Page 1

IN

SEW

DUST

ING

RI AL

F

INEST QUALITY

STY

LES

6 4

00H

634

00HT

C 0 L U M B I A®

MACHIN

8

ES

CATALOG

No.

121MP

HI

GH S

PEED

WITH

PINKING

CLASS

S

TREAMLI

63400

LOCKSTIT

AT

UNION SPECIAL CORPOR

CHICAGO

Price

$1.00

ED

C

AC

MA

C

HME

~

AT

S

Page 2

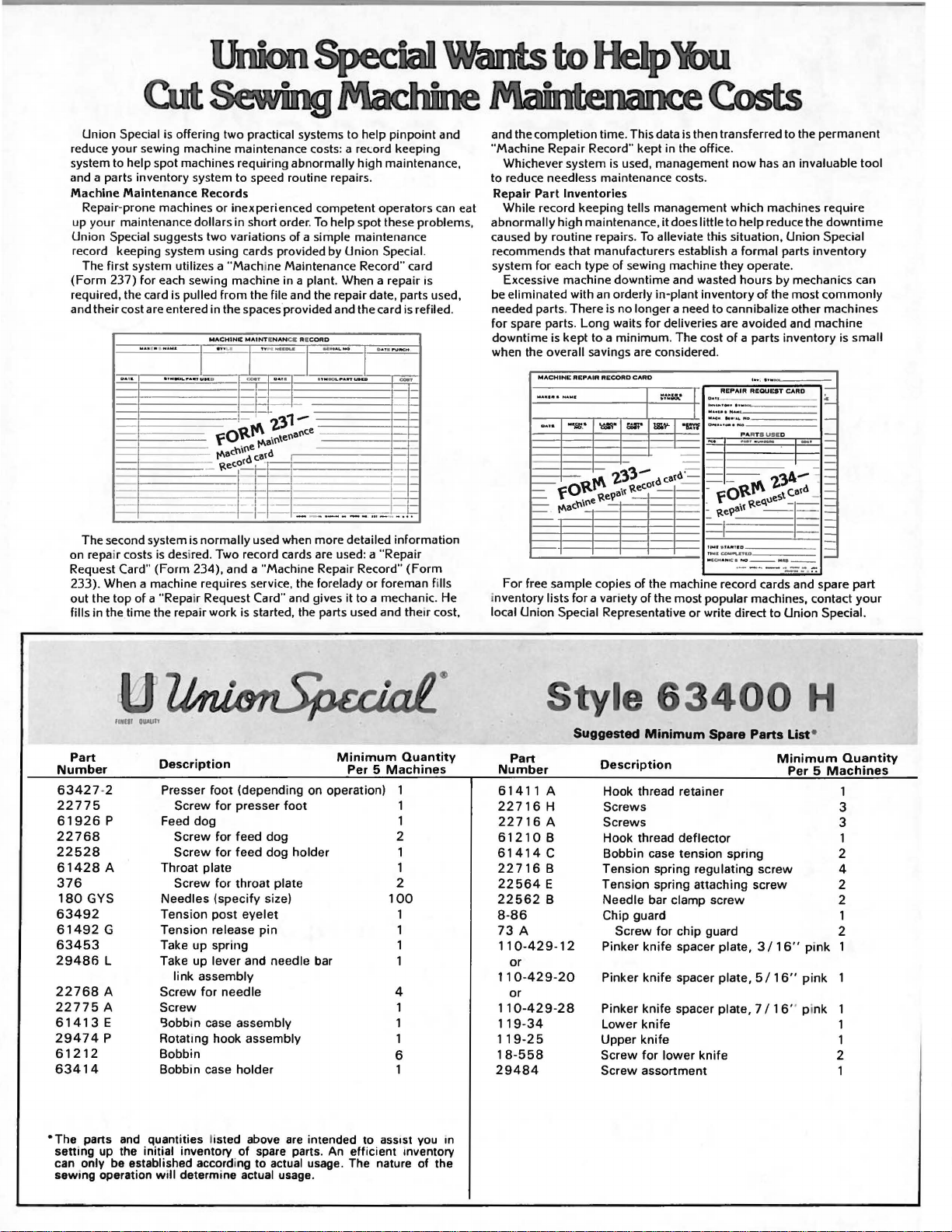

Union Special is offering two practical systems to help

reduce your sewing machine maintenance costs: a

system to

and a parts inventory system to speed routine repairs.

Machine

up your maintenance

Union Special suggests two variations

record keeping system using cards provided by Union

(Form

required, the card is pulled

and their cost are entered in the spaces'provided and the card is

on repair costs is desired. Two record cards are used: a "Repair

Request

233). When a machine requires service, the forelady

out

fills in the time the repair work is started, the parts used and

help spot machines requiring abnormally high maintenance,

Maintenance Records

Repair-prone machines

The first system utilizes a "Machine Maintenance Record" card

237) for each sewing machine in a plant. When a repair IS

........

........

IYM.OI..P'AitTUIIt

D4

"

The second system is

Card"

(Form

the top

of

a "Repair Request Card" and gives it to a mechanic. He

or

inexperienced competent operators

dollars in short order.

from

the file and the repair date, parts used,

MACHINC

MAINTI

.

..

u

'

I I I I

D

-

+

~:J ~

ottl'\

f . \enan

1'\8'"

1'\acnine catd

~tec.otd

.

