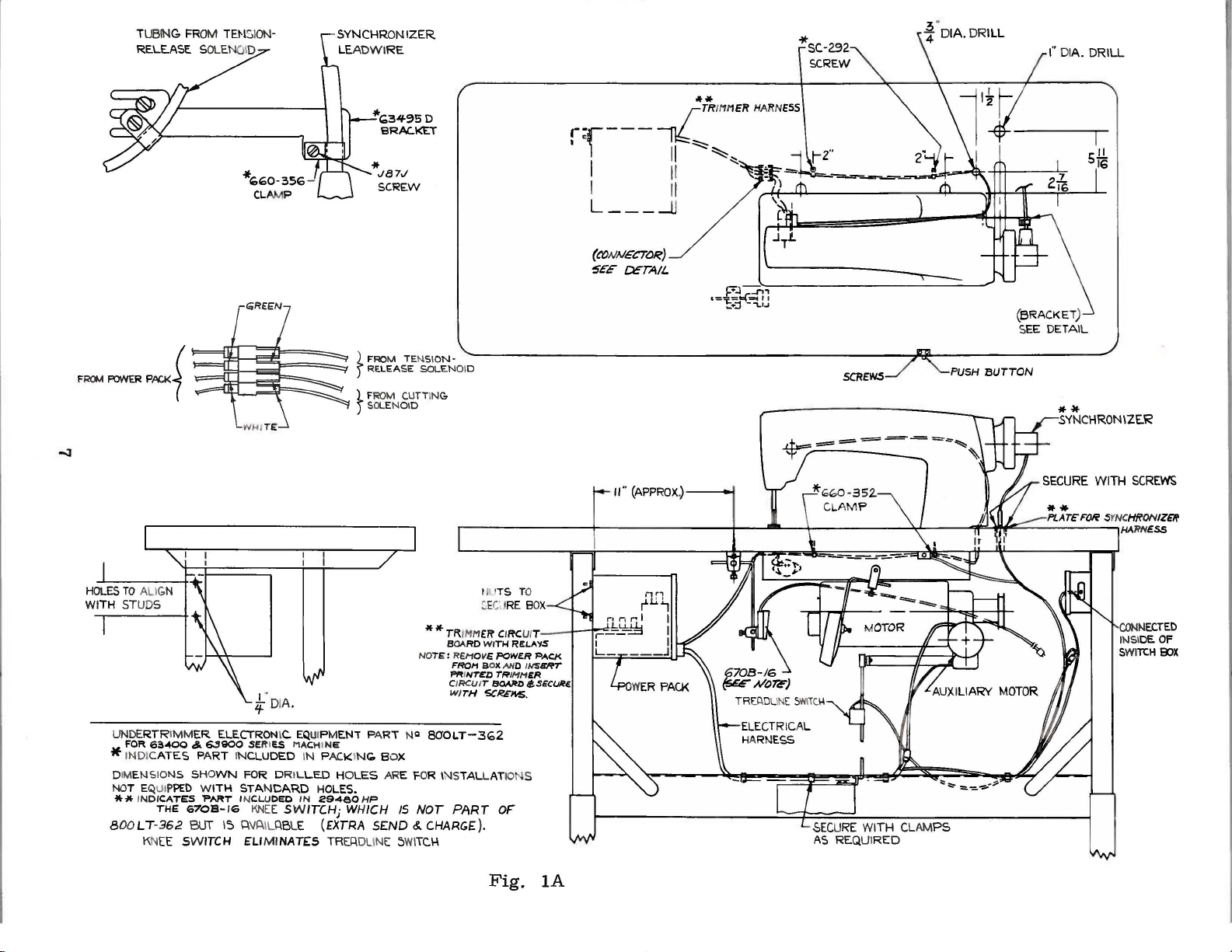

INSTALLING

CAUTION!

on

handwheel.

Before

carefully

packing

leaving

packed.

box,

PREPARATION

A

bag

of

attaching

cellaneous

lead

wire

tension

Insert

the

upper

Using

1.

Attach

(376

2.

Attach

3.

Slide

4.

Attach

STANDARD

Included

ing

one

its

clamp

and

screw,

essential

screw,

attachment

clamp,

release

hinge

frame

Fig.

the

A)

screws.

synchronizer

clamp

clamp

ACCESSORIES

also

bobbin

spring,

four

when

When

Using

factory,

After

the

following

OF

MACHINE

assembly

one

one

solenoid

studs

eyelet

lA

as a guide

synchronizer

(660

- 356)

to

synchronizer

with

winder

one

isolator

setting

unpacking,

both

hands

each

the

steps

parts,

extra

to

screw

bobbin,

the

for

lead

in

holes

(A,

Fig.

The

upper

to

adaptor

over

each

machine

assembly,

knee

lifter

pads

up

the

DO

on

bed

Union

machine

should

FOR

consisting

bed

plate,

synchronizer

wire.

provided

2A)

proceed

bracket

screw

of

synchronizer

bracket

the

assembly

and

clips,

machine.

NOT

casting,

Special

and

accessories

be

lift

machine

lift

machine

followed!

INSTALLATION

of

one

frame

two

hinge

one

studs,

synchronizer

lead

for

them

to

top

of

arm.

as

follows:

(63495

handwheel

is a box

machine

also

using

and

and

D)

to

to

hold

assembly

lead

wire.

(J87

of

STANDARD

mounting

its

rubber

one

machine

gently.

two

wire

in

rear

the

clamp

J)

out

of

box

is

sewed

have

been

thread

screws

bracket,

clamp

back

of

and

cloth

of

(660-352)

using

screw.

ACCESSORIES-

frame,

pad,

rest

one

bed

pin.

by

placing

off,

inspected

removed

eyelet,

for

holding

one

synchronizer

three

plate.

machine,

the

two

oil

drain

positioning

These

one

from

one

clamps

Assemble

using

in

position.

set

screws

contain-

parts

hand

eyelet

mis

two

jar

and

spring

are

and

the

-

for

.

6347

TABLE

BOAR

D

2

63

6A

284

6Q-

4 76

21393N

16

}

660-168

16630

6

651-16

21393

5

-

63476

C

Fig.

