Page 1

INDUSTRIAL

SEWING

FINEST

STYLES

63400

63400

®

QUALITY

c

KC

MACHINES

CATALOG

No.

121

KC

.

CLASS

STREAMLINED

HIGH

HIGH

SPEED

LOCKSTITCH

THROW

UNION SPECIAL

63400

MACHINES

CORPORATION

CHICAGO

Page 2

C a t a 1 o g N

(

S u p p 1 e m e n t t o C a t a 1 o g N

o.

1 2 1 K C

I N S T R U C T I 0 N S

F 0 R

A D J U S T I N G A N D 0 P E R A T I N G

S T 0 F P A R T S

L I

C L A S S 6 3 4 0 0

S t r e a m 1 i n e d L o c k s t i t c h

S t y 1 e s

o.

1 2 1 M )

6 3 4 0 0 C 6 3 4 0 0 K C

F i r s t E d i t i o n

@ 1 9 7 7

b y

U n i o n S p e c i a 1 C o r p o r a t i o n

R 1 g h t s R e s e r v e d i n A 1 1 C o u n t r i e s

UNION SPECIAL CORPORATION

INDUSTRIAL

SEWING

CHICAGO

MACHINES

P r i n t e d i n

2

U.

S.

A.

April,

1977

Page 3

Each

into

special.

tain

letter

fixed

the

the

UNION

name

Standard

letter

"Z".

to

the

SPECIAL

plate

Style

"Z".

When

Standard

only

machine

on

the

numbers

Example:

minor

Style

IDENTIFICATION

is

identified

machine.

have

"Style

changes

number. Example:

Style

one

63400

are

OF

MACHINES

by a

numbers

or

more

C".

made

Style

are

letters

Special

in a standard

"Style

number

classified

suffixed,

Style

63400 CZ".

which

as

numbers

machine,

is

standard

but

never

contain

a "Z"

stamped

and

con-

the

is

suf-

Styles

which

"63400".

junction

not

clarity,

KC

number,

NOTE:

column.

those

catalog

structions

herein.

in

given

of

differs

This

used

parts.

Opposite

When

Adjusting

in

This

this

from

handwheel

of

machines

from

catalog

therewith.

on

Style

certain

description,

ordering

Catalog

are

that

catalog

It

can

class.

the

the

and

the

ones

pertain

also

Reference

operator's

is

toward

63400 B

No. 121 M

similar

the

style

is a supplement

Only

63400 B

illustration

and amount

repair

operating

that

applies

be

the

number,

APPLICATION

those

are

illustrated

parts

specifically

applied

position

are

page,

parts

instructions

for

Style

are

different

specifically

to

direction,

operator.

in

construction

in

to

Catalog

parts

required.

always

with

which

shown

parts

63400 B. The

to

discretion

while

that

OF

and

in

use

for

from

Styles

to

the

such

seated

are

grouped

it

contains

CATALOG

No. 121 M and

are

used

listed

phantom

are

identified

the

Styles

Style

63400 C and

Standard

as

part

only

63400 B

to

some

right,

at

the

to

under a class

no

letters.

should

on

Styles

at

the

back

help

number

63400 C and

Styles

left,

machine.

locate

by

detail

listed

instructions

or

are

KC.

of

Special

front,

be

used

63400 C

of

this

the

number,

in

KC

are

included

additional

machines

Styles

back,

Operating

number

Example:

in

con-

and

KC,

but

book.

63400 C and

part

the

second

similar

in

in-

as

listed

of

machines

etc.,

direction

For

to

this

are

High Speed

Heavy

ulator,

System,

Bearing

Driving

Bar

63400 C

63400

Duty,

Stitch

Head

Adjustable

Link,

11

1/8

For

1

1/2

pre.sse

type

depending

KC

Same

thread

Streamlined

Drop

Feed,

Length

Oil

Siphon,

Feed Timing on Lower Main

inches

miscellaneous

inch

.r

and

foot,

size,

on

as

wiper

(38.1

Style

Long

Rotary

Indicator,

Adjustable

Feed

(282.58

throat

operation.

and

Eccentric,

mm)

attachments

63400 C,

prepared

Arm

mm).

plain

needle

plate,

STYLES

Lockstitch

Hook,

and

except

for

OF

Horizontal

One

Hook

Needle

seaming

bar

travel.

feed

dog,

guides.

use

with

MACHINES

Machines,

Reservoir

Oil

Control,

Bearings

Shaft,

operations

Type 180

stitches

Maximum

equipped

needle

One

Hook

Shaft,

Enclosed

for

Maximum

on

per

recommended

with

"Klipp-It",thread

positioner.

Needle,

Push

Automatic

Automatic

Take-up

Work

medium

GXS

or

inch,

Space

180

Light,

Button

Head

Lever

to

and

heavy

GYS

thread

speed

Medium and

Stitch

Lubricating

Oiling,

and

Needle

Right

needle.

size,

of

weight

needle

5000 R.P.M. -

undertrimmer,

Reg-

Needle

Bar

Needle

work,

Specify

Page 4

NEEDLES

Each U

number denot es the

The size number,

measured

the

and

Needle

description

Type

180

180

sample

on

No.

GXS

GYS

To

label.

NION

SPECIAL

in

thousandths

size

number

Type 180

and

the

Round

groove,

um

140/054, 150/060.

Round

groove,

sizes

150/060.

have

needle,

A

shank,

plated -sizes

shank,

075/029,

needle

or

complete

kind

stamped

represent

GXS

sizes

round

wide

wide

the

angle

round

angle

orders

type

order

needle

of

on

of

or

080/032,

has

both a type

shank,

the

an

180

available

075/029, 080/032,

promptly

and

would

point,

needle

inch

across

the

complete

GYS

Description

point,

groove,

point,

groove,

090/036,

size

read:

length,

shank,

the

symbol.

is

recommended

are

listed

and

lockstitch,

struck

lockstitch,

struck

100/040,

and

accurately

number

should

"1000

number and

groove,

denotes

eye.

below.

Sizes

short

groove,

090/036,

short

groove,

be

Needles,

size

finish

largest

Collectively,

for

Styles

length,

deep

100/040, 110/044,

length,

deep

110/044,

filled,

forwarded.

Type 180

diameter

63400 C and

ball

spot,

ball

spot,

125/049,

an

empty

number. The

and

other

of

the

type

eye,

ball

eye,

chromium

Use

GXS,

single

point,

125/049,

single

plated

140/054,

package,

description

Size

090/036".

type

details.

the

blade

number

KC.

Their

chromi-

a

used.

stitch

size

upon

kind

to

above,

er

than

Selection

Thread

formation.

The

strength

of

the

the

size

The

following

of

thread.

which

the

Cotton

Size

30 B

36 A

40

should

thread

of

size

Thread

0

of

proper

pass

requirement

employed.

the

needle

table

The

choice,

may

dictate

specified.

needle

freely

SELECTING

of

The

employed.

shows

however,

the

Mercerized

so

60 00

70 000

80

90 0000

100

size

through

THE

the

seam

quality

the

preferred

selection

Size

0000

should

the

SIZE

OF

produced

of

should

of a needle

Thread

A

0

be

determined

needle

THE

NEEDLE

the

work

size

give

by

eye

in

order

is

largely

desired

of

needle

consideration

size

for a given

slightly

150/060

140/054

125/049

110/044

110/044

100/040

090/036

080/032

080/032

075/029

the

size

to

dependent

is

largely

to

factors

to

to

to

to

to

to

of

thread

produce

upon

dependent

size

larger

Needle

Size

to

150/060

to

140/054

to

125/049

125/049

110/044

100/040

090/036

090/036

080/032

a good

the

and

referred

or

small-

4

Page 5

IDENTIFYING

PARTS

Where

Parts

which

too

distinguish

Part

appear.

IMPORTANT!

WHICH

PART

The

arrangement

replacement

The

ard

Styles

Each

plate

bled

position.

parts

with

particular

the

throat

chines.

Numbers

position

of

ordering

ed

view

plate

the

construction

small

numbers

IS

ORDERED.

parts

exploded

listed

presents

On

their

view

plate,

in

the

parts.

carries

permits,

for a complete

one

part

from

represent

ON

ALL

the

ORDERS,

ORDERING

of

this

for

Styles

view

part

being

the

part

Always

in

a

the

feed

first

this

in

plates

catalog

sector

page

opposite

numbers,

shown.

dog,

and

column

the

illustration.

use

the

a

reference

each

part

catalog

another

same

PLEASE

catalog

stamping

part,

INCLUDE

OF

REPAIR

is

that

is

regardless

to

facilitate

63400 C and 63400

at

the

and

of

the

machine,

the

descriptions

Following

presser

are

back,

reference

cover

Style

63400 B

illustration

and

the

exploded

foot

parts

combinations

Reference

part

number

number

for

listed

each

is

stamped

are

similar

PART

PARTS

KC.

the

the

numbers

in

part

identified

in

of

the

NAME

AND

easy

differences

covered

being

aligned

will

number

view

plates,

only,

numbers

the

second

available

with

its

by

part

letter

appearance.

catalog

STYLE

and

OF

accurate

between

in

Catalog

as

be

found a listing

of

pieces

are

available

and

merely

should

column. Each

for

number.

symbols

in

which

MACHINE

ordering

the

No. 121

in

their

required

plates

for

these

indicate

never

sale.

they

FOR

Stand-

assemof

in

covering

ma-

be

used

explod-

of

M.

the

the

the

in

Sub-assemblies,

or a solid

can

be

furnished

the

description

29480

34

35

63458 H

36

37

38

39

660-360

670 G-18

670 G-23

660-347

In

catalog,

parts

ed

in

for

the

tration.

Success

UNION

tion,

the

mum

SPECIAL

its

most

effici~ncy

line

FM

those

no

cases

specific

the

various

description,

in

Needles

subsidiaries

approved

and

which

box on

for

repairs,

of

the

Rotary

where a

usage

USE

the

operation

scientific

durability

are

the

picture

main

sub-assembly.