1-

normally

234), and a "Machine Repair Record"

used when more detailed information

To

help spot these problems,

of

a simple maintenance

NAN

CC AICOAD

1 . ,

M•IAL NO

..

.,

L~oiiiiTUSCD

~~

D41

-

13

-:e

-

_

-

pinpoint

relord

keeping

Special.

D.&? I

PUKM

-

__

'"

_ _

__

)7

-1~

1-

(Form

or

foreman fills

the1r

and

can

refiled.

cost,

and the

completion time . This data is then transferred to the permanent

"Machine Repair Record" kept in the office .

Whichever system is used, management

to reduce needless maintenance costs.

Repair

Part

While

eat

abnormally high maintenance, it does little to help reduce the

caused by routine repairs.

recommends that manufacturers establi

system

Excessive machine downtime and wasted hours

eliminated with an orderly in-plant inventory

be

needed parts. There is no longer a need to cannibalize other machines

for spare parts. Long waits for

downtime

when the overall savings are considered .

Inventories

record keeping tells management which machines require

To

alleviate this situation , Union Special

for

each type

is

kept

MACHINE

"'""''"'

........

-··

=

fO~~el'ait

~

-

1'\ac."'"

f--

REPAIR

-a;

of

sewing machine they operate .

deliveries are avoided and machine

. The cost

CARD

:::~

!&

'I'-

~

~tec.otd

c,at

"L"l'f

d'

-

_•

to a

RECORD

'<::!"

minimum

2'3'3-

- -

For

free sample copies

inventory

local

lists

Union

for

Special Representative

a variety

of

the machine record cards and spare part

of

the most popular machines, contact

now

has

an

invaluable tool

sh

a formal parts inventory

by

mechanics can

of

the most

of

a parts inventory is

....

;

•..

REPAIR

RltQUUT

Daoo

I

,_,

......

...

..

...

...

I

'""""

.......

-···-·-

-

-

fO~f'\

- .

~t

~'t

t

...

l'

l f AfU I D

,

...

coo."'-&T&D

M

ICH•HOCihO--H·--

·--····----

or

write direct to Union Special.

CARD

-.

PA

RT S

USE

D

·-·

~teq\les

2'3A-

\

catd

I

-·

..

downtime

commonly

~

-

-

=

~

=

-

=

-

-

I=

I=

-

small

your

holder

intended to

Minimum

Per 5 Machines

Part

Number

63427

-2 Presser

22775

61926

22768

22528

61428

376

180

63492

61492

63453

29486

22768

22775

61413

29474

61212

63414

"The

sett

can only be established according to actual usage. The nature of the

sew

p

A Throat plate 1

GYS

G

L Take

A

A

E

p

parts and

ing up the initial inventory

ing operation

Description

foot

Screw

Feed

Screw

Screw

Screw

Needles

Tension

Tension

Take

link

Screw

Screw

'3obbin case assembly 1

Rotatmg hook assembly

Bobbin

Bobbin case

quant1t1es

will

determine actual usage.

(depending on operation) 1

for

presser

dog

for

feed

for

feed

for

throat

(specify

post

release

up

spring 1

up

lever

assembly

for

needle

holder

listed above

foot

dog

dog

plate

size)

eyelet

pin

and needle bar

of

are

spare parts. An efficient mventory

Quantity

1

1

2

1

2

100

1

1

1

4

1

6

1

ass1st

you

1n

Part

Number

61411A

22716

22716

61210

61414

22716

22564

22562

8-86

73

110-429-12

H

A

B

c

B

E

B

A

or

110-429-20

or

110-429-28

119-34

119-25

1

8-558

29484

tyle

Suggested

Minimum

Description

Hook thread retainer

Screws

Screws

Hook thread

Bobbin case

Tension

Tension

Needle

Chip guard

Pinker

Pinker

Pinker

Lower

Upper

Screw

Screw

spring attaching

bar clamp

Screw

knife

knife

knife

knife

knife

for

assortment

400

Spare

deflector

tension

spring regulating

for

chip guard

spacer plate, 3 I

spacer plate, 5 I

spacer

lower

spring

screw

plate,

knife

Parts

Ust

Minimum

Per 5 Machines

screw

screw

16"

16"

7 I 16" pi

•

pi

nk

pink

nk

Quantity

1

3

3

1

2

4

2

2

1

2

1

1

1

2

1

Page 3

Catalog

(Supplement

No.

to

Catalog

INSTRUCTIONS

FOR

121

MP

No.

121

M)

ADJUSTING

Streamlined

63400

Union

Rights

LIST

CLASS

H

First

Copyright

Special

Reserved

AND

OF

Styles

Edition

by

in

OPERATING

PARTS

63400

Lockstitch

63400

19

6 3

Corporation

All

Countries

HT

October~

1977

UNION SPECIAL

INDUSTRIAL

CHICAGO

Printed

CORPORATION

SEWING

in

3

MACHINES

U.S.

A.