1

Page 7

*sc-2.92

SCREW

I"

Dt

A. DRILL

-.l

'""'""""'

CLAMP

P

K.K

~

*c;;34-~5

J87J

*

SCREW

2._

F

ROM

J RELEASE

)_ FROM

J

SOL

D

BRAC.KET

TE~SION-

SOLENO

CUTTING.

ENOID

ID

II"

(APPROX)

£:-l~~

~==di.C~u

• I

SCREW-S

PUSH

(

BRACKET)

S

BUTTON

EE DETA

**

·

.SYNCHR

IL

ONI

ZE.R

tlliTS

TO

C,EG

;JRE SOX

UNDE

RTR

IMME.R ELECTRONI

FOR 6::1-400 &

* INDIC

BOOL T -

ATES PART INCLUDED

DIMENSIONS SHO

NO

T EQUIP

**INDI

PED

CATES

THE

6708-

362

BUT

KNEE SWITCH

if

6.!1900

SERIES

WN

FOR

W

ITH

STANCARD

'PART

INCLUDED

16

KNE

IS P.VA\U:l.BLE.

E'LIMINATES

I "

DIA.

DRIL

E 5W

C.

EQ

UIP M

MA

CHINE

IN PACKIN

LED HOLES

HOLES.

IN

29480

ITC.Hj

(EXTRA SEND&.

TR

ENT PART

<;.

BOX

ARE

HP

WH

ICH

EP.Dl\

Nf: 5

**TRIMM£~

BOARD

NO

TE:

Pft1NT£D TRIMM

CIRCUIT BOA.'tD

WI

NC

BOOLT-3<;;2

'F

OR I

NS

IS

NOT

CHARGE

WI

TC.\-\

CIRCUIT

WI

TH

OVE

POWER

SCR'£115.

LATIONS

OF

REL.AY.S

ER

ltSECUIU.

RE.H

FROM B OX AND 1/r.i

TH

TAL

PART

).

Fig.

PACI<

trRT

lA

CONN

ECTED

INSI

DE

SWITCH

OF

B:>X

Page 8

TABLE

TOPS

Lockstitch

the

bed

plate

MACHINE

On a suitable

cut-out

through

over

the

nuts

1/16

retaining

of

the

as

but

lifter

maximum

within

raises

with

left

right

retaining

lightly.

Place

inch

board

Tip

the

shown.

must

Before

rod

the

approximately

machines

is

FLUSH

MOUNTING

tableboard.

the

hinge

hinge

hinge

sewing

clearance

plate

machine

All

not

the

should

lift

head.

plate

smartly

and

end

bind.

machine

of

pad

pad;

tighten

be

the

This

with

FRAME

lugs

and

insert

(21393

head

in

between

upward

locking

back

play

of

adjusted.

presser

may

5/16

are

the

place

to

tighten

round

R)

to

the

against

the

is

put

The

be

done

inch.

installed

top

INSTALLATION

the

rear

securely.

head

outside

frame

the

with a hammer

nuts

the

cross

into

left

bar

and

in

table

of

the

machine

machine

(Fig.

Assemble

wood

front

mounting,

cloth

production.

by

plate

securely.

rest

pin.

shaft

should

stop

its

parts

setting

screw

tops.

mounting

mounting

1).

Insert

screw

of

pan

and

edge

to

insure a good

and

assemble

be

the

(22597

do

not

the

stop

prepared

frame

the

bed

positioning

and

tighten

section.

after

and

taken

bell

crank

F)

interfere

screw

with

frame.

(21393

countersunk

securely.

as

shown.

being

the

up

sure

frame

grip

the

knee

by

(21665

should

so

that

the

cut-

out,

N)

in

the

wood

spring ( 634

and

there

sides.

on

the

press

cone

J)

of

be

set

so

with

moving

the

presser

so

that

machine

screw

7 4 A)

Assemble

snug

is

rap

underside

assembly

bearings.

the

that

up

about

the

knee

the

parts

bar

BOBBIN

directly

operation.

mechanism

the

winder,

wind

"Winding

BELTS

PREPARATION

1.

2.

3.

4.

5.

6.

WINDER

The

bobbin

in

front

The

to

the

bobbin.

the

These

Once

Wire

leg

Attach

Drill

Attach

Secure

using

clutch

Connect

release

to

Assemble

machines

again

leads

of

table

power

holes

electro

clamps

arm

green.

electrical

when

leads

solenoid

winder

of

the

base

be

moved

in

operation.

Re&ulation

Bobbin'.

OF

TABLE

using

with

frame.

pack

in

table

drive

and

switch

from

relays

should

sewing

of

the

closer

under

are

equipped

Fig.

striped

to

leg

to

cable

screws

and

power

(green

as

shown

be

secured

machine

winder

to

should

and

operation

OPERATOR'S

FRAME

1A

as a guide

ends

left

rear

if

required.

underside

and

leads

provided.

treadline

pack

leads).

in

has

or

to

to

leg

Fig.

to

belt

two

farther

exert

use

either

FOR

proceed

switch

of

table

of

table

to

underside

Connect

or

knee

to

cutting

Be

sure

41,

the

table

and

elongated

away

only

of

INSTRUCTIONS

INSTALLATION

box

switch.

page

top

will

from

enough

the

bobbin

#1

as

and

frame

board.

cable

solenoid

to

connect

16.

so

bear

attaching

belt

pressure

"Vee"

follows:

attach

using

of

tableboard

to

power

that

its

against

as

winder

or

round

switch

nuts

(white

white

pulley

holes.

needed.

against

is

in

Catalog

and

and

pack.

leads)

to

will

the

belt

which

The

described

No. 121

belts.

box

to

bolts

to

table

auxiliary

and

white

be

located

when

allow

pulley

the

belt

under

right

provided.

and

front

frame

drive.

tension

green

in

the

of

to

E.

THREADING

Thread

enlarged

for

machine

clarity.

as

indicated

Needle

is

threaded

in

Fig.