Tension

Rotary

Rotary

Female

Male Wire

Solenoid

part

will

machines

and,

if

GENUINE

and

Repair

and

authorized

principles,

sold

are

complete,

plate.

indicated

or

by

Component

by

indenting

separate

parts

their

part,

of

sub-assemblies,

descriptions

Example:

Release

Solenoid

Solenoid

Cov~r-----------------------------------

Assembly---------------------

Solenoid----------------------------------------Connector

Sleeve,

green--------------------------

Terminal--------------------------------------

Lead

is

be

are

necessary,

NEEDLES

of

these

Parts

are

assured.

Cover-------------------------------------

common

mentioned

not

distributors.

to

all

in

the

same,

the

difference

AND

REPAIR

machines

as

furnished

and

are

of

the

the

description.

the

specific

PARTS

can

be

by

They

made

machines

will

secured

the

are

with

Union

designed

utmost

usage

be

only

are

in a bracket

covered

by

However, when

will

be

shown

Special

with

in

the

genuine

Corpora-

according

precision.

which

under

1

1

1

2

2

1

this

the

mention-

illus-

to

Maxi-

parts

your

Genuine

are

guarantee

needles

stamped

of

with

the

are

packaged

the

highest

Union

quality

with

Special

in

labels

trademark,

materials

5

marked

U S Em

and workmanship.

~

blem.

. Genuine

Each

trademark

repair

is

Page 6

TERMS

!'rices

.tru

forwarded

wisu

directed.

CAUTION!

handwheel.

Before

carefully

box,

the

A

bag

attaching

cellaneous

The

bracket,

clamp

and

Insert

the

upper

are

f.o.b.

A

~1en

Using

leaving

packed.

following

of

assembly

screw,

attachment

bag

of

one

synchronizer

three

hinge

frame

strictly

shipping

charge

unpacking,

both

factory,

After

steps

PREPARATION

one

extra

to

assembly

clamps

studs

eyelet

net

is

hands

the

should

parts,

the

parts

lead

for

in

to

top

cash

point.

made

DO

on bed

each

machine

OF

consisting

bobbin,

bed

for

wire

tension

holes

of

and

subject

Parcel

to

cover

INSTALLING

NOT

lift

casting,

UNION

and

be

followed:

MACHINE

two

hinge

plate,

Style

clamp,

release

provided

arm (A,

to

Post

the

postage

machine

lift

SPECIAL

accessories

FOR

INSTALLATION

of

one

studs,

are

packed

fi3400

one

KC

screw

solenoid

for

them

Fig.

2A

change

shipments

and

out

gently.

machine

have

frame

thread

and

with

also

for

lead

in

rear

or

2B).

without

are

insurance.

of

box

by

is

sewed

been

eyelet,

two

screws

each

machine.

includes

synchronizer

wire.

of

cloth

notice.All

insured

placing

off,

unless

one

inspected

removed from

one

eyelet

for

holding

one

synchronizer

lead

plate.

shipments

other-

hand

on

and

packing

mis-

wire

Assemble

STANDARD

Included

one

bobbin

clamp

and

are

TABLE

spring,

screw,

essential

TOPS

Lockstitch

the

bed

plate

ACCESSORIES

also

with

winder

four

one

isolator

when

assembly,

knee

setting

machines

is

FLUSH

each

lifter

pads

are

with

machine

the

assembly

and

up

the

installed

the

is a box

machine

clips,

machine.

top

of

mounting

and

its

and

in

table

the

machine

of

STANDARD

frame,

rubber

one

machine

tops,

one

pad,

rest

prepared

mounting

ACCESSORIES-containing

oil

bed

positioning

pin.

with

drain

jar

These

cut-out,

and

spring

parts

so

its

frame.

that

6

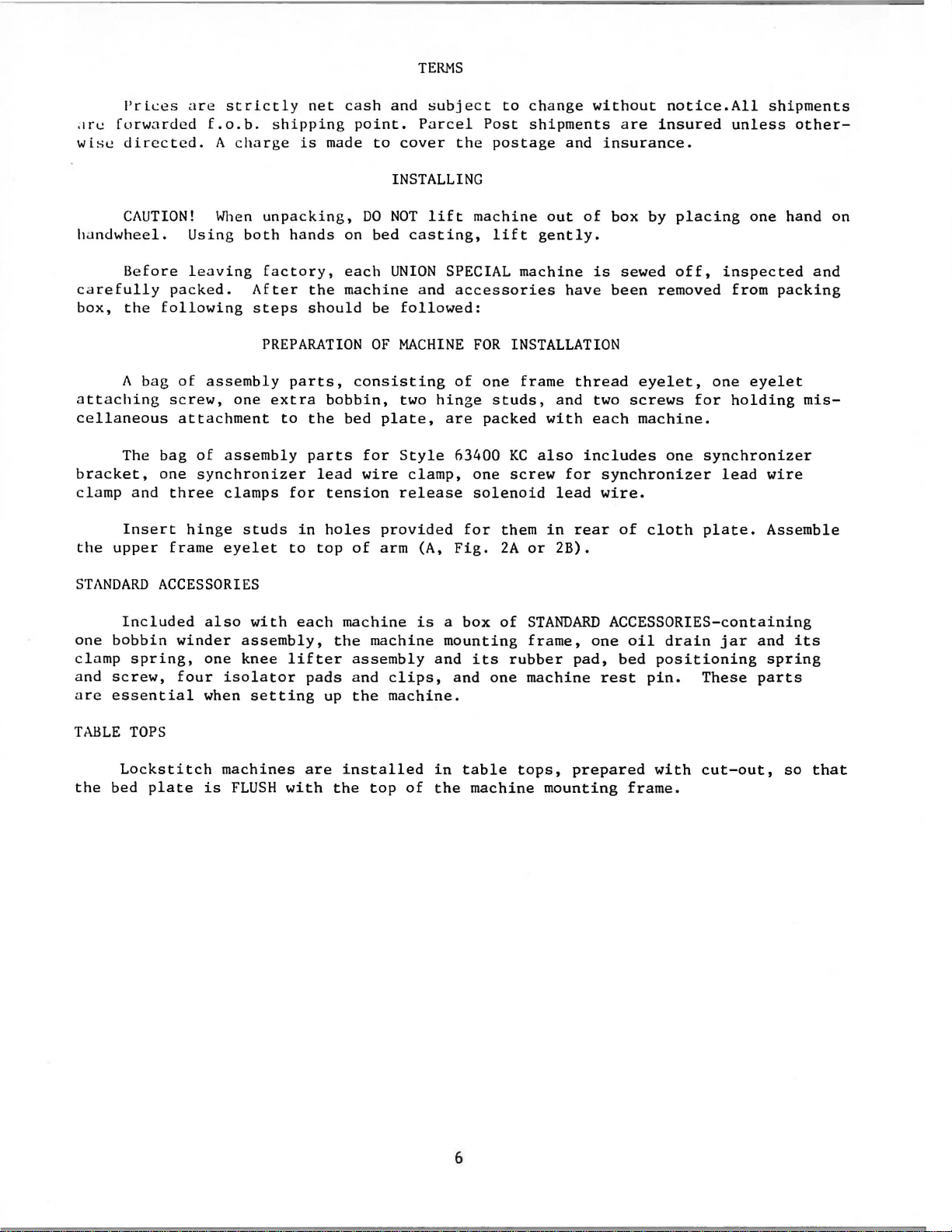

Page 7

MACHINE

MOUNTING

FRAME

INSTALLATION

On a suitable

cut-out

through

over

right

the

retaining

nuts

side

as

but

within

1/16

the

shown.

lifter

the

rises

lightly.

Place

inch

retaining

of

Tip

must

Before

maximum

approximately

with

left

the

the

not

rod

the

the

hinge

hinge

plate

sewing

(1.59

plate

board

machine

All

bind.

the

should

lift

head.

tableboard,

hinge

pad and

pad;

(21393

head

mm)

clearance

smartly

and

end

play

machine

be

of

the

This

5/16

lugs

tighten

insert

R)

in

the

tighten

back

against

of

the

is

put

adjusted.

presser

may

be

inch

place

to

the

round

to

outside

frame

between

upward

locking

cross

into

The

bar

done

(7.94

machine

rear

securely.Assemble

head

mounting,

the

with

nuts

the

rest

shaft

production,

left

and

by

setting

mm).

mounting

(Fig.

wood

a hammer

stop

its

1).

screw

front

and

cloth

securely.

pin,

should

screw

parts

the

of

Insert

and

pan

after

plate

to

and

be

the

do

stop

frame (21393

the

bed

positioning

tighten

section,

being

edge

and

insure

assemble

taken

bell

(22597 F)

not

a good

up by

crank

interfere

screw

N)

countersunk

spring(63474

securely.

as

shown, and

sure

the

so

the

grip

knee

the

(21665

should

that

there

frame

cone

be

with

the

in

the mac

is

sides,

on

press

J)

of

set

moving

presser

hin

wood

Assemble

screw

snug

about

rap

the

under-

assembly

bearings,

the

knee

so

that

parts

e

A)

up

bar

TABLE

BOARD

22846Q-16

63476

·.'-21393R

. ·-65

'-

213935

1-1

6

-

63476C

Fig.