Page 4

IDENTIFICATION

OF

MACHINES

Each

into

the

special.

contain

the letter

is s

uffixed

Styles

which

differs

This

junction

not

on Style

clarity,

63400

Hand

Opposite

number,

use

the

part

Adjusting

with

Styles

UNION

name

plate

Standard

the

letter

"Z".

of

When

to

the

machines

from

catalog

therewith.

s

63400

certain

HT

the

description,

number

and

63400

SPECIAL

on

Style

"Z''.

only

standard

machine

the

machine.

numbers

Example:

minor

Style

similar

the

style

number,

APPLICATION

is a supplement

Only

A

63400

those

or B are

A

or

parts.

illustration

and

amount

listed

operating

H

and

in

instructions

HT.

is

"Style

changes

number.

in

construction

to

parts

illustrated

B

parts

page,

required.

the

second

identified

Style

have

in

one

63400

that

Catalog

which

are

parts

column.

included

by a Style

numbers

or

H".

are

made

Example:

are

it

contains

OF

CATALOG

No.

are

used

and

listed

shown

are

identified

When

are

classified

more

letters

Special

in a standard

"Style

grouped

no

letters.

121

M

and

on

Styles

at

the

in

phantom

ordering

represent

number

which

suffixed,

Style

63400

numbers

HZ".

under a class

Example:

should

63400

back

of

to

by

detail

repair

only

areas

is

as

standard

machine,

be

used

Hand

this

book.

help

number,

parts

concerned

stamped

but

never

contain

number

"63400".

in

HT

locate

always

and

a 112

con-

and

For

the

part

11

The

herein.

in

this

given

of

High

and

Hook

from

handwheel

Speed

Heavy

Shaft,

Enclosed

Control,

Feed

Feed

63400

Eccentric,

Timing

H

similar

the

throw-out

63400

HT

ranging

catalog

It

can

class.

the

is

Streamlined

Duty,

Push

Automatic

Automatic

on

For

garments

width

Same

from

applies

also

specifically

be

applied

Reference

operator's

toward

the

LongArmLockstitch

with

Pinking

Button

Stitch

Lubricating

or

Manual

Needle

Lower

Bearings

Main

simultaneously

made

of

pink

for

ranging

pinking

as

Style

3/8

to

knife.

7/8

with

to

direction,

position

operator.

STYLES

Attachment,

Shaft.

seaming

of

light

from

63400

of

an

to

the

discretion

such

while

seated

OF

Regulator,

System.

Head

for

Oiling

Take-up

and

to

medium

3/16

H,

except

inch.

Standard

to

some

as

right,

at

the

MACHINES

Machines,

Drop

Stitch

Head

Length

Oil

Control,

Lever

pinking

weight

to

3/4

of

three

rows

Styles

Special

left,

machine.

One

Feed,

Siphon,

and

on

materials.

an

inch

of

of

front,

Needle,

Rotary

Indicator,

Needle

Needle

house

and

feed

machines

Styles

back,

Operating

Light,

Hook,

One

Adjustable

Bearing

Bar

Driving

dresses,

Two

rows

manually

and

the

width

as

of

machines

etc.,

direction

Medium

Horizontal

Reservoir

Hook

Adjustable

slips

of

operated

of

listed

are

Oil

Link,

and

feed,

pink

NOTE:

The

pinking

width

knife.