2A.

from

8

Threading

left

to

right.

at

check

spring

has

been

Page 9

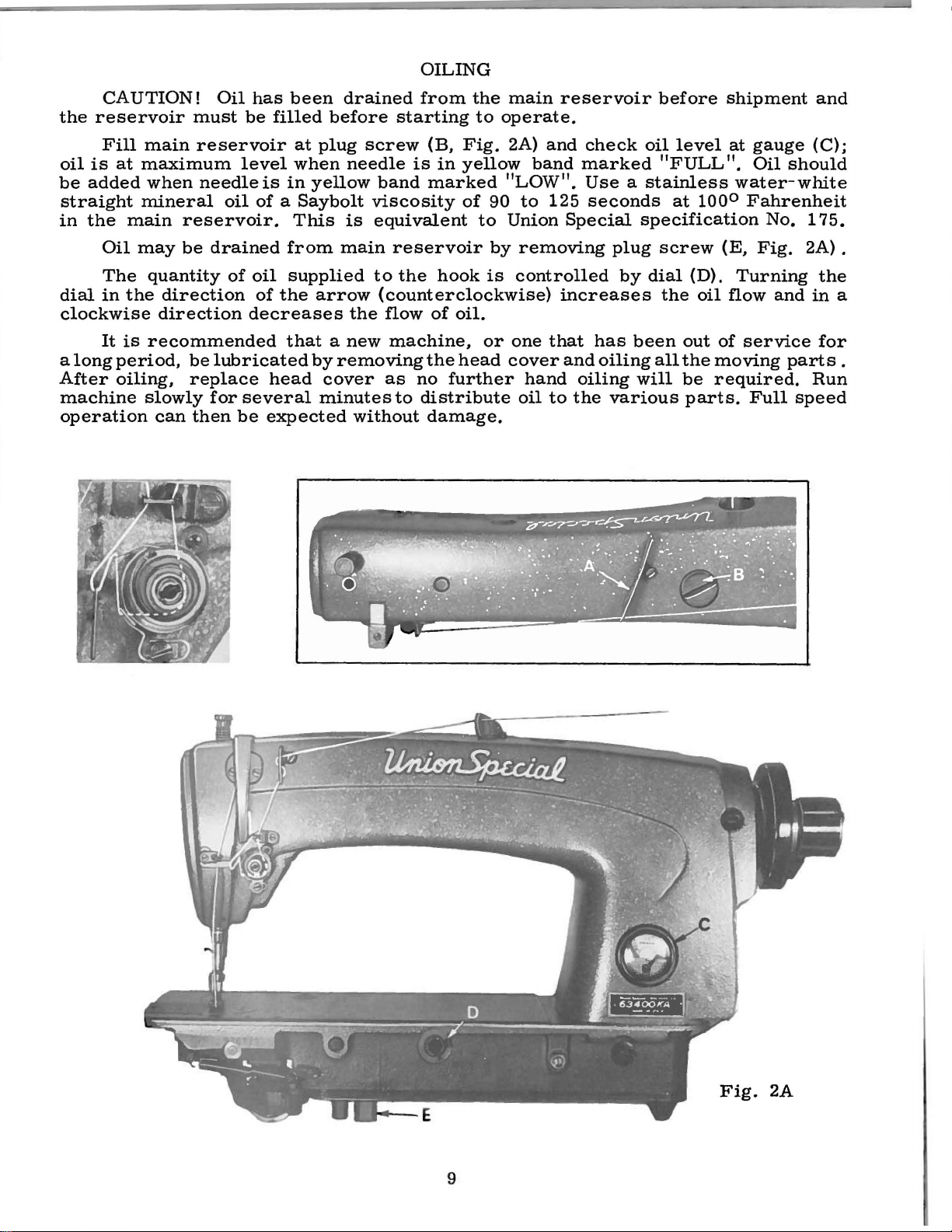

OILING

CAUTION!

the

reservoir

Fill

oil

is

at

be

added

straight

in

the

main

Oil

The

dial

in

the

clockwise

It

is

a

long

period,

After

machine

operation

oiling,

Oil

must

main

maximum

when

mineral

may

quantity

recommended

slowly

reservoir

needle

reservoir.

be

drained

direction

direction

be

lubricated

replace

for

can

then

oil

of

has

been

be

filled

at

level

several

be

when

is

in

yellow

of a Saybolt

This

from

oil

supplied

of

the

arrow

decreases

that a new

by

head

expected

drained

before

plug

screw

needle

viscosity

is

main

the

removing

cover

minutes

without

from

starting

is

band

equivalent

reservoir

to

the

(counterclockwise)

flow

machine,

as

no

to

distribute

the

to

(B,

Fig.

in

yellow

marked

of

to

hook

of

the

damage.

is

oil.

or

head

further

main

operate.

2A)

"LOW".

90

Union

by

controlled

one

cover

reservoir

and

check

band

to

removing

hand

oil

marked

Use a stainless

125

seconds

Special

increases

that

and

oiling

to

the

oil

specification

plug

by

has

been

oiling

will

various

before

level

"FULL".

at

100°

screw

dial

(D).

the

oil

out

all

the

be

parts.

shipment

at

gauge

Oil

water-white

Fahrenheit

No.

(E,

Fig.

Turning

flow

and

of

service

moving

required.

Full

and

(C);

should

175.

2A) .

the

in

for

parts

Run

speed

a

.

9

Fig.