1

Additional

Style

Needle

63400

Positioner".

instructions

KC

will

be

found

for

preparation

in

the

applicable

7

of

section

table

frame

covering "Electro-Drive

for

installation

of

and

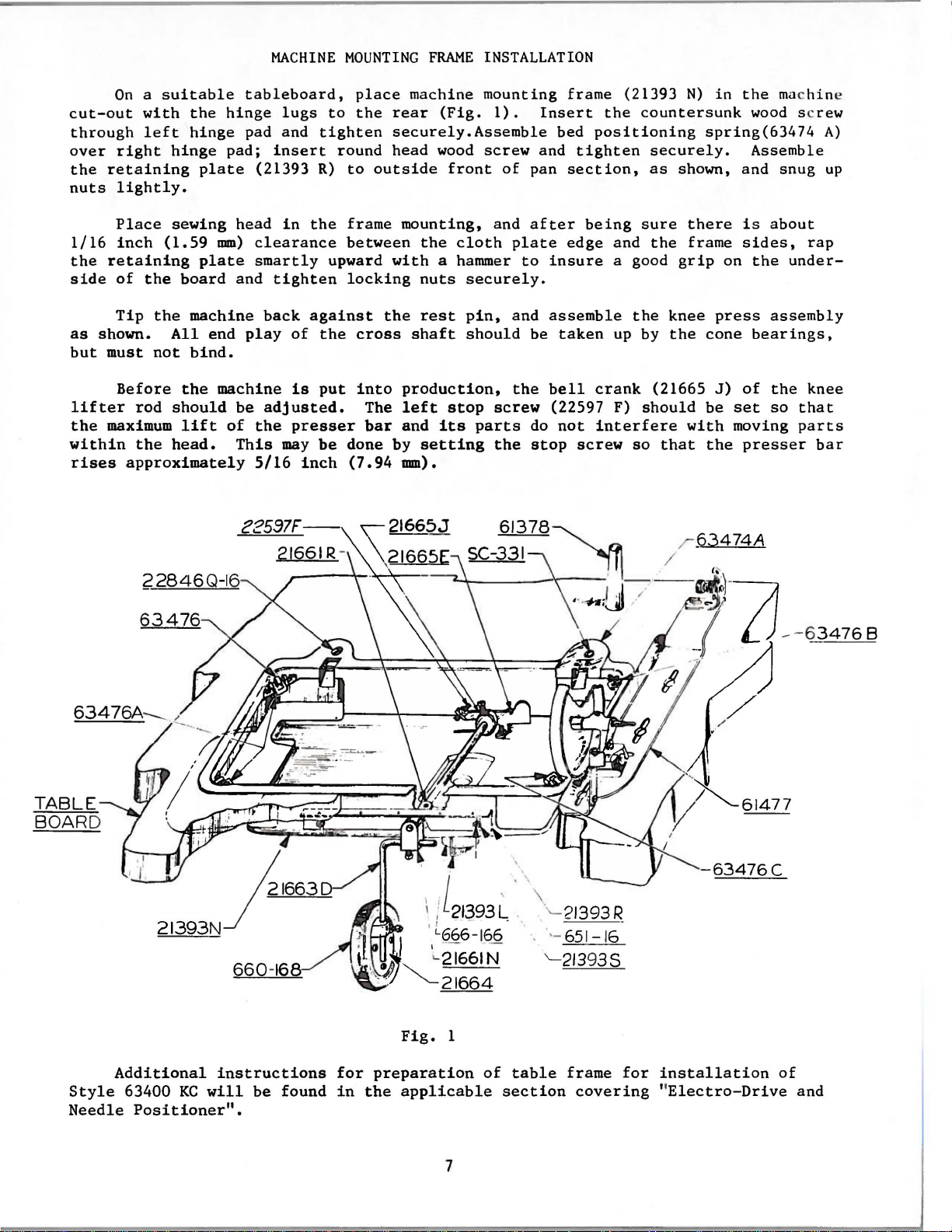

Page 8

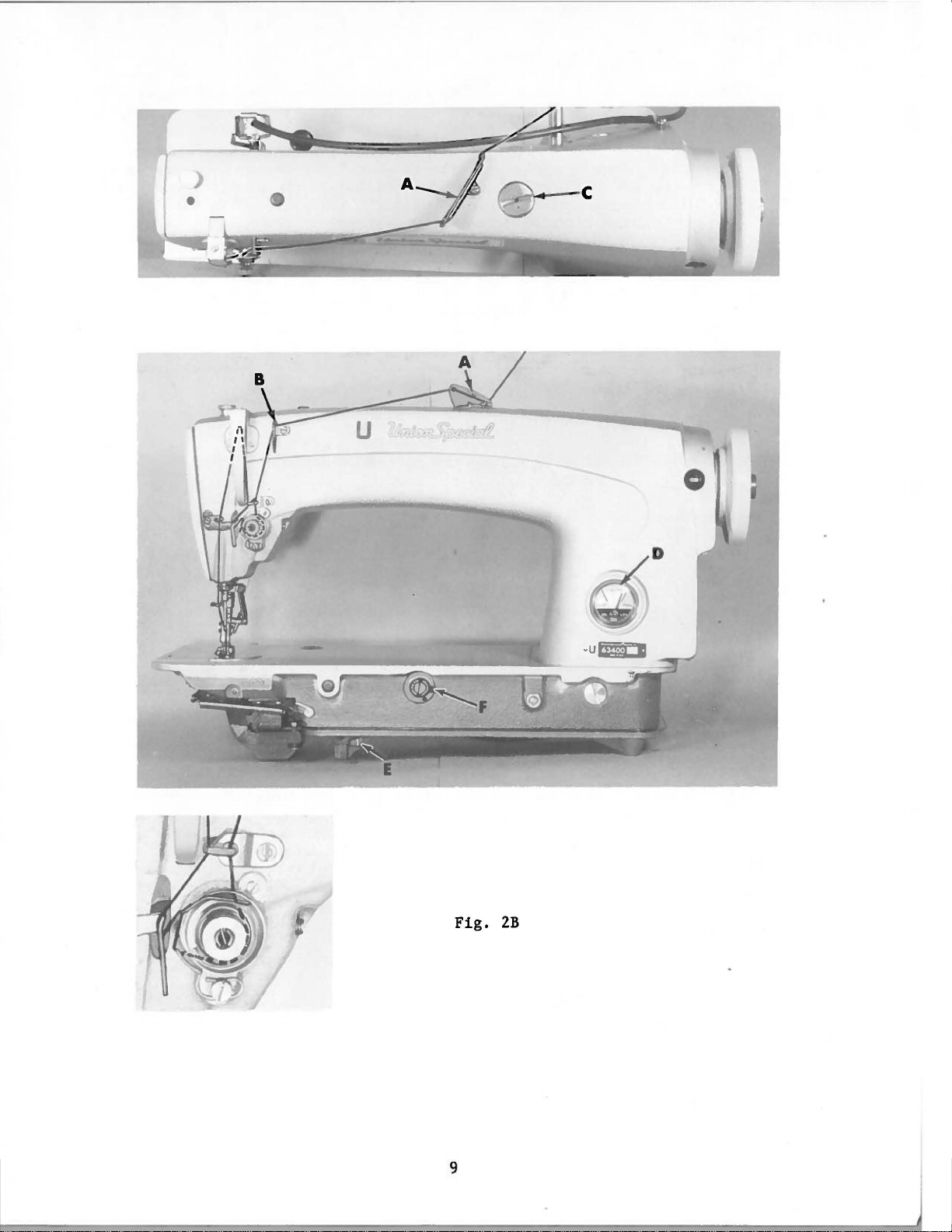

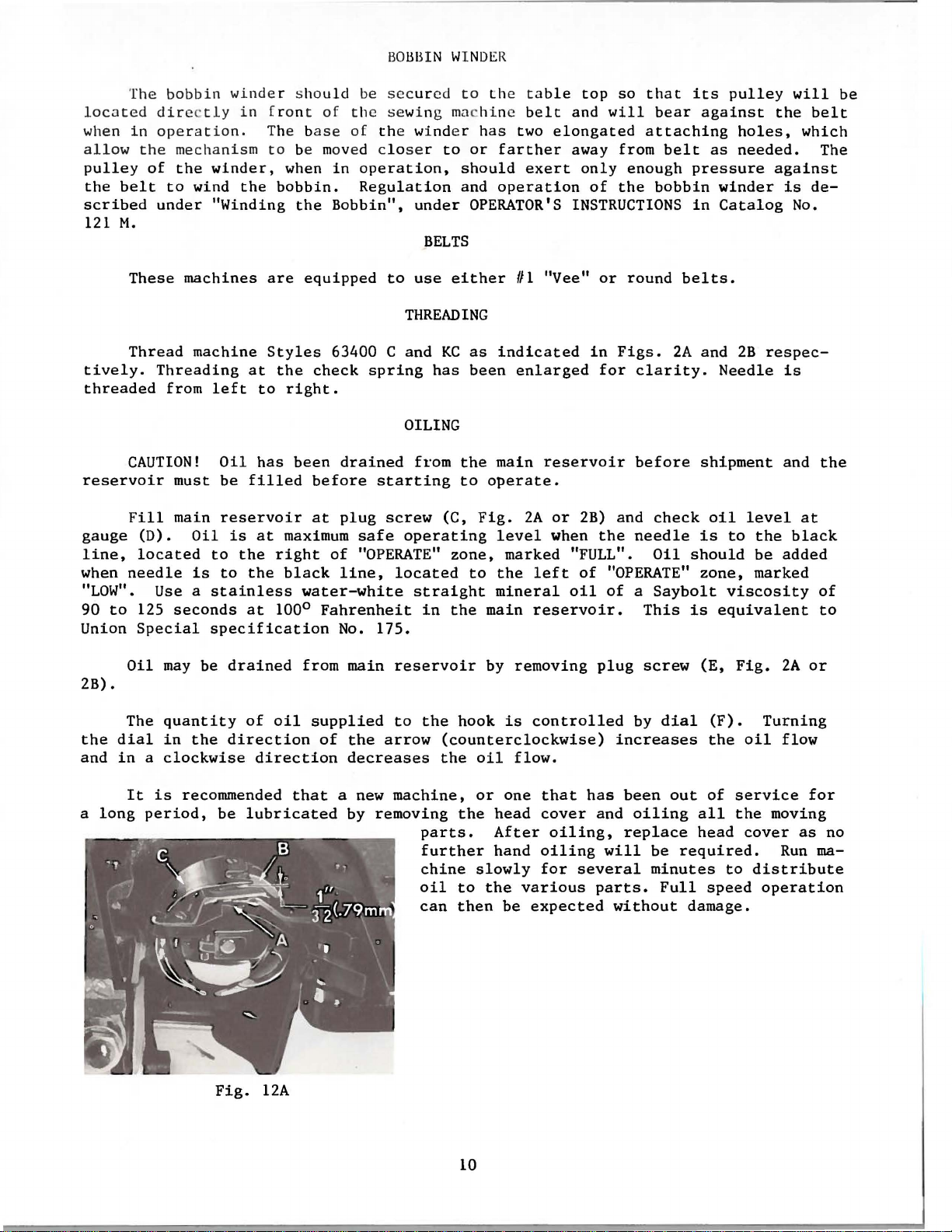

Fig.