of

pink

is

measured

from

4

the

centerline

of

needle

to

the

point

of

Page 5

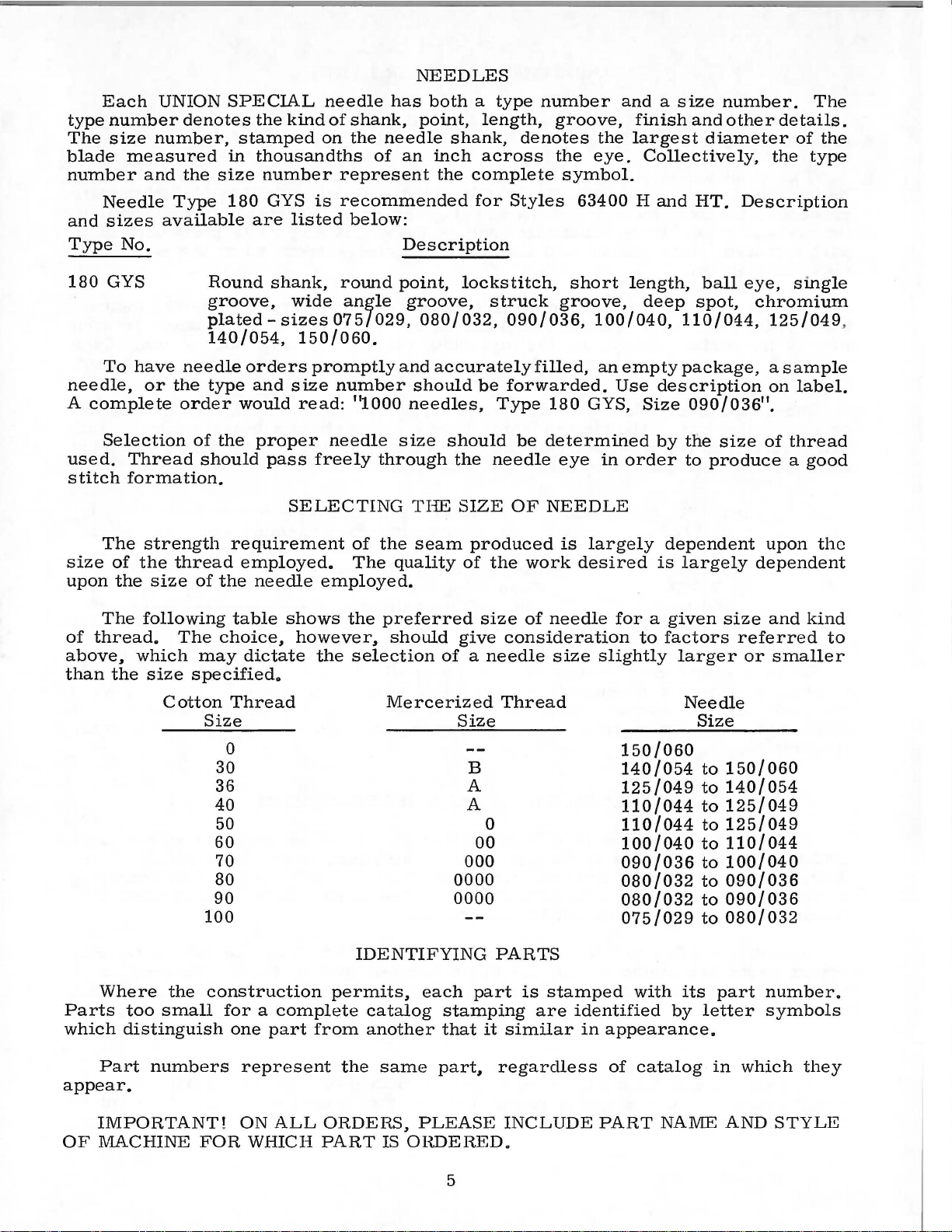

Each

type

number

The

size

blade

number

UNION

denotes

number,

measured

and

the

SPECIAL

the

stamped

in

thousandths

size

number

kind

needle

of

shank,

on

the

represent

has

needle

of

an

NEEDLES

both a type

point,

inch

shank,

the

length,

across

complete

number

groove,

denotes

the

symbol.

and a size

finish

the

largest

eye.

Collectively,

number.

and

other

diameter

The

details.

of

the

type

the

Needle

and

sizes

Type

180

GYS

To

needle,

A

complete

Selection

used.

stitch

The

size

upon

The

of

thread.

above,

than

the

available

No.

have

or

Thread

formation.

strength

of

the

the

size

following

which

size

Type

the

order

thread

The

180

GYS

is

recommended

are

listed

Round

groove,

plated140/054,

needle

type

of

the

should

of

the

choice1 however1 should

may

specifiedo

shank,

wide

sizes

150/060.

orders

and

would

proper

requirement

employed.

needle

table

dictate

promptly

size

read:

pass

freely

SELECTING

shows

the

round

angle

075/029,

number

needle

employed.

below:

Description

point,

groove,

and

"1000

size

through

of

the

The

quality

the

preferred

selection

lockstitch,

080/032,

accurately

should

needles,

should

the

THE

SIZE

seam

of

give

of a needle

for

Styles

struck

090/036,

filled,

be

forwarded.

Type

be

needle

OF

produced

the

work

size

of

consideration

63400

short

groove,

100/040,

an

empty

Use

180

GYS,

determined

eye

in

order

NEEDLE

is

largely

desired

needle

size

for a given

slightly

Hand

length,

deep

110/044,

package,

description

Size

by

dependent

is

largely

to

factors

larger

HT.

Description

ball

eye,

spot,

090/036".

the

size

to

produce a good

size

referred

or

single

chromium

125/049

as

ample

on

of

thread

upon

dependent

and

smaller

,

label.

the

kind

to

Where

Parts

which

appear.

OF

too

distinguish

Part

IMPORTANT

MACHINE

Cotton

Size

100

the

construction

small

numbers

FOR

Thread

0

30

36

40

50

60

70

80

90

for a complete

one

part

from

represent

!

ON

ALL

WHICH

PART

Mercerized

IDENTIFYING

permits,

catalog

another

the

same

ORDERS,

IS

Thread

Size

B

A

A

0

00

000

0000

0000

PARTS

each

PLEASE

ORDERED.

part

stamping

that

it

similar

part1 regardless

INCLUDE

is

stamped

are

150/060

140/054

125/049

110/044

110/044

100/040

090/036

080/032

080/032

075/029

with

identified

in

appearance.

of

catalog

PART

Needle

Size

to

to

to

to

to

to

to

to

to

its

by

letter

NAME

150/060

140/054

125/049

125/049

110/044

100/040

090/036

090/036

080/032

part

in

which

AND

number.

symbols

they

STYLE

5

Page 6

The

arrangement

replacement

parts

for

ORDERING

of

this

Styles

OF

catalog

is

to

63400 H and

REPAIR

facilitate

63400

HT.

PARTS

easy

and

accurate

ordering

of

Two

listed

presents

On

the

part

view

Numbers

the

position

in

ordering

exploded

Sub-assemblies~

or a solid

can

description

1

2

3

4

5

6

7

exploded

in

this

catalog

a

sector

page

numbers~

being

opposite

shown.

in

of

parts.

view

line

be

furnished

of

29482

447-137

22729 c

1012

71-29

869 L

4124-33

descriptions

the

the

plate

box

for

the

B

L

view

of

part

plates

and

Style

the

machine~

the

illustration

first

column

in

the

Always

carries

which

on

the

picture

repairs~

main

sub-assembly.