2A

Page 10

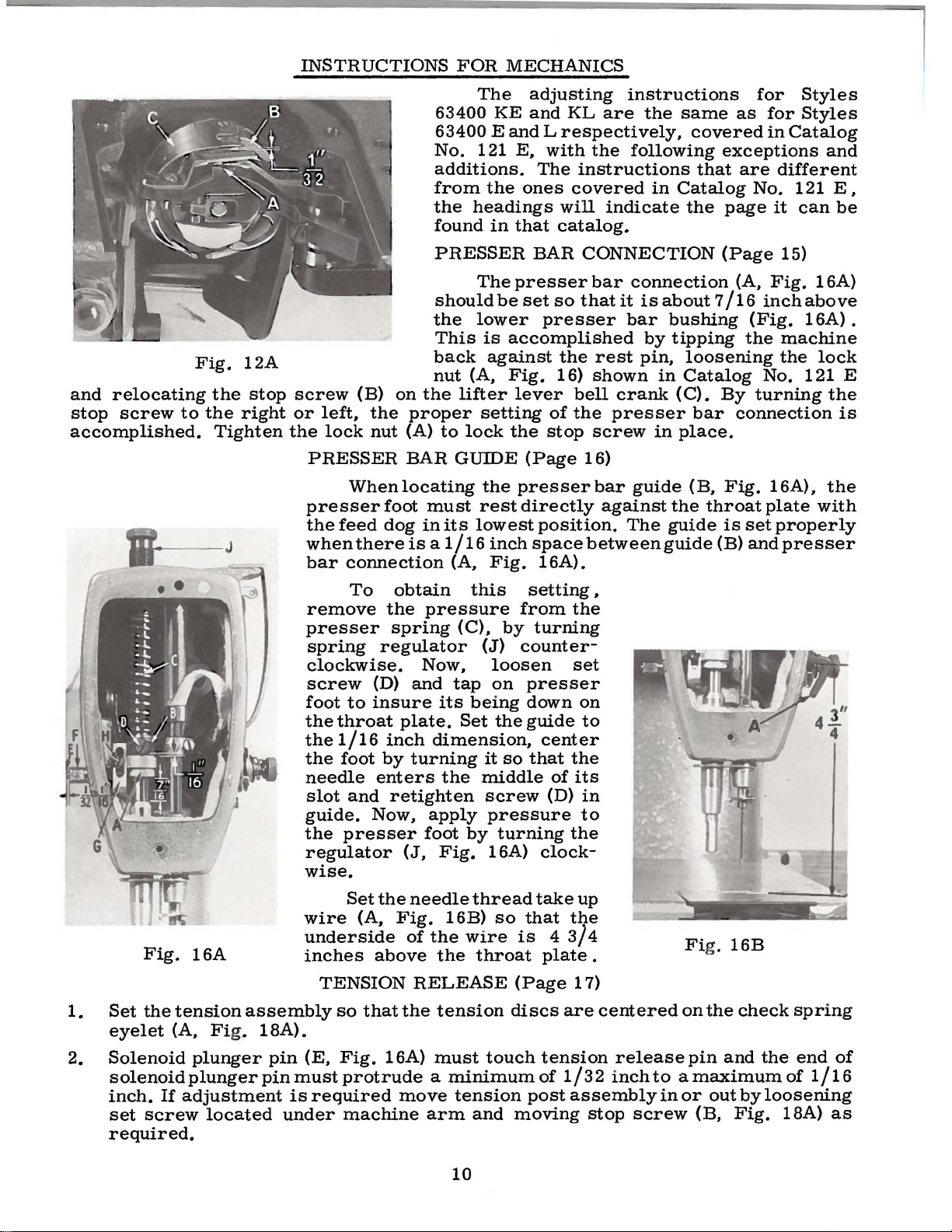

INSTRUCTIONS

FOR

MECHANICS

and

relocating

stop

accomplished.

screw

-

--

Fig.

to

12A

the

stop

the

right

Tighten

J

screw

or

left,

the

lock

PRESSER

presser

the

feed

when

bar

connection

63400

63400 E and L respectively,

No.

additions.

from

the

found

PRESSER

should

the

This

back

nut

(B)

on

the

the

proper

nut

(A)

to

BAR

Whenlocating

foot

dog

there

is a 1116

must

in

its

(A,

GUIDE

The

KE

121

the

headings

in

The

be

lower

is

accomplished

against

(A,

Fig.

lifter

setting

lock

the

rest

lowest

inch

Fig.

adjusting

and

KLare

E,

with

The

instructions

ones

that

presser

set

lever

the

presserbar

directly

covered

will

catalog.

BAR

(Page

spacebetweenguide

CONNECTION

so

that

presser

the

16)

bell

of

the

stop

position.

16A).

instructions

the

following

indicate

bar

it

bar

rest

shown

crank

presser

screw

16)

against

The

connection

guide

the

in

is

about

bushing

by

pin,

in

in

guide

same

covered

exceptions

that

Catalog

the

page

(Page

7116

tipping

loosening

Catalog

(C).

By

bar

place.

(B,

Fig.

the

throat

is

(B)

for

Styles

as

for

Styles

in

Catalog

are

different

No. 121

it

can

15)

(A,

Fig.

16A)

inch

above

(Fig.

the

turning

connection

set

and

16A).

machine

the

lock

No. 121 E

16A),

plate

with

properly

presser

and

E,

be

the

is

the

1.

Fig.

Set

the

eyelet

16A

tension

{A, Fig.

remove

presser

spring

clockwise.

screw

foot

the

the

the

needle

slot

guide.

the

regulator

wise.

wire

underside

inches

assembly

18A).

To

obtain

the

spring

regulator

(D)

to

insure

throat

1116

foot

TENSION

so

inch

by

enters

and

retighten

Now,

presser

Set

the

{A,

above

that

Fig.

pressure

(C),

Now,

and

tap

its

plate.

turning

(J,

needle

of

the

Set

dimension,

the

apply

foot

Fig.

16B)

the

wire

the

RELEASE

tension

this

by

(J)

loosen

on

being

the

it

so

middle

screw

pressure

by

turning

16A)

thread

so

throat

setting

from

counter-

that

is 4 3/4

(Page 1 7)

discs

the

turning

set

presser

down

guide

center

that

the

of

its

(D)

the

clock-

take

up

the

plate

are

on

to

in

to

,

.

centered

Fi

on

g.

the

16B

check

-

·-~

spring

2.

Solenoid

solenoid

inch.

set

screw

required.

plunger

plunger

If

adjustment

located

pin

pin

(E,

must

is

required

under

Fig.

16A)

protrude a minimum

machine

must

move

arm

touch

tension

and

10

moving

tension

of

1 I 3 2

post

release

inch

assembly

stop

screw

pin

and

the

to a maximum

in

or

out

by

loosening

{B,

Fig.

end

of

1 I

18A)

of

16

as

Page 11

3.

4.

Tension

Fig.

16A)

(E)

is

to

and

the

tension

discs.

This

between

tension

then

be

slipped

the

solenoid

too

much

tightening

The

manual

release

thread

release

with a set

have

approximately . 005

tension

can

be

the

head

release

plunger

pressure

set

screw

tension

TENSION

solenoid

screw

release

accomplished

of

solenoid

pin.