8

2A

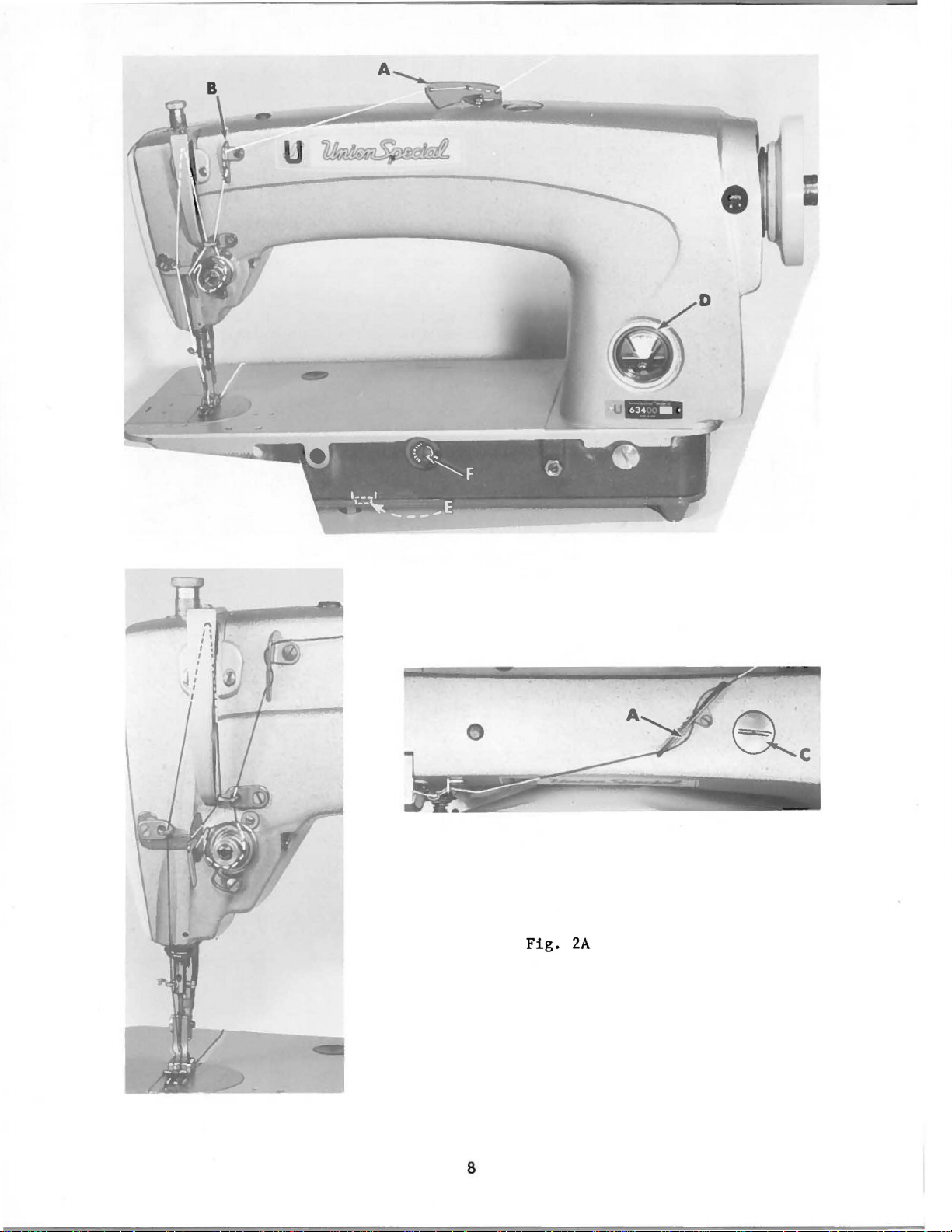

Page 9

B

Fig.

2B

Page 10

The

located

when

in

allow

pulley

the

belt

scribed

121

M.

bobbin

directly

operation.

the

mechanism

of

the

to

under

winde

winder,

wind

"Winding

in

the

BOBBI

r sho

uld

be

secured

f ront

The b

to

of

t he sewi ng machi ne

ase

of the wi nd e r has two

be moved closer to

when

bobbin.

the

in

operation,

Regulation

Bobbin",

N WI NDER

to Lhe t

should

and

under

BELTS

able

belt

elongated

or

farther

exert

operation

OPERATOR'S

top

so

that

and

will

away from

only

of

INSTRUCTIONS

bear

attaching

enough

the

bobbin

belt

its

pulley

against

holes,

as

needed.

pressure

winder

in

Catalog

will

the

belt

which

against

is

de-

No.

be

The

These

Thread

tively.

threaded

reservoir

gauge

line,

when

"LOW".

90

Union

2B).

the

and

Threading

CAUTION!

Fill

(D).

located

needle

Use a

to

125

Special

Oil

The

dial

in a clockwise

machines

machine

from

left

must

main

Oil

to

is

stainless

seconds

specification

may

be

quantity

in

the

are

Styles

at

the

to

Oil

has

be

filled

reservoir

is

at

the

right

to

the

at

100°

drained

of

oil

direction

direction

equipped

63400 C

check

right.

been

maximum

black

drained

before

at

plug

of

line,

water-white

Fahrenheit

No.

from

supplied

of

to

THREADING

and

spring

OILING

starting

screw

safe

operating

"OPERATE"

located

175.

main

decreases

the

reservoir

to

arrow

use

either

KC

has

from

straight

the

to

(C,

zone,

in

the

the

hook

(counterclockwise)

the

as

indicated

been

main

operate.

Fig.

level

to

the

mineral

main

by

oil

Ill

enlarged

marked

removing

is

flow.

"Vee"

reservoir

2A

or

2B)

when

"FULL".

left

of

oil

reservoir.

controlled

or

round

in

Figs.

for

clarity.

before

and

check

the

needle

Oil

"OPERATE"

of a Saybolt

This

plug

screw

by

dial

increases

belts.

2A

and

shipment

is

should

zone,

is

(E,

2B

respec-

Needle

oil

level

to

the

be

marked

viscosity

equivalent

Fig.

(F).

the

Turning

oil

is

and

at

black

added

of

2A

or

flow

the

to

It

is

a

long

recommended

period,

be

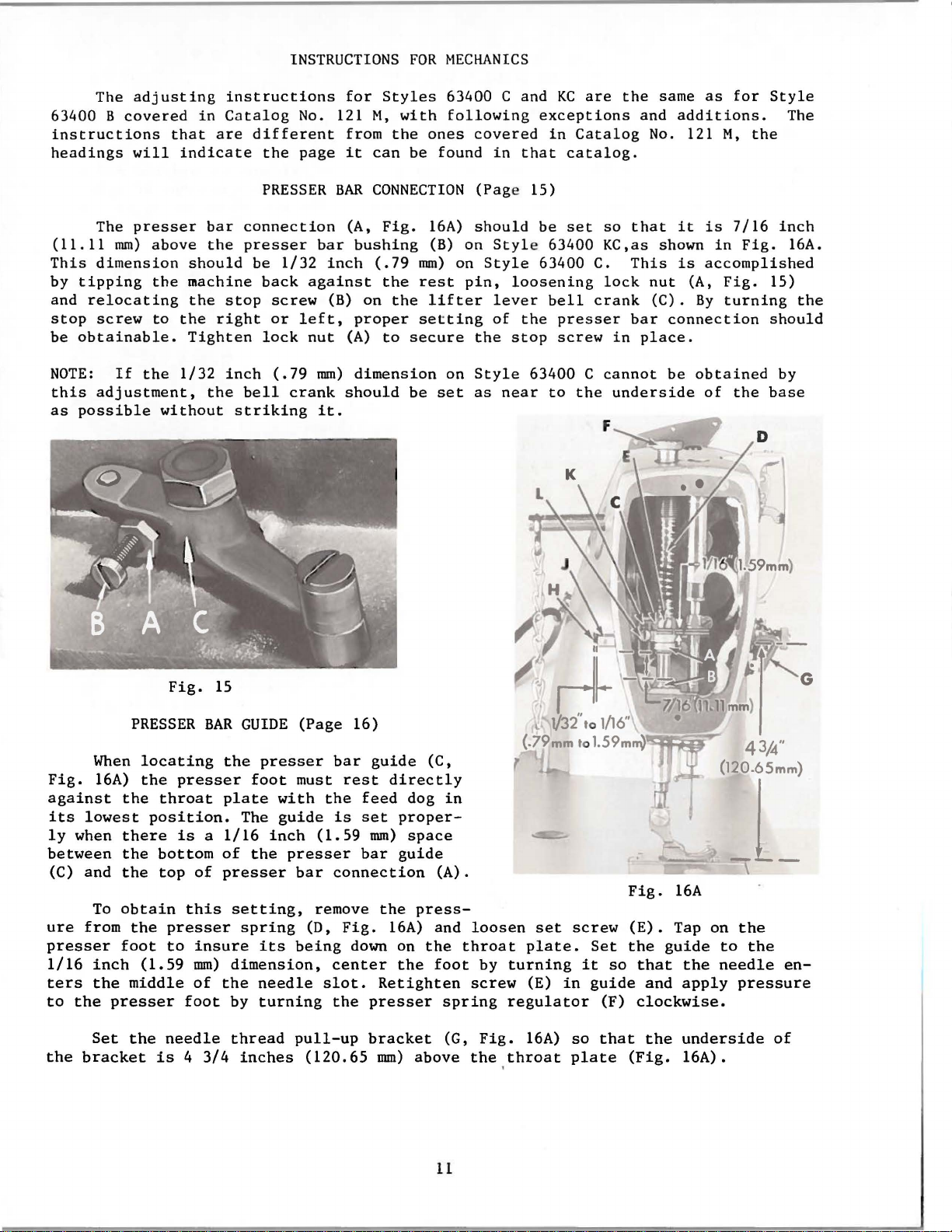

Fig.