Pinking

cover

63400 A covered

parts

will

and

the

number

are

reference

illustration.

use

the

part

a

reference

are

sold

complete~

plate.

are

indicated

Attachment~

Ball

Joint

Screw-----------------------------------

Nut#

Connecting

Nut~

Ball

Joint#

the

differences

being

aligned

be

found a listing

Reference

number

number

Component

by

Example:

Connecting

right

hand

Rod---------------------------

left

hand

lower-------------------------

in

Catalog

as

of

pieces

numbers

numbers

listed

for

or

by

separate

parts

indenting

between

in

required

only#

in

the

each

of

their

the

No.

121

their

assembled

of

the

in

and

should

second

part

available

part1 are

sub-assemblies~

descriptions

complete--------------------

Rod

thread

Assembly

--------------------

-----------

thread----------------------

Standard

M.

Each

parts

the

with

particular

merely

never

column.

in a bracket

Styles

plate

position.

their

indicate

be

used

Each

for

sale.

which

under

the

1

1

1

1

1

2

1

In

those

catalog#

the

parts

mentioned

illustration.

Success

UNION

oration,

to

the

SPECIAL

its

most

Maximum

Genuine

repair

parts

trademark

Prices

are

forwarded

otherwise

cases

no

specific

for

the

in

the

in

subsidiaries

approved

efficiency

needles

are

is

your

are

strictly

f.

directed.

where a part

usage

various

description#

USE

GENUINE

the

operation

Needles

and

scientific

and

durability

are

stamped

guarantee

net

o.

b.

shipping

A

is

will

machines

and~

NEEDLES

of

and

Repair

authorized

principles,

packaged

with

the

of

cash

and

point.

charge

common

be

mentioned

are

not

if

necessary~

these

machines

Parts

distributors.

and

are

assured.

with

labels

Union

the

highest

TERMS

subject

Parcel

is

made

to

all

in

the

AND

as

REPAIR

furnished

are

marked

Special

quality

to

change

Post

to

cover

of

the

machines

the

description.

same#

the

the

difference

PARTS

can

be

secured

by

the

They

made

trademark~

in

materials

are

with

~

without

shipments

the

postage

specific

will

only

Union

designed

the

utmost

U S

and

notice.

are

covered

by

However#

usage

be

shown

with

Special

will

in

genuine

Corp-

according

precision.

®

•

Genuine

Emblem.

workmanship.

All

shipments

insured

and

unless

insurance.

this

when

be

the

Each

6

Page 7

INSTALLING

CAUTION!

on

hand

wheel.

Before

carefully

packing

leaving

packed.

box~

the

PREPARATION

A

bag

of

assembly

attaching

screw~

miscellaneous

Insert

the

upper

STANDARD

Included

ing

one

its

clamp

and

screw~

washers

up

the

hinge

frame

ACCESSORIES

also

bobbin

spring~

four

and

nuts~

machine.

When

Using

unpacking~

both

factory~

After

following

OF

MACHINE

parts~

one

extra

attachments

studs

eyelet

with

winder

one

in

(A~

each

assembly~

knee

isolator

and

one

hands

each

the

machine

steps

FOR

consisting

bobbin~

to

the

holes

provided

Fig.

machine

lifter

pade

machine

DO

NOT

on

bed

Union

should

lift

casting~

Special

and

accessories

be

followed:

INSTALLATION

of

two

hinge

bed

plate~

for

2).

is a box

the

machine

assembly

and

rest

and

clips~

pin.

machine

lift

machine

one

frame

studs~

is

packed

them

of

in

STANDARD

mounting

its

rubber

one

chip

These

parts

out

of

box

gently.

is

sewed

have

been

thread

and

two

with

each

rear

of

ACCESSORIES-

frame~

pad~

chute~

are

by

off~

removed

eyelet~

screws

machine.

cloth

plate.

one

bed

positioning

its

attaching

essential

placing

inspected

for

oil

drain

when

one

hand

and

from

one

the

eyelet

holding

Assemble

contain-

jar

and

spring

screws~

setting

TABLE

Lockstitch

the

bed

TABLE

BOAR

D

TOPS

plate

machines

is

FLUSH

are

with

installed

the

top

of

in

the

table

tops~

machine

prepared

mounting

with

frame.

cut-out~

so

that

66 0 -168

7

Fig.

1

Page 8

INSTALLING

(Continued)

MACIITNE

MOUNTING

On a suitable

c

ut-out

t

hrough

o

ver

t

he

n

uts

1/ 16

r

etaining

s

ide

m

achine

f

all

play

with

left

right

retaining

lightly.

Place

sewing

inch

plate

of

the

Tip

the

mounting

away

from

of the

the

hinge

hinge

plate

clearance

board

machine

cross

Before the

lifter

maximum

within the

bar

rod

should

lift

head.

raises approximately

tableboard,

hinge

pad

pad;

( 213 9 3 R)

head

smartly

and

back

frame

the

operator.

shaft

machine

be

adjusted.

of

the

This

FRAME

lugs

to

and

tighten

insert

in

the

between

upward

tighten

against

with

should

is

put

presser

may

5/16

INSTALLATION

place

the

machine

rear

(Fig.

securely.

round

to

head

outside

frame

the

mounting,

cloth

with a hammer

locking

the

nuts

the

rest

attaching

Assemble

be

taken

into

production,

The

left

stop

bar

and

its

be

clone

by

inch.

mounting

Assemble

wood

front

plate

securely.