The

onto

bushing

pin.

thereby

remove

release

tension

when

RELEASE

is

secured

in

bracket.

pin

without

by

plunger

tension

and

Care

should

opening

spacer.

cam

the

presser

The

loosening

suit

the

release

foot

lift

securely.

(Page

to

inch

placing

release

moved

be

the

(G,

Fig.

tension

screw

sewing

point

above

17)

flat

of

Solenoid

clearance

thread

a.

005

pin

and

solenoid

in

until

taken

tension

16A)

foot

is

release

(H)

conditions.

is

between

the

(Continued)

bushing

(F,

plunger

between

between

inch

spacer

the

end

should

it

contacts

not

to

exert

disc.

After

should

raised

for

cam

and

then

1/4

throat

pin

it

the

of

be

set

back

can

raising

The

to

5/16

plate.

Fig.

so

that

tacking.

be

positioned

or

average

inch

Tighten

18A

it

will

lowering

tension

of

presser

screw

not

by

to

TRIMMER

machine

1.

There

(A,

Fig.

(B)

on

end

play

2.

Position

of

the

parallel

set

screw

knives

the

pin

to

the

Fig.

31

ADDITIONAL

ADJUSTMENTS

Remove

should

the

and

31).

pivot

or

relieving

upper

the

proceed

be

no

This

release

knife

positioning

with

the

upper

(E)

and

are

parallel.

hole

in

the

right

side

of

INSTRUCTIONS

positioning

as

follows:

bind

or

adjustment

lever

the

bind

(D)

parallel

finger.

Check

knife.

turn

A

the

good

eccentric

the

armofthe

NOTE:

bar

Head

link

connecting

bearings.

full

and

operates

finger

shake

can

(C)

as

and

in

be

and

the

with

to

see

If

this

is

eccentric

starting

bushing

positioningfinger

oil

rod.

Check

FOR

knife

lower

made

taking

case

the

that

not

bushing

point

(F)

oiler

wick

The

the

freely.

63400

assembly

knife

by

loosening

up

may

left

side

the

so,

loosen

would

located

bracket

in

the

wick

oil

KE

pivot

the

excessive

be.

of

lower

the

(F)

be

approx.

(Fig.

center

must

gauge

and

carrier

screw

the

knife

finger

until

to

must

63400

from

arm

is

the

have

90°

33).

locate

of

contact

to

be

the

sure

KL

the

slot

the

needle

in

needle

it

reads

the

D

Adjust

adjust

lower

CAUTION:

adjustment

lower

the

knife

knife

lower

and

Be

will

until

knife

counterclockwise

sure

bushing

have

to

it

just

turn

is

be

checked.

contacts

flange

not

turned

to

the

screw

raise

while

upper

(G)

it.

clockwise

making

11

knife.

this

To

to

Fig.

adjustment

32

or

parallel

Page 12

Fig.

projection

4.

Locate

Fig.

parallel

cutting

cutting

pivot

a

1/3 2 inch

when

in

position.

33

and

the

34)

as

with

solenoid

solenoid

release

knife

the

inside

cutting

far

forward

the

lever

plunger

lever

clearance

return

TRIMMER

should

positioning

the

the

adjustments

3.

edge

solenoid

line

of

(B)

(D),

to

spring

ADJUSTMENTS

The

lower

not

finger

run

out

of

positioning

Assemble

machine.

finger

holder

projection

the

and

1/32

of

as

possible

feed.

contacting

(C),

so

thatthere

be

(A,

until

bobbin

knife

inch

bobbin

bracket

With

adjust

maintained

Fig.

knife

extend

the

finger

loosen

positioning

Adjust

and

knife

the

(A,

case

assembly

clearance

case

(A,

and

the

the

the

is

35)

is

(A,

beyond

(B).

As

cutting

as

screws

assembly

finger

Fig.

holder

recess

(Continued)

Fig. 3 2)

the

the

lower

edge

indicated

(A,

finger

the

bobbin

recess

12A)

recess

attaching

between

(Fig.

left

(C)

Fig.

on

in

its

side

knife

must

at

point

and

case

by

turning

is

the

(B)

screws

12A).

extreme

of

the

moves

coincide

(D).

To

33)

and

position

knife

at

positioning

and

the

assembly

holder

the

the

top.

tighten

securely,

outside

left

position

arm

to

at a point

bobbin

of

the

right

make

positioning

finger

these

knife.

case

Place

the

finger

allowing

edge

the

,

of

into

the

into

of

5.

Adjust

Fig.

its

corner

left

case

CAUTION:

making

the

35)

so

extreme

(E,

side

of

holder.

this

Fig.

lower

when

right

Fig.

the

Be

adjustment.

35

hand

32)

needle

sure

knife

the

is

cutting

stop

lower

position,

in

slot

screw

knife

line

in

the

solenoid

Also

6.

7.

SYNCHRONIZER

is

the

with

bobbin

be

sure

Be

sure

contacts

knife

spring

wire

NOTE:

solenoid

position

Knife

tension

return

spring

or

to

(B,

in

left

the

lever

knife

is

in

wire

to

suit.

If

changed,

return

to

spring

bracket

the

contacts

does

the

spring

the

bobbin

its

extreme

does

positioning

bracket

cut

left

not

are

check

spring

threads.

loosen

(D)

to

decrease

ADJUSTMENT

not

to

case

make

(A,

the

Fig.

the

lower

hit

the

retainer

holder

right

contact,

finger

removed

step

Fig.

To

adjust

screw

right

the

34

knife

hook

wire

when

hand

assembly

5.

(C)

tension.

from

35)

and

to

increase

position.

to

tension

stop

point.

(B,

bend

or

machine

have

move

Fig.

the

lower

If

retainer

cutting

proper

of

tension

tension

when

33)

the

or

knife

(a)

Rotate

deflector

needle

handwheel

plate

on

the

up

in

(C,

stroke

operating

Fig.

12A)

of

the

direction

on

the

needle

until

rotating

bar.