that

lubricated

12A

a new

by

machine,

removing

parts.

further

chine

oil

can

or

the

slowly

to

then

10

one

head

After

hand

the

be

that

cover

oiling,

oiling

for

various

expected

has

and

will

several

parts.

without

been

out

oiling

replace

be

minutes

Full

of

service

all

the

head

required.

to

speed

damage.

moving

cover

as

Run

distribute

operation

for

no

ma-

Page 11

The

63400 B

instructions

headings

covered

adjusting

that

will

indicate

instructions

in

Catalog

are

INSTRUCTIONS

No.

different

the

page

for

121

from

it

Styles

H,

the

can

FOR

HECHANICS

63400 C and

with

following

ones

be found

covered

in

that

KC

are

exceptions

in

Catalog

catalog.

the

same

and

No.

as

for

additions.

121

M,

Style

The

the

The

(11.11

This

dimension

by

tipping

and

relocating

stop

screw

be

obtainable.

NOTE:

this

adjustment,

as

possible

presser

mm)

If

above

the

to

the

without

bar

the

should

machine

the

stop

the

right

Tighten

1/32

inch

the

PRESSER

connection

presser

be

1/32

back

screw

or

left,

lock

(.79

bell

striking

crank

BAR

(A,

bar

inch

against

(B) on

proper

nut

(A)

mm)

should

it.

CONNECTION

Fig.

bushing

(.79

the

to

dimension

the

secure

be

16A)

(B) on

mm)

rest

lifter

setting

on

set

(Pag

should

on

pin,

the

Style

as

e 15)

Styl

Style

loosening

lever

of

stop

near

be

set

so

that

e 63400 KC,as shown

63400 C.

bell

the

presser

screw

63400 C

to

the

This

lock

crank

bar

in

place.

cannot

underside

nut

(C).

connection

be

it

is

7/16

in

Fig.

is

accomplished

(A,

Fig.

By

turning

obtained

of

the

inch

16A.

15)

the

should

by

base

When

Fig.

against

its

ly

between

ure

presser

1/16

ters

to

the

(C)

16A)

lowest

when

and

To

from

inch

the

the

Set

bracket

PRESSER

locating

the

the

position.

there

the

the

obtain

the

foot

(1.59

middle

presser

the

is 4 3/4

Fig.

BAR

presser

throat

is a 1/16

bottom

top

of

this

presser

to

insure

mm)

of

foot

needle

15

GUIDE

the

presser

foot

plate

The

inch

of

the

presser

setting,

spring

its

dimension,

the

needle

by

turning

thread

inches

(Page

must

with

guide

presser

bar

(D,

being

pull-up

(120.65

16)

bar

guide

rest

the

feed

is

set

(1.59

remove

slot.

mm)

bar

connection

Fig.

down on

center

the

presser

bracket

(C,

directly

dog

proper-

space

guide

(A).

the

press-

16A)

Retighten

mm)

the

above

and

the

foot

in

loosen

throat

by

screw

spring

(G,

Fig.

the,throat

set

plate.

turning

(E)

in

regulator

16A)

screw

Set

it

guide

(F)

so

that

plate

Fig.

(E).

the

so

that

and

clockwise.

the

(Fig.

16A

Tap on

guide

the

apply

underside

16A).

the

to

the

needle

pressure

G

en-

of

11

Page 12

1.

2.

3.

Set

the

spring

Solenoid

plunger

inch

by

18A)

Tension

(J,

pin

ance

in

(.127

and

solenoid

until

taken

tension

(1.59

loosening

as

Fig.

(H)

between

the

This

mm)

the

it

not

tension

eyelet

plunger

pin

must

mm).

required.

release

16A)

is

to

tension

can

spacer

end

of

should

contacts

to

disc.

assembly

(A,

Fig.

pin

protrude

If

adjustment

set

screw

solenoid

with a set

have

approximately

it

and

the

disc.

be

accomplished

between

tension

then

the

exert

too

After

TENSION

(FOR

so

that

18A).

(H,

Fig.

a minimum

located

is

secured

screw

tension

the

release

be

slipped

solenoid

much

pressure

tightening

RELEASE

STYLE

the

16A)

is

under

in

.005

release

by

placing

head

pin.

onto

plunger

set

(Page

63400

tension

must

of

1/32

required

machine

to

flat

bracket.

inch

of

solenoid

The

bushing

pin.

thereby

screw

17)

KC)

discs

touch

inch

move

arm

of

Solenoid

(.127

pin

witl1out

a

.005

tension

and moved

Care

opening

remove

are

tension

(.79

tension

and

bushing

mm)

inch

plunger

release

should

spacer.

centered

release

mm)

post

moving

plunger

clear-

thread

pin

in

be

the

on

the

pin

and

to a maximum

assembly

stop

screw

Fig.

check

the

of

in

(B,

18A

end

1/16

or

of

out

Fig.

4.

The

release

and

release

above

NOTE:

the

slot

oil

gauge

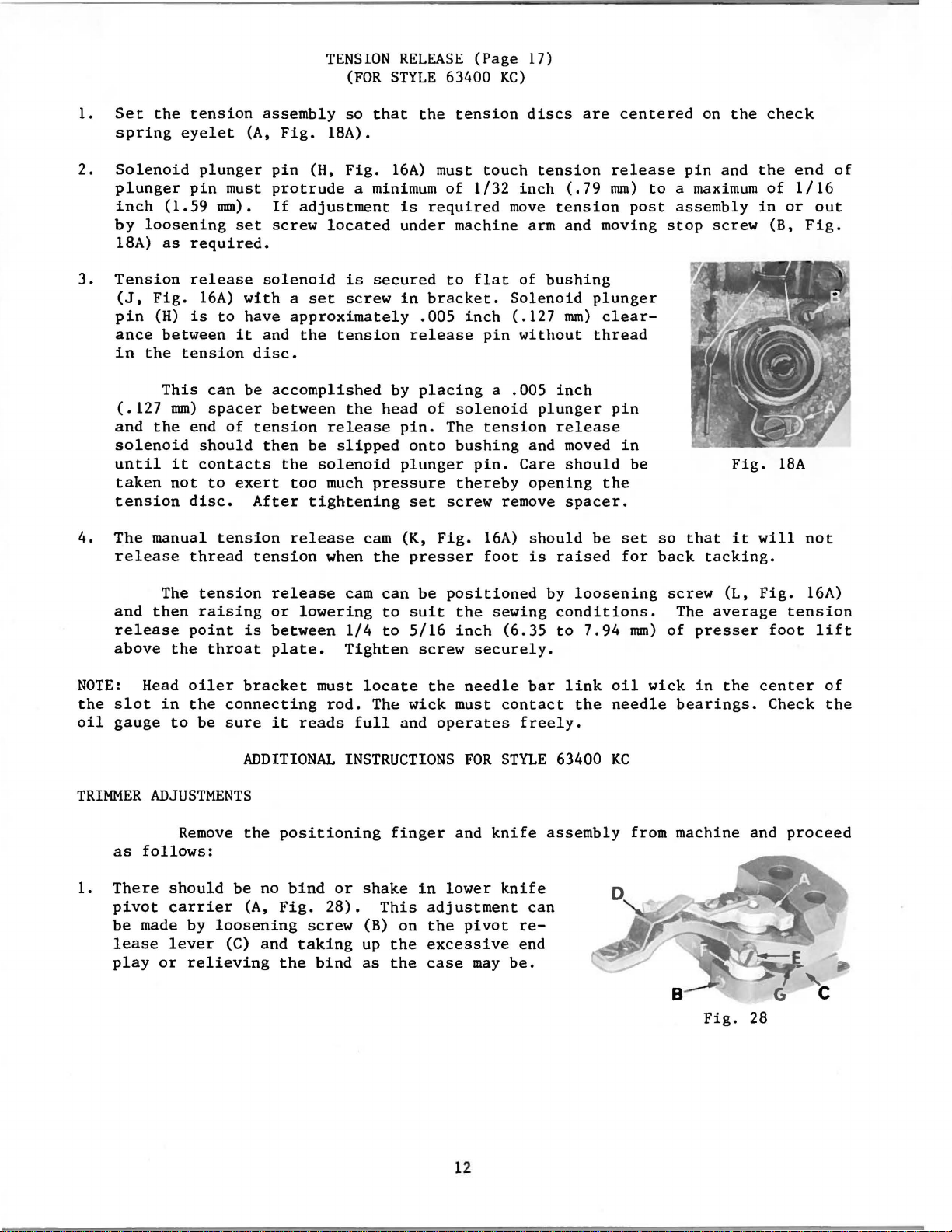

TRIMMER

as

1.