pin,

holes

the

knee

up

by

screw

parts

setting

1).

screw

of

pan

and

edge

to

and

the

the

do

the

frame

Insert

bed

and

the

positioning

tighten

section,

after

and

being

the

insure a good

assemble

to

the

right,

press

cone

(22597

bell

not

stop

assembly

bearings,

crank

F)

interfere

screw

(21393

U)

countersunk

spring ( 63474

securely.

as

shown,

sure

frame

sides,

grip

chip

chute

so

that

as

shown.

but

(21665

should

be

with

so

that

in

the

wood

and

there

on

(51278

the

must

J)

of

set

so

moving

the

machine

screw

Assemble

snug

is

about

rap

the

under-

F)

chips

will

All

not

bind.

the

knee

that

parts

presser

A)

up

the

to

end

the

BOBBIN

WINDER

The bobbin

located directly

when

allow

The

against

is

Catalog

in operation.

the

mechanism

pulley

the

described

No.

of

belt

under

121

BELTS

These

Thread

enlarged

machines

machine

for

clarity.

CAUTION!

the

reservoir

winder

in

the

to

M.

Oil

must

should

front

The

to

winder,

wind

"Winding

are

as

indicated

Needle

has

be

filled

be

of

the

base

be

of

moved

when

the

bobbin.

the

equipped

is

been

drained

before

secured

sewing

the

winder

closer

in

operation,

Regulation

Bobbin",

to

use

THREADING

in

Fig.

threaded

OILING

from

starting

to

the

machine

has

to

or

under

either

2.

Threading

from

the

to

table

belt

and

two

elongated

farther

should

and

operation

OPERATOR'S

# 1

"Vee"

left

to

right.

main

reservoir

operate.

top

will

away

exert

or

at

so

that

bear

attaching

from

only

of

round

check

before

its

puller

against

belt

enough

the

bobbin

holes.

will

the

as

needed.

pressure

winder

which

INSTRUCTIONS

belts.

spring

has

been

shipment

be

belt

in

and

Fill

oil

is

be

added

straight

in

the

main

at

maximum

when

mineral

main

reservoir

level

needle

oil

reservoir.

at

plug

is

when

in

needle

yellow

of a Saybolt

This

is

screw

(B,

is

band

marked

viscosity

equivalent

in

Fig.

yellow

11

of

90

to

2)

and

band

LOW".

to

Union

125

8

check

marked

oil

"FULL".

Use a stainless

seconds

Special

at

specification

level

100°

at

gauge

Oil

(C);

should

water-white

Fahrenheit

No.

17

5.

Page 9

OILING

(Continued)

It

is

a

long

After

period,

oiling,

machine

speed

operation

The

The

oil

control

manual

and

five

oiling

turn

or

preferably

Oil

may

The

quantity

dial

in

the

clockwise

NOTE:

lever

shaft

bearings

recommended

be

lubricated

replace

slowly

for

can

machine

is

stud

of

the

stud

180°

six

drops

at

starting

be

of

drained

of

direction

direction

All

moving

front

and

knife

and

holder

that a new

head

several

then

be

provided

(D,

Fig.

head

to

mechanism

expose

oil

should

time

from

oil

supplied

of

the

arrow

decreases

parts

rear,

shaft.

by

removing

cover

minutes

expected

with

2)

is

the

manual

be

and

mid-day.

main

to

the

of

pinking

also

oil

Major

Fig.

machine,

as

no

to

without

automatic

shown

be

introduced

reservoir

the

2

or

the

head

further

distribute

damage.

or

in

the

desired,

oiling

hook

is

one

cover

hand

manual

automatic

remove

port.

into

by

removing

controlled

(counterclockwise)

flow

of

oil.

attachment

two

oil

holes

oiling

9

for

points

that

has

and

oiling

oil

to

head

oiling

In

the

the

oiling

increases

to

be

oiled

lubricating

are

marked

been

oiling

will

the

various

mechanism

position,

locking

manual

port

plug

screw

by

dial

the

once

both

in

out

the

be

required.

screw

oiling

(E).

oil

daily.

red

of

service

moving

parts.

oil

control.

and

(G,

position,

twice

(F,

daily

Fig.

Turning

flow

and

Oil

sides

on

of

attachment.

for

parts.

Run

Full

should

Fig.

2)

2).

the

in

knife

lever

-

a

Page 10

INSTRUCTIONS

FOR A TTACIDNG

AND

ADJUSTING

PINKING

ATTACHMENT

29"

132

Fig.

2A

NOTE:

Styles

6_;3400

addition

All

63400 H and

Ii

covered

a 1

attachment.

ATTACIDNG

Check

lower

ing

rod

(Fig.

and

turn

to

obtain

Insert

in

end

(G)

against

Place

joint

tighten

Insert

washer

screw

(B)

the

ball

joints

assembly.

2A).

the

1

29/32

the

of

pinker

washer

and

screw

the

(M)

into

the

instructions

HT

in

instructions

PINKING

center

(A~

The

To

make

connecting

inch

upper

ball

driving

the

flat

on

(H)

then

screw

(K).

large

in

base

base

of

pertaining

are

the

Catalog

No.

pertain

ATTACHMENT

distance

B~

Fig.