12

the

hook

needle

assembly

clearance

is

in

line

cut

with

in

the

the

Page 13

SYNCHRONIZER

(b)

At

this

time

(A,

Fig.

36)

of

the

brush

(c)

position

described

(C)

in

The

needle

bottom

needle

in

synchronizer

of

stroke.

handwheel

(d)

screw

third

until

plastic

The

thread

from

off

it

at

from

and

needle

the

rotate

is

at

end

left

check

(D)

band

its

from

brush

band.

take-up

top

handwheel

thetop

of

synchronizer

(F)

the

ADJUSTMENT

the

brass

should

holder

be

(B).

flush

bar

step

(a),

and

positioner

until

at

it

end

left

is

should

If

not,

is

at

of

synchronizer

(E)

in

positioner

at

top

of

of

its

up

stroke.

in

of

its

stroke.

until

its

brush

up

and

down

(Continued)

contact

with

To

make

and

deflector

then

loosen

move

position

with

bottom.

in

operating

the

middle

should

its

stroke

If

operating

Then

and

rotate

is

in

positions

of

the

the

this

adjustment

set

as

power

Then

and

of

position

or

not,

with

direction

loosen

fourth

the

middle

left

band

front

edge

plate

screws

required.

needle

off

rotate

loosen

rotate

direction

the

black

needle

1/8

inch

power

until

screw

band

of

of

the

needle

as

at

the

black

bar.

plastic

Fig.

band.

36

Turn

on

power

(b)

Adjust

clutch

just

enough

located

above.

Fig.

clutch

is

engaged.

near

Tighten

so

to

unlock

the

37

that

Loosen

top

lock

clutcharm

lock

it,

which

on

right

screw

(E).

screw

end

CLUTCH

(a)

Set

needle

(b)

Adjust

that

treadle

washer

inch

(c)

Close

lever

there

microswitch.

needle

maintain

ADJUSTING

(a)

Depress

heard,

has

approximately1/16

(E,

Fig.

is

approximately

of

motor,

until

ARM

clutch

(B)

from

treadline

switch

is

no

positions

setting.

CLUTCH

treadle

which

37)

clutch

SWITCH

in

work.

arm

will

end

is

to

of

return

stud).

switch

adjusting

contact

Then

indicates

to

(where

one

full

is

ADJUSTMENT

spring

be

tighten

up.

unit

(A,

Fig.

to

stop

(wing

approximately

and

loosen

screw

between

(C),

it

screw

Tighten

until

switch

one

nut

click

is

1/Binchtravelbefore

it

says

turn.

engaged

"Lock

Adjust

as

Motor")

described

37)

clutch

and

until

(D)

open

screw

so

nut

1/2

until

the

to

is

.

CAUTION!

motor

running;

Clutch

one

must

click

not

must

engage

be

heard

when

before

clutch

lever

clutch

13

switch

is

engaged.

is

closed

or

auxiliary

Page 14

THREAD

1.

Rotate

(63470

top

2.

Thread

3.

Form

(63470

WIPER

thread

M),

of

its

wiper

thread

M).

ADJUSTMENTS

wiper

so

that

the

stroke.

lever

wiper

(63470

wire

mounting

hook

catches

E)

(63470

collar

must

R)

(63470

the

needle

return

for

H)

thread

with a snap

free

movement

and

adjust

when

when

in

thread

the

take-up

released.

thread

wiper guid

is

at

the

wiper

guide

e

CAUTION!

Move

Be

of

INSTALLATION

be

thread

sure

solenoid will

When

sure

Thread

wiper

to

loosen

installing

to

remove

wiper

guide

set

result

OF

hook

(63470

screws

if

it

is

INCHING

inching

jumper

between

socket

ing

or

properly.

B

switch

2

later

(A,

placed

A

tioning

up.

3

PUSHBUTTON

must

M)

when

not

SWITCH

switch,

wire

the

it

Should

date,

Fig.

not

so

that

adjusting

allowed

(No.

(A,

Fig.

pin

#2

(B)

before

inching

will

be

removed

the

3

8)

or

the

unit

will

prevent

hook

thread

to

return

670 B-21)

3 8)

located

and

pin

connect-

switch

not

the

must

function

inching

jumper

be

needle

not

FUNCTION

posi-

position

solenoid

does

#3

at

wire

not

wiper

completely.

on

plug

a

re-

from

stop

lever.

returningto

against

Premature

end

its

of

failure

stop.

tube.

Fig.

treadle

the

enables

with

trimmed

TREADLINE

loosen

more

moved

located

can

bushing

is

needle

the

the

needle

the

To

adjust

the

adjustment

and

to

obtain

If

more

be

compressed

(C)

3 8

heeled

will

operator

threads.

SWITCH

the

two

Allen

the

three

or

less

up

or

while

position

to

out

of

ADJUSTMENT

length

set

is

necessary

the

desired

pressure

more

down.

which

front

board,

cutter

chronizer

Therefore,

the

pushbutton

up

readjust

the

work,

of

the

screws

bushings

length.

or

less

If

the

is

edge

is

band

without

or

realign

but

pitman

in

the

the

cover

inside

is

required

accordingly

pushbutton,

mounted

of

the

depressed,

of

the

is

interrupted

when

is

depressed,

trimming.

the

without

rod

(A,

back

the

panel.

must

switch

when

by

on

the

table

the

syn-

the

This

garment

having

Fig.

39)

be

re-

re-

heeling

moving

If

.

the

the

treadle

pitman

Fig.

rod

39

the

spring

spring

tension

(B)

14

Page 15

TREAD

bushings,

should

The

switch

(E).

LINE

If

more

be

roller

actuator

SWITCH

travel

micro-

taken

on

switch

so

the

switch

bushing

ADJUSTMENT

is

required

actuator

that

only

should

(D).

enough

This

(Continued)

in

the

treadle

(D)

and

travel

not

be

is

accomplished

stop

is

provided

allowed

for

actuating

bushing

to

ride

by

the

(E),

must

to

actuate

over

adjustment

the

trim

be

the

level

of

the

cycle

lowered.

micro-

on

the

stop

the

two

Care

switch.

micro-

bushing

Fig.