There

pivot

be

made

lease

play

manual

The

then

Head

in

ADJUSTMENTS

follows:

should

carrier

lever

or

thread

tension

raising

point

the

throat

oiler

the

to

be

Remove

by

relieving

tension

connecting

sure

be

loosening

(C)

release

tension

release

or

is

between

plate.

bracket

it

ADDITIONAL

the

no

(A,

Fig.

and

the

when

lowering

must

rod.

reads

positioning

bind

28).

screw

taking

bind

cam (K,

the

presser

cam

can

be

to

suit

1/4

to

5/16

Tighten

locate

The

full

INSTRUCTIONS

or

shake

(B)

up

as

wick

and

finger

This

on

the

the

screw

in

adjustment

the

excessive

case

Fig.

foot

positioned

the

inch

securely.

the

needle

must

operates

FOR

and

lower

pivot

may

16A)

sewing

(6.35

contact

freely.

STYLE

knife

knife

reend

be.

should

is

raised

by

loosening

conditions.

to

bar

link

the

63400

assembly

can

be

7.94

set

for

mm)

oil

wick

needle

KC

from

so

that

back

screw

The

of

presser

in

bearings.

machine

it

tacking.

(L,

average

the

and

will

Fig.

tension

foot

center

Check

proceed

not

16A)

lift

of

the

12

Fig.

28

Page 13

TRIMMER

2.

Position

ing

ADJUSTMENTS

upper

finger.

knife

Check

0 good

(Continued)

(D)

parallel

to

see

If

this

the

eccentric

starting

centric

the

arm

with

that

the

is

not

so,

bushing

point

bushing

of

the. positioning

lower

loosen

would

(F)

the

left

knife

(F)

located

side

is

the

until

be

to

approx.

finger

of

parallel

finger

the

have

(Fig.

the

with

set

knives

the

90°

to

30).

arm

screw

are

pin

the

of

the

the

(E) and

parallel.

hole

right

position-

upper

in

knife.

turn

the

side

A

ec-

of

3.

4.

Fig.

Assemble

machine.

finger

holder

projection

the

and

1/32

projection

(Fig.

Locate

forward

solenoid

pivot

be

and

until

bobbin

knife

inch

12A).

the

release

maintained

29

Adjust

knife

(A,

case

assembly

(.79

and

cutting

as

possible

lever

Adjust

To

lower

CAUTION:

justment

tion

positioning

right,

a

To

position

positioning

the

assembly

the

finger

Fig.

mm)

the

(B)

lever

when

12A)

holder

attaching

clearance

inside

solenoid

and

contacting

(D),

knife

adjust

knife

The

should

point

make

bobbin

recess

on

recess

edge

parallel

so

return

lower

the

Be

or

lower

the

of

these

knife.

finger

case

by

turning

the

screws

between

bracket

the

that

knife

lower

and

sure

parallel

not

finger

run

the

adjustments

and

holder

is

positioning

(B) and

of

with

there

spring

until

counterclockwise

bushing

knife

extend

(B).

out

of

positioning

knife

the

at

the

tighten

securely,

the

bobbin

(A,

the

cutting

it

knife

adjustment

positioning

Fig.

is a 1/32

(A,

(A,

Fig.

beyond

As

the

cutting

loosen

assembly

bobbin

top.

finger

outside

case

31)

line

solenoid

Fig.

turn

is

finger

the

allowing

recess

just

flange

not

29)

the

the

case

Place

finger

edge

as

of

feed.

inch

32)

contacts

to

raise

turned

will

lower

into

plunger

have

in

its

left

edge

as

indicated

screws

into

the

of

far

With

(.79

is

in

the

screw

it.

while

to

extreme

side

knife

(C) must

(A,

the

(C),

mm)

position.

upper

(G)

clockwise

making

be

checked.

left

of

the

moves

Fig.

Fig.

adjust

clearance

to

coincide

at

point

30) and

30

cutting

knife.

this

arm

the

the

to

posi-

of

at

(D).

to

ad-

the

Fig.

12A

13

Fig.

31

Page 14

TRIMMER

5.

Adjust

extreme

left

ADJUSTMENTS

the

lower

right

side

of

hand

the

(Continued)

knife

needle

stop

position,

slot

screw

the

in

left

the

(B,

bobbin

Fig.

corner

32)

(E,

case

so

when

Fig.

holder.

the

29)

lower

is

in

knife

line

in

its

with the

CAUTION:

this

adjustment.

6.

Be

sure

tacts

is

in

spring

wire

NOTE:

solenoid

changed,

7.

1.

2.

If

Knife

tension

(C)

the

Rotate

(63470 P)

the

Thread

Be

sure

the

the

bobbin

its

extreme

wire

to

suit.

positioning

bracket

check

return

to

and

move

left

top

to

thread

so

of

wiper

cutting

Also

spring

does

are

step

cut

its

5.

spring

threads.

tension

decrease

wiper

that

stroke.

lever

solenoid

be

sure

retainer

case

holder

right

not

make

finger

removed from

(A,

spring

the

mounting

the

hook

(63470

knife

wire

hand

contact,

assembly

Fig.

To

adjust

bracket

tension.

THREAD

catches

E)

lever

does

(B,

when

position.

32)

collar

must

the

bend

or

machine

to

tension

WIPER

the

return

contacts

not

Fig.

lower

If

retainer

cutting

or

position

have

proper

(D)

to

ADJUSTMENTS

(63470

needle

with a snap

hit

30)

the

of

the

H)

the

the

con-

knife

knife

right

and

thread

lower

hook

return

to

adjust

when

when

knife

point.

spring

increase

thread

the

released.

stop

when making

Fig.

32

loosen

tension

wiper

take-up

screw

or

guide

is

at

to

3.

Form

(63470

CAUTION:

Move

Be

of

thread

sure

solenoid

thread

P).

Thread

to

loosen

wiper

will

wiper

wiper

guide

set

result

wire

screws

(63470 F)

hook must

(63470 P)

when

if

it

is

not

not

for

prevent

so

that

adjusting

allowed

free

hook

movement

solenoid

does

thread

to

return

in

from

not

wiper

completely.

thread

returning

stop

lever.

wiper

against

Premature

guide

to

its

plastic

stop.

tube.

failure

14

Page 15

ADJUSTING

AMCO

INSTRUCTIONS

FOR

ELECTRO

DRIVE

and

15

NEEDLE

POSITIONER

Page 16

......

0\

TU~G.

FR

RE.LU~

OM

TENSION

SOLENOID

-

-

CLAMP

- SY

NCHRONIZER

·~34~5D

SRAC..KET

J87J

*

S

CRE

.W

(CON

'SEE

I<I

ECTOI?)

a:rA/L

{:;

-.

=

,J

----:r.

,

-

..,.

,.

::::,

~,_,_,

*sc-

SC

2.92

REW

SCREWS

( DIA.

(BRACKET

S

EE

DETAIL

)-'

DRILL

R

ONI

ZE.R

NUTS TO

SECUR£

BOX

**

TRIMM

E!t

CiRCUIT I

WI

TH

RELAYS

FROM 8 0)( N/0 tWS

f¥11/'i

T£0

T,.

CIRCUIT

WI

IHM

eaAR

TH SCKE"S.

D /l.SECuRI!.

3~Z

ATIONS

OF

'FI.

UNDERTR

* IN DICA

DIM

NOT EQ

**

IMMER ELECTRONI

FOR 63<10

TES PART

ENSIONS

UIPPED WITH

INDIC

ATES 'PM T INCLUDED IN

Tf/E

800XT 362

NEE S

0

&.

6.3900 SEit

SHO

WN

Z<?J4tJDTV

BUT

IS

WI

TCH

1

..

ij: DIA.

C. EQUI

iES

INCLUDE

STANCARD

1=\

MACHINE

D IN

FOR

DRILLED

·KNE

E S

WI

\lr::\IL

~BL.

IM JN

E.

AT£S

E:L

P MENT

PAC

H

OLES

294eO

TCH;

(

EXTRA

TR

K IN

HOL

E:A

.

WHI

DLIN

PART

<;.

BOX

ES

AI<

E FOR INSTALL

HP

CH

IS NOT PART

SEND&.

E :JWITC.

BQ.\RD

NOTE

: REMOVE POWER PAC/<

NO

800XT-

CHARG£ ).

I-I

.

GRT

1':::::!

UNION

C

HIOI40,~

Fi

SPE

g . lA

CIAL

CO~f'O~ATION

ACII

S

?.Oi>/

0 U.

S.A

(.()IN

ECT

ED

1

1-JSIDE.

OF

SWITCH

EOX

.

AI?INT£0

U.

IN

S.A.

Page 17

PREPARATION

OF

TABLE

FRAME

FOR

INSTALLATION

Using

1.

Attach

2.

Attach

3.

Slide

4.

Attach

5.

Wire

leg

6.

Attach

ed.

7.

Attach

8.

Secure

using

drive,

9.

Connect

lease

(376

Fig.

the

A)

screws.

synchronizer

clamp

clamp

leads

of

table

power

Drill

electro

electrical

clamps

clutch

leads

solenoid

green.

10.

Assemble

SYNCHRONIZER

(a)

Rotate

handwheel

deflector

needle

on

1A

as a guide,

synchronizer

The

to

(660-356)

to

synchronizer

with

striped

frame.

pack

holes

in

to

table

drive

cable

and

screws

arm

switch

from power

(green

relays

as

shown

ADJUSTMENT

in

plate

the

up

(C,

stroke

proceed

bracket

upper

screw

adaptor

over

synchronizer

ends

left

rear

leg

to

underside

and

provided.

and

pack

leads).

in

operating

Fig.

12A)

of

(63495

also

of

bracket

to

switch

leg

if

required.

leads

treadline

to

cutting

Be

Fig.

direction

on

the

needle

as

follows:

D)

to

hold

handwheel

lead

using

box

of

table

of

table

to

underside

Connect

or

solenoid

sure

to

38.

until

the

rotating

bar.

to

the

clamp

assembly

wire.