2A)

distance

any

adjustment,

rod

(E)

in

dimension.

joint

(A)

shaft

ball

over

(F)

stud.

ball

into

hexagonal

of

pinking

machine.

to

the

same

121

as

M.

only

between

of

the

should

loosen

the

direction

Tighten

into

the

and

tighten

stud

of

the

pinker

head

screw

attachment

adjustment

those

The

to

the

the

upper

pinker

be

1

29/32

nuts

nuts

eccentric

set

the

lower

arm

(L)

and

of

for

Style

following

pinking

and

connect-

inch

(C,

D)

required

securely.

hole

screw

ball

(J)

and

and

its

tighten

SETTING

To

attachment

of

pink

NOTE:

point

may

bind

graph

SETTING

Set

Fig.

below

pinker

of

travel.

THE

set

and

of

pinking

and

"Setting

THE

the

2B)

so

top

edge

arm

the

to

The

upper

(B)

make a pencil

1/32

(Fig.

turn

tion

lowest

the

knife

of

inch

2B),

handwheel

until

point

1/32

so

it

lower

from

the

inch

coincides

knife.

WIDTH

width

the

left

to

the

width

knife.

it

may

Pinker

UPPER

pinking

its

point

of

lower

is

at

For

this

line

lower

loosen

inoperating

pinker

of

travel.

pencil

Tighten

OF

PINK

of

pink~

or

right

right

of

In

be

necessary

Driving

loosen

as

increases

pink

is

setting

Shaft".

KNIFE

knife

is

1/32

knife

its

lowest

adjustment~

on

upper

front

screw

(A~

inch

when

point

knife~

point

(C)

and

direc-

arm

line

with

is

at

Now~

on

upper

top

screw

its

set

edge

(C).

screw

required.

the

measured

pinking

to

move

(L~

Fig.

Moving

width

from

of

the

attachment

the

pinker

2A)

base

pink.

center

for a wide

driving

and

to

the

Tighten

line

move

left

of

pink

shaft:

base

decreases

screw

the

needle

the

refer

of

pinking

width

securely.

to

the

ball

joint

to

para-

NOTE:

both

Knife

ends.

can

be

sharpened

on

10

Fig.

2 B

Page 11

TIMING

upper

top

advance

The

knife

edge

THE

pinker

of

the

repositioning

Access

Fig.

loosen

wrench

moving.

feed

2C).

the

in

dog,

to

Using a 1/8

two

the

Turn

or

relationship

screws

securely

FINKE

is

timed

(in

its

lower

material.

the

pinker

this

gear

screws

last

the

backward

mentioned

and

R

correctly

upward

knife

This

driving

is

obtained

inch

in

the

screw

loosened

handwheel

to

above

replace

travel)

when

the

timing

gear

hexagonal

hub

of

forward

retard

the

is

attained.

plug.

when

is

1/16

feed

can

on

by

removing

socket

driving

to

prevent

feed

the

inch

dog

be

the

gear,

to

advance

dog,

Tighten

point

of

above

begins

changed

main

shaft.

plug

key

wrench

leaving

gear

until

the

the

to

by

(A,

from

the

the

both

SETTING

Moving

margin

bind.

To

should

(B,

Fig.

shaft

and

There

timing

as

tighten

should

has

PINKER

the

may

eliminate

be

relocated.

2C)

required

screws.

not

pinking

cause

and

be

no

been

DRIVING

attachment

the

ball

this

Loosen

loosen

and

while

Push

end

play

changed.

SHAFT

joints

bind

screws

holding

thrust

in

the

(A,

the

pinker

screws

in

shaft

collar

pinker

to a wide

B,

Fig.

driving

in

thrust

the

hub

in

position

(N,

Fig.

driving

of

pinking

2A)

to

shaft

collar

driven

move

2A)

against

shaft.

(N,

gear.

gear

Check

Fig.

Move

lug

to

Fig.

2A),

pinker

against

and

tighten

be

sure

2 C

remove

bed

screws.

the

plug

driving

casting

pinker

11

Page 12

12

Page 13

PINKER

THROAT

DRIVE

MECHANISM,

PLATES

AND

PRESSER

FEED

FEET,

DOGS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14A

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

37A

37B

38

39

40

41

42

43

44

45

46

47

48

Part

No.

61926

61428 B

63427-3

63430

63430

61330

63430

63430-3

22798

61926

61428

110-429-12

110-429-20

110-429-28

63427-2

63430

63430

61330

63430

63430-2

22798

63494

63479 F

22894

22525

63493

63479

22651

29475

22894

22839

22894

63479

63479 A

63479

63979

22730

63479

22657

21705

22894

21393

SC182

51278

N

A

E

B-39

B

8-66

p

A

73 A

8-86

A

E

B-35

B

8-66

B

J

c

A

E

CD-3

BK

v

u

G

c

A

666-244

D

E-24

666-198

c

93

u

F

652

B-12

651 H

Description

Feed

Throat

Presser

Feed

Throat

Pink·~r

Pinker

Pinker

Presser

Plug,

Pinker

Bed

Pinker

Main

Pinker

Pinker

Bushing,

Oil

Screw---------------------------------------------Bushing,

Screw---------------------------------------------Felt

Thrust

Screw,

Oil

Screw----------------------------------------------

Chip

Lock

Nut

Dog,

Presser

Spring

Hinge

Yielding

Presser

Screw------------------------------------------

Presser

Dog,

Screw------------------------------------------

Chip

Presser

Spring

Hinge

Yielding

Presser

Screw------------------------------------------

Presser

Screw-----------------------------------------Screw------------------------------------------