40

15

Page 16

FUSING

THE

POWER

PACK

The

safety

fuses

ing

type

and

the

5

AMP

Fig.

the

the

the

(B)

40)

AC

transformer

full

located

output

the

auxiliary

located

put

side

wiper

power

feature

of

which

and

consisting

two

are

third a straight

at

250 V.

located

input

wave

in

for

the

rectifier.

under

side

of

the

mot

or.

under

solenoid,

of

the

the

rectifier

(30

pack

are

rated

incorporates

of

2

blow

The

2

the

front

primary

as

well

The

the

chassis

full

wave

The 5 AMP

chassis

VDC)

of

the

AMP

AMP

panel

as

the

2

rectifier

fuses

for

cutter

three

slow

blow-

at

250 V

fuse

rated

fuse

fuses

winding

input

AMP

fuse

fuses

fuse

the

out-

the

thread

solenoid,

(3)

(A,

of

to

the

for

(C)

a

and

the

relay

coil

Fig·

control

41

circuit

(24

VDC).

16

Page 17

Before

at

suggestions

Both

Needle

thread

Bobbin

thread

Lower

the

Needle

random

Needle

all

threads

way

this

times.

thread

cut

thread

cut

knife

machine

If,

which

Condition

not

not

not

does

thread

lengths

unthreads

left

however,

may

cut

cut,

cut,

not

tears

of

when

the

prove

but

but

return

and

startin

factory

the

trimmer

beneficial

bobbin

needle

leaves

tail

g

starting

all

it

was

has

to

Solenoid

Lower

to

Lower

threads

Lower

slip

Spring

bobbin

position

Lower

enough

Hook

Bobbin

bobbin

Needle

big

Not

return

rough

tension

Lower

Too

tension

needle

pull-off

Tension

Needle

tioned

adjusted

been

you.

TRIMMER

not

knife

the

right

knife

behind

knife

off

when

retainer

case

knife

to

No.

thread

case

hole

or

has

enough

spring.

thread

on

knife

much

and

thread

at

disc

thread

properly

and

inspected

readjusted

TROUBLESHOOTING

Causes

working

not

too

far

knife

too

knife

wire

holder

does

right

29474 R or S used

not

in

throat

been

altered

tension

Dense

will

knife

return

rubbing

knife

excessive

eyelets

cone

not

take-up

and

moving

forward,

far

back,

returns

not

when

not

threaded

on

require

return

open

top

at

so

is

far

contacting

in

move

plate

lower

material

spring

hook

friction

and

not

of

as

to

not

enough

wipes

threads

catching

thru

is

knife

more

point

spring

in

thread

posi-

stro

give

you

trimming

far

in

too

and

in

ke

the

utmost

properly,

Check

Make

Reset

Relocate

radius

Relocate

Bend

Adjust

ting.

Operate

determine

contacting

position

Use

Thread

Use

hole,

Increase

turn

right

Raise

Unthread

right

tension

ly.

Check

solenoid

this

Check position

up . Must

top

satisfaction

see

lead

connections

continuity

stop

screw

knife.

knife

spring

stop

screw

Check

machine

if

stop

solenoid

only

No.

properly

throat

plate

if

available

tension

springby

lower

knife

some

of

the

tension

on

knife

Check thread

settin

and

soleno

id

be

of its up s

and

the

chart

Cures

check

Check

retainer

position

solenoid

29474 T hook

movingbracket

return

g

of tension

electrical

within

troke.

wire

to

standard

with

pivot

screw

if

necessary

with

smaller

on

lower

of

the

eyelets

post. Decrease

spring

pull-

off

needle

1/8 inch

durability

below

for

nicks

to

of

solenoid.

belt

lever

and

then

needle

knife

slight-

at

cones.

release

operation

thread

suit

off,

to

to

take-

of

set-

re-

re-

the

the

the

for

on

to

is

of

.

throat

short

thread

T.

of

plate

spring

C. S.

and

back edges

lower

of

is

tens-

lower

k

nif

too

e).

Bobbin

thread

breaks

Needle

big.

Bobbin

Overspin

Too

much

ion

Sharp

knife.

are

the

hole

thread

on

knife

edges

(Front,

T .

in

too

bobbin

return

on

point

C.S.

17

Use

throat

hole,

if

available.

See

bobbin

Check

wi nd

in

bobbin

Decrease

spring sligh

to

the

left

Stone

sharp edge s

if

e. (Front,

kn

are

the

T. C. S.

plate

with smaller

thread

break

of

bobb

case

te

in

holder

nsi

on

tly,

on

by moving bracket

ofT.

point and

of lower knife)

and

s

fit

k

nife

C. S.

back

needle

of

bobbin

return

oflower

edges

.

Page 18

Before this

satisfaction

and

is

ficial

ing

needle

(Fig.

and

not

to

you.

any

components on

positioner

41)

square

mach

ine

and

durability

positioning

NOTE:

and

square

relay /14

left

properly

A.

C.

the

portion,

relay

and

the

at

voltage

printed

65.

factory

all

times.

see

check

116. All

it

was

adjusted

If

however,

the

chart

200

- 250

circuit

positioner

the

volts.

boards.

trimmer circuitry

below

circuit

and

inspected

the

for

Remove

If

difficulty

board

needle

positioner

suggestions

all

relays

should

670

E-9,

is

on

so

the

as

to

has

which

before

be

encountered

round

trimmer

give

may

testing

relays

you

been

board

the

utmost

readjusted

prove

bene-

or

check-

with

#1, #2,

670

the

/13

E-5

Unit does

Unit

positions

position,

position

C

ondition

not

but

down

position

up

in

does

TYPICAL

second

not

NEEDLE POSITIONER

Causes

Bad

fuse

Synchronizer

ged

in

Dirty

brushes

Treadle

properly

No

input

Burnt

or

armature

Tight

fiber gear

teeth

on

Bad

relays

Diodes

The

treadle

openin

g

jack

properly

jack

not

power

dirty

fiber

shorted

not

or

plugged

(220

brushes

or

gear

out

switch

PROBLEMS

plu

g-

broken

in

V)

and

broken

is

not

Cures

Replace

Check

chronizer jack

necessary

Clean

Clean

jack

Check

Clean

or

Take

housing and

ive

place

Check

Fi

Replace

circu

The

the

is tur

aga

armature

replace

fiber

stock

41)

g.

it)

unit

first

ned

in

fuse (A,

connection

or

replace

connection

input

gear

remove

from

relays

with

diodes

will

time

off

or

power

or

out

hub, or re-

(Nos

teste

(220

position

aft

er

and

then

40)

Fig.

of

replace

brushes

of

treadle

brushes

of

excess

.