(J87

and

attach

frame

board.

of

cable

knee

switch.

connect

the

hook

back

(660-352)

using

J)

screw.

using

tableboard

to

power

(white

white

needle

assembly

of

machine,

switch

nuts

pack,

leads)

to

clearance

in

the

box

and

and

white

is

using

position.

two

set

to

right

bolts

to

table

auxiliary

and

tension

and

green

cut

in

line

two

screws.

front

provid-

frame

re-

to

in

the

with

the

Then

its

loosen

brush

up and

Fig.

down

screw

is

in

positions

33

at

the

end

middle

of

(b)

(C)

(d)

of

synchronizer

of

the

the

needle

At

this

(A,

Fig.

of

the

brush

position

scribed

in

synchronizer

Down

hook

needle

time".

to

this

position

point

by

If

synchronizer

in

operating

middle

The

thread

(3.18

with

of

needle

take-up

mm)

power

rection

and

black

plastic

bar.

time

33)

needle

in

step

has

5/64

not,

point.

the

positioner

from

off

until

rotate

the

brass

should

holder

bar

(a),

and

should

passed

of

an

with

Then

and

rotate

direction

black

at

top

the

top

rotate

it

is

fourth

band.

contact

be

flush

(B).

To

and

deflector

then

loosen

move

as

be a point

the

center

inch

power

(1.

off,

loosen

third

until

plastic

should

of

its

of

its

handwheel

at

the

top

band from

Turn

on power and

of

with

make

required.

at

98

mm)

rotate

screw

band

its

brush

band.

position

stroke

up

stroke.

in

of

the

left

the

front

this

adjustment

plate

set

screws

which

line

of

"loop

handwheel

(D)

at

from

needle

or

operating

its

stroke.

left

check

as

end

left

is

1/8

(F)

band

edge

de-

(C)

the

the

taking

of

in

inch

If

not,

until

the

(E)

the

di-

17

Page 18

CLUTCH

(a)

Set

(b)

Adjust

nut

(c)

Close

there

needle

ARM

needle

washer

treadline

is

SWITCH

in

clutch

{B)

no

contact

positions

ADJUSTMENT

work.

arm

spring

is

to

be

approximately

switch

up.

and

between

Tighten

(A,

loosen

Fig.

it

and

nut

34)

so

1/2

clutch

the

(D)

to

that

lever

microswitch.

maintain

inch

treadle

(12.70

switch

will

mm)

adjusting

Then

setting.

return

from end

screw

tighten

to

stop

of

screw

stud}.

(C),

until

(wing

until

ADJUSTING

(a)

Depress

(b)

Adjust

3.18

(where

one

the

clutch

Tighten

CAUTION!

lever

running;

clutch

INSTALLATION

No. M6665)

(A,

Fig.

#3

on

inching

properly.

full

top

switch

is

When

socket

switch

CLUTCH

clutch

mm)

it

is

Clutch

one

engaged.

installing

be

35)

treadle

travel

says

turn.

on

right

engaged

lock

must

is

closed

click

OF

INCHING

sure

located

(B)

plug

unit

so

that

before

"Lock

Adjust

end

screw

not

must

inching

to

between

before

or

until

clutch

clutch

Motor")

screw

of

motor,

as

described

(E).

engage

or

auxiliary

be

heard

SWITCH

remove

connecting

it

will

one

arm

is

just

located

when

before

switch,

jumper

pin

#2 and

not

click

has

engaged.

enough

near

until

above.

clutch

motor

(Amco

wire

pin

the

function

is

heard,

approximately

to

which

Loosen

unlock

indicates

1/16

lock

it,

to

screw

which

Fig.

switch

1/8

inch

(E,

Fig.

is

approximately

34

is

(1.59

34)

open.

to

Should

35)

must

PUSHBUTTON

edge

of

the

treadle

the

ables

with

trimmed

be

If

the

of

the

synchronizer

is

needle

the

operator

the

needle

the

"the

inching

replaced

FUNCTION

pushbutton,

table

heeled

will

threads.

board,

while

position

out

or

is

interrupted.

to

readjust

of

the

switch

the

needle

which

is

depressed,

the

pushbutton

up

without

work,

be

removed

positioning

is

mounted on

Therefore,

trimming.

or

realign

but

the

is

depressed,

the

without

18

at a later

unit

the

front

cutter

when

This

garment

having

date,

will

band

the

en-

not

the

jumper

position

Fig.

wire

up.

35

(A,

Fig.

Page 19

TREADLINE

To

adjust

36)

loosen

Adjust

adjustment

the

tain

the

less

tension

actuating

switch

ered.

is

on

bevel

is

rods

three

the

If

more

treadle,

accordingly

bushing

If

more

actuator

Care

provided

the

switch

on

accomplished

SWITCH

the

as

is

necessary

bushings

desired

or

the

travel

the

trim

should

to

should

the

micro-

ADJUSTMENT

the

length

two

Allen

required

inside

length.

less

pressure

spring

by moving

(C) up

(D)

actuate

by

or

is

cycle,

and

be

taken

the

not

switch

adjustment

of

the

set

screws

and

retighten

the

cover

the

switch

is

(B)

can

be

the

pitman

down.

required

the

stop

be

in

two

bushing

so

that

micro -switch.

allowed

actuator

of

pitman

in

the

screws.

must

be

relocated

required

compressed

rod

the

treadle

bushings,

(E),

only

to

ride

bushing

the

stop

rod

(A,

Fig.

back

removed

when heeling

spring

must

enough

bushing

If

to ob-

more

for

micro

be

travel

The

over

(D).

panel.

roller

more

and

or

low-

the

This

(E).

FUSING

consisting

The 1

in

as

slow

chassis

of

(B,

thread

relay

THE

The power

1/2

the

front

the

positioner

blow

the

transformer.

Fig.

wiper

coil

POWER

of

AMP

fuse

fuses

37)

control

PACK

pack

two

(2)

circuit

panel

located

solenoid

(A,

the

fuses

circuit

Fig.

AC

circuit

incorporates

fuses

breaker

input

The 5

under

(30

and a circuit

the

auxiliary

components.

38)

located

for

AMP

the

VDC),

(24

a

(A,

Fig.

the

primary

straight

chassis,

cutter

VDC).

safety

37)

motor

The 1

on

top

solenoid

feature

breaker.

located

of

winding

blow

for

as

1/4

fuse

the

the

well

AMP

and

Fig.

36

Fig.

37

19

Fi

g. 38

Page 20

Before

bility

for

suggestions

Both

N

eedle

thread

Bobbin

thread

Lower

the

way

this

at

all

threads

thread

cut

thread

cut

knife

machine

times.

which

Condition

not

cut

not

cut,

not

cut,

does

not

left

If

,

however,

may

but

but

return

the

factory,

prove

bobbin

needle

all

the

trimmer

beneficial

it

was

THii\1!\IEH

Solenoid

Lower

enough

Lower

wipes

Lower

slip

Spring

ing

catching

Lower

enough

Hook

Bobbin

in

Needle

big

Not

return

and

more

spring

adjusted

has

been

to

you

.

not

knife

to

knife

threads

knife

off

when

retainer

bobbin

position

knife

to

No.

thread

bobbin

case

hole

or

has

enough

spring. Dense

rough

tension

and inspected

readjusted

THOUBLESIIOOTING

Causes

working

moving

not

the

right

too

far

behind

too

far

back,

knife

returns

wire

case

holder

does

not

in

throat

altered

thread

on

not

threaded

on

knife

right

29474 H or S used

been

tension

knife

not

plate

lower

will

so

and

is

forward,

threads

contact-

when

move

thru

is

knife

material

r equi

return

as

not

far

in

far

too

re

to give

trimm

the

utmost

ing

properly,

Check

!\

lake

continu

Heset

stop

Hclocatc

on

radius

Helocatc

Bend

spring

Adjust

setting

noid.

Operat

off,

to

dcte

lever

is

and

the n

ne

cessary

U

se

only No.

Thread

Us c

throat

needle hole,

Incr

ease

r e

turn

to

the righ

satisfaction

sec

Cures

lead

connections

ity

screw

knife.

knife

retainer

stop

screw

.

Check

e m

rm inc

contact

reposition

properly

plate

if

tens

sprmg

t

the

char~

check

Check

wire

to

position

achine with

if

solenoid

ing

stop

29474

T

with

available

ion

on

lower

by

moving

and

dura

below

for

nicks

to

standard

of

sole-

pivot

screw

solenoid

hook

smaller

knif

brackP

-

suit.

belt

if

e

t

Needle

random

Needle

Bobbin

NOT

E :

thread

unthreads

thread

tears

lengths

breaks

Ref

er

to

information

of

starting

when

Amco

r e g

and

leavt!s

starting

or

QuicK

arding the

tail

Catalo

needle

Lower

Too

tension

needle

thread

Tension

Needle

tioned

Needle

b

ig

Bobbin

Overspin

Too

tension

Sharp edg

knif

edges

kmfe)

gs

furnish

position

knife

much

and

thread

pull-off

disc

thread

properly

hole

thread

much kni

(F

e.

are

ed

er

rubbing

knife

return

excessive

eyelets

at

cone

not

open

take-up

at

top

in

throat

too

short

on

bobb

in

thre

fe

return spring

es

on

T.

ront,

with

and

C.

point

the

T.

C.

each nee

electrical circuitry

hook

friction

not

of

plate

ad

S.

of

a

nd

of

S.

dl

point

spr

ing

in

and

in

posi-

stroke

is

too

lower

back

lower

positioner

.