Plug

Screw------------------------------------------

Shaft

Screw-----------------------------------------Screw-----------------------------------------Screw------------------------------------------

Shield,

Felt

Oil

Screw------------------------------------------

Drip

Disposal

Washer----------------------------------------

------------------------------------------------

22

teeth

Plate,

Foot,

Plate,

Knife

Knife

Knife

Foot,

for

Shaft

Shaft

Driving

Driving

Liner--------------------------------------

left

Wick,

Collar---------------------------------------

for

Pan----------------------------------------

for

Foot

-----------------------------------------

Pin

Section--------------------------------Foot

Foot

22

teeth

for

Guard

Spacer

Spacer

Spacer

Foot

-----------------------------------------

Pin

Section--------------------------------Foot

FootGuard

pinker

Driven

------------------------------------------Driving

Assembly---------------------------------

right

for

---------------------------------------

61414

Chute

per

inch,

Style

for

Shank

-------------------------------------Bottom,

Guard

Style

-------------------------------------

for

Shank

-------------------------------------Bottom,

driving

Shaft---------------------------------

Shaft

--------------------------------------

pinker

for

pinker

A----------------------------------

63400

Style

Style

63400

per

inch,

63400 H -----------------------

Plate,

Plate,

Plate,

63400 H ----------------------

Gear

Gear----------------------------

Sleeve---------------------------

driving

---------------------------------

for

Style

HT

---------------------

HT

---------------------

-----------------------------

marked

----------------------------for

3/16

5/16

7/16

-----------------------------

marked

-----------------------------

gear

access

----------------------------

shaft

driving

''AE-3

Style

inch

inch

inch

"AE-2"

hole--------------

bracket

shaft-----------------

13

63400

63400 H ---------

pink

pink

pink

HT

11

-------------

-------------

-------------

-------------

-------------

------------

--------

Amt.

Req.

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

2

1

2

3

1

1

2

1

2

2

1

1

1

1

1

1

1

1

2

1

1

2

1

1

2

1

2

2

Page 14

24

14

Page 15

PINKING ATTACHMENT

Ref.

No.

1

Part

No.

29482 B

2 447-137

3

4

22729

1012 L

5 71-29

6

869 L

7 4124-33

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

40-57

39536

1160

18-844

45-248

46-108

1776 L

18-71

CS331

CS231

40-101

45-249

34-26

18-558

119-25

3-46

119-34

475-68

99-143

21210 A

810 L

99-329

40-86

18-353

18-422

14-171

76-18

1203 L

45-247

14-172

99-134

18-178

21-309

18-547

1012 L

18-501

40-46

18-544

c

AD

L

Description

Pinking

Attachment,

Ball

Joint

complete

Connecting

--------------------

Rod

Assembly----------Screw---------------------------------Nut,

Connecting

Nut,

Ball

right

left

hand

Joint,

hand

thread

-------------------

Rod--------------------------

thread---------------------

lower-----------------------VVasher------------------------------------VVasher-------------------------------------

N~

----------------------------------------

Screw--------------------------------------

Lever,

Link,

for

for

throw-out

knife

throw-out---------------------

------------------------

Screw-------------------------------------Screw-------------------------------------Screw,

Nut,

for

for

No. 34-26

4124-33

--------------------------

-------------------------VVasher------------------------------------Lever,

Cam

Screw,

for

knife

Throw-out,

for

lower

throw-out

for

upper

cam--------------knife

knife----------------------UpperKnife--------------------------------Base--------------------------------------Lower

Edge

Edge

Knife

Guide

Guide

--------------------------------

---------------------------------

Holder--------------------------VVasher------------------------------------Screw--------------------------------------

Holder

-------------------------------------

VVasher------------------------------------Screw-------------------------------------Screw-------------------------------------Shaft,

for

base------------------------------

PinkerHandle-------------------------------

Screw,

for

No. 14-171

----------------------

PinkerArm---------------------------------

Shaft,

Holder,

Screw,

Flat

for

lever

for

for

-----------------------------

upper

No. 14-172

knife

----------------------

-----------------------

Spring---------------------------------

Screw------.--------------------------------

N~

----------------------------------------

Attaching

Screw,

for

No. 29482 B

VVasher-------------------------------------

Screw,

for

upper

knife-----------------------

--------------

-------------

Amt.

Req.

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

15

Page 16

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your

Special representatives

tory trained

promptly

tion, there

and

and

is

a Union Special Representative

serve you. Check with

ATLANTA, GA.

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES, CAL.

NEW YORK, N.

PHILADELPHIA, PA.

ILL.

TEXAS

Y.

particular operation. Union

and

service men

are

able

to serve your needs

efficiently. Whatever your loca-

him

today.

MONTREAL,

TORONTO, CANADA

BRUSSELS,

LEICESTER,

LONDON, ENGLAND

PARIS, FRANCE

STUnGART,

and

service

are

CANADA

BELGIUM

ENGLAND

GERMANY

will

fac-

to

Representatives

industrial

UNION SPECIAL

400

N.

FRANKLIN

ancl cllstrlbutora In

cities

throughout

CORPORATION

ST.,

CHICAGO,

all

the

Important

world.

ILL.

60610

Loading...

Loading...