1

&

r

V.

A.

down

the

power

back

syn-

if

bell

-

2.

C.

on

Unit

or

the

Unit

few

days

Unit

an

turns

shatters

fuse

blows

hours

keeps

inch

ing

the

the glass

the

or

on

speed

fuse

fus e

every

st

itchin

black

every

few

g

of

at

Diodes

Grounded

touch

Oil

Tight

Low

Ope

excessively

Bad

Synchronizer jack not plu

g

Damaged

iary

Synchronizer

wheel

Very

saturated

r at

rela

ed

in

are

shorted

armature, tie bolt

ing

field

fiber gear

volta

ge Us e 2 a mp. f

or

flutterin

y

properly

fie

loo

se " V" be

ld

motor

armature

g tread

coil

loo

se

lt

out

in auxil-

on

hand

g-

Replace

with

1000

board

Insula

te

s

hort

Clean

armatur

Tak

e fi

housing and remo

ive

s

toc

le

Caution operator

Ch

eck

rel

with t

este

Check

chronizer Jack

Re

place auxi

-

Tighten

handwheel

Reposition motor to su

diode

s,

PIV

tie bolt and

e

ber gea

k fr

connection

r out

om

hub

uset

ay (No.

r

lia

r y mot

s

ynchronizer

preferably

and

fiber

r e

mov

of b

ve exces

ron

1,

Fig

.41)

syn-

of

or

it

e

ell

s-

on

18

Page 19

TYPICAL

NEEDLE

POSITIONER

PROBLEMS

(Continued)

Auxiliary

clutch

is

motor

Units

positions

Auxiliary

hot

Condition

motor

engaged

slowly

motor

runs

with

runs

while

main

very

Clutch

opening

Clutch

Armature

mutation

ed

and

dirty

Tight

fiber

Bad

relays

Improper

arm

switch

Operator

arm

switch

Grounded

Bad

relays

Causes

arm

arm

has

or

is

gear

setting

fluttering

field

switch

switch

poor

partly

coil

is

broken

short-

of

clutch

clutch

not

com-

Adjust

properly

Replace

Dress

armature

ing

stone

Take

fiber

housing

i

ve

stock

Check

41)

Fig.

Adjust

properly

Caution

Check

sulate

Check

41)

Fig.

Check

times

move

brush

thereby

to

only

the

end

This

will

life

and

tenance

Cures

clutch

switch

gear

and

remove

from

relays

with

clutch

operator

with

tie

bolt

relays

with

operation

it

is

the

on

two

using

raise

of

greatly

minimize

arm

with

out

hub

(Nos.

tester

arm

tester

(Nos.

tester

.

possible

down

position

the

positioner

the

needle

operation.

the

switch

dress-

of

bell

excess-

1 &

2.

switch

in-

and

1 &

2.

Some-

to

re-

position

units,

at

prolong

main-

Unit

blows

tioning

fuse

is

first

Auxiliary

over

turn

power

know

Unit

does

to

solenoids

one

not

fuse

time,

put

motor

although

is

provide

after

not

in

will

feeding

posi-

when

not

you

power

it

Lead

rubbing

Brush

holders

armature

Bad

relays

Bad

armature

Tight

fiber

Solenoids

to

power

Bad

relays

Diodes

No

voltage

secondary

gray

blue,

gear

are

pack

shorted

from

on

and

armature

in

brush

against

brushes

not

connected

out

trimmer

transformer

white

leads

Isolate

Remove

motor

holder

Check

sulate

Check

Fig.

Replace

ary

Take

housing

ive

Check

Check

6,

Replace

circuit

Check

er,

transformer

from

end

and

with

tie

relays

41)

with

brushes

motor

fiber

and

stock

connections

relays

41)

Fig.

board

output

defective -replace

if

cap

relocate

tester

bolt

gear

remove

from

with

diode

armature

of

auxiliary

(Nos.

tester

on

out

excess-

hub

on

(Nos

. 3,

tester

on

trimmer

of

transform-

brush

and

1&

auxili-

of

leads

4,

in-

2.

bell

5.

19

Page 20

On

the

and

switch

These

ing

with

1.

ating

2.

the

bottom,

The

that

3.

30

A. C.

explanations

the

circuits

The

legend

the

various

DIODE

The

diodes

current

RELAY

A

relay

eight

TRANSFORMER

volt

(8)

as

relay

relay.

The

transformer

A. C.

is

converted

coil

following

systems

and

found

electrical

allow

(A.

C.)

is

nothing

prongs

shown

in

and

as

indicated

all

to

CIRCUITS

pages

incorporated

will

switch

in

current

to

at

the

of

reduces

D. C.

you

be

followed

systems.

the

lower

terms

direct

more

its

base

legend,

the

on

(direct

than

switches

the

AND SWITCHING

will

find a brief

in

the

needle

by

schematic

left

hand

corner

listed

to

flow

current

an

(which

represents

220

volt

schematic.

current).

below,

only

automatic

one

(D.

C.).

are

numbered

the

directly

A.

C.

SYSTEMS

explanation

positioner

drawings

of

the

should

direction,

switch.

relay

above

(alternating

Then

coil

the

through

of

the

and

trimmer

that

will

schematic

prove

thereby

The

accordingly).

which

coil

current)

the

drawings,

beneficial.

small

activates

are

an

to

use

various

powerpack

assist

converting

numbers

The

coil

the

integral

24

volt

of

the

diodes

circuits

in

trac-

together

altern-

indicate

at

switch.

part

A. C.

and

this

.

the

of

4.

CAPACITOR

In

most

the

relay

the

relay.

electrical

NOTE:

of

the

As

mitting

through

#1

is

contacts

motor

in

yellow,

until

brush

opens

When

24

volt