Hais

U

nthrcad

the

r Lg

crease

spring slightl

pull-off

Ch

ec k s e

s

olenoid

h

on

Check pos

take-up

of

the

t.:

sc thr oa t

ne dlc ho

Sec

bobbin

Check

bobbin

Decreas e t

sprtng

et

to

Ston

e s ha

low

e r knife .

back

low

e r k

for guar

e lowe r knife

some of

ht

of

the tension

tension

y.

at cones

tting of tension

and

of

this solenoid

lop

wm d

in

slightl

the le

edges

mfe

riian

elec

iti

on of

. . lus t

be

of its ups

pla

tc

le,

if a va

thread

of

bobbin

bobbin case

ension

y,

by mon ng br

ft

rp edg

(F

are

)

maint nance and

the

on kni fe

C

heck

trical

needl

witlnn

troke

w ith

ilabl

break

holder

on kn ife r

es

of

T . C . S. of

ront

,

the

T.

cvel

cts

pos t. De-

r !'

turn

thread

r e

lease

opera-

e t

hrPad

1

/B

in

s ma

ll<

e

s

and

ftt

ctu

ad-

p

oin

t a nd

C. S.

oth

to

ch

·r·

of

r·n

;-

of

er

20

Page 21

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1.

FOR

Unit

does

Unit

positions

Unit

trips

Unit

trips

Unit

keeps

Auxiliary

Unit

positions

Auxiliary

Unit

trips

Auxiliary

FOR

Check

the

TYPICAL

UNITS

not

position.

up

in

circuit

the

on

motor

motor

circuit

motor

UNITS

following:

breaker.

circuit

stitching

runs

slowly.

runs

breaker

will

TYPICAL

WITH

second

breaker

at

while

very

not

WITH

NEEDLE

PRINTED

position,

every

an

inching

clutch

hot.

after

turn

NEEDLE

PRINTED

positioning

over

POSITIONER

CIRCUIT

but

does

few

hours

speed.

is

engaged

one

although

POSITIONER

CIRCUIT

you

PROBLEMS

BOARD

not

position

or

every

with

main

time.

know

SOLUTIONS

BOARD

CONSTRUCTION

down.

few

days.

motor.

power

CONSTRUCTION

is

feeding

it.

Circuit

Synchronizer

Treadle

Input

Auxiliary

Loose

PrintedCircuitBoard(Check

nal

2.

The

the

3.

SCR

4.

Check

Grounded

Oil

Field

Operator

5.

Check

breaker

jack

power

motor

connection

End).

treadle

power

is

saturated

deteriorated.

the

switch

is

shorted.

the

following:

armature

fluttering

following:

jack

turned

armature.

and

brushes

brushes

(check

is

not

off

Replace

(tie

Replace.

treadle

and

soldered

forlooseconnection

opening.

and

then

board.

bolt

touching

excessively.

armature

connections)

The

back

unit

on

again.

field).

will

or

oxidation

position

down

on

the

Plug

first

in

Termi-

time

after

Synchronizer

Brush

Damaged

Synchronizer

Very

Defective

location

loose

field

V-belt.

brake

male

loose

and

on

synchronizer.

coil

in

on

SCR

female

auxiliary

handwheel.

circuit.

jacks.

motor.

Replace

Clean

printed

synchronizer.

circuit

21

board.

Page 22

6.

Treadle

7.

Armature

ture

8.

Check

switch

has

dressing

the

following:

is

not

poor

stone).

commutation

opening,

or

is

defective.

or

is

partially

shorted

and

dirty.

(Use

arma-

Setting

Opera

Grounded

Brake

No.

Check

two

position

of

the

9.

Check

Lead

Brush

10.

Check

Armature

The

of

treadle

tor

fluttering

field

gear

9855.

operation.

units,

operation.

the

rubbing

holder

the

following:

Chassis

switch.

coil

seized

Sometimes

thereby

This

following:

brushes

is

will

in

armature.

jammed

Equipped

the

(tie

on

and

treadle.

bolt),

hub.

greatly

against

brush

Replace

it

is

using

the

armature.

holder.

Voltage

With A Dual

or

defective

possible

positioner

prolong

field

with

new

to

remove

to

life

and

Adjustment

Value

Power

coil.

gear

only

and

the

raise

minimize

Resistor

Replace

brake

down

the

maintenance.

(See

field.

assembly,

position

Needle

Figure

brush

at

the

Part

on

end

(39).

As

Figure

portion

portion

is

is

39

to

be

used

shows

used

when

the

when

the

75

50

Ohm

resistor

the

supply

Ohm

over

220

has a value

line

voltage

voltage

Volt

Fig.

220

and

is

Volt

39

is

220

above

of

50

volts

220

ohm

or

volts.

and

75

lower,

ohm.

second

The

the

50

75

ohm

ohm

22

Page 23

ADJUSTING

INSTRUCTIONS

FOR

ELECTRO

DRIVE

QUICK

and

STOP

NEEDLE

POSITIONER

23

Page 24

G~O·

SSG.

~p

FO~

l'll~E

\1()\QR

TA4t&6M~O

,

...

L.,..M....

\(

N

~

65E'·J-~4

I t'Z#t?$ .x,e;Jo'S

()/"

A''T

/#hHcRJ

K ?9<1ti:)

""''

&V

/Nt'T

acx

~I!.E

10

SC333A

:SCI?EW

~fl-,/Oo'-'SNFA!S

~LSP,-'/'JI/£0

N l

nr'

9~304=7P

I \ i ' I

~~e>-20:,\

NOn:

BUXILIRRY

CONTR'OL

IJITH OUT

BOX, •

AVAILI\'BLE

CUST0l1ER

998-

PANEL,

MOU

NTING

Z98

FOR

REPAIR.

IS

O:.C·47Z

.

fr

tOP~PLVG

-~98·~15

FOI!

,.~Pil

1

;,,

TUBINt;

li'£L£A3£

376A

SC/i!£W

!ILL CAaU:: CLAI-IPS

'ROll

SC33SA

SC2E:W

/WIIIl

/1&£

CVSn:::J

M

E~

i

P

*

I

Pli?OM T£NS/ON

.SOLE:NOI

l.J.

'O

~

EAO

71·1/S

PLAN06eAPI-I

Dli!ILLEO

COMPDN£NTR4/CTS

NEE:OL£

TR

FOR

IMM

A

Eii'

~3400

I-IOLE:S

POSITIDN£1?.4

Clli'CIJ/Tii'Y-NR

~~:.r::~.

CAUTION

.SYNCHii?ONIZEI?

PER

ADJUS77N~

PUS~

aJTIO~

9'3578

B

WOO'O

AND

PARTS

NOTE:

UO:.E

&I!.EWS

SHOf..IS

O.e

/NCLUD£0

CHECK

SI.IPRIN4S

':>C

~33A

OI,.,ENS/ONS

INSTALLATIONS

ON

QUICK-STOP

KLIPP·!T

800.ST-~2

C.3900

IN.STI?UCTIONS.

THii'EAD

lvtAC/-IINE:.

IN

S£TTIN6

AS

R4C~

Poe

OF"

OF

INS1}1jLLATION PROCEDI.Ji?E

I.

INSTALL

AUXILIAii"Y

Z.

APT£/e

ACCO/i?DIN/;

f:'UIZNISI-IED

3.~7EP

TO

ACCORDIN4

T/ON5,

L:LLCTRICAL.

FOE'

I.

MOt.NT

AND

IN

Z.

Df?YLL

.3~

Wt"n-11?16HT

LI.SIN4

LAR4£

71-1£

PLACE:

a)

CONT..aL

MACHIN£

INS77J.LL/N4

TO

WITH

SE:CU.f?IN4 71-1£ .SYNCHRONlZEJi?

71-1£

HAIVD

TO

~·

774K£

71-1£

7D

77£

£NO

Wlli£

AND

R£CE:P'Ti4C.L£:

b)

PUN

ruE

Wlli?ES

71:>

~,eo

77-IROU6H

A~C#

TH£

/.11/ITE(CLEAP)

77-1£

7WO

HAii!NJ:SS

r..eetFN £ 14'/-IIT,.

PLA~

-f-1-1£'

1-/0L.£

l<!tCFPTACL.I!:

IJi,~XtLIJIIIeY

EXPOI!'TONL-Y-1./S£

SHI"'

~

Pi.AC£

or

NEW

I?£ST

FROM

n-t.e£AD

£:¥.'1.

CUC~·STOP

IN

TI-l~

WHE'EL

71-1£.

THC

R:JfJ...OWIN4

CONNECTIONS.

FDU.e PE.rxw:. PLU4AT'Ulai£D

Dr

Pt.ut:;

IN

TENSION

7H£

LIN0£RSJI)I£

TWO

SLEEVED

SCY-E:NOIOS

4.::S

tNOit::ATED

PLLA$

t::ONT~DL

.:;f349SF

USE

7M::5

LIP

OF

H/N4£

84SC.

M07?:Jii?'

80><'

7J.t£

TA8/L8DI'RD

TI-l£

ACC£55021£$

IN:571i!UCTIONS

THE

HACHtNE:.

AND

ADJ'USTIN4 INSTJ<?UC-

7U£ :SYNCHE'ONIZE:.f?

IT

INTO

TI-l£

1'1f:JnPRIW£J...

EEL.E:ASE SOL£1\K)lO

THE ~ 0/..4.

6li?££N

1D

TO

WI·IIT£)

:NT()

IN

KIT

BETW££N

TWO

CZ596.s£2DNS

N"

3:i!>A

PIN

HOI..£

OIL

.A4N'IN

PIN

:STANO

AND

AS

INDICA'Tt:O.

TIMING

IT

TWO

THE

R:JUiii>

or

THE

HOi.£,

AND

7H£

7HC

6l:.0-4ZO

1'4~£€/V

1/NO

TH£

:SI'A.

TN£'

NO~OFV

B£:0

SCREWS.

,APP.f?OX

LINE

WH£N

TWO

WIE£'3F1i?OM

B!:lX:

,ONLY

WITH

HOLE

T"o

-

99tr270